Heatcraft Refrigeration Products H-ENGM0806, H-ENGM0408 User Manual

H-ENGM0408, April 2008

(Replaces H-ENGM0806, August 2006)

Engineering Manual

Commercial Refrigeration

Cooling and Freezing

Load Calculations and Reference Guide

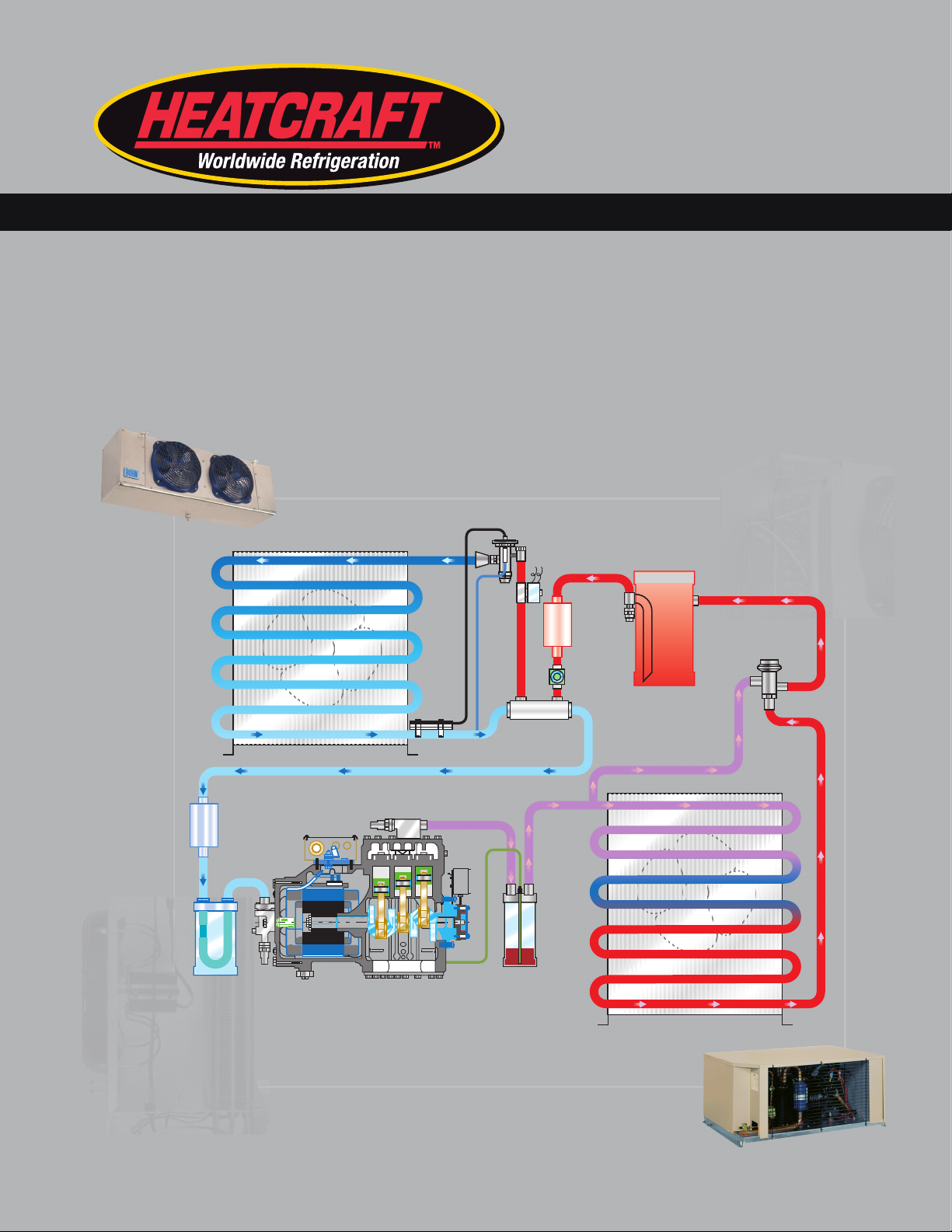

Expansion

Valve

Suction

Filter

Suction

Accumulator

Evaporator

Compressor

Liquid Line

Solenoid Valve

Separator

Heat

Exchanger

Oil

Filter-

Drier

Liquid Line

Sight Glass

Head Pressure

Control Valve

Receiver

Condenser

Forward

This edition of Heatcraft Refrigeration Products LLC’s, Engineering

Manual covering Commercial Refrigeration Cooling and Freezing

Load Calculations has been prepared in the form of a condensed

text and reference book.

The theory and principle of modern refrigeration has been

omitted due to the many excellent publications currently available

on these subjects. The purpose of this reference book is to furnish

the engineering, selling and servicing organizations with accurate

and useful data to simplify load calculations.

No attempt has been made to specify a particular make of

equipment. We sincerely hope that our eorts will be a tangible

contribution to our rapidly growing industry.

Table of Contents

Job Survey 4

Refrigeration Load Calculations 4-6

Sample Calculations:

Above 32ºF. (0ºC.) 7-9

Sample Calculations:

Rooms Below 32ºF. (0ºC.) 10-12

Refrigeration Equipment Selection 21

Type of Operation and Air Flow 22

®

choice for meeting the demanding needs of this industry

both in the United States and globally.

Refrigeration Equipment References on the World Wide Web

History of Leadership, Service

and Innovation

Bohn has been the

Supermarket Industry’s leading

brand of refrigeration products

since 1946. With an emphasis

on innovation and the

environment, Bohn is the clear

Derating Factors 22

General Guidelines 23

Unit Cooler Coil Placement 24

Sizing of Refrigerant Lines 25-32

Psychrometric Chart 37-39

Glossary of Refrigeration Terms 40

Quick Selection Guide 41

Rapid Load Calculator for Large Coolers & Freezers 43

History of High Performance,

Innovation and Product Selection

Larkin has been the most trusted

brand of refrigeration products for

clean environments since 1928. With

its innovative products, it is uniquely

qualied to meet the needs of

foodservice applications as well as

mission critical applications such as

data centers.

www.thecoldstandard.com

History of Dependability,

Technical Support and

Product Choice

Climate Control is the

brand that revolutionized

convenience store refrigeration in the 1970’s. Its reputation

of dependability and products designed to reduce

installation and operation costs still make it the number one

choice of convenience store owners everywhere.

www.coldyoucancounton.com

Right source. Right parts. Right now.

™

We are your link to a complete line of dependable and certied

Commercial Refrigeration Parts

www.interlinkparts.com

commercial refrigeration parts, accessories and innovative electronic

controls. Dependable. Versatile. Courteous. Finally, one simple source

for all of your parts needs from a name you can trust.

www.larkinproducts.com

Serving the Cold

Storage Industry with

Engineered Solutions

Chandler has been a

leading commercial refrigeration brand since 1933. Its

emphasis on partnership allows customers to give input

during the system design process, resulting in customized

solutions that are precisely engineered to order.

www.chandlerref.com

© 2008 Heatcraft Refrigeration Products LLC

2

Tables

Table

No.

1. Wall heat loads 13

2. Insulated block K factors 13

3. Allowance for sun eect ............................................................................13

4. Average air changes per 24 hours for storage

rooms above 32ºF. (0ºC.) due to door

openings and inltration 14

5. Average air changes per 24 hours for storage

rooms below 32ºF. (0ºC.) due to door

openings and inltration 14

6. Heat removed in cooling air to storage

room conditions (BTU per Cu. Ft.) 14

7. Storage requirements and properties of

perishable products 15-16

8. Heat of respiration 17

9. Heat loads of keg and bottled beer 18

10. Carcass weights 18

11. Heat equivalent of electric motors 18

12. Heat equivalent of occupancy 18

13. General standards for insulation

thickness in storage rooms 18

14. Heat gain due to operation of battery lift trucks 18

15. Specic heats of various liquids and solids 18

16. Banana room

refrigeration requirement 19

17. Meat cutting or preparation room 19

page

No.

Table

No.

18. Rapid load selection for back bars 19

19. Refrigeration requirements for hardening

ice cream 19

20. Glass door load 19

21. Summer outside air and ground

temperature design conditions 20

22. Suction and liquid line sizes for R-134A 25, 26

23. Suction and liquid line sizes for R-22 27, 28

24. Suction & liquid line sizes for R-404A, R-507/AZ50 29, 30

25. Pressure drop of liquid refrigerants in

vertical risers 31

26. Equivalent feet of pipe for

valves and ttings 31

27. Remote condenser line sizes for

R-134A, R-22, R-507/AZ50 and R-404A 32

28. L-type tubing– weight of refrigerants in copper

lines of operating systems 33

29. Fahrenheit-Celsius temperature

conversion chart 34

30. Conversion factors 35

31. Electrical formulas 35

32. English conversion factors and data 36

33. English to metric conversion factors 36

page

No.

3

Job Survey

The person involved in a heat transfer calculation needs

information in order to predict accurately the heat load on a

refrigerated structure. The more complete the information, the

better the calculation. Good calculations are the rst step in

assuring adequate refrigeration equipment is selected for the

project.

The initial job survey should be as complete as possible and

include the following:

Design Ambient Temperature

This is the ambient surrounding the box necessary for the load

calculations. Another ambient to be considered on air cooled

projects is the one surrounding the condensing unit which will

aect equipment selection.

Storage Temperature and Humidity Requirements

Refrigeration equipment by its nature is a dehumidication

process. We try to minimize or maximize the drying eect of the

equipment by selecting the appropriate Temperature Dierence

(T.D.) between the saturated suction temperature of the

evaporator and the room air. The T.D. selected approximates the

desired relative humidity (see page 21).

Dimensions, Insulation, Type of Construction,

Exposure

This criterion lends itself to well established, straight forward

calculations, but the information while elementary, is often

omitted from the initial job survey. Transmission load for 4”

Styrofoam is double the transmission load for 4” formed in place

urethane.

Inltration or Air Changed Load

Heat, both sensible and latent, enters an enclosure through door

openings whenever the air surrounding the enclosure is warmer

than the box temperature. Knowing the location, size and

number of the door openings and the temperature to which they

are exposed will greatly aid in determining the heat load of the

inltration air.

Product

1. Type - storage requirements

2. Weight

3. Entering temperature

4. Pull down time

Miscellaneous Loads

1. Lights

2. Motors including fan motors, fork lifts, conveyers

3. People

4. Glass doors

Operations

1. Holding cooler or freezer

2. Blast cooling or freezing

3. Preparation, processing or cutting rooms

4. Distribution warehouses

5. Reach-in or walk-in boxes

Unusual Conditions

Electrical Service and Type of Equipment Desired

While not directly aecting refrigeration load calculations,

this is essential in the job survey to select the proper equipment.

4

Refrigeration Load Calculations

With the initial survey complete, the heat load calculation is

separated into the following main sources of heat for a given 24

hour period:

1. Transmission load

2. Air change load

3. Miscellaneous load

4. Product load

Accuracy

Accuracy in calculation is the rst step in having a satised

customer. There are short cuts, based on averages, that may

be taken and which must be used when the product load is

indenite or unknown (see Quick Selection Guide on page 41

and the Rapid Load Calculator on page 43). But when all the data

necessary to calculate the four main sources of heat gain are

available, the complete calculation should be made.

Quick Selection Chart for Small

and Medium Coolers and Freezers

The Quick Selection Guide on page 41 may be used for a quick

comparison of heat load gured on Bulletins Above32-05 or

Below32-05 or to obtain approximate heat loads for small and

medium sized boxes. The loads are shown for a 95ºF. outside

temperature.

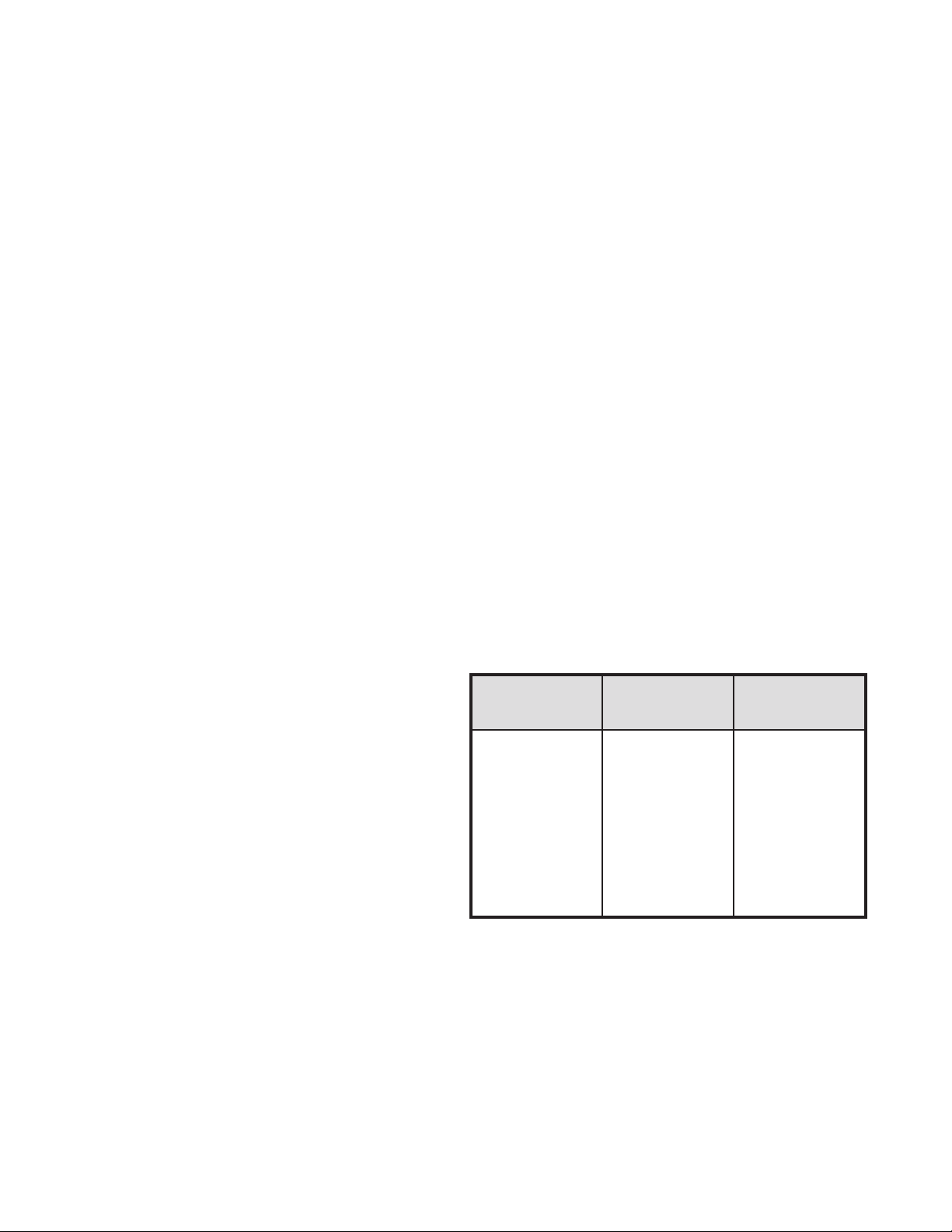

Rapid Load Calculator for Large Coolers and Freezers

The Rapid Load Calculator on page 43 may be used for quick

approximations of the heat load in large boxes and for a

reasonable comparison of heat loads gured on Bulletins

Above32-05 or Below32-05. The Calculator graph on page 43 is

based on the following average daily product loadings for coolers

and freezers:

Average Daily Average Daily

Volume- Product Loads (lbs.) Product Loads (lbs.)

Cu. Ft. for Coolers for Freezers

500 - 3,000 6,200 - 8,000 1,600 - 2,000

3,000 - 4,600 8,000 - 11,000 2,000 - 2,500

4,600 - 8,100 11,000 - 17,000 2,500 - 4,000

8,100 - 12,800 17,000 - 26,000 4,000 - 6,200

12,800 - 16,000 26,000 - 33,000 6,200 - 7,500

16,000 - 20,000 33,000 - 40,000 7,500 - 9,500

20,000 - 28,000 40,000 - 56,000 9,500 - 13,000

28,000 - 40,000 56,000 - 66,000 13,000 - 17,000

40,000 - 60,000 66,000 - 110,000 17,000 - 25,000

60,000 - 80,000 110,000 - 150,000 25,000 - 34,000

80,000 - up 150,000 - up 34,000 - up

1. Transmission Load

Methods of determining the amount of heat ow through walls,

oor and ceiling are well established. This heat gain is directly

proportional to the Temperature Dierence (T.D.) between the

two sides of the wall. The type and thickness of insulation used

in the wall construction, the outside area of the wall and the

T.D. between the two sides of the wall are the three factors

that establish the wall load. Tables are provided to simplify

the calculations (see Table 1, page 13). Some coolers for above

freezing temperatures have been constructed with only a oor

slab (no oor insulation). The factors shown in the wall heat gain

(Table 1) are based on a concrete oor slab and the T.D. between

the local ground temperature and the storage room temperature.

For freezers it becomes necessary to provide heat in the base slab

to avoid freezing of the ground water and heaving of the oor.

Minimum slab temperature should be at least 40ºF. Normally, 55ºF.

should be used for freezer applications.

cooler and one HP for each 12,500 C.F. in a storage freezer

which allows for fan motors and some forklift operations.

These gures can be higher in a heavily used area, i.e. loading

dock or distribution warehouse.

2. Air Change Load

(a) Average Air Change- when the door to a refrigerated room is

opened, warm outside air will enter the room. This air must be

cooled to the refrigerated room temperature, resulting in an

appreciable source of heat gain. This load is sometimes called

the inltration load. The probable number of air changes per

day and the heat that must be removed from each cubic foot

of the inltrated air, are given in tables based on experience

(see Table 4, 5 & 6, page 14). For heavy usage, the inltration

may be doubled or more.

(b) Inltration Through a Fixed Opening- As an alternate to the

average air change method using the Psychrometric Chart

(page 37), the following formulas may be used to calculate

the inltration resulting from natural ventilation (no wind)

through external door openings.

[ (4.88) ( door height) (area/2) (minutes open) ( temp. di. ºF.)

(enthalpy incoming air – enthaply warehouse air) ] [ (1–X)]

Specic Volume of Incoming Air

Where X = % of heat transmission blocked by thermal barrier.

The air change load can be substantial and every means

should be taken to reduce the amount of inltration entering

the box. Some eective means of minimizing this load are:

• Automatic closing refrigerator doors

• Vestibules or refrigerated anterooms

• Plastic strip curtains

• Air Curtains

• Inated bumpers on outside loading doors.

3. Miscellaneous Loads

Although most of the heat load in a refrigerated room

or freezer is caused by wall heat leakage, air changes and

product cooling or freezing, there are three other heat

sources that should not be overlooked prior to the selection

of the refrigeration equipment. Since the equipment has to

maintain temperature under design conditions, these loads are

generally averaged to a 24 hour period to provide for capacity

during these times.

(a) Lights- typically storage requirements are 1 to 1-1/2 watt per

square foot. Cutting or processing rooms can be double the

wattage. Each watt is multiplied by 3.42 BTU/watt to obtain a

BTUH gure. This is then multiplied by 24 to obtain a

daily gure.

(b) Motors- smaller motors are usually less ecient and tend to

generate more heat per horsepower as compared to larger

motors. For this reason Table 11, on page 18, is broken down

in to H.P. groups. Also, motors inside the refrigerated area will

reject all of their heat losses as shown in Table 11. However,

motors that are located outside but do the work inside, like

a conveyor, will reject less heat into the refrigerated space. If

powered material handling equipment is used, such as forklift

trucks, this must be included under Motor Heat Loads.

Generally only battery operated lift trucks are used in

refrigerated rooms, which represent a heat gain of 8,000 to

15,000 BTU/hr. or more over the period of operation. If motor

or loading conditions are not known, then calculate one

motor horsepower for each 16,000 cubic foot box in a storage

(c) Occupancy- People working in the refrigerated storage area

dissipate heat at a rate depending on the room temperature

(Table 12, page 18). Multiple occupancies for short periods

should be averaged over a 24 hour period. If occupancy load

is not known, allow one person per 24 hour for each 25,000

cubic foot space.

4. Product Load

Whenever a product having a higher temperature is placed

in a refrigerator or freezer room, the product will lose its

heat until it reaches the storage temperature. This heat load

consists of three separate components: (see Table 7, page 15-

16).

(a) Specic Heat- The amount of heat that must be removed

from one pound of product to reduce the temperature of this

pound by 1ºF., is called its specic heat. It has two values: one

applies when the product is above freezing; the second is

applicable after the product has reached its freezing point.

(b) Latent Heat- The amount of heat that must be removed from

one pound of product to freeze this pound is called the latent

heat of fusion.

Most products have a freezing point in the range of 26ºF. to

31ºF. If the exact temperature is unknown, it may be

assumed to be 28ºF.

There is a denite relationship between the latent heat of

fusion and the water content of the product and its specic

and latent heats.

Estimating specic and latent heats:

Sp. Ht. above freezing = 0.20 + (0.008 X % water)

Sp. Ht. below freezing = 0.20 + (0.008 X % water)

Latent Heat = 143.3 X % water

(c) Respiration- Fresh fruits and vegetables are alive. Even in

refrigerated storage they generate heat which is called the

heat of respiration. They continually undergo a change in

which energy is released in the form of heat, which varies with

the type and temperature of the product. Tabulated values are

usually in BTU/lb./24 hours (Table 8, page 17), and are applied

to the total weight of product being stored and not just the

daily turnover.

(d) Pull down Time- When a product load is to be calculated at

other than a 24 hour pull down, a correction factor must be

multiplied to the product load.

24 hours

Pull down Time

Note: While product pull down can be calculated, no

guarantee should be made regarding nal product

temperature due to many uncontrollable factors (i.e., type of

packaging, position in the box, method of stacking, etc.)

5. Safety Factor

When all four of the main sources of heat are calculated,

a safety factor of 10% is normally added to the total

refrigeration load to allow for minor omissions and

inaccuracies (additional safety or reserve may be available

from the compressor running time and average loading).

5

6. Hourly Heat Load

The hourly heat load serves as the guide in selecting

equipment. It is found by dividing the nal BTU/24 hour load

by the desired condensing unit run time.

35ºF. rooms with no timer 16 hr.

35ºF. rooms with timer 18 hr.

Blast coolers/Freezers with

positive defrost 18 hr.

Storage Freezers 18-20 hr.

25ºF. - 34ºF. coolers with hot gas

or electric defrost 20-22 hr.

50ºF. rooms and higher with coil

temperature above 32ºF. 20-22 hr.

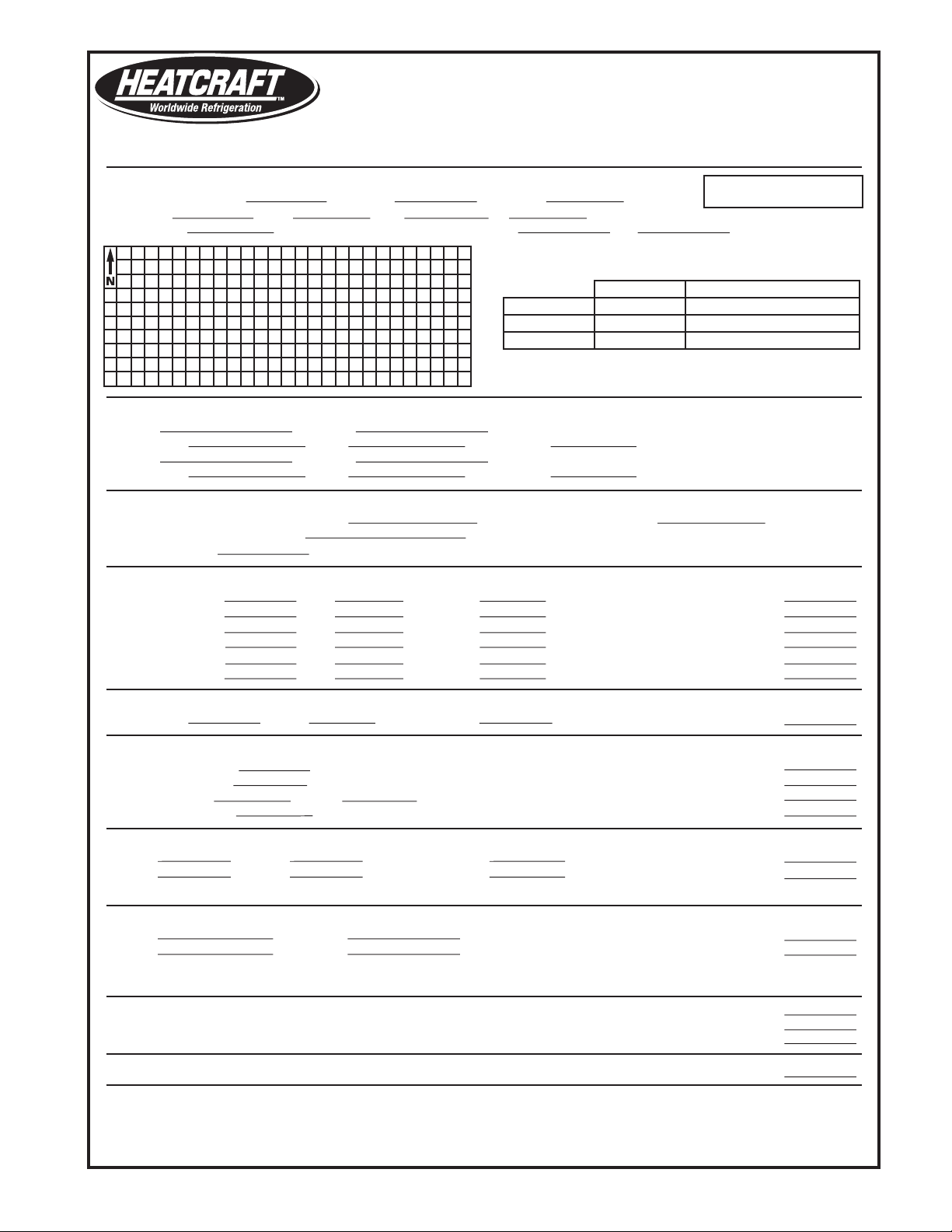

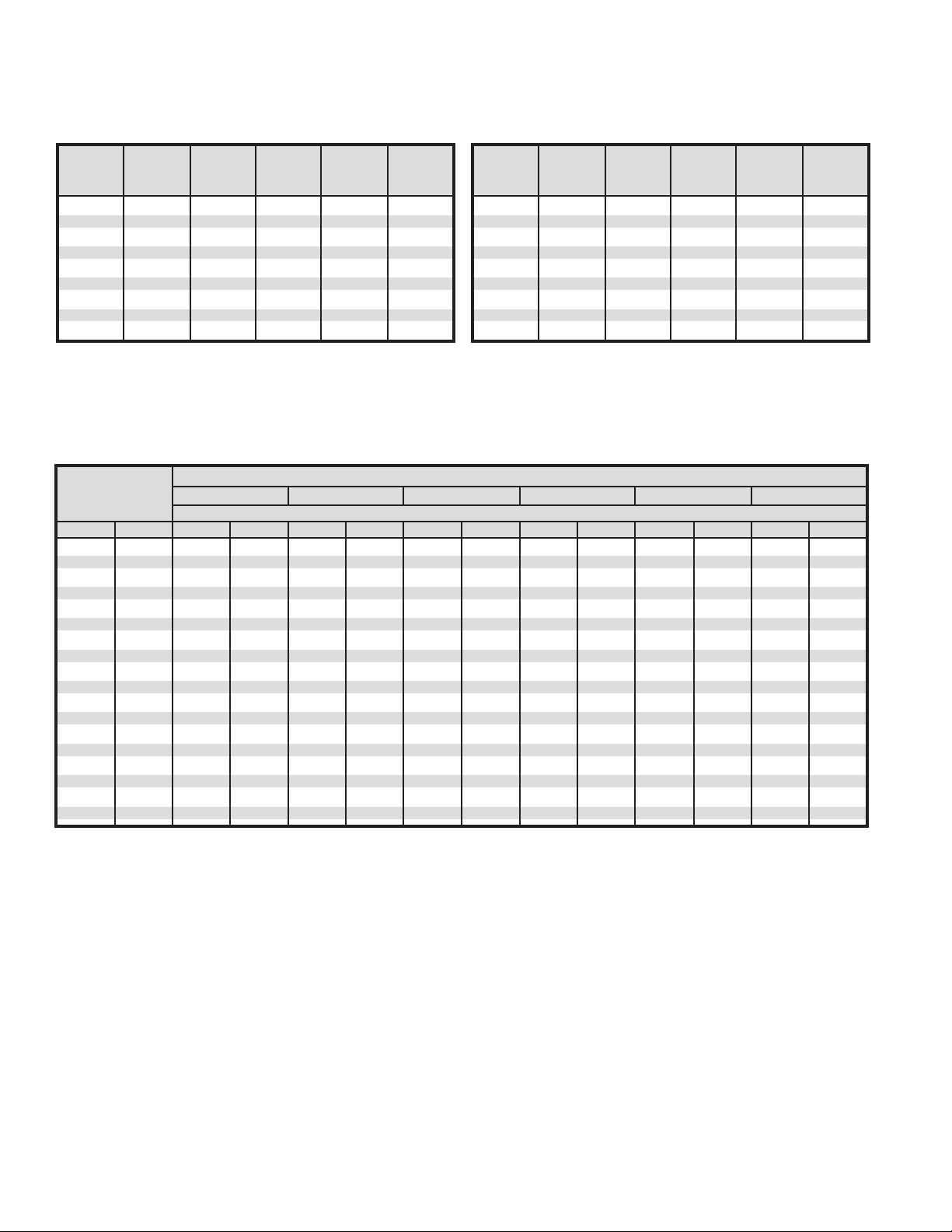

7. Load Calculation Forms

To simplify the calculation and tabulation of refrigeration

loads, there are two forms available:

Bulletin Above32-05 is used for all rooms above 32ºF. (0ºC.)

Bulletin Below32-05 is used for all rooms below 32ºF. (0ºC.)

All data and tables necessary to ll in the Load Calculation

Forms can be found in this manual.

A Word of Caution: The refrigeration load calculation

methods presented in this manual are intended for use

in selecting refrigeration equipment for rooms used for

holding and sometimes pulling product temperature down.

For process or unusual applications such as blast freezing or

food processing situations, please contact our Application

Engineering Department.

6

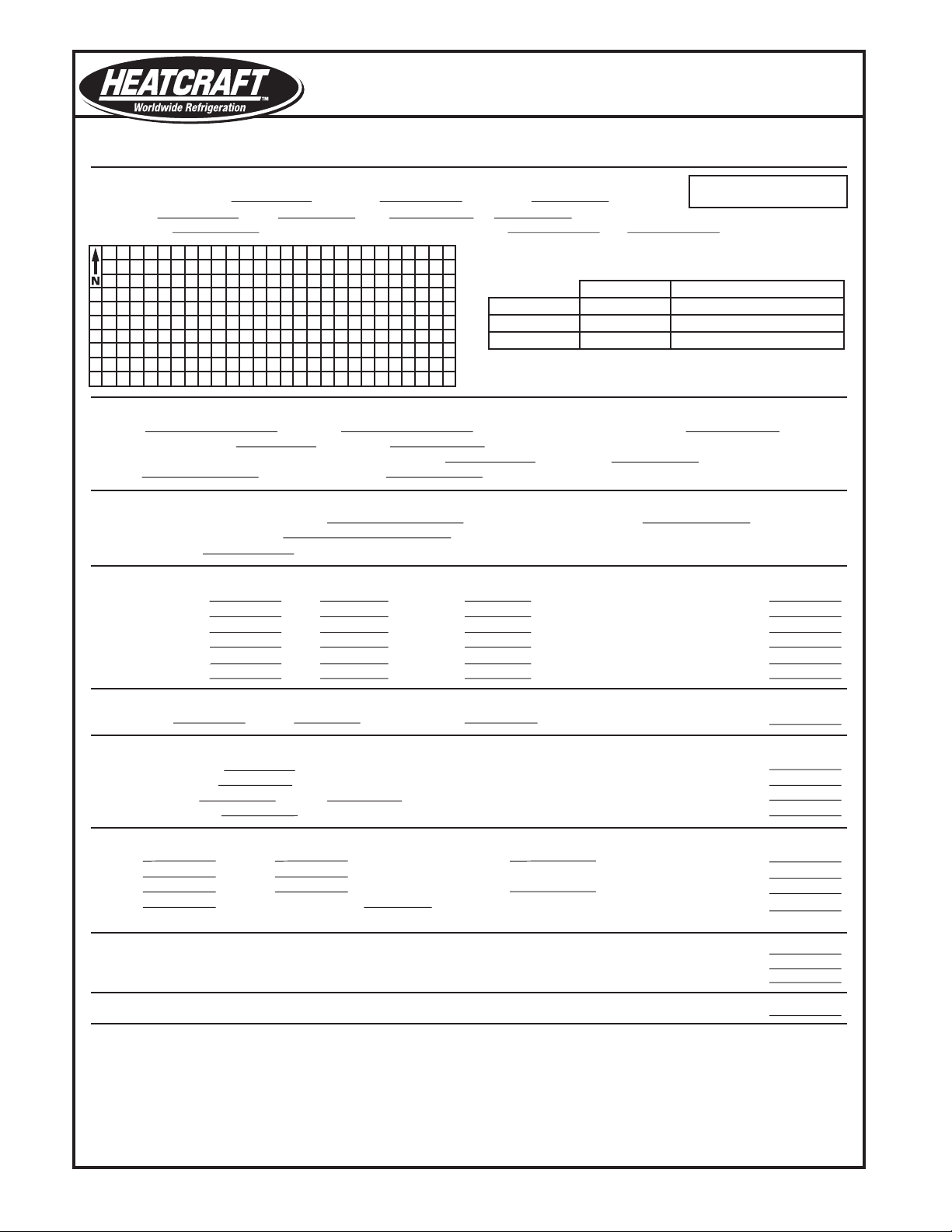

Refrigeration Load Estimate Form

(for rooms above 32ºF) Bulletin Above32-05

Estimate for: Estimate by: Date:

Example: 35ºF Convenience Store Cooler With Glass Doors

Basis for Estimate

8 28 8

Room Dimensions: Width ft. x Length f t. x Height ft.

28 8 8 1792

Volume: (L) x (W) x (H) = cu. ft.

85 35 50

Ambient Temp ºF. (Corrected for sun load) — Room Temp ºF. = ºF. T.D.

Inches

Ceiling

Walls

Floor

Product Load

2000 Beer

(a) lbs./day of to be reduced from entering

85 35 50

temp. of ºF. to ºF. Temp. Drop ºF.

200 Milk

(b) lbs./day of to be reduced from entering

40 35 5

temp. of ºF. to ºF. Temp. Drop ºF.

Miscellaneous

0.2 60

Motors (including all blower motors) HP Ground Temp. (Table 21)

224

Lights (assume 1 watt/sq.ft.) Watts

No. of people

0

1. Transmission Loads

28 8 72 16128

Ceiling: (L) x (W) x Heat Load (Table 1) =

28 8 72 16128

North Wall: (L) x (W) x Heat Load (Table 1) =

28 8 72 16128

South Wall: (L) x (W) x Heat Load (Table 1) =

East Wall: (L) x (W) x Heat Load (Table 1) =

8 8 72 4608

West Wall: (L) x (W) x Heat Load (Table 1) =

8 8 72 4608

Floor: (L) x (W) x Heat Load (Table 1) =

28 8 125 28000

(W)

(W)

(H)

(H)

(H)

(H)

4 Styrene

4 Styrene

6 Concrete

Note: Tables can be found in

Engineering Manual, H-ENG-2

Insulation

Type

2. Air Change Load

Volume: cu. ft. x Factor (Table 4) x Factor (Table 6) =

1792 13 1.86 43331

3. Additional Loads

0.2 15000

Electrical Motors: HP x 75000 BTU/HP/24 hr. =

224 18368

Electrical Lights: Watts x 82 =

0 —

People Load: People x BTU/24 hrs. (Table 12) =

10 192000

Glass Door Load: Doors x 19200 BTU/Door/24 hr. =

4. Product Load: Sensible (Product Load Figured @ 24 hr. Pulldown*)

2000 0.92 50 92000

(a) lbs./day x Spec. Heat (Table 7) x ºF. Temp Drop =

200 0.93 5 930

(b) lbs./day x Spec. Heat (Table 7) x ºF. Temp Drop =

*For product pulldown time other than 24 hrs. fi

5. Product Load: Respiration*

(a) lbs. stored x BTU/lbs./24 hrs. (Table 8) =

— — —

(b) lbs. stored x BTU/lbs./24 hrs. (Table 8) =

— — —

*For consideration of previously loaded product, a multiplier of (5) is normally applied to the daily

product load (Line #4)

447229

Total Refrigeration Load (1+2+3+4+5) BTU/24 hrs.

44723

Add 10% Safety Factor

491952

Total with Safety/Factor BTU/24 hrs.

Divide by No. of Operating Hrs. (16) to obtain BTUH Cooling Requirement

30747

Equipment Selection

Condensing Unit Unit Cooler System Capacity

Qty. Model No. Qty. Model No. BTU/hr.

gure 24 hr. load x (24/Pulldown Time)

2175 West Park Place Blvd. • Stone Mountain, GA 30087 • 770.465.5600 • Fax: 770.465.5990 • www.heatcraftrpd.com

7

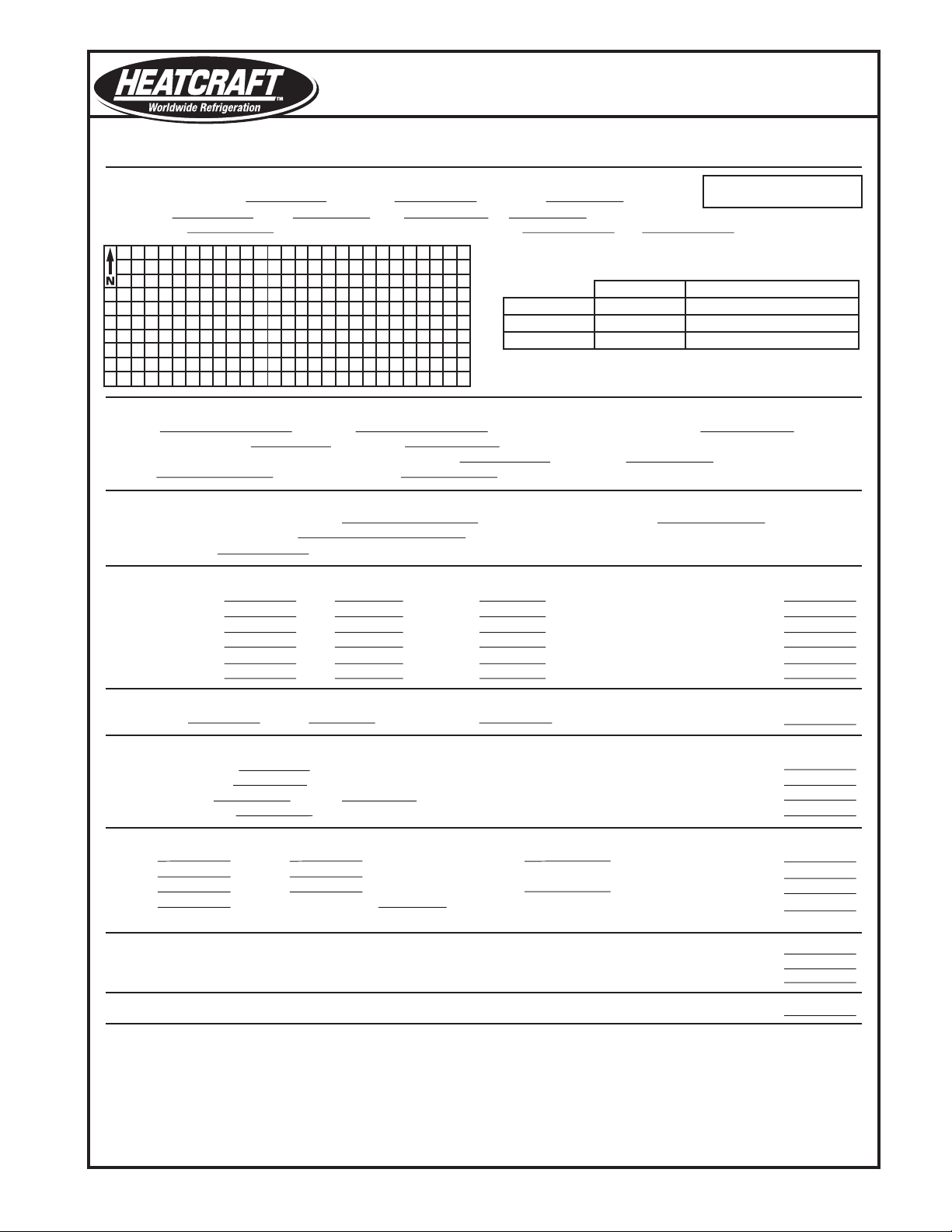

Refrigeration Load Estimate Form

(for rooms above 32ºF) Bulletin Above32-05

Estimate for: Estimate by: Date:

Example: 35ºF Beef Cooler

Basis for Estimate

14 16 8

Room Dimensions: Width ft. x Length f t. x Height ft.

16 14 8 1792

Volume: (L) x (W) x (H) = cu. ft.

95 35 60

Ambient Temp ºF. (Corrected for sun load) — Room Temp ºF. = ºF. T.D.

Inches

Ceiling

Walls

Floor

Product Load

1000 Beef

(a) lbs./day of to be reduced from entering

50 35 15

temp. of ºF. to ºF. Temp. Drop ºF.

— —

(b) lbs./day of to be reduced from entering

— — —

temp. of ºF. to ºF. Temp. Drop ºF.

Miscellaneous

0.1 60

Motors (including all blower motors) HP Ground Temp. (Table 21)

224

Lights (assume 1 watt/sq.ft.) Watts

No. of people

0

1. Transmission Loads

16 14 87 19488

Ceiling: (L) x (W) x Heat Load (Table 1) =

16 8 87 11136

North Wall: (L) x (W) x Heat Load (Table 1) =

16 8 87 11136

South Wall: (L) x (W) x Heat Load (Table 1) =

East Wall: (L) x (W) x Heat Load (Table 1) =

14 8 87 9744

West Wall: (L) x (W) x Heat Load (Table 1) =

14 8 87 9744

Floor: (L) x (W) x Heat Load (Table 1) =

16 14 125 28000

(W)

(W)

(H)

(H)

(H)

(H)

4 Styrene

4 Styrene

6 Concrete

Note: Tables can be found in

Engineering Manual, H-ENG-2

Insulation

Type

2. Air Change Load

1792 13 2.49 58007

Volume: cu. ft. x Factor (Table 4) x Factor (Table 6) =

3. Additional Loads

0.1 7500

Electrical Motors: HP x 75000 BTU/HP/24 hr. =

224 18368

Electrical Lights: Watts x 82 =

0 — —

People Load: People x BTU/24 hrs. (Table 12) =

0 —

Glass Door Load: Doors x 19200 BTU/Door/24 hr. =

4. Product Load: Sensible (Product Load Figured @ 24 hr. Pulldown*)

1000 0.77 15 11550

(a) lbs./day x Spec. Heat (Table 7) x ºF. Temp Drop =

— — — —

(b) lbs./day x Spec. Heat (Table 7) x ºF. Temp Drop =

*For product pulldown time other than 24 hrs. fi

5. Product Load: Respiration*

— — —

(a) lbs. stored x BTU/lbs./24 hrs. (Table 8) =

— — —

(b) lbs. stored x BTU/lbs./24 hrs. (Table 8) =

*For consideration of previously loaded product, a multiplier of (5) is normally applied to the daily

product load (Line #4)

184673

Total Refrigeration Load (1+2+3+4+5) BTU/24 hrs.

18467

Add 10% Safety Factor

203140

Total with Safety/Factor BTU/24 hrs.

Divide by No. of Operating Hrs. (16) to obtain BTUH Cooling Requirement

12696

Equipment Selection

Condensing Unit Unit Cooler System Capacity

Qty. Model No. Qty. Model No. BTU/hr.

gure 24 hr. load x (24/Pulldown Time)

2175 West Park Place Blvd. • Stone Mountain, GA 30087 • 770.465.5600 • Fax: 770.465.5990 • www.heatcraftrpd.com

8

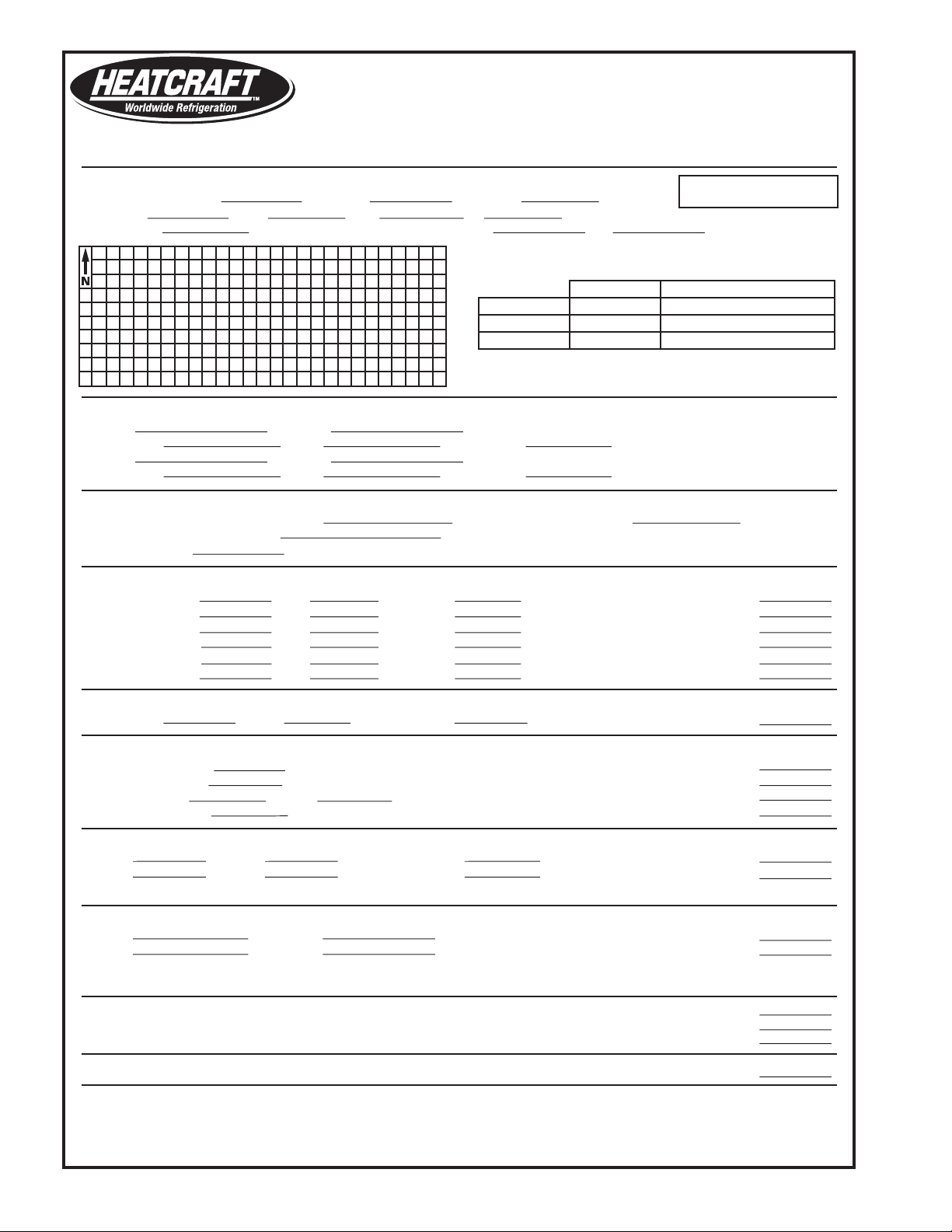

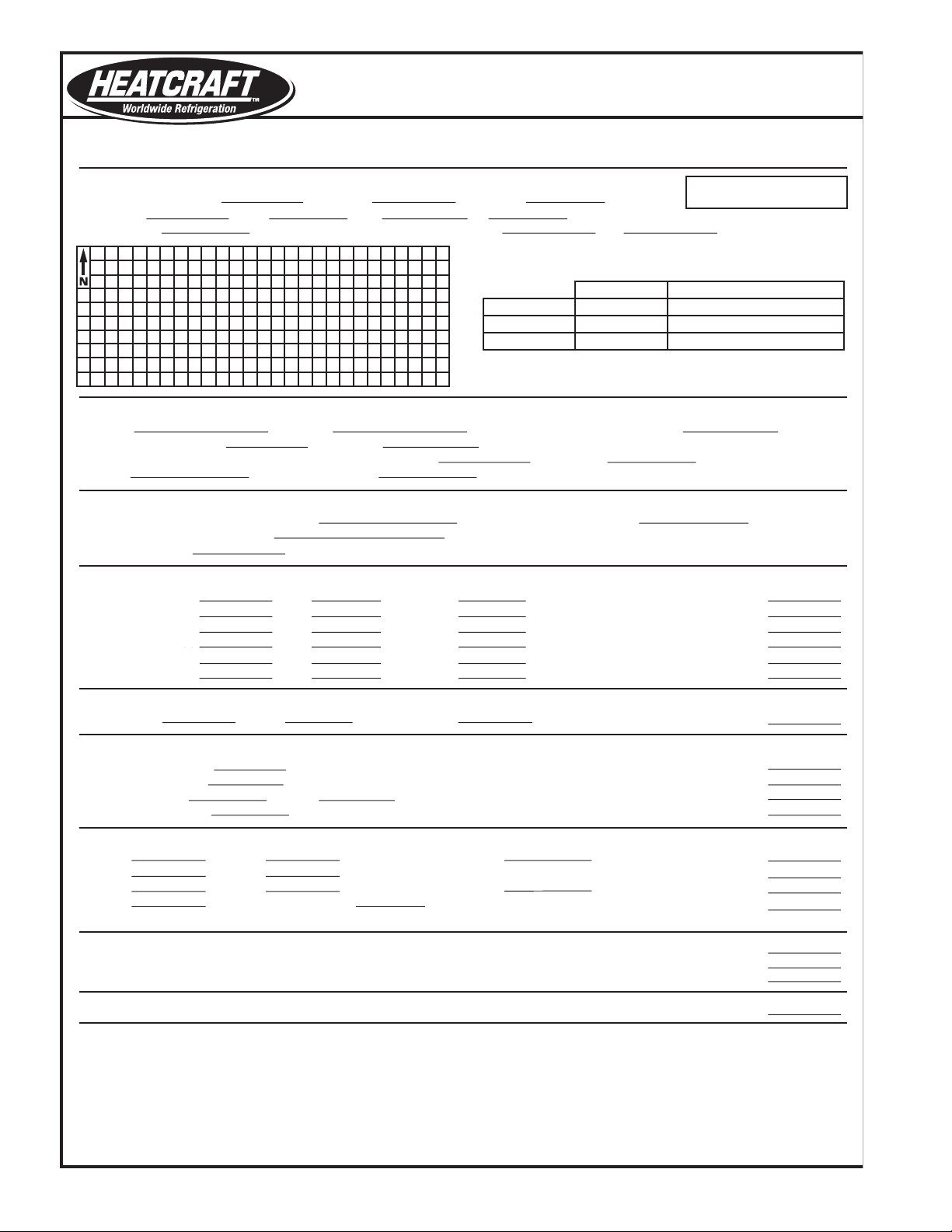

Refrigeration Load Estimate Form

(for rooms above 32ºF) Bulletin Above32-05

Estimate for: Estimate by: Date:

Basis for Estimate

Room Dimensions: Width ft. x Length ft. x Height ft.

Volume: (L) x (W) x (H) = cu. ft.

Ambient Temp ºF. (Corrected for sun load) — Room Temp ºF. = ºF. T.D.

Note: Tables can be found in

Engineering Manual, H-ENG-2

Insulation

Inches

Type

Ceiling

Walls

Floor

Product Load

(a) lbs./day of to be reduced from entering

temp. of ºF. to ºF. Temp. Drop ºF.

(b) lbs./day of to be reduced from entering

temp. of ºF. to ºF. Temp. Drop ºF.

Miscellaneous

Motors (including all blower motors) HP Ground Temp. (Table 21)

Lights (assume 1 watt/sq.ft.) Watts

No. of people

1. Transmission Loads

Ceiling: (L) x (W) x Heat Load (Table 1) =

North Wall: (L) x (W) x Heat Load (Table 1) =

South Wall: (L) x (W) x Heat Load (Table 1) =

East Wall: (L) x (W) x Heat Load (Table 1) =

West Wall: (L) x (W) x Heat Load (Table 1) =

Floor: (L) x (W) x Heat Load (Table 1) =

(W)

(W)

(H)

(H)

(H)

(H)

2. Air Change Load

Volume: cu. ft. x Factor (Table 4) x Factor (Table 6) =

3. Additional Loads

Electrical Motors: HP x 75000 BTU/HP/24 hr. =

Electrical Lights: Watts x 82 =

People Load: People x BTU/24 hrs. (Table 12) =

Glass Door Load: Doors x 19200 BTU/Door/24 hr. =

4. Product Load: Sensible (Product Load Figured @ 24 hr. Pulldown*)

(a) lbs./day x Spec. Heat (Table 7) x ºF. Temp Drop =

(b) lbs./day x Spec. Heat (Table 7) x ºF. Temp Drop =

*For product pulldown time other than 24 hrs. fi

5. Product Load: Respiration*

(a) lbs. stored x BTU/lbs./24 hrs. (Table 8) =

(b) lbs. stored x BTU/lbs./24 hrs. (Table 8) =

*For consideration of previously loaded product, a multiplier of (5) is normally applied to the daily

product load (Line #4)

Total Refrigeration Load (1+2+3+4+5) BTU/24 hrs.

Add 10% Safety Factor

Total with Safety/Factor BTU/24 hrs.

Divide by No. of Operating Hrs. (16) to obtain BTUH Cooling Requirement

Equipment Selection

Condensing Unit Unit Cooler System Capacity

Qty. Model No. Qty. Model No. BTU/hr.

gure 24 hr. load x (24/Pulldown Time)

2175 West Park Place Blvd. • Stone Mountain, GA 30087 • 770.465.5600 • Fax: 770.465.5990 • www.heatcraftrpd.com

9

Refrigeration Load Estimate Form

(for rooms below 32ºF) Bulletin Below32-05

Estimate for:

Estimate by: Date:

Example: -20ºF Ice Cream Hardening Freezer

Basis for Estimate

12 14 8

Room Dimensions: Width ft. x Length f t. x Height ft.

14 12 8 1344

Volume: (L) x (W) x (H) = cu. ft.

85 -20 105

Ambient Temp ºF. (Corrected for sun load) — Room Temp. ºF. = ºF. T.D.

Inches

Ceiling

Walls

Floor

Product Load

— — —

(a) lbs./day of to be reduced from entering temp. of ºF.

— —

to freezing point of ºF. (Table 7) = ºF. Initial temp. drop

— —

and then reduced from freezing point to storage Temp. of ºF. = (Table 7) ºF. Final temp. drop.

100 100%

(b) gallons of ice cream @ overrun

Miscellaneous

0.2 60

Motors (including all blower motors) HP Ground Temp. (Table 21)

168

Lights (assume 1 watt/sq.ft.) Watts

0

No. of People

1. Transmission Loads

14 12 76 12768

Ceiling: (L) x (W) x Heat Load (Table 1) =

14 8 76 8512

North Wall: (L) x (W) x Heat Load (Table 1) =

14 8 76 8512

South Wall: (L) x (W) x Heat Load (Table 1) =

East Wall: (L) x (W) x Heat Load (Table 1) =

12 8 76 7296

West Wall: (L) x (W) x Heat Load (Table 1) =

12 8 76 7296

Floor: (L) x (W) x Heat Load (Table 1) =

14 12 58 9744

(W)

(W)

(H)

(H)

(H)

(H)

4 Foamed In place Ure

4 Foamed In place Ure

4 Foamed In place Ure

Note: Tables can be found in

Engineering Manual, H-ENG-2

Insulation

Type

2. Air Change Load

1344 12 3.49 56287

Volume: cu. ft. x Factor (Table 5) x Factor (Table 6) =

3. Additional Loads

0.2 15000

Electrical Motors: HP x 75000 BTU/HP/24 hr. =

168 13776

Electrical Lights: Watts x 82 =

0 — —

People Load: People x BTU/24 hrs. (Table 12) =

10 —

Glass Door Load: Doors x 31200 BTU/Door/24 hr. =

4. Product Load: (Table 7) (Product Load Figured @ 24 hr. Pulldown*)

— — —

(a) lbs./day x Spec. Heat above freezing x ºF. Intial Te

— — —

lbs./day x Latent Heat Fusion =

lbs./day x Spec. Heat below freezing x ºF. Intial Temp. Drop =

— — —

100 425 X 2.4 (10 hr. Pull down)* 102000

(b) gallons of ice cream/day x BTU/gal (Table 19) =

*For product pulldown time other than 24 hrs. figure 24 hr. load x (24/Pulldown Time)

241191

Total Refrigeration Load (1+2+3+4+5) BTU/24 hrs.

24119

Add 10% Safety Factor

265310

Total with Safety/Factor BTU/24 hrs.

Divide by No. of Operating Hrs. (18) to obtain BTUH Cooling Requirement

14739

Equipment Selection

Condensing Unit Unit Cooler System Capacity

Qty. Model No. Qty. Model No. BTU/hr.

mp. Drop =

2175 West Park Place Blvd. • Stone Mountain, GA 30087 • 770.465.5600 • Fax: 770.465.5990 • www.heatcraftrpd.com

10

Refrigeration Load Estimate Form

(for rooms below 32ºF) Bulletin Below32-05

Estimate for:

Estimate by: Date:

Example: -10ºF Beef Freezer

Basis for Estimate

20 24 12

Room Dimensions: Width ft. x Length f t. x Height ft.

24 20 12 5760

Volume: (L) x (W) x (H) = cu. ft.

90 -10 100

Ambient Temp ºF. (Corrected for sun load) — Room Temp. ºF. = ºF. T.D.

Inches

Ceiling

Walls

Floor

Product Load

3000 Beef 35

(a) lbs./day of to be reduced from entering temp. of ºF.

28 7

to freezing point of ºF. (Table 7) = ºF. Initial temp. drop

-10 38

and then reduced from freezing point to storage Temp. of ºF. = (Table 7) ºF. Final temp. drop.

— —

(b) gallons of ice cream @ overrun

Miscellaneous

0.5 60

Motors (including all blower motors) HP Ground Temp. (Table 21)

480

Lights (assume 1 watt/sq.ft.) Watts

0

No. of People

1. Transmission Loads

24 20 72 34560

Ceiling: (L) x (W) x Heat Load (Table 1) =

24 12 72 20736

North Wall: (L) x (W) x Heat Load (Table 1) =

South Wall: (L) x (W) x Heat Load (Table 1) =

24 12 72 20736

East Wall: (L) x (W) x Heat Load (Table 1) =

20 12 72 17280

West Wall: (L) x (W) x Heat Load (Table 1) =

20 12 72 17280

Floor: (L) x (W) x Heat Load (Table 1) =

24 20 50 24000

(W)

(W)

(H)

(H)

(H)

(H)

4 Foamed In place Ure

4 Foamed In place Ure

4 Foamed In place Ure

Note: Tables can be found in

Engineering Manual, H-ENG-2

Insulation

Type

2. Air Change Load

5760 5.2 3.56 106629

Volume: cu. ft. x Factor (Table 5) x Factor (Table 6) =

3. Additional Loads

0.5 37500

Electrical Motors: HP x 75000 BTU/HP/24 hr. =

480 39360

Electrical Lights: Watts x 82 =

0 — —

People Load: People x BTU/24 hrs. (Table 12) =

0 —

Glass Door Load: Doors x 31200 BTU/Door/24 hr. =

4. Product Load: (Table 7) (Product Load Figured @ 24 hr. Pulldown*)

3000 0.77 7 16170

(a) lbs./day x Spec. Heat above freezing x ºF. Intial Te

3000 100 300000

lbs./day x Latent Heat Fusion =

3000 0.4 38 45600

lbs./day x Spec. Heat below freezing x ºF. Intial Temp. Drop =

(b) gallons of ice cream/day x BTU/gal (Table 19) =

— X 2.4 (10 hr. Pull down)* —

*For product pulldown time other than 24 hrs. figure 24 hr. load x (24/Pulldown Time)

679851

Total Refrigeration Load (1+2+3+4+5) BTU/24 hrs.

67985

Add 10% Safety Factor

747836

Total with Safety/Factor BTU/24 hrs.

Divide by No. of Operating Hrs. (18) to obtain BTUH Cooling Requirement

41546

Equipment Selection

Condensing Unit Unit Cooler System Capacity

Qty. Model No. Qty. Model No. BTU/hr.

mp. Drop =

2175 West Park Place Blvd. • Stone Mountain, GA 30087 • 770.465.5600 • Fax: 770.465.5990 • www.heatcraftrpd.com

11

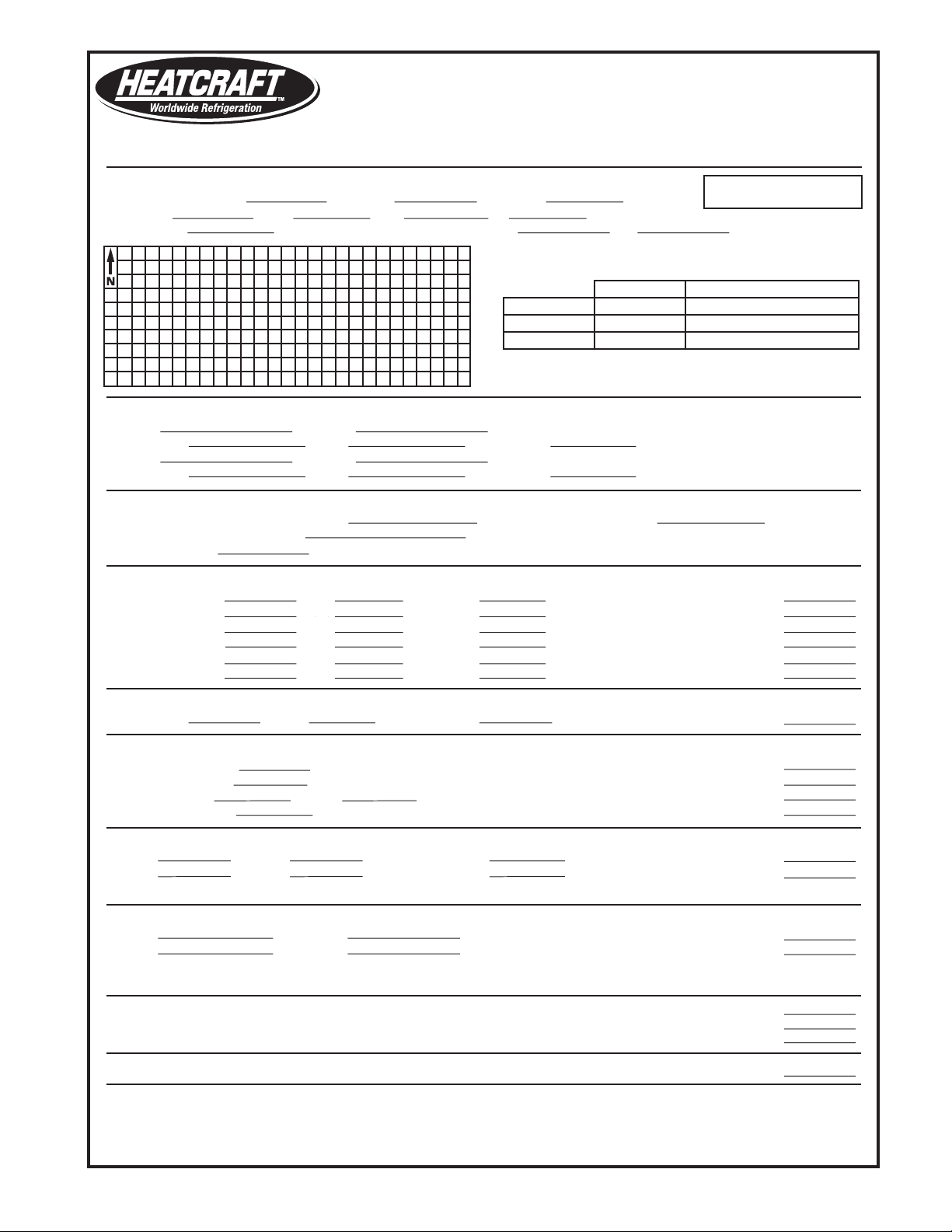

Refrigeration Load Estimate Form

(for rooms below 32ºF) Bulletin Below32-05

Estimate for:

Basis for Estimate

Room Dimensions: Width ft. x Length ft. x Height ft.

Volume: (L) x (W) x (H) = cu. ft.

Ambient Temp ºF. (Corrected for sun load) — Room Temp. ºF. = ºF. T.D.

Product Load

(a) lbs./day of to be reduced from entering temp. of ºF.

to freezing point of ºF. (Table 7) = ºF. Initial temp. drop

and then reduced from freezing point to storage Temp. of ºF. = (Table 7) ºF. Final temp. drop.

(b) gallons of ice cream @ overrun

Miscellaneous

Motors (including all blower motors) HP Ground Temp. (Table 21)

Lights (assume 1 watt/sq.ft.) Watts

No. of People

2. Air Change Load

Volume: cu. ft. x Factor (Table 5) x Factor (Table 6) =

3. Additional Loads

Electrical Motors: HP x 75000 BTU/HP/24 hr. =

Electrical Lights: Watts x 82 =

People Load: People x BTU/24 hrs. (Table 12) =

Glass Door Load: Doors x 31200 BTU/Door/24 hr. =

4. Product Load: (Table 7) (Product Load Figured @ 24 hr. Pulldown*)

(a) lbs./day x Spec. Heat above freezing x ºF. Intial Te

mp. Drop =

lbs./day x Latent Heat Fusion =

lbs./day x Spec. Heat below freezing x ºF. Intial Temp. Drop =

(b) gallons of ice cream/day x BTU/gal (Table 19) =

*For product pulldown time other than 24 hrs. figure 24 hr. load x (24/Pulldown Time)

Divide by No. of Operating Hrs. (18) to obtain BTUH Cooling Requirement

Equipment Selection

Condensing Unit Unit Cooler System Capacity

Qty. Model No. Qty. Model No. BTU/hr.

Total Refrigeration Load (1+2+3+4+5) BTU/24 hrs.

Add 10% Safety Factor

Total with Safety/Factor BTU/24 hrs.

1. Transmission Loads

Ceiling: (L) x (W) x Heat Load (Table 1) =

North Wall: (L) x (W) x Heat Load (Table 1) =

South Wall: (L) x (W) x Heat Load (Table 1) =

East Wall: (L) x (W) x Heat Load (Table 1) =

West Wall: (L) x (W) x Heat Load (Table 1) =

Floor: (L) x (W) x Heat Load (Table 1) =

Estimate by: Date:

Insulation

Inches

Ceiling

Walls

Floor

Type

Note: Tables can be found in

Engineering Manual, H-ENG-2

2175 West Park Place Blvd. • Stone Mountain, GA 30087 • 770.465.5600 • Fax: 770.465.5990 • www.heatcraftrpd.com

(W)

(W)

(H)

(H)

(H)

(H)

12

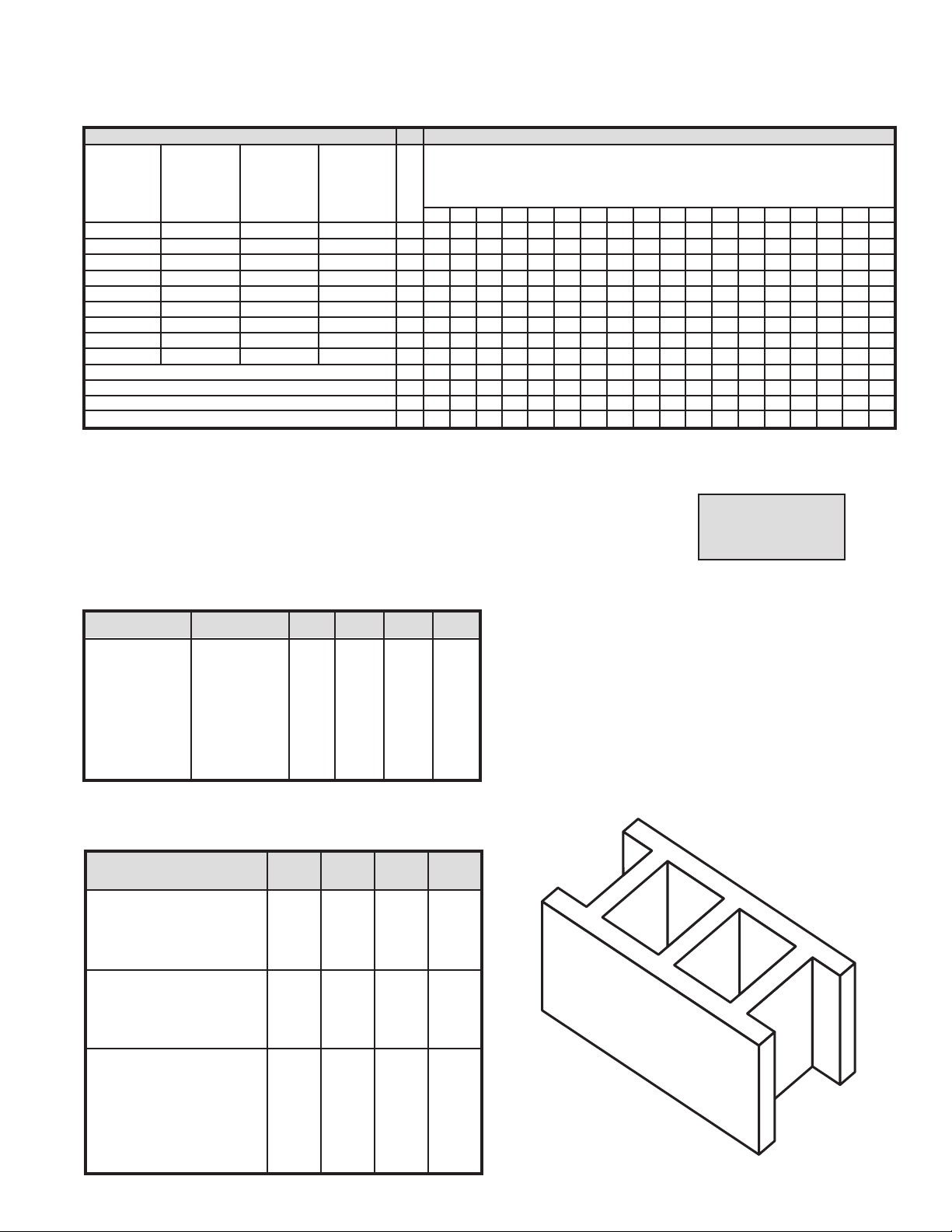

Appendix - Tables

Table 1

Wall Heat Loads

Insulation (Inches) Heat Load (BTU Per 24 Hours Per One Square Foot of Outside Surface)

Cork Glass Urethane

or Fiber or Urethane (Foamed Temperature Reduction in ºF.

Mineral Poly- (Sprayed) in R (Outside Air Temperature Minus Room Temperature)

Wool Styrene Place)

k = .30 k = .26 k = .16 k = .12 1 40 45 50 55 60 65 70 75 80 85 90 95 100 105 110 115 120

1 4 5.10 204 230 255 281 306 332 357 383 408 434 459 485 510 536 561 587 612

2 8 3.40 136 153 170 187 204 221 238 255 272 289 306 323 340 357 374 391 408

4 3 2 12.6 1.80 72 81 90 99 108 117 126 135 144 153 162 171 180 189 198 207 216

5 4 2 16.4 1.44 58 65 72 79 87 94 101 108 115 122 130 137 144 151 159 166 173

6 5 3 19.6 1.20 48 54 60 66 72 78 84 90 96 102 108 114 120 126 132 138 144

8 6 4 3 25 0.90 36 41 45 50 54 59 63 68 72 77 81 86 90 95 99 104 108

10 8 4 33 0.72 29 32 36 40 43 47 50 54 58 61 65 68 72 76 79 83 86

10 6 38.7 0.60 24 27 30 33 36 39 42 45 48 51 54 57 60 63 66 69 72

6 50 0.48 19 22 24 26 29 31 34 36 38 41 43 46 48 51 53 55 58

Single window glass . 9 27 1080 1215 1350 1490 1620 1760 1890 2030 2160 2290 2440 2560 2700 2840 2970 3100 3240

Double Window Glass 2.2 11 440 495 550 610 660 715 770 825 880 936 990 1050 1100 1160 1210 1270 1320

Triple Window Glass 3.4 7 280 315 350 390 420 454 490 525 560 595 630 665 700 740 770 810 840

6” Concrete Floor 4.8 5 200 225 250 275 300 325 350 375 400 425 450 475 500 525 550 575 600

Note: Above insulation “K” Factors [Thermal Conductivity, BTU

per (hour) (square foot) (ºF. per inch of thickness)] and heat

gain factors for Cork and Window Glasses are extracted and

Insulation Values

“K” Factor - Insulating Value of any material is rated by its thermal conductivity

“U” Factor - Overall coecient of heat transfer, BTU per hour/per square foot/per degree F.

“R” Factor - Thermal resistances

“X” = Inches of Insulation

Table 2

Eective K Factor in Block Thickness of Insulation

Insulation Insul. K Factor 6” 8” 10” 12”

Air 4.65 6.94 6.65 6.50 6.40

Vermiculite .47 2.73 2.67 2.64 2.62

Sawdust .45 2.70 2.65 2.62 2.60

Cork .38 2.62 2.57 2.55 2.53

Rock Wool .30 2.52 2.49 2.47 2.45

Mac. Paper .28 2.50 2.46 2.45 2.43

Styrofoam .24 2.45 2.42 2.40 2.40

Polyurethane .16 2.36 2.33 2.33 2.32

reprinted by permission from ASHRAE 1972 HANDBOOK OF

FUNDAMENTALS.

K = UX = X/R

U = K/X = 1/R

R = 1/U = X/K

Note: If blocks have 3 holes, add .75 to all of the values shown. The

above data is being shown for reference purpose only - this is a very

inecient method of construction/insulation due to:

1. Concrete webs are dominant factor in calculating insulating eect.

2. Filling techniques may leave blocks improperly lled.

3. No vapor seal present - moisture inltration decreases insulation

eect.

4. If used for freezers, moisture will freeze inside block and break

out the surface of the block.

5. Blocks are highly subject to setting cracks- more inltration.

Table 3

Allowance for Sun Eect

(Fahrenheit degrees to be added to the normal temperature dierence for heat leakage

calculations to compensate for sun eect- not to be used for air conditioning design.)

Type of East South West Flat

Surface Wall Wall Wall Roof

Dark Colored Surfaces,

Such as:

Slate Roong 8 5 8 20

Tar Roong

Black Paints

Light Colored Surface,

Such as:

White Stone 4 2 4 9

Light Colored Cement

White Paint

Medium Colored Surface,

Such as:

Unpainted Wood

Brick 6 4 6 15

Red Tile

Dark Cement

Red, Gray or Green Paint

13

Table 4

Average air changes per 24 hours for storage rooms

above 32ºF. (0ºC.) due to door openings and inltration.

Table 5

Average air changes per 24 hours for storage rooms

below 32ºF. (0ºC.) due to door openings and inltration.

Air Air Air

Volume Changes Volume Changes Volume Changes

Cu. Ft. Per 24hrs. Cu. Ft. Per 24hrs. Cu. Ft. Per 24hrs.

200 44.0 2,000 12.0 25,000 3.0

250 38.0 3,000 9.5 30,000 2.7

300 34.5 4,000 8.2 40,000 2.3

400 29.5 5,000 7.2 50,000 2.0

500 26.0 6,000 6.5 75,000 1.6

600 23.0 8,000 5.5 100,000 1.4

800 20.0 10,000 4.9 150,000 1.2

1,000 17.5 15,000 3.9 200,000 1.1

1,500 14.0 20,000 3.5 300,000 1.0

Note: For heavy usage multiply the above values by 2.0

For long storage multiply the above values by 0.6

Air Air Air

Volume Changes Volume Changes Volume Changes

Cu. Ft. Per 24hrs. Cu. Ft. Per 24hrs. Cu. Ft. Per 24hrs.

200 33.5 2,000 9.3 25,000 2.3

250 29.0 3,000 7.4 30,000 2.1

300 26.2 4,000 6.3 40,000 1.8

400 22.5 5,000 5.6 50,000 1.6

500 20.0 6,000 5.0 75,000 1.3

600 18.0 8,000 4.3 100,000 1.1

800 15.3 10,000 3.8 150,000 1.0

1,000 13.5 15,000 3.0 200,000 0.9

1,500 11.0 20,000 2.6 300,000 0.85

Table 6

Heat removed in cooling air storage room conditions

(BTU per Cu. Ft.)

Storage Temperature of Outside Air

Room 40ºF. (4.4ºC.) 50ºF. (10ºC.) 85ºF. (29.4ºC.) 90ºF. (32.2ºC.) 95ºF. (35ºC.) 100ºF. (37.8ºC.)

Temp. Relative Humidity of Outside Air, %

ºF. ºC. 70 80 70 80 50 60 50 60 50 60 50 60

55 12.8 – – – – 1.12 1.34 1.41 1.66 1.72 2.01 2.06 2.44

50 10.0 – – – – 1.32 1.54 1.62 1.87 1.93 2.22 2.28 2.65

45 7.2 – – – – 1.50 1.73 1.80 2.06 2.12 2.42 2.47 2.85

40 4.4 – – – – 1.69 1.92 2.00 2.26 2.31 2.62 2.67 3.65

35 1.7 – – 0.36 0.41 1.86 2.09 2.17 2.43 2.49 2.79 2.85 3.24

30 -1.1 0.24 0.29 0.58 0.66 2.00 2.24 2.26 2.53 2.64 2.94 2.95 3.35

25 -3.9 0.41 0.45 0.75 0.83 2.09 2.42 2.44 2.71 2.79 3.16 3.14 3.54

20 -6.7 0.56 0.61 0.91 0.99 2.27 2.61 2.62 2.90 2.97 3.35 3.33 3.73

15 -9.4 0.71 0.75 1.06 1.14 2.45 2.74 2.80 3.07 3.16 3.54 3.51 3.92

10 -12.2 0.85 0.89 1.19 1.27 2.57 2.87 2.93 3.20 3.29 3.66 3.64 4.04

5 -15.0 0.98 1.03 1.34 1.42 2.76 3.07 3.12 3.40 3.48 3.87 3.84 4.27

0 -17.8 1.12 1.17 1.48 1.56 2.92 3.23 3.28 3.56 3.64 4.03 4.01 4.43

-5 -20.6 1.23 1.28 1.59 1.67 3.04 3.36 3.41 3.69 3.78 4.18 4.15 4.57

-10 -23.3 1.35 1.41 1.73 1.81 3.19 3.49 3.56 3.85 3.93 4.33 4.31 4.74

-15 -26.1 1.50 1.53 1.85 1.92 3.29 3.60 3.67 3.96 4.05 4.46 4.42 4.86

-20 -28.9 1.63 1.68 2.01 2.00 3.49 3.72 3.88 4.18 4.27 4.69 4.66 5.10

-25 -31.7 1.77 1.80 2.12 2.21 3.61 3.84 4.00 4.30 4.39 4.80 4.78 5.21

-30 -34.4 1.90 1.95 2.29 2.38 3.86 4.05 4.21 4.51 4.56 5.00 4.90 5.44

Table 3, 4 & 5 extracted and reprinted by permission from ASHRAE 1972 Handbook of Fundamentals.

Table 6 extracted and reprinted by permission from ASHRAE 1967 Handbook of Fundamentals.

14

Loading...

Loading...