Heatcraft Refrigeration Products Air-Cooled Condensing Units User Manual

Air-COOLED CONDENSiNG UNiTS

1/2-6 HP Indoor and Outdoor Models

Technical Guide

BNHTSTB

April 2008

Replaces BN-HTSTB, May 2004

www.thecoldstandard.com

Table of Contents

®

Nomenclature ................................................................................................................................................................................. 2

Features & Benets ........................................................................................................................................................................

Options ..............................................................................................................................................................................................4

Hermetic Compressors ................................................................................................................................................................5

Performance Data ...............................................................................................................................................................5

Medium & High Temp., R–22 ................................................................................................................................5

Extended Temp., R–404A/507 ..............................................................................................................................6

Low Temp., R–404A/507 .........................................................................................................................................7

Unit Specication Data. .....................................................................................................................................................7

Electrical Data .......................................................................................................................................................................8

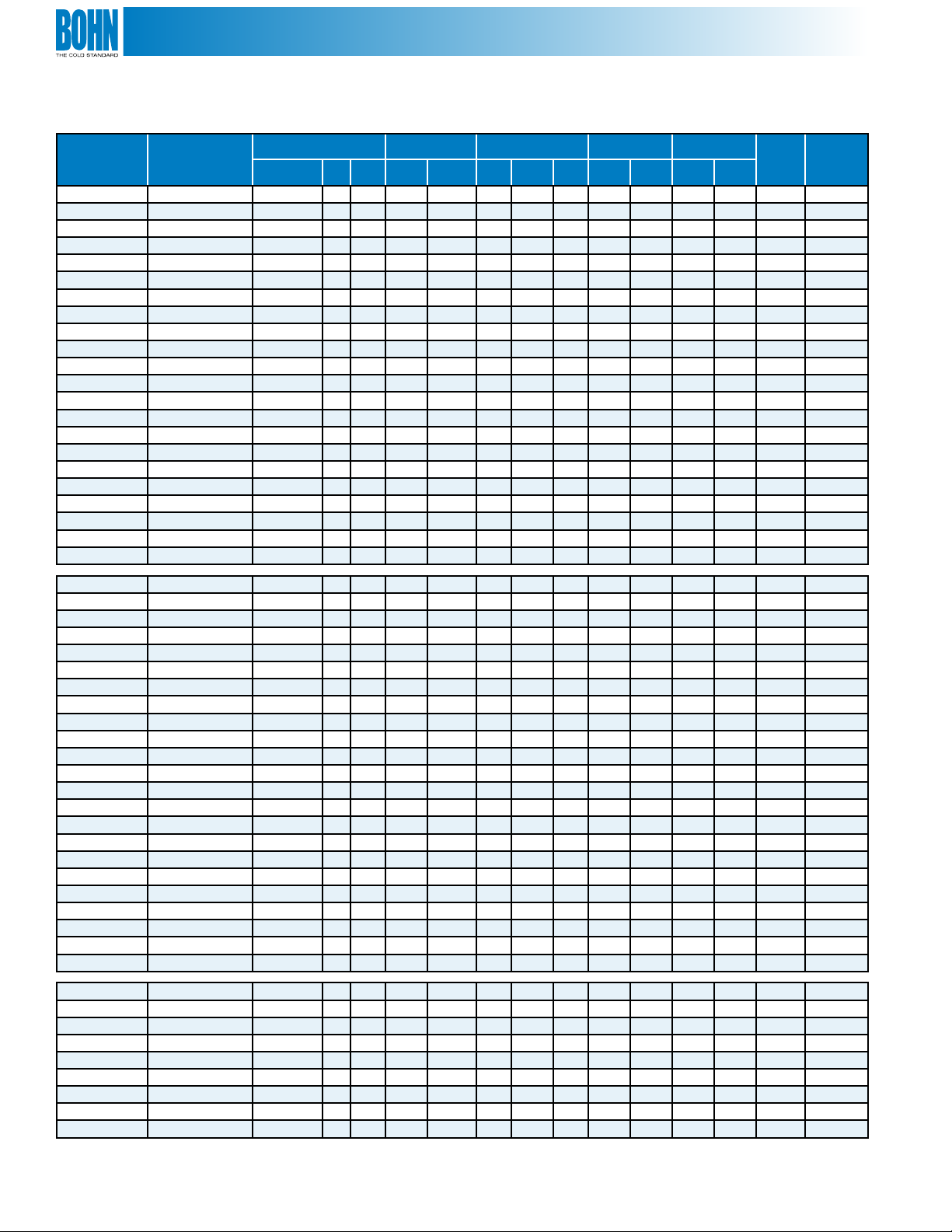

Scroll Compressors ........................................................................................................................................................................9

Performance Data ...............................................................................................................................................................9

Medium Temp., R–404A/507 ................................................................................................................................9

Low Temp., R–404A/507 ...................................................................................................................................... 10

Medium Temp., R–22 ............................................................................................................................................ 11

Low Temp., R–22 .................................................................................................................................................... 12

Unit Specication Data ................................................................................................................................................... 13

Electrical Data .................................................................................................................................................................... 13

Semi–hermetic Compressors .................................................................................................................................................. 14

Performance Data ............................................................................................................................................................14

High Temp., R–22 ................................................................................................................................................... 14

Medium Temp., R–404A/507 .............................................................................................................................15

Low Temp., R–404A/507 ...................................................................................................................................... 16

Unit Specication Data ................................................................................................................................................... 17

Electrical Data .................................................................................................................................................................... 18

Medium Temp. ........................................................................................................................................................ 18

Low Temp. ................................................................................................................................................................ 19

Replacement Parts by InterLink™ .......................................................................................................................................... 19

Dimensional Drawings of Cabinet ..................................................................................................................................20-21

3

MEA Accepted

We have made a commitment to customer needs, innovation and environmental stewardship

and have dedicated ourselves to delivering energy-ecient choices that reduce costs, improve

bottom lines and enhance equipment performance and service life. The PSC motor is an Energy

Solutions® feature and is optimized to help you save money by increasing energy eciency.

Nomenclature

B H T 030 L 6 C F

Model Compressor Application Equiv. HP Temp. Refrigerant Voltage Identier

B =

Bohn

2

H = Hermetic

S = Semi–herm.

Z = Scroll

T = Outdoor

N = Indoor

S = Beacon II™

Microprocessor

B = Bohnmizer

005 = 1/2 HP

008/009 = 3/4 HP

010, 011 = 1 HP

01* = 1–1/2 HP

02* = 2 HP

03* = 3 HP

04* = 4 HP

05* = 5 HP

060 = 6 HP

H = High

L = Low

M = Medium

E = Extra Low

X = Extended

Medium

2 = R–22

6 = R–404A/507

B = 208/230/1/60

C = 208/230/3/60

D = 460/3/60

G = 230/1/60

© 2008 Heatcraft Refrigeration Products LLC

F = Stock

Features & Benefits

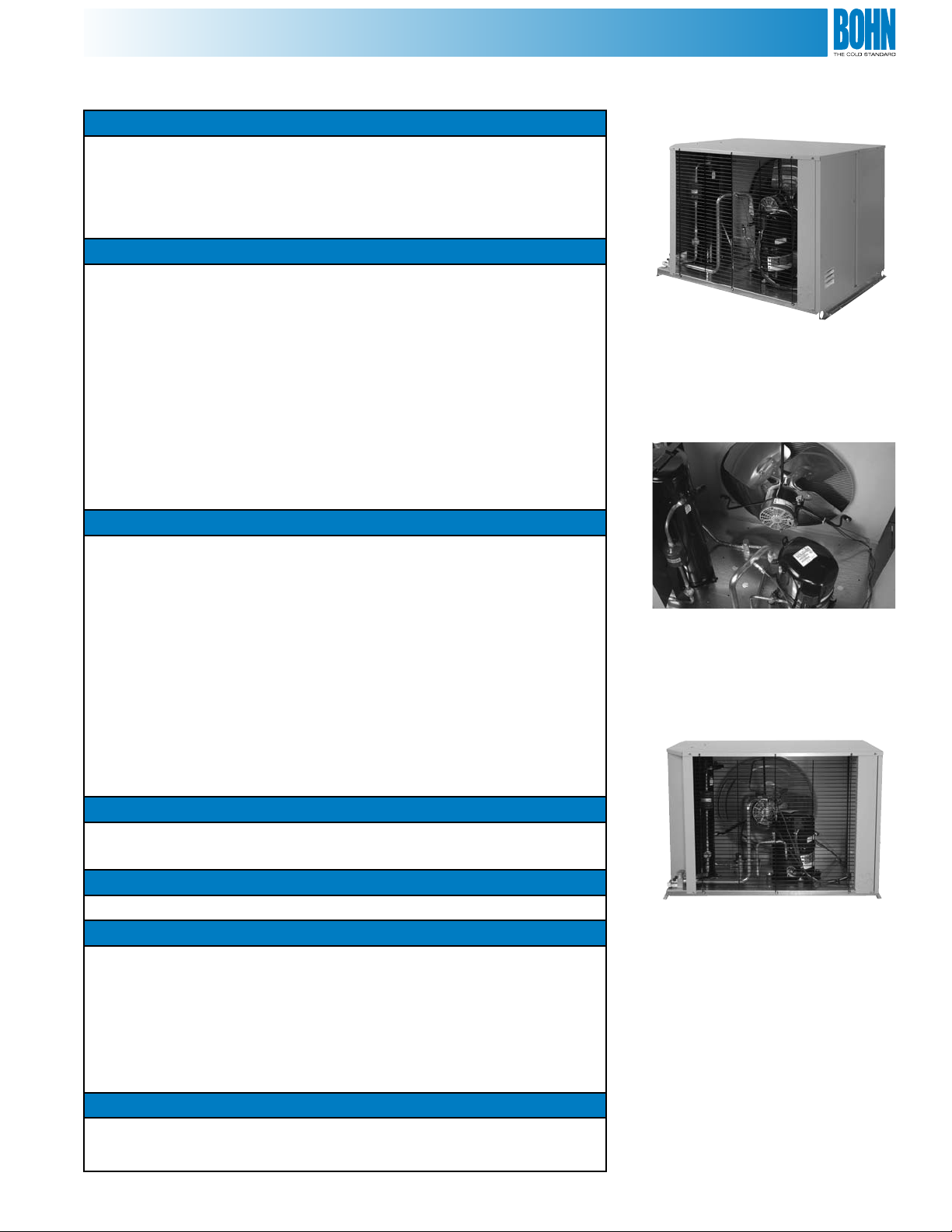

Cabinet & Construction

Painted galvanized cabinets for superior strength and corrosion

•

protection including hoods for outdoor units

Heavy duty steel raised base with 1-1/2" legs

•

Fan guards and wiring conduit on indoor models

•

Serviceability

Suction service valves for hermetic and scroll compressors located

•

outside the cabinet for quick installations. Semi-hermetic compressor

models have a suction valve on the compressor and an access tting

on the suction line entering the cabinet. A receiver with fusible plug,

liquid shuto valve and charging port is also standard

Large electrical panel for ease of access

•

Prefabricated wiring harnesses for tight crimp connections and

•

consistent labeling

Unit stays on line if the hood is removed for servicing

•

Sight glass is easily viewable

•

Quality

All units completely leak tested in a helium environment and

•

bump tested and allowed to cycle o on the high and low pressure

control. Each unit will have a copy of the run data shipped inside

the electrical panel

Electrical circuits are completely checked for continuity

•

Typical Outdoor Hermetic Unit

Typical Outdoor Unit with throwaway liquid-line

lter and sight glass

Piping is laid out to minimize stress and vibration and is pre-bent to

•

eliminate leaks

Encapsulated, auto-reset, high and low pressure controls to

•

eliminate leaks (standard on all high and medium temperature

models, adjustable low pressure control standard on low

temperature models)

Fans

Fans specically matched with motor and coil to attain maximum air

•

movement and cooling

Motors

Motors rated for 50 and 60 cycle application•

Compressor

Wide variety of compressors including: hermetic, semi-hermetic

•

and scroll. R-22 and R-404A/507 available for both medium and low

temperature applications

Spring-mounted compressors with vibration eliminators on all 1/2 - 6

•

HP semi-hermetic compressors

Discharge service valves on all compressors including hermetics

•

Options

Factory-installed Smart Defrost Kit™ (SDK)

•

Typical Outdoor Hermetic Unit with liquid lter drier

and sight glass

Liquid and suction lters available as options

•

3

™

Options

Electrical options: Outdoor Indoor Stock

Smart Defrost Kit™ Option Option N/A

Dual pressure control (not available on Beacon II™) Option Option N/A

Adjustable low pressure control for medium temp. comp. Option Option N/A

Crankcase heater Standard N/A Standard

Fused disconnect / Non-fused disconnect

Phase loss / low voltage monitor Option Option N/A

Fixed fan cycling — pressure or temperature (2 fan units)

(Pressure standard on Beacon II™)

Air or electric defrost timer only Option Option 1/2-3 HP low temp.

Electric defrost with timer & contactors (040-060 models only) Option Option 4-6 HP low temp.

Beacon II™ Option Option N/A

Mechanical options:

Head pressure control ooding valve Standard Option Standard

Liquid line drier, sight glass Option Option Standard

Suction line lter Option Option N/A

Suction accumulator (standard on X6 models) Option Option N/A

Oil separator with discharge line check valve (D cabinet) Option Option N/A

Liquid line solenoid valve and pumpdown switch Option Option N/A

Replaceable core liquid line lter (D cabinet) Option Option N/A

Replaceable core suction line lter (D cabinet) Option Option N/A

Precharged refrigerant with line sets and wire harnesses Option Option N/A

Oversize receiver (D cabinet) Option Option N/A

Low ambient kit with heated and insulated receiver, TD relay Option N/A N/A

12" Extended legs for snowbelt operation Shipped loose Shipped loose Shipped loose

Option Shipped loose N/A

Option Option N/A

The Beacon II™ Refrigeration System is a preassembled, factory installed refrigeration

system featuring an integrated microcomputer based electronic control board.

The Beacon II™ Refrigeration System replaces the expansion valve, solenoid valve, room

thermostat, defrost control and timer. It comes factory preset thereby eliminating all

of the expensive and time consuming ne tuning and adjustments necessary for a good system installation. For

additional information, contact your Sales Representative.

The Bohnmizer® System

The Bohnmizer® system is a complete factory furnished commercial refrigeration split system designed to operate

properly regardless of climatic conditions. As the ambient temperature falls below 75°F, the head pressure is

allowed to decrease in direct relationship to the ambient.

The heart of the system is the Bohnmizer valve, whose design allows the proper amount of refrigerant to ow to

the evaporator irrespective of the valve inlet pressure. The Bohnmizer valve also responds very rapidly to changes

in suction temperature, which assures the maintenance of low superheat, regardless of the ambient temperature.

The Bohnmizer system concept results in operational energy savings, increased compressor life, reduced

refrigerant costs and less maintenance expense.

4

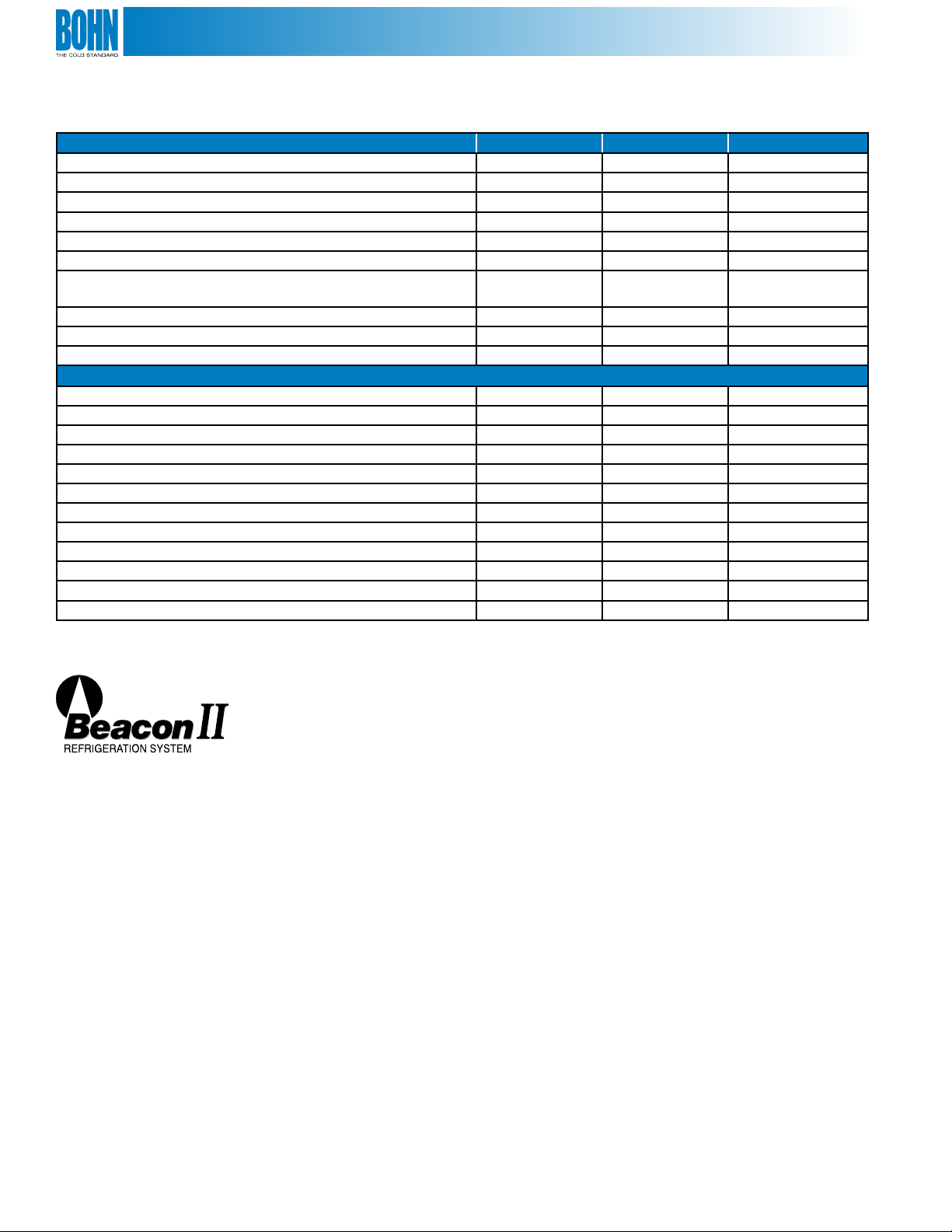

HERMETIC COMPRESSORS

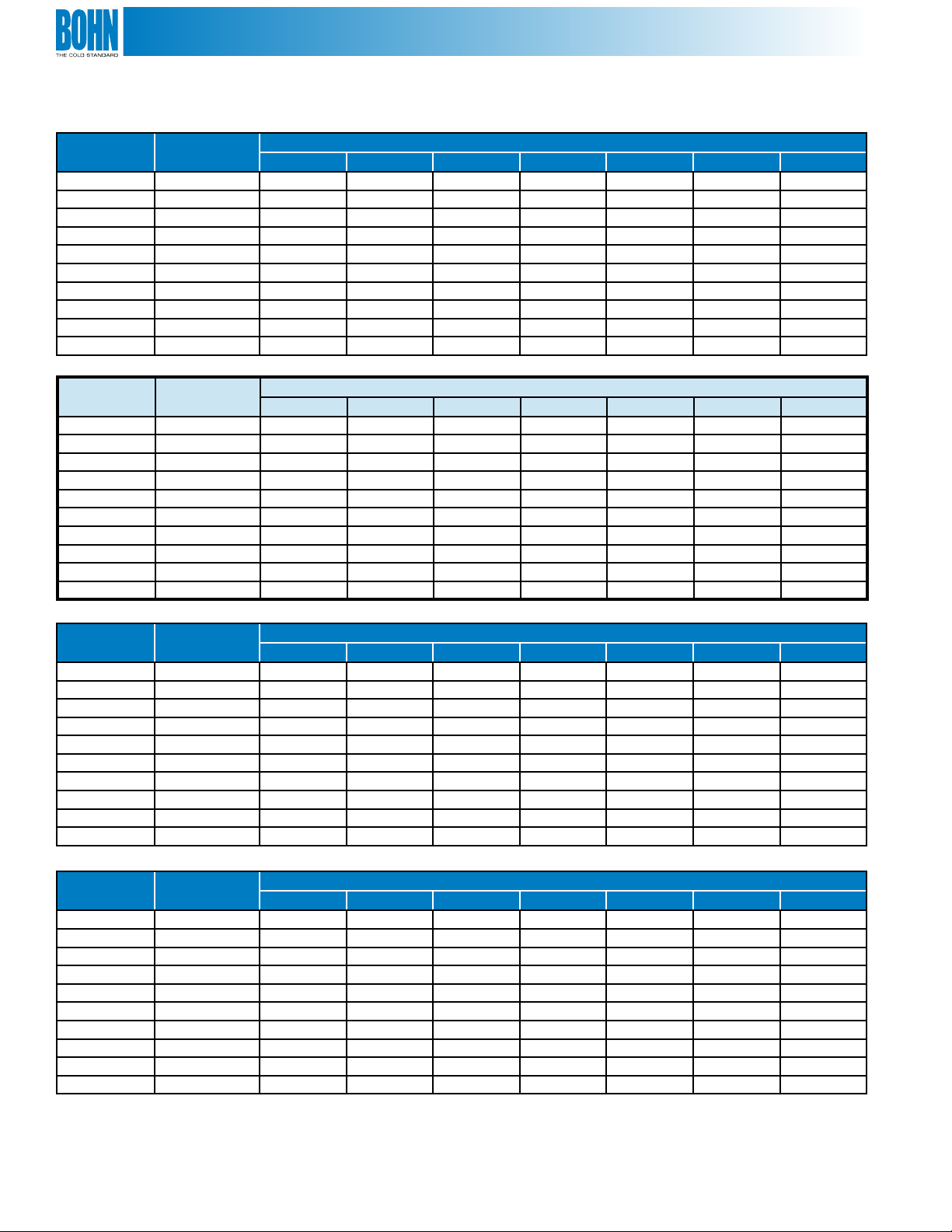

Performance Data - Medium & High Temperature (R-22)

R-22 Model Compressor

BH*-005H2 ART82C1 7,470 5,640 5,090 4,610 4,170 3,740 2,940

BH*-008H2 RS64C2 10,690 8,990 8,080 7,310 6,610 5,850 4,540

BH*-010H2 RS70C1 11,360 10,100 8,620 7,730 6,840 6,070 4,280

BH*-015H2 CR18KQ – 14,580 12,910 11,350 9,910 8,100 5,650

BH*-020H2 CR24KQ 24,360 19,930 17,760 15,650 13,650 11,640 8,560

BH*-029M2 CR37KQ – 26,210 23,630 21,300 18,870 16,620 11,700

BH*-030H2 CR37KQ 41,190 33,300 29,500 25,830 22,330 19,040 13,210

BH*-040H2 CR53KQ 57,430 46,140 40,790 35,620 30,740 26,150 18,100

BH*-050H2 CRN-0500 64,770 52,240 46,250 40,490 35,010 29,860 20,740

R-22 Model Compressor

BH*-005H2 ART82C1 7,170 5,410 4,870 4,410 3,990 3,580 2,790

BH*-008H2 RS64C2 10,280 8,540 7,740 6,980 6,310 5,580 4,320

BH*-010H2 RS70C1 10,870 9,120 8,150 7,350 6,490 5,740 3,870

BH*-015H2 CR18KQ – 13,830 12,210 10,670 9,260 7,510 5,130

BH*-020H2 CR24KQ 23,190 18,980 16,910 14,900 12,990 11,090 8,150

BH*-029M2 CR37KQ – 25,100 22,780 20,270 17,880 15,450 10,900

BH*-030H2 CR37KQ 38,230 31,710 28,090 24,610 21,260 18,140 12,580

BH*-040H2 CR53KQ 54,690 43,950 38,840 33,930 29,270 24,920 17,240

BH*-050H2 CRN-0500 61,680 49,760 44,050 38,560 33,340 28,440 19,750

40°F 30°F 25°F 20°F 15°F 10°F 0°F

40°F 30°F 25°F 20°F 15°F 10°F 0°F

Capacity BTUH @ 90°F Ambient Suction Temperature

Capacity BTUH @ 95°F Ambient Suction Temperature

R-22 Model Compressor

BH*-005H2 ART82C1 6,850 5,200 4,680 4,430 3,990 3,410 –

BH*-008H2 RS64C2 9,850 8,160 7,400 6,660 5,970 5,310 –

BH*-010H2 RS70C1 10,380 8,690 7,820 6,910 6,140 5,410 –

BH*-015H2 CR18KQ – 13,070 11,500 10,000 8,600 6,890 4,410

BH*-020H2 CR24KQ 22,030 18,030 16,070 14,160 12,340 10,540 7,740

BH*-029M2 CR37KQ – 23,980 21,720 19,260 16,910 14,470 –

BH*-030H2 CR37KQ 37,270 30,130 26,690 23,380 20,200 17,220 11,950

BH*-040H2 CR53KQ 51,960 41,760 36,890 32,240 27,820 23,670 16,390

BH*-050H2 CRN-0500 58,600 47,270 41,850 36,630 31,680 27,020 18,760

R-22 Model Compressor

BH*-005H2 ART82C1 6,240 4,960 4,430 4,010 3,550 3,190 –

BH*-008H2 RS64C2 8,930 7,820 6,710 6,020 5,390 4,770 –

BH*-010H2 RS70C1 9,490 8,250 6,950 6,170 5,440 4,380 –

BH*-015H2 CR18KQ – 11,590 10,100 8,230 6,880 5,650 –

BH*-020H2 CR24KQ 19,770 16,180 14,410 12,680 11,000 9,400 6,490

BH*-029M2 CR37KQ – 21,750 19,600 17,030 14,730 12,520 –

BH*-030H2 CR37KQ 33,900 27,120 23,870 20,760 17,820 15,080 10,350

BH*-040H2 CR53KQ 48,390 38,470 33,780 29,320 25,120 21,230 14,550

BH*-050H2 CRN-0500 54,770 43,730 38,490 33,470 28,740 24,340 16,760

* = T for Outdoor, N for Indoor, B for Bohnmizer, S for Beacon II™

40°F 30°F 25°F 20°F 15°F 10°F 0°F

40°F 30°F 25°F 20°F 15°F 10°F 0°F

Capacity BTUH @ 100°F Ambient Suction Temperature

Capacity BTUH @ 110°F Ambient Suction Temperature

Hermetic Compressors

5

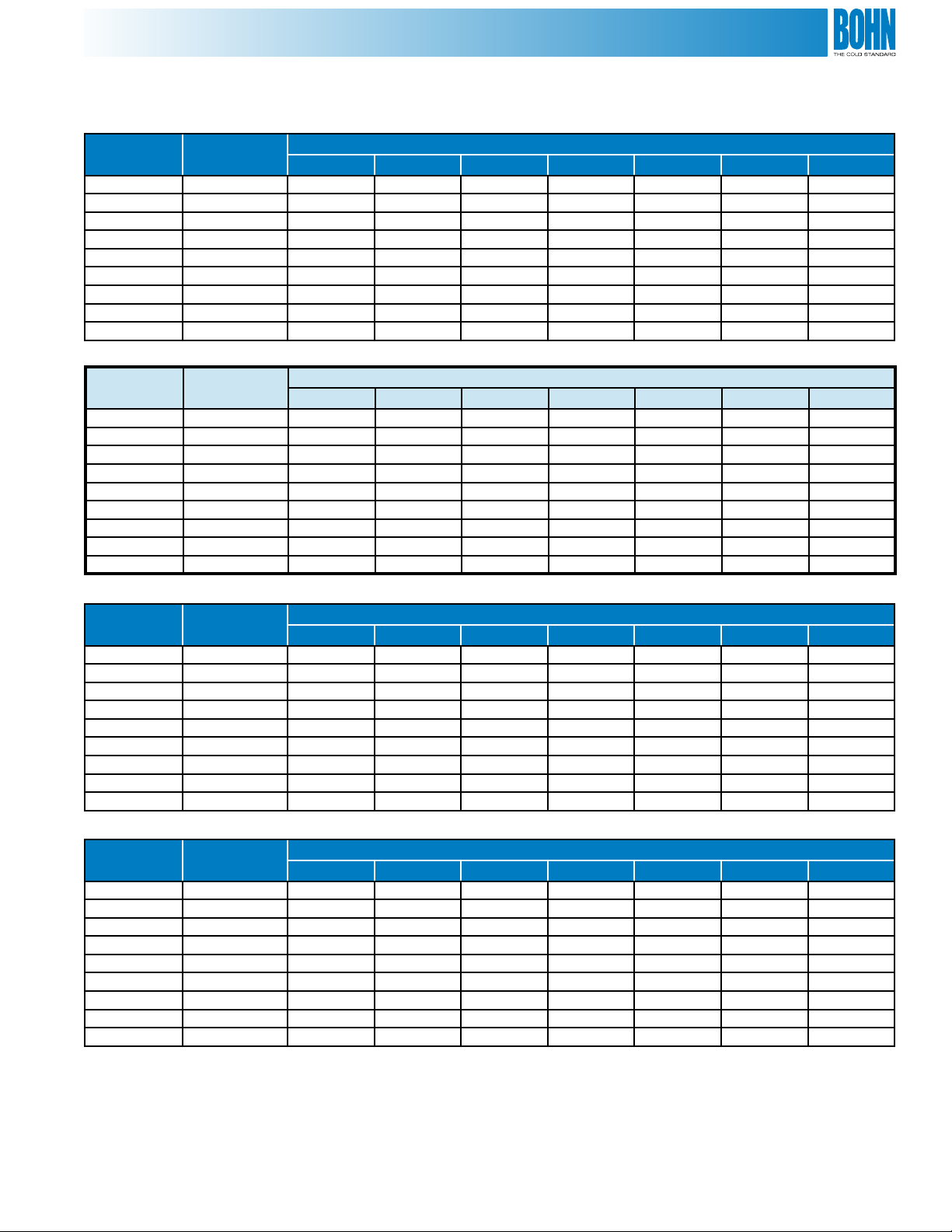

HERMETIC COMPRESSORS

Performance Data - Extended Temperature (R-404A/507)

R-404A/507

Model

BH*008X6 RS55C2E 8,490 8,050 7,480 4,260 2,350 1,750 1,130

BH*009X6 RS64C2E 9,710 9,090 8,310 5,220 4,130 3,240 2,400

BH*010X6 RS70C1E 10,060 9,300 8,660 5,540 4,080 2,750 2,050

BH*015X6 CS10K6E 16,430 15,090 13,550 7,910 5,280 3,610 2,970

BH*020X6 CS12K6E 18,590 17,000 15,420 9,110 6,330 4,030 3,270

BH*025X6 CS14K6E 20,150 18,630 17,270 10,900 8,050 5,740 4,760

BH*030X6 CS18K6E 29,490 27,030 24,550 14,390 10,600 7,380 6,180

BH*032X6 CS20K6E 32,420 29,620 26,840 15,930 12,200 8,780 7,000

BH*040X6 CS27K6E 43,970 39,510 35,150 20,560 14,980 11,830 8,690

BH*050X6 CS33K6E 44,600 43,160 39,300 24,160 17,610 13,500 11,700

R-404A/507

Model

BH*008X6 RS55C2E 8,010 7,590 7,060 4,020 2,220 1,650 1,070

BH*009X6 RS64C2E 9,170 8,580 7,850 4,920 3,900 3,060 2,260

BH*010X6 RS70C1E 9,400 8,850 8,170 5,120 3,770 2,610 1,820

BH*015X6 CS10K6E 15,400 13,960 12,800 7,220 5,060 3,330 2,630

BH*020X6 CS12K6E 17,490 16,000 14,470 8,370 5,830 3,860 2,830

BH*025X6 CS14K6E 18,920 17,490 16,250 10,090 7,530 5,230 4,330

BH*030X6 CS18K6E 27,840 25,490 23,130 13,480 9,710 6,750 5,620

BH*032X6 CS20K6E 30,530 27,890 25,240 14,800 11,200 7,930 6,220

BH*040X6 CS27K6E 41,480 37,270 33,160 19,400 14,130 11,160 8,200

BH*050X6

Compressor

Compressor

CS33K6E 42,300 41,000 37,180 22,370 17,300 12,700 10,900

30°F 25°F 20°F 0°F -10°F -20°F -25°F

30°F 25°F 20°F 0°F -10°F -20°F -25°F

Capacity BTUH @ 90°F Ambient Suction Temperature

Capacity BTUH @ 95°F Ambient Suction Temperature

R-404A/507

Model

BH*008X6 RS55C2E 7,530 7,130 6,640 3,780 2,090 1,550 1,010

BH*009X6 RS64C2E 8,620 8,060 7,380 4,630 3,660 2,870 2,130

BH*010X6 RS70C1E 8,790 8,290 7,680 4,760 3,430 2,230 1,570

BH*015X6 CS10K6E 14,210 13,150 11,780 6,660 4,580 2,930 2,270

BH*020X6 CS12K6E 16,410 14,990 13,380 7,700 5,280 3,420 2,420

BH*025X6 CS14K6E 17,730 16,390 15,220 9,390 6,950 4,770 3,930

BH*030X6 CS18K6E 26,190 23,970 21,800 12,570 8,880 6,120 5,110

BH*032X6 CS20K6E 28,600 26,160 23,750 13,740 10,300 7,050 5,370

BH*040X6 CS27K6E 38,980 35,030 31,180 18,240 13,290 10,500 7,700

BH*050X6 CS33K6E 39,800 38,760 34,810 20,760 16,200 11,800 10,000

R-404A/507

Model

BH*008X6 RS55C2E 6,150 5,900 5,520 2,730 2,050 1,620 1,190

BH*009X6 RS64C2E 7,370 6,840 6,300 4,070 3,000 2,380 1,750

BH*010X6

BH*015X6

BH*020X6 CS12K6E 14,270 12,980 11,550 6,460 4,410 2,580 1,660

BH*025X6 CS14K6E 15,430 14,450 13,230 8,100 5,760 3,860 2,990

BH*030X6

BH*032X6

BH*040X6 CS27K6E 35,150 31,240 27,520 15,210 11,290 8,920 6,550

BH*050X6 CS33K6E 35,200 34,060 30,530 19,000 14,100 10,400 9,010

* = T for Outdoor, N for Indoor, B for Bohnmizer, S for Beacon II™

Compressor

Compressor

RS70C1E 7,700 7,140 6,590 4,080 3,010 1,680 –

CS10K6E 12,150 11,110 10,030 5,410 3,650 2,140 1,540

CS18K6E 23,000 21,020 18,970 10,810 7,100 4,940 4,140

CS20K6E 24,840 22,790 20,580 11,490 8,260 5,270 3,630

30°F 25°F 20°F 0°F -10°F -20°F -25°F

30°F 25°F 20°F 0°F -10°F -20°F -25°F

Capacity BTUH @ 100°F Ambient Suction Temperature

Capacity BTUH @ 110°F Ambient Suction Temperature

6

HERMETIC COMPRESSORS

Performance Data - Low Temperature (R-404A/507)

R-404A/507

Model

BH*011L6 CF04K6E 7,030 6,240 5,370 3,850 3,330 2,630

BH*014L6 CF06K6E 10,500 9,380 7,830 6,090 4,890 4,080

BH*019L6 CF06K6E 12,100 10,180 8,910 6,580 5,530 4,570

BH*025L6 CF09K6E 15,550 14,500 12,700 9,000 7,560 6,230

BH*031L6 CF12K6E 18,840 17,800 15,140 11,540 9,790 8,070

R-404A/507

Model

BH*011L6 CF04K6E 6,840 5,750 4,920 3,650 3,020 2,360

BH*014L6 CF06K6E 9,900 8,840 7,750 5,670 4,710 3,680

BH*019L6 CF06K6E 11,400 10,100 8,750 6,040 5,030 4,150

BH*025L6 CF09K6E 15,400 13,700 12,000 8,300 6,950 5,750

BH*031L6 CF12K6E 17,690 16,800 14,360 10,910 9,170 7,470

R-404A/507

Model

BH*011L6 CF04K6E 6,310 5,170 4,460 3,300 2,660 2,070

BH*014L6 CF06K6E 9,310 8,280 7,280 5,280 4,350 3,510

BH*019L6 CF06K6E 10,700 9,430 8,170 5,810 4,570 3,700

BH*025L6 CF09K6E 14,500 12,800 11,200 8,130 6,410 5,220

BH*031L6 CF12K6E 17,600 15,090 13,410 10,700 9,040 7,320

R-404A/507

Model

BH*011L6 CF04K6E 5,240 4,450 3,620 2,630 2,100 –

BH*014L6 CF06K6E 8,310 7,340 6,420 4,580 3,730 2,990

BH*019L6 CF06K6E 9,330 8,170 7,040 4,920 3,980 3,090

BH*025L6 CF09K6E 12,700 11,400 9,900 7,030 5,760 4,590

BH*031L6 CF12K6E 15,700 14,000 12,400 9,250 7,690 6,100

Compressor

Compressor

Compressor

Compressor

Capacity BTUH @ 90°F Ambient Suction Temperature

0°F -5°F -10°F -20°F -25°F -30°F

Capacity BTUH @ 95°F Ambient Suction Temperature

0°F -5°F -10°F -20°F -25°F -30°F

Capacity BTUH @ 100°F Ambient Suction Temperature

0°F -5°F -10°F -20°F -25°F -30°F

Capacity BTUH @ 110°F Ambient Suction Temperature

0°F -5°F -10°F -20°F -25°F -30°F

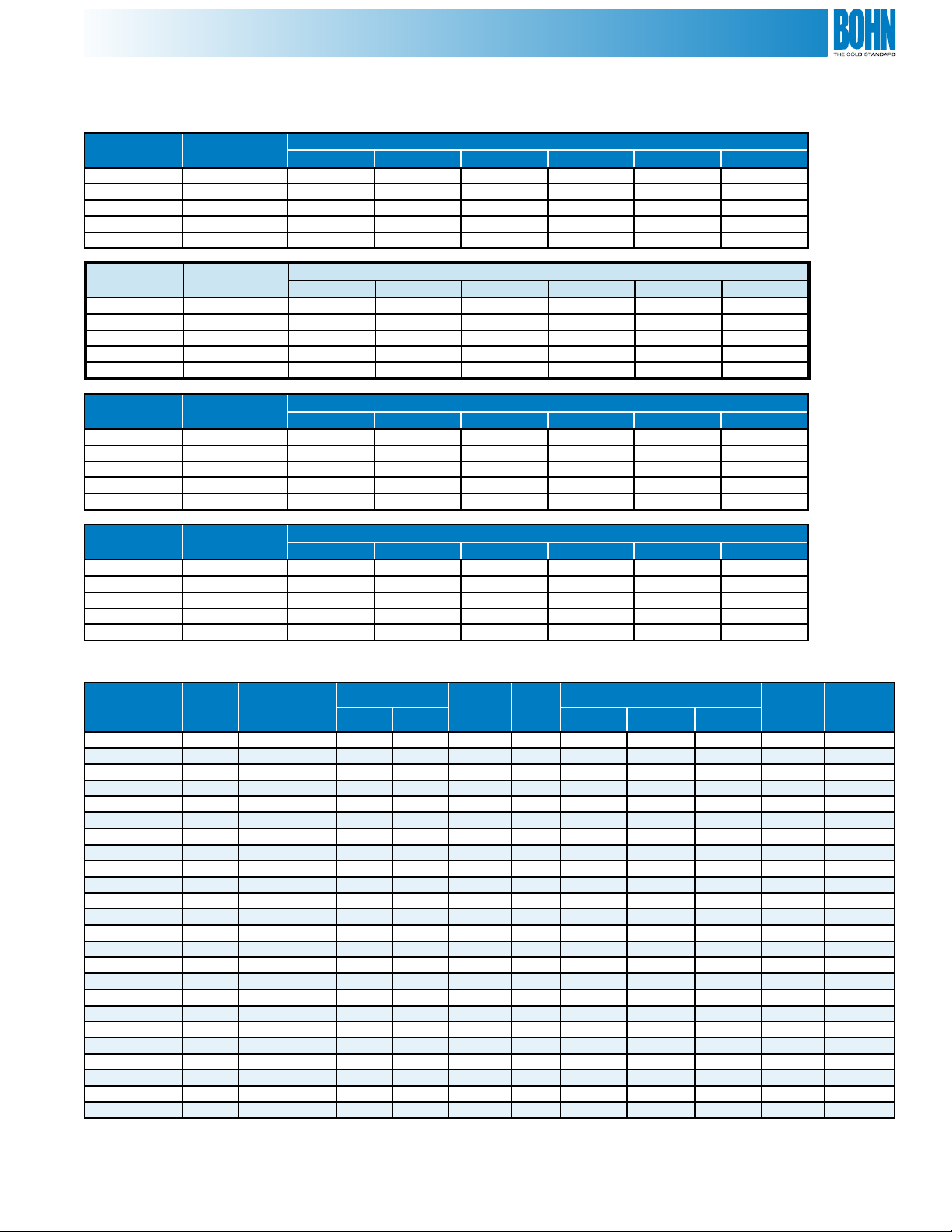

HERMETIC COMPRESSORS - Unit Specifications

Model Fig. ++ Compressor

BH*005H2 A ART82C1 3/8 1/2 6.0 1 28.25 23.75 17.25 187 67

BH*008H2 A RS64C2 3/8 1/2 6.0 1 28.25 23.75 17.25 141 68

BH*010H2 A RS70C1 3/8 5/8 6.0 1 28.25 23.75 17.25 136 68

BH*015H2 B CR18KQ 3/8 5/8 10.0 2 28.25 37.75 17.25 189 71

BH*020H2 B CR24KQ 3/8 7/8 10.0 2 28.25 37.75 17.25 193 72

BH*029M2 C CR37KQ 1/2 7/8 16.0 2 28.25 37.75 19.25 214 72

BH*030H2 D CR37KQ 1/2 7/8 22.0 1 30.25 42.50 29.75 281 73

BH*040H2 D CR53KQ 1/2 1-1/8 22.0 1 30.25 42.50 29.75 299 73

BH*050H2 D CRN-0500 1/2 1-1/8 22.0 1 30.25 42.50 29.75 310 75

BH*008X6 A RS55C2E 3/8 1/2 5.5 1 28.25 23.75 17.25 135 68

BH*009X6 A RS64C2E 3/8 5/8 5.5 1 28.25 23.75 17.25 144 68

BH*010X6 A RS70C1E 3/8 5/8 5.5 1 28.25 23.75 17.25 138 68

BH*015X6 B CS10K6E 3/8 5/8 9.0 2 28.25 37.75 17.25 193 71

BH*020X6 B CS12K6E 3/8 7/8 9.0 2 28.25 37.75 17.25 203 73

BH*025X6 B CS14K6E 3/8 7/8 9.0 2 28.25 37.75 17.25 208 74

BH*030X6 D CS18K6E 1/2 7/8 20.0 1 30.25 42.50 29.75 290 73

BH*032X6 D CS20K6E 1/2 7/8 20.0 1 30.25 42.50 29.75 275 76

BH*040X6 D CS27K6E 1/2 1-1/8 20.0 1 30.25 42.50 29.75 281 73

BH*050X6 D CS33K6E 1/2 1-1/8 20.0 1 30.25 42.50 29.75 313 73

BH*011L6 A CF04K6E 3/8 5/8 5.5 1 28.25 23.75 17.25 139 73

BH*014L6 A CF06K6E 3/8 5/8 5.5 1 28.25 23.75 17.25 170 73

BH*019L6 B CF06K6E 3/8 5/8 9.0 2 28.25 37.75 17.25 200 69

BH*025L6 B CF09K6E 3/8 7/8 9.0 2 28.25 37.75 17.25 222 76

BH*031L6 C CF12K6E 1/2 7/8 14.0 2 28.25 37.75 19.75 223 77

* = T for Outdoor, N for Indoor, B for Bohnmizer, S for Beacon II™ ++ = See Dimensional Drawings for details

†

= Estimated sound pressure values are 10 feet from the unit. For estimating sound pressure from the unit at dierent distances, deduct the following from the unit

values: 20 feet, deduct 6 dBA for 40 feet, deduct 12 dBA for 80 feet, deduct 18 dBA. This data is typical of “free eld” conditions for horizontal air cooled condensing

units at the outlet of the discharge air. The actual sound measurements may vary depending on the condensing unit installation. Factors such as reecting walls,

background noise and mounting conditions may have a signicant inuence on this data.

Connections (ID)

Liquid Suction D (In.) W (In.) H (In.)

Receiver

90% Full

Lbs.

Fan(s)

Dimensions

Net Wt.

Lbs.

Sound

Data dBA

†

7

HERMETIC COMPRESSORS

Electrical Data

Model

Number

BH*005H2B ART82C1-CAV 208-230 1 60 5.9 30.0 1 1/15 0.5 15.0 20 15 20 8 15

BH*008H2B RS64C2-CAV 208-230 1 60 6.9 37.0 1 1/15 0.5 15.0 20 15 20 8 15

BH*010H2B RS70C1-PFV 208-230 1 60 6.3 34.2 1 1/15 0.5 15.0 20 15 20 7 15

BH*010H2C RS70C1-TFC 208-230 3 60 4.2 31.0 1 1/15 0.5 15.0 20 15 20 8.6 15

BH*015H2B CR18KQ-PFV 208-230 1 60 8.1 41.0 2 1/15 1.0 15.0 24 15 25 6 19

BH*015H2C CR18KQ-TF5 208-230 3 60 4.9 40.0 2 1/15 1.0 15.0 24 15 20 7 19

BH*015H2D CR18KQ-TFD 460 3 60 2.8 23.0 2 1/15 1.0 15.0 20 15 20 ^ ^

BH*020H2B CR24KQ-PFV 208-230 1 60 12.2 70.5 2 1/15 1.0 20.0 29 25 30 6 23

BH*020H2C CR24KQ-TF5 208-230 3 60 6.7 40.0 2 1/15 1.0 15.0 24 15 25 9 19

BH*020H2D CR24KQ-TFD 460 3 60 3.6 28.0 2 1/15 1.0 15.0 20 15 20 ^ ^

BH*029M2B CR37KQ-PFV 208-230 1 60 16.7 100.3 2 1/15 1.0 21.8 38 35 50 12 30

BH*029M2C CR37KQ-TF5 208-230 3 60 9.9 85.0 2 1/15 1.0 15.0 38 20 40 12 30

BH*029M2D CR37KQ-TFD 460 3 60 5.0 39.0 2 1/15 1.0 15.0 15 15 25 ^ ^

BH*030H2B CR37KQ-PFV 208-230 1 60 16.7 100.3 1 1/3 3.5 24.3 38 40 50 12 30

BH*030H2C CR37KQ-TF5 208-230 3 60 9.9 85.0 1 1/3 3.5 20.0 38 25 40 12 30

BH*030H2D CR37KQ-TFD 460 3 60 5.0 39.0 1 1/3 1.9 15.0 24 15 25 ^ ^

BH*040H2B CR53KQ-PFV 208-230 1 60 26.0 140.0 1 1/3 3.5 36.0 48.0 50 60 12 35

BH*040H2C CR53KQ-TF5 208-230 3 60 16.3 107.0 1 1/3 3.5 23.9 38 40 50 12 30

BH*040H2D CR53KQ-TFD 460 3 60 8.1 55.0 1 1/3 1.9 15.0 29 15 30 11 23

BH*050H2B CRN5-0500-PFV 208-230 1 60 30.8 142.0 1 1/3 3.5 42.0 59 50 60 12 47

BH*050H2C CRN5-0500-TF5 208-230 3 60 19.2 130.0 1 1/3 3.5 28.0 40 45 50 12 30

BH*050H2D CRN5-0500-TFD 460 3 60 8.7 65.0 1 1/3 1.9 15.0 29 20 30 10 23

BH*008X6B

BH*009X6B RS64C2E-CAV 208-230 1 60 6.9 37.0 1 1/15 0.5 15.0 20 15 20 7 15

BH*010X6B RS70C1E-PFV 208-230 1 60 6.3 34.2 1 1/15 0.5 15.0 20 15 20 7 15

BH*010X6C RS70C1E-TFC 208-230 3 60 4.2 31.0 1 1/15 0.5 15.0 20 15 20 8.6 15

BH*015X6B CS10K6E-PFV 208-230 1 60 9.8 56.0 2 1/15 1.0 15.0 24 20 25 6 19

BH*015X6C CS10K6E-TF5 208-230 3 60 6.7 51.0 2 1/15 1.0 15.0 20 15 20 7 15

BH*020X6B CS12K6E-PFV 208-230 1 60 9.8 56.0 2 1/15 1.0 15.0 24 20 25 6 19

BH*020X6C CS12K6E-TF5 208-230 3 60 6.7 51.0 2 1/15 1.0 15.0 24 15 25 9 19

BH*025X6B CS14K6E-PFV 208-230 1 60 11.2 61.0 2 1/15 1.0 15.0 29 25 30 6 23

BH*025X6C CS14K6E-TF5 208-230 3 60 8.2 55.0 2 1/15 1.0 15.0 24 15 25 9 19

BH*025X6D CS14K6E-TFD 460 3 60 4.2 28.0 2 1/15 1.0 15.0 20 15 20 ^ ^

BH*030X6B CS18K6E-PFV 208-230 1 60 14.4 82.0 1 1/3 3.5 21.0 38 35 45 12 30

BH*030X6C CS18K6E-TF5 208-230 3 60 9.4 65.5 1 1/3 3.5 15.0 29 20 30 7 23

BH*030X6D CS18K6E-TFD 460 3 60 3.9 33.0 1 1/3 1.9 15.0 24 15 25 ^ ^

BH*032X6B CS20K6E-PFV 208-230 1 60 16.7 96.0 1 1/3 3.5 24.0 38 40 50 12 30

BH*032X6C CS20K6E-TF5 208-230 3 60 10.3 75.0 1 1/3 3.5 20.0 29 25 30 7 23

BH*032X6D CS20K6E-TFD 460 3 60 4.6 40.0 1 1/3 1.9 15.0 24 15 25 ^ ^

BH*040X6B CS27K6E-PFV 208-230 1 60 21.5 121.0 1 1/3 3.5 30.3 44 50 60 12 35

BH*040X6C CS27K6E-TF5 208-230 3 60 13.7 105.0 1 1/3 3.5 20.7 38 30 45 12 30

BH*040X6D CS27K6E-TFD 460 3 60 7.6 52.0 1 1/3 1.9 15.0 29 15 30 11 23

BH*050X6B CS33K6E-PFV 208-230 1 60 27.6 125.0 1 1/3 3.5 38.0 59 50 60 12 47

BH*050X6C CS33K6E-TF5 208-230 3 60 16.8 102.0 1 1/3 3.5 24.5 38 40 50 12 30

BH*050X6D CS33K6E-TFD 460 3 60 8.8 48.0 1 1/3 1.9 15.0 29 20 30 10 23

Part Number

RS55C2E-CAV 208-230 1 60 5.4 40.0 1 1/15 0.5 15.0 20 15 20 8 15

Power Supply Compressor Fan Motor MCA MOPD

Volts Ph Hz†RLA LRA Qty. HP FLA Air Elec. Air Elec.

Evap.

Amps

Fan

Defrost

Heater

Amps

BH*011L6B

BH*011L6C CF04K6E-TF5 200-230 3 60 3.9 52.0 1 1/15 0.5 15.0 20.0 15 20 8 15

BH*014L6B CF06K6E-PFV 208-230 1 60 10.3 59.2 1 1/15 0.5 15.0 20.0 20 25 4 15

BH*014L6C CF06K6E-TF5 200-230 3 60 6.3 52.0 1 1/15 0.5 15.0 24.0 15 25 9 19

BH*025L6B CF09K6E-PFV 208-230 1 60 15.0 87.0 2 1/15 1.0 20.0 29.0 30 40 6 23

BH*025L6C CF09K6E-TF5 200-230 3 60 9.2 72.2 2 1/15 1.0 15.0 21.0 20 25 7 15

BH*031L6B CF12K6E-PFV 208-230 1 60 17.0 105.0 2 1/15 1.0 22.3 37.5 35 50 12 30

BH*031L6C CF12K6E-TF5 200-230 3 60 10.7 85.0 2 1/15 1.0 15.0 28.8 25 30 7 23

BH*031L6D CF12K6E-TFD 460 3 60 5.3 42.0 2 1/15 1.0 15.0 23.8 15 25 ^ ^

* = T for Outdoor, N for Indoor, B for Bohnmizer, S for Beacon II™

Per UL and NEC, RLA values have been calculated by dividing the Maximum Continuous Current (MCC) by 1.56.

^ Power supplied by customer. † Consult factory for 50 HZ applications.

CF04K6E-PFV 208-230 1 60 8.6 59.2 1 1/15 0.5 15.0 20.0 15 25 7 15

8

Loading...

Loading...