Bulletin H-IM-71A

Part No. 4346B001

August 2002

(Replaces H-IM-71, August 1996)

Air Handler Unit

Installation & Operations Manual

TABLE OF CONTENTS

Coil Stacking ........................................................................................ 5

Condensate Drain Traps .......................................................................

Direct Expansion Coils .........................................................................

Filter Quantities ....................................................................................

Freezing Temperatures ........................................................................

Inspection ............................................................................................

Installation ...........................................................................................

Internal Isolation ..................................................................................

Maintenance ........................................................................................

Motors & Drives ...................................................................................

Replacement Parts ...............................................................................

Section Assembly .................................................................................

Shipment of Sections ...........................................................................

Start-up ................................................................................................

Steam Coils ...........................................................................................

Water Coils ...........................................................................................

Weights ................................................................................................

4

3

8

6

2

2

4

4

2

8

5

7

4

2, 3

3

7

Inspection

Shipment should be checked against the bill of lading to

verify that all items listed have been received.

All parts should be carefully inspected to determine if

any damage was incurred in shipment.

Any shortage and/or claims for damage should be

immediately reported to the delivering carrier followed

by filling a claim for shortages and/or damages.

Shipment of Units

Depending on the unit size and accessories included,

the shipment may be made in two or more sections.

Handling

Special care should be taken when handling and

assembling component sections of the unit. Rough

handling at the job site can result in damaged bearings,

bent shaft, etc.

All units are shipped on wooden skids. It is

recommended that units not be moved removed from

skids until they are at a place of installation. The

mounting legs/rails provided for isolators should be used

when lifting units into place.

Suspended Units

Unit sizes 03 through 41 may be ceiling suspended from

the mounting legs/based rails with 5/8” diameter rods

(furnished by others). These rods will pass through the

11/16” diameter mounting holes provided.

Unit sizes 50, 65, and 75 cannot be ceiling suspended.

Installation

It is very important that the unit be installed in a level

position to prevent distortion and to insure proper

damper operation and coil drainage.

Allow sufficient space around the unit for proper

maintenance. Major factors to be considered are

filter removal for cleaning or replacement, access

to all removal panels, removal of coils and shaft if

ever necessary, lubrication access and motor belt

adjustment.

Canvas duct connections should be used between the

unit and both supply and return air ducts.

Units are furnished with 1 1/4” F.P.T. Drain connection

on each side of the coil section. The drain line from

the drain pan connection must be adequately pitched

and should have a water seal of sufficient depth to

compensate for the air pressure within the units.

(See Condensate Drain Traps on page 4.)

When the unit is located on the roof, it must be mounted

on support beams that span load bearing walls. If this

is not done, excessive vibration may occur due to the

resiliency of the roof.

Fan noise is a function of the fan design, volume flow,

pressure, and the efficiency of the fan. Present methods

of measuring fan noise do not evaluate the pure tones

generated by some fans and these tones can be

objectionable when radiated into occupied spaces.

Therefore, on critical applications we recommend extra

sound attention in the octave band containing the tone.

Motors & Drives

All units will normally be shipped with motor and drive

installed.

When mounting a motor on the adjustable base (Installed

on the unit) extreme care should be taken to insure

proper alignment and belt tension.

All electrical work should be done in strict accordance

with local codes and regulations.

Steam Coils

Type “J” and “NFS” coils have supply and return

connections on the same end. Types “R”, “S”, and “RA”

coils have supply and return connections on opposite

ends.

Type “NFD” coils have supply connections one each end

of the coil , with a single return connection, one end only.

All piping should be in accordance with accepted

industry standards and local codes. Support all piping

independent of coil and provide adequate swing joints in

all piping to absorb expansion and contraction strains.

Run return piping the full size of the coil return connection

from the coil to a dirt pocket. (do not use reducing

fittings.)

Install drip traps in steam mains ahead of coils. Do not

drip steam mains through the coils.

Install a vacuum breaker (1/2” 15º check valve) ahead of

the trap on low pressure open gravity return systems and

on high pressure systems. Install a 1/2” 15º swing check

valve in a 1/2” vacuum equalizing line, bypassing the

condensate trap, on low pressure vacuum systems.

2

When two or more steam coils are furnished in a unit,

provide separate traps for each coil. Size traps with

ample capacity using the maximum heating load and

service factor recommended b y the trap manufacturer.

Select control valves in accordance with the

recommendations of the control manufacturer using

actual heating loads.

Install suitable strainer ahead of all automatic valves and

traps to catch dirt and scale. Provide adequate air vents

to expel air and other non-condensable.

Control valves used for Type “J”, “NFS”, “RA” and

“NFD” coils must be gradual acting modulating type with

veeport.

Where a control valve is used for Type “S” or “R” coils

and when the entering air temperature is below 35ºF.,

use a two position valve. Locate control element in the

entering air stream so that valve will remain open with

a minimum of five pounds steam pressure when the

entering air temperature is below 35ºF.

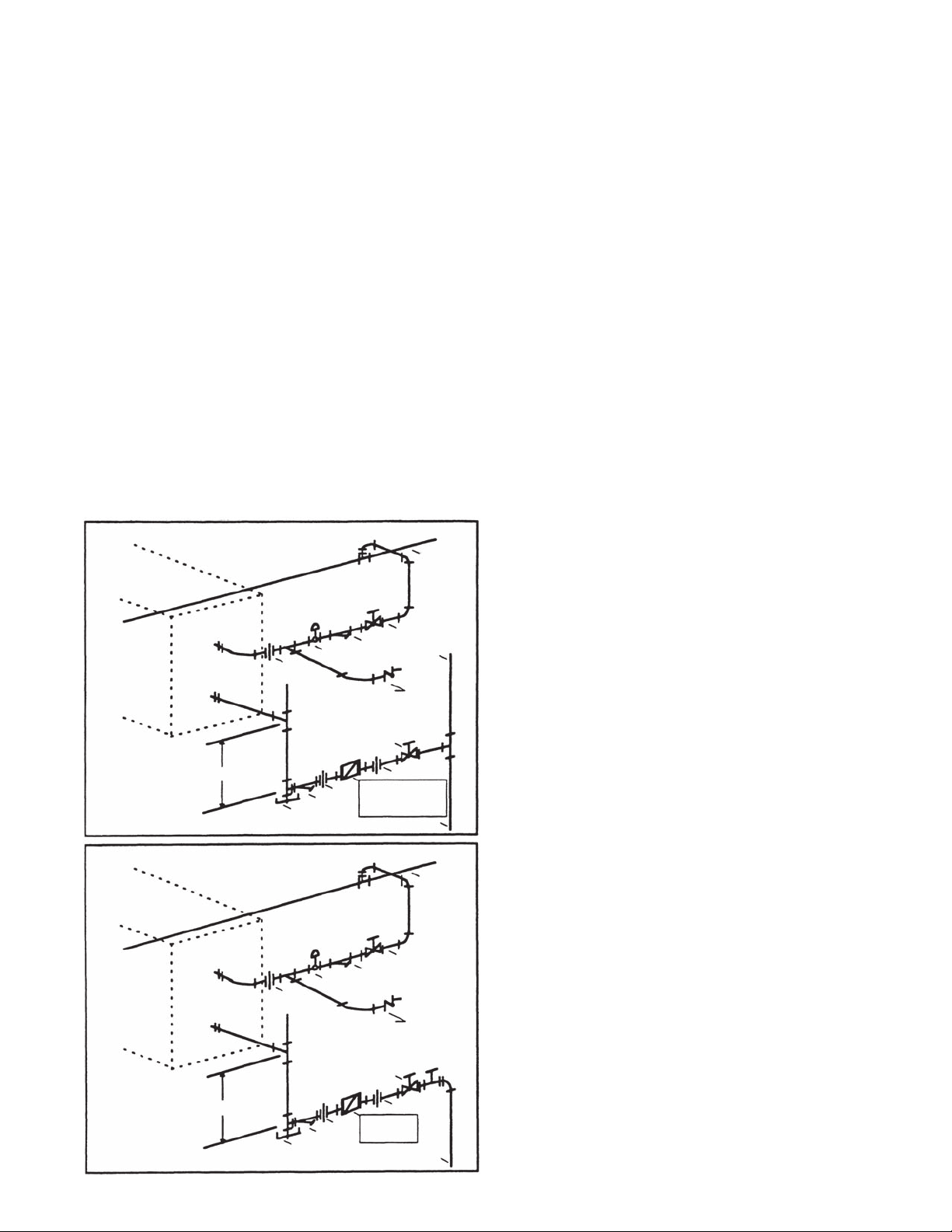

Typical Steam Coil Piping

Low Pressure Open Gravity Return System

Steam Main

Gate Valve

12” Minimum

High Pressure System

12” Minimum

Control Valve

Union

Vacuum Breaker

1/2”-15” Check Valve

Vent

Gate Valve

Union

Strainer

Dirt Pocket

Control Valve

Union

Vacuum Breaker

Vent

1/2”-15” Check Valve

Gate Valve

Union

Strainer

Dirt Pocket

Strainer

Combination Float

Thermostatic Trap

Strainer

Union

and

Return Main

Gate Valve

Union

Float or

Bucket Trap

Return Main

Open Vent

Steam Main

When the system is started up the damper should remain

closed for approximately ten minutes after the steam

valve is opened.

Properly locate all temperature sensing elements at a

point of true average air mixture temperature.

Refer to “Typical Steam Coil Piping Diagrams” for

controls positioning and piping configuration.

When face and bypass dampers are used, it is good

practice to install on the coil a valve which closes as

the face damper closes to prevent over heating due to

damper leakage or heat picked up by the air wiping the

exposed coil face.

Water Piping

All piping must be supported independent coils.

Swing joints or flexible fittings must be provided to absorb

expansion and contraction strains. Rigid piping may also

reduce effectiveness of vibration isolators.

The water supply should always be connected to the

bottom inlet of the coil. The coil connections are identified

with stickers.

Water coils , 3 through 10 rows, are supplied with a vent

and drain connection (1/4” MPT) which extends through

the unit casing.

For protection of coils exposed to freezing temperatures,

refer to page 6.

Coils must be adequately vented in order to prevent air

binding.

Direct Expansion

Both the liquid distributor and the suction line extend

through the casting.

The expansion valve utilized must be of the external

equalizer tube type. The expansion valve bulb must be

located on the suction line between the coil and the 1/4”

external equalizer tube. Never locate the bulb in a trap.

All refrigerant piping practices used should be in

accordance with local codes and latest ANSI Standard

B9 Safety Code. Hard drawn type “L” or “K” copper tubing

should be used. Soft tubing where bending is required

may be used provided it is protected in accordance with

local code restrictions.

Good Practice should be followed as to pulling adequate

vacuum, tubes cleaned of foreign material, etc.

3

Condensate Drain Trap

(Air Seal)

1 1/4” Pipe Drain

Start-Up

Make sure all bolts and screws are tight.

Remove tagged shipping tie-down bolts and spacers

from the fan and motor assembly before start-up.

(Internally isolated units only.)

Check the sheaves to see if they are alignment and

make suer the set screws are tight. Make sure that

the dimension across the top is equal on all grooves,

otherwise excessive belt wear will result.

Check for proper rotation of the blower pulley. Three

phase motor rotation can be reversed by exchanging

two of the three leads at the motor starter. The rotation

of single phase motors can be reversed by exchanging

leads inside the motor junction box. (See motor wiring

diagram.)

Check the amperage draw of the motor. This should not

exceed the nameplate amps shown on the motor serial

plate.

After approximately two weeks of operation, the belts

will have nearly acquired their permanent stretch. After

this interval, the belt tension should be checked again

and proper adjustment made.

Maintenance

The belt tension should be checked at three month

intervals.

The fan shaft bearings on Sizes 03, 06, 08, 10, and

12 with low pressure forward curved fans have lifetime

lubricated bearings. All other units have ball bearings

which can be relubricated. These bearings mounted

inside the fan section have extended lubrication lines

which are mounted on the outside of the fan panels.

The suggested greasing intervals indicated in a sticker

attached to the unit.

It is recommended that bearings be lubricated with a

high quality lithium grease at intervals indicated on

sticker attached to the unit.

Instructions are included on the motor nameplate for

lubricating the motor bearings.

The filter should be periodically inspected and replaced

or cleaned when necessary. Dirt filters reduce the sir

flow which reduces the capacity of the system.

Do not operate system without filters.

Condensate Drain Traps

The condensate drain trap piping must be properly

designed to insure the removal of condensate. Incorrect

trapping can hold water in pan causing overflow. On

blow-thru units, particular, system air can escape down

the drain with incorrect trapping.

(a) On draw-thru units (A) shall be equal to or

greater the coils section’s negative pressure at

operating conditions.

(b) On blow-thru units (A) can be as small as 1” but

(B) must equal or exceed the total static pressure

in the coil section.

Internally Isolated Units

Sizes 03-41 which have optional internal spring isolation

have four hold-down shipping braces. Remove the 1/2”

bolt between each shipping brace and the motor base,

then loosen the bolt to the frame and slide the brace to

the end of the slot so that the brace is 5/8” from motor

support base. Re-tighten the bolt so that the shipping

brace acts as a snubber on fan start up.

4

Typical ‘Accessory-to-Coil-Section’

and ‘Accessory-to-Accessory’ Attaching Method

5

Water Coils Exposed

to Freezing Temperature

Water coils exposed to freezing temperatures must be

protected from freeze-up by either adding anti-freeze

solution to coils or proper draining of the coils.

The coils are circuited so that there are no trapped

circuits. However, because of the serpentine nature of

the circuiting, it is almost impossible to adequately drain

the coils by gravity alone. Particularly on longer coils,

even a fraction of a degree deviation from a horizontal

plane can lead to water being trapped within the

serpentine.

Water that failed to drain from a single tube,

or even part of a tube, can cause the tube to

rapture upon freezing.

Draining Coils Using Supplemental

Air Blower

Ideally, a blower capable of delivering 150 CFM of air

at approximately 40-50 inches of water or more should

be used. Some small air compressors, while delivering

higher pressures, probably will not deliver sufficient

volume of air and this is equally as important.

1. Drain the coils by gravity after opening the

supply, return, vent and drain connection.

2. Connect the blower to large connection that

is at the greatest elevation. The small vent or

drain connection on the header to which the

blower is connected should be closed.

Refer to Figure 1 for typical hook -up during the

blow-out operation.

It is helpful to tap the coil causing along the

length of the coil during the draining process.

The blower should be operated until no moisture

can be detected leaving the coil. Then, shut the

blower off and permit the coil to stand for a few

minutes. This will permit the moisture that has

adhered to the walls to accumulate. Then the

blowing out operation should be repeated.

Ideally, the coil should be permitted to stand

twenty-four (24) hours and blown out again.

3. Leave all connections open until coil is put into

operation.

Installation of Anti-Freeze Solution

A second way to prevent a coil freeze-up is to add an

anti-freeze to the coil, such as industry inhibited glycol.

The coil should be valved off so that only the coil would

6

have anti-freeze added to it. The most positive way to

assure the mixing of the anti-freeze is to make a runaround loop with a circulating pump.

1. Open all connections and drain the coil as

thoroughly as possible.

2. The anti-freeze solution should be added to the

coil and circulated through the coil until the

solution is thoroughly mixed and all air is purged

from the coil. The air vent should be opened

during the filling operation and cracked during the

pumping operation to accomplish this. When

the solution has circulated for 15-20 minutes,

the concentration of the solution should be

checked with suitable hydrometer. If the

concentration is low, add more glycol and

operate the pump again. A typical piping diagram

is shown in Figure 2.

3. The anti-freeze solution may then be left in

the coils or drained and used to flush another

coil. The concentration must be checked for each

coil flushed.

The adding of anti-freeze to a system exposed to

freezing conditions may be necessary if the system

must be operation at a moment’s notice. This affects

the chiller and coil performance and must be taken into

consideration when selection the components.

Note: Most anti-freeze solution will be furnished with

a chart of concentration at freezing point. It is also

important to be certain that the anti-freeze solution

used is not corrosive to the tubing.

Air Handler Component Unit Size

Section

Model ID Description Fan

S Short FC

S Short AF

L Long FC

L Long AF

V Vertical FC

HD Heating Duty FC

HD Heating Duty AF

FO Fan Only FC

FO Fan Only AF

Flat -TA & Pleated 2”

Flat -Permanent 2”

Flat -Pleated 4”

High Capacity -TA & Pleated

High Capacity -Permanent

High Efficiency- 21” Section

High Efficiency- 28” Section

High Efficiency- 44” Section

Economizer

Combination Filter & Economizer

Internal Face and Bypass

External Face and Bypass

S Auxiliary Coil Module

L Auxiliary Coil Module

Electric Heater

Large Other Filter Fan and Coil

Coils Accessories Section Section

5/8” Tube

(Type 5)

10 FPI

1 Row

2 Row

3 Row

4 Row

6 Row

8 Row

10 Row

03 06 08 10 12 14 18 20 26 34 41 50 65 75

290 430 500 550 650 790 816 836 968 1188 1386 – – –

– – – – – – – 946 1177 1518 1782 2700 3300 4496

318 450 553 600 732 988 1033 1067 1221 1474 1672 – – –

– – – – – – – 1177 1430 1793 2057 2850 3480 4690

296 387 482 535 615 860 1004 1111 1254 1628 1881 – – –

170 280 312 360 450 510 564 605 693 902 1078 – – –

– – – – – – – 715 891 1221 1474 2600 3200 3359

162 266 296 342 428 485 536 575 658 857 1024 – – –

– – – – – – – 679 846 1160 1400 2470 3040 3191

60 73 83 95 99 104 106 108 115 160 185 255 315 384

66 79 89 101 106 114 126 135 165 240 275 390 460 560

75 88 98 110 119 124 126 127 130 185 210 298 351 428

149 168 187 206 215 224 230 234 244 260 290 360 440 535

155 176 196 216 225 234 240 244 254 365 450 520 650 790

82 95 112 133 133 153 175 180 194 235 248 269 330 359

103 121 143 170 170 196 225 224 246 296 318 345 425 463

127 150 173 201 201 230 264 274 299 358 380 412 516 552

174 195 216 224 236 247 254 260 300 430 550 680 800 975

323 363 403 430 451 471 484 494 544 690 840 1040 1240 1510

52 68 79 100 115 138 148 155 180 260 350 420 520 634

57 75 87 110 128 155 166 175 200 286 385 462 650 793

129 164 204 208 223 306 280 261 310 331 362 515 640 1305

157 184 257 258 305 504 497 492 563 617 648 665 820 1499

223 356 454 550 670 774 954 1104 1434 1760 2118 2481 3143 3599

36 56 70 80 94 106 110 112 144 195 239 339 406 538

50 80 101 120 143 164 169 173 228 318 396 562 673 891

64 106 134 161 195 223 231 236 314 444 557 737 936 1168

78 132 168 202 246 282 292 299 398 569 718 913 1199 1445

109 187 240 290 353 408 422 432 578 830 1052 1278 1677 2017

141 242 311 379 461 534 552 565 760 1092 1385 1638 2154 2589

172 297 383 467 569 659 682 699 942 1355 1718 2194 2893 3478

(Coil weight include the weight of water when filled)

To Estimate Weights for Other Coils

TA = Throw away type filters For 1/2” Tube (Type A): Multiply Type 5 Coil Weight by- 0.800

AF = Airfoil Fan For Small Coil: Multiply Large Coil Weight by- 0.823

FC = Forward Curved Fan For 14 FPI: Multiply 10 FPI Coil weight by- 1.121

For 12 FPI: Multiply 10 FPI Coil weight by- 1.065

For 8 FPI: Multiply 10 FPI Coil weight by- 0.935

For 6 FPI: Multiply 10 FPI Coil weight by- 0.915

Air Handler Motor and Drive Motor Horsepower, 1800 RPM

Weight in pounds

Motor

and Totally Enclosed Fan Cooled (TEFC)

Drive High Efficiency Open Single Speed

Weight Open 2 Speed, 2 Winding

T – Frame Size

Open Single Speed Motor

1 1.5-2 3 5 7.5 10 15 20 25 30 40 50 60 75

55 65 86 105 172 193 253 286 348 400 529 600 720 828

56 71 88 104 178 194 275 336 411 461 624 670 – –

67 74 114 127 209 216 341 384 396 427 621 623 – –

71 97 115 160 291 267 368 356 366 – – – – –

143 145 182 184 213 215 254 256 284 286 324 326 364 365

Central Station Air Handler, Shipment of Assemblies - Basic Unit

Horizontal Style Units, fan, coil, flat filter section Vertical Style Units, fan, coil, flat filter section

S, L, FO,

HD Sizes

03 – 18

S, L, FO,

HD Sizes

20 – 75

FS

FS

CS

CS

These diagram show

typical shipments.

FF

Some set-ups may

vary with certain units.

Consult the factory if

you require a specific

FF

assembly shipped in a

special way.

V Sizes

03 – 18

V Sizes

20 – 41

FS

CS

FS

CS

We ship high capacity

and high efficiency filter

sections, economizers,

FF

dampers, and electric

heat sections separately.

FF

7

Quantity and Dimensions of Filters for:

Flat Filter Section

Filter Air Handler Unit Size Filter

Dimensions Dimensions

2” x 16” x 20”

2” x 20” x 20”

2” x 16” x 25”

2” x 20” x 25”

03 06 08 10 12 14 18 20 26 34 41 50 65 75

1 – 2 – 3 1 2 6 4 – 6 7 8 4

1 – – – 3 1 2 4 8 – 12 – 20 10

– – 2 4 – 2 2 – – 4 – 14 – 4

– 2 – – – 2 2 – – 8 – – – 10

2” x 16” x 20”

2” x 20” x 20”

2” x 16” x 25”

2” x 20” x 25”

High Capacity Filter Sections

2” x 16” x 20”

2” x 20” x 20”

2” x 16” x 25”

2” x 20” x 25”

2 – – – – – – – – 4 – – – –

2 – – – – – – – – 20 – – – –

– – 6 2 8 4 6 4 2 – 4 – 12 14

– 4 – 4 – 4 4 6 10 – 20 30 30 35

2” x 16” x 20”

2” x 20” x 20”

2” x 16” x 25”

2” x 20” x 25”

High Efficiency Filter Sections

24” x 24”

12” x 24”

1 2 2 2 2 3 6 4 5 10 10 15 15 20

1 – 2 3 3 3 – 4 5 – 5 – 3 4

24” x 24”

12” x 24”

Replacement Parts- Note: Confirm the shaft Diameter, when Ordering Parts.

03-12, Forward Curved Shaft Bearing Bearing Shaft Blower

Unit Size, Fan Diameter, Type Diameter Part No. Type Part No. Assembly

03 FC 9” Low Pressure 3/4” 4215V Cartridge 4317Z 4317M

03 FC 9” Med Pressure 1” 4352N Pillow Block 4343N 4322M

06 FC 12” Low Pressure 1” 4350N Cartridge 4318Z 4318M

06 FC 12” Med Pressure 1 3/16” 4353N Pillow Block 4344N 4323M

08 FC 15” Low Pressure 1” 4350N Cartridge 4319Z 4319M

08 FC 15” Med Pressure 1 3/16” 4353N Pillow Block 4345N 4324M

10 FC 18” Low Pressure 1” 4350N Cartridge 4320Z 4320M

10 FC 18” Med Pressure 1 3/16” 4353N Pillow Block 4346N 4325M

12 FC 18” Low Pressure 1” 4350N Cartridge 4320Z 4320M

12 FC 18” Med Pressure 1 3/16” 4353N Pillow Block 4346N 4325M

Note: For sizes 03-12, it is less expensive to replace the blower assembly than to replace the blower wheel. Blower assembly also includes bearings and shaft

14-41, Forward Curved Shaft Pillow Block Shaft Blower Blower

Unit size, Fan Diameter, Type Diameter Bearing Wheel Wheel Cut-Off

14 FC 20” Low Pressure 1 3/16” 4353N 4342N 5154E Part of Housing

14 FC 20” Med Pressure 1 3/16” 4353N 4342N 5154E Part of Housing

18 FC 20” Low Pressure 1 3/16” 4353N 4342N 5154E Part of Housing

18 FC 20” Med Pressure 1 3/16” 4353N 4342N 5154E Part of Housing

20FC 22” Med Pressure 1 7/16” 5562N 4522R 5153E 4418T

26 FC 22” Med Pressure 1 7/16” 5562N 4522R 5153E 4418T

34 FC 25” Med Pressure 1 11/16” 5563N 4525R 5179D 4419T

41 FC 30” Med Pressure 1 15/16” 5564N 4500S 5178D 4421T

Note: For sizes 14-41 Forward Curved Fans, it is less expensive to replace the blower wheel than to replace the blower assembly.

26-75, Air Foils Shaft Pillow Block

Unit size, Fan Diameter, Type Diameter Bearing

20 AF 18 1/4” Med Pressure 1 7/16” 5562N

26 AF 18 1/4” Med Pressure 1 7/16” 5562N

34 AF 24 1/2” Med Pressure 1 15/16” 5564N

41 AF 30” Med Pressure 2 3/16” 5521T

50 AF 32 3/8” Med Pressure 2 7/16” 5597T

65 AF 39 3/8” Med Pressure 2 11/16” 5875E

75 AF 39 3/8” Med Pressure 2 11/16” 5875E

For sizes 41-75 Air Foils, for parts other than

bearing replacement, Contact the Factory.

with air handler model number, and discharge

arrangement. Heatcraft Refrigeration Products

can then advise the correct blower assembly

Air Foil Note:

Call the parts department, 800-686-7278,

description for you.

Visit our website at www.heatcraftrpd.com for technical literature online.

Since product improvement is a continuing effort, we reserve the right to make changes

in specifications without notice.

Heatcraft Refrigeration Products LLC

2175 West Park Place Blvd. • Stone Mountain, GA 30087

770.465.5600 • Fax: 770.465.5990 • www.heatcraftrpd.com

Loading...

Loading...