Heatcraft Refrigeration Products 25005601 User Manual

Reach-In

Unit Coolers

H-IM-77C February, 2005 Part No. 25005601

(Replaces H-IM-77B, October, 2004)

Installation and

Operation Manual

Table of Contents

Inspection ............................................................4

Installation ...........................................................4

Expansion Valve ..................................................4

Drain Line ............................................................4

Motors..................................................................4

Wiring ..................................................................4

Maintenance ........................................................4

Replacement Parts ..............................................5

Electric Defrost Troubleshooting .........................5

Thin Profile Air Defrost Unit Cooler .....................6

Thin Profile Electric Defrost Unit Cooler .......... 7-9

Extended Thin Profile Unit Cooler ...............10, 11

V Profile Unit Cooler ..........................................12

High Profile Unit Cooler .....................................13

Std. & Rev. Air Flow Wall Mullion Unit Cooler ...14

Wall Mount Back Bar Unit Cooler ................15, 16

Dual Aire Unit Cooler .........................................17

Twin Flow Air Defrost Unit Cooler ......................18

2

© 2005, Heatcraft Refrigeration Products LLC

3

General Information

Inspection

When the equipment is received, all items should be carefully checked against the bill of lading to make sure all crates

and cartons have been received. All units should be carefully inspected for hidden damage when received. If any damage is found, it should be reported to the carrier immediately and a claim should be filed. The unit nameplate should be

checked to make sure that the voltage agrees with the power supply available.

Installation

NOTE: Installation and maintenance are

to be performed only by qualified

personnel who are familiar with

local codes and regulations, and

experienced with this type of

equipment.

Installation and service of this equipment should be performed only by qualified and experienced commercial refrigeration

mechanics. Correct application and installation of this equipment is necessary to obtain optimum performance and

customer satisfaction. Install all equipment, piping and electrical in accordance with local and national codes and in

conformance with good practice required for proper operation. Work safely! Prevent accidents!

The final step in any installation is to instruct the customer or user in the operation of the equipment. The customer

should be shown how the equipment can be made to operate properly and efficiently. Maintenance requirements

should be explained.

Expansion Valve

Install expansion valve and feeler bulb inside cabinet of the unit. Recommended valve sizes are given for each

product family.

CAUTION: Sharp edges and coil surfaces are

a potential injury hazard. Avoid

contact with them.

Drain Line

After installing the fan panel assembly, connect the drain line to the fitting provided on the unit. A plastic hose or

metal drain line can be used.

The drain line should be pitched sharply and exit the cabinet as quickly as possible. Traps in the drain line should

be located in a warm ambient to prevent freeze-up.

If only a small portion of the drain line is located in the refrigerated area, a drain line heater will not be required.

If a drain line heater is required, use approximately 15 watts per foot of pipe. Connect the heater wire to the

terminals of the heater circuit (N and 3) at the terminal block in the junction box. The heater will then operate

during the defrost cycle.

All condensate water must be disposed of properly and should not be allowed to accumulate or cause a safety

hazard.

Motors

Motors are lifetime lubricated and thermally protected. Check an inoperative motor by disconnecting and applying

correct voltage across leads. If test fails, replace the motor.

Wiring

The nameplate on the unit is marked with the electrical characteristics to be used for wiring the unit. The unit must

be grounded. All wiring should be done in accordance with applicable national and local codes.

Maintenance

Periodically inspect unit for grease and soil accumulation. Clean with warm water and soap. Do not use cleaners containing

ammonia. Inspect the drain pan/fan panel occasionally for proper condensate drainage. Keep the drain opening clean.

WARNING: All power must be disconnected before cleaning drain pan/fan panel. It serves as a cover

of hazardous moving parts. Operation of unit without pan in place constitutes a hazard.

WARNING: Refrigerant can be harmful if it is inhaled. Refrigerant must be used and recovered

responsibly. Failure to follow this warning may result in personal injury or death.

4

General Information (contʼd)

Replacement Parts

Always give complete model numbers and serial numbers when ordering parts.

ELECTRIC DEFROST TROUBLESHOOTING

The electric defrost units are relatively simple and trouble-free in operation:

Timer

If the system does not go through its proper sequence , check timer operation through a defrost cycle. Check for loose

wires or terminals. Before replacing timer, check other components.

Operation of Paragon Timer

To set time of day grasp knob which is in the center of the inner (fail-safe) dial and rotate it in a counter-clockwise direction.

This will cause the outer (24 hour) dial to revolve. Line up the correct time of day on the outer dial with the time pointer.

Do not try to set the time control by grasping the other (24 hour) dial. Place pins in the outer dial at the time of day that

defrost is required.

Operation of Grasslin Timer

To set the time, turn the minute hand clockwise until the time of day (and AM or PM) on the outer dial is aligned with the

triangle marker on the inner dial. Do not rotate minute hand counter-clockwise. Move the white tab (tripper) on the

outer dial outward at each desired initiation time. Each white tab (tripper) is a 15 minute interval and provides 15 minutes

of defrost. For longer defrost duration, move additional tabs (following in time) from the initiation tab. For example, if a

45 minute defrost is to start at 7:00 AM, move the tabs outward that lie between 7:00 - 7:15, 7:15 - 7:30 and 7:30 - 7:45

on the AM side of the dial. The defrost will initiate at 7:00 AM and time terminate at 7:45 AM (if temperature termination

does not occur first).

Fan Motor

If the motor does not operate or it cycles on thermal overload, remove motor leads from terminal block and apply correct

voltage across the leads. If motor still does not operate satisfactorily, it must be replaced. Before starting the unit, rotate

fan blades to make sure they turn freely and have sufficient clearance.

Fan Delay & Defrost Termination Control

This control is a single pole double throw switch. The red lead wire is wired to common. The black wire is wired in series

with the fan motors. The brown wire is wired in series with the defrost termination solenoid in the timer. The brown and

red contacts close and the black and red contacts open when the temperature is above 55

close and the brown and red contacts open when the temperature is below 35ºF.

On initial “pull down” of a warm box the fan will not start until the coil temperature reaches approximately 35

is still comparatively warm (60

to 55ºF and thus stop the fan. Therefore, the fan may recycle on initial “pull down.” This control cannot be adjusted.

If the fan motor fails to start when the control is below 35

described for fan motors. Also check whether current is being supplied at “N” and “4” from the timer. The fan delay

control must be below 35ºF when checking for a closed circuit.

º

F) when the fan starts, then blowing this warm air over the coil may cause it to warm up

º

F, disconnect the fan motor leads and check the motor as

º

F. The black and red contacts

º

F. If the box

Defrost Heater

If unit shows very little or no defrosting and does not heat, disconnect heater and check to find if it is burned out. To test,

apply correct voltage across heater or use continuity flashlight battery tester.

Drain Pan

If drain pan has an ice build-up, drain line may be frozen. The drain line should be pitched sharply and exit cabinet

as quickly as possible. Sometimes location and ambient at the drain outside of cabinet may cause freeze-up. A drain

line heater may be required to correct the freeze-up. Any traps in the drain line must be located in a

warm ambient.

NOTE: After correcting faulty condition it is

essential that the coil and unit be free of

ice before placing unit back on automatic

operation.

5

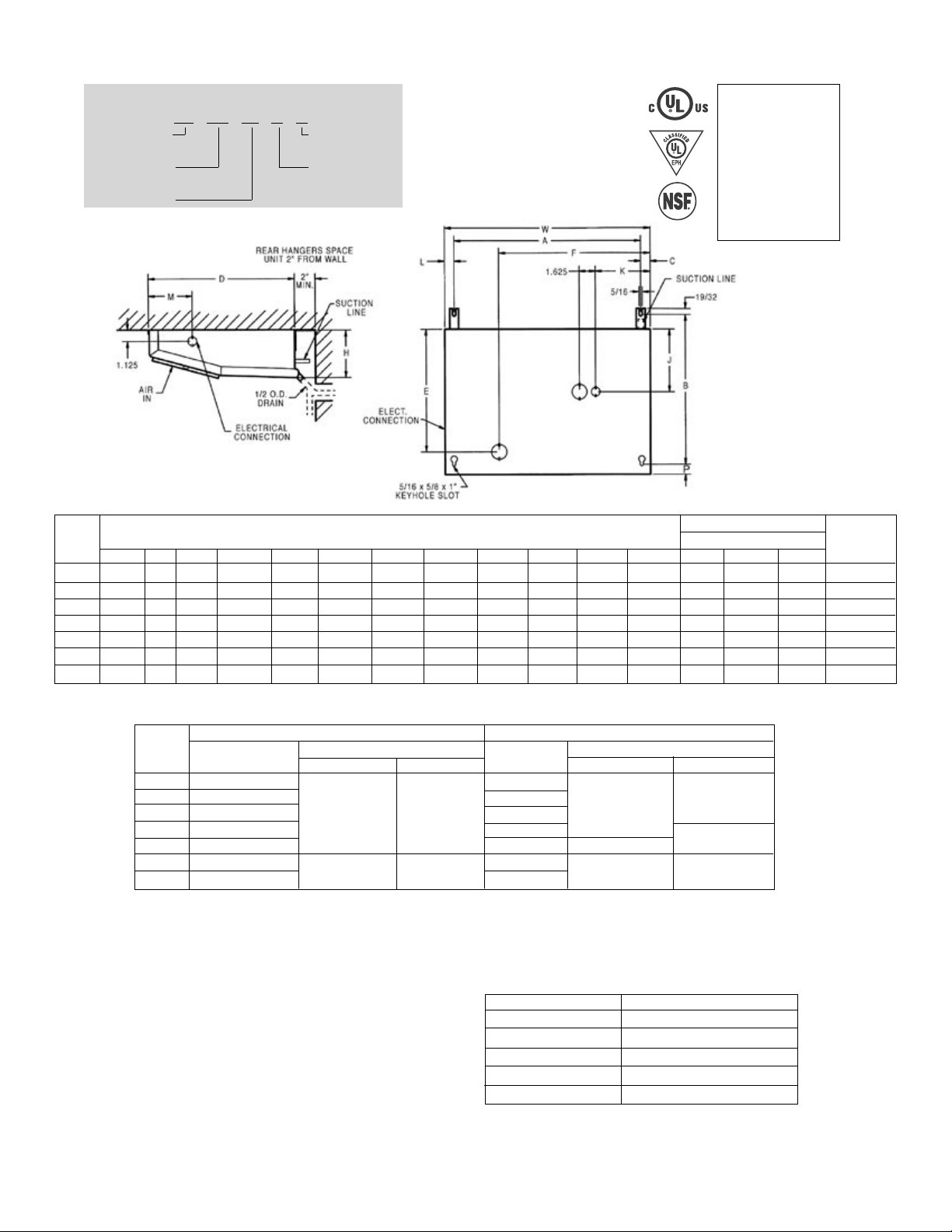

Thin Profile Air Defrost Unit Cooler

NOMENCLATURE

TA (K) 17 B G

Thin Profile Vintage

Unit Cooler

K = Coated Coil A = 115-1-60

(Optional) B = 208/230-1-60

Size

Dimensional Diagram

Dimensional Data

Connections (in.) Approx.

Model

Dimensions (in.) Coil Shipping

No. A B C D E F H J K L M W Inlet Suction Drain Wt. (lbs.)

10 14 5/8 14 15/16 13 1/2 10 1/2 11 3/8 4 1/2 8 7/8 2 1/2

13 18 5/8 14 15/16 13 1/2 10 1/8 10 1/

17 22 1/8 15 15/16 14 1/2 11 1/8 12 4 1/2 9 3/8 11 1/4 15/16 4 3/8 24 3/8 OD 1/2 ID 1/2 OD 21

4 1/

4

8 3/

2

9 1/

8

23 29 3/4 15 15/16 14 1/2 13 20 7/8 4 1/2 10 3/4 10 1/4 15/16 4 3/8 31 5/8 3/8 OD 1/2 ID 1/2 OD 28

30 38 1/8 15 15/16 14 1/2 13 29 3/4 4 1/2 10 3/4 9 3/4

43 51 1/2 15 15/16 14 1/2 13 48 3/4 4 1/2 10 3/4 13 1/4 15/16 4 3/8 53 3/8 1/2 OD 5/8 ID 1/2 OD 44

55 51 1/2 15 15/16 14 1/2 13 49 6 3/4 10 3/4 11

15

/16 4 3/8 16 1/2 3/8 OD 3/8 ID 1/2 OD 14

15

/

2

15

15

4 3/

16

8

/16 4 3/8 40 3/8 OD 1/2 ID 1/2 OD 33

/16 4 3/8 53 3/8 1/2 OD 5/8 ID 1/2 OD 53

20 1/

3

/8 OD 3/8 ID 1/2 OD 17

2

FOR FOOD

SERVICE

INSTALLATIONS

. . . seal any joint

between unit cooler

and cooler liner

with a sealant

listed by the

National Sanitation

Foundation,

Standard 51

Expansion Valve Recommendations

25°F Sat. Suction Temp. 20°F Sat. Suction Temp.

Model BTUH @ R-22 BTUH @ R-22

Size 10°F TD Alco Sporlan 15°F TD Alco Sporlan

10 1000 1500

13 1300 1950

17 1700 HFS-1/4HC EFV-1/5C 2550

HFS-1/4HC

23 2300 3450

30 3000 4500 HFS-1/2HC

43* 4300

55* 5500 8250

HFES-1/2HC EFVE-1/2C

6450

HFES-1HC EFVE-1C

EFV-1/5C

EFV-1/3C

* Size 43 and 55 use external equalized valves.

Mounting

The thin profile air defrost unit cooler is designed for

mounting from the top of the cooler. Drill holes for screws

in accordance with mounting dimensions A and B given

in Dimensional Data.

After unpacking the unit, remove the fan panel and arrange

the rear brackets as shown in the drawing. Insert the

screws for mounting the rear brackets into the top of the

cooler cabinet. Slip the rear brackets, attached to the unit,

between the screw head and cabinet and secure in place.

Install the front mounting screws. For proper drainage, the

unit should be installed level.

Replacement Parts

Description All Sizes Part Number

115V Motor 25300701

208/230V Motor 25300801

Fan Blade 5101B

Fan Guard 5054D

Motor Mount 91179001

6

Loading...

Loading...