Refrigeration

System Installation

H-IM-81A October 2004 Part No. 25001801

Replaces H-IM-81 (1/04)

Refrigeration System

For Indoor Applications

Table of Contents

1. Ownerʼs Installation Instructions

Performance/Electrical Data

Specifications ............................................................

Dimensional Diagrams ..............................................3

Space and Location Requirements

Recommended Unit Placement ................................. 4

Rigging

Mounting .................................................................... 5

2

Installation and

Operation Guide

Inspection

General Safety Information

Standard Installation Procedure ................................6

2. Freezers

Service Information

Maintenance

Sequence of Operation

Freezer System Pre-Setpoints

Electric Defrost Sequence of Operation

Programming Electric Defrost Controls ................7-10

Freezer Defrost Control

Medium and Large Cabinet .......................................7

Freezer Defrost Control

Small Cabinet ..........................................................10

3. Coolers

Defrost Controls

Sequence of Operation

Maintenance ............................................................ 11

4. Service Information

System Troubleshooting Chart ................................ 12

Replacement Parts .................................................. 13

5. Wiring Information

Electrical Wiring Diagrams .................................14-19

6. Warranty Information

......................................20

Performance / Electrical Data

Table 1. COOLERS — Air Defrost Systems

1. Ownerʼs Operating Instructions

BTUH @ 95° F. Matching

Model 35° F. 38° F. Unit Evap Plug NEMA

Number Box Temp Box Temp Voltage MCA MOPD Amps CFM Supplied Receptacle Fig.

PTN024H2A 2,540 2,650 115/1/60 10.2 15 10.2 340 Yes 5-20R A

PTN029H2A 3,070 3,180 115/1/60 10.6 15 10.6 340 Yes 5-20R A

PTN040H2A 4,240 4,350 115/1/60 11.7 15 11.7 340 Yes 5-20R A

PTN047H2A 4,980 5,300 115/1/60 16.9 20 14.2 350 Yes 5-20R B

PTN047H2B 4,980 5,300 208-230/1/60 8.6 15 7.3 350 Yes 6-15R B

PTN063H2B 6,680 7,100 208-230/1/60 9.8 15 9.9 550 Yes 6-15R B

PTN072H2B 7,630 8,060 208-230/1/60 10.9 15 9.3 500 Yes 6-15R B

PTN099H2B 10,490 11,340 208-230/1/60 17.1 20 14.7 875 Yes 6-20R C

PTN099H2C 10,490 11,340 208-230/3/60 14.7 20 13.3 875 No —- C

PTN128H2B 13,570 14,520 208-230/1/60 20.1 30 17.2 825 No —- C

PTN128H2C 13,570 14,520 208-230/3/60 14.1 20 12.8 825 No —- C

Table 2. FREEZERS — Electric Defrost Systems

BTUH @ 95° F. Matching

Model 0° F. -10° F. -20° F. Unit Evap Plug NEMA

Number Box Temp Box Temp Box Temp Voltage MCA MOPD Amps CFM Supplied Receptacle Fig.

PTN019L6A 2,470 1,850 N/A 115/1/60 13 20 13 340 Yes 5-20R A

PTN021L6A 2,680 2,160 1,340 115/1/60 14.5 20 12.3 350 Yes 5-20R B

PTN021L6B 2,680 2,160 1,340 208-230/1/60 7.6 15 6.5 350 Yes 6-15R B

PTN031L6B 4,220 3,190 2,060 208-230/1/60 13.8 15 11.6 550 Yes 6-15R B

PTN044L6B 5,870 4,530 3,400 208-230/1/60 15.9 20 13.3 520 Yes 6-20R B

PTN052L6B 7,000 5,360 3,910 208-230/1/60 18.1 20 15.5 900 Yes 6-20R C

PTN052L6C 7,000 5,360 3,910 208-230/3/60 15.0 15 11.3 900 No —- C

PTN069L6B 9,060 7,100 5,250 208-230/1/60 23.8 30 20.0 875 No —- C

PTN069L6C 9,060 7,100 5,250 208-230/3/60 15.9 20 14.2 875 No —- C

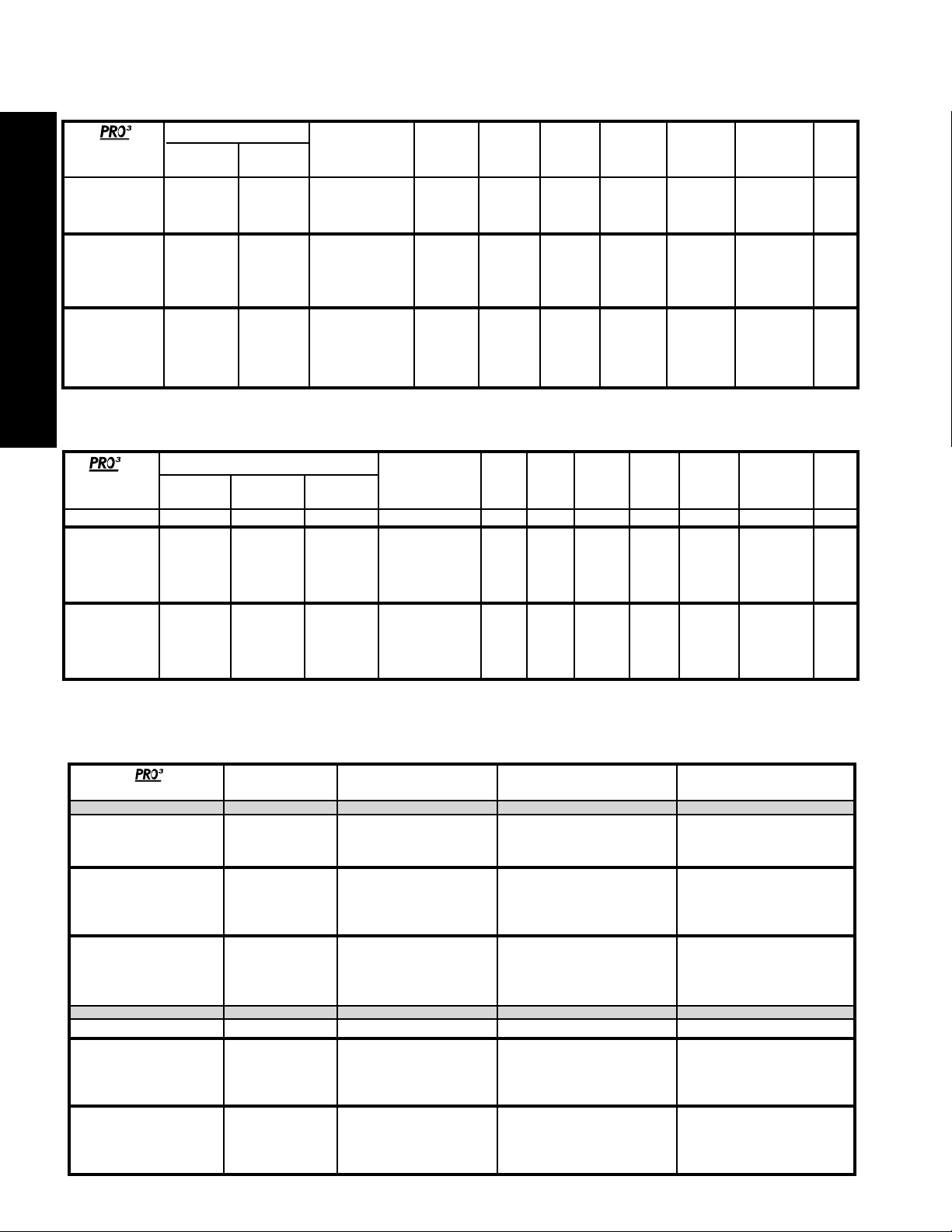

Table 3. Specifications

Refrigerant Total Heat of Approx. Net Weight

Model Refrigerant Chg. (oz.) Rejection (BTUH) Lbs.

COOLERS

Kg

PTN024H2A 22 12 3,000 88 43

PTN029H2A 22 16 3,800 90 43

PTN040H2A 22 14 5,500 92 43

PTN047H2A 22 27 6,700 192 100

PTN047H2B 22 27 6,700 192 100

PTN063H2B 22 29 8,700 207 100

PTN072H2B 22 32 9,700 211 100

PTN099H2B 22 47 16,800 270 127

PTN099H2C 22 47 16,800 265 127

PTN128H2B 22 52 18,000 290 127

PTN128H2C 22 52 18,000 285 127

FREEZERS

PTN019L6A 404A 14 4,000 101 43

PTN021L6A 404A 26 4,300 213 100

PTN021L6B 404A 26 4,300 213 100

PTN031L6B 404A 28 6,300 221 100

PTN044L6B 404A 29 9,900 225 100

PTN052L6B 404A 45 10,900 275 127

PTN052L6C 404A 45 10,900 270 127

PTN069L6B 404A 47 15,300 280 127

PTN069L6C 404A 47 15,300 275 127

2

© 2004, Heatcraft Refrigeration Products LLC

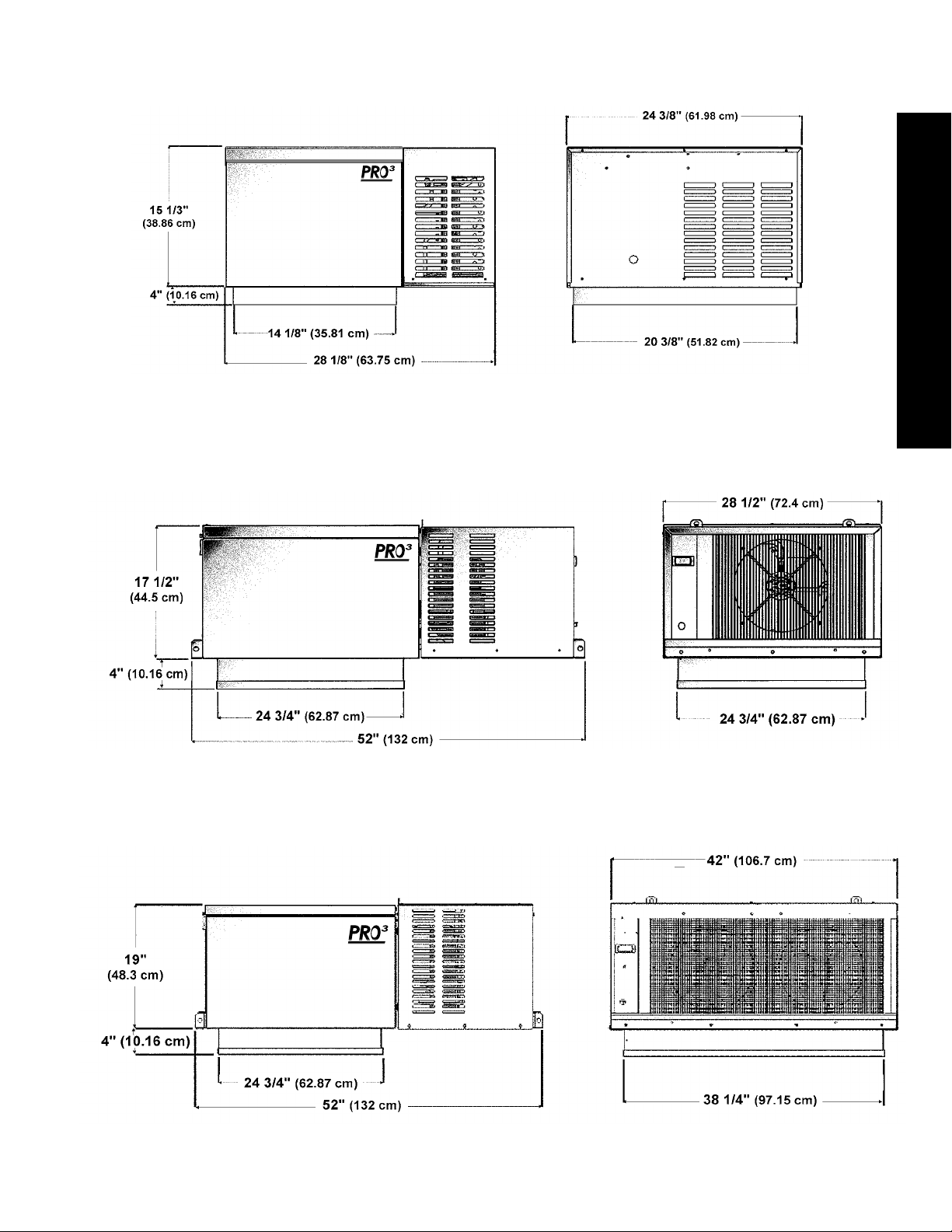

Dimensional Diagrams

Figure A. Small Cabinet Dimensions

(Models PTN 019, 024, 029, 040).

14 1/2” x 20 3/4” panel opening required for evaporator section of small cabinet sizes.

Figure B. Medium Cabinet Dimensions

(Models PTN 021, 031, 044, 047, 063, 072).

1. Ownerʼs Operating Instructions

25” x 25” panel opening required for evaporator section of medium cabinet sizes.

Figure C. Large Cabinet Dimensions

(Models PTN 052, 069, 099, 128).

25” x 38 1/2” panel opening required for evaporator section of large cabinet sizes.

3

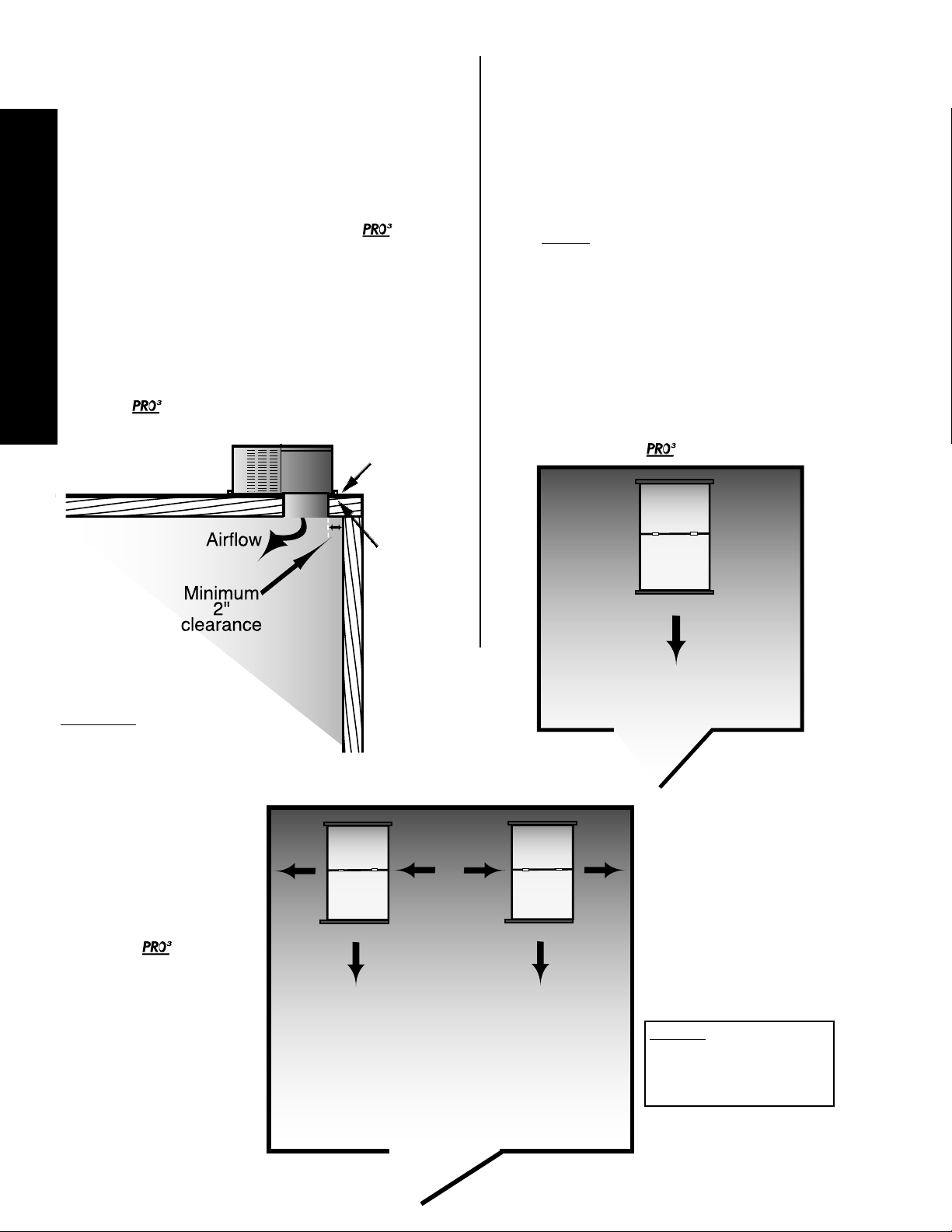

Space and Location Requirements

For PTN models.

The most important consideration which must be taken into account

1. Ownerʼs Operating Instructions

when deciding upon the location of air-cooled equipment is the

provision for a supply of ambient air to the condensing unit. Ignoring

this essential requirement will result in higher condensing pressure

and contribute to poor operation or potential equipment failure.

Units must not be located in the vicinity of steam, hot air or fume

exhausts. Adequate air circulation through the condensing unit is

critical to ensure proper equipment operation. Improper installation

can damage the unit and will void the warranty.

style packaged units are designed for indoor use only in ambient

temperatures of 50°F to 100°F. The unit cabinet is not approved

for weather tight applications.

Another important consideration is that the unit should be mounted

away from noise sensitive spaces and must have adequate support

to avoid vibration and noise transmission into the building. Storage

should not be allowed on top of walk-in structure. Unit must not be

enclosed in an unventilated space.

Figure 1. System Space and Location

Requirements for PTN models

Side View

Minimum 2" clearance from

opening to adjacent wall. No

storage is allowable on top of

walk-in structure.

IMPORTANT: Ventilation

air must be provided for the

condensing unit.

Structure must not be masked

to building ceiling, blocking air

flow to unit.

penthouse-

Allow 2 feet

clearance

above unit to

remove top

panel and to

allow service

access.

Mounting rails

may be used to

attach unit to

ceiling.Throughbolts should

be insulated or

non-conductive

to prevent

sweating.

Recommended Unit Placement

Some general rules for the evaporator section placement which

must be followed are:

1. Ensure that the structural integrity of the box can

withstand the weight of the top mounted equipment.

2. The air pattern must cover the entire room.

3.

NEVER locate the evaporator section over doors.

4. Location of aisles, racks, etc. must be known.

5. Never remove or unlock any panel cam-locks to

install top mounted equipment.

The size and shape of the storage will generally determine the

type and number of units to be used and their location.

Top View

One System

Evaporator

Section

Compressor

Section

Evaporator

Airflow

W

Min.

Evaporator

Section

Compressor

Section

2 x Width

Min.

Evaporator

Section

Compressor

Section

W

Min.

Multiple units must be spaced

properly to provide adequate

air circulation.

Top View

Two Systems

Evaporator

Airflow

Evaporator

Airflow

PTN Models

NOTE: Always avoid

W = Unit Width

placement of units

directly above

doors and door

openings.

4

Rigging

Trim Pieces (4)

Overlap as Shown

Evaporator Grill

Self Drilling Scre

w

Ceiling of Walk-in.

Mounting

Rigging holes are provided on all models. Caution should

be exercised when moving these units. To prevent

damage to the unit housing during rigging, cables or

chains used must be held apart by spacer bars. The

mounting platform or base should be level and located

so as to permit free access of supply air.

Access Requirements

Provide adequate space at the compressor end of the

unit for servicing. Provide two (2) feet of space above unit

for service.

Trim Ring Installation Detail

The system requires an opening in the ceiling to the

dimensions stated on page 3. Mounting rails are located

at both ends of the chassis. Mounting rails may be used

to attach unit to ceiling. Through-bolts should be insulated or non-conductive to prevent sweating. The chassis

is weather stripped around the air grille and will seal to

the box roof. The trim ring (shipped loose), when provided, should be installed around the air diffuser when

secured with the hardware provided. Be sure to adhere

to your local standard construction codes.

1. Ownerʼs Operating Instructions

5

Inspection

1. Each shipment should be carefully checked against the bill

1. Ownerʼs Operating Instructions

of lading.

Standard Installation Procedure

PTN Models

For Indoor Use Only

2. The shipping receipt should not be signed until all items

listed on the bill of lading have been accounted for.

3. Check packaging for signs of damage.

4. Any shortage or damages should be immediately reported

to the delivering carrier.

5. Damaged material becomes the delivering carrierʼs

responsibility, and should not be returned to the

manufacturer unless prior approval is given to do so.

6. When unpacking the system, care should be taken to

prevent damage.

7. Avoid removing the shipping base until the unit has been

moved to the final destination.

8. Complete warranty return card for each unit and mail to

Heatcraft Refrigeration Products.

General Safety Information

1. Installation and maintenance to be performed only by

a licensed contractor.

2. Ensure that the structural integrity of the box can withstand

the weight of the (See page 2, Table 3 for unit

weights).

3. Avoid contact with sharp edges and coil surfaces. They are

a potential injury hazard. Wear gloves during moving and

rigging.

4. Make sure all power sources are disconnected before any

service work is done on units.

1. Inspect packaging for shipping damage.

Open package and inspect unit for concealed damage.

2. Review the space and location requirements on page 5.

3. Provide a finished opening in the box ceiling, to the

appropriate dimensions and structural strength as stated on

page 2, Table 3.

4. DO NOT remove or disengage any box cam-locks in order

to install the

5. Clean the roof of the box to provide a good sealing

surface for the unit weatherstrip. Refer to box

manufacturerʼs instructions for any procedures or processes

necessary to ensure the integrity of the exposed foam in the

panels is not compromised.

6. Check the mounting surface with a level. units require

a surface that is within 1° of level or better and no more

than a 5/8" drop per 3 feet (17mm drop per meter).

7. For walk-in boxes with aluminum top panels, it is

recommended that a thermal break be placed on the roof

adjacent to the opening to prevent the possibility of

sweating.

8. Place the unit gently into the provided opening with the

evaporator air flow directed toward the door (See page 5).

Be careful not to damage the grill during installation.

9. Ensure that the condenser air flow is not obstructed.

10. Install the trim around the inside opening with the hardware

provided.

11. Connect unit to power supply using the cord with plug, if

provided, or hard wire. Adhere to local electrical/wiring

codes.

unit.

IMPORTANT:

• Do not use extension cords to connect unit to power.

Plug-in to grounded three prong outlet.

•

• Do not remove grounding prong.

• Do not use a power adapter.

12. Apply power to unit.

default settings (See Table 4).

13. Check unit for proper operation.

14. The correct time of day may be programmed on medium

and large cabinet freezer systems

(See page 11 for instructions).

Table 4. Control Factory Default Settings

Defrost Defrost Defrost

PTN Temperature Start Duration Drip Fan Termination

Models Set Points Times (Maximum) Time Delay Set Point

Cooler Models

All cabinet sizes 35°F 3 / day n/a --- --- 38°F

Freezer Models

Med. & Lg. cabinet -10°F 4:00 AM, 10:00 AM, 40 min. 2 min. 2 min. 65°F

4:00 PM, 10:00 PM

Small cabinet 0°F 4 / day 20 min. --- --- Time only

All controls are preset to factory

6

Loading...

Loading...