Heatcraft Refrigeration Products 25000102 User Manual

Installation and Operation

Manual

Bulletin No. H-IM-PCS October 2004 Part Number 25000102

(Replaces H-IM-72B, October 2004)

Parallel

Compressor

Systems

Installation and Operations Manual

Table of Contents

Introduction .............................................................................................................. 3

Inspection

Unit Designation

Model Denition

System Warranty ....................................................................................................... 4

Rigging

Location of Equipment - INDOOR

Clearances

Floor & Foundation Requirements

Vibration Mounts

Figure 1. Vibration Pad & Spring Isolator

Figure 2. Vibration Pad Locations

Location of Equipment - OUTDOOR ........................................................................ 5

Ground Mounting

Roof Mounting

Unit Vibration Isolation

Compressor Spring Vibration Isolators

Figure 3. Spring Mount

Unit Access ................................................................................................................6

Vertical Clearance

Lateral Clearance

Decorative Fences

Units in Pits

Multiple Units

Ventilation Requirements ........................................................................................7

Electrical

Refrigerant Piping

Suction P-Traps

Figure 4. P-Trap requirements

Figure 5. P-Trap construction

Figure 6. Double Suction Risers ............................................................................... 8

Figure 7. Inverted Trap

Refrigerant Line Insulation

Refrigerant Line Support

Figure 8. Pipe Support

Expansion Loops ....................................................................................................... 9

Figure 9. Osets

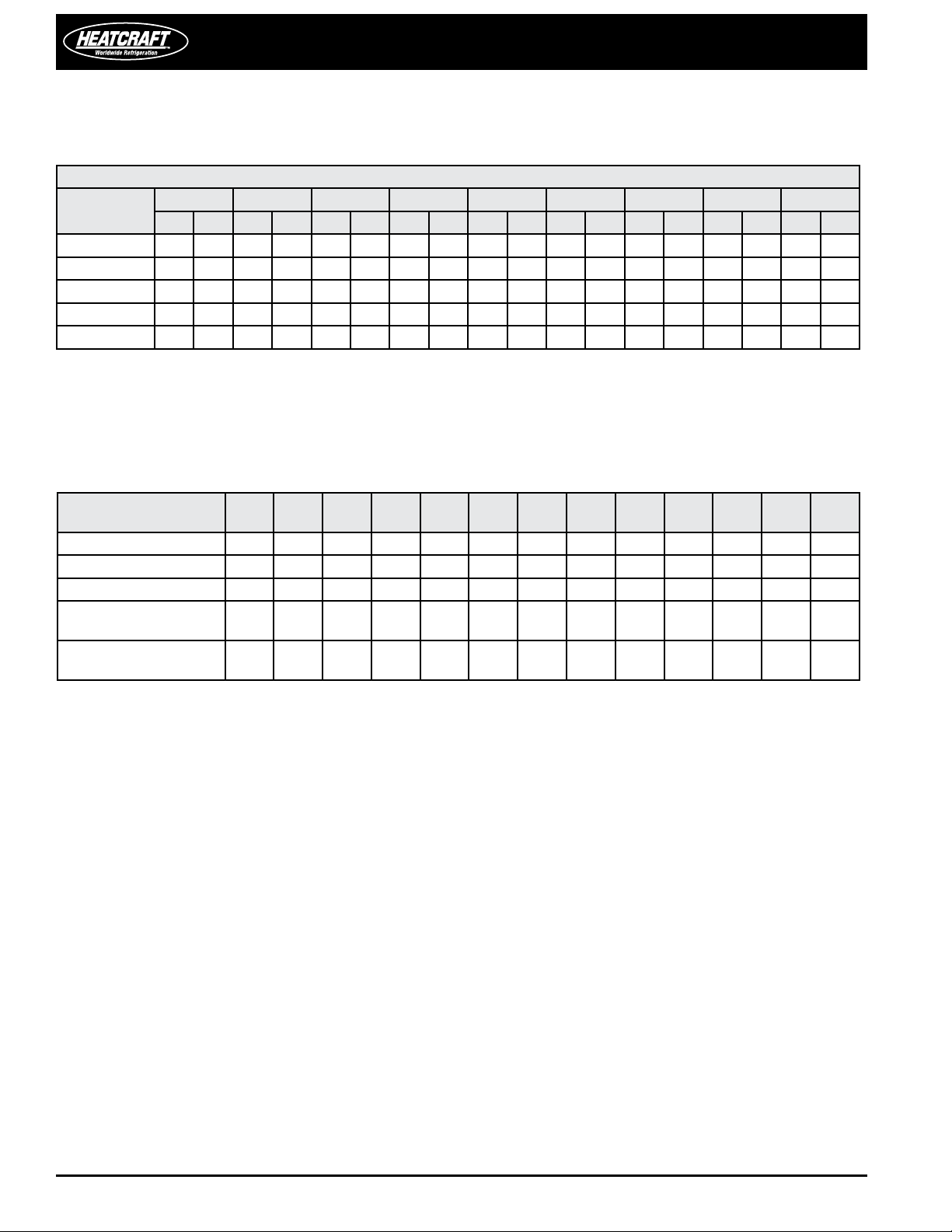

Table 1. Expansion Chart

Table 2. Pressure Loss of Liquid Refrigerants ....................................................... 10

Table 3. Equivalent Feet of Pipe

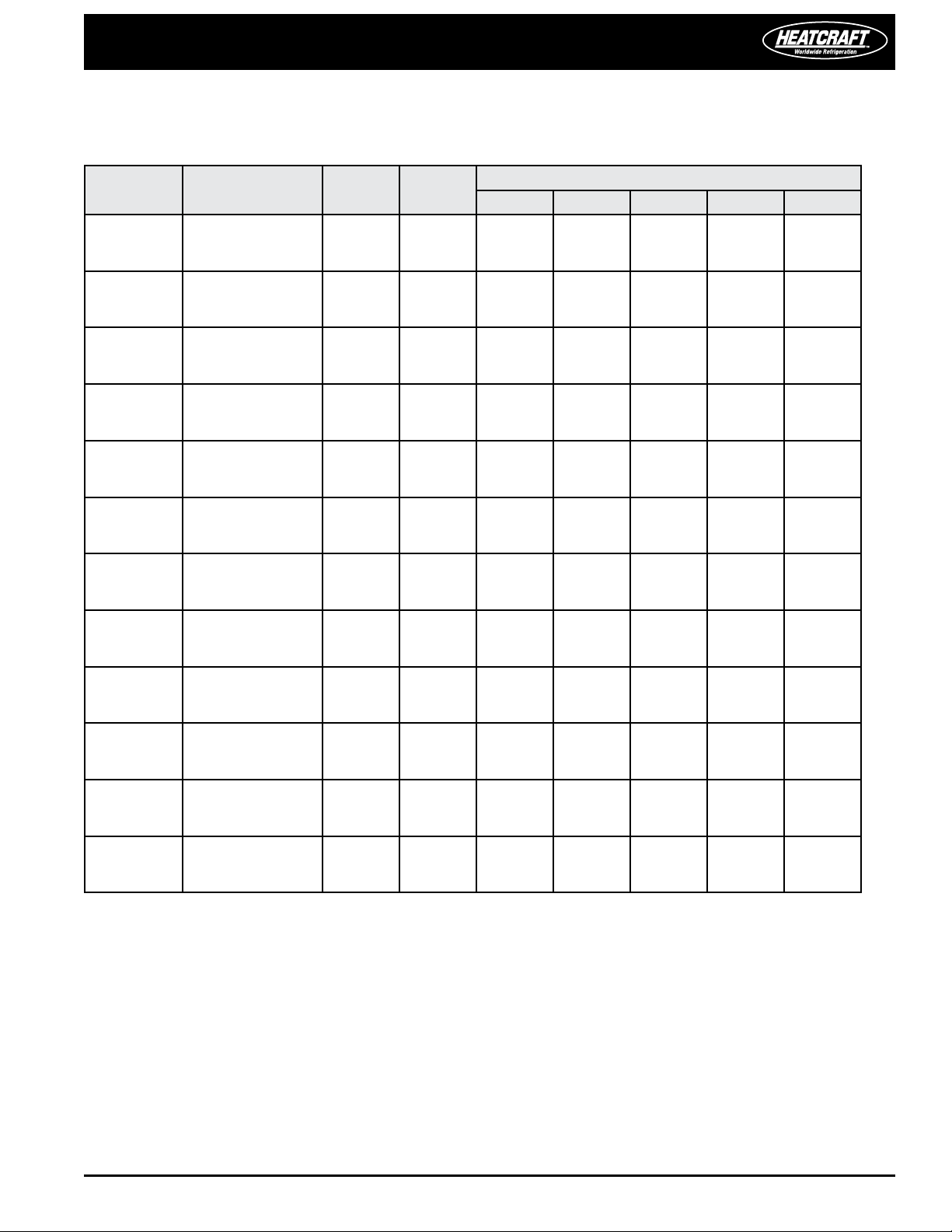

Table 4. Weight of Refrigerants in Copper Lines During Operation ................... 11

Table 5A. Recommended Line Sizes for R-404A and R-507 ................................ 12

Table 5B. Recommended Line Sizes for

R-404A and R-507 (continued) ..............................................................13

Table 6A. Recommended Line Sizes for R-22 ........................................................ 14

Table 6B. Recommended Line Sizes for R-22 (continued) ................................... 15

Table 7. Recommended Remote Condenser Line Sizes ....................................... 16

Leak Checking, Evacuation, and Start-up ............................................................. 17

Refrigerant Distribution ........................................................................................ 18

O-Cycle

Electric Defrost

Priority I Hot Gas Defrost

Head Pressure Control System

Electronic Control System ...................................................................................... 19

System Balancing

System Superheat (NOTE: Superheat is not preset at factory)

Evaporator Superheat

Alternative Superheat Method

Compressors ...........................................................................................................20

Copeland Compressors

Table 8. 3D/4D/6D Solid State Modules

Table 9. Typical Voltage Ranges

Table 10. Unloader Factors

Table 11. Oil Safety Switch ..................................................................................... 21

Table 12. Oil Charges

Approved Copeland Lubricants

Carlyle Compressors

Approved Carlyle Lubricants

Oil Pressure

Table 13. O6D/E Oil Pressure History

2 Part # 25000102

© 2007 Heatcraft Refrigeration Products LLC

Table 14. Oil Safety Switch ..................................................................................... 22

Table 15. Part Load Performance Multipliers

Table 16. Required Dierential Pressure

Three-Phase Voltage Monitor

Sight Glass & Moisture Indicator ........................................................................... 23

Figure 10. Sight Glass

Safety Relief Devices

Figure 11. Direct Type Relief Valves

Figure 12. 3-Way Relief Valve

Table 17. Henry Relief Valve Capacity Ratings .....................................................24

Table 18. Discharge Piping Table

Series P100 Pressure Control ................................................................................. 25

Figure 13. P100 Pressure Controls

Auto Reset Models

Manual Reset Models

Liquid Level Switch

S-9400 Level Switch Series

Table 19. Level Switch Table

Figure 14. S-9400

S-9400 Operation

Module Replacement .............................................................................................26

Figure 15. Module Replacement

Oil Control

Low Pressure Oil System

Figure 16. Low Pressure Oil System

Oil Separators

Table 20. AC&R Models...........................................................................................27

Temprite Models

Temprite Valve Adjustment

Table 21. Temprite Models

Figure 17. Temprite Oil System

Oil Level Regulators

Table 22. AC&R Model Regulators .........................................................................28

Troubleshooting Oil System

Liquid Filter-Driers & Suction Filters

Table 23. Sporlan Valve Company

Table 24. Alco Controls

Suction Filter ........................................................................................................... 29

Compressor Motor Burnout Clean-up Procedure

Sporlan Valve Company

Superior Valve Company ........................................................................................ 30

Table 25. Type F Filter

Table 26. Type DF (for clean-up)

Alco Controls

Table 27. Type AF Filter

Table 28. Type AFD (for clean-up)

Head Pressure Control

Valve Functions

Liquid Drain Control Method ................................................................................. 31

Recommended Valve Settings

Table 29. Pressure Range, Set Point & Change per Turn

Field Adjustment

Hot Gas Bypass Regulator Adjustment

Sporlan Valve Company

Valve Setting and Adjustment

Alco Controls ...........................................................................................................32

Valve Setting and Adjustment

Control Settings

Table 30. Control settings for R-404A/R-507

Table 31. Control settings for R-22

Low Pressure Switch Setting for RMCC

General Maintenance Schedule.............................................................................33

SERVICE DIAGNOSIS CHART .............................................................................34-35

Service Record ........................................................................................................ 36

System Reference Data

Parallel Compressor Systems

Introduction

Parallel Compressor systems are central refrigeration units

employing 2 to 8 parallel piped compressors, a control panel,

and receiver mounted on one common base frame. The system

may be designed for either Indoor or Outdoor use. The Outdoor

design may include the condenser mounted and piped.

The selection and design of the system is based on the needs

of the individual customer. The most important point in

planning an installation of the Heatcraft parallel system is the

proper selection of the system components for the particular

application.

Component parts have been selected for their dependability

and availability to keep service problems to a minimum.

Simplicity of design has also made the Heatcraft parallel

system one of the easiest to service and install. The simplicity

and compactness of the Heatcraft design make the addition of

hot gas defrost and/or heat reclaim a simple and economical

feature.

In the following pages will be found explanations of system

components, wiring and piping diagrams, control settings, and

operational guides.

Inspection

Unit inspection should be assigned to a dependable individual.

Inspect the parallel system and any accessories shipped with

them for damages or shortages before and during unloading.

All items on bill of lading should be accounted for prior to

signing the shipping receipt. Note any shortages or damage on

carrier’s delivery receipt (Specify the extent and type of damage

found). Unit should be inspected carefully for concealed

damage. Notify the Heatcraft sales representative and the

carrier of the damage immediately. Request an immediate

joint inspection with the carrier (Do not repair the unit until

inspected by carrier’s representative). Care should be exercised

when uncrating units to prevent damage.

The system is shipped with a holding charge of dry nitrogen.

Check to see that pressure is still in the unit upon receipt.

Report lack of pressure immediately to the Heatcraft service

department.

NOTE: Accessory items such as drier cores,

mounting pads, modems, etc. may be

packaged in a separate carton. Be sure

that you receive all items.

Unit Designation

Units are identied by letter, brand, compressor type, quantity

of compressors, horsepower, condenser type, control voltage,

defrost type, refrigerant/range, unit voltage and application.

Unless otherwise requested by the customer all refrigeration

circuits are numbered from one to the highest and from left to

right while facing the electrical panel.

Model Denition:

1st digit - Brand (B, C, H, or L)

2nd digit - Compressor Type

H - Hermetic

R - Reciprocating

S - Screw

O - Open

Z - Scroll

C - Compound

3rd digit - Unit Construction

R - Remote Condenser

U - Attached Condenser

H - Hybrid

M - Multi-compressor Platform

F - Frame Hybrid (Frame + Standard Unit)

4th digit - Compressor Quantity

2 - 2 Compressors

3 - 3 Compressors

4 - 4 Compressors

Etc.

5th, 6th, & 7th digit - Horsepower

030 - 30 HP

075 - 75 HP

100 - 100 HP

Etc.

8th digit - Condenser Type

A - Air

W - Water

E - Evaporative

9th digit - Control Voltage

A - 115/1/60

B - 208-230/1/60

C - 24/1/60

10th digit - Defrost Type

A - Air/O-Cycle

E - Electric

G - Hot Gas

M - Multiple

W - Water

11th digit - Temperature Range

L - Low

M - Medium

H - High

C - Combination

X - Ultra Low

12th digit - Refrigerant Type

2 - R-22

4 - R-134A

6 - R-404A, R-507

8 - Multiple

13th digit - Unit Voltage

C - 208-230/3/60

D - 460/3/60

E - 575/3/60

J - 208/3/60

K - 230/3/60

M - 380/3/60

14th digit - Application

1 - Indoor

2 - Outdoor

®

Parallel Compressor Systems Installation & Operations Manual, October 2004 3

Installation and Operations Manual

System Warranty

This equipment is designed to operate properly and produce

the rated capacity when installed in accordance with good

refrigeration practice.

The following conditions should be adhered to when installing

this unit to maintain the manufacturers warranty:

(a) System piping must be in accordance with good

refrigeration practices

(b) Inert gas must be charged into the piping during

brazing

(c) The power supply to the unit must meet the following

conditions:

• All voltages must be +/- 10% of the n a m e p l a t e

ratings

• Phase (voltage) imbalance cannot exceed 2%

(d) All control and safety switch circuits must be properly

connected according to the wiring diagram

(e) The factory installed wiring must not be changed without

written factory approval

Rigging

Warning: Careful considerations for lifting should be made

before the unit is lifted by any means. The only part of the unit

designed to carry any of the lifting load is the welded channel

base. The unit may be lifted at the base with a forklift or by

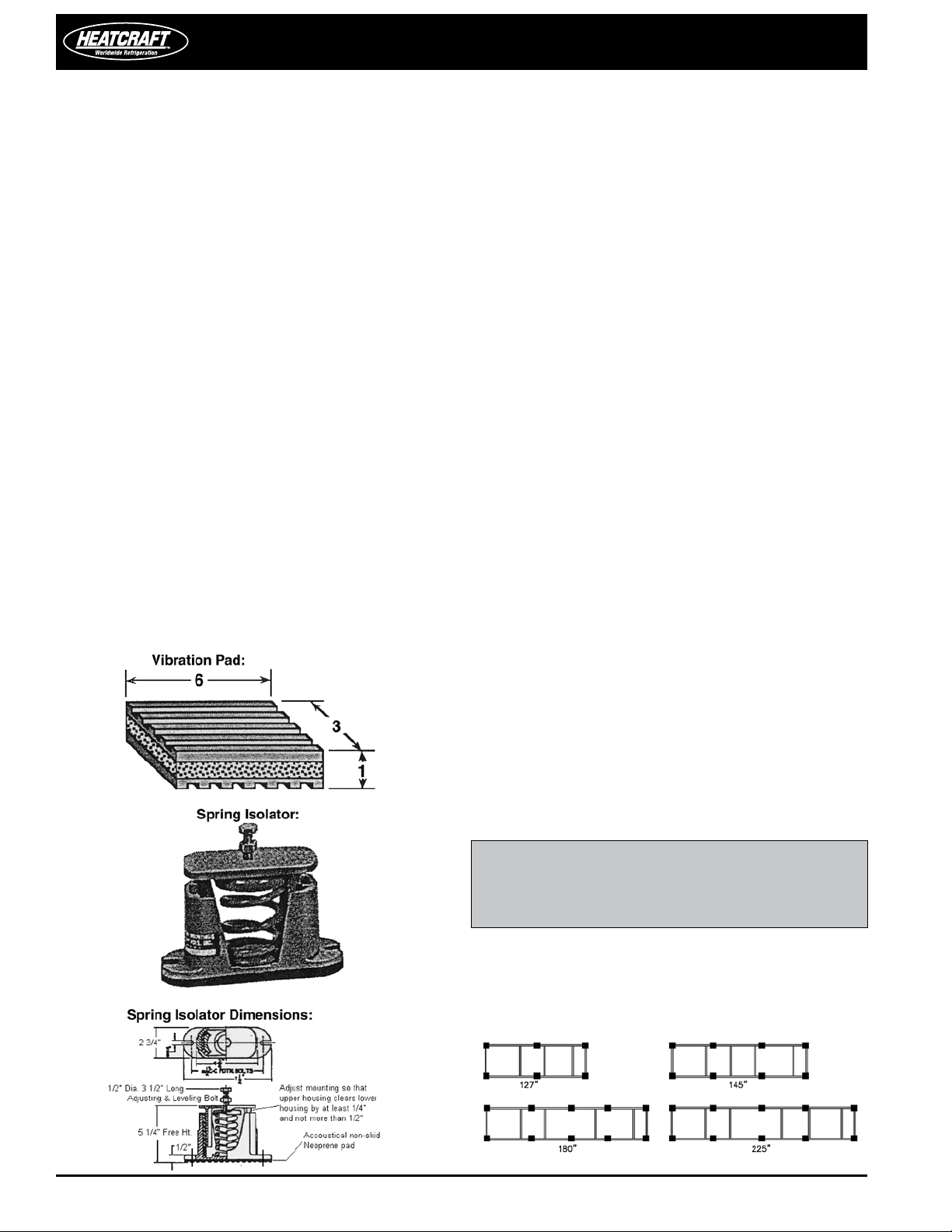

Figure 1. Vibration Pad and Spring Isolator

means of cables at the four corners of the base. If cables are

used, the lifting cables should be prevented from contacting

any of the unit piping or electrical components.

Location Of Equipment - Indoor

Clearances

The parallel systems should be located so they are level and

easily serviced. The minimum suggested clearance around

the units should be 24 inches at the rear and 42 inches in the

front of panel (or as required by National or Local Codes). For

parallel system units placed end to end, 24 inches between

units is suggested.

Floor & Foundation Requirements

The total weight of a single unit will vary between 1200 pounds

and 10,000 pounds. Allowances must be made for the parallel

rack and all other equipment installed in the same area as the

parallel units. The location and installation of all equipment

should be in accordance with all local and national code

requirements.

While each unit is constructed with a welded steel base frame

adequately designed to withstand vibration, the natural

pulsating action of the interconnected motor-compressors

may cause considerable noise and vibration if the unit is not

mounted on a rm level surface and isolated from the structure

of the building.

Vibration Mounts

In ordinary ground level or basement installations, all that is

necessary to assure a vibration-free installation is to place the

unit on the concrete oor with the wae-surfaced resilient pads

supplied. See Figure 2 for suggested pad locations. Mezzanine

and other installations require some special considerations.

The equivalent of 6 inch thick properly reinforced concrete

floor must be provided for mounting parallel units above

grade. It is recommended that the suggestions previously

given for rigid oor construction on above-grade installations

be closely adhered to. If this is not possible, special vibration

NOTE: Turn each leveling nut until the tip casting

rises 1/4” to 3/8” above the bottom

casting. MOUNT ADJUSTMENT SHOULD

NEVER EXCEED 3/4”.

Figure 2. Vibration Pad Locations

4 Part # 25000102

Parallel Compressor Systems

absorbing spring mounts (optional equipment) must be placed

under the base frame of each unit. See Figure 1 for view of

Spring Isolator. The spring mounts are placed under the unit

and the unit carefully lowered on to the mounts. Note that no

other mounting hardware is required and any unevenness in

the oor or uneven weight distribution may be compensated

for by turning the spring mount leveling nuts with an openend wrench. This adjustment should be made after all piping

is installed and the system is charged with refrigerant.

Location of Equipment - Outdoor

The mounting platform or base should be level and located

•

so as to permit free access of supply air.

Units must not be located in the vicinity of steam, hot air

•

or fume exhausts.

The unit should be mounted away from noise sensitive

•

spaces such as oces.

The unit must have adequate support to avoid vibration and

•

noise transmission into the building. Sound and structural

consultants should be retained for recommendations.

Ground Mounting

The unit must be set on a at and level foundation. A single

piece concrete slab with footings extending below the frost

line and raised approximately six inches above ground level

provides a suitable base. Raising the base above ground level

provides some protection from ground water and wind blown

matter. The concrete slab should be isolated from the building

structure. Finally, before tightening mounting bolts, recheck

the level of the unit.

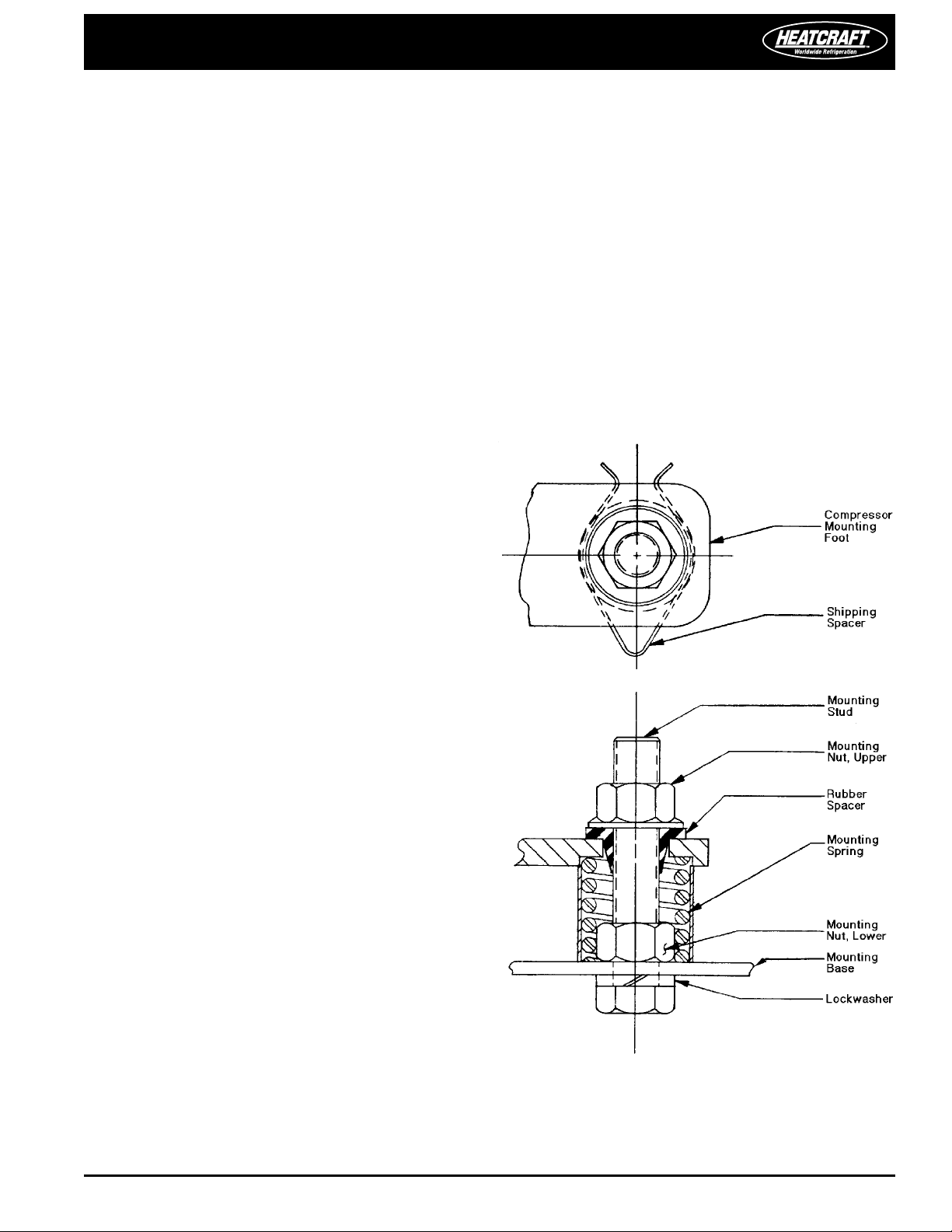

Compressor Spring Vibration Isolators

On units with this option, the compressors are secured rigidly

to make sure there is no transit damage. Before operating the

unit, it is necessary to follow these steps:

1. Remove the upper nuts and washers

2. Discard the shipping spacers

3. Install the neoprene spacers (Spacers located in the electrical

panel or tied to compressor)

4. Replace the upper mounting nuts and washers

5. Allow 1/16 inch space between the mounting nut/washer

and the neoprene spacer

Figure 3. Spring Mount

Roof Mounting

Rooftop installations require adequate structural beams to

support the weight of the unit and service personnel. The

design of the beams/supports must minimize deection and

attendant vibration transmission.

Due to the weights involved, a structural analysis by a qualied

engineer may be required before mounting. Also, for sound

sensitive applications, unit vibration isolators should be used.

Unit Vibration Isolation

Under certain critical conditions, it is recommended that

vibration isolators, of a suitable type, be installed under the

base. The isolators must be designed for the operating weight

of the unit. Rubber-in-shear or spring type isolators (by others)

are available for this purpose.

Parallel Compressor Systems Installation & Operations Manual, October 2004 5

Installation and Operations Manual

Unit Access

Always provide sucient clearance for unit maintenance and

service. Minimum clearances for most situations are described

below (except 60 Inches of free space is required in front of the

control panel). Please note that these are minimums and more

clearance may be required by local codes.

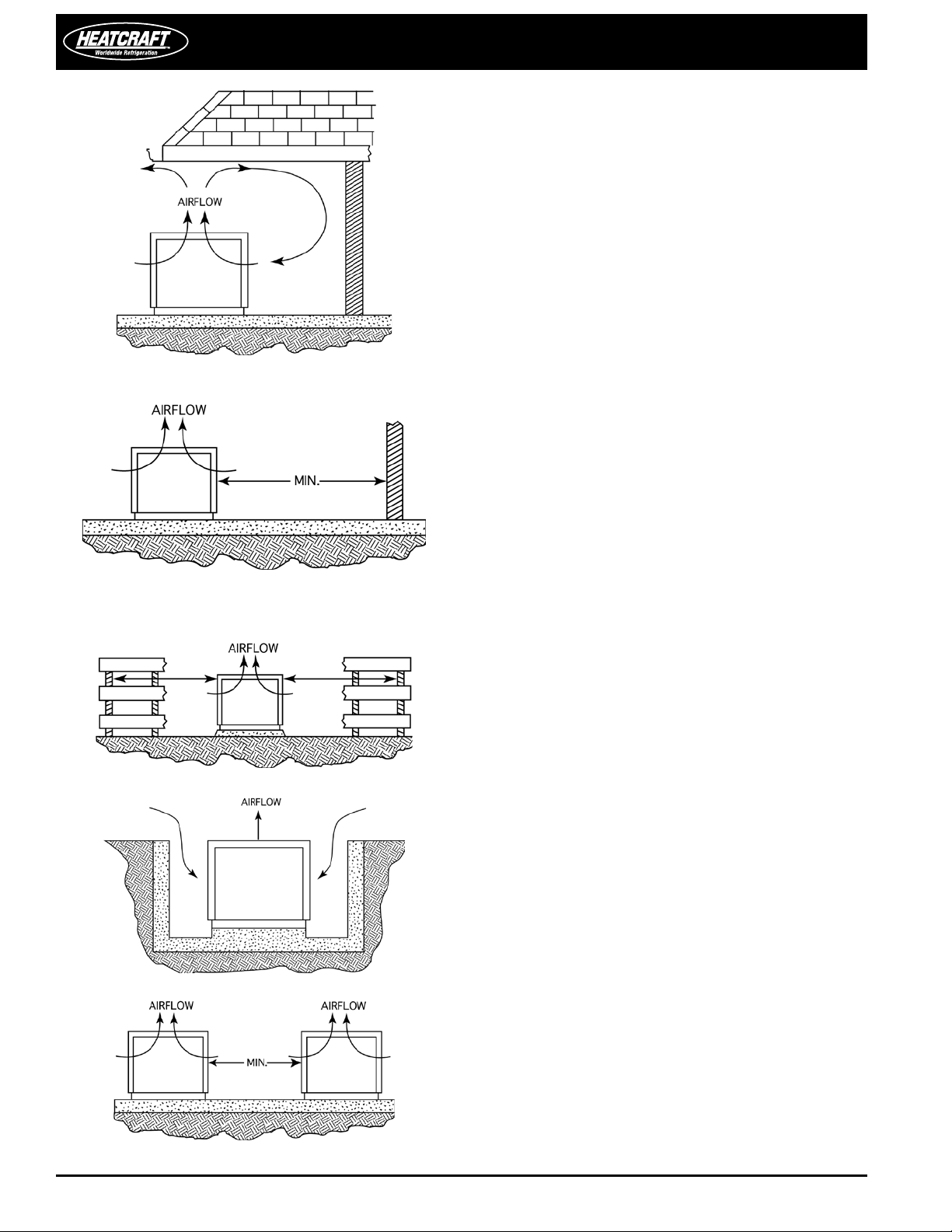

Vertical Clearance

Overhead obstructions are not permitted. Vertical air discharge

from the condenser must have no obstructions that can cause

the discharge air to be recirculated back to the inlet side of

the unit.

Lateral Clearance (Walls or Obstructions)

The unit should be located so that air may circulate freely and

not be recirculated. For proper air ow and access, all sides of

the unit (except control panel end ) should be a minimum of

four feet (1.2 m) away from any wall or obstruction. It is preferred

that this distance be increased whenever possible. Care should

be taken to see that ample room is left for maintenance work

through access doors and panels. When the unit is in an area

where it is enclosed by three walls the unit must be installed

under the guidelines for unit installations in pits.

Decorative Fences

Fences may be installed closer than the four foot (1.2 m) lateral

minimum (except on the control panel end) requirement

whenever fences permit sucient free area to allow adequate

air ow to the unit. Once again, care should be taken to leave

ample room for unit service. Recommended service clearances

are listed above.

Units in Pits

The top of the unit should be level with the top of the pit. If the

top of the unit is not level with the top of the pit, a wider pit or

discharge stacks must be used to raise discharge air to the top

of the pit. This is a minimum requirement.

Multiple Units (Unit-to-Unit Clearance)

For units placed side by side, the minimum distance between

units is eight feet (2.4 m) to prevent air recirculation.

6 Part # 25000102

Parallel Compressor Systems

Ventilation Requirements

Indoor Units

If compressors or condensing units are located in a machine

room, adequate ventilation air must be provided to avoid

an excessive temperature rise in the room. To allow for peak

summer temperatures a 10°F temperature rise is recommended,

although a 15°F rise might be acceptable.

With compressors with remote condensers, approximately 10%

of the heat rejected is given o by the compressor casting and

the discharge tubing. The correct formula for calculating the

ventilation requirement of the Indoor Parallel unit is:

CFM = 10% of THR / hr

10° TD

The air intake should be positioned so that air passes over the

units. All State, Local, and National codes should be followed.

Electrical

To insure the proper operation of equipment and reduce the

possibility of interruption of refrigeration due to electrical

power failure, the following precautions must be observed:

• All electrical work must be done in accordance with the

National Electrical Code and existing local codes

• The power supply must be the same as specied on the unit

data plate

• An adequate power supply must be provided

• Voltage uctuations in excess of 10 percent must

be corrected

• Overload relays (Carrier compressors only) are selected

in accordance with specied limits as determined by the

motor-compressor manufacturer. They must not be changed

in size or shorted-out

• Control panels must be provided with a single phase, 60

Hertz supply. See the unit wiring diagram for the voltage

requirement

• Before starting up a parallel unit, insure that all fuses and

motor-protective devices are in place and that all wiring is

secure. A complete wiring diagram for troubleshooting the

unit will be found inside the control panel cover

Refrigerant Piping

The system as supplied by Heatcraft, was thoroughly cleaned

and dehydrated at the factory. Foreign matter may enter the

system by way of the eld piping required. Therefore, care must

be used during installation of the piping to prevent introduction

of foreign matter.

Install all refrigeration system components in accordance with

all applicable local and national codes and in conformance

with good practice required for the proper operation of the

system.

Proper size refrigeration lines are essential to good refrigeration

performance. Suction lines are more critical than liquid or

discharge lines. Oversized suction lines may prevent proper oil

return to the compressor. Undersized lines can rob refrigeration

capacity and increase operating cost. Consult the line sizing

charts in this manual for proper pipe sizes.

The following procedures should be followed:

1. Do not leave dehydrated compressors or lter-driers open

to the atmosphere

2. Use only refrigeration grade copper tubing, properly sealed

against contamination

3. Suction lines should slope 1/4” per 10 feet towards the

compressor

4. Discharge lines should slope 1/4” per 20 feet toward the

condenser

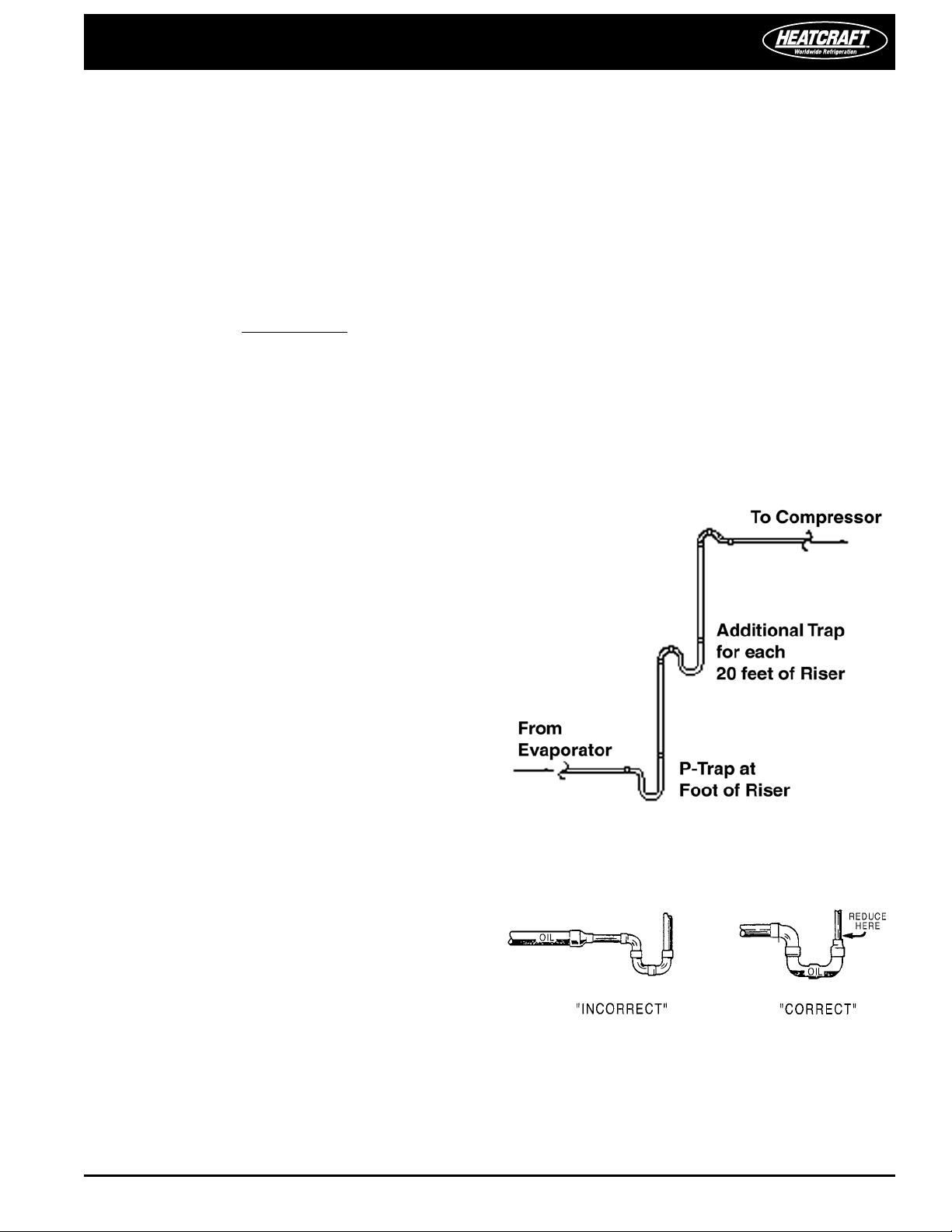

Suction P-Traps

• Provide P-Traps at the base of each suction riser of four (4)

feet or more to enhance oil return to the compressor. Use a

P-Trap for each 20 feet section of riser. See Figure 4 below:

Figure 4. P-Trap Requirements

*The P-Trap should be the same size as the horizontal line

See Figure 5 below

Figure 5. P-Trap Construction

Parallel Compressor Systems Installation & Operations Manual, October 2004 7

Installation and Operations Manual

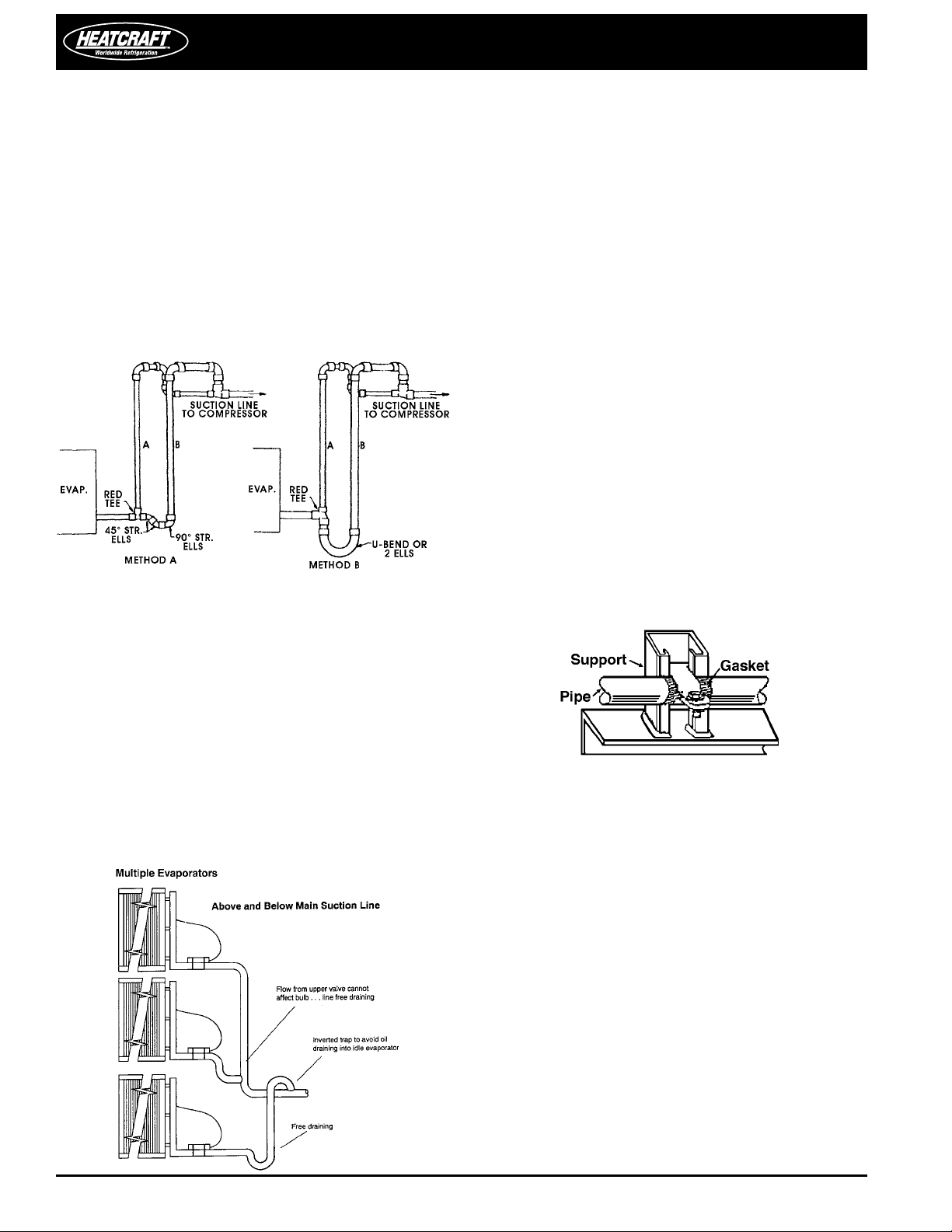

In systems equipped with capacity control compressors,

•

or where multiple compressors are used with one or more

compressors cycled o for capacity control, double suction

risers should be installed. See Figure 6 below. The two

lines should be sized so that the total cross-section area

is equivalent to the cross section area of a single riser that

would have both satisfactory gas velocity and acceptable

pressure drop at maximum load conditions. The two lines

normally are dierent in size, with the larger line trapped as

shown. The smaller line must be sized to provide adequate

velocities and acceptable pressure drop when the entire

minimum load is carried in the smaller riser.

Figure 6. Double Suction Risers

•

When brazing refrigerant lines, an inert gas should

be passed through the line at low pressure to prevent

scaling and oxidation inside the tubing. Dry nitrogen is

preferred.

•

Use long radius ell’s for lower pressure drop.

•

Provide expansion loops in long straight refrigerant

lines that are subject to expansion and contraction. See

Expansion Loops in this manual for more information.

Refrigerant Line Insulation

Insulate suction lines from the evaporators to the parallel

•

unit with minimum 3/4” thick ness closed-cell type

insulation on low temperature circuits. Insulate suction

lines on medium temperature circuits with minimum 1/2”

thick insulation to prevent condensation.

Long liquid lines run in areas exposed to high temperatures

•

should be fully insulated with minimum 1/2” insulation.

Suction and liquid lines should never be taped or

•

soldered together.

Refrigerant Line Support

Strap and suppor t tubing to prevent excessive line

•

vibration and noise. All tubing clamps should have an

insulating material (i.e. Hydra Sorb bushing) to prevent

metal to metal contact.

In operation, at maximum load conditions gas and

•

entrained oil will be flowing through both risers. At

minimum load conditions, the gas velocity will not be

high enough to carry oil up both risers. The entrained oil

will drop out of the refrigerant gas ow and accumulate

in the “P” trap forming a liquid seal. This will force all of the

ow up the smaller riser, there by raising the velocity and

assuring oil circulation through the system.

When connecting more than one suction line to a main

•

trunk line, connect each branch line with an inverted trap.

See Figure 7 below:

Figure 7. Inverted Trap

Figure 8. Pipe Support

Straight runs should be supported near each end.

•

Long runs require additional supports.

•

A general guide is:

•

3/8” to 7/8” every 5 feet

•

1-1/8” to 1-3/8” every 7 feet

•

1-5/8” to 2-1/8” every 10 feet

•

When changing directions, supports should be placed a

•

maximum of 2 feet in each direction.

Piping attached to a vibrating object (such as a compressor

•

or compressor base) must be supported in such a manner

that will not restrict the movement of the vibrating object.

Rigid mounting will fatigue the copper tubing.

Use only a suitable silver solder alloy on suction and liquid

•

lines.

Limit the soldering paste or ux to the minimum required

•

to prevent contamination of the solder joint internally. Flux

only the male portion of the connection, never the female.

After brazing, remove excess ux.

8 Part # 25000102

Parallel Compressor Systems

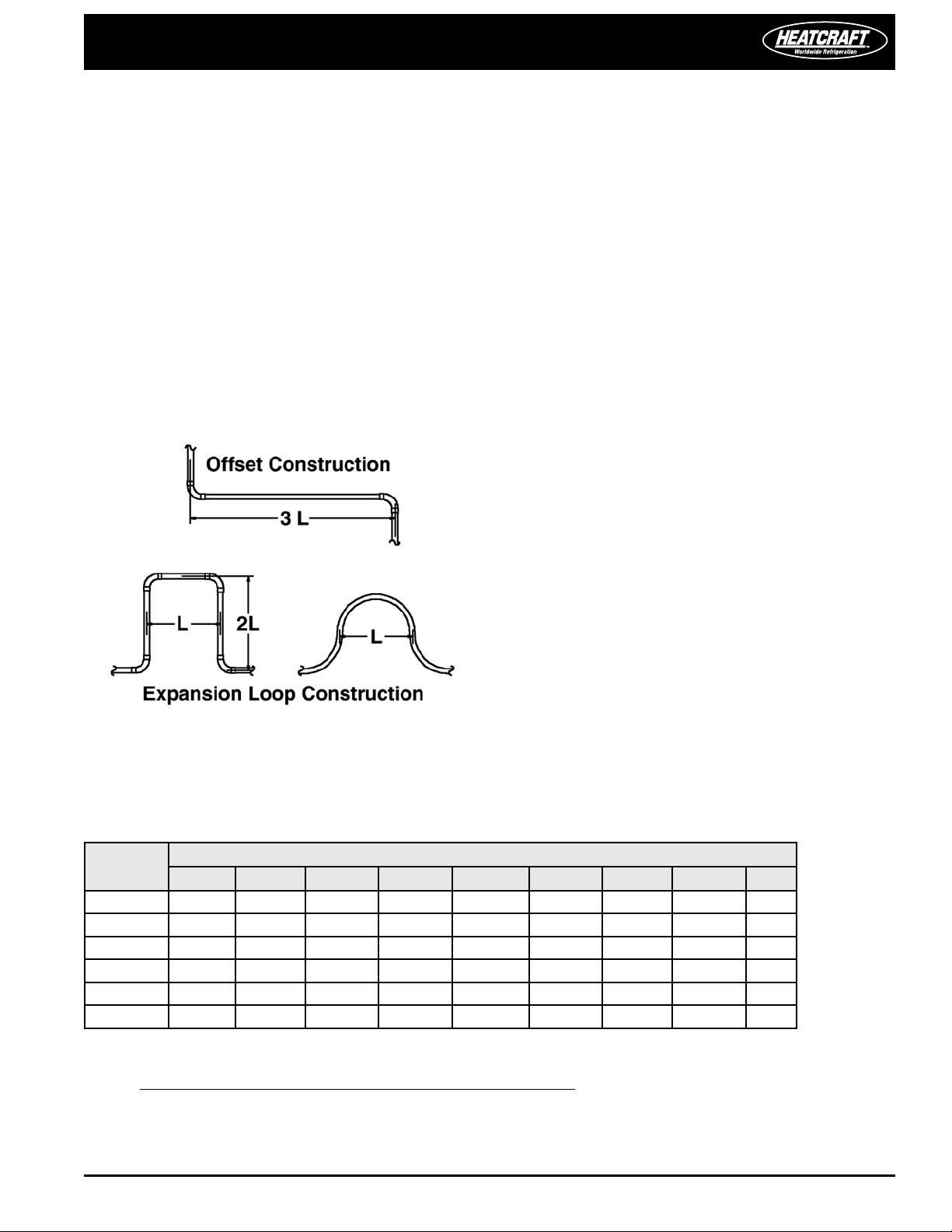

Expansion Loops

Suction, liquid and remote condenser lines are subject to

expansion and contraction and proper piping techniques

must be employed (especially on hot gas lines) to prevent line

breakage. This is critical on long straight runs of generally 70’ or

more where expansion loops must be provided and hangers

should allow for longitudinal movement of the piping.

On a refrigeration system with gas defrost, the refrigerant lines

expand and contract with temperature changes. The suction

line normally has the greatest movement since it has the

largest temperature change during defrost. If the expansion

and contraction is not planned for during the installation of

refrigeration lines, kinking and breaking of the lines could

occur.

Figure 9. Osets

In order to compensate for the expansion of the tubing, it

is necessary to estimate the amount of expansion and then

provide osets or loops in the refrigerant piping. Normally the

area to be most concerned with is the straight line distance

from the xture to the parallel compressor unit.

A simple form of expansion loop can be made of soft tempered

copper tube by bending it to the correct size and shape. A

neater type is made by assembling hard tube with solder elbows

as in Figure 9. The correct proportions of such expansion loops

to meet various conditions are shown in Table 1.

In compensating for expansion and contraction, two items

are very important:

Liquid and suction lines can not be joined together and

•

should not touch at any point

Pipe hangers must be located and installed in such a

•

manner as not to restrict the expansion and contraction

of the tubing. All tubing clamps should have an insulating

material (i.e. Hydra Sorb bushing) to prevent metal to metal

contact

Table 1. Expansion Chart

Table of Values for “L”

Ref. Line

OD (in.)

7/8 10 15 19 22 25 27 30 34 38

1-1/8 11 16 20 24 27 29 33 38 42

1-3/8 11 17 21 26 29 32 36 42 47

1-5/8 12 18 23 28 31 35 39 46 51

2-1/8 14 20 25 31 34 38 44 51 57

2-5/8 16 22 27 32 37 42 47 56 62

NOTES: Calculations for expansion and contraction should be based on the average coecient of expansion of copper which is .0000094

per degree Fahrenheit between 77°F and 212°F. Example, the expansion for each 100 feet of length of any size of tube heated from room

temperature of 70°F to 170°F, a rise of 100°F, is:

100°F (rise °F) X 100 (linear feet) X 12 (inches) X.0000094 (coecient) = 1.128 inches

(Reprinted from Copper & Brass Research Association)

Parallel Compressor Systems Installation & Operations Manual, October 2004 9

1/2 1 1-1/2 2 2-1/2 3 4 5 6

Amount of Expansion (in.)

Installation and Operations Manual

Table 2. Pressure Loss of Liquid Refrigerants

(In Liquid Line Risers - Expressed in Pressure Drop, PSIG, and Subcooling Loss, °F)

Liquid Line Rise in Feet

Refrigerant

R-12 5.4 2.8 8.1 4.2 10.7 5.4 13.4 6.9 16.1 8.3 21.5 11.3 26.9 14.3 40.3 22.4 53.7 31.0

R-22 4.8 1.6 7.3 2.3 9.7 3.1 12.1 3.8 14.5 4.7 19.4 6.2 24.2 8.0 36.3 12.1 48.4 16.5

R-502 4.9 1.5 7.3 2.2 9.7 3.0 12.1 3.7 14.6 4.5 19.5 6.0 24.3 7.6 36.4 11.5 48.6 14.8

R-134A 4.9 2.0 7.4 2.9 9.8 4.1 12.3 5.2 14.7 6.3 19.7 8.8 24.6 11.0 36.8 17.0 49.1 23.7

R-404A/R-507 4.1 1.1 6.1 1.6 8.2 2.1 10.2 2.7 12.2 3.3 16.3 4.1 20.4 5.6 30.6 8.3 40.8 11.8

Based on 110°F liquid temperature at bottom of riser

10’ 15’ 20’ 25’ 30’ 40’ 50’ 75’ 100’

PSIG °F PSIG °F PSIG °F PSIG °F PSIG °F PSIG °F PSIG °F PSIG °F PSIG °F

Table 3. Equivalent Feet of Pipe

(Due to Value and Fitting Friction)

Copper Tube

OD, Type “L”

Globe Value (Open) 14 16 22 28 36 42 57 69 83 99 118 138 168

Angle Value (Open) 7 9 12 15 18 21 28 34 42 49 57 70 83

90° Turn Through Tee 3 4 5 6 8 9 12 14 17 20 22 28 34

Tee - Straight Through

or Sweep Below

90° Elbow or Reducing

Tee (Straight Through)

1/2 5/8 7/8 1-1/8 1-3/8 1-5/8 2-1/8 2-5/8 3-1/8 3-5/8 4-1/8 5-1/8 6-1/8

.75 1 1.5 2 2.5 3 3.5 4 5 6 7 9 11

1 2 2 3 4 4 5 7 8 10 12 14 16

10 Part # 25000102

Parallel Compressor Systems

Table 4. Weight of Refrigerants in Copper Lines During Operation

(Pounds per 100 Lineal Feet of Type “L” Tubing)

Line Size

OD (in.)

3/8

1/2

5/8

7/8

1-1/8

1-3/8

1-5/8

2-1/8

2-5/8

3-1/8

3-5/8

4-1/8

Refrigerant

12, 134A

22

R-507, 502, 404A

12, 134A

22

R-507, 502, 404A

12, 134A

22

R-507, 502, 404A

12, 134A

22

R-507, 502, 404A

12, 134A

22

R-507, 502, 404A

12, 134A

22

R-507, 502, 404A

12, 134A

22

R-507, 502, 404A

12, 134A

22

R-507, 502, 404A

12, 134A

22

R-507, 502, 404A

12, 134A

22

R-507, 502, 404A

12, 134A

22

R-507, 502, 404A

12, 134A

22

R-507, 502, 404A

Liquid

Line

4.0

3.9

3.4

7.4

7.4

6.4

11.9

11.8

10.3

24.7

24.4

21.2

42.2

41.6

36.1

64.2

63.5

55.0

90.9

90.0

78.0

158

156

134

244

241

209

348

344

298

471

465

403

612

605

526

Hot Gas

Line

.15

.22

.31

.30

.41

.58

.47

.65

.93

.99

1.35

1.92

1.70

2.30

3.27

2.57

3.50

4.98

3.65

4.96

7.07

6.34

8.61

12.25

9.78

13.70

18.92

13.97

18.95

27.05

18.90

25.60

36.50

24.56

33.40

47.57

Suction Line at Suction Temperature

-40°F -20°F 0°F 20°F 40°F

.01

.02

.03

.01

.03

.04

.02

.05

.07

.05

.10

.15

.08

.17

.26

.14

.27

.40

.20

.37

.56

.34

.65

.98

.52

1.01

1.51

.75

1.44

2.16

.99

1.94

2.92

1.29

2.53

3.80

.01

.03

.04

.03

.05

.07

.05

.08

.11

.10

.16

.23

.17

.28

.39

.26

.42

.58

.37

.59

.82

.64

1.03

1.43

.99

1.59

2.21

1.41

2.28

3.15

1.91

3.08

4.25

2.49

4.01

5.55

.02

.04

.06

.04

.07

.13

.07

.12

.17

.15

.24

.37

.26

.42

.63

.40

.64

.95

.57

.90

1.35

.98

1.57

2.35

1.51

2.42

3.62

2.16

3.45

5.17

2.92

4.67

6.97

3.81

6.08

9.09

.04

.06

.09

.07

.11

.16

.12

.17

.25

.24

.36

.51

.41

.61

.86

.61

.93

1.32

.87

1.33

1.86

1.51

2.30

3.23

2.32

3.54

5.00

3.31

5.05

7.14

4.48

6.83

19.65

5.84

8.90

12.58

.06

.08

.13

.11

.15

.24

.17

.25

.35

.36

.51

.72

.60

.87

1.24

1.91

1.33

1.87

1.30

1.88

2.64

2.24

3.26

4.58

3.47

5.03

7.07

4.96

7.18

9.95

6.69

9.74

13.67

8.75

12.70

17.80

Parallel Compressor Systems Installation & Operations Manual, October 2004 11

Loading...

Loading...