Heatcraft H-IM-RACC Installation Manual

Installation and Operations

Manual

Bulletin H-IM-RACC August 2007 Part Number 2500018

Replaces H-IM-73A and H-IM-43B

Remote Air-Cooled Condenser

Table of Contents

Inspection ������������������������������������������������������������������������������ 2

Rigging and Moving Units

Installation Requirements

Unit Location

Space and Location Requirements ��������������������������������������� 3

Walls or Obstructions

Units in Pits

Multiple Units

Decorative Fences

Sound Vibration

Vertical and Horizontal Condenser Assembly ��������������������� 4

Typical Piping Arrangements ����������������������������������������������� 5

Installation, Refrigerant Piping

Electrical Wiring ��������������������������������������������������������������������� 6

Start Up ���������������������������������������������������������������������������������� 8

Operation

Winter Operation Head Pressure Control

Fan Cycling Method

Fan Cycling Operation and Installation

Variable Speed

Flooded Head Pressure Control Valve ���������������������������������� 9

Operation

Piping

Maintenance

Cleaning Instructions

System Warranty ������������������������������������������������������������������ 11

In-Warranty Return Materials Procedure

Condenser Specications�����������������������������������������������12-13

General Fan Layout

Dimensions

Replacement Parts by InterLink™ ��������������������������������������� 14

Installation and Operations Manual

Inspection

Shipment should be checked against the bill of lading to verify

that all items listed have been received. All parts should be

carefully inspected to determine if any damage was incurred

in shipment.

Any shortage and/or claims for damage should be immediately

reported to the delivering carrier, followed by ling a claim for

shortages and/or damages.

When uncrating, care should be taken to prevent damage.

Heavy equipment should be left on its shipping base until it

has been moved to the nal location.

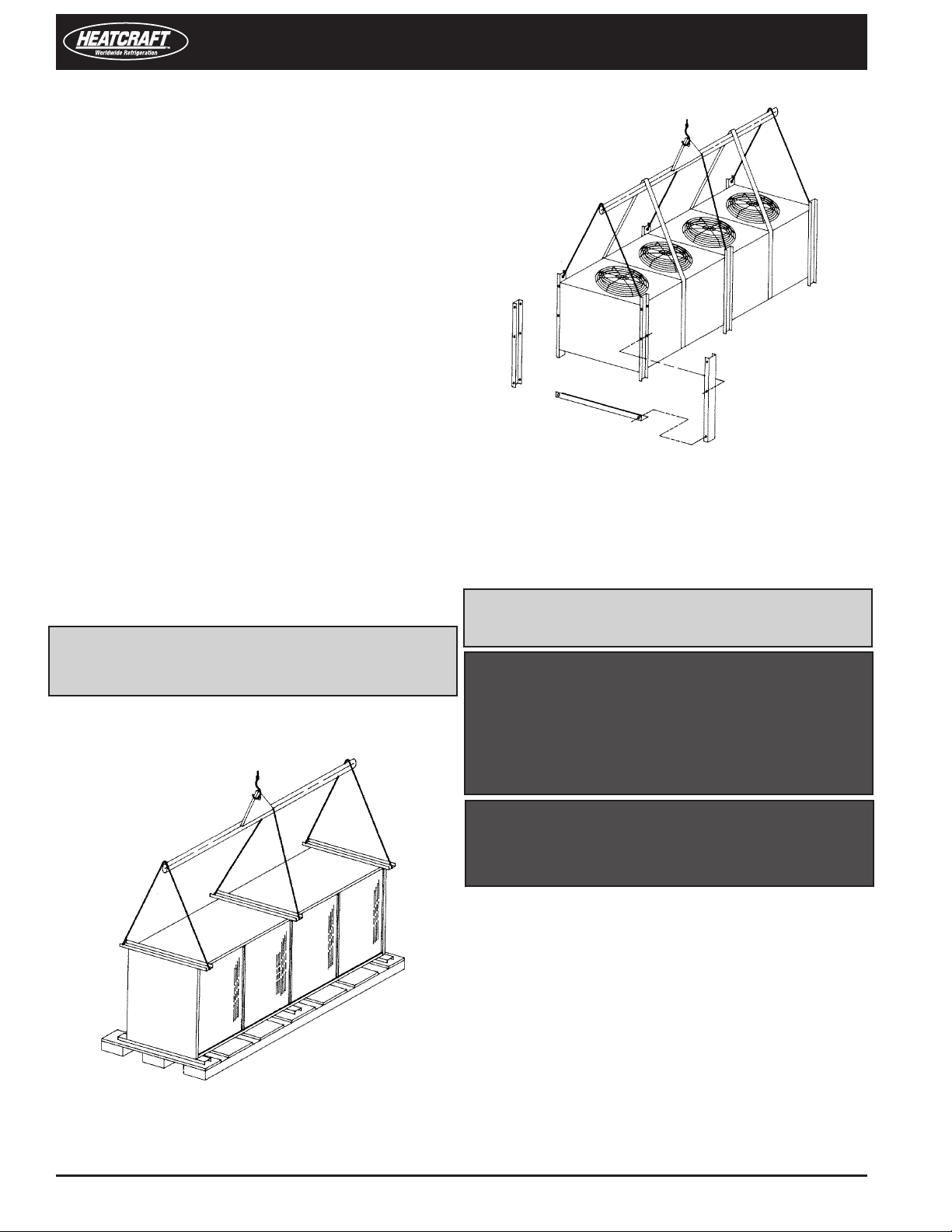

Rigging and Moving Units

The exact method of handling and setting the unit depends

on available equipment, size of unit, nal location and other

variables. It is the judgement of the riggers and movers to

determine the specic method of handling each unit.

All units are shipped on heavy skids and enclosed in open

crating. Generally, it is advisable to bring the unit as close

to its final location as possible before removing crating.

Units are provided with lifting ears near the four corners. Under

no circumstances should the coil headers or return bends be

used for moving these units.

NOTE FOR ALL MODELS: Spreader bars must be used

(contractor-supplied)� Safety slings should be used when

making lift�

Figure 1: Suggested Rigging

Figure 2: Leg Mounting

Installation Requirements

NOTE: Installation and maintenance to be performed only

by qualied personnel who are familiar with local codes

and regulations and are experienced with this type of

equipment�

CAUTION: Sharp edges and coil surfaces are a potential

injury hazard� Avoid contact with them�

WARNING: This equipment may contain a substance that

harms public health and the environment by destroying

ozone in the upper atmosphere� Venting of cer tain

refrigerants to the atmosphere may be illegal in your

location� Refrigerant recovery devices should be used

when installing or servicing this product� Consult your

local codes for requirements in your location�

WARNING: Refrigerant can be harmful if it is inhaled�

Refrigerant must be used and recovered responsibly�

Failure to follow this warning may result in personal injury

or death�

Unit Location

Units are designed for outdoor application and may be

mounted on a roof or concrete slab (ground-level installation).

Concrete slabs used for unit mounting should be installed level

and be properly supported to prevent settling. A one-piece

concrete slab with footings extending below the frost line

is recommended.

Roof-mounted units should be installed level on steel channels

or an I-beam frame to support the unit above the roof. Use of

vibration pads or isolators is recommended. The roof must be

strong enough to support the weight of the unit.

2 Part # 2500018

© 2007 Heatcraft Refrigeration Products LLC

Remote Air-Cooled Condenser

The condenser should be located no closer than four feet from

any wall or other obstruction to provide sucient clearance

for air entrance. Do not attach ductwork to the coil inlet or fan

outlet. Care should be taken to avoid air recirculation conditions

that can be caused by sight screening, walls, etc. Keep unit fan

discharge away from any building air intakes.

Space and Location Requirements

The most important aspect in selecting a location for air-cooled

equipment is a supply of ambient air to the condenser and the

adequate removal of heated air from the condenser area. If

the requirement for adequate air circulation is not adhered to,

higher head pressures will result, creating poor operation and

possible failure of equipment. Units must not be located in the

vicinity of steam, hot air or fume exhausts.

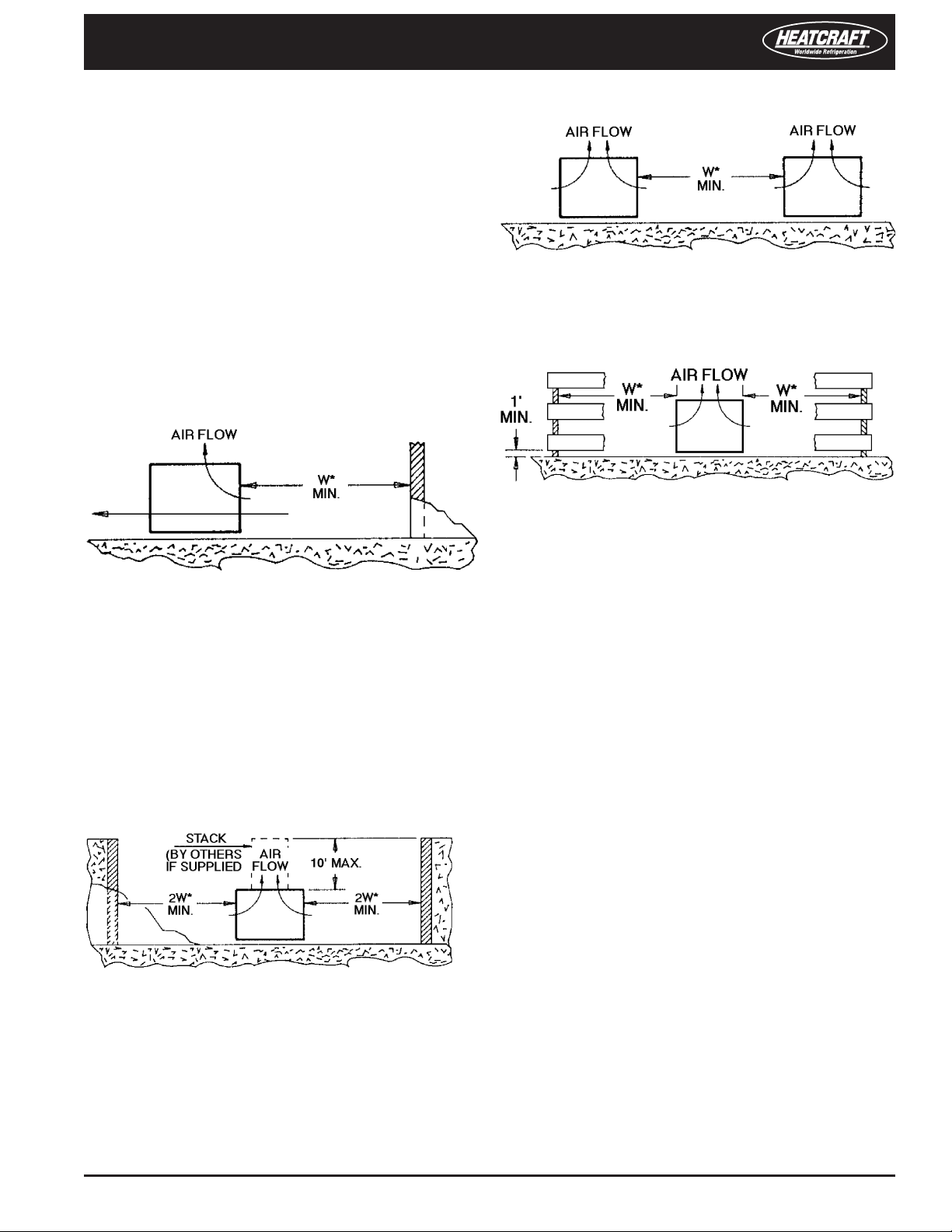

Walls or Obstructions

Multiple Units

For units placed side by side, the minimum distance between

units is the width of the largest unit. If units are placed end to

end, the minimum distance between units is four feet.

Decorative Fences

Fences must have 50 percent free area, with a one-foot undercut,

a minimum clearance equal to the width of the unit and must

not exceed the height of the unit. If these requirements are not

met, unit must be installed as indicated for units in pits.

The unit should be located so that air may circulate freely and

not be recirculated. For proper air ow and access, all sides of

the unit should be a minimum of the width of the unit away

from any wall or obstruction. It is preferable for this distance

be increased whenever possible.

Care should be taken to see that ample room is left for

maintenance through access doors and panels. Overhead

obstructions are not permitted. When the unit is in an area

where it is enclosed by three walls the unit must be installed

as indicated for units in a pit.

Units In Pits

The top of the unit should be level with the top of the pit and

side distance increased to two times the width of the unit.

Sound and Vibration

Units should be installed away from occupied spaces

to redu ce the trans miss ion of soun d and vibratio n

to o ccupied spaces. U nits shou ld be mounted o ver

corridors, utility areas, rest rooms and other auxiliary areas

where high levels of sound are not an important factor.

So und and struc tural consultants should be retained

for recommendations.

Th e refr igerant piping should be flexible enou gh to

prevent the transmission of noise and vibration from the

unit into the building. If the refrigerant lines are to be

suspended from the structure of the building, isolation

hangers should be used to prevent the transmission

of vibration.

Where piping passes through a wall, it is advisable to pack

berglass and sealing compound around the lines to minimize

vibration and retain exibility in the lines. The unit needs to

be secured in its nal location. Holes are provided in the base

runner for this purpose.

If the top of the unit is not level with the top of pit, discharge

cones or stacks must be used to raise discharge air to the top

of the pit. This is a minimum requirement.

*W = Total width of the condenser.

Remote Air-Cooled Condenser Installation and Operations Manual, August 2007 3

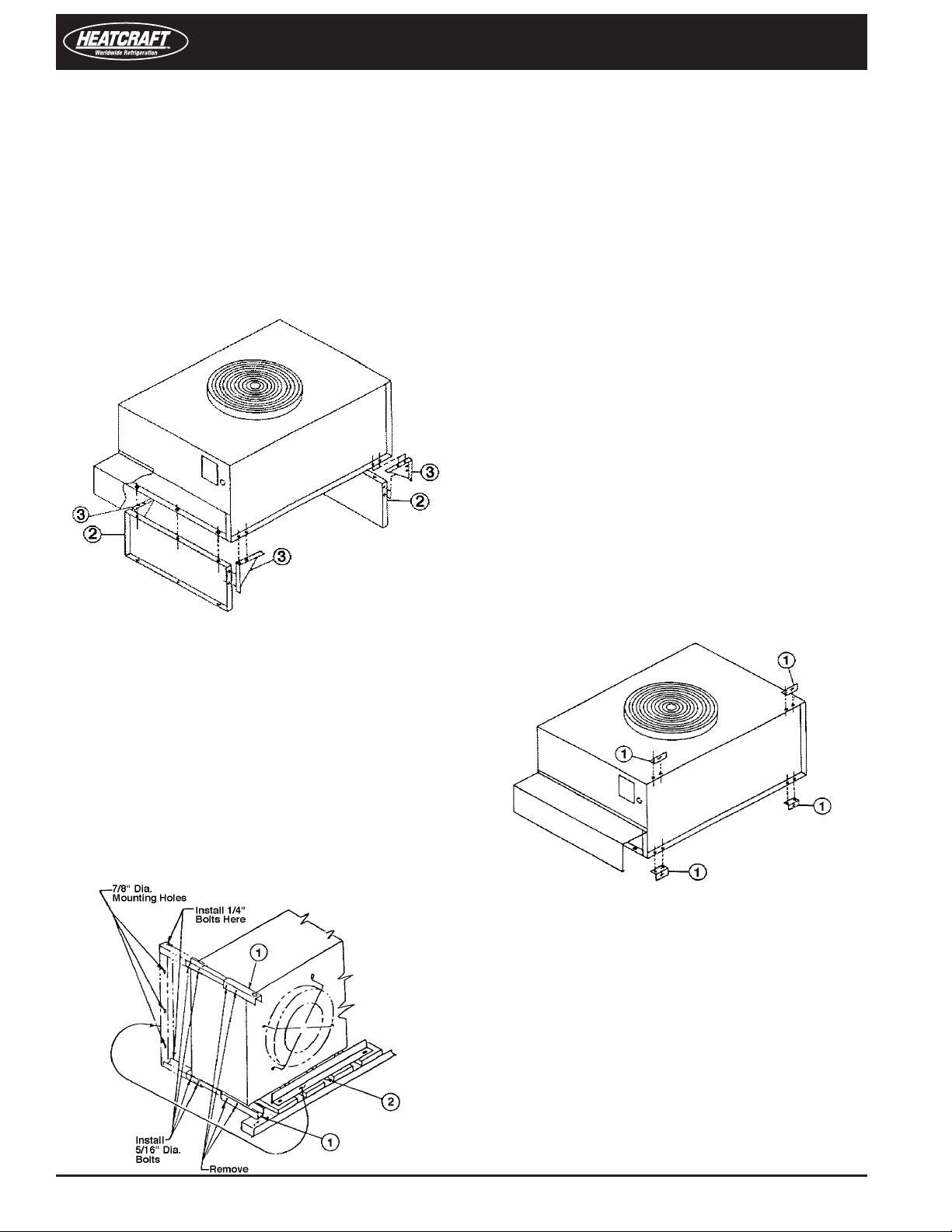

Vertical Condenser

Vertical airow units should be located no closer than the width

of the unit from a wall or other obstruction. If two or more units

are to be positioned in the same area, a similar distance should

be maintained between adjacent units. Sufficient free area

should be left around and below unit to avoid air restriction

to coil.

Leg Assembly for Vertical Airow Installation

(Models 008-016; 1-3)

Figure 3. Leg assembly (vertical airow, models 008-016; 1-3)

Installation and Operations Manual

Remove fasteners securing condenser to skid.

1.

Remove leg extensions (Figure 4, item 1) by removing four

2.

5/16” x 3-1/2” bolts.

Install as shown in dotted lines with same four bolts.

3.

Install mounting angle (item 2) as shown (dotted lines) with

4.

four 1/4 - 20 x 3/4” bolts provided.

Condenser can be hoisted by attaching hooks into 1-1/2”

5.

holes in leg assemblies.

Horizontal Condenser

Horizontal airow units should be installed with the coil (inlet

air side) facing the prevailing winds. Where strong winds

are common, it is recommended that a wind deflector (not

supplied) be used to discharge the air vertically from the unit,

to prevent capacity loss during varying wind conditions. The

wind deector should be installed on the fan side of the unit.

If horizontal airow units are installed with the air inlet facing

a wall, a distance of at least 48 inches should be maintained

between unit and wall. If it is necessary to have the unit

positioned so the air discharge is toward a wall, it should be

spaced at a distance no less than three times the coil face

height from the wall.

Assemble the unit’s two legs (Figure 3, item 2) using three

1.

1/4 - 20 x 3/4” long bolts per leg. Captive nuts are provided

on unit for this assembly.

Fo ur gus sets (Fi gure 3 , item 3) are p rovided for

2.

leg support.

Assemble the gusset in each corner with 1/4 - 20 x 3/4” long

3.

bolts and 1/4” nuts.

Discard the four mounting angles (Figure 5, item 1).

4.

Leg Assembly for Vertical Airow Installation

(Models 024-133; 5-26)

Figure 4. Leg assembly (vertical airow, models 024-133; 5-26)

Leg Assembly for Horizontal Airow Installation

(Models 008-016; 1-3)

Figure 5. Leg assembly (horizontal airow, models 008-016 ; 1-3)

Attach four mounting angles (Figure 5, item 1) to the

1.

unit, using two 1/4 - 20 x 3/4” long bolts and 1/4” nuts per

mounting angle.

Discard the two legs, (Figure 3, item 2) and four gussets

2.

(Figure 3, item 3).

4 Part # 2500018

Remote Air-Cooled Condenser

Leg Assembly for Horizontal Airow Installation

(Models 024-133; 5-26)

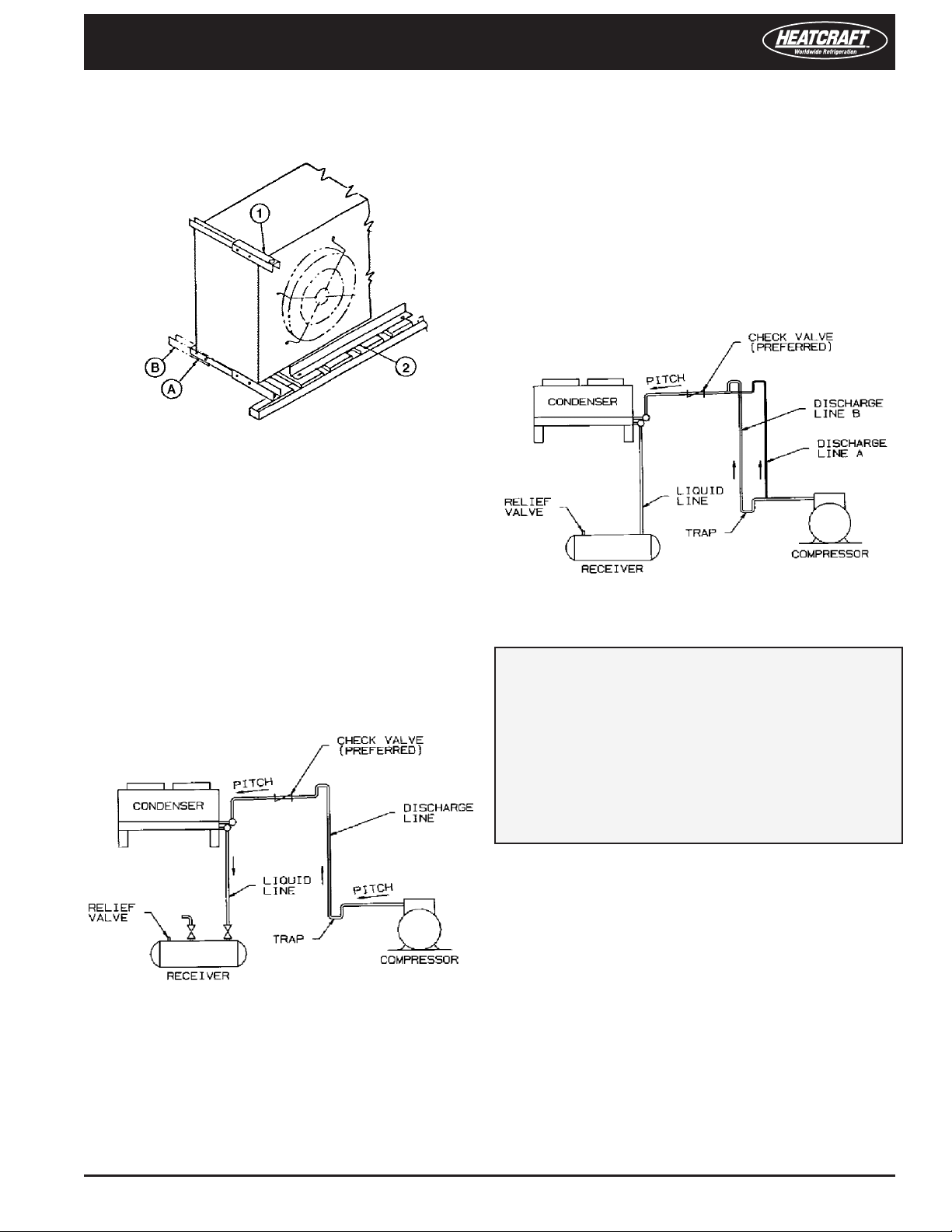

Figure 6. Leg assembly (horizontal airow, models 024-133; 5-26)

Remove bolts securing condenser to skid.

1.

Remove item 1 and attach to rear of bottom leg (item A)

2.

to complete mounting base. Item 2 is not required in the

horizontal discharge application and may be discarded.

Co ndenser can be hoisted by the 1- 1/2” holes in

3.

leg assemblies.

This condition can be overcome in one of two following

ways:

The discharge line may be properly sized for the desired

1.

pressure drop at full load conditions and an oil separator

installed at the bottom of the trap in the discharge line from

the compressor.

A double riser discharge line may be used as shown

2.

in Figure 8. Line A should be sized to carry the oil

at mini mum load con dition s a nd L ine B s hould

be sized so that at full load conditions, both lines would have

sucient ow velocity to carry the oil to the condenser.

Figure 8

Typical Piping Arrangements

Figure 7 illustrates a typical piping arrangement with

a remote condenser located at a higher elevation, common

when the condenser is on a roof and the compressor and

receiver are on grade level or in a basement equipment

room.

Figure 7

In this case, the design of the discharge line is very critical. If

properly sized for full load conditions, the gas velocity might

be too low at reduced loads to carry oil through the discharge

line and condenser coil. Reducing the discharge line size would

increase the gas velocity suciently at reduced load conditions;

however, when operating at full load, the line would be greatly

undersized and create an excessive refrigerant pressure drop.

For more complete information, please refer to the ASHRAE

Handbook on Systems.

NOTES:

All oil traps are to be as short in radius as possible�

1�

Common practice is to fabricate the trap using three

90-degree ells�

Pressure relief valves are recommended at the condenser

2�

to protect the coil�

A drain line check valve is recommended for applications

3�

where the condenser may be at a lower temperature

than the receiver�

See Tables 1, 2, and 3 for discharge and liquid drain line size

recommendations for remote condenser selections.

Installation, Refrigerant Piping

Install piping according to standard accepted refrigeration

practice. The following recommendations should be adhered

to:

Use only refrigeration-grade copper tubing.

1.

Soft solder joints are not acceptable.

2.

Put dry nitrogen through lines while brazing.

3.

Do not leave dehydrated piping or components open to the

4.

atmosphere any longer than is necessary.

Remote Air-Cooled Condenser Installation and Operations Manual, August 2007 5

Loading...

Loading...