Heatcraft DSV120BM6 User Manual

Air-Cooled Condensing Units

BN-SCUTB | March 2015

with Compact Screw Compressors

Technical Bulletin

Models SSV | DSV

Table of Contents

Nomenclature Chart ............................................................................................................................ 2

Introduction ......................................................................................................................................... 3

TM

Bitzer

Compressors ......................................................................................................................... 4

Magnum

TM

Microprocessor ................................................................................................................ 5

Condenser Features ........................................................................................................................... 6

Unit Features and Options .................................................................................................................. 7

Performance Data ............................................................................................................................... 8

Medium Temperature ............................................................................................................... 8-9

R-404A/R-507 ............................................................................................................. 8

R-407C ........................................................................................................................ 9

High Temperature ..................................................................................................................... 10

R-407C ........................................................................................................................ 10

Physical Data ...................................................................................................................................... 11

Dimensional Drawings ........................................................................................................................ 11

Electrical Data ..................................................................................................................................... 12-13

Nomenclature

S S V OOOB M 6 D

Number of Circuits Compressor

Style

S = Single S = Screw V= Vertical 050B – 50 M = Medium 6 = R-404A, D = 460/3/60

D = Dual 060B – 60 H = High R-507 E = 575/3/60

2

Airflow Horsepower Temp. Range Refrigerant

Type

070B – 70 7 = R-407c

080B – 80

090B – 90

100B - 100

110B - 110

125B - 125

140B - 140

Voltage

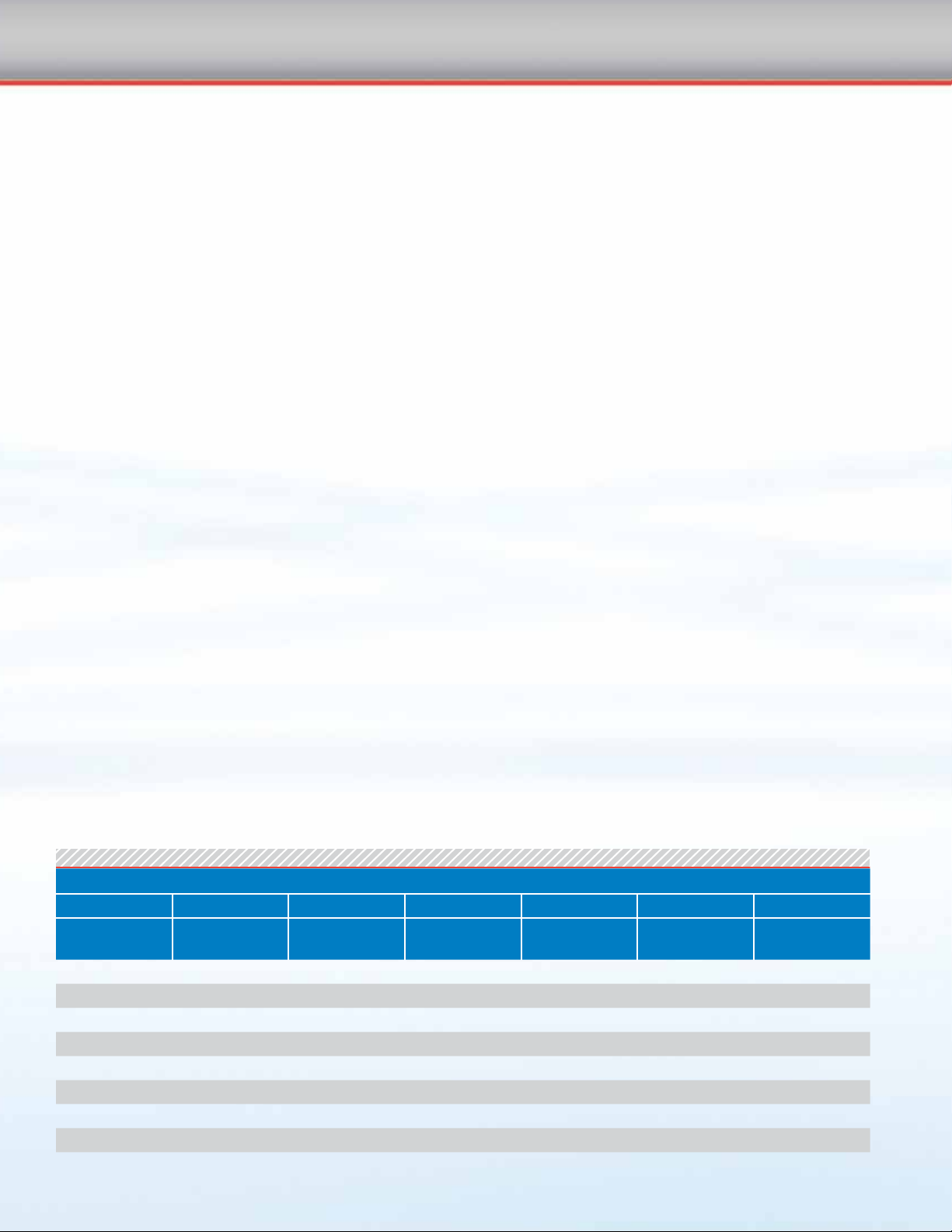

THE RIGHT CHOICE FOR LARGE COOLING APPLICATIONS

The screw compressor condensing unit is an important addition to the Heatcraft air-cooled condensing unit product

family, featuring innovative compact screw compressors and advanced microprocessor controls. The unit is designed

to provide increased system reliability, reduced installation and operation costs, as well as, improved product integrity

in commercial and industrial refrigeration applications.

Increased Reliability

The Heatcraft screw compressor condensing unit is a reliable and rugged system, designed for the commercial and industrial

refrigeration markets. Compact screw compressors have fewer moving parts than reciprocating compressors, resulting in improved

durability. Additionally, a semi-hermetic motor design eliminates shaft seal and coupling concerns, while an integral oil system

provides improved lubrication performance. The screw compressors utilize slide valve unloading which increases motor life through

unloaded compressor starting. The new screw condensing units are factory equipped with an advanced microprocessor control

system. This control system constantly monitors and adapts by modifying multiple parameters to guarantee safe and reliable

system performance. Finally, all screw compressor condensing units come standard with a floating tube condenser coil design,

minimizing the potential for refrigerant leaks.

Reduced Costs of Ownership

Screw compressor condensing units allow owners and

operators to reduce both their installation and operating

costs. Screw compressor condensing units yield more

capacity per compressor than traditional reciprocating

compressor condensing units. The result is a reduced

number of units on large projects and subsequent

savings of time and cost during installation and

commissioning. Built-in features such as soft starting,

slide valve unloading, and digital controls make Heatcraft

screw compressor condensing units the optimum choice

for maximum performance with minimal operating costs.

Improved Product Integrity

With advanced digital controls and variable capacity capability, the screw compressor condensing units have the capability to

maintain more precise temperature control and stable product environment. Minimizing temperature fluctuations results in maximum

product integrity; all while maintaining overall system performance. Screw compressor condensing units are the right choice and the

perfect match for large, mission critical cooling applications.

3

COMPACT SCREW COMPRESSORS : FEATURES AND BENEFITS

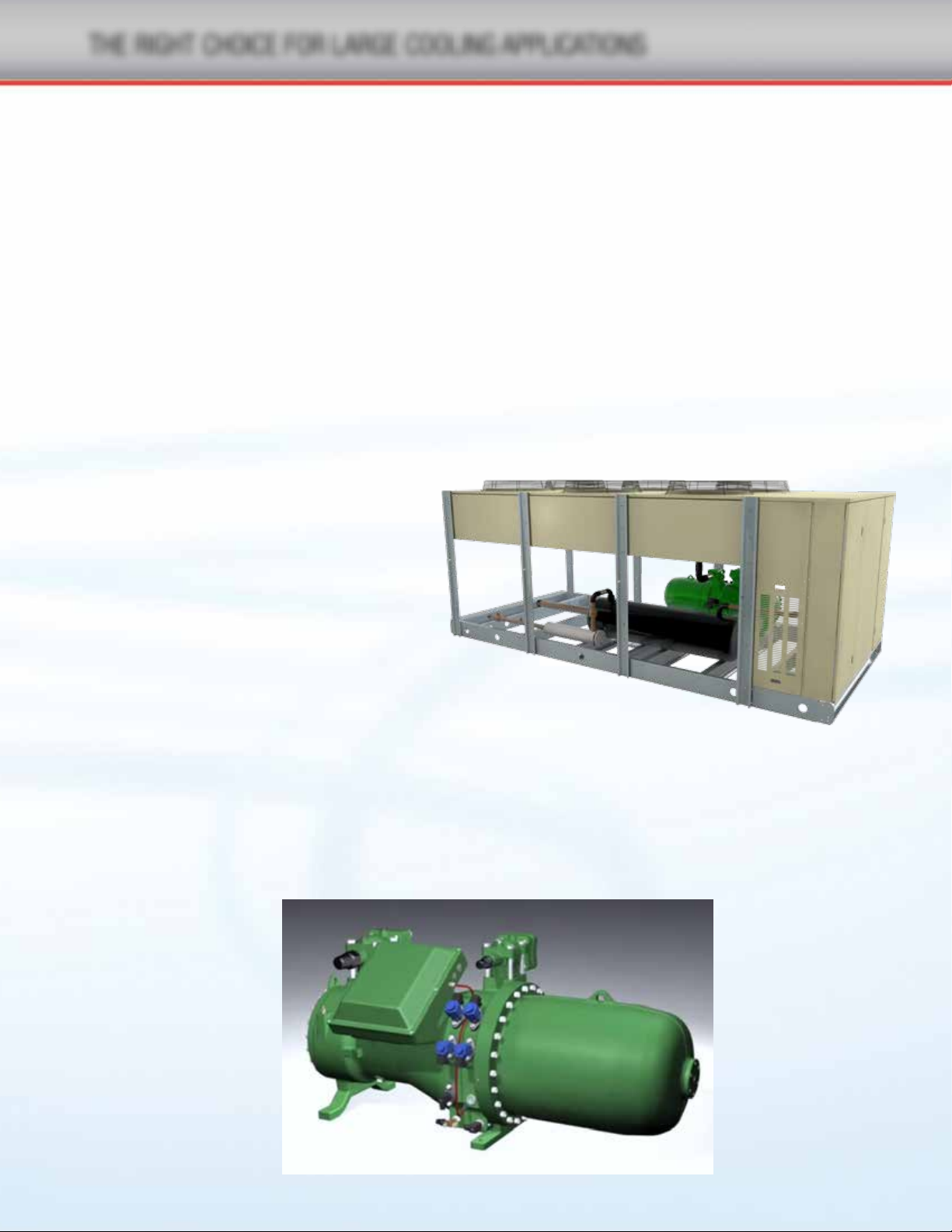

Compact Screw Compressors

The Bitzer CSH compact screw compressor is the result of

continuous development for a simplified, space and energy

efficient semi-hermetic screw compressor. Using state of the

art technology, this screw compressor is not only smooth

running, quiet, and efficient; but also meets the same stringent

performance and reliability benchmarks that have set the

industry standard.

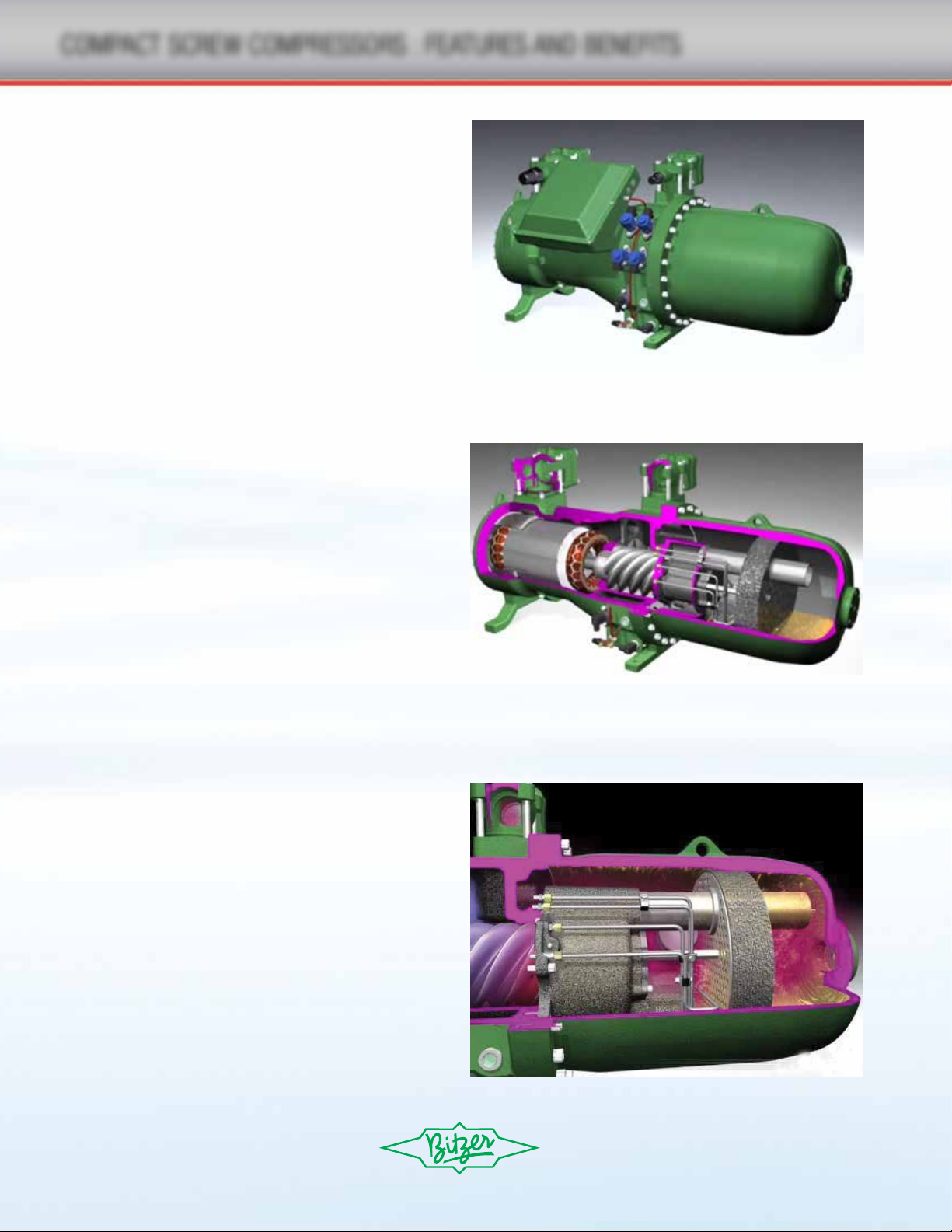

Robust Design

The compact screw compressors feature a newly developed

efficient twin rotor geometry. The rotors are precisely located at

both ends by bearings that prevent radial and axial movement

reducing unit vibration. Rotors and housing are machined for

tight tolerances allowing optimum efficiency while preventing

wear. Compressors are constructed with a double wall rotor

casing for reduced sound transmission. Rotor and casing design,

in conjunction with oversized oil supply chambers, result in a

significantly more robust compressor.

Optimized Oil Management

The compact screw compressors are designed with an integral

three-stage oil separator and a 10-micron oil filter. Oil system also

includes an oil level control, oil level sight glass, crankcase oil

heater, and an oil service valve. The integral oil system reduces

the system piping complexity, and subsequently minimizes

potential leak points.

4

MICROPROCESSOR CONTROLLER: FEATURES AND BENEFITS

Magnum™ Microprocessor

The Magnum

temperatures improving product integrity. Advanced control algorithms provide for proper compressor control resulting in more efficient

operation and longer compressor life. The microprocessor is factory installed and features pre-loaded factory set points allowing for

faster startup and commissioning. Advanced diagnostic, monitoring, and data logging options assist in efficient trouble shooting should

an issue arise, minimizing costs and allowing quick system recovery.

TM

microprocessor control produces a more stable operating system resulting in precise process and product

Microprocessor monitors and controls:

n

Room temperature

n

Compressor Suction Temperature

n

Compressor Discharge Temperature

n

Compressor Suction Pressure

n

Compressor Discharge Pressure

n

Compressor Amps

n

Defrost Time Schedules

n

Defrost Termination (Electric Defrost Equipped Models)

n

Evaporator Fan Delay (Electric Defrost Equipped Models)

n

Evaporator Defrost Hold Out (Electric Defrost Equipped Models)

In addition, microprocessor controls:

n

Compressor Slide Valve

n

Compressor Unloaded Start

n

Condenser Fan Cycling

n

Pre-Start System Pumpdown

Finally, the MagnumTM monitors:

n

Ambient Temperature

n

Compressor Module

n

Phase Loss Monitor

n

Optical Oil Level Control

n

Compressor Run time

n

Compressor Cycles

n

Alarms and Error Codes

Magnum is a trademark of Micro Control Systems

5

Loading...

Loading...