Heatcraft ACCR-009-C6S User Manual

BN-CHILTB | April 2015

Air-Cooled Package Chillers

For Process Applications

Technical Bulletin

Models ACCZ | ACCR

INTRODUCTION

The ACC air-cooled process chiller product family is an important addition to the Heatcraft line of process cooling

equipment. ACC chillers are designed to provide an efficient and reliable solution for a variety of process cooling

applications. Units feature compact, high efficiency braze plate evaporators for improved heat transfer, advanced

microprocessor controllers for optimized operation, and floating tube condenser coils for enhanced refrigerant leak

protection. ACC air-cooled process chillers provide owners with dependable cooling for critical applications.

Typical applications include:

Machining (Cutting, Welding)

Printing

Plastic molding

Brewing

Concrete Mixing

and other Industrial Processes

Table of Contents

Introduction ......................................................................................................................................................................2

Nomenclature Chart and Table of Contents ...................................................................................................................2

Unit Features and Options ..............................................................................................................................................3

Unit Performance

Single Compressor R-407C........…….....................................………………………………………...........................4-7

Single Compressor R-404A….………………………………………..........................………….……........................8-11

Dual Compressor R-407C…...........……………………………….............................……………….......................12-15

Dual Compressor R-404A…………………………………...........................……………………..…........................16-19

Unit Physical Specifications......................................................................................................….............................. 20-21

Unit Electrical Data ...............................................................................................................................….................22-23

Nomenclature

ACC Z 000 C 6 S

Air-Cooled Chiller Compressor Style

Z = Scroll 005 = 5 tons C = 208-230/3/60 6 = R404A/R507 S = Single Blank = Chiller Only

R = Reciprocating D = 460/3/60 7 = R407C D = Dual P = Pump only

Nominal Capacity

(Tons)

Unit Voltage Refrigerant

E = 575/3/60 T = Pump/Integral Tank

Number of

Compressors

Pump/Tank Options

-

2

UNIT FEATURES AND OPTIONS

Standard Features

n

ACCZ models feature a hermetic scroll compressor

with suction and discharge service valves, and a

crankcase heater per circuit

n ACCR models feature a spring mounted semi-

hermetic reciprocating compressor with suction and

discharge service valves, suction and discharge

vibration eliminators, oil sight glass and a crankcase

heater per circuit

n

Air-cooled condenser with copper tubes and

aluminum fins. Condenser features Heatcraft's

Floating Tube™ coil design. Refrigerant-carrying

copper tubes do not contact any metal support

sheets; instead, the coil is constructed with

expanded anchor tubes that support the coil

construction and do not carry refrigerant. This coil

design eliminates one of the major causes of leaks

in refrigeration systems

n

Limited five-year warranty against condenser tube

sheet and center support leaks

n

Condenser fan motors are thermally protected with

permanently lubricated ball bearings

n

Condenser fans have rust resistant aluminum fan

blades

n

Adjustable two-valve head pressure control system

including drain line check valve per circuit

n

Liquid receiver with pressure relief valve per circuit

n

Suction accumulator per circuit

n

Sealed liquid line filter drier, moisture indicator/sight

glass, solenoid valve and thermal expansion valve

per circuit on single compressor models 012 and

below and dual compressor models 025 and below

n

Replaceable core liquid line filter drier, moisture

indicator/sight glass, solenoid valve and thermal

expansion valve per circuit on single compressor

models 015 and above and dual compressor

models 030 and above

n

Hot gas bypass system with pressure regulator and

solenoid valve for capacity control per circuit

n Heated and insulated stainless steel braze plate

evaporator

n

ETL listed control panel

l

Microprocessor unit controller including fluid

temperature, compressor staging and condenser

fan cycling control

l

24V control circuit transformer (single compressor

models)

l

115V control circuit transformer (dual compressor

models)

l

Phase Monitor

l

Compressor contactor

l

Condenser fan motor contactors with fusing

l

Suction and discharge pressure transducers

l

Entering and leaving fluid temperature sensors

l

Suction and discharge temperature sensors

n

Painted galvanized steel cabinet with removable

access panels

n

Galvanized steel frame

n

Fluid flow switch (shipped loose)

Factory Installed Options

n Stainless steel end suction system pump with suction

and discharge isolation valves, strainer and motor

starter with overload

n

Integral insulated polypropylene baffled tank with

stainless steel end suction system pump, stainless

steel end suction recirculating pump and strainer,

suction and discharge isolation valves per pump and

motor starters with overloads per pump (Models 012

and below)

n

Low ambient kit with heated and insulated receiver

n

Compressor circuit breaker

n

Unit thru-the-door circuit breaker (vertical discharge

units only)

n

Compressor cylinder unloading on ACCR models

n

Replaceable core liquid line filter drier per circuit on

single compressor models 012 and below and dual

compressor models 025 and below

n

Oil separator per circuit

n

Copper finned or Bohn Guard condenser coil

n

Industrial condenser coil coatings

n

Extended compressor warranty

3

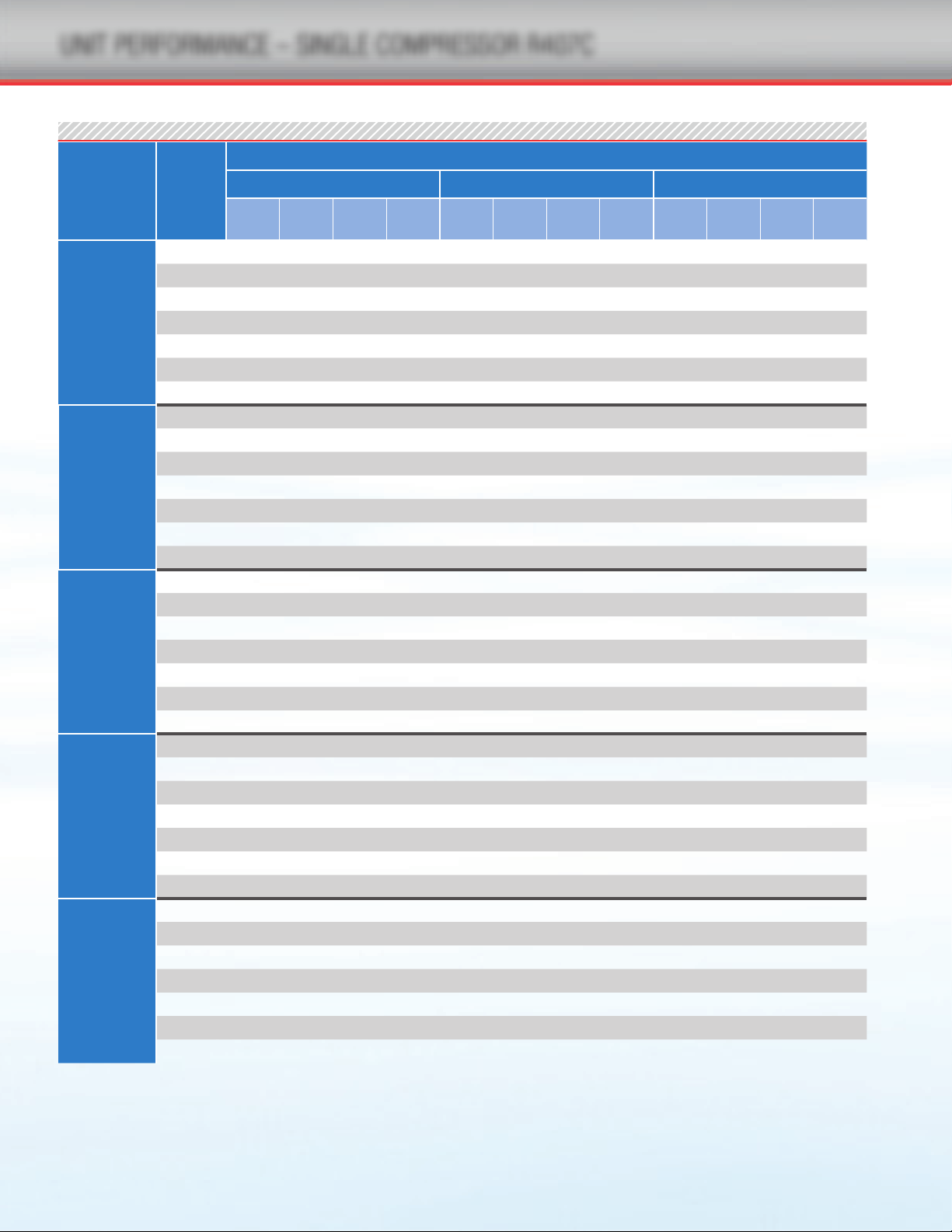

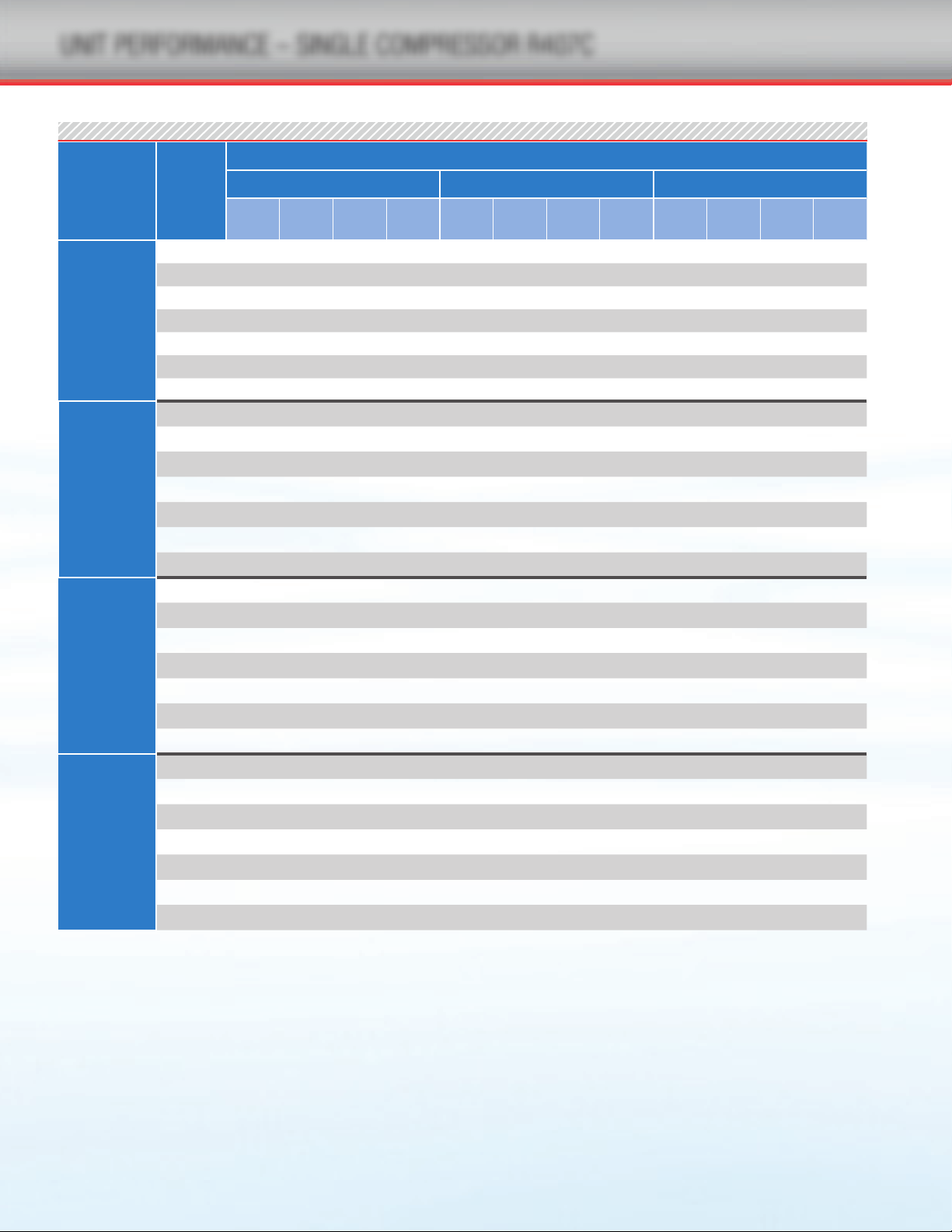

UNIT PERFORMANCE – SINGLE COMPRESSOR R407C

Ambient Temperature

Model

Number

ACCZ-005-*7S

ACCZ-008-*7S

ACCZ-010-*7S

ACCR-009-*7S

ACCR-012-*7S

Lvg. Fluid

Temp. °F

Tons KW GPM

20 3.1 4.0 8.1 5.0 3.0 4.3 7.8 4.8 2.9 4.6 7.6 4.7

25 3.5 4.2 9.1 4.9 3.4 4.4 8.8 4.7 3.3 4.7 8.5 4.5

30 3.9 4.3 10.1 4.7

35 4.3 4.4 11.2 5.3

40 4.8 4.5 12.4 6.7

45 5.3 4.7 12.6 5.6

50 5.7 4.8 13.8 6.6

20 4.4 6.3 11.4 4.3

25 4.9 6.4 12.8 4.2 4.8 6.8 12.4 4.0 4.6 7.2 12.0 3.9

30 5.5 6.6 14.2 4.0

35 6.1 6.7 15.8 3.9

40 6.7 6.9 17.5 4.8

45 7.5 7.1 17.9 4.3

50 8.2 7.3 18.9 4.7 8.0 7.7 19.2 4.9 7.8 8.1 18.6 4.6

20 6.3 9.3 16.4 5.0

25 7.1 9.6 18.4 4.9

30 7.9 9.8 20.5 4.7

35 8.8 10.2 22.8 5.4 8.5 10.7 22.1 5.0 8.2 11.4 21.3 4.7

40 9.7 10.5 25.2 6.9 9.4 11.1 24.4 6.4 9.1 11.8 23.5 5.9

45 10.8 10.9 25.7 5.7 10.4 11.5 24.9 5.4 10.1 12.1 24.2 5.1

50 11.8 11.3 28.3 6.8

20 5.9 8.0 15.3 4.7

25 6.6 8.5 17.1 4.5

30 7.3 8.9 19.0 4.3 7.1 9.2 18.4 4.2 6.8 9.4 17.7 4.1

35 8.1 9.4 21.0 4.5 7.9 9.7 20.3 4.2 7.6 10.0 19.6 3.9

40 8.9 9.8 23.1 5.7 8.7 10.2 22.4 5.3 8.4 10.5 21.6 4.9

45 9.8 10.3 23.4 4.8

50 10.7 10.6 25.7 5.6 10.3 11.1 24.7 5.3 10.0 11.6 23.9 4.9

20 7.8 10.9 20.3 5.0 7.6 11.1 19.6 4.8 7.3 11.4 18.9 4.6

25 8.7 11.5 22.6 4.8 8.5 11.8 22.0 4.6 8.2 12.2 21.2 4.5

30 9.7 12.2 25.1 4.6

35 10.7 12.8 27.8 5.1 10.4 13.2 27.0 4.8 10.1 13.7 26.1 4.4

40 11.8 13.4 30.6 6.5 11.4 14.0 29.7 6.1 11.1 14.4 28.6 5.6

45 13.0 14.1 31.1 5.4 12.5 14.6 30.0 5.1 12.1 15.2 29.1 4.7

50 14.2 14.7 34.0 6.3 13.7 15.2 32.9 5.9 13.2 15.9 31.7 5.5

80°F 85°F 90°F

Press.

Drop

Tons KW GPM

3.8 4.5 9.8 4.6 3.7 4.8 9.5 4.4

4.2 4.7 10.9 5.0 4.1 4.9 10.5 4.6

4.6 4.8 12.0 6.3 4.5 5.1 11.6 5.9

5.1 4.9 12.2 5.3 4.9 5.2 11.8 5.0

5.6 5.1 13.4 6.3 5.4 5.4 13.0 5.9

4.3 6.6 11.1 4.1 4.1 7.0 10.7 4.0

5.3 7.0 13.8 3.9 5.2 7.3 13.4 3.8

5.9 7.1 15.4 3.8 5.7 7.5 14.9 3.7

6.6 7.3 17.0 4.5 6.4 7.7 16.5 4.3

7.3 7.5 17.4 4.1 7.0 7.9 16.9 3.9

6.1 9.9 15.9 4.8 5.9 10.5 15.3 4.7

6.9 10.1 17.8 4.7 6.6 10.8 17.1 4.5

7.7 10.4 19.9 4.6 7.4 11.1 19.1 4.4

11.5 11.9 27.5 6.4 11.1 12.6 26.6 6.0

5.7 8.2 14.8 4.5 5.5 8.4 14.2 4.3

6.4 8.7 16.5 4.3 6.1 8.9 15.9 4.2

9.5 10.6 22.7 4.5 9.2 11.0 22.0 4.2

9.4 12.6 24.4 4.5 9.1 12.9 23.6 4.3

Press.

Drop

Tons KW GPM

Press.

Drop

*Placeholder for voltage (C – 208-230/3/60, D – 460/3/60, E – 575/3/60)

Ratings at 40°F leaving fluid and below are based on 35% Propylene Glycol

Ton = 12,000 BTUH

KW = Input power for compressor and condenser fans

Pressure drop = PSIg

4

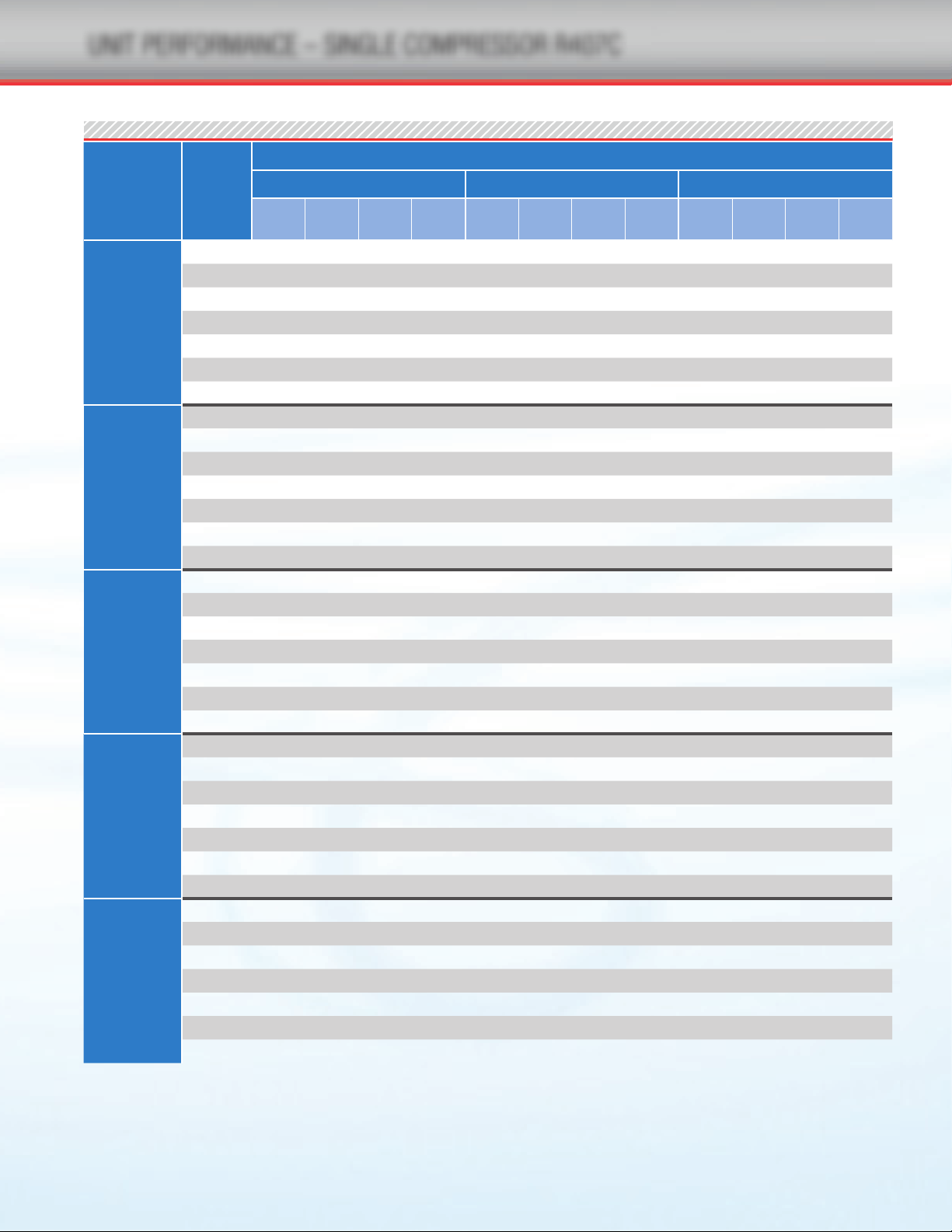

UNIT PERFORMANCE – SINGLE COMPRESSOR R407C

Ambient Temperature

Model

Number

ACCZ-005-*7S

ACCZ-008-*7S

ACCZ-010-*7S

ACCR-009-*7S

ACCR-012-*7S

Lvg. Fluid

Temp. °F

Tons KW GPM

20 2.8 4.9 7.3 4.5 2.7 5.2 7.0 4.3 2.6 5.5 6.8 4.1

25 3.2 5.0 8.2 4.4 3.0 5.3 7.9 4.2 2.9 5.6 7.6 4.0

30 3.5 5.1 9.1 4.2

35 3.9 5.2 10.2 4.3

40 4.3 5.4 11.2 5.5

45 4.8 5.5 11.4 4.7

50 5.2 5.7 12.6 5.6

20 4.0 7.4 10.3 3.8

25 4.5 7.6 11.6 3.7 4.3 8.0 11.2 3.6 4.1 8.5 10.8 3.5

30 5.0 7.8 13.0 3.7

35 5.6 8.0 14.4 3.6

40 6.2 8.2 16.0 4.0

45 6.8 8.3 16.4 3.7

50 7.6 8.5 18.1 4.4 7.3 9.1 17.5 4.1 7.1 9.5 17.0 3.9

20 5.6 11.1 14.7 4.5

25 6.4 11.4 16.5 4.3

30 7.1 11.8 18.4 4.2

35 7.9 12.1 20.6 4.3 7.6 12.8 19.8 3.9 7.3 13.6 19.0 3.8

40 8.8 12.4 22.8 5.5 8.5 13.1 22.0 5.1 8.1 14.0 21.1 4.6

45 9.7 12.8 23.3 4.8 9.4 13.6 22.5 4.5 0.0 0.0 0.0 0.0

50 10.7 13.3 25.7 5.7

20 5.2 8.5 13.6 4.1

25 5.9 9.1 15.3 4.0

30 6.6 9.7 17.0 3.9 6.3 9.9 16.3 3.7 6.0 10.1 15.6 3.6

35 7.3 10.3 18.9 3.8 7.0 10.5 18.2 3.6 6.7 10.7 17.4 3.4

40 8.0 10.9 20.8 4.5 7.7 11.1 20.0 4.2 7.4 11.4 19.2 3.8

45 8.8 11.4 21.1 3.9

50 9.6 12.0 23.0 4.6 0.0 13.1 0.0 0.0 0.0 13.4 0.0 0.0

20 7.0 11.6 18.2 4.4 6.7 11.8 17.5 4.2 6.4 12.0 16.7 4.0

25 7.9 12.4 20.4 4.3 7.6 12.7 19.6 4.1 7.3 12.9 18.9 4.0

30 8.8 13.3 22.8 4.2

35 9.7 14.1 25.2 4.1 9.4 14.4 24.2 3.9 9.0 14.8 23.4 3.7

40 10.7 14.9 27.7 5.2 10.3 15.3 26.7 4.8 9.9 15.7 25.7 4.4

45 11.7 15.7 28.0 4.4 11.3 16.1 27.1 4.2 0.0 17.2 0.0 0.0

50 12.7 16.4 30.6 5.2 0.0 17.9 0.0 0.0 0.0 18.3 0.0 0.0

95°F 100°F 105°F

Press.

Drop

Tons KW GPM

3.4 5.4 8.8 4.1 3.3 5.8 8.5 3.9

3.8 5.6 9.8 4.0 3.6 5.9 9.4 3.8

4.2 5.7 10.8 5.0 4.0 6.1 10.4 4.6

4.6 5.9 11.0 4.4 4.4 6.2 10.6 4.1

5.1 6.0 12.1 5.2 4.9 6.4 11.7 4.9

3.8 7.9 9.9 3.7 3.7 8.3 9.5 3.5

4.8 8.2 12.5 3.5 4.7 8.7 12.1 3.4

5.4 8.4 13.9 3.4 5.2 8.9 13.5 3.3

6.0 8.6 15.5 3.7 5.8 9.1 14.9 3.4

6.6 8.8 15.9 3.4 6.4 9.3 15.4 3.2

5.4 11.8 14.1 4.3 5.2 12.5 13.4 4.1

6.1 12.1 15.8 4.2 5.8 12.8 15.2 4.0

6.9 12.4 17.8 4.1 6.6 13.2 17.0 3.9

0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0

5.0 8.6 12.9 3.9 4.7 8.7 12.3 3.7

5.6 9.3 14.6 3.8 5.4 9.4 13.9 3.6

8.5 11.8 20.4 3.7 0.0 12.6 0.0 0.0

8.4 13.6 21.9 4.0 8.1 13.8 21.0 3.9

Press.

Drop

Tons KW GPM

Press.

Drop

* Placeholder for voltage (C – 208-230/3/60, D – 460/3/60, E – 575/3/60)

Ratings at 40°F leaving fluid and below are based on 35% Propylene Glycol

Ton = 12,000 BTUH

KW = Input power for compressor and condenser fans

Pressure drop = PSIg

5

UNIT PERFORMANCE – SINGLE COMPRESSOR R407C

Ambient Temperature

Model

Number

ACCR-015-*7S

ACCR-025-*7S

ACCR-030-*7S

ACCR-040-*7S

Lvg. Fluid

Temp. °F

Tons KW GPM

20 9.5 13.5 24.7 4.5 9.1 13.8 23.7 4.4 8.8 14.2 22.8 4.2

25 10.8 14.3 22.8 3.6 10.4 14.7 28.1 4.5 10.0 15.0 27.0 4.3

30 12.2 15.2 31.6 4.4 11.7 15.6 30.4 4.2 11.2 16.0 29.2 4.0

35 13.6 16.2 35.2 4.6 13.1 16.6 33.9 4.3 12.6 17.1 32.5 3.9

40 15.1 17.1 38.9 5.9 14.5 17.6 37.5 5.5 13.9 18.2 36.0 5.0

45 16.6 18.1 39.7 5.0 16.0 18.6 38.3 4.7 15.4 19.2 36.8 4.4

50 18.2 18.9 43.7 6.0 17.6 19.5 42.2 5.6 16.9 20.1 40.5 5.2

20 15.9 19.1 41.4 5.2

25 17.9 20.4 46.4 5.1 17.2 20.8 44.7 4.9 16.5 21.2 42.8 4.6

30 20.0 21.7 51.9 5.0 19.2 22.2 49.9 4.8 18.5 22.6 47.9 4.6

35 22.3 22.9 57.8 5.8

40 24.7 24.3 63.9 7.4

45 27.2 25.6 65.3 6.2 26.3 26.3 63.0 5.8 25.4 26.9 60.8 5.4

50 29.9 27.0 71.3 7.3 28.9 27.7 69.4 6.8 27.9 28.3 66.9 6.4

20 19.2 25.6 49.9 5.4 18.5 26.3 48.0 5.2 17.9 26.9 46.4 5.0

25 21.5 27.2 55.7 5.3

30 23.9 29.0 61.9 5.2 23.1 29.8 60.0 5.0 22.3 30.6 57.8 4.8

35 26.5 30.8 68.7 6.1

40 29.3 32.6 75.8 7.8 28.3 33.5 73.3 7.2 27.3 34.5 70.7 6.7

45 32.2 34.4 77.2 6.4 31.3 35.4 74.9 6.1 30.1 36.5 72.2 5.7

50 35.3 36.3 80.7 7.0

20 23.1 29.4 60.1 5.2 22.3 30.2 57.9 5.0 21.4 30.9 55.8 4.8

25 26.0 31.3 67.4 5.1

30 29.1 33.1 75.4 5.0 28.1 34.1 72.8 4.8 27.0 35.1 70.1 4.6

35 32.4 35.0 83.9 5.7

40 36.0 36.8 93.1 7.3

45 39.9 38.6 95.6 6.3

50 43.9 40.5 105.2 7.5

80°F 85°F 90°F

Press.

Drop

Tons KW GPM

15.3 19.5 39.7 5.0 14.6 19.8 38.0 4.7

21.5 23.5 55.7 5.3 20.6 24.0 53.5 4.9

23.8 24.9 61.6 6.8 22.9 25.4 59.3 6.3

20.7 28.0 53.7 5.1 20.0 28.8 51.8 4.9

25.6 31.7 66.4 5.7 24.7 32.5 64.1 5.2

34.2 37.4 82.0 7.2 33.1 38.4 79.5 6.7

25.0 32.2 65.0 4.9 24.2 33.0 62.7 4.7

31.4 36.0 81.2 5.3 30.2 37.1 78.2 4.9

34.8 38.0 90.0 6.8 33.6 39.1 87.0 6.3

38.6 39.9 92.5 5.9 37.2 41.2 89.2 5.5

42.6 41.9 102.1 7.0 41.1 43.3 98.6 6.6

Press.

Drop

Tons KW GPM

Press.

Drop

*Placeholder for voltage (C – 208-230/3/60, D – 460/3/60, E – 575/3/60)

Ratings at 40°F leaving fluid and below are based on 35% Propylene Glycol

Ton = 12,000 BTUH

KW = Input power for compressor and condenser fans

Pressure drop = PSIg

6

UNIT PERFORMANCE – SINGLE COMPRESSOR R407C

Ambient Temperature

Model

Number

ACCR-015-*7S

ACCR-025-*7S

ACCR-030-*7S

ACCR-040-*7S

Lvg. Fluid

Temp. °F

Tons KW GPM

20 8.4 14.5 21.8 4.0

25 9.6 15.4 25.9 4.1 9.2 15.8 24.8 3.9 8.8 16.1 23.8 3.8

30 10.8 16.5 28.0 3.9 10.3 16.9 26.8 3.7 9.9 17.3 25.6 3.5

35 12.0 17.6 31.2 3.8 11.5 18.1 29.8 3.6 11.0 18.5 28.6 3.4

40 13.3 18.7 34.5 4.5 12.8 19.2 33.1 4.1 12.2 19.7 31.7 3.8

45 14.7 19.8 35.2 4.0

50 16.1 20.8 38.7 4.8 15.5 21.4 37.1 4.4 0.0 22.9 0.0 0.0

20 14.0 20.2 36.4 4.5 13.3 20.5 34.6 4.3 12.7 20.7 33.1 4.1

25 15.8 21.6 41.1 4.4 15.1 21.9 41.4 4.5 14.4 22.3 37.4 4.0

30 17.7 23.1 46.0 4.4 17.0 23.4 44.1 4.2 16.2 23.8 42.1 4.0

35 19.8 24.5 51.4 4.5 19.0 25.0 49.2 4.1 18.2 25.4 47.2 3.9

40 22.1 26.0 57.2 5.8 21.2 26.5 54.8 5.3 20.3 26.9 52.6 4.8

45 24.4 27.5 58.5 5.0 23.5 28.0 56.3 4.7 22.5 28.5 53.9 4.3

50 26.9 29.0 64.5 6.0 25.9 29.5 62.2 5.6 24.8 30.1 59.5 5.1

20 17.1 27.5 44.6 4.8 16.5 28.1 42.9 4.6 15.8 28.6 41.1 4.4

25 19.2 29.4 49.9 4.7 18.5 30.0 48.0 4.5 17.7 30.6 46.1 4.3

30 21.5 31.4 55.7 4.6 20.6 32.1 53.5 4.4 19.8 32.8 51.3 4.2

35 23.8 33.4 61.7 4.8 22.9 34.2 59.3 4.4 22.0 34.9 57.0 4.1

40 26.3 35.4 68.2 6.2 25.3 36.3 65.6 5.7 24.3 37.1 62.9 5.2

45 29.0 37.5 69.5 5.3 27.9 38.4 66.9 4.9 26.8 39.3 64.3 4.5

50 31.9 39.6 76.4 6.3 30.7 40.6 73.6 5.8 29.5 41.6 70.7 5.4

20 20.6 31.7 53.5 4.5 19.7 32.3 51.3 4.3 18.9 32.8 49.0 4.1

25 23.2 33.8 60.2 4.5 22.3 34.5 57.8 4.3 21.3 35.2 55.4 4.1

30 26.1 35.9 67.6 4.5 25.0 36.8 64.8 4.3 23.9 37.6 62.0 4.0

35 29.1 38.1 75.4 4.5 28.0 39.1 76.7 4.7 26.7 40.0 69.3 4.0

40 32.3 40.3 83.6 5.8 31.1 41.4 80.4 5.3 29.8 42.4 77.0 4.8

45 35.9 42.5 86.0 5.1 34.4 43.7 82.5 4.7 33.0 44.8 79.2 4.4

50 39.6 44.7 95.0 6.1 38.1 45.9 91.4 5.7 36.6 47.2 87.7 5.3

95°F 100°F 105°F

Press.

Drop

Tons KW GPM

8.0 14.8 20.9 3.8 7.7 15.1 20.1 3.7

14.1 20.3 33.8 3.7 13.5 20.9 32.3 3.4

Press.

Drop

Tons KW GPM

Press.

Drop

*Placeholder for voltage (C – 208-230/3/60, D – 460/3/60, E – 575/3/60)

Ratings at 40°F leaving fluid and below are based on 35% Propylene Glycol

Ton = 12,000 BTUH

KW = Input power for compressor and condenser fans

Pressure drop = PSIg

7

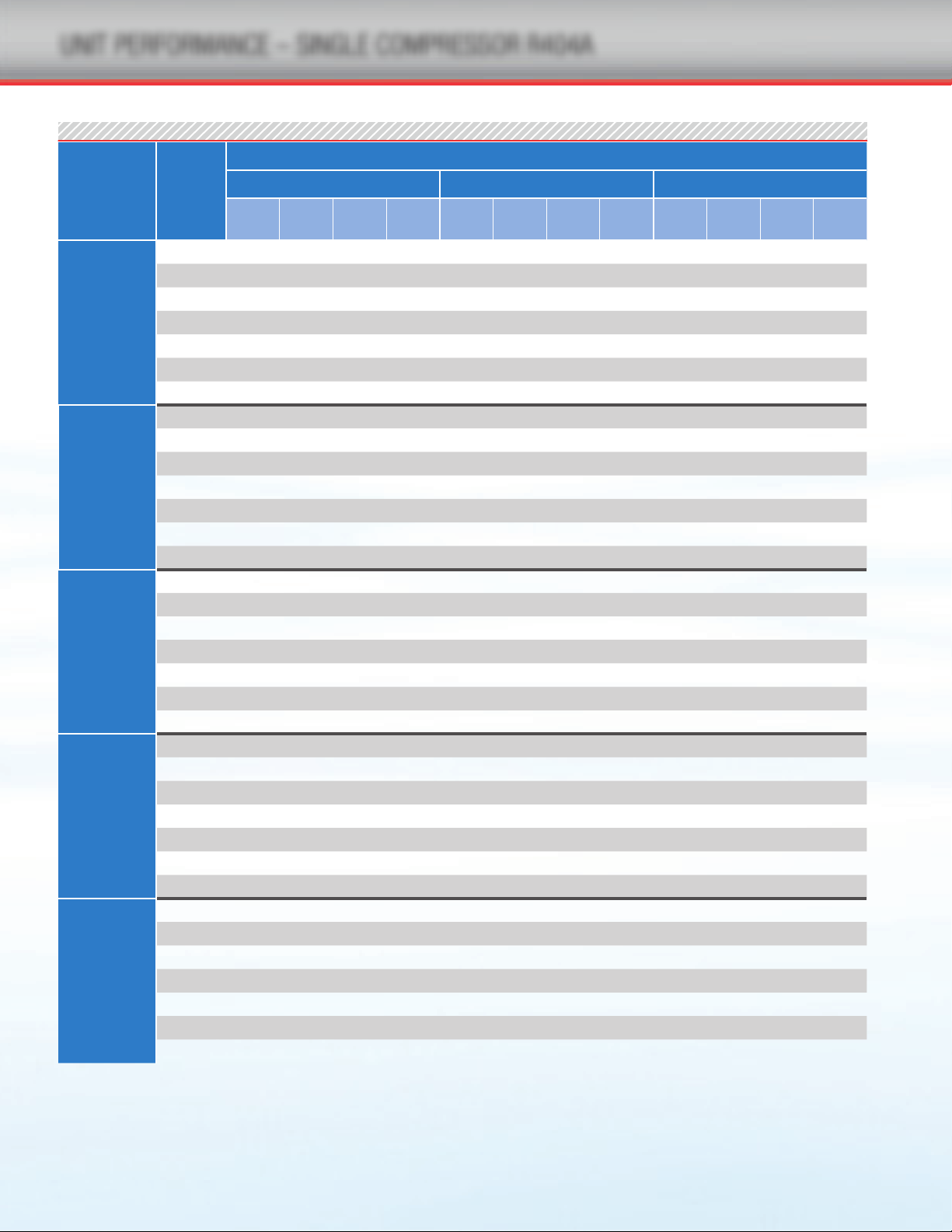

UNIT PERFORMANCE – SINGLE COMPRESSOR R404A

Ambient Temperature

Model

Number

ACCZ-005-*6S

ACCZ-008-*6S

ACCZ-010-*6S

ACCR-009-*6S

ACCR-012-*6S

Lvg. Fluid

Temp. °F

Tons KW GPM

20 3.6 4.9 9.3 4.6 3.4 5.3 8.9 4.4 3.3 5.6 8.5 4.2

25 3.9 5.1 10.1 4.3 3.7 5.4 9.7 4.1 3.6 5.7 9.3 3.9

30 4.3 5.2 11.0 4.1

35 4.6 5.3 12.0 3.9

40 5.0 5.4 13.0 4.7

45 5.4 5.5 13.0 4.0

50 5.9 5.6 14.1 4.6

20 5.4 7.3 14.0 4.2

25 5.9 7.5 15.3 4.0 5.7 7.9 14.7 3.8 5.4 8.3 14.1 3.7

30 6.5 7.6 16.7 3.8

35 7.0 7.8 18.2 3.6

40 7.6 8.0 19.8 4.0

45 8.3 8.3 19.8 3.5

50 9.0 8.5 21.5 4.0 8.6 8.8 20.6 3.7 8.2 9.3 19.7 3.4

20 7.7 11.1 19.9 4.9

25 8.4 11.4 21.8 4.6

30 9.1 11.8 23.6 4.3

35 9.9 12.2 25.6 4.3 9.5 12.8 24.6 3.9 9.1 13.5 23.5 3.8

40 10.7 12.6 27.6 5.2 10.2 13.2 26.5 4.7 9.8 13.9 25.3 4.3

45 11.5 12.9 27.7 4.3 11.1 13.5 26.5 4.0 10.6 14.2 25.4 3.7

50 12.4 13.3 29.8 4.9

20 6.7 9.1 17.4 4.2

25 7.4 9.6 19.1 4.0

30 8.0 10.1 20.9 3.8 7.7 10.4 20.0 3.7 7.4 10.7 19.1 3.5

35 8.8 10.6 22.7 3.6 8.4 10.9 21.8 3.5 8.0 11.2 20.8 3.3

40 9.5 11.0 24.7 4.0 9.1 11.4 23.6 3.7 8.7 11.7 22.6 3.3

45 10.4 11.5 24.8 3.5

50 11.2 11.9 26.9 4.1 10.7 12.3 25.7 3.7 10.2 12.7 24.5 3.4

20 9.1 12.7 23.8 4.4 8.8 13.0 22.8 4.2 8.4 13.3 21.8 4.0

25 10.0 13.4 26.0 4.1 9.6 13.7 25.0 4.0 9.2 14.1 23.9 3.8

30 11.0 14.1 28.4 3.9

35 11.9 14.8 31.0 3.7 11.4 15.2 29.6 3.6 10.9 15.6 28.3 3.4

40 13.0 15.6 33.6 4.3 12.4 16.0 32.2 3.9 11.8 16.4 30.7 3.5

45 14.1 16.3 33.8 3.7 13.5 16.7 32.3 3.4 12.9 17.2 30.8 3.1

50

15.2 17.0 36.5 4.3 14.6 17.5 34.9 3.9 13.9 18.0 33.3 3.6

80°F 85°F 90°F

Press.

Drop

Tons KW GPM

4.1 5.5 10.6 3.9 3.9 5.8 10.1 3.8

4.4 5.6 11.5 3.8 4.3 5.9 11.0 3.6

4.8 5.7 12.5 4.3 4.6 6.0 11.9 3.9

5.2 5.8 12.5 3.7 5.0 6.1 12.0 3.4

5.6 5.9 13.5 4.2 5.4 6.3 12.9 3.9

5.2 7.7 13.4 4.1 4.9 8.1 12.9 3.9

6.2 8.1 16.0 3.7 5.9 8.5 15.4 3.5

6.8 8.2 17.5 3.5 6.5 8.7 16.7 3.3

7.3 8.4 19.0 3.7 7.0 8.8 18.2 3.4

7.9 8.6 19.0 3.2 7.6 9.1 18.2 3.0

7.3 11.8 19.1 4.7 7.0 12.4 18.3 4.5

8.0 12.1 20.8 4.4 7.7 12.7 20.0 4.2

8.7 12.4 22.7 4.2 8.4 13.1 21.7 4.0

11.9 13.9 28.6 4.6 11.4 14.6 27.3 4.2

6.4 9.4 16.7 4.1 6.1 9.7 16.0 3.9

7.1 9.9 18.3 3.9 6.8 10.2 17.5 3.7

9.9 11.8 23.8 3.2 9.5 12.2 22.7 3.0

10.5 14.5 27.2 3.8 10.0 14.9 26.0 3.6

Press.

Drop

Tons KW GPM

Press.

Drop

* Placeholder for voltage (C – 208-230/3/60, D – 460/3/60, E – 575/3/60)

Ratings at 40°F leaving fluid and below are based on 35% Propylene Glycol

Ton = 12,000 BTUH

KW = Input power for compressor and condenser fans

Pressure drop = PSIg

8

Loading...

Loading...