Page 1

WHP - Water Source Heat Pump

Design, Installation &

Operations Manual

Revision 02A

Page 2

Page 3

WattMaster WHP

Installation & Operations Manual

Section 1.................................................................................... Design Guide

Section 2...................................................................Installation and Wiring

Section 3....................................................................................Programming

Section 4....................................................... Start-Up and Troubleshooting

This document is subject to change without notice.

WattMaster Controls, Inc. assumes no responsibility

for errors, or omissions herein.

WHP Installation & Operations Manual - Form WM-WHP-IO-02A

Copyright 2004 WattMaster Controls, Inc.

All rights reserved.

Page 4

Page 5

Section 1

Table of Contents

Conventions .....................................................................1

General Information......................................................... 2

Water Source Heat Pump Units.......................................................................................2

Water Source Heat Pump Systems ..................................................................................3

WattMaster WHP Control System...................................................................................4

WHP Controller...........................................................................................................4

Make Up Air Controller...............................................................................................5

WHP Sequence of Operation ........................................... 6

HVAC Mode of Operation...............................................................................................6

Occupied/Unoccupied Mode of Operation......................................................................7

Vent Mode Operation ......................................................................................................7

Off Mode of Operation ....................................................................................................7

HVAC Operation w/ Reversing Relay.............................................................................8

HVAC Operation w/ Heat/Cool Relays...........................................................................9

WHP Loop Controller Sequence of Operations .............10

Summary........................................................................................................................10

Pump Control.............................................................................................................10

Pump VFD Control....................................................................................................11

Compressor Control...................................................................................................11

Heat Rejection Control ..................................................................................................12

Staged Heat Rejection................................................................................................12

Heat Addition Control ...................................................................................................12

Staged Heat Addition.................................................................................................13

Proportional Heat Addition........................................................................................13

Water Temperature Alarming........................................................................................14

Fire Alarm......................................................................................................................14

Notes:............................................................................. 16

Table of Figures

Figure 1-1: Typical Water Source Heat Pump..............................................................3

Figure 1-2: Typical Water Source Heat Pump System.................................................3

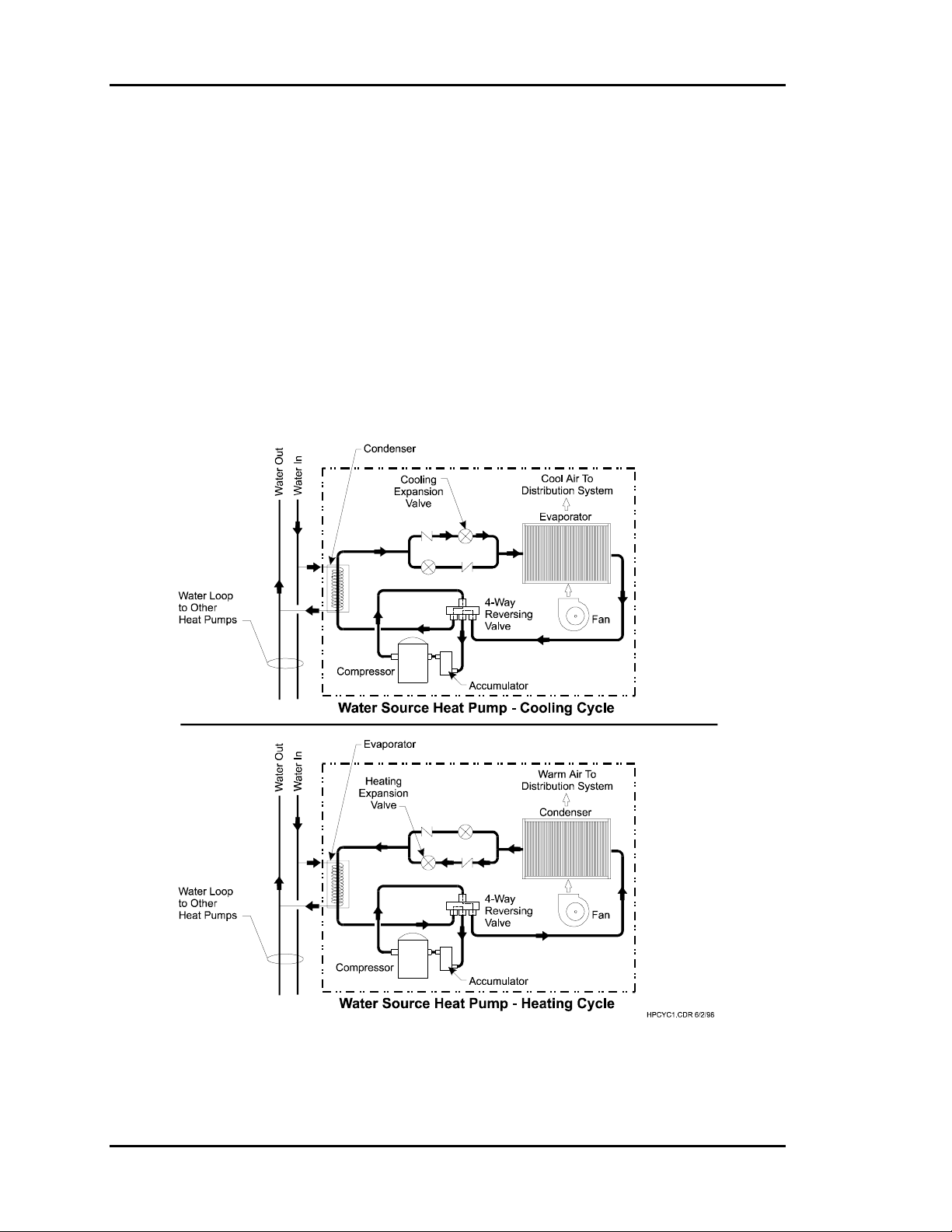

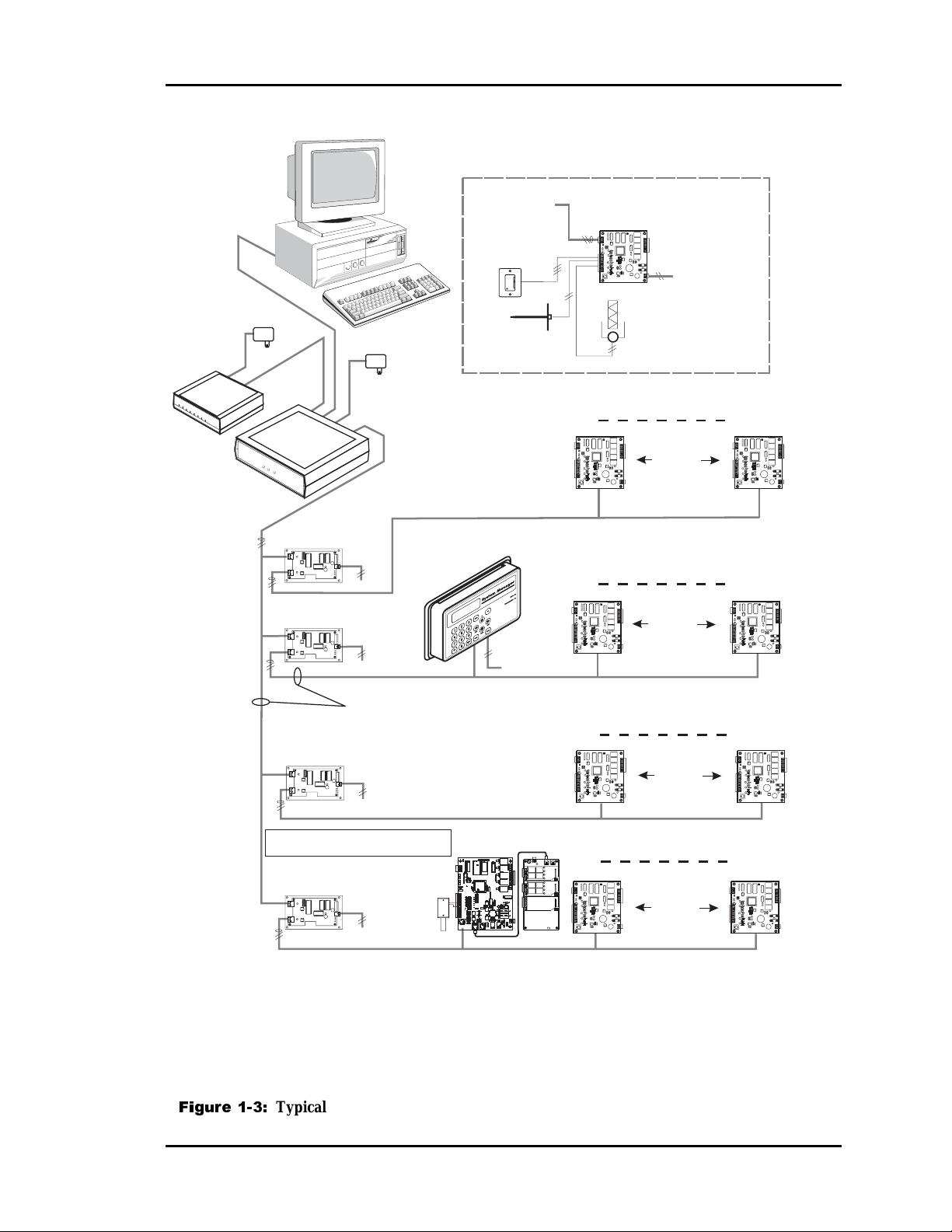

Figure 1-3: Typical WattMaster WHP System...........................................................15

Design Guide

Page 6

Page 7

WattMaster WHP Section 1

Conventions

This document uses the following definitions throughout as a guide to the user in

determining the nature of the information presented:

Note: Additional information which may be helpful.

Tip: Suggestion to make installation, set-up, and troubleshooting easier.

Caution: Items which may cause the equipment not to function correctly but will

not otherwise damage components.

Warning: Errors which can result in damage to equipment and void warranties.

Design Guide 1-1

Page 8

Section 1 WattMaster WHP

General Information

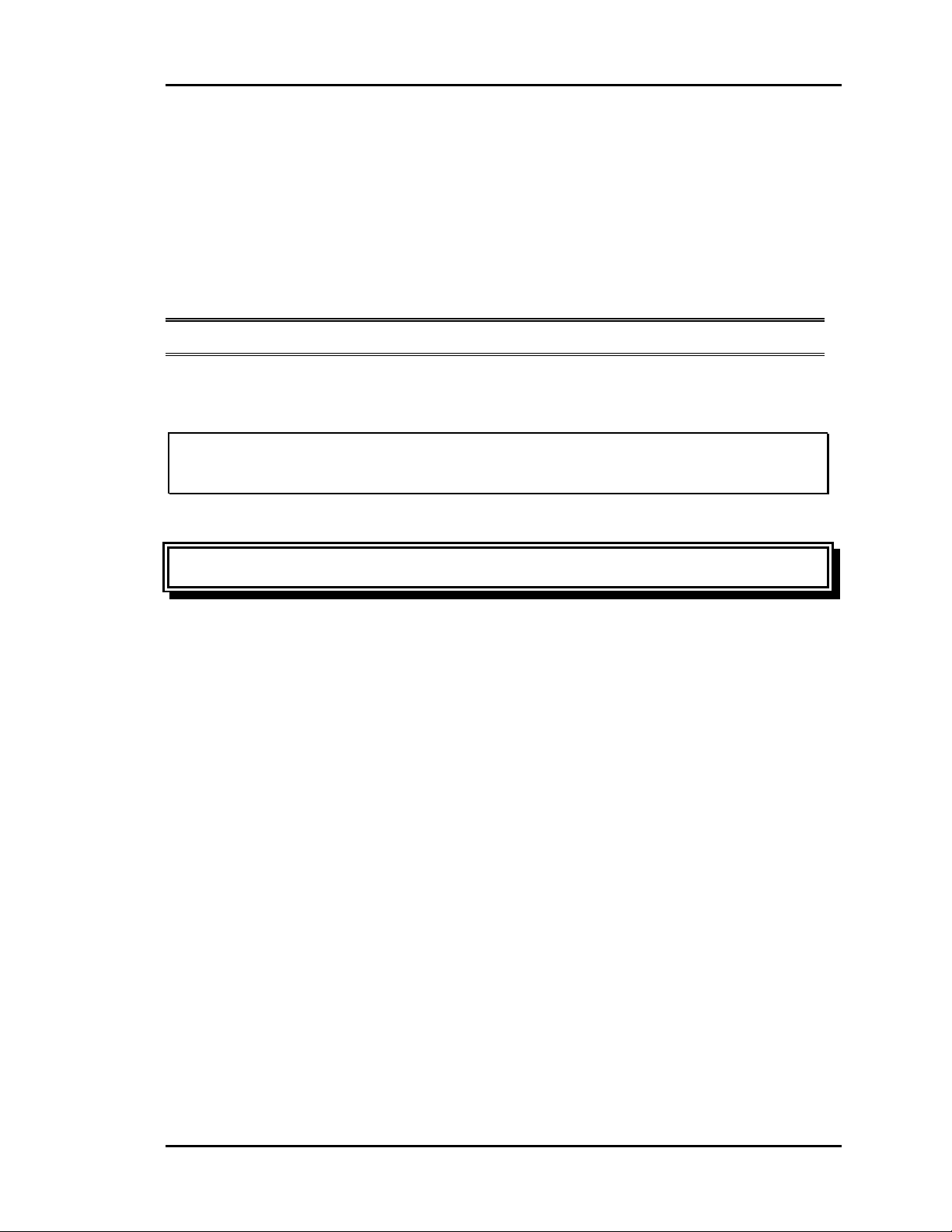

Water Source Heat Pump Units

A water source heat pump is a self-contained water-cooled packaged heating and cooling

unit with a reversible refrigerant cycle. Its components are typically enclosed in a

common casing, and include a tube-in-tube heat exchanger, a heating/cooling coil, a

compressor, a fan, a reversing valve and controls

.

1-2 Design Guide

Page 9

WattMaster WHP Section 1

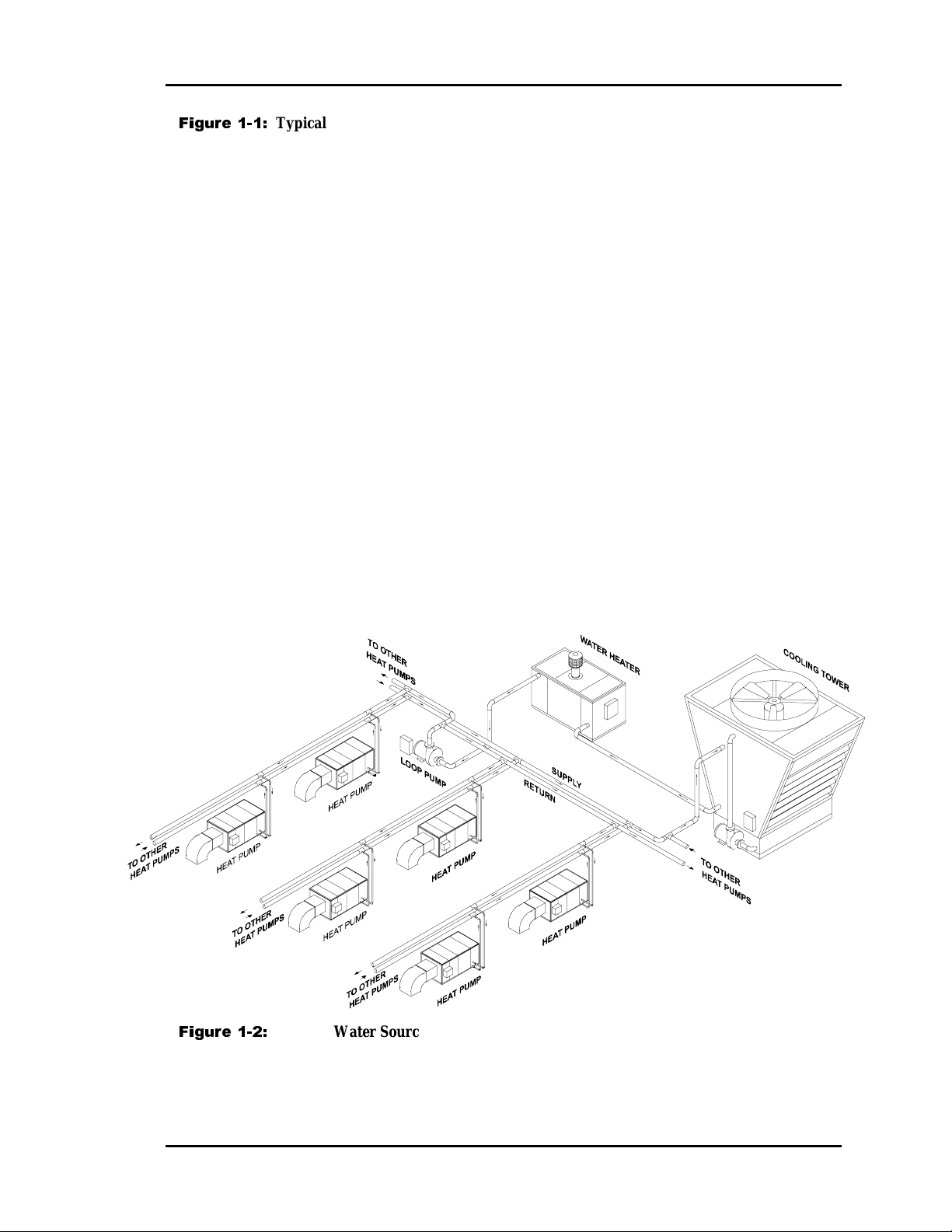

Figure 1-1:

Typical Water Source Heat Pump

During the cooling mode, the tube-in-tube heat exchanger functions as a condenser and

the coil as an evaporator. In heating mode, the tube-in-tube heat exchanger functions as

an evaporator and the coil as a condenser. A reversing valve is installed in the refrigerant

circuit permitting changeover from heating to cooling, and vice versa. The condenser and

evaporator tubes are designed to accept hot and cold refrigerant liquid or gas.

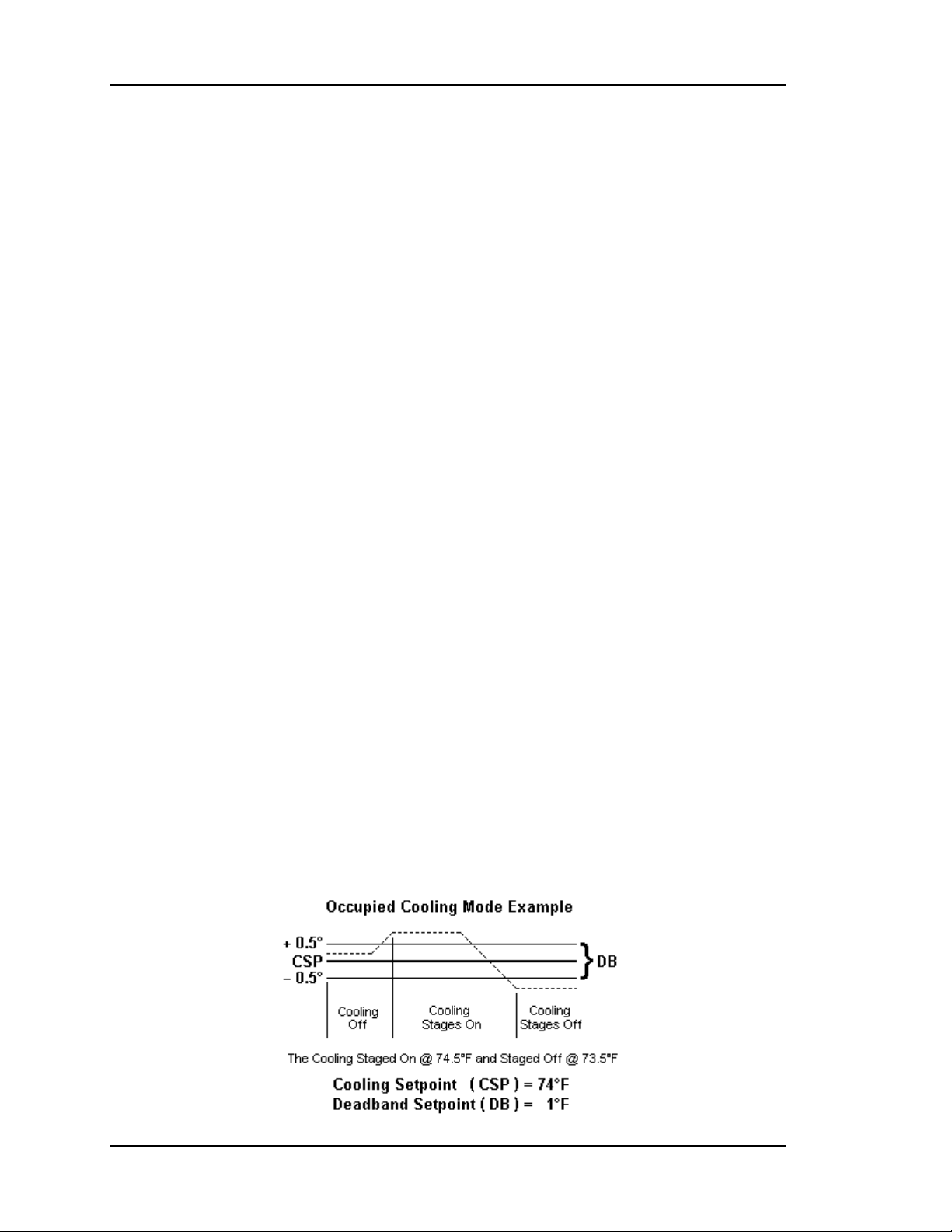

Water Source Heat Pump Systems

The water source heat pump system is, by definition, a heat recovery system. It is best

applied to buildings that have simultaneous cooling and heating loads. This is the case

during winter months when the interior zones of a typical building require cooling while

the exterior zones require heating. When a water source heat pump system is used, the

heat rejected by the cooling units is used to warm the zones calling for heat. A water

heater is generally used for adding heat to the condensing water during peak heating

periods, if necessary. The system also utilizes a water cooling tower to reject the heat

energy from the condenser water loop during periods of high cooling demand.

Water source heat pump units can be suspended in the ceiling plenum, floor mounted

behind walls or placed directly in the occupied space as a console unit. There are also

rooftop and unit ventilator type water source heat pumps.

Figure 1-2:

Typical Water Source Heat Pump System

Water source heat pump systems generally cost less to install than central built-up

systems. They offer individual zone control with the added flexibility of being able to

Design Guide 1-3

Page 10

Section 1 WattMaster WHP

accommodate changes in location and sizes as thermal zones or zone occupancy change.

This system is often installed in ceiling plenums, which frees up valuable floor space.

Another valuable benefit of water source heat pumps is that they can accommodate

simultaneous calls from zones requiring heating or cooling. Depending on the climate,

outside air may require preheat or cooling prior to being introduced to the unit. In the

example of ceiling mounted water source heat pumps, put outside air ducts near each unit

to improve indoor air quality.

Normally, multiple units serve an occupied space. This gives component redundancy to

the system so if one unit were to fail, the other units could back it up until the unit was

repaired. The packaged design of most unit types allows quick change-out by service

personnel so maintenance can typically be performed off site.

As with any HVAC system, there is a negative side as the water source heat pump system

often requires higher maintenance costs than conventional air side systems. The system

also typically has a shorter replacement life than other systems because of continuous fan

and compressor operation during heating and cooling modes. The system can also create

room noise since the compressor and fan are commonly located close to the zone

occupant. Placing units away from the occupied space and ducting the supply air to the

zone can minimize potential noise problems.

WattMaster WHP Control System

The WattMaster WHP system is used to control the water loop and the individual water

source heat pumps installed in a typical water source heat pump system. The WHP

system is an excellent alternative over programmable thermostats. The WHP control

system provides one central location to monitor and program all the water source heat

pumps on the system instead of having to program each water source heat pumps

thermostat individually. The system has many features typically not found with

programmable thermostats such as: central operators interface, heating/cooling failure

alarm, auxiliary alarm, and holiday scheduling, to name but a few.

WHP Controller

The Water Source Heat Pump Controller (WHP) is used for controlling individual water

source heat pump units. The WHP Controller can operate stand-alone or it can be used

with the Water Source Heat Pump Loop Controller and in this configuration shares

common data, such as outside air temperature, proof of flow etc., over a network. A

System Manager is connected to the WHP Controller to provide a central operators

interface to all WHP Controllers on the network. WHP Controllers are designed with

Room Temperature, Room Setpoint Adjust, Discharge Air Temperature, Leaving Water

Temp or Dirty Filter Alarm and Auxiliary Lockout inputs. Relay outputs provided are;

Fan (Continuous or Cycling), Reversing Valve-ON/OFF, Compressor-ON/OFF, Heat

1-4 Design Guide

Page 11

WattMaster WHP Section 1

Pump Reset and Aux. Heating or Cooling. An internal seven day schedule and holiday

schedule functions are also built into each WHP Controller.

With the WHP system the sometimes complex control requirements of a large water

source heat pump system can be handled with an off the shelf controls system that has

most of the features of a full blown building automation system but at a much lower cost.

Included with the WHP system is a communications interface module, which allows you

to connect a computer to the system onsite and a modem connection for remote

monitoring.

Prism, a Windows based software package is available at no additional charge. Some of

Prism’s features include graphics, trend logging, and remote alarm call out capabilities.

WHP Loop Controller

The Water Source Heat pump Loop Controller can be supplied with the system to control

the water loop and its various pieces of equipment. The Loop Controller can operate

stand-alone or used with the Water Source Heat Pump Controller (WHP) and in this

configuration communicates common data, such as outside air temperature, proof of flow

etc., over a network. A System Manager is connected to the Loop Controller to provide a

central operator’s interface to the Loop Controller’s setpoints and operating

configurations. The Loop Controller is designed with inputs for Supply and Return W ater

Temperature, Outdoor Air Temperature, Loop Water Pressure Switch or 0-50 PSI Loop

Pressure Sensor (4-20ma), Manual Reset Contact, Phase Loss Contact, Request to Run

Relay, and Fire/Smoke Relay. Analog outputs (0-10VDC) are supplied for Pump VFD

and Proportional Heat. Binary outputs are provided for Compressor Enable, Main Pump

Relay, Standby Pump Relay, Alarm Contacts and (8) Relays that can be configured for

Heat Rejection or Heat Addition.

Make Up Air Controller

A Make Up Air Controller, for treating 100% outdoor air, is available for use with the

Water Source Heat Pump system. Please consult factory for more information on this

product.

Design Guide 1-5

Page 12

Section 1 WattMaster WHP

WHP Sequence of

Operation

HVAC Mode of Operation

There are four possible modes of operation. These are Cooling Mode, Heating Mode,

Vent Mode, and the Off Mode. The HVAC mode of operation is calculated the same way

in both occupied and unoccupied modes of operation.

Off Mode The schedule is off and no overrides are active. There is no heating or

cooling demand in the space. Under these conditions, all outputs will be

off and the analog output will be set to 0.0 vdc.

Vent Mode No heating or cooling demand exists during the occupied mode of

operation. The fan will be on if the WHP is programmed for Constant Fan

operation. The compressor demand request will not be sent to the Loop

Controller. If no WHP units are sending a request, the Loop Controller

will discontinue operation after 15 minutes.

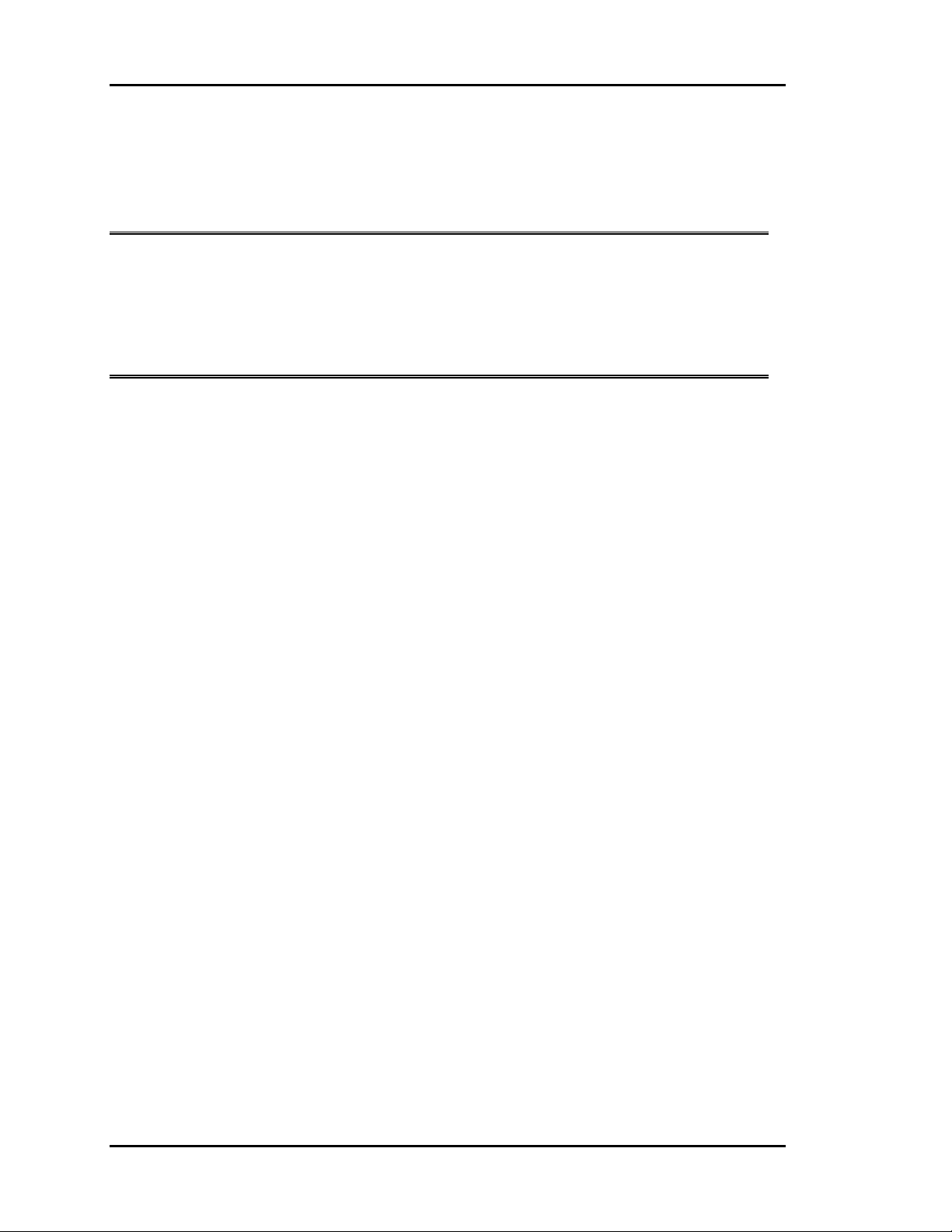

Cool Mode A cooling demand is generated when the space temperature rises half the

amount of the Deadband Setpoint above the currently active Cooling

Setpoint. The space is considered satisfied when it drops that amount

below the Cooling Setpoint.

Heat Mode A heating demand is generated when the space temperature drops half the

amount of the Deadband Setpoint below the currently active Heating

Setpoint. The space is considered satisfied when it rises that amount above

the Heating Setpoint.

1-6 Design Guide

Page 13

WattMaster WHP Section 1

Occupied/Unoccupied Mode of

Operation

Since the WHP contains its own built in Real Time Clock, it can operate from its own

internal scheduling system. This schedule supports two Start & Stop events per day and

up to 14 Holiday periods. The Holidays all use the same special Holiday Start/Stop times

programmed by the user.

If the current operating mode is unoccupied, the WHP can accept a push-button override

back to the occupied mode. Push-button overrides are not recognized if the current mode

is already occupied. The push-button override duration is user programmed. If the user

wants to extend the current override without reprogramming the Duration, they can reinitialize the existing programmed period by pressing the override button anytime during

the current override. If the current override had been active for 1 hour and 45 minutes and

the user presses the push-button again, the override will reset for another 2 hour period (if

they programmed a 2 hour period), bringing the total override time to 3 hours and 45

minutes. If the user wants to cancel an override before it can time-out, simply hold the

push-button for a period of time between 3 and 10 seconds.

The WHP calculates its current heating and cooling setpoints based on the current mode

of operation. If the command is for unoccupied mode, the WHP adds the unoccupied

setbacks to the occupied heating and cooling setpoints.

Vent Mode Operation

During occupied hours when there is no heating or cooling demand, the WHP reverts to a

Vent Mode of operation. The fan is running and the heating and cooling outputs are held

off.

See the section titled HVAC Mode of Operation for a graphical description of how the

Vent Mode is calculated.

Off Mode of Operation

After the schedule goes unoccupied and both heating and cooling demands go away, the

fan stops running, all relay outputs are turned off. No outputs are allowed to activate in

the Off Mode until a heating or cooling demand occurs. During occupied hours this

would be the Vent Mode.

Design Guide 1-7

Page 14

Section 1 WattMaster WHP

HVAC Operation w/ Reversing Relay

If the user has configured the WHP to control a Reversing Valve and a Compressor, the

following sequence of operation occurs during a heating or cooling demand.

Note: If you configure the WHP to look for a proof of flow Enable signal from the

Loop Controller then the following sequence assumes a request was made by

the WHP during a demand condition and that the Loop Controller gave

permission for the WHP to start its compressor. Otherwise, the WHP will

ignore the Enable signal and operate anytime there is a heating or cooling

demand.

a. If the last mode was the opposite of the current demand mode, make sure

the Changeover Delay has been satisfied.

b. If the unit is configured to control an Isolation Valve, the valve relay is

activated ( Relay #5 ). The Minimum Off Timer is reset to ZERO and

must be satisfied before any further operations are allowed.

c. If the current mode requires the Reversing Valve to be activated, its relay

contact is closed and a 10 second delay is started.

d. Ten seconds after the Reversing Valve is activated, the Compressor relay

is activated.

e. If the Space Temperature continues to exceed the affected setpoint by the

full amount of Deadband and you have configured for 2 stages in the

current mode of operation, relay #5 will activate for the second stage of

heating and/or cooling. A second stage of either implies that no Isolation

Valve exists!

f. Once the Space Temperature has crossed back over the affected setpoint,

stage 2 will be turned off if the unit has a stage 2.

g. As the Space Temperature continues to cross back over the affected

setpoint by half the Deadband value, the compressor will then be allowed

to turn off if the Minimum Run Time has been satisfied.

1-8 Design Guide

Page 15

WattMaster WHP Section 1

HVAC Operation w/ Heat/Cool Relays

If the user has configured the WHP to control Individual Heating and Cooling relays the

following sequence of operation occurs during a heating or cooling demand.

NOTE: If you configure the WHP to look for a proof of flow Enable signal from the

Loop Controller then the following sequence assumes a request was made by

the WHP during a demand condition and that the Loop Controller gave

permission for the WHP to operate its heating or cooling. Otherwise, the WHP

will ignore the Enable signal and operate anytime there is a heating or cooling

demand.

Once a heating or cooling demand exists, the following conditions must be met before

any relays can be activated:

a. Make sure any stages of the opposite mode are staged off.

b. Verify the system has been configured for at least one stage of heating or

cooling.

c. Make sure the Minimum Cycle Time has been satisfied.

d. If the last mode was the opposite demand mode, make sure the

Changeover Delay has been satisfied.

e. Check the current Minimum Off Timer to make sure this stage has been

off long enough since the last time it was cycled on and back off.

f. If there is more than 1 stage, check the Minimum Run Time from the

previous stage to be sure it has elapsed before activating the second stage.

g. Make sure the Space Temperature Demand is the full amount of Deadband

from the setpoint before activating the second stage.

h. Once the compressor or stage 2 has been turned off, a Minimum Off Time

must be satisfied before it can stage on again. A Minimum Cycle time can

also be utilized to limit the number of times per hour that the compressor

can be activated. If you don’t need this limitation, set the Minimum Cycle

Time to be shorter than the Minimum Run Time setpoint.

i. If the Reversing Valve was configured to cycle with the compressor, it will

now turn off also. It can be configured to remain active until the opposite

mode of operation is called for to reduce wear on the valve.

Design Guide 1-9

Page 16

Section 1 WattMaster WHP

WHP Loop Controller

Sequence of Operations

Summary

The Water Source Heat Pump Loop Controller waits for a Request to Run signal from a

Heat Pump or from a Binary Contact Closure. Once the request is received the Loop

Controller activates a Pump to initiate water flow to the Heat Pumps. Once the pump is

activated and proof of flow has been determined, a Global is broadcast to all Heat Pumps

to enable them to go ahead and run their compressors. The main goal of the Loop

Controller is to provide water flow and to maintain the loop water temperature by

monitoring either the Loop Inlet or Loop Outlet temperature. If a higher temperature is

required, Heat Addition is enabled. If the temperature needs to be lowered, Heat

Rejection is enabled.

Once the Loop Controller has been activated by a request, it will run for a minimum of 15

minutes to prevent cycling on and off due to borderline requests from the Heat Pumps.

If a Fire Alarm is detected, the Loop Controller generates a Global broadcast to all Heat

Pumps to turn off.

If the High Pressure option is configured, the Loop Controller can generate a Global

broadcast to force the Heat Pumps to open their Isolation Valves to reduce loop pressure

if the high limit has been exceeded.

Pump Control

If WattMaster Water Source Heat Pump Controllers are used in conjunction with the

Loop Controller, a Global Binary signal from the attached Heat Pumps sends a Request to

run or Enable to Run command to the Loop Controller. If the Loop Controller is used in a

stand alone configuration, a contact closure on the AIN 2 of the Analog Expansion board

gives the controller a request to run. When a request to run is received, the Loop

Controller activates a pump to initiate water flow to the heat pumps. The pumps can

either be constant flow or controlled by a VFD. If the request goes away for at least one

minute, the request to run command is removed. If the loop controller has been running a

minimum of 15 minutes then it can be turned off, since there is no longer a request to run.

If the proof of flow is lost while the pumps are running, the pump is shut off immediately

if the changeover to the Standby Pump had already been made.

The pumps are Lead/Lag controlled based on a user definable number of hours. If one

pump exceeds the other pumps run time by this amount, the lead is changed until that

1-10 Design Guide

Page 17

WattMaster WHP Section 1

pump exceeds the first pumps run time by the same amount. This keeps both pumps with

roughly the same number of hours on each pump. Changeover occurs at the time the run

time setpoint is exceeded. The running pump is shut off at the same time the standby

pump is energized, this prevents any down time or alarms. The unit can be configured to

control either the Loop Inlet temperature or the loop outlet temperature.

A user adjustable low outdoor air temperature setting of XX degrees will allow the unit to

run the pumps continuously for protection against freezing.

If the pump is constant volume, and the pump has been started, it has 3 seconds to

generate flow or the standby pump is activated. If the pump is controlled by a VFD, once

it starts, it has 60 seconds to generate flow and if it doesn’t the standby pump is activated.

If the standby pump fails, an alarm is generated and the Loop controller deactivates any

active heat rejection or addition stages. At the same time an alarm is generated, we

energize relay #5 on the Loop Controller board so that it may used to turn on a local

alarm signal.

Loop flow can be determined by a binary contact closure on input #3 or a 0 to 50 PSI

pressure sensor on input #3. If a pressure sensor is used, the user can program the

pressure setpoint that needs to be met for proof of flow.

Pump VFD Control

An optional Pump VFD signal can be modulated if the system is configured for

proportional control and a pressure sensor is attached to analog input #3.

At a user defined rate, the VFD signal is ramped up when the pressure is below

a user defined setpoint by a user defined deadband. The signal ramps down when the

pressure exceeds the setpoint by the deadband value. If the pressure ever exceeds the high

pressure setpoint, an emergency override activates and begins cutting the VFD signal in

half each time the control loop is polled by the software. This protects against run away

over-pressurization.

The pump relay outputs are still activated and Lead/Lagged as described above

and the pump relay remains on until the Request signal is removed, provided it

has been operating for at least 15 minutes.

Compressor Control

Anytime a pump is running and proof of flow has been established, the compressor output

is activated.

Design Guide 1-11

Page 18

Section 1 WattMaster WHP

Heat Rejection Control

If the compressor is not running, no heat rejection can be active. If any heat rejection is

still active when the compressor is turned off, the heat rejection will be immediately

removed, without regard to any minimum run or off times.

Heat rejection cannot be active at the same time as heat addition, so any heat addition is

removed or staged off before the heat rejection can be started.

A maximum of 8 stages of heat rejection can be controlled.

Staged Heat Rejection

Heat Rejection is staged up based on a different deadband level for each stage. Basically,

if the user programmed a 2° deadband, then the first stage could activate at the setpoint,

stage 2 would activate 2° above the setpoint, stage 3 would activate 4° above the setpoint,

etc...

Staging down is calculated in the same manner, except the water temperature would need

to drop below the setpoint by the deadband amount. If stage 3 was activated at 4° above

setpoint, it would de-activate when the temperature fell to within 2° of setpoint, stage 2

would de-activate at setpoint and stage 1 would de-activate 2° below setpoint.

A user defined staging up and down interval must be met before any heat rejection stages

can be added or removed. If the selected Water Temperature is above the current staging

level and the timer has been satisfied, an additional stage can be added, up to the

maximum available 8 stages. If the selected Water Temperature is below the staging

down level and the timer has been satisfied, a stage can be removed.

Heat Addition Control

If the compressor is not running, no heat addition can be active. If any heat addition is

still active when the compressor is turned off, the heat addition will be immediately

removed, without regard to any minimum run or off times.

Heat addition cannot be active at the same time as heat rejection, so any heat rejection is

removed or staged off before the heat addition can be started.

A maximum of 4 stages of heat addition can be controlled or proportional heating can be

configured, and an analog output signal will be modulated to control the heat.

1-12 Design Guide

Page 19

WattMaster WHP Section 1

Staged Heat Addition

Heat Addition is staged up based on a different deadband level for each stage. Basically,

if the user programmed a 2° deadband, then the first stage could activate at the setpoint,

stage 2 would activate 2° below the setpoint, stage 3 would activate 4° below the setpoint,

etc...

Staging down is calculated in the same manner, except the water temperature would need

to increase above the setpoint by the deadband amount. If stage 3 was activated at 4°

below setpoint, it would de-activate when the temperature rises t o within 2° of setpoint,

stage 2 would de-activate at setpoint and stage 1 would de-activate 2° above setpoint.

A user defined staging up and down interval must be met before any heat addition stages

can be added or removed. If the selected Water Temperature is below the current st aging

level and the timer has been satisfied, an additional stage can be added, up to the

maximum available 8 stages. If the selected Water Temperature is above the staging

down level and the timer has been satisfied, a stage can be removed.

Proportional Heat Addition

If the Water Temperature is below the addition setpoint, a Boiler Enable relay is

activated. If the Water Temperature rises 1° above the setpoint the Boiler Enable relay is

de-activated.

At a user defined rate, the analog output signal is proportionally controlled from 0.0 VDC

at 1° above setpoint to the full 10.0 VDC signal as the water temperature drops below the

setpoint by the user defined deadband amount. If a 5° deadband was entered, the

maximum voltage would be reached at 4° below the setpoint and the minimum volt age

would be set at 1° above the setpoint. Since this is strictly proportional control, at 1.5°

below setpoint the controller would set 5.0 VDC since that would be half the deadband

amount.

Design Guide 1-13

Page 20

Section 1 WattMaster WHP

Water Temperature Alarming

The controlling water temperature is monitored to prevent it from exceeding both a user

defined High and Low Alarm Limit. If either limit is exceeded for a user defined length of

time, an alarm is generated and the compressor output is de-activated. If the high limit is

exceeded, the heat addition outputs are de-activated and if the low limit is exceeded, the

heat rejection outputs are de-activated. The alarming and shutdown only pertains to the

controlling water temperature. This does not affect the pump operation.

If a external manual alarm reset button is connected between ground and input #5, All

outputs are turned off and ALL timers are reset. This forces the loop controller to stage

off. This reset WILL shut down the pumps and force them to restart!

Fire Alarm

If the Fire Alarm is activated on input #1 of the Analog Input Expansion Board (Contact

OPENS for Alarm!) then ALL outputs and timers are reset and held off for the duration of

the Fire Alarm signal.

If the Fire Alarm is not required, input #1 of the Analog Input Expansion Board must

have a shorting wire to ground to allow the equipment to operate.

1-14 Design Guide

Page 21

WattMaster WHP Section 1

COMPUTER

(OPTIONAL)

RS-485

Comm Loop

32K

8K

COMM

RELAY

OUTPUT

T

Room Sensor

with Optional

Override & Adj.

COM

1-3

SHLD

OUT

R

1

OUT

RAM EPROM

485

LD4

2

COMM

OUT

3

REC.

OUT

OUT

4

OUT

5

COM

CPU

4-5

4-5

COMM

12V

TEST

ADDRESS ADD

AIN

1

AIN

2

AIN

3

EWDOG

AIN

4

AIN

5

GND

GND

0-5

VDC

AOUT

PWR

PRESSURE

GND

SENSOR

YS101564

0-1

VDC

24VAC

24 VAC

110/24 VAC

Power Pak

Modem

(Optional)

M

R

T

R

S

D

R

D

O

H

C

D

A

A

H

S

CommLink II

Multiple Loop

Interface

C

COMM

O

M

M

L

LINK

IN

K

I

II

I

L

O

C

O

O

M

P

M

O

D

P

E

M

WCLI

AT

T

M

A

S

T

E

R

O

N

T

R

O

S

,

N

C

MiniLink

Loop # 1

K

N

I

L

I

N

I

M

MINILINK

N

NETWORK

1

2

E

4

T

T

8

W

16

SH

O

32

R

R

K

24VAC24VAC

GND

L

LOOP

T

O

O

SH

P

R

24VAC

MiniLink

Loop # 2

K

N

I

L

I

N

I

M

MINILINK

N

NETWORK

1

2

E

4

T

T

8

W

16

SH

O

32

R

R

K

24VAC24VAC

GND

L

LOOP

T

O

O

SH

P

R

24VAC

Typical Network & Local Loop Wiring

2 Conductor Twisted Pair with Shield

(Beldon #82760 or Equivalent)

MiniLink

Loop # 3

K

N

I

L

I

N

I

M

MINILINK

N

NETWORK

1

2

E

4

T

T

8

W

16

SH

O

32

R

R

K

24VAC

GND

L

LOOP

T

O

O

SH

P

R

24VAC

NOTE: * Only One Outside Air Sensor

is Required per WHP System

MiniLink

Loop # 4

K

N

I

L

I

N

I

M

MINILINK

N

NETWORK

1

2

E

4

T

T

8

W

16

SH

O

32

R

R

K

24VAC

GND

GND

L

LOOP

T

O

O

SH

P

R

Loop # 4

Notes:

1.) 24 VAC Must Be Connected

So That All Ground Wires

Remain Common.

2.) All Wiring To Be In Accordance

With Local And National Electrical

Codes and Specifications.

24VAC

110/24 VAC

Power Pak

Network Loop

RS-485

19200 Baud

Local Loop

RS-485

9600 Baud

Local Loop

RS-485

9600 Baud

Local Loop

RS-485

9600 Baud

*OutsideAir

Sensor

Supply

Air

or Leaving Water Temp

F

Sensor

Typical WHP Controller Wiring

#1

32K

8K

COMM

RELAY

OUTPUT

T

COM

1-3

SHLD

OUT

R

1

OUT

RAM EPROM

485

LD4

2

COMM

OUT

3

REC.

OUT

OUT

4

OUT

5

COM

CPU

4-5

4-5

COMM

12V

TEST

ADDRESS ADD

AIN

1

AIN

2

AIN

3

EWDOG

AIN

4

AIN

5

GND

GND

0-5

VDC

AOUT

PWR

PRESSURE

GND

SENSOR

YS101564

0-1

VDC

24VAC

System Manager

#1

32K

8K

COMM

RELAY

OUTPUT

T

COM

1-3

SHLD

OUT

R

1

OCCUPIED

ALARMS

03/31/04 03:38PM WED

NO

OUT

RAM EPROM

485

LD4

2

COMM

OUT

3

REC.

OUT

OUT

4

OUT

5

COM

CPU

4-5

4-5

COMM

12V

TEST

ADDRESS ADD

AIN

1

AIN

2

AIN

3

EWDOG

AIN

4

AIN

5

GND

GND

0-5

VDC

AOUT

PWR

PRESSURE

GND

SENSOR

YS101564

0-1

VDC

24VAC

24VAC

#1

32K

8K

COMM

RELAY

OUTPUT

T

COM

1-3

SHLD

OUT

R

1

OUT

RAM EPROM

485

LD4

2

COMM

OUT

3

REC.

OUT

OUT

4

OUT

5

COM

CPU

4-5

4-5

COMM

12V

TEST

ADDRESS ADD

AIN

1

AIN

2

AIN

3

EWDOG

AIN

4

AIN

5

GND

GND

0-5

VDC

AOUT

PWR

PRESSURE

GND

SENSOR

YS101564

0-1

VDC

24VAC

WHP Loop

Controller

C21

1

U3

D

3

CX1

X

CX2

U2

RN1

C

CX4

1

U1

U4

1

2

G

Y

4

L

N

V

TB1

COMM

T

SHLD

R

CX5

LD6

COMM

LD7

PWR

LD8

LED1

LD9

LED2

R1

TESTPOINT

U7

RV1

VREFADJ

INPUTS

+VDC

AIN1

AIN2

AIN3

AIN4

AIN5

GND

GND

AOUT1

AOUT2

AIN7

GND

PJ1

TB3

PRESSURE

SENSOR

EXPANSION

V1

R

A

D

C

2

D

V2

V3

2

Y

L

R

COM1-3

3

D

U5

PAL

R1

RS-485

1

EPROM

RAM

R2

COMM

3

Y

TUC-5RPLUS

1

L

HH

R

R3

(1MEG)

4

YS101816REV.2

2

U6

D

3

N

YS101790

4RLYIOBD.

R4

N

R

R

C1

R5

P1

4

COM4-5

Y

L

R

+VREF

TB2

CX6

5

5.11V

D

2

V4

C

S

IP

EWDOG

1

IL

X

V5

H

P

5

R28

Y

L

3

R

C

1

ADD

ADDRESS

U8

1

4

4RLYIOBD.

N

2

R

RN5

4

NE5090NPB3192

8

PU1

X

0PS

8

C

U9

D6

16

PU2

32

D7

TOKEN

PU3

NETWORK

D8

SW1

PU4

D9

PU5

D11

C

C

C10

PU7

-1

-5

D

D

0

0

V

V

JP1

D14

C12

U13

CX13

D15

C17

U15

C20

CX15

R26

3

2

J

J

P

P

AIN1

CX10

C7

AIN2

R6

AIN3

0

7

1

U10

R

D

AIN4

0

3

1

1

L1

C9

R

D

GND

CX12

1

1

1

D12

C

1

1

X2

AOUT1

9936

1

R13

R

U

MC34064A

SC1

C13

R15

U12

CX14

C14

C16

R19

U14

TB4

C15

D19

GND

R22

7

2

6

R24

R

R

1

E

D

8

7

6

R25

1

1

W

V

9

8

D

D

O

1

1

P

C

C

7824CT

24VAC

M

VR1

VR2

T'STAT

3.) The Local Loop With The Loop Controller

Installed Can Only Have Up To 29

WHP Controllers Attached As The WHP

Loop Controller Occupies Address #30.

4.) Systems may consist of up to 20 Local

Loops (600 WHP Controllers). Consult

factory for systems that exceed these quantities.

4ANALOGIN MOD I/O BD.

YS101784

COMM

T

SHLD

R

LD4

YS101790

REC.

12V

AIN

1

AIN

2

AIN

3

AIN

4

AIN

5

GND

GND

AOUT

PRESSURE

SENSOR

#1

RAM EPROM

485

COMM

ADDRESS ADD

EWDOG

YS101564

32K

8K

COM

1-3

COM

CPU

4-5

4-5

COMM

TEST

0-5

VDC

0-1

VDC

See Note #3

RELAY

OUTPUT

OUT

1

OUT

2

OUT

3

OUT

OUT

4

OUT

5

PWR

GND

24VAC

Dirty Filter Alarm

Loop #1

WHP

Controllers

Loop #2

WHP

Controllers

Loop #3

WHP

Controllers

Loop #4

WHP

Controllers

Local Loop

RS-485

9600 Baud

COMM

COMM

LD4

REC.

PRESSURE

SENSOR

COMM

T

SHLD

R

LD4

REC.

12V

AIN

AIN

AIN

AIN

AIN

GND

GND

AOUT

PRESSURE

SENSOR

T

SHLD

R

12V

AIN

1

AIN

2

AIN

3

AIN

4

AIN

5

GND

GND

AOUT

#30

T

SHLD

R

LD4

REC.

12V

AIN

1

AIN

2

AIN

3

AIN

4

AIN

5

GND

GND

AOUT

PRESSURE

SENSOR

#30

1

2

3

4

5

YS101564

COMM

T

SHLD

R

LD4

REC.

PRESSURE

SENSOR

YS101564

485

COMM

YS101564

RAM EPROM

485

COMM

ADDRESS ADD

EWDOG

#30

12V

AIN

1

AIN

2

AIN

3

AIN

4

AIN

5

GND

GND

AOUT

YS101564

#29

RAM EPROM

485

COMM

ADDRESS ADD

EWDOG

32K

8K

RELAY

OUTPUT

COM

1-3

OUT

1

OUT

RAM EPROM

2

OUT

3

OUT

OUT

4

OUT

5

COM

CPU

4-5

4-5

COMM

TEST

ADDRESS ADD

EWDOG

0-5

VDC

PWR

GND

0-1

VDC

24VAC

32K

8K

RELAY

OUTPUT

COM

1-3

OUT

1

OUT

2

OUT

3

OUT

OUT

4

OUT

5

COM

CPU

4-5

4-5

COMM

TEST

0-5

VDC

PWR

GND

0-1

VDC

24VAC

32K

8K

RELAY

OUTPUT

COM

1-3

OUT

1

OUT

RAM EPROM

485

2

COMM

OUT

3

OUT

OUT

4

OUT

5

COM

CPU

4-5

4-5

COMM

TEST

ADDRESS ADD

EWDOG

0-5

VDC

PWR

GND

0-1

VDC

24VAC

32K

8K

RELAY

OUTPUT

COM

1-3

OUT

1

OUT

2

OUT

3

OUT

OUT

4

OUT

5

COM

CPU

4-5

4-5

COMM

TEST

0-5

VDC

PWR

GND

0-1

VDC

24VAC

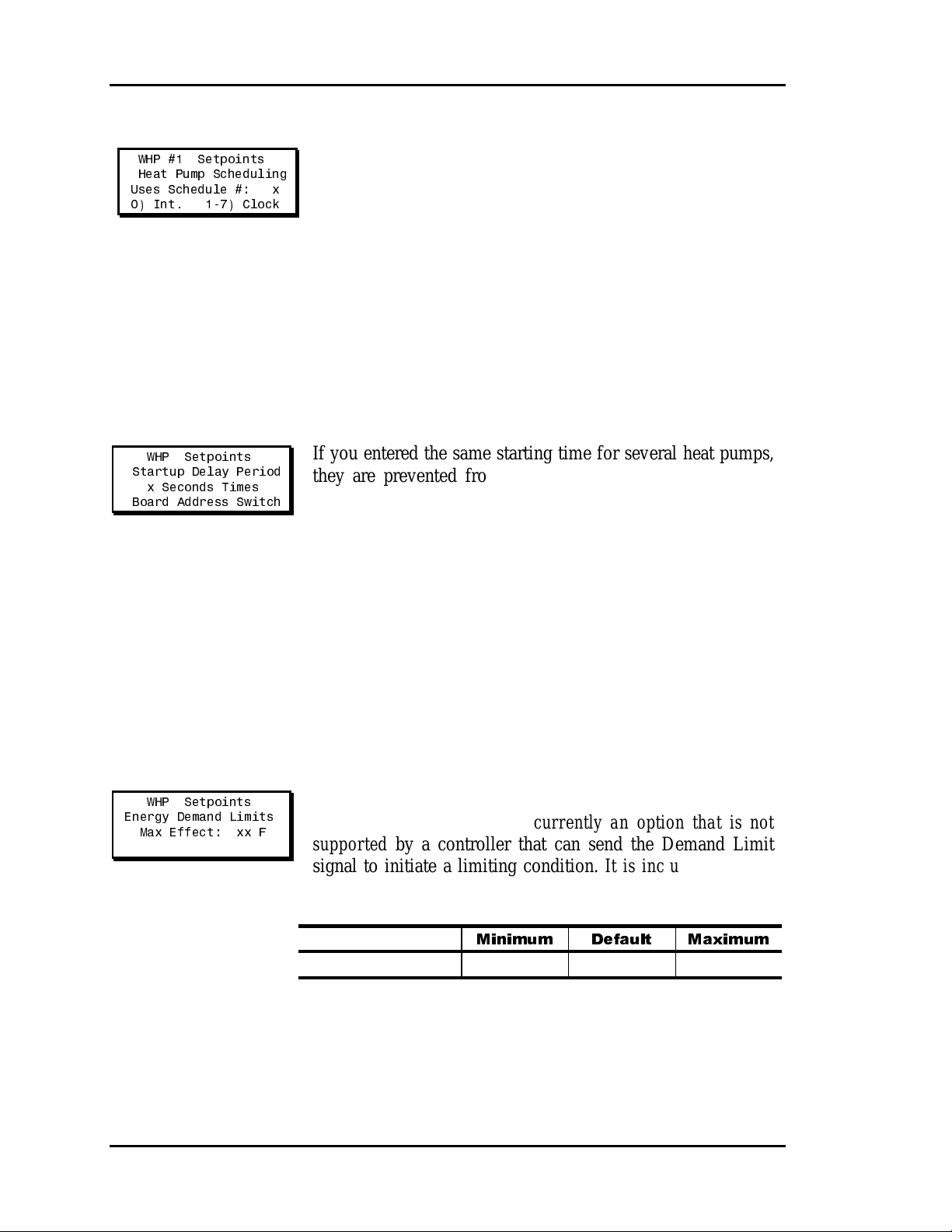

Figure 1-3:

Typical WattMaster WHP System

Design Guide 1-15

Page 22

Section 1 WattMaster WHP

Notes:

1-16 Design Guide

Page 23

Section 2

Table of Contents

Tips Before Beginning Installation.................................. 1

Communications Loops ...................................................3

Communications Loop Wiring Overview....................................................4

WHP Loop Controller .......................................................6

WHP Loop Controller Addressing ....................................9

Supply & Return Water Temperature Sensors.............. 10

Outside Air Temperature Sensor................................... 12

CommLink II Interface................................................... 13

WHP Controller ..............................................................14

WHP Controller Addressing ...........................................17

MiniLink Addressing ...................................................... 18

Room Sensors ................................................................ 19

Supply Air Temperature Sensor .................................... 21

Leaving Water Temperature Sensors............................ 22

Installation and Wiring

Page 24

Section 2

Table of Figures

Figure 2-1: System Overview........................................................................................2

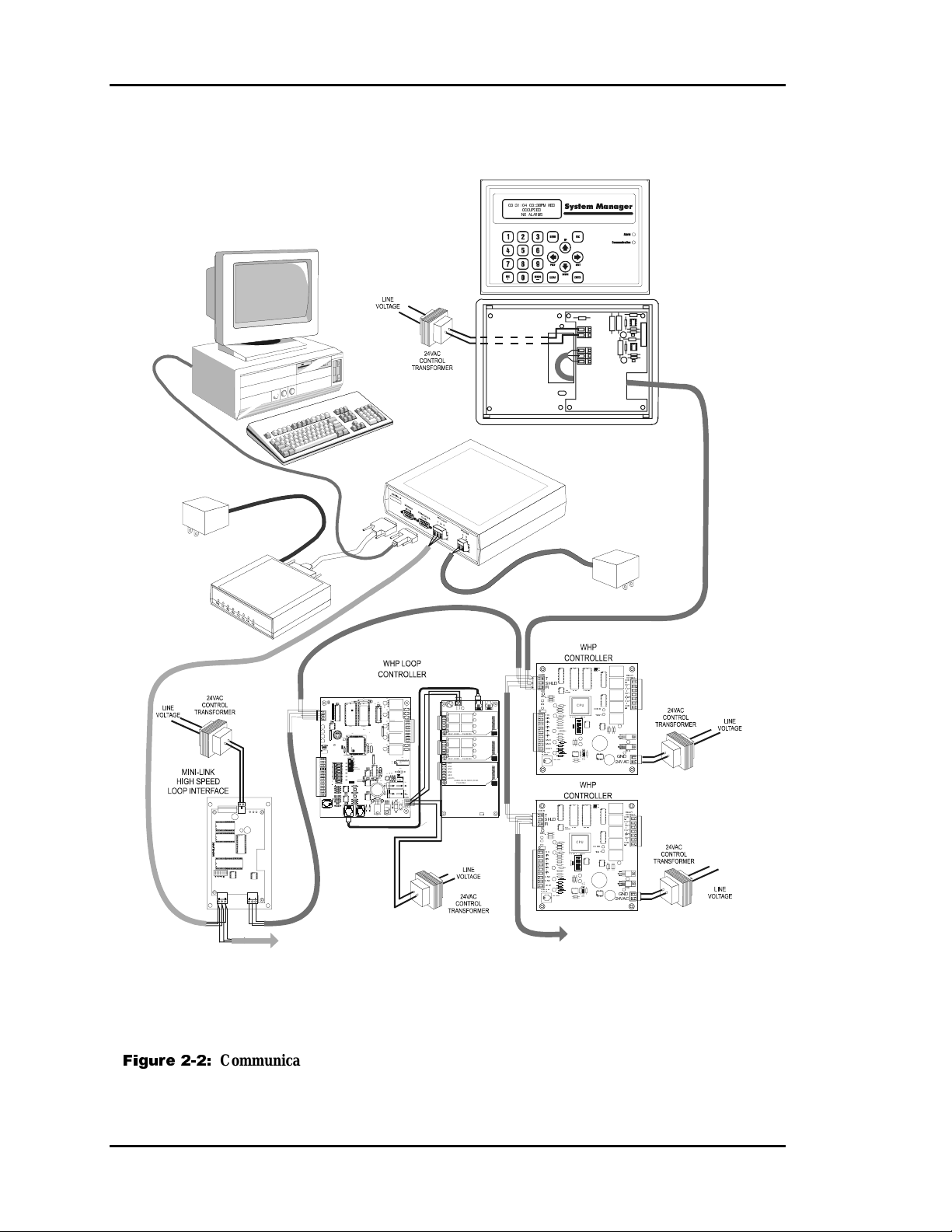

Figure 2-2: Communication Loop Wiring, Daisy-Chain Configuration .......................4

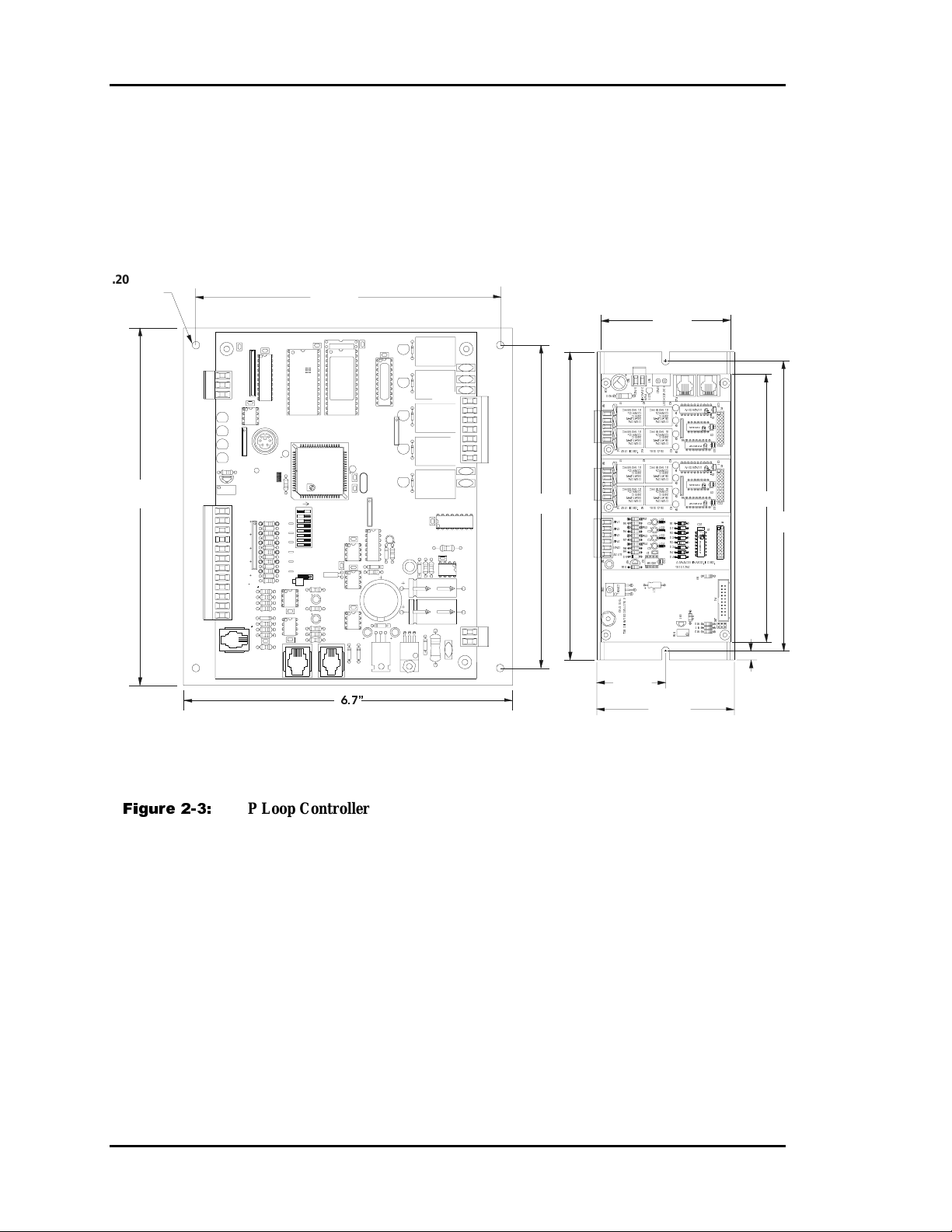

Figure 2-3: WHP Loop Controller.................................................................................6

Figure 2-4: WHP Loop Controller Wiring ....................................................................7

Figure 2-5: WHP Loop Controller Address Switch Setting..........................................9

Figure 2-6: Duct Sensor with Thermowell...................................................................10

Figure 2-7: Strap-On Water Temperature Sensor ........................................................11

Figure 2-8: Outside Air Temperature Sensor...............................................................12

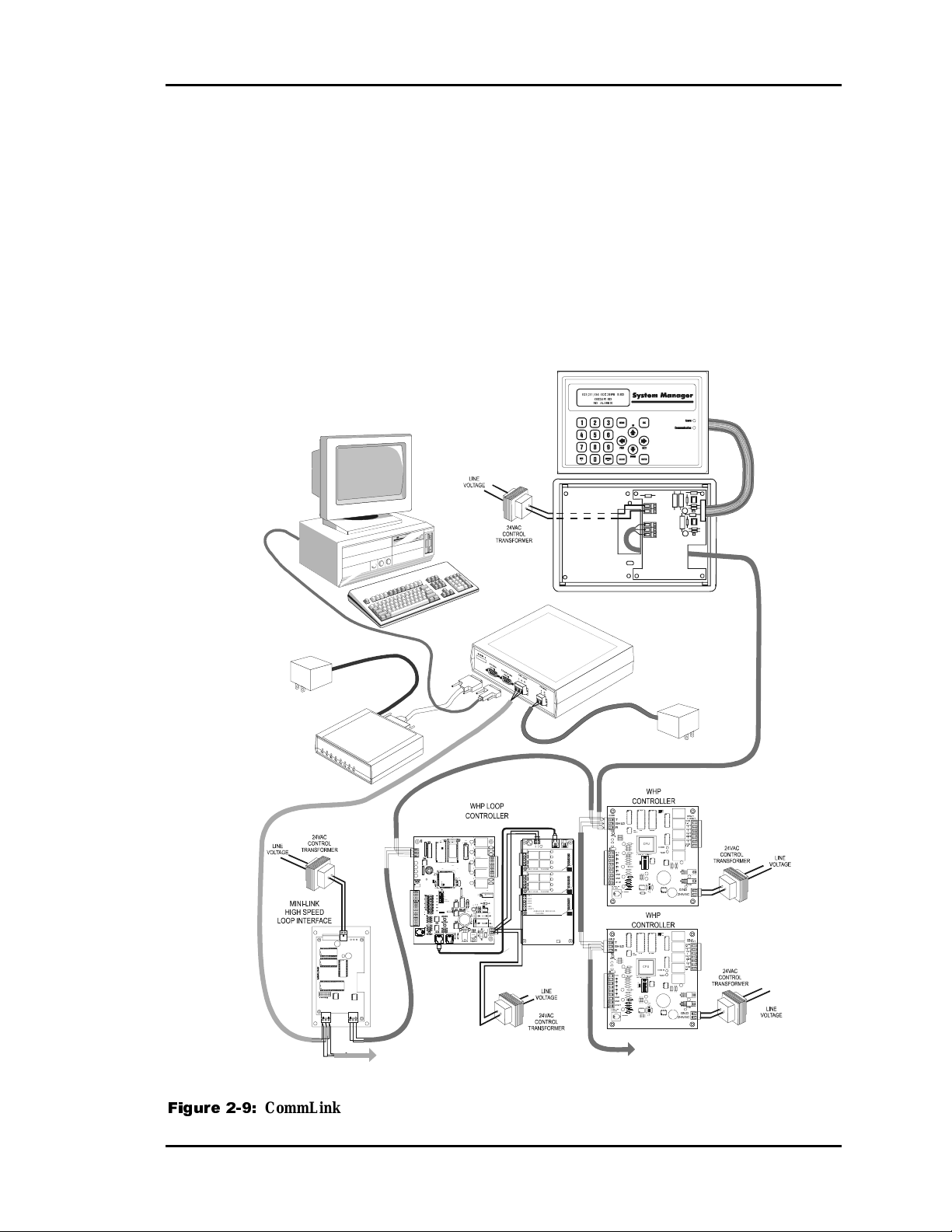

Figure 2-9: CommLink Interface Wiring.....................................................................14

Figure 2-10: WHP Controller .....................................................................................14

Figure 2-11: WHP Controller Wiring.........................................................................15

Figure 2-12: WHP Controller Address Switch Setting...............................................17

Figure 2-13: MiniLink Address Switch Setting.........................................................18

Figure 2-14: Room Sensor Wiring..............................................................................19

Figure 2-15: Room Sensor..........................................................................................20

Figure 2-16: Supply Air Temperature Sensor..............................................................21

Figure 2-17: Water Temperature Sensor .....................................................................22

Figure 2-18: Water Temperature Sensor .....................................................................22

Installation and Wiring

Page 25

WattMaster WHP Section 2

Tips Before Beginning

Installation

Take a few moments to review the following before beginning installation of the

WattMaster WHP System.

• Familiarize yourself with all system components and review all documentation. Pay

special attention to “Cautions” and “Warnings” since these may keep you from

experiencing unnecessary problems.

• Before installing controllers, be sure to tag it with its appropriate location. It is also

best to set the controller address switches before mounting. Use the WHP Address

Worksheet to list all WHP unit locations. This will assist you greatly when setting up

the system.

• Be sure and install all wiring according to local, state, and national electric codes.

• Pay close attention to communication wiring since the most common mistakes are

made in this area. Polarity is the most important rule. Make notes on your wiring

diagrams as to which color wire you will be using on each terminal.

• When in doubt - ask! Contact your local WattMaster distributor if you have any

questions. The only dumb questions are the ones you don’t ask.

• Remember - each electronic device contains only one puff of smoke. If you release it,

you have voided the warranty! So please be careful and pay attention.

Installation and Wiring 2-1

Page 26

Section 2 WattMaster WHP

COMPUTER

(OPTIONAL)

RS-485

Comm Loop

32K

8K

COMM

RELAY

OUTPUT

T

Room Sensor

with Optional

Override & Adj.

COM

1-3

SHLD

OUT

R

1

OUT

RAM EPROM

485

LD4

2

COMM

OUT

3

REC.

OUT

OUT

4

OUT

5

COM

CPU

4-5

4-5

COMM

12V

TEST

ADDRESS ADD

AIN

1

AIN

2

AIN

3

EWDOG

AIN

4

AIN

5

GND

GND

0-5

VDC

AOUT

PWR

PRESSURE

GND

SENSOR

YS101564

0-1

VDC

24VAC

24 VAC

110/24 VAC

Power Pak

Modem

(Optional)

M

R

T

R

S

D

R

D

O

H

C

D

A

A

H

S

CommLink II

Multiple Loop

Interface

C

COMM

O

M

M

L

LINK

IN

K

I

II

I

L

O

C

O

O

M

P

M

O

D

P

E

M

WCLI

AT

T

M

A

S

TE

R

O

N

T

R

O

S, N

C

MiniLink

Loop # 1

K

N

I

L

I

N

I

M

MINILINK

N

NETWORK

1

2

E

4

T

T

8

W

16

SH

O

32

R

R

K

24VAC

GND

L

LOOP

T

O

O

SH

P

R

24VAC

MiniLink

Loop # 2

K

N

I

L

I

N

I

M

MINILINK

N

NETWORK

1

2

E

4

T

T

8

W

16

SH

O

32

R

R

K

24VAC

GND

L

LOOP

T

O

O

SH

P

R

24VAC

Typical Network & Local Loop Wiring

2 Conductor Twisted Pair with Shield

(Beldon #82760 or Equivalent)

MiniLink

Loop # 3

K

N

I

L

I

N

I

M

MINILINK

N

NETWORK

1

2

E

4

T

T

8

W

16

SH

O

32

R

R

K

24VAC

GND

L

LOOP

T

O

O

SH

P

R

24VAC

NOTE: * Only One Outside Air Sensor

is Required per WHP System

MiniLink

Loop # 4

K

N

I

L

I

N

I

M

MINILINK

N

NETWORK

1

2

E

4

T

T

8

W

16

SH

O

32

R

R

K

24VAC24VAC

GND

L

LOOP

T

O

O

SH

P

R

Loop # 4

Notes:

1.) 24 VAC Must Be Connected

So That All Ground Wires

Remain Common.

2.) All Wiring To Be In Accordance

With Local And National Electrical

Codes and Specifications.

24VAC

110/24 VAC

Power Pak

Network Loop

RS-485

19200 Baud

Local Loop

RS-485

9600 Baud

Local Loop

RS-485

9600 Baud

Local Loop

RS-485

9600 Baud

*OutsideAir

Sensor

Supply

Air

or Leaving Water Temp

F

Sensor

Typical WHP Controller Wiring

#1

32K

8K

COMM

RELAY

OUTPUT

T

COM

1-3

SHLD

OUT

R

1

OUT

RAM EPROM

485

LD4

2

COMM

OUT

3

REC.

OUT

OUT

4

OUT

5

COM

CPU

4-5

4-5

COMM

12V

TEST

ADDRESS ADD

AIN

1

AIN

2

AIN

3

EWDOG

AIN

4

AIN

5

GND

GND

0-5

VDC

AOUT

PWR

PRESSURE

GND

SENSOR

YS101564

0-1

VDC

24VAC

System Manager

D

E

W

M

P

8

3

:

3

D

0

E

I

4

S

P

0

M

U

/

R

C

1

A

C

3

L

O

/

A

3

0

O

N

24VAC

#1

32K

8K

COMM

RELAY

OUTPUT

T

COM

1-3

SHLD

OUT

R

1

OUT

RAM EPROM

485

LD4

2

COMM

OUT

3

REC.

OUT

OUT

4

OUT

5

COM

CPU

4-5

4-5

COMM

12V

TEST

ADDRESS ADD

AIN

1

AIN

2

AIN

3

EWDOG

AIN

4

AIN

5

GND

GND

0-5

VDC

AOUT

PWR

PRESSURE

GND

SENSOR

YS101564

0-1

VDC

24VAC

#1

32K

8K

COMM

RELAY

OUTPUT

T

COM

1-3

SHLD

OUT

R

1

OUT

RAM EPROM

485

LD4

2

COMM

OUT

3

REC.

OUT

OUT

4

OUT

5

COM

CPU

4-5

4-5

COMM

12V

TEST

ADDRESS ADD

AIN

1

AIN

2

AIN

3

EWDOG

AIN

4

AIN

5

GND

GND

0-5

VDC

AOUT

PWR

PRESSURE

GND

SENSOR

YS101564

0-1

VDC

24VAC

WHP Loop

Controller

C21

1

U3

D

3

CX1

X

CX2

U2

RN1

C

CX4

1

U1

U4

1

2

G

Y

4

L

N

V

TB1

COMM

T

SHLD

R

CX5

LD6

COMM

LD7

PWR

LD8

LED1

LD9

LED2

R1

U7

RV1

VREFADJ

INPUTS

+VDC

AIN1

AIN2

AIN3

AIN4

AIN5

GND

GND

AOUT1

AOUT2

AIN7

GND

PJ1

TB3

PRESSURE

SENSOR

V1

R

A

D

C

2

D

V2

V3

2

Y

L

R

COM1-3

3

D

U5

PAL

R1

RS-485

1

EPROM

RAM

R2

COMM

3

Y

TUC-5RPLUS

1

L

HH

R

R3

(1MEG)

4

YS101816REV.2

2

U6

D

3

N

YS101790

4RLYIOBD.

R4

N

R

R

C1

R5

P1

4

COM4-5

Y

L

R

+VREF

TB2

CX6

5

5.11V

D

TESTPOINT

2

V4

C

S

IP

EWDOG

1

IL

X

V5

H

P

5

R28

Y

L

3

R

C

1

ADD

ADDRESS

U8

1

4

4RLYIOBD.

N

2

R

RN5

4

NE5090NPB3192

8

PU1

X

0PS

8

C

U9

D6

16

PU2

32

D7

TOKEN

PU3

NETWORK

D8

SW1

PU4

D9

PU5

D11

C

C

C10

PU7

-1

-5

D

D

0

0

V

V

JP1

D14

C12

U13

CX13

D15

C17

U15

C20

CX15

R26

3

2

J

J

P

P

EXPANSION

AIN1

CX10

C7

AIN2

R6

AIN3

0

7

1

U10

R

D

AIN4

0

3

1

1

L1

C9

R

D

GND

CX12

1

1

1

D12

C

1

1

X2

AOUT1

9936

1

R13

R

U

MC34064A

SC1

C13

R15

U12

CX14

C14

C16

R19

U14

TB4

C15

D19

GND

R22

7

2

6

R24

R

R

1

E

D

8

7

6

R25

1

1

W

V

9

8

D

D

O

1

1

P

C

C

7824CT

24VAC

M

VR1

VR2

T'STAT

3.) The Local Loop With The Loop Controller

Installed Can Only Have Up To 29

WHP Controllers Attached As The WHP

Loop Controller Occupies Address #30.

4.) Systems may consist of up to 20 Local

Loops (600 WHP Controllers). Consult

factory for systems that exceed these quantities.

4ANALOGIN MOD I/O BD.

YS101784

COMM

T

SHLD

R

LD4

YS101790

REC.

12V

AIN

1

AIN

2

AIN

3

AIN

4

AIN

5

GND

GND

AOUT

PRESSURE

SENSOR

#1

RAM EPROM

485

COMM

CPU

ADDRESS ADD

EWDOG

YS101564

32K

8K

RELAY

OUTPUT

COM

1-3

OUT

1

OUT

2

OUT

3

OUT

OUT

4

OUT

5

COM

4-5

4-5

COMM

TEST

0-5

VDC

PWR

GND

0-1

VDC

24VAC

See Note #3

Dirty Filter Alarm

Loop #1

WHP

Controllers

Loop #2

WHP

Controllers

Loop #3

WHP

Controllers

Loop #4

WHP

Controllers

Local Loop

RS-485

9600 Baud

#30

32K

8K

COMM

RELAY

OUTPUT

T

COM

1-3

SHLD

OUT

R

1

OUT

RAM EPROM

485

LD4

2

COMM

OUT

3

REC.

OUT

OUT

4

OUT

5

COM

CPU

4-5

4-5

COMM

12V

TEST

ADDRESS ADD

AIN

1

AIN

2

AIN

3

EWDOG

AIN

4

AIN

5

GND

GND

0-5

VDC

AOUT

PWR

PRESSURE

GND

SENSOR

YS101564

0-1

VDC

24VAC

#30

32K

8K

COMM

RELAY

OUTPUT

T

COM

1-3

SHLD

OUT

R

1

OUT

RAM EPROM

485

LD4

2

COMM

OUT

3

REC.

OUT

OUT

4

OUT

5

COM

CPU

4-5

4-5

COMM

12V

TEST

ADDRESS ADD

AIN

1

AIN

2

AIN

3

EWDOG

AIN

4

AIN

5

GND

GND

0-5

VDC

AOUT

PWR

PRESSURE

GND

SENSOR

YS101564

0-1

VDC

24VAC

#30

32K

8K

COMM

RELAY

OUTPUT

T

COM

1-3

SHLD

OUT

R

1

OUT

RAM EPROM

485

LD4

2

COMM

OUT

3

REC.

OUT

OUT

4

OUT

5

COM

CPU

4-5

4-5

COMM

12V

TEST

ADDRESS ADD

AIN

1

AIN

2

AIN

3

EWDOG

AIN

4

AIN

5

GND

GND

0-5

VDC

AOUT

PWR

PRESSURE

GND

SENSOR

YS101564

0-1

VDC

24VAC

#29

32K

8K

COMM

RELAY

OUTPUT

T

COM

1-3

SHLD

OUT

R

1

OUT

RAM EPROM

485

LD4

2

COMM

OUT

3

REC.

OUT

OUT

4

OUT

5

COM

CPU

4-5

4-5

COMM

12V

TEST

ADDRESS ADD

AIN

1

AIN

2

AIN

3

EWDOG

AIN

4

AIN

5

GND

GND

0-5

VDC

AOUT

PWR

PRESSURE

GND

SENSOR

YS101564

0-1

VDC

24VAC

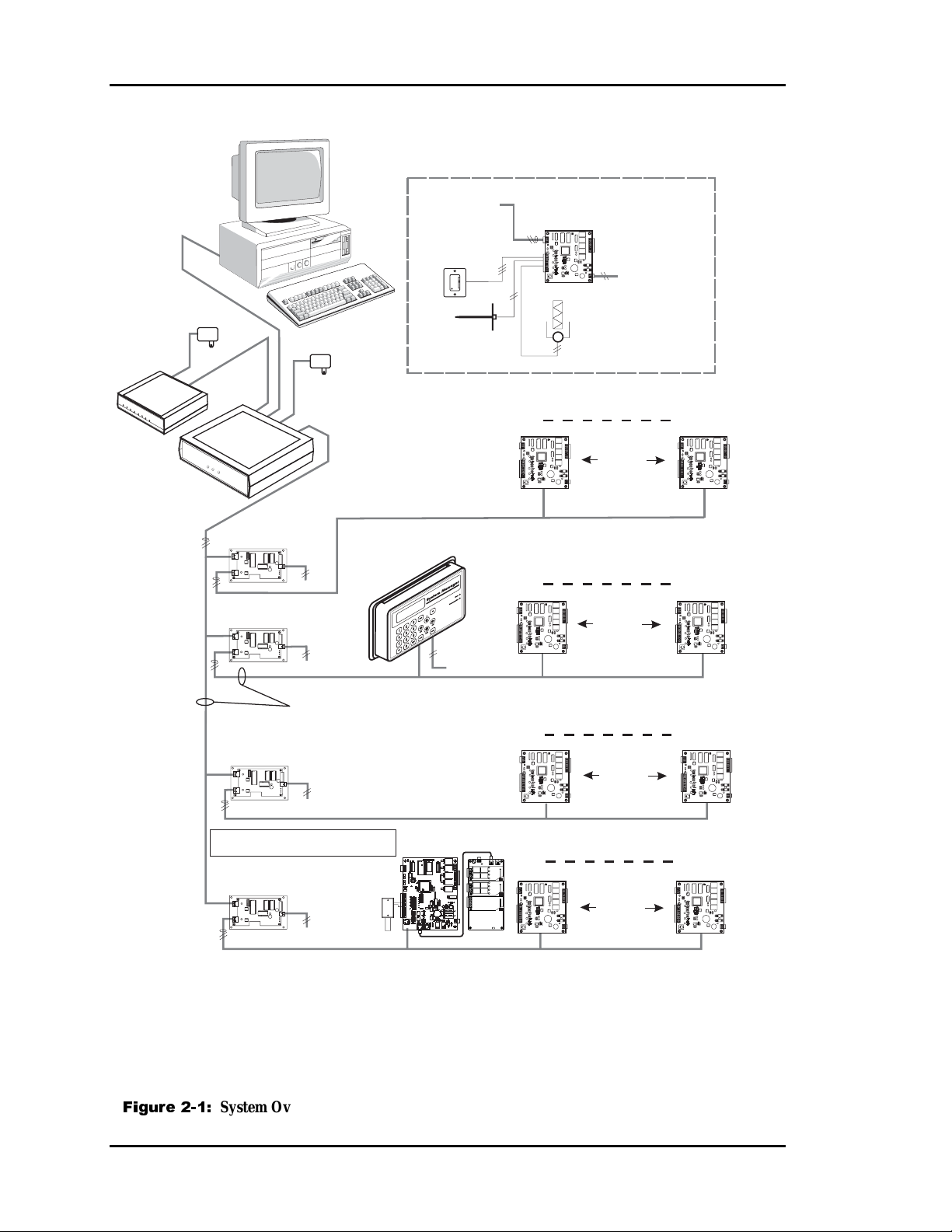

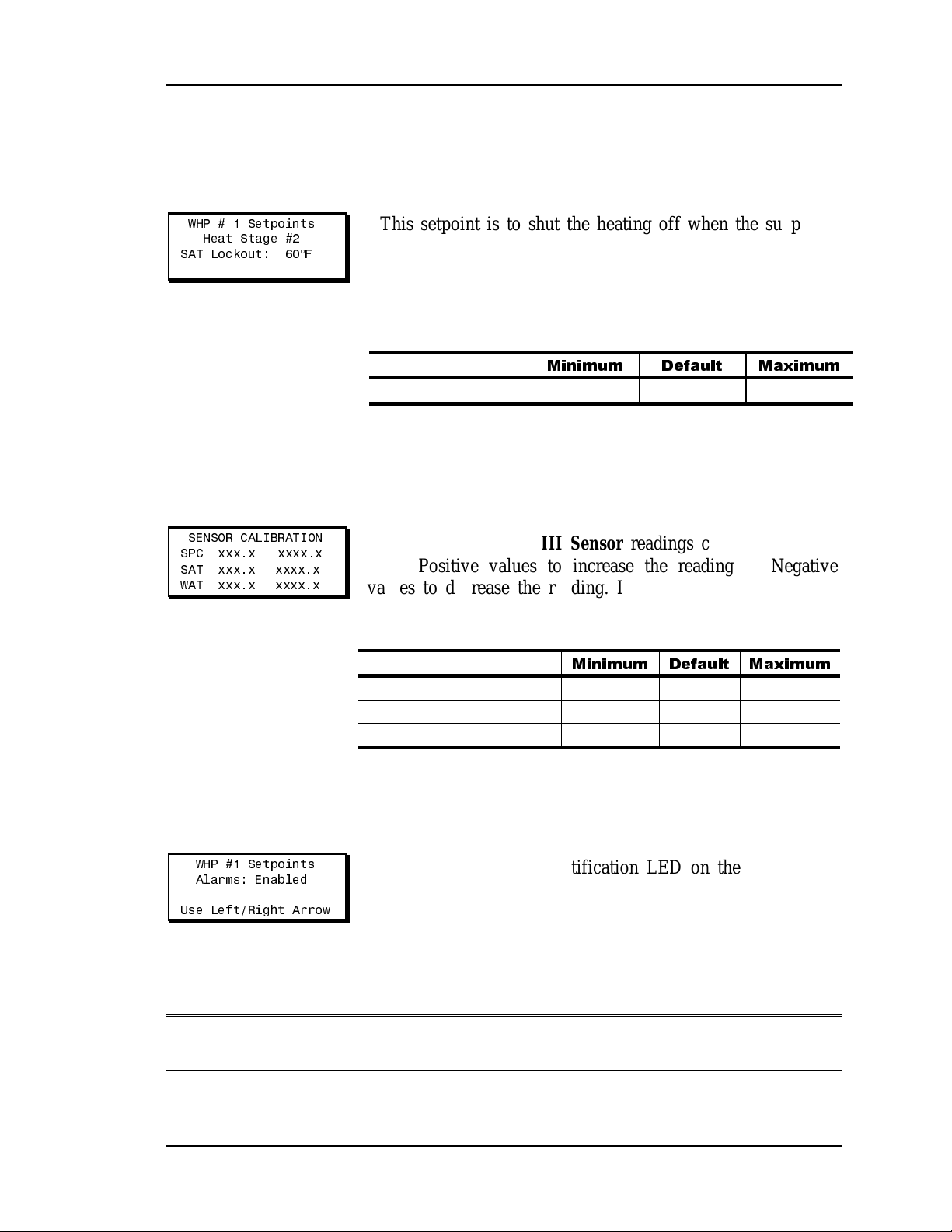

Figure 2-1:

System Overview

2-2 Installation and Wiring

Page 27

WattMaster WHP Section 2

Communications Loops

The Communications Loop is two wire shielded RS-485. The loop is best connected in

daisy chain configuration, meaning the loop is connected from one controller to another.

It is not necessary to sequentially address the WHP Controllers in relation to their

location on the loop. Cable must be Belden No. 82760 or equivalent.

Tip: Incorrect wiring of the communications loop is the most common mistake made

during installation. Before beginning installation, write down the wire color used

on each terminal connection and consistently maintain that color code. It is

recommended that a continuous wire run be made between devices. Anytime a

splice is made in the cable you increase your chance of problems.

Caution: Make sure when you are inserting wires into the terminal blocks that

strands of wire do not stick out and touch the next terminal. This could

cause a short or erratic operation.

Installation and Wiring 2-3

Page 28

Section 2 WattMaster WHP

STANDARD WALL MOUNT

120/24 VAC POWER SUPPLY

( MAY ALSO BE POWERED FROM 2 4VAC )

(NETWORK TERMINAL S ONLY)

Y

SYSTEM MANAGER POWER SUPPLY

GND

24VAC

POWER

LOOP

A

A

4

T

3

A

4

Y

CPU

A

A

4

T

3

A

4

Y

CPU

A

A

A

A

Y

4

4

4

2

4

V

A

C

G

N

D

U6

C1

U2

U3

U4

V1V2V3V5V4

L1

R6

C9

6

M

U8

U9

C7

CX10

CX12

CX14

CX13

X2

INPUTS

+

A

A

A

A

A

RS-485

S

COMM

COMM

U1

COMM

LED1

LED2

R1

U7

VREF ADJ

TEST POINT

C

C

CX15

Communications Loop Wiring Overview

03/31/04 03:38P M WED

OCCUPIED

COMPUTER

(OPTIONAL)

NO ALARMS

SYSTEM MANAGER

(SET TO MULTIPLE LOOP)

COMMUNICATIONS

T

SHLD

R

RS-485

COMM LINK II

INTERFACE

UNIT COMES WITH

S101716 REV. 1

Remote Link

(OPTIONAL)

2K

COMM

T

SHLD

R

LD4

REC.

12V

IN

1

AIN

2

AIN

3

AIN

4

AIN

5

GND

GND

OUT

PRESSURE

SENSOR

COMM

T

SHLD

R

LD4

REC.

12V

IN

1

AIN

2

AIN

3

AIN

4

AIN

5

GND

GND

OUT

PRESSURE

SENSOR

NETWORK

T

C21

CX1

RN1

1

TB1

T

HLD

R

CX5

U5

LD6

LD7

1

PWR

LD8

RN3

LD9

P1

+VREF

5.11V

EWDOG

RV1

R28

VDC

RN5

IN1

IN2

IN3

IN4

IN5

C10

GND

GND

C12

AOUT1

AOUT2

AIN7

D15

C17

GND

PJ1

TB3

C20

R26

PRESSURE

SENSOR

GND

24VAC

R

SH

T

R

SH

EXPANSION

D1

CX2

CX3

CX4

RLY1

D2D3D4D5

RLY2RLY3RLY4RLY5

OM1-3

PAL

R1

1

EPROM

RAM

HH

PHILIPS

ADD

ADDRESS

1

2

4

PU1

8

D6

16

PU2

32

D7

TOKEN

PU3

NETWORK

D8

SW1

PU4

D9

PU5

D11

PU7

0-5

0-1

VDC

VDC

D14

JP1

U13

U15

PJ3

PJ2

R2

TUC-5R PLUS

R3

(1 MEG)

YS101816 REV. 2

R4

RN2

R5

OM4-5

TB2

CX6

C2

X1

C3

1

RN4

NE5090NPB3192

0PS

CX8

U10

R7

D10

R10

D13

D12

C11

993

R13

R11

U11

MC34064A

SC1

C13

R15

U12

C14

C16

R19

U14

C15

R22

R24

R25

TB4

D19

GND

R27

D16

V6

D18

D17

POWER

C19

C18

7824CT

24VAC

VR1

VR2

T'STAT

RLY IO BD.

RLY IO BD.

IN1

IN2

IN3

IN4

GND

AOUT1

YS101790

YS101790

ANALOG IN MOD I/O BD.

S101784

TO OTHER MINILINKS

Figure 2-2:

Communication Loop Wiring, Daisy-Chain Configuration

8K

RELAY

OUTPUT

COM

1-3

OUT

1

RAM EPROM

85

COMM

DDRESS AD D

EWDOG

S101564

RAM EPROM

85

COMM

DDRESS ADD

EWDOG

S101564

OUT

2

OUT

3

OUT

OUT

4

OUT

5

COM

4-5

-5

COMM

EST

0-5

VDC

PWR

GND

0-1

VDC

24VAC

2K

8K

RELAY

OUTPUT

COM

1-3

OUT

1

OUT

2

OUT

3

OUT

OUT

4

OUT

5

COM

4-5

-5

COMM

EST

0-5

VDC

PWR

GND

0-1

VDC

24VAC

TO OTHER WHP CONTROLLERS

2-4 Installation and Wiring

Page 29

WattMaster WHP Section 2

The daisy chain is the best method for running a communications loop since there is only

one starting point and one ending point for each of the communications loops. Even

though the daisy chain configuration is preferred, the star configuration can also be used.

If required, a combination of the two can also be used. Remember, the best

communication loop wiring is the one which utilizes the minimum number of ends while

using the shortest wiring path.

Note: The loop does not have to follow the controller address sequence.

Caution: If the comm loop is not installed in conduit, be careful to position the

cable away from high noise devices like fluorescent lights, transformers,

VFD’s, etc. Conduit is not required for comm loop wiring unless

required by local codes.

Make sure CommLink jumper is set for “Multi”.

Installation and Wiring 2-5

Page 30

Section 2 WattMaster WHP

RLY1D1D

2D3D4D5CX

3

C3C

2

R11U1

1

D13

6

M

R10

CX8U9X1R7D10

RN4

R

N

2

R

LY2RLY3RLY4RLY5

6.2’’

WHP Loop Controller Expansion Board

WHP Loop Controller Main Board

.20 Dia.

W

V

A

J

V

T

T

A

/

V

Y

V

J

V

T

V

X

X

V

Y

T

V

X

X

JO3JO4JO2J

A

T

A

A

A

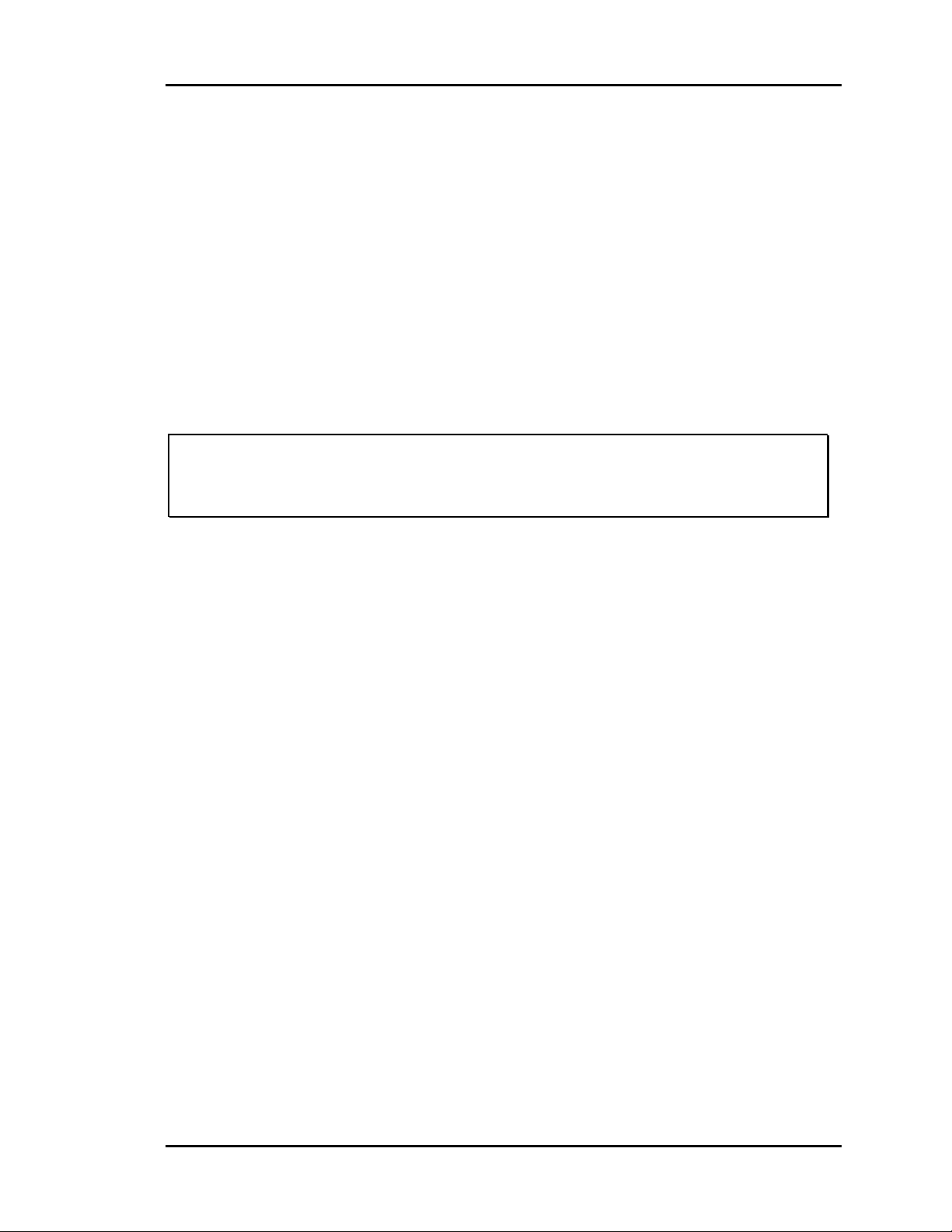

WHP Loop Controller

The WHP Loop Controller may be installed in any convenient protected location. It is

recommended that the loop controller be mounted indoors in a secure location, that is not

subject to extremes in temperature or moisture.

Typ. of 4

7.3”

TB1

COMM

T

SHLD

R

LD6

COMM

LD7

PWR

LD8

LED1

LD9

LED2

R1

U7

INPUTS

+VDC

AIN1

AIN2

AIN3

AIN4

AIN5

GND

GND

AOUT1

AOUT2

AIN7

GND

PJ1

TB3

PRESSURE

SENSOR

C21

RN1

1

CX5

1

RN3

+VREF

TEST POINT

RV1

VREF ADJ

RN5

C10

C17

EXPANSION

CX1

U1

U5

RS-485

COMM

HH

C1

P1

5.11V

EWDOG

R28

ADDRESS

PU1

D6

PU2

D7

PU3

D8

PU4

D9

PU5

D11

PU7

D14

C12

U13

D15

C20

R26

PJ2

U3

CX2

U2

RAM

YS101816 REV. 2

U6

PHILIPS

ADD

1

2

4

8

16

32

TOKEN

NETWORK

SW1

X2

0-5

0-1

VDC

VDC

JP1

R15

C14

R19

CX13

U15

C15

R22

R24

R25

CX15

PJ3

EPROM

TUC-5R PLUS

U10

C11

U14

CX10

U12

CX14

D17

T'STAT

6.7”

(1 MEG)

CX4

U4

PAL

1

CX6

1

C7

CX12

D18

L1

D12

R13

SC1

D19

C19

C18

7824CT

VR1

VR2

D16

COM1-3

COM4-5

NE5090NPB3192

0PS

R6

R27

V6

C9

993

R1

R2

R3

R4

R5

U8

MC34064A

C13

C16

GND

POWER

24VAC

V1

V2

V3

TB2

V4

V5

9.5”

6.6”

TB4

B

1

B

1

B

1

R

8

C

8

R20

1K1

4

4RLY IO BD.

1K1

4

4RLY IO BD.

IN1

IN2

IN3

AIN4

GND

OUT1

R10

T

C

4

2

8

7

S

1

0

1

7

8

2

2.12”

T

T

B

B

2

1

+

G

G

2

2

N

4

N

4

D

D

P

D

L

C

D

C

-

P

1

I

R

-

N

O

2

K

U

2

UL

5A250VAC

5A250VAC

UL

CONTACT:

CONTACT:

24VDC

24VDC

G5L-114P-PS

G5L-114P-PS

OMRON

OMRON

UL

UL

5A250VAC

5A250VAC

CONTACT:

CONTACT:

24VDC

24VDC

G5L-114P-PS

G5L-114P-PS

OMRON

OMRON

K

K

4

3

YS101790

K

2

UL

5A250VAC

5A250VAC

UL

CONTACT:

CONTACT:

24VDC

24VDC

G5L-114P-PS

G5L-114P-PS

OMRON

OMRON

UL

UL

5A250VAC

5A250VAC

CONTACT:

CONTACT:

24VDC

24VDC

G5L-114P-PS

G5L-114P-PS

OMRON

OMRON

K

K

4

3

S101790

PU1

O1

R5

C2

R1

PU2

R6

R7

R8

R9

D5

S

L

O

M

O

D

U

L

R

I

O

B

D

.

D1

C3

R2

PU3

D2

C4

R3

PU4

D3

C5

R4

C1

D4

C

U

Q

X

2

LM358

2

1

C

7

4

K1

K2

K3

RN1

K4

K1

K2

K3

RN1

K4

4 ANALOG IN MOD. I/O BD.

YS101784

R

9

R

R

1

1

6

R

1

8

C

1

P

1

ULN2803A/

PHILIPS

T L

HA

AN

I D

U1

C

74HC04N

2

U2

PCF8574P

CX3

U

3

C

1

P

1

ULN2803A/

PHILIPS

T L

HA

AN

I D

U1

C

74HC04N

2

U2

PCF8574P

CX1

P

C

F

8

5

9

1

P

R10

R11

R12

8.29”

CX3

U

3

P

1

U1

T L

HA

PHILIPS

AN

I D

P

4

P

4

8.96”

0.28”

4.24”

4.0”

Figure 2-3:

WHP Loop Controller

2-6 Installation and Wiring

Page 31

WattMaster WHP Section 2

R (24 VAC By Others)

WHP Loop Controller Expansion Board

WHP Loop Controller Expansion Board

R10

R11

Fire Alarm Contact (N.C.)(See Note 5)

4.)When a Water Pressure Transmitter

Required VA For T ransformer

A

A

A

A

A

Y

4

4

4

2

4

V

A

C

G

N

D

24 VAC

24 VAC

Heating/Cooling #4

Heating/Cooling #4

Heating/Cooling #3

Heating/Cooling #3

Heating/Cooling #2

Heating/Cooling #2

Heating/Cooling #1

Heating/Cooling #1

RLY1D1D2D3D4D5CX3

E

C3C

2

PHILIPS

C

PALC

T

Y

T

N

A

GND

24VAC

L

D16

R6C9S

R11U1

1

D13

C

6

V

M

T

C

R10

V

C18

N

U

CX8U9X1R7D10

R13D

U

U12U

PJ3

EXPANSION

R

R

R

C15R19R15C

D18D1

7

0-5VDC0-1VD

C

C11

RN4

1

RN3

RN2

1

RLY2RLY3RLY4RLY

5

(

Return Water

Temp Sensor

See Note 4

Optional Pressure

Transmitter

Manual

Reset

Pump VFD

Optional

Modulating Heat

Notes:

1.)24 VAC Must Be Connected So

2.)All Wiring To Be In Accordance

3.)All Communication Wiring To Be

Connect T o Next WHP Controller

And/Or MiniLink On Local Loop

Local Loop RS-4 85

9600 Baud

Outside Ai r

Temp. Sensor

Supply Water

Temp Sensor

Proof of

Flow

Phase

Loss

+

+

That All Ground Wires Remain

Common.

With Local And National Electrical

Codes And Specifications.

2 Conductor Twisted Pair With

Shield. Use Belden #82760 Or

Equivalent.

TB1

COMM

T

SHLD

R

LD6

COMM

LD7

PWR

LD8

LED1

LD9

LED2

R1

INPUTS

+VDC

AIN1

AIN2

AIN3

AIN4

AIN5

GND

GND

AOUT1

AOUT2

AIN7

GND

PJ1

TB3

PRESSURE

SENSOR

CX5

U7

RV1

VREF ADJ

C21

RN1

1

1

+VREF

TEST POINT

CX1

CX2

U2

U1

U5

RS-485

RAM

COMM

HH

U6

C1

P1

5.11V

EWDOG

R28

ADD

DDRESS

1

RN5

C10

C12

C17

R26

2

4

PU1

8

D6

16

PU2

32

D7

TOKEN

ETWORK

PU3

SW1

PU4

D9

PU5

D11

PU7

D14

JP1

U13

14

CX13

D15

U15

C20

CX15

PJ2

Request to Run Contact (N.O.)

X2

22

24

25

U3

PROM

UC-5R PLUS

S101816 RE V. 2

10

14

T'STAT

X4

U4

1 MEG)

X6

CX10

C7

CX12

CX14

1

12

C1

D19

C19

7824CT

R1

R2

N.C. Pilot Duty Relays

COM1-3

R1

R2

R3

R4

R5

COM4-5

8

E5090NPB3192

0PS

993

R27

V6

(By Others)

V1

V2

V3

R1

Compressor Enable

R2

Main Pump

R3

B2

V4

V5

N.C. Pilot Duty Relays

(By Others)

Standby Pump

Alarm Indicator

MC34064A

13

16

Loop Controller = 8VA Min.

B4

GND

POWER

24VAC

Line Voltage

See Note 1

R4

R5

R6

R7

RLY IO BD.

YS101790

R8

R9

YS101790

RLY IO BD.

IN1

IN2

IN3

IN4

GND

OUT1

Relay Contacts

(By Others)

ANALOG IN MOD I/O BD.

S101784

Is Used, a 250 Ohm Resistor is

Installed Between AIN3 & GND and

The Pull Up Resistor PU3 is

Removed.

5.)If a Fire Alarm Contact is Not

Connected to AIN1 on The Analog

Expansion Board, Then a Jumper

Must Installed Between AIN1 and