Page 1

INSTALLATION

INSTRUCTIONS

SMALL DUCT HIGH VELOCITY:

Duct Layout

Heat Controller, Inc. • 1900 Wellworth Ave. • Jackson, MI 49203 • (517)787-2100 • www.heatcontroller.com

Page 2

Bulletin 100-135 / August 2010

Installation Guide

This instruction is a summary of the basic rules and applies to most applications.

Duct Layout

Outlets

7 two inch outlets Per Ton / 5 two and a half inch outlets Per Ton (3.5 kW). For refrigerant cooling applications the

airflow must be between 200 and 250 CFM per nominal ton [27 to 33 L/s per nominal cooling kW]. For hot water or chilled

water systems, refer to performance charts for determine the required airflow. The allowable airflow range per 2 inch outlet

is 20 to 40 CFM [9.4 and 19 L/s] and 25 to 55 CFM [11.8 and 23.75 L/s], where the typical ou tlet will deliv er 35 CFM [17

L/s] if the plenum static pressure is 1.5 inches [0.37 kPa] and the branch duct length is 10-foot (3 meter) without any

balancing orifices. Therefore, the average project will require about 7 2 inch outlets or 5 two and a half inch outlets per

nominal ton although more will be needed if the branch ducts are longer, balancing orifices are used, the plenum static

pressure is less than 1.5 inches of water [0.37 kPa], or it is desirable to make the system as quiet as possible. For example,

two runs with 50% balancing orifices are equal to one branch run without any orifices.

10% Rule. For supply ducts longer than 10 feet (3 meter), the air is reduced in that run by 10% for every 5 feet over 10

(every 1.5 meter over 3 meters). For example, a 30 foot [9 meter] run is 60% of an outlet that is 10 foot [3 m] yielding a

reduction of 40% (30-10=20, 20

Consider Traffic Pattern. Place outlets out of traffic pattern. A corner, 5-inch [127 mm] from each wall, is a good location,

or along walls, or in soffits blowing horizontally. Consider floor outlets (with screens) for units located in basement. Slotted

outlets can be used for high wall locations or in ceilings where there is insufficient room for bending tubing.

Allow for Aspiration. Locate outlets so the air stream does not impinge on any objects or people — at least 3 feet [1 m]

away. Use outlet deflectors and outlet balancing orifices sparingly as they disrupt the aspiration.

Minimize Length, Minimize Restriction. Keep the supply duct length as close to 10 feet [3 m] as possible and never less

than 6 feet [1.8 meters]. Use the fewest number of bends as possible. Maximize the radius of any bends making sure the

bend in the sound attenuator tubing near the outlet is at least 6-inch [152 mm].

Plenum

Maximize Length, Minimize Restriction. Run main trunk (plenum) as long as possible; it is better to lengthen the plenum

if you can shorten even two outlet runs. Use full flow tees with turning vanes (when applicable) and full flow elbows. The

maximum total plenum length is 150 ft [45 m]; consider the first tee equal to 30 ft [9 m] and elbows equal to 15 ft [4.6 m].

60/40 Rule. When using a tee split the flow as close to 50/50 as possible — no more than 60/40. Always use a turning vane.

70/30 Rule. Turn the tee 90° to make a side branch with no more than 30 percent of the air. Do not use a turning vane

Horseshoe Patterns. (Best Method). Use a tee at least 24 inches [610 mm] off unit. For the 4860 unit, use 10-inch [254

mm] metal up to and including tee; then use 9-inch [229 mm] both directions. For the 3642 unit, use 9-inch [229 mm]

insulated metal up to and including tee; then use 7-inch [178 mm] both directions. If possible, close the horseshoe into a

perimeter loop.

5=4, 410=40%).

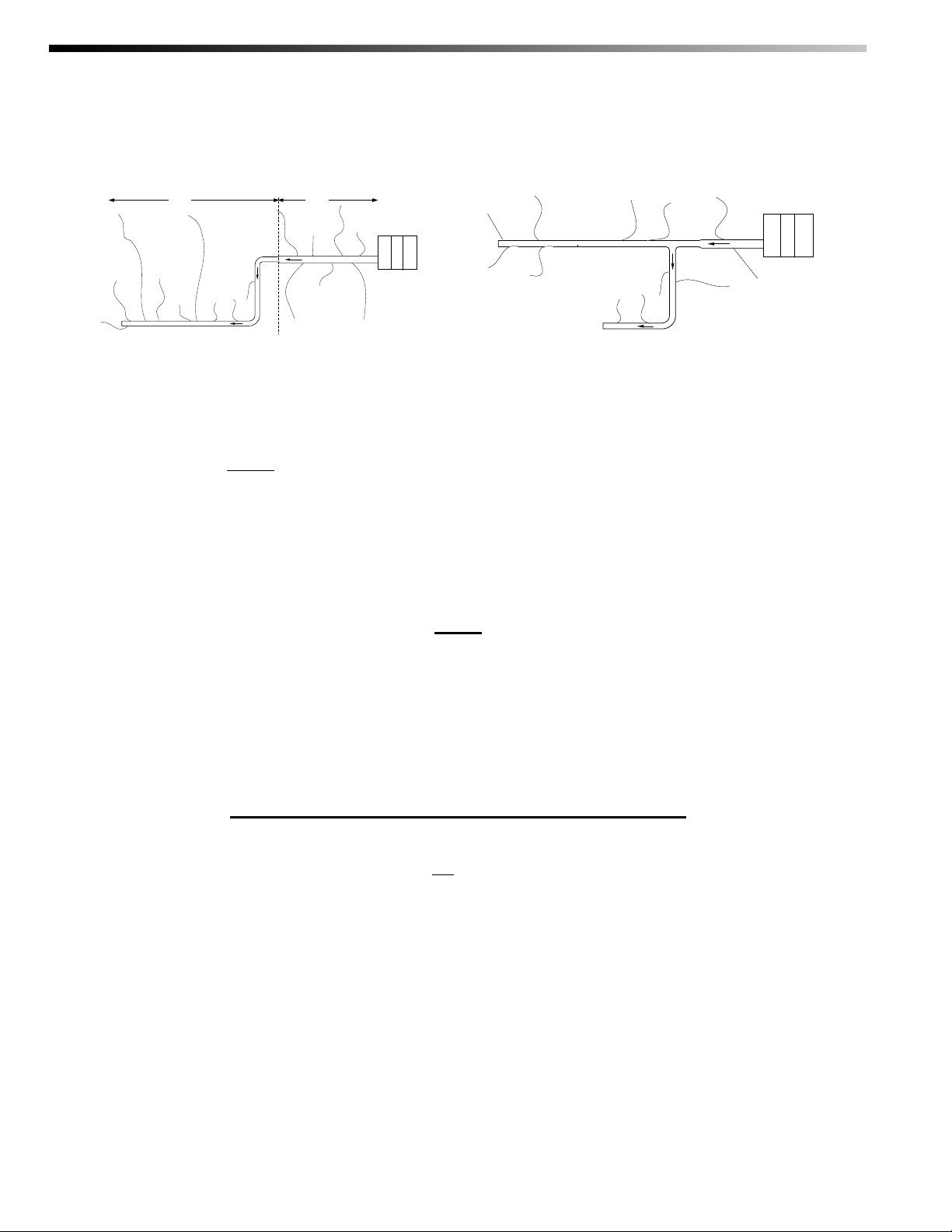

PERIMETER LOOP SYSTEM

DOGLEG SYSTEM

Note — Specifications, Ratings, and Dimensions are subject to change without notice. Copyright© 2010 Heat Controller, Inc.

IL00121.CVS

IL00123.CVS

HORSESHOE SYSTEM

'H' SYSTEM

IL00122.CVS

IL00125.CVS

Page 3

Bulletin 100-135 — Page 2

V

Plenum (cont.)

Shotgun Pattern. For the SDAH48 and SDAH60 series units, use 10-inch [254 mm] insulated metal duct for the first 30

percent; then reduce to 9-inch [229 mm] if desired. For the SDAH36 unit, use 9-inch [229 mm] insulated metal duct for the

first 40 percent; then reduce to 7-inch [178 mm] if desired. For the SDAH24 unit, 7-inch [178 mm] may be run the entire

length.

40 %60 %

9-INCHDIA.

7-INCHDIA.

24-inch (610 mm) Rule. Use at least 24-inch [610 mm] of straight plenum before any fitting, such as an elbow, tee, or

IL00124.CN

30% MAX.

IL00126.CNV

takeoff. Electric duct heaters require 48 inches [1.2 m]. Avoid elbows directly off units.

Space Takeoffs Evenly. Maintain distance between takeoffs as evenly as possible. Space the takeoffs at least 6-inch [152

mm] apart and 12-inch [305 mm] from end cap.

Sound

Sound Attenuators. Always use at least 3 feet [1 m] of the Heat Controller supplied sound attenuator supply tubing (SD-

26C or SD-226C) at the end of each run. For runs up to 12 feet [3658 mm], you may use the sound attenuator for the entire

run. For greater lengths, use the aluminum core supply tubing (SD-25 or SD-225) with a 3 foot [1 m] sound attenuator at the

end.

Return Air Duct Attenuation. Use the Heat Controller Return Air Duct (SD-04) sheet metal with acoustical duct liner.

Never use flex duct with a solid plastic liner in place of SD-04.

Isolation. Isolate the air handler with foam rubber strips under the unit. Either hang the unit from the structure using angle

iron framework under unit (do not hang directly with hooks in the cabinet) or set on a platform.

Piping

Secondary Drain Pan. Always use a secondary drain pan wherever overflow of condensate can cause water damage. Do

not trap secondary drain line or connect to primary drainpipe. Place secondary drain line exit so that it is apparent when

being used. For example, pipe the drain line so it drips on an outdoor windowsill and causes splashing to be noticed.

Primary Drain. Always trap primary drain line and run drain line per local plumbing codes.

Refrigerant Lines. Follow outdoor section manufacturer's instructions for running refrigerant lines. Size and trap per their

instructions.

Check Total System Airflow. Check the airflow at each outlet with a Turbometer centered over the outlet. Add up the cfm

for all outlets – it should not differ by +/- 5% from the design airflow.

STARTUP — DO THIS BEFORE BOXING-IN THE DUCT WORK.

Check Static Pressure (optional). Measure the external static pressure in plenum 2 feet [610 mm] from unit and before any

fitting. Set as close as possible to 1.5 inches of water [0.37 kPa] or less, but no less than 1.0 IWC [0.25 kPa] or greater than

1.8 IWC [0.48 kPa], by providing a dequate number of full

Check Amperage. Measure the amperage and voltage of the motor. Verify that it matches within +/- 5% of the values for

the desired (design) cfm in the installation manual or the motor amperage table shipped with each air handler. Also, use a

Turbometer

®

to measure airflow from each outlet. If the total airflow measured by the Turbometer at the outlets is

outlets and minimum plenum fittings (full flow).

significantly less than airflow determined by motor amperage, check for system air leaks.

Check for Full Flow. Inspect each outlet for full flow (except where balancing orifices or used or for long branch ducts).

Investigate for blockage or kinks if flow is insu ffi ci ent.

Check Refrigerant Charge. Charge unit per outdoor manufacturer's instructions and Unico's Installation instructions. For

best results use the subcooling method during the cooling cycle. Heat pu mps should be checked in both heating and cooling.

TurboMeter® is a registered trademark of Davis Instruments

Page 4

INSTALLATION

INSTRUCTIONS

SMALL DUCT HIGH VELOCITY:

SDAH18 Air Handler

Heat Controller, Inc. • 1900 Wellworth Ave. • Jackson, MI 49203 • (517)787-2100 • www.heatcontroller.com

Page 5

Bulletin 100-150 / August 2010

INSTALLATION MANUAL

SHAH18 Air Handler

NOTICE TO INSTALLER AND EQUIPMENT OWNER: RETAIN THIS MANUAL AT THE JOB

Il0015 9.CV5

General

The information on the following pages is to help the installer save

time, provide the best possible installation and insure continuous

trouble-free operation.

Scope

These instructions apply to the Heat Controller SDAH18 fan-coil

unit. Installation instructions for the air distribution system are

covered in other bulletins. Before beginning any installation, a

detailed system layout must be done in accordance with Bulletin

100-255 System Sizing and Layout bulletin.

SUFFICIENT BUILDING INSULATION IS

ESSENTIAL FOR THE MOST ECONOMICAL

OPERATION

General Precautions and Safety Tips

Do not attempt to install or startup unit without first reading and

understanding the appropriate sections in this manual. Before

operating, be sure the unit is properly grounded.

Installation should be in accordance with all local codes and

regulations and with the National Fire Protection Association and

Underwriters Laboratories applicable standards and regulations. In

case of conflict, local codes take precedence.

All electrical wiring should be in accordance with the latest edition

of the National Electrical Code and all local codes and regulations.

Condensate piping should be installed in accordance with

governing code.

Always install a secondary drain pan when an overflow of

condensate could cause damage.

TABLE OF CONTENTS

INTRODUCTION........................................................ 1

UNPACKING .............................................................. 2

LOCATION ................................................................. 2

SECONDARY DRAIN PAN ........................................ 3

MOUNTING................................................................ 4

Horizontal Platform .............................................. 4

Horizontal Suspended ......................................... 4

Ceiling.................................................................. 4

Vertical................................................................. 5

DUCT CONNECTION ................................................ 5

Supply Plenum..................................................... 5

Return Duct.......................................................... 5

PIPING ....................................................................... 6

Condensate Lines................................................ 6

Refrigerant Lines.................................................. 7

Expansion Valve ................................................... 7

Water Connections .............................................. 7

CHARGING AND STARTUP...................................... 8

Sequence of Operation........................................ 8

Fan Speed ............................................................ 8

Checking Airflow ................................................... 9

Charging a Cooling System .................................. 9

Low Ambient Control Kit ..................................... 11

Charging a Heat Pump System .......................... 11

Mild Weather Kit ................................................. 11

APPENDIX A - Hot Water Coil Capacities ................ 12

APPENDIX B – Chilled Water Coil Capacities .......... 12

APPENDIX C - Specifications ................................... 13

Part Numbers

This manual does not always include the latest revision

letter when referring to SD part numbers. Refer to the latest

Price List and Spec Sheets for the current revision letter.

INTRODUCTION

The Heat Controller Small Duct High Velocity air handler is

a complete indoor comfort system that includes an indoor

fan coil unit and small duct system. The fan coil unit and

duct system were designed to operate together to provide

the proper airflow in every installation. The conditioned air

is supplied through a series of two-inch or 2 ½ inch

diameter ducts as a stream of air that entrains and mixes

with the room air. This process of aspiration produces a

more even temperature distribution throughout the occupied

space.

Page 6

Bulletin 100-150 — Page 2

Heating Only

Blower Cabinet

+ Hot Water Coil)

Cooling Only

Blower Cabinet

+ Cooling Coil

Horiz ontal

Flow

Vert ical

UpFlow

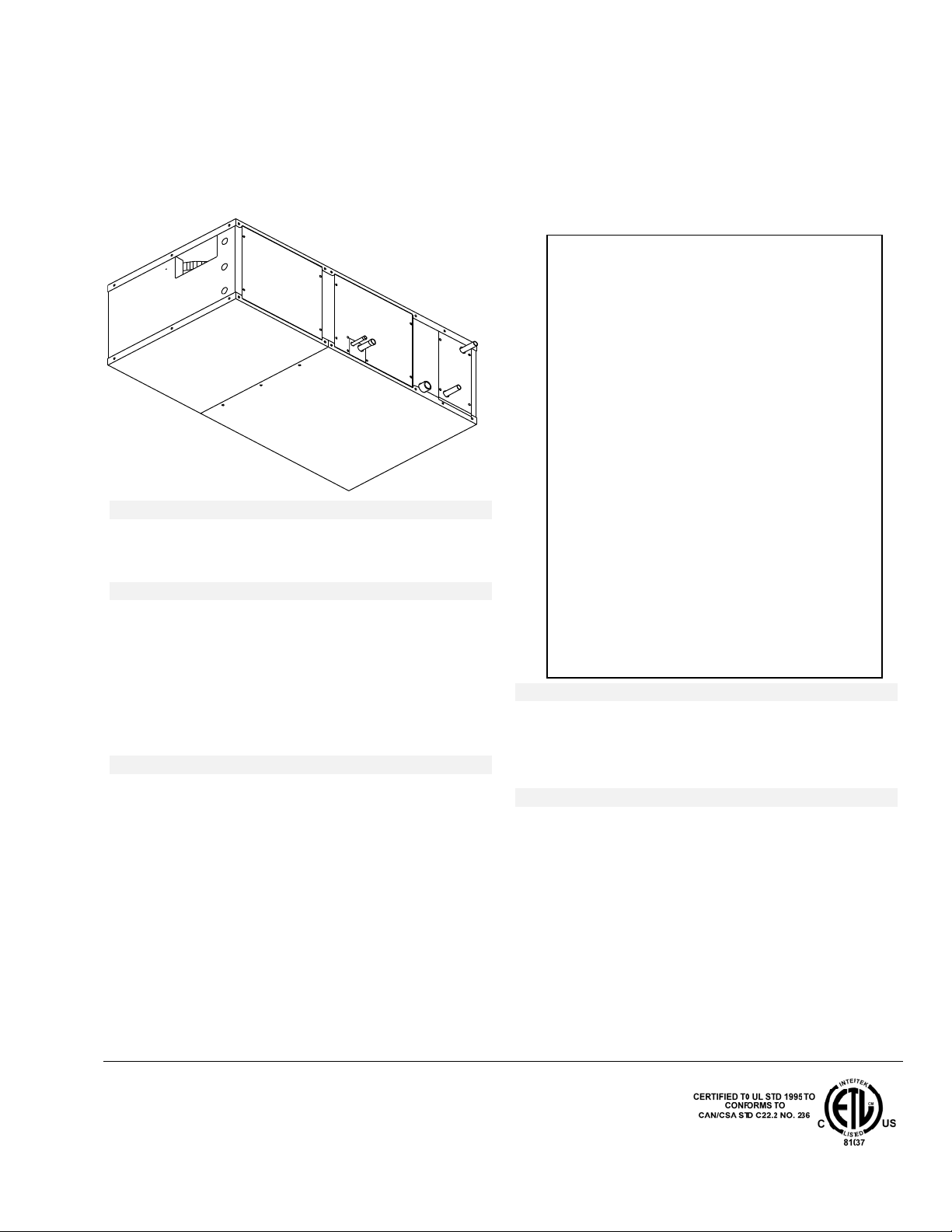

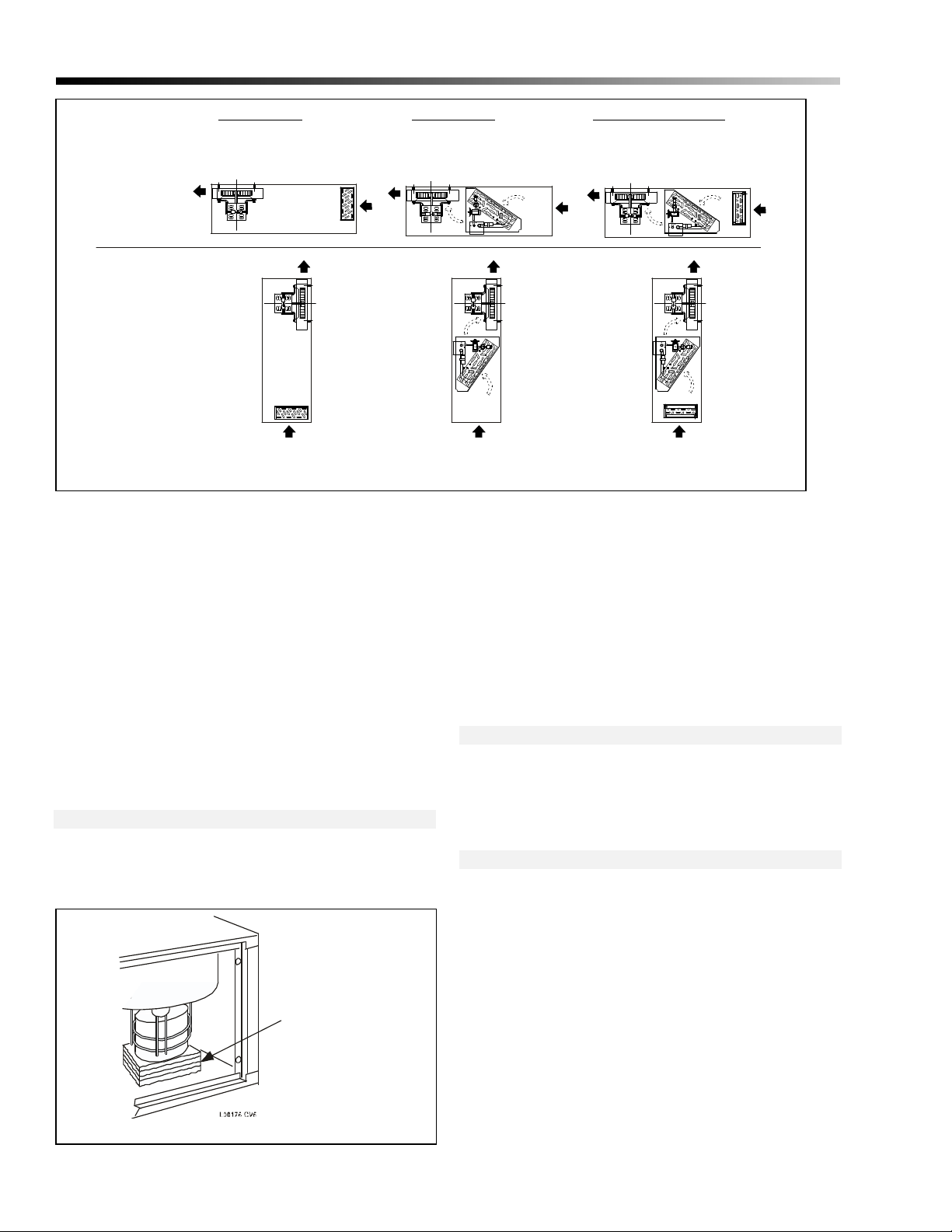

Figure 1. Unit Arrangement

The Heat Controller SDAH18 fan-coil unit is a single

packaged unit. The cooling and heating coils are contained

within the same cabinet. The unit can be mounted in a

vertical up-flow or horizontal-flow configuration. The coils

can be combined as a heating-only, cooling-only, or heating

and cooling fan coil unit. See Fig. 1.

Heating and Cooling

Blower Cabinet

+ Hot water Coil

+ Cooling Coil

OUT

IN

IL00148.CV5

Open the carton to remove the unit. Inspect unit for visible

signs of concealed damage and notify carrier of any such

damage. All materials are sold FOB Factory and it is the

responsibility of the consignee to file any claims with the

delivering carrier for materials received in a damaged

condition.

The unit is available in one size; 38-in L x 20-in W x 12-in

H (965-mm x 508 mm x 305-mm). The heating only system

includes the blower/motor and a hot water coil. The cooling

only system includes the blower/motor and a cooling coil.

For the heating and cooling system both coils are provided.

The cooling coil may be a heat pump coil or a chilled water

coil. The electrical panel is located inside of the cabinet.

UNPACKING

All units are inspected prior to shipping and are carefully

packaged in individual cartons. Inspect all cartons prior to

unpacking. Notify carrier of any damage.

CARDBOA RD

SUP PORTS

Figure 2. Location of Motor Shipping Supports

Open the blow er access panel to remov e the

motor shipping support. See Fig. 2. . The

expansion valve is shipped loose and is located in

the coil compartment near the connections.

MOUNTING

The unit ships installation ready for either horizontal or

vertical airflow applications (see Fig. 1) and may be

mounted to a structure using the optional mounting rails

(SD- 95).

LOCATION

Locate the air handler to minimize the number of plenum

elbows and fittings while keeping the supply duct runs as

short as possible. (See Bulletin 100-250, Component

Layout). The fully insulated cabinet allows installation with

zero clearance to the top, bottom, or sides of the unit.

However, clearance must be provided for servicing which is

dependent on how the unit is installed. Servicing of the

blower/motor assembly and coils can be performed in three

different ways:

1. The complete top panel, which is attached to

blower/motor assembly, can be removed. To do this,

the motor leads must be disconnected in the control

compartment.

Page 7

1 (25) Minimum

Supply plenum

1(25)Minimum

Supply Plenum

Supply plenum

All dimensions in inches (mm).

Side View

Air Flow

Air Flow

Air Flow

18 (457) bottom

clearance for

Top View

24(610) side

clearance for service

Suspended Installation

Side View

service

12

Return Duct

"

38

"

Return Duct

20

"

38

"

12

Return Duct

"

38

"

IL00149.CV5

Figure 3. Minimum Clearances

2. For side access remove the control panel, cooling coil

panel, or heating panel which are located on the same

side as the refrigerant, drain, and water connections.

3. Where the unit is suspended or mounted on the wall

using the mounting rails, the panel below the

blower/motor assembly can be removed for servicing.

In this case access to the coils must be from the side

access panels. See Fig. 3.

Bulletin 100-150 — Page 3

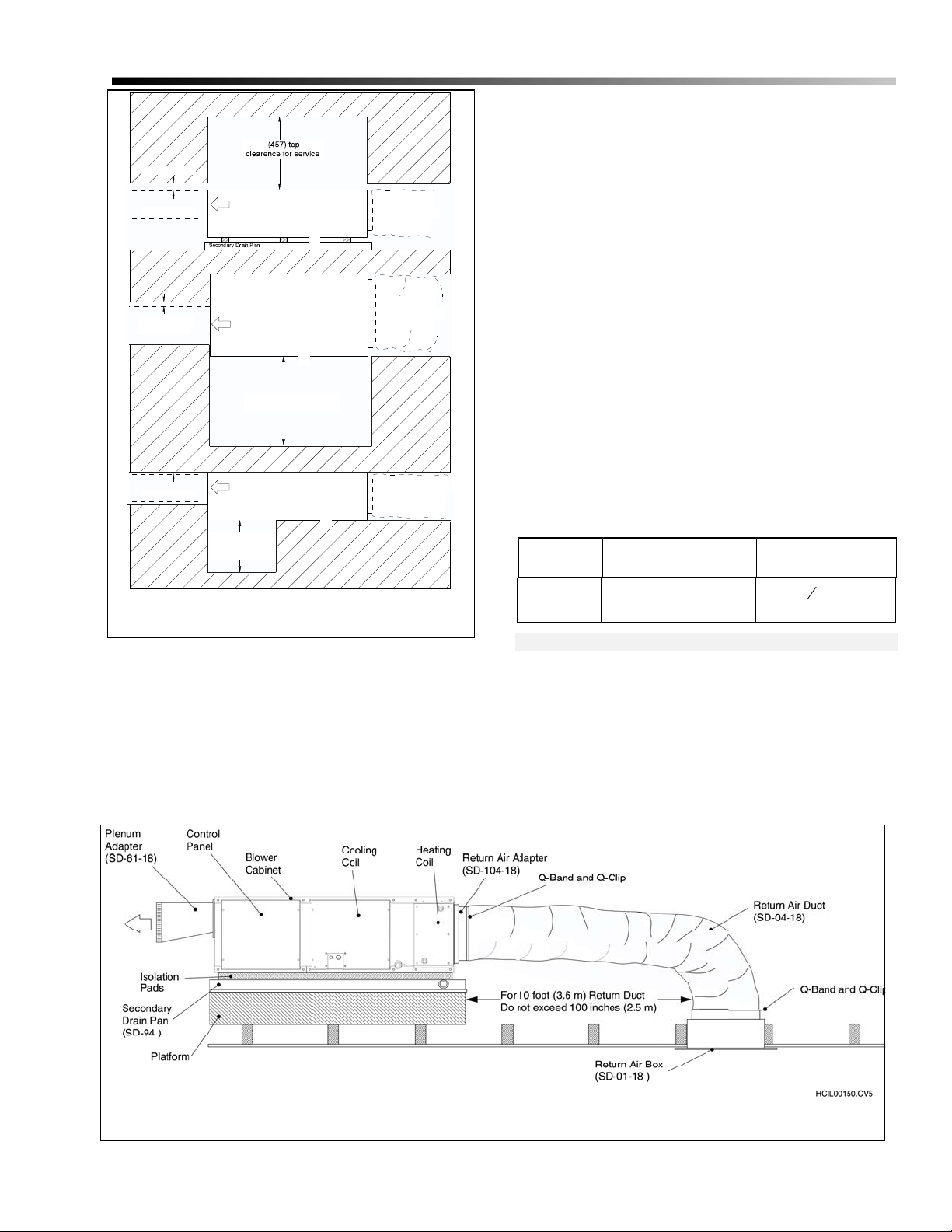

Position the return air box and filter near the unit allowing

at least one 90° bend in the return duct for proper acoustical

performance. Fig. 4 shows a typical horizontal attic

installation

The standard return duct is 10 feet (3 m) in length so it may

have to be cut to avoid bunching if the distance to the unit is

significantly less than 100 inches. If needed, up to two

return ducts can be coupled to make a 20-ft (6-m) duct. The

minimum length should be 6 feet (2 m). When given a

choice, maximize the distance and make at least one 90°

bend for the best sound attenuation.

Each unit is designed to fit into a small space where a

conventional unit could not be used. The 12-in. height

allows the unit to fit through joists or studs spaced at least

16-inches (406 mm) on center. If no access is provided, an

opening must be cut. It is suggested to use the opening

required for the return air box, especially in an attic

installation. The opening size for the return air box is listed

in Table 1. If the joists or studs are significantly less than 1 6

inches (406 mm) center-to-center or running the wrong

direction it would be necessary to cut and header the joists.

Table 1. Return Air Box Opening

Model Return Air Box Part No.

SDAH18 SD-01-18

Size of opening

inches (mm)

3

20 ½

14

8

(365 521)

Secondary Drain Pan

Where an overflow of condensate could cause water

damage, a secondary drain pan MUST BE INSTALLED .

Place the drain pan on the mounting base, platform or angle

iron support frame. Be sure to allow enough room for the

drain line and connection (refer to Table 2). The unit should

be placed over the secondary drain pan. Use rubber pads for

isolation to raise the unit high enough in the secondary

drain pan for the drain line to clear the side.

Figure 4. Typical Horizontal Attic Installation, SDAH18

Page 8

Bulletin 100-150 — Page 4

Table 2. Secondary Drain Pan

Unit Size Part No.

SDAH18 SD- 94

† NOTE — The drain fitting extends 7/8 inch (22 mm) beyond this dimension.

Dimensions

inches (mm)

40 x 22=

(1016 x 559)

Horizontal Platform Mounting

Mount the unit horizontally when vertical height is limited

such as in an attic or crawl space. It is easiest to mount the

unit on a platform but care must be taken to assure proper

drain line pitch.

The platform height must allow for proper pitch of the

condensate drain lines — at least ¼ inch drop per linear foot

(20 mm per meter). The platform can be built from a sheet

of ½ inch (13 mm) plywood and stud frame. Table 3 lists

the maximum horizontal drain line run for various framing

materials and still provide adequate drainage.

Table 3. Horizontal Dist ance of Drain Piping for

Different Framing Materials

Frame Lumber:

Max. Horizontal Run,

ft. (m)

2 x 4 2 x 6 2 x 8 2 x 10

18 (5) 26 (8) 34 (10) 42 (13)

CAUTION

DO NOT HANG UNIT FROM TOP OF

CABINET IF NOT USING MOUNTING RAILS

TO AVOID DAMAGING THE EQUIPMENT.

Use either four (4) chains or steel cables with 80 lbs. (36

kg) test strength to hang the unit. Use eyebolts and ‘J”

hooks as applicable to attach the chains or cables to the unit

and the ceiling.

Place the unit inside of the secondary drain pan as you

would for platform support with the angle iron supports

lengthwise under the secondary drain pan. Level the unit by

adjusting the length of the chains or cables.

If using the alternative method, hang the secondary drain

pan from the unit using self-tapping screws and metal straps

or wires. Adjust the straps or wires to pitch the secondary

drain pan toward the drain connection.

The platform size should be a minimum of 22 x 40 inches

(559 x 1016 mm).

Place secondary drain pan on platform and unit on top of

isolation pads inside of secondary drain pan. Be sure that

the unit is raised high enough in the drain pan to allow for

primary drain line condensate connection.

Figure 5. Typical Platform Installation

Horizontal Suspended Mounting

The unit can also be suspended from the ceiling or rafters.

The preferred method is to support the unit and the

secondary drain pan from underneath with angle iron

supports (see Fig. 6). As an alternative, the unit can be hung

with the mounting rails.

Figure 6. Typical Horizontal Suspension Mounting

Ceiling Mounting

If desired, the unit can be mounted flush to the ceiling (see

Fig. 7) using the optional mounting rails (SD–95). Remove

top screws from both sides of the unit. Align holes on

mounting rails with the holes on the unit. Fasten mounting

rails to the unit with the screws that were removed earlier.

Attach unit to a structural member. Suspend secondary

drain pain from the unit with metal straps or wires.

Joist

Ceiling

Mounting Rails

Unit

Metal Straps o r Wires

Figure 7. Typical Ceiling Mounting

IL00164.CV 5

Seconda ry Drain Pa

Page 9

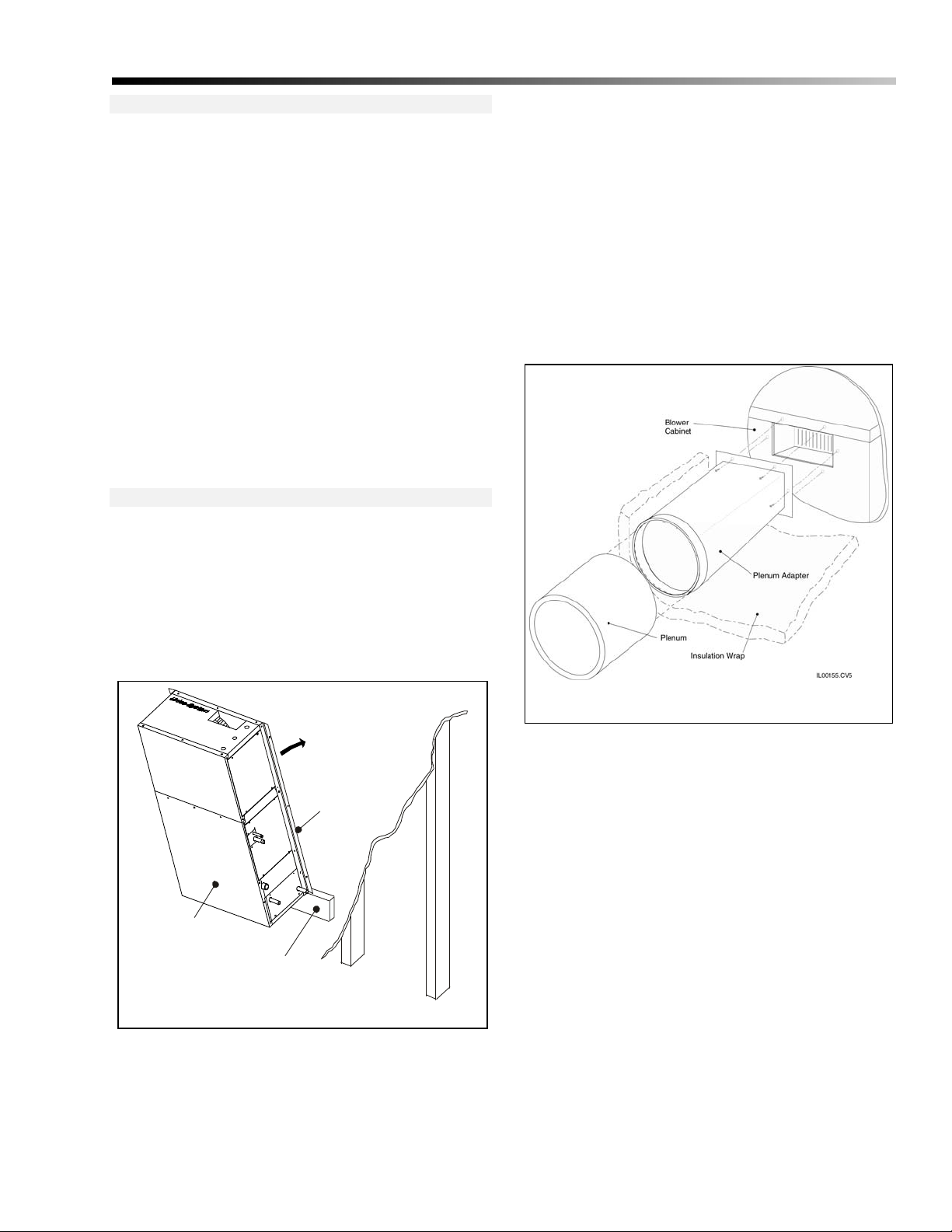

Vertical Rail Mounting

The unit can only be mounted in the vertical up-flow

configuration. The vertical rail mounting method is shown

in Figure 9. Mark hole pattern on wall and install stud

screws or lag screws (see Fig. 8).

To install the unit vertically, such as in a closet, basement,

or utility room, attach the mounting rails (SD-95) to the top

of the unit as explained previously. Screw or nail a

temporary board to the wall at the bottom of the location

where the unit will be mounted. The unit will rest on this

board during mounting. If the wall covering is not adequate

enough to hold the weight of the unit, use lag screws to

attach the rails to the structure. Use six (6) lag screws a

minimum of 3 inches (77 mm) long, which will be screwed

directly into a stud or structural member. If the wall

covering is sufficient, toggle screws may be used to mount

the unit. The board can be moved when the mounting of the

unit is completed.

DUCT CONNECTION

Supply Plenum

The standard supply plenum is a 7-inch (178-mm) diameter

duct, although this can be reduced to a 6-inch (152-mm)

diameter duct. The SDAH18 plenum adapter (SD-61-18)

provides a convenient connection to a 7 in (178-mm) duct.

Bulletin 100-150 — Page 5

on the unit. Mount the adapter with six (6) sheet metal

screws. See Figure 10.

Attach the plenum to the adapter by inserting it over the

collar. Use three (3) or four (4) equally spaced sheet metal

screws to secure the duct to the collar and then tape around

the seam with UL 181A aluminum tape. Then wrap the 1-in

fiberglass blanket duct insulation around the adapter and

seal with UL 181A aluminum tape.

The supply plenum also can be square or rectangular. The

inside dimensions of the duct must provide a minimum of

30 sq. in. (194 sq. cm.) of flow area, e.g. 5 x 6-in, 4 x 7 ½in (125 x 150, 100 x 190 mm).

The supply plenum can be a 7-inch ID rigid round

fiberglass or a sheet metal duct with a minimum thickness

of 26 gage. Refer to a separate bulletin for the installation of

the ductwork.

Wall

Mounting Rail

(SD-95)

Unit

Mounting Board

(temporary)

Il00162.Cv5

Figure 9. Typical vertical Rail Mounting

A 6-in plenum can be used so long as a 7-in duct is attached

to the unit and is then reduced at least 4-ft from the unit.

To attach the plenum adapter to the unit, align the holes on

the adapter with the holes located around the supply outlet

Figure 10. Plenum Adapter Installation

Return Duct

The Heat Controller return air system has a single return

that includes the return air box with filter, the acoustical

flex return duct, and the return air adapter (refer to Fig. 4).

Multiple returns or extra long returns are possible so long as

the maximum pressure loss is not exceeded. The return

system is designed for a maximum static pressure drop of

0.15 inches of water (37 Pa) including the filter. The return

duct should have at least one 90 degree bend between the

unit and filter box to reduce sound transmission directly

from the unit.

Although Heat Controller only supplies a single return

system, the return system can be redesigned for multiple

returns. The return duct system is a conventional duct

design not high velocity; therefore, the return system may

be different; provided, the static pressure does not exceed

0.15 inches of water column and there is some form of

sound attenuation. Generally, this means sizing the duct for

a pressure loss of 0.05 inches of water column at the

required airflow and sizing the filter for a pressure dr op of

0.10 inches of water column at the required airflow. Sound

Page 10

Bulletin 100-150 — Page 6

attenuation can be accomplished with fabricated duct board,

lined sheet metal, or acoustical flex (Part number SD-04-

18). For best attenuation, always have at least one 90

degree bend to eliminate direct line-of-site from the unit to

the return opening.

To install the return filter and grille, cut an opening for the

return box as specified in Table 1. If the joists or studs are

on 16 inch (410 mm) centers, there is no need to build a

frame to hold the return air box. Otherwise, it will be

necessary to construct a frame around the opening. Center

the return air box so the filter frame flange covers all the

gaps and make sure the flange is flush against the wall or

ceiling. Install the return air box against the frame using

nails or screws. Holes are provided in the return air box.

Use the four (4) ¼-inch (6.4 mm) holes. The other holes are

for mounting the filter grille.

Install filter frame into the return air box using four (4) nails

or screws. Insert filter and hold in place by rotating metal

clips. Close grille and secure with clips.

Connect the return air adapter to the unit u sing sheet metal

screws. Then attach the return duct to the adapter and to the

return air box using the supplied band. Tape the seams with

UL 181B duct tape.

PIPING

All piping must be in accordance with all local codes and

ordinances.

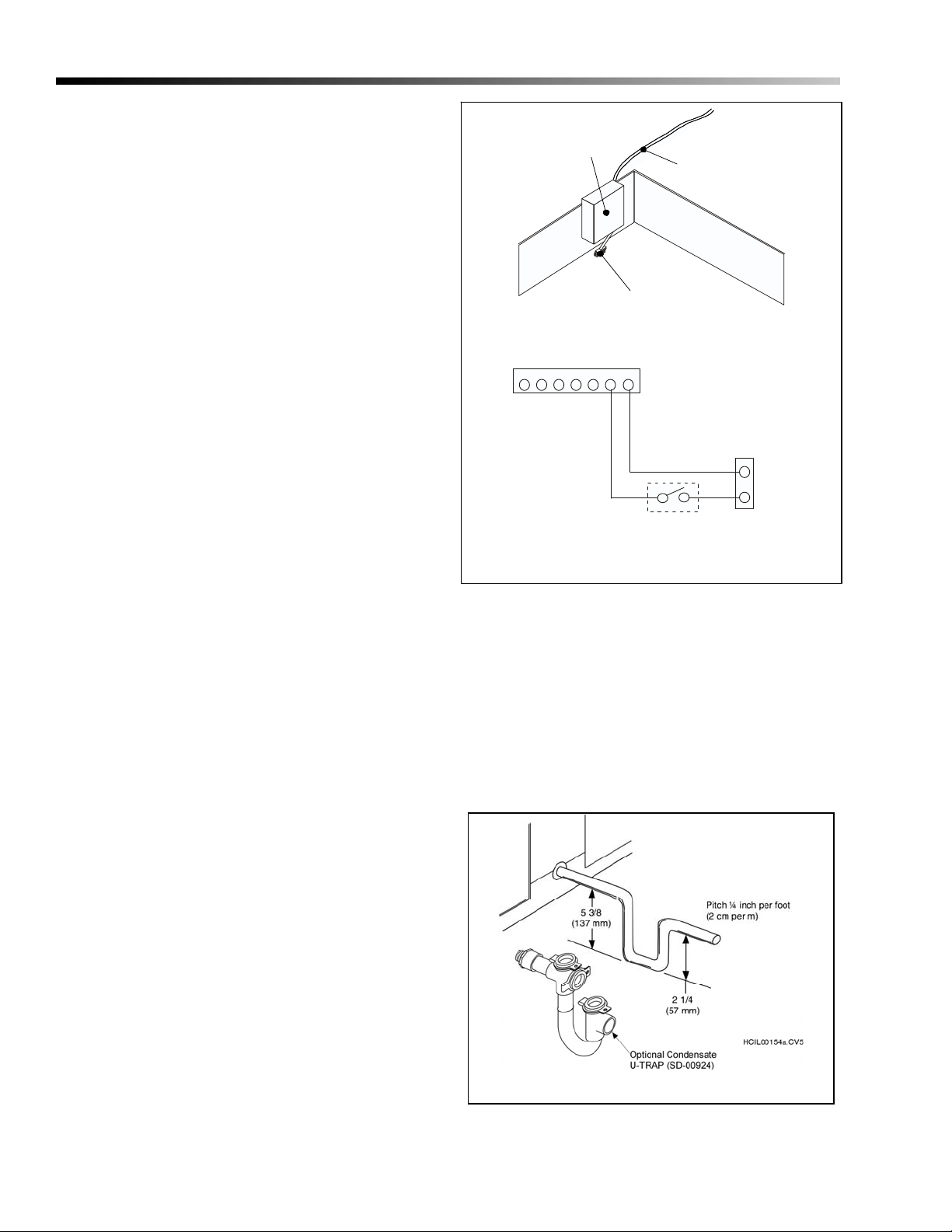

Condensate Lines

The primary drain pan condensate connection is a 1/2 inch

(13 mm) female pipe thread fitting and the secondary drain

pan connection is a 3/4 inch (19 mm) PVC socket fitting.

Elevate the unit so the condensate lines are pitched at least

¼ inch per lineal foot (20 mm per meter). Trap the

condensate line near the unit as shown in Figure 12. In

some cases it may be necessary to wrap the condensate line

near the unit with insulation to prevent water from

condensing on the outside of the pipe. In some climates or

locations it may be necessary to protect trap from freezing

in the winter.

Switch

Paper Fuse

Leads

Il00156.Cv5

Location of Paper Fuse

Indoor Terminal Block

1234 56 7

Condenser

R

Y

Switch

Il00157.CNV

Figure 13. Wiring Diagram for Paper Fuse

will dissolve and the switch will open causing th e outside

unit to shut down until it is serviced.

Also available is the Heat Controller Condensate U-Trap

which features a clear trap that is easy to visually inspect for

clogs. The U-Trap is designed for the Heat Controller

SDAH18 with a 2.5 inch (64mm) deep trap to handle the

higher static pressures. The U-Traps also feature easy to

remove clean-out caps and incorporate to tees to

accommodate any piping arrangement (Part No. SD-00924).

Do not trap the secondary drain line and do not terminate

line into the primary drain line. Run secondary drain line so

that any drainage will be immediately known without

causing damage to property. A typical location is to

terminate the secondary drain line above a windowsill so

that the drainage splashes on the window. This will serve as

an indicator that there is a problem with the primary drain.

An alternative method of notifying the homeowner about a

leakage problem is to use a paper fuse and micro switch.

See Fig. 13. Install a micro switch upside down on the side

of the secondary drain pan. Making sure that the switch is

open. Next, sandwich a paper fuse between the switch and

the bottom of the drain pan so that the switch is closed.

When water is present in the secondary drain pan, the fuse

Figure 12. Typical Condensate Trap

Page 11

Refrigerant Connections

CAUTION: WHEN BRAZING, PURGE WITH

NITROGEN GAS TO PREVENT THE

FORMATION OF OXIDES.

The refrigerant lines are copper sweat connections. The

liquid line is 3/8 inch (9.5 mm) OD and the suction line is

5/8 inch (16 mm) OD. Refer to the condensing unit

manufacturer’s instruction for proper line sizing information

based on distance from condenser.

Install a liquid line filter drier as close to the coil as possible

to protect the evaporator from foreign object debris. For

troubleshooting purposes, especially for attic installations or

when using long line sets, an optional moisture indicating

sight glass should also be installed between the filter-drier

and expansion valve near the indoor unit.

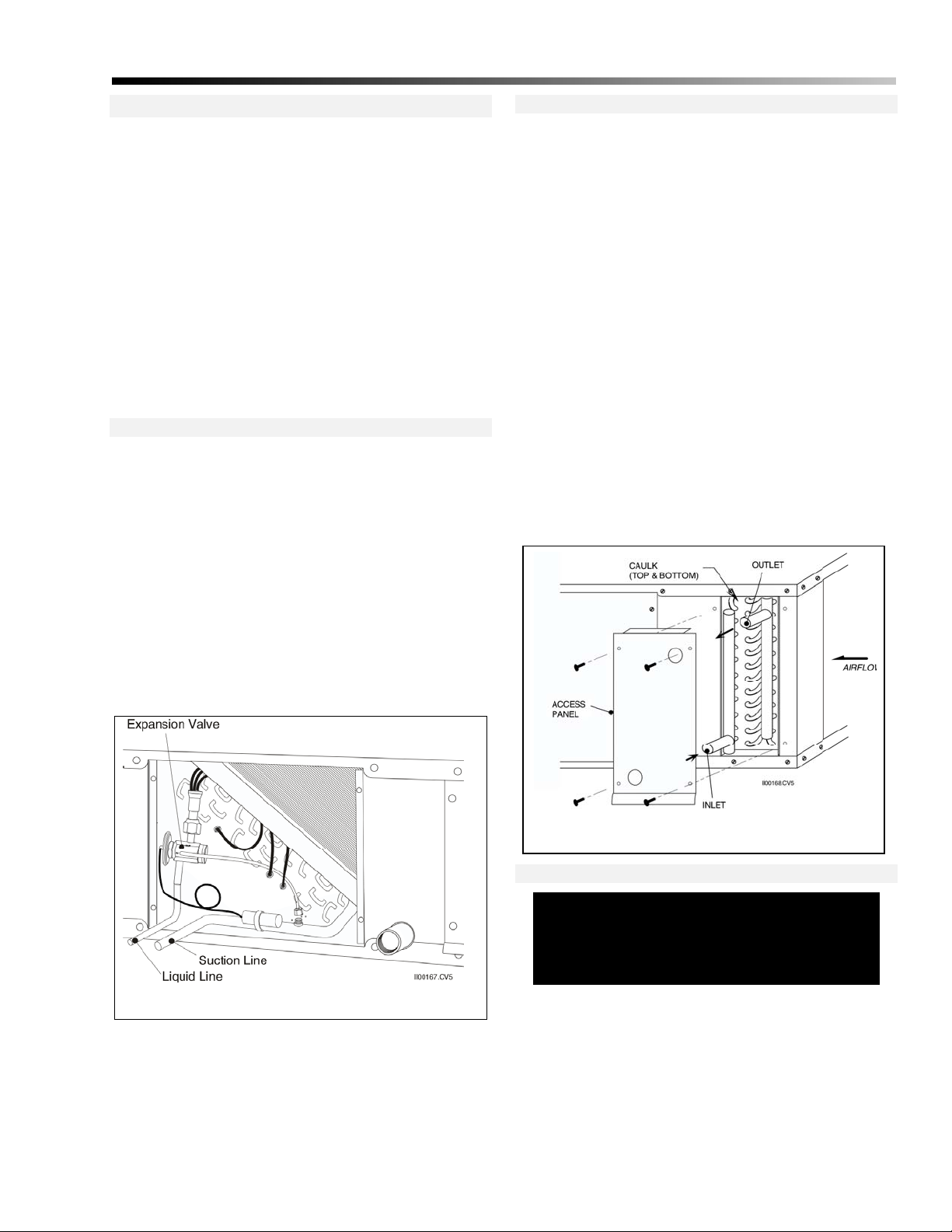

Expansion Valve

The expansion valve is shipped loose inside the unit in the

blower section. Install the valve inside the unit as shown in

Fig. 14. Use the following steps when installing:

1. Remove plastic caps to external equalizer line and

distributor inlet.

Bulletin 100-150 — Page 7

Water Connections

If you are installing the hot water coil, remove the side coil

access panel. Slide the coil into the cabinet if not already

installed at the factory and reinstall the door panel. After

removing plugs in the inlet and outlet holes, caulk around

connections to prevent leakage.

Pump and pipe sizing should be based on proper flow rate.

Refer to Appendix A for water coil capacities based on flow

rate.

All water connections are 5/8 inches OD (16 mm) sweat

connections. Sweat the water connections, then fill the

system. Install a vent valve at the highest point and a drain

valve at the lowest point of the water system (refer to Fig.

17). Fill and bleed the air from the system. If unit is in an

unconditioned space care must be taken to prevent the water

from freezing. Use a glycol-water antifreeze solution with a

freezing point below the coldest temperature expected.

As an alternate to an anti-freeze solution, the water can be

continuously circulated to prevent freezing. If the coil will

not be used for an extended period of time during cold

temperatures, drain the system then flush with a glycol

solution.

2. Connect valve to distributor and tighten flare nut.

3. Connect external equalizer line and tighten flare nut.

4. Connect to the outlet the 3/8” (9.5 mm) OD copper

refrigerant fitting. Make sure the flare nut is tight.

5. After all lines have been connected, pressure-check the

connections by charging the system with 150 psig of

dry nitrogen and check for leaks at all connections.

Figure 14. Expansion Valve Location

Locate the bulb at the 12 O’clock position on a horizontal

straight section of the 5/8” (16 mm) suction line (see Fig

15). Attach the bulb to the tubing with the two straps that

are provided. For satisfactory expansion valve control, good

thermal contact between the bulb and the suction line is

essential.

Figure 15. Hot Water Coil Connection

Wiring

WARNING!

DISCONNECT ELECTRICAL SUPPLY BEFORE WIRING UNIT TO PREVENT INJURY

OR DEATH FROM ELECTRICAL SHOCK.

All electrical wiring must comply with all local codes and

ordinances. Make electrical connection in accordance with

the wiring diagram shown in Fig. 18. Use a separate 1 ph 230/208V – 60/50 Hz power supply with a 15 amp fuse or

breaker and appropriate wire gauge per local code. Refer to

bulletin 100-180 for more information on wiring the System

Interface Board (SIB).

Page 12

Bulletin 100-150 — Page 8

Charging and Startup

Sequence of Operation

The sequence of operation depends greatly on the options

installed and type of control thermostat used. Most

thermostats have a fan AUTO-ON switch. When the fan

switch is set to ON, the “G” circuit is closed and the blo wer

relay is energized. The indoor blower starts after about a 20

second delay. The following paragraphs describe the

sequence of operation when the fan is set to AUTO. If the

fan switch is set to ON, the sequence is the same except the

“G” circuit is always closed and the indoor fan is always

operating.

Cooling Cycle (A/C or Heat Pump). When the thermostat calls for cooling, the “Y” and the “G” circuits are

closed, and a 24 V signal is sent to the compressor contactor

in the outdoor unit and fan relay in the indoor unit. After

about 20 seconds, the indoor blower starts. At the same

time, the compressor and outdoor fan also start. Depending

on the control circuitry in the outdoor unit, there may be a

time delay before the outdoor unit starts. If the system was

just turned off, the time delay could be as much as five

minutes. The cooling system is now operating.

For heat pump thermostats setting the switch to ‘cooling’

immediately closes the “O” circuit, which is used to

energize the reversing valve solenoid if required by the heat

pump. Otherwise, the “B” circuit, which closes when

switched in heating, is used to energize the reversing valve

solenoid. (Refer to the heat pump manufacturer’s

instructions to see which mode the solenoid needs to be

energized – whether in heating or cooling.)

When the thermostat is satisfied, the 24 V signals open and

the outdoor unit stops. The indoor blower continues to

operate for about 40 seconds, then stops. The system is now

off.

Heating Cy cle (Heat Pump). Setting the thermostat to

HEATING will automatically switch the reversing valve

solenoid. This setting closes the “B” circuit which sends a

24V signal to energize the solenoid if required by the heat

pump. Otherwise the “B” circuit is not used and the

solenoid is not energized during heating.

When the thermostat calls for heating, the “Y” and “G”

circuits are closed, sending a 24 V signal to the compressor

contactor in the outdoor unit and the fan relay in the indoor

unit. This starts the indoor blower and the outdoor

compressor and blower. There is a time delay of about 20

seconds for the indoor unit. The heating system is now

operating in stage one.

If the first stage does not satisfy the thermostat, the second

stage thermostat calls for more heat. This closes the “W2”

contacts and energizes the sequencer for electric heat. When

the second stage thermostat is satisfied, the “W2” circuit is

broken and the sequencer is de-energized. The electric

heating system is now off.

When the first stage thermostat is satisfied, the 24 V signals

open and the outdoor unit stops. The indoor blower

continues to operate for about 40 seconds, then stops. The

system is now off.

Heating Cy cle (Electric Heat). When the thermostat

calls for heating, the “W” and “G” circuits are closed. The

W circuit completes the 24V signal to the sequencer in the

electric duct heater, which cycles on the electric heating

elements. The G circuit completes the 24V signal to the fan

relay in the indoor unit, which starts the indoor blower after

a time delay of about 20 seconds. The heating system is

now operating.

When the thermostat is satisfied, the 24 V signals open and

the indoor blower stops after about 40 seconds. At the same

time the sequencer cuts the power to the electric elements.

The system is now off.

Note: Use a thermostat designed for electric

heat. A normal heating-cooling thermostat will

not close the “G” circuit on heating.

Heating Cy cle (Hy dronic Heat). When the thermostat

calls for heating, the “W” circuit is closed sending a 24 V

signal to the field installed heating relay. This relay closes

two circuits. One completes the boiler circuit, which either

opens a valve or starts a pump. The other completes the fan

relay circuit, energizing the blower motor relay and starting

the blower after a 20-second delay.

If an aquastat is utilized, the fan relay circuit will remain

open until the aquastat is satisfied.

When the thermostat is satisfied, the 24 V signal to the heat

relay opens and the pump or valve circuit opens which stops

the pump or closes a valve. The fan circuit opens and deenergizes the fan relay. After about 40-seconds the blower

stops.

Fan Speed

The SDAH18 comes standard with a 2-speed motor and

the Heat Controller SIB (System Interface Board). For

more information on this feature refer to Bulletin 100-

180.

Table 4. Motor Amperage versus Airflow

2-Speed

Motor

*Low speed for the optional 2- Speed motor produces half the

high speed airflow (1.0 amp @ 230V)

Airflow

CFM (l /s)

200 (94) 1.15 *

300 (142) 1.30 *

400 (189) 1.48 *

Check for the proper airflow by measuring the

amperage and compare to Table 4. For hot water

systems, refer to Appendix A for minimum airflow.

Amperage @ 230V

High Speed Low Speed

Page 13

Checking Airflow.

CAUTION. DO NOT OPERATE BLOWER

WITH FREE DISCHARGE OR LOW STATIC

PRESSURES (BELOW 1 INCH WC (250 Pa))

TO PREVENT MOTOR FROM OVERLOADING.

After the system is installed and before charging system,

check for proper airflow. Record the plenum static pressure

and the motor amperage and voltage. With this information,

the amount of airflow can be determined.

As a recommended further check on airflow, use a

velometer to measure the CFM from each outlet. The most

convenient instrument to use is a hand held vane type

velocity meter that fits directly over the outlet. The TurboMeter (Davis Instruments Catalog No. DS105I07) or

equivalent meter will give a direct LED readout on the

KNOTS (FPM x 100) setting, when multiplied by 2 gives

the CFM of the outlet within an accuracy of 10%.

By measuring and totaling the CFM of all outlets, the to tal

airflow of the system can be closely approximated and

provide a crosscheck for the airflow determined from the

motor amperage and Table 4. Use Table 5 to help

troubleshoot airflow problems.

Static Pressure

Measure the external static pressure (see the following

section) in the supply plenum at least two feet (0.6 m) from

the unit and verify that it is within the allowable range.

The plenum static pressure should be 1.4 to 1.6 inches of

water column (350 to 400 Pa).

It is not necessary to measure the return duct static pressure

unless it was field fabricated. The maximum return static

pressure (including filters) should be 0.15 inches of water

column (37 Pa). If it is greater than 0.15 inches of water

column, add the return system pressure drop to the supply

plenum static pressure to get the total static pressure drop.

For example: If the supply static pressure is measured to

be 1.6 inches w.c. and the return sy stem pressure drop is

0.25 inches w .c., the total static pressure drop is: 1.6 +

0.25 = 1.85. In this case the static pressure is too high.

Motor Amperage

Bulletin 100-150 — Page 9

Remove the control panel and measure the current with an

amp meter and compare to Table 4.

How to Measure Static Pressure

Measure the supply plenum static pressure at least 24 inches

(610 mm) from the unit, but before any tee or elbow. A

distance of between 2 and 3 feet (0.6 to 0.9 m) is best. Use

an inclined manometer capable of reading at least 2.5 inches

of water column (622 Pa), such as Dwyer Instrument’s

model 109 manometer. Be sure to zero the scale and level

the manometer. A magnehelic gauge that measures up to at

least 2.5 inches of water may also be used.

Use a metal tube, typically 1/4-inch (6 mm) diameter, to

measure the static pressure. Determine where you want it

and cut or punch a small hole in the duct. Make the hole the

same size as the metal tube to prevent leakage. Insert the

metal tube one-inch (25 mm) so that the tip of the tube is

flush to inside wall of the duct and perpendicular to the air

stream.

Attach the metal tube to the manometer using a rubber hose

(usually supplied with the manometer). Record the pressure.

Note: If the tube is not perpendicular to the air

stream, the reading will be in error. You will get a

higher reading if the tube is angled toward the air

stream.

Charging a Cooling System

DO NOT VENT REFRIGERANT TO THE

ATMOSPHERE!! It is a violation of federal law and in

some cases local ordinances. Always use a refrigerant

recovery or recycling device.

If charging a heat pump, refer to Bulletin 100-160, The

following procedure is only valid for charging the system

during the cooling mode.

To check for proper charge record the refrigerant pressures

and temperatures. Check the refrigerant charge by

measuring the amount of sub-cooling (or ‘approach’

temperature for some condensing units). If the outdoor

manufacturer does not have sub-cooling or “approach”

temperature charts, then be sure that the sub-cooling is

between 3 and 8 °F (2 to 5°C). For long refrigerant lines or

Table 5. Airflow Troubleshooting Chart

Problem Probable Cause Remedy

Low Static

and

Low Amperage

Low static,

high amperage

High Static,

Low Amperage

Blocked filters, restriction in return duct.

Low Voltage.

Blower Wheel not aligned properly.

Large number of outlets or open duct. Add balancing orifices to outlets, check for missing

Restrictive duct system. Add outlets, add splitter vane in tee, reduce the

Clear restriction.

Check with local utility

Center wheel inside of inlet ring. Position on shaft for

1/8 inch (3 mm) clearance from inlet ring.

end caps or separated plenum.

number of tees and elbows in plenum, increase

plenum size to 9” equivalent.

Page 14

Bulletin 100-150 — Page 10

when the evaporator is above the condenser, the sub-cooling

should be close to 8°F; otherwise, aim for the low end of the

range.

After the refrigerant lines and evaporator have been carefully leak tested and evacuated, release the R-410a

operating charge in the condensing unit. The system is now

ready for refrigerant charge adjustment.

Start up the system and check line voltage to assure it is

within acceptable limits for the system as dictated by the

condensing unit manufacturer. Run the system for 20 to 30

minutes to get reasonably stabilized conditions. Do not

attempt to adjust charge with outdoor temperature below

75°F (24 °C). An outdoor temperature of 75 to 85°F (24 to

29 °C) is preferred.

In some cases, such as in a hot attic, the liquid line will pick

up heat and lose its subcooling. Th is will be apparent if the

subcooling at the evaporator is low. In these cases, the

liquid line should be insulated or strapped to the suction line

and both insulated. The same problem can occur for long

refrigerant lines; in this case, increase the size of the liquid

line to reduce the pressure drop.

CAUTION. TO MAINTAIN PROPER HEAT

PUMP OPERATION, DO NOT STRAP THE

LIQUID AND SUCTION LINES TOGETHER

FOR HEAT PUMP SYSTEMS.

Superheat Method Do not charge the system based on

superheat. Superheat measurements should only be used to

verify that the expansion valve is working properly.

If the system charge must be checked when the outdoor

temperature is below 80°F (26.7 °C), block the condenser

coil until the head pressure is appro ximately equal to what

its charging chart specifies for an 85°F (29 °C) day.

For heat pumps always check the charge in cooling mode. If

this is not possible because of low outdoor temperatures,

charge the system in the heating mode, but return later when

the weather is warmer before the system is switched to

cooling.

Subcooling Method. Many condensing unit

manufacturers publish the amount of subcooling that the

condenser will produce. Follow their instructions to charge

the unit. Typical subcooling values will be between 8 and

15°F (5 to 9 °C). The unit should ALWAYS have some

amount of subcooling. To be sure there is enough

subcooling, especially if the unit is in a hot attic, check the

liquid line sight glass near the evaporator for bubbles or

measure the refrigerant liquid line pressure and temperature

at the evaporator.

To measure subcooling use the following procedure:

1. Measure and record the liquid line pressure using an

accurate refrigerant gauge. Record the corresponding

saturation temperature for this pressure (see Table 6).

2. Measure and record the liquid line temperature using an

accurate metal or glass thermometer, or thermocouple.

Tape or strap the sensor firmly against the surface of the

liquid line and cover with insulation.

3. Determine the subcooling with the following equation:

The superheat should be between 8 to 12°F (4 to 7°C) at the

indoor coil. In some cases, particularly for the larger

capacity match-ups (i.e. 3 ton and 5 ton), a superheat of 15

to 18°F (8 to 10°C) is satisfactory. It is not uncommon to

measure a superheat above 20 to 25°F (11 to 14°C) at the

condensing unit.

Be aware that the superheat value is also dependent on the

outdoor air temperature. At lower air temperatures the

superheat will be higher than at higher air temperatures. If

the condenser ambient temperature is between 75 and 85°F

(24 to 29°C), superheat should be approximately 10 to 12°F

(5 to 7°C). If the outdoor temperature is between 85 and

105°F (29 to 40°C), superheat should be approximately 8 to

10°F (4 to 5°C).

To measure the superheat use the following:

1. Measure and record the suction pressure at the

evaporator outlet using an accurate refrigerant gauge. If

this is not possible, measure the pressure at the service

port on the suction valve fitting at the condensing unit

and add the estimated pressure loss in the suction line

between the condensing unit and evaporator. Record the

corresponding saturation temperature for this pressure

(see Table 6).

2. Measure the suction line temperature at the evaporator

outlet using an accurate metal or glass thermometer, or

thermocouple. Insert the thermometer under the

insulation on the suction line and tape firmly against the

surface of the suction tube.

3. Determine the superheat with the following equation:

SATURATED TEMPERATURE

- LIQUID LINE TEMPERATURE

SUBCOOLING

If the subcooling temperature at the condenser is low, the

system is undercharged. If it is high, the system is

overcharged and some refrigerant must be removed and

collected in an empty refrigerant container. Do not vent the

refrigerant; it is a violation of federal law!

Suction Line Temperature

— Saturated Temperature

= Superheat

Charging by Gauge Pressures

Page 15

It is not possible to charge the system by gauge pressures.

Gauge pressure should only be used to verify the system is

working properly

The Heat Controller unit will show a lower suction pressure

during the cooling mode than a conventional system.

Generally, it will be 10 to 15 psi (70 to 100 kPa) less. For

example, a normal suction pressure for the Heat Controller

will be about 130 psig (896 kPa) with an 85 to 95°F (29

unit

to 35°C) outdoor temperature. Expect lower pressures when

the outdoor temperatures are lower.

The head pressures should be similar to a conventional

system when in the cooling mode.

Using a Low Ambient Control Kit

Since the Heat Controller unit operates at colder coil

temperatures (in cooling mode), an anti-frost switch is

installed on the coil to prevent coil freeze-up. In certain

instances, such as when the outdoor ambient temperature is

low, the condensing unit will cycle on the anti-frost switch.

This may reduce the cooling capacity at a time when the

cooling load is still fairly high. To provide better control

and comfort, install a low ambient control on the

condensing unit. Typically, a low ambient control is

necessary when operating the unit at outdoor temperatures

below 80°F (26.6 °C).

Bulletin 100-150 — Page 11

Charging in Heating Mode.

on heating where the return air temperature is significantly

lower than the normal operating range of 65 to 75 °F (18.2

to 23.8 C), the suction pressure can be very low. Operate

the system to bring up the return air temperature, using

auxiliary heat if necessary, before checking system charge.

In heating mode, the Heat Controller unit will have a

slightly higher discharge (LIQ.) pressure then a

conventional system, usually about 30 to 40 psig higher. It

is this higher pressure that produces a warmer air

temperature; preventing “cold blow”, where the house is

being heated with an air stream that feels cold.

Using a High Head Kit (Mild Weather Kit). When any

heat pump is operated during mild weather (temperatures

above 50°F (10 C)) the compressor may trip out on the high

pressure limit. The Heat Controller System is particularly

sensitive to this since it operates at a higher pressure.

To overcome this problem, install a mild weather kit to

cycle the outdoor fan based on the compressor discharge

pressure. However, be sure this control is compatible with

the outdoor heat pump section being used.

If the system is started up

These controls come in different configurations such as the

Hoffman Controls Corp. series 800AA head pressure

control. This control modulates the outdoor blower to

maintain a minimum liquid line temperature. Other controls

may cycle the fan on off. In either case check with the

condensing unit manufacturer to determine what controls

are compatible with the condensing unit.

Charging a Heat Pump System

Charging in Cooling Mode. Charging a heat pump, by

its nature, is more difficult than a cooling-only refrigerant

system. Quite often the ideal charge for cooling is different

than the ideal charge for heating, making the system much

more sensitive to the amount of charge. In some cases, the

compressor will trip on high head pressure during the

heating mode because it is overcharged if the system was

charged during cooling. Likewise, the system may cycle on

the anti-frost control because of a low refrigerant charge if

the system was charged during heating.

To compensate for this charge difference some outdoor unit

manufacturers have a charge compensator device that stores

charge while in heating mode. Unfortunately there are no

add-on devices to accomplish the same thing and only a few

(usually the most expensive) model lines will have one. For

this reason, it is often necessary to compromise the charge.

Although the unit can be charged in the heating mode, it is

best to charge the unit during the cooling mode as described

earlier. Then recheck the charge in the heating mode to be

sure the system is not over charged.

Page 16

Bulletin 100-150 — Page 12

Entering

Water

Temperature

°F °C GPM (L/s) MBH (KW) MBH (KW) MBH (KW) ft. water (KPa)

2 (0.13) 10.2 (2.97) 13.7 (4.01) 16.2 (4.76) 0.9 (2.69)

120 (48.9)

130 (54.4)

140 (60)

150 (65.5)

160 (71.1)

170 (76.7)

4 (0.25) 10.6 (3.10) 14.9 (4.37) 18.5 (5.42) 3.2 (9.57)

6 (0.38) 10.7 (3.13) 15.3 (4.49) 19.3 (5.65) 7.1 (21.23)

8 (0.50) 10.7 (3.15) 15.5 (4.54) 19.7 (5.76) 12.5 (37.38)

2 (0.13) 12.2 (3.58) 16.5 (4.83) 19.6 (5.75) 0.9 (2.69)

4 (0.25) 12.7 (3.72) 18.0 (5.26) 22.3 (6.52) 3.2 (9.57)

6 (0.38) 12.8 (3.76) 18.4 (5.40) 23.2 (6.79) 7.1 (21.23)

8 (0.50) 12.9 (3.78) 18.6 (5.46) 23.6 (6.93) 12.5 (37.38)

2 (0.13) 14.3 (4.19) 19.3 (5.66) 23.0 (6.74) 0.9 (2.69)

4 (0.25) 14.8 (4.35) 21.0 (6.15) 26.1 (7.64) 3.2 (9.57)

6 (0.38) 15.0 (4.39) 21.5 (6.31) 27.1 (7.94) 7.1 (21.23)

8 (0.50) 15.1 (4.41) 21.8 (6.38) 27.6 (8.09) 12.5 (37.38)

2 (0.13) 16.4 (4.79) 22.2 (6.50) 26.4 (7.75) 0.9 (2.69)

4 (0.25) 17.0 (4.98) 24.1 (7.05) 29.9 (8.75) 3.2 (9.57)

6 (0.38) 17.1 (5.02) 24.6 (7.22) 31.0 (9.10) 7.1 (21.23)

8 (0.50) 17.2 (5.04) 24.9 (7.29) 31.6 (9.27) 12.5 (37.38)

2 (0.13) 18.4 (5.40) 25.0 (7.33) 29.9 (8.76) 0.9 (2.69)

4 (0.25) 19.1 (5.60) 27.1 (7.94) 33.7 (9.88) 3.2 (9.57)

6 (0.38) 19.3 (5.65) 27.7 (8.13) 35.0 (10.25) 7.1 (21.23)

8 (0.50) 19.4 (5.67) 28.0 (8.21) 35.6 (10.44) 12.5 (37.38)

2 (0.13) n/a n/a 27.9 (8.17) 33.3 (9.77) 0.9 (2.69)

4 (0.25) n/a n/a n/a n/a 37.5 (11.00) 3.2 (9.57)

6 (0.38) n/a n/a n/a n/a 38.9 (11.41) 7.1 (21.23)

8 (0.50) n/a n/a n/a n/a 39.6 (11.61) 12.5 (37.38)

Appendix A – Hot Water Coil Performance

3

Water

Flowrate

Airflow, SCFM (m

200 (0.09) 300 (0.14) 400 (0.19)

Capacity Capacity Capacity WPD

/s)

Appendix B – Chilled Water Coil Performance

3

Entering

Water

Temperature

°F °C GPM (L/s) MBH (KW) SHR MBH (K W) SHR MBH (KW) SHR ft. water (KPa)

35 (1.7)

40 (4.4)

45 (7.2)

50 (10.0)

55 (12.8)

Water

Flowrate

3 (0.19) 13.6 (3.98) 0.59 17.2 (5.03) 0.60 19.7 (5.77) 0.62 1.8 (5.37)

4 (0.25) 14.4 (4.23) 0.58 18.9 (5.53) 0.59 22.1 (6.48) 0.60 3.4 (10.15)

5 (0.32) 14.9 (4.37) 0.58 20 (5.86) 0.59 23.8 (6.98) 0.59 5.3 (15.83)

3 (0.19) 11.8 (3.46) 0.60 14.9 (4.38) 0.62 17.2 (5.03) 0.64 1.8 (5.37)

4 (0.25) 12.6 (3.69) 0.59 16.4 (4.81) 0.61 19.2 (5.63) 0.62 3.4 (10.15)

5 (0.32) 13.0 (3.81) 0.59 17.4 (5.10) 0.60 20.7 (6.06) 0.61 5.3 (15.83)

3 (0.19) 10.0 (2.92) 0.62 12.6 (3.69) 0.65 14.6 (4.27) 0.68 1.8 (5.37)

4 (0.25) 10.6 (3.10) 0.61 13.8 (4.05) 0.63 16.2 (4.75) 0.66 3.4 (10.15)

5 (0.32) 11.0 (3.21) 0.61 14.6 (4.28) 0.62 17.4 (5.10) 0.64 5.3 (15.83)

3 (0.19) 8.0 (2.34) 0.67 10.2 (2.99) 0.71 11.9 (3.49) 0.74 1.8 (5.37)

4 (0.25) 8.5 (2.48) 0.66 11.1 (3.25) 0.68 13.1 (3.84) 0.71 3.4 (10.15)

5 (0.32) 8.8 (2.56) 0.65 11.7 (3.42) 0.67 14.0 (4.09) 0.70 5.3 (15.83)

3 (0.19) 6.0 (1.75) 0.76 7.8 (2.30) 0.80 9.3 (2.72) 0.84 1.8 (5.37)

4 (0.25) 6.2 (1.83) 0.74 8.3 (2.44) 0.78 10.0 (2.93) 0.81 3.4 (10.15)

5 (0.32) 6.4 (1.88) 0.73 8.7 (2.53) 0.77 10.5 (3.07) 0.80 5.3 (15.83)

200 (0.09) 300 (0.14) 400 (0.19)

Capacity Capacity Capacity WPD

Airflow, SCFM (m

/s)

Page 17

Bulletin 100-150 — Page 13

Appendix C – Engineering Specifications

Heat Controller Part No.

Construction

Dimensions, inch (mm): 12 H x 20 W x 38 L (31 x 51 x 97)

Cabinet Type: Galvanized or Painted (P option)

Insulation: 1 inch (2.5 mm) coated fiberglass duct liner

Drain pan: Stainless Steel

Drain pan connection: 1/2 inch FPT

Standard Return Duct ID, in (cm): 12 (30.5)

Standard Plenum ID, in (cm): 7.0 (17.8)

Electrical

Type: 1 ph - 60/50 Hz - 230/208V

Power Input, W: 310

Fan Relay: Snap acting with inherent time-delay A00056-G02

Transformer: 50 VA, 230/208V-24V A00057-G02

Motor 2-speed A00331-001

Size, hp (kW): 1/3 (0.25)

Running Speed @ rated airflow: 1650/1350 RPM

FLA: 1.5

RLA: Refer to Amperage Chart

Bearing Type: Permanently Lubricated Ball

Blower Wheel A00137-003

Airflow, CFM (m

Static Pressure**, in. wc (Pa) 1.80 (448) 1.50 (373) 1.00 (249) 0.70 (174)

Type: SISW Forward Curved

Nom. Diameter, inch (cm): 9.5 (24)

Width, inch (cm): 1.5 (3.8)

Refrigerant Coil (Heat Pump) A00326-001

Nominal Capacity, tons (kW): 1 to 1.5 (3.5 to 5.3)

Rated Airflow, CFM (m

Min. Airflow, CFM/ton (m

Refrigerant Type: R-410A

Face Area, ft² (m²): 1.167 (0.108)

Number of Rows: 6

Number of Circuits: 3

Fin Density, fins/in. (fins/cm): 15 (6)

Fin Type and pattern, in. (cm): Corrugated, 1 x 0.625 (2.540 x 1.588)

Tube Diameter, in (cm): 3/8 (0.953)

Tube Type: Rifled

Expansion Device (AC option) TXV with Bleed Port A00365-001

Expansion Device (HP option) TXV with Bleed Port and Internal Check Valve A00366-001

Liquid Line Connection 3/8 (.953)

Suction Connection OD, in. (cm) 5/8 (1.588)

Hot Water Coil (HW option) SDHW-18

Fluid Type Water or Glycol-Water Solution

Face Area, ft² (m²) 1.0 (0.093)

Number of Rows 4

Number of Circuits 4

Fin Density, fins/in. (fins/cm): 10 (4)

Fin Type and pattern, in. (cm): Raised Lance, 1 x .866 (2.540 x 2.200)

Tube Diameter, in (cm): 3/8 (.953)

Connection OD SWT, in (cm): 5/8 (1.587)

Chilled Water Coil (HW option) A00397-G01

Fluid Type Water or Glycol-Water Solution

Face Area, ft² (m²) 1.167 (0.108)

Number of Rows 6

Number of Circuits 6

Fin Density, fins/in. (fins/cm): 15 (6)

Fin Type and pattern, in. (cm): Corrugated, 1 x 0.625 (2.540 x 1.588)

Tube Diameter, in (cm): 3/8 (.953)

Connection OD SWT, in (cm): 5/8 (1.587)

* The highest speed is not used.

** Static pressure across unit without hot water coil, using 6 inch ID plenum. Motor speed set to high for 2-speed motors.. Static pressure will

be greater when using 7 inch ID plenum.

3

/s): 200 (.094) 300 (.142) 400 (.189) 450 (.212)

3

/s): 450 (0.212)

3

/s•kW): 200 (0.027)

Page 18

INSTALLATION

INSTRUCTIONS

SMALL DUCT HIGH VELOCITY:

SDAH 24, 36, 48 Air Handler

Heat Controller, Inc. • 1900 Wellworth Ave. • Jackson, MI 49203 • (517)787-2100 • www.heatcontroller.com

Page 19

GENERAL

The information on the following pages is to help the

installer save time by provide the best possible installation and ensure continuous trouble-free operation.

SCOPE

These instructions apply to the Heat Controller SDAH

Series. Installation instructions for the air distribution

system are covered in Bulletin 100-145. Before beginning any installation a detailed system layout must be

done in accordance with the System Sizing and Layout

Procedure, Bulletin 100-255 and the Component Layout

Instructions, Bulletin 100-250.

NOTICE TO INSTALL ER AN D EQUIPMENT

OWNER: RETAIN THIS MANUAL AT THE JOB.

FULL BUILDING INSULATION IS ESSENTIAL

FOR THE MOST ECONOMICAL OPERATION

GENERAL PRECAUTIONS AND SAFETY TIPS

Do not attempt to install or startup unit without first

reading and understanding the appropriate sections in

this manual.

Before operating, be sure the unit is properly grounded.

Installation should be in accordance with all local codes

and regulations and with the National Board of Fire Underwriters regulations. In case of conflict, local codes

take precedence.

All electrical wiring should be in accordance with the

latest edition of the National Electrical Code and all local codes and regulations. The unit is safety certified to

UL 1995 and listed with ETL.

Always install a secondary drain pan when an overflow

of condensate could cause damage.

Bulletin 30-20 Installation Manual

HEAT CONTROLLER

INSTALLATION MANUAL

FOR

SDAH SERIES

TABLE OF CONTENTS

INTRODUCTION................................................................... 1

OPTIONS ............................................................................. 2

UNPACKING......................................................................... 2

LOCATION............................................................................ 2

UNIT ASSEMBLY.................................................................. 3

Anti-Frost Switch Wires.................................................. 3

Fastening Modules Together.......................................... 3

Horizontal Installation ..................................................... 3

Control Box ..................................................................... 4

Secondary Drain Pan..................................................... 4

MOUNTING........................................................................... 4

Horizontal Platform Mounting......................................... 4

Horizontal Suspended Mounting .................................... 5

DUCT CONNECTIONS ........................................................ 5

Supply Plenum............................................................... 5

Return Duct.................................................................... 6

Multiple Returns .............................................................. 7

PIPING.................................................................................. 7

Condensate Lines .......................................................... 7

Refrigerant Lines............................................................ 7

Water Connections......................................................... 9

Coil Cleaning................................................................. 10

WIRING............................................................................... 10

Ventilation Speed Mode ............................................... 10

STARTUP ........................................................................... 10

Sequence of Operation ................................................ 10

Checking Airflow ........................................................... 11

How To Measure Air Flow............................................. 12

How to Measure Static Pressure................................... 12

Charging the System.................................................... 13

Low Ambient Control Kit............................................... 13

R-410A Refrigerant ............................................................. 13

Maintenance ...................................................................... 14

Module Configuration Illustrations........................................ 15

Blower Performance............................................................. 15

Specifications...................................................................... 16

PART NUMBERS

This manual does not always include the latest revision

letter when referring to SD part numbers. Refer to the

latest Price List and Spec Sheets for the current SD revision letter. For example, in SD-00x the ‘x’ indicates the

latest revision.

INTRODUCTION

Heat Controller offers a complete indoor comfort system

that includes an indoor air handling unit and small du ct

system. The air handler and duct system were designed

to operate together to provide the proper airflow in every

installation. The conditioned air is supplied through a

© Copyright 2010 Heat Controller, Inc.

Page 20

Bulletin 100-155 — Page 2

series of 2-inch or 2 ½ inch ducts as a stream of air that

entrains and mixes the room air. This process of aspiration produces a more even temperature distribution in

the room.

The SDAH Series consist of a motor, blower wheel,

housing, controls, and an option of either a heat pump or

chilled water coil. For additional options, the SDAH

series features a latching mechanism for easy installation

of a Hot Water Coil module and/or Horizontal Return

Air Module. This series of air handlers must be installed

in the horizontal flow position to allow for proper drainage (See Fig. 1).

All insulated modules feature closed-cell insulation for

improved sound attenuation. There is no exposed fiberglass insulation.

SDAH module is available in three sizes: 24, 36, and 48.

The SDAH24 is sized for 1.5-2.0 tons, SDAH36 is sized

for2.5- 3 ton, and the SDAH48 is sized for a 3.5-4 tons.

The coils can be arranged to provide only the options

needed as shown in Figure 1 (with details on page 14).

Heating-only systems require the blower with a heat

pump coil, and a hot water coil. Cooling-only systems

include the blower with the heat pump coil used for

cooling. For heating and cooling use the refrigerant coil

with the hot water coil module or electric furnace.

Heat Controller blowers feature direct drive motors that

are located in the air stream. Each blower wheel is balanced to Heat Controller specifications. The blowers

feature a quick twist-and-lock motor mount for easy

maintenance (see page 16). The motorized blower assembly consists of the motor, which is mounted to the

inlet ring, and the wheel, which is fastened to the motor

shaft.

OPTIONS

Other options and modules are also available to add

additional features or to simplify installation. These include an electric duct furnace, hot water coil module,

and a horizontal return air module. Please refer to the

latest Heat Controller Catalog for information on these

and other options.

Open each carton and inspect unit for visible signs of

concealed damage and notify carrier of any such damage.

All materials are sold FOB Factory and it is the responsibility of the consignee to file any claims with the delivering carrier for materials received in damaged condition.

LOCATION

Design the system layout to minimize the number of

plenum elbows and fittings while keeping the supply

duct runs as short as possible. (See Bulletin 100-250,

Component Duct Layout Design). Provide minimum

clearance on both sides for servicing the unit as shown in

Fig. 2.

If installing the unit in an attic, avoid placing the unit

above a bed. The ideal location is above a central hall, a

closet, a bathroom, or any normally unoccupied space.

The unit can also be installed in a closet, crawlspace, or

basement. If the local codes allow, the unit may be installed in the garage provided the ductwork is well

sealed, especially the return duct. Although the unit is

not designed for outdoor use, it may be located outside

provided adequate weather protection is used; typically a

roof installation requires mounting on blocks with a

sheet metal cover or cap to protect the unit from rain and

extreme weather conditions.

Be sure to position the return air box and filter near the

unit allowing at least one 90° bend in the return du ct for

proper acoustical performance (refer to figure 3 for a

typical attic installation). The section on Return Air

Ducts in the manual provides more details.

Table 1. Return Air Box Opening

Models

24 SD-01-2 4

36 SD-01-3 6

48 SD-01-4 8

Return Air Box

Part No.

Size of opening

inches (mm)

3

25 ½ (365 648)

14

8

3

1

30

14

8

2

3

1

30

24

8

2

(365 775)

(619 775)

UNPACKING

All Heat Controller products are inspected prior to shipping and are carefully packaged in individual cartons.

Inspect all cartons prior to unpacking. Notify carrier of

Heating or Cooling w/ Heat Pump Coil

Horizontal

Flow

Heating or Cooling w/ Chilled Water Coil Only

Figure 1. Basic Module Arrangement (refer to detail figures shown on Page 15)

any damage.

© Copyright 2010 Heat Controller, Inc.

Heat Pump Coil w/ Hot Water Coil

IL00010E.cvx

Page 21

Bulletin 100-155 — Page 3

A

UNIT ASSEMBLY

The units should be assembled horizontally. Refer to

Fig. 1 for your particular flow arrangement. If you use a

refrigerant coil, the anti-frost switch wires must be

routed to the control box during installation.

Anti-Frost Switch Wires

Remove the coil access panel and unravel the anti-frost

switch wires. Feed the wires through the bushing in the

motor partition panel and connect to the conden ser terminal block on the SIB.

Fastening Modules Together

To fasten the modules together tilt the units to insert the

connection flange over the mating flange as shown in

Fig. 4. It may be necessary to squeeze the units together

as you are inserting the flange to compress the rubber

gaskets. If the hook flange has a small gap, use a large

flat bladed screwdriver to pry the gap apart. Secure the

modules together with the latches, compressing the gasket further.

Figure 2. Minimum Clearances

All SDAH modules except are designed to fit through a

14-inch (356 mm) opening, typical of a joist spaced at

16-inch (406 mm) center distance. If no access is provided, an opening must be cut. It is suggested to use the

opening required for the return air box, especially in an

attic installation. The opening for the return air module

is listed in Table 1. If the joists or studs are less than 16-

ches (406-mm) center-to-center or running the wrong

n

i

direction it will be necessary to cut and header the joists.

Blower

Module

Control

Box

Plenum

dapter

(SD-61-xx)

Isolation

Pads

Secondary

Drain Pan

(SD-20x or 24x)

Platform

Figure 3. Typical Horizontal Attic Installation

(SDAHxx)

HP or CWC

(SDAHxxB)

or

(SDAHxxC)

Heating

Module

(SDCMxxH)

Figure 4. Module Flange Connection

All systems are to be installed in the horizontal configuration, with the air going from right to left when looking

at the connections (as shown in figure 1).

Return AirAdapter

(SD-104-xx)

Band (supplied with return air box)

Typical 10 foot (3.6 m) Return Duct

Use at least one 90° bend.

Return Air Box

(SD-01-xx)

Horizontal Installation

Return Air Duct

(SD-04-xx)

Band

IL00009.CVS

IL00039D.CVS

© Copyright 2010 Heat Controller, Inc.

Page 22

Bulletin 100-155 — Page 4

Control Box

The control box is shipped with all SDAH models. It can

be installed on either the discharge side of the blower

cabinet or on top of the blower cabinet, depending on

what is most convenient.

To install, first remove the two knockouts on the side or

top of the cabinet, where it will be installed. Mount the

control box using four (4) sheet metal screws as shown

in Fig. 5. Feed the wires from the anti-frost switch

through the hole and bushing nearest the side of the unit

and connect the leads to the AFS terminals on the SIB

(System Interface Board) condenser terminal strip. The

motor wiring harness will slip through the other hole.

Then simply connect the plug on the motor wiring harness. (For additional information see section on wiring.)

Figure 5. Mounting the Control Box.

Secondary Drain Pan

Where an overflow of condensate could cause water

damage, a secondary drain pan MUST BE INSTALLED.

Place the drain pan on the mounting base, platform or

angle iron support frame. Be sure to allow enough room

for the drain line and connection (refer to Table 3). The

b

led unit should be placed over the secondary

assem

drain pan supported by rails with rubber pads for isolation to raise the unit above the 1.5-inch (38mm) sides o f

the secondary drain pan.

Table 2 shows the secondary drain pans to be used for

ri

zontally mounted modules.

ho

Table 2. Secondary Drain Pan Dimensions, inches (mm)

Unit

Size

24 SD-94

Part No.

SDAH SDAH + Hot Water Coil

Dimensions

inches (mm)

40 x 22 (1016 x 559)

Part No.

Dimensions

inches (mm)

Like the modules, all the secondary drain pans except

SD-24C will fit through the return air opening. For these

drain pans it will be necessary to fold the pans in order

to pass through the return opening.

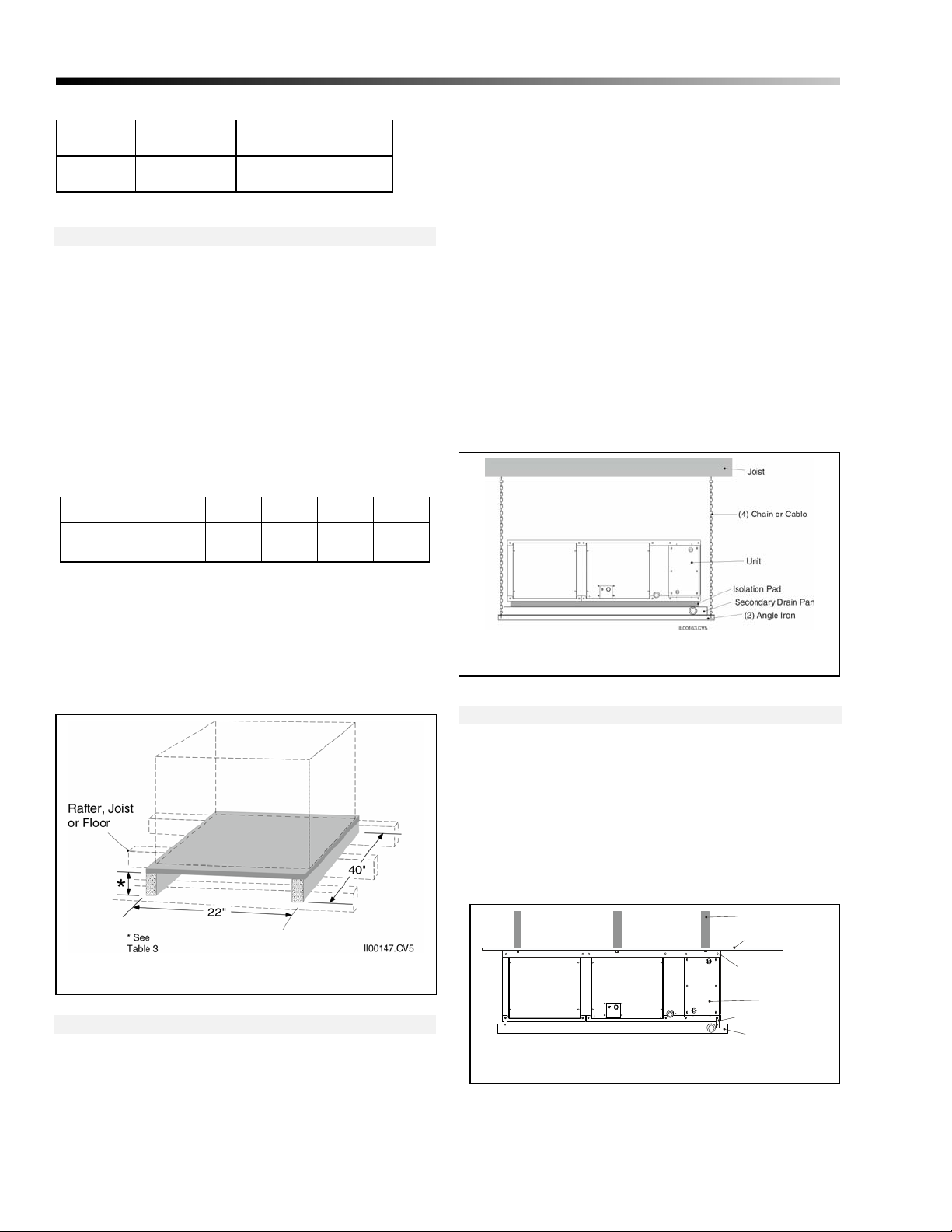

Horizontal Platform Mounting

It is easiest to mount the unit on a platform but care must

be taken to assure proper drain line pitch (see Table 3).

Rafter, Joist

or Floor

B

*

A

IL00036a.CNV

Figure 6. Typical Platform Installation

The platform height must allow for proper pitch of the

condensate drain lines — at least ¼ inch drop per lineal

foot (20 mm per meter). The platform can be built from

a sheet of ½ inch (13 mm) plywood and stud frame. Table 3 lists the maximum horizontal drain line run for

rious framing materials and still provide adequate

a

v

drainage.

Table 3. H orizontal Distance of Drai n Pipi ng for Di fferent

Framing Materials

Frame Lumber:

Max. Horizontal Run, ft. (m)

The platform size must allow for the number of modules

being used. For dimensions for minimum platform size

see Fig. 6.

Unit 24 36 48 24 36 48

A 25 (635) 30 (762) 38 (965) 25 (635) 38 (965)

B 26 (660) 38 (965)

Place secondary drain pan on platform and unit on top of

isolation pads inside of secondary drain pan. Be sure that

the unit is raised above the height of the drain pan side to

allow duct connections.

2 4 2 6 2 8 2 10

18 (5) 26 (8) 34 (10) 42 (13)

SDAH SDAH + Hot Water Coil

36

SD-20B

48

SD-24B

† NOTE — The drain fitting extends 7/8 inch (22 mm) beyond this dimension.

© Copyright 2010 Heat Controller, Inc.

27 29.5†

(686 749)

40 29.5†

(1016 749)

SD-20C

SD-24C

27 41.75†

(686 1060)

40 41.75†

(1016 1060)

Page 23

Horizontal Suspended Mounting

CAUTION

Do no t h ang unit fr om top of unit c abinet as this could distort unit.

The modules can also be suspended from the ceiling or

rafters. A typical suspension method is shown in Fig. 7.

Screw four (4) “J” hooks into rafters. Suspend four (4)

chains from “J” hooks and attach eyebolts to chains.

Secure angle iron to eyebolts and place secondary drain

pan on top. Put isolation pads in drain pan, making sure

unit sits above sides of drain pan.

As an alternative, rest the unit on the angle iron supports,

and hang the secondary drain pan from the same supports. As above, install “J” hooks, chains, and angle iron.

Secure angle iron to eyebolts and put isolation padding

on angle iron.

Adjust the length of the eyebolts and chains so there is a

slight pitch towards the drain end.

HOOK

RAFTER

CHAIN

Bulletin 100-155 — Page 5

Figure 8. Round Supply Plenum Adapter Dimensions

CFM per nominal ton (27-34 L/s per nominal kW).

Measure the motor amperage and use this to ensure the

200-250 CFM per nominal ton (27-34 L/s per nominal

kW) has been achieved. If elevated sound levels are noticed at the outlets and there is more that 250 CFM per