Page 1

OWNER’S MANUAL

Packaged Terminal

Air Conditioners & Heat Pumps

7,000-15,000 BTUH

Cooling with Electric Heat

PTAC07A130A

PTAC09A130A

PTAC12A130A

PTAC12A150A

PTAC15A150A

PTAC15A130A

Heat Pump with Electric Heat

PTHP07A130A

PTHP09A130A

PTHP12A130A

PTHP12A150A

PTHP15A150A

PTHP15A130A

Heat Controller • 1900 Wellworth Ave. • Jackson, MI 49203 • (517)787-2100 • www.heatcontroller.com

Page 2

PACKAGED TERMINAL A/C OWNER’S MANUAL Heat Controller

CONTENTS

UNIT FEATURES ...................................................... 2

INSTALLATION INSTRUCTION ................................ 4

WIRING ..................................................................... 8

OPERATING INSTRUCTIONS

(Accessory Optional). ................................................ 9

MAINTENANCE AND CLEANING ............................11

NORMAL OPERATING SOUNDS

AND CONDITION .................................................... 13

DIAGNOSTIC CODES ............................................ 13

TROUBLE SHOOTING ........................................... 14

IMPORTANT NOTES:

Before using this manual, check the serial plate for

proper model identication.

The installation and servicing of this equipment must

be performed by qualied,experienced technicians

only.

THE FOLLOWING WARNINGS ARE

VERY IMPORTANT FOR SAFETY.

PLEASE READ THEM CAREFULLY

BEFORE INSTALLATION!

1. This air conditioner must be installed by a

certicated installer.

2. Please insure that there is an available ground in

the power supply system before installation.

3. To avoid electric shock or death, the socket

or terminal blocks for power supply to the air

conditioner(include 277V and 115V and 208-230V

series and the units that have LCDI power cord)

must have a Ground Fault Circuit Interrupter.

4. During installation, do not cross connect or reverse

L1 and neutral. Please be sure the ground wire is

rmly connected otherwise it is possible to result in

electrical shock or death.

RECOGNIZE THIS SYMBOL

AS A SAFETY PRECAUTION

WARNING

!

Due to policy of continual product improvement, the

right is reserved to change specications and design

without notice.

IMPORTANT NOTE TO THE OWNER

The service portion of this manual is to be used by

qualied,professionally trained HVAC technicians

only. The manufacturer does not assume any

responsibility for property damage or personal injury

for proper service procedures or services performed

by an unqualied person.

IMPORTANT NOTE TO THE SERVICER

Read this manual and familiarize yourself with the

specic items which must be adhered to before

attempting to service this unit. The precautions

listed in this Installation Manual are intended as

supplemental to existing practices. However, if there

is a direct conict between existing practices and the

content of this manual, the precautions listed here

take precedence.

THE MANUFACTURER WILL NOT BE RESPONSIBLE

FOR ANY INJURY OR PROPERTY, DAMAGE

ARISING FROM IMPROPER SERVICE OR

SERVICE PROCEDURES. IF YOU INSTALL OR

PERFORM SERVICE ON THIS UNIT, YOU ASSUME

RESPONSIBILITY FOR ANY PERSONAL INJURY OR

PROPERTY DAMAGE WHICH MAY RESULT, MANY

JURISDICTIONS REQUIRE A LICENSE TO INSTALL

OR SERVICE HEATING AND AIR CONDITIONING

EQUIPMENT.

!

WARNING

HIGH VOLTAGE

DISCONNECT ALL POWER BEFORE

SERVICING OR INSTALLING THIS UNIT.

MULTIPLE POWER SOURCES MAY BE PRESENT,

FAILURE TO DO SO MAY CAUSE PROPERTY

DAMAGE, PERSONAL INJURY OR DEATH

1

Page 3

Heat Controller OWNER’S MANUAL Packaged Terminal A/C

UNIT FEATURES

This unit has many features which are different than

those found on conventional PTAC units. The servicer

must be familiar with these features in order to

property handle the unit.

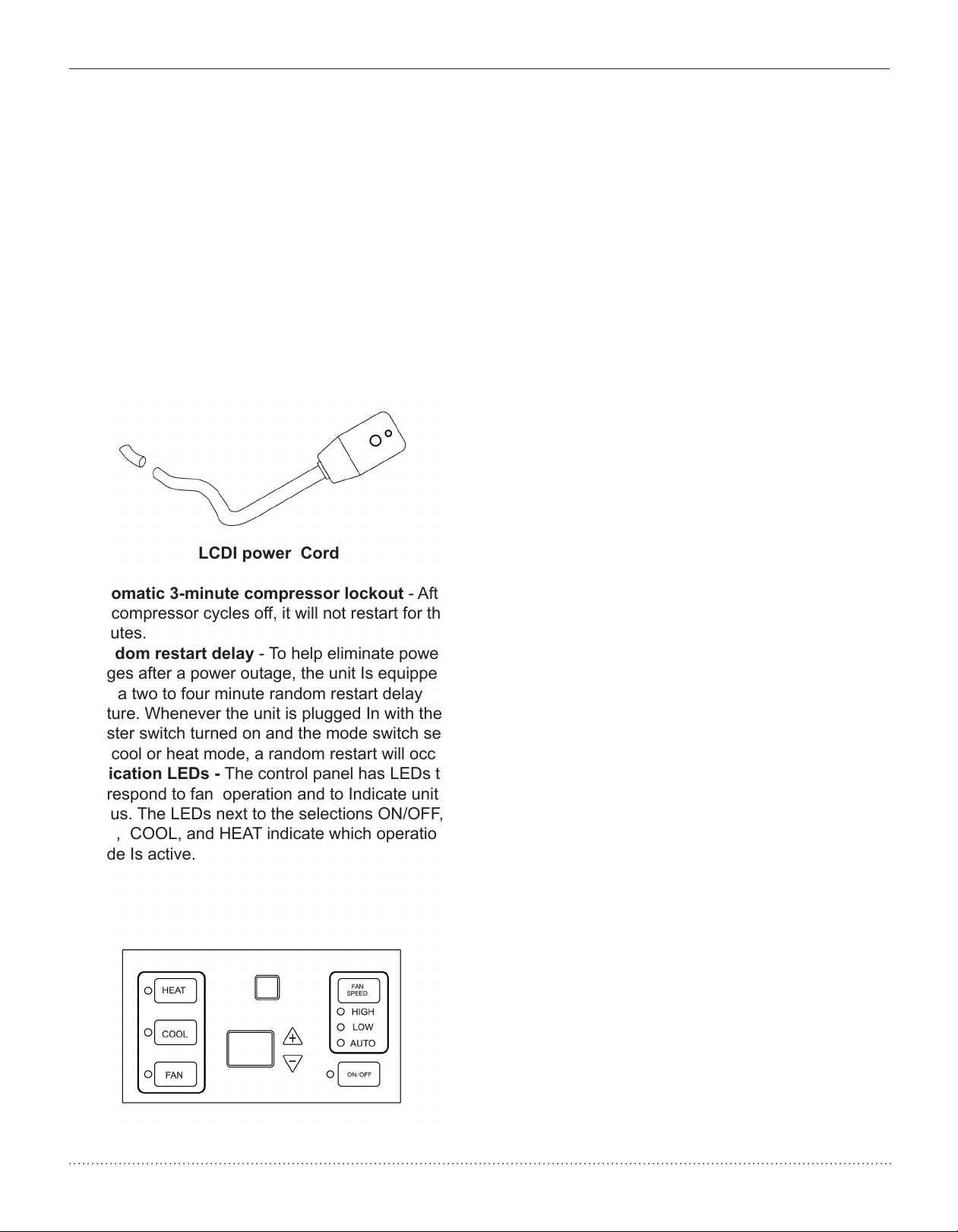

• LCDI Cords - Underwriters Laboratories and the

National Electric Code (NEC) now require power

cords that sense current leakage and can open

the electrical circuit to the unit on units rated at

250 volts or less. In the event that unit does not

operate,check the reset button located on or near

the head of the power cord as part of the normal

troubleshooting procedure.

LCDI power Cord

• Automatic 3-minute compressor lockout - After

the compressor cycles off, it will not restart for three

minutes.

• Random restart delay - To help eliminate power

surges after a power outage, the unit Is equipped

with a two to four minute random restart delay

feature. Whenever the unit is plugged In with the

master switch turned on and the mode switch set in

the cool or heat mode, a random restart will occur.

• Indication LEDs - The control panel has LEDs that

correspond to fan operation and to Indicate unit

status. The LEDs next to the selections ON/OFF,

FAN, COOL, and HEAT indicate which operational

mode Is active.

• High Pressure Protection - The unit will shut off

automatically when the pressure in the system

is over 638 psi and within 10 minutes, after the

compressor turns off, the unit will restart when the

pressure turns back below 551 psi. This protection

can effectively avoid the burst and leakage of

pipes, lessen the system failures and prolong the

service life.

• Failure Tolerance - If the unit is in protection mode

less than 4 times in one hour, the accumulation

times will reset to avoid system failure. Only when

the unit enters protection mode more than 4 times in

one hour will, the system fail to restart automatically

and need manual restart.

• Standard Physical Dimensions - The series PTAC

uses standard dimensions, 42” wide x 16” high x

13-3/4” deep.

Replacement of older units is made easy.

• Weather - Protected Electrical Components

-Vital electrical components are protected from the

weather by locating them on the indoor side of the

weather barrier.

• Highly Featured Microprocessor Controls

- Microprocessor controls are programmed to

interface with the temperature sensors to maximize

comfort conditions for the room occupant.

Thermistors are used to sense small changes in

temperature to give excellent room control and

allow the microprocessor to monitor and react to

changing conditions.

• Automatic Emergency Heat on Heat Pump

Units-Automatically uses electric resistance heat if

the heat pump falls.

• High-Temperature Heat Pump Operation

Protection

-Automatically protects the compressor if heat pump

is operated with high indoor coil temperatures.

Power to the outdoor fan and the compressor

are turned off if the indoor coil gets too hot during

heat pump operation to prevent damage to the

compressor.

2

Page 4

PACKAGED TERMINAL A/C OWNER’S MANUAL Heat Controller

• Fan Motors Permanently Lubricated - All units

have two fan motors for quiet operation and

maximum operating efciency.

Motors are permanently lubricated to reduce

maintenance and totally enclosed to keep dirt and

water out of the motor windings.

• Indoor Fan Speed Selections LOW /HIGH - Unit

may be operated in low fan speed or high fan

speeds. Some speeds may not be present based

on unit capacities.

• Rotary Compressor - smoother operation for quiet,

dependable service and high efciency.

• Indoor Coil Frost Control - prevents indoor coil

from freezing. Frost can form on the Indoor coil

when the unit is operated in cooling when the

outdoor temperature is low. The unit automatically

shuts the compressor off until the indoor coil

temperature warms to the point where frosting will

no longer occur, then restarts the compressor.

ON position enables continuous fan for heating. The

default setting Is fan cycled for heating.

No. 8 -Fan CYC/CON for cooling ON position

enables fan cycle for cooling. The default setting is

fan continuous for cooling.

WARNING: Before service, you must disconnect

the power cord to avoid electric shock! Do not

reprogram DIP switches No. 1 to No. 4, when

powered this could cause damage or re. Power the

unit on again, the new function will be activated.

WARNING

!

HIGH VOLTAGE

DISCONNECT ALL POWER BEFORE SERVICING

OR INSTALLING THIS UNIT. MULTIPLE POWER

SOURCES MAY BE PRESENT,FAILURE TO DO SO

MAY CAUSE PROPERTY DAMAGE,PERSONAL

INJURY OR DEATH.

• LS Control (front-desk control) - The unit can

be turned ON/OFF by a front desk control switch.

The control wire, colored purple, locates in the wall

mounted thermostat interface (refer to Fig. 7 on

page 8).

The control logic as belows:

1. Turn ON unit: short circuit R and LS then release

one time within 5 seconds.

2. Turn OFF unit: short circuit R and LS then release

for twice within 5 seconds.

3. Force unit shut down for one time: connect LS to R

for over 5 seconds.

NOTE: After force shut down, you can turn the unit

ON again by hand-held remote controller or the

control panel.

• Special control functions for DIP switches - The

DIP switches are on main board. No. 5 auto

heating (for units with heat). When unit is connected

to the power supply, and room temperature Is

lower than 10°C/50°F for 3 minutes, unit will start

heating automatically no matter what the setting

mode is. Only when room temperature reaches

13°C/55°F will heating stop.

ON position enables this function.

No. 6 -Electric Power-off Memory. After power on,

the unit will run the same settings as last time.

ON position enables this function. No. 7-Fan

CON/CYC for heating.

UNIT ACCESSORIES

This unit is designed for through-the-wall installation

in new or existing buildings. To complete the

installation of this PTAC, an insulated wall sleeve and

an outdoor grille (either the stamped aluminum

grille, or the architectural grille) are required.

Consult with your distributor to acquire any optional

accessories.

The chassis and the cabinet front are shipped in one

carton.

3

Page 5

Heat Controller OWNER’S MANUAL Packaged Terminal A/C

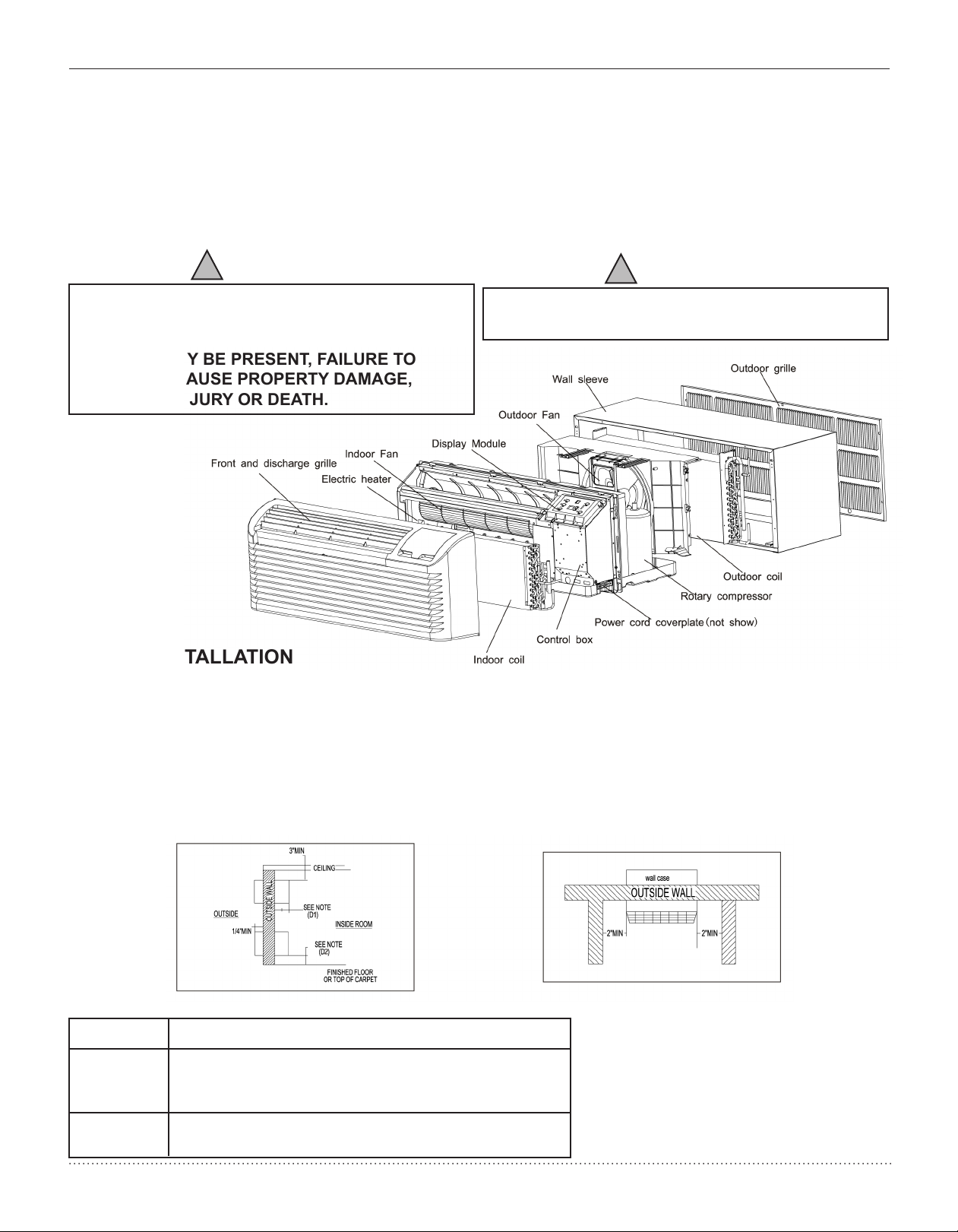

INSTALLATION INSTRUCTIONS

To ensure that the unit operates safely and efciently, it must be installed, operated and maintained according

to these installation and operating instructions and all local codes and ordinances or,in their absence, with the

latest edition of the National Electric Code (or CEC for Canadian Installations). The proper installation of this

unit is described in the following sections. Following the steps in the order presented should ensure proper

installation.

WARNING

!

HIGH VOLTAGE

DISCONNECT ALL POWER BEFORE SERVICING

OR INSTALLING THIS UNIT. MULTIPLE POWER

SOURCES MAY BE PRESENT, FAILURE TO

DO SO MAY CAUSE PROPERTY DAMAGE,

PERSONAL INJURY OR DEATH.

REMOVE FRONT PANEL, DO NOT DIRECTLY

TOUCH THE FIN.

WARNING

!

SLEEVE INSTALLATION

Wall sleeve location

When making the wall opening, please observe the following requirements:

A) The air inlet and outlet should be unblocked so the air can be delivered to every corner of the room.

B) Install the unit in places that are away from heat or sources of ammable gases.

C) Do not install the unit in places that are subject to heavy dust.

D) Do not install the unit in places where the operational noise and exhausted air might trouble your neighbor.

E) There should be sufcient space around the unit to facilitate maintenance and repairs

(refer to Figs. 1 and 2).

Fig. 1 Fig. 2

Dimension Recommended installation clearance

D1 Projection of case into room - 1/2” minimum up to 1-3/4”

maximum without use of electrical sub-base.

Note: 2-3/8” minimum when sub-base is used.

D2 Height above nished oor or top of carpet - 1/2” minimum

2” recommended without sub-base - 3” minimum with sub-base.

4

Page 6

PACKAGED TERMINAL A/C OWNER’S MANUAL Heat Controller

Fig. 3

Preparation of the Wall

The sleeve should be installed during construction

and lintels should be used to support the block above

the wall sleeve. The sleeve can not support the load

of bricks/ blocks.

For existing construction, wall opening must be

created,the proper dimensions are necessary to

avoid use of llers or additional framing .The sleeve is

modular in height and width (refer to Fig. 3 & Chart 2).

Height:

Fits 2 courses concrete block

Fits 6 courses standard brick

Fits 5 courses jumbo brick

Width: Fit approximately 3 stud spaces.

Fig. 5

OUTDOOR GRILLE

(OPTIONAL ACCESSORY)

An outside grille must be Installed to direct air ow for

proper unit operation and also protect the outdoor

coil. The grille must be installed before installing

the chassis. When replacing an old chassis with an

existing grille or using a specialized grille In a new

Installation, please check with after-sales engineer

of supplier to determine if the new chassis should

be used with the nonstandard specialized grille.

An improper outdoor grille can decrease cooling or

Chart 2

Minimum Finished

Opening Dimensions Approximate Sleeve Dimensions

Height Width Height Width Depth

16-1/4” 42-1/2” 16” 42” 13-3/4”

heating capacity,increase energy usage and shorten

compressor life and possibly void the warranty.

STAMPED ALUMINUM GRILLE

Note: Sleeves may vary be slightly manufacturer.

Ensure that the unit ts the sleeve before installation.

In order for condensate water to drain property inside

the unit, the sleeve must be installed properly:

• Level from right to left.

• A slight downward pitch from the indoor side to the

outdoor side as shown below Fig. 4).

• Fasten the wall sleeve (Fig. 5).

Fig. 4 Proper Sleeve Tilt

ARCHITECTURAL GRILLE

5

Page 7

Heat Controller OWNER’S MaNual Packaged Terminal

CHASSIS INSTALLATION

1. Remove the cabinet front from the chassis as

described In Front Removal.

2. Insert the chassis into the wall sleeve.

Chassis Installation View 1

3. Slide the chassis into the wall sleeve until the

chassis anges contact the front edge of the wall

sleeve.

IMPORTANT NOTES:

1. The unit is equipped with a rubber grommet

mounted compressor. These grommets are factory

set and require no adjustment.

2. Check the indoor and outdoor grilles for

obstructions to air ow. The unit must be located

where curtains, furniture, trees, or other objects do

not block the air ow to and from the unit. If air is

obstructed and/or deected back into the unit,the

air conditioner compressor may cycle on and off

rapidly. This could damage the compressor or

possibly void the warranty.

FRONT REMOVAL

1. Grasp the cabinet front.

Screws

(2 on each

side of unit)

Chassis Installation View 2

4. Secure the chassis to the wall sleeve using two

screws on each side of the chassis to ensure a

proper seal between the chassis and the wall

sleeve. The screws are supplied in a plastic bag.

Cabinet Front Removal View 1

2. Pull the bottom of the cabinet front away from

the chassis until the retaining clips disengage.

Cabinet Front Removal View 2

3. Lift the cabinet front off the chassis. Reverse this

procedure to reinstall the cabinet front.

6

Page 8

PACKAGED TERMINAL OWNER’S MaNual Heat Controller

WIRING

Cord connection to a wall socket is not permitted for

265V units. All 265V units must be hard wired using

the hard wire kit or make use of the plug in receptacle

in the standard subbase.

230~208V units are equipped with LCDI power cords

and can open the electrical circuit to the unit. In

the event the unit does not operate, check the reset

button located on or near the head of the power cord

as part of the normal procedure.

WARNING

!

HIGH VOLTAGE

DISCONNECT ALL POWER BEFORE SERVICING OR

INSTALLING THIS UNIT MULTIPLE POWER SOURCES BE

PRESENT, FAILURE TO DO SO MAY CAUSE PROPERTY

DAMAGE, PERSONAL INJURY OR DEATH.

DO NOT SERVICE THIS UNIT WITHOUT FIRST SHUTTING

OFF THE POWER TO THE UNIT FROM THE CIRCUIT

BREAKER AND/OR REMOVING THE UNIT CORD SET PLUG

FROM THE WALL OUTLET.

WARNING

!

TO AVOID THE RISK OF PROPERTY DAMAGE, PERSONAL

INJURY OR FIRE, USE ONLY COPPER CONDUCTORS.

Operating Voltage

Unit Voltage Voltage Utilization Range

Rating Minimum Minimum

230/208 187 253

265 238 292

Chart 3 - Operating Voltage

Perpendicular

230/208V 20 Amp

265V 20 Amp

Large tandem

230/208V 30 Amp

265V 30 Amp

Fig. 6 Receptacles / Sub-bases

WARNING

!

TO AVOID THE RISK OF PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH DUE TO ELECTRICAL SHOCK, DO NOT

USE AN EXTENSION CORD WITH THIS UNIT.

WARNING

!

TO AVOID THE RISK OF PROPERTY DAMAGE, PERSONAL

INJURY OR FIRE. DO NOT INSTALL WITH POWER CORD

STRETCHED OR UNDER A STRAIN AS THIS MAY CREATE

LOOSE PLUG/RECEPTACLE CONNECTION.

WARNING

!

TO AVOID THE RISK OF PERSONAL INJURY, WIRING TO THE

UNIT MUST BE PROPERLY POLARIZED AND GROUNDED.

WARNING

!

THIS AIR CONDITIONER IS NOT MEANT TO PROVIDE

UNATTENDED COOLING OR LIFE SUPPORT FOR PERSONS

OR ANIMALS WHO ARE UNABLE REACT TO THE FAILURE

OF THIS PRODUCT.

THE FAILURE OF AN UNATTENDED AIR CONDITIONER MAY

RESULT IN EXTREME HEAT IN THE CONDITIONED SPACE

CAUSING OVERHEATING OR DEATH TO PERSONS OR

ANIMALS.

Thermostat

VOLTAGE MEASUREMENTS

Once the unit is properly wired, measure the unit

supply voltage. Voltage must fall within the voltage

range given in Chart 3.

Fig. 7 wall mounted thermostat wiring

NOTE: See the “Remote Thermostat Change”

Instructions before using the thermostat.

7

Page 9

Heat Controller OWNER’S MaNual Packaged Terminal

OPERATING INSTRUCTIONS

Operation mode buttons

Press these buttons to select

the unit mode heat, cool or

fan.

Operation mode

indicator lamps

When the unit operates on

heat or cool or fan mode

the indicator lamps will be

activated.

Digital Displayer

On normal operation indicates room temperature;

When pressing + or - button, indicates setting temperature;

On time operation, indicates timer time;

On failure operation, indicates fault code.

Receiver of IR remote controller signal

Fig. 8 Use of unit mounted control panel

Fan Speed button

Press this button to

select the fan speed on

high, low or auto.

Fan speed indicator lamp.

Operation indicator

lamp.

ON/OFF button

Press this button to turn

the unit ON or OFF.

Warm button

Press this button to set room

temperature warmer.

COOL button

Press this button to set room

temperature cooler.

8

Page 10

PACKAGED TERMINAL OWNER’S MaNual Heat Controller

COOL / FAN / HEAT MODE

OPERATION PROCEDURE

Control panel:

• Press the ON/OFF button.

• Press the HEAT/COOL/FAN button, select the

operation mode: heat/cool/fan.

• Press + or - button, to set your desired temperature.

The setting temperature range is 60-90°F (16-32°C).

• Press the FAN SPEED button, to set your desired

air ow rate: high/low/auto.

TIMER PROCEDURE (Remote controller)

When batteries are inserted, the present time Is

automatically set to AM 0:00.E.X.:set to AM10:30.

• Open the back cover,push the CLK button .The time

Indicator is ickering and can set the present time.

• Press the HOUR button.(set to AM 10:00)

• Press the MIN button. (set to 30)

• Press the CLK button again, and then close the back cover.

SET UP OPERATION

1) Temperature shift key: Press + and - button at the

same time for 3 seconds, the temperature is shifted

between Fahrenheit and centigrade.

2) Temperature setting limiting: Press + and SPEED

button at the same time to enter the maximum

and minimum temperature setting. R1~R8 will be

displayed every 3 seconds. Release the two keys

to ensure the setting is effective and the gures will

last for 5 seconds. The temperature setting range

is between so 60°F ~90°F as factory default.

VENTILATION CONTROL

The ventilation control lever is located at left side of

unit, behind front panel.

NOTE: The vent door shipping tape must be removed

before using vent control lever. See Fig. 9 and Fig. 10.

When set to closed, only the air Inside the room is

circulated and ltered;

When set to open, some outdoor air will be drawn into

room, this will reduce heating or cooling efciency.

Shipping tape

Fig. 9 Shipping Tape Location

Remove shipping

screw if present

Chart 4. Temperature setting limiting

R1 R2 R3 R4 R5 R6 R7 R8

Heating Temperature Limits (°F)

86 88 90 74 92 90 72 90

Cooling Temperature Limits (°F)

63 65 72 72 67 69 68 60

3) Remote thermostat change: In standby off

mode, press HEAT and+ button, for 3 seconds,

the buzzer will chime and LED display will read “P”

or “R”.

P: unit control panel has control of unit.

R: wall thermostat has control of unit.

Fig. 10 Shipping Screw Location

The vent control allows outside air to be drawn into the

conditioned area. This outside air can provide ventilation

when the blower Is operating, but it will increase the

heating or cooling load and operating costs.

To obtain access to the vent control

1. Remove the cabinet front (see Front Removal).

2. Remove the shipping screw (if installed) from the

vent door.

3. Remove the label (if present) from over the vent

control lever on the left side of the chassis. Remove

the vent door shipping screw.

4. Rotate the vent control lever to either open or close

the damper.

9

Page 11

Heat Controller OWNER’S MaNual Packaged Terminal

WARNING

!

HIGH VOLTAGE

DISCONNECT ALL POWER BEFORE SERVICING OR

INSTALLING THIS UNIT. MULTIPLE POWER SOURCES BE

PRESENT, FAILURE TO DO SO MAY CAUSE PROPERTY

DAMAGE, PERSONAL INJURY OR DEATH.

Discharge Air Flow

3. Remove the seven (7) screws which secure the

discharge air grille to the cabinet front.

Location of 7 Screws

Discharge Air Flow Grille Removal

4. Rotate the grille 180° clockwise

5. Reinstall the screws securing the discharge air grille

to the cabinet front. Reinstall the cabinet front on

the unit.

Vent door lever positions

AIR DISCHARGE GRILLE

The discharge grille can be adjusted to expel air at

either a 15° or 55° angle.

15°

Discharge

Air

Discharge Grille Orientation Options

55°

Discharge

Air

MAINTENANCE AND CLEANING

WARNING

!

HIGH VOLTAGE

DISCONNECT ALL POWER BEFORE SERVICING OR

INSTALLING THIS UNIT. MULTIPLE POWER SOURCES BE

PRESENT, FAILURE TO DO SO MAY CAUSE PROPERTY

DAMAGE, PERSONAL INJURY OR DEATH.

MONTHLY MAINTENANCE AND CLEANING

Intake Air Filters

To properly maintain the operational performance of

your PTAC unit, it is extremely important that the inlet

air lters be cleaned once per month or more often

if operated in dusty or dirty locations or conditions.

The intake air lters are constructed of durable

polypropylene. The “air intake” air lters can be easily

inserted into the cabinet front, using the lter guides.

Before cleaning the intake lter, turn the unit off by

setting the mode switch to the OFF position. Filter

should be cleaned as required.

Use the following procedure to change the angle of the

discharge air ow:

1. Remove the front cabinet (see Front Removal).

2. Position the front so that the backside is accessible.

The following procedure is used to remove the

intake lter:

1. Grasp each lter by its molded handle, located on the

front edge of the front, below the discharge grill.

10

Page 12

PACKAGED TERMINAL OWNER’S MaNual Heat Controller

2. Pull the lter straight up and remove.

3. Clean lter with vacuum or with running water.

Reverse this procedure to reinstall the lter.

Filter is removed by

grasping the lter’s top

and gently pulling up

Front removal is not

necessary to remove

the lter

Vent Screen

Before cleaning the vent screen, disconnect power

to the unit by unplugging the power cord at the wall

outlet or subbase, or disconnect power at the fuse

box or circuit breaker. If unit is operated with vent door

closed,the vent screen does not need to be cleaned.

1. Remove the cabinet front as described in Front

Removal.

2. Remove the four screws securing the chassis to the

wall sleeve.

3. Slide the chassis out of the wall sleeve far enough so

that the vent screen is accessible.

4. Clean the vent screen, slide the chassis back into the

wall sleeve, secure it in place with four screws and

reinstall the front cabinet.

Cabinet Front

The cabinet front and discharge air grille can be cleaned

with a water dampened cloth. Under no circumstances

should hydrocarbon-based cleaners (e.g. acetone,

benzene, naphtha gasoline,etc.) or ammonia based

cleaners be used to clean the front or air grilles. Use

care when cleaning the control area.

YEARLY MAINTENANCE AND CLEANING

NOTE: Use a mild biodegradable detergent when

cleaning the unit. Special care must be taken to protect

the unit’s control board and other electrical components

from getting any water on them while cleaning. The use

of harsh or caustic cleaning agents or materials such as

bleach or coil cleaners that are not designed for PTAC

products will cause damage or deterioration of the

aluminum n or coil material and is not recommended.

Care must be taken not to bend the aluminum n stock.

Routine scheduled Maintenance

To achieve continuing top performance and high

efciency, establish a “once a year” cleaning/inspection

schedule for the unit. Take the unit out of the sleeve and

thoroughly clean and rinse. Be sure to include in the

yearly cleaning the evaporator coil, and condenser coil,

basepan, and drain passages.

Scheduled maintenance can be accomplished by either

qualied local maintenance staff or by an authorized

servicer. They must follow the instructions described in

this manual.

Adverse Operating Conditions Maintenance

Units operating in dusty or corrosive locations; i.e.

dusty construction site or sea coast, must be cleaned

more often. A minimum of four (4) times a year will

maintain proper operational conditions and protect unit

components.

Wall sleeve

Clean the wall sleeve while cleaning the unit. The

caulking around the sleeve should be checked to make

sure that any potential air and water openings around

the sleeve are properly sealed. The wall sleeve’s level

should also be rechecked. Proper leveling for most

installations are a 1/4 bubble tilt to the outside and

level from right to left. Contact your sales person for

detailed maintenance or cleaning instructions.

CAUTION

!

DO NOT USE COMMERCIAL GRADE COIL CLEANERS.

SOME OF THESE CLEANERS MAY CONTAIN ETHYLENE

DIAMINE TETRACTEIC ACID (EDTA) WHICH CAN SHORTEN

THE LIFE OF THE CONDENSER COIL.

Base pan and Condenser coil

Before cleaning the base pan and condenser coil, turn

OFF unit mode switch and disconnect power to the unit.

To disconnect power, either unplug the power cord at

the wall outlet or subbase, or disconnect power at the

fuse box or circuit breaker

1. Create a water tight seal by tightly covering the entire

control panel area and fan motor with plastic. Creating

this seal prevents water from entering the control area

or the fan motor and damaging the unit.

2. Spray condenser coil and base pan down with water.

3. Rinse condenser coil and base pan with water again.

NOTE: Ensure water pressure is no higher than that

of an ordinary garden hose and the water temperature

no higher than 120°F.

11

Page 13

Heat Controller OWNER’S MaNual Packaged Terminal

4. Tilt the non-compressor side of the unit up no higher

than 45 degrees and allow water to drain out the other

side of the unit.

5. Remove excess water left in the base pan by wiping

the base pan with a dry cloth.

6. Remove the water-tight seal from the motor and

control panel area.

7. Reinstall unit back into wall sleeve.

8. Allow unit to dry for 24 hours before reapplying

power. When power is reapplied test unit for proper

operation.

9. Place a non-acidic algaecide in the base pan to inhibit

bacteria growth. Ensure the algaecide is compatible

with wet coil operation and is not corrosive to the coil.

CAUTION

!

HIGH PRESSURE AND HIGH TEMPERATURE CLEANING IS

NOT RECOMMENDED.

DOING SO COULD DAMAGE THE ALUMINUM FIN STOCK

AND ELECTRICAL COMPONENT.

Clearance Check

Clearances around the unit should also be checked to

make sure that the intake air and discharge air paths

have not become blocked or restricted. A minimum of

eight inches clearance is needed from unit to furniture,

beds, or other objects for proper operation. Restricted

discharge or intake air will reduce the unit’s operational

performance. In severe airow restrictions, damage

can occur to unit components such as the compressor,

electric heater or fan motor.

Air sounds

The fan cycle switch sets the operational mode of the

fan. In the ON position the fan will run continuously

whenever power is applied in this mode. In the

AUTO position, the fan will cycle on and off with the

compressor or electric heater.

Starting delay

You may notice a few minutes delay in the starting if

you try to restart the unit too soon after turning it off or if

you adjust the thermostat right after the compressor has

shut off. This is due to a built-in delay to protect the

compressor.

Buzzer Response

The buzzer will chime (0.1 sec) as response when

receiving an order from key pad control and remote

control.

DIAGNOSTIC CODES

The Diagnostic Maintenance provides detailed

information on PTAC control operation and operational

status including present modes, failures, airow

restriction warnings, operating temperatures, and past

failures.

To enter Diagnostic Status Report mode,press and

hold the down arrows and,while holding press the FAN

SPEED key for a period of ve (5) seconds.

The meaning of gure on display pad is as below:

X.X---(0~4: time of protection)

L---is protection mode(1: anti-frost; 2: overheat; 3: high

pressure; 4: anti-freezing)

NORMAL OPERATING SOUNDS

AND CONDITIONS

Water trickling sounds

Water is picked up and distributed over the coil. This

improves the efciency and helps with water removal.

Water dripping

Water will collect in the base pan during high humidity

days. This can cause overow and drip from the outside

of the unit.

Failure

code Content or detect

E2 Indoor coil temperature sensor failure

E3 Indoor temperature sensor failure

E5 Outdoor coil temperature sensor failure

E8 Overheating protectlon/defrostlng

E9 High pressure protection

12

Page 14

PACKAGED TERMINAL OWNER’S MaNual Heat Controller

TROUBLESHOOTING

POSSIBLE CAUSES

UNIT DOES NOT START

• Unit may be unplugged

• Fuse may have blown

• Circuit breaker may have tripped

• Unit may be off or in wall thermostat mode.

Check section on dipswitch settings to verify dipswitches

are set properly.

• Unit may be in a protection or diagnostic failure mode. See

section on diagnostic codes.

DISPLAY HAS STRANGE NUMBERS/CHARACTERS ON IT

UNIT MAKING NOISES

UNIT NOT COOLING / HEATING ROOM

• Unit air discharge section is blocked

• Temperature setting is not high or low enough

Note: Setpoint limits may not allow the unit to heat or cool the

room to the temperature desired. Check section on dipswitch

settings.

• Unit air lters are dirty.

• Room is excessively hot or cold when unit is started

• Vent door left open

• Unit may be in a protection or diagnostic failure mode. Check

section on Intelligent Self --- checking Control.

• Compressor is in time delay. There is a protective time delay

(approx. 3 minutes) on starting the compressor after a power

outage (or restarting after it has been turned off), to prevent

tripping of the compressor overload.

SOLUTIONS

• Check that plug is plugged securely in wall receptacle.

Note: Plug has a test/reset button on it. Make sure that the

plug has not tripped.

• Replace the fuse.

• Reset circuit breaker.

• Turn unit on (bottom right button on keypad).

Note: lf the unit turns on, the LED will be green. If the unit is off,

the LED will be red. If there is no LED on, there is a problem

with power or damage to the control.

• The unit may be in a diagnostic condition. Check diagnostic

codes --- checking Control section to determine if unit has had

a failure.

• The unit may be set for °C (instead of °F), see the SET UP

OPERATION.

• Clicking, gurgling and whooshing noises are normal during

operation of unit.

• Make sure that curtains, blinds or furniture are not restricting

or blocking unit airow.

• Reset to a lower or higher temperature setting.

• Remove and clean lters.

• Allow sufcient amount of lime for unit to heat or cool

the room. Start heating or cooling early before outdoor

temperature, cooking heat or gatherings of people make room

uncomfortable.

• Close vent door.

• Check dipswitch settings for desired comfort.

• Wait approximately 3 minutes for compressor to start

WATER DRIPPING INSIDE

WATER DRIPPING INSIDE

• Wall sleeve is not installed level

ICE OR FROST FORMS ON INDOOR COIL

• Low outdoor temperature

• Dirty lters

COMPRESSOR PROTECTION

• Power may have cycled, so compressor is in a restart

protection.

• If a drain kit has not been installed, condensation runoff during

very hot and humid weather is normal. See Note 2. If a drain

kit has been installed and is connected to a drain system,

check gaskets and ttings around drain for leaks and plugs.

• Wall sleeve must be installed level for proper drainage of

condensation. Check that installation is level and make any

necessary adjustments.

• When outdoor temperature is approximately 55°F (12.8 °C) or

below, frost may form on the indoor coil when unit is in Cooling

mode. Switch unit to FAN operation until ice or frost meIts.

• Remove and clean lters.

• Random Compressor restart-Whenever the unit is plugged in,

or power has been restarted, a random compressor restart will

occur. After a power outage, the compressor will restart after

approximately 3 minutes.

• Compressor Protection-To prevent short cycling of the

compressor, there is a startup delay of 3 minutes and a

minimum compressor run time of 3 minutes.

13

Page 15

Heat Controller OWNER’S MANUAL Packaged Terminal A/C

Page 16

'XHWRRQJRLQJSURGXFWLPSURYHPHQWVVSHFLILFDWLRQVDQGGLPHQVLRQVDUH

VXEMHFWWRFKDQJHDQGFRUUHFWLRQZLWKRXWQRWLFHRULQFXUULQJREOLJDWLRQV'HWHUPLQLQJWKH

DSSOLFDWLRQDQGVXLWDELOLW\IRUXVHRIDQ\SURGXFWLVWKHUHVSRQVLELOLW\RIWKHLQVWDOOHU

$GGLWLRQDOO\WKHLQVWDOOHULVUHVSRQVLEOHIRUYHULI\LQJGLPHQVLRQDOGDWDRQWKHDFWXDOSURGXFW

SULRUWREHJLQQLQJDQ\LQVWDOODWLRQSUHSDUDWLRQV

,QFHQWLYHDQGUHEDWHSURJUDPVKDYHSUHFLVHUHTXLUHPHQWVDVWRSURGXFWSHUIRUPDQFH

DQGFHUWLILFDWLRQ$OOSURGXFWVPHHWDSSOLFDEOHUHJXODWLRQVLQHIIHFWRQGDWHRIPDQXIDFWXUH

KRZHYHUFHUWLILFDWLRQVDUHQRWQHFHVVDULO\JUDQWHGIRUWKHOLIHRIDSURGXFW

7KHUHIRUHLWLVWKHUHVSRQVLELOLW\RIWKHDSSOLFDQWWRGHWHUPLQHZKHWKHUDVSHFLILF

PRGHOTXDOLILHVIRUWKHVHLQFHQWLYHUHEDWHSURJUDPV

:HOOZRUWK$YH-DFNVRQ0,3KZZZKHDWFRQWUROOHUFRP

9/2014

Loading...

Loading...