Page 1

MGD Series Gas Furnace Installation Instructions

INSTALLATION INSTRUCTIONS

SEALED COMBUSTION

DOWNFLOW MGD SERIES

GAS FURNACE SIZES 60, 75, 90

FOR INSTALLATION IN: MANUFACTURED (MOBILE) CAUTION: READ ALL SAFETY GUIDES

HOMES, RECREATIONAL VEHICLES, PARK MODELS, BEFORE INSTALLING THIS FURNACE

MODULAR HOMES AND BUILDINGS

GENERAL INFORMATION

These down flow sealed combustion furnaces install in

Manufactured Homes, Recreational Vehicles or Modular

Construction. The furnaces conform to Part 3280 (a) (2) of

HUD Manufactured Homes Construction and Safety

Standards. They must be installed only with listed RJ-Roof

Jack, Sealed Combustion venting system.

NOTE: These instructions are intended to assist qualified

individuals experienced in the installation of heating

equipment.

Some state and local codes require installation personnel to be

licensed. Read all instructions before starting the installation.

SAVE THIS MANUAL

WARNING-RISK OF FIRE OR ELECTRICAL SHOCK

Only qualified service personnel shall be used to install

and provide maintenance of this furnace.

NOTICE – Furnace set-up and any adjustment needed is

responsibility of the installer/ retailer/ contractor and is not

covered by the furnace manufacturers warranty.

CHECKLIST: FURNACE START-UP

1. Has furnace roof jack crown been correctly installed?

2. Has the furnace gas valve and burner orifice been

cleaned?

3. Is the gas line outlet pressure set for the fuel used?

4. If the home uses a crossover air connector duct, is it

installed per homebuilders installation instructions?

5. Has furnace been operated through complete heating

cycle?

Heat Controller, Inc. Jackson, MI 49203 MGD Installation Instructions 1

Page 2

MGD Series Gas Furnace Installation Instructions

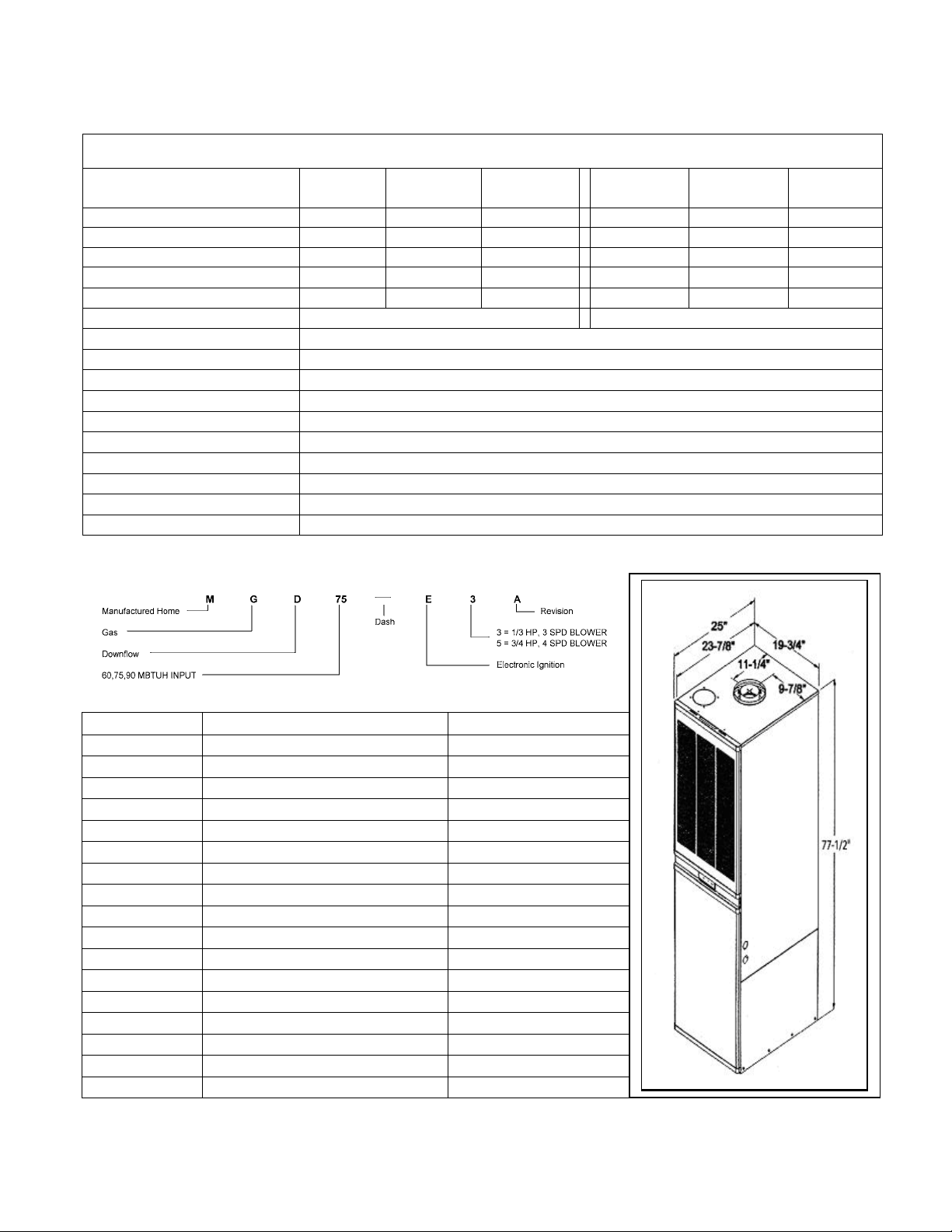

SPECIFICATIONS

80 AFUE- AUTOMATIC HOT SURFACE

IGNITION

Model No. MGD60-E3A MGD75-E3A MGD90-E3A MGD60-E5A MGD75-E5A MGD90-E5A

Input, BTUH 60,000 75,000 90,000 60,000 75,000 90,000

Output, BTUH 48,000 60,000 72,000 48,000 60,000 72,000

AFUE, % 80.0 81.0 80.0 80.0 81.0 80.0

With A-Coil Cabinet YES YES YES YES YES YES

Ignition Type Auto-Elect Auto-Elect Auto-Elect Auto-Elect Auto-Elect Auto-Elect

Air Temperature Rise, Range-F 40-70 45-75 50-80 40-70 45-75 50-80

Blower 10 X 8, 1/3 HP, 3 SPD 10 X 8, 3/4 HP, 4 SPD

Designed Max Outlet Air Temp-F

Max. External SP (Duct),In. W.C. .30 Heating

Factory Equipped Fuel Natural Gas (Factory Equipped) - LP Orfice Furnished

High Altitude For elevations above 2,000 feet, reduce input 4% for each 1,000 ft. elevation above sea level

Furnace Flue Pipe Must Use RJS Roof Jack for Sloped Roof or RJF Roof Jack for Flat Roof

Gas Connection 1/2" FPT

Electric Service 115 VAC, 60 HZ, 1 PH

Fuse or Circuit Breaker 15 Amp

Thermostat Circuit 24VAC, 60Hz, 40VA

Filters 1-16"x40"x1" Washable

PRODUCT CODE

165 °

PART NO. DESCRIPTION NOTES

90-RJF1729-AL Body, Roof Jack, Gas-FLAT Height 94 1/2 X 106 1/2

90-RJF2551-AL Body, Roof Jack, Gas-FLAT Height 102 1/2 X 128 1/2

90-RJS1729-AL Body, Roof Jack, Gas-SLOPE 3/12 Height 94 1/2 X 106 1/2

90-RJS2551-AL Body, Roof Jack, Gas-SLOPE 3/12 Height 102 1/2 X 128 1/2

90-RJS3868-AL Body, Roof Jack, Gas-SLOPE 3/12 Height 115 1/2 X 145 1/2

90-RJS6399-AL Body, Roof Jack, Gas-SLOPE 3/12 Height 140 1/2 X 176 1/2

90-RJCRWN-AL Crown, Roof Jack, Gas Use w/ Gas Roof Jack Body

90-TRN-RNG Ceiling Trim Ring, Roof Jack Trim out to inside RJ - Pipe

90-OUTXT16-AL Roof Jack Outdoor Extension - Gas 16" Extend pipes / crown - 16 in.

90-INXST10-AL Roof Jack Indoor Extension - Gas 10" Extend pipes / crown - 10 in.

90-RJS56 5-6/ 12 Slope, Roof Saddle Adapter Add to RJS 3/12 Roof Jack

90-DCU0-01 86AA0013 Duct Conn + 87FB0005 Flr Base Floor to Duck 1 in. - 4 in.

90-DCU0-02 86AA0014 Duct Conn + 87FB0005 Flr Base Floor to Duck 6 in. - 8 in. STD

90-DCU0-03 86AA0015 Duct Conn + 87FB0005 Flr Base Floor to Duck 8 in. - 12 in.

90-CABEXT4 White, Top, Cabinet Extender Plate Fill alcove 76" top opening

87-1008-3/12A1 A/C Blower, 3 Speed - 1/3 HP 2 - 4 Ton A/C

87-1008-4/16A1 A/C Blower, 3 Speed - 3/4 HP 2 - 5 Ton A/C

Heat Controller, Inc. Jackson, MI 49203 MGD Installation Instructions 2

Page 3

MGD Series Gas Furnace Installation Instructions

SAFETY CONSIDERATIONS INSTALLATION STANDARDS

• ELECTRIC POWER - turn off all electrical

power to furnace before performing any

maintenance or service on unit. Failure to take

this precaution may result in personal injury due

to electrical shock.

• SERVICE - a qualified service technician

should service this unit. Fuel burning appliances

can generate toxic flue products. Modification of

the appliance can cause carbon monoxide in

deadly amounts. To prevent a safety hazard,

maintain this

appliance in a safe operating manner and do not

modify.

• DO NOT modify vent or operate the unit with a

blocked vent or inlet air pipe.

• DO NOT re-drill a burner orifice. If the orifice

size must be changed, use only a new orifice.

• DO NOT use matches, lighters, candles, or

other sources of open flame to check for gas

leaks.

• PROPER maintenance for this unit requires

certain mechanical skills and tools. If you are at

all uncertain, contact your Heating Service Co.

for maintenance and service.

• CONSULT with a service technician for any

problems or questions you may have pertaining

to this appliance.

• ALWAYS inspect the appliance before starting

a new heating season, paying special attention to

vent pipes and fuel lines.

NOTE: The words “Shall” or “Must” indicate a

requirement, which is essential to satisfactory and safe

furnace performance.

The words “Should” or “May” indicate a recommendation

which may be helpful or enhance performance.

CODE COMPLIANCE

The installer shall become familiar with and follow all local

codes and regulations which govern the installation of this

furnace. Where applicable, local codes may take precedence.

• Federal Manufactured Home Construction and Safety

Standards – HUD Title 24, Part 3280.

• National Fuel Gas Code – ANSI-Z223.1/NFPA-54

• Unit electrical wiring and grounding shall comply with

National Electrical Code – ANSI/NFPA-70

• “M anufactured Housing” – NFPA-501 and Fi re Safety Crit eria

for Mobile Home Installations – NFPA 501A

• “Recreational Vehicles” – ANSI – 119/NFPA – 501C

HIGH ALTITUDE INSTALLATION

For elevations above 2,000 feet derate furnace input 4% for each

1,000 feet of elevation above sea level. Furnace deration is

accomplished by reducing the burner orifice size. See

DERATING CHART for orifice size and CONVERSION

INSTRUCTIONS, Page 16.

INSTALLATION CLEARANCES

These furnaces are design certified for the following minimum

clearances from combustible materials in alcove or close

instllations.

Top ……………………………….6 in.

Sides ……………………………...0 in.

Back ………………………………0 in.

Alcove-front of furnace ………….18 in.

Closet-front of furnace ……………6 in.

Duct ……………………………….0 in.

Vent/Roof Jack ……………………0 in.

* If the return air opening is below the top of the

furnace, clearance to the side or rear shall be 6”.

** See Return Air for clearances less than 6”.

Locate furnace to ensure adequate room for service access to all

vent connections, controls and the heat exchanger. A front

clearance of 18” minimum (24” recommended) shall be

provided by a closet door or spacing away from a facing wall or

partition.

For installation on combustible flooring (except carpeting) using

manufacturers supplied floor base P/N 87FB0005 and duct

Connector Series P/N 86AA001, included in 90-DCU0-01/03

kits.

Heat Controller, Inc. Jackson, MI 49203 MGD Installation Instructions 3

Page 4

MGD Series Gas Furnace Installation Instructions

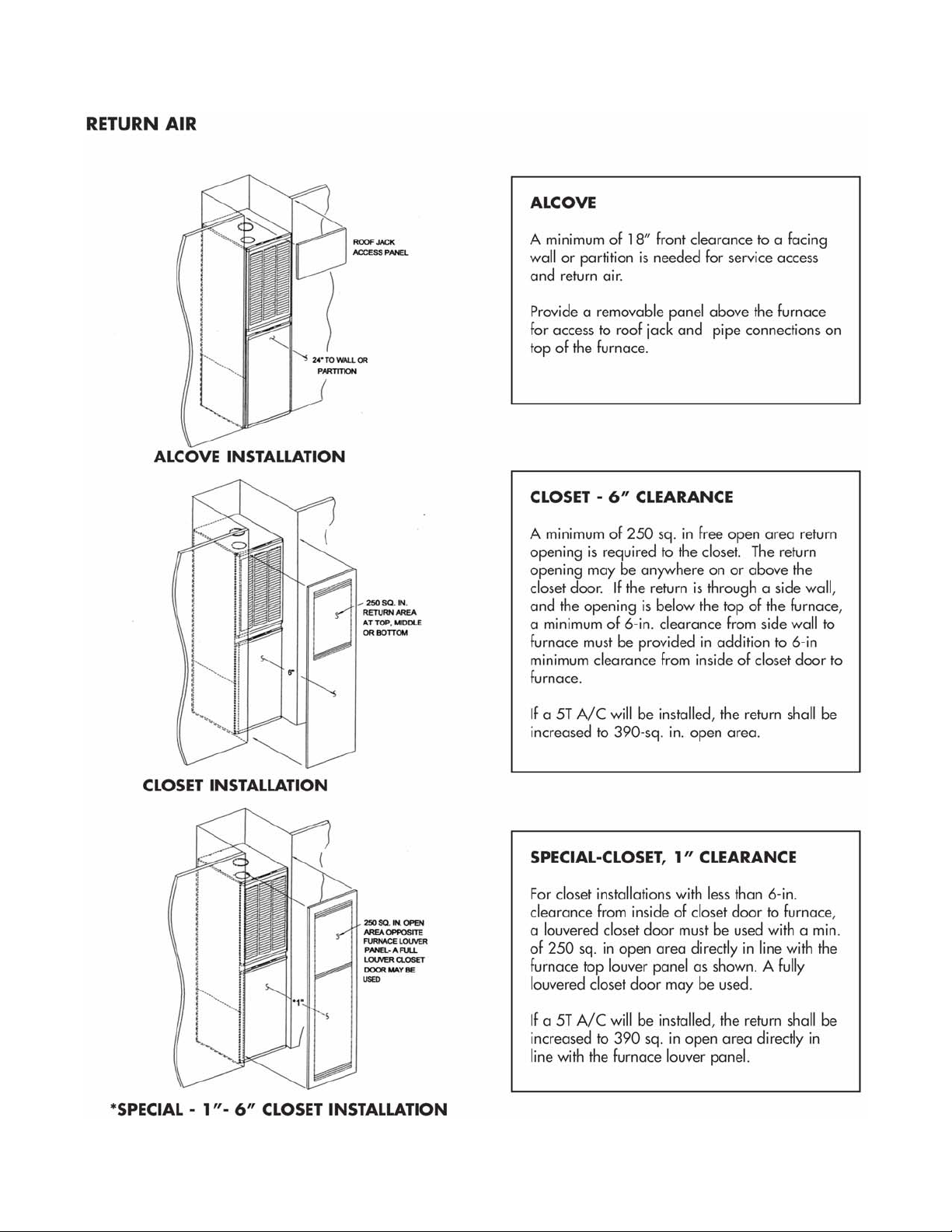

RETURN AIR

ALCOVE INSTRUCTION

The furnace may be installed free standing or in an

alcove with a free flow of air back to the furnace. A

minimum of 18” shall be provided at the front for

return air and service access.

CLOSET INSTALLATION – 6 in.

Note: If return air is through a side wall, there must

be a minimum of 6-in. clearance from side wall to

furnace in addition to 6-in. minimum clearance from

inside of closet door to front of furnace.

If a louvered door complying with the minimum air

requirements is used, the front clearance my be reduced to

1”.

CLOSET INSTALLATIONS

Additional Requirements

Concerning under floor or ceiling return air systems,

the following item (1 – 10) must be adhered to:

1. The return-air opening into the closet, regardless

of location, is to be sized not less than specified

on the appliance rating plate.

2. If the return-air opening is located in the floor of

the closet (versus the vertical front or side wall),

the opening is to be provided with means to

prevent its inadvertent closure by a flat object

placed over the opening.

3. The cross-sectional area of the return system

(when located in the floor or ceiling of the

manufactured home) leading into the closet is to

be not less than that of the opening specified on

the appliances rating plate.

4. The total free area of openings in the floor or

ceiling registers serving the return-air duct

system is to be not less than 150% of the size

opening specified on the appliance rating plate.

At least one such register is to be located where

the likelihood of its being covered by carpeting,

boxes, and other objects is minimized.

5. Materials located in the return duct system have

a flame spread classification of 200 or less.

6. Non-combustible pans having one-inch upturned

flanges are located beneath openings in the floor

return duct system.

7. Wiring materials located in the return d uct system

conform to Article 300-22 (B&C) of the National

Electric Code, ANSI / NFPA-70.

8. Gas piping is not run in or through the return duct

system.

9. The negative pressure in the closet, as determined by

test with the air-circulating fan operating at high

heating speed and the closet door closed, is to be not

more negative than minus 0.05-inch water column.

10. For floor return systems, the manufactured home

manufacturer or installer shall affix a prominent

warning where it is easily read when the closet door

is open.

The marking shall read:

Heat Controller, Inc. Jackson, MI 49203 MGD Installation Instructions 4

Page 5

MGD Series Gas Furnace Installation Instructions

Heat Controller, Inc. Jackson, MI 49203 MGD Installation Instructions 5

Page 6

MGD Series Gas Furnace Installation Instructions

Heat Controller, Inc. Jackson, MI 49203 MGD Installation Instructions 6

Page 7

MGD Series Gas Furnace Installation Instructions

SEALED COMBUSTION ROOF JACK – (REQUIRED)

Heat Controller, Inc. Jackson, MI 49203 MGD Installation Instructions 7

Page 8

MGD Series Gas Furnace Installation Instructions

CUTTING ROOF JACK OPENING

A proper installation of the roof jack requires that

openings in roof and ceiling be on the same vertical

centerline as the furnace flue collar. See FIG. 1

Mark the center point on the ceiling and scribe a 4” radius

(8” diameter) around this mark. If furnace is in place

during this step, cover the furnace and flue opening to

prevent debris from entering flue.

INSTALLING ROOF JACK

The roof jack body should be secured to the furnace

before the roof flashing is secured to the roof.

1. Insert roof jack body into opening in the roof.

2. From above, canter the roof jack body aligning with

the furnace collar.

3. From inside the home, pull down 4-3/16” D flue pipe

seating the pipe fully and firmly over the furnace flue

collar.

4. Next pull down the 7” D combustion air pipe seating

it over the mating furnace collar. Rotate the

combustion air pipe lining up to the screw hole on the

7” collar.

5. Check and make sure the combustion air pipe is fully

seated. Then drive a # 10 sheet metal screw, attaching

pipe firmly to furnace collar.

6. Install optional ceiling trim ring, 90-TRM-RNG

7. On the roof, caulk liberally under the roof jack

flashing.

8. Drive nails or screws through the flashing onto the

roof surface about 1 – 11/2” apart. Caulk again to

ensure a leak tight joint.

9. Install roof jack crown and fasten to roof jack body

with three (3) screws (provided) using pre-punched

holes.

.

INSTALLATION IN SNOW REGIONS

When the combustion air inlet to the roof jack is

blocked with snow, the furnace will not operate

properly due to the depleted combustion air supply.

Therefore, if the furnace will be located in regions where

snow accumulation on the roof exceeds 7” or in H.U.D.

Snow Load Zones, a roof jack extension – Part5 No. 90OUTXT16-AL is recommended.

ROOF JACK ON HI-PITCH ROOF

To install the RJS (3/12) Series Roof Jack on roofs which

have a slope between 4.5/12 – 6/12, install a Part No. 90RJS56 Roof Saddle, FIG. J. The combined assembly of

the RJS Roof Jack and Roof Saddle will conform to the

higher roof pitch. If roof pitch is greater than 6/12, field

fabricate a suitable adapter, or consult with factory.

Heat Controller, Inc. Jackson, MI 49203 MGD Installation Instructions 8

Page 9

MGD Series Gas Furnace Installation Instructions

CONNECT POWER SUPPLY

1. Remove the furnace control panel cover.

2. Insert 115 V wiring through a strain relief

bushing on the left side of the furnace.

3. Connect the HOT wire to the black pigtail lead;

connect the NEUTRAL wire to the WHITE

pigtail lead. Secure the connections with suitable

wire nuts and wrap with electrical tape. Refer to

Wiring Diagram on Pg. 11 for connections.

4. Connect the GROUND wire to a grounding screw

in the control panel.

5. Reinstall and secure the control panel cover with

screws.

Heat Controller, Inc. Jackson, MI 49203 MGD Installation Instructions 9

Page 10

MGD Series Gas Furnace Installation Instructions

GAS PIPE AND TUBING-MIN SIZES

MODEL TYPE LENGTH PIPE TUBING

MGD OF SIZE SIZE

GAS (FT.) (IN.) (IN. OD)

to 20 3/8 5/8

Natural to 60 1/2 -

60 to 70 - 3/4

to 40 3/8 Propane to 70 - 5/8

to 80 1/2 to 20 - 5/8

to 50 1/2 Natural to 60 - 3/4

75 to 80 3/4 -

to 30 3/8 Propane to 60 - 5/8

to 80 1/2 to 40 1/2 3/4

Natural to 50 - 3/4

90 to 30 3/8 Propane to 40 - 5/8

to 60 1/2 3/4

Heat Controller, Inc. Jackson, MI 49203 MGD Installation Instructions 10

Page 11

MGD Series Gas Furnace Installation Instructions

WIRING DIAGRAM, MGD

Heat Controller, Inc. Jackson, MI 49203 MGD Installation Instructions 11

Page 12

MGD Series Gas Furnace Installation Instructions

REPLACEMENT PARTS

Heat Controller, Inc. Jackson, MI 49203 MGD Installation Instructions 12

Page 13

MGD Series Gas Furnace Installation Instructions

MGD Gas Furnace Parts List

ITEM NO. USED ON FURNACE MODEL PART NO. QTY DESCRIPTION

1 All R68DD0010 1 Pressure Switch, -0.20 N.O.

2 All R71CA0006 2 ft. Silicon Tubing

3 All R68CA0005 1 Limit Switch, Manual, Upper-180F

4 All R86GF0050 1 Boost Blower Assembly, w/ Air Orifices

5 All R68GF0001 1 Integrated Control Board, HSI

6 All R68GF0006 1 Gas Valve for HSI Electric Ignition

7 All R68BKN007 1 Valve Bracket & Orifice Holder

MGD60 R86GF0051 1 Heat Exchanger & Gaskets

8

MGD75, 90 R86GF0052 1 Heat Exchanger & Gaskets

9 All R68GF0004 1 Flame Sensor

10 All R68DD0009 1 System Switch - SPST

11 All R68GF0002 1 Transformer (115V-24V, 40VA)

12 All R68CA0004 1 Limit Switch - Open 140 F - Close 110 F

13 All R86GF0054 1 Burner Assembly

14 All R68GF0005 1 Hot Surface Igniter

15 All R76AA0002 2 Filter (16" X 20" X 1")

16 All R86GF0055 1 Door Panel - Upper

17 All R86GF0143 1 Door Panel - Lower

MGD60/90-E3A R65GF0002 1 Motor - 1/3 HP

18

19 MGD60/90-E5A R86GF0056 1 Motor Mount Assembly

20

21 All R69AB0001 1 Blower Wheel - 10 x 8

30 All R86GF0058 4 Door Latch, Set

32

33 All R87NNE001 1 Filter Retainer Bracket

MGD60/90-E5A R65GF0003 1 Motor - 3/4 HP

MGD60/90-E3A R68DE0002 1 Capacitor - 15/370M

MGD60/90-E5A R68DE0003 1 Capacitor - 25/370V

MGD60 (Natural Gas) 72AG-144 1 Main Burner Orifice - #27

MGD75 (Natural Gas) 72AG-166 1 Main Burner Orifice - #20

MGD90 (Natural Gas) 72AG-177 1 Main Burner Orifice - #16

MGD60 (Propane) 72AG-089 1 Main Burner Orifice - #43

MGD75 (Propane) 72AG-101 1 Main Burner Orifice - #38

MGD90 (Propane) 72AG-110 1 Main Burner Orifice - #35

Heat Controller, Inc. Jackson, MI 49203 MGD Installation Instructions 13

Page 14

MGD Series Gas Furnace Installation Instructions

Reference: NFPA No. 54, ANSI Z 223.1 National Fuel Gas Code

Table shows 4% Input Reduction per 1,000 feet elevation

For Canadian High Altitude (2,000-4,500 feet), reduce gas pressure to burner manifold (manifold Ps.) to 3.0” W.C. and 9.0” W.C. for LP (Propane) Gas

Heat Controller, Inc. Jackson, MI 49203 MGD Installation Instructions 14

Loading...

Loading...