Page 1

OWNER’s MANUAL

Packaged Terminal

Air Conditioners & Heat Pumps

7,000-15,000 BTUH

Cooling with Electric Heat

EKTC07-1G

EKTC09-1G

EKTC12-1G

EKTC15-1G

Heat Pump with Electric Heat

EKTH07-1G

EKTH09-1G

EKTH12-1G

EKTH15-1G

EKTC07-2G

EKTC09-2G

EKTC12-2G

EKTC15-2G

EKTH07-2G

EKTH09-2G

EKTH12-2G

EKTH15-2G

Heat Controller • 1900 Wellworth Ave. • Jackson, MI 49203 • (517)787-2100 • www.heatcontroller.com

Page 2

Packaged Terminal A/C OWNER’S MANUAL Heat Controller

■ ...........................1

■ ................................... 2

■

.................................

4

■ ................................. 8

■ ........................... 9

■

...............................

13

■

.......................

14

■

...............................

15

■

................. ..............

12

■ ............................1

■ .....................................5

CONTENTS

SYSTEM CONFIGURATION

HOW TO CONNECT

SAFETY CONSIDERATIONS

GENERAL INFORMATION

UNIT FEATURES

ELECTRICAL DATA

INSTALLATION

OPERATION

CARE AND CLEANING

PREVENTATIVE MAINTENANCE

TROUBLESHOOTING

........

TABLE OF CONTENTS

Safety Considerations ........................................................................................................ 2

General Information .......................................................................................................... 2

Unit Features ...................................................................................................................... 3

Electrical Data .................................................................................................................... 5

Installation .......................................................................................................................... 6

How to Connect .................................................................................................................. 9

System Conguration .......................................................................................................10

Operation ..........................................................................................................................13

Care and Cleaning ............................................................................................................ 14

Preventative Maintenance ............................................................................................... 15

Troubleshooting ................................................................................................................16

The figures in this manual may be different with the material objects, please refer

to the material objects for reference.

This symbol stands for the items

should be forbidden

This symbol stands for the items

should be followed

Do not dispose this product as unsorted municipal waste.

Collection of such waste separately for special treatment

is necessary.

1

Page 3

Heat Controller OWNER’S MANUAL Packaged Terminal A/C

Safety Considerations

Recognize safety information. This is the safety-alert symbol .When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury. Understand these signal words: DANGER, WARNING, and CAUTION. These

words are used with the safety-alert symbol.

DANGER identies the most serious hazards which will result in severe personal injury or death.

WARNING signies hazards which could result in personal injury or death.

CAUTION is used to identify unsafe practices which may result in minor personal injury or product and property damage.

NOTE is used to highlight suggestions which will result in enhanced installation, reliability, or operation.

WARNING

!

!

PERSONAL INJURY AND/OR PROPERTY DAMAGE HAZARD

Failure to follow this warning could result in personal injury, death and/or property damage. For your safety, the

information in this manual must be followed to minimize the risk of re or explosion, electric shock, or to prevent

property damage, personal injury, or loss of life.

• This unit must be properly installed in accordance with the Installation Instructions before it is used.

• Immediately repair or replace all electric service cords that have become frayed or otherwise damaged.

• Unplug or disconnect the unit at the fuse box or circuit breaker before making any repairs.

NOTE: We strongly recommend that any servicing be performed by a qualied individual.

GENERAL INFORMATION

Heat Controller package terminal air conditioners and heat pumps provide a high standard of quality in performance, workmanship, durability and appearance as they heat and cool the occupied air space year round.

This manual provides information for ease of installation, operation and maintenance. All models are designed for through-thewall installation. Separate installation instructions are included with all accessory components.

BEFORE YOU BEGIN

Read these instructions completely and carefully.

IMPORTANT: Save these instructions for local inspector’s use.

IMPORTANT: Observe all governing codes and ordinances.

NOTE TO INSTALLER

Be sure to leave these instructions with the owner.

NOTE TO OWNER

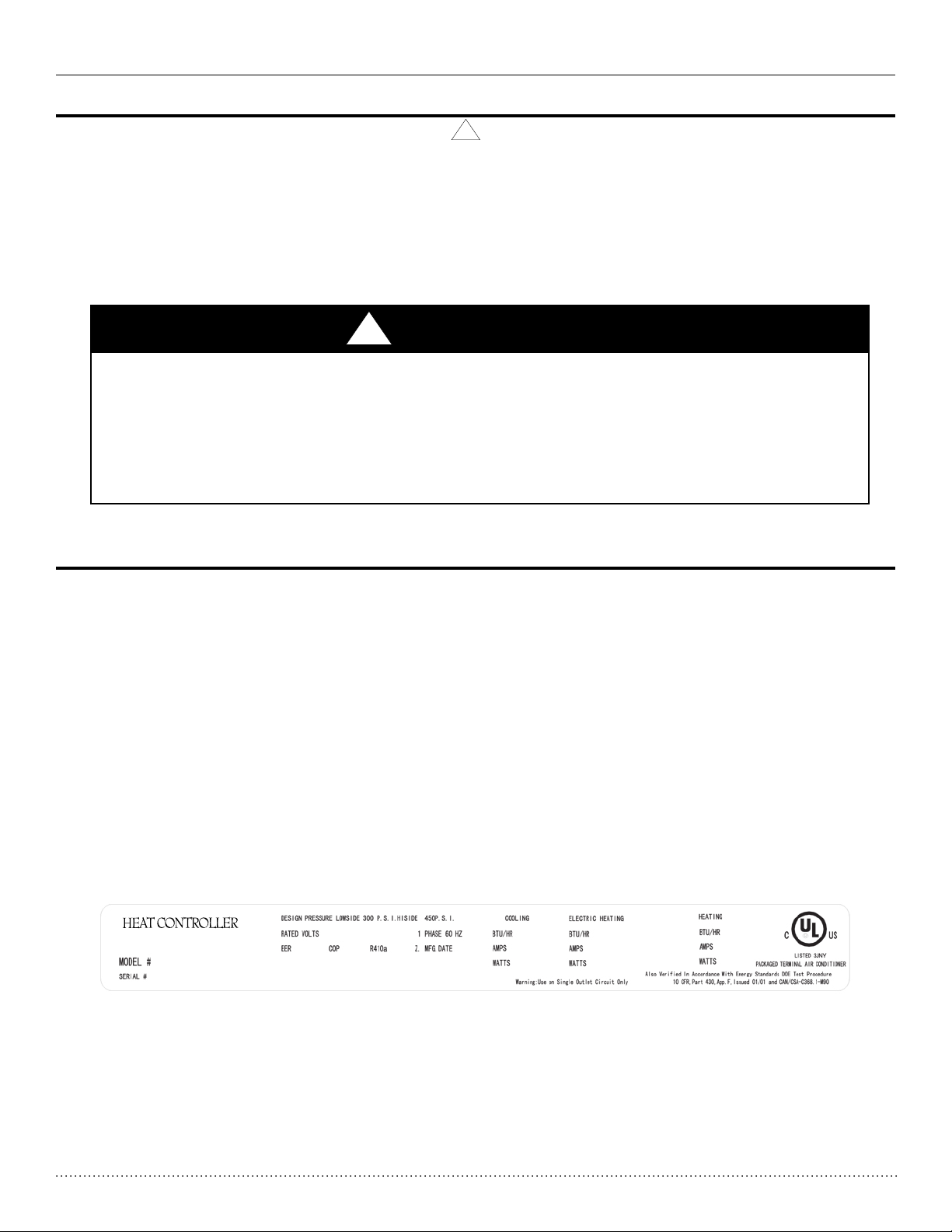

Keep these instructions for future reference. Be sure to write down the model and serial number of unit on space provided

on back page. The model and serial number can be located on the serial number plate attached to unit. These numbers are

required for service. See Fig. 1.

Fig. 1 – Sample Data Information Plate

2

Page 4

Packaged Terminal A/C OWNER’S MANUAL Heat Controller

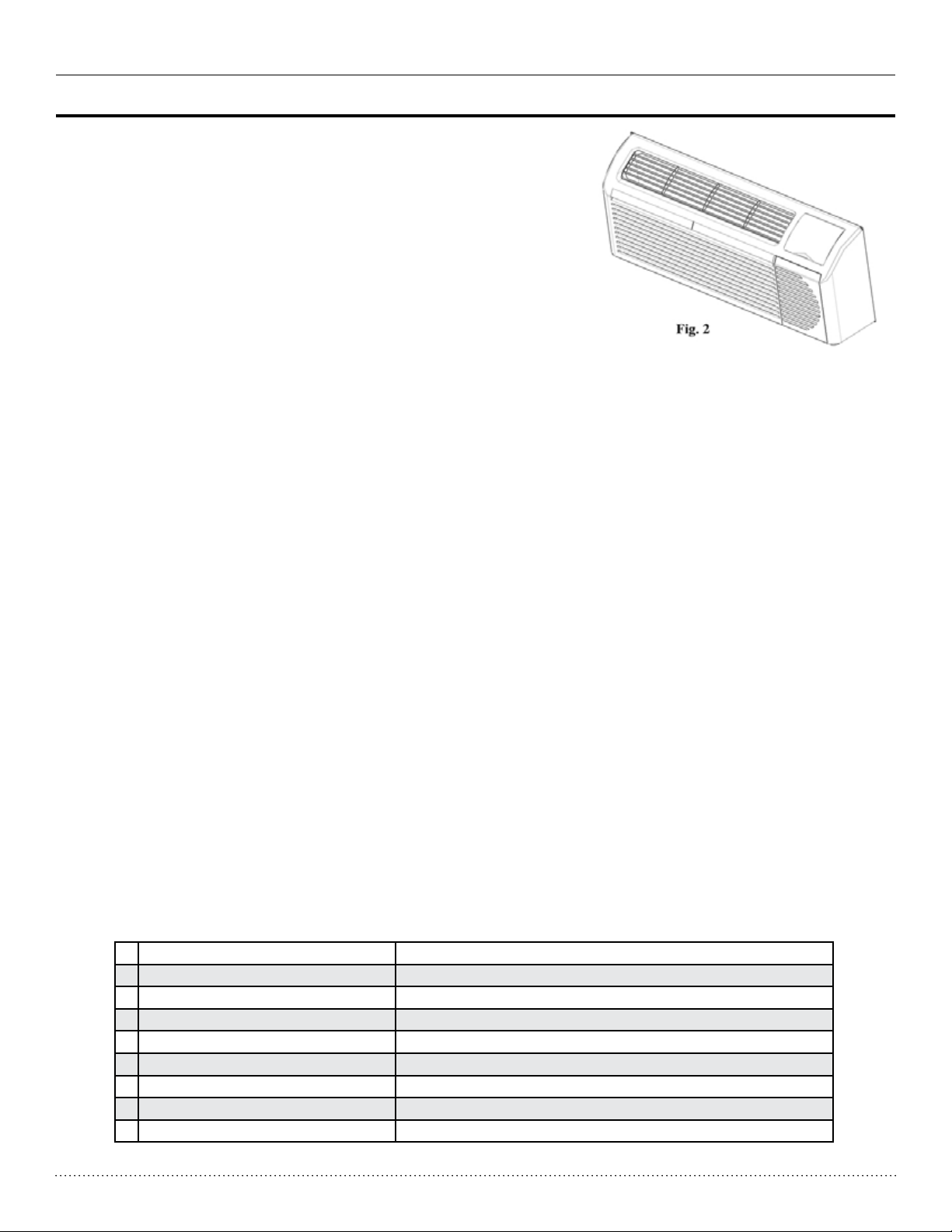

UNIT FEATURES

This unit has many exciting features which are different than those found on

standard PTAC models. The owner must be familiar with these features in order to

fully understand the operation and capability of the unit.

• SELF DIAGNOSITICS—The unit has an onboard computer that utilizes real-

time diagnostics to prolong the life of your unit. There is an LED indicator on

the control board located behind the front panel, that will ash an error code

if the unit has detected some kind of fault condition. In many cases, the unit

will automatically clear the fault condition and continue operating with no

interruption. In some cases, the condition cannot be cleared and the unit will

require service. In those cases, an “Fx” failure mode will be displayed on the

digital display. For a detailed list of all error codes and “Fx” conditions, see

Table 6—Status LED Indicator Denitions for further details.

• AUTO RESTART—If power is lost, all of the control settings (setpoint, mode,

fan speed, on/off and conguration) are stored. So when power is restored, the unit will start back up in the mode (and conguration) it was in when power was lost.

• QUIET OPERATION—The unit has 2 fan motors and a tangential blower wheel to reduce noise. The indoor fan will always run

a minimum of 10 seconds before the compressor, to help reduce any compressor starting noise.

• RANDOM COMPRESSOR RESTART—To help prevent power surges after a power outage (from many of your PTAC/HPs starting

at the same time), the compressor is equipped with a 2:45 to 3:15 minute random restart delay feature.Whenever the unit is

plugged in, or power has been restarted, a random compressor restart will occur between the random restart time frame.

• COMPRESSOR PROTECTION—To prevent short cycling of the compressor and maximize it’s life, there is a random start--up

delay of 3 minutes on the compressor and a minimum compressor run time of 3 minutes.

•AUTOMATIC ROOM FREEZE PROTECTION—The unit will automatically will keep the temperature in the room from getting

too cold, where water pipes might freeze. If the unit is congured for the freeze protection feature to be active (which is the

default condition), and while power is supplied to the unit, if the unit senses temperature below 40°F, the fan motor and

electric heater are turned on and will warm the room to 50°F. If Freeze protection is not required, change the conguration

switch to turn the feature off (see section on unit conguration).

• AUTOMATIC DEFROST PROTECTION (FOR HEAT PUMP MODELS ONLY)—When the outdoor temperature gets too cold (ap-

prox. 35°F) and the unit can no longer effectively heat with the compressor, the unit will automatically switch to electric heating. The unit will then heat with electric heat until the outside temperature rises enough (approx. 40°F), so the compressor

can be used to effectively heat again.

• AUTOMATIC QUICK WARM-UP (FOR HEAT PUMP MODELS ONLY)—If the room temperature falls to 5°F below the set point

temperature, the reverse cycle heat is shut off and the electric strip heat is turned on for one cycle, until heating is satised.

•LED INDICATOR’S AND BUTTONS—The touch pad has buttons for MODE, FAN SPEED, ON/OFF, SETPOINT UP and SETPOINT

DOWN. It also has LEDs that correspond to the mode, fan speed and setpoint operation, to indicate the unit’s status. The

LEDs below the mode button, FAN, COOL, and HEAT, indicate which operating mode is active. The LEDs below the Fan button,

Low, Med and Hi, indicate the fan speed that is selected. The LED located in the lower right corner is the unit On/Off status

LED. If the unit is in ON mode, the LED will be green. If the unit is OFF, the LED will be red.

• CONFIGURE FAN TO OPTIMIZE SELECTED APPLICATION—This unit can be optimized to specic applications by conguring

the fan to run in a continuous mode or to cycle on and off with the compressor and electric heater (can be different for both

heating and cooling modes). In cycle mode, fan will continue to run after compressor or electric heater stops in order blow off

any residual heat or cool left on coil. In continues mode, the fan remains on at all times even when the compressor is off.

Table 6—STATUS LED Indicator Denitions

1 Indoor air temp sensor open/short 7 Segment display ‘F1’, with STATUS light ash 1 time,off 2 seconds

2 Indoor coil sensor open/short 7 Segment display ‘F2’, with STATUS light ash 2 times and off 2 seconds

3 Outdoor coil sensor open/short 7 Segment display ‘F4’, with STATUS light ash 4 times and off 2 seconds

4 Freeze Guard protection 7 Segment display ‘FP’

5 Thermostat wiring error STATUS light ash 9 times and off 3 sec, repeat

6 Indoor coil high temp protection STATUS light ash 8 times and off 3 sec, repeat

7 Defrost (heat pump type) STATUS light ash 7 times and off 3 sec, repeat

8 Outdoor coil high temp protection STATUS light ash 6 times and off 3 sec, repeat

9 Indoor coil freeze protection STATUS light ash 5 times and off 3 sec, repeat

NOTE: When status light is ashing, it will be ON for 0.5 seconds and OFF for another 0.5 seconds.

3

Page 5

Heat Controller OWNER’S MANUAL Packaged Terminal A/C

Unit Features CONTINUED

• Unit Conguration —There are many different conguration possibilities, through both dipswitches and the digital keypad,

that allow you to congure the unit for your exact application. See section on unit conguration for more details. Following

are the conguration selections that have not previously been mentioned:

• °F or °C—The unit can display in either °F or °C

• Indoor Temperature Sensor Biasing —Optimize the room temperature sensor reading to your exact

application (one for cooling and another for heating).

• Emergency Heat (forHeat Pump Only)—Disable the compressor during heating mode operation (heat

only with Electric Heat).

• Display Setpoint OR Room Temperature—The unit can be congured to display the room temperature

OR setpoint only, during heating and cooling modes. See section on unit conguration for more details.

• Limit the Setpoint Range—The unit can be congured to limit the controlling setpoint range.The display

will always show the complete setpoint range, but the controlling setpoint will be limited to the congured

minimum and maximum setpoint selected. See section on unit conguration for more details.

• Energy Management—Sometimes known as Front Desk Control, an input is provided so that the unit can

be manually disabled from a different location. If the unit detects 24 vac on this input, it will automatically

turn itself off. If no voltage is detected on the input, the unit will run normally.

• Wall Thermostat Control—A wired wall thermostat can be connected to the unit. If it is, the unit must be

congured to disable the keypad. See section on wired inputs and unit conguration for more details.

UNIT NOMENCLATURE

EKTC—Cooling only with Electric Heat

EKTH—Heat Pump with Electric Heat

EKTC 07 - 1 G

BTU/H

07K

09K

12K

15K

Fig. 3 – Unit Nomenclature

VOLTAGE CODE

1=208/230V-60Hz

2=265V-60Hz (consult factory)

MODEL REVISION

G=Green R-410A

Refrigerant Gas

4

Page 6

Packaged Terminal A/C OWNER’S MANUAL Heat Controller

ELETRICAL DATA

WARNING

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury or death and/or property damage. DO NOT alter cord or plug or use an extension cord.

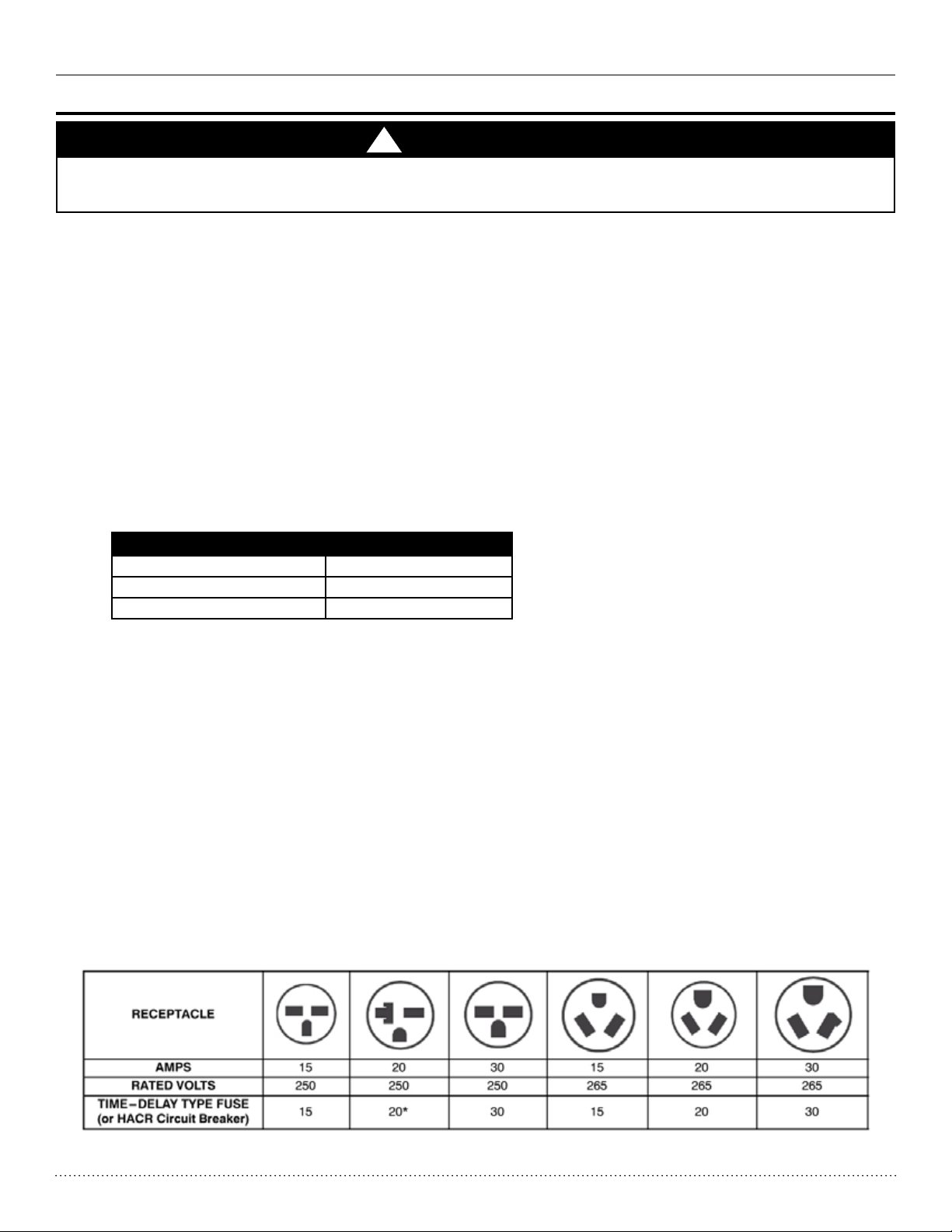

POWER CONNECTION OPTIONS

Appropriate power cord accessory kit is determined by the voltage, and amperage of the branch circuit. The unit does not come

with a power cord (or hard wire kit). An accessory power cord kit must be ordered to connect the unit to the outlet. If the unit is

to be hard wired, an accessory hard wire kit must be ordered.

IMPORTANT: For 265V units, if a power cord is selected, it must plug into the 265V subbase accessory.

Be sure that your outlet matches the appropriate blade conguration of the plug and that it is within reach of the service cord.All

wiring, including installation of the receptacle, must be in accordance with the NEC and local codes, ordinances and regulations.

National codes require the use of an arc fault or leakage current detection device on all 208/230V power cords. Be sure to select

the correct cord for your installation.

ALL UNITS

Wire Size

Use recommended wire size given in Table 1 and install a single branch circuit.All wiring must comply with local and national

codes. All units are designed to operate off ONE single branch circuit only.

NOTE: Use copper conductors only.

Table 1—SUGGESTED BRANCH CIRCUITWIRE SIZES*

NAMEPLATE AMPS

7.0 to 12 14

12.1 to 16 12

16.1 to 24 10

AWG WIRE SIZE

LEGEND

AWG --- American Wire Gauge

* Single circuit from main box.

Based on copper wire at 60°C temperature rating.

Grounding

For safety and protection, the unit is grounded through the service cord plug or through separate ground wire provided on

hard wired units. Be sure that the branch circuit or general purpose outlet is grounded.

VOLTAGE SUPPLY

Check voltage supply at outlet. For satisfactory results, the voltage range must always be within the ranges found on the

data information plate.

Cord-connected Units

The 250V eld supplied outlet must match the plug for the standard 208/230V units and be within reach of the service

cord. The standard cord-connected 265V units require an accessory electrical subbase for operation. Refer to Table 2 for

proper receptacle and fuse type.

Power Cord Protection

The power cord for 230/208v units provide power cord re protection.Unit power automatically disconnects when unsafe conditions are detected. Power to the unit can be restored by pressing the reset button on plug head. Upon completion of unit instal-

lation for 230/208V models, an operational check should be performed using the TEST/RESET buttons on the plug head.

NOTE: The 265V models do not incorporate this feature as they require use of the electrical subbase accessory.

Table 2—RECEPTACLES AND FUSE TYPES: 250, 265 VOLTS

LEGEND

HACR—Heating, Air Conditioning, Refrigeration * May be used for 15 amp applications

5

Page 7

Heat Controller OWNER’S MANUAL Packaged Terminal A/C

INSTALLATION

Proper installation is the responsibility of the installer.

Product failure due to improper installation is not covered under the Warranty. See the warranty card enclosed with your

unit for more details.

CHASSIS INSTALLATION

Units are shipped without a sleeve. In applications where unit is a replacement, it is recommended that a Heat Controller sleeve

be used.

These units can retrot General Electric, Amana, Carrier, Trane, Friedrich and many other eld installed sleeves/grilles (be sure

outdoor grille is installed on the sleeve). See Table 3 for details.

For any sleeve retrot applications, be sure that the foam seals (factory--installed on the tube sheets) provide a good seal between the grille and outdoor coil tube sheets. These foam seals provide a barrier to separate outdoor coil leaving air from mixing

with the outdoor incoming air (known as air recirculation).

Table 3—Retrot Wall Sleeves

CAUTION

!

UNIT DAMAGE AND/OR OPERATION HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

For retrot applications, foam seals on outdoor coil tube

sheets must make a seal between the coil and the grille or

loss of performance and premature damage to the major

components can result.

Manufacturer Wall Sleeve Part Number

General Electric

Carrier

Amana

Trane

Friedrich

* FR-SLEEVE-EXT accessory is required for retrot into Friedrich (T -Series)

wall sleeves.

Metal Sleeve RAB71

Plastic Sleeve RAB77

Metal Sleeve SLEEVE-STEEL-1PK

Plastic Sleeve SLEEVE-INSUL-1PK

Metal Sleeve WS900B

Metal Sleeve SLV149

T---Series Metal 111/2---in. Deep Wall

Sleeve*

Standard Depth Wall Sleeve

16 X 42 X 133/4---in. PXWS

Fig. 4—Unit Components

6

Page 8

Packaged Terminal A/C OWNER’S MANUAL Heat Controller

RETROFIT SLEEVE PREPARATION

IMPORTANT: Inspect wall sleeve thoroughly prior to installation. Manufacturer does not assume responsibility for costs

or damages due to defects in sleeve or for improper installation.

WARNING

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Disconnect all power to unit to avoid possible electrical

shock during installation.

NOTE: See installation instructions included with wall sleeve

for information on installation.

NOTE: Wall sleeves with a depth of 13.75” to 13.88” can be

used in combination with competitive grilles.

7

Page 9

Heat Controller OWNER’S MANUAL Packaged Terminal A/C

INSTALL UNIT INTO WALL SLEEVE

1. Carefully remove shipping tape from the front panel and vent door. See Fig. 5.

2. Remove shipping screw from the vent door, if present. See Fig. 6.

3. Remove front panel. See Fig. 7.

4. Lift unit level and slide unit into wall sleeve until foam seal rests rmly against front of wall sleeve.

5. Secure with four screws (supplied) through the unit ange holes. See Fig. 8.

6. Reinstall front panel. See Fig. 9.

CAUTION

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Failure to remove shipping tape and screw will prevent

fresh air vent door from opening and may result in

damage to vent door cable

Fig. 5—Shipping Tape Location

Fig. 4—Shipping Screw Location

Pull out at the bottom to release it from the tabs (1).

Then lift up (2).

Fig. 7—Removing Front Panel

Fig. 8—Securing Unit

Place tabs over top rail (1). Push Inward at bottom

until panel snaps into place (2).

Fig. 9—Replacing Front Panel

8

Page 10

Packaged Terminal A/C OWNER’S MANUAL Heat Controller

HOW TO CONNECT

IMPORTANT: Please read following electrical safety data carefully.

WARNING

!

ELECTRICAL SHOCK AND/OR UNIT OPERATION AND DAMAGE HAZARD

Failure to follow this warning could result in personal injury or death and/or unit operation and damage.

• Follow the National Electrical Code (NEC) or local codes and ordinances.

• For personal safety, this unit MUST BE properly grounded.

• Protective devices (fuses or circuit breakers) acceptable for unit installations are specied on the nameplate of each unit.

• Do not use an extension cord with this unit.

• Aluminum building wiring may present special problems -- consult a qualied electrician.

• When unit is in STOP position, there is still voltage to electrical controls.

• Disconnect power to unit before servicing by:

1. Removing power cord (if it has one) from wall receptacle.

2. Removing branch circuit fuses or turning circuit breakers off at panel.

1. Remove front panel. See Fig. 7.

2. Remove junction box.

• Remove junction box cover by removing three screws from front. Remove junction box by taking out top, rear and side

screws. See Fig. 10.

3. Connect accessory power supply cord or hard wire connector to unit connector. See Fig. 11.

• Units must be installed using the appropriate power supply kit. See Table 4—POWER CONNECTION CHART. These

connections must be followed.

4. Reinstall junction box and cover.

S Use wire clamp to attach power cord to basepan. Secure with screws (included) See Fig. 12.

S Relace junction box and cover with screws removed from Step 2. Tighten securely.

5. Replace front panel. See Fig. 9.

6. Connect power to unit.

Fig. 10—Junction Box Location

Fig. 12—Wire Clamp

Fig. 11—Power Connection

Table 4—Power Connection Chart

CODE OF POWER SUPPLY KIT

UNIT MODEL

EKTC07-1G

EKTH07-1G

EKTC09-1G

EKTH09-1G

EKTC12-1G

EKTH12-1G

EKTC15-1G

EKTH15-1G

EKTC07-2G

EKTH07-2G

EKTC09-2G

EKTH09-2G

EKTC12-2G

EKTH12-2G

EKTC15-2G

EKTH15-2G

* Using 30A on these units could result in damage to your unit.

9

30A 20A 15A

230/208 VOLT

N/A*

7602-530A-230

265 VOLT

N/A*

7602-530A-265

230/208 VOLT

7602-520A-230

265 VOLT

7602-520A-265

230/208 VOLT

7602-515A-230

265 VOLT

7602-515A-265

Page 11

Heat Controller OWNER’S MANUAL Packaged Terminal A/C

SYSTEM CONFIGURATION

VENTILATION CONTROL

The ventilation control lever is located at left side of unit,

behind front panel.

NOTE: The vent door shipping hardware must be removed

before using vent control lever. See Installation Instructions.

When set at CLOSE, only the air inside the room is circulated

and ltered.

When set at OPEN, some outdoor air will be drawn into room.

This will reduce heating or cooling efciency.

Energy Tip:Keep the vent control at CLOSE. Room air will

be ltered and circulated.

ADJUSTING AIR DIRECTION

To adjust air direction from outward (default) to upward:

1. Remove front panel. See Fig. 7.

2. Remove louver screws that hold louver insert in place (from back side of front panel). See Fig. 13.

3. Turn louver insert and rotate 180°. See Fig. 14.

4. Replace louver insert.

5. Replace screws and front panel.

Fig. 12—Ventilaiton Control Location

Fig. 13—Backside of Front Panel

Fig. 14—Adjusting Louvers

10

Page 12

Packaged Terminal A/C OWNER’S MANUAL Heat Controller

DIP SWITCHES

Auxiliary dip switch controls are located behind front panel,

through an opening below the control panel. To access, remove front panel. See Fig. 7.

Dip switches are accessible without opening the control box.

Unit must be powered OFF to effectively change their status.

Factory settings for dip switches will be in the DOWN position.

See Table 5—Dip Switch Functions for functions of each dip

switch position.

Fig. 15—Dip Switches

Fig. 16—Dipswitch Location on Unit

Table 5—DIP SWITCH FUNCTIONS

d

d

d

d

Electric Heating Only / Emergency Heat (For Heat Pump Units Only)

This setting is typically used for EmergencyHeating.

Wall Thermostat Enable

A wired wall thermostat can be connected to the unit. If it is, this dipswitch must be moved to the Wall Thermostat Enable

Position, before the wall thermostat will begin control.

Heat and Cool Fan CON/CYC Dip--switches

Allows the fan to operate in continuous or cycle modes while the unit is in heating or cooling mode (continuous or cycle):

CON (Continuous)

Allows fan to run continuously, circulating air even when the temperature setting has been satised. This switch helps to

maintain the room temperature closer to the thermostat setting.

CYC (Cycle)

This setting allows the fan to cycle on and off with the compressor or electric heater. The fan stops a short time after the temperature

setting is satised.

Setpoint Temperature Limits

Provides a restricted range of temperature control.

Room Freeze Protection

If unit senses a room temperature below 40°F, the fan motor and electric strip heat will turn on and warm the room to 50°F. The

fan stops a short time after the temperature is satised.

11

Page 13

Heat Controller OWNER’S MANUAL Packaged Terminal A/C

KEYPAD CONFIGURATION

Allows further conguration of system to desired application such as whether th unit displays in °F or °C, whether the display

shows the set point or room air temperature, and to set controls for sensor biasing. Changes do not take affect until power is

cycled on the unit.

To enter Keypad conguration

Cycle power to unit. Press and hold the Fan Speed Button and the COOLER button for 5 continuous seconds, within 30

seconds of the unit being powered up. If the unit has had power for more than 30 continuous seconds, keypad conguration

cannot be entered. When keypad conguration mode is rst entered, it will default to Fahrenheit/ Celsius Display Mode.

To scroll through the Keypad Conguration Options

Press and release the Fan Speed button. The stored value will be displayed.

To modify conguration settings

Press and release the Setpoint Up or Setpoint Down buttons.

To exit Keypad Conguration

Keypad Congurationwill end on its own 30 seconds after the last button press or when the MODE button on the Keypad is

pressed.

Fahrenheit/ Celsius Display Switch:

Change between degrees Fahrenheit and Celsius on the display. An “F” indicates Fahrenheit display and ‘C’ indicates

Celsius. Default is degrees “F”.

Indoor Air Temperature Sensor Biasing for Cooling mode:

Sometimes known as an anticipator, the air temperature sensor bias is used to adjust the room air temperature

reading when in cooling mode. (Not normally required.)

Indoor Air Temperature Sensor Biasing forHeating mode:

Sometimes known as an anticipator, the air temperature sensor bias is used to adjust the room air

temperature reading when in heating mode. (Not normally required.)

Indoor Temperature Display:

Change between showing setpoint only on the display during heating and coolingmodes “SP” or displaying

room temperature during heating and cooling modes “AA”. “SP” mode is the default mode.

• If “SP” is selected, only the setpoint will be displayed during heating and cooling modes, regardless of what the

real temperature is in the room.

• If “AA” mode is selected, the room temperature will be displayed during heating, cooling and fan only modes.

— If the mode button has been changed to either heating or coolingmodes, setpoint will be displayed for 10 seconds. After the

10 seconds, the room temperature will again be displayed.

— If the on/off button is depressed (when the unit is off) and the last mode was either cooling or heating mode, the setpoint

will be displayed for 10 seconds before displaying room temperature.

— During heating and cooling modes, if either the up or down setpoint key is depressed, the display will show the setpoint until

10 seconds after the last up or down key press. Then the room temperature will be displayed again.

12

Page 14

Packaged Terminal A/C OWNER’S MANUAL Heat Controller

OPERATION

ABOUT THE CONTROLS ON YOUR UNIT

NOTE: In case of a power failure, the unit will remember the last programmed settings and will restart to those settings.

IMPORTANT: When unit is rst started, high humidity conditions can cause condensation to form on discharge grille. Keep doors

and windows closed. Room humidity will decrease and moisture will evaporate as the unit operates.

Fig. 17 – PTAC CONTROLS

1. TEMP CONTROL

Temp Control is used to maintain room temperature. Compressor will cycle on and off to keep room at the

requested level of comfort.

COOLER—Lowers temperature. (Minimum temperature setting is 61°F/16°C)

WARMER—Raises temperature. (Maximum temperature setting is 86°F/30°C)

2. FAN SPEED, MODE & ON/OFF

FAN SPEED—Set fan operation for HI, MED, or LO speed.

MODE-COOL—For cooling

MODE-HEAT—For heating

NOTE: If unit is a heat pump, raising the heat setting by 5°F will cause unit to use its electric heating elements for one

cycle in order to reach the new requested temperature quickly.

MODE-FAN—For fan--only operation

ON/OFF—Turns the unit on or off.

NOTE: The LED above the ON/OFF button will be green when unit is ON and red when the unit is OFF. All other

LEDs will be off when unit is set to OFF mode.

NOTE: Power remains connected to unit even when the unit is in the OFF mode.

13

Page 15

Heat Controller OWNER’S MANUAL Packaged Terminal A/C

CARE AND CLEANING

FRONT PANEL AND CASE

Turn unit off and disconnect power supply.

To clean, use water and a mild detergent. DO NOT use bleach or abrasives. Some commercial cleaners may damage the plastic parts.

OUTDOOR COIL

Coil on outdoor side of unit should be checked regularly. Unit will need to be removed to inspect dirt build-up that will occur on

the inside of the coil. If clogged with dirt or soot, coil should be professionally cleaned.

NOTE: Never use a high-pressure spray on coil.

CAUTION

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Airow restriction may cause damage to the unit.

Fig. 18—Outdoor Coil

BASE PAN

In some installations, dirt or other debris may be blown into unit from outside and settle in base pan (bottom of unit). Check

base pan periodically and clean, if necessary.

AIR FILTERS

IMPORTANT: TURN UNIT OFF BEFORE CLEANING

CAUTION

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage or improper operation.

Do not operate unit without lters in place. If a lter becomes torn or damaged, it should be replaced immediately.

Operating without lters in place or with damaged lters will allow dirt and dust to reach indoor coil and reduce

cooling, heating, airow and efciency of unit. Airow restriction may cause damage to unit.

Themost important thing you can do to maintain unit efciency is to clean the lters at least every 30 days (or sooner depending

on application). Clogged lters reduce cooling, heating and airow.

Keeping lters clean will:

• Decrease cost of operation.

• Save energy.

• Prevent clogging the indoor coil.

• Reduce risk of premature component failure.

To Clean Air Filters:

• Vacuum off heavy soil.

• Run water through lters.

• Air dry thoroughly before replacing.

Fig. 19—Identifying Clogged Filter

Fig. 20—Removing and Replacing Air Filter

14

Page 16

Packaged Terminal A/C OWNER’S MANUAL Heat Controller

PREVENTATIVE MAINTENANCE

Preventative maintenance is essential to proper unit operation, efciency and longevity.

To ensure equipment operates properly, it must be properlymaintained. Equipment operation should be checked and veried

several times during each year. During regular unit inspection and maintenance, follow the guidelines below:

• Clean both sides of outdoor coil. (Never use high pressure spray on coils.)

• Clean basepan and outdoor vent lter.

• Clean outdoor orice and fan.

• Clean indoor coil. (Never use high pressure spray on coils.)

• Clean indoor fan, wire screen and front panel.

• Clean or install new indoor-air inlet lter(s).

• Clean wall sleeve and outdoor grille.

• Inspect cord and receptacle.

• Secure electrical connections.

• Ensure front panel is properly mounted and not damaged.

• Ensure wall sleeve is installed properly.

• Ensure heat and cool cycles operate properly.

15

Page 17

Heat Controller OWNER’S MANUAL Packaged Terminal A/C

TROUBLESHOOTING

TROUBLESHOOTING

POSSIBLE CAUSES SOLUTIONS

UNIT DOES NOT START

• Unit may have become unplugged

• Fuse may have blown

Circuit breaker may have tripped

• Circuit breaker may have been tripped

S Unit may be off or in wall thermostat mode.

Check section on dipswitch settings to verify

dipswitches are set properly.

Unit may be in a protection or diagnostic failure

• Unit may be in a protection or diagn ostic failure

mode. See section on self diagnostics.

mode. See section on Intelligent Self --- checking

Control.

UNIT NOT COOLING/HEATING ROOM

• Check that plug is plugged securely in wall receptacle.

Note :Plug has a test/reset button on it. Make sure that the plug

has not tripped.

• Replacethefuse.SeeNote1.

• Reset circuit breaker. See Note 1.

• Turn unit on (bottom right button on keypad).

Note: If the unit turns on, the LED will be green. If the unit is off,

the LED will be red. If there is no LED on, there is a problem

with power or damage to the control.

Check dipswitch settings

S Unit air discharge section is blocked

S Temperature setting is not high or low enough

Note: Setpoint limits may not allow the unit to heat

or cool the room to the temperature desired.

Check section on dipswitch settings.

S Unit air filters are dirty.

S Room is excessively hot or cold when unit is started.

S Vent door left op en

S Unit may be in a protection or diagnostic failure

Unit may be in protection or diagnostic failure mode.

Check section on self diagnostics.

mode. Check section on Intelligent Self---checking

Control.

Compressor is in time delay mode. There is a protective

S Compressor is in time delay. There is a protective

time delay (approx. 3 minutes) on starting the

compressor after a power outage (or restarting

after it has been turned off), to prevent tripping of

the compressor overload.

DISPLAY HAS STRANGE

NUMBERS/CHARACTERS ON IT

UNIT MAKING NOISES • Clicking, gurgling and whooshing noises are normal during

WATER DRIPPING OUTSIDE • If a drain kit has not been installed, condensation runoff during

WATER DRIPPING INSIDE

• Wall sleeve is not installed level • Wall sleeve must be installed level for proper drainage of

ICE OR FROST FORMS ON INDOOR COIL

• Low outdoor temperature

• Dirty filters

S Make sure that curtains, blinds or furniture are not restricting or

blocking unit airflow.

S Reset to a lower or higher temperature setting.

S Remove and clean filters.

S Allow sufficient amount of time for unit to heat or cool the room.

Start h eating or cooling early before outdoor temperature, cooking

heat or gatherings of people make room uncomfortable.

S Close vent door.

S Check dipswitch settings for desired comfort.

Wait approximately 3 minutes for compressor to start

The unit may be in a diagnostic condition. Check self diagnostic

• The unit may be in a diagnostic condition. Check Intelligent Self---

section to determine if the unit has had a failure.

checking Control section to determine if unit has had a failure.

• The unit may be set for _C (instead of _F), see the keypad

configuration section

operation of unit.

very hot and humid weather is normal. See Note 2. If a drain kit has

been installed and is connected to a drain system, check gaskets

and fittings around drain for leaks and plugs.

condensation. Check that installation is level and make any

necessary adjustments.

• When outdoor temperature is approximately 55_F or below, frost

may form on the indoor coil when unit is in Cooling mode. Switch

unit to FAN operation until ice or frost melts.

• Remove and clean filters.

COMPRESSOR PROTECTION

• Power may have cycled, so compressor is in a

restart protection.

NOTES:

1. If circuit breaker is tripped or fuse is blown more than once, contact a qualified electrician.

2. If unit is installed where condensation drainage could drip in an undesirable location, an accessory drain kit should be installed and connected to drain

system.

• Random Compressor restart --- Whenever the unit is plugged in,

or power has been restarted, a random compressor restart will

occur. After a power outage, the compressor will restart after

approximately 3 minutes.

• Compressor Protection --- To prevent short cycling of the

compressor, there is a random startup delay of 3 minutes and a

minimum compressor run time of 3 minutes.

16

Page 18

9/2013

Design, specications, performance data and materials subject to change without notice.

:HOOZRUWK$YH-DFNVRQ0,3KZZZKHDWFRQWUROOHUFRP

Loading...

Loading...