Page 1

Wall Mounted

Mini-Split System

Single-Zone

Air Conditioning/Heat Pump

Service Manual

DMC09SB-0/DMH09SB-0

DMC12SB-0/DMH12SB-0

DMC18SB-1/DMH18SB-1

DMC24SB-1/DMH24SB-1

Before servicing the unit, read the

“safety precautions” in this manual.

Only for authorized service personnel.

HEAT CONTROLLER, INC.

Page 2

Air Conditioner Service Manual

TABLE OF CONTENTS

Safety Precautions..........................................................................................................................................3

Dimensions......................................................................................................................................................9

Symbols Used in this Manual.....................................................................................................................9

Indoor Unit..................................................................................................................................................9

Outdoor Unit.............................................................................................................................................11

Introduction...................................................................................................................................................12

Installation.....................................................................................................................................................13

Selection of the Best Location..................................................................................................................16

Piping Length and Elevation.....................................................................................................................17

How to Fix Installation Plate.....................................................................................................................18

Drill a Hole in the Wall..............................................................................................................................18

Drain hose junction...................................................................................................................................18

Flaring work and connection of piping.......................................................................................................19

Flaring work..............................................................................................................................................19

Connection of Piping Indoor.....................................................................................................................20

Connection of the Pipes-Outdoor.............................................................................................................26

Connecting the cable between indoor unit and outdoor unit...................................................................26

Connect the Cable....................................................................................................................................26

Checking the drainage and forming the pipings........................................................................................28

Checking the Drainage.............................................................................................................................28

Form the Piping........................................................................................................................................29

AIR PURGING................................................................................................................................................29

Air purging................................................................................................................................................30

Air purging with vacuum pump.................................................................................................................30

Test Running.................................................................................................................................................33

Operation.......................................................................................................................................................34

Function of Controls.................................................................................................................................34

Display Function ......................................................................................................................................38

Self-diagnosis Function............................................................................................................................38

Remote Control Operations......................................................................................................................39

Disassembly..................................................................................................................................................40

Indoor Unit................................................................................................................................................40

Troubleshooting Guide.................................................................................................................................43

Refrigeration Cycle Diagram....................................................................................................................43

2-way, 3-way Valve .................................................................................................................................44

Cycle Parts...............................................................................................................................................50

Electronic Parts........................................................................................................................................51

Schematic Diagram.......................................................................................................................................61

Electric Control Device.............................................................................................................................61

Wiring Diagram.........................................................................................................................................64

Components Location ..............................................................................................................................66

Product Specifications.................................................................................................................................71

2 Room Air Conditioner

Page 3

Service Manual 3

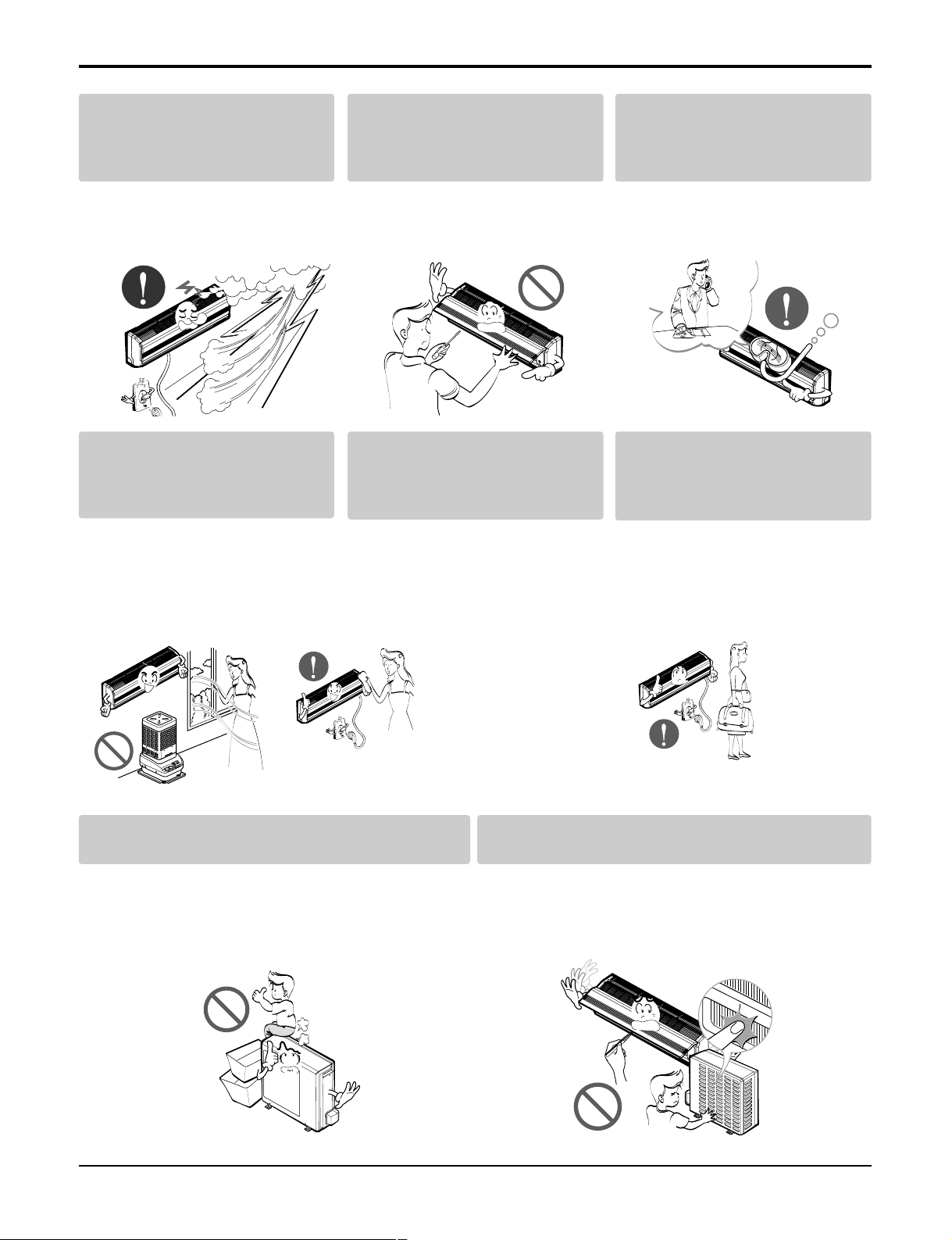

Safety Precautions

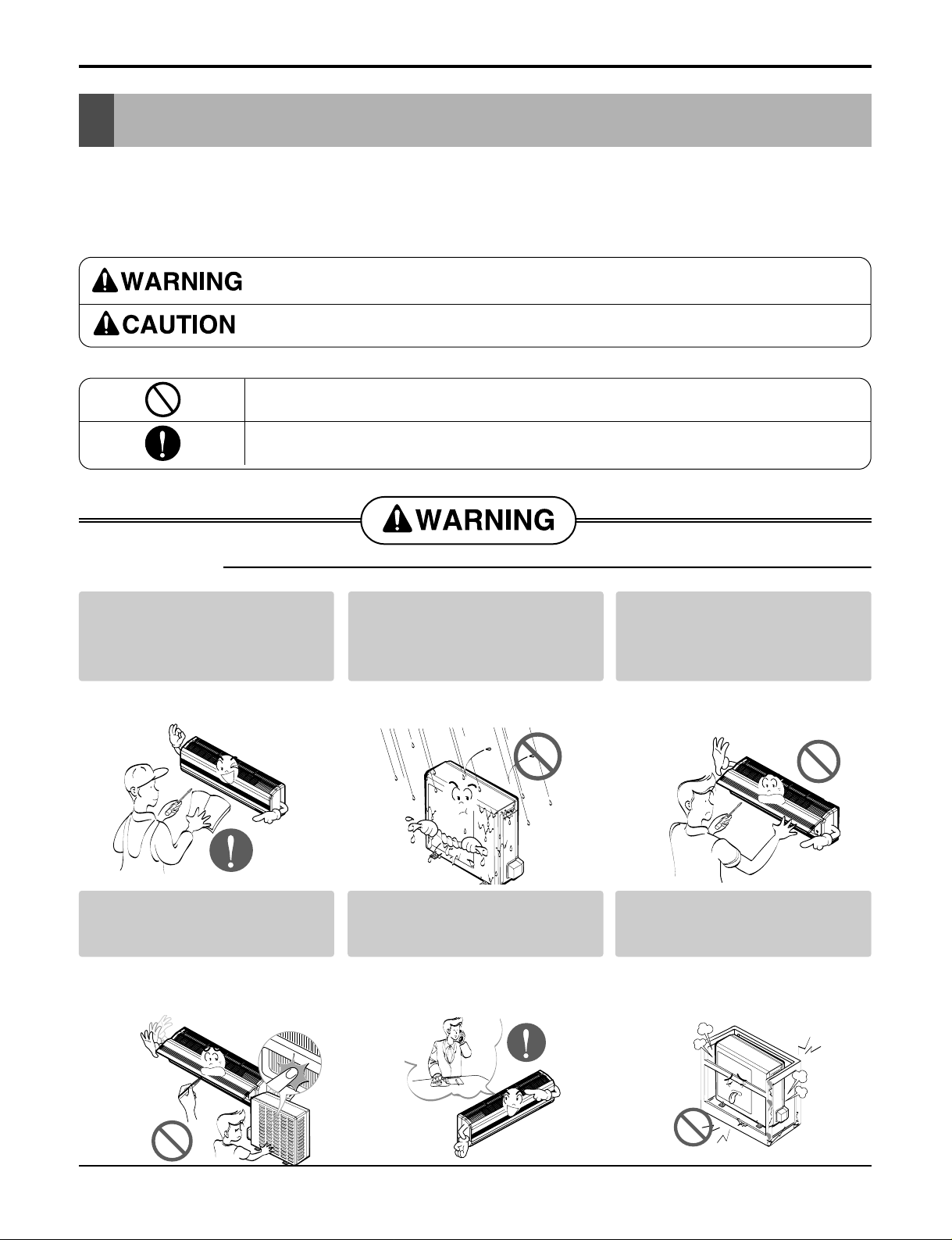

Safety Precautions

To prevent injury to the user or other people and property damage, the following instructions must

be followed.

■ Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is

classified by the following indications.

■ Meanings of symbols used in this manual are as shown below.

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage to properties only.

Be sure not to do.

Be sure to follow the instruction.

■ Installation

For electrical work, contact the

dealer, seller, a qualified electrician, or an Authorized Service

Center.

• There is risk of fire or electric shock.

Install the panel and the cover of

control box securely.

• There is risk of fire or electric shock.

Do not install, remove, or re-install

the unit by yourself (customer).

• There is risk of fire, electric shock,

explosion or injury.

Be cautious when unpacking and

installing the product.

• Shape edges could cause injury. Be

especially careful of the sharp

edges.

For installation, always contact the

dealer or an Authorized Service

Center.

• There is risk of fire, electric shock,

explosion, or injury.

Do not install the product on a

defective installation stand.

• It may cause injury, accident, or

damage to the product.

Page 4

4 Room Air Conditioner

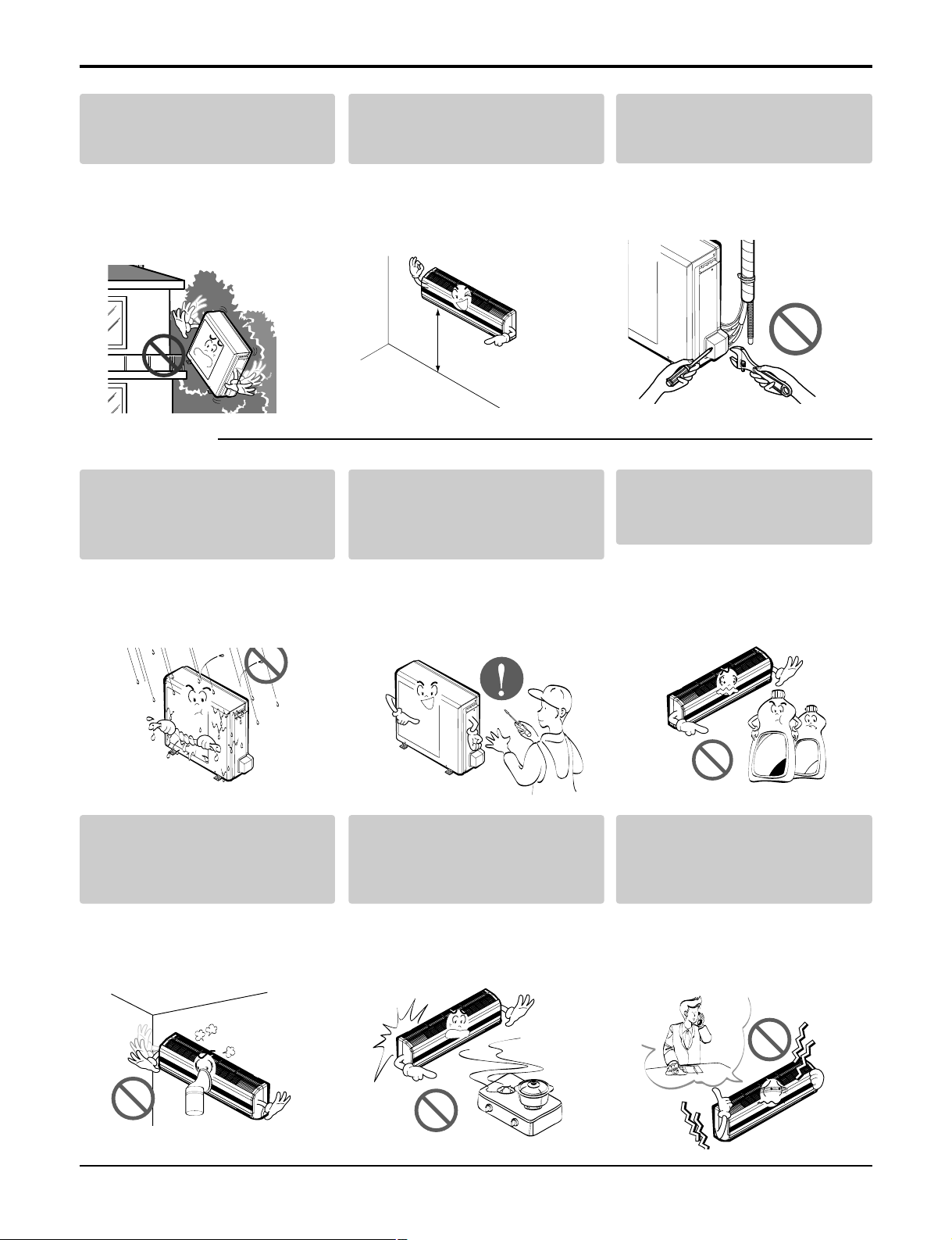

Safety Precautions

■ Operation

Be sure the installation area does

not deteriorate with age.

• If the base collapses, the air conditioner could fall with it, causing property damage, product failure, and

personal injury.

Install the indoor unit on the wall

where the height from the floors

more than 8ft(2.4m)

• There are sharp moving parts that

could cause personal injury.

Do not handle the pipe by yourself(Costomer)

• High-Pressure refrigent may cause

personal injury.

Do not allow water to run into

electric part.

• There is risk of fire, failure of the

product, and/or electric shock.

Do not let the air conditioner run

for a long time when the humidity

is very high and a door or a window is left open.

• Moisture may condense and wet or

damage furnishings.

Do not store or use flammable gas

or combustibles near the air conditioner.

• There is risk of fire or product failure.

Do not use the product in a tightly

closed space for a long time.

• Oxygen deficiency could occur.

•

Some ventilation by opening window is

necessary for the fresh air

When flammable gas leaks, turn off the gas

and open a window for ventilation before

turning the product on. Do not use the telephone or turn switches on or off.

• There is risk of explosion or fire.

Turn off breaker to the unit if

strange sounds odors or smoke

comes from it.

•

There is risk of fire, Product faiure,

and/or electric shock.

8ft(2.4m)

Wax

Thinner

Page 5

Service Manual 5

Safety Precautions

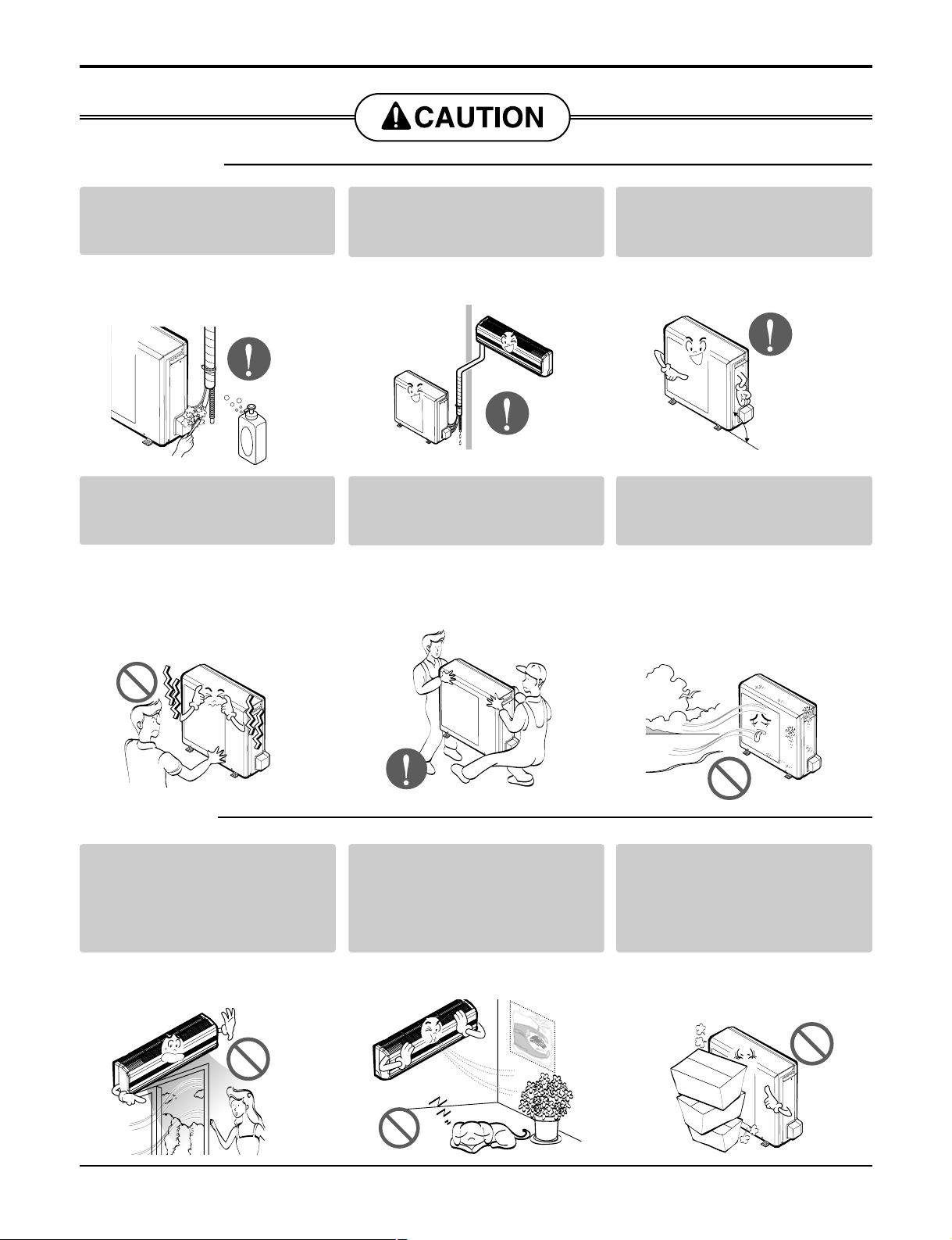

Stop operation and close any window in storm or hurricane before

the hurricane arrives.

• There is risk of property damage,

failure of product, or electric shock.

Do not open the inlet grill of the

product during operation. (Do not

touch the electrostatic filter, if the

unit is so equipped.)

• There is risk of physical injury, electric shock, or product.

When the product is soaked (flooded or submerged), contact an

Authorized Service Center.

• There is risk of electrical shock.

Ventilate the product from time to

time when operating it together

with a stove, etc.

• There is risk of fire or electrical

shock.

Turn off breaker to the appliance

before performing cleaning or

maintenance.

• There is risk of electric shock.

When the product is not be used

for a long time disconnect the

power supply by turning off the

breaker.

• There is risk of product damage or

failure, or unintended operation.

Take care to ensure that nobody could step on or fall

onto the outdoor unit.

• There could result in personal injury and product damage.

Do not insert hands or other objects through the air

inlet or outlet while the air conditioner is on.

• There are sharp and moving parts that could cause personal injury.

Page 6

6 Room Air Conditioner

Safety Precautions

Always check for gas(refrigerant)

leakage after installation or repair

of product.

• Low refrigerant levels may cause

product failure.

Install the drain hose to ensure that

water is drained away properly.

• A bad connection may cause water

leakage.

Keep level even when installing the

product.

• To avoid vibration or water leakage.

Do not install the product where

the noise or hot air from the outdoor unit could offend neighbors.

• It may cause a problem for your

neighbors.

Use two or more people to lift and

transport the air conditioner.

• Avoid personal injury.

Do not install the product where it

will be exposed to sea wind (salt

spray) directly.

• It may cause corrosion in the product. Corrosion, particularly on the

condenser and evaporator fins,

could cause product malfunction or

inefficient operation.

Do not direct airflow at room occupants.

• This could damage your health.

Do not use the product for special

purposes, such as preserving foods,

works of art, etc. It is a consumer air

conditioner, not a precision refrigeration system.

• There is risk of damage or loss of

property.

Do not block the inlet or outlet of

air flow.

• It may cause product failure.

■ Installation

■ Operation

90˚

Page 7

Service Manual 7

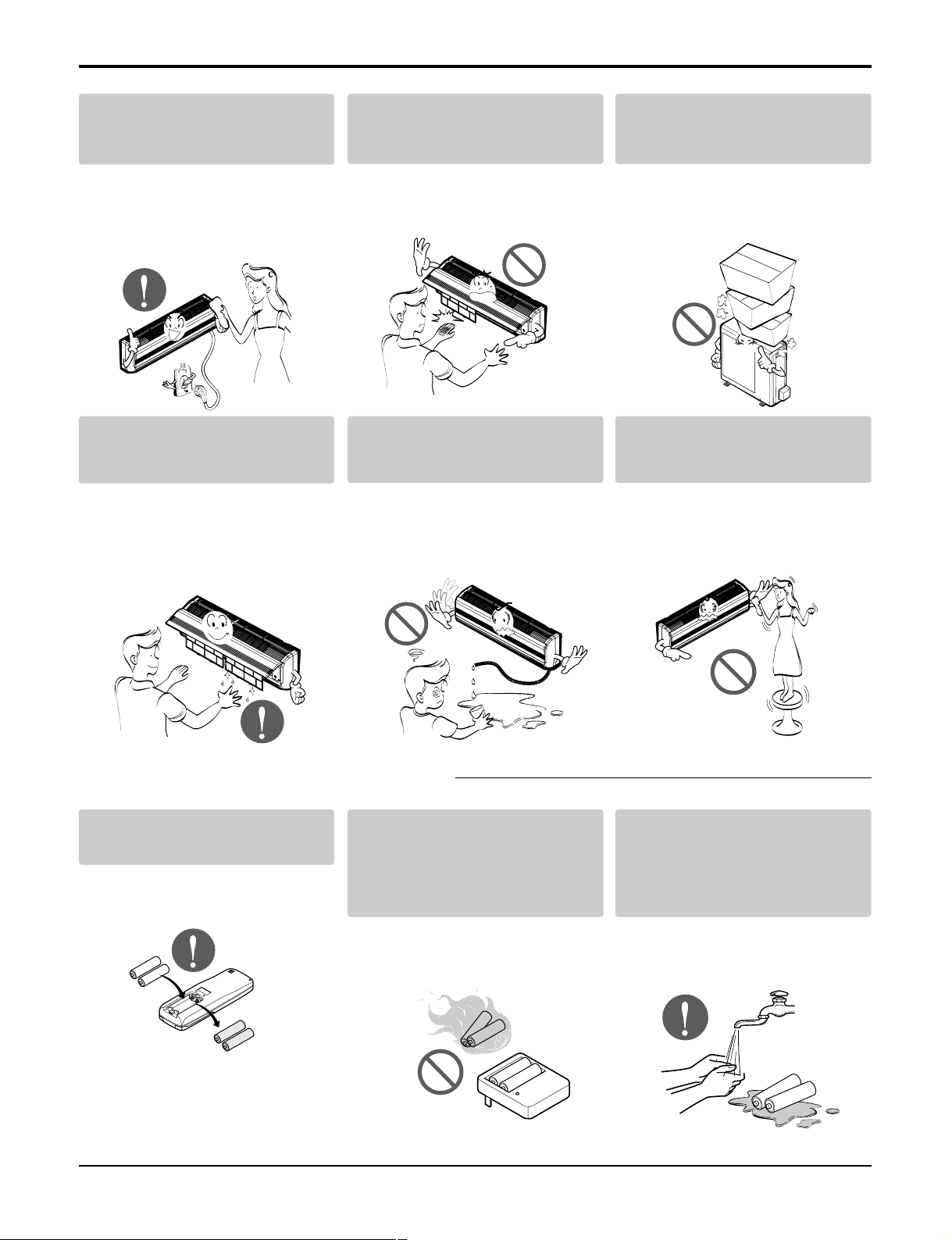

Safety Precautions

Use a soft cloth to clean.

Do not use harsh detergents, solvents, etc.

• There is risk of fire, electric shock or

damage to the plastic parts of the

product.

Do not touch the metal parts of the

product when removing the air filter. They are very sharp!

• There is risk of personal injury.

Do not step on or put anything on

the product. (outdoor unit)

• There is risk of personal injury and

failure of product.

Always insert the filter securely.

Clean the filter every two weeks or

more often if necessary.

• A dirty filter reduces the efficiency of

the air conditioner and could cause

product malfunction or damage.

Do not drink the water drained from

the unit.

• It is not sanitary and could cause

serious health issues.

Use a firm stool or ladder when

cleaning or maintaining the air conditioner.

• Be careful and avoid personal injury.

Replace all the batteries in the

remote.

• There is risk of fire or explosion.

Do not recharge or disassemble

the batteries. Do not dispose of

batteries in a fire.

• They may burn or explode.

If the liquid from the batteries gets

onto your skin or clothes, wash it

well with clean water. Do not use

the remote if the batteries have

leaked.

• The chemicals in batteries could

cause burns or other health hazards.

■ Disuse

Page 8

8 Room Air Conditioner

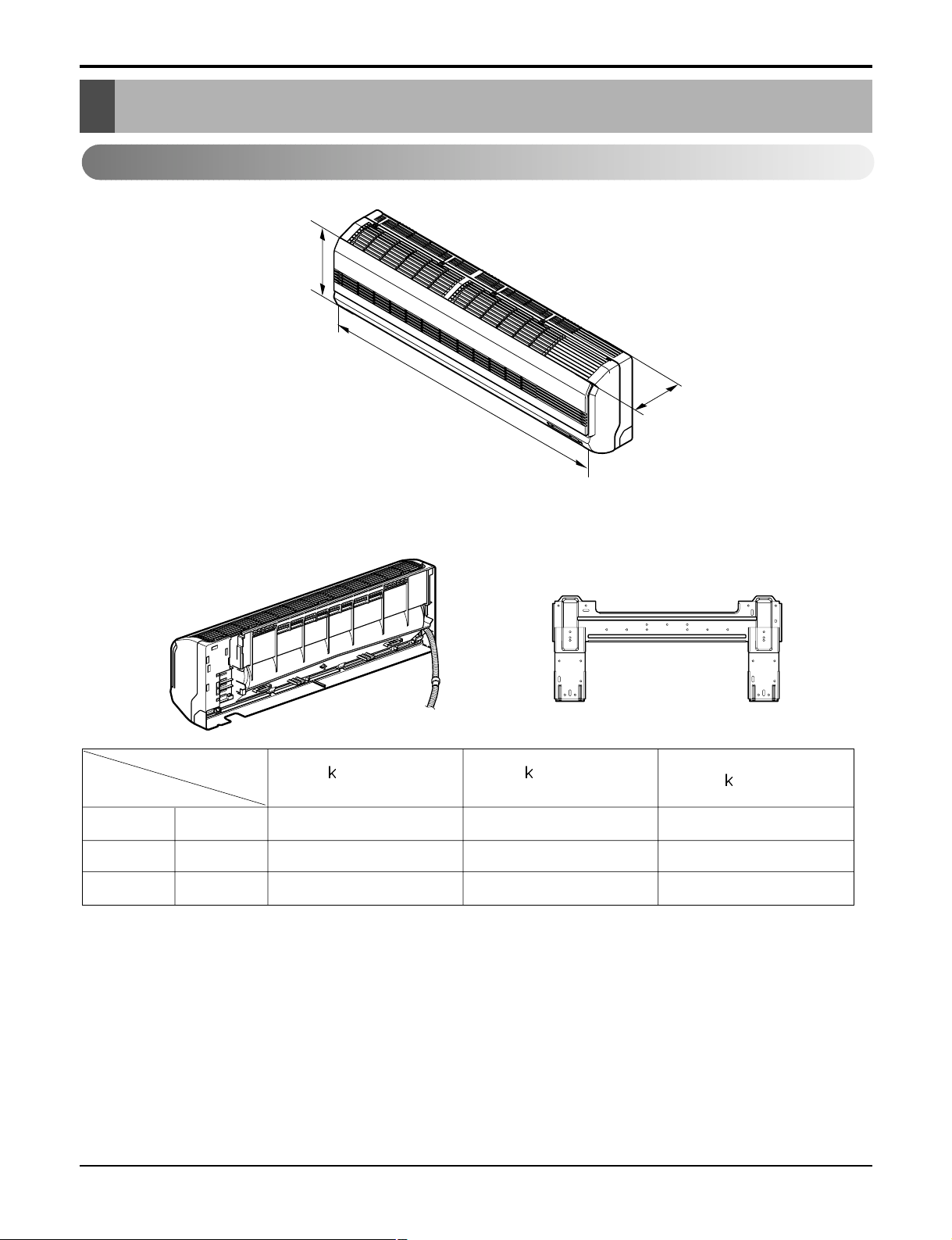

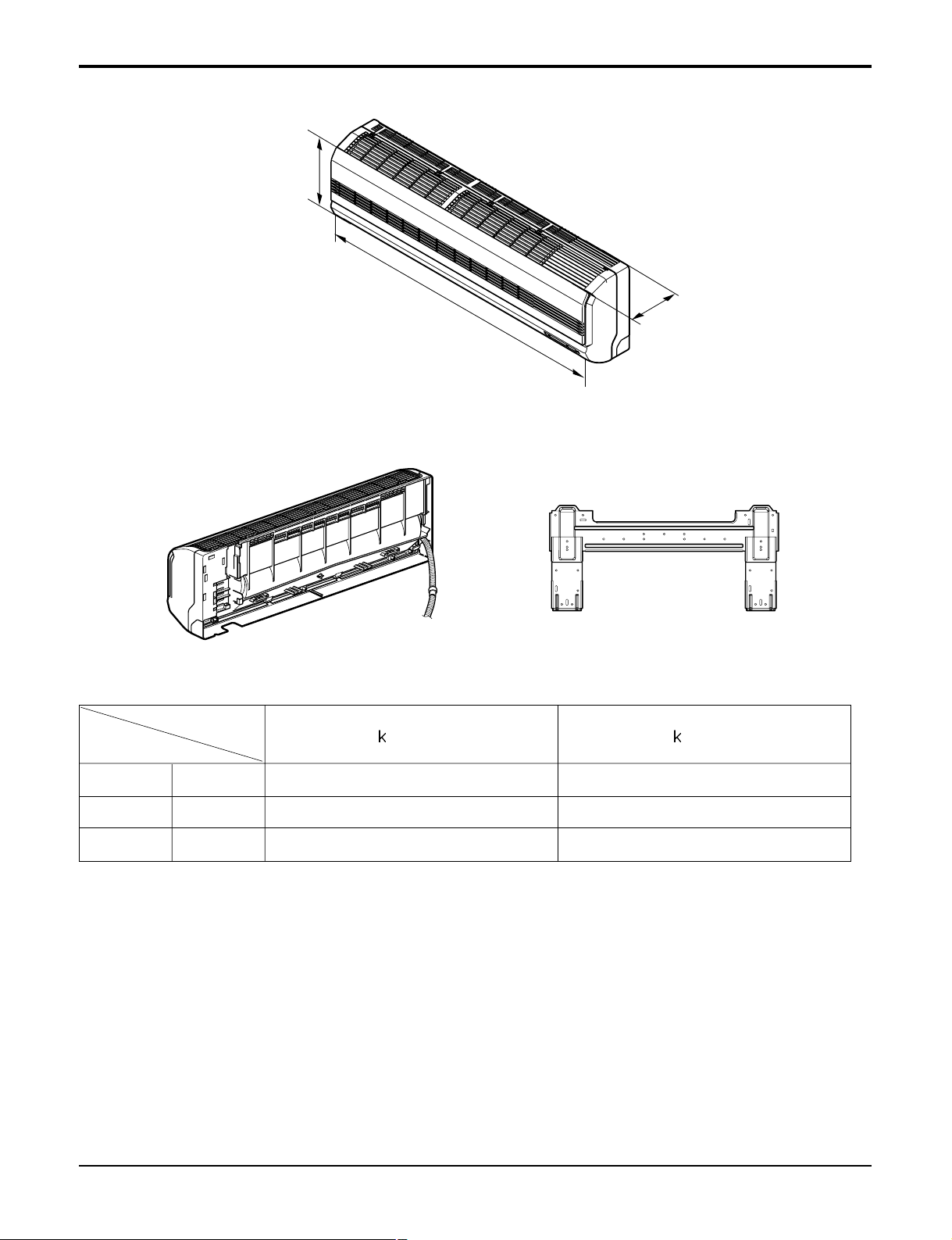

Dimensions

Dimensions

D

H

W

Installation plate

W mm(inch) 840(33.1) 894(35.2) 894(35.2)

H mm(inch) 270(10.6) 295(11.6) 295(11.6)

D mm(inch) 153(6.0) 165(6.5) 165(6.5)

Model

Dimension

9 Btu Series

(C/O)

9 Btu Series

(H/P)

12

Btu Series

Indoor Unit

Page 9

Service Manual 9

Dimensions

D

H

W

Installation plate

W mm(inch) 1090(42.9) 1090(42.9)

H mm(inch) 300(11.8) 300(11.8)

D mm(inch) 178(7.0) 178(7.0)

Model

Dimension

18 Btu Series 24 Btu Series

Page 10

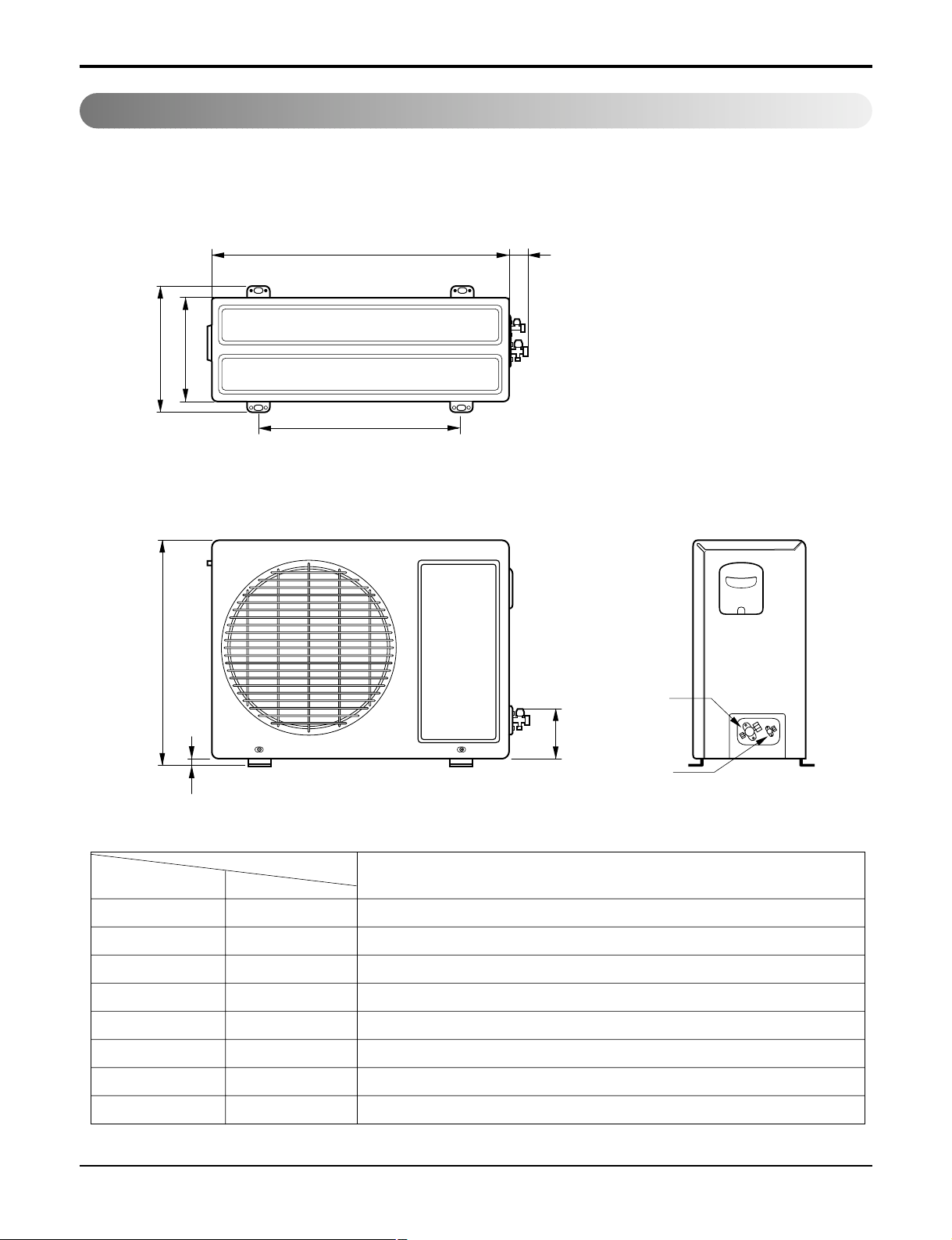

10 Room Air Conditioner

Dimensions

Outdoor Unit

1. 9k, 12k

W

L2

L3

L1

D

H

L4

L5

Gas side

(3-way valve)

Liquid side

(2-way valve)

MODEL

9k, 12k

DIM unit

W mm(inch) 770(30.3)

H mm(inch) 540(21.3)

D mm(inch) 245(9.6)

L1 mm(inch) 287(11.3)

L2 mm(inch) 64(2.5)

L3 mm(inch) 518(20.4)

L4 mm(inch) 10(0.4)

L5 mm(inch) 100(3.9)

Page 11

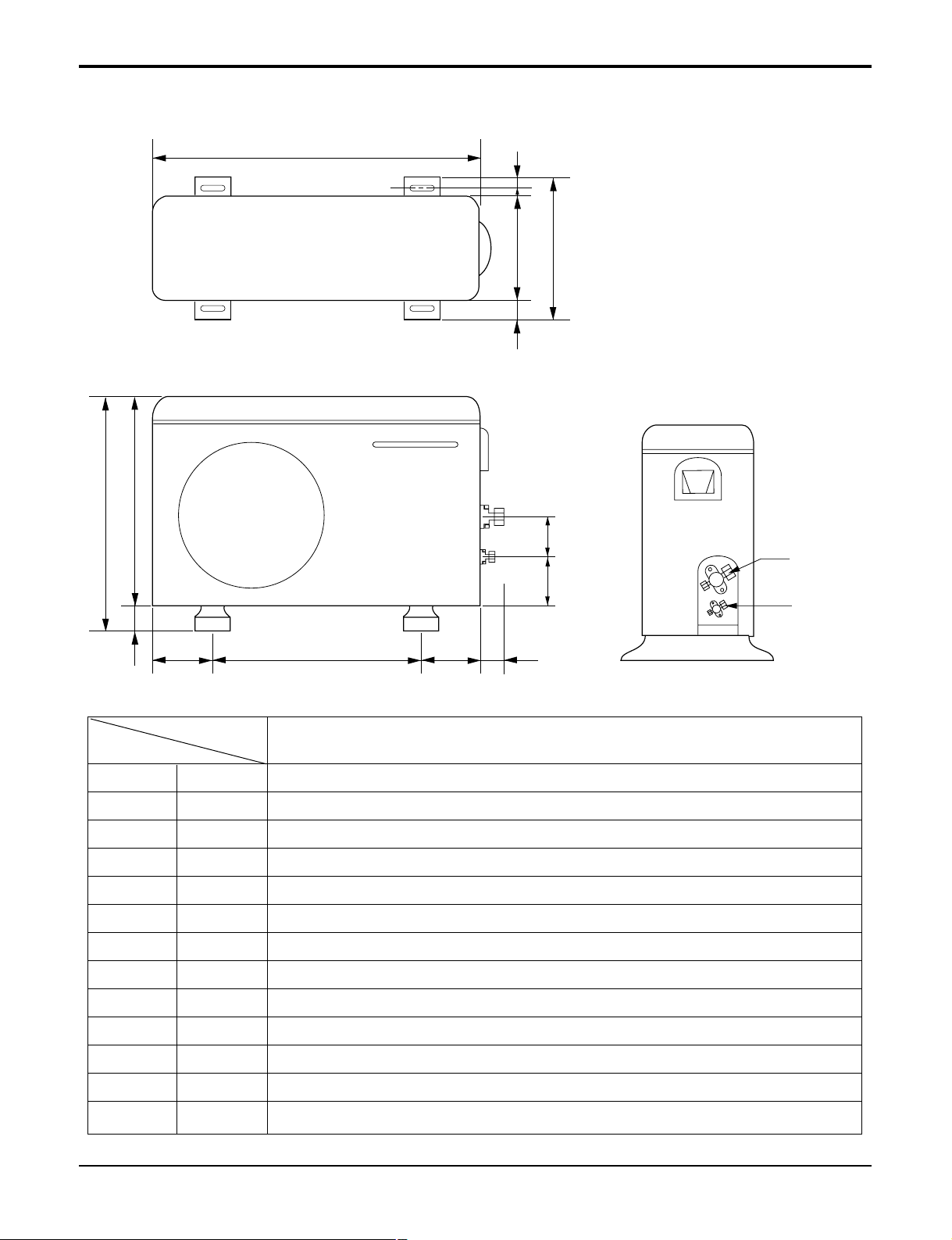

Service Manual 11

Dimensions

2. 18k, 24k

W

L6 L5 L7 L8

D

L1

L2

L9L10

L3L4

H

MODEL

18k, 24k

DIM

W mm(inch) 870(34.3)

H mm(inch) 655(25.8)

D mm(inch) 320(12.6)

L1 mm(inch) 370(14.6)

L2 mm(inch) 25(1.0)

L3 mm(inch) 630(24.8)

L4 mm(inch) 25(1.0)

L5 mm(inch) 546(21.5)

L6 mm(inch) 162(6.4)

L7 mm(inch) 162(6.4)

L8 mm(inch) 54(2.1)

L9 mm(inch) 74.5(2.9)

L10 mm(inch) 79(3.1)

Page 12

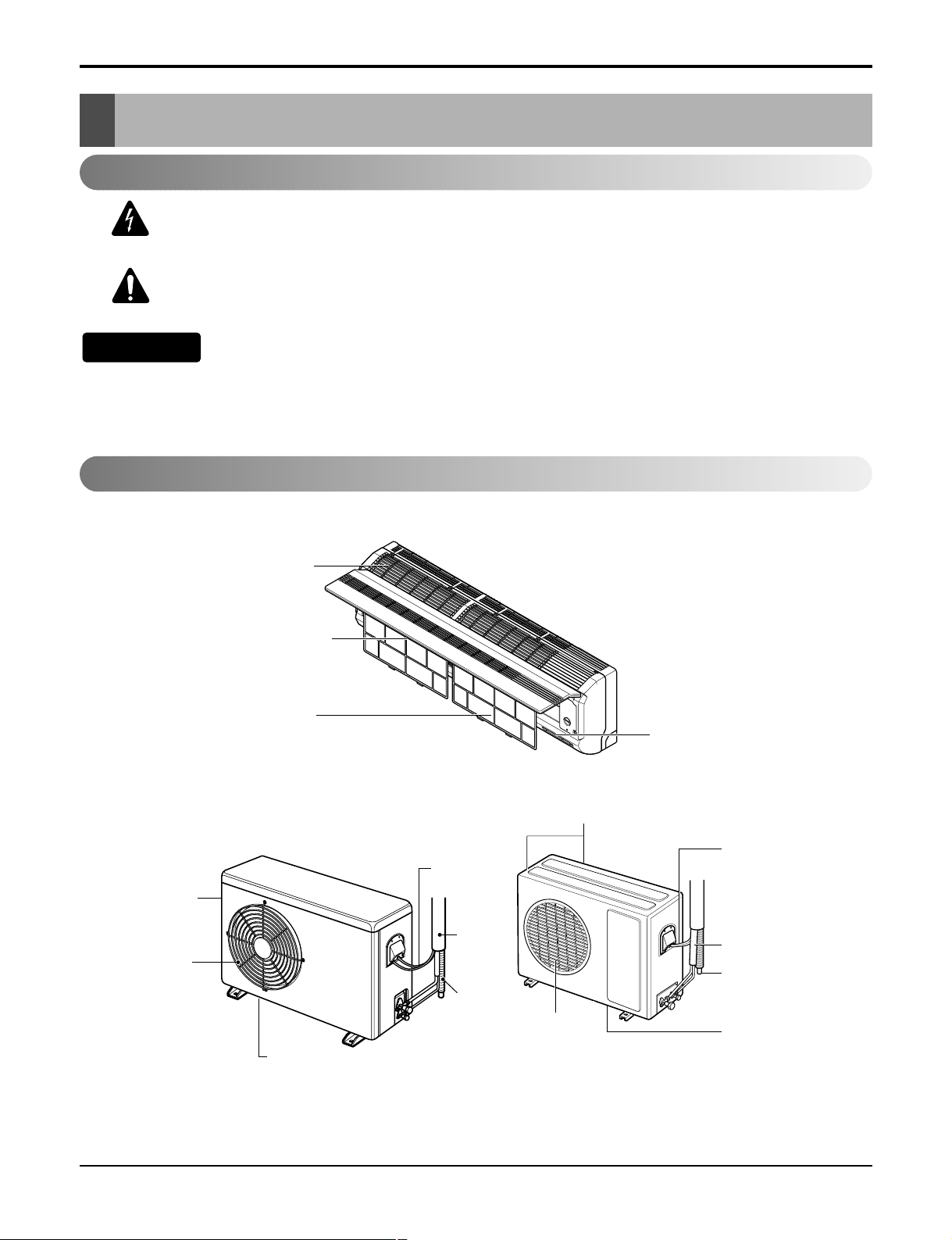

12 Room Air Conditioner

Introduction

Introduction

This symbol alerts you to the risk of electric shock.

This symbol alerts you to hazards that may cause harm to the air conditioner.

This symbol indicates special notes.

NOTICE

Symbols Used In This Manual

Features

Air Intake Vents

Air Outlet Vents

Connecting

Wires

Piping

Drain Hose

Base Plate

Air Outlet

Vents

Air Intake

Vents

Piping

Connecting

Wires

Drain Hose

Base Plate

Air Inlet

Front Panel

Air Filter

Signal Receptor

Page 13

Service Manual 13

Introduction

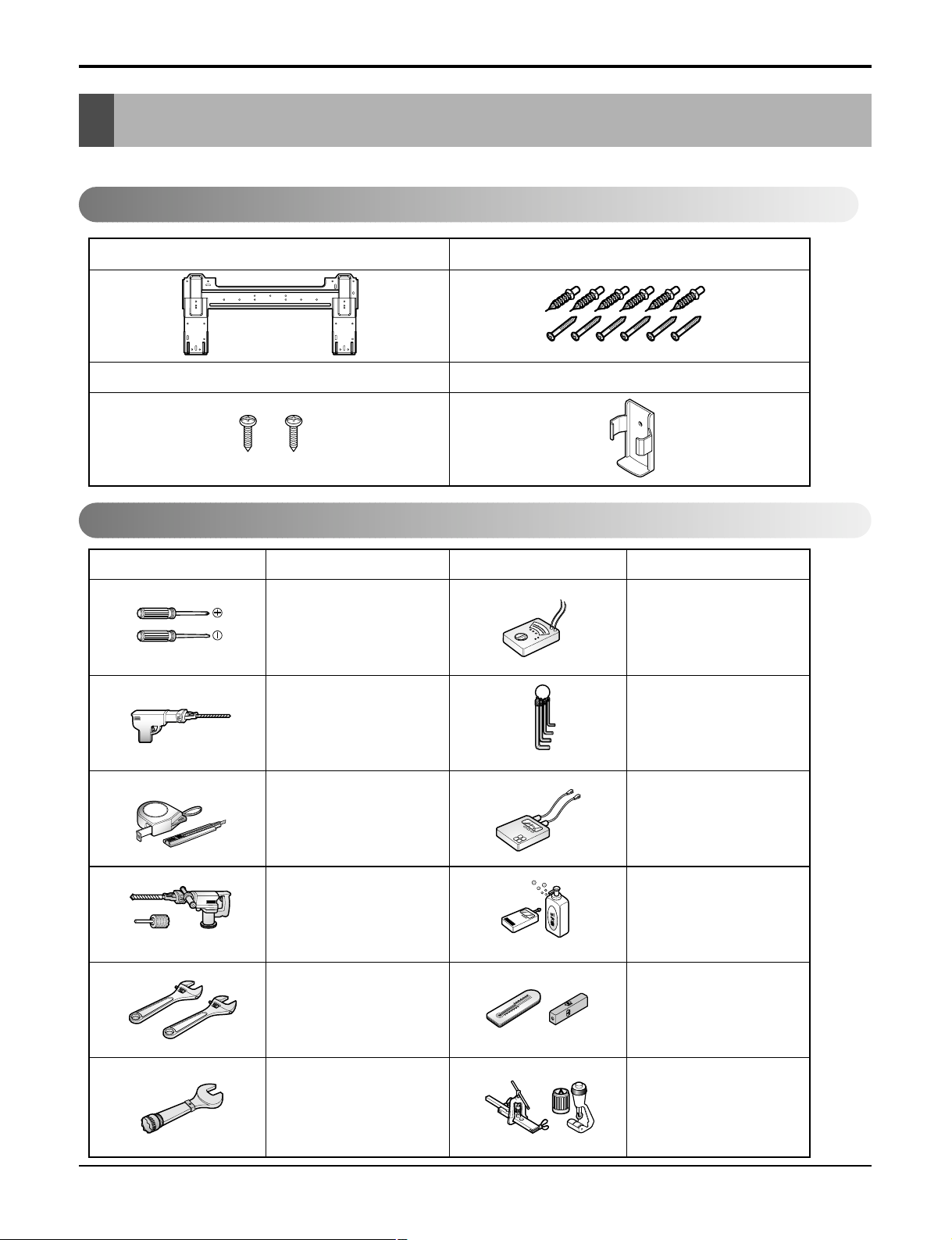

Type "A" screw and plastic anchor

Type "B" screw

Remote Control Holder

Installation plate

Figure FigureName

Screw driver

Electric Drill

Measuring Tape, Knife

Hole Core Drill

Spanner

Torque wrench

Ohmmeter

Hexagonal wrench

Ammeter

Gas Leak Detector

Thermometer,

Level

Flaring Tool Set

Name

Installation Parts

Installation Tools

Read carefully, and then follow step by step.

Installation

Page 14

14 Room Air Conditioner

Installation

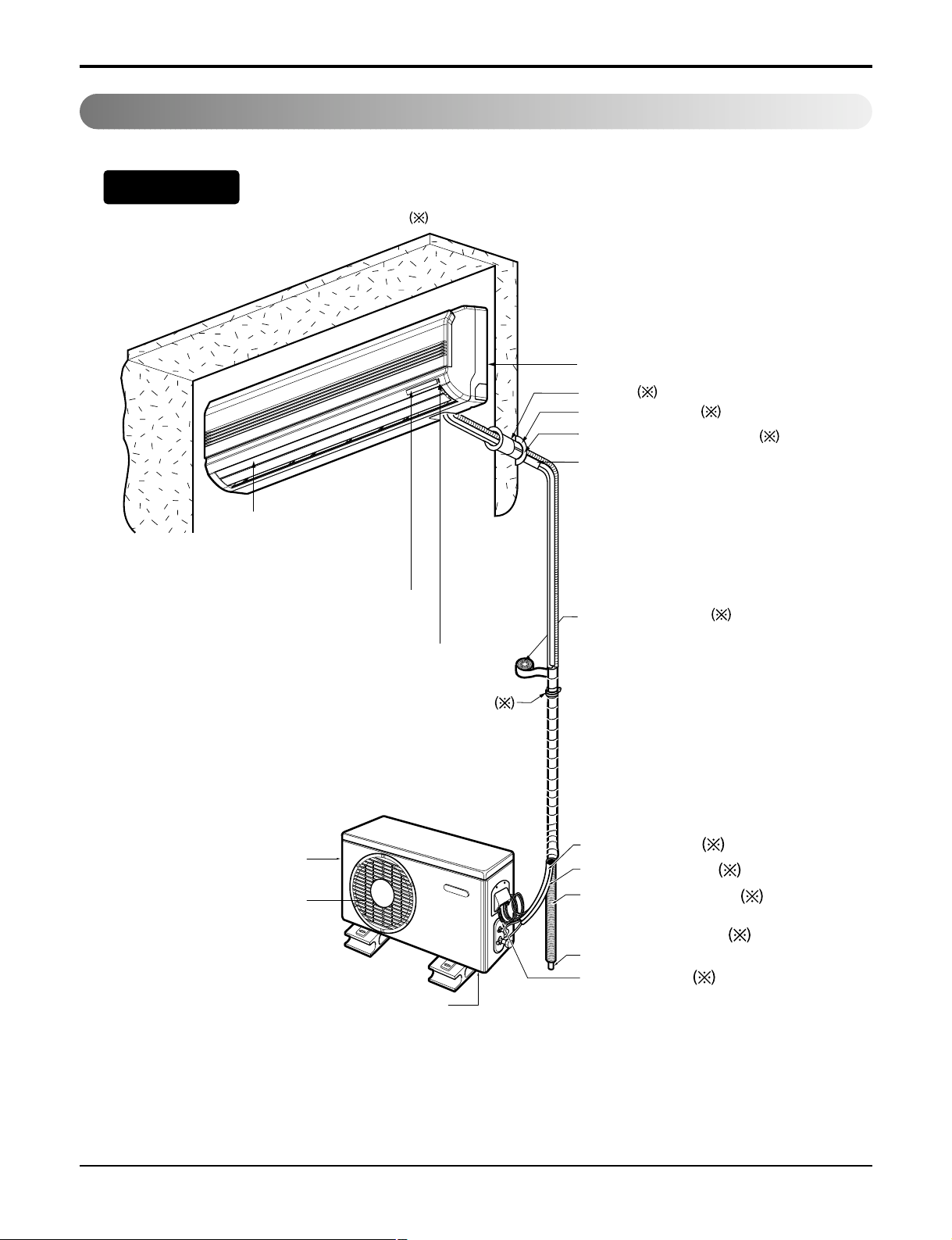

Installation Map

Base Plate

Air Inlet Vents

Air Outlet Vents

Installation parts you should purchase.

Air Discharge

Forced Operation Button

Operation Indication Lamps/

Signal Receptor

Vinyl tape (Wide)

• Apply after carrying out a

drainage test.

• To carry out the drainage

test, remove the air filters

and pour water into the heat

exchanger.

Saddle

Gas side piping (Optional Parts)

Liquid side piping (Optional Parts)

Additional drain pipe

Vinyl tape (Narrow)

Drain Hose

Connecting cable

(Optional Parts)

Installation plate

Sleeve

Bushing-Sleeve

Putty(Gum Type Sealer)

Bend the pipe as closely

on the wall as possible,

but be careful that it

doesn't break.

NOTICE

Page 15

Service Manual 15

Installation

1. Check the quality label on the indoor and outdoor unit.

2. Make certain that the refrigerant is R-410A.

THIS PRODUCT CONTAINS R-410A REFRIGERANT

1) Different compressor oil

- R-410A(Polyol ester) / R-22(Mineral).

- Do not mix the existing mineral oil.

- Do not apply used pipe, tools and gauges covered with the existing mineral oil.

2) Absorption of moisture

-Compressor’s oil has the high absorption rate of moisture.

3) Composition

- R-410A(R32:R125=50:50wt%).

NOTE: Never mix with other refrigerants

4) High pressure.

- 1.6 times higher than R-22.

- High Pressure refrigerant may cause personal injury.

Do not handle the pipe by yourself (customer) High-pressure refrigerant may cause personal injury.

- manifold gauge ,charging and any piping tools must be dedicated to R-410A systems.

NOTICE

Confirm The Refrigerant

Page 16

16 Room Air Conditioner

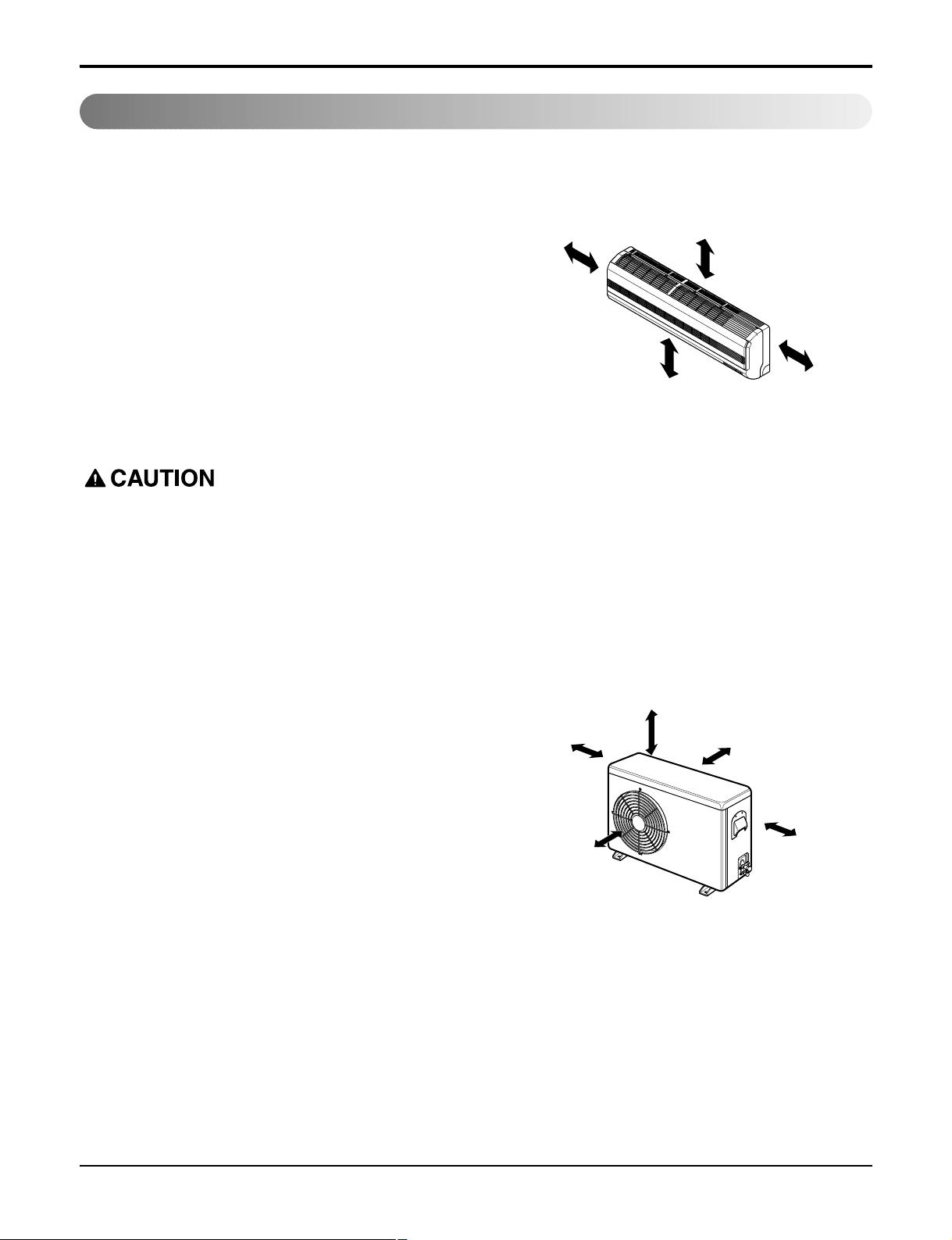

Outdoor unit

1. If an awning is built over the unit to prevent

direct sunlight or rain exposure, make sure that

heat radiation from the condenser is not

restricted.

2. Ensure that the space around the back and

sides is more than 10cm(3.9in). The front of the

unit should have more than 70cm(27.6in) of

space.

3. Do not place animals and plants in the path of

the warm air.

4. Take the air conditioner weight into account and

select a place where noise and vibration are

minimum.

5. Select a place so that the warm air and noise

from the air conditioner do not disturb neighbors.

Rooftop Installations

If the outdoor unit is installed on a roof structure, be sure to level the unit. Ensure the roof structure and

anchoring method are adequate for the unit location. Consult local codes regarding rooftop mounting.

If the outdoor unit is installed on roof structures or walls, this may result in excessive noise and vibration, and may be also classed as non serviceable installation.

Indoor unit

1. Do not have any heat or steam near the unit.

2. Select a place where there are no obstacles in

front of the unit.

3. Make sure that condensation drainage can be

conveniently routed away.

4. Do not install near a doorway.

5. Ensure that the space around the left and right

of the unit is more than 30cm(11.8in). The unit

should be installed as high on the wall as possible, allowing a minimum of 12cm(4.7in) from

ceiling.

6. Use a stud finder to locate studs to prevent

unnecessary damage to the wall.

Select The Best Location

Install the indoor unit on the wall where the height from the floors more than 2.3meters(7.6ft).

A minimum pipe run of 7.5meters(24.6ft) is required to minimize vibration and excessive noise.

More than

12cm(4.7in)

More than

30cm(11.8in)

More than

30cm(11.8in)

More than 2.4meters(8ft)

More than

10cm(3.9in)

More than

10cm(3.9in)

More than

60cm(23.6in)

More than

60cm(23.6in)

More than

70cm(27.6in)

Installation

Page 17

Service Manual 17

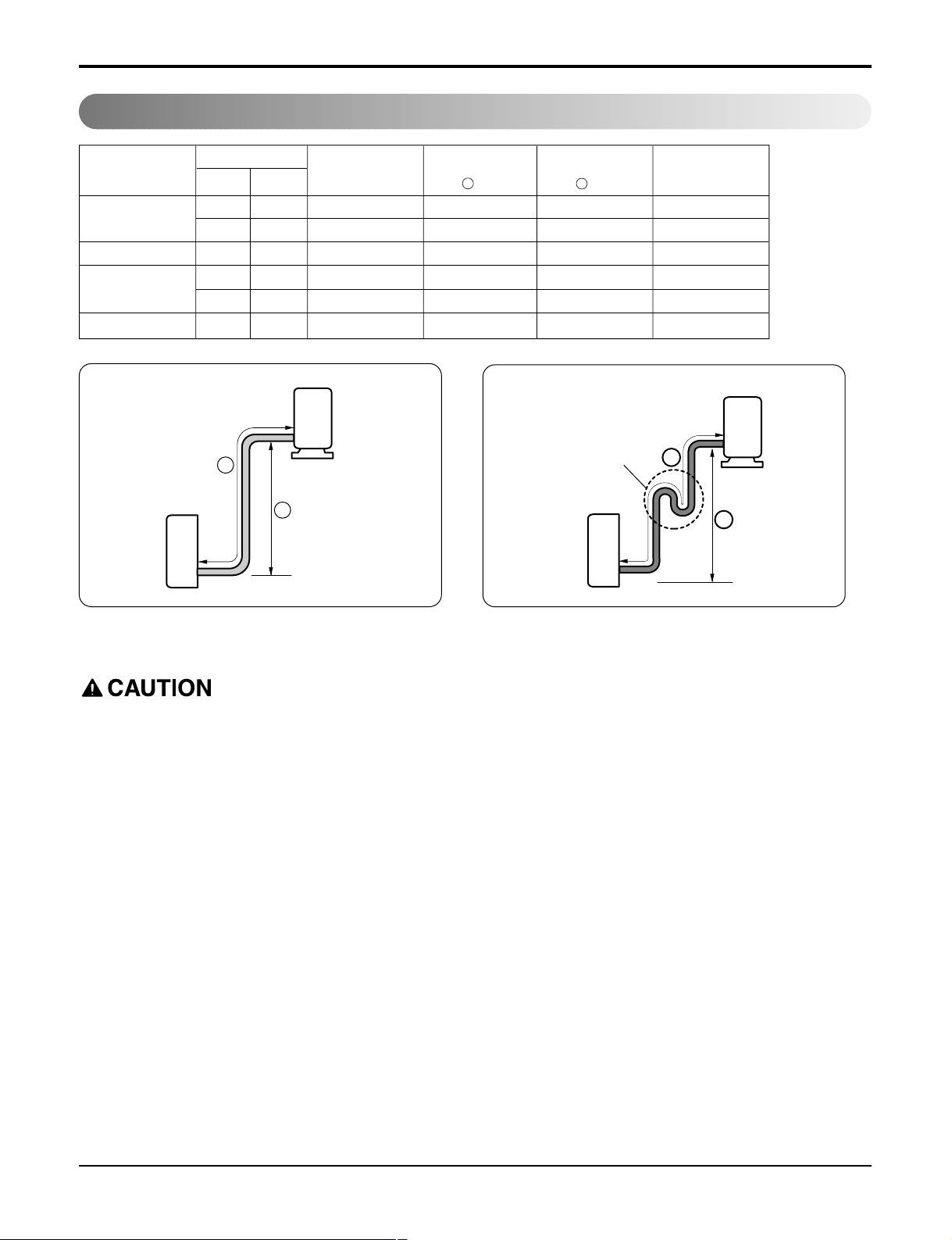

Piping Length And Elevation

• Capacity is based on standard length and maximum allowance length is on the basis of reliability.

• Oil trap should be installed every 5~7meters (16.4~23.0ft).

In case more than 5m(16.4ft)

Outdoor unit

Indoor unit

A

B

A

Oil trap

Outdoor unit

Indoor unit

B

Pipe Size

Capacity

(Btu/h)

Suction

Evap

Max.

length

A

m(ft)

Additional Refrigerant

g/m(oz/ft)

Max.

Elevation

B m(ft)

Standard

Length

m(ft)

9k

3/8" 1/4" 7.5(25) 7.5(25) 15(49) 20(0.22)

1/2" 1/4" 7.5(25) 7.5(25) 15(49) 20(0.22)

12k 1/2" 1/4" 7.5(25) 7.5(25) 15(49) 20(0.22)

18k

1/2" 1/4" 7.5(25) 15(49) 30(98) 20(0.22)

5/8" 1/4" 7.5(25) 7.5(25) 15(49) 20(0.22)

24k 5/8" 1/4" 7.5(25) 7.5(25) 15(49) 20(0.22)

Installation

Page 18

18 Room Air Conditioner

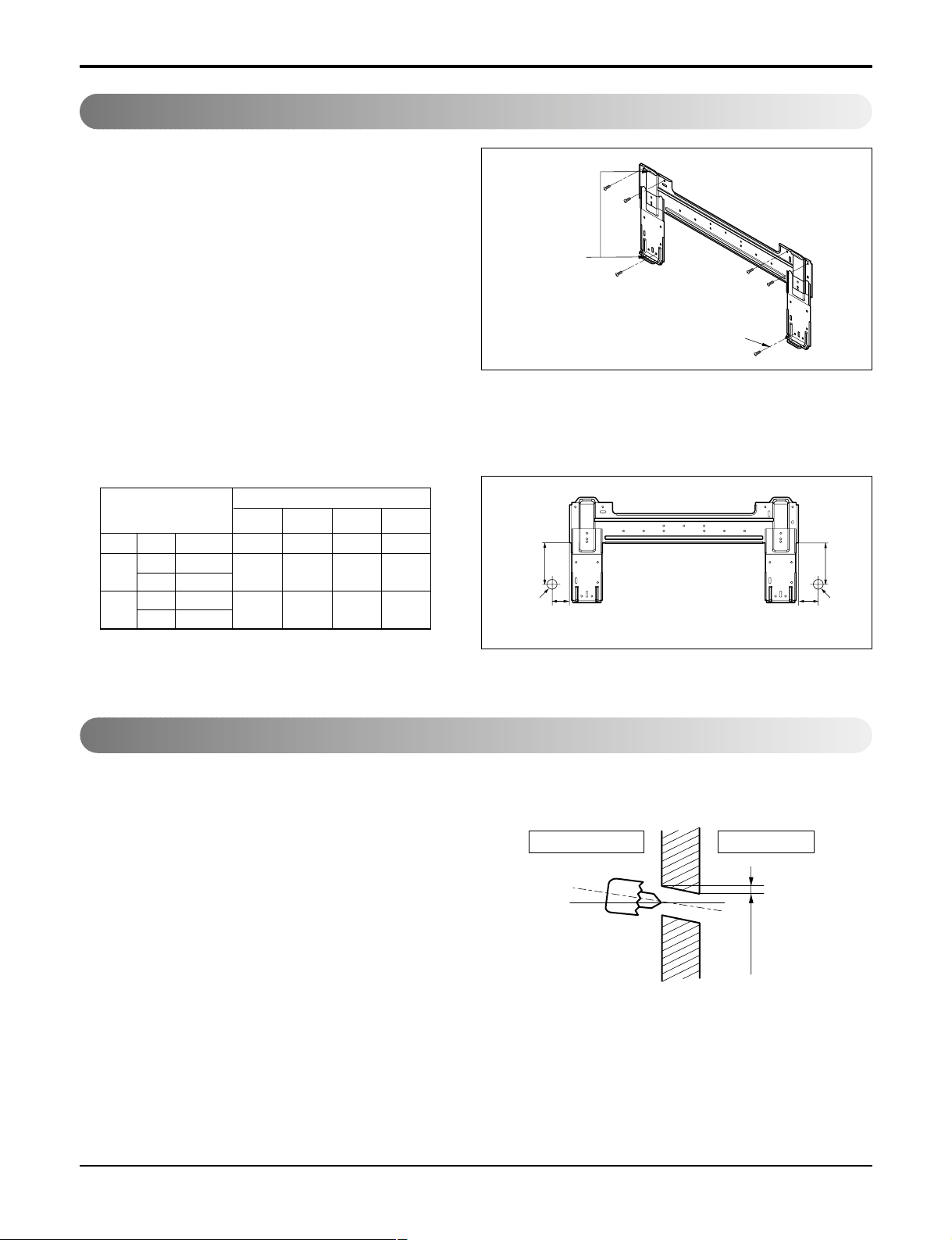

The wall you select should be strong and solid enough

to prevent vibration

1. Mount the installation plate on the wall with

type "A" screws. If mounting the unit on a concrete

wall, use anchor bolts.

• Mount the installation plate horizontally by aligning the

centerline using a level.

How To Mount Installation Plate

Chassis

Hook

Installation Plate

Type “A”

• Drill the piping hole with a ø70mm(2.76in) hole

core drill. Drill the piping hole at either the right

or the left with the hole slightly slanted to the outdoor side.

Drill a Hole In The Wall

5-7mm

(0.2~0.3")

Indoor

WALL

Outdoor

2. Measure the wall and mark the centerline. It is also important to use caution concerning the location of the installation plate-routing of the wiring to power outlets is through the walls typically. Drilling the hole through the wall

for piping connections must be done safely.

Installation plate

Left rear piping Right rear piping

Ø70mm

Ø70mm

D

B

A

C

S4 9k C/O 1.97 4.13 2.32 4.13

SE

9k H/P

2.56 4.33 3.35 4.33

12k C/O, H/P

S5

18k C/O, H/P

3.74 4.80 9.25 4.80

24k C/O, H/P

CHASSIS

(Grade)

Distance (inch)

ABCD

Installation

Page 19

Service Manual 19

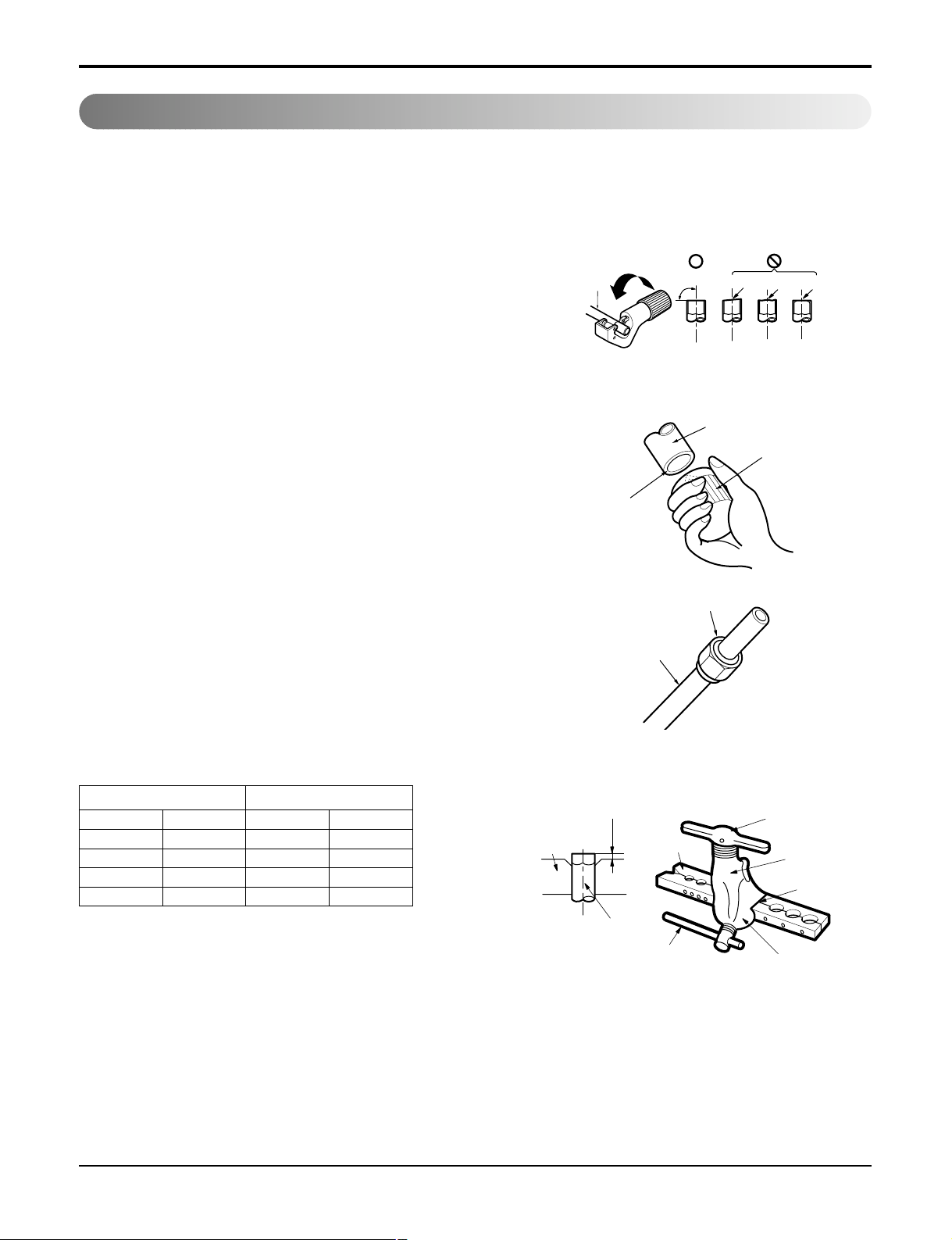

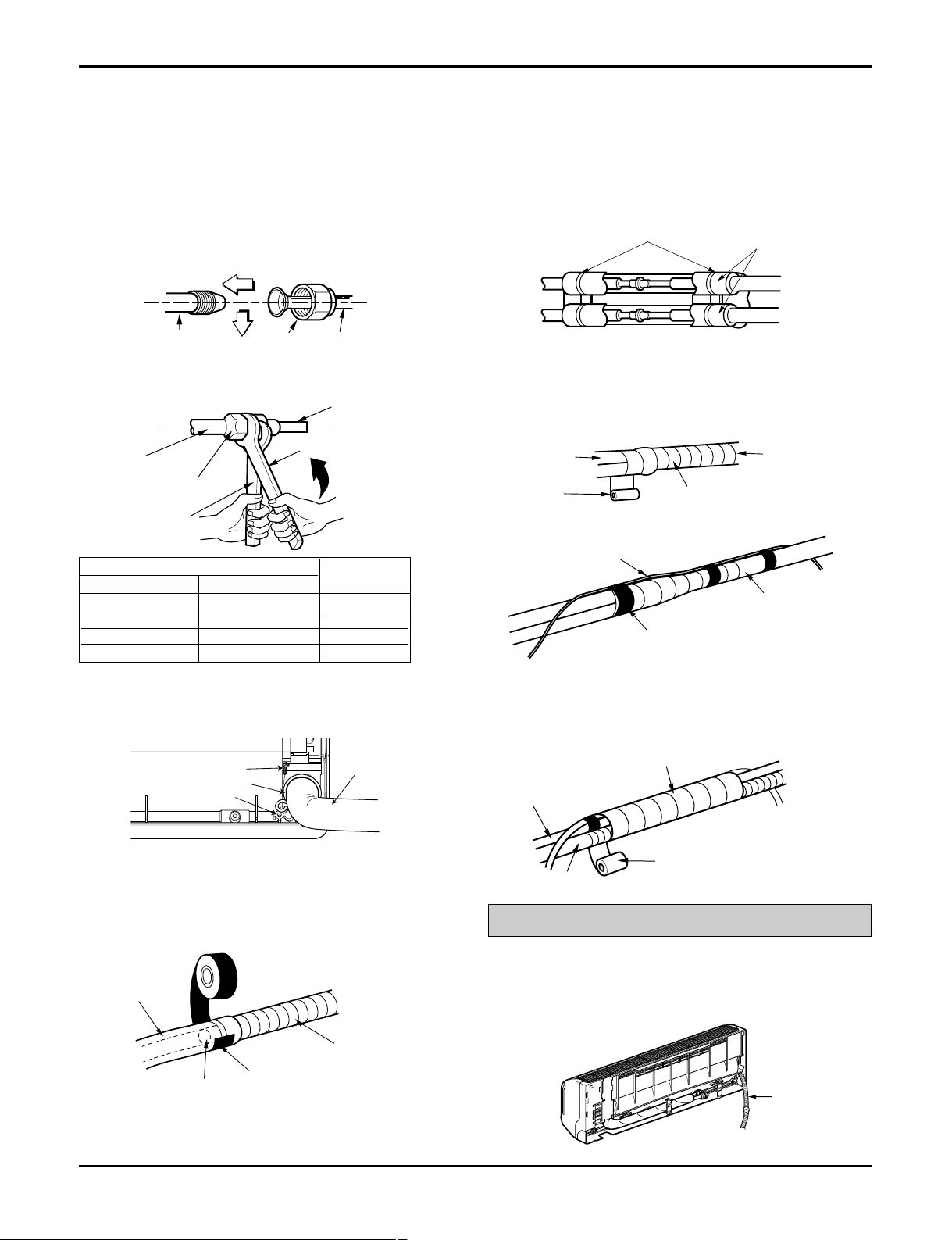

Flaring Work

Cut the pipes and the cable.

1. Use the piping kit accessory or the pipes purchased

locally.

2. Measure the distance between the indoor and the out-

door unit.

3. Cut the pipes a little longer than measured distance.

4. Cut the cable 1.5m(59.1in) longer than the pipe length.

Burrs removal

1. Completely remove all burrs from the cut cross section

of pipe/tube.

2. Put the end of the copper tube/pipe in a downward

direction as you remove burrs in order to avoid dropping burrs into the tubing.

Putting nut on

• Remove flare nuts attached to indoor and outdoor unit,

then put them on pipe/tube having completed burr

removal.

(not possible to put them on after flaring work)

Flaring work

• Carry out flaring work using flaring tool as shown below.

Main cause for gas leakage is due to defect in flaring work. Carry out correct flaring work in the following procedure.

Bar

Copper pipe

Clamp handle

Red arrow mark

Cone

Yoke

Handle

Bar

"A"

Pipe

Reamer

Point down

Copper

pipe

90°

Slanted Uneven Rough

Firmly hold copper pipe in a die in the dimension shown in the table abov e .

Flare nut

Copper tube

mm inch mm inch

Ø6.35 1/4 0~0.5 0~0.020

Ø9.52 3/8 0~0.5 0~0.020

Ø12.7 1/2 0~0.5 0~0.020

Ø15.88 5/8 0~1.0 0~0.039

Outside diameter A

Installation

Page 20

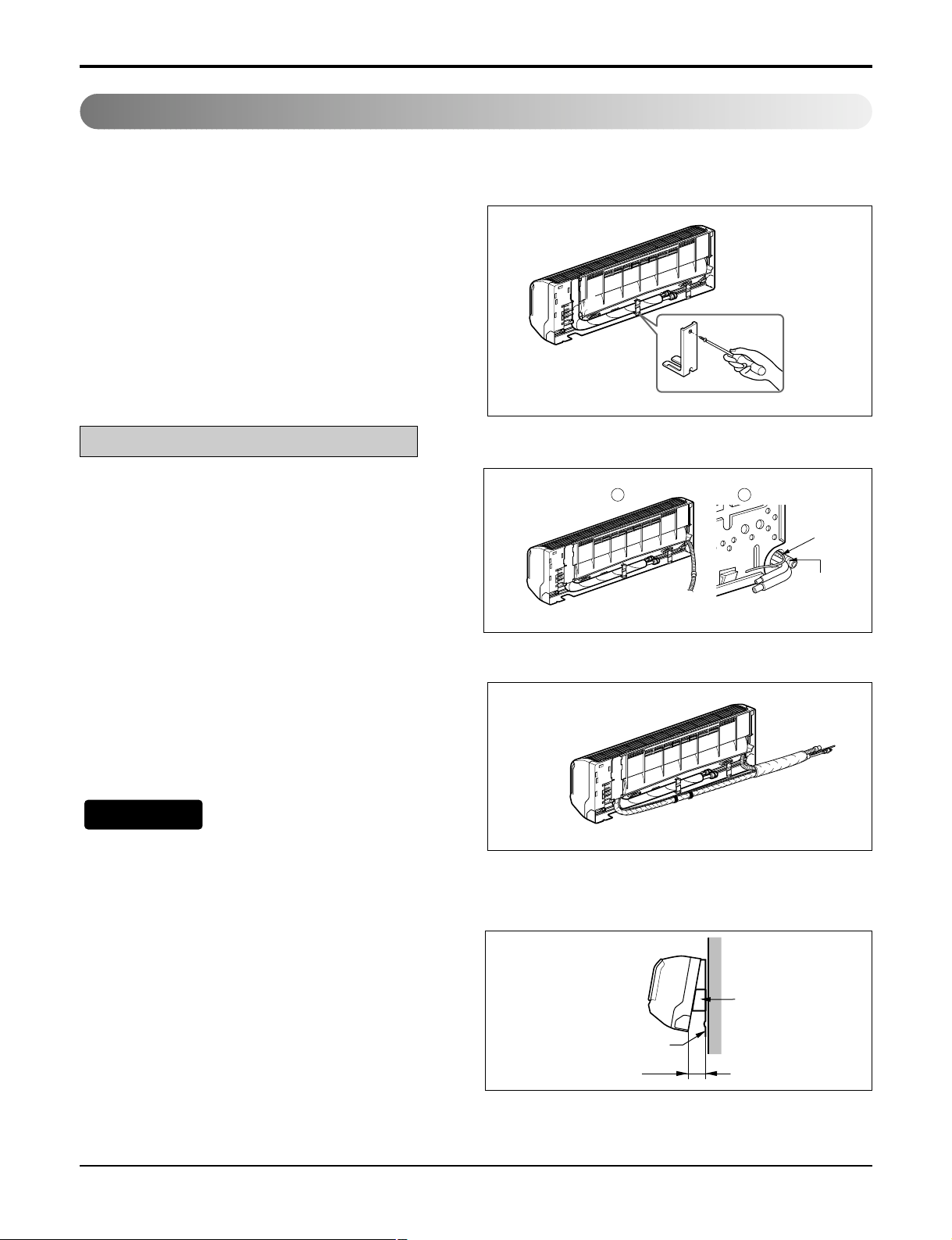

20 Room Air Conditioner

Indoor

1. Prepare the indoor unit's piping and drain hose for installation through the wall.

2. Remove the plastic tubing retainer(see the illus-

tration by) and pull the tubing and drain hose

away from chassis.

3. Replace only the plastic tubing holder 1, not the

holder 2 in the original position.

Route the indoor tubing and the drain

hose in the direction of rear left.

Insert the connecting cable into the indoor unit

from the outdoor unit through the piping hole.

• Do not connect the cable to the indoor unit.

• Make a small loop with the cable for easy con-

nection later.

Tape the tubing, drain hose and the connecting

cable. Be sure that the drain hose is located at the

lowest side of the bundle. Locating at the upper

side can cause drain pan to overflow inside the

unit.

If the drain hose is routed inside the room, insulate the hose with an insulation material* so that

dripping from "sweating"(condensation) will not

damage furniture or floors.

*Foamed polyethylene or equivalent is recom-

mended.

Indoor unit installation

• Hook the indoor unit onto the upper portion of

the installation plate.(Engage the three hooks of

the rear top and rear lower of the indoor unit with

the upper edge and lower edge of the installation

plate.) Ensure that the hooks are properly seated

on the installation plate by moving it left and

right.

NOTICE

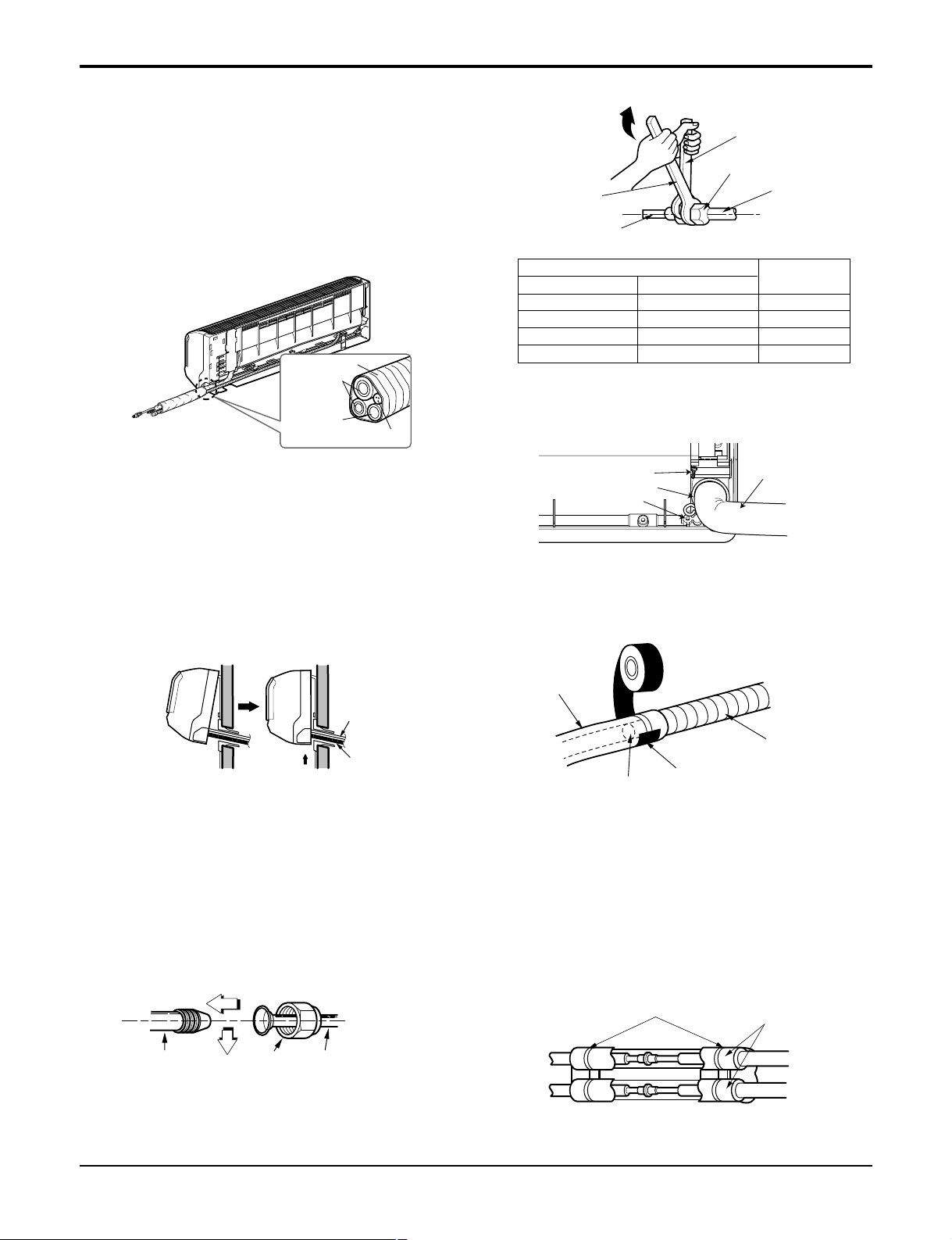

Connecting The Piping

For left rear piping

Installation

1 2

Connecting

cable

Drain pipe

Indoor unit

Spacer

Installation plate

8cm

Page 21

Service Manual 21

Wrap the insulation material around the

connecting portion.

• Overlap the connection pipe insulation material

and the indoor unit pipe insulation material. Bind

them together with vinyl tape so that there is no

gap.

Route the indoor tubing and the drain

hose to the required piping hole position.

Plastic bands

Insulation material

Connection pipe

Flare nut

Indoor unit tubing

Torque wrench

Spanner (fixed)

Vinyl tape(narrow)

Adhesive

Drain pipe

Indoor unit drain hose

• When extending the drain hose at the indoor

unit, install the drain pipe.

• Tighten the flare nut with a wrench.

For right rear piping

Connecting the pipings to the indoor unit

and drain hose to drain pipe.

• Put a couple drops of refrigerant oil on the face

of the flare before assembling taking care not to

add any contaminants.

• Align the center of the pipings and sufficiently

tighten the flare nut by hand.

Indoor unit tubing Flare nut Pipings

Drain hose

Ø6.35 1/4 13.0

Ø9.52 3/8 30.4

Ø12.7 1/2 39.8

Ø15.88 5/8 47.7

Outside diameter

mm inch

Torque

Vinyl tape(narrow)

Connection

pipe

Connecting cable

Vinyl tape

(wide)

Wrap with vinyl tape

Indoor

unit pipe

Pipe

• Bundle the piping and drain hose together by

wrapping them with vinyl tape over the range

within which they fit into the rear piping housing

section.

Wrap with vinyl tape

Drain hose

Pipe

Vinyl tape(wide)

• Wrap the area which accommodates the rear piping

housing section with vinyl tape.

• Mount the clamp on the boss with a type "B"

screw.(SE-H/P: 9k, 12k C/O: 12k)

Installation

Type "B" screw

Clamp

Boss

Drain hose

Page 22

22 Room Air Conditioner

Insert the connecting cable into the indoor

unit.

• Don't connect the cable to the indoor unit.

• Make a small loop with the cable for easy con-

nection later.

Tape the drain hose and the connecting cable.

• Connecting cable

Connecting the pipings to the indoor unit

and the drain hose to drain pipe.

• Put a couple drops of refrigerant oil on the face

of the flare before assembling taking care not to

add any contaminants

• Align the center of the pipings and sufficiently

tighten the flare nut by hand.

• Tighten the flare nut with a wrench.

Indoor unit tubing Flare nut Pipings

Torque wrench

Indoor unit tubing

Spanner (fixed)

Connection pipe

Flare nut

Indoor unit installation

• Hook the indoor unit onto the upper portion of

the installation plate.(Engage the three hooks of

the rear top and rear lower of the indoor unit with

the upper edge and lower edge of the installation

plate.) Ensure that the hooks are properly seated

on the installation plate by moving it left and

right.

Vinyl tape

Adhesive

Drain hose

Indoor unit drain hose

(narrow)

• When extending the drain hose at the indoor

unit, install the drain pipe.

Connecting

pipe

Connecting cable

Tape

Drain hose

Drain hose

Connecting

cable

• Mount the clamp on the boss with a type "B"

screw.(SE-H/P: 9k, 12k C/O: 12k)

Wrap the insulation material around the

connecting portion.

• Overlap the connection pipe heat insulation and

the indoor unit pipe heat insulation material.

Bind them together with vinyl tape so that there

is no gap.

Plastic bands

Insulation material

Ø6.35 1/4 13.0

Ø9.52 3/8 30.4

Ø12.7 1/2 39.8

Ø15.88 5/8 47.7

Outside diameter

mm inch

Torque

(lbf.ft)

Installation

Type "B" screw

Clamp

Boss

Drain hose

Page 23

Service Manual 23

Reroute the pipings and the drain hose

across the back of the chassis.

Reroute the pipings and the drain hose

across the back of the chassis.

Drain hose

Vinyl tape(narrow)

Pipe

Wrap with

vinyl tape(wide)

• Bundle the piping and drain hose together by

wrapping them with cloth tape over the range

within which they fit into the rear piping housing

section.

Piping for

passage through

piping hole

Drain hose

Connecting

cable

• Wrap the area which accommodates the rear

piping housing section with vinyl tape.

Vinyl tape(narrow)

Connection

pipe

Connecting cable

Indoor

unit piping

Pipe

Vinyl tape

(wide)

Wrap with vinyl tape

Installation

Page 24

24 Room Air Conditioner

Installation Information. For left piping. Follow the instruction below.

Correct case

• Press on the upper side of clamp and unfold the tubing to downward slowly.

Incorrect case

• Following bending type from right to left may cause damage to the tubing.

Installation

Page 25

Service Manual 25

Put a couple drops of refrigerant oil on

the face of the flare before assembling

taking care not to add any contaminants.

Align the center of the pipings and sufficiently tighten the flare nut by hand.

• The drain hose can be connected at two different

positions. Use the most convenient position and, if

necessary, exchange the position of the drain pan,

rubber cap and the drain hose.

➊ Drain pan

➋ Rubber cap

➌ Drain hose

➍ Exchange if necessary

• Remove the drain hose.

• Securely insert both the rubber plug and drain hose

into the drain outlets.

Be sure the rubber the cap is securely fastened so

that there is no leakage.

Finally, tighten the flare nut with torque

wrench until the wrench clicks.

• When tightening the flare nut with torque

wrench, ensure the direction for tightening follows the arrow on the wrench.

Outdoor unit

Suction Line piping

(Bigger diameter)

Evaporator Line

piping

(Smaller

diameter)

Torque wrench

1

2

3

4

Connection Of The Drain Hose

Connection Of Piping -Outdoor

Ø6.35 1/4 13.0

Ø9.52 3/8 30.4

Ø12.7 1/2 39.8

Ø15.88 5/8 47.7

Ø19.05 3/4

47.7

Outside diameter

mm inch

Torque

(lbf.ft)

Installation

Page 26

26 Room Air Conditioner

Connection Of The Cable

1

Indoor Unit Outdoor Unit

2

3

4

1

2

3

4

5

6

G

To

branch

circuit

Ground

Power supply

a

L1

*

L2

Connecting cable(Low voltage)

b

Terminal

(4P)

Terminal

(6P)

Outdoor unit

Wiring Diagram

Terminal block

Over 5mm

(0.2")

Cover control

Conduit panel

Connecting

cable

Power supply

cord

*

L1 is neutral for 115V models.

1. Remove the cover control from the unit by

loosening the 3 screws.

2. Dismount caps on the conduit panel.

3. Temporarily mount the conduit tubes on the

conduit panel.

4. Properly connect both the power supply and

low voltage lines to the corresponding terminals on the terminal block.

5. Ground the unit in accordance with local

codes.

6. Be sure to size each wire allowing several

inches longer than the required length for

wiring.

7. Use lock nuts to secure the conduit tubes.

1. shows field wiring.

2. Separately wire the high and low voltage line.

3. Use heat-proof electrical wiring capable of

withstanding temperatures up to 167°F(75°C).

4. Use outdoor and waterproof connection cable

rated more than 300V for the connection

between indoor and outdoor unit.

(For example, Type SJOW)

• Be sure to comply with local codes while

running the wire from the indoor unit to

the outdoor unit(size of wire and wiring

method, etc).

• Every wire must be connected firmly.

• No wire should be allowed to touch refrigerant tubing, the compressor or any moving parts.

Connector trade size for this unit is 1/2" for

instructions on connecting depending on

the wire type you are using.

Power Suppl y

Model

Power source

9k Cooling 1ø, 115V 18 8.6 15

9k Heating 1ø, 115V 14 14.3 20

12k Cooling 1ø, 115V 14 14.3 20

12k Heating 1ø, 115V 14 14.3 20

18k Cooling 1ø, 230/208V 14 13.6 20

18k Heating 1ø, 230/208V 14(12) 17.7 30

24k Cooling 1ø, 230/208V 14(12) 17.7 30

24k Heating 1ø, 230/208V 14(12) 17.7 30

AWG(MIN.)

AWG MCA

MOP(MAXIMUN OVER-

CURRENT PRO TECTION)

NOTICE

NOTICE

Installation

Page 27

Service Manual 27

After the confirmation of the above conditions, prepare the wiring as follows:

1)

Never fail to have an individual power cir cuit specificall y for the air conditioner. As for the

method of wiring, be guided by the circuit diagram posted on the inside of contr ol cover.

2) The screw which fasten the wiring in the casing of electrical fittings are liable to come

loose from vibrations to which the unit is subjected during the course of transportation.

Check them and make sure that they are all tightly fastened. (If they are loose, it could

cause burn-out of the wires.)

3) Specification of power source.

4) Confirm that electrical capacity is sufficient.

5) Confirm that the starting voltage is maintained at more than 90 percent of the rated voltage marked on the name plate.

6) Confirm that the cable thickness is as specified in the power source specification.

(Particularly note the relation between cable length and thickness.

7) Always install an GFCI circuit breaker in a wet or moist area.

8) The following would be caused by voltage drop.

• Vibration of a magnetic switch, which will damage the contact point, open fuse, disturbance of

the normal function of the overload.

9) The means for disconnection from a power supply shall be incorporated in the fixed

wiring and have an air gap contact separation of at least 3mm(0.12in) in each

active(phase) conductors.

Installation

Page 28

28 Room Air Conditioner

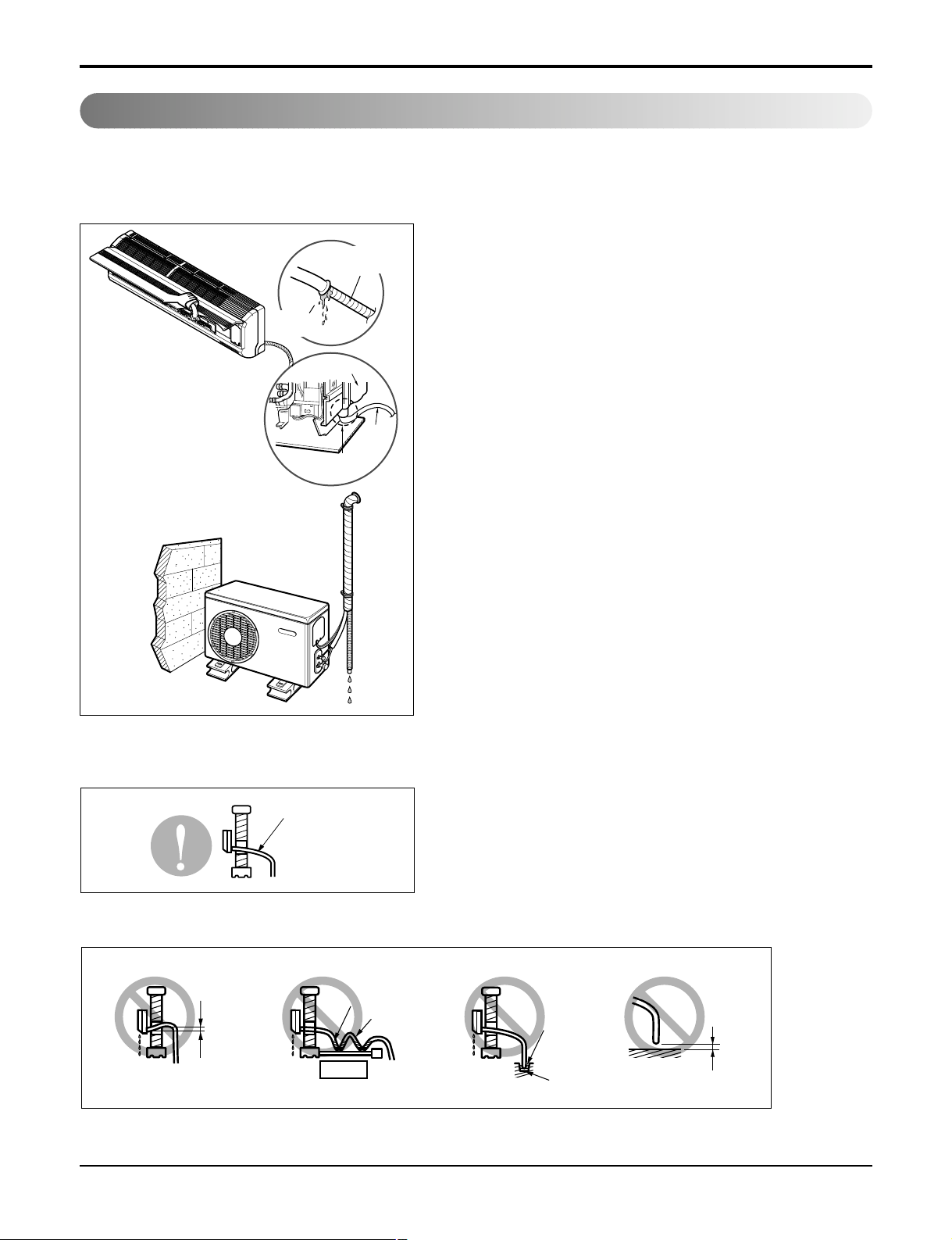

Checking The Drainage

• Pour a glass of water on the drain pan.

• Ensure the water flows through the drain hose of the indoor unit without any leakage and goes out the

drain exit.

Drain piping

• The drain hose should point downward for easy drain flow.

Drain pan

Drain

hose

Leakage

checking

Connecting area

drain hose

Leakage

checking

• Avoid these situations.

Do not raise

Accumulated

drain water

Tip of drain hose

dipped in water

Air

Waving

Water

leakage

Water

leakage

Ditch

Less than

50mm gap

Water

leakage

Installation

Downward slope

Page 29

Service Manual 29

Forming The Piping

Form the piping by wrapping the connecting portion of the indoor unit with insulation material and secure it with two kinds

of vinyl tapes.

• If you want to connect an additional drain hose,

the end of the drain outlet should be routed

above the ground. Secure the drain hose appropriately.

In cases where the outdoor unit is

installed below the indoor unit perform the

following.

• Tape the piping, drain hose and connecting

cable from down to up.

• Secure the tapped piping along the exterior wall

using saddle or equivalent.

Taping

Drain

hose

Pipings

Connecting

cable

Trap is required to prevent water

from entering into electrical parts.

Seal small openings

around pipings with a

gum type sealer.

In cases where the Outdoor unit is

installed above the Indoor unit perform

the following.

• Tape the piping and connecting cable from

down to up.

• Secure the taped piping along the exterior wall.

Form a trap to prevent water entering the room.

• Fix the piping onto the wall by saddle or equivalent.

Seal a small opening

around the pipings

with gum type sealer.

Trap

Trap

Installation

Page 30

30 Room Air Conditioner

Air Purging

Air purging With Vacuum Pump

Lo Hi

Indoor unit

Outdoor unit

Manifold valve

Charge hose

Nitrogen gas

cylinder(in vertical

standing position)

Pressure

gauge

Air and moisture remaining in the refrigerant system have undesirable effects as indicated below.

• Pressure in the system rises.

• Operating current rises.

• Cooling(or heating) efficiency drops.

• Moisture in the refrigerant circuit may freeze and block capillary tubing.

• Water may lead to corrosion of parts in the refrigeration system.

Therefore, the indoor unit and tubing between the indoor and outdoor unit must be leak tested and

evacuated to remove any noncondensables and moisture from the system.

Preparation

• Check that each tubing(both liquid and gas side

tubes) between the indoor and outdoor units have

been properly connected and all wiring for the test

run has been completed. Remove the service

valve caps from both the gas and the liquid side on

the outdoor unit. Note that both the liquid and the

gas side service valves on the outdoor unit are

kept closed at this stage.

Leak test

• Connect the manifold valve(with pressure gauges)

and dry nitrogen gas cylinder to this service port

with charge hoses.

• Pressurize the system to no more than 150

P.S.I.G. with dry nitrogen gas and close the cylinder valve when the gauge reading reached 150

P.S.I.G. Next, test for leaks with liquid soap.

• Do a leak test of all joints of the tubing(both

indoor and outdoor) and both gas and liquid side

service valves.

Bubbles indicate a leak. Be sure to wipe off the

soap with a clean cloth.

• After the system is found to be free of leaks,

relieve the nitrogen pressure by loosening the

charge hose connector at the nitrogen cylinder.

When the system pressure is reduced to normal,

disconnect the hose from the cylinder.

Be sure to use a manifold valve for air purging. If it

is not available, use a stop valve for this purpose.

The "Hi" knob of the manifold valve must always be

kept close.

To avoid nitrogen entering the refrigerant system in

a liquid state, the top of the cylinder must be higher

than its bottom when you pressurize the system.

Usually, the cylinder is used in a vertical standing

position.

Installation

Page 31

Service Manual 31

Evacuation

• Connect the charge hose end described in the

preceding steps to the vacuum pump to evacuate

the tubing and indoor unit.

Confirm the "Lo" knob of the manifold valve is

open. Then, run the vacuum pump.

The operation time for evacuation varies with tubing length and capacity of the pump. The following table shows the time required for evacuation.

• When the desired vacuum is reached, close the

"Lo" knob of the manifold valve and stop the vacuum pump.

Finishing the job

• With a service valve wrench, turn the valve stem

of liquid side valve counter-clockwise to fully

open the valve.

• Turn the valve stem of gas side valve counterclockwise to fully open the valve.

• Loosen the charge hose connected to the gas

side service port slightly to release the pressure,

then remove the hose.

• Replace the flare nut and its bonnet on the gas

side service port and fasten the flare nut securely

with an adjustable wrench. This process is very

important to prevent leakage from the system.

• Replace the valve caps at both gas and liquid

side service valves and fasten them tight.

This completes air purging with a vacuum pump.

The air conditioner is now ready to test run.

(1) Remove the caps from the gas side and liquid side

valves.

(2) Remove the service-port cap from the gas side

valve.

(3) To open the gas side valve turn the valve stem

counterclockwise approximately 90°, wait for about

2~3 seconds, and close it.

(4) Apply a soap water or a liquid neutral detergent on

the indoor unit connection or outdoor unit connections by a soft brush to check for leakage of the connecting points of the piping.

(5) If bubbles come out, the pipes have leakage.

Soap water method

Suction Line

Evaporator Line

Cap

Hexagonal wrench

3-way valve

(Open)

3-way valve

(Close)

Required time for evacuation when 4 CMF vacu-

um pump is used

10 min. or more 15 min. or more

If tubing length is less

than 10m (33 ft)

if tubing length is longer

than 10m (33 ft)

Indoor unit

Outdoor unit

Lo Hi

Manifold valve

Vacuum pump

Pressure

gauge

Open

Close

Installation

Page 32

32 Room Air Conditioner

Charging

■ Each outdoor unit is factory charged (nameplate charge) for the evaporator as well as a 7.5m(25ft)

line set. Any time a line set is used either shorter or longer then the nominal 7.5m(25ft) line set

length the refrigerant charge has to be adjusted.

■ Whether the line set is made shorter or longer you must adjust the charge based on how many ft of

tubing are either added or removed based on 20g(0.22oz) of R-410A per meter(foot).

Example: A 30ft line set is used

5 additional ft X 0.22 ounce per foot= add 1.1 ounces of R-410A

Important:(Unit is critically charged)

If you are ever uncertain of the unit charge, reclaim, evacuate and weigh in the correct charge using the unit nameplate charge

adjusting for line sets longer or shorter than 7.5m(25ft).

Confirm the refrigerant R-410A. Use manifold gauge and hose for R-410A.

Pipe Size

Capacity

(Btu/h)

Suction

Evap

Max.

length

A m(ft)

Max.

Elevation

B m(ft)

Standard

Length

m(ft)

9k

3/8" 1/4" 7.5(25) 7.5(25) 15(49) 20(0.22)

1/2" 1/4" 7.5(25) 7.5(25) 15(49) 20(0.22)

12k 1/2" 1/4" 7.5(25) 7.5(25) 15(49) 20(0.22)

18k

1/2" 1/4" 7.5(25) 15(49) 30(98) 20(0.22)

5/8" 1/4" 7.5(25) 7.5(25) 15(49) 20(0.22)

24k 5/8" 1/4" 7.5(25) 7.5(25) 15(49) 20(0.22)

Installation

Page 33

Service Manual 33

Outside ambient TEMP. The pressure of the gas side service valve

95°F(35°C)

8.5~9.5kg/cm2 G(120~135 P.S.I.G.)

Settlement of outdoor unit

■ Anchor the outdoor unit with a bolt and

nut(ø10mm(0.39in) tightly and horizontally on a

concrete or rigid mount.

■ When installing on the wall, roof or rooftop,

anchor the mounting base securely with a nail

or wire assuming the influence of wind and

earthquake.

■ In the case when the vibration of the unit is conveyed to the hose, secure the unit with an anti-

vibration rubber.

1. Check that all tubing and wiring have been

properly connected.

2. Check that the gas and liquid side service

valves are fully open.

Prepare remote control

1. Remove the battery cover

by pulling it according to the

arrow direction.

2. Insert new batteries making

sure that the (+) and (–) of

battery are installed correctly.

3. Reattach the cover by

pushing it back into position.

NOTE:

• Use 2 AAA(1.5volt) batteries. Do not use

rechargeable batteries.

• Remove the batteries from the remote control if

the system is not going to be used for a long

time.

Evaluation of the performance

Operate unit for 15~20 minutes, then check the

system refrigerant charge:

1. Measure the pressure of the gas side service valve.

NOTE: If the actual pressure are higher than

shown, the system is most likely overcharged, and charge should be removed. If

the actual pressure are lower than shown,

the system is most likely undercharged,

and charge should be added.

The air conditioner is now ready for use.

Bolt

Tubing connection

This is performed when the unit is to be relocated

or the refrigerant circuit is serviced.

Pump Down means collecting all refrigerant in the outdoor unit without loss of refrigerant.

CAUTION:

Be sure to perform Pump Down procedure with the unit

cooling mode.

Pump Down Procedure

1. Connect a low-pressure gauge manifold hose to the

charge port on the gas side service valve.

2. Open the gas side service valve halfway and purge the

air from the manifold hose using the refrigerant gas.

3. Close the liquid side service valve(all the way in).

4. Turn on the unit's operating switch and start the cooling

operation.

5. When the low-pressure gauge reading becomes 1 to

0.5kg/cm2G(14.2 to 7.1 P.S.I.G.), fully close the gas

side valve stem and then quickly turn off the unit. At that

time, Pump Down has been completed and all refrigerant will have been collected in the outdoor unit.

PUMP DOWN

2. Measure the temperature of the intake and discharge

of air.

3. Ensure the difference between the intake tem-

perature and the discharge is more than

14.4°F(8°C) (Cooling) or (Heating).

4. For reference; the gas side pressure of optimum

condition is as below.(Cooling)

Discharge

temperature

Discharge air

Intake temperature

Test Running

Test Running

Page 34

Operation

Function of Controls

Operation

• DISPLAY

1) C/O Model

Operation Indicator

• ON while in appliance operation, OFF while in appliance pause.

• Flashing while in disconnection or short in Thermistor. (3 sec off / 0.5 sec on)

Timer Indicator

• ON while in timer mode (on/off), OFF when timer mode is completed or canceled.

Comp. Running Incidator

• While in appliance operation, ON while in outdoor unit compressor running, OFF while in compressor off.

2) H/P Model

Operation Indicator

• ON while in appliance operation, OFF while in appliance pause.

• Flashing while in disconnection or short in Thermistor. (3 sec off / 0.5 sec on)

Timer Indicator

• ON while in timer mode (on/off), OFF when timer mode is completed or canceled.

Defrost Indicator

• OFF except when hot start during heating mode operation or while in defrost control.

■ Cooling Mode Operation

• When the intake air temperature reaches 0.5°C(0.9°F) below the setting temp, the compressor and

the outdoor fan stop.

• When it reaches 0.5°C(0.9°F) above the setting temp, they start to operate again.

Compressor ON Temp ➲ Setting Temp+0.5°C(0.9°F)

Compressor OFF Temp ➲ Setting Temp-0.5°C(0.9°F)

• While in compressor running, operating with the airflow speed set by the remote control. While in

compressor not running, operating with the low airflow speed regardless of the setting.

■ Healthy Dehumidification Mode

• When the dehumidification operation input by the remote control is received, the intake air temperature is detected and the setting temp is automatically set according to the intake air temperature.

26°C(78.8°F) ≤ Intake Air Temp ➲ 25°C(77°F)

24°C(75.2°F) ≤ Intake Air Temp<26°C(78.8°F) ➲ Intake Air Temp-1°C(1.8°F)

18°C(64.4°F) ≤ Intake Air Temp<24°C(75.2°F) ➲ Intake Air Temp-0.5°C(0.9°F)

Intake Air Temp<18°C(64.4°F) ➲ 18°C(64.4°F)

34 Room Air Conditioner

Page 35

Service Manual 35

Operation

• While in compressor off, the indoor fan repeats low airflow speed and pause.

• While the intake air temp is between compressor on temp. and compressor off temp., 10-min dehumidification operation and 4-min compressor off repeat.

Compressor ON Temp. ➲ Setting Temp+0.5°C(0.9°F)

Compressor OFF Temp. ➲ Setting Temp-0.5°C(0.9°F)

• In 10-min dehumidification operation, the indoor fan operates with the low airflow speed.

■ Heating Mode Operation

• When the intake air temp reaches +3°C(5.4°F) above the setting temp, the compressor is turned

off. When reaches the setting temp, the compressor is turned on.

Compressor ON Temp. ➲ Setting Temp.

Compressor OFF Temp. ➲ Setting Temp.+3°C(5.4°F)

• While in compressor on, the indoor fan is off when the indoor pipe temp. is below 20°C(68°F), when

above 28°C(82.4°F) , it operates with the low or setting airflow speed. When the indoor pipe temp is

between 20°C and 28°C(82.4°F), it operates with Super-Low(while in sleep mode, with the medium

airflow speed).

• While in compressor off, the indoor fan is off when the indoor pipe temp is below 33°C(91.4°F),

when above 35°C(95°F) , it operates with the low airflow speed.

• If overloaded while in heating mode operation, in order to prevent the compressor from OLP operation, the outdoor fan is turned on/off according to the indoor pipe temp.

• While in defrost control, both of the indoor and outdoor fans are turned off.

■ Defrost Control

• While in heating mode operation in order to protect the evaporator pipe of the outdoor unit from

freezing, reversed to cooling cycle to defrost the evaporator pipe of the outdoor unit.

• After 40 min heating mode operation, at 4 min interval, whether to carry out defrost control or not

and the time of defrost control are determined according to the following conditions.

1) While in heating mode operation, the maximum of the indoor pipe temperature is measured and it is

compared with the present indoor pipe temperature to get the difference of the indoor pipe temperatures (=the maximum temperature of indoor pipe & the present temperature of indoor pipe),

according to which, whether to carry out defrost control or not is determined.

2) According to the need of defrost control shown above and the elapsed time of heating mode opera-

tion at that moment, the defrost control time is determined.

3) When the determined time of defrost control is below 7 min, heating mode operation continues

without carrying out defrost control. According to the procedure stated above, the determination is

made again. When the defrost control time is 7 min or longer, defrost control is then carried out.

• While in defrost control, the minimum temp of the indoor pipe is measured and it is compared with

the present temp of the indoor pipe to get the difference of the indoor pipe temperatures (=the present temperature of the indoor pipe & the minimum temperature of the indoor pipe). When the difference is 5°C(41°F) or higher, defrost control is completed and heating mode operation is carried out.

• While in defrost control, if the defrost time determined before the start of defrost control is completed, defrost control stops and heating mode operation is carried out regardless of the above condition.

• When the indoor pipe temp is 42°C(107.6°F) or above, defrost control is not carried out even if the

condition is one of the defrost conditions above.

• While in defrost control, the compressor is on and the indoor fan, the outdoor fan, and the 4 way

valve are off.

Page 36

36 Room Air Conditioner

■ Airflow Speed Selection

• The airflow speed of the indoor fan is set to high, medium, low, or chaos (auto) by the input of the

airflow speed selection key on the remote control.

■ Sleep Timer Operation

• When the sleep time is reached after <1,2,3,4,5,6,7,0(cancel) hr> is input by the remote control

while in appliance operation, the operation of the appliance stops.

• While the appliance is on pause, the sleep timer mode cannot be input.

• While in cooling mode operation, 30 min later since the start of the sleep timer, the setting tempera-

ture increases by 1°C(1.8°F). After another 30 min elapse, it increases by 1°C(1.8°F) again.

• When the sleep timer mode is input while in cooling cycle mode, the airflow speed of the indoor fan

is set to the low.

• When the sleep timer mode is input while in heating cycle mode, the airflow speed of the indoor fan

is set to the medium.

■ Chaos Natural Wind Mode

• When the Chaos Natural Wind mode is selected and then operated, the high, medium, or low speed

of the airflow mode is operated for 2~15 sec. randomly by the Chaos Simulation.

■ Jet Cool Mode Operation (C/O Model)

• If the Jet Cool key is input at any operation mode while in appliance operation, the Jet Cool mode

operates.

• In the Jet Cool mode, the indoor fan is operated at super-high speed for 30 min at cooling mode

operation.

• In the Jet Cool mode operation, the room temperature is controlled to the setting temperature,

18°C(64.4°F)

• When the sleep timer mode is input while in the Jet Cool mode operation, the Jet Cool mode has

the priority.

• When the Jet Cool key is input, the upper/lower vanes are reset to those of the initial cooling mode

and then operated in order that the air outflow could reach further.

■ Jet Cool Mode Operation (H/P Model)

• While in heating mode or Fuzzy operation, the Jet Cool key cannot be input. When it is input while

in the other mode operation (cooling, dehumidification, ventilation), the Jet Cool mode is operated.

•

In the Jet Cool mode, the indoor fan is operated at super-high speed for 30 min at cooling mode operation.

• In the Jet Cool mode operation, the room temperature is controlled to the setting temperature,

18°C(64.4°F).

• When the sleep timer mode is input while in the Jet Cool mode operation, the Jet Cool mode has

the priority.

• When the Jet Cool key is input, the upper/lower vanes are reset to those of the initial cooling mode

and then operated in order that the air outflow could reach further.

Operation

Page 37

Service Manual 37

Operation

■ Forced operation

• Operation procedures when the remote control can't be used.

• The operation will be started if the power button is pressed.

• If you want to stop operation, re-press the button.

• While in forced operation, the key input by the remote control has no effect and the buzzer sounds

10 times to indicate the forced operation.

■ Test operation

•

During the TEST OPERATION, the unit operates in cooling mode at high speed fan, regardless of

room temperature and resets in 18±1 minutes.

•

During test operation, if remote controller signal is received, the unit operates as remote controller

sets.

If you want to use this operation, open the front panel upward and Press the power button let it be

pressed for about 3 seconds.

•

If you want to stop the operation, re-press the button.

■ Auto restart

•

In case the power comes on again after a power failure, Auto Restarting Operation is the function to

operate procedures automatically to the previous operating conditions.

■ Protection of the evaporator pipe from frosting

• If the indoor pipe temp is below 0°C in 7 min. after the compressor operates without any pause

while in cooling cycle operation mode, the compressor and the outdoor fan are turned off in order to

protect the indoor evaporator pipe from frosting.

• When the indoor pipe temp is 7°C or higher after 3 min. pause of the compressor, the compressor

and the outdoor fan is turned on according to the condition of the room temperature.

■ Buzzer Sounding operation

• When the appliance-operation key is input by the remote control, the short "beep-beep-" sounds.

• When the appliance-pause key is input by the remote control, the long "beep—" sounds.

Heat pump Model

Cooling Model

Room Temp. ≥ 24°C(75.2°F) 21°C(69.8°F) ≤Room Temp. < 24°C(75.2°F) Room Temp. < 21°C(69.8°F)

Operating mode Cooling Cooling Healthy Dehumidification Heating

Indoor FAN Speed High High High High

Setting Temperature 22°C(71.6°F) 22°C(71.6°F) 23°C(73.4°F) 24°C(75.2°F)

Page 38

38 Room Air Conditioner

Self-diagnosis Function

Display Function

1. Heating Model 2. Cooling Model

• Cooling, Soft Dry, Fan, Heating • Cooling, Soft Dry, Fan

• Hot-start, Deice

Operation Indicator

Deicer Indicator

Operation Indicator

Compressor on Indicator

Error

Code

1

Error Display LED

(Indoor body operation LED)

Error contents

• Indoor room temperature

thermistor open/short

• Indoor pipe temperature

thermistor open/short.

• Indoor Thermistor

assembly check

SVC check point

Operation

(once)

3sec 3sec 3sec

Page 39

Service Manual 39

Operation

Remote Control Operations

The controls will look like the following.

1. START/STOP BUTTON

Operation starts when this button is pressed and

stops when the button is pressed again.

2. OPERATION MODE SELECTION BUTTON

Used to select the operation mode.

3. ROOM TEMPERATURE SETTING BUTTONS

Used to select the room temperature.

4. INDOOR FAN SPEED SELECTOR

Used to select fan speed in four steps

low, medium, high and CHAOS.

5.

JET COOL

Used to start or stop the speed cooling.(speed cooling

operates super high fan speed in cooling mode.)

6. CHAOS SWING BUTTON

Used to stop or start louver movement and set

the desired up/down airflow direction.

7. ON/OFF TIMER BUTTONS

Used to set the time of starting and stopping operation.

(See page 22)

8. TIME SETTING BUTTONS

Used to adjust the time. (See page 22)

9. TIMER SET/CANCEL BUTTON

Used to set the timer when the desired time is obtained and

to cancel the Timer operation. (See page 22)

10. SLEEP MODE AUTO BUTTON

Used to set Sleep Mode Auto operation.

(See page 22)

11. AIR CIRCULATION BUTTON

Used to circulate the room air without cooling or heating.

(See page 23)

12. ROOM TEMPERATURE CHECKING BUTTON

Used to check the room temperature.

13. NEO PLASMA(OPTIONAL)

Used to start or stop the plasma-purification function. (See

page 20)

14. HORIZONTAL AIRFLOW DIRECTION CONTROL

BUTTON (OPTIONAL)

Used to set the desired horizontal airflow direction.

15. RESET BUTTON

Used prior to resetting time.

16. 2nd F Button

Used prior to using modes printed in blue at the bottom of

buttons. (See page 21)

17. AUTO CLEAN (OPTIONAL)

Used to set Auto Clean mode.

18. ˚C TO ˚F SWITCHING BUTTON

Used to switch temperature reading from Centigrade to

Fahrenheit.

ON

OFF

CANCEL

AUTO CLEAN

SET

1

3

5

4

9

10

12

14

16

18

7

2

8

13

15

11

6

Cooling Operation

Auto Operation or Auto Changeover

Healthy Dehumidification Operation

Flip-up door

(opened)

Heating Operation

Signal transmitter

•

Cooling Model( ), Heat Pump Model( )

17

Operation Mode

Page 40

40 Room Air Conditioner

Disassembly

Indoor Unit

Disconnect the unit from power supply before making any checks.

Be sure the power switch is set to “OFF”.

To remove the Grille from the Chassis.

• Set the up-and-down air discharge louver to open

position (horizontally) by finger pressure.

• Remove the securing screws.

• To remove the Grille, pull the lower left and right

side of the grille toward you (slightly tilted) and lift it

straight upward.

1. Before removing the control box, be sure to

take out the wire screwed at the other end.

Earth

Conductor

Operation

Page 41

Service Manual 41

Disassembly

2. To remove the Control Box.

• Remove securing screws.

• Pull the control box out from the chassis

carefully.

3. To remove the Discharge Grille.

• Unhook the discharge grille and pull the

discharge grille out from the chassis carefully.

4. To remove the Evaporator.

• Remove 3 screws securing the evaporator(at the

left 2EA in the Eva Holder, at the right 1EA).

Screw

• When repair, do not damage the Caution label.

Page 42

42 Room Air Conditioner

• Unhook the tab on the right inside of the chassis

at the same time, slightly pull the evaporator

toward you until the tab is clear of the slot.

5.To remove the Motor Cover

• Remove 2 securing screw.

• Pull the motor cover out from the chassis

carefully.

6.To remove the Cross-Flow Fan

• Loosen the screw securing the cross-flow fan to

the fan motor (do not remove).

• Lift up the right side of the cross-flow fan and the

fan motor, separate the fan motor from the

cross-flow fan.

• Remove the left end of the cross-flow fan from

the self-aligning bearing.

Motor cover

Bearing

Cross-flow fan

Disassembly

Page 43

Service Manual 43

Troubleshooting Guide

Troubleshooting Guide

INDOOR UNIT OUTDOOR UNIT

INDOOR UNIT OUTDOOR UNIT

HEAT

EXCHANGE

(EVAPORATOR)

HEAT

EXCHANGE

(EVAPORATOR)

HEAT

EXCHANGE

(CONDENSER)

HEAT

EXCHANGE

(CONDENSER)

COMPRESSOR

COMPRESSOR

ACCUMU

LATOR

GAS SIDE

GAS SIDE

3-WAY VALVE

LIQUID SIDE

LIQUID SIDE

3-WAY VALVE

CAPILLARY TUBE

CAPILLARY TUBE

CHECK VALVE

(Heating Model only)

COOLING

HEATING

REVERSING

VALVE

(Heating Model Only)

(1) Cooling Only Models

Refrigeration Cycle Diagram

(2) Cooling & Heating Models

Page 44

44 Room Air Conditioner

Troubleshooting Guide

2-way, 3-way Valve

2-way Valve (Liquid Side) 3-way Valve (Gas Side)

Shaft position Shaft position Service port

Closed Closed Closed

(with valve cap) (with valve cap) (with cap)

Open Closed Open

(counter-clockwise) (clockwise) (push-pin or with

vacumm pump)

Open Open Closed

(with valve cap) (with valve cap) (with cap)

Closed Open Open

(clockwise) (counter-clockwise) (connected manifold

gauge)

Open Open Open

(with charging

cylinder)

Open Open Open

(with charging

cylinder)

Open Open

Open Open

Works

Shipping

Air purging

(Installation)

Operation

Pumping down

(Transfering)

Evacuation

(Servicing)

Gas charging

(Servicing)

Pressure check

(Servicing)

Gas releasing

(Servicing)

1.

2.

3.

4.

5.

6.

Valve cap

Open position

Closed position

Pin

Service

port

Service

port cap

To outdoor unit

Flare nut

To

piping

connection

To outdoor unit

Hexagonal wrench (4mm)

Open position

Closed position

To

piping

connection

Flare nut

Open

(with charging

cylinder)

Open

(with charging

cylinder)

Page 45

Service Manual 45

Troubleshooting Guide

• Procedure

(1) Confirm that both the 2-way and 3-way

valves are set to the open position.

– Remove the valve stem caps and confirm

that the valve stems are in the raised position.

– Be sure to use a hexagonal wrench to

operate the valve stems.

(2) Operate the unit for 10 to 15 minutes.

(3) Stop operation and wait for 3 minutes,

then connect the charge set to the service

port of the 3-way valve.

– Connect the charge hose with the push pin

to the service port.

(4) Air purging of the charge hose.

– Open the low-pressure valve on the charge

set slightly to air purge from the charge

hose.

(5) Set the 2-way valve to the closed position.

(6) Operate the air conditioner at the cooling

cycle and stop it when the gauge indicates 1kg/cm

2

g.

(7) Immediately set the 3-way valve to the

closed position.

– Do this quickly so that the gauge ends up

indicating 3 to 5kg/cm

2

g.

(8) Disconnect the charge set, and mount the

2-way and 3-way valve’s stem nuts and

the service port nut.

– Use torque wrench to tighten the service

port nut to a torque of 1.8 kg.m.

– Be sure to check for gas leakage.

Lo

Closed

Purge the air

Outdoor unit

Indoor unit

Liquid side

Gas side

CLOSE

Open

2-Way

valve

3-Way

valve

CLOSE

Pumping Down

Do not use the existing charge set for R-22.

It is necessary to use new charge set for R410A. The pressure of R-410A is 1.6 times

higher than that of R-22. Thus, the high pressure side gauge of charge set should be used

higher pressure gauge of 50kg/cm2range.

Page 46

46 Room Air Conditioner

Troubleshooting Guide

Balance Refrigerant of the 3-way Valve

(Gas leakage)

• Procedure

(1) Confirm that both the 2-way and 3-way

valves are set to the back seat.

(2) Connect the charge set to the 3-way

valve’s port.

– Leave the valve on the charge set closed.

– Connect the charge hose to the service

port.

(3) Open the valve (Lo side) on the charge set

and discharge the refrigerant until the

gauge indicates 0 kg/cm

2

G.

– If there is no air in the refrigerant cycle (the

pressure when the air conditioner is not

running is higher than 1 kg/cm

2

G), discharge the refrigerant until the gauge indicates 7.1PSI. if this is the case, it will not

be necessary to apply a evacuatin.

– Discharge the refrigerant gradually; if it is

discharged too suddenly, the refrigeration

oil will also be discharged.

Lo

Open

Open

3-Way

valve

3-Way

valve

Gas side

CLOSEOPEN

Outdoor unit

Liquid side

Indoor unit

Page 47

Service Manual 47

Troubleshooting Guide

Evacuation

(All amount of refrigerant leaked)

• Procedure

(1) Connect the vacuum pump to the center

hose of charge set center hose

(2) Evacuation for approximately one hour.

– Confirm that the gauge needle has moved

toward -76 cmHg (vacuum of 4 mmHg or

less).

(3) Close the valve (Lo side) on the charge

set, turn off the vacuum pump, and confirm that the gauge needle does not move

(approxima-tely 5 minutes after turning off

the vacuum pump).

(4) Disconnect the charge hose from the vac-

uum pump.

– Vacuum pump oil.

If the vacuum pump oil becomes dirty or

depleted, replenish as needed.

Lo

Open

Open

Vacuum pump

3-Way

valve

Outdoor unit

Liquid side

Indoor unit

Gas side

3-Way

valve

CLOSE

OPEN

Use vacuum pump equipped with check value

applied to be prevented from flowing backward.

Page 48

48 Room Air Conditioner

Troubleshooting Guide

Gas Charging

(After Evacuation)

• Procedure

(1) Connect the charge hose to the charging

cylinder.

– Connect the charge hose which you dis-

connected from the vacuum pump to the

valve at the bottom of the cylinder.

– If you are using a gas cylinder, also use a

scale and reverse the cylinder so that the

system can be charged with liquid.

(2) Purge the air from the charge hose.

– Open the valve at the bottom of the cylin-

der and press the check valve on the

charge set to purge the air. (Be careful of

the liquid refrigerant). The procedure is

the same if using a gas cylinder.

(3) Open the valve (Lo side on the charge set

and charge the system with liquid refrigerant.

– If the system can not be charged with the

specified amount of refrigerant, it can be

charged with a little at a time (approximately 0.33 lb each time) while operating the air

conditioner in the cooling cycle; however,

one time is not sufficient, wait approximately 1 minute and then repeat the procedure (pumping down-pin).

(4) Immediately disconnect the charge hose

from the 3-way valve’s service port.

– Stopping partway will allow the gas to be

discharged.

– If the system has been charged with liquid

refrigerant while operating the air conditioner turn off the air conditioner before

disconnecting the hose.

(5) Mount the valve stem nuts and the service

port nut.

– Use torque wrench to tighten the service

port nut to a torque of 13 lb·ft.

– Be sure to check for gas leakage.

This unit is charged with R-410A.

Pay attention not to charge R-22.

\

This is different from previous procedures.

Because you are charging with liquid refrigerant

from the gas side, absolutely do not attempt to

charge with larger amounts of liquid refrigerant

while operating the air conditioner.

Liquid side

Gas side

Lo

Charging

cylinder

Indoor unit

Check valve

(1)

OPEN

CLOSE

3-Way

Open

valve

Open

3-Way

valve

Outdoor unit

Page 49

Service Manual 49

Troubleshooting Guide

Additional gas charging

(Gas leakage)

• When refrigerant is insufficient by leakage, recharge the unit with the refrigerant up to normal operating suction pressure.

• Use the graph or the equation below to get operating suction pressure according to indoor and outdoor temperature.

Suction pressure was measured at 3-way valve service port after operating the unit for 10 minutes.

The method of using graph

- Find outdoor temperature.

- Find indoor temperature onto the curve of outdoor temperature.

- Read suction pressure at the axis of ordinates.

The method of using equation

-. Calculate suction pressure after putting indoor and outdoor temperature into the equation.

184.9

(At operating the Unit for 10 minutes)

Suction Pressure

(PSI)

Outdoor Temp.

(˚F)

Indoor Temp. (˚F)

170.7

156.5

142.2

128

113.8

99.5

85

71.1

41 50 59 68 77 86 95 104

122˚F

104˚F

86˚F

68˚F

50˚F

0˚F

Operating Suction Pressure (For R410A)

(According to Indoor & Outdoor Temperature)

Page 50

50 Room Air Conditioner

Troubleshooting Guide

Trouble analysis

1. Check temperature difference between intake and discharge air and operating current.

Temp. Difference

Temp. difference : approx. 0°F(0°C)

Current : less than 80% of

rated current

Temp. difference : approx. 14°F(8°C)

Current : less than 80% of

rated current

Temp. difference :

less than 14°F(8°C)

Current : over the reated

current

Temp. difference : over 14°F(8°C)

Operating Current

• All amount of refrigerant leaked

out. Check refrigeration cycle.

• Refrigerant leakege

Clog of refrigeration cycle

Defective compressor

• Excessive amount of refrigerant

• Normal

Temperature difference between intake and discharge air depends on room air humidity. When the room air

humidity is relativery higher, temperature difference is smaller. When the room air humidity is relatively lower

temperature difference is larger.

2. Check temperature and pressure of refrigeration cycle.

1. The suction pressure is usually 120.9~135.1PSI(Cooling) at normal condition.

2. The temperature can be measured by attaching the thermometer to the low pressure tubing and wrap it with

putty.

NOTICE

NOTICE

Suction pressure Temperature

(Compared with (Compared with Cause of Trouble Description

the normal value) the normal valve)

Defective compressor Current is low.

Defective 4-way reverse valve

Excessive amount of High pressure does not quickly

Normal refrigerant rise at the beginning of

operation.

Insufficient amount of Current is low.

Lower Higher refrigerant (Leakage)

Clogging Current is low.

High

Higher

Cycle Parts

Page 51

Service Manual 51

Troubleshooting Guide

Electronic Parts (9k model)

Product does not operate at all.

(* Refer to Electronic Control Device drawing and Schematic diagram.)

Turn off Main Power

Turn on Main Power

Does "beeping" sound is made from the Indoor Unit?

Primarily, the operating condition of Micom is OK.

Check the voltage of power(About AC 115V, 60Hz)

• Main power's voltage

• Voltage applied to the unit