Page 1

INSTALLATION, OPERATION

& MAINTENANCE MANUAL

Horizontal/Side Discharge

Condensing Units

Models:

CMA18SB-1

CMA24SB-1

CMA30SB-1

CMA36SB-1

Heat Controller • 1900 Wellworth Ave. • Jackson, MI 49203 • (517)787-2100 • www.heatcontroller.com

Page 2

Horizontal/Side Discharge Condensing Units Heat Controller

Horizontal/Side Discharge Condensing Units:

Installation, Operation and Maintenance

TABLE OF CONTENTS

Safety Precautions ................................................................................................................... 3

General Operating Instructions................................................................................................. 4

General Product Information .................................................................................................... 5

Outdoor Unit Installation ........................................................................................................ 6-7

Unit Wiring ........................................................................................................................... 8-10

Wiring Diagrams .................................................................................................................. 8-10

Refrigerant Piping ................................................................................................................... 11

Leak Test, Evacuation & Release of Refrigerant .................................................................... 11

Initial Start-Up & Checks ........................................................................................................ 12

Field Charging ........................................................................................................................ 12

Field Inspection ...................................................................................................................... 12

2

Page 3

Heat Controller Horizontal/Side Discharge Condensing Units

SAFETY PRECAUTIONS

Please read this installation manual completely before installing the product.

If the power cord is damaged, replacement work shall be performed by authorized personnel only.

Installation work must be performed in accordance with all local and national codes by authorized

personnel only.

Contact an authorized service technician for repair, maintenance or installation of this unit.

All the pictures in the instructions are for explanation purposes only, and may differ from the actual

product you purchased.

The design and specifications are subject to change without prior notice for product improvement.

Consult with the sales agency or manufacturer for details.

The seriousness of safety precautions is classified by the following indications:

WA R NI NG

CA UT ION

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage to property.

WAR N ING

1) Install according to this installation instructions strictly. If installation is defective, it will cause water

leakage, electrical shock fire, and may void the warranty.

2) Use the manufacturer’s specified and supplied parts only

3) Install in a strong and firm location which is able to withstand the unit’s weight. If the strength is

insufficient or installation is not properly done, the units can fall and cause injury.

4) For electrical work, follow all local

An independent circuit and single outlet must be used. If electrical circuit capacity is not enough or a

defect found in electrical work, it may cause electrical shock or fire.

and National electrical codes and these installation instructions.

5) Use the specified cable, connect tightly and clamp the cable so that no external force will be acted

on the terminal. If connection is loose, it may cause excessive heat build up.

6) Wiring

cover is not fixed perfectly, it will cause heat build up at connection point of terminal, fire or electrical shock.

When carrying out piping connection, take care not to let air substances other than the specified

7)

refrigerant go into refrigeration circuit. Otherwise, it will cause lower capacity, abnormal high pressure

in the ref

routing must be properly arranged so that control board cover is fixed properly. If control board

rigeration cycle, explosion and injury.

8) Do not modify the length of the power supply cord or use an extension cord, and do not share the

single outlet with other electrical appliances. Otherwise, it may cause fire or electrical shock.

.

CAUTION

1) This equipment must be properly grounded and installed with and ground leakage current breaker,

otherwise it may cause

2) Do not install the unit in place where leakage of flammable gas may occur. If gas leaks and

accumulates near or surroundings the unit, it may cause fire.

3) Carry out drainage piping as mentioned in installation instructions. If drainage is not properly done,

water may enter the room and damage the furniture.

electrical shock.

3

Page 4

Horizontal/Side Discharge Condensing Units Heat Controller

OPERATING INSTRUCTIONS

Air conditioners are designed to provide comfort

cooling at outside temperatures above 65°F

(18°C) but less than 109°F (43°C). Operating the

air conditioner outside of this temperature range

may cause unit failure and will void the warranty.

If you have need for cooling at lower outdoor

temperatures a “low ambient cooling” can be eld

installed. Contact your local contractor or call the

factory.

TO OPERATE:

NOTE: The thermostat operation may vary

by type and model used. Please consult the

operating manual that was provided with

the thermostat. The instructions below are

generalized for most standard thermostat

models.

1. Set the switch on your wall thermostat to the

‘cool’ position.

2. Set the desired temperature (between 63-86°F

or 17-30°C) you want to maintain by moving the

temperature setting on your thermostat. If the

room is warmer than the setting, the unit will

turn on and begin to blow cool air after a few

minutes. A warm, humid room or building may

take several hours of continuous operation to

cool to the thermostat set point the rst time.

Once the set temperature is reached the unit

will cycle on and off.

3. Set the ‘Fan’ switch on the thermostat to ‘auto’

if you want the fan to run only when cooling

is needed or to ‘on’ if you want continuous

air circulation. The ‘on’ setting of the fan

generally provides better temperature control by

eliminating stagnant air.

NOTE: A properly installed and sized unit will

not cycle more than 10 times per hour. If you

notice more frequent starts call your service

contractor.

4. For energy conservation reasons, you may want

to set your thermostat at a higher temperature

when you are away. Do not raise the

temperature setting by more than 5 degrees.

Changing the temperature by more than 5

degrees or shutting the unit ‘off’ can actually

cost more than leaving the setting at a constant

temperature.

IMPORTANT

Wait at least 3 minutes after turning your air

conditioner off before trying to restart it. This

gives the unit the time needed to stabilize

before restarting. Failure to do so may cause

unit damage and failure.

MAINTENANCE:

Only simple periodic maintenance is required:

1. Change or clean the indoor unit air ler monthly

or more frequently if unusual conditions are

encountered. If you have a disposable type,

throw the old one away and install a fresh one

of the same size and type. If your unit has a

washable type then vacuum and wash with

soap and water. Flush thoroughly and dry

before re-installing.

2. Keep the coil in the outdoor unit clean.

Periodically ush the coil thoroughly with a

garden hose. Clean away all foreign materials

such as dust, leaves, grass clippings, papers,

etc.

WARNING

Turn the power off rst! Serious injury or death

may result if water spray is directed at live

electrical connections or power sources.

IMPORTANT!

Alterations and replacement parts:

Altering the product or replacing parts

with non-authorized parts will void the

factory Warranty and may result in adverse

operational performance and/or a possible

hazardous safety condition to service

personnel and occupants. If you are in doubt

as to how to service this unit or where to nd

factory replacement parts, call Heat Controller

at (517) 787-2100 for assistance.

4

Page 5

Heat Controller Horizontal/Side Discharge Condensing Units

GENERAL PRODUCT INFORMATION

UNPACKING AND INSPECTION:

The condensing unit is shipped completely

assembled and in it’s own package. All goods are

inspected at the factory and released to the freight

company in good condition. When received at the

site, a visual inspection of all packages should be

made immediately. Any evidence of rough handling

or apparent damage should be noted on the

delivery receipt and the material inspected in the

presence of the carrier’s representative. If damage

is found a claim should be immediately le with the

freight company.

COOLING OPERATION

TEMPERATURE LIMITS:

Heat Controller Condensing units are designed

to operate in cooling at outside temperatures

between 65°F (18°C) and 109°F (43°C). If

the condensing unit will be used to cool at

temperatures below 65°F (18°C), a low ambient

control must be eld installed. Operation below

65°F (18°C) without low ambient control will void

the warranty.

INDOOR UNIT USE

AND SYSTEM EFFICIENCY:

Heat Controller condensing units are designed to

be compatible with most major brands of domestic

evaporator coils/air handlers. Imported ductless air

handlers maybe used but often do not include an

expansion device. A properly sized thermostatic

expansion valve is recommended. Consult AHRI’s

directory of certied products for indoor matches.

THERMOSTAT AND INDOOR

FAN TIME DELAY:

All indoor units should include a fan time delay.

This may be accomplished by using a digital wall

thermostat or installation of a 60 second fan time

delay designed to work with your specic furnace/

air handler.

Most brands of electronic thermostats include a

fan delay. Properly specied thermostats are the

responsibility of the installer. Proper temperature

control and unit operation depends on proper

thermostat selection and location. Refer to the

thermostat manufacturer’s installation instructions

for specied recommendations. Good practice is

to avoid outside walls, locations where the sun

may shine directly on the thermostat, and locations

where the air from supply registers or unit outlets

blow on the thermostat. Also avoid locations where

the thermostat could be jarred by a closing door or

high trafc area.

WARNING: An in-line lter drier is required

when the unit is installed. The lter drier is

not provided by the factory, therefore a locally

purchased lter drier must be used to remove

any particulates or moisture that may be

present in the system. Installations without an

in-line lter drier may void the warranty.

5

Page 6

Horizontal/Side Discharge Condensing Units Heat Controller

OUTDOOR UNIT INSTALLATION

UNIT LOCATION AND MOUNTING:

Choose a location that places the condensing

unit as close to the indoor unit as possible. The

maximum unit separation and vertical lift (compressor

above evaporator) must be taken into account [See

Fig 1]. Do not exceed allowable pipe lengths.

Fig. 1

Refrigerant Piping

Liquid-Gas In. 1/4 - 1/2 3/8 - 3/4

Max. Refrigerant

Line Length*

Max. Elevation

Vertical Lift**

CMA 18 CMA 24 CMA 30 CMA 36

Ft. 82 98

Ft. 33 49

*Minimum pipe length must not be less that 15 feet.

** “P” trap risers every 10 ft. when outdoor unit is installed

above indoor unit.

NOTE: Oil traps must be installed every 10ft. when

the outdoor unit is installed above the indoor unit.

Model No.

An awning can be built over the outdoor unit to

prevent direct sunlight or rain exposure or snowfall.

Ensure that the awning is at least 2 ft. above the

top of the unit’s housing.

During heating and defrost modes, the condensate

should be properly drained away from the unit.

Insure free ow of air into and out of the unit.

Inlets/outlets should stay clear of obstructions such

as walls and shrubs. Minimum clearances must be

adhered to [See Fig. 4 & 5 on page 7].

Do not locate two or more units in a way that will

block air ow or in a way that hot air from one unit

will blow into a nearby unit [See Fig. 3].

Install the outdoor unit on a rigid surface, able to

withstand the unit’s weight, such as a concrete slab.

If the installation location allows the unit to be

exposed to strong winds (such as sea side

applications), ensure that the unit has a barrier from

the wind [See Fig. 2]. This will assist with the proper

operation of the fan by obstructing strong gusts of

wind from entering the unit’s cabinet.

Avoid areas where water, snow, or ice may fall

from a roof onto the unit. In climates where snow

is a consideration, locate the unit away from areas

prone to drifting. Ensure the location of the unit will

not be subject to snow drifts, heavy accumulation

of snow or leaves or other seasonal debris. If

unavoidable, provide the awning for the unit.

6

Page 7

Heat Controller Horizontal/Side Discharge Condensing Units

OUTDOOR UNIT INSTALLATION continued

Clearances

1. Ensure that there is sufcient clearance

around the unit for installation and maintenance.

Clearance must be maintained to ensure that the

air inlets and outlets are not obstructed.

[See Fig. 4].

Anchor the outdoor unit with a 10mm (3/8 inch)

diameter bolt and nut tightly on a concrete or

rigid surface [See Fig. 5]. Anchoring is especially

recommended in seaside/high wind applications

and/or areas prone to earthquakes.

1. Split type outdoor unit clearances

Fig. 4

1. Split type outdoor unit dimensions

Fig. 5

LQFK

LQFK

LQFK

LQFKHV

Units in inches

7

Page 8

Horizontal/Side Discharge Condensing Units Heat Controller

UNIT WIRING

ELECTRICAL WIRING

AND SUPPLY VOLTAGE:

All electrical wiring must be done according to

NEC and local codes. Nameplate data indicates

the operating voltage, phase, ampacity, maximum

over current protection, and minimum voltage.

The contractor is to provide an individual branch

circuit for over current protection for the unit as

required by code. Run power supply wiring through

a weatherproof disconnect box and conduit to the

unit connection. Disconnects are required to be

within sight and easy reach of the unit (usually

within 3 feet).

Check the unit wiring diagram for the number of

conductors required. Route neatly and protect from

sharp edges and damage.

Inadequate wiring and/or improper electrical

supply will likely result in failure of the compressor

and other electrical components and voids the

warranty.

NOTE: The supply voltage must be consistent

with the rated voltage of the air conditioner, not

to exceed +/- 10%. Ensure the unit is properly

grounded.

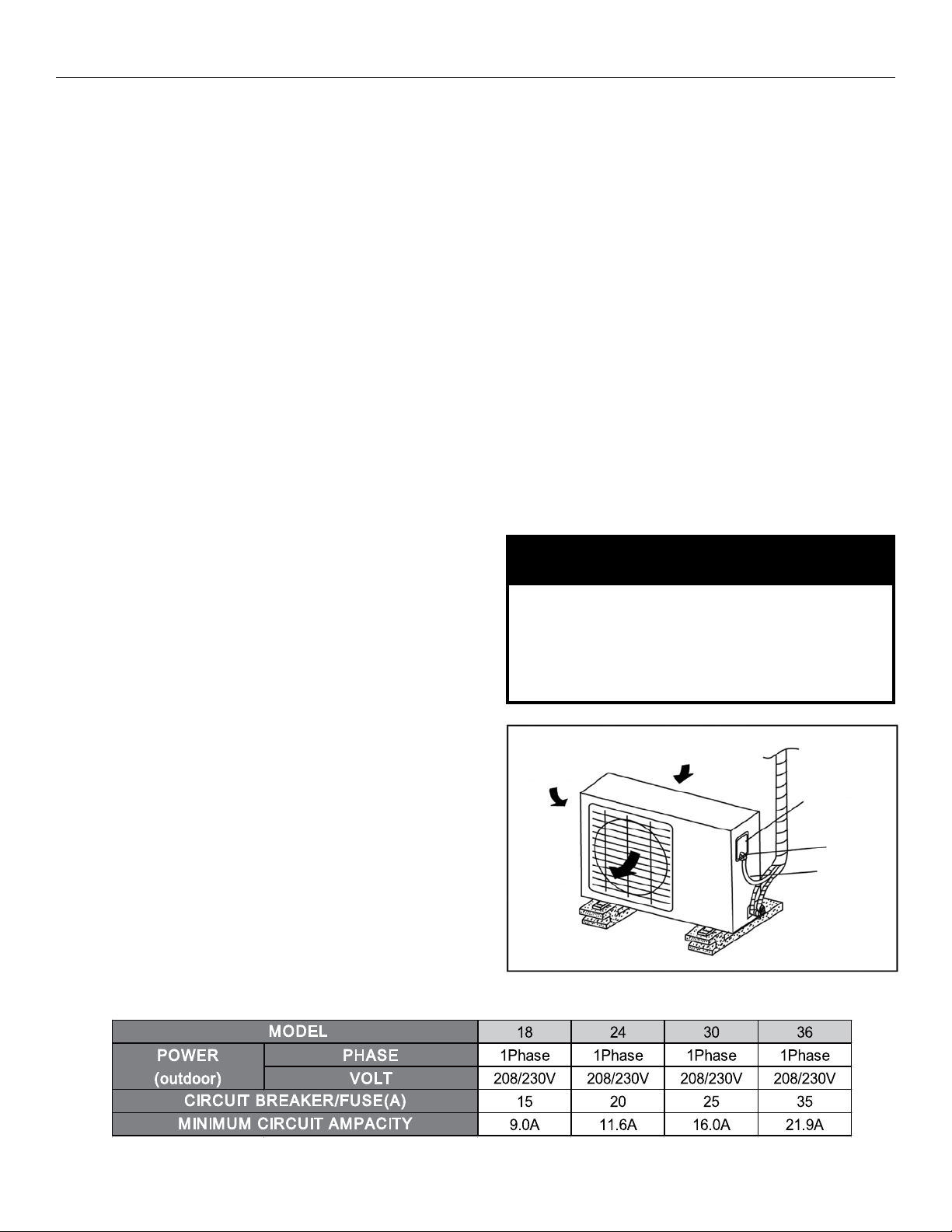

Outdoor unit wiring connection

1. Remove the electrical control cover from the

outdoor unit.

2. Connect the cables to the terminals as

identied with their respective designated

terminal spaces on the terminal block of indoor

and outdoor units. 600V THHN 14 AWG/4

conductor unshielded stranded copper cable

is recommended, however NEC/local codes

prevail.

3. To prevent the entrance of water into outdoor

unit, form a loop in the cable [See Fig. 6].

4. Insulate any unused conductors with PCV/

Electrical tape, so that they do not touch any

other exposed electrical or metal parts.

CAUTION

Incorrect wiring connections may cause

electrical parts to malfunction. All wiring must

comply with local and national electrical

codes and be installed by qualied and skilled

electricians.

8

Page 9

Heat Controller Horizontal/Side Discharge Condensing Units

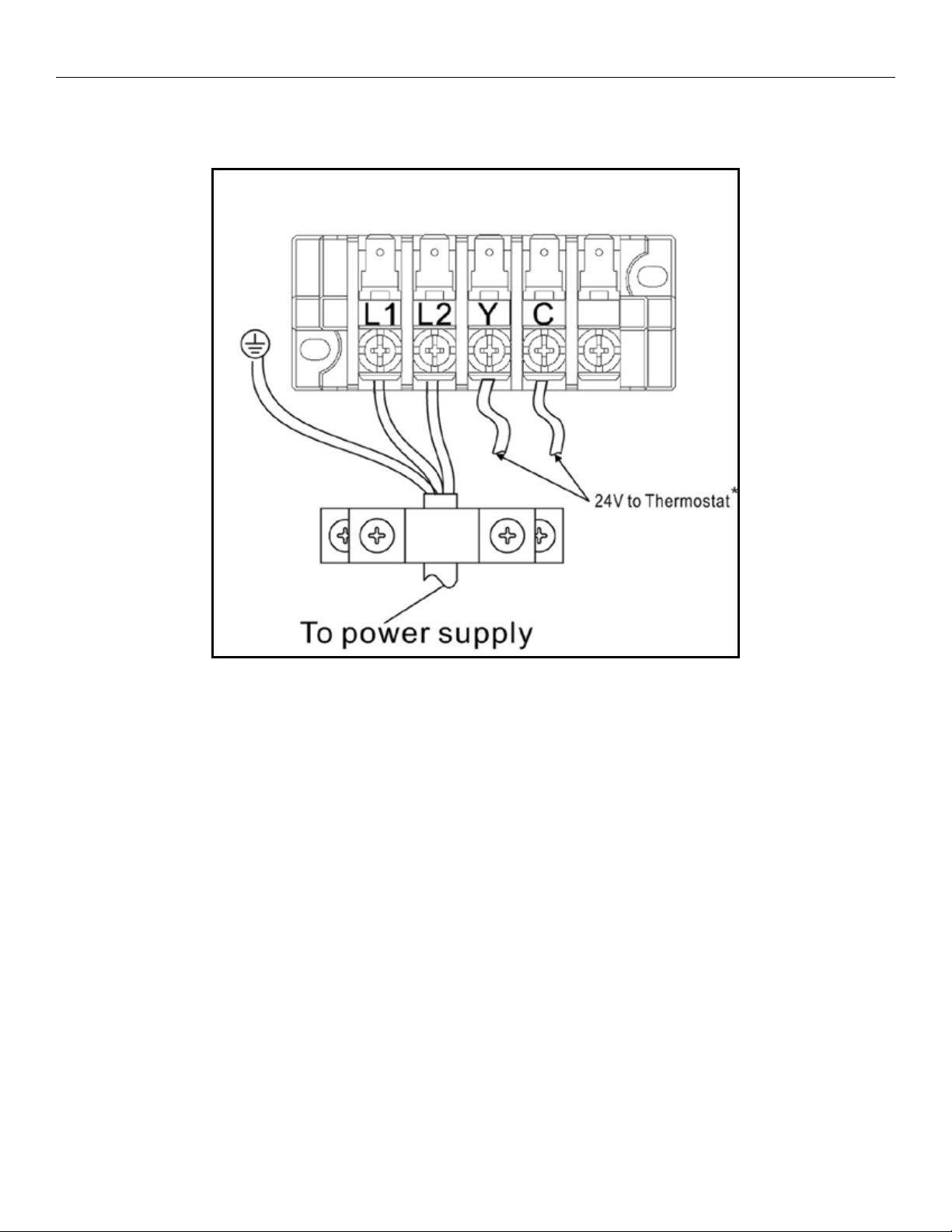

OUTDOOR UNIT WIRING CONNECTION continued

TERMINAL bLOCk OF OUTDOOR UNIT

*NOTE: Please refer to the installation instructions of the 24V

thermostat used in conjunction with this unit for additional wiring

instructions.

9

Page 10

Horizontal/Side Discharge Condensing Units Heat Controller

OUTDOOR UNIT WIRING CONNECTION continued

CMA18SB-1 & CMA24SB-1

CMA30SB-1

CMA36SB-1

10

Page 11

Heat Controller Horizontal/Side Discharge Condensing Units

REFRIGERANT PIPING

The length of refrigerant lines and the number of

bends determine the pressure drop which affects

capacity and efciency of the system and oil return

to the compressor. The outdoor unit connections

are are type. Tube size should always be the

same diameter as the connections provided at

the service valves. Up sizing of lines can result

in inadequate oil return to the compressor and

excessive refrigerant charge and will void the

warranty [See Table 1].

Refrigerant Piping

Liquid-Gas In. 1/4 - 1/2 3/8 - 3/4

Max. Refrigerant

Line Length*

Max. Elevation

Vertical Lift**

*Minimum pipe length must not be less that 15 feet.

** “P” trap risers every 10 ft. when outdoor unit is installed

above indoor unit.

Choose a location that places the condensing

unit as close to the indoor unit as possible. The

maximum separation is dependent on model.

Use only clean refrigeration grade tubing. Avoid

piping on wet or rainy days. Always keep the tube

ends capped until you are ready to make the nal

connections. Remove burrs from cut ends of tubing.

Use tube benders to avoid kinking.

Insulate the suction line with Armaex or equivalent

with a wall thickness of at least 3/8”. Support the

tubing adequately to avoid sags that can trap oil.

Isolate the tubing so as not to transmit noise to the

building structure. Avoid sharp edges that could cut

the tubes. Maximum vertical lift (compressor above

evaporator) is dependent on model. Trap risers with

a ‘P’ trap every 10 feet.

CMA 18 CMA 24 CMA 30 CMA 36

Ft. 82 98

Ft. 33 49

Model No.

WARNING

It is illegal to discharge refrigerant into the

atmosphere. Use proper reclaiming methods

and equipment when working on the refrigerant

containing parts of the unit. Service should be

performed by a QUALIFIED service agency and

certied technicians.

LEAk TEST,

EVACUATION

& RELEASE OF

REFRIGERANT

The condensing unit is supplied with R-410a

charge sufcient for most matching evaporator

units. Charge must be added for interconnecting

tubing.

The unit’s service valves are shipped in the closed

position and should not be opened until nal

connections and evacuation are completed.

The recommended procedure for leak test,

evacuation, and release of refrigerant is

outlined below:

1. Complete the nal piping connections to the

indoor and outdoor units using high temperature

brazing alloy.

2. Connect a charging manifold to the service ports

provided at the service valves.

3. Pressurize the lines and evaporator with

nitrogen and leak check all connections with

soap bubbles. Repair as necessary any

faulty joints. If brazing is required be sure to

RELEASE THE NITROGEN FIRST. Re-test as

needed.

4. Connect a vacuum pump to the manifold center

connection, start the pump and open the

manifold valves.

5. Evacuate to 500 microns or less for a minimum

of 30 minutes. Close the manifold valves and

shut off the pump. Note the vacuum reading and

wait 15 minutes. Take a new vacuum reading. A

reading of 800 microns or higher indicates the

presence of moisture or a leak.

6. Repair as necessary and repeat steps 3, 4 & 5.

7. Conrm that manifold valves are closed and

disconnect the vacuum pump.

8. Remove the caps from the services valves.

Open the valves to the fully ‘back-seat’ position.

Replace service valve caps and tighten.

11

Page 12

Horizontal/Side Discharge Condensing Units Heat Controller

INITIAL START-UP & CHECkS

Operation of the unit is automatic and will provide

cooling depending on the setting of the thermostat.

IMPORTANT!

All panels must be installed, main power turned

on and the thermostat properly connected before

operating the unit.

1. System check - set thermostat system switch to

“Off” position and fan switch to “Auto” position.

Turn the power supply breaker on.

2. Set the fan switch to “On,” blower should

operate.

3. Return the fan switch to “Auto”. Blower should

shut off. Set the system switch to “Cool” and

lower thermostat set point to coldest setting.

The compressor, condenser fan, and evaporator

blower should all come on. Cool air will be

supplied after a couple of minutes of run time.

4. Proceed to the “FIELD CHARGING” section of

these instructions.

FIELD CHARGING

Unit performance, efciency, and life depends,

to a large extent, on a proper system charge.

Time spent on getting the charge right at start-up

will payoff in the long run. Operating conditions

such as voltage, air ow, evaporator coil size,

and indoor and outdoor temperature and humidity

all have an effect on the system pressures and

superheat conditions.

FINAL INSPECTION

Do a nal visual inspection of the entire installation

and complete any nal details and clean up.

Review Unit Operation with the homeowner/user.

The pressure/temperature chart can be used as a

reference to ensure performance.

2XWGRRU$PELHQW7HPSHUDWXUH963UHVVXUH

2XWGRRU7HPSHUDWXUH

36,

1RWH³,'7´ ,QGRRU7HPSHUDWXUH

³2'7´ 2XWGRRU7HPSHUDWXUH

5HPRYHUHIULJHUDQWLIWKHSUHVVXUHLVDERYHWKHFKDUWYDOXH

$GGUHIULJHUDQWLIWKHSUHVVXUHLVEHORZWKHFKDUWYDOXH

Charge must be added for the interconnecting

tubing. Evaporator coils require thermostatic

expansion valves. These units should be critically

charged to ensure proper performance. Some

systems may require additional charging of

refrigerant, depending on line set lengths.

12

R(oz): Additional refrigerant to be charged

L(ft): The length of the liquid pipe

T(oz): The quantity of the charged refrigerant

per additional foot

oz/ft

0.16 0.32

Page 13

Heat Controller Horizontal/Side Discharge Condensing Units

4/2014

Design, material, performance specications and components

subject to change without notice.

:HOOZRUWK$YH-DFNVRQ0,3KZZZKHDWFRQWUROOHUFRP

13

Loading...

Loading...