Hearth & Home PVI-SLP-B Installation Instructions

PVI-SLP-B

Power Vent Inline

- Installation Instructions -

NOTICE

DO NOT DISCARD THIS MANUAL

• Read, understand and follow

these instructions for safe

installation and operation.

• Leave this manual with

party responsible for use

and operation.

1 1

• Important operating

and maintenance

instructions included.

Introduction

Table of Contents

1 Introduction

A. Components and Service Parts List ..................2

B. Installation of PVI-SLP-B ..........................3

2 Vent Information and Diagrams

A. Installation of Vent Pipe ...........................4

B. Vent/Pipe Regulations .............................4

C. Venting Length - Model Categories and Length

Requirements by Termination Type ................. 11

D. Vent Termination Minimum Clearances .............. 14

3 Framing and Clearances

A. Framing and Clearances ......................... 15

4 Electrical Information

A. Wiring the Appliance for the PVI-SLP-B with IntelliFire®

or IntelliFire® Plus (IPI) Controls .................... 19

B. Wiring the Appliance for the PVI-SLP-B with IntelliFire

Touch® (IFT) Controls ............................24

5 Operating Instructions

A. Installation Inspection ............................29

B. Vacuum Switch Orientation ....................... 29

C. Setting the PVI-SLP-B Bafe Adjustment ............ 29

D. Power Vent Operating Instructions ................. 30

E. Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

F. PVI-SLP-B Troubleshooting .......................32

G. IFT-Controls and PVI-SLP Power Vent Troubleshooting . 33

1 Hearth & Home Technologies • Power Vent Inline (PVI-SLP-B) Instructions • 2196-902 Rev. S • 7/20

Installation of the PVI-SLP-B may be done by a qualied

service technician only. Installation MUST comply with local, regional, state and national codes and regulations.

IMPORTANT: Failure to read and follow these instruc-

tions may create a possible hazard and will void the replace warranty.

These instructions must remain with the equipment.

CAUTION! Risk of Cuts or Abrasions. Wear protective

gloves and safety glasses during installation. Sheet metal

edges are sharp.

INTRODUCTION

The Power Vent Inline (PVI-SLP-B) is certied for use only

on replaces manufactured by Hearth & Home Technologies with IPI (intermittent pilot ignition) gas controls and

is for use only on top-vented applications. Fireplaces

equipped with millivolt type gas controls CANNOT use

this product.

DO NOT

DISCARD

Note: PVI-SLP-B requires special control system

congurations:

• For IntelliFire® and IntelliFire® Plus models, an

RC100, RC200, or RC300 and PV-IPI-CK control

system is required for installation (except on PRIMO

models). The PV-IPI-CK is sold separately.

• For IntelliFire Touch® models, an IFT-ACM and

IFT-RC400 are required for installation. The IFTRC400, which includes the IFT-ACM, will need to be

purchased if the appliance is not already equipped

with IFT.

• The battery-backup feature cannot be used with

models congured with the PVI-SLP-B.

• The wired wall switch feature cannot be used with

models congured with the PVI-SLP-B.

• An appliance with PVI-SLP-B installed cannot be

operated with battery-backup or a wired wall switch.

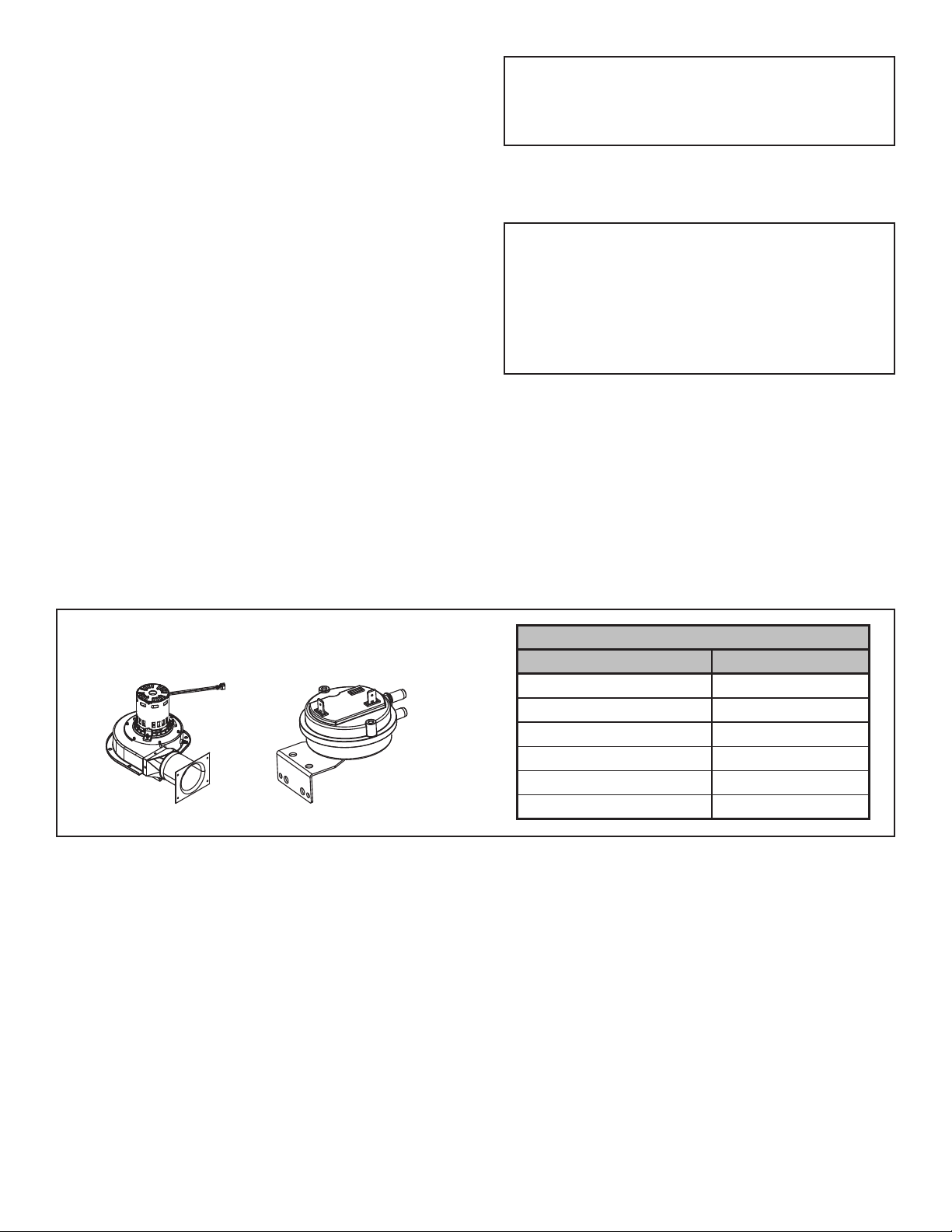

A. Components and Service Parts List

Service Parts List

Replacement parts can be obtained from your dealer. Repair

of the Power Vent should only be done by a qualied service

technician.

Note: The battery back-up and wired wall switch feature

of any IPI system are removed when the PVI-SLP-B

power vent is installed. The replace may no longer be

operated with battery back-up and/or a wired wall switch.

The PVI-SLP-B operates on 120VAC, 60Hz electrical service which is supplied at the replace junction box.

IMPORTANT OPERATIONAL NOTE: When the control

being used to run the replace is activated, a 120 second

delay will occur before ignition occurs. This is to allow a

pre-purge by the PVI-SLP-B. If replace does not light

after 135 seconds, refer to the Troubleshooting section of

this instruction for further direction. There will also be a 20

minute post-purge in which the PVI-SLP-B will continue to

run after appliance is turned off.

BLOWER ASSEMBLY

2196-025

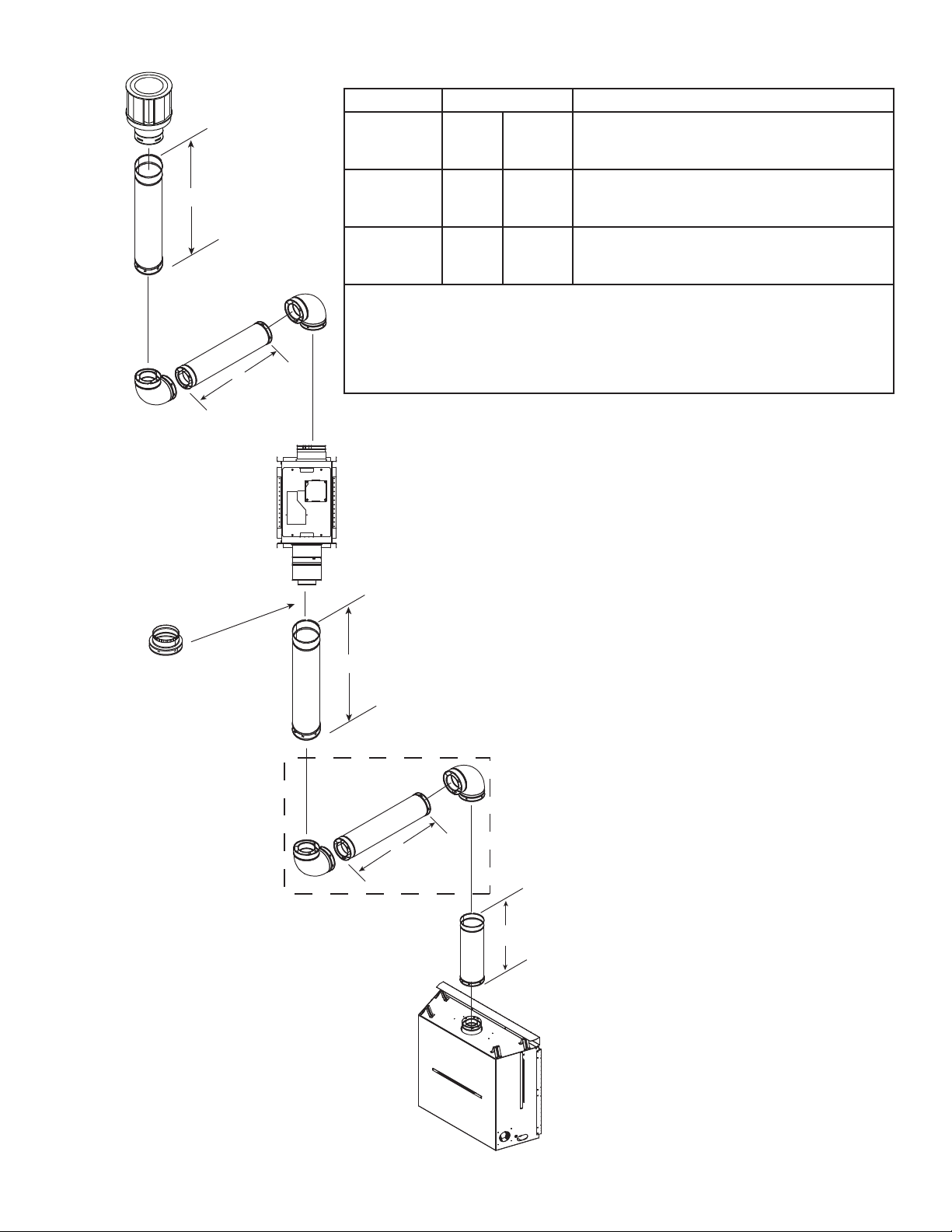

Figure 1.1 Service Parts

VACUUM SWITCH

2196-326

Required Wire Harness

Lengths Available Part Number

10 ft. PV Wire Harness PVI-WH10

20 ft. PV Wire Harness PVI-WH20

40 ft. PV Wire Harness PVI-WH40

60 ft. PV Wire Harness PVI-WH60

80 ft. PV Wire Harness PVI-WH80

100 ft. PV Wire Harness PVI-WH100

2 Hearth & Home Technologies • Power Vent Inline (PVI-SLP-B) Instructions • 2196-902 Rev. S • 7/20

B. Installation of PVI-SLP-B

1. INSTALLATION PRECAUTIONS

a. This device must be installed by a qualied installer

in accordance with these instructions.

b. Safety inspection of the venting system should

be performed before and after installation of this

power vent. Consult local code ofcials and follow

applicable installation codes.

c. DO NOT INSTALL DAMAGED EQUIPMENT OR

VENT COMPONENTS.

d. Disconnect electrical power supply before making

wiring connections.

e. Venting of more than one appliance in a common

vent system is prohibited.

f. Clearances between the vent pipe and combustible

materials must be maintained at 1-1/2-inch top,

1-inch sides and bottom.

g. All outer pipe joints must be sealed with high tem-

perature silicone. See Section 2.A.

h. The access panel opening must be located such

that access for service and adjustment is available.

The NEC requires a minimum of 30 inches of space

around the opening and 36 inches in front of the

opening to the access panel. Consult ofcials having jurisdiction regarding regional requirements.

CAUTION! Failure to install, operate, and maintain the

power venting system in accordance with manufacturer's

instructions will result in conditions which may produce

bodily injury and/or property damage.

NOTICE: The blower motors present in this Power Vent

will generate sound during operation. The effects of the

increased sound level can be minimized with careful planning during installation of the system. Locating the Power

Vent service access grill in an area remote of immediate

living space will reduce the effects of the added sound

generated during operation.

2. INSTALLATION GUIDELINES

WARNING: RISK OF FIRE AND BURNS. DO NOT

install PVI-SLP-B with the access panel facing upward.

Overheating may occur.

NOTICE: Installation of the PVI-SLP-B in an attic is not

recommended in regions where temperatures reach 0°F

(-18°C) and relative humidity exceeds 60% simultaneously.

Low temperatures and high moisture content may cause

the PVI-SLP-B to freeze.

a. If the PVI-SLP-B is being installed in a conned space

(such as a utility closet, mechanical room or attic space)

with a total volume less than 250 cubic feet, an access

hole with minimum dimensions of 8 inches by 16 inches

will be required directly in front of the access panel.

The recommended access hole size is 12 inches by 17

inches. This size will allow full access to the 11 inch x

16 inch access panel on the PVI-SLP-B. See Figure

3.1. The conned space where the PVI is installed, and

the space to which the access hole opens, must add up

to at least 250 cubic feet. This hole may be covered with

a decorative cover as long as the cover has a minimum

of 50% open air. If the PVI-SLP-B is being installed in

a space greater than 250 cubic feet the access hole is

still required, but a solid cover may be used. This also

applies to a replace chase.

The decorative cover CANNOT be located on an outside

wall that is open to the environment.

b. For installations near loose-ll insulation (such as attics)

a minimum clearance of six inches must be maintained

between the access panel and the insulation.

c. The PVI-SLP-B CANNOT be installed with the access

panel facing upward.

d. The exit termination of mechanical draft systems shall

not be less than seven feet above grade when located

adjacent to public walkways.

e. A mechanical drafting venting system shall terminate at least

three feet above any forced air inlet located within 10 feet.

3 Hearth & Home Technologies • Power Vent Inline (PVI-SLP-B) Instructions • 2196-902 Rev. S • 7/20

2 2

Vent Information and Diagrams

A. Installation of Vent Pipe

For information on standard procedures for venting the

appliance, refer to the "Vent Information and Diagrams"

section of the appliance installation manual.

For the allowable pipe lengths and elbow combinations for

an appliance utilizing the PVI-SLP-B, consult the Power

Vent diagrams in the Vent Information and Diagrams section of the appliance installation manual. The PVI-SLP-B

uses SLP pipe (6-5/8 inch) connections for both the inlet

and outlet.

The following termination caps are available for use with

the power vent inline (PVI-SLP-B): SLP-TVHW, SLP-LPC,

SLP-TRAP, SLP-HHW2, SLP-HRC-SS, SLP-HRC-ZCSS, SLP-TB1. Check installation manual for termination

caps specications.

In certain cases, a pipe adapter may be used in the vent

run. The DVP-2SL adapts from 5 in. / 8 in. DVP series

starting collars to 4 in. / 6-5/8 in. SLP series vent pipe.

Either SLP or DVP venting may be used throughout the

vent run except on certain models that require DVP pipe.

See Table 2.1. Refer to Section 2.B for more information

regarding venting regulations.

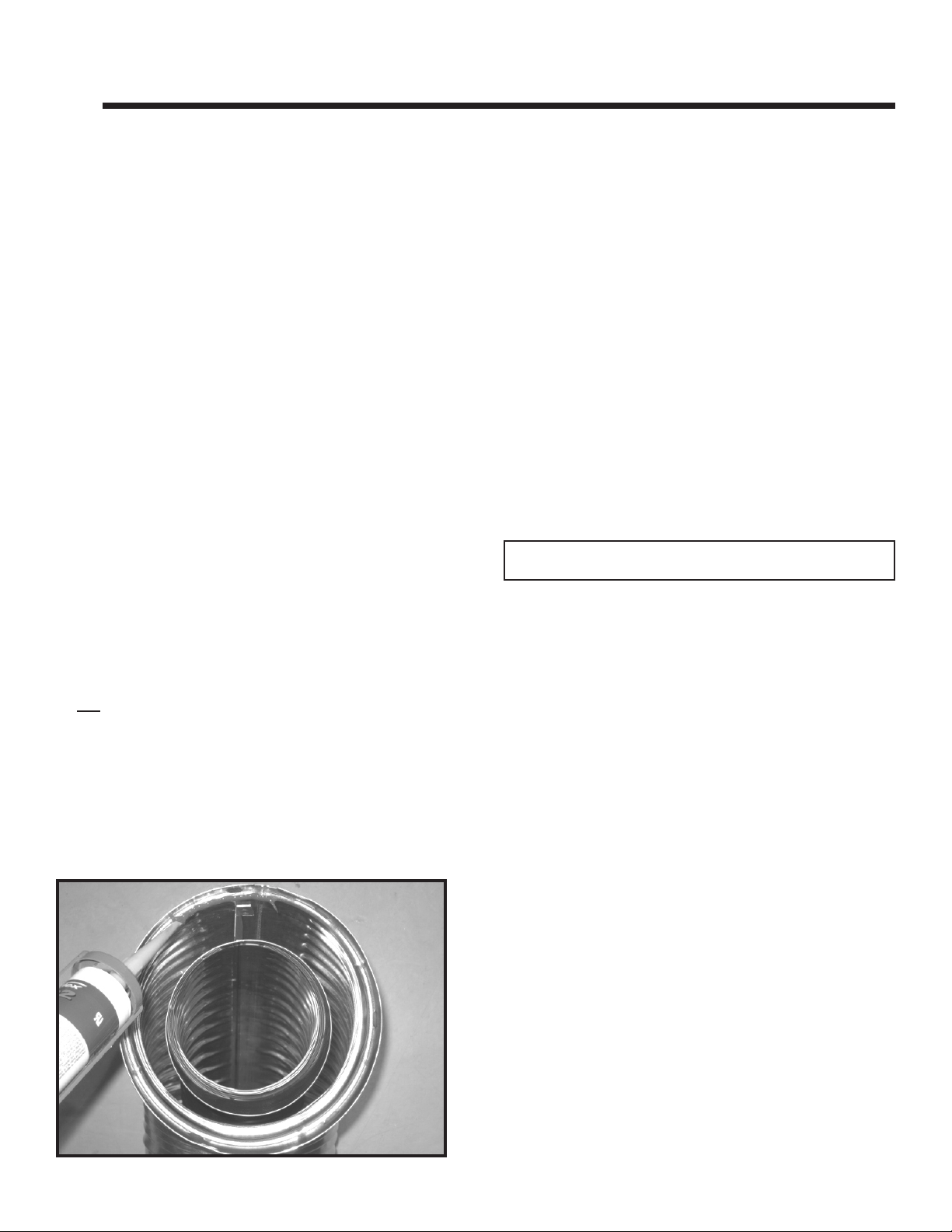

SLP pipe may be used on the termination side of the PVI.

All outer pipe joints must be sealed with high temperature

silicone (with a minimum of 300 ºF continuous exposure

rating), including the slip section that connects directly to

the horizontal termination cap.

• Apply a bead of silicone sealant inside the female out-

er pipe joint prior to joining sections. See Figure 2.1.

OR

• Apply aluminum foil tape (300 ºF minimum continuous

exposure rating) to the outside of connecting joint after

joining sections. On horizontal pipe runs, it is recommended that the tape seam is positioned on the bottom side of the vent pipe.

• Only outer pipes need to be sealed. All unit collar, pipe,

slip section, elbow and cap outer ues shall be sealed

in this manner, unless otherwise stated.

B. Vent/Pipe Regulations

WARNING! Risk of Fire!

Maintain minimum pipe length between appliance and PVISLP-B on all models. Combustible materials surrounding

pipe may overheat.

1. A minimum length of venting is required between the

appliance and the PVI-SLP-B. This minimum length

requirement varies for the specic appliance. Refer to

Table 2.1. for requirements for specic models. Once

the minimum length requirement is met, the PVI-SLPB may be installed at any location within the vent run

conguration.

2. A minimum of 18 inches is required between the PVISLP-B and the termination cap to allow room for the

pipe to go through a wall or roof.

3. If PVI-SLP-B is installed in the vertical position, a minimum of two 90 degree elbows and two feet of pipe is

required between the appliance and the PVI-SLP-B.

4. Total allowable length decreases by 2 ft. for every 1 ft.

of vertical drop.

Note: See Table 2.1 for model specic vent requirements.

Figure 2.1 High Temperature Silicone Sealant

4 Hearth & Home Technologies • Power Vent Inline (PVI-SLP-B) Instructions • 2196-902 Rev. S • 7/20

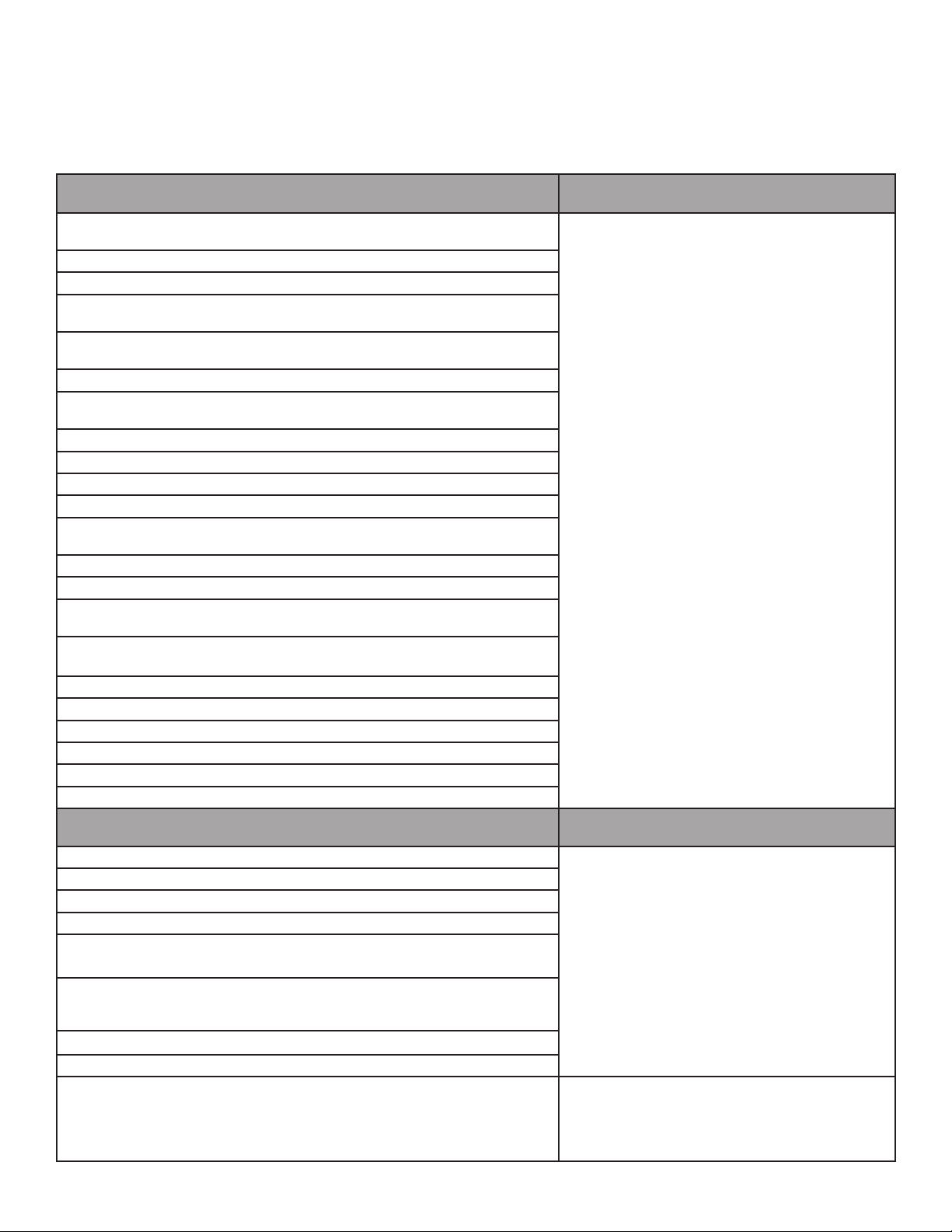

B. Vent/Pipe Regulations (continued)

WARNING! Risk of Fire!

• PVI-SLP-B cannot be installed directly on appliance. The PVI-SLP-B and combustible materials surrounding vent pipe

may overheat.

• A minimum length run of initial vent pipe is required between the appliance and the inlet of the PVI-SLP-B. The initial

minimum vent run requirement varies depending on the specic appliance and its venting conguration.

• Some models require DVP Series pipe for the initial minimum vent section directly off the appliance.

MODEL MINIMUM VENTING BETWEEN APPLIANCE

AND PVI-SLP-B

6000C, 6000CL, 6000CLX (IPI and IFT)

8000C, 8000CL, 8000CLX (IPI and IFT), 6000BEC-IPI

6000CMOD, 8000CMOD (IPI and IFT)

CD4236, CD4842, CNXT4236, CNXT4842 (IPI and IFT)

DBDV36I, DBDV42I, DBDV36PLATI, DBDV42PLATI,

MERID36I, MERID42I, MERIDPLA36I, MERIDPLA42I

ECLIPSE-32, ECLIPSE-36, EVEREST-B,

GDST3831, GDST4336, GDFL4136, GDCR4136,GDCL4136

RCOR-DV36IN, LCOR-DV36IN

NDV3630, NDV3933, NDV4236, NDV4842, NDV30-IFT, NDV33-IFT, NDV36-IFT

NDV42-IFT

NEVO3630, NEVO4236

PEARL36PRIN, PEARL36STIN

ALL QUARTZ32, QUARTZ36, QUARTZ42

NNXT3933, NNXT4236, NNXT33-IFT, NNXT36-IFT

ST-36TR. ST-36TR, ST-36TRB, PIERI-36TR, PIER-36TRB, LCOR-36TRB,

RCOR-36TRB

RED40, RED40ST

REVO-S21, REVO-H31, ION-S7, ION-H7

ALL COSMO32-IFT, RAVE32-IFT, JADE32IN, SLR32,

ALL RAVE3012I, RAVE3012-IFT

ALL COSMO36-IFT, COSMO42-IFT, RAVE36-IFT, RAVE42-IFT

ALL RAVE4013I, RAVE4013-IFT, ALL JADE42IN, JADE42IL, ALL SLR

SL-350TRS, SL-550TRS, SL-750STRS

SL-550TR, SL-750TR, SL-950TR

SL-550METRO, SL-550-BE-M

SL-5, SL-7, SL-9, SL-5F, SL-7F, SL-5F-IFT, SL-7F-IFT, SL-5-IFT, SL-7-IFT, SL-9-IFT

SL-3X, SL-5X, SL-7X, SL-9X, SL-3X-IFT, SL-5X-IFT, SL-7X-IFT, SL-9X-IFT

ODMEZG-36

MODEL MINIMUM VENTING BETWEEN APPLIANCE AND

ALL ESC-42ST

ESCAPE-36DV, ESCAPE42DV

ALL HEIR36, HEIR42, HEIR50

ALL LUX36, LUX42

ALL CRAVE4836, CRAVE4836ST, CRAVE6048, CRAVE6048ST

CRAVE7260, CRAVE7260ST, CRAVE8472, CRAVE8472ST

ALL MEZZO36, MEZZO36ST, MEZZO48, MEZZO48ST

MEZZO60, MEZZO60ST, MEZZO72, MEZZO72ST, ALL ECHEL36IN,

ECHEL36STIN, ECHEL48IN, ECHEL48STIN, ECHEL60IN, ECHEL72IN

ALL TRUE-36, TRUE-42, TRUE-50, CERONA-36, CERONA-42

MARQ36IN, MARQ42IN, MARQ42STIN, ODFORTG-36

PRIMO48, PRIMO48ST, PRIMO60, PRIMO60ST, PRIMO72, PRIMO72ST

Table 2.1

5 Hearth & Home Technologies • Power Vent Inline (PVI-SLP-B) Instructions • 2196-902 Rev. S • 7/20

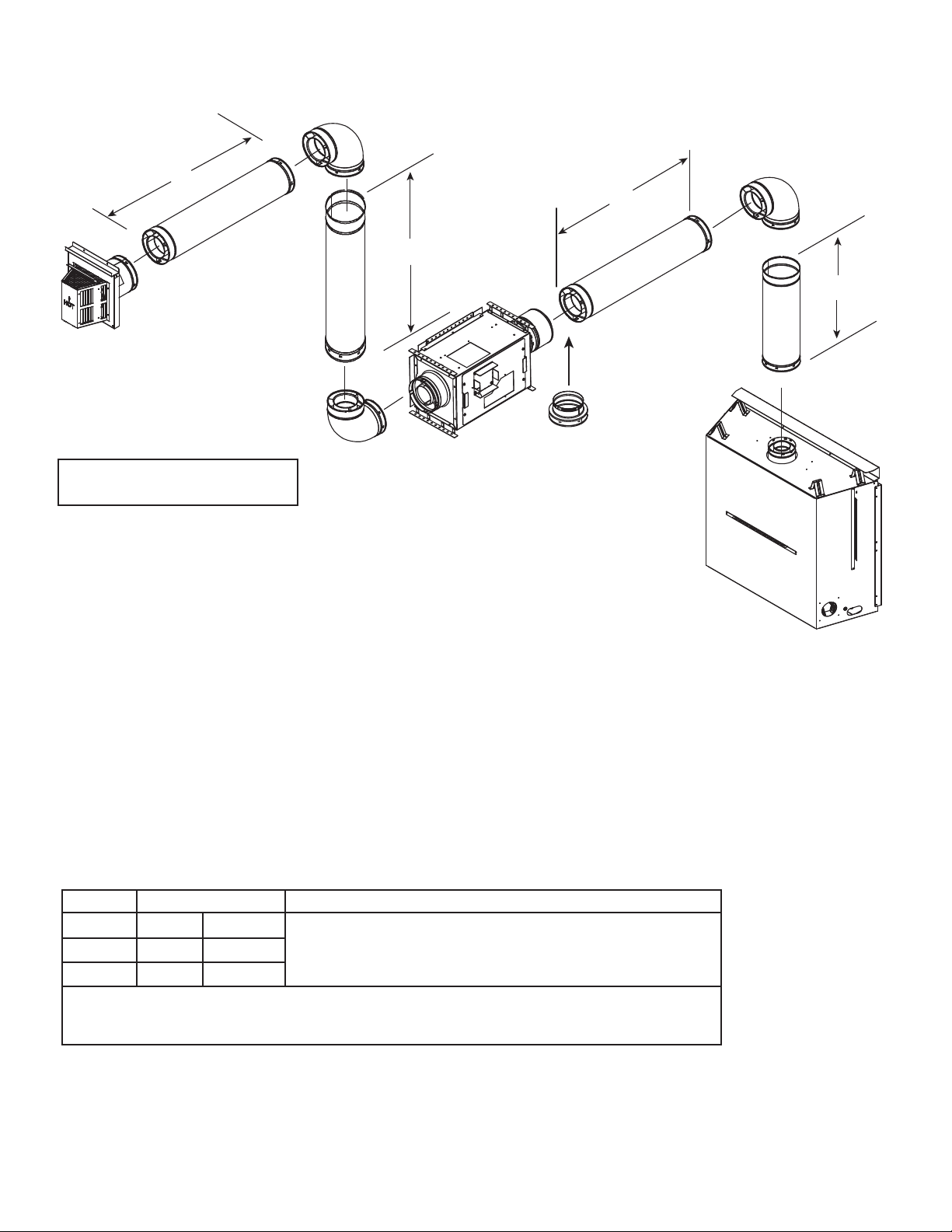

PVI installed horizontal orientation: One 90 degree

elbow and a total of two feet of straight horizontal or

straight vertical SLP pipe. See Figure 2.2 and Figure

2.5.

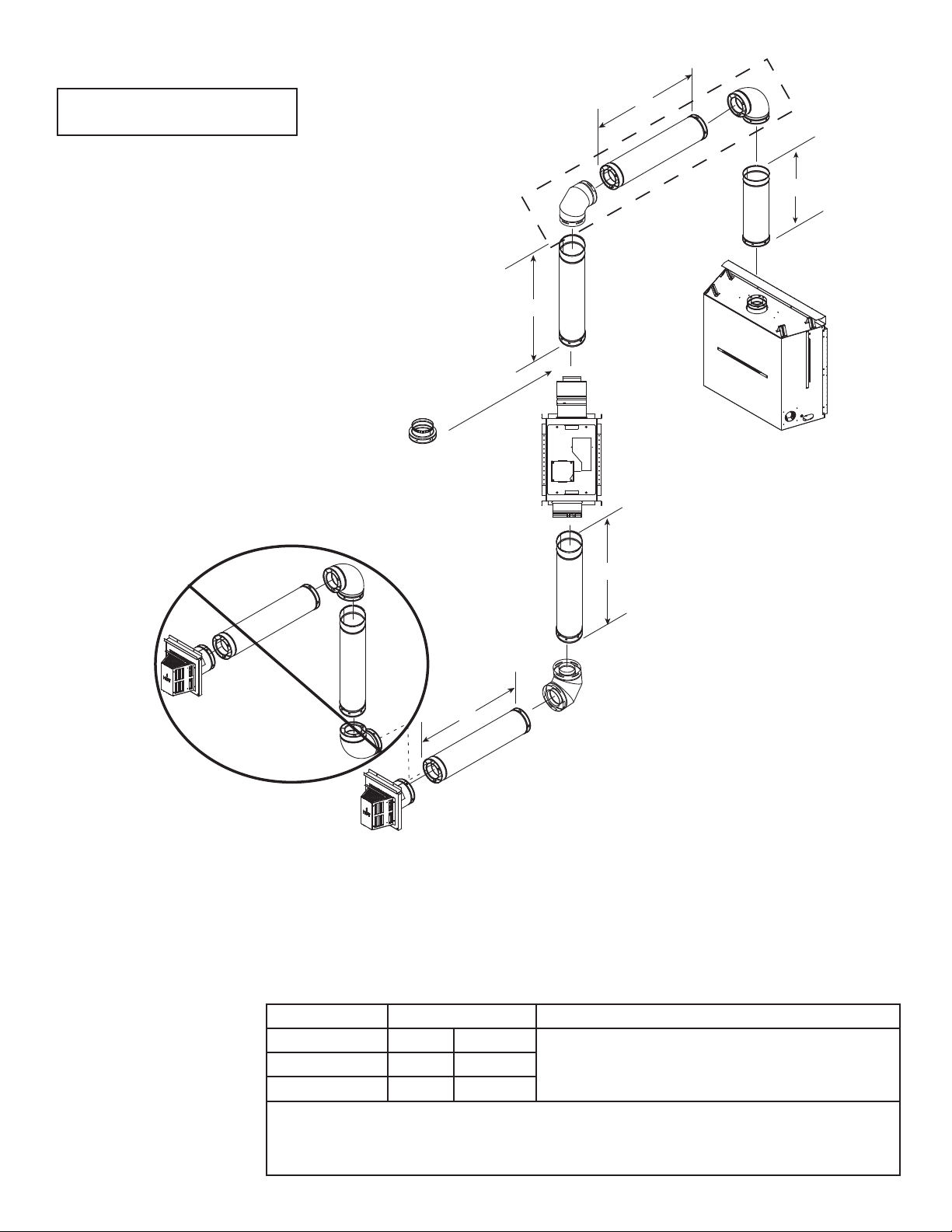

PVI installed vertical orientation: Two 90 degree

elbows and a total of two feet straight horizontal or

straight vertical SLP pipe. See Figure 2.3, 2.4, 2.6.

PVI-SLP-B

PVI installed horizontal orientation: Minimum two

feet straight vertical DVP pipe directly off appliance

followed by 90 degree elbow and two feet DVP pipe.

DVP-2SL or DVP-SLP24 adapter must be located

directly between initial DVP pipe and PVI-SLP-B. See

Figure 2.2 and Figure 2.5.

PVI installed vertical orientation: Minimum two feet

straight vertical DVP pipe directly off appliance, followed

by two 90 degree elbows and a total of two feet straight

horizontal or straight vertical DVP pipe. DVP-2SL or

DVP-SLP24 adapter must be located directly between

initial DVP pipe and PVI-SLP-B. See Figure 2.3, Figure

2.4, Figure 2.6.

PVI installed vertical or horizontal orientation:

Minimum three feet of DVP or SLP pipe is required

before connecting the PVI-SLP-B system. The 3 foot

minimum does not include the factory-installed six inch

DVP pipe.

Top Vent - Horizontal Termination

H

2

Note: 1 ft. of vertical drop decreases

total allowable length by 2 ft.

H

1

V

2

V

1

A DVP-2SL ADAPTER

is required in this position

in the vent run on certain

models. See Table 2.1.

WARNING! Risk of Fire! Use DVP pipe between appliance and PVI-SLP-B on these models:

ESCAPE-42DV, ESCAPE-36DV, ESC-42ST, HEIR36, HEIR42, HEIR50, LUX36, LUX42, TRUE-36, TRUE-42,

TRUE-50, CERONA-36, CERONA-42, MEZZO36, MEZZO36ST, CRAVE4836, CRAVE4836ST, MEZZO48,

MEZZO48ST, CRAVE6048, CRAVE6048ST, MEZZO60, MEZZO60ST, CRAVE7260, CRAVE7260ST, MEZZO72, MEZZO72ST, CRAVE8472, CRAVE8472ST, MARQ36IN, MARQ42IN, MARQ42STIN, ECHEL36IN,

ECHEL36STIN, ECHEL48IN, ECHEL48STIN, ECHEL60IN, ECHEL72IN, ODFORTG-36, ODMEZG-36

Combustibles surrounding pipe may overheat.

Note: For PRIMO models, see the PRIMO Installation Manual for vent congurations.

Minimum Maximum

H1 + V

H

2

V

2

A minimum of 2 ft. of vertical piping is required between the appliance and the PVI-SLP-B in addition to

the minimum venting described above when installing PVI-SLP-B with certain appliance models. See

Table 2.1.

Figure 2.2 Horizontal PVI Orientation

24 in. 610 mm

1

18 in. 457 mm

0 in. 0 mm

See Chart in Section 2.C: "Venting Length - Model Categories and

Length Requirements by Termination Type."

6 Hearth & Home Technologies • Power Vent Inline (PVI-SLP-B) Instructions • 2196-902 Rev. S • 7/20

Note: 1 ft. of vertical drop decreases

total allowable length by 2 ft.

WARNING! Risk of Overheating!

- Minimum inital length of vent pipe required between

appliance and vertically positioned PVI-SLP-B.

- Must include two 90 degree elbows.

NOTICE: If pipe configuration includes a vertical component that goes

downward, a vertical component going back upward is not allowed.

A DVP-2SL ADAPTER

is required in this position

in the vent run on certain

models. See Table 2.1.

H

1

V

1

V

2

V

3

H

2

WARNING! Risk of Fire! Use DVP pipe between appliance and PVI-SLP-B on these models:

ESCAPE-42DV, ESCAPE-36DV, ESC-42ST, HEIR36, HEIR42, HEIR50, LUX36, LUX42, TRUE-36, TRUE-42, TRUE50, CERONA-36, CERONA-42, MEZZO36, MEZZO36ST, CRAVE4836, CRAVE4836ST, MEZZO48, MEZZO48ST,

CRAVE6048, CRAVE6048ST, MEZZO60, MEZZO60ST, CRAVE7260, CRAVE7260ST, MEZZO72, MEZZO72ST,

CRAVE8472, CRAVE8472ST, MARQ36IN, MARQ42IN, MARQ42STIN, ECHEL36IN, ECHEL36STIN, ECHEL48IN,

ECHEL48STIN, ECHEL60IN, ECHEL72IN, ODFORTG-36, ODMEZG-36

Combustibles surrounding pipe may overheat.

Note: For PRIMO models, see the PRIMO Installation Manual for vent congurations.

Minimum Maximum

H1 + V1 + V2 24 in. 610 mm

H

2

V

3

18 in. 457 mm

0 in. 0 mm

A minimum of 2 ft. of vertical piping is required between the appliance and the PVI-SLP-B in addition

to the minimum venting described above when installing PVI-SLP-B with certain appliance models.

See Table 2.1. V minimum = 2 ft. and V2 + H1 + V1 minimum = 4 ft. for certain appliance models.

Figure 2.3 Vertical PVI Orientation

7 Hearth & Home Technologies • Power Vent Inline (PVI-SLP-B) Instructions • 2196-902 Rev. S • 7/20

See Table 2.1.

See Chart in Section 2.C: "Venting Length - Model Categories and Length Requirements by Termination Type."

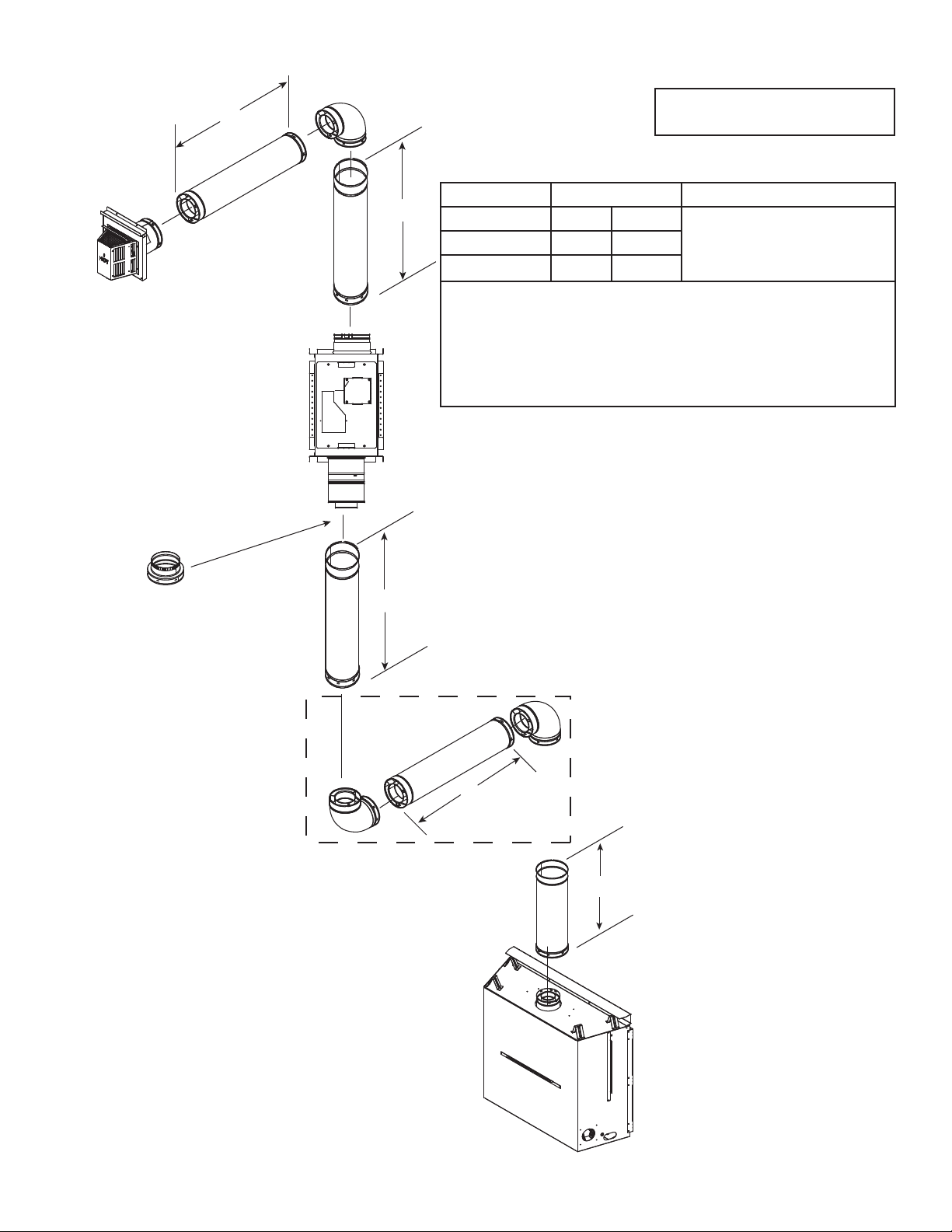

Top Vent - Horizontal Termination - (continued)

H

2

Note: 1 ft. of vertical drop decreases

total allowable length by 2 ft.

Minimum Maximum

V

3

H1 + V1 + V

V

3

H

2

24 in. 610 mm See Chart in Section 2.C: "Vent-

2

0 in. 0 mm

18 457 mm

ing Length - Model Categories

and Length Requirements by

Termination Type."

A minimum of 2ft. of vertical piping is required between the appliance

and the PVI-SLP-B in addition to the minimum venting described above

when installing PVI-SLP-B with certain appliance models. See Table

2.1.

V minimum = 2 ft. and V2 + H1 + V1 minimum = 4 ft. for certain appliance

models. See Table 2.1.

A DVP-2SL ADAPTER

is required in this position

V

2

in the vent run on certain

models. See Table 2.1.

WARNING! Risk of Fire! Use DVP pipe between appliance

and PVI-SLP-B on these models:

ESCAPE-42DV, ESCAPE-36DV, ESC-42ST, HEIR36,

HEIR42, HEIR50, LUX36, LUX42, TRUE-36, TRUE42, TRUE-50, CERONA-36, CERONA-42, MEZZO36,

MEZZO36ST, CRAVE4836, CRAVE4836ST, MEZZO48,

MEZZO48ST, CRAVE6048, CRAVE6048ST, MEZZO60,

MEZZO60ST, CRAVE7260, CRAVE7260ST, MEZZO72,

MEZZO72ST, CRAVE8472, CRAVE8472ST, MARQ36IN,

MARQ42IN, MARQ42STIN, ECHEL36IN, ECHEL36STIN,

ECHEL48IN,ECHEL48STIN,ECHEL60IN,ECHEL72IN,

ODFORTG-36, ODMEZG-36

Combustibles surrounding pipe may overheat.

WARNING! Risk of Overheating!

- Minimum inital length of vent pipe required between

appliance and vertically positioned PVI-SLP-B.

H

1

- Must include two 90 degree elbows.

V

1

Note: For PRIMO models, see the PRIMO Installation

Manual for vent congurations.

Figure 2.4 Vertical PVI Orientation

8 Hearth & Home Technologies • Power Vent Inline (PVI-SLP-B) Instructions • 2196-902 Rev. S • 7/20

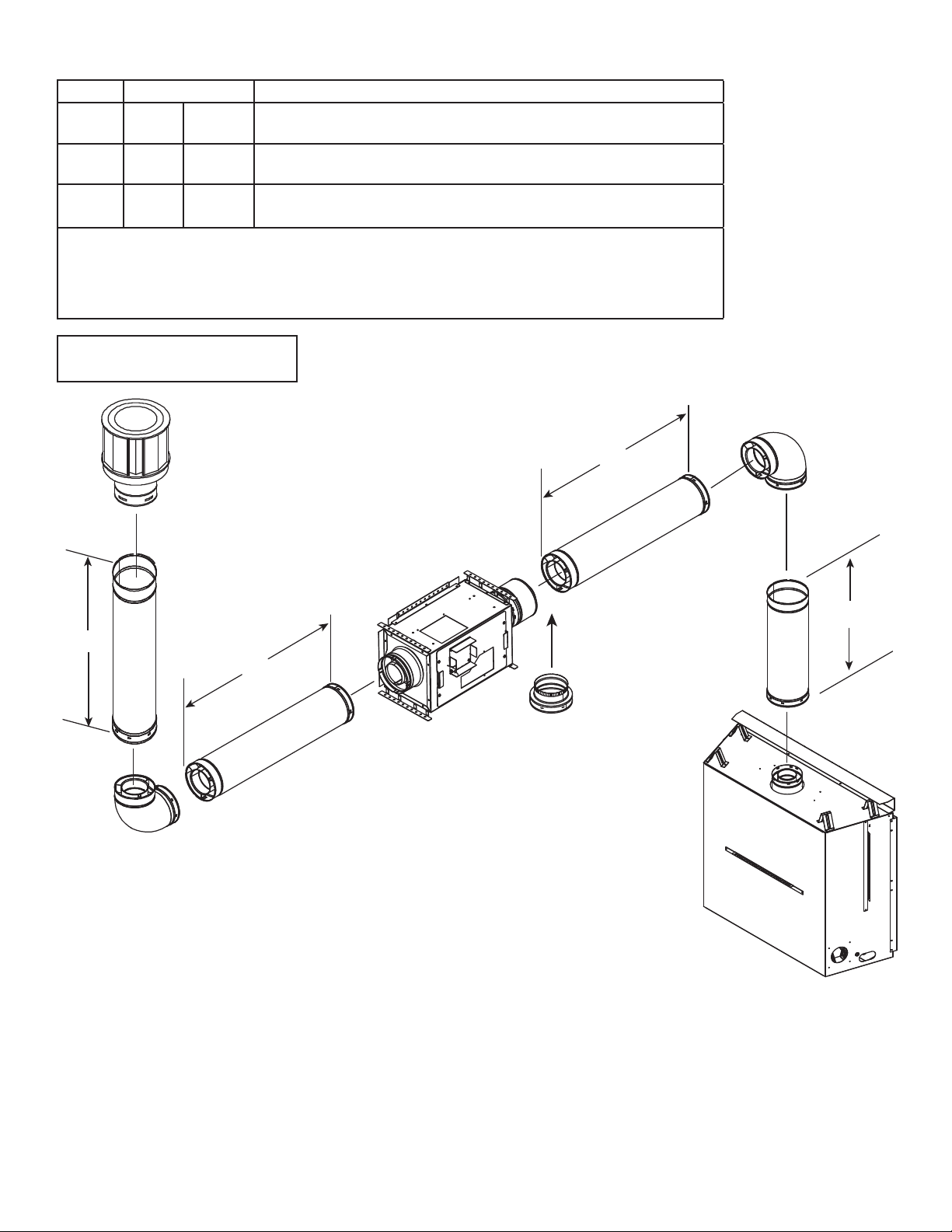

Top Vent - Vertical Termination

Minimum Maximum

H1 + V124 in. 610 mm See Chart in Section 2.C: "Venting Length - Model Categories and Length

Requirements by Termination Type."

V

H

TOTAL

A minimum of 2ft. of vertical piping is required between the appliance and the PVI-SLP-B in addition to the

minimum venting described above when installing PVI-SLP-B with certain appliance models. See Table

2.1.

V minimum = 2 ft. and H1 + V1 minimum = 4 ft. with certain appliance models. See Table 2.1.

Note: 1 ft. of vertical drop decreases

total allowable length by 2 ft.

18 in. 457 mm See Chart in Section 2.C: "Venting Length - Model Categories and Length

2

0 0

Requirements by Termination Type."

30% of total vent length allowed in chart: "Venting Length - Model Categories

and Length Requirements by Termination Type" in Section 2.C.

H

1

V

2

H

2

A DVP-2SL ADAPTER

is required in this position

in the vent run on certain

models. See Table 2.1.

WARNING! Risk of Fire! Use DVP pipe between appliance and PVI-SLP-B on these models:

ESCAPE-42DV, ESCAPE-36DV, ESC-42ST, HEIR36, HEIR42, HEIR50, LUX36, LUX42,

TRUE-36, TRUE-42, TRUE-50, CERONA-36, CERONA-42, MEZZO36, MEZZO36ST,

CRAVE4836, CRAVE4836ST, MEZZO48, MEZZO48ST, CRAVE6048, CRAVE6048ST,

MEZZO60, MEZZO60ST, CRAVE7260, CRAVE7260ST, MEZZO72, MEZZO72ST,

CRAVE8472, CRAVE8472ST, MARQ36IN, MARQ42IN, MARQ42STIN, ECHEL36IN,

ECHEL36STIN, ECHEL48IN, ECHEL48STIN, ECHEL60IN, ECHEL72IN, ODFORTG-36,

ODMEZG-36

Combustibles surrounding pipe may overheat.

V

1

Note: For PRIMO models, see the PRIMO Installation Manual for vent congurations.

Figure 2.5 Horizontal PVI-SLP-B Orientation

9 Hearth & Home Technologies • Power Vent Inline (PVI-SLP-B) Instructions • 2196-902 Rev. S • 7/20

Top Vent - Vertical Termination - (continued)

H1 + V1 + V224 in. 610 mm See Chart in Section 2.C: "Venting Length - Model

V

V

3

3

H

TOTAL

A minimum of 2ft. of vertical piping is required between the appliance and the PVISLP-B in addition to the minimum venting described above when installing PVI-SLP-B

with certain appliance models. See Table 2.1.

Minimum Maximum

Categories and Length Requirements by Termination Type."

18 in. 457 mm See Chart in Section 2.C: "Venting Length - Model

Categories and Length Requirements by Termination Type."

0 in. 0 in. 30% of total vent length allowed in chart: "Venting

Length - Model Categories and Length Requirements by Termination Type" in Section 2.C.

H

2

A DVP-2SL ADAPTER

is required in this position

in the vent run on certain

models. See Table 2.1.

V minimum = 2 ft. and v2 + H1 + V1 minimum = 4 ft. for certain appliance models. See

Table 2.1.

WARNING! Risk of Fire! Use DVP pipe between appliance and PVI-SLPB on these models:

ESCAPE-42DV, ESCAPE-36DV, ESC-42ST, HEIR36, HEIR42, HEIR50,

LUX36, LUX42, TRUE-36, TRUE-42, TRUE-50, CERONA-36, CERONA-42, MEZZO36, MEZZO36ST, CRAVE4836, CRAVE4836ST,

MEZZO48, MEZZO48ST, CRAVE6048, CRAVE6048ST, MEZZO60,

MEZZO60ST, CRAVE7260, CRAVE7260ST, MEZZO72, MEZZO72ST,

CRAVE8472, CRAVE8472ST, MARQ36IN, MARQ42IN, MARQ42STIN,

ECHEL36IN, ECHEL36STIN, ECHEL48IN, ECHEL48STIN, ECHEL60IN,

ECHEL72IN, ODFORTG-36, ODMEZG-36

Combustibles surrounding pipe may overheat.

V

2

Note: For PRIMO models, see the PRIMO Installation Manual for vent

congurations.

WARNING! Risk of Overheating!

- Minimum inital length of vent pipe required between

appliance and vertically positioned PVI-SLP-B.

- Must include two 90 degree elbows.

H

1

V

1

Figure 2.6 Vertical PVI-SLP-B Orientation

10 Hearth & Home Technologies • Power Vent Inline (PVI-SLP-B) Instructions • 2196-902 Rev. S • 7/20

Loading...

Loading...