Page 1

WSK-MLT MULTIFUNCTION WALL SWITCH

- INSTALLATION AND OPERATING INSTRUCTIONS -

Introduction

The WSK-MLT multifunctional wall switch is designed to

control fl ame height, blower speed, and auxiliary functions

on your gas fireplace. For models equipped with the

Intellifi re system (IPI), the cold climate function can control

the pilot fl ame as well. The wall switch is equipped with

thermostat functions which can automatically control the

temperature in the room in which it is installed. The wall

switch interfaces with both intermittent and standing pilot

systems. An auxiliary function provides 110-120 VAC

source for added features the fi replace may have installed.

Electrical ratings for the control box are 110 VAC, 60 Hz,

and is required for operation of this device.

Installation precautions

This remote is tested and safe when installed in accordance

with this installation manual. It is your responsibility to

read all instructions before starting installation and to

follow these instructions carefully during installation. Do

not install any components that may be damaged. Do not

modify, disassemble, or substitute any of the components

included with this kit. Installation of this unit must be done

by a qualifi ed service technician.

Placement of this wall switch may affect performance

or accuracy of the automatic (thermostat) control. An

assessment of the space should be done prior to installation

for optimal performance. See the installation instructions

section I for recommendations.

NOTE: The electrical junction box provided with the fi replace

must be wired with 110 VAC before installing this kit. See

owners manual for details.

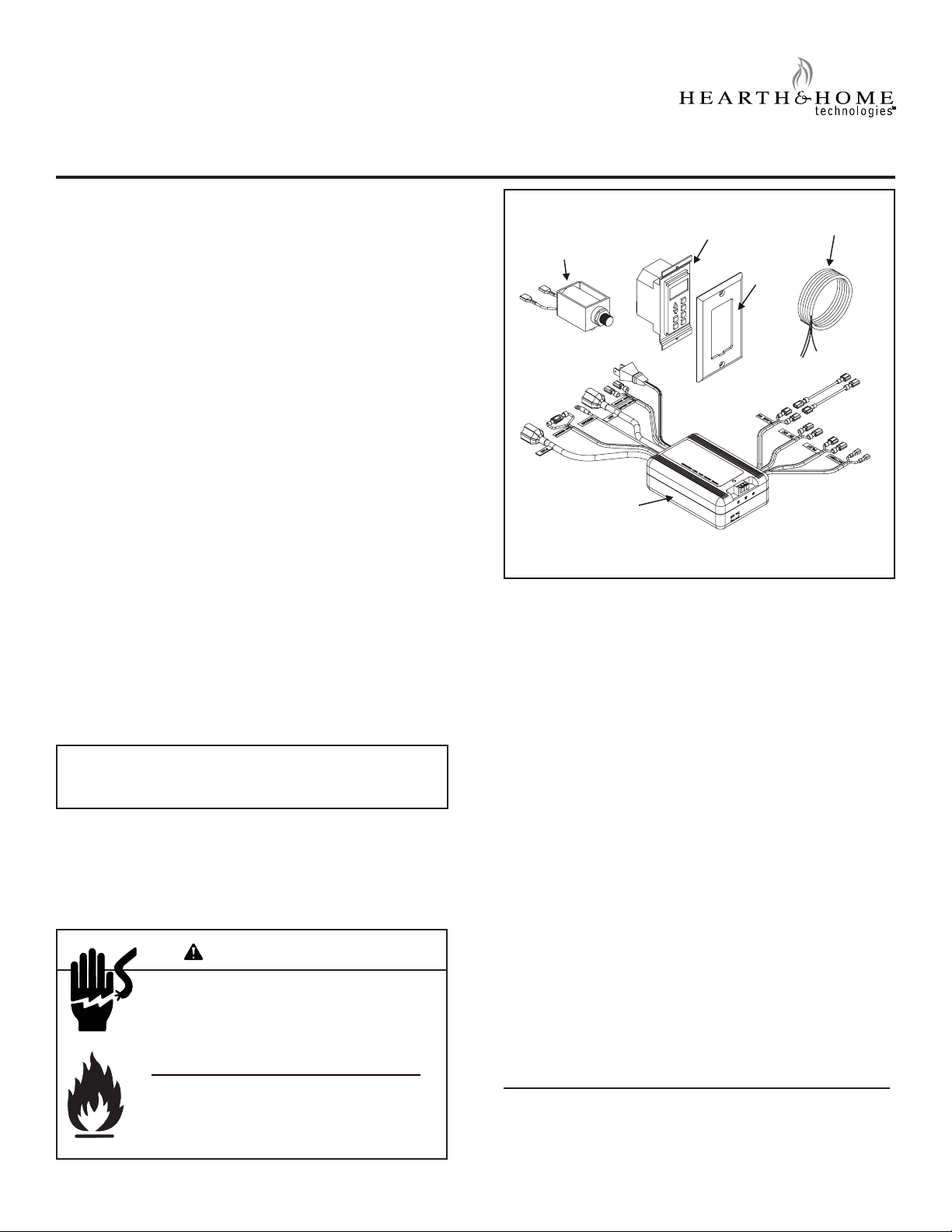

CONTROL

WIRE

FLAME

SOLENOID

Figure 1.

CONTROL

BOX

WALL SWITCH

COVER

PLATE

1.0 Installation instructions

1.1 Determine location

Determine the location for the wall switch. The chosen

location should provide an accessible location in the

same space as the gas fi replace. Never place this unit in

a separate room. The control wire supplied with this switch

is 33 ft (10M) in length. The distance from the fi replace to

the switch may be lengthened provided that the wire used

never exceeds 50 ft, and that the distance from the fi replace

to the switch never exceeds 30 ft.

All wiring should be done by a qualifi ed electrician and

shall be in compliance with local codes and with the

National Electric Code ANSI/NFGA No. 70- current (in the

United States), or with the current CSA C22.1 CANADIAN

ELECTRIC CODE (in Canada).

WARNING

Shock Hazard

Do not provide any power to this unit until all

wiring is completed. Failure to do so may destroy

parts of this device and render it unusable, and

may lead to possible electrical shock.

Fire Hazard

Modification of any parts or installation of

damaged components will void the warranty,

and you may possibly cause a fi re hazard.

The switch should be mounted into a listed electrical junction box. The junction box should be dedicated to this wall

switch. Never install this wall switch into a junction box

that is shared with other electrical service or devices. If

possible, install this unit on an interior wall of the residence

at a recommended height of 5 ft from the fl ooring. Should

the switch be installed on an exterior wall, be certain wall

insulation is kept intact and not damaged or dislodged during the installation of the electrical junction box.

For exterior wall installations, it is recommended that the

junction box be sealed with caulking material. This will

minimize heat loss through this location and improve the

accuracy of the automatic (thermostat) operation.

Copyright 2007

Hearth & Home Technologies Inc.

20802 Kensington Blvd., Lakeville, MN 55044

1

130-911G 12/07

Page 2

1.2 Wiring the wall switch

Once a location is chosen and the electrical box is installed

proceed as follows. Install the provided control wire from the

fi replace to the switch location. (Control wire for Heatilator

products is supplied with the fi replace). Use caution not

to stress the wire around tight or sharp corners. Do not

run the control wire adjacent to existing or future phone,

data, cable, or electrical lines. The wire should not come

into contact with any part of the fi replace exterior with the

exception of where it exits the outer wrap. Feed the wire

to the electrical junction box and through a provided or

approved strain relief. Using a screw driver, connect the

red wire to the “R” terminal, the yellow or white wire to the

“W” or “Y” terminal, and the green wire to the “G” terminal.

Do not over-tighten. Using the screws provided, mount the

switch to the electrical junction box right side up. Install

provided cover plate using the screws provided. Do not

use a substitute cover even though it may fi t. The provided

one is specifi cally designed for the automatic (thermostat)

function of the unit.

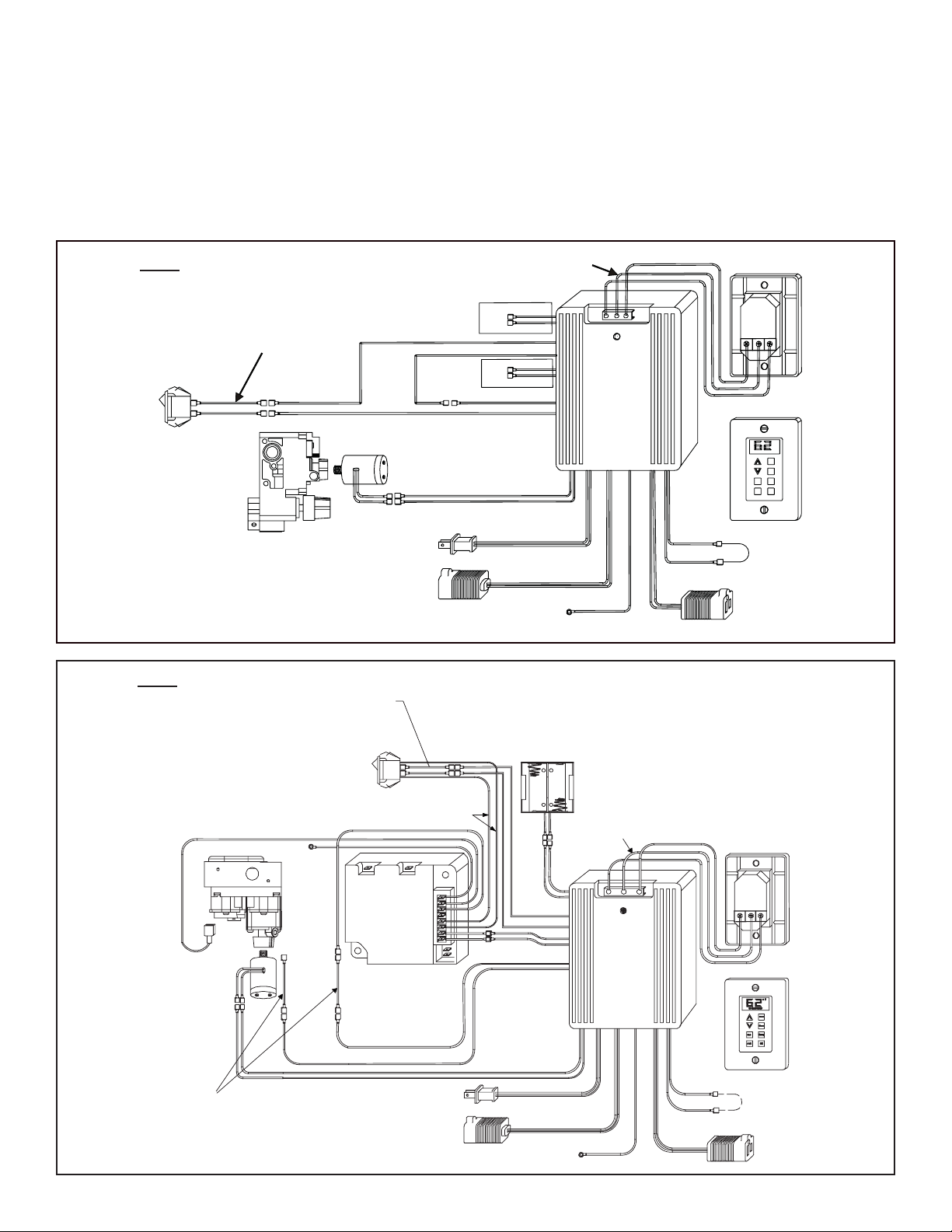

For units WITH factory installed Rocker Switch

WIRES WITH LABEL "FOR USE WITH

WALL SWITCH ONLY"

(LOCATED UNDER FIREPLACE)

VALVE

*May be labeled as “W” or “Y”.

FLAME

SOLENOID

AUX

CONNECTION

Figure 2. Standing Pilot Wiring Diagram

For units WITH factory installed Rocker Switch

WIRES WITH LABEL "FOR USE WITH WALL SWITCH

ONLY" (LOCATED UNDER FIREPLACE)

BROWN

BROWN

RED

FLAME HIGH/LOW

AC

PLUG

NOT

USED

NOT

USED

RED

ORANGE

GROUND PIGTAIL

GREEN

YELLOW OR

RED

BLACK

RED

BLACK

ORANGE

BLACK

WHITE

BLACK

RED

GREEN

G

W

R

*

YELLOW

YELLOW

FAN THERMOSTAT

REAR VIEW

*

W

G

R

FRONT VIEW

FACTORY

CONNECTED

TOGETHER

FAN

CONNECTION

ORANGE

GROUND

IPI

VALVE

FLAME

SOLENOID

ADAPTER WIRES

BLACK

RED

(FEMALE/MALE)

*May be labeled as “W” or “Y”.

Figure 3. Intellifi re (IPI) Wiring Diagram

GREEN

IPI

MODULE

RED

(MALE/FEMALE)

FLAME ON

FLAME HIGH/LOW

BROWN

1

2

3

4

5

6

7

8

RED

RED

AC

PLUG

AUX

CONNECTION

BATTERIES

RED

RED

ORANGE

YELLOW

or

WHITE

G W* R

RED

GREEN

YELLOW

YELLOW

FAN THERMOSTAT

BLACK

REAR VIEW

W*

R

G

FRONT VIEW

FACTORY

CONNECTED

TOGETHER

CONNECTION

FAN

3V DC

BLACK

BLACK

BLACK

BLACK

BROWN

BROWN

RED

BLACK

ORANGE

GROUND

PIGTAIL

GREEN

2

Page 3

1.3 Installing the control box

CAUTION

• Do NOT install the control box when fi replace is hot.

• Do NOT plug control box in until all connections are

complete.

1. Place control box into the base pan area of the fi replace.

Place unit as close to the louvers or decorative front as

possible and to either the left or right side.

2. Connect the red, yellow or white, and green wires to the

appropriate labeled terminals on the control box.

For units WITH factory installed rocker switch.

3. Find the red and brown pigtail wire (labeled “ FOR USE

WITH REMOTE OR WALL SWITCH ONL Y”) which are

attached to the fi replace ON/OFF rocker switch.

Standing Pilot Ignition: Connect these wires with the

red and brown wires extending from control box (Fig 2).

Intellifi re (IPI): Connect these wires with the brown

wires extending from the control box (see Figure 3).

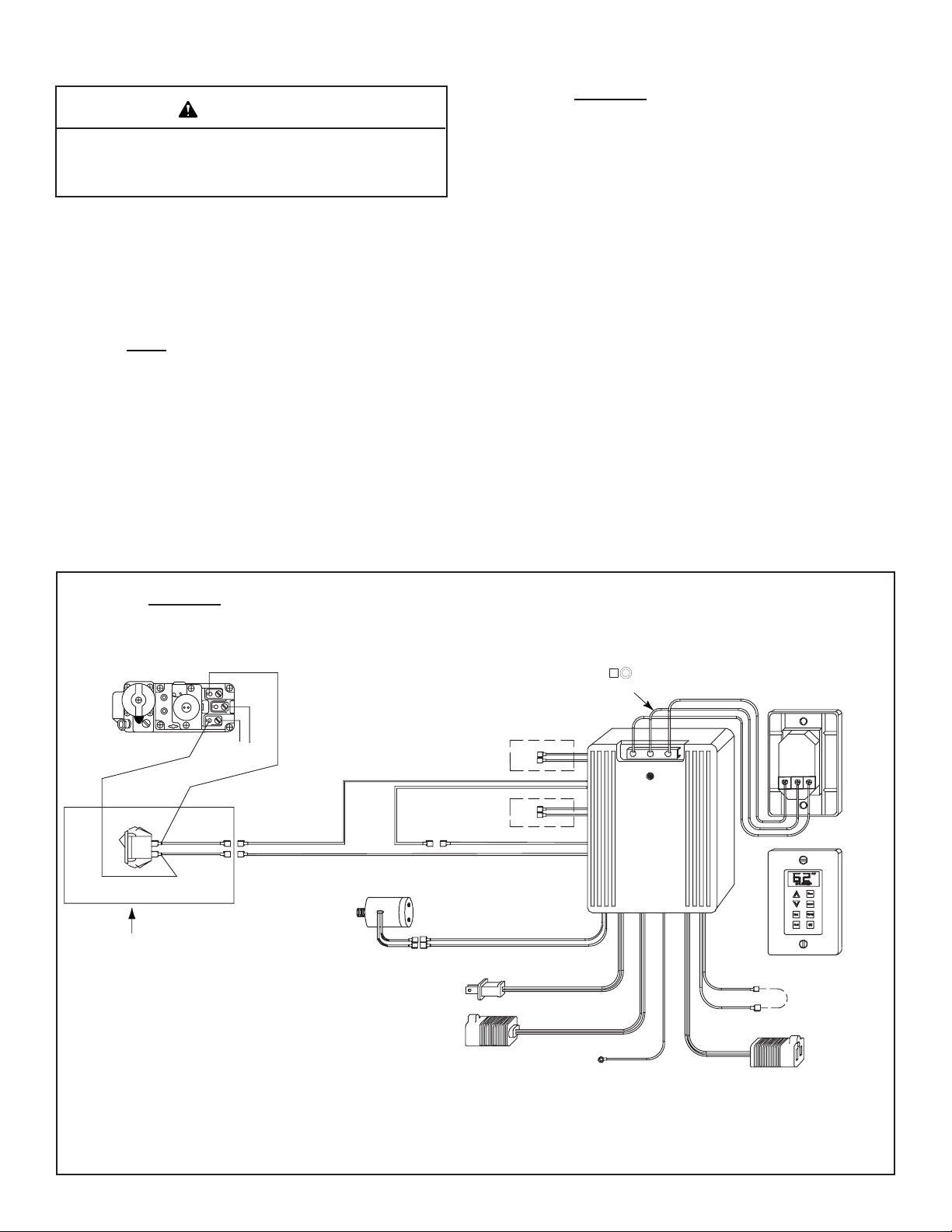

For units WITHOUT factory installed rocker switch.

Standing Pilot Ignition:

Find these parts packed with WSK-MLT:

• Rocker switch

• Rocker switch bracket

• Strips of Velcro

• Black and white wire pigtails - (2)

• Female ends (only used on Standing Pilot

applications) - (2)

Cut male ends off black wires on each pigtail. Strip each

end of wire approximately 1/4 inch. Slide each stripped

wire into a female end and crimp. Slide rocker switch into

bracket until it snaps into place. Attach end of each pigtail

to each side of rocker switch. Find the top (brown) and

bottom (red) wires from the control box and attach to white

wires from rocker switch. Attach one black wire to the TH/TP

side of gas valve and the other to the TH side of the gas

valve. Attach the Velcro to the bottom of the rocker switch

bracket and mount in a convenient location next to gas

valve. (Refer to Figure 4).

For units WITHOUT factory installed Rocker Switch

VALVE

WHITE

WHITE

BLACK

SWITCH AND WIRE

ASSEMBLY SUPPLIED

WITH WSK-MLT

* May be labeled as “W” or “Y”.

BLACK

To

Thermopile

FLAME

SOLENOID

CONNECTION

FLAME HIGH/LOW

AC PLUG

AUX

RED

RED

RED

NOT

USED

BLACK

BROWN

BROWN

RED

NOT

USED

BLACK

ORANGE

ORANGE

BLACK

BLACK

GROUND PIGTAIL

GREEN

YELLOW

WHITE

G W* R

RED

GREEN

YELLOW

YELLOW

FAN THERMOSTAT

BLACK

REAR VIEW

W*

G

R

FRONT VIEW

FACTORY

CONNECTED

TOGETHER

CONNECTION

FAN

Figure 4. Standing Pilot Wiring Diagram

3

Page 4

For units WITHOUT factory installed Rocker Switch

BLACK

SWITCH AND WIRE

ASSEMBLY

SUPPLIED

WITH WSK-MLT

WHITE

BROWN

1

2

3

4

5

6

7

8

RED

RED

AC

PLUG

AUX

CONNECTION

ORANGE

GROUND

IPI

VALVE

FLAME

SOLENOID

RED

ADAPTER WIRES

* May be labeled as “W” or “Y”.

BLACK

(FEMALE/MALE)

GREEN

IPI

MODULE

RED

(MALE/FEMALE)

FLAME ON

FLAME HIGH/LOW

3V DC

BATTERIES

BLACK

BLACK

BROWN

BROWN

RED

BLACK

ORANGE

BLACK

BLACK

GROUND

RED

RED

ORANGE

PIGTAIL

GREEN

YELLOW

or

WHITE

G W* R

RED

GREEN

YELLOW

YELLOW

FAN THERMOSTAT

BLACK

REAR VIEW

W*

R

G

FRONT VIEW

FACTORY

CONNECTED

TOGETHER

CONNECTION

FAN

Figure 5. Intellifi re (IPI) Wiring Diagram

Intellifi re (IPI):

Find these parts packed with WSK-MLT:

• Rocker switch

• Rocker switch bracket

• Strips of Velcro

• Black and white wire pigtails - (2)

• Female ends (not used on IPI applications) - (2)

Slide rocker switch into bracket until it snaps into place.

Attach one pigtail to one side of rocker switch and the other

pigtail to the other side of the rocker switch. Find the two

brown wires from IPI module and attach them to the two

black wires from the rocker switch. Find the two brown

wires from the control box and attach them to the white

wires from the rocker switch. Attach the Velcro to rocker

switch bracket and place rocker switch next to control box.

(Refer to Figure 5).

Proceed to Step 4.

4. If equipped with a fan, plug the fan cord into the power

cord labeled “FAN”. Disconnect the two wires from the

fan thermostat switch on the fi replace. Disconnect the

two yellow wires from each other and connect them to

the fan thermostat switch. Use one of the existing wires

on the thermostat to connect to the proper end on the

male terminated yellow wire.

Note: The fan rheostat has now been removed from the

circuit and is inoperable. Use the wall switch to change fan

speeds. The fan temperature sensor is still operable and

will turn the fan on and off when the fi replace heats up and

cools down.

5. Remove the screw and knob from the variable regulator

and discard.

6. Unscrew the nut from the regulator and discard.

7. Remove the bag containing a washer and blue and red

plungers from the side of the fl ame control solenoid.

8. Place washer on fl ame control solenoid (see Figure 6).

4

Page 5

GAS CONTROL

VALVE

WASHER

KNOB

SCREW

NUT

VARIABLE REGULATOR

WASHER

VARIABLE

REGULATOR

FLAME CONTROL

Figure 6.

SOLENOID

9. Insert the correct plunger (blue - natural gas, red - propane) into the fl ame control solenoid (see Figure 6).

10. Thread the fl ame control solenoid with correct plunger

into the thread hole in the variable regulator. T urn into

valve approximately two full turns. Do not tighten or

damage may occur.

1 1. Set the valve manifold pressure to the proper setpoint.

The setpoint is adjusted by rotating the solenoid to

adjust its depth into the valve. Using a manometer

to monitor pressure, rotate the solenoid so that the

output is set to proper range.

12. Tighten the jam nut on the threaded shaft of the

solenoid against the valve regulator. Use an openended ½” wrench to tighten the nut, while holding

the solenoid in the proper position. This step will ensure that the solenoid remains locked into the proper

position.

13. Connect orange wires from control box to the fl ame

control solenoid.

14. Ground the control box by attaching the green ground

wire (has round ring-terminal on end) to the fi replace

base pan or appropriate ground.

SOLENOID

VARIABLE

REGULATOR

PLUNGER

JAM NUT

Intellifi re (ipi) models only

For units with factory installed rocker switch see Fig. 3.

For units without factory installed rocker switch see

Fig. 5.

14. Disconnect main valve wire (green) from the front of

the valve. Connect red control wire to red adapter wire

containing one large male end and one small female

end and connect to valve terminal (see Figure 3).

Connect the other red control wire to red adapter wire

containing one large female end and one small male

end and connect the green module wire (previously

disconnected from valve front).

15. Carefully unplug battery pack wires from IPI module.

Plug battery pack into red and black battery wires

(labeled “Battery”).

16. Plug red and black wires from control box (labeled

“3V DC”) to the red and black wires extending from IPI

module (labeled “3V DC”). Red connects to red, black

connects to black.

CAUTION

Lay the control box and wires fl at on the base pan to avoid

potential overheating problems.

13. Connect auxiliary functions. This unit is equipped with

a 1 10 VAC supply cord (labeled “AUX”) for controlling

auxiliary functions such as an electric ember bed.

NOTE: Transformer supplied with the IPI system is NOT

used. Disconnect the transformer from the electrical junction

box. Transformer may be removed from the fi replace, but we

recommend leaving it connected to the IPI module.

5

Page 6

2.0 Operating Instructions

For units WITH factory installed rocker switch.

The ON/OFF rocker switch on the fi replace (located near

the gas valve) must be in the “OFF” position for use with

the WSK-ML T system. The ON/OFF rocker switch will NOT

function with this device on Intellifi re (IPI) models except

during a power outage.

For units WITHOUT factory installed rocker switch.

The ON/OFF rocker switch now installed on the fi replace

must be in the OFF position for use with the IPI or standing pilot system. The ON/OFF rocker switch will only be

used to control the fi replace in a no-power condition. For

standing pilot systems use the rocker switch to turn the

fi replace on and off. When power is restored switch the

rocker switch to OFF. For IPI system refer to “Operation

Under Battery Power” for instructions.

After all connections are made and the control box is

grounded, plug power cord into the fi replace junction box.

The wall switch will be functional at this time.

NOTE: The temperature displayed by the wall switch may

take up to 30 minutes to stabilize on initial power-up.

NOTE: Check control box and assure switch is in the “OFF”

position. This switch is only used on Intellifi re (IPI) control

systems under battery operation.

Figure 7.

• Once pressure is achieved spin jam-nut on solenoid stem

tight against regulator face to prevent rotation. Do not

overtighten.

• Press fl ame button twice to turn fi replace off.

• Remove manometer tube and tighten or close pressure

tap. Use a soap solution to carefully check the pressure

tap for leaks.

2.2 Wall Switch Button Operation

(Refer to Figure 7)

Flame Button

• Button Press: Unit On / Flames High, Turns on auxiliary

power

• Button Press: Flames Low

• Button Press: Unit Off / Flames Off, Turns off auxiliary

power

Fan / Blower Button

• Button Press: Fan High (“3”)

• Button Press: Fan Medium (“2”)

• Button Press: Fan Low (“1”)

• Button Press: Fan Off

Temperature Button

• Button Press will toggle between Automatic and Manual

Operation

• Press and Hold the button for 3 seconds to toggle between

Fahrenheit and Centigrade Temperature Display.

Automatic Operation: Controller will monitor temperature

and control unit according to the set point.

Manual Operation: Controller will not automatically change

settings.

SET

Set Temperature Button

• Button Press: Displays Set Point

• Use Up and Down Arrows to Adjust Set Point

• Press Set Button to Store New Set Point

Temperature Set Point can be adjusted between the ranges of:

45-900 Fahrenheit or 7-320 Centigrade

2.1 Setting Flame Height/manifold pressure

(To be done by a qualifi ed service technician). Upon initial

power-up of this device, valve pressure must be set for

fl ame adjustment.

• Loosen output pressure tap on valve and connect with

pressure manometer.

• Press fl ame button once (Fig. 7); fi replace will light with

fl ames on high.

• Turn solenoid clockwise to increase pressure, counterclockwise to decrease pressure until manifold pressure

on high is 3.5” water column for natural gas (NG), 10.0”

water column for propane (LP).

NOTE: The controller will turn off the fi replace at 20 F over

set point and turn it back on at 20 F below set point.

Up and Down Arrows

<>

• Push to adjust set point temperature under automatic

control.

AUX

Auxiliary Button

• Button Press: Turns on auxiliary power

• Button Press: Turns off auxiliary power

Can be operated independently of all functions.

6

Page 7

Child Proof Mode

To Enter Child Proof Mode:

• Press the Up Arrow Button twice and Down Arrow Button

once. The unit will send out 3 beeps and an indicator in

the LCD panel will show that the child proof is on.

To Leave Child Proof Mode:

• Press the Up Arrow Button twice and Down Arrow Button

once. The unit will send out 3 beeps and the indicator in

the LCD panel that shows that the child proof is on will

disappear.

NOTE: When in Child Proof Mode, only the arrow buttons

will have functionality. Unit can enter Child Proof when the

fi replace is on or off.

CONTROL

BOX

Figure 8

BATTERY

OPERATION

SWITCH

“OFF”

POSITION

“BATTER Y ON”

POSITION

INTELLIFIRE (IPI) MODELS ONLY

Cold Climate Button

• Button Press: Turns on Climate Control

• Button Press: Turns off Climate Control

This allows the pilot fl ame to stay lit when activated, a ben-

efi t of this is reduced condensation on the glass at start-up

in colder climate conditions.

Operation Under Battery Power

A switch on the control box allows for battery power under

no-power conditions (see Figure 8). By controlling the

power supply with this switch, the batteries are supplying

power only when needed, thus extending battery life. The

switch also provides a convenient means for switching to

battery power should there be a loss of 1 10 VAC power to

the control box.

• In the event of a power failure, switch the battery

operation switch to the “Battery ON” position.

• The fi replace can now be turned on and off with the ON/

OFF rocker switch located near the gas valve.

SERVICE PARTS LIST

DESCRIPTION SERVICE PART NO.

SOLENOID HTI-17-006

WALL SWITCH/KEY PAD HTI-12-007

CONTROL WIRE HTII-23-007

COVER PLATE HTI-21-007

CONTROL BOX HTI-13-007

ACTUATOR PINS HTI-17-116

SWITCH KIT HTI-25-007

• The wall switch functions will not operate under battery

power.

• Under battery control the only available function is fl ame

“On” and “Off” in the high position.

• To maximize battery life, and to restore full function

capability of the wall switch, fl ip switch to “OFF” position

after 120 VAC power is restored.

7

Loading...

Loading...