Hearth and Home Technologies VRT-BZ-N-CE, VRT-BZ-P-CE, VRT-GY-N-CE, VRTIKL-CE, VRT-GY-P-CE User Manual

...Page 1

VRTIKL-CE

FREESTANDING STOVE

MODEL:

VRT-BZ-N-CE

VRT-GR-N-CE

VRT-GY-P-CE

VRT-BZ-B-CE

Installer’s Guide

Installation and Operation

0063-06

VRT-GY-N-CE

VRT-BZ-P-CE

VRT-GR-B-CE

VRT-GY-B-CE

VRT-GR-P-CE

CAUTION

DO NOT DISCARD THIS MANUAL

• Important operating

and maintenance

instructions included.

WARNING: If the information in these

instructions is not followed exactly, a fi re

or explosion may result causing property

damage, personal injury, or death.

• Do not store or use gasoline or other fl am-

mable vapors and liquids in the vicinity of this

or any other gas stove.

• What to do if you smell gas

- Do not try to light any gas stove. Do not

touch any electrical switch. Do not use

any phone in your building.

- Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

- If you cannot reach your gas supplier, call

the fi re department.

• Installation and service must be performed

by a qualifi ed installer, service agency, or the

gas supplier.

• Read, understand and follow

these instructions for safe

installation and operation.

DO NOT

DISCARD

• Leave this manual with

party responsible for

use and operation.

WARNING

HOT SURFACES!

Glass and other surfaces are hot during

operation AND cool down.

Hot glass will cause burns.

• DO NOT touch glass until it is cooled

• NEVER allow children to touch glass

• Keep children away

• CAREFULLY SUPERVISE children in same room as

fi replace.

• Alert children and adults to hazards of high temperatures.

High temperatures may ignite clothing or other fl ammable

materials.

• Keep clothing, furniture, draperies and other fl ammable

materials away.

This appliance has been supplied with an integral barrier

to prevent direct contact with the fi xed glass panel. DO

NOT operate the appliance with the barrier removed.

Contact your dealer if the barrier is not present or help is

needed to properly install one.

Installation and service of this gas stove should be performed

by qualifi ed personnel.

These instructions are valid for the following countries:

GB, IE

Î

1Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Page 2

Read this manual before installing or operating this gas stove.

Please retain this owner's manual for future reference.

Congratulations

Congratulations on selecting a Heat & Glo gas stove - an

elegant and clean alternative to wood burning stoves. The

Heat & Glo gas stove you have selected is designed to

provide the utmost in safety, reliability, and efficiency.

As the owner of a new gas stove, you'll want to read and

carefully follow all of the instructions contained in this

Owner's Manual. Pay special attention to all Cautions and

Warnings.

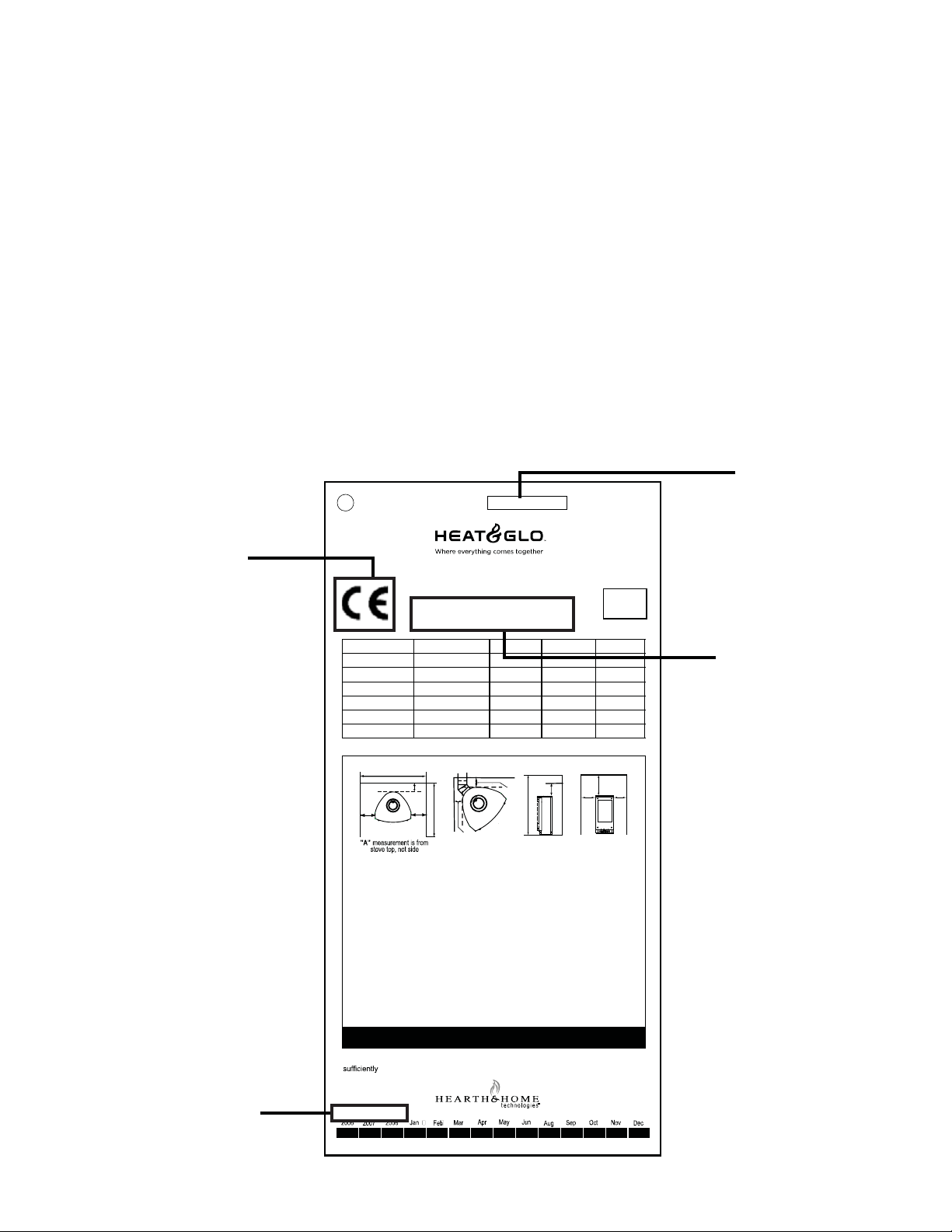

SAMPLE OF RATINGS LABEL

LOCATION: IN CONTROL AREA, INSIDE LOWER ACCESS DOOR

SERIAL NO.

Test Lab &

Report No.

Gas Type G20 G20 G20 G25

Destination ES, GB, IE, PT, NO DE, LU FRNL

CAT

Qn 7.6 7.6 7.6 6.2

Pn 20 mbar 20 mbar 20/25 mbar 25 mbar

Pmax 8.7 mbar 8.7 mbar 8.7 mbar 8.7 mbar

Injector #39DMS #39DMS #39DMS #39DMS

Heat & Glo, a brand of Hearth & Home Technologies, Inc.

0087

F

A

20802 Kensington Boulevard

Lakeville, MN 55044, USA

Model:

I

2H

Not for use with solid fuel.

B

E

This Owner's Manual should be retained for future reference.

We suggest that you keep it with your other important

documents and product manuals.

The information contained in this Owner's Manual, unless

noted otherwise, applies to all models and gas control

systems.

Y our new Heat & Glo gas stove will give you years of durable

use and trouble-free enjoyment. Welcome to the Heat & Glo

family of gas stove products!

Serial No.

ww w.heatnglo.com

ION

-CE

MADE

IN USA

Model Name

I

2E

C

C

I

2E R

H

D

Alcove

G

AAA

I

2L

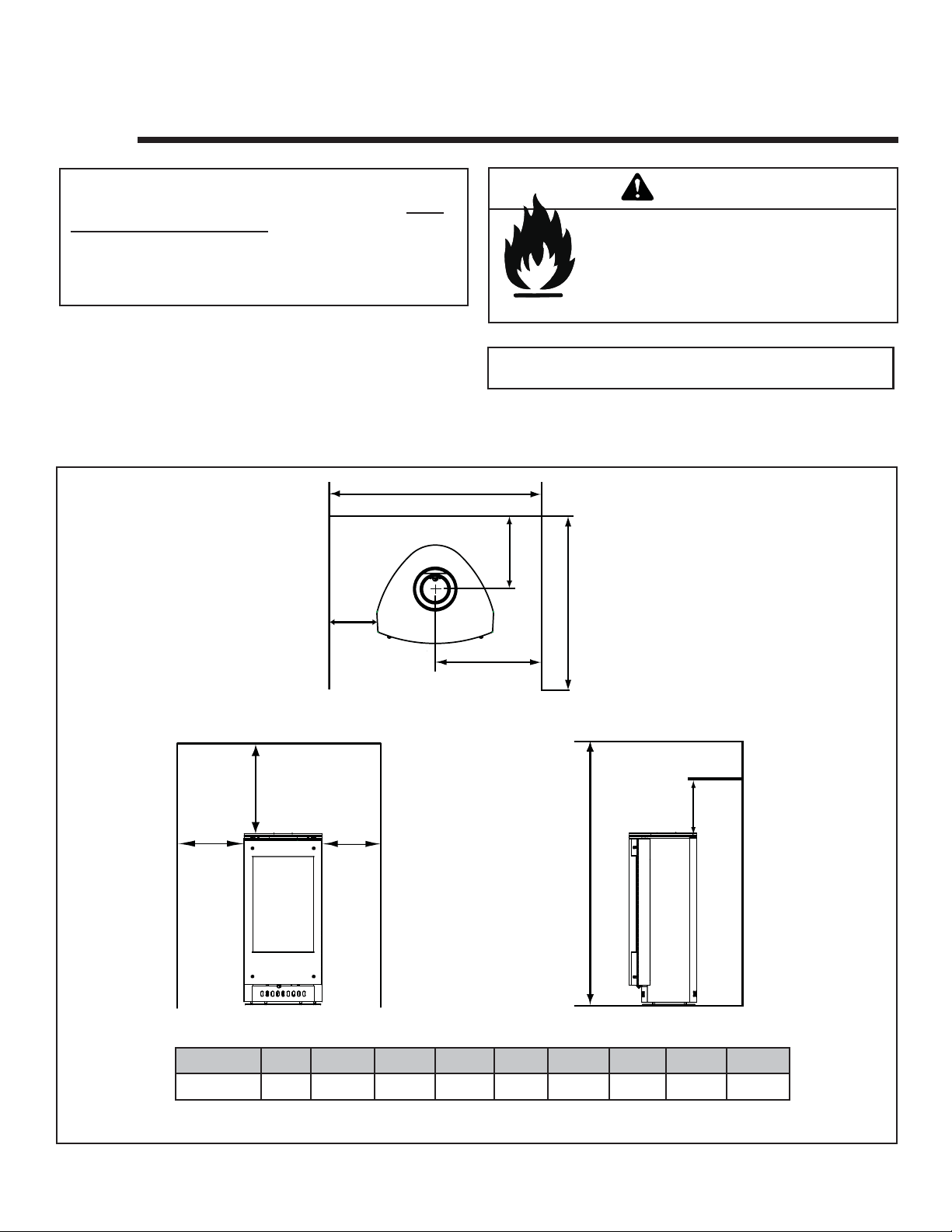

Minimum Clearances to Combustibles

A - Side of appliance top to side wall..............15.2 cm

B - Rear of appliance to back wall................... 7.6 cm

C - Corner of appliance top to side wall..........12.7 cm

D - MinimumAlcove Height...........................137.2 cm

E - MaximumAlcove Depth ............................91.4 cm

SAMPLE

F - MinimumAlcove Width............................. 78.1 cm

G- Top of appliance to alcove ceiling ........... 33.7 cm

H - Mantle Clearance from appliance top .......26.7 cm

DO NOT REMOVE OR COVER THIS LABEL.

This appliance must be installed in accordance with the codes enforced, and used only in

ventilatedspace. Consult instructionsbefore installation anduse of this appliance.

Manufactured by:

Manufactured

Date of Manufacture:

Date

2 Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Page 3

- TABLE OF CONTENTS -

Section 1: Listing and Code Approvals

A. Gas Stove Certifi cations ...........................4

B. Glass Specifi cations .................................4

C. Non-Combustible Materials ......................4

D. Combustible Materials ..............................4

Section 2: Getting Started

A. Design & Installation Considerations ........5

B. Inspect Gas Stove & Components ............5

Section 3: Gas Stove Location & Clearances

A. Selecting Gas Stove Location ...................6

B. Clearances to Combustibles .....................6

C. Optional Stone Surround Installed ............7

Section 4: Termination Locations

A. Flue Termination Clearances ....................8

Section 5: Flue Information

A. Flueing Components ...............................10

B. Use of Elbows .........................................10

C. Measuring Standards ..............................10

D. Flueing Diagrams ....................................11

E. Horizontal Termination ............................16

F. Slim Line Wall Thimble ..........................17

G. Vertical Termination ................................19

H. Vertical Flue Restrictor ...........................21

Section 6: Gas Information

A. Gas Pressure Requirements ..................22

B. Gas Connection.. ....................................22

Section 7: Electrical Information

A. Ignition System Wiring ............................23

Section 8: Gas Stove Setup

A. Remove Shipping Materials ....................24

B. Unbolting Gas Stove from the Pallet .......24

C. Leveling and Lagging Down the

Gas Stove ...............................................24

D. Accessories ............................................25

E. Top to Rear Vent Conversion .................25

F. Installing the Baffl e .................................26

G. Positioning the Logs ...............................27

H. Mineral Wool ...........................................27

I. Front Door Glass Assembly ....................28

J. Inner Glass Door Replacement ..............28

Section 9: Operating Instructions

A. Before Lighting Gas Stove ......................29

B. Lighting Gas Stove .................................30

C. After Gas Stove is Lit ..............................31

D. Frequently Asked Questions ...................31

Section 10: Maintaining & Servicing Gas Stove

A. Maintenance Tasks ..........................................33

B. Service and Maintenance Log ......................... 34

Section 11: Troubleshooting ............................35

Section 12: Reference Materials

A. Gas Stove Dimension Diagram ..............35

B. Gas Stove Dimension with Stone

Surround Diagram ..................................36

C. Flue Components Diagram .....................37

D. Flue Components List .............................38

E. Service Parts List ....................................40

F. Warranty Policy .......................................43

G. Contact Information ................................44

Î = Contains updated information.

3Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Page 4

1

Listing and Code Approvals

A. Appliance Certifi cation

MODEL VRTIKL-CE

LABORATORY Gastec Certifi cation B.V .

TYPE Gas Stove

STANDARD EN 613:2001

DIRECTIVE CAD90/396/EEC

These instructions are only valid if the following country

symbol is on the gas stove. If this symbol is not present

on the gas stove, it is necessary to refer to the technical

instructions which will provide the necessary information

concerning the modifi cation of the gas stove to the

conditions of use for the country.

B. Glass Specifi cations

This gas stove is equipped with 5mm ceramic glass behind

the curved glass. Replace glass only with 5mm ceramic

glass. Please contact your dealer for replacement glass.

C. Non-Combustible Materials

Materials that are reported as passing ASTM E 136, Standard

Test Method for Behavior of Materials in a Vertical Tube

Furnace at 750°C, shall be considered non-combustible

materials.

D. Combustible Materials

Materials made of or s urfaced with wood, compressed paper,

plant fibers, plastics, or other materials t hat can ignite and

burn, whether flame proofed or not, or whether plastered or

unplastered shall be considered combustible materials.

WARNING

Do NOT use this gas stove if any part has been under water.

Immediately call a qualifi ed service technician to inspect

the gas stove and to replace any part of the control system

and any gas control which has been under water.

4 Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Page 5

2

Getting Started

A

. Design & Installation Considerations

Heat & Glo direct fl ue gas stoves are designed to operate

with all combustion air siphoned from outside of the building

and all exhaust gases expelled to the outside. No additional

air source is required.

CAUTION

Check building codes prior to installation.

• Installation MUST comply with local, regional, state

and national codes and regulations.

• Consult local building, fi re offi cials or authorities having

jurisdiction about restrictions, installation inspection,

and permits.

When planning an installation, it is necessary to determine

the following information before installing.

• Where the gas stove is to be installed.

• The fl ue system confi guration to be used.

• Gas supply piping.

• Electrical wiring.

B. Inspect Appliance & Components

WARNING

Inspect gas stove and components for

damage. Damaged parts may impair safe

operation.

• Do NOT install damaged components.

• Do NOT install incomplete components.

• Do NOT install substitute components.

Report damaged parts to dealer.

• Carefully remove the gas stove and components from

the packaging.

• Remove door and set aside on protective surface.

• Remove log set and component pack from fi rebox.

• Report to your dealer any parts damaged in shipment,

particularly the condition of the glass.

• Read all of the instructions before starting the installation. Follow these instructions carefully during the

installation to ensure safety and benefi t.

WARNING

Hearth & Home Technologies disclaims any

responsibility for, and the warranty will be

voided by, the following actions:

• Installation and use of any damaged gas stove or fl ue

system component.

• Modifi cation of the gas stove or fl ue system.

• Installation other than as instructed by Hearth & Home

Technologies.

• Improper positioning of the gas logs or the glass door.

• Installation and/or use of any component part not

approved by Hearth & Home Technologies.

Any such action may cause a fi re hazard.

5Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Page 6

3

Appliance Location and Clearances

NOTE:

· Illustrations refl ect typical installations and are FOR

DESIGN PURPOSES ONLY.

· Illustrations/diagrams are not drawn to scale.

· Actual installation may vary due to individual design

preference.

A. Selecting Appliance Location

When selecting a location for your gas stove it is important

to consider the required clearances to walls (see Figure

3.1).

B. Clearances to Combustibles

F

A

WARNING

Fire Risk

Provide adequate clearance:

• Around air openings

• To combustibles

• For service access

Locate gas stove away from traffi c areas.

NOTE: For actual gas stove dimensions refer to Section 12.

B

E

A

Centimeters

I

“A” measurement is from gas stove top, not side.

Alcove

G

A

D

AB C DEFGH I

15.2 25.7 30.8 137.2 91.4 78.1 33.7 33.7 39.4

H

Figure 3.1

6 Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Page 7

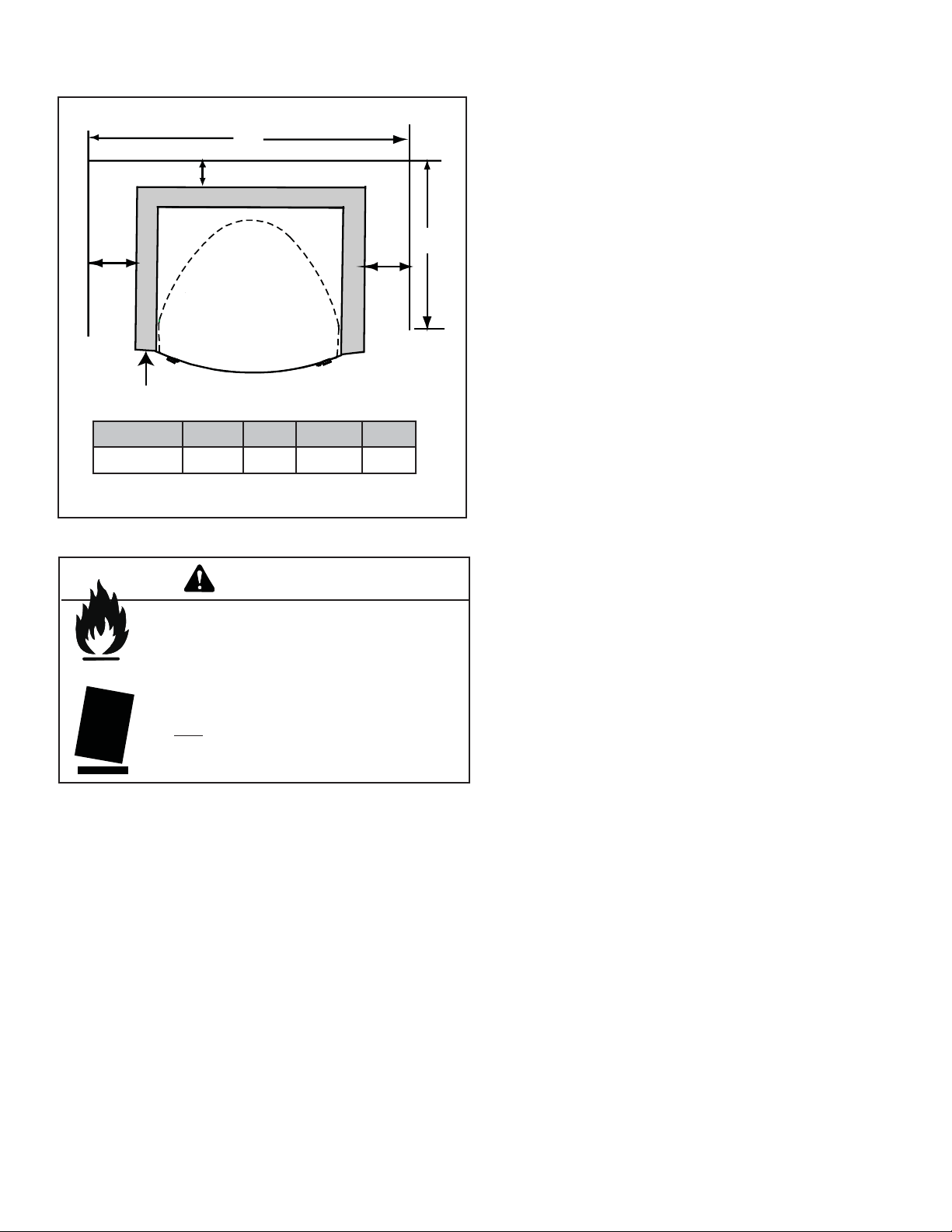

C. Optional Stone Surround Installed

C

B

D

A

Centimeters

Figure 3.1

A

ABC D

8.3 10.2 78.1 91.4

WARNING

Fire Risk.

Odor Risk.

Tipping Risk

• Install gas stove on a stable, level platform/

fl oor strong enough to support gas stove

without tipping.

• USE wood fl ooring, ceramic tile, brick hearth

or high pressure laminate fl ooring applied

directly over the sub-fl ooring material.

7Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Page 8

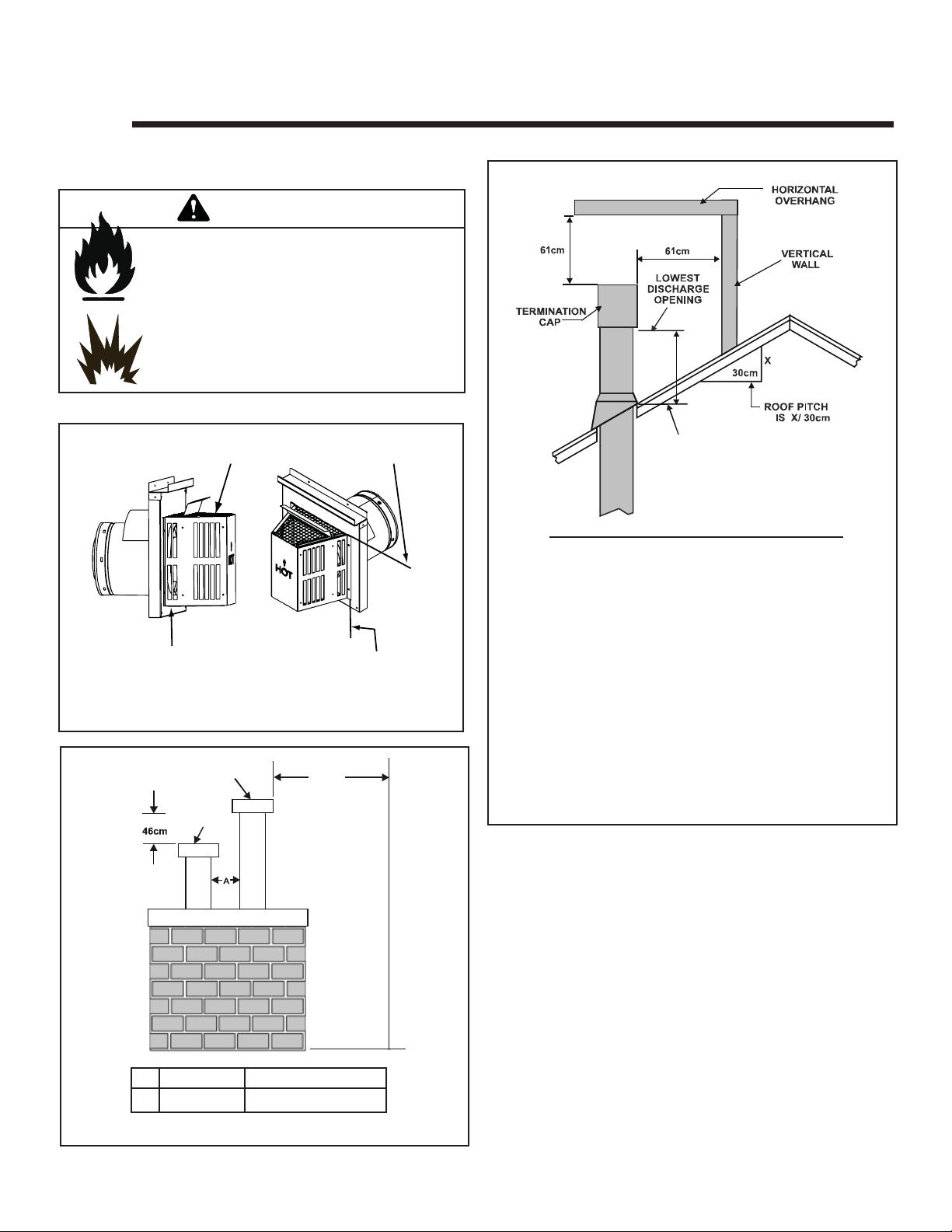

Termination Locations

4

A. Flue Termination Minimum Clearances

WARNING

Fire Risk.

Explosion Risk.

Maintain fl ue clearance to combustibles

as specifi ed.

• Do not pack air space with insulation or

other materials.

Failure to keep insulation or other materials

away from fl ue pipe may cause fi re.

Measure vertical clearances from this surface.

Measure horizontal clearances from this surface.

(See Figure 4.4 for specifi c clearances.)

Figure 4.1 Termination Clearances

GAS, W OOD OR FUEL

OIL TERMINATION

(MINIMUM) TO

PERPENDICULAR

GAS

TERMINATION

WALL

(GAS ONLY)

61cm

H (MIN.) - MINIMUM HEIGHT FROM ROOF

TO LOWEST DISCHARGE OPENING

Roof Pitch H (Min.) M

Flat to 6/12..............................................................30*

Over 6/12 to 7/12 ....................................................38*

Over 7/12 to 8/12 ....................................................46*

Over 8/12 to 9/12 ....................................................61*

Over 9/12 to 10/12 ..................................................76

Over 10/12 to 11/12 ................................................99

Over 11/12 to 12/12 .............................................1.22

Over 12/12 to 14/12 .............................................1.52

Over 14/12 to 16/12 .............................................1.83

Over 16/12 to 18/12 .............................................2.13

Over 18/12 to 20/12 .............................................2.29

Over 20/12 to 21/12 .............................................2.44

*.91M minimum in snow regions

Figure 4.3 Minimum Height from Roof to Lowest Discharge

Opening

Figure 4.3 specifi es minimum fl ue heights for various

pitched roofs.

Gas Termination Wood & Fuel Oil Termination

15 cm 51 cm

A

Figure 4.2 Multiple Vertical Termination

8 Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Page 9

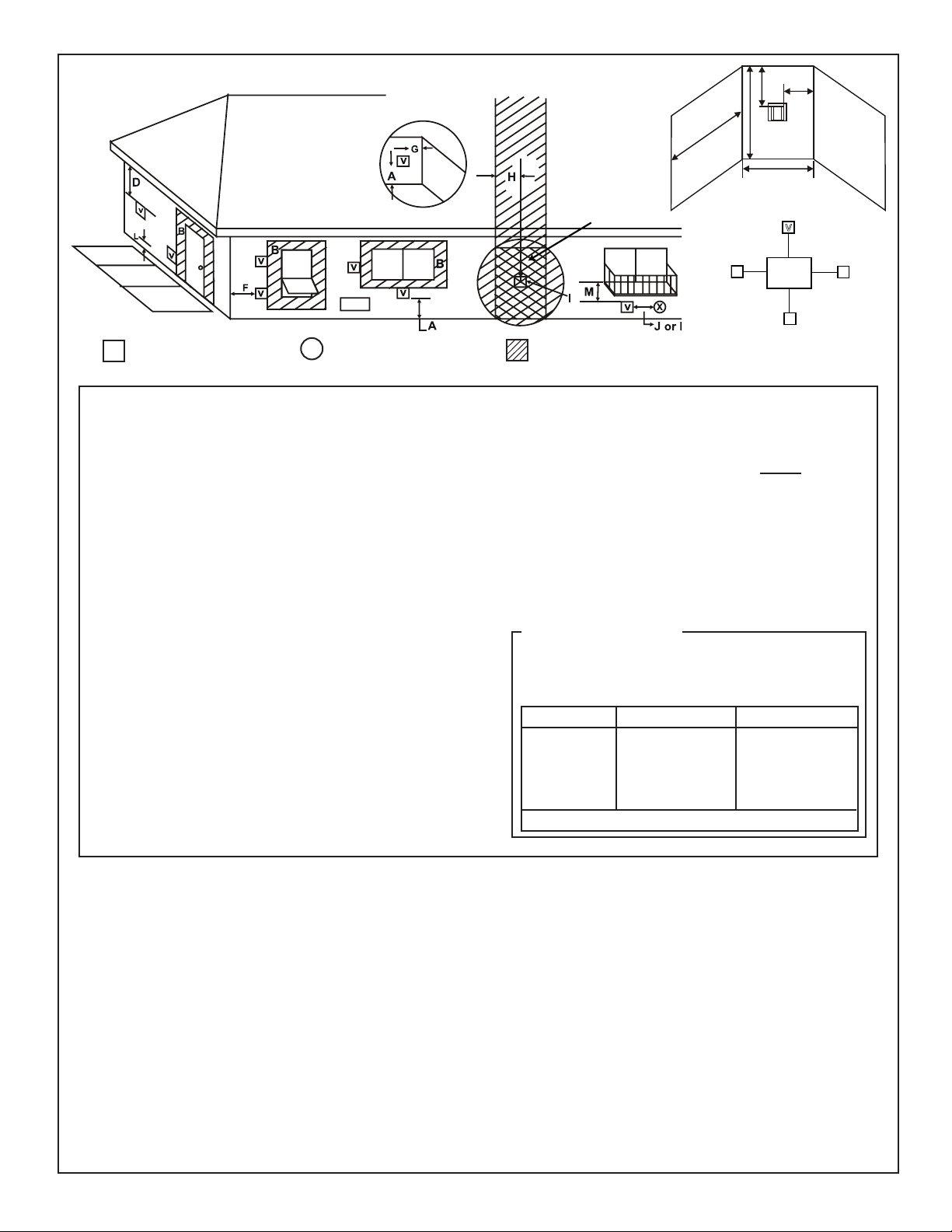

R

M

P

Q

(See Note 2)

N

= VENT TERMINAL

V

X

= AIR SUPPLY INLET

A = 31 cm ....................clearances above grade, veranda,

(See Note 1)

porch, deck or balcony

B = 31 cm ....................clearances to window or door

that may be opened, or to permanently closed window. (Glass)

D* = 31 cm ....................vertical clearance to unventilated

soffi t or to ventilated soffi t located

above the terminal

76 cm .....................for vinyl clad soffi ts and below

electrical service

F = 23 cm ...................clearance to outside corner

G = 15 cm ....................clearance to inside corner

H = 91 cm ....................not to be installed above a gas

meter/regulator assembly within 90

cm horizontally from the center-line

of the regulator

I = 1.8 M .....................clearance to gas service regulator

vent outlet

J = 31 cm ......................clearance to non-mechanical

air supply inlet to building or the

combustion air inlet to any other

gas stove

See Notes 3 & 4

V

S

V

T

Electrical

Service

D*

V

S

V

= AREA WHERE TERMINAL IS NOT PERMITTED

K = 1.8 M .......................clearance to a mechanical

(powered) air supply inlet

L** = 2.1 M .......................clearance above paved

(See Note 1)

sidewalk or a paved driveway

located on public property

M*** = 46 cm ......................clearance under veranda, porch,

deck, balcony or overhang

1.1 M ......................vinyl

S = 15 cm .......................clearance from sides of elec-

(See Note 5)

trical service

T = 31 cm ........................clearance above electrical

(See Note 5)

service

Alcove Applications

N = 15 cm .....................non-vinyl sidewalls

31 cm .....................vinyl sidewalls

P = 2.4 M

Q

MIN

1 cap .91 M 2 x Q

2 caps 1.8 M 1 x Q

3 caps 2.7 M 2/3 x Q

4 caps 3.7 M 1/2 x Q

Q

= # termination caps x 3 R

MIN

= (2 / # termination caps) x Q

MAX

R

MAX

ACTUAL

ACTUAL

ACTUAL

ACTUAL

ACTUAL

** a fl ue shall not terminate directly above a sidewalk or paved driveway

which is located between two single family dwellings and serves both

dwellings.

*** only permitted if veranda, porch, deck or balcony is fully open on a

minimum of 2 sides beneath the fl oor, or meets Note 2.

NOTE 1: On private property where termination is less than 7 feet above

a sidewalk, driveway, deck, porch, veranda or balcony, use of a listed cap

shield is suggested. (See fl ue components page)

NOTE 2: Termination in an alcove space (spaces open only on one side

and with an overhang) are permitted with the dimensions specifi ed for vinyl

or non-vinyl siding and soffi ts. 1. There must be 2.7M minimum between

termination caps. 2. All mechanical air intakes within 3M of a termination

cap must be a minimum of 2.7M below the termination cap. 3. All gravity

air intakes within 2.7M of a termination cap must be a minimum of .31M

foot below the termination cap.

Figure 4.4 Minimum Clearances for Termination

NOTE 3: Local codes or regulations may require different

clearances.

NOTE 4: Termination caps may be hot. Consider their proximity to

doors or other traffi c areas.

NOTE 5: Location of the fl ue termination must not interfere with

access to the electrical service.

Heat & Glo assumes no responsibility for the improper performance

of the gas stove when the fl ueing system does not meet these

requirements.

9Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Page 10

5

Flue Information

A. Flue Components

These models are approved to use Simpson Dura-Vent or

Hearth & Home Technologies series pipes, components and

termination. Approved components are labeled for identifi ca-

tion. This pipe is tested and listed as an approved component of the stove.

DO NOT USE FIELD-FABRICATED FLUE COMPONENTS.

Refer to the flue manufacturer’s instructions.

This product is approved to be flued either horizontally,

through the side wall or vertically through t he roof. You may

flue through a Class A or masonr y chimney if an approved

adapter is used.

This gas stove is a balanced fl ue gas stove. All combus-

tion air must come directly from the outside of the building.

The fl ue pipe for this unit consists of an inner and an outer

pipe. The inner pipe carries the gas stove exhaust out of the

system, and the outer pipe brings fresh combustion air into

the gas stove.

• A round support box/wall thimble or heat shield is

required when the fl ueing passes through a combus-

tible wall.

• A support box or ceiling fi restop is required when the

fl ueing passes through a combustible ceiling.

• Roof fl ashing and a storm collar are required when fl ue-

ing passes through the roof.

• Follow instructions provided with the fl ueing for installa-

tion of these items.

B. Use of Elbows

CAUTION

ALL fl ue confi guration specifi cations MUST be followed.

• This product is tested and listed to these

specifi cations.

• Appliance performance will suffer if specifi cations are

not followed.

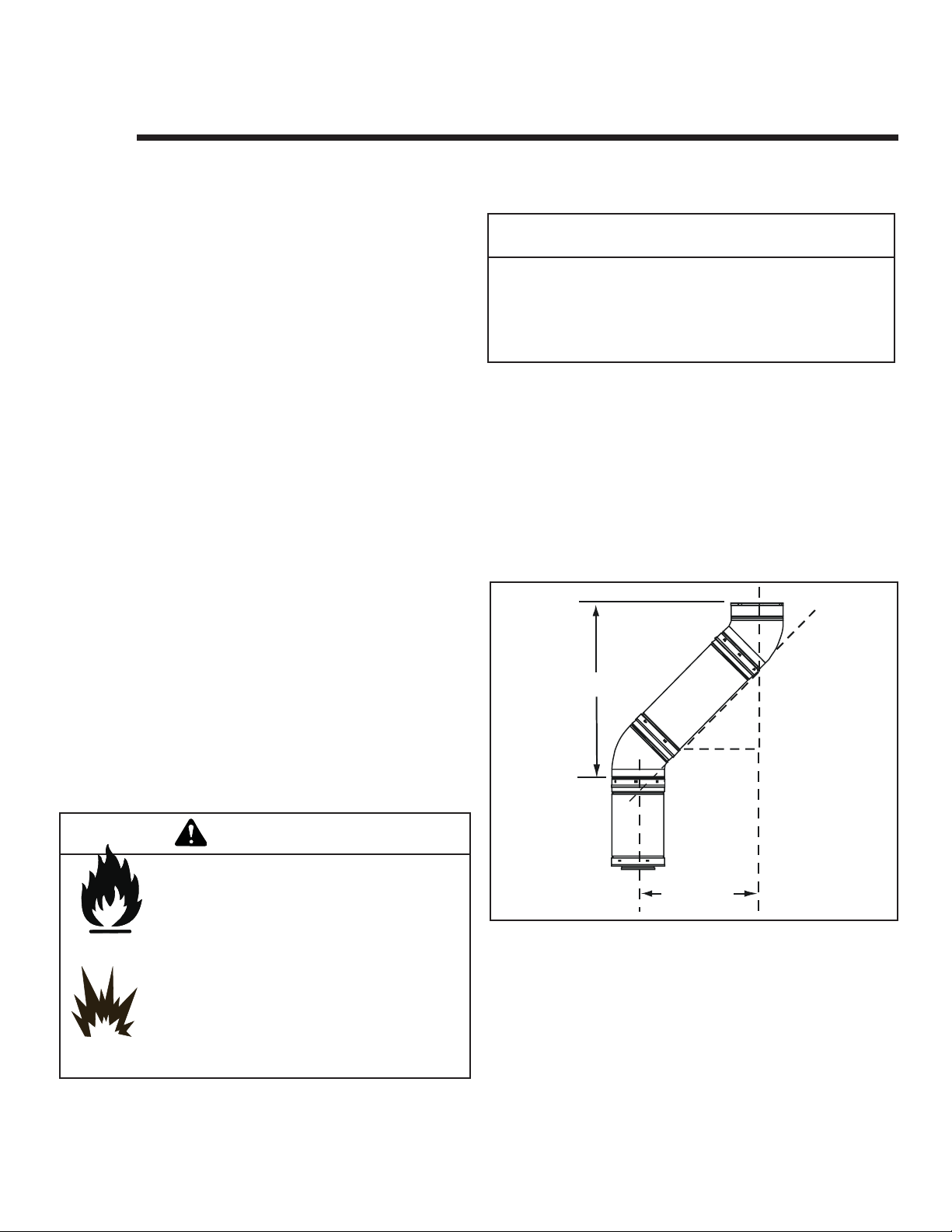

Diagonal runs have both vertical and horizontal flue aspects

when calculating the effects. Use the rise for the vertical

aspect and the run for the horizontal aspect. (See Figure

5.1.)

Two 45° elbows may be used in place of one 90° elbow. On

45° runs, one foot of diagonal is equal to 21.6 cm horizontal run and 21.6 cm vertical run. A length of straight pipe is

allowed between two elbows. (See Figure 5.1.)

Vertical

30.5 cm

21.6 cm

21.6 cm

WARNING

Fire Hazard.

Explosion Risk.

Asphyxiation Risk.

Do NOT connect this gas gas stove to a chimney

fl ue serving a separate solid-fuel or gas burning

gas stove.

• Flue this gas stove directly outside.

• Use separate fl ue system for this gas stove.

May impair safe operation of this gas stove or

other gas stoves connected to the fl ue.

10 Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Figure 5.1

C. Measuring Standards

Vertical and horizontal measurements were made using the

following standards.

• Pipe measurements are from center line to center line.

• Horizontal terminations are measured to the outside of

the mounting surface (fl ange of termination cap). See

Figure 4.1 on page 8.

• Horizontal pipe should be installed level with no rise.

Horizontal

Page 11

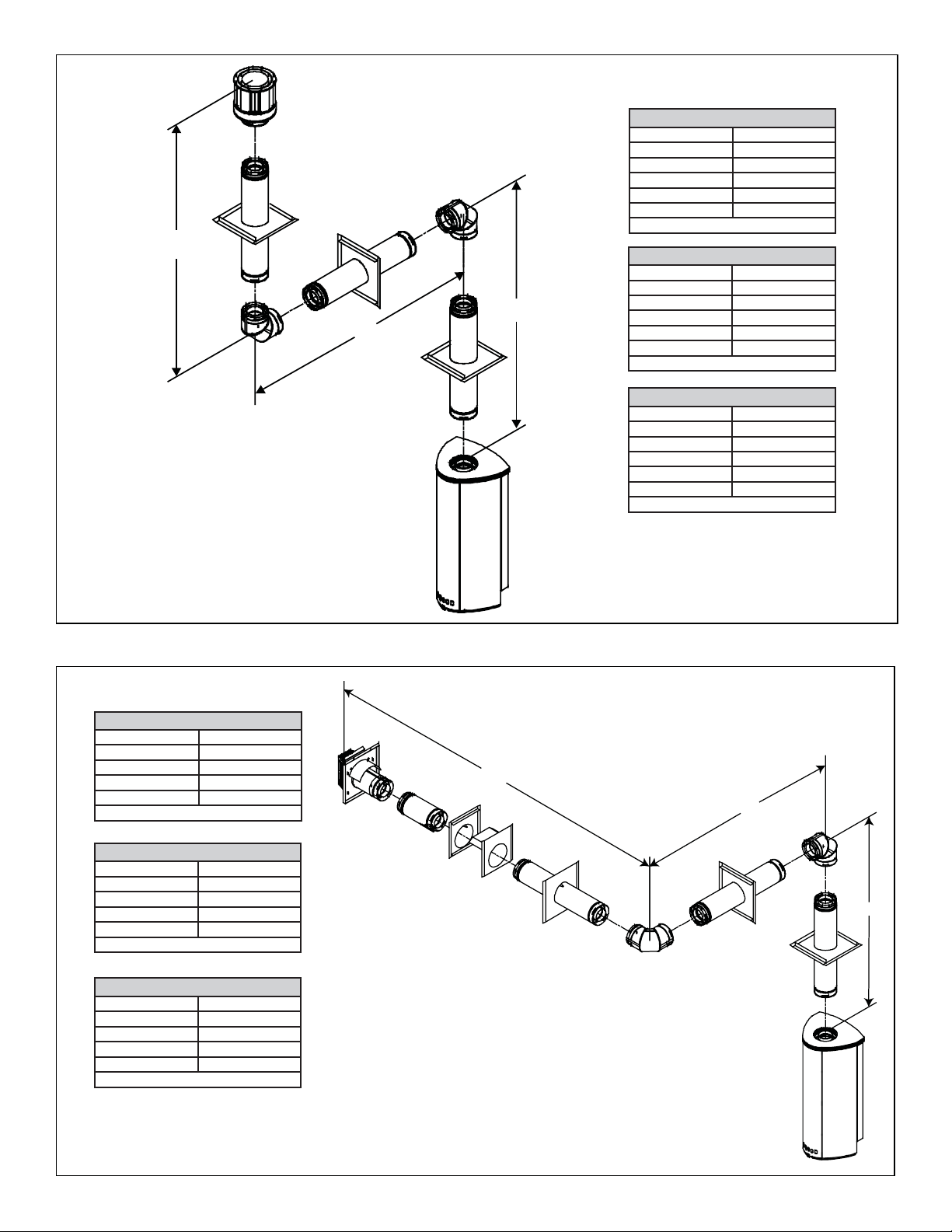

D. Flueing Diagrams

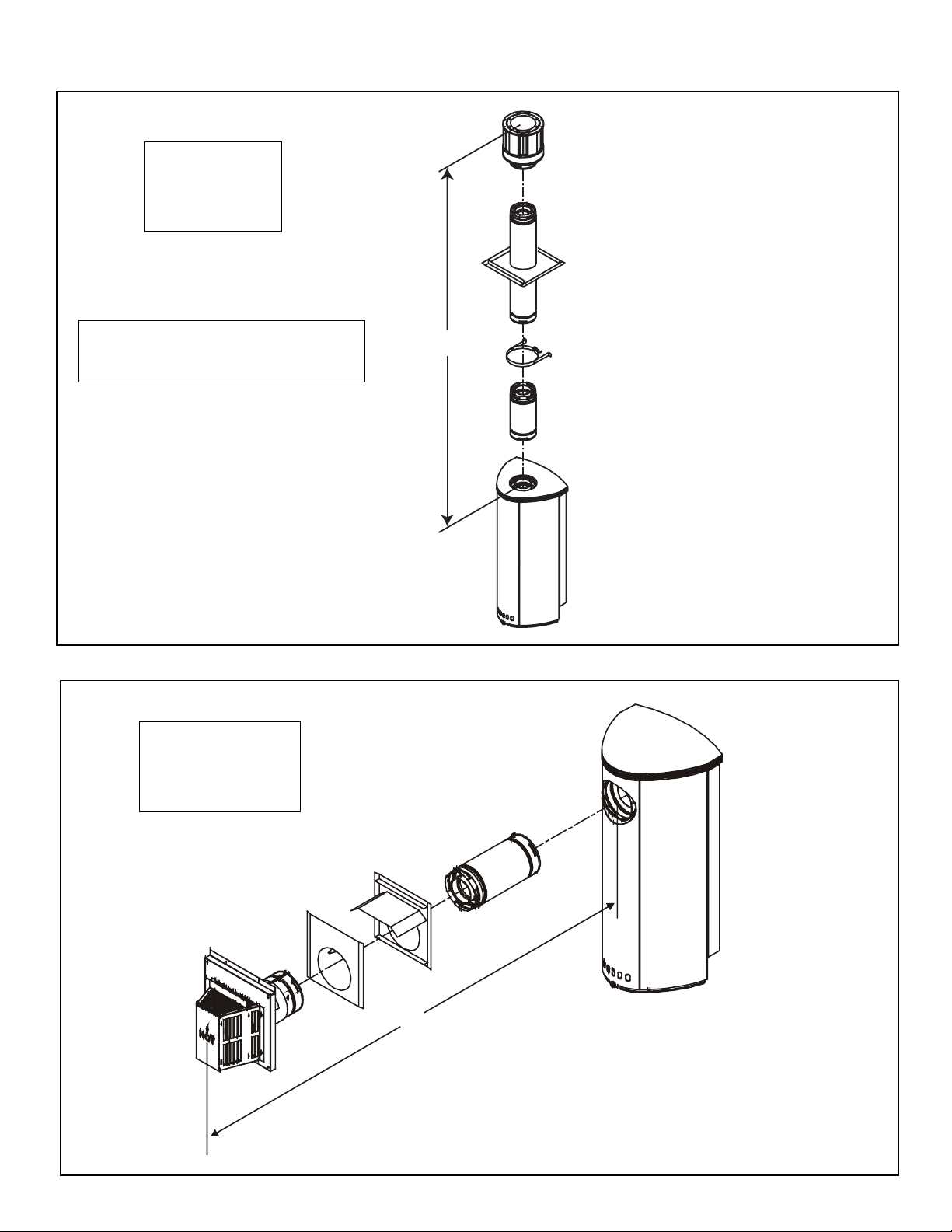

STRAIGHT UP

VERTICAL FLUE

V

11.8M Maximum

For Natural, Propane and Butane Gases.

Note: For this type of installation, the vertical

fl ue restrictor must be added. See section H

for instructions.

Figure 5.2

STRAIGHT OUT

HORIZONTAL FLUE

H

61cm Maximum

V

For Natural, Propane and Butane Gases.

Figure 5.3

H

11Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Page 12

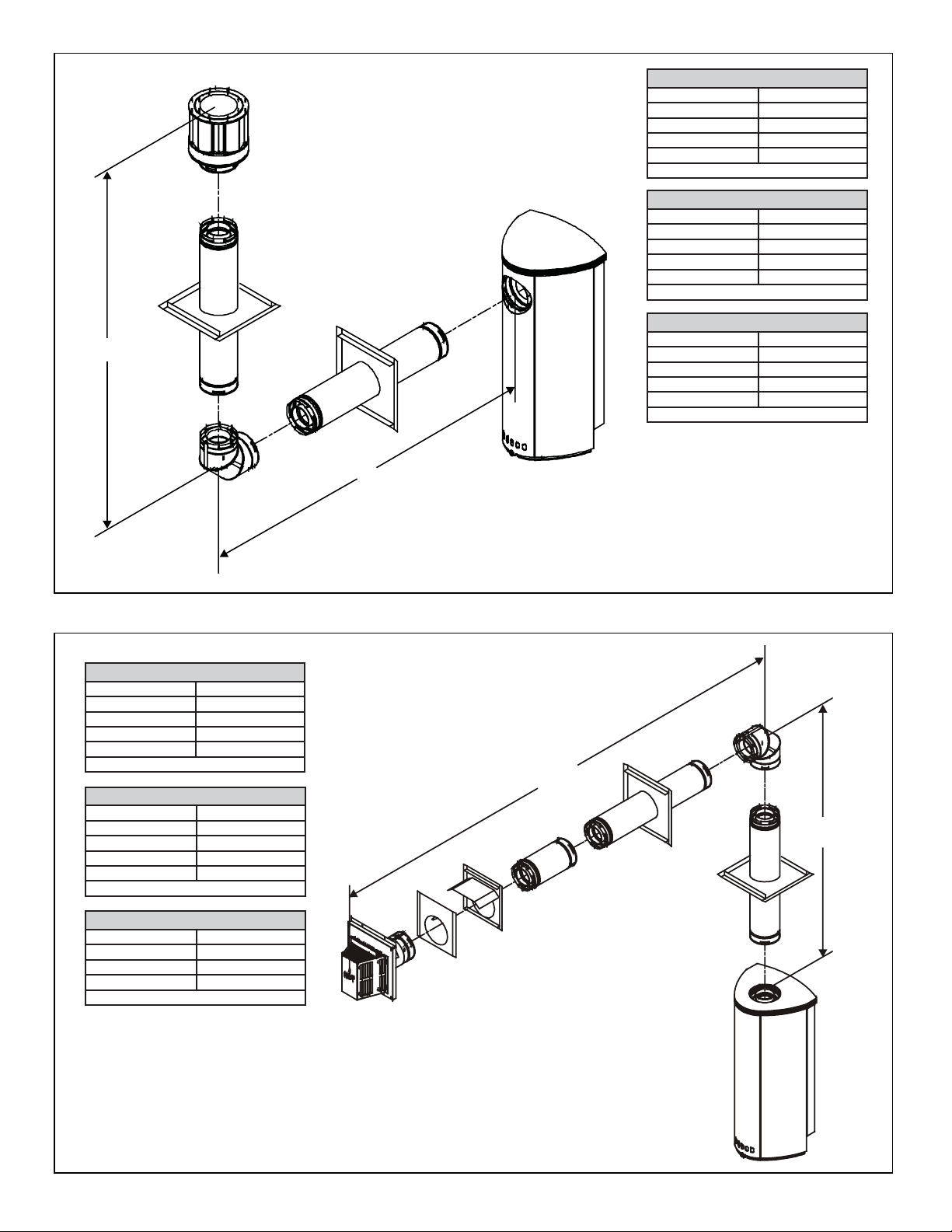

Natural Gas • One 900 Elbow System

V Minimum H Maximum

46 cm 1.3 M

92 cm 2.7 M

1.4 M 4.1 M

1.8 M 5.0 M

V+H = Max 11.6 M H Max = 5.0 M

Propane • One 900 Elbow System

V Minimum H Maximum

46 cm 92 cm

92 cm 1.8 M

1.4 M 2.8 M

1.8 M 3.6 M

V+H = Max 11.6 M H Max = 3.6 M

Butane • One 900 Elbow System

V

H

V Minimum H Maximum

46 cm 46 cm

92 cm 92 cm

1.4 M 1.4 M

1.8 M 1.8 M

V+H = Max 10 M H Max = 1.8 M

Figure 5.4

Natural Gas • One 900 Elbow System

V Minimum H Maximum

46 cm 1.3 M

92 cm 2.7 M

1.4 M 4.1M

1.8 M 5.0 M

V+H = Max 11 M H Max = 5.0 M

Propane • One 900 Elbow System

V Minimum H Maximum

46 cm 92 cm

92 cm 1.8 M

1.4 M 2.8 M

1.8 M 3.6 M

V+H = Max 11 M H Max = 3.6 M

Butane • One 900 Elbow System

V Minimum H Maximum

1.22 M 92 cm

1.4 M 1.4 M

1.8 M 1.8 M

V+H = Max 10 M H Max = 1.8 M

H

V

Figure 5.5

12 Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Page 13

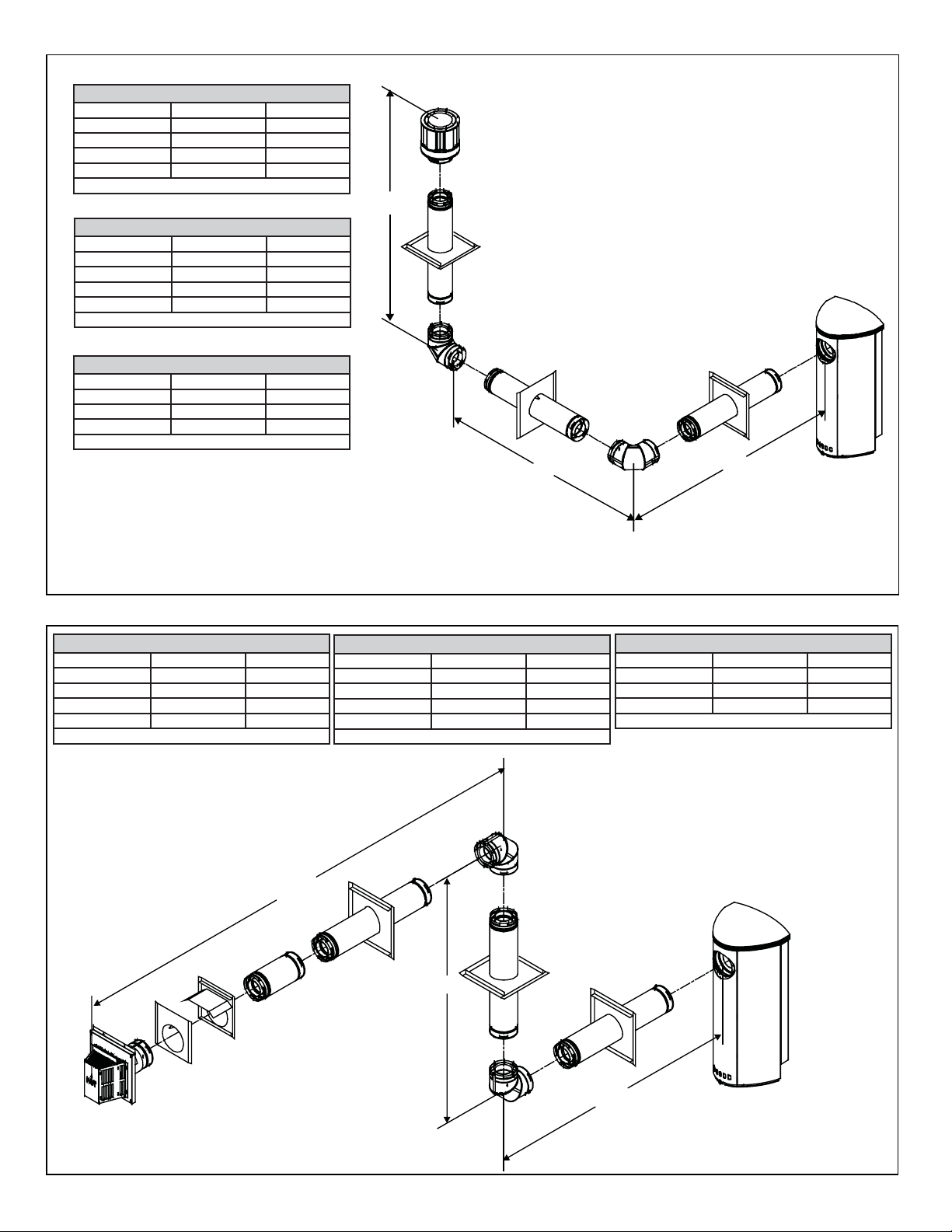

Natural Gas • Two 900 Elbows System

V Min. H1 Max. H1 + H2 Max.

46 cm 55 cm 1.1 M

92 cm 1.1 M 2.2 M

1.4 M 1.7 M 3.5 M

1.8 M 2.2 M 4.5 M

V+H1+H2 = Max 11.0M H1 Max = 2.2M H1+H2 = Max 4.5M

Propane • Two 900 Elbows System

V Min. H1 Max. H1 + H2 Max.

46 cm 39 cm 69 cm

92 cm 75 cm 1.3 M

1.4 M 1.1 M 2.1 M

1.8 M 1.5 M 2.7 M

V+H1+H2 = Max 10.6M H1 Max = 1.5M H1+H2 = Max 2.7M

Butane • Two 900 Elbows System

V Min. H1 Max. H1 + H2 Max.

1.22 M 48 cm 61 cm

1.4 M .5 M .7 M

1.8 M .7 M .9 M

V+H1+H2 = Max 10M H1 Max = .7M H1+H2 = Max .9M

V

H2

H1

Figure 5.6

Natural Gas • Two 900 Elbows System

V Min. H1 Max. H1 + H2 Max.

46 cm 55 cm 1.1 M

92 cm 1.1 M 2.3 M

1.4 M 1.7 M 3.5 M

1.8 M 2.2 M 4.5 M

V+H1+H2 = Max 10M H1 Max = 2.2M H1+H2 = Max 4.5M

H2

Propane • Two 900 Elbows System

V Min. H1 Max. H1 + H2 Max.

46 cm 39 cm 69 cm

92 cm 75 cm 1.3 M

1.4 M 1.1 M 2.1 M

1.8 M 1.5 M 2.7 M

V+H1+H2 = Max 10M H1 Max = 1.5M H1+H2 = Max 2.7M

V

Butane • Two 900 Elbows System

V Min. H1 Max. H1 + H2 Max.

1.22 M 48 cm 61 cm

1.4 M .5 M .7 M

1.8 M .7 M .9 M

V+H1+H2 = Max 10M H1 Max = .7 H1+H2 = Max .9M

Figure 5.7

H1

13Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Page 14

V

Natural Gas • Two 900 Elbows System

V1 Min. H Max.

31 cm 93 cm

61 cm 1.8 M

91 cm 2.7 M

1.2 M 3.6 M

1.5 M 4.5 M

V1+V2+H = Max 11.4M H Max = 4.5M

2

V1

H

Propane • Two 900 Elbows System

V1 Min. H Max.

31 cm 62 cm

61 cm 1.2 M

91 cm 1.8 M

1.2 M 2.4 M

1.5 M 3.0 M

V1+V2+H = Max 11.4M H Max = 3.0M

Butane • Two 900 Elbows System

V1 Min. H Max.

31 cm 31 cm

61 cm 61 cm

92 cm 92 cm

1.2 M 1.2 M

1.5 M 1.5 M

V1+V2+H = Max 10 M H Max = 1.0 M

Figure 5.8

Natural Gas • Two 900 Elbows System

V Min. H1+H2 Max.

61 cm 1.6 M

91 cm 2.4 M

1.2 M 3.2 M

1.5 M 4.0 M

V+H1+H2 = Max 11.4M H1+H2 = Max 4.0M

Propane • Two 900 Elbows System

V Min. H1+H2 Max.

61 cm 1.0 M

91 cm 1.5 M

1.2 M 2.0 M

1.5 M 2.6 M

V+H1+H2 = Max 11.4M H1+H2 = Max 2.6M

Butane • Two 900 Elbows System

V1 Min. H1+H2 Max.

61 cm 42 cm

92 cm 64 cm

1.2 M .8 M

1.5 M 1.0 M

V+H1+H2 = Max 10 M H1+H2 = Max 1.5 M

H2

H1

V

Figure 5.9

14 Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Page 15

V

Natural Gas • Three 900 Elbows System

V1 Min. H1 Max. H1 + H2 Max.

46 cm 55 cm 1.1 M

92 cm 1.1 M 2.3 M

1.4 M 1.7 M 3.5 M

1.8 M 2.2 M 4.5 M

V1+V2+H1+H2=Max11M H1 Max=2.2M H1+H2=Max 4.5M

Propane • Three 900 Elbows System

V1 Min. H1 Max. H1 + H2 Max.

46 cm 34 cm 69 cm

92 cm 65 cm 1.3 M

1.4 M 1.0 M 2.1 M

1.8 M 1.8 M 2.7 M

V1+V2+H1+H2=Max 11M H1 Max=1.8M H1+H2=Max 2.7M

2

Butane • Three 900 Elbows System

V1 Min. H1 Max. H1 + H2 Max.

46 cm 14 cm 32 cm

92 cm 23 cm 64 cm

1.4 M 35 cm .8 M

1.8 M 45 cm 1.0 M

V1+V2+H1+H2=Max 10M H1 Max=45cm H1+H2=Max 1.0M

H2

H1

V1

Figure 5.10

Natural Gas • Three 900 Elbows System

V1 Min. H1 Max. H1 + H2 Max.

46 cm 55 cm 1.0 M

92 cm 1.1 M 2.0 M

1.4 M 1.7 M 3.0 M

1.8 M 2.2 M 3.9 M

V1+V2+H1+H2=Max 11M H1 Max=2.2M H1+H2=Max 3.9M

V2

H2

V1

Propane • Three 900 Elbows System

V1 Min. H1 Max. H1 + H2 Max.

46 cm 34 cm 55 cm

92 cm 65 cm 1.1 M

1.4 M 1.0 M 1.6 M

1.8 M 1.8 M 2.1 M

V1+V2+H1+H2=Max 10M H1 Max=1.8M H1+H2=Max 2.1M

Butane • Three 900 Elbows System

V1 Min. H1 Max. H1 + H2 Max.

64 cm 16 cm 32 cm

92 cm 23 cm 36 cm

1.4 M 35 cm .7 M

1.8 M 45 cm .9 M

V1+V2+H1+H2=Max 10M H1 Max=45 cm H1+H2=Max .9M

Figure 5.11

H1

15Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Page 16

E. Horizontal Termination

C

90 DEGREE

ELBOW

PIPE LENGTH

WALL THIMBLE

COVER

PIPE LENGTH

WALL THIMBLE

TERMINATION CAP

Note: Female ends of balanced flue pipe/elbows are

designed to slide straight onto the male ends of adjacent

pipes by orienting the pipe indentations so they match and

slide into the entry slots on the male ends, see Figure 5.13.

Push the pipe sections completely together, then twist-lock

one section clockwise approximately one-quarter turn, until

the two sections are fully locked. The female locking lugs

may not be visible from the outside. They may be located by

examining the inside of the female ends.

Female Locking Lugs

Male Locking Lugs

Figure 5.13

WARNING

Fire Risk.

Explosion Risk.

Combustion Fume Risk.

Use fl ue run supports per installation instructions.

Connect fl ue sections per installation instructions.

• Maintain all clearances to combustibles.

• Do NOT allow fl ue to sag below connection

point to gas stove.

Improper support may allow fl ue to sag or separate.

ENTER

LINE

Figure 5.12

6 in.

4 in.

CENTER LINE

Step 1.

Determine the desired location of the gas stove. Check to

ensure that wall studs or roof rafters are not in the way when

the flue system is being planned. If this is the case, you may

want to adjust the location of the gas stove.

Step 3.

For installations using a round support box/wall thimble

(check pipe manufacturer's instructions), mark the wall for

a 25.4 cm x 25.4 cm square hole. The center of the square

hole should line up with the center line of the horizontal

WARNING

Fire Hazard.

Exhaust Fume Risk.

• Ensure fl ue components are locked together correctly.

• Pipe may separate if not properly joined.

Impaired Performance of Appliance.

pipe, as shown in Figure 5.12. Cut and frame the hole in

the exterior wall where the flue will be terminated. If the wall

being penetrated is constructed of noncombustible material,

i.e. masonry block or concrete, a 17.8 cm diameter hole is

acceptable.

Step 4.

Position the horizontal termination cap in the center of the

Step 2.

Balanced flue pipe is designed with a locking connection. To

connect the flue system to the gas stove flue outlet, a twistlock adapter is built into the gas stove at the factory. Wall

thickness may vary. Remember to include wall thickness in

25.4cm x 25.4cm square hole and run a bead of non-hardening mastic around its outside edges, to make a seal between

it and the wall. Attach termination cap to the exterior wall

with the four wood screws provided. The arrow on the flue

cap should be pointing up.

minimum clearances when figuring flueing lengths for your

installation needs.

16 Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Page 17

F. Slim Line Wall Thimble

BEFORE YOU BEGIN:

Review the fl ueing confi gurations in Figures A, B and C on

the next page.

1. Assembling Slim Line Trim Ring and Heat Shield

Figure 5.14

Lay the trim ring on fl at surface and bend up the six welded

brackets into a 90 degree position. The brackets along the

outer edge of the ring are for locating the ring in the center

of the hole.

Figure 5.16

Attach the heat shield to the trim ring with the four screws

provided. Screws go through the heat shield and into the

brackets on the trim ring.

2. Installing Slim Line Trim Ring and Heat Shield

Measure from the fl oor to the center of the fl ue pipe. Cut

out a 25.4 cm hole in the wall. Hold the trim ring/heat shield

assembly in place and put a mark on the shield with a black

marker where it protrudes through the exterior wall. Figure

A on the next page.

Use that mark as a guide to trim off excess heat shield with

a pair of sheet metal shears.

Figure 5.15

The heat shield is shipped fl at and must be hand bent into a

half circle before attaching it to the trim ring. Bend the heat

shield as shown.

CAUTION

Sharp Edges

• Wear protective gloves

and safety glasses during

installation.

Figure 5.17

When installing the trim ring/heat shield assembly make

sure the trim ring is centered in the hole and that the shield

is above the pipe. There must be a minimum of 2 cm minimum clearance maintained to combustibles from the top of

the heat shield.

Ensure that framing on the inside of the wall is a minimum

inner framing diameter of 25.4 cm x 25.4 cm.

The four trim ring mounting screws provided should be

replaced with appropriate fasteners for stucco, brick, concrete, or other types of sidings.

17Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Page 18

FIG. A 90 DEGREE ELBOW

C

Place mark where protrudes through

exterior wall to cut off excess.

O

90 ELBOW

CENTER

LINE

USE HEAT SHIELD / WALL THIMBLE

PIPE

LENGTH

TRIM

RING

PIPE LENGTH

FIG. B MINIMUM CLEARANCE

INTERIOR WALL

51mm clearance

from rear of stove

ENTER LINE

Figure 5.18

MINIMUM OF 152 mm

OF PIPE THROUGH THE WALL

WALL THIMBLE

HEAT SHIELD OVER

TOP HALF OF PIPE

TRIM RING

18 Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Page 19

G. Vertical Termination

1. Balance Flue Pipe

STORM COLLAR

VERTICAL

TERMINATION CAP

FLASHING

FIRESTOP

SUPPORT

BOX

PIPE LENGTH

On vertical terminations use only Part #SLK-991DA

Figure 5.19

Step 1.

Check the installation instructions for required 2.5 cm clearances (air space) to combustibles when passing through

ceilings, walls, roofs, enclosures, attic rafters, or other

nearby combustible surfaces. (See Figure 5.14). Check the

instructions for maximum vertical rise of the flueing system,

and any maximum horizontal offset limitations. All offsets

must fall within the set parameters of the flue charts (Figure

5.2) located on pages 11-15.

11.8M

MAXIMUM

Figure 5.20

Step 2.

Set the gas gas stove in its desired location. Drop a plumb

bob down from the ceiling to the position of the gas stove

flue exit, and mark the location where the flue will penetrate

the ceiling. Drill a small hole at this point. Next, drop a plumb

bob from the roof to the hole previously drilled in the ceiling,

and mark the spot where the flue will penetrate the roof.

Determine if ceiling joists, roof rafters, or other framing will

obstruct the flueing system. You may wish to relocate the

gas stove, or to offset, as shown in Figure 5.21 to avoid

cutting load bearing members.

NOTE: Maximum vertical rise allowable is 11.8 M, Figure

5.2.

WARNING

Fire Risk.

Explosion Risk.

Maintain fl ue clearance to combustibles as speci-

fi ed.

• Do not pack air space with insulation or other

materials.

Failure to keep insulation or other materials away

from fl ue pipe may cause fi re.

METAL STRAP

CONNECTED TO

WALL STRAP

WALL

STRAP

TWO 45 DEGREE

ELBOWS

Figure 5.21

19Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Page 20

Step 3.

To install the round support box/wall thimble cover in a flat

ceiling, cut a 25.4cm square hole in the ceiling, centered

on the hole drilled in Step 2. Frame the hole as shown in

Figure 5.22.

CEILING JOISTS

FRAMING

SHINGLES OVERLAP ON

TOP EDGE OF FLASHING

ROUND CEILING

SUPPORT BOX/WALL

THIMBLE COVER

4 cm LONG

WOOD SCREWS

Figure 5.22

Step 4.

Assemble the desired lengths of pipe and elbows necessary

to reach from the gas stove up through the round support

box. Ensure that all pipe and elbow connections are in their

fully twist-locked position. Assemble as instructed.

Step 5.

Cut a hole in the roof centered on the small drill hole placed in

the roof in Step 2. The hole should be of sufficient size to meet

the minimum requirements for clearance to combustibles, as

specified. Continue to assemble lengths of pipe and elbows

necessary to reach from the ceiling support box/wall thimble

up through the roof line. Galvanized pipe and elbows may

be utilized in the attic, as well as above the roofline. The

galvanized finish is desirable above the roofline, due to its

higher corrosion resistance (compared to black pipe).

CAP AND STORM COLLAR NOT S HOWN FOR CLARITY

Figure 5.23

Step 7.

Continue to assemble pipe sections until the height of the

flue (before adding the termination cap) meets the minimum

local code requirements. Note that for steep roof pitches, the

flue height must be increased. See Roof Pitch Table (Figure

4.3). In high wind conditions, nearby trees adjoining rooflines,

steep pitched roofs, and other similar factors can result in

poor draft, or down drafting. In these cases increasing the

flue height or switching to the high wind termination cap may

solve this problem.

Step 8.

Slip the storm collar over the pipe, and push it down to the

top of the flashing (Figure 5.24). Use non-hardening sealant

above and below the joint between the storm collar and the

pipe.

SECURE FLASHING WITH

NON-HARDENING SEALANT

AND ROOFING NAILS

NOTE:

(1) If an offset is necessary in the attic to avoid obstructions,

it is important to support the flue pipe every 91.4cm to

avoid excessive stress on the elbows, and possible

separation. Wall straps are available for this purpose,

Figure 5.10, page 15.

(2) Whenever possible, use 45° elbows, instead of 90°

elbows. The 45° elbow offers less restriction to the flow

of flue gases and intake air.

Step 6.

Slip the flashing over the pipe section(s) protruding through

the roof. Secure the base of the flashing to the roof with

roofing nails. Ensure the roofing material overlaps the top

edge of the flashing as shown in Figure 5.23. Verify that the

chimney is the required height above the roof. See roof pitch

table, Figure 4.3.

20 Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Figure 5.24

Page 21

Step 9.

Twist-lock the flue cap and seal.

Note: For multi-story vertical installations, a ceiling firestop

is required at the second floor, and any subsequent floors

(Figure 5.25). The opening should be framed to 25.4cm x

25.4cm inside dimensions, in the same manner as shown in

Figure 5.22.

NAILS

CEILING FIRESTOP

MIN. 25.4 cm

CLEARANCE

MIN. 25.4 cm

CLEARANCE

MIN. 25.4 cm

CLEARANCE

H. Vertical Flue Restrictor

If the fireplace installation requires a vertical flue off the

top of the unit with no horizontal flue or elbows, the vertical

flue restrictor must be added. Reinstall heat shield when

completed. See Figure 4.25.

FLUE

RESTRICTOR

PLATE

HEAT SHIELD

Figure 5.26

Figure 5.25

MIN. 25.4 cm

CLEARANCE

WARNING

Fire Risk.

Explosion Risk.

•

Any occupied areas above the first floor, including

closets and storage spaces, which the vertical flue

passed through must be enclosed. The enclosure

may be framed and sheetrocked with standard

construction materials; however, refer to these

installation instructions for the minimum allowable

clearance between the outside of the flue pipe and

the combustible surfaces of the enclosure. Do not

fill any of the required air space with insulation.

21Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Page 22

6

Gas Information

A. Gas Pressure Requirements

Pressure requirements for VRTIKL-CE Stoves are shown in

Table 1 below.

Two taps are provided on the right hand side of the gas control

for a test gauge connection to measure the inlet and outlet

pressures. See Section 10: Maintaining and Servicing the

Appliance.

The stove and its individual shut-off valve must be disconnected

from the gas supply piping system during any pressure testing

of the system at test pressures in excess of 60 mbar.

If the stove must be isolated from the gas supply piping

system by closing an individual shut-off valve, it must be of

the handle-less type.

WARNING

Fire Risk

Explosion Risk

High pressure will damage valve.

• Disconnect gas supply piping BEFORE

pressure testing gas line at test pressures

above 60 mbar.

• Close the manual shutoff valve BEFORE

pressure testing gas line at test pressures

equal to or less than 60 mbar.

B. Gas Connection

Note: Have the gas supply line installed in accordance with

local building codes by a qualifi ed installer approved

and/or licensed as required by the locality.

Note: Before the fi rst fi ring of the stove, the gas supply

line should be purged of any trapped air.

Note: Consult local building regulations to properly size

the gas supply line leading to the (Rp 1/2 in.) hook-up

at the unit.

Incoming gas line should be piped into the valve compartment

and connected to the ISO 7-Rp 1/2 (BSP Rp 1/2 ) threaded

gas inlet connection on the manual shutoff valve.

Leak test all gas line points and the gas control valve prior to

and after starting the gas stove.

WARNING

CHECK FOR GAS LEAKS

Fire Risk

Explosion Risk

Asphyxiation Risk

• Check all fi ttings and connections.

• Do not use open fl ame.

• After the gas line installation is complete,

all connections must be tightened and

checked for leaks with a commercially

available, non-corrosive leak check

solution. Be sure to rinse off all leak check

solution following testing.

Fittings and connections may have loosened

during shipping and handling.

Table 1

Natural Gas

(G20)

Inlet Pressure 20mbar 37 or 50mbar 30 or 50mbar 25mbar

Manifold Pressure 4-8.4mbar 15.7-25mbar 15.7-25mbar 4-8.4mbar

3

Gas Rate .72

Max.Input (NETCV) 6.9 kW 6.6 kW 5.8 kW 5.5 kW

Burner Injector DMS 39 DMS 53 DMS 55 DMS 39

Pilot Injector 51 30 30 51

22 Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

m

/

h

.26

Propane

(G31)

3

m

/

h

.10

Butane

(G30)

3

m

/

h

Natural Gas

(G25)

.67 m3/

h

Page 23

Electrical Information

7

A. Ignition System Wiring

• This gas stove is equipped with an electronic ignition

system which operates on a 6 volt system.

• The batteries are located within the ignition module

which is located behind the glass door assembly . A wiring

diagram is shown in Figure 7.1.

• The battery pack requires four AA batteries (not included).

WARNING

Shock Risk

• Replace damaged wire with type 105° C rated wire.

• Wire must have high temperature insulation.

CAUTION

CAUTION

Battery polarity must be correct or module damage will

occur.

PILOT

IGNITION MODULE

6VDC

BATTERY PORT

(4 AA BATTERIES)

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and dangerous

operation. Verify proper operation after servicing.

FLAME SPARKER/

SENSOR

REMOTE

CONTROL

ANT.

VALVE

ON/OFF

WALL SWITCH

IGNITION

MODULE

(6V)

ON/OFF

SWITCH

Figure 7.1 Electronic Ignition Wiring Diagram

PILOT GAS LINE

CONNECTED TO

BACK OF VALVE

THERMOCOUPLE

BLOCK

(CONNECTED TO

BACK OF VALVE)

VALVE

23Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Page 24

8

ALLEN HEAD SCREWS

LEVELING

SCREWS

LAG BOLT

HOLE

Appliance Setup

A. Remove Shipping Materials

Remove shipping materials from inside or underneath the

fi rebox.

The gas line is shipped inside back panel. To access the gas

line remove the top plate from the gas stove. Remove and

retain the two Allen head screws that hold the back panel in

place. Replace panel when fi nished.

ALLEN HEAD SCREWS

Figure 8.1

C. Leveling and Bolting Down the Appliance

SECURING THE GAS STOVE

IS REQUIRED.

WARNING

Tipping Risk

• Install gas stove on a stable, level platform/

fl oor strong enough to support gas stove

without tipping.

• USE wood fl ooring, ceramic tile, brick hearth

or high pressure laminate fl ooring applied

directly over the sub-fl ooring material.

LEVELING

SCREWS

LAG BOLT

HOLE

B. Unbolting Appliance from the Pallet

The gas stove is bolted and screwed to the pallet for shipping. Use a 1/2 in. socket to remove the bolt in center of

bottom plate. Use a Phillips screwdriver to remove the two

screws in the front of the bottom plate and the two screws

holding the metal strap across the back of the gas stove.

Refer to Figure 8.2 for locations.

Figure 8.2

Figure 8.3

After unbolting the gas stove from the pallet, insert two 1/4

20 x 1-1/2 (or equivalent) counterscrews.

Using pliers, adjust the counterscrews to level the gas

stove.

24 Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Page 25

CLEARANCE

IINNER EXTENSION COLLAR

DV ADAPTER

ALLEN HEAD

SCREWS

HOLE

Figure 8.4

The manufacturer recommends securing the lag bolt from

the component bag in the center hole in the bottom plate

(clearance hole). This bolt will help to prevent tipping forward.

E. Top to Rear Flue Conversion

KIT CONTENTS: Top cover (without hole);

Back panel (with hole).

1. Remove the front door assembly by pulling bottom

of front away from gas stove and lifting it off of the

hooks on top of the gas stove. Set door aside.

ON TOP OF APPLIANCE:

2. Remove the top plate with hole and discard. (Figure 8.6)

Figure 8.5

Using pliers, adjust the counter screws to level the gas

stove.

D. Accessories

Install approved accessories per instructions included with

accessories. Refer to Section 12F for appropriate accessories.

WARNING

Shock or fi re risk.

Use ONLY optional accessories approved for

this gas stove.

• Using non-listed accessories voids

warranty.

• Using non-listed accessories may result in a

safety hazard.

• Only Hearth & Home T echnologies approved

accessories may be used safely.

Figure 8.6

3. Remove and retain the Allen head screws that hold

the solid back panel in place (Figure 8.8). Remove

and discard the solid back panel.

NNER EXTENSION COLLAR

DV ADAPTER

ALLEN HEAD

SCREWS

Figure 8.7

4. Remove the inner extension collar (Shown in Figure

8.7) and set aside.

5. Remove the four screws from the DV adapter collar

(Figure 8.7). Set aside DV adapter collar and

screws.

25Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Page 26

ON BACK OF APPLIANCE:

IINNER EXTENSION COLLAR

6. Remove the four screws from the cover plate on rear

of gas stove. Set cover plate aside. Retain screws.

(See Figure 8.8). Attach DV adapter collar in its

place. Install the inner extension collar.

NNER EXTENSION COLLAR

Figure 8.8

ON TOP OF APPLIANCE:

8. Install the new back panel (without hole) to the rear of

gas stove. Replace the Allen head screws removed

in Step 3 to hold the back panel in place.

9. Install the new top as shown in Figure 8.10.

Figure 8.10

7. Install the cover plate with gasket to the top of gas stove

with screws previously removed (Figure 8.9).

Figure 8.9

F. Installing the Baffl e

The baffl e is shipped wrapped, inside the fi rebox. Install

the baffl e with the embedded “T” side up, place it on top

of the brackets on the inside of the fi rebox, ensuring back

edge of baffl e makes contact with the back of the fi rebox.

Figure 8.11

26 Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Page 27

G. Positioning the Logs

While still breakable, the logs do not become fragile until

after the gas stove is burned and they have cured. After

curing, any handling must be done with care as breakage

can easily occur.

PLEASE NOTE: Logs have been designed to work specifically with the burner of this gas stove. Exact placement will ensure proper operation of your gas stove.

Figure 8.12

Figure 8.14

Locate log #2 over the pin in log #1 and into notch in log #1.

Lean the log back toward the left corner of the firebox.

H. Placing Mineral Wool

WARNING

Explosion Risk.

• Follow ember placement instructions in

manual.

• Do NOT place embers directly over

burner ports.

• Replace ember material annually.

Improperly placed embers interferes with proper burner

operation.

Figure 8.13

Place log #1 into the cradle in the burner. Lean the log back

towards right corner of firebox.

Figure 8.17

Apply 1.5 cm size pieces sparingly along ports as shown in

Figure 8.17. Do not block ports.

27Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Page 28

I. Front Door Glass Assembly Installation

J. Inner Glass Door Assembly Replacement

Remove the front door assembly by pulling bottom of front

away from gas stove and lifting it off of the hooks on top of

the gas stove (see Figure 8.15).

Refer to Figure 8.16: Position the four fl at 6 mm spacer

washers on the front door so that the four mounting screws

pass through them. Position the glass over the front door.

Install the four protective barrels into the glass and the four

nylon washers on top of the glass.

From inside the door front, pass the screws through to the

outside and thread on the caps until tight.

Turn the gas stove OFF and let it cool down before replacing

the inner glass door assembly.

With the front door assembly removed from the gas stove,

remove the inner glass door assembly by disengaging the

spring-loaded latches at the bottom of the gas stove and

lifting off of the two spring-loaded latches at the top of the

gas stove.

Replace with a new inner glass door assembly.

Figure 8.15

Cap and Barrel Fastener System

Nylon washer on back

and front of glassScrew

Protective barrel sleeve

through hole in the glass

Finishing Cap

Figure 8.17 Complete Assembly

CAUTION

Handle glass assembly with care.

• Inspect the gasket to ensure it is undamaged.

• Inspect the glass for cracks, chips or

scratches.

• Do NOT strike, slam or scratch glass.

• Do NOT operate gas stove with glass door

removed, cracked, broken or scratched.

• Replace glass assembly as a complete

assembly.

Back side of

front door

Figure 8.16

28 Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Page 29

9

Operating Instructions

A. Before Lighting Appliance

Read this entire manual prior to using the gas stove. Failure

to follow the instructions may result in property damage,

bodily injury, or even death.

• Remove all shipping materials from inside and/or underneath the fi rebox.

• Review proper placement of logs, mineral wool.

• Check the wiring.

• Check the baffl e adjustment.

• Ensure that there are no gas leaks.

• Ensure that the glass is sealed and in the proper position.

• Ensure that the fl ow of combustion and ventilation air is

not obstructed (front grilles and fl ue caps).

WARNING

Glass door must be in place when gas stove is

operating.

Risk of:

• Combustion Fumes

• Fire

Do NOT operate gas stove with glass door

removed.

• Open viewing glass for servicing only.

WARNING

HOT SURFACES!

Glass and other surfaces are hot during

operation AND cool down.

Hot glass will cause burns.

• DO NOT touch glass until it is cooled

• NEVER allow children to touch glass

• Keep children away

• CAREFULLY SUPERVISE children in same room as

fi replace.

• Alert children and adults to hazards of high temperatures.

High temperatures may ignite clothing or other

fl ammable materials.

• Keep clothing, furniture, draperies and other fl ammable

materials away.

This appliance has been supplied with an integral barrier

to prevent direct contact with the fi xed glass panel. DO

NOT operate the appliance with the barrier removed.

Contact your dealer if the barrier is not present or help is

needed to properly install one.

WARNING

Improper installation, adjustment, alteration, service or

maintenance can cause injury or property damage. Refer to

the owner’s information manual provided with this gas stove.

For assistance or additional information consult a qualifi ed

installer, service agency or the gas supplier.

Î

• Glass door MUST be in place and sealed before

operating gas stove.

• Only use glass door certifi ed for use with gas stove.

• Glass replacement should be done by qualifi ed

technician.

WARNING

Do NOT use this gas stove if any part has been under water.

Immediately call a qualifi ed service technician to inspect the

gas stove and to replace any part of the control system and

any gas control which has been under water.

29Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Page 30

B. Lighting the Appliance

Electronic Ignition

FOR YOUR SAFETY

READ BEFORE LIGHTING

WARNING: If you do not follow these instructions

exactly, a fi re or explosion may result causing property

damage, personal injury or loss of life.

A. This gas stove is equipped with

an electronic pilot ignition device

which automatically lights the

burner. Do not try to light the

burner by hand.

B. BEFORE LIGHTING, smell all

around the gas stove area for gas.

Be sure to smell next to the fl oor

because some gas is heavier than

air and will settle on the fl oor.

WHA T TO DO IF YOU SMELL GAS

• Do not try to light any gas stove.

• Do not touch any electric switch;

WARNING:

DO NOT CONNECT 240 VAC

TO THE CONTROL VALVE.

Improper installation, adjustment,

alteration, service or maintenance

can cause injury or property damage. Refer to the owner’s information manual provided with this gas

stove.

This gas stove needs fresh air for

safe operation and must be installed

so there are provisions for adequate

combustion and ventilation air.

If not installed, operated, and maintained in accordance with the manufacturer’s instructions, this product

could expose you to substances in

fuel or fuel combustion.

Keep burner and control compartment clean. See installation and

operating instructions accompanying

gas stove.

do not use any phone in your building.

• Immediately call your gas supplier

from a neighbor’s phone. Follow

the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fi re department.

C. Do not use this gas stove if any part

has been under water. Immediately

call a qualifi ed service technician

to inspect the gas stove and to

replace any part of the control

system and any gas control which

has been under water.

CAUTION:

Hot while in operation. Do not touch.

Keep children, clothing, furniture,

gasoline and other liquids having

fl ammable vapors away.

Do not operate the gas stove with

panel(s) removed, cracked or broken. Replacement of the panel(s)

should be done by a licensed or

qualifi ed service person.

NOT FOR USE

WITH SOLID FUEL

For use with natural, propane and

butane gases.

LIGHTING

INSTRUCTIONS

1. This gas stove is equipped with an

ignition device which automatically

lights the burner. Do not try to light

the burner by hand.

GAS

VALVE

2. Wait fi ve (5) minutes to clear out any

gas. Then smell for gas, including

near the fl oor. If you smell gas, STOP!

Follow “B” in the Safety Information

located on the left side of this label. If

you don’t smell gas, go to next step.

3. To light the burner, simultaneously

press the star and up arrow buttons on the remote control until a

short acoustic signal confi rms the start

sequence has begun.

4. If the gas stove will not operate, check

the batteries then follow the instructions “To Turn Off Gas to Appliance”

and call your service technician or gas

supplier.

TO TURN OFF

GAS TO APPLIANCE

1. Push the ‘OFF’ button on remote.

2. Remove batteries from receiver.

30 Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Page 31

C. After Appliance is Lit

Initial Break-in Procedure

When you light your gas stove, you may notice that it produces heat which does have an associated odor or smell. If

you feel this odor is excessive it may require the initial three

to four hour continuous burn on high followed by a second

burn up to 12 hours to fully drive off any odor from paint and

lubricants used in the manufacturing process. Condensation

on the inside of the glass is normal.

NOTE: The gas stove should be run three to four hours

on the initial start-up. Turn it off and let it cool completely.

Remove and clean the glass. Replace the glass and run the

gas stove for an additional 12 hours. This will help to cure

the products used in the paint and logs.

During this break-in period it is recommended that some

windows in the house be opened for air circulation. This will

help avoid setting off smoke detectors, and help eliminate

any odors associated with the gas stove’s initial burning.

CAUTION

• Prevent accidental gas stove operation when not

attended.

• Unplug or remove batteries from remote control if absent

or if gas stove will not be used for an extended period of

time.

• Property damage possible from elevated temperatures.

CAUTION

Smoke and odors released during initial operation.

• Open windows for air circulation.

• Leave room during initial operation.

• Smoke may set off smoke detectors.

Smoke and odors may be irritating to sensitive

individuals.

WARNING

WARNING

Fire Risk.

High Temperatures.

Keep combustible household items away from gas stove.

Do NOT obstruct combustion and ventilation air.

• Do NOT place combustible items on top of or in front of

gas stove.

• Keep furniture, draperies away from gas stove.

• Do NOT store fl ammable materials in the gas stove’s

vicinity.

• Do NOT use gasoline, lantern fuel, kerosene, charcoal

lighter fl uid or similar liquids in this gas stove.

• Combustible materials may ignite.

Fire Hazard.

Keep combustible materials, gasoline

and other fl ammable vapors and liquids

clear of gas stove.

D. Frequently Asked Questions

ISSUE SOLUTIONS

Condensation on the glass This is a result of gas combustion and temperature variations. As the gas stove warms,

this condensation will disappear.

Blue fl ames This is a result of normal operation and the fl ames will begin to yellow as the gas stove

is allowed to burn for 20 to 40 minutes.

Odor from gas stove When fi rst operated, this gas stove may release an odor for the fi rst several hours.

This is caused by the curing of the paint and the burning off of any oils remaining from

manufacturing.

Film on the glass This is a normal result of the curing process of the paint and logs. Glass should be

cleaned within 3 to 4 hours of initial burning to remove deposits left by oils from the

manufacturing process. A non-abrasive cleaner such as gas gas stove cleaner may be

necessary. See your dealer. Ensure glass has cooled before cleaning.

Metallic noise Noise is caused by metal expanding and contracting as it heats up and cools down,

similar to the sound produced by a furnace or heating duct. This noise does not affect

the operation or longevity of the gas stove.

31Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Page 32

Maintaining and Servicing Appliance

10

Although the frequency of your gas stove servicing and

maintenance will depend on use and the type of installation,

a qualifi ed service technician should perform an gas stove

check-up at the beginning of each heating season.

WARNING

Risk of injury or property damage.

Before servicing:

• Turn off gas.

• Turn off electricity to gas stove.

• Ensure gas stove is completely cooled.

After servicing:

• Replace any screen or barrier that was removed.

• Reseal and reinstall any venting removed for servicing.

WARNING

Annual inspection by qualifi ed technician recommended.

Check:

• Condition of glass, glass assembly and glass seal.

• Obstructions of combustion and ventilation air.

• Obstructions of termination cap.

• Burner ignition and operation.

• Burner air shutter adjustment

• Gas connections and fi ttings.

Clean:

• Glass

• Air passageways, grilles,

control compartment

• Burner, burner ports

Risk of:

• Fire

• Delayed ignition or explosion

• Exposure to combustion fumes

• Odors

CAUTION

Handle glass assembly with care.

NOTE: Clean glass after initial 3-4 hours

operation. Longer operation without cleaning

glass may cause a permanent white fi lm on

glass.

When cleaning glass door:

• Avoid striking, scratching or slamming glass.

• Do NOT use abrasive cleaners.

• Use a hard water deposit glass cleaner on white fi lm.

• Do NOT clean glass when hot.

• Turn off gas stove after 3-4 hours of operation and ALLOW

TO COOL.

• Remove and clean glass assembly.

• Replace glass assembly and operate gas stove for

additional 12 hours.

Refer to maintenance instructions.

WARNING

Inspect external fl ue cap regularly.

• Ensure no debris blocks cap.

• Combustible materials blocking cap

may ignite.

• Restricted air fl ow affects burner

operation.

32 Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Page 33

A. Maintenance Tasks

Inspect Maintenance Tasks

Doors 1. Inspect for scratches, dents or other damage and repair as necessary.

2. Verify no obstructions to air fl ow.

3. Verify maintenance of proper clearance to combustible household objects.

Gasket Seal, Glass

Assembly and Glass

Valve Compartment

and Firebox Top

Logs 1. Inspect for broken, damaged, or missing logs. Replace as necessary.

Firebox 1. Inspect for paint condition, warpage, corrosion or perforation. Sand and repaint as necessary.

Burner Ignition and

Operation

Flueing 1. Inspect fl ueing for blockage or obstruction such as bird nests, leaves, etc.

Remote Control 1. Verify operation of remote.

1. Inspect gasket seal and its condition.

2. Inspect glass for scratches and nicks that can lead to breakage when exposed to heat.

3. Confi rm there is no damage to glass or glass frame, Replace as necessary.

4. Verify that latches engage properly and glass attachment components are intact and operating properly. Replace as necessary.

5. Clean glass. Replace glass assembly if severely coated with silicate deposits that cannot be

removed.

1. Vacuum and wipe out dust, cobwebs, debris or pet hair. Use caution when cleaning these

areas. Screw tips that have penetrated the sheet metal are sharp and should be avoided.

2. Remove any foreign objects.

3. Verify unobstructed air circulation.

2. Verify correct log placement and no fl ame impingement causing sooting. Correct as necessary.

2. Replace gas stove if fi rebox has been perforated.

1. Verify burner is properly secured and aligned with pilot or igniter.

2. Clean off burner top, inspect for plugged ports, corrosion or deterioration. Replace burner if

necessary.

3. Replace ember material with new 1.5 cm pieces. Do not block ports or obstruct lighting paths.

4. Check for smooth lighting and ignition carryover to all ports. Verify there is no ignition delay.

5. Inspect for lifting and other fl ame problems.

6. Inspect orifi ce for soot, dirt or corrosion.

7. Verify manifold and inlet pressures. Adjust regulator as required.

8. Inspect pilot fl ame strength. Clean or replace orifi ce as necessary.

9. Inspect thermocouple sensor rod for soot, corrosion and deterioration. Clean with emery

cloth or replace as required.

10. Verify millivolt output. Replace as necessary.

2. Confi rm that termination cap remains clear and unobstructed by plants, etc.

3. Verify that termination cap clearance to subsequent construction (building additions, decks,

fences or sheds) has been maintained.

4. Inspect for corrosion or separation.

5. Verify weather stripping, sealing and fl ashing remains intact.

2. Replace batteries in remote transmitters and battery-powered receivers.

33Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Page 34

Troubleshooting

11

With proper installation, operation and maintenance your gas stove will provide years of trouble-free service. If you do

experience a problem, this troubleshooting guide will assist a qualifi ed service person in the diagnosis of a problem and the

corrective action to be taken. This troubleshooting guide can only be used by a qualifi ed service technician.

Electronic Ignition System

Symptom Possible Causes Corrective Actions

1. No transmission, motor does

not turn.

2. No ignition. No tone.

3. No ignition; one 5 seconds

continuous tone (7 shorts

beeps might be heard prior to

the 5 seconds tone).

4. No pilot fl ame and control

continues to spark.

5. Pilot is lit and control

continues to spark. Valve

shuts off after 10...30

seconds. Valve operates

manually.

6. Pilot is lit, sparking stops if a

fl ame is present. Valve shuts

off after 10...60 seconds.

Valve does not work manually.

7. 3 short beeps while the motor

turns. A.

8. Pilot fl ame lights but there is

no main gas fl ow. A.

9. Pilot sparks, but pilot will not

light.

Receiver must learn new

code.

A.

Receiver Replace receiver and reprogram code.

A.

ON/OFF switch is in OFF

A.

position.

B. Loose wire. Secure wire.

C. Receiver. Replace receiver and reprogram.

Bent pins on 8 wire

D.

connector.

E. Valve. Replace valve.

A. Air in the pilot supply line. Purge the line or start ignition several times.

Thermocouple circuit

B.

wired incorrectly.

No spark at pilot burner. Check spark gap, check wiring connection. Check for spark in location along

C.

D. Valve. Replace valve. Do not over tighten.

Over tightened

E.

thermocouple interrupter.

F. Receiver. Replace receiver and reprogram code.

Receiver. Replace receiver and reprogram code.

A.

A. Thermocouple. Replace thermocouple.

Low inlet pressure to

B.

valve.

C. Valve. Replace valve. Do not tighten the thermocouple interrupter.

Batteries are low. Replace batteries - quality alkaline recommended. WARNING: Creating an

Manual override know

(if equipped) is in MAN

position.

Valve turned don to pilot

B.

fl ow.

Low inlet pressure to

C.

valve.

D. Valve. Replace valve.

Correct gas supply. Verify that incoming gas line ball valve is “open”. Verify that inlet pressure reading

A.

B. Ignitor gap is too large. Verify that spark gap from ignitor to pilot hood is .43 cm.

C. Module is not grounded. Verify module is securely grounded to metal chassis of stove.

Press and hold the receiver’s reset button until you hear 2 acoustic signals.

After the second longer acoustic signal, release the reset button and within the

subsequent 20 seconds, press the down arrow on the remote handset until you

hear an additional long acoustic signal confi rming the new code is set.

Push switch to ON position.

Straighten pins on 8 wire connector.

Check polarity of the thermocouple wires.

cable.

Replace valve and thermocouple interrupter.

Confi rm suffi cient inlet pressure to the valve. Adjust or replace inlet regulator if

necessary.

electrical short between the batteries/battery box and metal parts of the appliance

may render the receiver inoperable.

Turn Manual override know to ON position.

Turn fl ame to high fi re by pressing up button on remote handset.

Confi rm suffi

necessary.

is within acceptable limits, inlet pressure must not exceed 50 mbar.

cient inlet pressure to the valve. Adjust or replace inlet regulator if

34 Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Page 35

Reference Materials

12

A. Appliance Dimension Diagram

Dimensions are actual gas stove dimensions. Use for reference only. For clearances to combustibles refer to Section 3.

A

C

B

Height includes 9.53 mm hearth pad.

E

G

Hearth Pad

H

D

F

I

Centimeters

Figure 12.1 Appliance Dimensions

47.9 104.5 103.5 40.3 7.6 18.1 76.2 73.3 86.7

AB C DEFGH I

35Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Page 36

B. Appliance Dimension with Stone Surround Diagram

A

B

D

C

Hearth Pad

E

F

Height includes 9.53 mm hearth pad.

G

Height includes 9.53 mm hearth pad.

ABCDEFG

Centimeters

Figure 12.2 Appliance Dimensions with Stone Surround

36 Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

75.3 62.0 76.8 8.3 42.8 86.7 112.6

Page 37

C. Flue Components Diagram

16.5 cm

23.5 cm

SL-45D

43.2-61.0 cm

16.8 cm

16.2 cm

16.5 cm

24.4 cm

16.2 cm

16.8 cm

24.4 cm

SL-90D

16.5 cm

22.2 cm

SL-17/24D

(SL17-24D)

30.5-43.2 cm

29.8 cm

SL-12D

60.3 cm

14.6 cm

16.8 cm

SL-06D

121.3 cm

90.8 cm

Figure 12.3

SL-09D

SL-12/17D

SL-24D

SL-48DSL-36D

(SL-12-17D)

SL D-Series Balance Flue Component Specifi cations 10.2 cm inner pipe, 16.8 cm outer pipe.

37Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Page 38

D. Flue Components List

COMPONENTS

Ceiling Support / Wall Thimble, Black 656-230

Cathedral Ceiling Support, Black 941

15 cm Pipe Length, Black 908B

22 cm Pipe Length, Black 907B

31 cm Pipe Length, Black 906B

60 cm Pipe Length, Black 904B

91 cm Pipe Length, Black 903B

121 cm Pipe Length, Black 902B

28 - 37 cm Pipe Length, Black 911B

31 - 43 cm Pipe, Adjustable, Black 912B

45 degree Elbow, Black 945B

90 degree Elbow, Black 990B

15 cm Pipe SL-06D

22 cm Pipe SL-09D

31 cm Pipe SL-12D

60 cm Pipe SL-24D

91 cm Pipe SL-36D

121 cm Pipe SL-48D

45 degree Elbow SL-45D

90 degree Elbow SL-90D

0/12 - 6/12 Roof Flashing SL-F6D

7/12 - 12/12 Roof Flashing SL-F12D

Storm Collar SL-SCD

Ceiling Firestop SL-FCD

Wall Firestop SL-FWD

Pipe Support Strap SL-PSD

Decorative Radius Cover DRC-RADIUS

HTI Wall Thimble HTI-DV-WT

TERMINATION KITS

Trapezoid Termination Kit 19.7 cm - 28 cm, 2 Firestops SLK-01TRD

Vertical Termination Cap - High Wind SLK-991DA

38 Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Page 39

Service Parts

VRTIKL-CE

Service Parts Diagram

1

2

6

7

3

4

5

17

16

Beginning Manufacturing Date: June 2006

Ending Manufacturing Date: Active

15

14

13

10

9

8

12

Log Set Assembly

11

Part number list on following page.

39Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

Page 40

E. Service Parts

VRTIKL-CE

Service Parts List

IMPORTANT THIS IS DATED INFORMATION: When requesting service or replacement parts for your appliance please

provide model number and serial number. All parts listed in this manual may be ordered from an authorized dealer.

ITEM DESCRIPTION SERIAL # PART NUMBER

Log Set Assembly

1 Removable T op Assembly

2 Grill Assembly

3 Adaptor 4 inch fl ue collar

4 DV Adaptor

5 Firebox Assembly 2123-004

Glass Frame Assembly

Latch Assembly Lower

Latch Assembly Upper

6 Side Assembly Left

7 Exhaust Baffl e

8 Access Door Assembly

9 Front Door Assembly

10

11 Bottom Plate Assembly

12

13 Control Assembly

14

15

16 Cover Plate Gasket

17 Cover Plate

Firebox Bottom Assembly N

Firebox Bottom Assembly P/B

Blower Bracket

Air Defl ector 7031-140

Control Module

Block Control Wire 2098-148

Control Cable 2098-143

Side Assembly Right 7031-020

Back Panel Assembly 7031-021

Flue Restrictor

Touch Up Paint (Pewter)

Beginning Manufacturing Date: June 2006

Ending Manufacturing Date: Active

7031-033

7031-017

7031-013

200-2470

7000-162

Pre Sept 2007 7031-015

Post Sept 2007 2123-005

Pre Sept 2007 7031-041

Post Sept 2007 386-122A

7003-006

7031-024

7031-219

7031-023

Bronze 2123-028

Green 2123-029

Gray 2123-016

2123-002

2123-003

2123-015

7031-194

7031-059

2098-142

7010-160

7010-159

7031-192

TUPP-12

Top Vent Conversion Kit

Conversion Kit (N to P/B)

Conversion Kit (P/B to N)

Conversion Kit (P to B or B to P)

Pilot Orifi ce N 2098-518

Pilot Orifi ce P 2098-512

Additional service part numbers appear on following page.

40 Heat & Glo • VRTIKL-CE • 7031-292 Rev E • 12/07

PAL-TR

N2PB-VRT-CE

PB2N-VRT-CE

P2B/B2P-VRT-CE

Page 41

Service Parts

VRTIKL-CE

Valve Assembly

Valve Assembly Parts List

Beginning Manufacturing Date: June 2006

Ending Manufacturing Date: Active

1

2

3

4

5

7

8

6

13

12

11

10

9