Hearth and Home Technologies CFL-18NG-C, CFL-24LP-C, CFL-24NG-IPI, ST-CFL-24LP-B, CFL-24LP-IPI User Manual

...Page 1

MODELS:

NATURAL GAS PROPANE

CFL-18NG-C CFL-18LP-C

CFL-24NG-C CFL-24LP-C

CFL-30NG-C CFL-30LP-C

ST-CFL-24NG-B ST-CFL-24LP-B

CFL-24NG-IPI CFL-24LP-IPI

Owner’s Manual

Installation and Operation

CAUTION

DO NOT DISCARD THIS MANUAL

• Important operating

and maintenance

instructions included.

WARNING: If the information in these

instructions is not followed exactly, a fi re

or explosion may result causing property

damage, personal injury, or death.

• Do not store or use gasoline or other fl am-

mable vapors and liquids in the vicinity of

this or any other appliance.

• What to do if you smell gas

- Do not try to light any appliance.

- Do not touch any electrical switch. Do not

use any phone in your building.

- Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s instructions.

- If you cannot reach your gas supplier, call

the fi re department.

• Read, understand and follow

these instructions for safe

installation and operation.

DO NOT

DISCARD

• Leave this manual with

party responsible for use

and operation.

WARNING

HOT SURFACES!

Glass and other surfaces are hot during

operation AND cool down.

Hot glass will cause burns.

• Do not touch glass until it is cooled

• NEVER allow children to touch glass

• Keep children away

• CAREFULLY SUPERVISE children in same room as

fi replace.

• Alert children and adults to hazards of high temperatures.

High temperatures may ignite clothing or other fl ammable

materials.

• Keep clothing, furniture, draperies and other fl ammable

materials away.

This appliance has been supplied with an integral barrier

to prevent direct contact with the fi xed glass panel. DO

NOT operate the appliance with the barrier removed.

Contact your dealer or Hearth & Home Technologies if the

barrier is not present or help is needed to properly install one.

• Installation and service must be performed

by a qualifi ed installer, service agency , or the

gas supplier.

In the Commonwealth of Massachusetts:

• Installation must be performed by a licensed plumber

or gas fi tter.

• The chimney fl ue damper, when used with gas logs,

will be welded open or completely removed.

• A CO detector shall be installed in the room where the

appliance is installed.

Heat & Glo • CFL-18/24/30-C, CFL-24-IPI, ST-CFL-24-B • 526-910 Rev. E • 10/08

Installation and service of this appliance should be

performed by qualifi ed personnel. Hearth & Home

Technologies suggests NFI certifi ed

or factory trained professionals, or

technicians supervised by an NFI

certifi ed professional.

1

Page 2

Read this manual before installing or operating this appliance.

Please retain this owner’s manual for future reference.

Congratulations

Congratulations on selecting a Heat & Glo gas appliance

—an elegant and clean alternative to wood burning

appliances. The Heat & Glo gas appliance you have

selected is designed to provide the utmost in safety,

reliability, and effi ciency .

As the owner of a new appliance, you’ll want to read and

carefully follow all of the instructions contained in this

Owner’s Manual. Pay special attention to all Cautions and

Warnings.

Homeowner Reference Information

This Owner’s Manual should be retained for future

reference. We suggest that you keep it with your other

important documents and product manuals.

The information contained in this Owner’s Manual, unless

noted otherwise, applies to all models and gas control

systems.

Your new Heat & Glo gas appliance will give you years of

durable use and trouble-free enjoyment. Welcome to the

Heat & Glo family of appliance products!

We recommend that you record the following pertinent

information about your appliance.

Model Name: ___________________________________________ Date purchased/installed: __________________

Serial Number: __________________________________________ Location on appliance: ____________________

Dealership purchased from: _______________________________ Dealer Phone: __________________________

Notes: _______________________________________________________________________________________

_____________________________________________________________________________________________

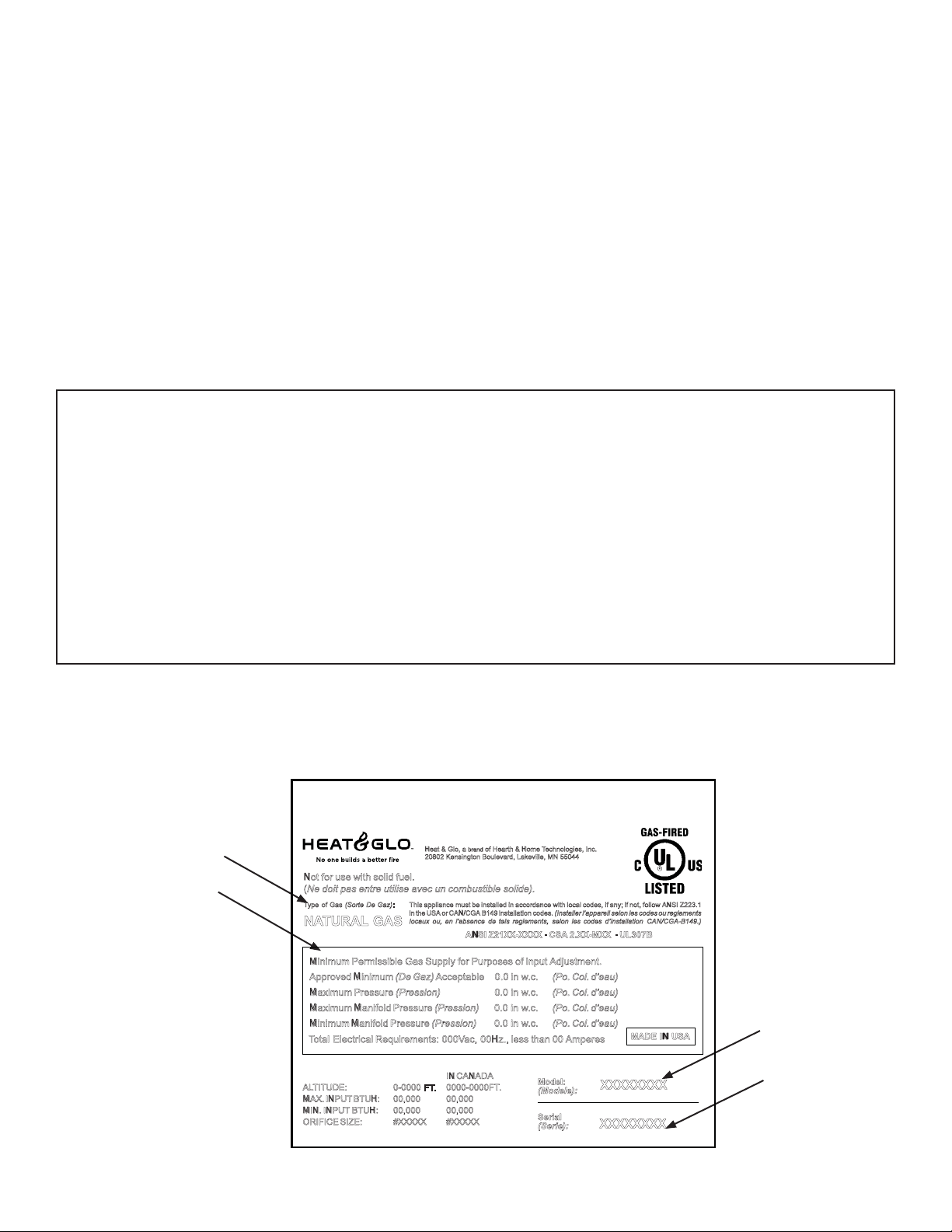

Listing Label Information/Location

This product may be covered by one or more of the following patents: (Nos produits sont couverts par un ou plusieurs des brevets suivants): (United States)

4593510,4686807, 4766876, 4793322, 4811534,5000162,5016609,5076254, 5113843,5191877, 5218953, 5263471, 5328356,5341794, 5347983, 5429495,

5452708,5542407,5601073, 5613487, 5647340, 5688568, 5762062, 5775408, 5890485, 5931661, 5941237, 594711 2,5996575, 6006743, 6019099, 6048195,

6053165, 6145502, 6170481, 6237588, 6296474, 6374822, 6413079, 6439226, 6484712, 6543698, 6550687, 6601579, 6672860, 6688302B2, 6715724B2,

6729551, 6736133, 6748940, 6748942, D320652, D445174, D462436; (Canada)1297749, 2195264, 2225408; or other U.S. and foreign patents pending (ou

autresbrevets americains et etrangers en attente).

Type of Gas

Gas Information

Not for use with solid fuel .

(Ne doit pas entre utilise avec un combustible solide).

Ty pe of Gas (Sorte De Gaz) :

NATURA L GAS

Minimum Permissible Gas Supply for Purpos es of Input Adjustment .

Approved Minimum (De Gaz) Acceptabl e 0. 0 in w. c. (Po. Col. d’eau)

Maximum Pressure (Pression) 0. 0 in w. c. (Po. Col. d’eau)

Maximum Manifold Pressure (Pression) 0. 0 in w. c. (Po. Col. d’eau)

Minimum Manifold Pressure (Pression) 0. 0 in w. c. (Po. Col. d’eau)

T o tal Electrical Requirements: 000V ac, 00Hz., less than 00 Ampere s

AL TI TUDE : 0-0000 FT . 0000-0000FT .

MAX. INPU T BTUH: 00,000 00,000

MIN. INPU T BTUH: 00,000 00,000

ORIFICE SIZE: #XXXXX #XXXXX

The model information regarding your specifi c appliance can be found on

the rating plate usually located in the control area of the appliance.

He at & Gl o, a of Hearth & Ho me Te chnologies, Inc.

bran d

20802 Kensington Boulevard, Lakeville, MN 5504 4

This appliance must be installed in accordance with local codes, if any; if not, follow ANSI Z223.1

in the USA or CAN/CG A B149 installation codes. (Installer l’ appa re il selon lescodes ou regl emen ts

lo caux ou , en l’absence de tels reglements, selon les codes d’in stallation CAN/CGA-B149.)

ANSI Z21X X-XXXX · CS A 2.XX-MXX · UL307B

IN CANADA

Mode l:

(Modele):

Serial

(Serie):

XXXXXXXX

XXXXXXXX

MADE IN US A

Model Number

Serial Number

2

Heat & Glo • CFL-18/24/30-C, CFL-24-IPI, ST-CFL-24-B • 526-910 Rev. E • 10/08

Page 3

Table of Contents

1 Introduction

A. Appliance Certifi cation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

B. High Altitude Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Getting Started

A. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Operating Guidelines and Maintenance Instructions

A. Before Lighting Appliance. . . . . . . . . . . . . . . . . . . . . . . . . . 9

B. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 Troubleshooting

A. Standing Pilot Ignition System . . . . . . . . . . . . . . . . . . . . . 12

B. Intellifi re Ignition System . . . . . . . . . . . . . . . . . . . . . . . . . 14

5 Reference Materials

A. Service Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

B. Limited Lifetime Warranty . . . . . . . . . . . . . . . . . . . . . . . . . 26

C. Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

= Contains updated information.

Heat & Glo • CFL-18/24/30-C, CFL-24-IPI, ST-CFL-24-B • 526-910 Rev. E • 10/08

3

Page 4

1

1

Introduction

A. Appliance Certifi cation

The information in this manual pertains to Models CFL-18

NG/LP-C, CFL-24 NG/LP-C, CFL-30 NG/LP-C. CFL-24

NG/LP-IPI and ST-CFL-24NG/LP-B.

These gas log sets have been tested and listed in the U.S.

in accordance with ANSI Z21.60b-2004. They have been

listed by Underwriters Laboratories Inc. for installation and

operation in the United States and Canada as described in

these Installation and Operation Instructions. All components are UL, AGA, CGA or CSA safety certifi ed.

Check with your local building code agency prior to installing this appliance to ensure compliance with local codes,

including the need for permits and follow-up inspections. In

the absence of local codes, comply with the National Fuel

Gas Code, ANSI Z223.1-Latest Edition in the U.S. If any

assistance is required during installation, please contact

your local dealer.

WARNING

Fire Risk

Asphyxiation Risk

• This log set must NOT be installed in an unvented

appliance.

• Open the chimney damper to its fully open position when

burning this gas log set.

• Logs must never be burned without the fl ue damper in the

full open position. Failure to do so is dangerous to your

health and voids all warranties.

• All gas appliances produce some carbon monoxide when

operated. Carbon monoxide is a colorless, odorless,

poisonous gas. Adequate provisions must be made to

provide combustion air for this gas log set. If outside air

is not included in the fi replace, it may be necessary that

an additional combustion air source be provided.

opening provided by the fi replace chimney damper to vent

the fl ue products must not be less than 51 square inches

(328 cm

ner to maintain the minimum permanent vent opening. This

may be accomplished by fastening the damper stop clamp

provided to the edge of the damper to prevent its closing.

The installation, including provisions for combustion and

ventilation air, must conform with the National Fuel Gas

Code ANSI Z223.1 (in the United States), the CAN/CGA

B-149 Installation Code (in Canada) and applicable local

building codes.

These models can be installed in a bedroom (in the United

States) which has a total volume of unconfi ned space ap-

propriate to the particular installation. Refer to the National

Fuel Gas Code ANSI Z223.1/NFPA 54-(current edition).

The Uniform Mechanical Code (current edition), and Local

Building Offi cials for the options allowed in obtaining an

effective bedroom volume of unconfi ned space.

Always keep the appliance area clear and free from combustible materials, gasoline, and other fl ammable vapors

and liquids.

Do not use this appliance if any part has been under water.

Immediately call a qualifi ed service technician to inspect

the unit and to replace any part of the control system and

any gas control which has been under water.

2

). The chimney damper MUST be fi xed in a man-

WARNING

Fire Risk

• THIS UNIT IS NOT FOR USE WITH SOLID

FUEL. Solid fuels shall not be burned in a

fireplace where a decorative appliance is

installed. Failure to follow these instructions

will result in a fi re.

CAUTION

Check the construction of the fi replace before installing the

gas log set. The area of the fl ue should not be less than 1/11

the area of the fi replace opening. Non-airtight glass doors

should be installed on the fi replace if the area of the fl ue

is less than 1/11 the area of the fi replace opening. Airtight

doors must never be used with this gas log set.

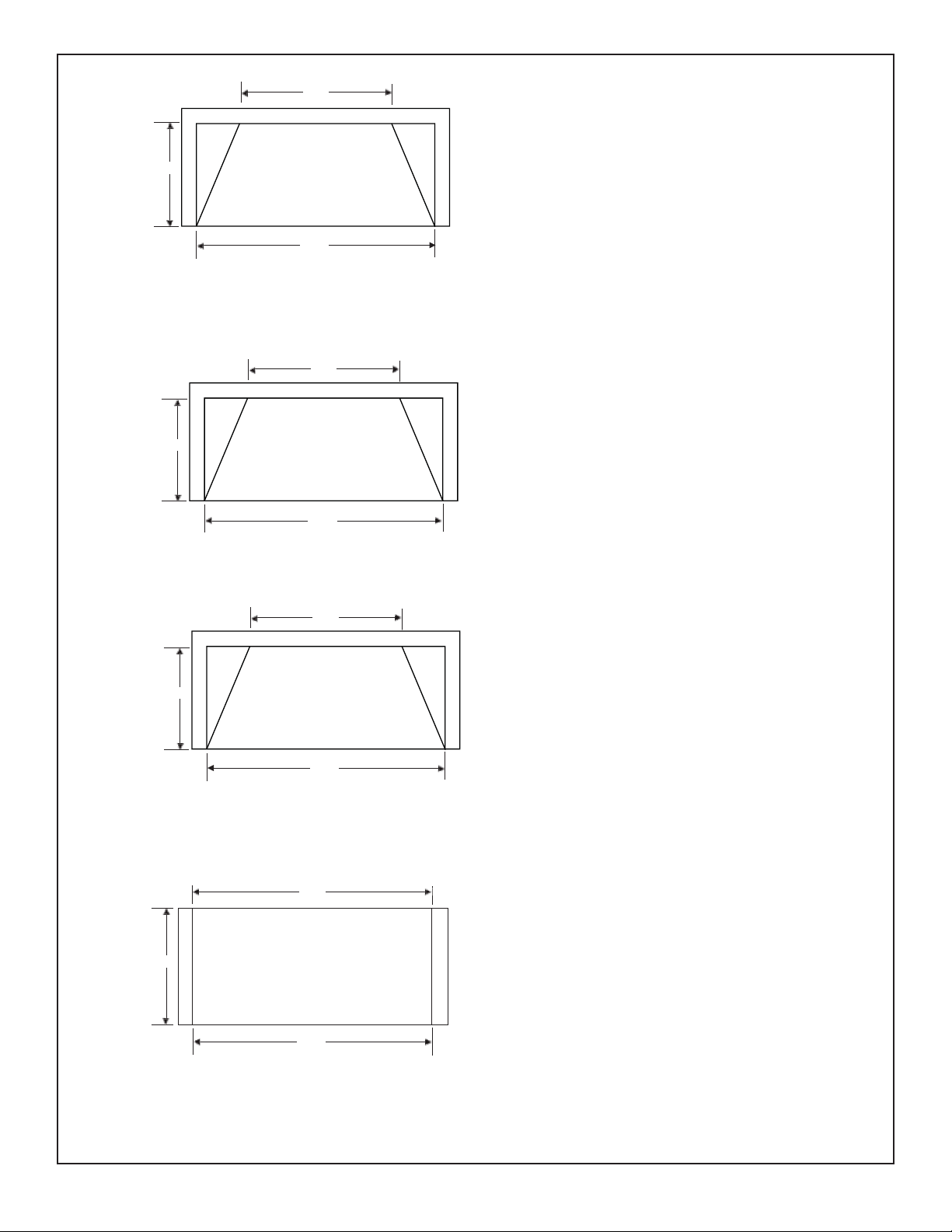

Gas Log Sets are Decorative Gas Appliances for Installation in a Solid-fuel Burning Fireplace. Minimum fi replace

sizes for these models is shown in Figure 1.

This log set is to be installed only in a solid-fuel burning fi replace with a working fl ue and one constructed of

noncombustible material. The minimum permanent vent

4

Heat & Glo • CFL-18/24/30-C, CFL-24-IPI, ST-CFL-24-B • 526-910 Rev. E • 10/08

B. High Altitude Installation

U.L. Listed gas appliances are tested and approved

without requiring changes for elevations from 0 to 2,000

feet in the U. S. A. and in Canada.

When installing this appliance at an elevation above

2,000 feet, it may be necessary to decrease the input

rating by changing the existing burner orifi ce to a smaller

size. Input rate should be reduced by 4% for each 1000

feet above a 2000 foot elevation in the U.S.A. or 10% for

elevations between 2000 and 4500 feet in Canada. If the

heating value of the gas has been reduced, these rules

do not apply . To identify the proper orifi ce size, check with

the local gas utility.

If installing this appliance at an elevation above 4,500 feet

(in Canada), check with local authorities.

Page 5

13 1/2

15 1/2

19 1/2

TOP VIEW

23 1/2

22

TOP VIEW

27 1/2

MODEL CFL-18-C

MINIMUM FIREPLACE SIZE

FRONT WIDTH : 23 1/2” (750mm)

REAR WIDTH : 19

1/2” (521mm)

DEPTH : 13 1/2” (331mm)

HEIGHT : 22” (508mm)

MINIMUM FIREPLACE SIZE

FRONT WIDTH : 27 1/2” (750mm)

REAR WIDTH : 22” (521mm)

DEPTH : 15 1/2” (331mm)

HEIGHT : 22” (508mm)

15 1/2

17

24

TOP VIEW

30

24

TOP VIEW

MODEL CFL-24-C

MODEL CFL-30-C

MINIMUM FIREPLACE SIZE

REAR WIDTH : 24” (521mm)

DEPTH : 17” (331mm)

HEIGHT : 20” (508mm)

MINIMUM FIREPLACE SIZE

FRONT WIDTH : 30” (750mm)

REAR WIDTH : 24” (521mm)

DEPTH : 15 1/2” (331mm)

HEIGHT : 22” (508mm)

FRONT WIDTH : 24” (521mm)

24

MODEL ST-CFL-24-B

Figure 1. Minimum Fireplace Sizes for CFL-18/24/30-C and ST-CFL-24-B

Heat & Glo • CFL-18/24/30-C, CFL-24-IPI, ST-CFL-24-B • 526-910 Rev. E • 10/08

5

Page 6

2

2

Getting Started

CAUTION

When installing this log set in a factory built fi replace, be

certain to consult the fi replace installation manual. ALL

knockouts in the fi replace through which the gas supply line

is run MUST be resealed with insulation after the gas line

is in place.

These models contain complete gas-burner, grate(s), and

log components needed. Use caution when handling logs

to avoid damage. Position the gas-burner assembly to the

rear of the fi replace. The ST-CFL-24 log set should be

positioned in the center of the unit. Once fully assembled,

the front log will extend forward of the burner assembly.

CAUTION

T o minimize the possibility of spillage and to maximize proper

draft, position the log set as close to the back of the fi replace

as possible. The ST-CFL-24 log set should be positioned in

the center of the unit.

A. Installation

1. Run proper size gas line into fi replace. A 1/2 inch

(13mm) gas line, with a 3/8 inch (10mm) reduction for

hook-up, is usually suffi cient for the Gas Log set; how-

ever, if the run is unusually long, a larger line may be required. Contact your local gas company or Department

of Building and Safety if there are any questions.

2. Minimum inlet gas supply pressure for purposes of input adjustment, shall be 7.0 inches w.c. (1.75kPa) for

natural gas and 1 1.0 inches w .c. (2.75kPa) for propane

(LP gas). Maximum inlet gas supply pressure shall be

14.0 in. w.c. (3.5kPa) for both natural gas and propane

(LP gas). Manifold (outlet) pressure should be 3.5

inches w.c. (.87kPa) for natural gas and 10.0 inches

w.c. (2.5kPa) for LP gas.

3. The appliance and its individual shut off valve must be

disconnected from the gas supply piping system during

any pressure testing of the system at test pressures in

excess of 1/2 psig (3.5kPa).

4. This appliance must be isolated from the gas supply

piping system by closing its individual manual shut off

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than

1/2 psig (3.5kPa).

Note: The gas supply line should be purged of any trapped

air prior to the fi rst fi ring of the unit.

CAUTION

Standing Pilot units only: During the initial purging and

subsequent lightings, NEVER allow the gas control valve knob

to remain depressed in the "PILOT" position without pushing

the ignitor button at least once every second.

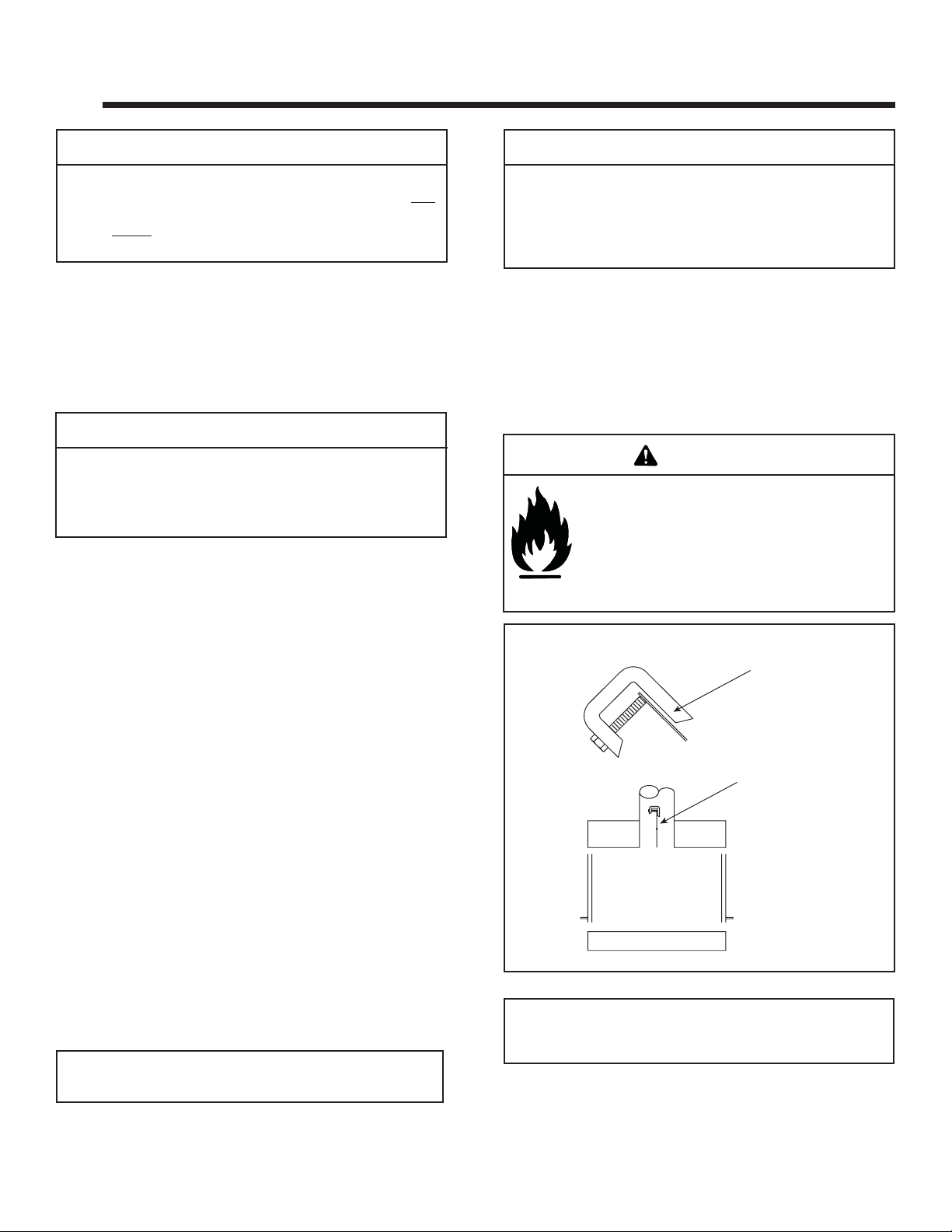

5. A damper stop clamp with set screw is provided to

prevent full closure of the fi replace damper blade. Attach

the clamp to the edge of the damper blade with pliers or

wrenches. If the damper stop supplied does not fi t the

application, use a permanent means that will keep the

damper open to a MINIMUM of 51 square inches (328cm2).

See Figure 2.

WARNING

Fire Risk

• Open the chimney damper to its FULLY

OPEN position when burning this gas log set.

• Logs must NEVER be burned without the fl ue

damper in the FULL OPEN position. Failure

to do so is dangerous to your health and

voids all warranties.

DAMPER CLAMP

OPEN DAMPER

Figure 2.

Note: The Commonwealth of Massachusetts requires that

the chimney fl ue damper, when used with gas logs, shall be

welded open or completely removed.

6

Heat & Glo • CFL-18/24/30-C, CFL-24-IPI, ST-CFL-24-B • 526-910 Rev. E • 10/08

Page 7

7. Test fi re the unit after referring to the SAFETY INFOR-

MATION and LIGHTING INSTRUCTIONS found in

Section 3 in this manual, or on the label plate assembly

found on the gas-burner.

8. After the gas line installation is complete, all connections

must be tightened and checked for leaks with a commercially-available, non-corrosive leak check solution.

Be sure to rinse off all leak check solution following

testing. Refer to Section 3, OPERA TING GUIDELINES

and MAINTENANCE INSTRUCTIONS.

9. Once the gas-burner is test fi red and gas supply lines

are purged, assemble the grate(s) and logs. Be certain

to follow the Log Placement Instructions shipped with

the unit. Remember to keep the Log Instructions along

with this manual for future use.

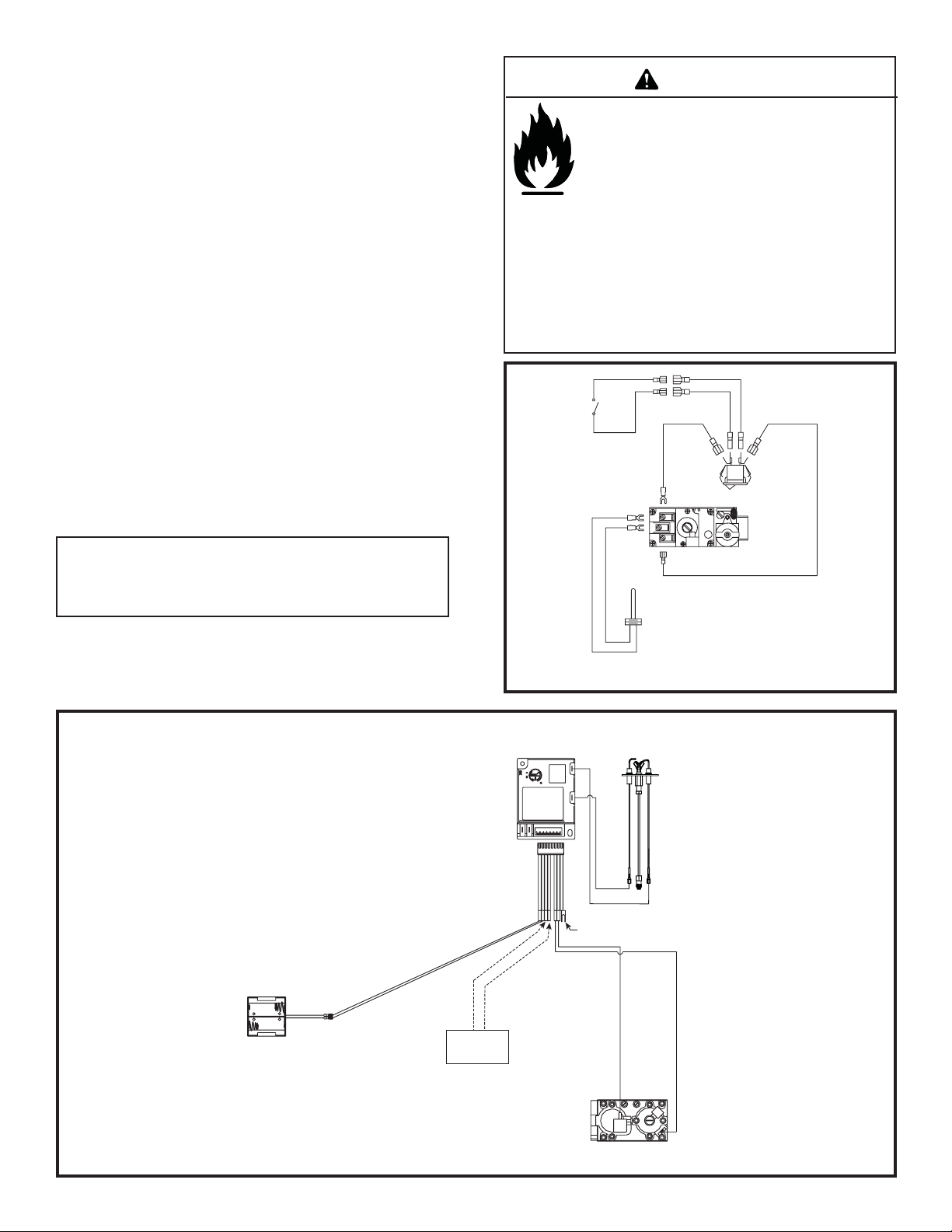

• This appliance may be used with a wall switch and/or

remote control.

• Use low resistance thermostat wire for wiring from ignition system to the wall switch.

• Keep wire lengths as short as possible by removing any

excess wire length.

• Low voltage and 110 VAC voltage cannot be shared

within the same wall box.

WARNING

Hearth & Home Technologies disclaims any

responsibility for, and the warranty will be voided

by, the following actions:

• Installation and use of any damaged appliance

or vent system component.

• Modifi cation of the appliance.

• Installation other than as instructed by Hearth &

Home Technologies.

• Improper positionsing of the gas logs.

• Installation and/or use of any component part

not approved by Hearth & Home Technologies.

Any such action may cause a fi re hazard.

BLACK BLACK

REMOTE

OR WALL

SWITCH

ON/OFF

SWITCH

Note: This appliance must be electrically wired and grounded

in accordance with local codes or, in the absence of local

codes, with National Electric Code ANSI/NFPA 70-latest

edition or the Canadian Electric Code, CSA C221.1.

BATTERY PACK

(BATTERIES REQUIRED)

RED

THERMOPILE

WHITE

Figure 4.

IGNITION MODULE 3 VAC INTERMITTENT PILOT IGNITOR

I

S

WHITE

ORANGE

GROUND TO

FIREPLACE

CHASSIS

RED

BLACK

WIRES

(TO BROWN)

Figure 3. IPI Wiring Diagram-CFL-24NG-IPI and CFL-24LP-IPI

Heat & Glo • CFL-18/24/30-C, CFL-24-IPI, ST-CFL-24-B • 526-910 Rev. E • 10/08

REMOTE OR

WALL SWITCH

ORANGE

VALVE

GREEN

7

Page 8

• If a remote control is used, the receiver cannot

be placed under the burner. If possible, place the

receiver outside the combustion chamber.

• If the receiver must be placed in the combustion

chamber, the protective heat shield MUST be used.

See Figure 5.

Figure 5. Protective Heat Shield

• Position receiver on left side of gas log set (opposite

the pilot). Place protective heat shield over receiver.

See Figure 5.

Figure 6. Receiver Location-Left Side of Log Set

8

Heat & Glo • CFL-18/24/30-C, CFL-24-IPI, ST-CFL-24-B • 526-910 Rev. E • 10/08

Page 9

3

3

Operating Guidelines and Maintenance Instructions

A. Before Lighting Appliance

Before lighting this appliance determine if it has a Standing

Pilot or Intellifi re ignition system by viewing the wiring

system and gas valve. If this appliance has a red or black

ignitor button (see Figure 3 and Figure 4) this appliance

has a Standing Pilot ignition system. If there is no red or

black ignitor button, this appliance has an Intellifi re ignition

system.

WARNING

Fire Risk

Be sure fi replace screen or glass doors are in

place when burning fi replace logs. Unless other

provisions for combustion air are provided, the

screen or doors shall have an opening for introduction of combustion air. THIS GAS LOG SET

IS NOT DESIGNED TO OPERATE WITH AIR

TIGHT GLASS DOORS. Adequate combustion

and cooling air must be provided or the unit will

not function properly.

WARNING

Fire Risk

Explosion Risk

WARNING: To avoid possible injury, fi re and

explosion, please read and follow these precautions and all instructions on this appliance

before lighting the pilot. This appliance uses

L.P . (Propane) gas which is heavier than air and

will remain at fl oor level if there is a leak. Before

lighting, smell at fl oor level and/or use other

means (such as using a commercially-available,

non-corrosive leak check solution on all piping

and connections, using a gas detector, etc.) to

check for gas leaks. NOTE: L.P . (Propane) gas

can become odorless and CANNOT always be

detected by smell.

WARNING

HOT SURFACES!

Glass and other surfaces are hot during

operation AND cool down.

Hot glass will cause burns.

• Do not touch glass until it is cooled

• NEVER allow children to touch glass

• Keep children away

• CAREFULLY SUPERVISE children in same room as

fi replace.

• Alert children and adults to hazards of high temperatures.

High temperatures may ignite clothing or other

fl ammable materials.

• Keep clothing, furniture, draperies and other fl ammable

materials away.

This appliance has been supplied with an integral barrier

to prevent direct contact with the fi xed glass panel. Do

NOT operate the appliance with the barrier removed.

Contact your dealer or Hearth & Home Technologies if the

barrier is not present or help is needed to properly install one.

WARNING

Improper installation, adjustment, alteration, service or

maintenance can cause injury or property damage. Refer to

the owner’s information manual provided with this appliance.

For assistance or additional information consult a qualifi ed

installer, service agency or the gas supplier.

WARNING

Do NOT use this appliance if any part has been under water.

Immediately call a qualifi ed service technician to inspect the

appliance and to replace any part of the control system and

any gas control which has been under water.

Before operating this appliance have a qualifi ed tech-

nician:

• Remove all shipping materials.

• Review proper placement of logs, rockwool, lava rock,

and vermiculite.

• Check the wiring.

• Ensure that there are no gas leaks.

Upon completing the gas line connection, a small amount

of air will be in the lines. When fi rst lighting the pilot light,

it will take a few minutes for the lines to purge themselves

of this air. Once the purging is complete, the pilot and

burner will light and operate as indicated in the instruction manual. Subsequent lighting of the appliance will not

require such purging.

Heat & Glo • CFL-18/24/30-C, CFL-24-IPI, ST-CFL-24-B • 526-910 Rev. E • 10/08

B. Maintenance

Periodically remove the logs and examine the burner. If

dirty , clean with a soft brush. Also examine the area around

the burner air shutter and the pilot. Any dirt or lint in this

area should be removed. This will ensure long life and

trouble-free operation.

The appliance and venting system should be inspected

before initial use and inspected and cleaned at least annually by a qualifi ed fi eld service person.

9

Page 10

Lighting Instructions (IPI)

The IPI system must be operated with two D-cell batteries.

FOR YOUR SAFETY

READ BEFORE LIGHTING

WARNING: If you do not follow these instructions exactly, a fi re or explosion

may result causing property damage, personal injury or loss of life.

A. This appliance is equipped with an

intermittent pilot ignition (IPI) device

which automatically lights the burner. DO NOT try to light the burner by

hand.

B. BEFORE LIGHTING, smell all around

the appliance area for gas. Be sure to

smell next to the fl oor because some

gas is heavier than air and will settle

on the fl oor.

WHA T TO DO IF YOU SMELL GAS

• DO NOT try to light any appliance.

• DO NOT touch any electric switch; do

not use any phone in your building.

WARNING:

DO NOT CONNECT 110 VAC TO

THE CONTROL VALVE.

Improper installation, adjustment, alteration, service or maintenance can

cause injury or property damage. Refer to the owner’s information manual

provided with this appliance.

This appliance needs fresh air for

safe operation and must be installed

so there are provisions for adequate

combustion and ventilation air.

If not installed, operated, and maintained in accordance with the manufacturer’s instructions, this product

could expose you to substances in fuel

or fuel combustion which are known to

the State of California to cause cancer, birth defects, or other reproductive

harm.

Keep burner and control compartment

clean. See installation and operating

instructions accompanying appliance.

• Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fi re department.

C. DO NOT use this appliance if any

part has been under water. Immediately call a qualifi ed service tech-

nician to inspect the appliance and

to replace any part of the control

system and any gas control which

has been under water.

CAUTION:

Hot while in operation. DO NOT touch.

Keep children, clothing, furniture, gasoline and other liquids having fl ammable

vapors away.

DO NOT operate the appliance with

fi xed glass assembly removed, cracked

or broken. Replacement of the fi xed

glass assembly should be done by a

licensed or qualifi ed service person.

NOT FOR USE

WITH SOLID FUEL

For use with natural gas and propane.

A conversion kit, as supplied by the

manufacturer, shall be used to convert

this appliance to the alternate fuel.

Also Certifi ed for Installation in a

Bedroom or a Bedsitting Room.

For assistance or additional information, consult a qualifi ed installer, ser-

vice agency or the gas supplier.

LIGHTING

INSTRUCTIONS

(IPI)

1. Turn off all electric power to the appliance.

2. This appliance is equipped with an ignition

device which automatically lights the burner.

DO NOT try to light the burner by hand.

GAS

VALVE

3. Wait fi ve (5) minutes to clear out any gas.

Then smell for gas, including near the fl oor. If

you smell gas, STOP! Follow “B” in the Safety

Information located on the left side of this label. If you do not smell gas, go to next step.

4. Turn on all electric power to the appliance.

5. To light the burner, fl ip the ON/OFF switch to

the “ON” position. (The ON/OFF switch may

include a wall switch if so equipped).

6. If the appliance will not operate, follow the instructions “To Turn Off Gas to Appliance” and

call your service technician or gas supplier.

TO TURN OFF

GAS TO APPLIANCE

1. Turn wall control or ON/OFF switch to “OFF”.

2. Turn off all electric power to the appliance if

service is to be performed.

593-913F

Hearth & Home Technologies fi replace, please refer to www.fi replaces.com.

For additional information on operating your

Final inspection by

Figure 7. IPI Lighting Instructions

10

Heat & Glo • CFL-18/24/30-C, CFL-24-IPI, ST-CFL-24-B • 526-910 Rev. E • 10/08

Page 11

Lighting Instructions (Standing Pilot)

FOR YOUR SAFETY

READ BEFORE LIGHTING

WARNING: If you do not follow these instructions

exact ly, a fi re or explosion may result causing proper ty

damage, personal injury or loss of life.

A. This appliance has a pilot which

must be lighted by hand. When

lighting the pilot, follow these instructions exactly.

B. BEFORE LIGHTING, smell all

around the appliance area for gas.

Be sure to smell next to the fl oor

because some gas is heavier than

air and will settle on the fl oor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do

not use any phone in your building.

• Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

WARNING:

• If you cannot reach your gas supplier, call the fi re department.

C. Use only your hand to push in or

turn the gas control knob. Never

use tools. If the knob will not push

in or turn by hand, don’t try to repair it, call a qualifi ed service tech-

nician. Force or attempted repair

may result in a fi re or explosion.

D. Do not use this appliance if any

part has been under water. Immediately call a qualifi ed service tech-

nician to inspect the appliance and

to replace any part of the control

system and any gas control which

has been under water.

CAUTION:

LIGHTING

INSTRUCTIONS

1. Turn off all electric power to the appliance.

2. Push in gas control knob

slightly and turn clockwise

to “OFF”.

NOTE: Knob cannot be turned from “PILOT” to “OFF”

unless knob is pushed in slightly. Do not force.

3. Wait fi ve (5) minutes to clear out any gas.

Then smell for gas, including near the fl oor. If

you smell gas, STOP! Follow “B” in the Safety

Information located on the left side of this label. If

you don’t smell gas, go to next step.

4. Find the pilot. The pilot is inside

combustion chamber next to the

main burner.

5. Turn knob on gas control counter clockwise

to “PILOT”.

6. Push in control knob all the way and hold in. Immediately depress red or black piezo button. It may

require several depressions of the red or black

piezo button until PILOT lights. If PILOT light does

not light after 10 seconds, return to step 3. Continue to

hold the control knob in for about one minute after the

pilot is lit. Release knob and it will pop back out. Pilot

should remain lit. If it goes out, repeat steps 3 through 6.

DO NOT CONNECT 110 VAC TO

THE CONTROL VALVE.

Improper installation, adjustment, alteration, service or maintenance can

cause injury or property damage. Refer to the owner’s information manual

provided with this appliance.

This appliance needs fresh air for

safe operation and must be installed

so there are provisions for adequate

combustion and ventilation air.

If not installed, operated, and maintained in accordance with the manufacturer’s instructions, this product

could expose you to substances in fuel

or fuel combustion which are known to

the State of California to cause cancer, birth defects, or other reproductive harm.

Keep burner and control compartment

clean. See installation and operating

instructions accompanying appliance.

For additional information on operating your

Hearth & Home Technologies fi replace, please refer to www.fi replaces.com.

Hot while in operation. Do not touch.

Keep children, clothing, furniture, gasoline and other liquids having fl ammable

vapors away.

Do not operate the appliance with

panel(s) removed, cracked or broken.

Replacement of the panel(s) should be

done by a licensed or qualifi ed service

person.

NOT FOR USE

WITH SOLID FUEL

For use with natural gas and propane.

A conversion kit, as supplied by the

manufacturer, shall be used to convert

this appliance to the alternate fuel.

Also Certifi ed for Installation in a

Bedroom or a Bedsitting Room.

For assistance or additional information, consult a qualifi ed installer, ser-

vice agency or the gas supplier.

• If knob does not pop up when released, stop and immediately call your service technician or gas supplier.

• If the pilot will not stay lit after several tries, turn

the gas control knob to “OFF” and call your service

technician or gas supplier.

7. Turn gas control knob counterclockwise to

“ON”.

8. To light Burner, fl ip the on/off switch to the “ON”

position, and close access grille.

9. Turn on all electric power to the appliance.

TO TURN OFF

GAS TO APPLIANCE

1. Turn off all electric power to the appliance if

service is to be performed.

2. Open control access panel.

3. Move switch to “OFF” position.

4. Push in gas control knob slightly and turn clock-

wise to OFF”. Do not force.

5. Close control access panel.

Final inspection by

Figure 8. Lighting Instructions

Heat & Glo • CFL-18/24/30-C, CFL-24-IPI, ST-CFL-24-B • 526-910 Rev. E • 10/08

11

Page 12

4

4

Troubleshooting

With proper installation, operation, and maintenance your gas appliance will provide years of trouble-free service. If you do

experience a problem, this troubleshooting guide will assist a qualifi ed service technician in the diagnosis of a problem and

the corrective action to be taken. This troubleshooting guide can only be used by a qualifi ed service technician. Contact

your dealer to arrange a service call by a qualifi ed service technician.

A. Standing Pilot Ignition System

Symptom Possible Causes Corrective Action

1. After repeated triggering

of the red or black piezo

ignitor button, the spark

ignitor will not light the

pilot.

2. The pilot will not stay lit

after carefully following

the lighting instructions.

3. The pilot is burning,

there is no burner

fl ame, the valve knob is

in the ON position, and

the ON/OFF switch is in

the ON position.

A. No gas or low gas pressure. Check the remote shut-off valves from the appliance. Usually, there

is a valve near the gas main. There can be more than one valve

between the appliance and the main.

B. No lp in tank. Check the LP (propane) tank. You may be out of fuel.

C. Ignitor. Check the spark at the electrode and pilot. If no spark and electrode

wire is properly connected, replace the ignitor. Verify that there is no

short in electrode wire.

D. Pilot or misaligned electrode

(spark at electrode).

A. Thermocouple. Check that the pilot fl ame impinges on the thermocouple. Adjust the

B. Improper gas inlet pressure. Natural gas should be 5-14 in. w.c. LP should be 10-14 in. w.c.

C. Valve. If the thermocouple is producing 8-16 millivolts, replace control valve.

A. On/off switch or wires. Check the ON/OFF switch and wires for proper connections. Place

B. Thermopile may not be gen-

erating suffi cient millivoltage.

Using match, light the pilot. If the pilot lights, turn off the pilot and

trigger the piezo ignitor button again. If the pilot lights, an improper

gas/air mixture caused the bad lighting and a longer purge period is

recommended. If the pilot will not light, ensure the gap at the elec-

trode and pilot is one-eighth in. to have a strong spark. If the gap is

OK, replace the pilot.

pilot for proper fl ame impingement.

Ensure that the thermocouple connection at the gas valve is fully

inserted and tight (hand tighten plus 1/4 turn).

Verify proper voltage output from the thermocouple to the valve.

Place one millivolt meter lead wire on the thermocouple copper lead.

Place the second lead wire on the solder button on the back of the

valve (blue wire). Start the pilot and hold the valve knob in. The

millivolt reading should read 8-16 millivolts. If millivolt reading is

less than 8 millivolts, replace thermocouple.

Verify pressure with manometer.

the jumper wires across the terminals at the switch. If the burner

comes on, replace the switch. If the switch is OK, place the jumper

wires across the switch wires at the gas valve. If the burner comes

on, the wires are faulty or connections are bad.

Check that the pilot fl ame impinges thermopile properly.

Be sure the wire connections from the thermopile at the gas valve

terminals are tight and that the thermopile is fully inserted into the

pilot bracket.

Check the thermopile with a millivolt meter. Take the reading at

TH-TP&TP terminals of the gas valve. The meter should read 350

millivolts minimum, while holding the valve knob depressed in the

pilot position, with the pilot lit, and the ON/OFF switch in the OFF

position. Replace the thermopile if the reading is below the specifi ed

minimum.

With the pilot in the ON position, disconnect the thermopile leads

from the valve. Take a reading at the thermopile leads. The read-

ing should be 350 millivolts minimum. Replace the thermopile if the

reading is below the minimum.

12

Heat & Glo • CFL-18/24/30-C, CFL-24-IPI, ST-CFL-24-B • 526-910 Rev. E • 10/08

Page 13

Troubleshooting (continued)

Symptom Possible Cause Corrective Action

3. (Continued) c. Valve. Turn the valve knob to the ON position. Place the

ON/OFF switch in the ON position. Check the millivolt

meter a the thermopile terminals. The millivolt meter

should read greater than 125mV. If the reading is acceptable, and if the burner does not come on, replace

the gas valve.

d. Plugged burner orifi ce. Check the burner orifi ce for stoppage. Remove stop-

page.

e. Wall switch or wires. Follow the corrective action in Symptom and Possible

Cause 1.a above. Check the switch and wiring.

4. Frequent pilot outage

problem.

5. The pilot and main

burner extinguish

while in operation.

6. Glass soots. a. Flame impingement. Adjust the log set so that the fl ame does not exces-

a. Pilot fl ame may be too high or too low, or blow-

ing out (high pressure), causing pilot safety to

drop out.

a. No LP in tank. Check the LP (propane) tank. Refi ll the fuel tank.

b. Improper gas inlet pressure. Verify with manometer. NG should read 5-14 in. w.c.

c. Inner vent pipe leaking exhaust gases back into

the system.

d. Glass installed improperly. Check to ensure glass is installed properly. Replace

e. Thermopile or thermocouple. Replace pilot if necessary.

f. Improper vent cap installation. Check for proper installation and freedom from debris

b. Improper air shutter setting. Refer to manual for shutter set points. Ensure that

c. Debris around air shutter. Inspect the opening at the base of the burner. NO MA-

Clean thermocouple and adjust the pilot fl ame for

proper fl ame impingement. Follow lighting instructions

carefully.

LP should read 10-14 in. w.c.

Check venting system for damage. Replace/repair

improperly assembled pipe sections.

glass panel assembly.

or blockage.

sively impinge on it. Refer to log instructions.

set point is correct for appliance/gas type. If unit has

adjustable shutter, it may be necessary to increase

shutter opening.

TERIAL SHOULD BE PLACED IN THIS OPENING.

7. Flame burns blue

and lifts off burner.

a. Insuffi cient oxygen being supplied. Ensure that the vent cap is installed properly and free

of debris. Ensure that the vent system joints are tight

and have no leaks.

Ensure that no debris has been placed at the base of,

or in the area of the air holes in the center of the base

pan beneath the burner.

Ensure that the glass is tightened properly on the unit,

particularly on top corners.

Heat & Glo • CFL-18/24/30-C, CFL-24-IPI, ST-CFL-24-B • 526-910 Rev. E • 10/08

13

Page 14

B. Intellifi re Ignition System

Symptom Possible Cause Corrective Action

1. Pilot won’t light.

The ignitor/module

makes noise, but no

spark.

2. Pilot won’t light,

there is no noise or

spark.

a. Incorrect wiring. Verify “S” wire (white) for sensor and “I” wire (orange) for ignitor

are connected to correct terminals on module and pilot assembly.

b. Loose connections or electrical

shorts in the wiring.

c. Ignitor gap is too large. Verify gap of igniter to right side of pilot hood. The gap should be

d. Module. Turn ON/OFF rocker switch or wall switch to OFF position. Remove

a. No power. Check batteries.

b. A shorted or loose connection in

wiring confi guration or wiring har-

ness.

Verify no loose connections or electrical shorts in wiring from

module to pilot assembly. Verify connections underneath pilot assembly are tight; also verify connections are not grounding out to

metal chassis, pilot burner, pilot enclosure, mesh screen if present,

or any other metal object.

approximately .17 in. or 1/8 in. (3 mm).

ignitor wire “I” from module. Place a grounded wire about 3/16 in. (5

mm) away from “I” terminal on module. Place ON/OFF rocker switch

or wall switch in ON position. If there is no spark at “I” terminal

module must be replaced. If there is a spark at “I” terminal, module

is fi ne. Inspect pilot assembly for shorted sparker wire or cracked

insulator around electrode. Replace pilot if necessary .

Remove and reinstall the wiring harness that plugs into module.

Verify there is a tight fi t. Verify pilot assembly wiring to module. Re-

move and verify continuity of each wire in wiring harness. Replace

any damaged components.

3. Pilot sparks, but

Pilot will not light.

c. Improper wall switch wiring. Check wiring connections.

d. Module not grounded. Verify black ground wire from module wire harness is grounded to

metal chassis of appliance.

e. Module. Turn ON/OFF rocker switch or wall switch to OFF position. Re-

move ignitor wire “I” from module. Place ON/OFF rocker switch

or wall switch in ON position. If there is no spark at “I” terminal

module must be replaced. If there is a spark at “I” terminal, module

is fi ne. Inspect pilot assembly for shorted sparker wire or cracked

insulator around electrode.

a. Gas supply. Verify that incoming gas line ball valve is “open”. Verify that inlet

pressure reading is within acceptable limits, inlet pressure must

not exceed 14 in. W.C.

b. Ignitor gap is incorrect. Verify that spark gap from ignitor to pilot hood is .17 in. or 1/8 in (3 mm).

c. Module is not grounded. Verify module is securely grounded to metal chassis of appliance.

d. Module voltage output / Valve/Pilot

solenoid ohms readings.

Verify battery voltage is at least 2.7 volts. Replace batteries if volt-

age is below 2.7.

14

Heat & Glo • CFL-18/24/30-C, CFL-24-IPI, ST-CFL-24-B • 526-910 Rev. E • 10/08

Page 15

Intellifi re Ignition System - (continued)

Symptom Possible Cause Corrective Action

4. Pilot lights but continues to spark, and main

burner will not ignite.

(If the pilot continues

to spark after the

pilot fl ame has been lit,

fl ame rectifi cation has

not occurred.)

a. A shorted or loose connection in fl ame

sensing rod.

b. Poor fl ame rectifi cation or contaminated

fl ame sensing rod.

c. Module is not grounded. Verify module is securely grounded to metal chassis of

d. Damaged pilot assembly or contami-

nated fl ame sensing rod.

e. Module. Turn ON/OFF rocker switch or wall switch to OFF position.

Verify all connections to wiring diagram in manual. Verify

connections underneath pilot assembly are tight. Verify

connections are not grounding out to metal chassis, pilot

burner, pilot enclosure or screen if present, or any other

metal object.

With fi xed glass assembly in place, verify that fl ame is en-

gulfi ng fl ame sensing rod on left side of pilot hood. Flame

sensing rod

rect pilot orifi ce is installed and gas inlet is set to pressure

specifi cations. Clean fl ame sensing rod with emery cloth to

remove any contaminants that may have accumulated on

fl ame sensing rod.

appliance. Verify that wire harness is fi rmly connected to

the module.

Verify that ceramic insulator around the fl ame sensing

rod is not cracked, damaged, or loose. Verify connection

from fl ame sensing rod to white sensor wire. Clean fl ame

sensing rod with emery cloth to remove any contaminants

that may have accumulated on fl ame sensing rod. Verify

continuity with a multimeter with ohms set at lowest range.

Replace pilot if any damage is detected.

Remove ignitor wire “I” from module. Place ON/OFF rocker

switch or wall switch in ON position. If there is no spark at

“I” terminal module must be replaced. If there is a spark at

“I” terminal, module is fi ne.

should glow shortly after ignition. Verify cor-

Heat & Glo • CFL-18/24/30-C, CFL-24-IPI, ST-CFL-24-B • 526-910 Rev. E • 10/08

15

Page 16

5

5

Reference Materials

13

12

A. Service Parts

Service Parts Diagram

11

CFL-18NG-C, CFL-18LP-C

Beginning Manufacturing Date: Nov. 2007

Ending Manufacturing Date: ______

14

15

Log Set Assembly

10

8

6

1

3

17

16

5

9

7

2

4

Part number list on following page.

16

Heat & Glo • CFL-18/24/30-C, CFL-24-IPI, ST-CFL-24-B • 526-910 Rev. E • 10/08

Page 17

Service Parts List

IMPORTANT: THIS IS DATED INFORMATION. When requesting service or replacement

parts for your appliance please provide model number and serial number. All parts listed

in this manual may be ordered from an authorized dealer.

ITEM DESCRIPTION COMMENTS PART NUMBER

1 Log 1

2 Log 2

3 Log 3

4 Log 4

5 Log 5

6

Log 6

7 Log 7

8

Log 8

9 Log 9

10

1 1 Burner Assembly

12 Flexible Gas Connector

13 Grate Assembly

14

15 ON/Off Switch 060-521A

16 Flex Ball Valve Assembly

17

Log 10

Valve NG 418-500

Valve LP 418-501

Pilot Assembly NG 2103-010

Pilot Assembly LP 2103-011

Thermocouple 2103-511

Thermopile 2103-512

Pilot Orifi ce NG 2103-1 16

Pilot Orifi ce LP 2103-1 17

CFL-18NG-C, CFL-18LP-C

SRV481-766

SRV481-755

SRV481-701

SRV481-705

SRV446-702

SRV481-703

SRV402-701

SRV446-706

526-010A

477-301A

526-360

302-320A

Stocked

at Depot

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Mineral Wool

Orifi ce NG (1.55) 526-801

Orifi ce LP (2.30 mm)

Piezo Ignitor

Remote Heat Shield

Vermiculite

Wire Assembly 24 in 089-550A

Heat & Glo • CFL-18/24/30-C, CFL-24-IPI, ST-CFL-24-B • 526-910 Rev. E • 10/08

050-721

526-800 Y

291-513

526-199

060-720

Y

Y

Y

17

Page 18

Service Parts

CFL-24NG-IPI, CFL-24LP-IPI

13

12

Service Parts Diagram

11

Beginning Manufacturing Date: June 2008

Ending Manufacturing Date: ______

14

15

16

Log Set Assembly

10

8

6

18

17

5

9

7

Part number list on following page.

18

Heat & Glo • CFL-18/24/30-C, CFL-24-IPI, ST-CFL-24-B • 526-910 Rev. E • 10/08

1

2

3

4

Page 19

Service Parts List

IMPORTANT: THIS IS DATED INFORMATION. When requesting service or replacement

parts for your appliance please provide model number and serial number. All parts listed

in this manual may be ordered from an authorized dealer.

ITEM DESCRIPTION COMMENTS PART NUMBER

1 Log 1

2 Log 2

3 Log 3

4 Log 4

5 Log 5

6

Log 6

7 Log 7

8

Log 8

9 Log 9

10

1 1 Burner Assembly

12 Flexible Gas Connector

13 Grate Assembly

14

15 Control Module 593-592 Y

16 ON/Off Switch 060-521A Y

17 Flex Ball Valve Assembly

18

Log 10

Valve NG 593-500 Y

Valve LP 593-501 Y

Pilot Assembly NG 2090-012 Y

Pilot Assembly LP 2090-013 Y

Pilot Orifi ce NG 593-528 Y

Pilot Orifi ce LP 593-527 Y

CFL-24NG-IPI, CFL-24LP-IPI

SRV481-766

SRV481-755

SRV526-701

SRV481-705

SRV446-702

SRV481-703

SRV402-701

SRV446-706

526-010A Y

477-301A Y

526-360

302-320A Y

Stocked

at Depot

Battery Pack 593-594A Y

Mineral Wool

Module Heat Shield

Orifi ce NG (1.55) 526-801 Y

Orifi ce LP (2.30 mm)

Remote Heat Shield

Vermiculite

Wire Assembly

Heat & Glo • CFL-18/24/30-C, CFL-24-IPI, ST-CFL-24-B • 526-910 Rev. E • 10/08

050-721

526-198

526-800

526-199

060-720

593-590A Y

Y

19

Page 20

Service Parts

CFL-24NG-C, CFL-24LP-C

13

12

Service Parts Diagram

11

Beginning Manufacturing Date: Nov. 2007

Ending Manufacturing Date: ______

14

15

Log Set Assembly

10

8

6

1

2

3

4

17

16

5

9

7

Part number list on following page.

20

Heat & Glo • CFL-18/24/30-C, CFL-24-IPI, ST-CFL-24-B • 526-910 Rev. E • 10/08

Page 21

Service Parts List

IMPORTANT: THIS IS DATED INFORMATION. When requesting service or replacement

parts for your appliance please provide model number and serial number. All parts listed

in this manual may be ordered from an authorized dealer.

ITEM DESCRIPTION COMMENTS PART NUMBER

1 Log 1

2 Log 2

3 Log 3

4 Log 4

5 Log 5

6

Log 6

7 Log 7

8

Log 8

9 Log 9

10

1 1 Burner Assembly

12 Flexible Gas Connector

13 Grate Assembly

14

15 ON/Off Switch 060-521A Y

16 Flex Ball Valve Assembly

17

Log 10

Valve NG 418-500 Y

Valve LP 418-501 Y

Pilot Assembly NG 2103-010 Y

Pilot Assembly LP 2103-011 Y

Thermocouple 2103-511 Y

Thermopile 2103-512 Y

Pilot Orifi ce NG 2103-1 16 Y

Pilot Orifi ce LP 2103-1 17 Y

CFL-24NG-C, CFL-24LP-C

SRV481-766

SRV481-755

SRV526-701

SRV481-705

SRV446-702

SRV481-703

SRV402-701

SRV446-706

526-010A Y

477-301A Y

526-360

302-320A Y

Stocked

at Depot

Mineral Wool

Orifi ce NG (1.55) 526-801 Y

Orifi ce LP (2.30 mm)

Piezo Ignitor

Remote Heat Shield

Vermiculite

Wire Assembly 24 in 089-550A Y

Heat & Glo • CFL-18/24/30-C, CFL-24-IPI, ST-CFL-24-B • 526-910 Rev. E • 10/08

050-721

526-800

291-513 Y

526-199

060-720

Y

21

Page 22

Service Parts

CFL-30NG-C, CFL-30LP-C

13

12

Service Parts Diagram

11

Beginning Manufacturing Date: Nov. 2007

Ending Manufacturing Date: ______

14

15

Log Set Assembly

10

8

6

1

3

17

16

5

9

11

7

2

4

Part number list on following page.

22

Heat & Glo • CFL-18/24/30-C, CFL-24-IPI, ST-CFL-24-B • 526-910 Rev. E • 10/08

Page 23

Service Parts List

IMPORTANT: THIS IS DATED INFORMATION. When requesting service or replacement

parts for your appliance please provide model number and serial number. All parts listed

in this manual may be ordered from an authorized dealer.

ITEM DESCRIPTION COMMENTS PART NUMBER

1 Log 1

2 Log 2

3 Log 3

4 Log 4

5 Log 5

6

Log 6

7 Log 7

8

Log 8

9 Log 9

10

11 Log 11

12

13 Flexible Gas Connector

14

15

16 ON/Off Switch 060-521A Y

17 Flex Ball Valve Assembly

18

Log 10

Burner Assembly

Grate Assembly

Valve NG 418-500 Y

Valve LP 418-501 Y

Pilot Assembly NG 2103-010 Y

Pilot Assembly LP 2103-011 Y

Thermocouple 2103-511 Y

Thermopile 2103-512 Y

Pilot Orifi ce NG 2103-1 16 Y

Pilot Orifi ce LP 2103-1 17 Y

CFL-30NG-C, CFL-30LP-C

SRV526-766

SRV526-755

SRV526-701

SRV481-705

SRV446-702

SRV481-704

SRV446-705

SRV446-706

SRV530-703

526-010A Y

477-301A Y

526-360

302-320A Y

Stocked

at Depot

Mineral Wool

Orifi ce NG (1.55) 526-801 Y

Orifi ce LP (2.30 mm)

Piezo Ignitor

Remote Heat Shield

Vermiculite

Wire Assembly 24 in 089-550A Y

Heat & Glo • CFL-18/24/30-C, CFL-24-IPI, ST-CFL-24-B • 526-910 Rev. E • 10/08

050-721

526-800

291-513 Y

526-199

060-720

Y

23

Page 24

Service Parts

ST -CFL-24NG-B, ST -CFL-24LP-B

15

Service Parts Diagram

14

Beginning Manufacturing Date: Nov. 2007

Ending Manufacturing Date: ______

16

17

20

18

19

Log Set Assembly

1

10

7

8

9

6

11

12

13

Part number list on following page.

24

Heat & Glo • CFL-18/24/30-C, CFL-24-IPI, ST-CFL-24-B • 526-910 Rev. E • 10/08

2

4

3

5

Page 25

Service Parts List

IMPORTANT: THIS IS DATED INFORMATION. When requesting service or replacement

parts for your appliance please provide model number and serial number. All parts listed

in this manual may be ordered from an authorized dealer.

ITEM DESCRIPTION COMMENTS PART NUMBER

Log 1 SRV569-710

1

Log 2

2

Log 3

3

Log 4

4

Log 5

5

6 Log 6 SRV569-708

Log 7 SRV569-709

7

8 Log 8 SRV569-704

Log 9 SRV569-706

9

10 Log 10 SRV569-707

11

12 Log 12 SRV569-703

13

14 Burner Assembly 526-01 1A Y

15

16 Grate Assembly 526-360

17

18 ON/Off Switch 060-521A Y

19

20

Log 11 SRV569-702

Log 13 SRV569-705

Flexible Gas Connector 477-301A Y

Valve NG 418-500 Y

Valve LP 418-501 Y

Flex Ball Valve Assembly 302-320A Y

Pilot Assembly NG 2103-010 Y

Pilot Assembly LP 2103-011 Y

Thermocouple 2103-511 Y

Thermopile 2103-512 Y

Pilot Orifi ce NG 2103-1 16 Y

Pilot Orifi ce LP 2103-1 17 Y

ST -CFL-24NG-B, ST -CFL-24LP-B

SRV569-711

SRV482-755

Stocked

at Depot

Mineral Wool 050-721

Orifi ce NG (1.55) 526-801 Y

Orifi ce LP (2.30 mm)

Piezo Ignitor 291-513 Y

Remote Heat Shield 526-199

Vermiculite 060-720

Wire Assembly 24 in 089-550A Y

Heat & Glo • CFL-18/24/30-C, CFL-24-IPI, ST-CFL-24-B • 526-910 Rev. E • 10/08

526-800

Y

25

Page 26

B. Limited Lifetime Warranty

Hearth & Home Technologies LIMITED WARRANTY

Hearth & Home Technologies (“HHT”) and its respective brands extends the following warranty for HHT gas, wood, pellet

and electric appliances purchased from an authorized HHT dealer and installed in the United States of America or Canada.

Warranty starts with date of purchase by the original owner (End User) except as noted for replacement parts.

Warranty Period HHT Manufactured Appliances and Venting

Parts Labor Gas Wood Pellet

1 Year XXXXXX

EPA

Wood

Electric Venting

Components Covered

All Parts and Material Except as

covered by Conditions, Exclusion,

and Limitations listed

XX

2 years

3 years X Firepots

5 years 3 years X X Castings & Baffl es

7 years 3 years X X X

10 years 1 year X Burners, Logs & Refractory

Limited

Lifetime

1 year X Firebox & Heat Exchanger

90 Days XXXXXX All Replacement Parts

XXXX Blowers

X Molded Refractory Panels

Igniters, Electronic Components,

and Glass

Firebox, HHT Chimney,

Termination & Heat

Exchanger

See Conditions, Exclusions, and limitations. 9-01-08

CONDITIONS, EXCLUSIONS & LIMITATION OF LIABILITY

• This warranty applies to the original owner and is transferable up to two years from date of purchase to the new homeowner,

provided the purchase was made through an authorized dealer or distributor of HHT, and the appliance remains in its

original place of installation.

• The maximum amount recoverable under this warranty is limited to the purchase price of the product.

• In no event shall HHT be liable for any incidental or consequential damages caused by defects in the product.

• Adjustments, regular maintenance, cleaning and temporary repairs, or the failure to duplicate the problem in the home is

not covered under this warranty.

Page 1 of 2 4021-645A 09-01-08

26

Heat & Glo • CFL-18/24/30-C, CFL-24-IPI, ST-CFL-24-B • 526-910 Rev. E • 10/08

Page 27

B. Limited Lifetime Warranty (continued)

• This limited warranty does not extend to or include surface fi nish on the appliance or terminations, door gasketing, glass

gasketing, glass discoloration, fi rebrick, pellet logs, kaowool or other ceramic insulating materials. Rust and/or corrosion

on any of the metal surfaces, cast iron components, baffl es, fi repots, doors, or fi rebox area are not covered by this

warranty.

• Noise resulting from minor expansion, contraction, or movement of certain parts is normal and complaints related to this

noise are not covered by this warranty.

• HHT’s obligation under this warranty does not extend to damages resulting from: (1) installation, operation or maintenance

of the appliance not in accordance with the installation instructions; operating instructions and the listing agent identifi cation

label furnished with the appliance; (2) installation which does not comply with local building codes; (3) shipping, improper

handling, improper operation, abuse, misuse, accident or unworkmanlike repairs; (4) environmental conditions, inadequate

ventilation or drafting caused by tight sealing construction of the structure or handling devices such as exhaust fans or forced

air furnaces or other such causes; (5) use of fuels other than those specifi ed in the operating instructions; (6) installation

or use of components not supplied with the appliance or any other components not expressly authorized and approved

by HHT; and/or (7) modifi cation of the appliance not expressly authorized and approved by HHT in writing.

• This warranty does not apply to non-HHT venting components, hearth components or other accessories used in conjunction

with the installation of this product.

• This warranty is void if the appliance has been over-fi red or operated in atmospheres contaminated by chlorine, fl uorine,

or other damaging chemicals the appliance is subject to prolonged periods of dampness or condensation, or there is any

damage to the appliance or other components due to water or weather damage which is the result of, but not limited to,

improper chimney or venting installation.

• HHT’s liability under this warranty is limited to the replacement and repair of defective components or workmanship during

the applicable period. HHT may fully discharge all of its obligations under such warranties by repairing the defective

component(s) at HHT’s discretion. Shipping costs are not covered under this warranty.

• Some states do not allow exclusions or limitation of incidental or consequential damages, so those limitations may not

apply to you. This warranty gives you specifi c rights; you may also have other rights, which vary from state to state.

• EXCEPT TO THE EXTENT PROVIDED BY LAW, HHT MAKES NO EXPRESS WARRANTIES OTHER THAN THE

WARRANTY SPECIFIED HEREIN. THE DURATION OF ANY IMPLIED WARRANTY IS LIMITED TO DURATION OF

THE WARRANTY SPECIFIED ABOVE.

This Limited Warranty is effective on all HHT appliances sold after September 01, 2008 and supersedes any and all

warranties currently in existence.

If warranty service is needed, you should contact your installing dealer. If the installing dealer is unable to provide necessary

parts or components, contact the nearest authorized HHT dealer or supplier.

Page 2 of 2 4021-645A 09-01-08

Heat & Glo • CFL-18/24/30-C, CFL-24-IPI, ST-CFL-24-B • 526-910 Rev. E • 10/08

27

Page 28

C. Contact Information

Heat & Glo, a brand of Hearth & Home Technologies Inc.

20802 Kensington Boulevard, Lakeville, MN 55044

www.heatnglo.com

Please contact your Heat & Glo dealer with any questions or concerns.

For the location of your nearest Heat & Glo dealer,

please visit www.heatnglo.com.

- NOTES -

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

CAUTION

DO NOT DISCARD THIS MANUAL

• Important operating

and maintenance

instructions included.

• Read, understand and follow

these instructions for safe

installation and operation.

• Leave this manual with

party responsible for use

and operation.

This product may be covered by one or more of the following patents: (United States) 4593510, 4686807, 4766876, 4793322, 4811534, 5000162, 5016609, 5076254, 51 13843, 5191877, 5218953, 5263471,

5328356, 5341794, 5347983, 5429495, 5452708, 5542407, 5601073, 5613487, 5647340, 5688568, 5762062, 5775408, 5890485, 5931661, 5941237, 5947112, 5996575, 6006743, 6019099, 6048195,

6053165, 6145502, 6170481, 6237588, 6296474, 6374822, 6413079, 6439226, 6484712, 6543698, 6550687, 6601579, 6672860, 6688302B2, 6715724B2, 6729551, 6736133, 6748940, 6748942, 6769426,

6774802, 6796302, 6840261, 6848441, 6863064, 6866205, 6869278, 6875012, 6880275, 6908039, 6919884, D320652, D445174, D462436; (Canada) 1297749, 2195264, 2225408, 2313972; (Australia)

780250, 780403, 1418504 or other U.S. and foreign patents pending.

28

Heat & Glo • CFL-18/24/30-C, CFL-24-IPI, ST-CFL-24-B • 526-910 Rev. E • 10/08

Printed in U.S.A. - Copyright 2008

Loading...

Loading...