Hearth and Home Technologies TOPAZ-D-CWL, 839-1320, TOPAZ-D-CSB, 839-1290, 839-1340 User Manual

...Page 1

R

Quartet Front

• Important operating and

maintenance instructions

included.

TOPAZ

DIRECT VENT ROOM HEATER

Owner’s Manual

Installation and Operation

Model:

839-1290

839-1320

839-1340

844-4120

TOPAZ-D-CSB

TOPAZ-D-CWL

CAUTION

DO NOT DISCARD THIS MANUAL

• Read, understand and

follow these instructions

for safe installation and

operation.

• Leave this manual with

party responsible for use

and operation.

Tested and

Listed by

OMNI-Test Laboratories, Inc.

Solitaire Front

DO NOT

DISCARD

O-T L

C

US

Portland

Oregon USA

WARNING: If the information in these

instructions is not followed exactly, a fire

or explosion may result causing property

damage, personal injury, or death.

• Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

• What to do if you smell gas

- Do not try to light any appliance.

Do not touch any electrical switch. Do not use any

phone in your building.

- Immediately call your gas supplier from a neigh-

bor’s phone. Follow the gas supplier’s instructions.

- If you cannot reach your gas supplier, call the fire

department.

• Installation and service must be performed by a

qualified installer, service agency, or the gas supplier.

This appliance may be installed as an OEM installation in manufactured

home (USA only) or mobile home and must be installed in accordance with

the manufacturer's instructions and the manufactured home construction

and safety standard, Title 24 CFR, Part 3280 or Standard for Installation

in Mobile Homes, CAN/CSA Z240MH.

This appliance is only for use with the type(s) of gas indicated on the

rating plate.

www.quadrafire.com

WARNING

HOT SURFACES!

Glass and other surfaces are

hot during operation AND cool

down.

Hot glass will cause burns.

• Do not touch glass until it is

cooled

• NEVER allow children to touch glass

• Keep children away

• CAREFULLY SUPERVISE children in the same

room as appliance

• Alert children and adults to hazards of high

temperatures

High temperatures may ignite clothing or other

flammable materials.

• Keep clothing, furniture, draperies and other

combustibles away.

In the Commonwealth of Massachusetts:

• installation must be performed by a licensed plumber or gas

fitter.

See Table of Contents for additional Commonwealth of Massachusetts requirements.

Installation and service of this appliance should be

performed by qualified personnel. Hearth & Home

Technologies suggests NFI certified or factory-trained

professionals, or technicians supervised by an NFI

certified professional.

7009-113G

September 1, 2008

Page 2

and Welcome to the Quadra-Fire Family!

Hearth & Home Technologies welcomes you to our tradition

of excellence! In choosing a Quadra-Fire appliance, you

have our assurance of commitment to quality, durability,

and performance.

This commitment begins with our research of the market,

including ‘Voice of the Customer’ contacts, ensuring we

make products that will satisfy your needs. Our Research

and Development facility then employs the world’s most

advanced technology to achieve the optimum operation

SAMPLE OF SERIAL NUMBER / SAFETY LABEL

LOCATION: HANGING ON A CHAIN ON BACK OF APPLIANCE

Portland

Report No. / Rapport Numéro

061-S-19B-5

APPROVED FOR CANADA AND USA TO:

ANSI Z21.88a-2000 / CSA 2.33a-M-00 Vented Gas Fireplace Heaters, and

applicable sections of UL307b Gas Burning Heating Appliances for

Manufactured Homes and Recreational Vehicles, CAN/CGA 2.17-M91

“Gas Fired Appliances for use at High Altitudes.” This appliance is

manufactured for operation with Natural Gas.

FAN TYPE VENTED CIRCULATOR / VENTILATEUR CIRCULATOIRE

Blower Electrical Rating / Évaluation du Ventilateur

115 V., 1.5 Amps, 60 Hz, 150 Watts

Top Vent/Rear Vent:

Input Rate on “HI” (BTU/Hr)

Input Rate on “LO” (BTU/Hr)

Maximum Output (BTU/Hr)**

Main Burner Orifice (DMS)

Minimum Inlet Pressure (Inches W.C.)

Maximum Inlet Pressure (Inches W.C.)

Manifold Pressure on “HI” (Inches W.C.)

**Max Venting, Blower On

This appliance equipped only for altitudes 0-2000’ (0-610m) in USA; and in Canada for altitudes of 0-4500’ (0-1370m). In USA for Altitudes above 2000’, the vent

configuration, orifice, or combination of both may need to be changed. See Owner’s Manual for information on making these changes.

This appliance must be installed in accordance with local codes, if any (and Commonwealth of Massachusetts approved); if none, follow National Fuel Gas Code ANSI Z223.1,

or Canadian Installation Codes, CAN/CGA-B149 in Canada. Install and use only in accordance with manufacturer’s installation and operating instructions.

supply line installed in accordance with local building codes by a qualified installer approved and/or licensed as required by the locality. (In the Commonwealth of Massachusetts, installation

must be performed by a licensed plumber or gas fitter.)

Cet appareil est équipé pour les altitudes de 0-2000’ (0-610m) aux États-Unis; et au Canada pour les altitudes de 0-4500’ (0-1370m). Pour les altitudes au dessus de 2000’

aux États-Unis, la configuration du ventilateur, son orifice ou les deux peuvent possiblement avoir à être changé. Voyez le manuel du propriétaire pour les informations sur

Cet appareil doit être installé en accord avec les codes locaux, s’il-y-a lieu (et approuvé par dans la République de Massachusetts); sinon lisez au National

ces changements.

Fuel Gas Code ANSI Z223.1, ou aux code courant d'installation Installez et utilisez en accords avec les instructions d’installation et d’opération du manufacturier.

Le conduit gaz doit être installé conformément aux codes de construction locaux. L'installation doit être effectuée par un technicien qualifeé et/ou muni d'une licence de manière à

respecter les règlements municipaux. (Dans la République de Massachusetts, l'installation doit être effectuée par un plombier ou un installateur d'appareils à gaz agrée.)

This appliance must be installed in accordance with the current Standard CAN/CSA Z240 MH, Mobile Housing or with Manufactured Home Construction and Safety Standard,

Title 24 CFR, Part 3280, or when such standard is not applicable, ANSI/NCSBCS A225.1/NFPA 501A, Manufactured Home Installation Standard.

WARNING:

Do not operate the appliance until all sections have been assembled and installed in accordance with the manufacturer's instructions.

Installer l'appareil selon la norme CAN/CSA-Z240, Série MM, Maisons mobiles ou la norme 24 CFR Part 3280, Manufactured Home Construction and Safety Standard. Si ces

normes ne sont pas pertinentes, utilisez la norme ANSI/NCSBCS A225.1/NFPA 501A, Manufactured Home Installations Standard.

AVERTISSEMENT: Ne pas utiliser l'appareil tant que toutes les sections n'ont pas ete assemblees et installees selon les instructions du fabricant.

This appliance must be properly connected to a venting system in accordance with the manufacturer's installation instructions.

Cet apprareil doit être correctement raccordé à un système d'évacuation, conformément aux instructions du fabricant

MODEL / MODÈLE: TOPAZ

VENTED GAS FIREPLACE HEATER FOURNAISE AU GAZ AVEC

VENTILATION. NOT FOR USE WITH SOLID FUEL / NE PAS UTILISER

For use with Natural Gas

Usage au Gaz Naturel

0-2000’

39,500

26,500

33,600

.125”

4.5“

7.0”

3.5”

AVEC LE COMBUSTIBLE SOLIDE.

APPROUVÉ POUR LE CANADA ET LES ÉTATS-UNIS:

ANSI Z21.88a-2000 / CSA 2.33a-M-00 Fournaises au Gaz avec Ventilation,

et les sections applicable de UL 307b Appareils de Chauffage Au Gaz pour

les Maisons Mobiles et les Véhicules Motorisés, CAN/CGA 2.17-M91 “Gas

Fired Appliances for use at High Altitudes”.

Cet appareil est manufacturé pour l’opération avec le Gaz Naturel.

Thermal Efficiency / Efficacité Thermique* 85% NG (blower on / avec ventilateur allumé)

85% LP (blower on / avec ventilateur allumé)

Électrique:

For use with Propane

Usage au Gaz Propane

0-2000’

38,000

30,500

32,500

.073” (49DMS)

11“

14”

10”

P.4.1-02 Canada Minimum pipe (P.4.1-02 Le canada tuyau minimum) 62.98% NG / 64.14% LP

SERIAL NO.

* With Maximum horizontal length. / Avec longueur horizontale maximum.

Bouche Supérieure/Conduit postérieur:

Puissance Évaluée à “HI” (BTU/Hr)

Puissance Évaluée à “LO” (BTU/Hr)

Puissance Maximum (BTU/Hr)**

Orifice du Brûleur Principal

Pression Minimum de la Valve (pouces W.C.)

Pression Maximum de la Valve (pouces W.C.)

Pression du Collecteur d’ Échappement à “HI” (pouces W.C.)

** Ventilation Maximum, Ventilateur Allumé

SAMPLE

F

B

E

A

A

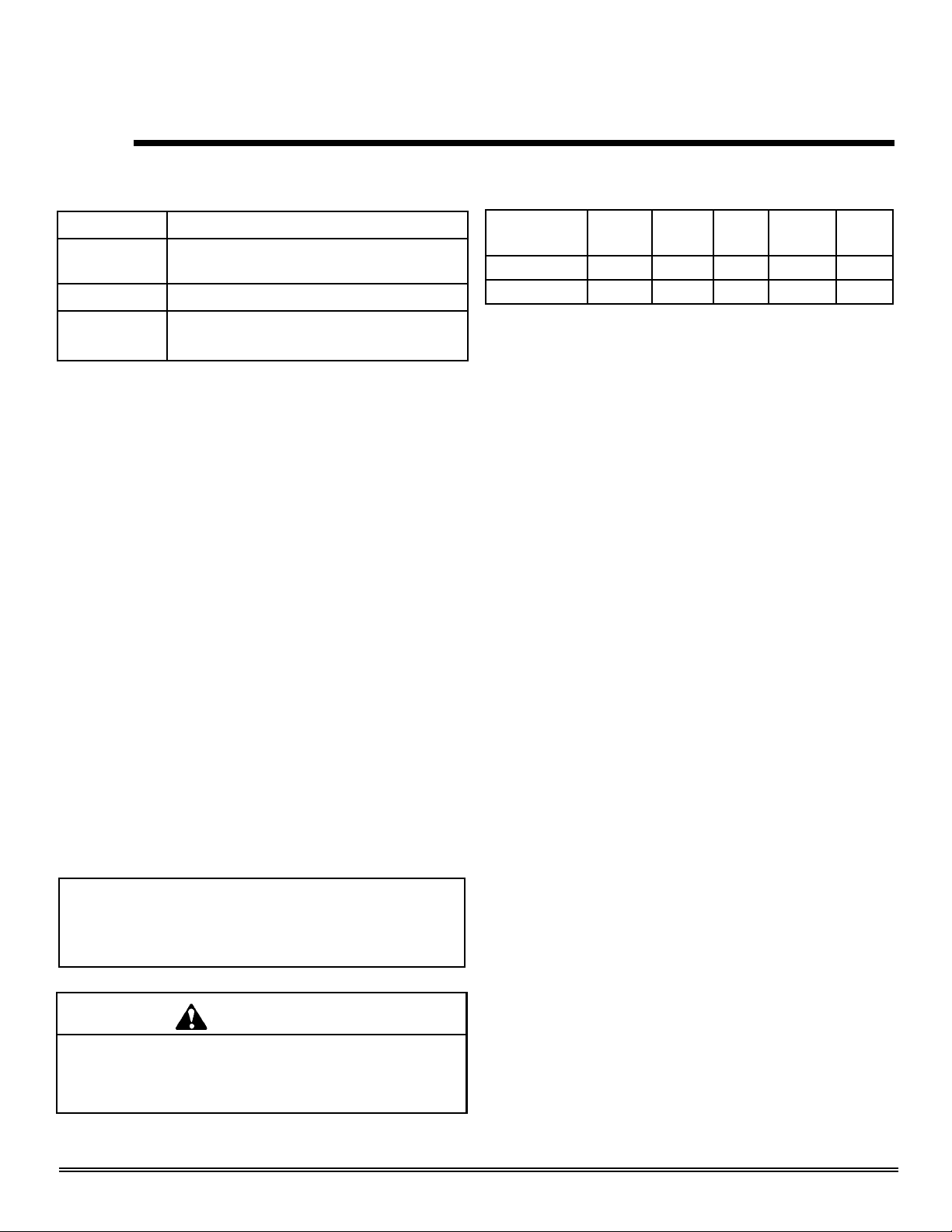

A. Side of stove top to side wall 6.5" (152 mm) Du coté du poêle au coté du mur

B. Rear of stove top to back wall 6" (100 mm) Le contrôle arrière au mur arrière

C. Corner of stove top to side wall 1" (152 mm) Du Coin du poêle du mur

D. Minimum Alcove Height 54" (1372 mm)

E. Maximum Alcove Depth 36" (914 mm) Profondeur maximale de l'alcôve

F. Minimum Alcove Width 40"(915 mm)

G. Mantle clearance from stove top 23"(584mm) Espace libre du poêle au manteau

HEARTH: A non-combustible hearth pad is not required. However, the floor beneath the stove must be stable, level, and strong enough to support the stove without a tipping hazard.

CHEMINÉE: Un coussinet non-combustible de cheminée n’est pas exigé. Cependant, le plancher en dessous du poêle doit être droit, à niveau et assez fort pour

supporter le poêle sans le hasard de basculer.

2008 2009 2010 Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Jan

DO NOT REMOVE THIS LABEL / NE PAS ENLEVER L’ÉTIQUETTE

C

C

Date of Manufacture / Date du Manufacturier

G

D

Made in U.S.A. / Fait Aux États-Unis

of our stoves, inserts and fireplaces. And yet we are oldfashioned when it comes to craftsmanship. Each appliance

is meticulously fabricated and gold and nickel surfaces are

hand-finished for lasting beauty and enjoyment. Our pledge

to quality is completed as each model undergoes a quality

control inspection.

We wish you and your family many years of enjoyment in

the warmth and comfort of your hearth appliance. Thank

you for choosing Quadra-Fire.

1445 North HIghway

Colville, WA 99114

www.quadrafire.com

Serial Number

Barcode

Model Name

Test Lab & Report No.

NOTE: Have the gas

REMARQUE:

A

Hauteur minimum du plancher au plafond

A

Largeur minimum de l'alÔve

250-7141

Manufactured Date

Page 2

Quadra-Fire · Topaz · 7009-113G

September 1, 2008

Page 3

- TABLE OF CONTENTS -

Section 1: Listing and Code Approvals

A. Appliance Certifications ......................4

B. Glass Specifications ............................4

C. BTU Specifications ..............................4

D. High Altitude Installations ....................4

E. Non-Combustible Materials .................4

F. Combustible Materials ........................4

G. Requirements for the

Commonwealth of Massachusetts ......5

Section 2: Getting Started

A. Design & Installation

Considerations ....................................6

B. Tools and Supplies Needed................6

C. Inspect Appliance & Components .......6

Section 3: Appliance Location & Clearances

A. Selecting Appliance Location..............7

B. Clearances to Combustibles ...............7

Section 4: Termination Locations

A. Vent Termination Minimum

Clearances..........................................8

Section 7: Electrical Information

A. Recommendation for Wire ..................27

B. Connecting to the Appliance ...............27

C.

Section 8: Appliance Setup

A. Remove Shipping Materials ................29

B. Top to Rear Vent Conversion .............29

D. Accessories .........................................30

E. Front Installation .................................31

F. Brick Installation ..................................31

G. Positioning the Logs ............................32

H. Mineral Wool .......................................33

I. Glass Door Assembly Replacement ...34

J. Blower Installation ...............................34

K. Damper Adjustment ............................36

L. Shutter Adjustment .............................36

Section 9: Operating Instructions

A. Before Lighting Appliance ...................37

B. Controls ...............................................37

C. Lighting Appliance ...............................38

D. After Appliance is Lit ...........................39

E. Frequently Asked Questions ...............39

Standing Pilot Ignition System Wiring

C. Leg Leveling System ...........................30

..27

Section 5: Vent Information

A. Venting Components ..........................10

B. Use of Elbows .....................................10

C. Measuring Standards ..........................10

D. How to Use the Vent Graph ................11

E. Venting Guidelines ..............................11

F. Horizontal Termination ........................12

G. Vertical Termination ............................15

Section 6: Gas Information

A. Fuel Conversions ................................23

B. Gas Pressures ....................................25

C. Gas Connection.. ................................26

Section 10: Troubleshooting ............................... 40

Section 11: Maintaining & Servicing Appliance

A. Maintenance Tasks .............................43

Section 12: Reference Materials

A. Appliance Dimension Diagram ...........44

B. Vent Components Diagram ................45

C. Vent Components List ........................46

D. Service Parts List ................................48

E. Accessories ........................................52

F. Service and Maintenance Log ............53

G. Warranty Policy ...................................54

H. Contact Information ............................56

September 1, 2008

Quadra-Fire · Topaz · 7009-113G

Page 3

Page 4

1

Listing and Code Approvals

A. Appliance Certification

MODEL:

LABORATORY:

TYPE:

STANDARD:

The product is listed to ANSI standards for “Vented Gas

Appliance Heaters” and applicable sections of “Gas Burning

Heating Appliances for Manufactured Homes and Recreational Vehicles” and "Gas Fired Appliances for use at High

Altitudes".

Manufactured Home or Mobile Home installation may occur

only after the home is site located and must conform with

the Manufactured Home Construction and Safety Standard,

Title 24 CFR, Part 3280, or, when such a standard is

not applicable, the Standard for Manufactured Home

Installations, ANSI/NCSBCS A225.1, or Standard for Gas

Equipped Recreational Vehicles and Mobile Housing, CSA

Z240.4.

Topaz

OMNI Test Laboratories, Inc.

061-S-24-5

Direct Vent Gas Heater

ANSI Z21.88a-2000

UL307bּCAN/CBA 2.17-M91

ּCSA 2.33a-M00ּ

C. BTU Specifications

Model

(US or Canada)

Topaz (NG)

Topaz (LP)

* Thermal efficiency maximum pipe with blower on.

** Canada minimum pipe.

Maximum

Input BTU

39,500 26,500 .125 85 63

38,000 30,500 .073 85 64

Minimum

Input

BTU

Orifice

Size

*Efficiency

Up To

**P.4

%

D. High Altitude Installations

Omni-Test Laboratories listed gas appliances are tested and

approved without requiring changes for elevations from 0 to

2000 feet in the U.S.A. and 0 to 4500 feet in Canada.

When installing this appliance at an elevation above 2000

feet, it may be necessary to decrease the input rating by

changing the existing burner orifice to a smaller size. Input

rate should be reduced by 4% for each 1000 feet above a

2000 foot elevation in the U.S.A. If the heating value of the

gas has been reduced, these rules do not apply. To identify

the proper orifice size, check with the local gas utility.

When installed, the appliance must be electrically grounded

in accordance with local codes or, in the absence of local

codes, with the National Electrical Code, ANSI/NFPA 70, or

the Canadian Electrical Code, CSA C22.1.

B. Glass Specifications

This appliance is equipped with 5mm ceramic glass. Replace

glass only with 5mm ceramic glass. Please contact your

dealer for replacement glass.

NOTE: This installation must conform with local codes. In the

absence of local codes you must comply with the National

Fuel Gas Code, ANSI Z223.1-latest edition in the U.S.A.

and the CAN/CGA B149 Installation Codes in Canada.

WARNING

Do NOT use this appliance if any part has been under water.

Immediately call a qualified service technician to inspect

the unit and to replace any part of the control system and

any gas control which has been under water.

If installing this appliance at an elevation above 4500 feet (in

Canada), check with local authorities.

E. Non-Combustible Materials

Materials that are reported as passing ASTM E 136,

Standard Test Method for Behavior of Materials in a Vertical

Tube Furnace at 750°C, shall be considered non-combustible

materials.

F. Combustible Materials

Materials made of or surfaced with wood, compressed

paper, plant fibers, plastics, or other materials that can ignite

and burn, whether flame proofed or not, or whether plastered

or unplastered shall be considered combustible materials.

Page 4

Quadra-Fire · Topaz · 7009-113G

September 1, 2008

Page 5

NOTE: The following requirements reference various

Massachusetts and national codes not contained in this

document.

G. Requirements for the Commonwealth of

Massachusetts

For all side wall horizontally vented gas fueled equipment

installed in every dwelling, building or structure used in whole

or in part for residential purposes, including those owned or

operated by the Commonwealth and where the side wall

exhaust vent termination is less than seven (7) feet above

finished grade in the area of the venting, including but not

limited to decks and porches, the following requirements

shall be satisfied:

Installation of Carbon Monoxide Detectors

At the time of installation of the side wall horizontal vented

gas fueled equipment, the installing plumber or gas fitter shall

observe that a hard wired carbon monoxide detector with an

alarm and battery back-up is installed on the floor level where

the gas equipment is to be installed. In addition, the installing

plumber or gas fitter shall observe that a battery operated or

hard wired carbon monoxide detector with an alarm is installed

on each additional level of the dwelling, building or structure

served by the side wall horizontal vented gas fueled equipment. It shall be the responsibility of the property owner to

secure the services of qualified licensed professionals for the

installation of hard wired carbon monoxide detectors.

In the event that the side wall horizontally vented gas fueled

equipment is installed in a crawl space or an attic, the hard

wired carbon monoxide detector with alarm and battery backup may be installed on the next adjacent floor level.

In the event that the requirements of this subdivision can not

be met at the time of completion of installation, the owner shall

have a period of thirty (30) days to comply with the above

requirements; provided, however, that during said thirty (30)

day period, a battery operated carbon monoxide detector with

an alarm shall be installed.

Approved Carbon Monoxide Detectors

Each carbon monoxide detector as required in accordance

with the above provisions shall comply with NFPA 720 and

be ANSI/UL 2034 listed and IAS certified.

Signage

A metal or plastic identification plate shall be permanently

mounted to the exterior of the building at a minimum height

of eight (8) feet above grade directly in line with the exhaust

vent terminal for the horizontally vented gas fueled heating

appliance or equipment. The sign shall read, in print size no

less than one-half (1/2) inch in size, “GAS VENT DIRECTLY

BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS.”

Inspection

The state or local gas inspector of the side wall horizontally

vented gas fueled equipment shall not approve the installation unless, upon inspection, the inspector observes carbon

monoxide detectors and signage installed in accordance with

the provisions of 248 CMR 5.08(2)(a) 1 through 4.

Exemptions

The following equipment is exempt from 248 CMR 5.08(2)(a)

1 through 4:

The equipment listed in Chapter 10 entitled “Equipment

•

Not Required To Be Vented” in the most current edition of

NFPA 54 as adopted by the Board; and

Product Approved side wall horizontally vented gas fueled

•

equipment installed in a room or structure separated from

the dwelling, building or structure used in whole or in part

for residential purposes.

MANUFACTURER REQUIREMENTS

Gas Equipment Venting System Provided

When the manufacturer of Product Approved side wall

horizontally vented gas fueled equipment provides a venting system design or venting system components with the

equipment, the instructions provided by the manufacturer for

installation of the equipment and the venting system shall

include:

•

Detailed instructions for the installation of the venting system design or the venting system components; and

•

A complete parts list for the venting system design or

venting system.

Gas Equipment Venting System NOT Provided

When the manufacturer of a Product Approved side wall horizontally vented gas fueled equipment does not provide the

parts for venting the flue gases, but identifies “special venting systems”, the following requirements shall be satisfied by

the manufacturer:

•

The referenced “special venting system” instructions shall

be included with the appliance or equipment installation

instructions; and

•

The “special venting system” shall be Product Approved

by the Board, and the instructions for that system shall

include a parts list and detailed installation instructions.

A copy of all installation instructions for all Product Approved

side wall horizontally vented gas fueled equipment, all venting instructions, all parts lists for venting instructions, and/or

all venting design instructions shall remain with the appliance or equipment at the completion of the installation.

See Gas Connection section for additional Commonwealth of Massachusetts requirements.

September 1, 2008

Page 5Quadra-Fire · Topaz · 7009-113G

Page 6

Getting Started

2

A

. Design & Installation Considerations

Quadra-Fire direct vent gas appliances are designed to operate with all combustion air drawn from outside of the building

and all exhaust gases expelled to the outside. No additional

air source is required.

CAUTION

Check building codes prior to installation.

• Installation MUST comply with local, regional, state

and national codes and regulations.

• Consult local building, fire officials or authorities having

jurisdiction about restrictions, installation inspection,

and permits.

C. Inspect Appliance & Components

WARNING

Inspect appliance and components for

damage. Damaged parts may impair safe

operation.

• Do NOT install damaged components.

• Do NOT install incomplete components.

• Do NOT install substitute components.

Report damaged parts to dealer.

• Carefully remove the appliance and components from

the packaging.

When planning an installation, it is necessary to determine

the following information before installing:

• Where the appliance is to be installed.

•

The vent system configuration to be used.

• Gas supply piping.

• Electrical wiring.

• Whether optional accessories - devices such as a blower,

thermostat or remote control - are desired.

WARNING

Keep appliance dry.

• Mold or rust may cause odors.

• Water may damage controls.

B. Tools and Supplies Needed

Before beginning the installation be sure that the following

tools and building supplies are available. Note: Not all

tools will apply to every installation.

• Remove cast door and glass door, and set aside on pro-

tective surface. See page 34.

• Remove log set and component pack from firebox.

• Report to your dealer any parts damaged in shipment,

particularly the condition of the glass.

• Read all of the instructions before starting the installation. Follow these instructions carefully during the

installation to ensure maximum safety and benefit.

WARNING

Hearth & Home Technologies disclaims any

responsibility for, and the warranty will be

voided by, the following actions:

• Installation and use of any damaged appliance or vent

system component.

• Modification of the appliance or vent system.

• Installation other than as instructed by Hearth & Home

Technologies.

• Improper positioning of the gas logs or the glass door.

• Installation and/or use of any component part not approved

by Hearth & Home Technologies.

Any such action may cause a fire hazard.

Reciprocating saw

Pliers

Hammer

Phillips Screwdriver

Flat Blade Screwdriver

Plumb Line

Level

Manometer

Tape Measure

Page 6

Variable Speed Drill/Driver

Wrench Set

Framing Square

Framing Material

Hi temp caulking material

Voltmeter

Gloves

Safety Glasses

Non-corrosive Leak Check Solution

or combustible gas detector

Quadra-Fire · Topaz · 7009-113G

September 1, 2008

Page 7

3

Appliance Location and Clearances

NOTE:

· Illustrations reflect typical installations and are FOR

DESIGN PURPOSES ONLY.

· Illustrations/diagrams are not drawn to scale.

· Actual installation may vary due to individual design

preference.

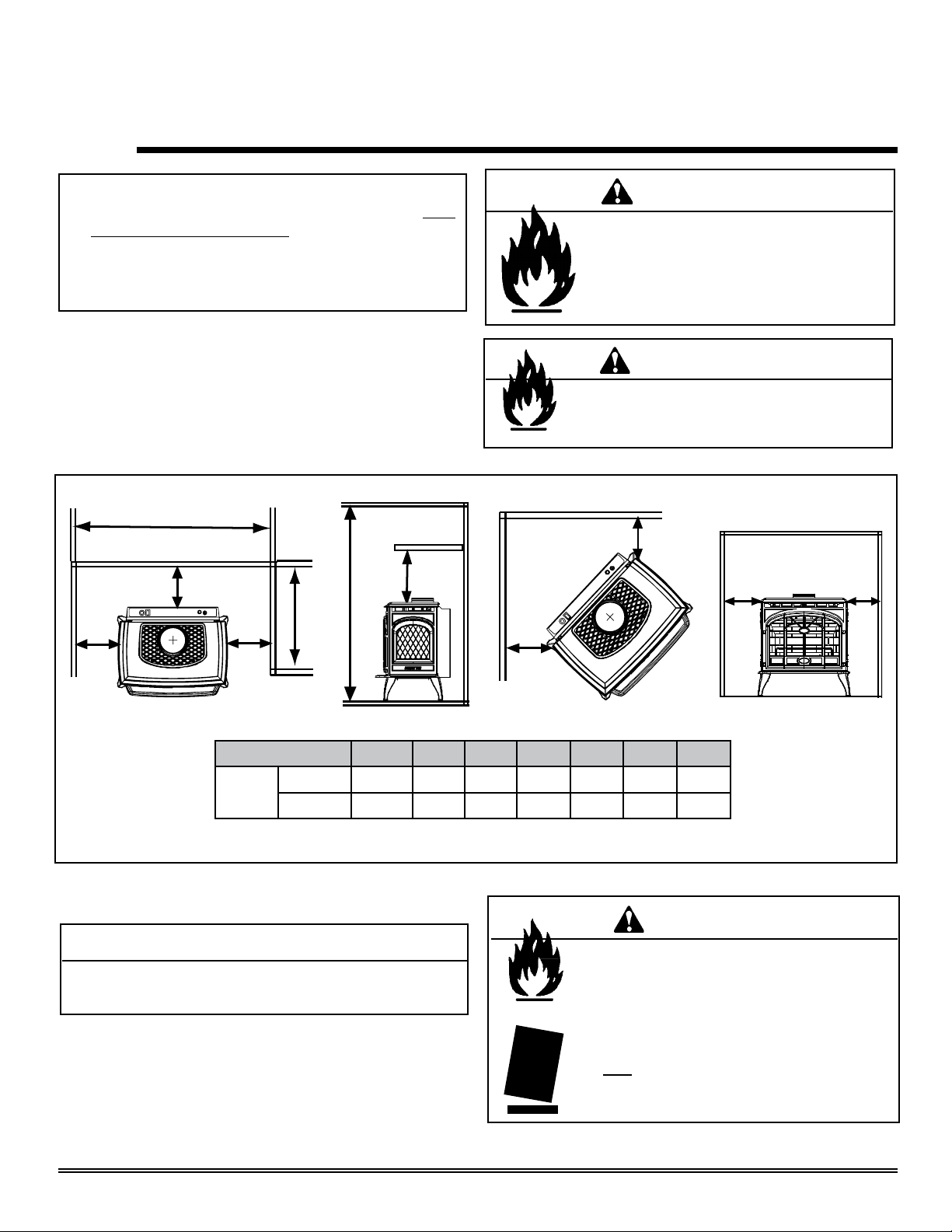

A. Selecting Appliance Location

When selecting a location for your appliance it is important to

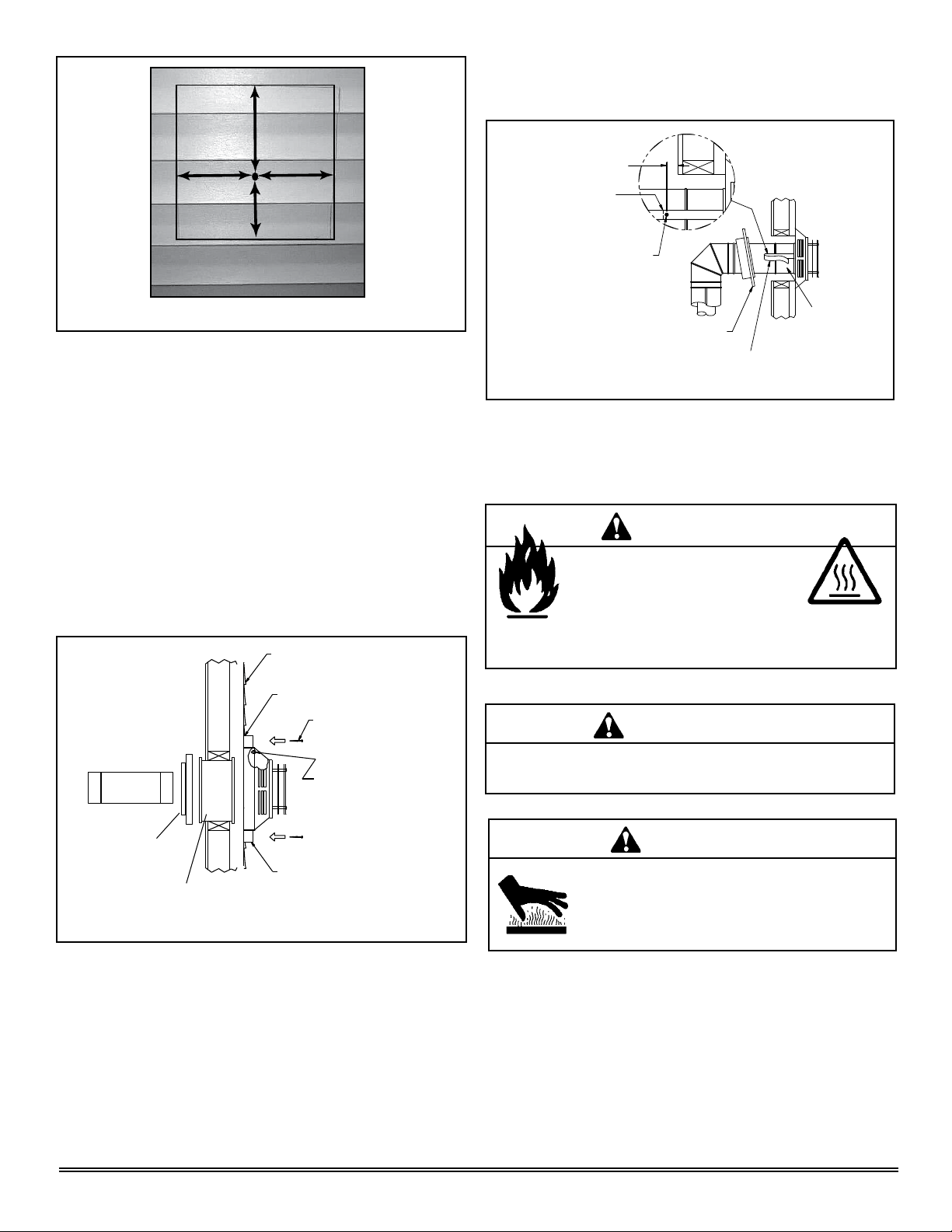

consider the required clearances to walls (see Figure 3.1).

B. Clearances

F

D

G

B

E

WARNING

Fire Risk

Provide adequate clearance:

• Around air openings

• To combustibles

• For service access

Locate appliance away from traffic areas.

WARNING

Fire Risk.

• Locate and install appliance to all

clearance specifications in manual.

C

A

A

A

Figure 3.1

It is permissible to place the appliance on carpet.

A

Model ABCDEFG

Topaz

Inches

Millimeters

6-1/2 6 1 54 36 40 23

165 152 25 1372 914 1016 584

CAUTION

Some carpet materials may be sensitive to radiant heat from the

appliance causing discoloration or odor.

NOTE: Flooring beneath appliance may reach 90 degrees

plus room ambient temperature. Check with flooring

manufacturer for maximum temperature allowed on flooring

surfaces.

C

WARNING

Fire Risk.

Odor Risk.

Tipping Risk

• Install appliance on a stable, level platform/

floor strong enough to support appliance

without tipping.

USE wood flooring, ceramic tile, brick hearth

•

or high pressure laminate flooring applied

directly over the sub-flooring material.

September 1, 2008

Page 7Quadra-Fire · Topaz · 7009-113G

Page 8

Termination Locations

4

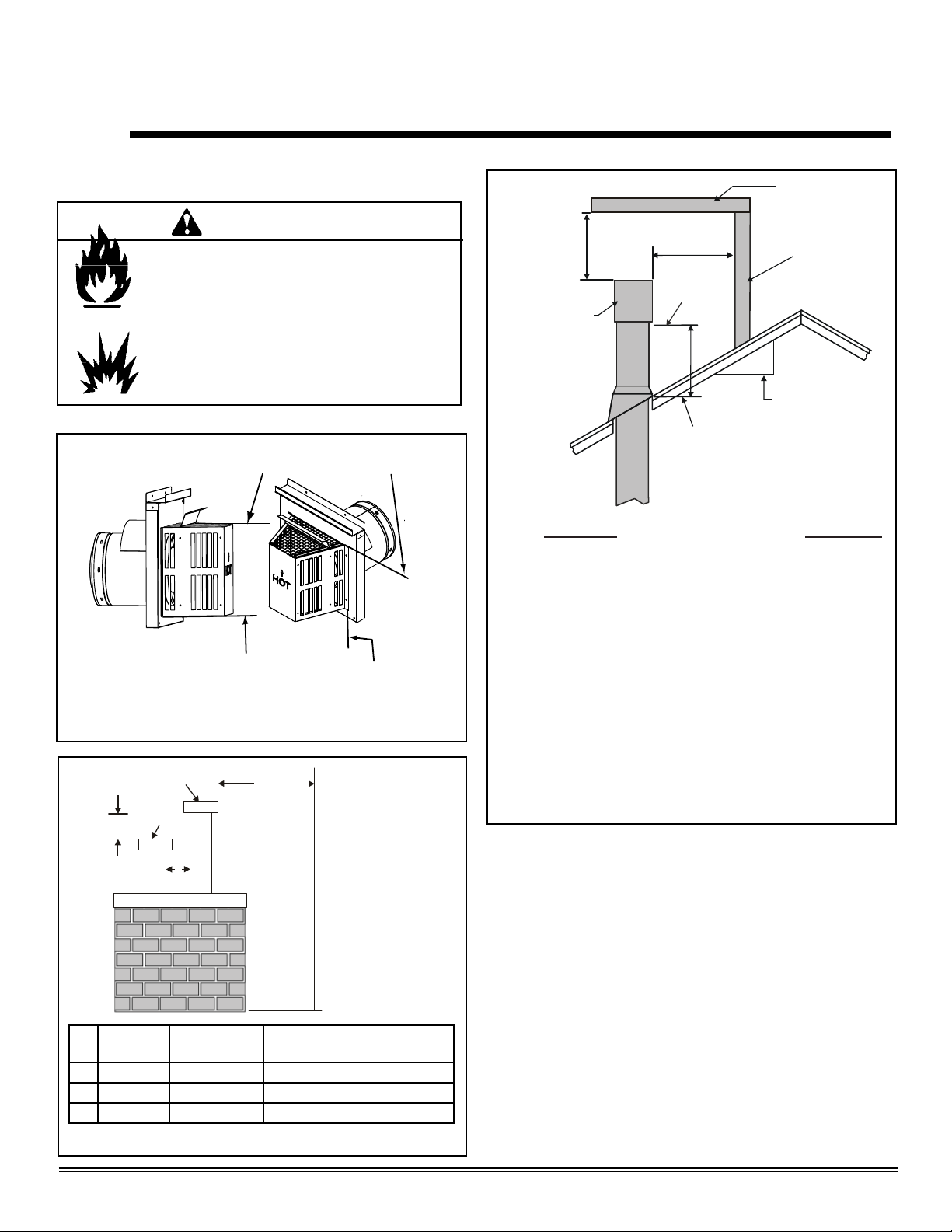

A. Vent Termination Minimum Clearances

HORIZONTAL

OVERHANG

WARNING

Fire Risk.

Explosion Risk.

Maintain vent clearance to combustibles

as specified.

• Do not pack air space with insulation or

other materials.

Failure to keep insulation or other materials

away from vent pipe may cause fire.

Measure vertical clearances from this surface.

Measure horizontal clearances from this surface.

(See Figure 4.4 for specific clearances.)

Figure 4.1 Termination Clearances

2 FT.

MIN.

GAS DIRECT VENT

TERMINATION CAP

20 INCHES MIN.

LOWEST

DISCHARGE

OPENING

X

12

ROOF PITCH

IS X/ 12

H (MIN.) - MINIMUM HEIGHT FROM ROOF

TO LOWEST DISCHARGE OPENING

Roof Pitch H (Min.) Ft.

Flat to 6/12 .........................................................1.0*

Over 6/12 to 7/12........................................................ 1.25*

Over 7/12 to 8/12 ............................................... 1.5*

Over 8/12 to 9/12 ............................................... 2.0*

Over 9/12 to 10/12 ............................................. 2.5*

Over 10/12 to 11/12 ........................................... 3.25

Over 11/12 to 12/12 ........................................... 4.0

Over 12/12 to 14/12 ........................................... 5.0

Over 14/12 to 16/12 ........................................... 6.0

Over 16/12 to 18/12 ........................................... 7.0

VERTICAL

WALL

GAS, WOOD OR FUEL

OIL TERMINATION

GAS

TERMINATION

C

A

Gas

Termination

A 6 in. 20 in. min. Horizontal distance between terminations

B 20 in. 24 in. min. Distance to perpendicular wall

C 18 in. 18 in. Vertical distance between terminations

Figure 4.2 Multiple Vertical Termination

Wood & Fuel Oil

Termination

Page 8

B

Comments

Quadra-Fire · Topaz · 7009-113G

Figure 4.3 Minimum Height from Roof to Lowest Discharge

Opening

Figure 4.3 specifies minimum vent heights for various

pitched roofs.

September 1, 2008

Page 9

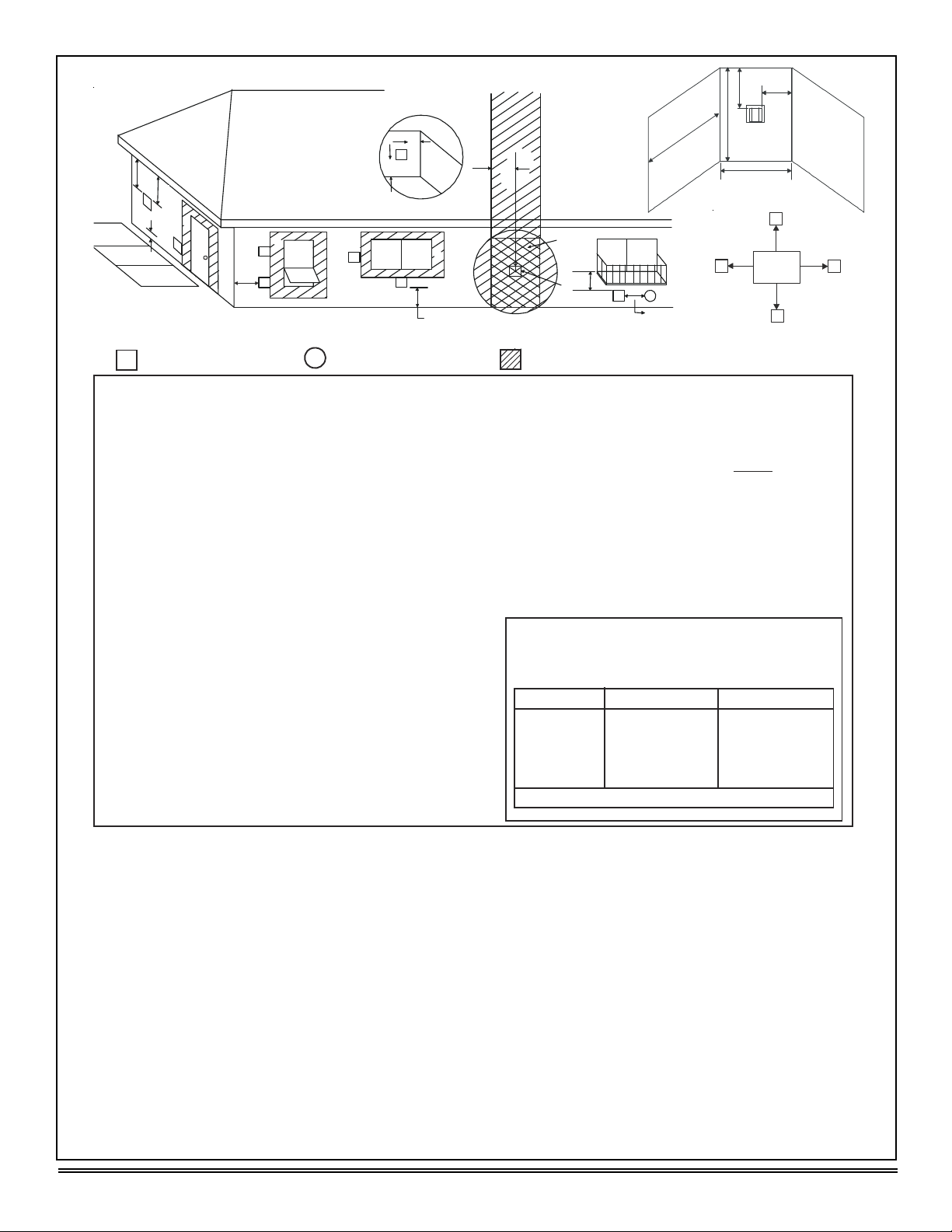

M

N

P

X

J or K

R

Q

(See Note 2)

S

V

V

T

Electrical

Service

D*

V

S

V

G

v

D

E

v

B

L

v

B

v

F

v

A

B

v

B

v

H

U.S.

(3 FT)

M

I

v

A

= VENT TERMINAL

V

A = 12 inches ............. clearances above grade, veran-

(See Note 1)

X

= AIR SUPPLY INLET = AREA WHERE TERMINAL IS NOT PERMITTED

da, porch, deck or balcony

B = 12 inches ............ clearances to window or door

that may be opened, or to permanently closed window. (Glass)

D* = 18 inches ............. vertical clearance to unventilat-

ed soffit or to ventilated soffit located above the terminal

*30 inches............ for vinyl clad soffits and below

electrical service

F = 9 inches .............. clearance to outside corner

G = 6 inches ............... clearance to inside corner

H = 3 ft. (Canada) ...... not to be installed above a gas

meter/regulatorassembly within3

feet (90cm) horizontally from the

center-line of the regulator

I

= 3 ft. ................

.......

clearance to gas service regula-

tor vent outlet

J = 9 inches (U.S.A.)

12 inches (Canada)clearance to non-mechanical air

supply inlet to building or the

combustion air inlet to any other

appliance

K = 3 ft. (U.S.A.)

6 ft. (Canada) ......... clearance to a mechanical

(powered) air supply inlet

L** = 7 ft. ......................... clearance above paved

(See Note 1)

sidewalkor a paved driveway

located on public property

M*** = 18 inches .............. clearance under veranda ,

porch, deck, balconyor overhang

42 inches .............. vinyl

S = 6 inches ................. cleara n ce from sides of

(See Note 3)

electrical service

T = 12 inches ................ clearance above electrical

(See Note 3)

service

Alcove Applications

N = 6 inches ................. non-vinyl sidewalls

P=8ft.

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

12 inches ............... vinyl sidewalls

Q

MIN

1 cap 3 feet 2 x Q

2 caps 6 feet 1 x Q

3 caps 9 feet 2/3 x Q

4caps 12feet 1/2xQ

Q

= # termination caps x 3 R

MIN

= (2 / # termination caps) x Q

MAX

R

MAX

ACTUA L

ACTUA L

ACTUA L

ACTUA L

ACTUAL

_

_

_

_

** a vent shall not terminate directly above a sidewalk or paved

driveway which is located between two single family dwellings and

serves both dwellings.

*** only permitted if veranda, porch, deck or balcony is fully open on

a minimum of 2 sides beneath the floor, or meets Note 2.

NOTE 1: On private property where termination is less than 7 feet above

a sidewalk, driveway, deck, porch, veranda or balcony, use of a listed

cap is suggested. (See vents components pages.)

NOTE 2: Termination in an alcove space (spaces only open on one side

and

without

an overhang) are permitted with the dimensions specified for

vinyl or non-vinyl siding and soffits. 1. There must be at least 3 feet

minimum between termination caps. 2. All mechanical air intakes within

10 feet of a termination cap must be a minimum of 3 feet below the

termination cap. 3.All gravity air intakes within 3 feet of a termination cap

must be a minimum of 1 foot below the termination cap.

NOTE 3: Location of the vent termination must not interfere with access

to the electrical service.

Figure 4.4

September 1, 2008

NOTE: Local codes or regulations may require different

clearances.

NOTE: Termination caps may be hot. Consider their proximity to

doors or other traffic areas.

WARNING: In the U.S.: Vent system termination is NOT permitted

in screened porches. You must follow side wall, overhang and

ground clearances as slated in the instructions.

In Canada: Vent system termination is NOT permitted in screened

porches. Vent system termination is permitted in porch areas with

two or more sides open. You must follow side wall, overhang and

ground clearances as stated in the instructions.

Quadra-Fire assumes no responsibility for the improper performance of the appliance when the venting system does not meet

these requirements.

CAUTION: IF EXTERIOR WALLS ARE FINISHED WITH

VINYL SIDING, IT IS SUGGESTED THAT A VINYL PROTECTOR KIT BE INSTALLED.

Page 9Quadra-Fire · Topaz · 7009-113G

Page 10

5

Vent Information

A. Venting Components

In order to comply with applicable codes and product

warranties, use only following venting components:

• Hearth & Home Technologies (HHT)

• Simpson Dura-Vent

• Selkirk Direct-Temp

• Amerivent Direct

• Security Secure Vent

DO NOT USE FIELD-FABRICATED VENTING

COMPONENTS. Refer to the venting manufacturer’s

instructions.

This product is approved to be vented either horizontally,

through the side wall or vertically through the roof. You may

vent through a Class A or masonry chimney if an approved

adapter is used.

This appliance is a direct vent heater. All combustion air must

come directly from the outside of the building. The vent pipe

for this unit consists of an inner and an outer pipe. The inner

pipe carries the appliance exhaust out of the system, and the

outer pipe brings fresh combustion air into the appliance.

• A round support box/wall thimble or heat shield is

required when the venting passes through a combustible wall.

• A support box or ceiling firestop is required when the

venting passes through a ceiling.

• Roof flashing and a storm collar are required when venting passes through the roof.

• Follow instructions provided with the venting for installation of these items.

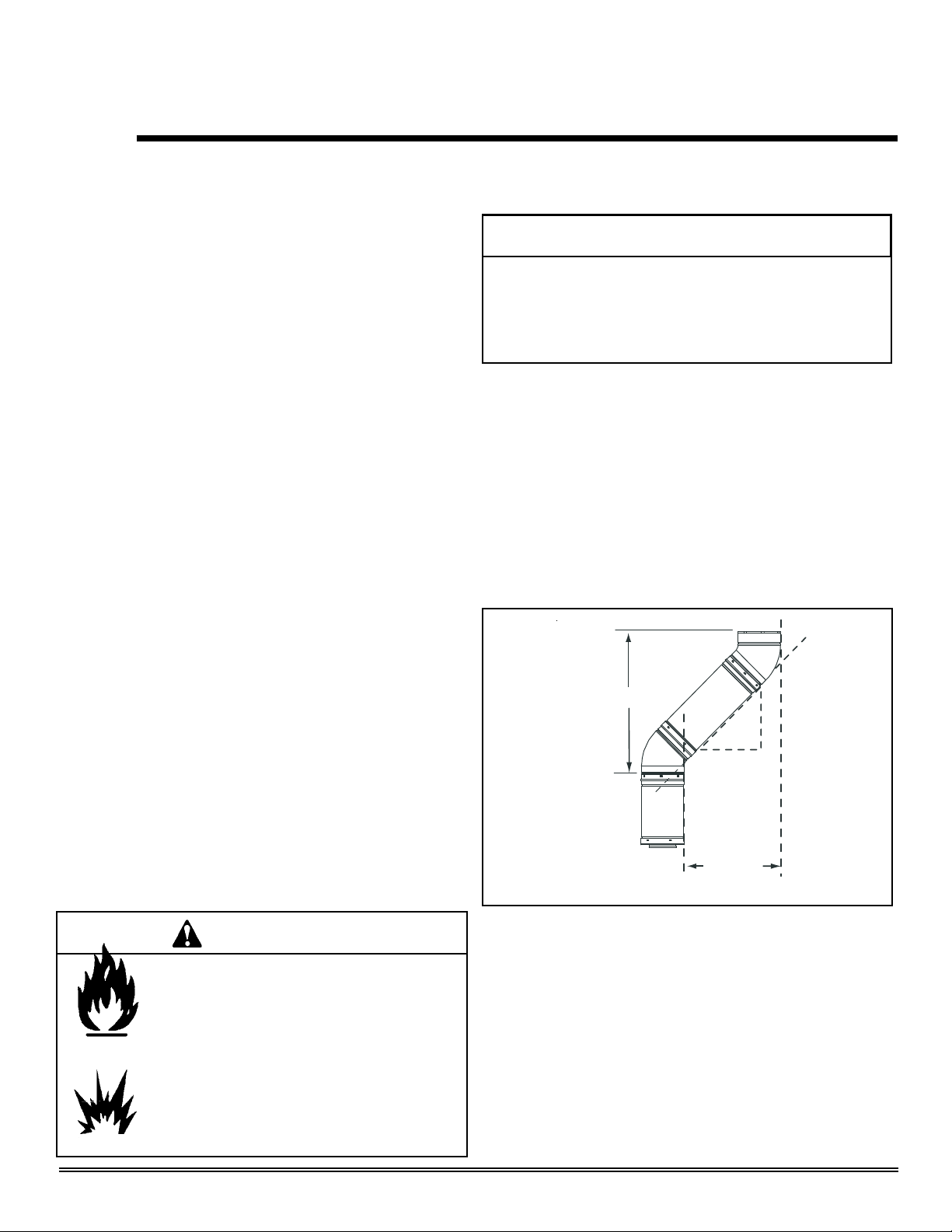

Use of Elbows

B.

CAUTION

ALL vent configuration specifications MUST be followed.

• This product is tested and listed to these

specifications.

• Appliance performance will suffer if specifications are

not followed.

Diagonal runs have both vertical and horizontal vent aspects

when calculating the effects. Use the rise for the vertical

aspect and the run for the horizontal aspect. (See Figure

5.1.)

Two 45° elbows may be used in place of one 90° elbow. On

45° runs, one foot of diagonal is equal to 8-1/2 in. (216mm)

horizontal run and 8-1/2 in. (216mm) vertical run. A length of

straight pipe is allowed between two elbows. (See Figure

5.1.)

Vertical

8-1/2 in.

Horizontal

Figure 5.1

12 in.

.

8-1/2 in

Page 10

WARNING

Fire Hazard.

Explosion Risk.

Asphyxiation Risk.

Do NOT connect this gas appliance to a chimney

flue serving a separate solid-fuel or gas burning

appliance.

• Vent this appliance directly outside.

• Use separate vent system for this appliance.

May impair safe operation of this appliance or

other appliances connected to the flue.

Quadra-Fire · Topaz · 7009-113G

C. Measuring Standards

Vertical and horizontal measurements were made using the

following standards.

• Pipe measurements are from center line to center line.

• Horizontal terminations are measured to the outside of

the mounting surface (flange of termination cap). See

Figure 4.1 on page 8.

• Vertical terminations are measured to the top of the last

pipe before termination cap.

• Horizontal pipe installed level with 1/4 in. rise.

September 1, 2008

Page 11

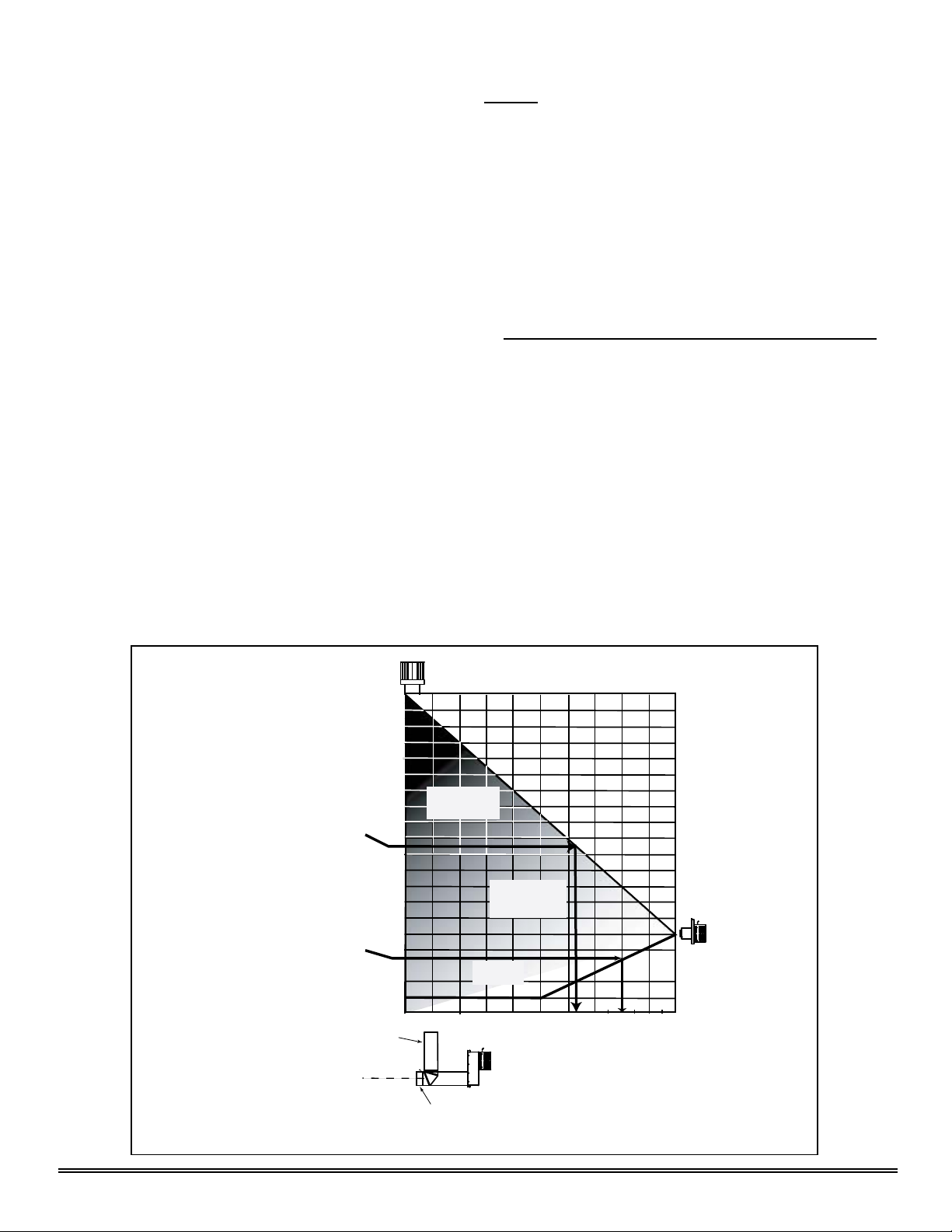

D. How to Use the Vent Graph E. Venting Guidelines

1. Measure the vertical distance from the center line of the

flue pipe to the center of the 90° elbow. On the graph

below, draw a horizontal line from that measurement

on the vertical axis across until it intersects with the

slanted line.

2. From the point of this intersection, draw a vertical line to

the bottom of the graph.

3. The point at which this line meets the bottom line of the

graph is the maximum length of the horizontal run.

EXAMPLE 1: If the vertical dimension from the center line

of the flue vent to the center of the 90° elbow is 7 ft. (2m),

the horizontal run to the outer wall flange must not exceed

16 ft. (5m).

EXAMPLE

2: If the vertical dimension from the center line

of the flue vent is 21ft. (6m), the horizontal run to the outer

wall flange must not exceed 12 ft. 10 in. (4m).

4. Each 90° elbow is equivalent to 3 ft. (914mm) of vent

pipe and each 45° elbow is equivalent to 1ft. (305mm)

of vent pipe, and must be subtracted from the vent pipe

run. A single horizontal to vertical 90° elbow is already

calculated into the allowable 20 ft. (6m) run. Each

additional 90° elbow reduces the maximum horizontal

distance by 3 ft. (914mm).

EXAMPLE:

The use of 3 elbows would reduce the allowable

horizontal run to 9 ft. (3 -1 = 2 elbows x 3 ft. = 6 ft.; 20 ft.

max. - 6 ft. = 14 ft. max.).

NOTES

The maximum horizontal vent run is 20 ft. (6m) when the

vertical vent rise is 10 ft. (3m).

The minimum horizontal vent run is 6 in. (152mm)

Horizontal sections require a 1/4 in. (6mm) rise for every 12

in. (305mm) of horizontal travel.

Exterior Vent Diameter = 6-5/8 in. (168mm); Inner Vent

Diameter = 4 in. (102mm).

Horizontal sections require noncombustible support every 3

ft. (914mm), e.g. wall straps.

For any vertical termination a minimum of 6 ft. (2m) vertical

must be used.

EXCEPTIONS FOR HORIZONTAL INSTALLATIONS:

*When installing the Topaz in a rear vent configuration

with no vertical rise, a Snorkel Kit must be used.

*The maximum horizontal vent run is 3 ft. (914mm).

*The maximum horizontal vent run with a 45° elbow is 2

ft. (609mm).

*The minimum horizontal vent run is 6 in. (152mm).

INDIVIDUAL INSTALLATIONS MAY VARY. PERCENTAGE

CLOSED BASED ON FULL RANGE OF DAMPER

TRAVEL.

NOTE

: If your installation falls within the gray-shaded

area on graph, see information on VERTICAL DAMPER

ADJUSTMENT in Section 8.

*In the Commonwealth of Massachusetts, the word damper

shall be replaced with the words flue restrictor.

40 ft. (12m)

Maximum Vertical

VERTICAL DISTANCE

FROM APPLIANCE TO

90

° ELBOW

6 in. (152mm) Minimum

Vertical Termination

C

For rear vent or top of

L

appliance for top vent

Figure 5.2

Example 2

Example 1

C

40'

39'

38'

37'

36'

35'

34'

32'

30'

28'

Damper position

26'

more CLOSED in

24'

22'

20'

18'

16'

14'

'

12

10'

8'

6'

4'

2'

this area

Damper position

more OPEN in

this area

No damper

in this area

2' 4' 6 ' 8' 10' 12' 14' 15' 16' 17' 18' 19' 20'

3 ft. (914mm) Maximum Horizontal run with no

vertical pipe and with 1/4 in (6mm) rise per foot.

L

Must use Snorkel cap.

6 in. (152mm) Minimum starter pipe

September 1, 2008

Page 11Quadra-Fire · Topaz · 7009-113G

Page 12

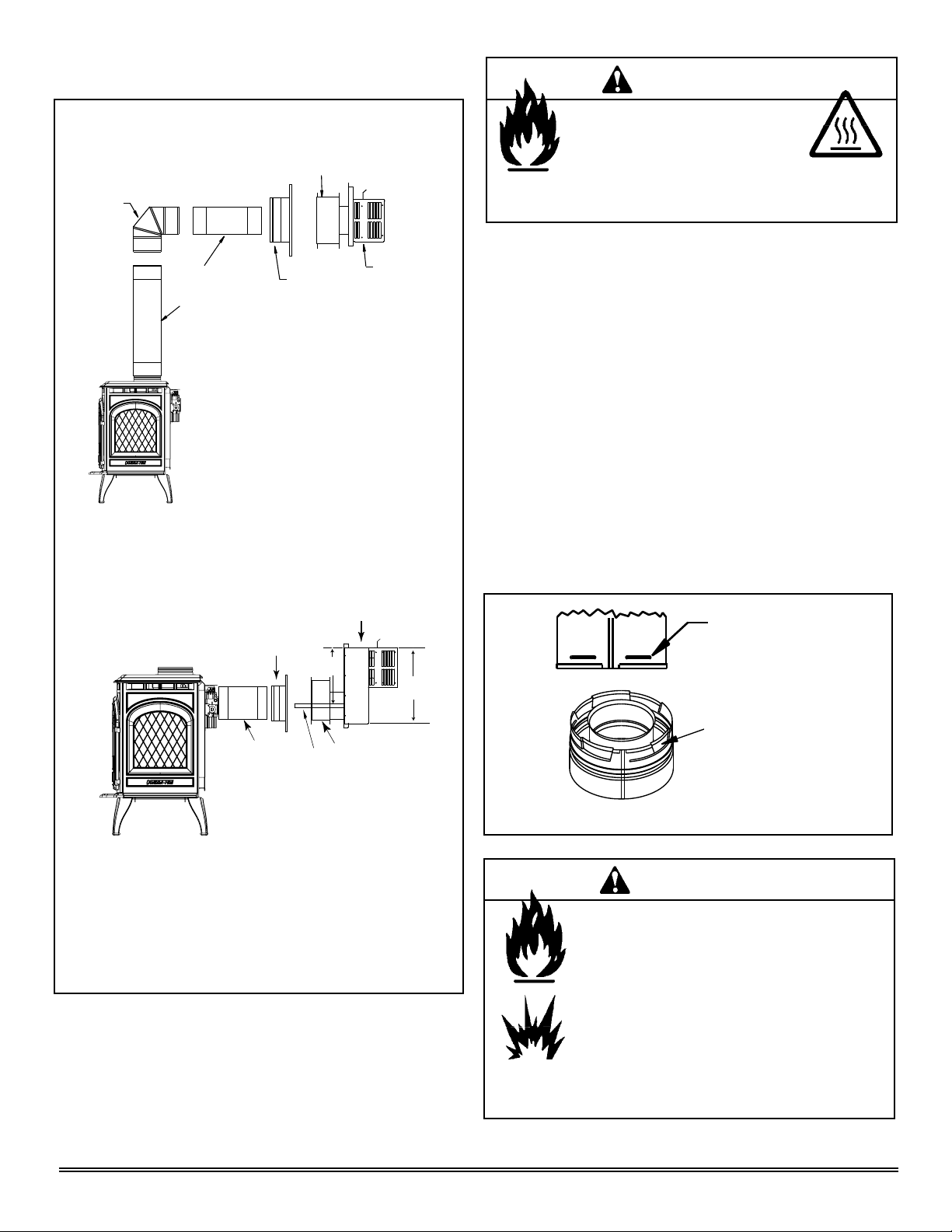

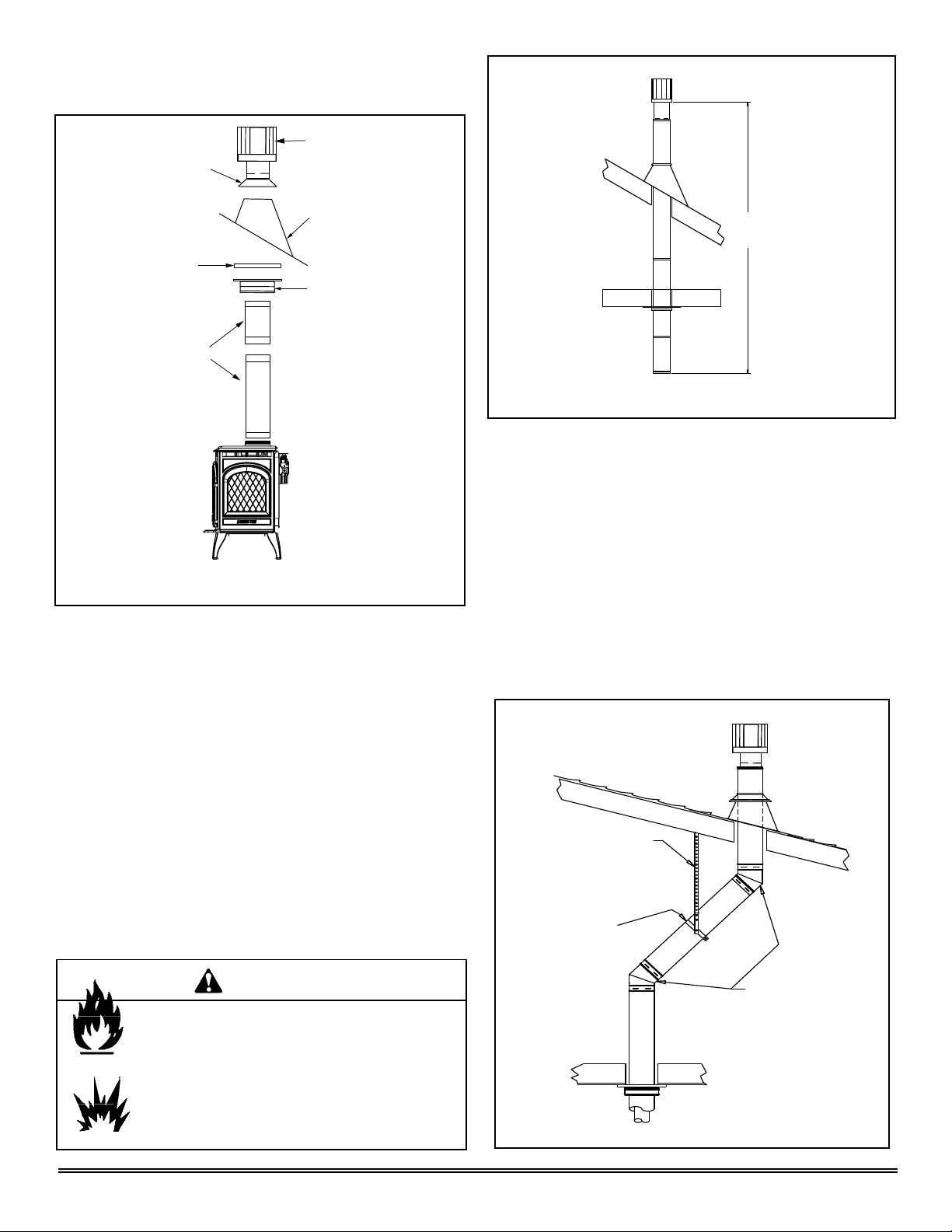

F. Horizontal Termination

Up & Out Installations for Top Vent

Type A -

90º Degree

Elbow

Configurations

Wall Thimble

WARNING

Fire Hazard.

Exhaust Fume Risk.

Impaired Performance of Appliance.

• Ensure vent components are locked together correctly.

• Pipe may separate if not properly joined.

Type B -

Pipe Length

Pipe Length

Wall Thimble Cover

Termination Cap

Rear Installations for Use with Rear Vent

Kit

Snorkle Kit

Wall Thimble Cover

15-5/8 in.

(397mm)

C

L

21 in.

(533mm)

Step 2.

Direct vent pipe is designed with a locking connection. To

connect the venting system to the appliance flue outlet, a

twist-lock adapter is built into the appliance at the factory.

Wall thickness may vary. Remember to include wall

thickness in minimum clearances when figuring venting

lengths for your installation needs.

Note: Female ends of direct vent pipe/elbows are designed

to slide straight onto the male ends of adjacent pipes by

orienting the pipe indentations so they match and slide into

the entry slots on the male ends, see Figure 5.4. Push

the pipe sections completely together, then twist-lock one

section clockwise approximately one-quarter turn, until the

two sections are fully locked. The female locking lugs may

not be visible from the outside. They may be located by

examining the inside of the female ends.

Female Locking Lugs

Pipe Length

Wall Thimble

Wall Strap

14 in. (356mm) Wide

(See Section 12 for conversion kit and venting

components.) This is the only venting configuration that

requires the use of the rear vent derating orifice that

comes with the rear vent kit. NOTE: A Snorkel Kit is

required.

Figure 5.3

Step 1.

Determine the desired location of the appliance. Check to

ensure that wall studs or roof rafters are not in the way when

the venting system is attached. If this is the case, you may

want to adjust the location of the appliance.

Male Locking Lugs

Figure 5.4

WARNING

Fire Risk.

Explosion Risk.

Combustion Fume Risk.

Use vent run supports per installation instructions.

Connect vent sections per installation instructions.

• Maintain all clearances to combustibles.

• Do NOT allow vent to sag below connection

point to appliance.

• Maintain specified slope (if required).

Improper support may allow vent to sag or separate.

Page 12

Quadra-Fire · Topaz · 7009-113G

September 1, 2008

Page 13

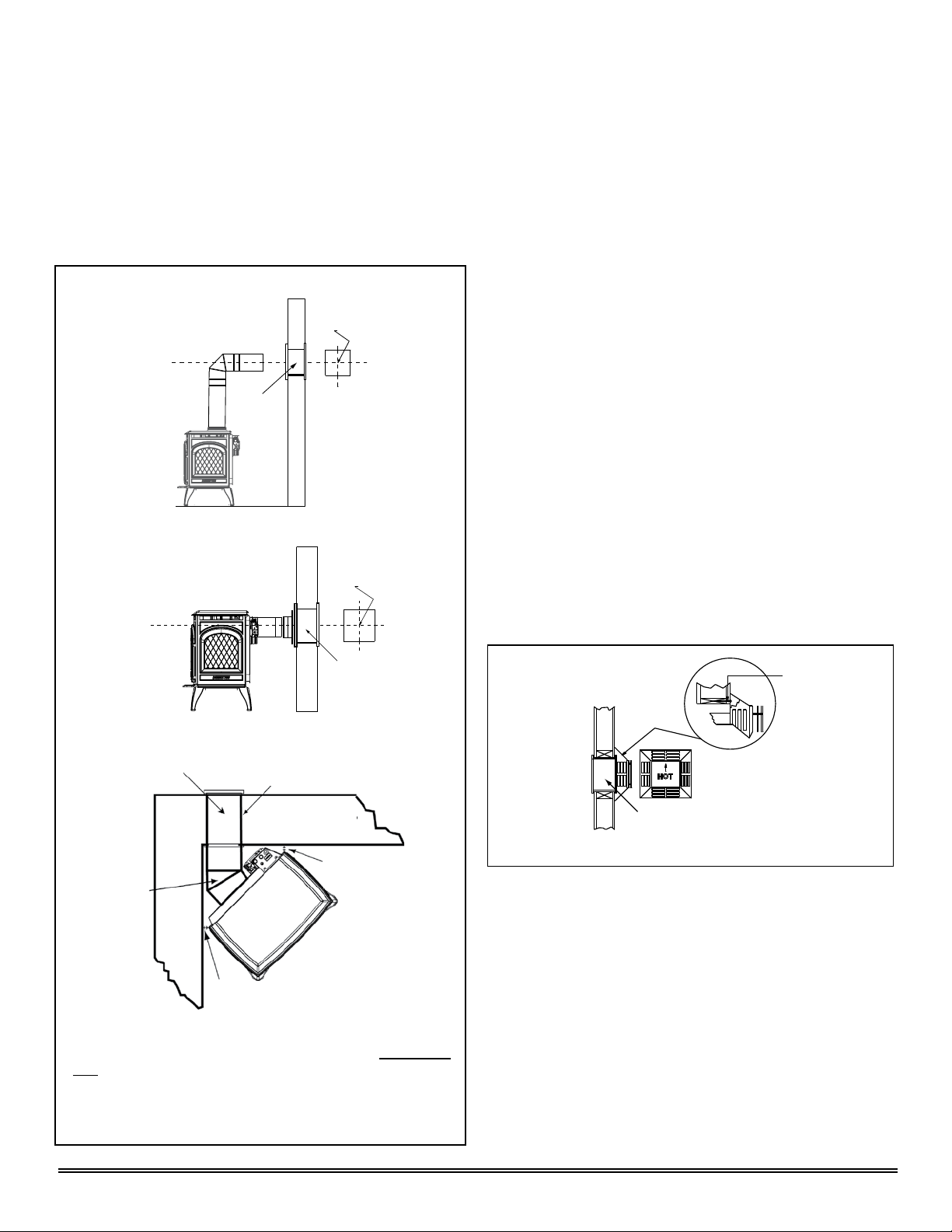

Step 3.

For installations using a round support box/wall thimble

(check pipe manufacturer's instructions), mark the wall for a

10 in. x 10 in. (254mm x 254mm) square hole. The center

of the square hole should line up with the center line of the

horizontal pipe, as shown in Figure 5.5. Cut and frame the

hole in the exterior wall where the vent will be terminated. If

the wall being penetrated is constructed of noncombustible

material, i.e. masonry block or concrete, a 7 in. (178mm)

diameter hole is acceptable.

Top Vent

Center of Hole

Center Line

Wall Thimble

Center Line

Rear Vent

Center of Hole

Center Line

NOTE:

(1) Installation requires a minimum of 6 in. (152mm)

horizontal run of vent with a 1/4 in. (6mm) rise run towards

the termination. Each 1 ft. (305mm) of horizontal venting

must include a 1/4 in. (6mm) rise. Never allow the vent

to run downward. This could cause high temperatures

and may present the possibility of a house or structure

fire.

(2) The location of the horizontal vent termination on an

exterior wall must meet all local and national building

codes, and must not be easily blocked or obstructed,

see Figure 4.4 on page 9.

(3) For installations requiring a vertical rise on the exterior

of the building, a snorkel kit is available with a 14 in.

(356mm) and a 36 in. (914mm) tall snorkel termination

cap. Follow the same installation procedures as used

for standard horizontal terminations. If the snorkel

termination must be installed below grade (i.e. basement

application), proper drainage must be provided to

prevent water from entering the snorkel termination. Do

not backfill around snorkel termination.

Step 4.

Position the horizontal termination cap in the center of the 10

in. x 10 in. (254mm x 254mm) square hole and run a bead

of non-hardening mastic around its outside edges, so as to

make a seal between it and the wall, attach termination cap

to the exterior wall with the four wood screws provided. The

arrow on the vent cap should be pointing up (Figure 5.6).

Center Line

Wall Thimble

45° Elbow in Corner Installation

Wall Thimble

45°

Elbow

When installing in a rear vent configuration with no vertical

rise: a Snorkel Kit must be used, and a derating orifice must

be installed. The appropriate orifice is supplied with the Rear

Vent Kit.

14 in. (356mm) Pipe Length

Max. Wall Depth

10 in. (254mm)

1 in. (25mm)

clearance from

appliance corner to

1 in. (25mm) clearance from appliance

corner to combustible wall

WOOD

SCREW

HOT

WALL THIMBLE

Figure 5.6

NOTES:

(1) The four wood screws provided should be replaced

with appropriate fasteners for stucco, brick, concrete,

or other types of sidings.

(2) A termination cap with a built-in vinyl siding standoff is

highly recommended on a building with vinyl siding. The

pilot hole will be 2 in. (51mm) closer to the bottom of the

square than the top. Using a framing square, draw a 14

in. x 14 in. (356mm x 356mm) square around the pilot

hole in the siding. See Figure 5.7 on the next page.

Figure 5.5

September 1, 2008

Page 13Quadra-Fire · Topaz · 7009-113G

Page 14

8 in.

(203mm)

7 in.

(178mm)

7 in.

(178mm)

6 in.

(152mm)

the vent pipe. Use the two sheet metal screws provided to

connect the strips to the pipe section (Figure 5.9).

1/4 in. (6mm)

Fold Strap Here

Sheet Metal Screw

Figure 5.7

(NOTE: Some termination caps may cause the vent

pipe to be off center on flashing). Ensure that proper

clearances to combustible materials are maintained. If

you are not using an approved termination cap with a

built-in vinyl siding standoff on a building with vinyl siding,

a vinyl siding standoff should be installed between the

termination cap and the exterior wall (Figure 5.8). Follow

manufacturer’s instructions for attaching the vinyl siding

standoff to the horizontal termination cap. The vinyl

siding standoff prevents excessive heat from possibly

melting the vinyl siding material. The vent terminal cap

shall not be recessed into a wall or siding. Remove

siding from the area where the standoff will be located.

VINYL SIDING

Apply sealant to all four sides

SCREWS

Bolt horizontal top to vinyl

standoff

Wall Thimble

Figure 5.9

Wall Thimble Cover/Ceiling

Firestop as Required by Local

Jurisdiction

Strap

Note: The attachment from the vent pipe to the vent

termination cap must be sealed with silicone. Termination

caps shall not be recessed into a wall or siding.

WARNING

Fire Hazard.

Exhaust Fume Risk.

Impaired Performance of Appliance.

• Ensure vent components are locked together correctly.

• Pipe may separate if not properly joined.

WARNING

Do NOT connect a pipe section to a termination cap without

using the telescoping flue section found on the termination cap.

WALL THIMBLE COVER

WALL THIMBLE

Figure 5.8

SCREWS

Vinyl siding standoff with siding beneath

removed

Step 5.

Place the wall thimble cover over the pipe assembly and

slide the appliance and vent assembly towards the wall,

carefully inserting the vent pipe into the vent termination

cap assembly. It is important that the vent pipe extend into

the vent termination cap a sufficient distance so as to result

in a minimum pipe overlap of 1-1/4 in. (32mm). Secure the

connection between the vent pipe and the vent termination

cap by attaching the two sheet metal strips extending from

the vent termination cap assembly into the outer wall of

Page 14

Quadra-Fire · Topaz · 7009-113G

WARNING

Burn Risk.

• Local codes may require installation of a cap

shield to prevent anything or anyone from

touching the hot cap.

September 1, 2008

Page 15

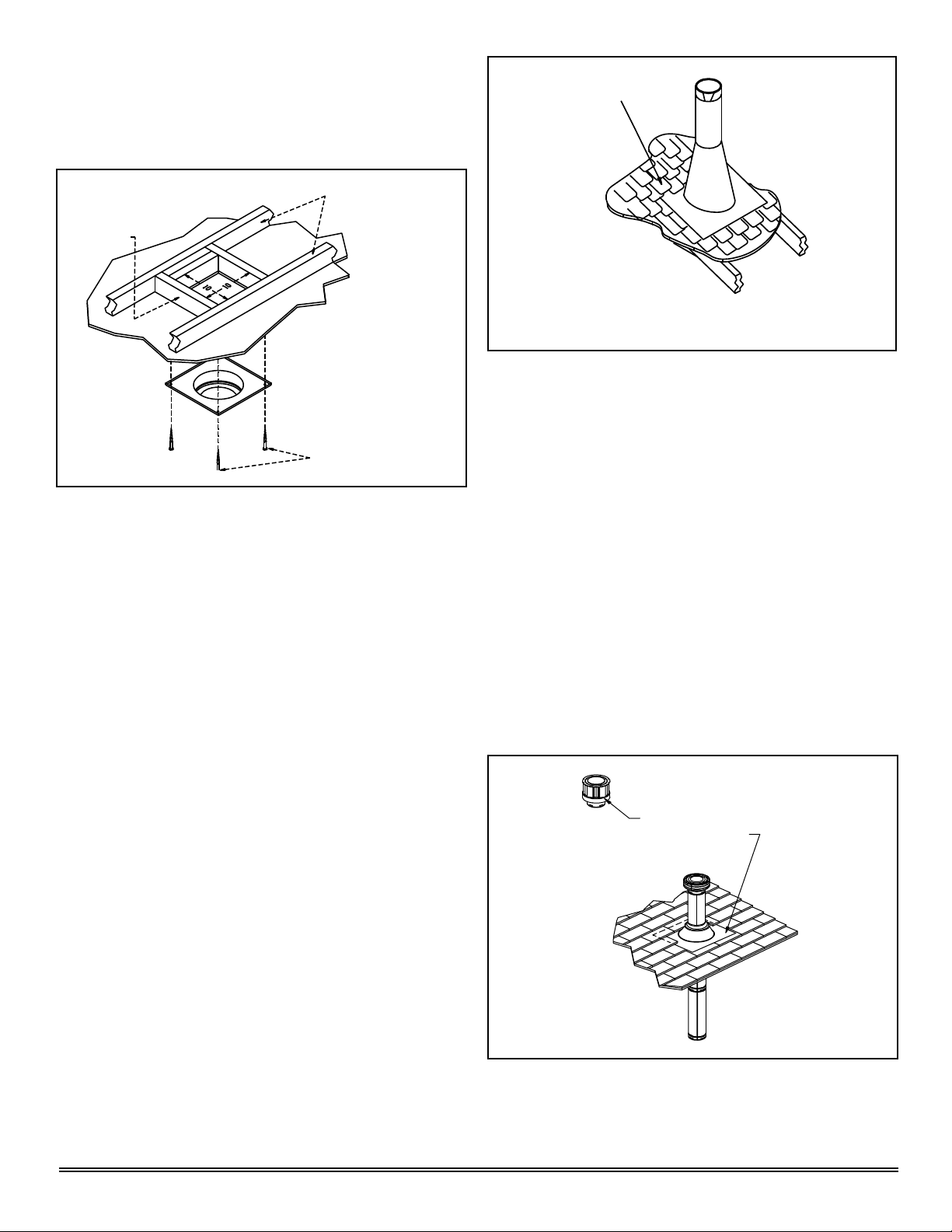

G. Vertical Termination

1. Direct Vent Pipe

Storm Collar

Vertical Termination Cap

Flashing

Firestop

Support Box

Pipe Length

Figure 5.10

Step 1.

Check the installation instructions for required 1 in. (25mm)

clearances (air space) to combustibles when passing

through ceilings, walls, roofs, enclosures, attic rafters, or

other nearby combustible surfaces. See page 16, Figure

5.16. Check the instructions below for maximum vertical rise

of the venting system, and any maximum horizontal offset

limitations. All offsets must fall within the set parameters of

the vent graph (Figure 5.2) located on page 11.

40 ft. (12m)

Maximum

Figure 5.11

Step 2.

Set the gas appliance in its desired location. Drop a plumb

bob down from the ceiling to the position of the appliance

flue exit, and mark the location where the vent will penetrate

the ceiling. Drill a small hole at this point. Next, drop a plumb

bob from the roof to the hole previously drilled in the ceiling,

and mark the spot where the vent will penetrate the roof.

Determine if ceiling joists, roof rafters, or other framing will

obstruct the venting system. You may wish to relocate the

appliance, or to offset, as shown in Figure 5.12 to avoid

cutting loadbearing members. When location is determined,

drill small hole.

NOTE: Maximum vertical rise allowable is 40 ft. (12m)

Figure 5.11).

NOTE: Maximum number of 45° elbows permitted for a

vertical installation is eight, provided their installation

does not decrease maximum allowable horizontal run (as

specified by vent graph, on page 11).

WARNING

Fire Risk.

Explosion Risk.

Maintain vent clearance to combustibles as speci-

fied.

• Do not pack air space with insulation or other

materials.

Failure to keep insulation or other materials away

from vent pipe may cause fire.

September 1, 2008

Plumber’s Tape

connected to

Wall Strap

Wall Strap

Two 45˚ Elbows

Figure 5.12

Page 15Quadra-Fire · Topaz · 7009-113G

Page 16

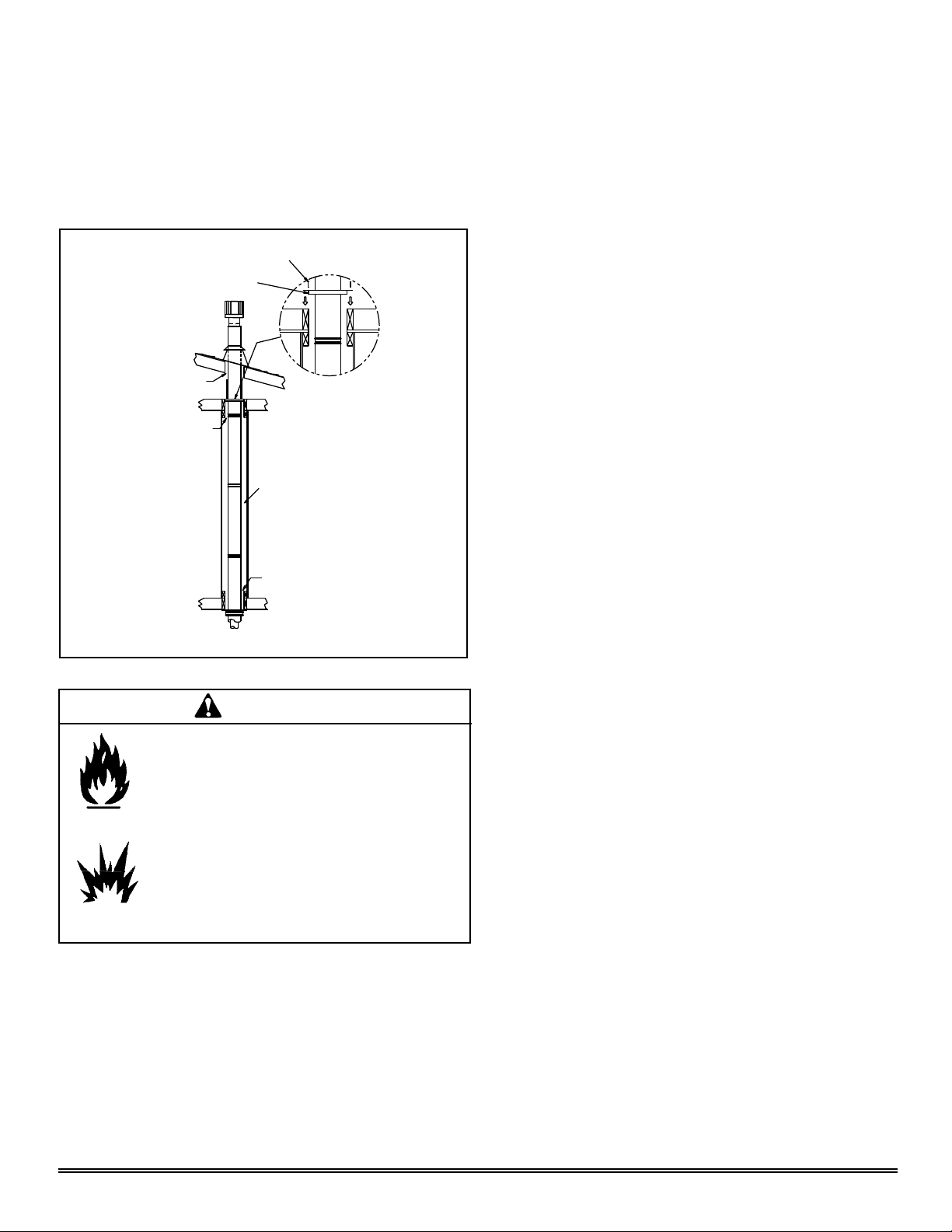

Step 3.

To install the round support box/wall thimble cover in a flat

ceiling, cut a 10 in. (254mm) square hole in the ceiling,

centered on the hole drilled in Step 2. Frame the hole as

shown in Figure 5.13.

Ceiling

Joists

Framing

Figure 5.13

Step 4.

1 - 1/2 in. (38mm) Long

Wood Screws

Assemble the desired lengths of pipe and elbows necessary

to reach from the appliance up through the round support

box. Ensure that all pipe and elbow connections are in their

fully twist-locked position. Assemble as instructed.

Step 5.

Cut a hole in the roof centered on the small drill hole placed in

the roof in Step 2. The hole should be of sufficient size to meet

the minimum requirements for clearance to combustibles, as

specified. Continue to assemble lengths of pipe and elbows

necessary to reach from the ceiling support box/wall thimble

up through the roof line. Galvanized pipe and elbows may

be utilized in the attic, as well as above the roofline. The

galvanized finish is desirable above the roofline, due to its

higher corrosion resistance.

NOTE:

(1) If an offset is necessary in the attic to avoid obstructions,

it is important to support the vent pipe every 3 ft. (914mm)

to avoid excessive stress on the elbows, and possible

separation. Wall straps are available for this purpose,

Figure 5.12, page 15.

CAP AND STORM

COLLAR NOT SHOWN

FOR CLARITY

Figure 5.14

Shingles overlap on

top edge of flashing

Step 7.

Continue to assemble pipe sections until the height of the

vent (before adding the termination cap) meets the minimum

code requirements as outlined in the current CAN/CGA-B149

Installation Codes (in Canada), the National Fuel Gas Code

NFPA 54/ANSI Z223.1 (in USA), or local codes. Note that

for steep roof pitches, the vent height must be increased.

See Roof Pitch Table (Figure 4.3, on page 8). In high wind

conditions, nearby trees adjoining rooflines, steep pitched

roofs, and other similar factors can result in poor draft, or

down drafting. In these cases increasing the vent height or

switching to the high wind termination cap may solve this

problem.

Step 8.

Slip the storm collar over the pipe, and push it down to the

top of the flashing (Figure 5.15). Use non-hardening sealant

above and below the joint between the storm collar and the

pipe.

Optional High Wind Termination Cap

Secure Flashing with Non-Hardening

Sealant and Roofing Nails

(2) Whenever possible, use 45° elbows, instead of 90°

elbows. The 45° elbow offers less restriction to the flow

of flue gases and intake air.

Step 6.

Slip the flashing over the pipe section(s) protruding through

the roof. Secure the base of the flashing to the roof with

roofing nails. Ensure the roofing material overlaps the top

edge of the flashing as shown in Figure 5.14. Verify that the

chimney is the required height above the roof. See roof pitch

table, Figure 4.3, on page 8.

Page 16

Quadra-Fire · Topaz · 7009-113G

Figure 5.15

September 1, 2008

Page 17

Step 9.

Twist-lock the vent cap and seal.

Note: For multi-story vertical installations, a ceiling firestop

is required at the second floor, and any subsequent floors

(Figure 5.16). The opening should be framed to 10 in. x

10 in. (254mm x 254mm) inside dimensions, in the same

manner as shown in Figure 5.13.

Nails

Ceiling Firestop

Minimum 1 in.

(24mm) Clearance

Minimum 1 in.

(24mm) Clearance

Minimum 1 in.

(24mm) Clearance

Figure 5.16

Minimum 1 in.

(24mm) Clearance

WARNING

Fire Risk.

Explosion Risk.

• Any occupied areas above the first floor, including

closets and storage spaces, which the vertical

vent passed through must be enclosed. The

enclosure may be framed and sheetrocked with

standard construction materials; however, refer

to these installation instructions for the minimum

allowable clearance between the outside of the

vent pipe and the combustible surfaces of the

enclosure. Do not fill any of the required air space

with insulation.

September 1, 2008

Page 17Quadra-Fire · Topaz · 7009-113G

Page 18

2. Cathedral Ceiling

Step 1.

Follow installation Steps 1 and 2 under vertical installation

section, page 15.

Step 2.

Using the plumb-bob, mark the center line of the venting

system on the ceiling, and drill a small hole through the

ceiling and roof at this point. From the roof, locate the drill

hole and mark the outline of the cathedral ceiling support

box.

Step 3.

Remove shingles or other roof covering as necessary to cut

the rectangular hole for the support box. Cut the hole 1/8 in.

(3mm) larger than the support box outline.

Step 4.

Lower the support box through the hole in the roof until the

bottom of the support box protrudes at least 2 in. (51mm)

below the ceiling (Figure 5.17). Align the support box both

vertically and horizontally with a level. Temporarily tack the

support box in place through the inside walls and into the

roof sheathing.

Level

Cathedral Ceiling

Support Box

Figure 5.18

Step 6.

Complete the cathedral ceiling installation by following the

same procedures outlined in steps 7 through 9 for vertical

installations, pages 16-17.

Step 7.

Place the support clamp (provided with the support box)

inside the support box (at the bottom), and secure to the pipe

section. The clamp allows the support box to support the

weight of the pipe sections. Continue to add pipe sections

until you are above the roofline.

2 in. (51mm)

Min. below

finished ceiling

Cut hole 1/8 in. (3mm)

greater in size than

pattern of support box

as it is projected onto

roof line

Figure 5.17

Step 5.

Using tin snips, cut the support box from the top corners

down to the roofline, and fold the resulting flaps over the

roof sheathing (Figure 5.18). Before nailing it to the roof,

run a bead of non-hardening mastic around the top edges

of the support box to make a seal between it and the roof.

Clean out any combustible material from inside the support

box.

Step 8.

Install the black trim collar around the outside of the cathedral

ceiling support box (Figure 5.19). The two pieces of the trim

collar slide over one another to allow for easy adjustment

around the support box. Using the six screws provided,

secure the four corners and the overlapping sections of the

trim collar to the ceiling. You may want to predrill the holes for

the overlapped sections for ease of installation.

Trim Collar

Cathedral

Ceiling

Support

Screws

Box

Page 18

Figure 5.19

Quadra-Fire · Topaz · 7009-113G

September 1, 2008

Page 19

3. Class A Metal Chimney

Existing

Metal Chimney System

Direct Vent Pipe

Termination Cap

Top Adaptor

Flashing

4 in. (102mm) Flex Pipe

Retro Connector

Step 4.

Pass the flex pipe down through the center of the chimney

system, and center the top adapter on the top of the chimney

pipe. Drill four 1/8 in. (3mm) diameter holes through the

top adapter, and into the chimney top. Ensure that you are

drilling into the metal on the chimney. Twist lock the high

wind termination cap onto the top adapter (Figures 5.22

and 5.23).

Figure 5.20

CAUTION

Ensure that existing chimney is functionally sound and clean.

• Have inspection done by qualified chimney sweep or

professional installer BEFORE converting to direct vent

appliance.

Step 1.

Remove existing chimney cap.

Step 2.

Measure the distance from the top of the chimney to the

bottom of the ceiling support box, add 3 in. (76mm) to this

measurement, and cut a section of 4 in. (101mm) flex pipe to

that length (the flex should be fully extended).

Step 3.

Connect the end of the flex pipe section to the underside

of the top adapter, using four sheet metal screws (Figure

5.21).

Top Adapter

Figure 5.22

High Wind Termination

Cap

Sheet Metal Screws

Drill Four 1/8 in.

(3mm) Diamater

Holes

Figure 5.23

Step 5.

Pull the flex pipe down through the ceiling support box, until

it protrudes approximately 3 in. (76mm). Connect the flex

pipe to the retro connector, and attach with sheet metal

screws.

Flex Pipe

Figure 5.21

September 1, 2008

Sheet Metal Screws

Step 6.

Push the flex pipe back up into the ceiling support box,

center the retro connector, and attach it to the support box

with sheet metal screws.

Step 7.

The connection between the appliance and the retro

connector may be completed with sections of direct vent

pipe.

Page 19Quadra-Fire · Topaz · 7009-113G

Page 20

4. Existing Masonry Chimney

Type A - Up & Out Installations for Top Vent

Configurations

Termination Cap

Top Adaptor

Retro Connector

90° Elbow

Direct Vent Pipe

Flashing

4 in. (102mm)

Flex Liner

Type B - Hearth Rear Vent Installations for Use With

Rear Vent Kit (see Section 12 for conversion kit and

venting components.)

Chimney Liner

Termination Cap

3 in. (76mm)

Co-Axial to

Co-Linear Connector

Pipe Length

Optional

Flex Liner

Figure 5.24

Co-Axial to

Co-Linear

Connector

Pipe Length

Optional

Chimney Liner

Termination Cap

30 ft. (9m) of 3 in.

(76mm) Flex Liner

Exhaust Section

This section of the

chimney must be

sealed

The chimney must be sealed

from the 4 ft. (1m) section to

termination using a smoke

shelf or a damper.

The seal should be 6 in.

(152mm) below the end of the

4 ft. (1m) Air Intake section.

4 ft. (1m) of 3 in.

(76mm) Flex Liner

Air Intake Section

Page 20

Quadra-Fire · Topaz · 7009-113G

September 1, 2008

Page 21

CAUTION

Ensure that existing chimney is functionally sound and clean.

• Have inspection done by qualified chimney sweep or

professional installer BEFORE converting to direct vent

appliance.

Step 1.

Before cutting any holes, assemble the desired sections

of direct vent pipe to determine the center of the masonry

penetration.

Step 2.

Once the center point of the penetration has been determined,

cut a 6 in. (152mm) diameter hole in the masonry. If the hole

is too large, the retro connector might not mount properly; if

the hole is too small, the appliance might starve for intake

air. If there is a frame wall in front of the masonry wall, cut

and frame a 10 in. (254mm) square opening in the wall

(centered around the 6 in. (152mm) masonry opening). If

there is sheet rock only (no studs) in front of the masonry the

10 in. (254mm) opening is still needed, but does not need

to be framed. If the hole is framed a round support box/wall

thimble is required. This allows the retro connector to mount

directly on the masonry and provide the correct clearances

to combustibles (Figure 5.25).

Cut and bend flashing as needed

to fit

Sealant adhesive

Figure 5.26

Step 4.

To determine the length of flex needed, measure from 3 in.

(76mm) above the top of the flashing down to the level of the

opening. Add the distance from the center of the chimney

out through the wall. Cut a piece of 4 in. (102mm) flex to this

length (extended to its nominal length). Be sure to leave 2-3

in. (51-76mm) of flex above the existing chimney to allow for

connection to the termination kit.

Step 5.

Connect the flex liner to the top adapter using three sheet

metal screws (Figure 5.21 page 19).

Studwall

10 in. x 10 in. (254mm x 254mm)

framed opening in wall

Retro Connector

Wall Thimble Cover

(4) Masonry Bolts

(Not Included)

NOTE: For hearth applications refer to page 20, Figure 5.24 for

the use of a co-axial to co-linear appliance connector.

Figure 5.25

Masonry

Chimney

Step 3.

Secure the flashing to the top of the masonry chimney using

a bead of non-hardening sealant-adhesive. If the flashing is

larger than the top of the chimney, cut and fold flashing as

needed to fit chimney (Figure 5.26).

Step 6.

Feed the flex liner through the flashing into the chimney.

Carefully feed the flex liner down the chimney to the bottom

and out the opening in the masonry wall, forming an angle to

line up the flex liner with the vent opening on the appliance.

WARNING

Fire Risk.

Explosion Risk.

Do not let the flex liner sag below the level at

•

which it will connect to the appliance or connector.

This could allow hot gas to become trapped and

potentially become a fire hazard. The flex liner path

should always be sloped up toward the termination

cap.

Step 7.

If additional lengths of flex liner are needed to span the

chimney height, use a flex coupler to connect the pieces of

flex liner together. Connect the flex to the coupler by using

four sheet metal screws for each side (Figure 5.27, on the

next page).

September 1, 2008

Page 21Quadra-Fire · Topaz · 7009-113G

Page 22

Figure 5.27

Flex Liner

Flex Coupler

Sheet Metal Screws

6 in. (152mm) diameter

opening in masonry wall

Figure 5.29

Retro Connector

(3) Masonry Bolts

(Not included)

Step 8.

Secure the top adapter to the flashing. Use three sheet

metal screws through the side of the top adapter into the

flange on the flashing (Figure 5.28). Twist lock the high

wind termination cap on to the top adapter.

High Wind

Termination Cap

Top Adaptor

(3) Sheet Metal Screws

Flashing

Figure 5.28

Step 10.

Slide wall thimble cover over retro connector and secure

with masonry bolts (Figure 5.30). If you have a framed wall

in front of the masonry, use wood screws to mount wall

thimble cover to framed wall, over retro connector and 10

in. (254mm) square framed opening (Figure 5.25, on page

21). If needed, add a section of direct vent pipe to the retro

connector in order to extend through the opening in the wall

thimble cover.

Retro Connector

Wall Thimble Cover

(4) Masonry Bolts

(Not included)

Figure 5.30

Step 9.

Attach the flex to the retro connector. Use three sheet metal

screws to attach the flex liner to the connector (Figure

5.29). Mount the retro connector to the masonry wall using

masonry bolts. Redrill larger holes on connector as needed.

Be careful to ensure that the connector is centered in the

opening and the mounting holes line up with the masonry

wall.

Page 22

Quadra-Fire · Topaz · 7009-113G

Step 11.

The connection between the appliance and the retro

connector may be completed with sections of direct vent

pipe.

September 1, 2008

Page 23

Gas Information

6

A. Fuel Conversions

Before making gas connections ensure that the appliance

being installed is compatible with the available gas type.

Any natural or propane gas conversions necessary to meet

the appliance and locality needs must be made by a qualified technician using Hearth & Home Technologies specified

and approved parts.

1. Converting to LP Gas

NOTE: Gas conversions should only be performed

by a qualified service person, and/or where required

by state and local codes, licensed installer/service

technician. In the Commonwealth of Massachusetts,

installation must be performed by a licensed plumber

or gas fitter.

KIT CONTENTS: Replacement orifice; replacement pilot

injector; and valve regulator.

3 screws

Figure 6.3 Remove the three screws on the front of the burner

support. Set screws aside.

TOOLS REQUIRED: Power drill (a 90° handle is helpful); #2

Phillips bit; 5/32 in. Allen wrench; 5/8 in. open end wrench.

Opens Left Closes Right

Figure 6.1 Disconnect power and turn off gas supply if

installed. Remove front, glass, and logs if installed. Loosen

the shutter adjustment nut (located underneath the appliance) with a 7/16 in. wrench. Slide the shutter to the left

(open position).

Figure 6.4 Slide the burner support to the left to access the

orifice.

Figure 6.5 Remove the main burner orifice using a 5/8 in.

wrench and replace the orifice with the proper size as indicated below for your gas type and venting.

Burner Screws

Figure 6.2

ing the two screws indicated and lifting the burner out.

September 1, 2008

Burner removal: Remove burner by first remov-

Page 23Quadra-Fire · Topaz · 7009-113G

Page 24

2. Valve Regulator Replacement

WARNING

Fire Risk.

Explosion Risk.

• Disconnect any electrical cords and

turn off gas supply to unit before

proceeding if converting fuel on an

appliance already fully installed.

Figure 6.6 Pull off pilot hood and set it aside.

NOTE: Do not remove the retaining clip from the hood.

Figure 6.7 Use a 5/32 in. Allen wrench to remove the pilot

injector.

Replace pilot injector with the one supplied with the appliance (#35 for Propane, #62 for Natural Gas).

Replace pilot hood, snapping it into position, making sure

notch and tab line up.

Reinstall burner by placing it into the firebox. Make sure to

reinstall all the screws previously removed.

Reinstall logs, glass and front.

Remove upper and lower back shield. Loosen the set collars on the extension rods with the 3/32 in. Allen wrench.

Remove the rods and adapter cap.

A

Mounting Screws

B

Pressure Regulator Tower

C

Diaphragm

Figure 6.8 Turn control knob to the OFF position, ensure that

gas supply to the valve has been turned off. Using a Torx

TH20, or slotted screwdriver, remove the three pressure regulator mounting screws (A), pressure regulator tower (B),

and diaphragm (C).

PROPANE NATURAL GAS

.073 (49 DMS) .0125 (1/8 in.)

Page 24

Quadra-Fire · Topaz · 7009-113G

September 1, 2008

Page 25

Screws

E

D

Rubber Gasket

Identification Label

Figure 6.9 Ensure that the rubber gasket (D) is properly posi-

F

tioned and install the new HI/LO pressure regulator assembly to the valve using the new screws (E) supplied with the

kit. Tighten screws securely. (Reference torque = 25 in./lb.)

Install the enclosed identification label (F) to the valve body

where it can be seen.

Fill out the conversion label and attach it to the valve cover.

B. Gas Pressures

Proper input pressures required for optimum appliance performance, gas line sizing requirements need to be followed

from NFPA51.

WARNING

Fire Risk.

Explosion Hazard.

High pressure will damage valve.

• Disconnect gas supply piping BEFORE

pressure testing gas line at test pressures

above 1/2 psig.

• Close the manual shutoff valve BEFORE

pressure testing gas line at test pressures

equal to or less than 1/2 psig.

WARNING

Verify inlet pressures.

• High pressure may cause overfire

condition.

• Low pressure may cause explosion.

Install regulator upstream of valve if line pressure

is greater than 1/2 psig.

WARNING

Fire Risk.

Explosion Risk.

Gas Leak Risk.

• Rubber gasket must be seated properly on valve

face.

• Do no install a valve or regulator that has been

dropped.

WARNING

Fire Risk.

Explosion Risk.

• If the information in these instructions is

not followed exactly, a fire, explosion or

production of carbon monoxide may result

causing property damage, personal injury

or loss of life.

•

The qualified service agency is responsible

for the proper installation of this conversion

kit. The installation is not proper and

complete until the operation of the converted

appliance is checked as specified in the

manufacturer’s instructions supplied with

the kit.

Pressure requirements for appliance are shown in the table

below.

PRESSURE NG LP

Minimum Inlet Pressure 5 inches w.c. 11 inches w.c.

Maximum Inlet Pressure 10 inches w.c. 13 inches w.c.

Manifold Pressure on “HI” 3.5 inches w.c. 10 inches w.c.

If the pressure is not sufficient, ensure:

1) the piping used is large enough.

2) the supply regulator is adequately adjusted.

3) that the total gas load for the residence does not exceed

the amount supplied.

The supply regulator (the regulator that attaches directly to the

residence inlet or to the propane tank) should supply gas at

the suggested input pressure listed above. Contact the local

gas supplier if the regulator is at an improper pressure.

September 1, 2008

Page 25Quadra-Fire · Topaz · 7009-113G

Page 26

C. Gas Connection

NOTE: Have the gas supply line installed in accordance with

local building codes, if any. If not, follow ANSI Z223.1. Installation should be done by a qualified installer approved and/or

licensed as required by the locality. (In the Commonwealth of

Massachusetts, installation must be performed by a licensed

plumber or gas fitter.)

A small amount of air will be in the gas supply lines.

•

When first lighting appliance it will take a short time for

air to purge from lines. When purging is complete the

appliance will light and operate normally.

Air only needs to be purged again if gas valve has been

turned to the OFF position.

WARNING

NOTE: A listed (and Commonwealth of Massachusetts