Page 1

EPA CERTIFIED WOODBURNING FIREPLACE

Owner’s Manual

Installation and Operation

Model:

7100FP-BK-B

7100FP-GD-B

7100FP-NL-B

7100FP

R

Tested and

Listed by

O-T L

C

OMNI-Test Laboratories, Inc.

Oregon USA

US

Portland

CAUTION

DO NOT DISCARD THIS MANUAL

•

Important operating

and maintenance

instructions included.

WARNING

If the information in these instructions is not followed exactly, a

fire may result causing property

damage, personal injury, or death.

• Do not store or use gasoline or other flam

mable vapors and liquids in the vicinity of this

or any other appliance.

• Do not overfire - If heater or chimney connec

tor glows, you are overfiring. Overfiring will

void your warranty.

• Comply with all minimum clearances to com

bustibles as specified. Failure to comply may

cause house fire.

• Read, understand and

follow these instructions

for safe installation and

operation.

-

DO NO

DISCARD

• Leave this manual with

party responsible for

use and operation.

T

WARNING

HOT SURFACES!

Glass and other surfaces are

hot during operation AND

cool down.

Hot glass will cause burns.

• Do not touch glass until it is cooled

• NEVER allow children to touch glass

• Keep children away

-

-

• CAREFULLY SUPERVISE children in the same room

as appliance

• Alert children and adults to hazards of high

temperatures

High temperatures may ignite clothing or other

flammable materials.

• Keep clothing, furniture, draperies and other

combustibles away.

Installation and service of this appliance should be

performed by qualified personnel. Hearth & Home

Technologies recommends NFI certified professionals, or technicians supervised by an

NFI certified professional.

www.quadrafire.com

433-1390G

WARNING

Fire Risk.

For use with solid wood fuel only.

Other fuels may overfire and generate

poisonous gases (i.e. carbon monoxide).

September 1, 2008

Page 2

y

7100FP EPA Woodburning Fireplace

R

and Welcome to the Quadra-Fire Famil

Hearth & Home Technologies welcomes you to our tradition

of excellence! In choosing a Quadra-Fire appliance, you

have our assurance of commitment to quality, durability, and

performance.

This commitment begins with our research of the market,

including ‘Voice of the Customer’ contacts, ensuring we

make products that will satisfy your needs. Our Research

and Development facility then employs the world’s most

advanced technology to achieve the optimum operation

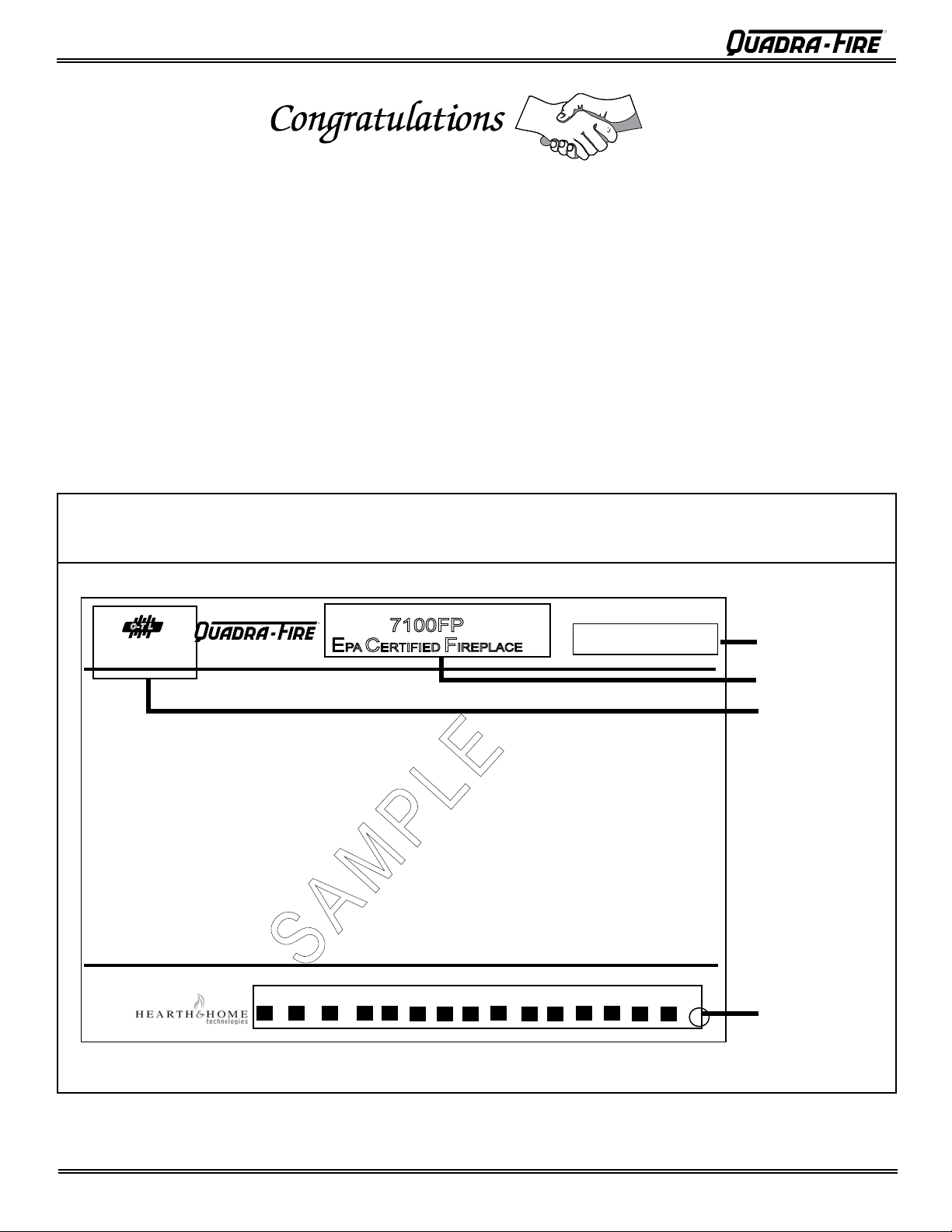

SAMPLE: CLEARANCE TO COMBUSTIBLES LABEL

LOCATION: on hang tag on right side of fireplace

Tested and

Listed by

OMNI-Test Laboratories, Inc.

Report #061-S-41-2

UL 127, ULC-S610-M87

LISTED FIREPLACE, SOLID FUEL TYPE, ALSO SUITABLE FOR MOBILE

HOME INSTALLATION. (UM) 84 HUD.

Install and use only in accordance with manufacturer's installation, venting and operating instructions.

Any area incorporating warm or cold air ducts shall be enclosed in accordance with the manufacturer's

installation instructions.

Contact Your Local Building Or Fire Officials Or Authority Having Jurisdiction About Restrictions,

Installation Inspection And Permits Required In Your Area.

WARNING - For Mobile Homes:

must be provided and unrestricted while unit is in use. The structural integrity of the mobile home floor,

ceiling and walls must be maintained. The fireplace needs to be properly grounded to the frame of the

mobile home.

Components required for installation: HTI SLSeries Pipe or Dura Plus System, Termination Cap, Hearth

Extension and required accessory Chimney Air Kit Part CAK4A.

Do not connect this unit to a chimney serving another appliance.

DANGER: Risk of electrical shock. Disconnect power supply before servicing.

Electrical Rating: 115 VAC <3.0 AMPS 60 Hz

Do not use grate or elevate fire. Build wood fire directly on firebrick.

Do not overfire. If heater or chimney connector glows, you are overfiring.

Do not use a fireplace insert or other products not specified for use with this product.

WARNING TO REDUCE RISK OF FIRE OR INJURY, DO NOT INSTALL AN UNVENTED GAS LOG SET OR ANY LOG SET

INTO FIREPLACE.

Must provide a source of air to prevent air starvation from combustion which could result of high levels

of carbon monoxide.

Replace glass only with 5mm ceramic available from your dealer.

Optional Fire Screen Part Mesh-EPA, may be used ONLY in

Product covered by US Patents 4,766,876; 5,113,843; 5,341,794

Patent pending

Mfg by:

Portland

O-T L

Oregon USA

US

C

TESTED TO:

"For Use with Solid Wood Fuel Only."

Do not install in a sleeping room. An outside combustion air inlet

THIS FIREPLACE HAS NOT BEEN TESTED WITH AN UNVENTED GAS LOG SET OR ANY LOG SET.

U.S. ENVIRONMENTAL PROTECTION AGENCY - Certified to comply with July 1990 particulate emission standards.

www.quadrafire.com

2008 2009 2010 Jan Feb Mar Apr May June July Aug Sept Oct. Nov. Dec.

R

EPA CERTIFIED FIREPLACE

USA

SAMPLE

DO NOT REMOVE THIS LABEL

Model:

7100FP

Minimum Clearances To Combustible Material

Chimney sections at any level require a 2” (51mm) minimum

air space clearance between the framing and chimney section.

WITHIN ENCLOSURE AREA

Appliance to backwall 1/2" (13mm)

Appliance to sidewall 1" (25mm)

Duct boots to framing 0" (0mm)

Top standoffs to header 0" (0mm")

EXPOSED SURFACES

Faceplate to sidewall 16" (406mm)

Remote outlet air grills to ceiling 12" (305mm)

MANTEL

Mantel from base of fireplace 60" (1524mm)

Maximum mantel depth 12" (305mm)

FLOOR PROTECTION

Combustible flooring 20" (508mm) in front of and 8" (203mm) to

either side of the fuel opening must be insulated with

non-combustible floor protection with a minimum thickness of 1"

(25mm) and ("k" value = 0.43

In Canada: The hearth extension must be installed according to

the installation instructions.

Made in U.S.A

!

of our stoves, inserts and fireplaces. And yet we are oldfashioned when it comes to craftsmanship. Each unit is

meticulously fabricated and gold and nickel surfaces are

hand-finished for lasting beauty and enjoyment. Our pledge

to quality is completed as each model undergoes a quality

control inspection.

We wish you and your family many years of enjoyment in the

warmth and comfort of your hearth appliance. Thank you for

choosing Quadra-Fire.

Serial No / Numéro De Série

007

).

433-1400

Serial Number

Model Name

Test Lab

& Report No.

Manufactured

Date

Page 2

433-1390G

September 1, 2008

Page 3

TABLE OF CONTENTS

Section 1: Listing and Code Approvals

A. Appliance Certification . ...................4

B. Mobile Home Approved ....................4

C. Glass Specifications . .....................5

D. BTU & Efficiency Specifications . ............5

Section 2: Getting Started

A. Design and Installation Considerations ........6

B. Fire Safety ..............................6

C. Negative Pressure. . . . . . . . . . . . . . . . . . . . . . . .6

D. Typical Fireplace System . .................8

E. Tools and Supplies Needed . ...............9

F. Inspect Fireplace and Components . .........9

Section 3: Framing and Clearances

A. Selecting Fireplace Location ...............10

B. Clearances . ...........................11

C. Frame the Fireplace . ....................12

D. Electrical Access and Wiring Diagram . ......13

E. Construct the Chase .....................14

Section 4: Installation of Fireplace

A. Install the Outside Air Kit ..................15

B. Auxiliary Convection Air System ............17

C. Convection Air Lock . ....................18

D. Secure the Fireplace .....................19

Section 5: Chimney Assembly

A. Chimney Requirements. . . . . . . . . . . . . . . . . . .21

B. Chimney Termination Requirements .........21

C. Using Offsets/Returns ....................22

D. Assemble the Chimney Sections . ..........23

E. Assembling Chimney Sections

for SL-300 Series . ......................23

F. Install the Ceiling Firestops ................24

G. Install the Attic Insulation Shield . ...........25

H. Double-check the Chimney Assembly. . . . . . . .25

I. Secure the Chimney . ....................25

Section 6: Complete the Enclosure

A. Chimney Termination (2-10-03 Rule) . .......26

B. SL-300 Series Ceiling/Roof Thimble .........28

C. Chase Top .............................29

D. Install the Termination Cap . ...............29

Section 7: Replacement Parts

A. Blower Replacement .....................31

B. Baffle Removal and Installation. . . . . . . . . . . . .32

C. Door and Door Gasket . ..................32

D. Heat Zone Kit . .........................33

E. Timer Assembly Replacement . ............36

F. Manual Timer Override . ..................37

Section 8: Finishing

A. Hearth Extension. . . . . . . . . . . . . . . . . . . . . . . .38

B. Calculating Alternate Floor Protection ........38

C. Position the Hearth Extension ..............41

D. Finishing Material . ......................41

E. Non-Combustible Facing Material Installation. .42

F. Mantel ................................43

Section 9: Operating Instructions

A. Over-firing Your Appliance. . . . . . . . . . . . . . . . .44

B. Clear Space Near the Appliance ............44

C. General Information . ....................45

D. Wood Fuel .............................46

E. Burning Process . .......................47

F. Automatice Combustion Control (ACC) . .....48

G. Burning Guidelines . .....................48

H. Burn Rates . ...........................48

I. Starting a Fire . .........................49

J. Correct Baffle and Blanket Placement . ......50

K. Outside Air. . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

L. Firescreen .............................51

M. Glass Doors . ..........................51

N. Blower Operation . ......................52

O. Heat Zone Operation. . . . . . . . . . . . . . . . . . . . .52

P. Opacity . ..............................52

Q. Chimney Fire ...........................52

Section 10: Troubleshooting

A. Understanding Vent Problems . ............53

B. Draft Problems . ........................53

C. Diagnostics and Problem Solving ...........55

Section 11: Maintenance and Servicing the

Fireplace

A. General Maintenance . ...................57

B. Glass Replacement ......................58

C. Brick Replacement . .....................59

D. Care and Cleaning of Plated Surfaces .......60

E. Maintenance Task List ....................60

F. Service and Maintenance Log. . . . . . . . . . . . . .61

Section 12: Reference Materials

A. Fireplace Dimensions . ...................62

B. Chimney Components. . . . . . . . . . . . . . . . . . . .63

C. Components Diagrams and Schematics ......65

D. Fireplace Diagram .......................66

E. Service Parts ...........................67

F. Accessories ............................68

G. Warranty Policy .........................69

H. Contact Information ......................72

September 1, 2008

433-1390G

Page 3

Page 4

7100FP EPA Woodburning Fireplace

Listing and Code Approvals

1

R

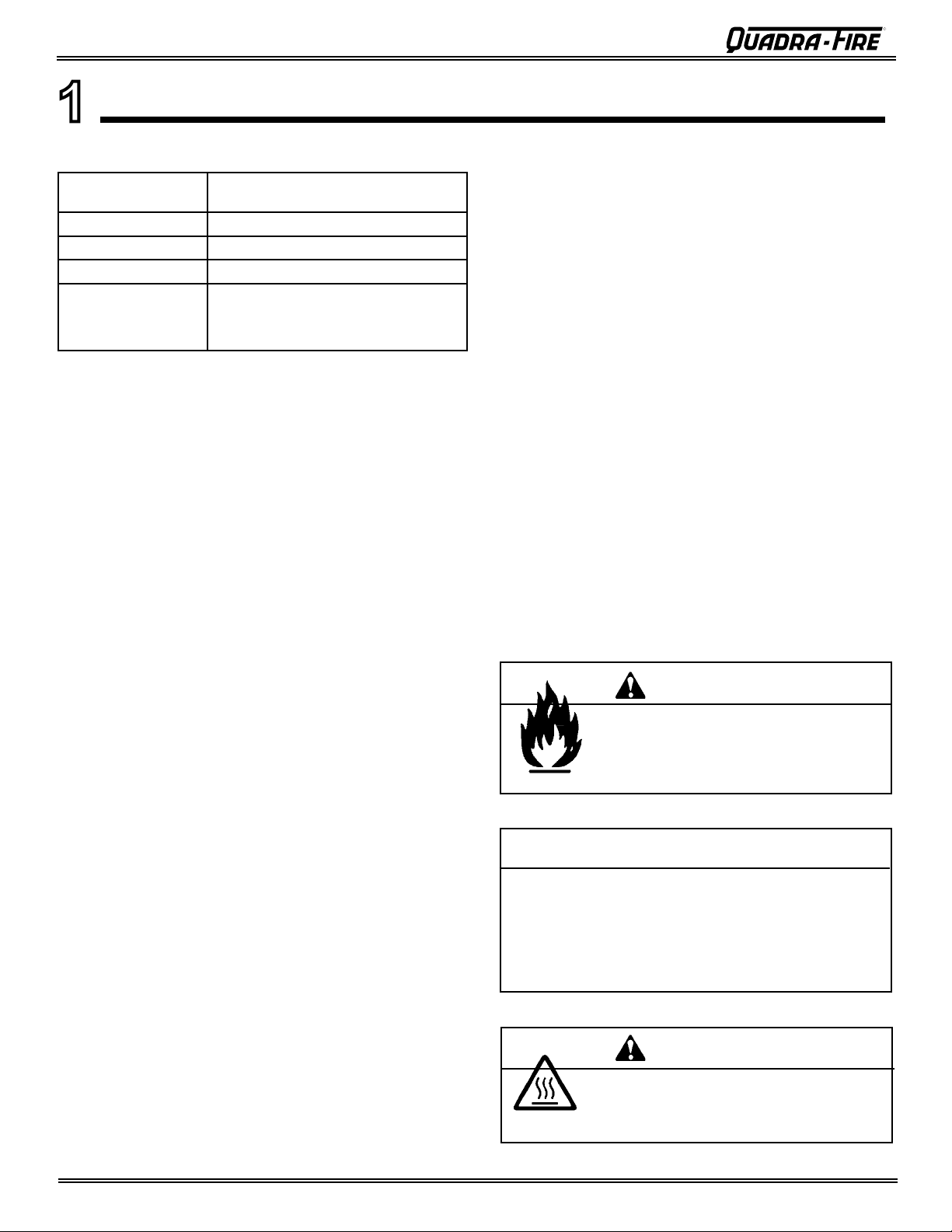

A. Appliance Certification

Model:

Laboratory: OMNI Test Laboratories, Inc.

Report No:

Type:

Standard: UL127 and ULC-S610-M87 and

This fireplace system has been tested and listed in

accordance with UL127 and ULC-S610-M87 standards,

and has been listed by OMNI Test Laboratories, Inc., for

installation and operation in the United States and Canada

as described in this manual. This fireplace has been tested

and listed for use with the SL-300 Series chimney (with

the the CAK4A Air Kit) and fireplace components listed in

Section 12. The Dura-Plus is also an approved venting

system manufactured by Dura-Vent Systems.

Check with your local building code agency before you begin

your installation to ensure compliance with local codes,

including the need for permits and follow-up inspections. Be

sure local building codes do not supersede UL specifications

and always obtain a building permit so that insurance protection benefits cannot be unexpectedly cancelled.

7100FP EPA Certified Woodburning

Fireplace

061-S-41-2

Wood Fireplace

(UM) 84-HUD, Mobile Home

Approved.

2. The fireplace is to be secured to the mobile home structure.

Use same holes that attached the fireplace to the pallet to

secure it to the floor using 1/4 in. x 2 in. (6 mm x 51 mm)

lag bolts or equivalent.

3. Unit must be grounded with #8 solid copper grounding

wire or equivalent and terminated at each end with N.E.C.

approved grounding device.

Refer to Minimum Clearances to Combustibles on pages

4.

11-12 and chimney components on pages 62-63.

5. Floor protections requirements on pages 39-41 must be

followed precisely.

6. Use silicone to create an effective vapor barrier at the

location where the chimney or other component penetrates

to the exterior of the structure.

7.

Follow the chimney and chimney connector manufacturer’s

instructions when installing the flue system for use in a mobile

home.

8.

If unit burns poorly while an exhaust blower is on in home,

(i.e., range hood), increase combustion air.

NOTE: Top sections of chimney must be removable to

allow maximum clearance of 13.5 ft (411 cm) from ground

level for transportation purposes.

B. Mobile Home Approved

This appliance is approved for mobile home installations

when not installed in a sleeping room and when an outside

combustion air inlet is provided. The structural integrity of

the mobile home floor, ceiling, and walls must be maintained.

The fireplace must be properly grounded to the frame of the

mobile home and use only listed double-wall connector pipe.

Outside Air must be installed in a mobile home installation.

An outside air termination cap is supplied with your 7100

Fireplace for installation in a mobile home. If you use

an alternative material it must be designed to prevent

material from dropping into the area beneath the mobile

home, and to prevent rodents from entering from the

outside.

1. An outside air inlet must be provided for combustion and

must remain clear of leaves, debris, ice and/or snow. It

must be unrestricted while unit is in use to prevent room air

starvation which can cause smoke spillage and an inability

to maintain a fire. Smoke spillage can also set off smoke

alarms.

WARNING

Fire Risk.

For use with solid wood fuel only.

Other fuels may overfire and generate

poisonous gases (i.e. carbon monoxide).

CAUTION

Maintain structural integrity of mobile home:

• Floor, wall, ceiling and/or roof.

Do NOT cut through:

• Floor joist, wall, studs or ceiling trusses.

• Any supporting material that would affect the structural

integrity.

WARNING

Asphyxiation Risk.

• Never install in a sleeping room.

Consumes oxygen in the room.

Page 4

433-1390G

September 1, 2008

Page 5

R

C. Glass Specifications

This fireplace is equipped with 5mm ceramic glass. Replace

glass only with 5mm ceramic glass. Please contact your

dealer for replacement glass.

D. BTU & Efficiency Specifications

EPA # and Original Date:

EPA Certified:

Efficiency:

BTU Output

with EPA test fuel:

with cord wood:

Heating Capacity:

Vent Size:

Max Wood Length:

Fuel:

Shipping Weight:

#571 4-1-03

3.1 grams per hour

up to 77%

58,500/ hr.

90,000/hr

up to 3,500 sq ft

8 inches

24 inches

Cord Wood

570 lbs

7100FP EPA Woodburning Fireplace

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause injury or property

damage. Refer to the owner’s information manual

provided with this fireplace. For assistance or additional information consult a qualified installer, service

agency or your dealer.

NOTE: Hearth & Home Technologies, manufacturer of

this appliance, reserves the right to alter its products,

their specifications and/or price without notice.

WARNING

Fire Risk

•

Do not install or operate damaged fireplace.

• Do not modify fireplace.

• Installation other than as instructed by Hearth &

Home Technologies Inc. is strictly prohibited.

• Do not operate the fireplace without fully assembling

all components.

• Do not overfire.

• Do not install an unvented gas log set. This

fireplace has not been tested for use with unvented

gas log sets.

• Installation and/or use of any component part not

approved by Hearth & Home Technologies.

Hearth & Home Technologies disclaims any responsibility

for, and the warranty and agency listing will be voided by

the above actions.

September 1, 2008

433-1390G

Page 5

Page 6

7100FP EPA Woodburning Fireplace

Getting Started

2

A. Design and Installation Considerations

When planning a fireplace installation, it is necessary to determine the following information before installing:

• Where the fireplace is to be installed. See Sections

3 and 4.

• The vent system configuration to be used. See Sections

5 and 6.

• Electrical wiring. See Section 3.

• Framing and finishing details. See Sections 3, 6 and 8.

• Whether optional accessories are desired. See

Section 12.

CAUTION

Check building codes prior to installation.

• Installation MUST comply with local, regional,

state and national codes and regulations.

• Consult insurance carrier, local building inspector,

fire officials or authorities having jurisdiction about

restrictions, installation inspection and permits.

R

WARNING

Fire Risk.

Hearth & Home Technologies disclaims any

responsibility for, and the warranty will be

voided by, the following actions:

• Installation and use of any damaged appliance.

• Modification of the appliance.

• Installation other than as instructed by Hearth & Home

Technologies.

• Installation and/or use of any component part not approved

by Hearth & Home Technologies.

• Operating appliance without fully assembling all

components.

• Operating appliance without legs attached (if supplied with

unit).

• Do NOT Overfire - If appliance or chimney connector glows,

you are overfiring.

Any such action that may cause a fire hazard.

WARNING

B. Fire Safety

To provide reasonable fire safety, the following should be

given serious consideration:

1. Install at least one smoke detector on each floor of

your home to ensure your safety. They should be

located away from the heating appliance and close

to the sleeping areas. Follow the smoke detector

manufacturer’s placement and installation instructions,

and be sure to maintain regularly.

2. A conveniently located Class A fire extinguisher

to contend with small fires resulting from burning

embers.

3. A practiced evacuation plan, consisting of at least two

escape routes.

4. A plan to deal with a chimney fire as follows:

In the event of a chimney fire:

a Evacuate the house immediately

b. Notify fire department

Fire Risk.

• Do not operate appliance before reading and

understanding operating instructions.

• Failure to operate appliance properly may

cause a house fire.

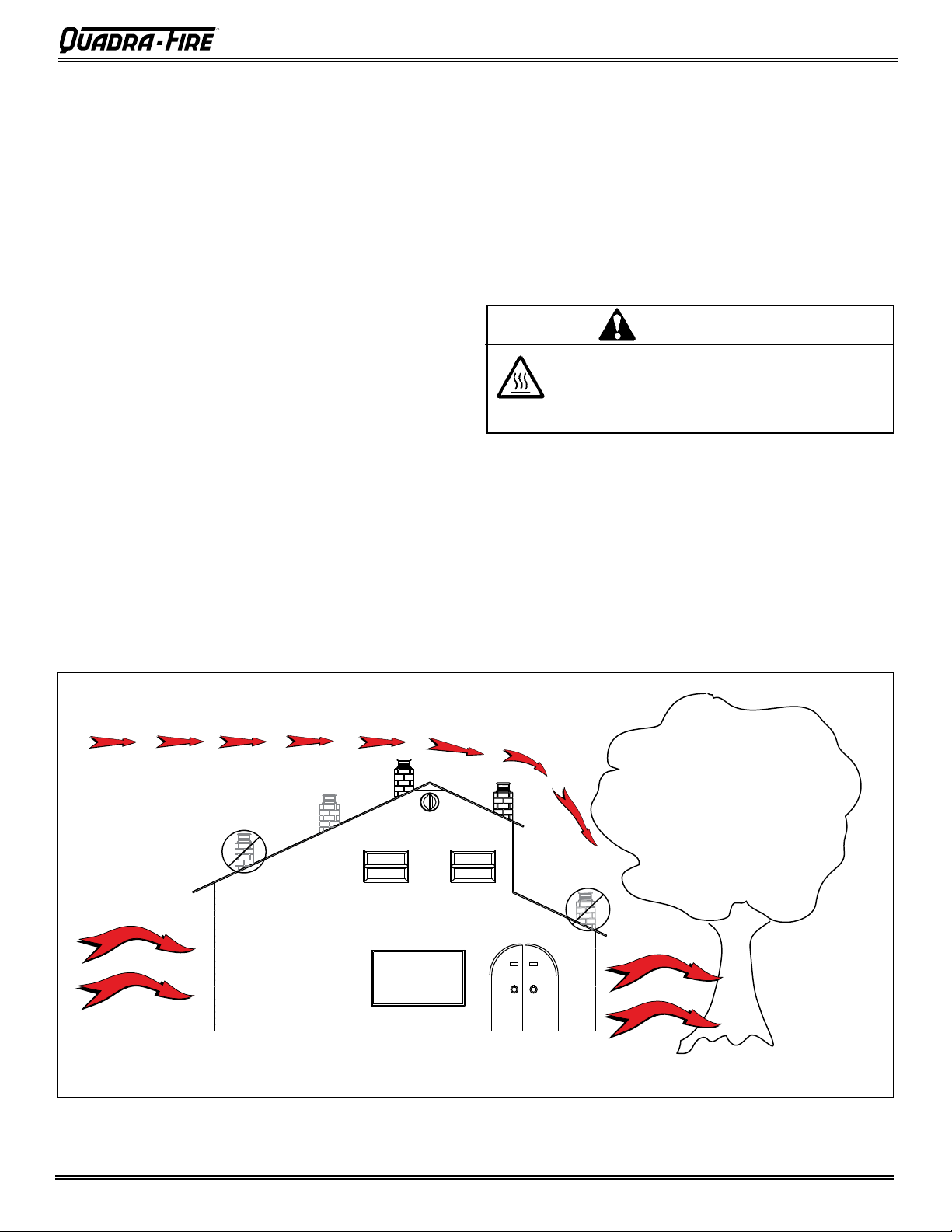

C. Negative Pressure

Draft is the pressure difference needed to vent fireplaces

successfully. Considerations for successful draft include:

• Preventing negative pressure

• Location of fireplace and chimney

Negative pressure results from the imbalance of air available for the fireplace to operate properly. Causes for this

imbalance include:

• Exhaust fans (kitchen, bath, etc.).

• Range hoods.

• Combustion air requirements for furnaces, water heaters

and other combustion appliances.

• Clothes dryers.

Page 6

• Location of return-air vents to furnace or air

• Imbalances of the HVAC air handling system.

• Upper level air leaks: recessed lighting, attic hatch

433-1390G

conditioning.

opening, duct leaks.

September 1, 2008

Page 7

R

7100FP EPA Woodburning Fireplace

To minimize the effects of negative air pressure, the following must be considered:

• Install the outside air kit.

• Ensure adequate outdoor air is supplied for combustion

appliances and exhaust equipment.

• Ensure furnace and air conditioning return vents are not

located in the immediate vicinity of the fireplace.

• Avoid installing the fireplace near doors, walkways or small

isolated spaces.

• Recessed lighting should be a “sealed can” design; attic

hatches weather stripped or sealed; attic mounted duct

work and air handler joints and seams taped or sealed.

Location of the fireplace and chimney will affect performance.

As shown in Figure 7.1, the chimney should:

• Be installed through the warm airspace enclosed by the

building envelope. This helps to produce more draft,

especially during lighting and die-down of the fire.

• Penetrate the highest part of the roof. This minimizes the

effects of wind turbulence.

The 7100FP Fireplace requires a minimum flue draft of -0.10

inches of water column on High, and -0.04 inches of water

column on Low, as measured with a draft meter. Most dealers have draft meters available to measure your flue draft if

you suspect a problem.

If the fire is difficult to start, and smoke spills out of the door,

or you find it hard to establish and maintain a moderately

high burn rate, then the flue draft is too low and corrective

measures must be taken.

NOTE: Cold air infiltration can cause frosting on glass.

WARNING

Asphyxiation Risk

Negative pressure can cause spillage of

combustion fumes and soot. Fire needs to draft

properly for safe operation.

• Be located away from trees, adjacent structures, uneven

roof lines and other obstructions.

Offsets can restrict draft so their use should be minimized.

Consider the fireplace location relative to floor and ceiling

and attic joists.

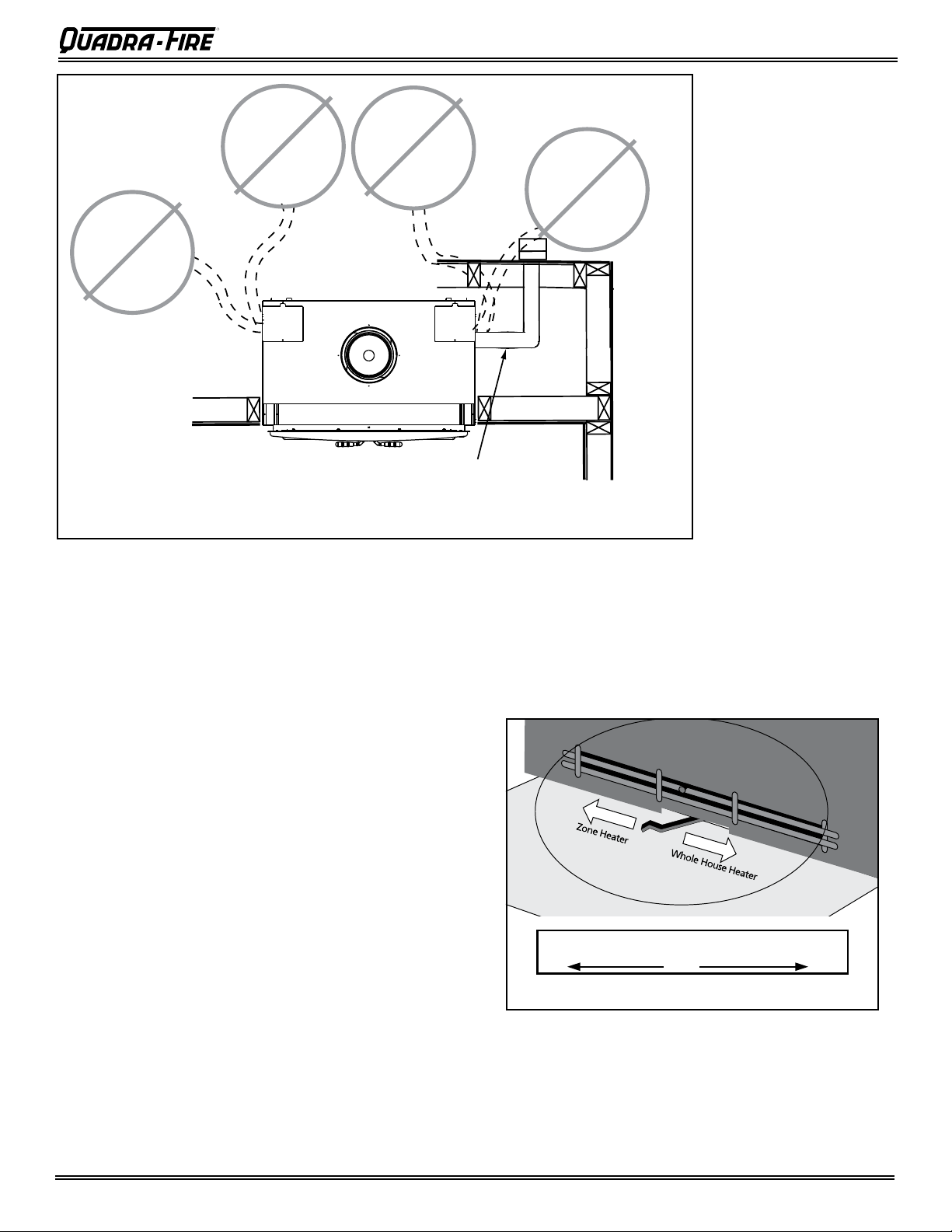

Recommended

Location

Marginal

Location

Location

Not

Recommended

Windward

Recommended

Location

Location NOT

Recommended

Figure 7.1 Recommended Chimney Locations

September 1, 2008

Multi-level Roofs

433-1390G

Leeward

Page 7

Page 8

7100FP EPA Woodburning Fireplace

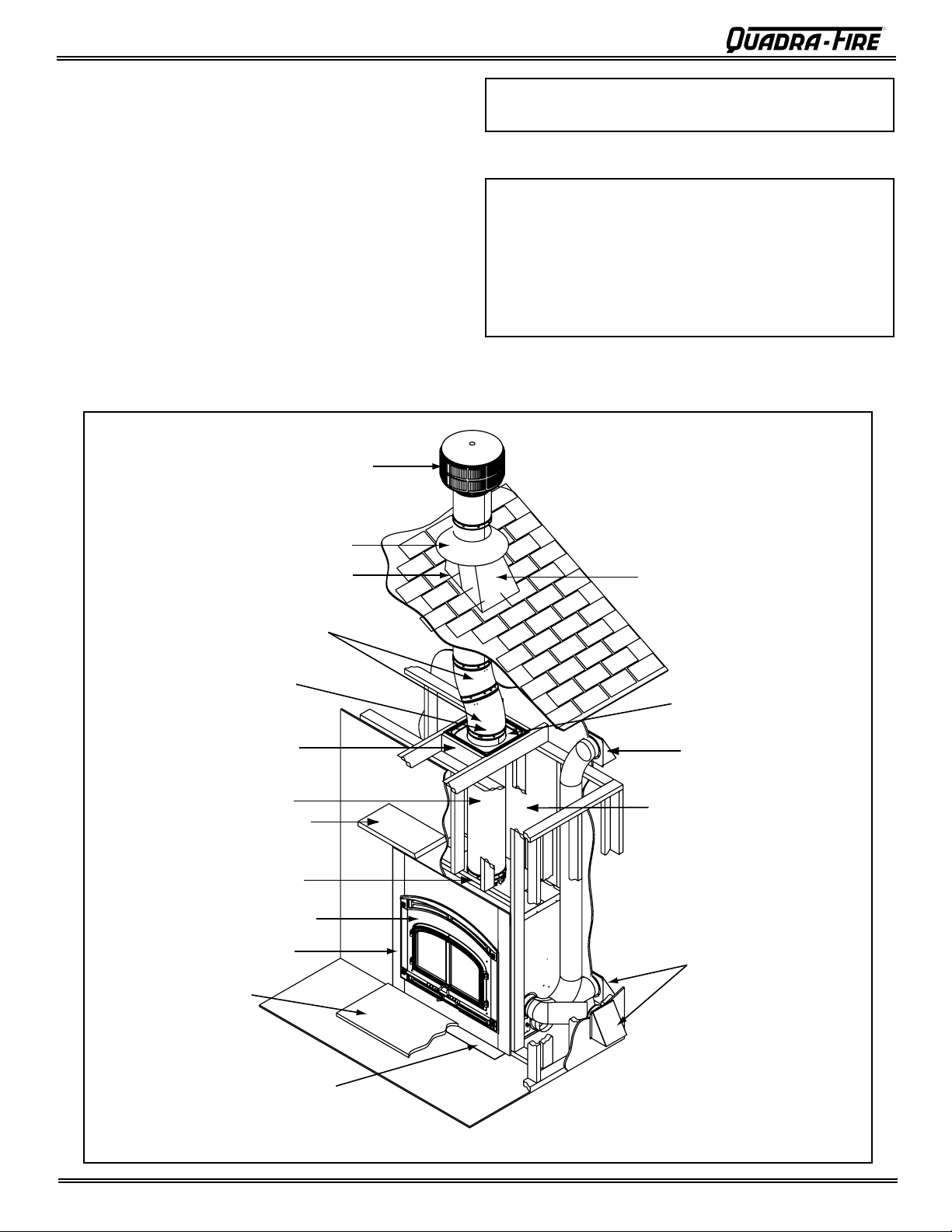

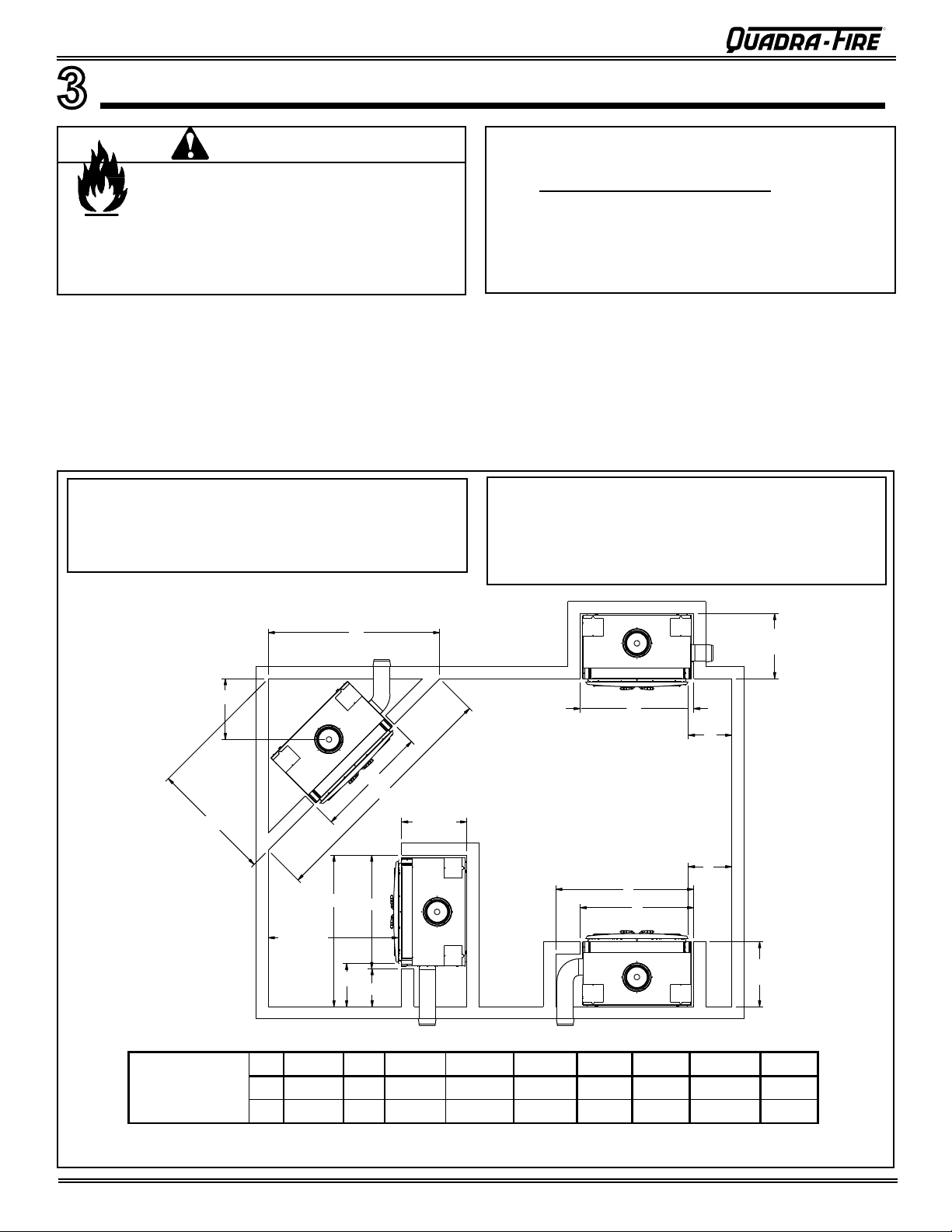

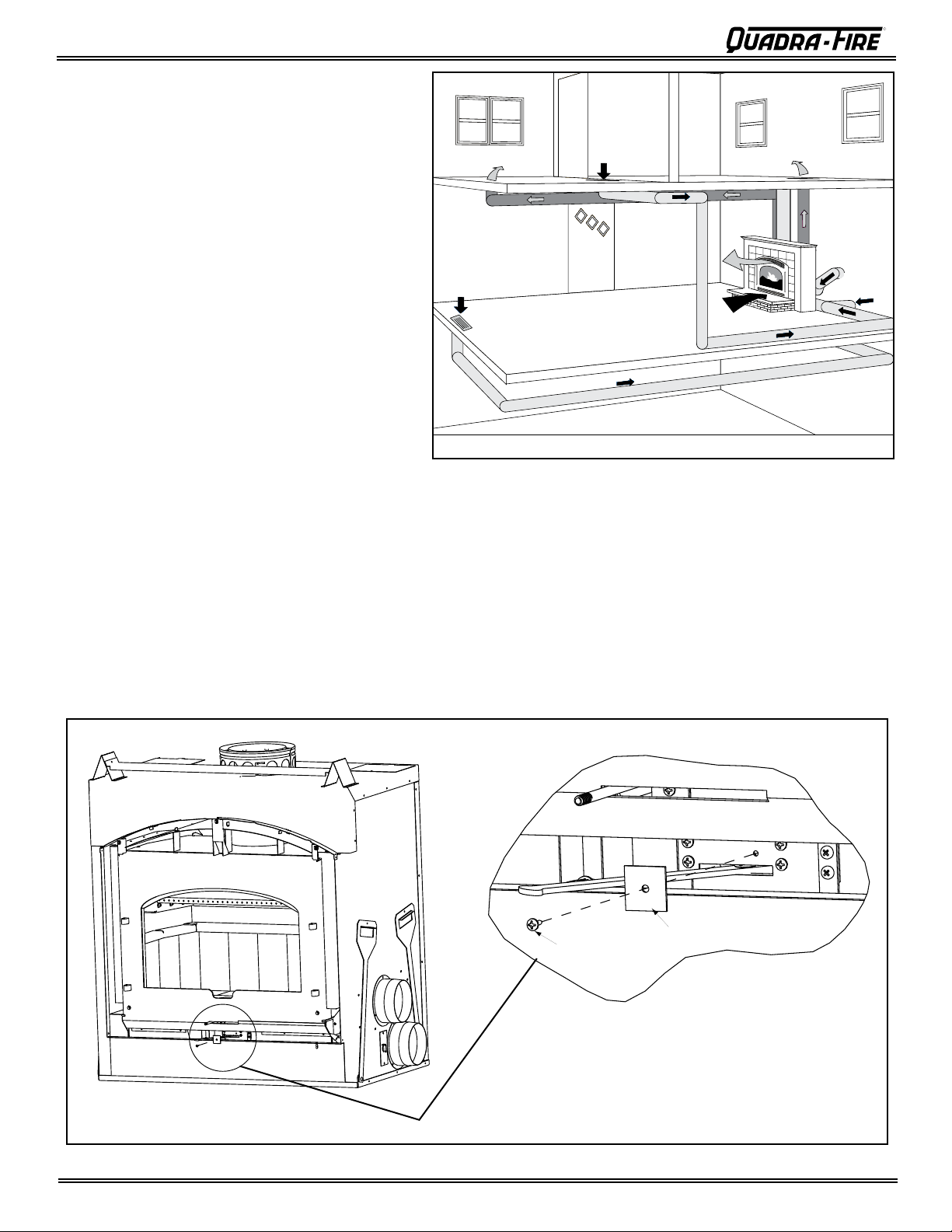

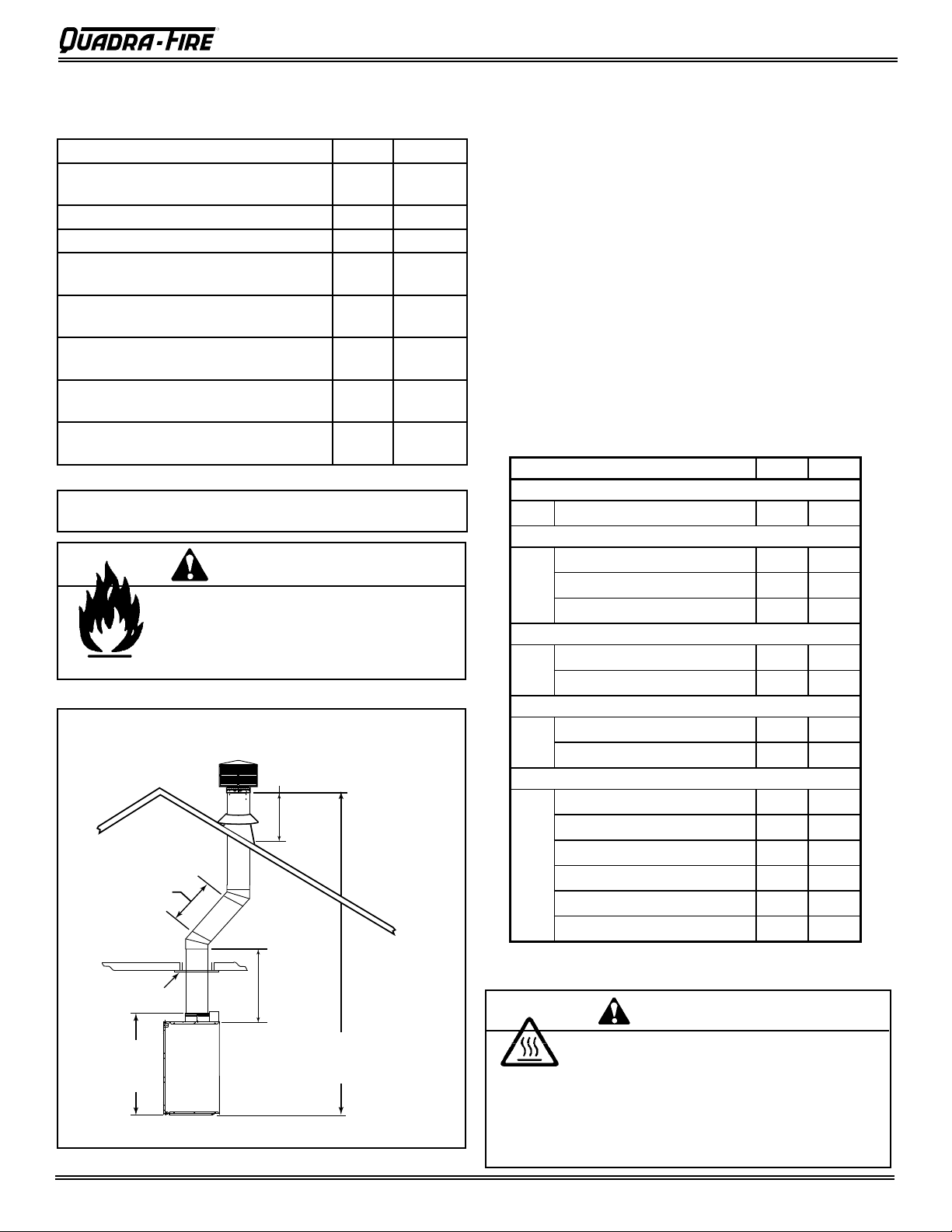

D. Typical Fireplace System

The Quadra-Fire fireplace system consists of the following:

• Fireplace

• Firebrick

• Chimney termination cap

• Chimney system

• Hearth extension

• Outside air

Required components include:

• Chimney Air Kit (with SL 300 Series Pipe)

Optional components include:

• Firescreen

• Lintel Bar

• Heat Zone Kit

• Top Vent Kit

Termination Cap

R

Note: Junction box should be installed during initial setup

to avoid major reconstruction.

NOTE: Illustrations used throughout these instructions

reflect “typical installations” and are for design purposes

only. Actual installation may vary slightly due to individual

design preferences. However, minimum clearances must

be maintained at all times.

The illustrations and diagrams used throughout these installation instructions are not drawn to scale.

Additional lateral

support for chimney

above roof (or enclosed

in chase) if needed

Chimney penetrates roof

preferably without affecting

roof rafters

Offset/Return

(with hanger straps)

Attic insulation shield

(not shown) must be

used here to keep

insulation away

from chimney if

attic is insulated

Framing headed

off in ceiling joists

Chimney system

Combustible

framing/header

on top of V-shaped

standoffs (spacers)

Factory-built fireplace

Decorative facing

and trim

Hearth extension

Storm Collar

Mantel

Non-combustible

roof flashing maintains

minimum clearance

around chimney

Support straps

on rafter supports

chimney (not shown)

Ceiling firestop

on floor of attic

Outside

combustion air

Enclosed space above

and around fireplace

Outside

combustion air

Page 8

Protective metal

hearth strip(s)

Figure 8.1 Typical Fireplace System

433-1390G

September 1, 2008

Page 9

R

7100FP EPA Woodburning Fireplace

E. Tools and Supplies Needed

Before beginning the installation be sure the following tools

and building supplies are available:

Reciprocating saw Framing material

Pliers High temp caulking material

Hammer Gloves

Phillips screwdriver Framing square

Flat blade screwdriver Electric drill and bits

Plumb line Safety glasses

Level Tape measure

1/2-3/4 in. length, #6 or #8 self-drilling screws

Misc. screws and nails

CAUTION

• Keep fireplace dry.

• Mold or rust may cause odors.

F. Inspect Fireplace and Components

WARNING

Fire Risk

Explosion Risk

Inspect fireplace and components for

damage. Damaged parts may impair safe

operation.

• Do NOT install damaged components.

• Do NOT install incomplete components.

• Do NOT install substitute components

Report damaged parts to dealer.

• Carefully remove the fireplace and components from the

packaging.

• Doors are shipped on the fireplace.

• Report to your dealer any parts damaged in shipment.

WARNING

Fire Risk.

• Do not operate appliance before reading and

understanding operating instructions.

• Failure to operate appliance properly may

cause a house fire.

September 1, 2008

433-1390G

Page 9

Page 10

7100FP EPA Woodburning Fireplace

Framing and Clearances

3

R

WARNING

Fire Risk

Provide adequate clearances.

• Around air openings

• To combustibles

• For service access.

Locate fireplace away from traffic areas.

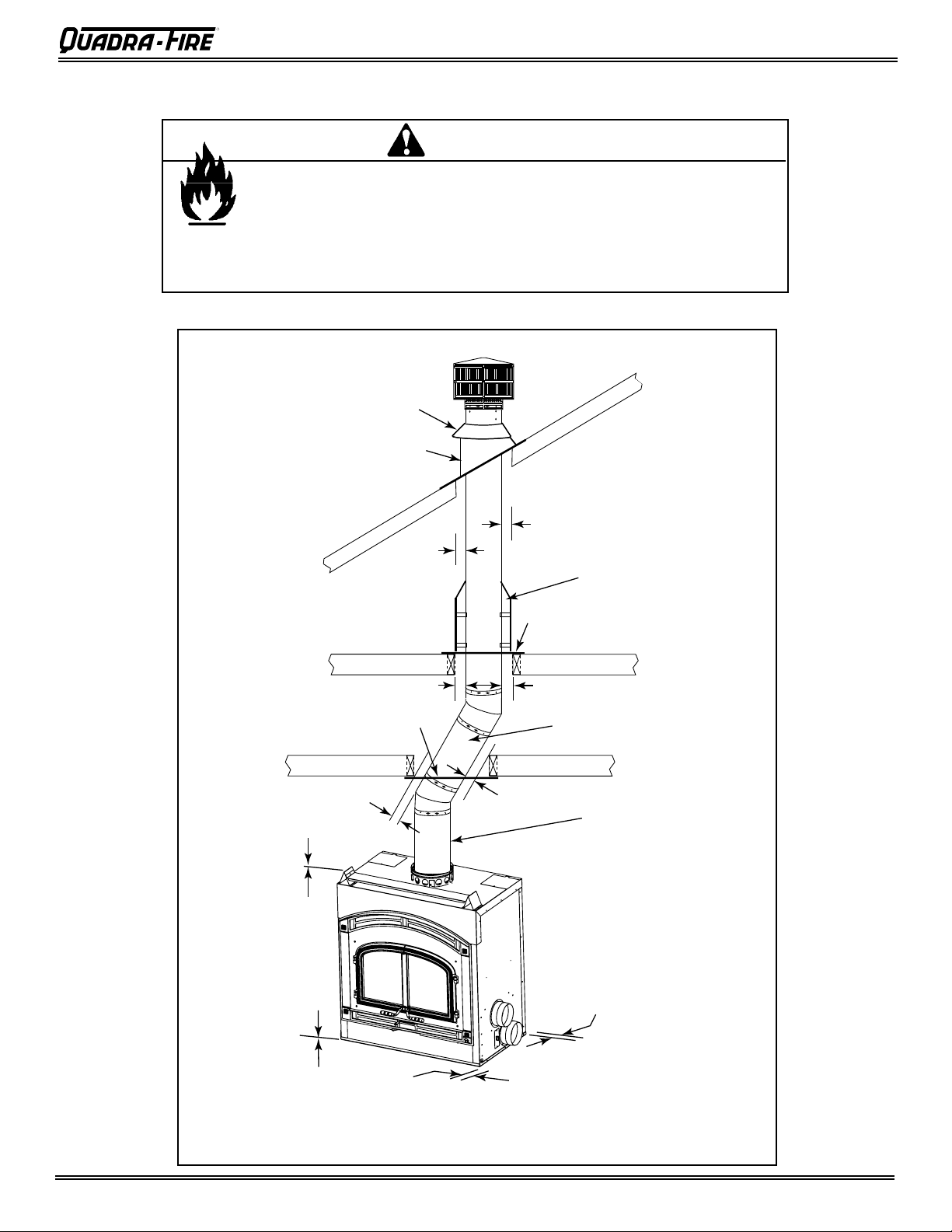

A. Selecting Fireplace Location

Several options are available to you when choosing a location for your fireplace. This fireplace may be used as a room

divider, installed along a wall, across a corner or used in an

exterior chase. See Figure 10.1.

Locating the fireplace in a basement, near frequently opened

doors, central heat outlets or returns, or other locations of

Note: A minimum 1/2 in. air clearance must be maintained at the

back and 1 in. minimum clearance to the sides of the fireplace

assembly.

Chimney sections at any level require a 2 in. minimum air

space clearance between the framing and chimney sections.

Note:

• Illustrations and photos reflect typical installations and

are FOR DESIGN PURPOSES ONLY.

• Illustrations/diagrams are not drawn to scale.

• Actual installation/appearance may vary due to individual

design preference.

• Hearth & Home Technologies reserves the right to alter

its products.

considerable air movement can affect the performance and

cause intermittent smoke spillage from the front of the fireplace when no outside air is used. Outside air must be used

for combustion. The 7100FP comes equipped with an outside air inlet to feed combustion air from outside the home,

along with an outside air termination cap. Consideration

should be given to these factors before deciding on a location. See Sections 2 and 10.

Note: In addition to these framing dimensions, also reference the

following sections:

• Clearances (Section 3.B.)

• Mantel (Section 8.F.)

• Fireplace Dimensions (Section 12.A.)

E

F

Model

#7100FP

(Dimensions for

finished walls)

As a

room

divider

48 in.

(1219mm)

D

A

In an exterior chase

or projecting into a

garage

Across a corner

A

C

24 in.

(610mm)

Along a wall

H

A

B

G

I

A

B

B

24 in.

(610mm)

24 in.

(610mm)

ABC D E FG H I

in. 41-7/8 16 89-1/2 63-5/16 22-7/16 44-3/4 14-1/16 55-15/16 50-7/8

mm 1063 406 2273 1608 570 1137 357 1421 1292

Figure 10.1 Fireplace Locations

Page 10

433-1390G

September 1, 2008

Page 11

B. Clearances

R

7100FP EPA Woodburning Fireplace

WARNING

Fire Risk

• Comply with all minimum clearances to combustibles as specified.

• Framing or finishing material used on the front of, or in front of, the

appliance closer than the minimums listed, must be constructed entirely

of non-combustible materials (i.e., steel studs, concrete board, etc.).

Failure to comply may cause fire.

Storm Collar

(roof)

Roof Flashing

0 in. to level

of standoffs

2 in. min.

(51 mm)

(attic)

2 in. (51 mm) min.

Ceiling Firestop

2 in. (51 mm) min.

2 in. (51 mm) min.

Attic

Insulation

Shield

Ceiling Firestop

(ceiling)

2 in. (51 mm) min.

2 in. (51 mm) min.

Offset/Return with

hanger straps

(ceiling)

2 in. (51 mm) min.

Must have 2 in. (51 mm)

minimum clearance

to header

September 1, 2008

0 in.

to floor

Figure 11.1 Clearances to Combustible Materials

(except at nailing flanges where it is 1/2 in. [13 mm])

433-1390G

1/2 in. (13 mm) to back

of appliance

1 in. (25mm) to side of appliance

Page 11

Page 12

7100FP EPA Woodburning Fireplace

Minimum Clearances to Combustibles

WITHIN ENCLOSURE AREA

Appliance to backwall 1/2 in. (13 mm)

Appliance to sidewall 1 in. (25 mm)

Duct boots to framing 0 in. (0 mm)

Top standoffs to header 0 in. (0 mm)

Door opening to sidewall 22-7/8 in. (581 mm)

EXPOSED SURFACES

Faceplate to sidewall 16 in. (406 mm)

Heat zone air grills to ceiling 12 in. (305 mm)

MANTEL

Combustible and non-combustible

mantel minimum height

Maximum mantel depth 12 in. (305 mm)

OPTIONAL FRAMING CONSTRUCTION / REDUCED

MANTEL HEIGHT:

Non-combustible mantel material minimum height from base

of fireplace to underside of mantel 46 in. (1168mm) when the

following enclosure construction materials are used:

Non-combustible framing materials must be used above fireplace to height of 84 in. (2134mm) from base of fireplace for

all construction materials, framing members, sheeting, and

all finish materials.

Non-Combustible Materials

Materials which will not ignite and burn. Such materials are

those consisting entirely of steel, iron, brick, tile, concrete,

slate, glass or plasters, or any combination thereof.

Materials that are reported as passing ASTM E 136, Standard Test Method for Behavior of Materials, in a Vertical

Tube Furnace at 750°C, shall be considered non-combustible materials.

60 in. (1524 mm)

R

WARNING

Fire Risk

•

Non-combustible mantels installed at a

reduced height may GET EXTREMELY

HOT during use of the fireplace.

• DO NOT TOUCH or place heat sensitive

combustible items on the mantel.

MANTEL

Combustible and non-combustible mantel minimum height

from base of fireplace to underside of mantel

60 in. (1524 mm)

Maximum mantel depth 12 in. (305 mm)

CHIMNEY SECTIONS

Chimney sections at any level require a 2 in. (51 mm) minimum air space clearance between the framing and chimney

section.

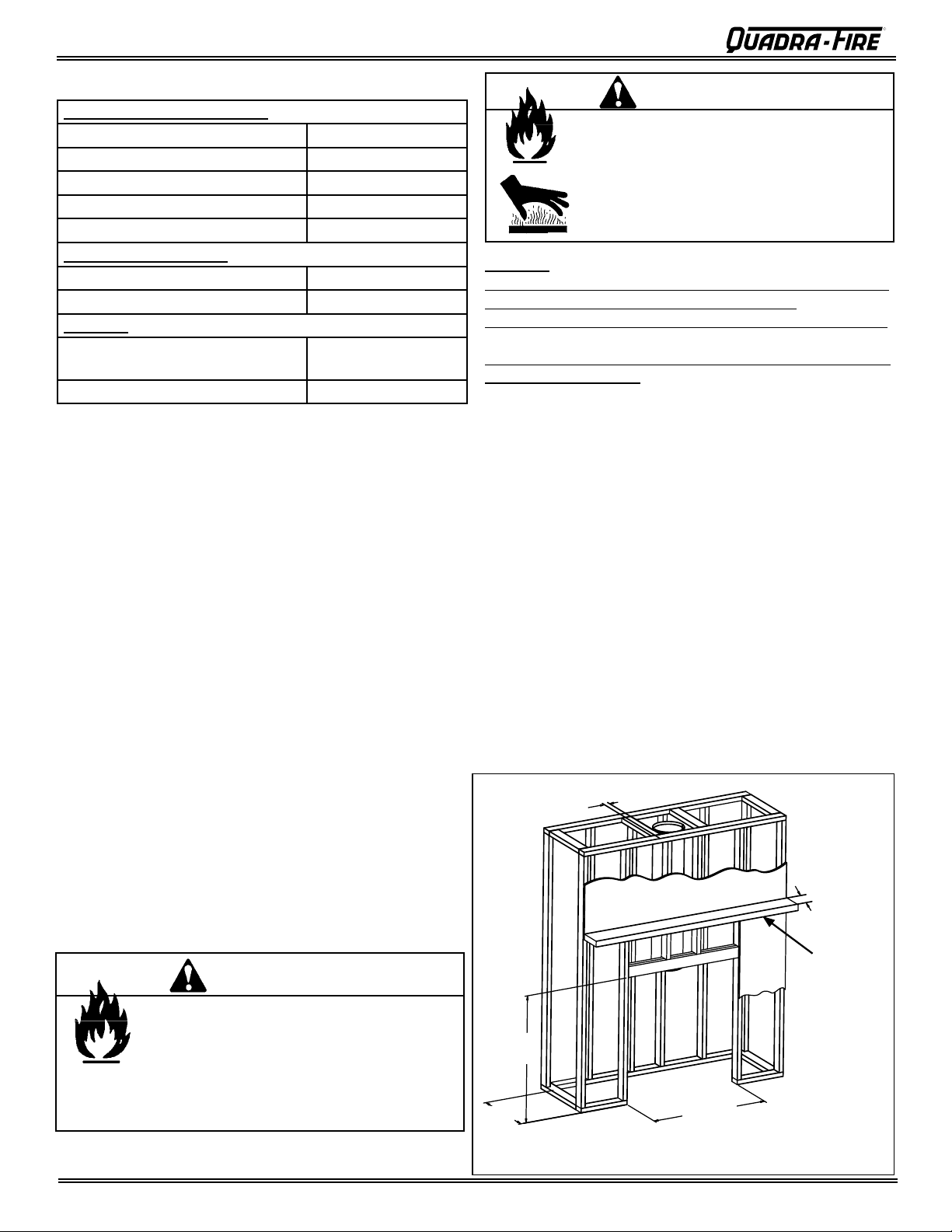

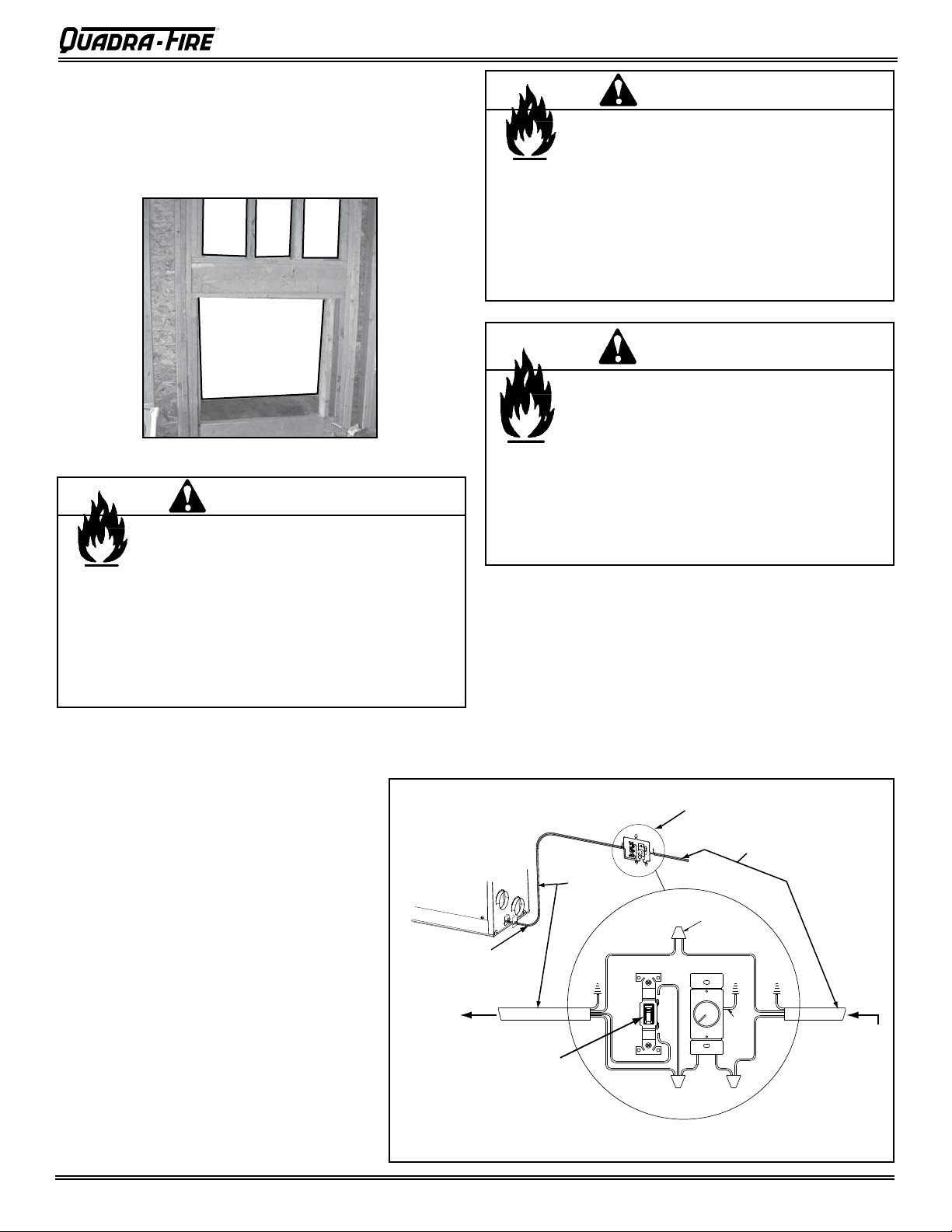

C. Frame the Fireplace

NOTE: Wiring for blowers must be done before framed

enclosure is completed. If using a Heat Zone kit, it also

must be installed before enclosure is complete.

The 7100FP Fireplace will fit a framed opening height of

45-7/8 in. (1165 mm) tall and width of 42 in. (1067 mm). The

finished cavity depth must be no less than 24 in. (610 mm).

Framing must extend straight up all the way to the ceiling.

Figure 12.1 shows a typical framing (using 2 x 4 lumber)

of the fireplace, assuming combustible materials are used.

All required clearances to combustibles around the fireplace

must be adhered to. See Figure 11.1, on page 11. Any framing across the top of the fireplace must be above the level of

the top standoffs. (No recess above standoffs.)

2 in.

(51mm)

Combustible Materials

Materials made of or surfaced with wood, compressed paper,

plant fibers, plastics, or other materials that can ignite and

burn, whether flame proofed or not, or whether plastered or

un-plastered shall be considered combustible materials.

WARNING

Fire Risk

Hearth & Home Technologies is not responsible for discoloration, cracking or other material failures of finishing materials due to heat

exposure or smoke.

• Choose finishing materials carefully.

Page 12

433-1390G

45-7/8 in.

(1165mm)

24 in.

(610mm)

Figure 12.1 Framing the Fireplace

12 in.

(305mm)

Position

combustible/

non-combustible

mantel 60 in.

(1524mm)

from base of

the fireplace

42 in.

(1067mm)

September 1, 2008

Page 13

R

Suggestions:

1. Insulate chase.

2. Finish chase walls with dry wall 5/8 in. (16mm) Type X

face tape.

3. All dimensions are to finished walls and ceilings.

Figure 13.1 Sheetrocked Chase

WARNING

Fire Risk

Comply with all minimum clearances specified.

• A minimum 1/2 in. (13mm) air clearance

must be maintained at the back and 1

in. (25mm) to the sides of the fireplace

assembly.

• Chimney sections at any level require a 2

in. (51mm) minimum air space clearance

between the framing and chimney section.

7100FP EPA Woodburning Fireplace

WARNING

Fire Risk

Do not apply combustible finishing materials

over any part of the front of this fireplace.

• The metal fireplace face may only be

covered with noncombustible materials

such as ceramic tile, brick, or stone.

• Do not cover or block any cooling air

slots.

The decorative fascia must be removable

for future serviceability of the Automatic

Combustion Control.

WARNING

Fire Risk

• Maintain clearances.

• Use only non-combustible material below

standoffs, material such as cement board

is acceptable.

• Framing or finishing material used on the front

of, or in front of, the appliance closer than the

minimums listed, must be constructed entirely of

noncombustible materials (i.e., steel studs, concrete

board, etc.).

D. Electrical Access and Wiring Diagram

NOTE: The manual override switch, rheostat

speed control and cover plate are supplied. You

will need to supply: 14-3 wire with ground; 14-2

wire with ground; standard wall mount junction

box; wire nuts.

1. Remove junction box cover plate on the

bottom right side of the fireplace.

2. Thread the 14-3 with ground wire through

the opening with the strain relief on the cover

plate.

3. Match colors to wire harness, (red to red,

white to white, etc) and secure with wire

nuts.

NOTE: Wiring for blowers must be done

before framed enclosure is completed.

If using a Heat Zone kit, it also must be

installed before enclosure is complete.

September 1, 2008

Match colors to wire

harness (red to red,

white to white, etc) and

secure with a wire nut

14-3 w/ground

Power to the Fireplace

Snap Disc

bypass switch

Figure 13.2 Fan Wiring Diagram

433-1390G

RED

WHITE

BLACK

Standard wall mount with

Junction Box

14-2 w/ground

WIRE NUT

WHITE

GREEN

Incoming Power

BLACK

(110V)

Page 13

Page 14

7100FP EPA Woodburning Fireplace

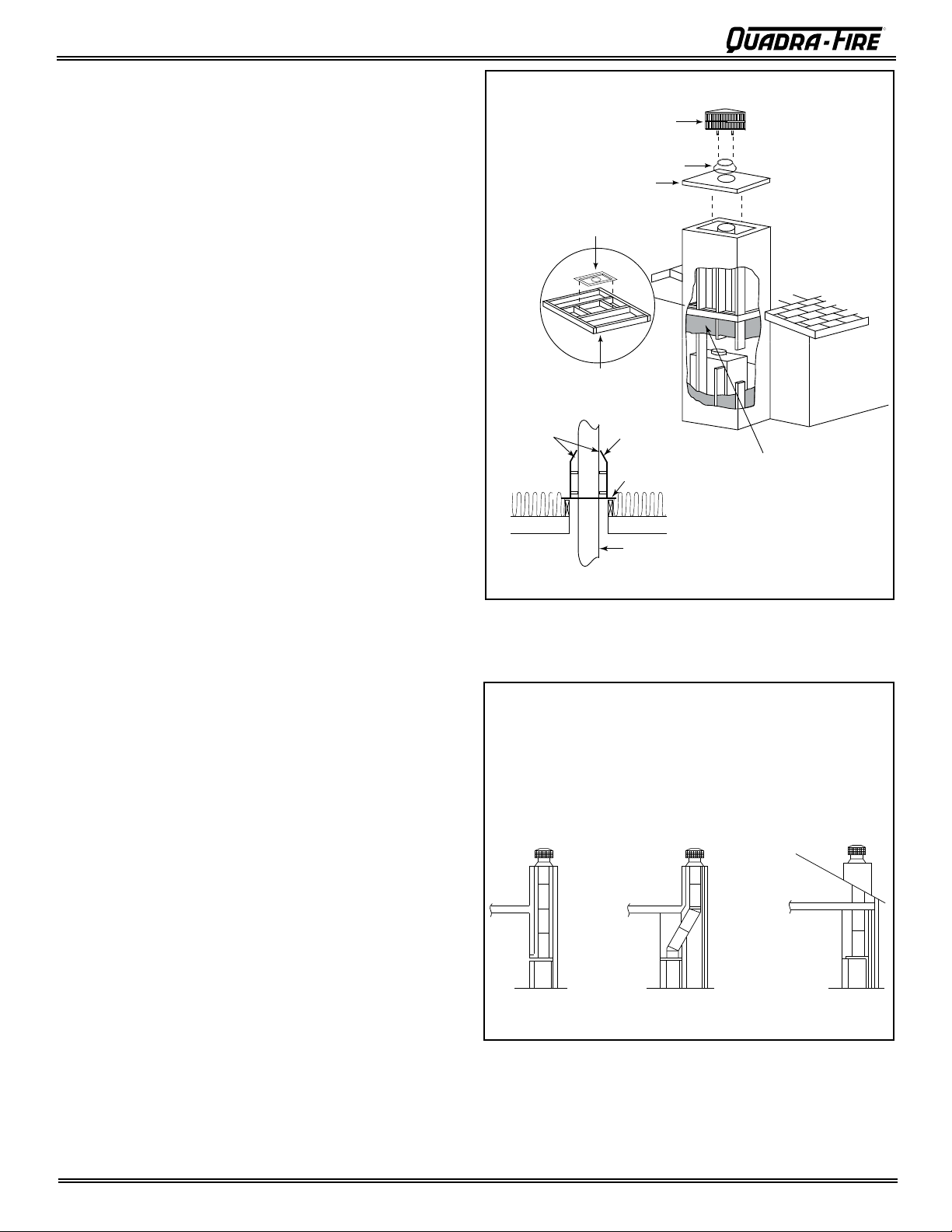

E. Construct the Chase

A chase is a vertical boxlike structure built to enclose the fireplace and/or its vent system. Vertical chimneys that run on

the outside of a building must be installed inside a chase.

In cold climates, it is recommended that the chase be well

insulated using batt type insulation between the joists.

Construction of the chase may vary with the type of building. These instructions are not substitutes for the requirements of local building codes. Local building codes MUST

be checked.

Chases should be constructed in the manner of all outside

walls of the home to prevent cold air drafting problems. The

chase should not break the outside building envelope in any

manner. All outer walls need to be insulated.

Building codes require false ceiling and ceiling firestops at

each floor of the chase or every 10 ft (3048 mm) of clear

space to control spread of fire.

Walls, ceiling, base plate and cantilever floor at the first level

of the chase should be insulated. See Figure 14.1. Vapor

and air infiltration barriers should be installed in the chase

as per regional codes for the rest of the home. Additionally,

Hearth & Home Technologies recommends that the inside

surfaces be sheet rocked and taped (or the use of an equivalent method) for maximum air tightness.

Holes and other openings should be caulked with high temperature caulk or stuffed with unfaced fiber glass insulation.

Round Termination Cap

Storm Collar

Metal Chase Top

Ceiling

Firestop

False Ceiling

Attic

Tabs

Insulation

False Ceiling

Figure 14.1 Chase Assembly

Insulation

Shield

Ceiling

Firestop

Insulation

False Ceiling

Chimney

R

Insulation in the

outside walls

of the chase

Materials

a. The chase is constructed using framing materials much

the same as the walls in your home. A variety of siding

materials may be used including brick, stone, veneer

brick, or standard siding materials.

b. In constructing the chase, several factors must be con-

sidered:

1) Maintain a 2 in. (51 mm) air space around the chim-

ney.

2) The chase top must be constructed of non-combus-

tible material.

3) In cold climates, a firestop spacer should be installed

in an insulated false ceiling at the 8 ft. (2438 mm)

level above the fireplace assembly. This reduces heat

loss through the chase.

4) In cold climates, the walls of the chase should be

insulated to the level of the false ceiling as shown in

Figure 14.1. This will help reduce heat loss from the

home around the fireplace.

Three examples of chase applications are shown in Figure 14.2.

1. Fireplace and chimney enclosed in an exterior chase.

2. Chimney offset through exterior wall and enclosed in

chase.

3. Chase constructed on roof.

All outside walls should be insulated.

1 2 3

Figure 14.2 Chase Constructions

Page 14

433-1390G

September 1, 2008

Page 15

R

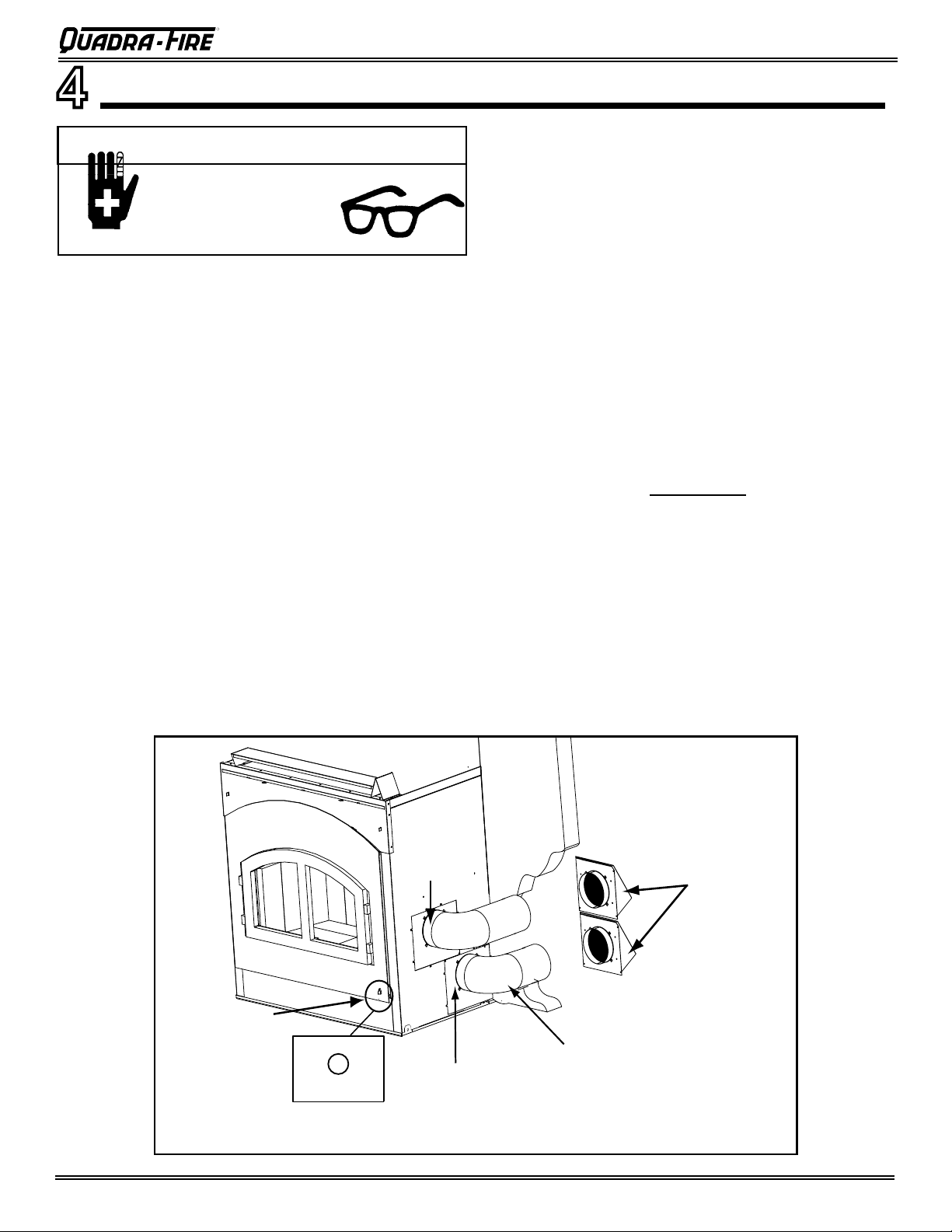

Installation of Fireplace

4

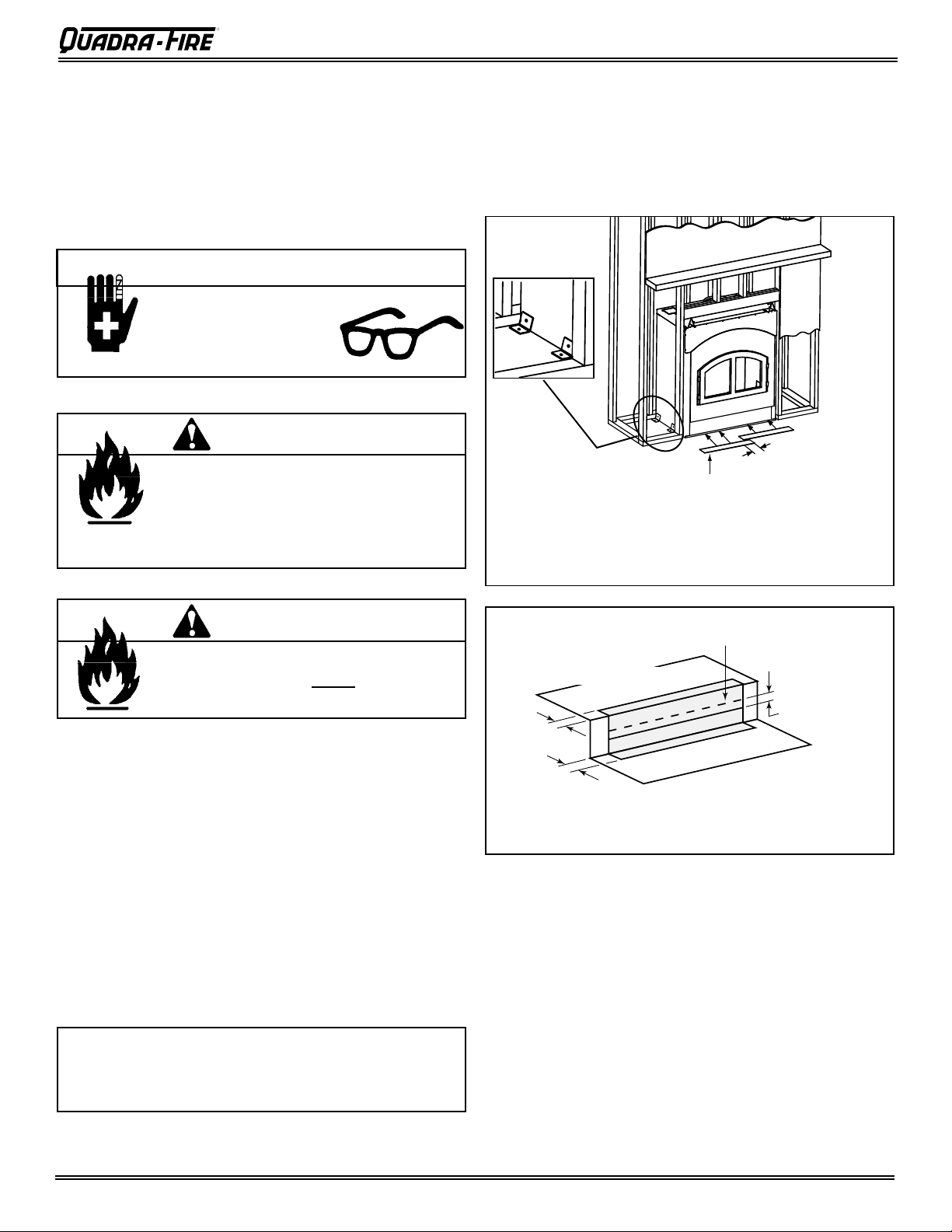

CAUTION

Sharp Edges

• Wear protective gloves

and safety glasses during

installation.

A. Install the Outside Air Kit

This fireplace will operate correctly only if adequate ventilation is provided to allow proper draft to the fireplace system.

See Section 2.

Using an outside air kit must be used for combustion to minimize the effects of negative pressure within the structure.

We recommend you utilize the shortest duct run to optimize

the performance of the outside air kit. The outside air kit inlet

should be positioned in a manner that will not allow snow,

leaves, etc. to block the inlet. In some installations the air

duct may need to be run vertically. In such an installation, a

3 ft (914 mm) height difference must be maintained from the

top of the uppermost chimney section to the outside combustion air inlet. See Figure 16.1 on page 16.

See Figure 16.2 on page 16 for proper placement of outside

air inlet.

The outside air kit is installed on the right hand side of the

fireplace. See Figure 15.1 for handle location/operation.

7100FP EPA Woodburning Fireplace

1.

Cut a 6 in. (152 mm) hole in outside wall to accommodate

air piping. The outside air is located on top, auxiliary

convection air intake is located on the bottom. See Figure

15.1.

2. Use 6 in. (152 mm) metal flex or rigid piping (not supplied)

to directly connect outside air to fireplace intake. Insulate

the pipe to prevent frost condensation.

3. Use the supplied termination caps.

4. Seal between the wall and the pipe with silicone to prevent

moisture penetration and air leaks.

5. Seal between the termination cap and the house with

silicone to prevent air infiltration.

NOTE: A control knob allows you control of the outside air

inlet. Use of outside air for combustion is required to

conserve heated air within the structure and to provide

make up air to keep the fireplace venting properly.

IMPORTANT!

TURN CLOCKWISE TO “OPEN” POSITION.

OUTSIDE AIR KNOB MUST BE IN THE “OPEN” POSITION TO OPERATE FIREPLACE PROPERLY.

MAY BE CLOSED WHEN NOT IN USE TO PREVENT

COLD AIR INFILTRATION.

Figure 15.1 Outside Air Installation

September 1, 2008

Open/Close

Knob for

outside air

CLOSED

OUTSIDE AIR

OPEN

Outside Air

intake

Auxiliary

Convection

Air

433-1390G

Termination

Caps supplied

with fireplace

6 in. (152 mm) rigid or flex pipe

(not provided)

Page 15

Page 16

7100FP EPA Woodburning Fireplace

t

WARNING

Fire Risk

Asphyxiation Risk

Do not draw outside combustion air from:

• Wall, floor or ceiling cavity.

• Enclosed space such as an attic or

garage.

• Close proximity to exhaust vents or

chimneys.

Fumes or odor may result.

CAUTION

Risk of Smoke Spillage

Outside air inlet must be located to prevent blockage

from:

• Leaves

• Snow/ice

• Other debris

Blockage may cause combustion air starvation.

R

Handle Left - Closed

Handle Right - Open

Figure 16.2 Locating the Outside Air Control

Attic insulation shield

must be used to keep

insulation away from

chimney.

Ceiling firestop

on floor of attic.

Figure 16.1 Outside Air Inlet Locations

3 ft. (91cm) min. from

uppermost chimney

section to air inlet.

Page 16

433-1390G

September 1, 2008

Page 17

NO

Outlet placed

higher than 3 ft

below the

termination cap

R

NO

Attic space

NO

Garage or

combustible

liquids storage

Use only duct materials

specified by manufacturer

7100FP EPA Woodburning Fireplace

NO

Outlet blocked by

snow, leaves, etc.

Figure 17.1 Outside Convection Air Placement

B. Auxiliary Convection Air System

Both the Outside Air and Auxiliary Air kits are installed

on the right hand side of the fireplace.

Auxiliary convection air allows you to use outside air to flow

over the blowers, where it is heated and then distributed

into the room producing positive pressure inside the home.

Alternatively, you can also run a 6 in. (152 mm) duct to another

location in your home and use as a cold air return within the

home.

The auxiliary convection lever allows you to change the

fireplace from a zone heater into a whole house heater.

LEFT: Slide to the left and use the fireplace as a zone heater.

This option pulls room air into the bottom grille of the fireplace,

heats the air and re-circulates it to the room(s).

RIGHT:

house heater for room convection air.

Slide to the right and use the fireplace as a whole

Left = Room Air Right =Auxiliary Air

The auxiliary convection lever

lower panel. See Figure 17.2.

September 1, 2008

is located underneath the front

433-1390G

Figure 17.2 Auxiliary Convection Air Lever

Page 17

Page 18

7100FP EPA Woodburning Fireplace

The auxiliary convection lever allows you to choose

where the convection air is coming from. You can either use room air from the same room where the fireplace is installed (all the way to the left) or from duct

work which can be run to another room in the house

or to the exterior of the home to use outside air (all

the way to the right).

NOTE: If you live in an area that experiences

very cold winter months, you will want to pull in

room air from your home as opposed to pulling

in cold air from the outside of the home. This will

eliminate creating a draft of cold outside air infiltrating your home when your are not using your

fireplace.

R

Figure 18.1

C. Convection Air Lock

Auxiliary convection air control is locked. If you are going

to use this function for air movement you must remove the

lock.

After removing the fascia, remove the one screw and plate

to allow the handle to be moved in the full motion right to left.

See Figure 18.2.

Discard the plate and screw. Replace fascia.

Convection Lock Bracket

8-32 Screw

Figure 18.2

Page 18

433-1390G

September 1, 2008

Page 19

R

7100FP EPA Woodburning Fireplace

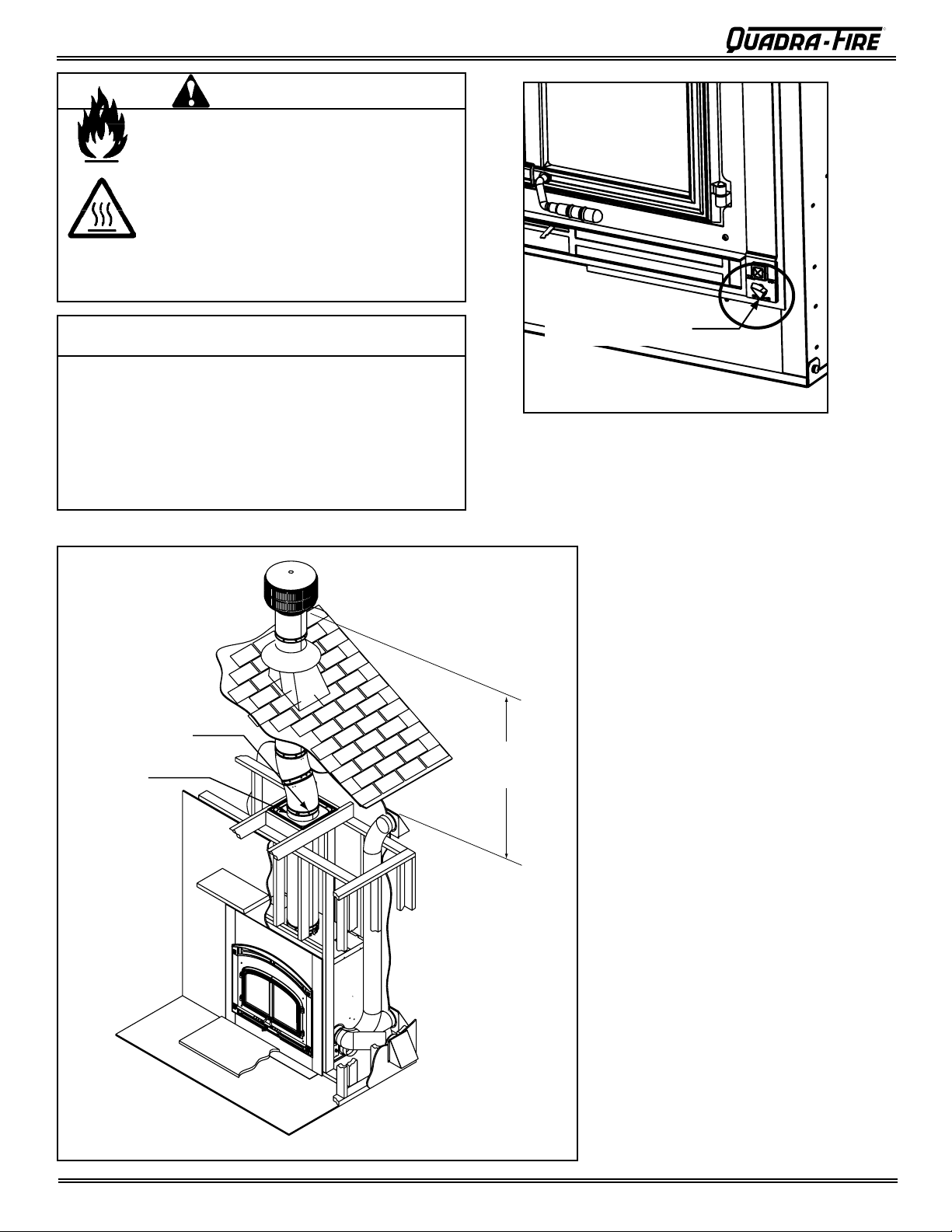

D. Secure the Fireplace

• Position the Fireplace

This fireplace may be placed on either a combustible or

non-combustible continuous flat surface. Follow the instructions for framing in Section 3.C. Slide the fireplace

into position. Be sure to provide the minimum 1 in. (25 mm)

air clearance at the sides and 1/2 in. (13 mm) at back of

the fireplace assembly. See Section 3.B.

CAUTION

Sharp Edges

• Wear protective gloves

and safety glasses during

installation.

WARNING

Fire Risk!

• Prevent contact with sagging, loose

insulation.

• Do NOT install against vapor barriers or

exposed insulation.

• Level the Fireplace

Level the fireplace side-to-side and front-to-back. Shim

with noncombustible material, such as sheet metal, as

necessary. Secure the fireplace (using the pallet mounting brackets located on either side of the fireplace) to the

subfloor.

Pallet Mounting

Brackets

Metal strips 2 in. (51mm) under edge of

Fireplace and Hearth Extension and 2 in.

(51mm) on both side of fireplace opening.

Nail or screw metal strips in place.

Figure 19.1 Position the Protective Metal Hearth Strips

1 in. (25mm) Overlap

WARNING

Fire Risk!

• Metal hearth strips MUST be installed.

Sparks or embers may ignite flooring.

• Place the Protective Metal Hearth Strips

Included with your fireplace you will find two metal

hearth strips measuring approximately 23 in. x 4 in.

(584 mm x 102 mm). These strips are used to provide

added protection where the fireplace and the hearth extension meet.

Slide each metal strip 2 in. (51 mm) under the front edge

of the fireplace. The individual pieces must overlap each

other by 1 in. (25 mm) minimum in the middle of the fireplace to provide continuous coverage of the floor. See

Figure 19.1. These metal strips should extend from the

front and sides of the fireplace opening by 2 in. (51 mm).

Nail or screw metal strips in place.

Note: When elevating the fireplace above the hearth

extension the front of the elevated platform must be

protected with a protective metal hearth strip (not included)

as shown in Figure 19.2.

Top piece must overlap

bottom piece

Raised Platform

2 in.

(51 mm)

Floor

2 in.

(51 mm)

Figure 19.2 Protect the Front of an Elevated Platform

Nail or screw metal strips in place.

1 in. (25 mm) min.

overlap

September 1, 2008

433-1390G

Page 19

Page 20

7100FP EPA Woodburning Fireplace

oo

C

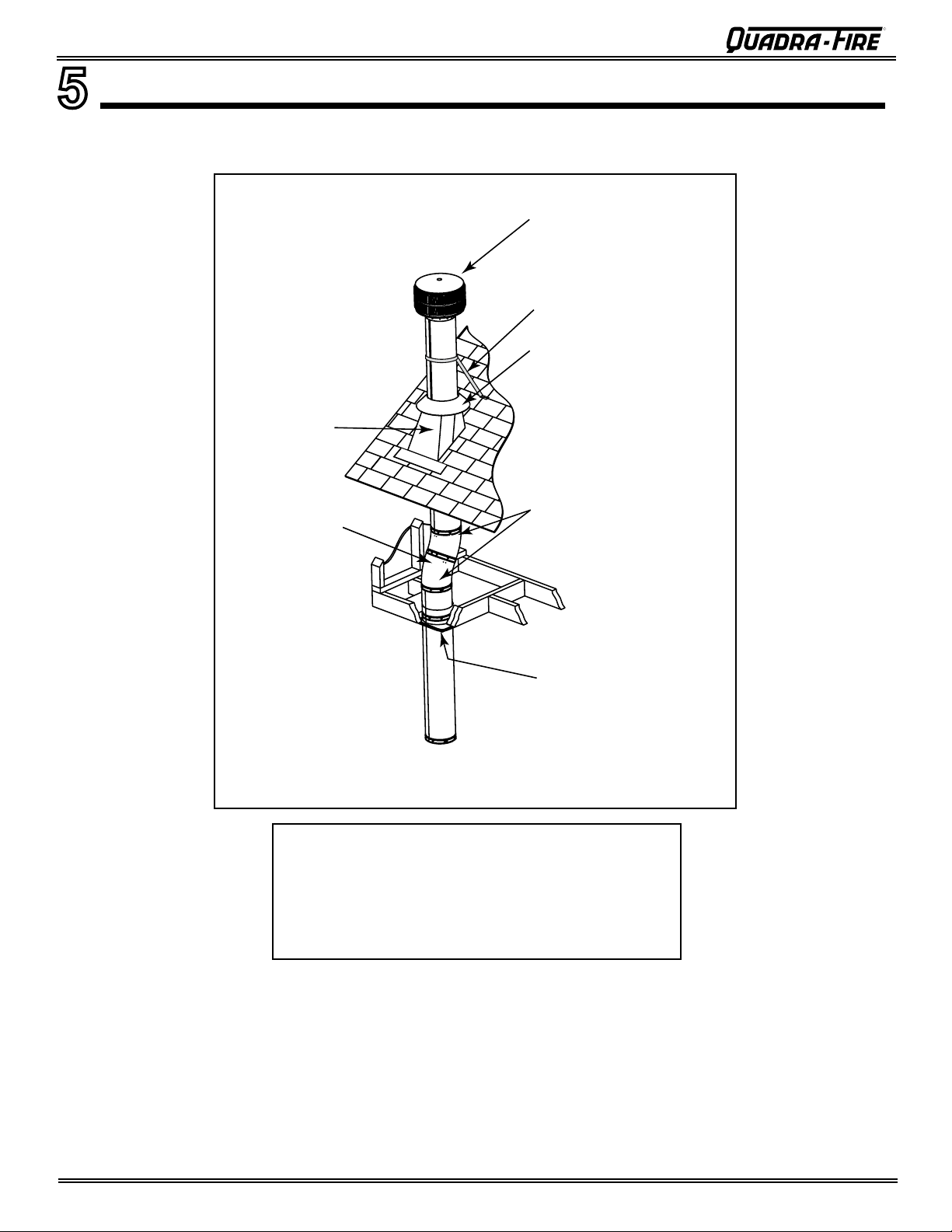

Chimney Assembly

5

R

Chimney must extend

beyond combustible

roof structure

Maintain minimum

height of chimney

above roof

Install roof flashing

according to minimum

requirements

Offsets/returns

may not exceed

30° from vertical

Termination

Additional

support for

tall chimneys

Storm Collar

Maintain minimum

clearances to

combustibles as

specified

Support straps for offsets/

returns must be secured

to adequate framing

ap

Figure 20.1 Typical Chimney System - Guidelines for Chimney System Installation

NOTE:

• Chimney performance may vary.

• Trees, buildings, roof lines and wind conditions affect

performance.

• Chimney height may need adjustment if smoking or

overdraft occurs.

Ceiling firestops

are required where

chimney passes

through ceiling or

r

fl

Page 20

433-1390G

September 1, 2008

Page 21

R

7100FP EPA Woodburning Fireplace

A. Chimney Requirements

Vertical distances are measured from the base of the fireplace as shown in Figure 21.1.

Minimum overall straight height 13 ft 3.96 m

Minimum height with single offset/

14.5 ft 4.42 m

return

Double offset/return minimum height 20 ft 6.1 m

Maximum height 50 ft 15.24 m

Maximum chimney length between an

20 ft 6.1 m

offset and return

Maximum distance between chimney

35 ft 10.67 m

stabilizers

Maximum unsupported chimney

6 ft 1.83 m

length between the offset and return

Maximum unsupported chimney

35 ft 10.67 m

height above the fireplace

Maximum unsupported chimney

6 ft 1.83 m

above roof

Note: A maximum of two pairs of offsets and returns may

be used.

WARNING

Fire Risk

• Must maintain 2 in. (51 mm) air clearance

to insulation and other combustible

materials.

6 ft (1.83 m) max.

unsupported chimney

above roof

6 ft (1.8 m) max.

unsupported

run

20 ft (6.10 m) max.

pipe between an

offset & return

35 ft (10.7 m)

Ceiling firestop

46 in.

(1168 mm)

to top of

standoffs

Figure 21.1 Chimney Requirements

max. straight

unsupported

chimney height

14.5 ft (4.42 m) min. height/single offset-return

20 ft. (6.10 m) min. height/double offset-return

50 ft (15.24 m) max. height

B. Chimney Termination Requirements

To determine the chimney components needed to complete

your particular installation, follow the steps below:

• Determine the total vertical height of the fireplace

installation. This dimension is measured from the base of

the fireplace assembly to the point where the smoke exits

the termination cap.

• Subtract the effective height of the fireplace assembly from

the overall height of the fireplace installation (measured

from the base of the fireplace to the bottom of the

termination cap, 13 ft. (4m).

• Refer to Table 21.2 to determine what components must

be selected to complete the fireplace installation.

• Determine the number of ceiling firestops, stabilizers,

roof flashing, etc. required to complete the fireplace

installation.

Table 21.2

HEIGHT OF CHIMNEY COMPONENTS in. mm

Chimney Stabilizer

SL3 4-3/4 121

Ceiling Firestops

FS338 0 0

FS339 0 0

FS340 0 0

Offsets/Returns

SL315 13-3/8 340

SL330 15-1/2 394

Roof Flashing

RF370 0 0

RF371 0 0

Chimney Sections*

SL306 4-3/4 121

SL312 10-3/4 273

SL318 16-3/4 425

SL324 22-3/4 578

SL336 34-3/4 883

SL348 46-3/4 1187

* Dimensions reflect effective height.

WARNING

Asphyxiation Risk.

• Do NOT connect this unit to a chimney flue

servicing another appliance.

• Do NOT connect to any air distribution duct or

system.

May allow flue gases to enter the house.

September 1, 2008

433-1390G

Page 21

Page 22

7100FP EPA Woodburning Fireplace

R

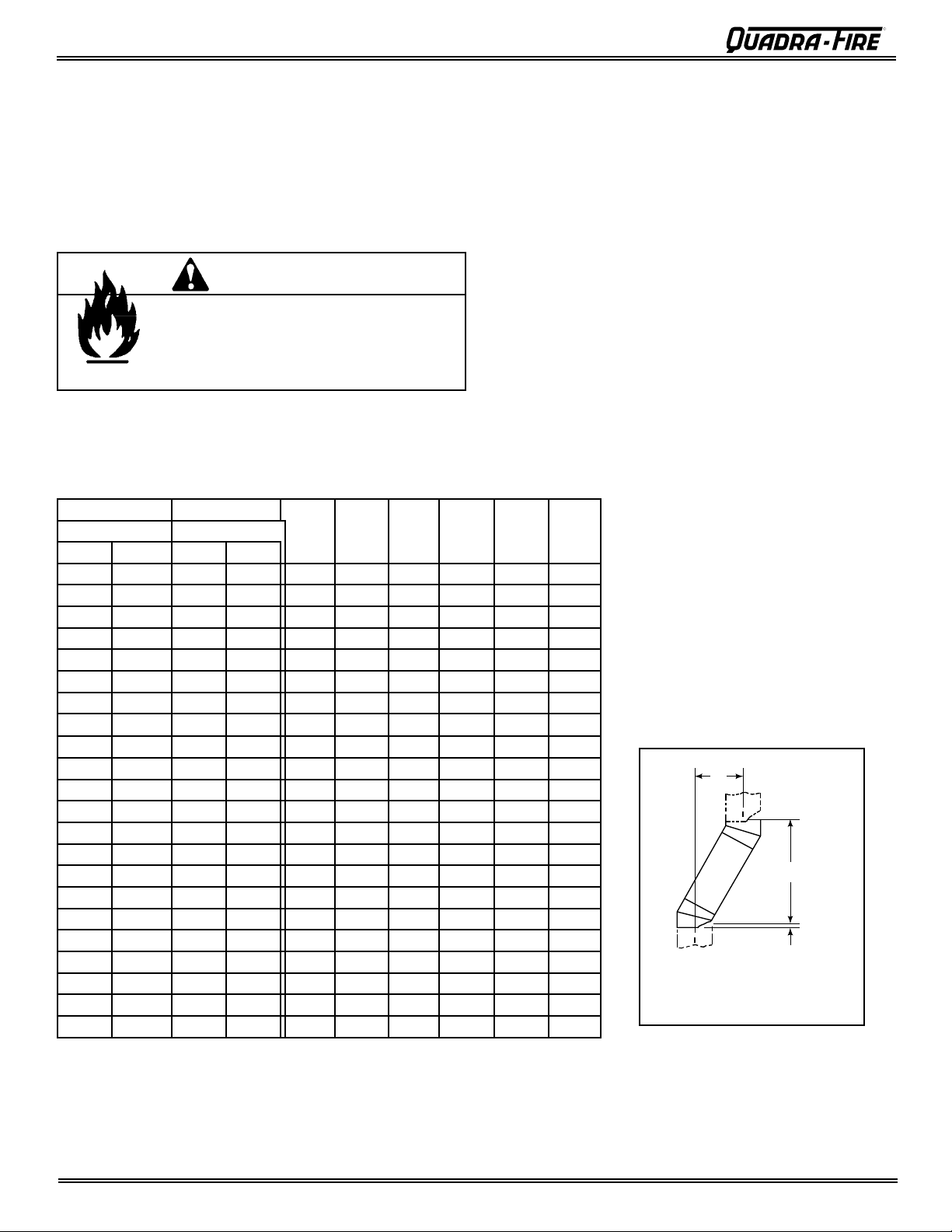

C. Using Offsets/Returns

To bypass any overhead obstructions, the chimney may be

offset using an offset/return.

An offset and return may be attached together or a chimney

section(s) may be used between an offset and return.

Perform the following steps to determine the correct chimney component combination for your particular installation:

• Measure how far the chimney needs to be shifted to enable

it to avoid the overhead obstacle. See Figure 22.2. Use

dimension “A” to determine chimney section required to

achieve the needed shift.

• After determining the offset dimension, refer to Table 22.1

and find the “A” dimension closest to but not less than the

distance of shift needed for your installation.

• The “B” dimension that coincides with the “A” dimension

represents the required vertical clearance that is needed

to complete the offset and return.

WARNING

Fire Risk

DO NOT combine offsets to create an offset

greater than 30° from vertical.

• Draft will be restricted.

• Read across the chart and find the number of chimney

sections required and the model number of those particular

chimney parts.

• Whenever the chimney penetrates a floor/ceiling, a ceiling

firestop must be installed.

• The effective height of the fireplace assembly is measured

from the base of the fireplace.

Table 22.1

Part SL315 Part SL315

15° 30°

ABAB

1-5/8” 13-3/8” 3-7/8” 14-1/2” - - - - - -

2-7/8” 17-3/4” 6-1/4” 18-5/8” 1 - - - - -

- - 8-5/8” 22-3/4” 2 - - - - -

4-1/2” 23-5/8” 9-1/4” 23-3/4” - 1 - - - -

- - 11-5/8” 27-7/8” 1 1 - - - -

6” 29-3/8” 12-1/4” 29” - - 1 - - -

7-1/4” 34” 14-5/8” 33” - 2 - - - -

- - 15-1/4” 34-1/8” - - 2 1 - -

- - 17-5/8” 38-1/4” 1 - - 1 - -

- - 20-5/8” 43-1/2” - - - - - -

10-5/8” 46-3/4” 21-1/4” 44-5/8” - - - - 1 -

11-7/8” 51-3/8” 23-5/8” 48-3/8” 1 - - - 1 -

- - 26-5/8” 53-7/8” - - - 2 - -

13-3/4” 58-3/8” 27-1/4” 55-3/4” - - - - - -

15” 63” 29-5/8” 59” 1 - - - - 1

16-1/2” 68-3/4” 32-5/8” 64-1/4” - 1 - - - 1

18” 74-5/8” 35-5/8” 69-1/2” - - 1 - - 1

- - 38-5/8” 74-5/8” - - - 1 - 1

- - 41” 78-3/4” 1 - - 1 - 1

22-3/4” 91-7/8” 44-5/8” 85” - - - - 1 1

24” 96-1/2” 47” 89-1/8” 1 - - - 1 1

25” 103-1/2” 50-5/8” 95-1/2” - - - - - 2

SL306 SL312 SL318 SL324 SL336 SL348

Example:

Your “A” dimension from Figure 22.2 is

14 1/2 in. (368 mm). Using Table 22.1

the dimension closest to, but not less

than 14 1/2 in. (368 mm) is 14 1/2 in.

(368 mm) using a 30° offset/return. It is

then determined from the table that you

would need 34 1/8 in. (867 mm) (Dimension “B”) between the offset and return.

The chimney component that best fits

your application is one SL324.

A

B

1-1/4 in. (32 mm)

OVERLAP

Figure 22.2 Chimney Offset/

Return

Page 22

433-1390G

September 1, 2008

Page 23

R

7100FP EPA Woodburning Fireplace

D. Assemble the Chimney Sections

Attach either a straight chimney section or an offset to the

top of the fireplace (depending on your installation requirement). Chimney sections are locked together by pushing

downward until the top section meets the stop bead on the

lower section.

The inner flue is placed to the inside of the flue section below

it. The outer casing is placed outside the outer casing of the

chimney section below it. See Figure 23.1.

If you are using a different approved venting system, follow

the instructions that were supplied with that system.

Figure 23.1 Assembling Chimney Sections

E. Assembling Chimney Sections for the SL-

300 Series

NOTE: Chimney Air Kit, Part CAK4A is REQUIRED

when using the SL-300 Pipe Series. Detailed instructions are supplied with the kit.

If using the Dura-Plus System (must be 8 in. (203

mm) in diameter), the starter ring that came with the

fireplace must be removed and replaced with the

Dura-Plus Base Plate. The CAK4A is not required

with a Dura-Plus System.

Installing CAK4A and Flex Pipe

NOTE: FOLLOW DETAILED INSTRUCTIONS THAT COME

WITH THE CAK4A.

1. Install the chimney pipe first.

2. Hand bend the tabs in position before placing on the

fireplace.

3. Place the box on top of the fireplace around the chimney

pipe, push both pieces together and secure with screws

provided.

4. Use the pre-punched holes in the tabs as guides and drill

holes through the fireplace top.

5. Secure the CAK4A in place.

6. Seal around the kit at the flue and at the top of the can

with caulk.

Note: Inner flue and outer liner sections cannot be

disassembled once locked together. Plan ahead to ensure

the proper installation height is achieved with the selected

chimney components.

WARNING

Fire Risk

Do NOT install substitute or damaged

chimney components.

• MUST use chimney system described in

this manual.

• NO OTHER chimney components may

be used.

Substitute or damaged chimney components

may impair safe operation.

Attach

Flue First

Secure with Screws

Provided

CAK4A

Secure to Top

Figure 23.2 Installing the CAK4A

Push Together

NOTES:

1.

The outside air termination cap must be a minimum of 6 ft

(1829 mm) above the ground and kept free of debris and

must be at least 3 ft (914 mm) below the chimney top, if

installed in the chase zone.

2. Seal around the cap and flex with caulk to stop air from

getting in to the chase (See Figure 24.1 on page 24).

September 1, 2008

433-1390G

Page 23

Page 24

7100FP EPA Woodburning Fireplace

R

WARNING

Fire Risk

• The flex hose must never be

compressed or deformed!

Restricting the airflow inside the flex pipe

may increase flue pipe temperatures causing

a chase fire.

Wire Ties

Figure 24.1 Installing Flex Pipe

4" Flex

Wire Ties

Note: The ceiling firestop MUST be nailed to the bottom

of the ceiling joists EXCEPT when the space above is

uninsulated and the attic insulation shield is not being used

(see Figure 24.2). When the attic insulation shield is used

the ceiling firestop may be above or below the joist of an

insulated ceiling.

ROOM ABOVE (non-insulated ceiling)

B

A

Ceilng firestop

attached to bottom

of framing

ATTIC ABOVE (insulated ceiling)

Ceiling firestop

attached to top of

framing

2 in. (51mm)

clearance

When attic insulation

shield not used

F. Install the Ceiling Firestops

• Mark and cut an opening in the ceiling for the ceiling

firestop being used. See Figure 24.2.

• Frame the opening with the same size lumber used in the

ceiling joists.

• Install the firestop spacer.

These firestop spacers are designed to provide the

minimum 2 in. (51 mm) air space required around the

chimney. In all situations, the firestop spacers are to be

nailed to the ceiling joists from the bottom or fireplace

side, EXCEPT when the space above is an insulated

ceiling or attic space. In this situation, the firestop spacer

must be nailed from the top side to prevent loose insulation from falling into the required 2 in. (51 mm) air space

around the chimney.

NOTE: See Figures 25.1 and 25.2 on page 25.

CAUTION

2 in. (51mm)

clearance

Note: Use same dimensional lumber for framing

ceiling firestop and joists.

AB

Catalog #

FS338 14-1/2 368 14-1/2 368

FS339 14-1/2 368 18-3/8 467

FS340 14-1/2 368 23 584

Figure 24.2 Installing the Ceiling Firestop

in. mm in. mm

Note: You must provide support for the pipe during

construction and check to be sure inadvertent loading has

not dislodged the chimney section from the fireplace or at

any chimney joint.

• Ceiling firestops must be used at ceiling/floor.

• Chase construction requires ceiling firestops at each

floor or every 10 ft (3.05 m) of clear space.

• Use same dimensional lumber as joists.

Ceiling firestop slows spread of fire and reduces cold air

infiltration.

Page 24

433-1390G

September 1, 2008

Page 25

R

y

A

7100FP EPA Woodburning Fireplace

G. Install the Attic Insulation Shield

An insulation shield must be installed when there is a possibility of insulation coming into contact with the factory built

chimney system.

• Bend the tabs at the top of the attic insulation shield inward.

This will help keep the chimney section centered in the

shield.

• Position the shield over the vertical chimney section where

it penetrates a ceiling firestop.

• Slide the shield down until it rests on the ceiling firestop.

The ceiling firestop will support the insulation shield. See

Figures 25.1 and 25.2.

Tabs

14-1/2 in. (368mm)

24 in.

Insulation

Figure 25.1 Install Attic Insulation Shield Above the Ceiling

(610mm)

10-1/2 in.

(267mm)

Chimne

2 in. (51mm)

Attic Insulation

Ceiling Firestop

Shield

H. Double-check the Chimney Assembly

Continue assembling the chimney sections up through the

ceiling firestops as needed. While doing so, be aware of the

height and unsupported chimney length limitations given under Section 5.A. Chimney Requirements.

Check each section by pulling up slightly from the top to ensure proper engagement before installing the succeeding

sections. If they have been connected correctly, they will not

disengage when tested.

I. Secure the Chimney

When offsets and returns are joined to straight pipe sections,

they must be locked into position with the screws provided*

(outer only), using the predrilled holes. To prevent gravity

from pulling the chimney sections apart, the returns and the

chimney stabilizers have hanger straps for securing these

parts to joists or rafters. See Figure 25.3.

* Use #6 or #8 sheet metal screw, or larger, no longer than

1/2 in. (13mm).

Ceiling

Firestop

Straps

Joint

Band

14-1/2 in. (368 mm)

Insulation

10-1/2 in.

(267 mm)

24 in.

(610 mm)

Chimney

Tabs

Attic

Insulation

Shield

2 in. (51mm)

Ceiling Firestop

Optional

dditional

Support

Figure 25.3 Secure the Chimney

WARNING

(Optional)

Fire Risk

• Secure offsets with screws (not to exceed

Figure 25.2 Install Attic Insulation Shield Below the Ceiling

1/2 in. / 13mm in length).

• Secure returns with strapping.

• Straight chimney sections may be secured with screws

WARNING

Fire Risk

(not to exceed 1/2 in./13 mm in length) at the joints.

Keep chimney sections from separating or twisting.

• DO NOT pack insulation or other combustibles:

between ceiling firestops; between chimney

and attic insulation shield.

• ALWAYS maintain specified clearances around

chimney and ceiling firestop systems.

• Install ceiling firestops as specified.

Failure to keep insulation or other material away from chimney

pipe may cause fire

September 1, 2008

.

433-1390G

Page 25

Page 26

R

7100FP EPA Woodburning Fireplace

Complete the Enclosure

6

A. Chimney Termination (2-10-03 Rule)

Chimney Termination Requirements (See Figures 26.1 and 26.2)

• Must have a cap approved and listed for this fireplace system

• Must not be located where it will become plugged by snow or other material

• Must terminate at least 3 ft (914 mm) above the roof and at least 2 ft (610 mm) above any portion of the roof within 10 ft

(3.05 m)

• Must be located away from trees or other structures

Pitched Roof

3 ft. (91cm)

Minimum

Flat Roof

2 ft. (61cm)

Wall or Parapet

10 ft. (305cm) To Nearest Roofline

10 ft. (305cm) or more

3 ft. (91cm) Minimum

Less than 10 ft. (305cm)

2 ft. (61cm)

3 ft. (91cm) Minimum

3 ft. (91cm)

Minimum

Less than 10 ft. (305cm)

2 ft. (61cm)Minimum

Page 26

Figure 26.1 Termination Requirements

18 in.

(457 mm)

Gas

Termination

Termination Caps Staggered Height

A Gas Termination Wood or Fuel Oil Termination

B 6 in.

Figure 26.2 Multiple Chimneys

(152 mm) min.

Gas, Wood or Fuel

Oil Termination

A

B

20 in.

433-1390G

8 ft

(2.44 m)

(min. for B-Vent)

20 in.

(508 mm)

(min. for direct vent)

to

Perpendicular

Wall

(508 mm) min.

September 1, 2008

Page 27

R

NOTE: Wiring for blowers must be done before framed

enclosure is completed. If using a Heat Zone kit, it also

must be installed before enclosure is complete.

• Mark the Exit Point of the Roof

Locate the point where the chimney will exit the roof by

plumbing down to the center of the chimney. Drive a nail

up through the roof to mark the center. See Figure 27.1.

• Cut Out the Hole in the Roof

Measure to either side of the nail and mark the 14-1/2 in.

x 14-1/2 in. (368 mm x 368 mm) opening required. This

is measured on the horizontal; actual length may be larger depending on the pitch of the roof. Cut out and frame

the opening. See Chapter 25 of the Uniform Building

Code for roof framing details.

WARNING

Fire Risk

• Must maintain 2 in. (51 mm) air clearance

to insulation and other combustible

materials.

7100FP EPA Woodburning Fireplace

• Assemble the Chimney Sections Through the

Roof

Continue to add chimney sections through the roof opening, maintaining at least a 2 in. (51 mm) air space to combustible materials.

• Install the Roof Flashing

If a roof flashing is to be used, install the roof flashing

appropriate to the roof pitch and install a termination cap

and storm collar following the instructions shipped with

the cap.

For chase installations you can use a round termination

cap, a round telescoping termination cap or a square

termination cap (See pages 61-62). A chase installation

must use a chase top. Chase tops are available from your

dealer. See page 14 for building a chase.

• Install the Chimney Air Kit (required in Canada):

When installing the chimney air kit, follow the instructions

provided with this accessory. See page 23.

• Completion of the Enclosure

Complete the fireplace enclosure, allowing space for

outside air ducts. Electrical wiring should not come in

contact with the fireplace. A minimum clearance of 1/2 in.

(13 mm) must be maintained between the fireplace

back and 1 in. (25 mm) minimum clearances to sides

and the enclosure.

Figure 27.1 Ceiling/Attic Construction

September 1, 2008

433-1390G

Page 27

Page 28

7100FP EPA Woodburning Fireplace

A

B.

SL-300 Series Ceiling/Roof Thimble

R

NOTE: REQUIRED for manufactured homes with vaulted

ceilings.

1. Locate the point where the chimney will exit the roof by

plumbing down to the center of the chimney. Lay out, cut

and frame a 14-1/2 in. (368 mm) square opening (measured

on the horizontal) through the ceiling and roof structure.

Consult local codes for framing details.

2. The thimble must extend completely through the roof struc-

ture shielding combustible materials. Five location holes

have been provided to allow for a variety of ceiling/roof

thicknesses. A Thimble Extension is required when the

ceiling/roof thickness exceeds 12-1/2 in. (318 mm). The

extension should overlap the thimble one inch.

3. To attach the extension to the thimble, drill 1/8 in. (3 mm)

holes through the outer shield of the thimble using the

predrilled holes in the extension as guides. Attach the

extension to the thimble using the screws provided with

the extension.

4. Install the thimble assembly and nail it securely to the fram-

ing members.

5. Center the flashing over the chimney and nail it to the roof

using the Stormguard nails provided. Keep gaps between

the flashing plate and the roof to a minimum. Caulk the flashing plate and roof junction as well as the vertical seam on

the flashing. All nail heads must be caulked with a roofing

sealant.

CHIMNEY

FLASHING

FLASHING

Figure 28.2 Installing Part 12966A, Configuration 2

FLASHING

DJUSTABLE

EXTENSION

HOLES

Figure 28.3 Installing Part 12966A Configuration 3

PLATE

THIMBLE

EXTENSION

SCREW

NAIL

THIMBLE

CHIMNEY

FLASHING

PLATE

SCREW

NAIL

THIMBLE

THIMBLE

EXTENSION

6. Finish assembling the chimney storm collar and termination cap following the installation instructions provided with

them.

CHIMNEY

FLASHING

Figure 28.1 Installing Part: 12966A, Configuration 1

FLASHING

PLATE

JOISTS

NAIL

THIMBLE

Page 28

433-1390G

September 1, 2008

Page 29

R

C. Chase Top

A metal chase top is required to seal the top of the chase

around the chimney pipe. The top should include a turndown and drip edge to prevent water from seeping into the

chase. Provide a 1/8 in. (3 mm) gap around the flue pipe

and slope the top downward away from the penetration. See

Figure 29.1.

• All seams must be caulked to prevent leaks.

• A chase installation must use a chase top. Chase tops are

available from your Quadra-Fire dealer or may be field

constructed.

• Attach the chase top to the top of the chase.

Termination Cap

2 in. (51 mm) Collar

Caulk

Figure 29.1 Chase Top Construction

on Chase Top

Storm Collar

Slope Downward

Turn-down

Drip Edge

Chase

(Chimney)

.018 (26 ga) min.

Galvanized

Chase Top

7100FP EPA Woodburning Fireplace

WARNING

Fire Risk

• Never install a single wall slip section or

smoke-pipe in a chase structure.

The higher temperature of this single wall

pipe may radiate sufficient heat to combustible chase materials to cause a fire.

D. Install the Termination Cap

Note: To protect against the effect of corrosion on those

parts exposed to the weather, the termination cap can be

painted with a rust-resistant paint.

WARNING

Fire Risk

• The minimum overlap of cap to pipe

MUST be met or chimney may separate

from cap.

Separation allows sparks, heat and embers

to escape.

• Install the chimney sections up through the chase

enclosure. When using a Round Termination Cap, the

uppermost top section of pipe must extend 6 in. (152 mm)

above the top of the flashing collar to allow installation of

the storm collar and termination cap. See Figure 29.3.

Minimum 1-1/2 in. (38 mm) overlap of cap over pipe

• Chase Top Framing

Framing to top of chase must be constructed to support

service persons, snow load, etc. Maintain 2 in. (51 mm)

clearance to combustibles. Top of framing should be

sheeted with plywood particle board. See Figure 29.2.

Exterior sheeting

Chase top framing

Figure 29.2

September 1, 2008

6 in. (152mm) min.

• For installations utilizing a Round Telescoping Termination

433-1390G

Storm Collar

2 in. (51 mm) min.

Flashing Collar

Figure 29.3 Installing a TR344 Round Termination Cap

2 in. (51 mm) min. collar

Cap, the uppermost chimney section must be below the

top of the chase top, but not more than 14-1/2 in. (368 mm)

below the top of the chase top. Minimum overlap of

chimney and termination cap must be 1-1/2 in. (38 mm).

See Figure 30.1 on page 30.

Page 29

Page 30

7100FP EPA Woodburning Fireplace

• For installations utilizing a Round Telescoping Termination

Cap, the uppermost chimney section must be below the

top of the chase top, but not more than 14-1/2 in. (368 mm)

below the top of the chase top. Minimum overlap of

chimney and termination cap must be 1-1/2 in. (38 mm).

See Figure 30.1.

Storm Collar

Flashing Collar

2 in. (51 mm) min.

Flashing

Collar

1-1/2 in.

(38 mm)

min.

overlap

Top of Pipe

R

2 in.

(51 mm)

min.

3 in.

(76 mm)

max.

14-1/2 in. (368mm) max.

Top of Pipe

Figure 30.1 Installing a TR342 Round Telescoping Termination

1-1/2 in. (38 mm) min.

overlap

Cap

NOTE: TR342/TR344: For less air restriction to flue

gases, use top vent kit listed in Section 12.

• For installations utilizing an ST375 Square Termination

Cap the last chimney section must not be more than

4-1/2 in. (114 mm) below the chase top. See Figure

30.2.

Flashing Collar

Cap Standoff

1-1/2 in.

(38 mm) min.

overlap

Top of Pipe

2 in. (51 mm) min.

4-1/2 in.

(114 mm)

max.

Figure 30.3 Installing a TS345/TS345P Square Termination Cap

• For chase installations you can use a Round Termination

Cap, a Round Telescoping Termination Cap, or a Square

Termination Cap.

• Install termination caps following instructions provided

with them.

Figure 30.2 Installing an ST375 Square Termination Cap

• For installations utilizing a TS345/TS345P Square

Termination Cap, the uppermost chimney section must

not be more than 3 in. (76 mm) below the chase top. See

Figure 30.3.

Page 30

433-1390G

September 1, 2008

Page 31

R

Replacement Parts

7

A. Blower Replacement

Blower Cord Location