Page 1

INSTALLATION

AND

OPERATING

INSTRUCTIONS

Save these

instructions

1050 Fountain St. N.

Cambridge, Ontario, Canada N3H 4R7

Bus. (519) 650-5501 Fax (519) 650-3773

Toll Free Phone 1-800-361-1517

Toll Free Fax 1-800-327-5609

for future use

Note: Please read these instructions

thoroughly before attempting to install

this unit.

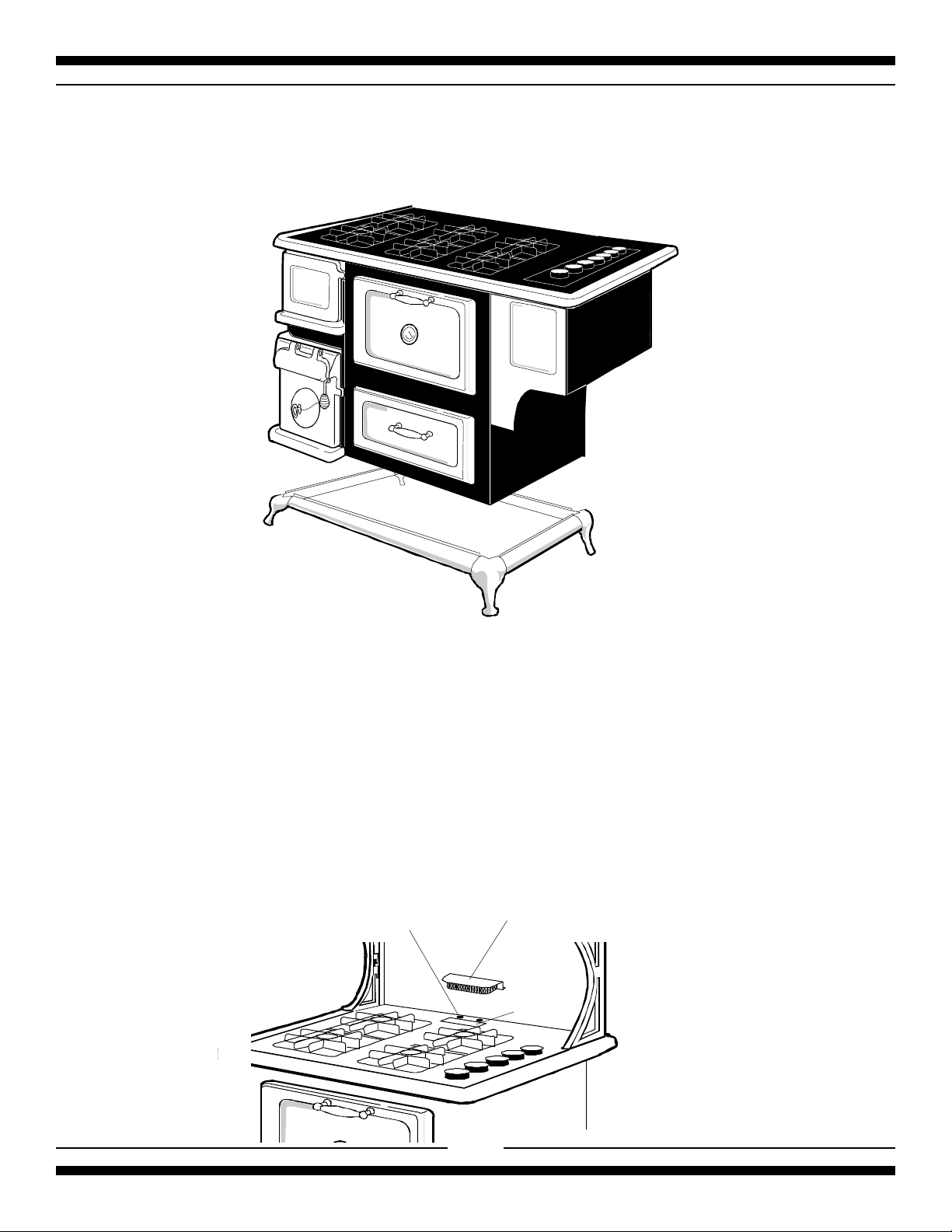

Model

9100

Model

7100

WARNING: Improper installation, adjustment, alteration, service or

maintenance can cause injury or property damage. Refer to this

manual. For assistance or additional information, consult a qualified

installer, service agency, manufacturer (dealer) or the gas supplier.

Note

: This appliance can only be installed in the state of

Massachusetts by a Massachusetts licensed plumber or gasfitter.

The oven door thermometer does not sense temperature. It is for

aesthestics only and is nonfunctional.

®

CERTIFIED

C

These symbols on the nameplate mean the product has been

design certified by American Gas Association Laboratories and

Canadian Gas Association Laboratories.

US

MODEL 9100/7100

Manual #7715

REV 111204

© 2004 HEARTLAND APPLIANCES INC.

ATTENTION INSTALLER:

GAS RANGE

Leave this manual with appliance

Page 2

Gas Models 9100/7100

CONSUMER WARRANTY

ENTIRE PRODUCT – LIMITED ONE YEAR WARRANTY

HEARTLAND warrants the replacement or repair of all parts, including gas components of this Cookstove which prove

to be defective in material or workmanship, with the exception of the painted or porcelain enamel finish or plated

surfaces, for one year from the date of original purchase. Such parts will be repaired or replaced at the option of

Heartland without charge, subject to the terms and conditions set out below.

The warranty period against defects in the painted or porcelain enamel finish, or plated surfaces, is 90 days from

date of original purchase. The warranty does not include replacement of oven lamps or charcoal filters.

TERMS AND CONDITIONS

1. This warranty applies only for single family domestic use when the Cookstove has been properly installed

according to the instructions supplied by Heartland and is connected to an adequate and proper utility service.

Damage due to faulty installation, improper usage and care, abuse, accident, fire, flood, acts of God,

commercial, business or rental use, and alteration, or the removal or defacing of the serial plate, cancels all

obligations of this warranty. Service during this warranty must be performed by a factory Authorized Service

Person.

2. Warranty applies to product only in the country in which it was purchased.

3. Heartland is not liable for any claims or damages resulting from any failure of the Cookstove or from service delays

beyond their reasonable control.

4. To obtain warranty service, the original purchaser must present the original Bill of Sale, Model and Serial number.

Components repaired or replaced are warranted through the remainder of the original warranty period only.

5. The warranty does not cover expense involved in making this appliance readily accessible for servicing.

6. This warranty gives you specific legal rights. Additional warranty rights may be provided by law in some areas.

7. Adjustments such as calibrations, levelling, tightening of fasteners, or utility connections normally associated

with original installation are the responsibility of the dealer or installer and not that of the Company.

TO ENSURE PROMPT WARRANTY SERVICE, SEND IN YOUR WARRANTY CARD WITHIN 10 DAYS OF PURCHASE.

If further help is needed concerning this warranty, contact:

Customer Service

Heartland Appliances Inc.

1050 Fountain St. N.

Cambridge, Ontario,

Canada N3H 4R7

PLACE OF PURCHASE______________________________

DATE OF PURCHASE_______________________________

SERIAL NUMBER__________________________________

Business (519) 650-5775

Fax (519)650-3773

Toll Free Telephone 1-800-361-1517

Toll Free Fax 1-800-327-5609

MODEL NUMBER__________________________________

Page 3

To move range for service or

cleaning

WARNING

Range body rests on base.

When moving, move by base

only.

1. Disconnect electrical power.

2. Place temporary floor protection in front of

range.

3. Slide out from wall and place floor protection

under front legs and slowly pull out to gain

access to rear.

4. To reinstall, reverse these instructions.

The use of a gas cooking appliance results

in the production of heat and moisture in

the room in which it is installed. Ensure

that the kitchen is well ventilated: keep

natural ventilation holes open or install a

mechanical device (mechanical extractor

hood)

Prolonged intensive use of the appliance

may call for additional ventilation, for

example opening of a window, or more

effective ventilation, for example increasing

the level of mechanical ventilation where

present.

!

—FOR YOUR SAFETY—

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPOURS OR

LIQUIDS IN THE VICINITY OF THIS APPLIANCE.

* Do not use the range as a heater.

* Do not heat unopened glass or metal containers in the oven.

* Grease accumulation is the cause of many cooking fires. Clean the oven and broiler compartment

regularly.

* Do not attempt to extinguish a grease fire with water. Cover grease fires with a pot lid or baking

soda.

* Avoid the use of aerosol containers near the range.

* Never place pans, cookie sheets or roasters directly on the oven bottom -use the rack in its lowest

position.

* Do not cover the entire bottom of the oven with aluminium foil. Allow at least 1" of space all around

pots, pans or cookie sheets in the oven to permit convection air flow.

WARNING

• ALL RANGES CAN

TIP

• INJURY TO PERSONS

COULD RESULT

• SEE INSTALLATION

INSTRUCTIONS

WARNING: If the information in this manual is

not followed exactly, a fire or explosion may

result causing property damage, personal injury

or death.

Do not store or use gasoline or other flammable

vapours and liquids in the vicinity of this or any other

appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

• Immediately call your gas supplier from a

neighbour’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the

fire department.

Installation and service must be performed by a

qualified installer, service agency or the gas supplier.

Page 4

Page 5

T ABLE OF CONTENTS

1. Assembly and Installation.................................. 2

2. Assembly of Range Base...................................... 2

3. Assembly of Range Body to Base......................... 3

4. Assembly of Exhaust Hood to Range .......................4

5. Positioning the Range ........................................... 4

6. Installation Clearances .......................................... 5

7. Electrical and Gas Installation............................... 6

8. Exhaust Hood...................................................... 7

9. Ventless Installation.............................................. 7

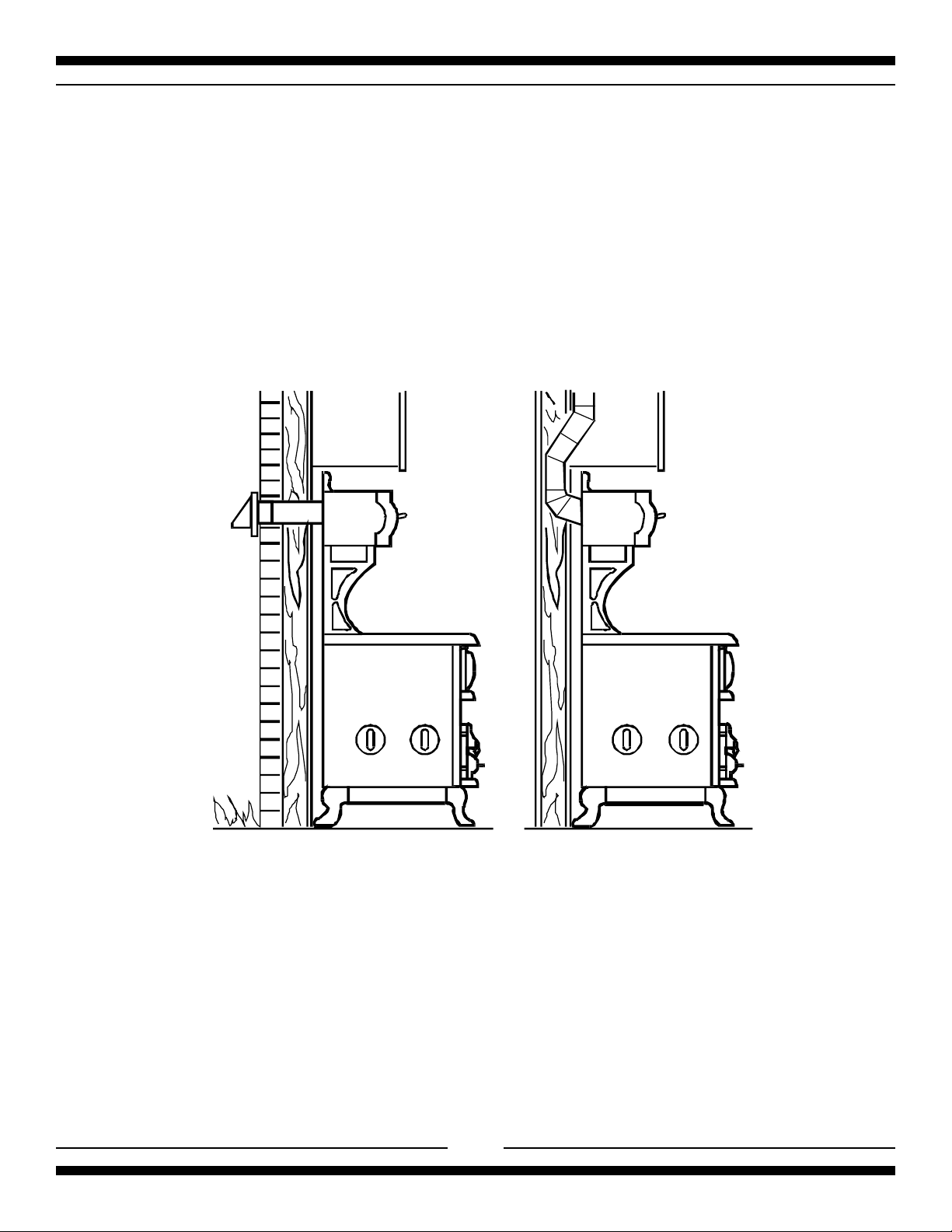

10. Vented Installation ................................................ 7

11. Installation of Ducting .............................................8

12. Venting Safety Guidelines .................................... 9

13.Gas Line Installation ................................................9

14. Important Safety Instructions ...........................10

29. Care and Cleaning............................................18

30. Porcelain .............................................................18

31. Oven Cleaning .....................................................19

32. Surface Burners...................................................1 9

33. Nickel Trim ..........................................................20

34. Exhaust Hood......................................................20

35. Oven and Cabinet Light .......................................20

36. Interior Oven Rack Removal.................................21

37. Rack Supports Removal ..................................... 21

38. Oven Door Removal .............................................22

39. Broiling................................................................23

40. Broiling Pan.........................................................23

41. Oven Light............................................................23

42. Broiler Drawer Removal .......................................24

15. Exhaust Hood Safety...........................................1 0

16. Features .............................................................11

17. Sealed Burner Features.......................................1 1

18. Oven Features .....................................................12

19. Other Features ................................................... 12

20. Control Panel Layout .......................................... 13

21. Operation...........................................................14

22. Top Burner Operation...........................................14

23 Oven Lighting......................................................15

24.Range Thermostat.................................................15

25 Power Failure Operation .......................................16

26. Manually Lighting the Top Burners.......................16

27. Manually Lighting the Oven Burner.........................16

28. Clock/Timer..........................................................17

43. Setup and Trouble Shooting ...........................25

44. Burner Setup and Adjustment .............................25

45. Range Problem Solver .........................................25

46. Air Shutter Adjustment ........................................26

47. Oven Burner Assembly.......................................26

48. Trouble Shooting Guide .......................................27

49. Conversion Kits and Information...................28

50. Products ............................................................29

51. Products .............................................................31

52. Parts Diagram ...................................................32

53. Parts List............................................................33

54.RatingPlate.........................................................34

55. Wiring Diagrams ...............................................35

1

Page 6

Assembly and Installation

To fully enjoy your new range, it is important that you read this booklet thoroughly.

Note:

Please check for any damage that may have occurred during shipping. In the unlikely event that you find any shipping

damage, inform your dealer immediately!

The Model 7100 and 9100 Range consists of three main parts:

The Range Base

The Range Body, and

The Exhaust Hood or Cresting Assembly

Tools required for assembly:

Slot screw driver

7/16” (11 mm) wrench or crescent wrench

5/16" (8 mm) wrench or crescent wrench

Teflon

Glider

T eflon Glider

Figure 1a

(You must have a qualified gas technician install this appliance to be sure

the installation codes and rules are observed.)

1/8"- 1/4"

Painted section

Nickel plated section

Figure 1

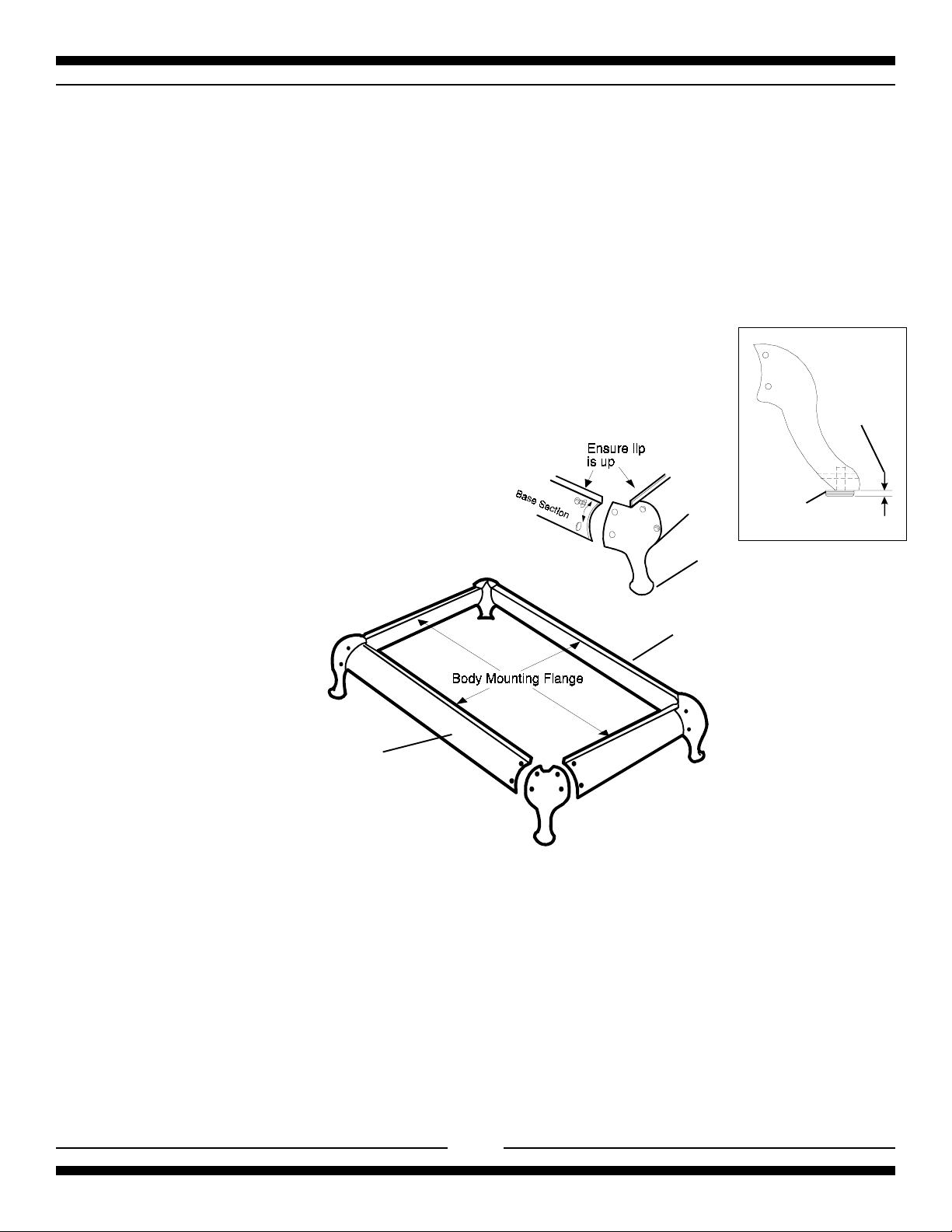

Assembly of Range Base

1. Unpackage the base sections, legs and hardware package which are located in a carton fastened to the skid

at rear of the range (it would be a good idea to check for any damage that may have occurred during shipping).

2. Screw the base levelling bolts (with teflon glider attached) into each of the four legs. The levelling bolts are

located in the hardware package. When installing the levelling bolts, the teflon glider should

the bottom of the leg by approximately 1/8"-1/4". Adjusting levelling bolts in too far will cause the leg to drag

on the floor potentially causing damage to flooring. (see figure 1a ) . Check that gliders and floor are free of

any debris, this will ensure you do not scratch your floor.

3. Assemble base to legs using the nuts and bolts provided. For the 48" the shorter base sections are the sides

and the longer sections are front and rear. (the black painted section goes to the rear, see fig. 1). For the 30"

the base sections are all the same length, the black painted section goes to the rear, see fig. 1.

4. Hand tighten the nuts and bolts until the range base is completely assembled. Ensure that all base sections

are installed with the lip up.

5. Adjust base sections to the most upper position and tighten up the nuts and bolts.

extend

beyond

2

Page 7

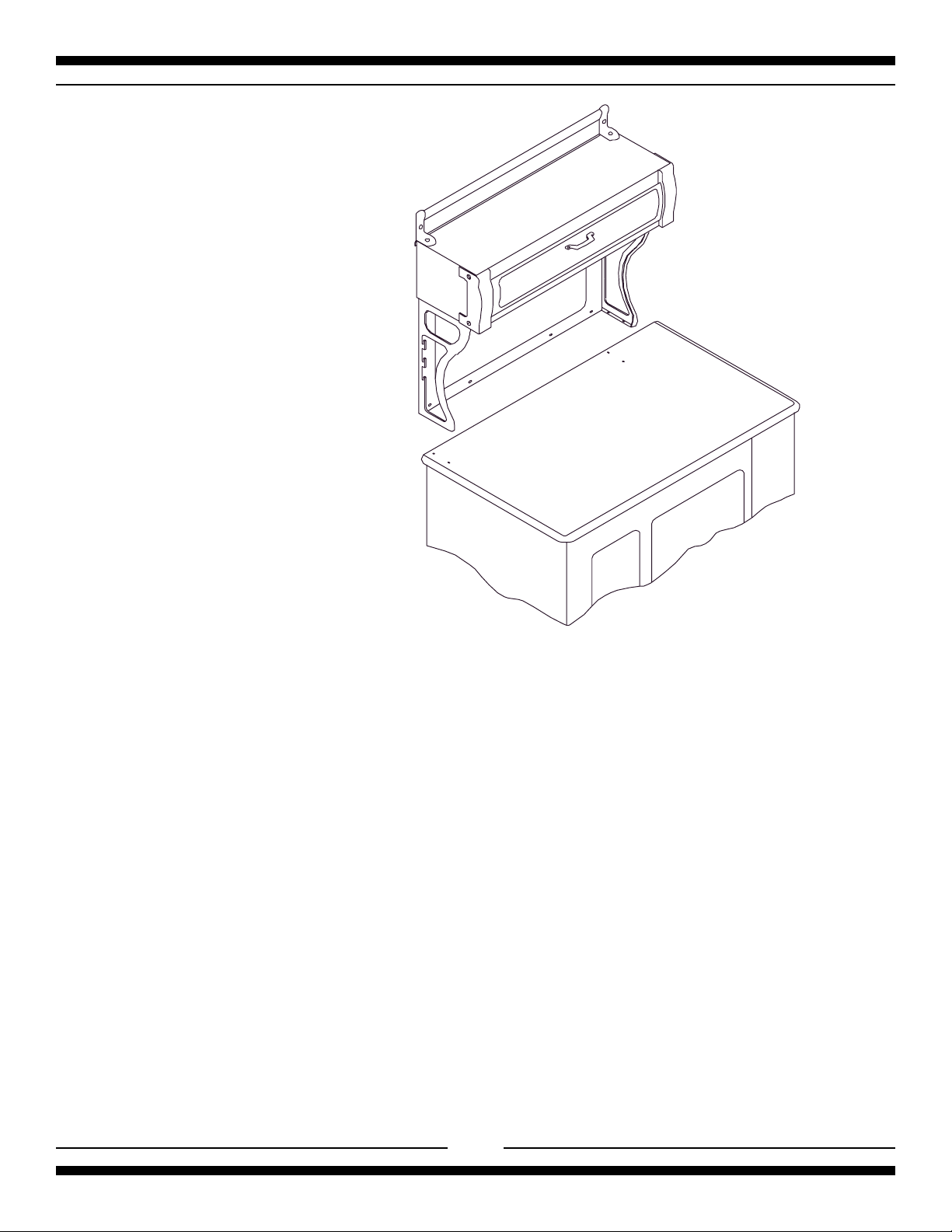

Assembly of Range Body to Base

Lift the range at the front and rear,

do not lift by nickel trim.

1. The range body rests directly on the base - no bolts are required. Two people are needed to lift it on

to the base.

2. In order not to damage the nickel trim or enamel finish, lift the range from the front and the rear . The

person at the front can first remove the oven door and use the oven opening for a hand hold. The rear

of the oven body at the bottom can be used to lift from the back.

3. Lift the range off pallet and onto base, making sure the range is sitting square and level on base. The

stove sits over the lip of the base assembly. Helpful hint: Instead of trying to square the entire stove

over the base, put one side or back on first then slowly lower the other side into position.

4. Lastly, install the oven vent deflector on the top of the cooking surface over the oven vent. Loosen

the two screws enough to slip the oven vent under the screws , and tighten up the screws. (see

illustration below)

Loosen two screws

Oven vent deflector

Oven vent

3

Page 8

Assembly of Exhaust Hood to

Range

See the manual entitled "Cabinet Assembly

Instructions for Gas , Electric

,Combination and Wood Stoves" which

is included with the cabinet .

Positioning the Range

1. When the range is fully assembled, recheck all electrical connections especially between the

exhaust hood and the back of the range. As well, check that all nuts and bolts have been tightened.

2. Ensure teflon gliders and flooring are clean, (as described in the second paragraph under

"Assembly of Range Base".)

3. Caution: On flooring with very rough surfaces or deep, large grooves the appliance may have to be

lifted and slowly slid into position.

4. Put both hands on the trim and carefully push the range into place, make sure floor is clear of all

debris. Don't forget to plug in the main power cord and the exhaust hood power cable

before the range is in its final position. See cabinet installation instructions.

5. To level the range, simply adjust the levelling screws with teflon pads located at the bottom of each

leg (the ones you assembled in step 2 of "Assembly of Range Base"). Using a 5/16 (8 mm) openend wrench turn the adjusting screw clockwise to raise up the corner, and counter-clockwise to lower

the corner. (Don't forget the teflon glider should

extend

beyond the bottom of the leg by approximately

1/8"-1/4")

6. Note: On soft kitchen flooring, the weight of the stove may cause slight depressions in the flooring.

When the range is in position and levelled, you may want to place coasters under the teflon gliders

of each leg, to protect the floor. Remove the coasters when moving the range for cleaning or

servicing.

4

Page 9

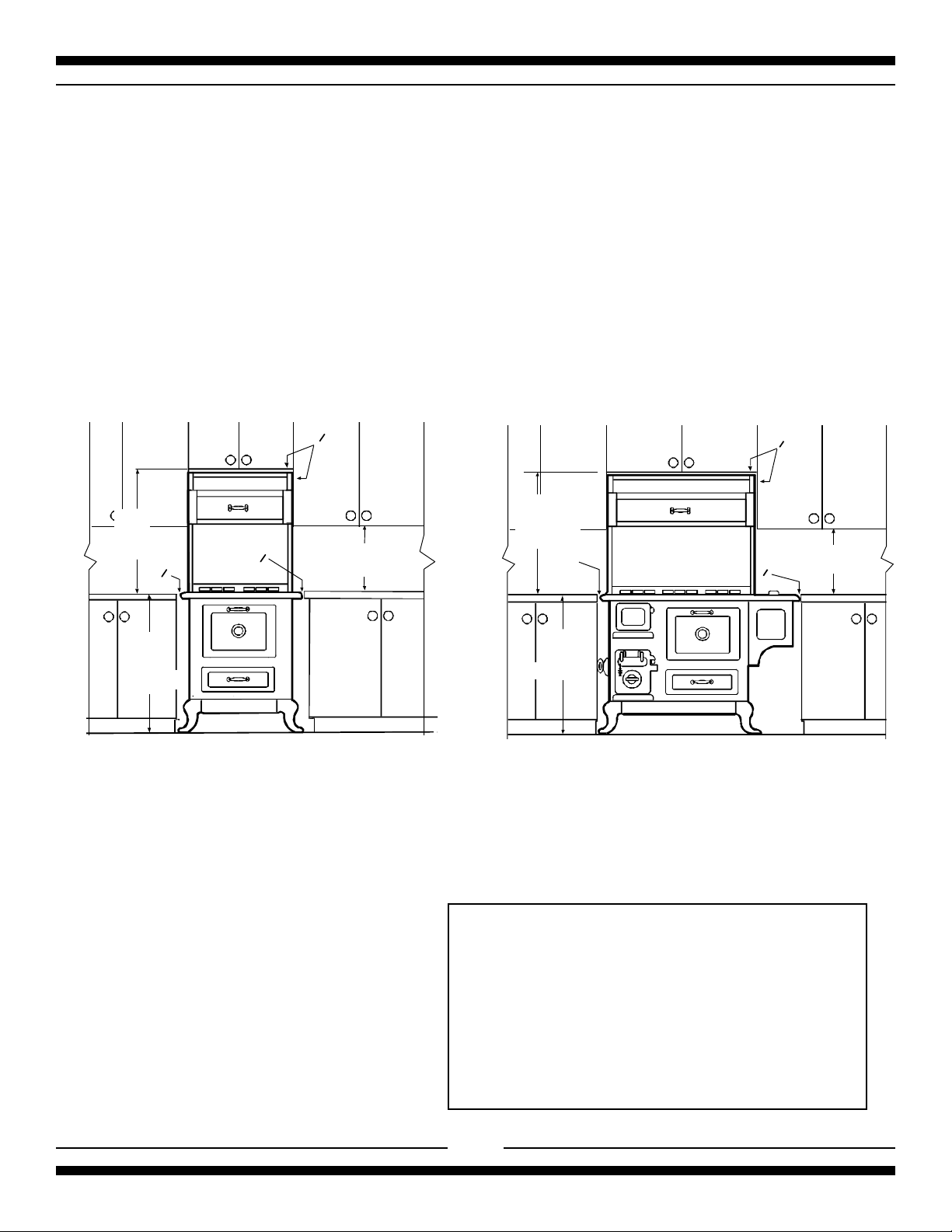

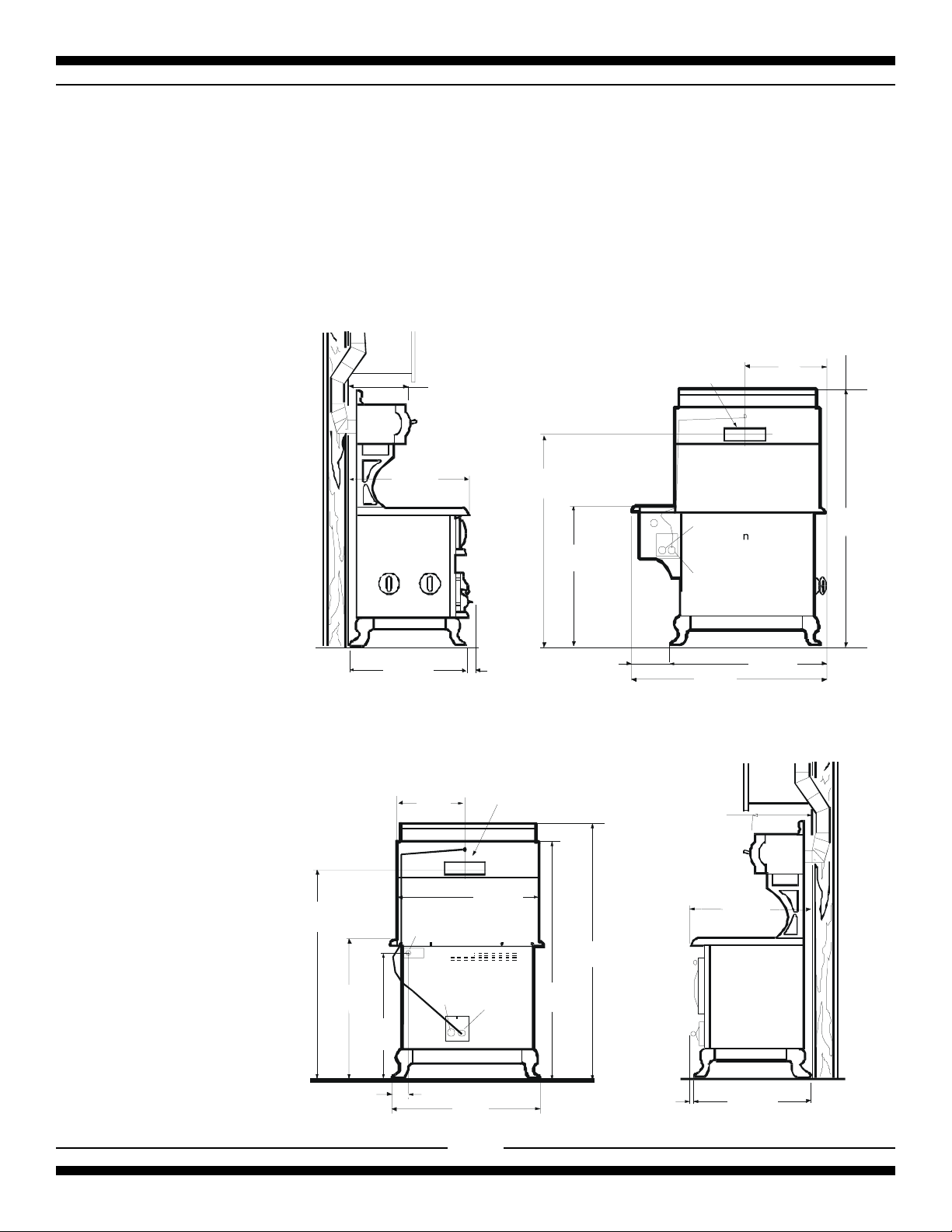

Installation Clearances

If the range must stand beside a refrigerator, it is important for proper air circulation, that there be at least

5" of space between the two appliances.

Do not install range closer than 1/2" from adjacent surfaces.

To eliminate the risk of burns or fire by reaching over heated surface units, installation of cabinet storage

space above the surface units should be avoided. If there is existing cabinet storage space have at least

30" of clearance. (see fig 3)

For best cooking results, your range should be level. This can be checked with a carpenter’s level

on top of the cooking surface and across the oven rack. If levelling is required, adjust the leveller screws

under one or more of the legs (see "Positioning the Range" step 4).

min

30 1/4"

768 m m

0

0

max

36 "

914 mm

Model 9100 Installation Clearance

0

768 mm

min 18"

457 mm

Fig 3 Installation Clearances

Installation Clearances

min

30 1/4"

1"

25 mm

min

36 "

914 mm

0

0

Model 7100 Installation Clearance

min 18"

457 mm

The clearances in the table are also stated on the

rating plate and on a reproduction of the plate on the

back page of this manual. (see "installation

clearances" diagram Fig. 3)

Surface adjacent to cook top-left (7100).............. 1” (25mm)

Surface adjacent to cook top-right (7100) ............ 0” (0 mm)

Surface adjacent to cook top (9100) .................... 0” (0 mm)

Surface adjacent to warming oven........................ 0” (0 mm)

Cook top to underside of adjacent cabinets ... 18” (457 mm)

Cook top to underside of cabinets.............30 1/4” (768 mm)

Maximum depth of overhead cabinets ............ 13” (330 mm)

Maximum depth of counters .......................... 24” (610 mm)

Maximum height of counters.......................... 36” (914 mm)

Rear clearance..................................................... 0” (0 mm)

5

Page 10

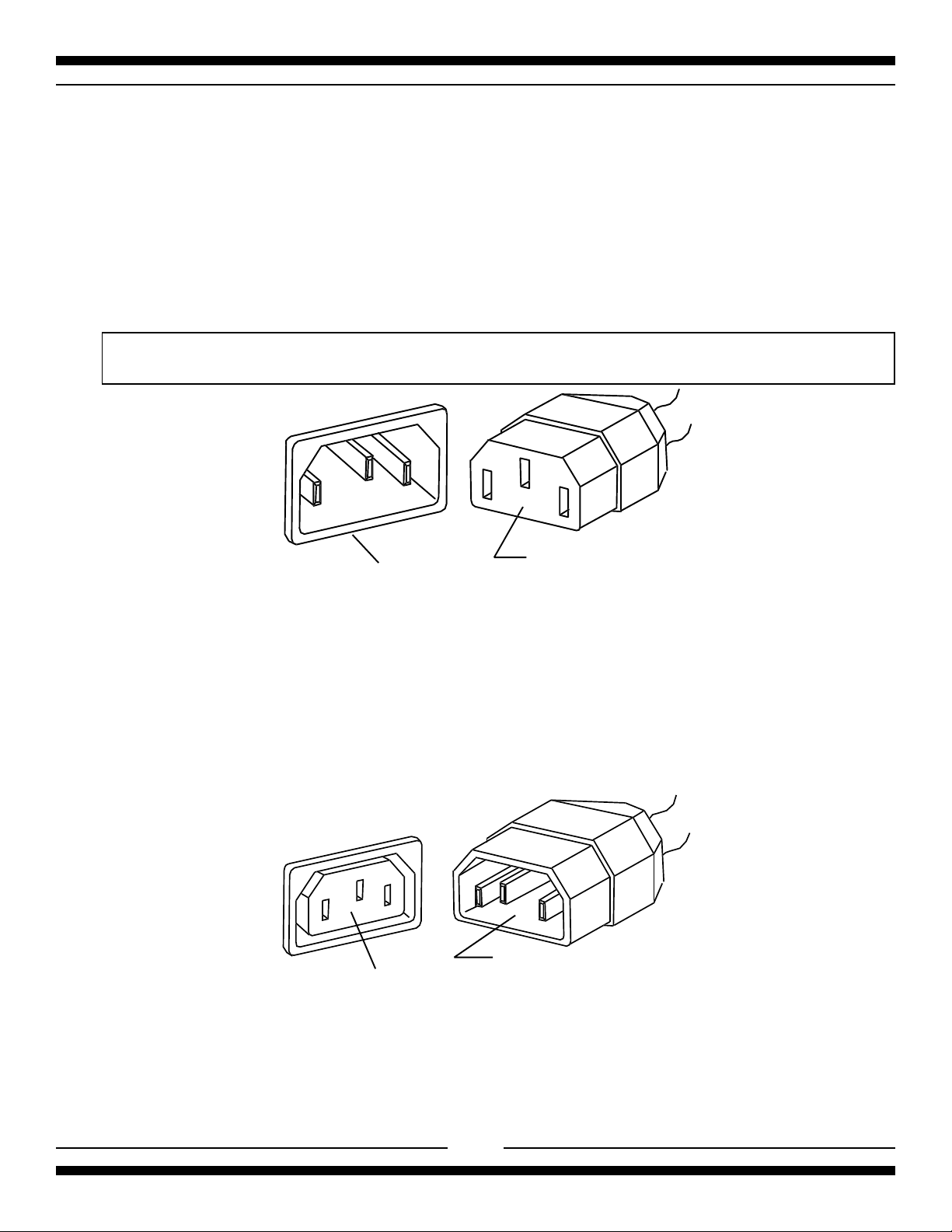

Electrical Installation

THE MODEL 7100/9100 GAS RANGE MUST BE ELECTRICALLY GROUNDED IN COMPLIANCE WITH LOCAL

CODES AND IN THE ABSENCE OF LOCAL CODES, WITH THE NATIONAL ELECTRICAL CODE ANSI/NFPA

70 “LATEST EDITION” IN THE U.S. OR THE CANADIAN ELECTRICAL CODE, PART I, CSA STANDARD C22.1

IN CANADA or YOUR NATIONAL ELECTRICAL CODE

Connect the female end of the power cord to the main power (male) receptacle at the rear of the stove. See page 8 for

receptacle locations and figure 4 for receptacle illustration

This range must be plugged into a properly grounded/earth, receptacle. The grounding/earth prong must not be removed,

from the plug. DISCONNECT THE ELECTRICAL SUPPLY BEFORE SERVICING THE APPLIANCE.

The receptacle to be used for this appliance must be wired to STANDARD WIRING PRACTICES.

male receptacle

Main power hook-up

Figure 4

female end of

the power cord

Exhaust Hood Electrical Connection

After your exhaust hood has been installed the very last thing to do is to connect the special plug to the range. The

female receptacle for the exhaust hood is located at the rear of the stove by the main power (male) receptacle (See

page 8 for receptacle locations and figure 5 for receptacle illustration). Simply plug the cabinet power cord into the

receptacle, be sure to test all functions of the cabinet.

male end of the

cabinet power cordfemale receptacle

Cabinet power hook-up

Figure 5

6

Page 11

Exhaust Hood

Your range is equipped with a two speed range hood that may be either vented directly to the outside, or may be

installed ventless. A set of exhaust filters are included with your hood. The filters should be cleaned periodically in

soapy water. Extras are available from your dealer or directly from Heartland Appliances Inc. Please order 4 or more

filters at one time to save freight and handling charges. Phone your dealer for pricing and ordering instructions.

Ventless Installation

Your unit is already set up for ventless operation. Cooking fumes are drawn through the filters and exhausted thru

the rear of the hood, back into the room. Install the exhaust filters in their location under the cabinet by first removing

the light lens. Then on one side, insert one of the filters into the grooves (front and rear of the cabinet) and slide

into place. Repeat these steps for the second filter

Figure 6

Exhaust venting

options

Vented Installation, Tools, Material, and Dimensions

Tools required to install vented hood:

Hammer Slot screwdriver

Pliers Electric drill

Measuring tape Drill bits

Sabre saw OR Keyhole saw

Materials Required:

Duct—enough to go through wall or attic to outside. Elbows as required.

Roof cap or wall venthood

Caulking to seal around duct

Sheet metal screws

The above are standard parts and are available at any hardware store or heating contractor.

7

.

Page 12

Installation of Ducting

Installation through an outside wall

Remove air deflector (used for ventless operation only). Cut appropriate-sized hole through the wall directly behind

the range hood outlet (see Figure 6 ,page 7), making sure no wall studs are cut. Push range into position. From

outside of the house, measure distance from the siding to the range outlet. Cut duct pipe that length, plus 1" (25mm)

for overlap into outlet. Attach vent hood to pipe. Caulk the back of vent hood and around pipe where it goes through

wall and into range hood outlet so caulking seals against outside siding.

Complete installation by following directions under Ventless Installation.

Installation through an attic

to an outside wall

If the vent elbows are

embedded in the wall, the

range may be positioned as

shown in Figure 6. Continue

the duct through the ceiling

into the attic. Terminate duct

either on an outside wall just

below the sofit using a vent

hood or through the roof with

a roof cap. Seal with caulking

around and under cap or hood.

Complete your installation by

following directions under

Ventless Installation.

787

29

756

31.0"

mm

3/4 "

mm

14 7/8 "

378mm

14"

356 mm

56 "

1416 mm

1/8"

36

917

mm

1 1/4 "

mm

32

235

9 ¼"

Model 7100

Range H ood

O utlet : 3 1 /4"x 10"

83 mm x 254 mm

Range Hood Outlet:

3

1/4" x 10"

83 mm x 254mm

Power In

(

direct con ect)

8 ft (2.4m) cord supplied

Exhaust Hood In

(female recepticle)

47 1/2"

1207 mm

mm

14. 0"

356 mm

19"

483

38 1/4"

72 m m9

mm

66

1682

1/ 4"

mm

56 "

142 2 mm

36 1/8"

917 m m

864 m m

33/4"/92mm

34 "

29 3/4"

756 mm

Gas Inlet-1/2 NPT

Power In

direct

(

connection)

8 ft (2 .4 m ) c o rd

supplied

29 3 /4"

756 mm

Exhaust

HoodIn

8

66 1 /4 "

1682 m m

62 3/8"

1585 m m

Model 9100

2"

51 mm

31.0"

787 m m

29 3 /4 "

756 m m

Page 13

Venting Safety Guidelines

Installation must be done in accordance with all local and national codes. Use only materials which conform to local codes

in effect. Be sure power is disconnected before doing any electrical work. All duct work must be metal. Do not use plastic

duct. The range hood should never be exhausted into a wall cavity or an attic where an accumulation of grease

could become a fire hazard.

When the installation is completed, turn on the fan and make sure that there are no obstructions in the line.

Gas Line Installation

The Model 7100 / 9100 can be operated on either natural gas or liquid propane (LP) and are set for natural gas OR

propane (LP) gas at the factory. Be sure your range is correctly installed by a qualified serviceman or installer for the

type of gas on which it is to be used.

When preparing to install the 9100, be aware that there are several alternative locations for the gas supply pipe to enter

into the stove. For reasons of appearance you may want to conceal the gas supply pipe, and this can be achieved by

routing the supply pipe through knockouts located on the rear or at the bottom of the stove (see illustration below). To

use the alternative locations, the back panel must be disassembled and the selected knockout removed. Route the pipe

through the knockout and up to the manifold. Reassemble the back panel to the stove. Model 7100 has only one supply

pipe installation location. (see illustration below)

THE RANGE MUST BE INSTALLED IN COMPLIANCE WITH LOCAL CODES, AND IN THE ABSENCE OF LOCAL

REQUIREMENTS, THE INSTALLATION MUST CONFORM WITH THE NATIONAL GAS CODE.

Note

: Appliances installed in the state of Massachusetts:

- This appliance can only be installed in the state of Massachusetts by a Massachusetts licensed plumber or

gasfitter

- This appliance must be installed with a three (3) foot / 36 inch long flexible gas connector

- A “T” handle type manual gas valve must be installed in the gas supply line to this appliance

THE APPLIANCE MUST BE ISOLATED FROM THE GAS SUPPLY PIPING SYSTEM BY CLOSING ITS INDIVIDUAL

MANUAL SHUTOFF VALVE DURING ANY PRESSURE TESTING OF THE GAS SUPPLY PIPING SYSTEM AT TEST

PRESSURES EQUAL TO OR LESS THAN 3.5 KPS (1/2 PSIG).

The maximum propane/natural gas supply inlet must not exceed 14 inches of water column. The minimum gas supply

inlet should be at least 5 inches of water column for natural gas or at least 11 inches of water column for LP gas.

5 1/4"

133 mm

G as Inlet on manifold

All electrical

components

behind panel.

Knock-o uts for

gas piping in

bottom panel.

34

864 mm

9 1/2

240 mm

3 3/4

95 mm

4 1/2

115mm

9100 optional gas inlet locations

Knock-outs for gas

piping behind back

panel.

13 3/4

350mm

5 7/8

149 mm

30"

762 mm

10"

254 mm

Gas Inlet to manifold

7100 optional gas inlet location

9

Page 14

Important Safety Instructions

1. PROPER INSTALLATION—BE SURE YOUR APPLIANCE IS PROPERLY INSTALLED AND GROUNDED BY

A QUALIFIED TECHNICIAN.

2. NEVER use this appliance as a space heater to heat or warm the room. Doing so may result in Carbon

Monoxide poisoning and in overheating of the oven.

3. Do not leave children alone. Children should not be left alone or unattended in area where appliance is in use.

They should never be allowed to sit or stand on any part of the appliance.

4. Wear proper apparel—loose-fitting or hanging garments should never be worn while using the appliance.

5. User servicing—do not repair or replace any part of the appliance unless specifically recommended in the

manual. All other servicing should be referred to a qualified technician.

6. Storage in or on appliance—flammable materials should not be stored in an oven, near surface units or in range

cabinet.

7. Do not use water on grease fires—smother fire or flame or use dry chemical or foam-type extinguisher.

8. Use only dry potholders—moist or damp potholders on hot surfaces may result in burns from steam. Do not

let potholder touch hot heating elements. Do not use a towel or other bulky cloth.

9. NEVER cover any slots, holes and passages in the oven bottom or cover an entire rack with materials such as

aluminum foil. Doing so blocks air flow through the oven and may cause Carbon Monoxide poisoning. Aluminum

foil linings may also trap heat, causing a fire hazard.

10. It is a good practice to install CO detectors when any gas appliance or furnace is present in the home. Please

follow manufacturer’s recommendations for location and installation of CO detectors.

Exhaust Hood Safety

Caution: Do not store items of interest to children in cabinet above the range or on top of range cabinet.

Children climbing on range to reach items could be seriously injured.

1. Clean exhaust hood frequently—grease should not be allowed to accumulate on hood or filter.

2. When flaming foods under the hood, turn the fan off. The fan if operating may spread the flame.

Oven Safety

Do not touch heating elements or interior surfaces of oven—heating elements may be hot even though they

are dark in colour. Interior surfaces of an oven become hot enough to cause burns. During and after use, do not touch,

or let clothing or other flammable materials to contact heating elements or interior surfaces of oven until they have

had sufficient time to cool. Other surfaces of the appliance may become hot enough to cause burns—among these

surfaces are, for example, oven vent openings and surfaces near these openings, oven doors.

1. Use care when opening door—let hot air or steam escape before removing or replacing food.

2. Do not heat unopened food containers—buildup of pressure may cause container to burst and result in injury.

3. Keep oven vent ducts unobstructed.

4. Placement of oven racks—always place oven racks in desired location while oven is cool. If rack must be moved

while oven is hot, do not let potholder contact hot heating element in oven.

10

Page 15

A

Features

J

F

I

Figure 7

B

D

C

E

H

Cooking Controls

The cooking controls are located on the right hand side of the cooktop; these controls offer an infinite number of heat

settings for ease and accuracy in cooking and baking.

Sealed Burner Features (see fig. 7)

A) Centre Burners - are two maximum 8,000 BTU (2.34 kW)(L/P 7,000 BTU) with simmer of 600 BTU (.2 kW)

sealed gas burners,easy clean, for medium duty cooking tasks.

B) Left Burners - front sealed burner is maximum 10,000 BTU (2.93 kW) (L/P 9,000 BTU) with simmer of 1000

BTU (.3 kW) and rear is maximum 8,000 BTU (2.34 kW)(L/P 7,000 BTU) with simmer of 600 BTU (.2 kW)

accurately maintain temperature.

C) Right Burners (48" models only) - front sealed burner is maximum 10,000 BTU (2.93 kW) (L/P 9,000 BTU)

with simmer of 1000 BTU (.3 kW)and rear is maximum 8,000 BTU (2.34 kW)(L/P 7,000 BTU) with simmer of

600 BTU (.2 kW) , one for large jobs, one for small, easy clean.

D) Gas Burner Controls - allow an infinite selection of cooking temperatures, 4 controls on model 9100 and 6 controls

on model 7100. All models feature "auto-reignition", which means if for any reason the flame goes out, it

automatically begins to spark to re-ignite the burner!

11

Page 16

G

K

Fig. 8

L

Oven Features

E) Oven Temperature Control - With infinite bake temperature and broil control. All units feature "auto gas shutoff",

which means that if for any reason the flame goes out, gas to the oven burner shuts off!

F) Gas Oven Features: -baking

-3 position racking

-2 cubic feet of energy efficient area (.05 cubic meters)

-13,500 BTU (3.96Kw) oven burner

Other Features (see fig. 8)

G) Digital Clock - With minute minder.

H) Broiler - Broiler drawer located under the oven, glides open for easy access, for all your broiling needs.

I) More Storage - (model 7100 only) lift and open the cast door to gain access to more storage area.

J) Cabinet Door - the minute minder, exhaust fan control and overhead light switch are concealed behind the cabinet

door.

K) Three position switch - Controls high and low for exhaust fan centre position is “OFF”.

L) On -off switch - controls overhead light in exhaust hood.

12

Page 17

Control Panel Layout

Model 7100

Control Panel

0

6

5

4

6

5

4

6

5

4

6

5

4

6

5

4

6

5

4

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

Left Rear Burner

Control(Medium)

Left Front Burner

Control (Large)

Centre Rear Burner

Control (Medium)

Centre Front Burner

Control (Medium)

Right Rear Burner

Control(Medium)

Right Front Burner

Control(Large))

Oven Control

The control panel is laid out in a straight line

and each control is identified by a graphic on

the right side of the knob.

Model 9100

Control Panel

0

6

5

4

6

5

4

6

5

4

6

5

4

F

C

200

95

250

120

300

145

5

0

3

1

7

0

0

4

0

5

0

2

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

5

2

6

5

0

4

5

5

3

2

Left Rear Burner

Control(Medium)

Right Rear Burner

Control(Medium)

Left Front Burner

Control (Large)

Right Front Burner

Control(Medium)

Oven Control

The operation of the controls

are described in the following

pages.

13

Page 18

OPERATION

Top Burner Operation

Lighting the Top Burners

Your range is equipped with a spark ignition system that is electrically operated. You need only to push

in and turn the knob to any position and the burner will light. When you turn the knob, you will hear a

distinct clicking noise. After the burner lights, the clicking noise will stop. Note: when lighting any one

burner, all burners will spark, but only the burner that you have selected will light. All models feature

"auto-reignition", which means if for any reason the flame goes out, it automatically begins to spark

to re-ignite the burner!

See page 16 for manual lighting procedure.

0

6 (HI) - Quick start for cooking, brings water to

boil.

5 (MED HI) - Fast fry, pan broil, maintain fast boil

on large amount of food.

6

4 (MED) - Saute and brown; maintain slow boil on

large amount of food.

5

3 (MED LOW) - Cook after starting at MAX; cook

with little water in covered pan.

2-1 (LOW) - Steam rice, cereal; maintain serving

temperature of most foods.

For safety reasons, always adjust the burner controls so that flames do not extend beyond

the edges of pots, pans or other cooking utensils.

Large pots or other over-sized cooking utensils may cause random sparking from the

burner. To avoid this condition lower the flame size or use smaller-sized cooking utensils.

Do not use a griddle directly on top of grates. To avoid random sparking, please use the

Heartland Griddle Pan Kit for Classic Ranges part #7602 (complete with griddle pan

support) may be purchased from your dealer or directly from Heartland.

4

Top Burner Control

3

1

2

14

Page 19

Oven Cooking

Oven Lighting

Open oven door. There are 2 holes in the oven bottom so you can view the oven flame. Push

in and hold down the oven knob and select the desired oven temperature. You should hear

sparking until the oven flame ignites. You must continue to keep oven knob depressed

for 5-6 seconds after the oven ignition has occurred. The extra 5-6 seconds is to heat up

the safety thermocouple to allow proper oven control. (releasing the knob too early will

extinguish the flame) All units feature flame sensing auto shutoff, so if for any reason the

flame goes out, the gas supply to

the oven is shut off automatically!

Please note: the first time the oven

is used, the oven lighting procedure

may have to be repeated 2-4 times

to push out any air in the gas lines.

If the oven flame

does not light

in

10 seconds, STOP. Release oven

knob, this will prevent any further

gas from going into the oven. Wait

at least 1 minute before trying to

light oven again. If you are still not

successful see "trouble shooting

guide".

250

120

300

145

200

95

F

C

0

Range Thermostat

The temperature in the oven is

transmitted to the thermostat by

5

1

7

0

0

0

4

5

0

2

0

5

4

5

3

2

5

0

0

6

2

5

3

0

the sensor tube located at the rear

of the oven. It must always be in

Oven Control Knob

position on its mounting clips and

should not be bent. The sensor

causes the burner to maintain the

desired oven temperature.

Broil

When broiling, the oven control knob should be set at 550°F (290°C). The oven door should

be positioned at the first stop position on the door hinge, which will leave the door open approx.

5 inches. If the door is closed during broiling, the temperature in the oven could reach 550°F,

causing the oven burner to cycle down to the "low position", which will effect your broiling time.

15

Page 20

Power Failure Operation

If electrical power is interrupted in your area, you can still cook meals on your Heartland gas range .By following these simple

directions you will be able to use the burners and oven without the benefit of electricity.

Caution: make sure your hands and clothing are clear of the burner you are lighting!

Top Burner Control

Manually Lighting the Top Burners

1) Remove cast grate, for unobstructed access to the burner head.

2) Hold a flame source to the desired burner head.

We recommend a barbecue lighter to use as a flame source.

3) Push in and turn the corresponding control knob to the medium setting.

4) Carefully replace cast grate, keep fingers clear of the flame.

5) After the burner lights, adjust flame size as required.

Please note that the "auto reignition" feature will not function without electricity, therefore pay close attention to

any burners in use while electrical power is interrupted!

When lighting top burners manually, set control to the

medium setting to prevent potential injury from the

flame when replacing the grate.

Manually Lighting the Oven Burner

The oven can be operated safely by lighting the oven burner in the following

manner:

1. Remove the oven bottom.

2. Hold a flame source at the front of the burner directly beside the igniter. We

recommend a barbecue lighter as flame source.

3. Push in and hold down the knob, continue to hold down the oven knob and

select the desired oven temperature.

4. You must hold oven knob down for at least 10 seconds after ignition, to

activate the oven safety thermocouple. (releasing the knob too early will

extinguish the flame).

When lighting oven burner manually, light the burner

at the igniter. Keep hands and clothing away from

open flame!

5. If the oven flame

this will prevent any further gas from going into the oven. Wait at least 1

minute before trying to light oven again. If you are still not successful see

"trouble shooting guide".

6. Place oven bottom back onto position, Caution keep fingers and clothing

does not light

in 10 seconds, STOP. Release oven knob,

away from the flame!

Please note that the flame sensing auto shutoff feature

if for any reason the flame goes out, the gas supply to the oven is shut off automatically!

is still functional

without the benefit of electricity so

16

Oven Burner and

Igniter

Page 21

Minute minder

Bell symbol indicates minute

minder in operation

Clock / Timer

NOTE: Clock must be set or your timer will not function!

Adjust setting up

Adjust setting down

Functions:

Power on

Display is flashing

Set time of day

Press left button" ". Set time of day with " " and

" " buttons. This function remains activated for 7

seconds after the last " " / " " operation!

Set minute minder

This function is permanently activated and can be immediately

set with " " and " " buttons.

During setting, the units are 10 seconds.

During count down the minute minder has priority in the

display. The units are seconds.

The maximum time is 99 minutes.

Reset minute minder

Press " " and " " button together and release

" " button first.

Signal

The signal after time out will stay on 7 minutes if

it is not been reset with the " " button (Only one

touch.)

Signal Sound

The sound of the signal can be changed if desired.

When the display show time-of-day, the signal

frequency can be selected by pressing the " "

button.

Three different frequencies are selectable.

17

Page 22

Care and Cleaning

CAUTION: When cleaning the cooking surface around the valve cover plate, be aware that

detergents may corrode the electrical contacts on the valve switches (preventing an ignition

spark) and may also degrade the gasket seal on the valve itself (causing a gas leak). To

prevent damage to these components, remove valve cover and wipe up excess detergents

around and on these components, or, remove valve cover for cleaning, thereby eliminating

the chance of detergents coming in contact with these components. When removing valve

cover remember to unplug the power to the range.

Porcelain

Keeping it clean

The porcelain is very serviceable and simple to clean, but because it is glass, it will not

withstand rough handling or abuse. Never clean porcelain parts while stove is hot. Porcelain

is glass and sudden changes in temperature may cause cracking. Clean porcelain surfaces,

using warm soapy water, glass cleaner or non-abrasive cleaner and a soft cloth. Avoid

abrasive cleaners.

If any acid-based food or liquid, such as lemon juice or tomato juice is spilled on the range wipe

it at once to prevent staining.

Note: Red appliances only - a red wax coating has been added for preparation purposes which

may wear off during cleaning - this is normal and does not affect finished product.

To move range for service or cleaning

WARNING

RANGE BODY RESTS ON BASE

WHEN MOVING , MOVE BY BASE ONLY

1. Disconnect gas line and electrical power.

2. Place temporary floor protection in front of range.

3. Slide out from wall and place floor protection

under front legs and slowly pull out to gain access

to rear.

4. To reinstall, reverse these instructions.

Important

Keep appliance clear from combustible materials,

gasoline and other flammable vapour and liquids.

Do not obstruct the flow of combustion and ventilation

air.

18

Page 23

Oven Cleaning

Your range must be kept clean and free of accumulations of grease or spillovers which may ignite.

This is most important in the oven and broiling compartment. When cleaning the oven, make sure

the oven is turned “Off” and oven is cool. For simple spills, clean the oven with a strong solution of

detergent, then wipe with a clean damp cloth and dry.

When food or grease has burned on the oven lining, apply a strong oven cleaning compound. Follow

directions on the package, but avoid applying a strong cleaner to the front flanges or sides of end

panels because it may destroy the oven door seals or plated surfaces.

Oven racks, oven rack supports, broiler pan rack, oven bottoms, and broiler pan are all removable

for easy cleaning. Oven racks may be cleaned in your sink with dish cloth and detergent. If spillage

has remained on the racks for an extended period, more vigorous cleaning with a steel wool soap

pad may be required.

Surface Burners

Top burners require little care other than to wipe off the head of each burner. If a boilover occurs,

the burner cap can be easily lifted out so burner port holes can be cleaned in hot soapy water with

a soft brush. There are no bolts or screws to remove. The igniter must also be kept clean to ensure

quick positive starts. Simply lift the burner cap and clean. When replacing, be sure the tab is locked

securely in position on the burner base. For normal or everyday cleaning of light spills, wipe the

burner caps with a damp cloth. For heavy duty cleaning—cooked spills, oil stains, etc. scrub with

a tub and tile type of cleaner. Rinse thoroughly after every cleaning operation. Wipe away excess

water .

cap

flame spreader

burner base

19

Page 24

Nickel-Plated Trim

Nickel may be cleaned with any non- abrasive chrome and metal polish or Windex and a soft

cloth. If any acid-based food or liquid, such as lemon juice or tomato juice, is spilled on the

range, wipe it at once to prevent staining.

Exhaust Hood

Exhaust filters are included with your exhaust hood. The filters may be cleaned periodically

in soapy water. The filters should be replaced every 4 months or when they begin to restrict

air flow. Extras are available from your dealer or directly from Heartland Appliances. Please

order four or more at one time to save freight and handling charges.

See instructions for ordering on page 7 under " EXHAUST HOOD "

The inside of your exhaust hood should be inspected periodically for grease buildup (a fire

hazard) and cleaned as required with soap and water.

Oven and Cabinet Light Replacement

Before replacing lamp, disconnect the power at the main fuse or circuit breaker panel. When

replacing light bulbs, wait until the oven and bulb are cool. Remove oven light lens by simply

unscrewing it counterclockwise. The bulb can then be unscrewed easily. Always handle the

bulb with a dry (never wet) cloth to protect hands. If light bulb should break, disconnect power

to range by unplugging it or removing the fuse from the panel before touching the bulb.

Replace the bulb. Use only a 40 watt oven bulb available at your local hardware store or

appliance dealer.

When cleaning the oven, do not touch lens with a wet cloth.

WARNING!

Do not sit, lean, lift or stand on the

doors or drawers of this range as

possible injuries may result.

20

Page 25

Interior Oven Rack

The oven rack is designed with stop-locks so that when placed correctly on the supports, it (a) will stop before

coming completely out of the oven, (b) will not tip when placing or removing food.

To install, place the rack "feet" on the rack support and push the oven rack backward along the rack support.

(see 1 )

Push the oven rack all the way to the back until the oven rack slips off the end of the rack support.

(see 2 )

Then pull rack support ahead slightly to engage the "feet" with the rack support. (see 3 ) To remove reverse

assembly procedure.

Oven rack "feet"

1

Oven rack

Rack Support

2

3

Rack Supports

The oven rack supports are designed to interlock into the oven sides but are easy to remove. First remove

oven racks, then grasping the lower portion of the rack support swing it out to approx. 45 degrees and gently

pull down. Assemble in reverse order.

21

Page 26

Removal of Oven Door

At times you may want to remove the oven door for thorough cleaning of the oven. Removal of the oven door

is easy:

1) Open oven door, and latch the brass catches on to the upper leg of the hinge. (see below).

Make sure the catch is securely hinged.

2) With a hand on each side of the door lift the door slightly, and pull out.

3) The door weighs about 17 lbs (8 kg) , so exercise caution when removing the door.

4) To replace the door reverse this sequence.

WARNING!

Do not sit, lean, lift or stand on the doors

or drawers of this range as possible

injuries may result.

Make sure the brass catch is

securely hinged

Upper leg

Brass catch

Oven door

22

2) and pull out

1) lift the door slightly,

Page 27

Broiling

Broiling is cooking by direct radiated heat from above the food. It is fast because no preheat time is required

and the food is close to the burner.

When broiling, the oven control knob should be set to the broil symbol or the 550 setting on the knob. The oven

door should be positioned at the first stop position on the door hinge, which will leave the door open approx.

5 inches. If the door is closed during broiling, the temperature in the oven could reach 550 F causing the oven

burner to cycle down to the "low position", which will affect your broiling time.

Broiling guide charts in most cookbooks are approximate. Your personal experience using the broiler will

establish the most desirable cooking time.

Broiling Pan

The broiling pan grille allows for the proper drainage of cooking grease into the lower pan. Both the griddle and

pan should always be used when broiling.

Optimum Broiling Area

Broiling Pan and Griddle

Always remove the broiler pan from the compartment as soon as you finish broiling. It makes the pan much

easier to wash and there is no chance that the pan and drippings will be forgotten. Grease left in the pan can

catch fire if the oven is used without removing the grease. Let the pan cool first, then wash the pan and griddle

in hot soapy water.

Oven Light

The oven light switch is located below the nickel band on the right front side on the model 7100 and on the model

9100 right side.

switch location on

7100

23

switch location on

9100

Page 28

Storage Drawer

To remove storage drawer:

1. Remove oven door.

2. Remove oven bottom.

3. Pull drawer out until it stops.

4. With the aid of a flashlight, locate and remove the drawer stop at the left side of the drawer by removing the

two screws. (see figure 1).

5. Pull the drawer again gently until it stops. At the same time, from underneath, pull on both release

tabs (see figure 2) to disengage the drawer from the track and pull drawer out.

6. To reinstall: line up the drawer's tracks with each other, press on the bottom of the drawer and push

all the way back (see figure 3).

7. Reattach drawer stop. Please ensure the drawer is back far enough to clear

stove's fixed stops.

Drawer Stop

Reverse View/Angle

Figure 1

Drawer

Pull out to release

drawer glide

Figure 2

Stove Tracks

Figure 3

24

Page 29

SETUP AND TROUBLESHOOTING

Timer

Exhaust Fan

Speed Control

Light Switch

Burner and Oven

Controls

Oven Light

Switch

Oven Light

Broiler Drawer

Filters

Splashback

Timer

Exhaust Fan

Speed Control

Light Switch

Burner and O ven

Controls

Oven Light

Switch

Oven Light

Broiler Drawer

Filters

Splashback

Pot Storage

Burner Setup & Adjustment

The range was carefully set up and inspected at the factory but some final adjustments may be necessary

once the unit is installed.

You should check the following:

i) First check to make sure there are no gas leaks. Propane and natural gas have a very distinct smell

which is easily detected by the human nose. If in doubt, soak each pipe joint with soapy water and look

for bubbles. Do not use an open flame for testing.

ii) Check that all the controls are operating properly by lighting each of the burners. Turn the burners

on by pushing down and turning counter clockwise. Try them at low, medium and high settings.

iii) Check the quality of the flame. The top burners should have a steady, relatively quiet flame with

a 1/2" (13mm) sharp blue cone. There should be no orange flame. The oven burner should have

a clean blue flame with inner cones of 1/4" to 1/2" (6.35mm to 13mm). See figure 8.

If everything checks out, you’re “cooking with gas”. If not, refer to the gas trouble shooting guide,

page 27.

Outer Cone

In ner C one

figure 8.

25

Page 30

Air Shutter Adjustment (oven burner only)

The quality of the flame can be changed by adjusting the air shutters. Factory setting on the air shutter is 0.40" (10.6mm).

(see figure 9)

loosen screw

Reduce the shutter opening if:

• the flame appears unsteady

• is not burning all the way around

• is noisy like a small blow torch.

.4"

Increase the shutter opening if:

• the flame has yellow tips

• there is no sharp blue cone

air shutter adjustment

Figure 9

• soot appears on the bottom of cooking pans.

The oven burner air shutter is located at the base of the burner inside the broiler compartment. It can not be adjusted in place

and the oven bottom must be removed to reach it. The burner must be removed to adjust shutter.( see page 30 for burner removal)

The air shutter is adjusted by loosening the locking screw and rotating the shutter to allow more or less air into the tube. The

centred position is usually about right. Tighten the screw, replace the assembly and check the flame pattern.

Oven Burner Assembly

The oven burner assembly is visible and accessible for servicing when the oven bottom panel is removed. The burner assembly

is made up of several components as shown below.

10.6 mm

thermocouple

burner

igniter

IMPORTANT

The thermocouple and igniter positioning is very important

to the operation of the oven. These two items must be

checked before putting the appliance into operation. (see

figure 11)

NOTE: Before putting the 7100 /9100 Gas Range into service,

be sure that all the setup procedures recommended in this

manual have been completed.

Oven burner assembly

Figure 10

3/16"

4.7mm

Top View

Side Vie w

1/8"

Critical

3.0mm

Thermocouple

1/8"

C r it ic al

3.0m m

The ov en ignit or m ust

be on the cen tre of

the pipe in t he m id dle

of the first and s econd

po rt

26

figure 11

Page 31

TROUBLESHOOTING GUIDE

FOR ALL BURNERS EQUIPPED FOR REIGNITION

WITH " FLAME RECTIFICATION "

Problem Cause Remedy

A. Spark Ignition

1. No sparks when any control

knob is turned to “light”

2. No sparks when one or

some control knob(s) is

(are) turned to “light”

3. Sparking occurs at

electrodes when all control

knobs are turned off

4. All burners that are turned

on have lighted but

electrodes are still sparking

No power to spark module - module

switch faulty

Reignition electrode controlled by

knob switch is grounded or has

a high resistance leak

Electrode to far from burner

base

Disconnected switch lead or short

in switch lead

High resistance or open connection

between spark output terminal and

H.V. wire receptacle (spark will

jump small gap but sensing current

will not)

Check electrical supply to spark module with voltmeter - replace module

Check high voltage wires carefully for loose connections or pinches in the

wires; if connections are tight, replace high voltage wire

The igniter is on a eccentric pin, so rotating the igniter in its place will bring

the igniter closer to the burner base

Check all switch lead connections for looseness and wires for damage

Push receptacles firmly onto all terminals

Check positioning of shrink sleeving on receptacle – should be flush with end

of receptacle – trim if necessary

5. One or more burners have

lighted but eletrodes are still

sparking

B. Oven Burner

1. No main burner flame

2. Oven will not maintain

proper baking temperature

Defective module

Ground/Earth lead to module

disconnected or range chassis not

properly connected to ground/earth

by ground/earth lead or through

third prong of power cord plug,

combined with reversed power

supply polarity

Pots or cooking utensils (i.e. griddle

plates) are too large and are

smothering the flame causing the reignition to spark

Defective safety thermocouple Make sure thermocouple is hand tightened +1/4 turn

Defective thermostat (unit under

oven control knob) , no main burner

flame at any setting

Oven bulb not in proper location Secure oven bulb in clips that hold it in proper location

Oven bulb coated with foreign

material (i.e. oven cleaner etc.)

Oven bottom covered with aluminium

foil

Utensils too large for oven reducing

free circulation of air

Replace module

Check ground/earth connection of range chassis and ground/earth lead

connection to module

Use smaller sized pots or reduce size of flame. Do not use

griddle plate directly over top of grates. Heartland Appliances

sells a griddle kit #7602 complete with griddle support.

Replace safety thermocouple- NOTE: There are no field adjustments for this

control

Replace thermostat above - always check gas pressure before replacing

thermostat

Use fine steel wool or scouring pad to gently clean the surface of the bulb

- NOTE: Replace carefully in locating clips

If foil blocks holes or slots in oven bottom, oven heat distribution will be

affected - remove foil

Allow at least 1 1/2" to 2" (38mm to 5.0mm) clearance for air circulation

between utensils and between utensils and oven surface

27

Page 32

Conversion Kits and Information

Normally, Model 7100 and 9100 are ordered from the factory preset for either Natural Gas or Propane.

However, they can be converted after installation by performing a conversion procedure to the gas

components with the appropriate conversion kit.

The components requiring conversion are,

1) the pressure regulator,

2) top burner controls,

3)oven burner control,

4) the top burners

5) oven burner

Kits can be ordered from your dealer or directly from Heartland.

Each kit contains all the parts required for conversion, as well as instructions and a orifice removal tool.

The kits available are:

7698 7100 ORIFICE KIT NAT DOMESTIC -SABAF

7698I 7100 ORIFICE KIT NAT DOMESTIC SABAF/ISPHORDING

7699 9100 ORIFICE KIT NAT DOMESTIC -SABAF

7699I 9100 ORIFICE KIT NAT DOMESTIC SABAF/ISPHORDING

7702 7100 ORIFICE KIT LP DOMESTIC SABAF

7702I 7100 ORIFICE KIT LP DOMESTIC SABAF/ISPHORDING

7703 9100 ORIFICE KIT LP DOMESTIC SABAF

7703I 9100 ORIFICE KIT LP DOMESTIC SABAF/ISPHORDING

When ordering your kit please include your serial number to ensure the correct conversion kit is supplied

to you.

28

Page 33

See our complete line of kitchen appliances:

3010- 30" Classic II Series Refrigerator, 18 cubic

feet capacity, bottom-mount freezer drawer, and

convienient top-mount fresh food compartment.

Ice maker is available as an option. The Classic

series also offers an optional Cowl. Energy efficiency

rating 548 kwh/year. Also available in Metro 3220

and Legacy 3060 models.

3110- 36" Classic II Series Refrigerator, 22 cubic

feet capacity, top-mount freezer, counter-depth

design. Ice maker is standard. The Classic series

also offers an optional Cowl. Energy efficiency

rating 552 kwh/year. Also available in Metro 3310

and Legacy 3160 models.

3530- Legacy Gas / Electric kitchen range - 4 sealed

gas burners, electric convection oven fits in a 30"

opening! Also available in stainless steel as model 3535

Metro. Cooktop versions for both Metro 3805 and

Legacy 3800 models are available.

3630- Legacy 36" Gas / Electric kitchen range - 6

sealed gas burners or 4 sealed burners and centre grill!

Electric convection oven comes standard. Also

available in stainless steel as model 3635 Metro.

Cooktop versions for both Metro 3825 and Legacy

3820 models are available.

9720 (Built-in)- Dual oven, one convection, one

standard radiant. Also available with a

oven feature

, as model 9730

self clean

4200- 30" Gas / Electric kitchen range - 4 sealed gas

burners, electric convection oven fits in a 30" opening!

Model 3110:

shown with the

Optional cowl

(available only

with the Classic

Series)

Also available with a

self clean oven feature

, as

model 4210

5200- 48" Gas / Electric kitchen range- 6 sealed gas

burners, electric convection oven, dual fuel! Also available

with the convenience of a

self clean oven

, as model

5210

6200- 48" Electric kitchen range- 5 solid element

burners, convection oven. Also available with the

convenience of a

self clean oven

, as model 6210

8200- 30" Electric kitchen range- 4 solid element

burners, convection oven fits in a 30" opening! Also

available with a

self clean oven feature

, as model 8210

Model 1903

7100- 48" Gas or propane kitchen range - 6 sealed

gas burners, a chef's dream come true!

9100- 30" Gas or propane kitchen range - 4 sealed

gas burners, fits in a 30" opening!

1900 (Oval)- Wood burning cookstove-old

fashioned cooking available in two models

2600 (SweetHeart)- Wood burning cookstovesame as the Oval, in a smaller version!

For more information please call your dealer, or call

Heartland Appliances:

Phone 1-800-361-1517 or Fax 1-800-327-5609

29

Page 34

7100/9100 PARTS CHART

1599

1546

159 2

16071

157 0

155 6

152 11

7374

754 5

753 0

631 3

13021

130 7

111 0

111 5

914 1

1125

11201

132 0

1311

132 5

133 0

602 9

401 2

245 5

1596

15451

1575

1610

1588

6536

1551

7162

16601

5208

8455

7528

7591

3556

8200

1325

9237

6679

6198

8202

7590

6677

6676-#7100

6675-#9100

6197

6202

8204

652 2

9147

845 2

8449

1599

1546

4575

1592

46071

4570

1556

45231

7374

9530

7545

8313

9141

1110

112 01

112 5

9106

91051

9106

910

51

1115

9533

1596

45451

1610

1588

8536

1551

7162

#7100-7580

7558

7557

7560

7559

7551

7552

#9100-7581

H-976

75 77

7376

7374

752 1

7364

7956

6455

707 3

7518

1115

4012

8455

8455

75622

7561

7570

7569

7571

7917

7123

Page 35

Model 7100 / 9100 Gas Range Parts Chart

TO ENSURE THE CORRECT COLOR MATCH WHEN ORDERING

COLORED PANELS, BOTH THE COLOR AND SERIAL NUMBER

MUST BE PROVIDED.

1110 Oven Door Handle Stanchion

1120 Outer Oven Door Panel

1125 Oven Door Thermometer (Non Functional)

1307 Fire Door Frame (7100 only)

1311 Ash Pan Door - Complete (7100 only)

1320 Wire Spring Handle (7100 only)

1325 Bell Damper Handle w/rod (7100 only)

1327 Cast Bell Damper Handle (7100 only)

1330 Bell Damper (7100 only)

1546 Heartland nameplate/Clips

1551 Right Cabinet Bracket

1556 Left Cabinet Bracket

1570 Lower Cabinet Strip (7100 only)

1575 Upper Cabinet Strip (7100 only)

1588 Right Cabinet Cast Corner

1592 Left Cabinet Cast Corner

1596 Right Cresting Corner

1599 Left Cresting Corner

1610 Cabinet Door Handle

2455 Base Rail Front (7100 only)

2456 Base Rail Rear (7100 only, not shown)

3556 Gas Regulator

4012 Base Leg

4570 Lower Cabinet Strip (9100only)

4575 Upper Cabinet Strip (9100 only)

5208 Reservoir Front (7100 only)

6029 Ash Catch (7100 only)

6197 2 Speed Blower Control Switch

6198 Range Light Switch

6202 Oven Light Bulb - 40W

6313 Curved Band - Cook Surface (7100 only)

6397 Oven Door Handle

6437 Oven Door Hinges L&R (not shown)

6455 Broiler Pan & Cover 2 Pc

6522 Exhaust Hood Deflector

6536 Closet Wrap (7100 only)

6675 Exhaust Filter (9100 only)

6676 Exhaust Filter (7100 only)

6677 Exhaust Adapter Boot to 3 1/4 x 10

6679 Exhaust Blower

7073 Broiler Drawer Rack

7123 Broiler Drawer Spring

7161 Oven Control Knob

7162 Top Burner Control Knob

7355 Oven Burner

7364 Oven Burner Igniter/Wire

7374 Flue Deflector

7518 Gas Oven Drawer Heat Shield

7521 Oven Bottom Pan

7528 Valve Cover Plate (7100 only)

7530 Stove Top (7100 only)

7545 Grate - Cast

7551 Control Valve Medium Burner

7552 Control Valve Large Burner

7555 6 burner reignition harness c/w switches

7556 4 burner reignition harness c/w switches

7557 Medium Burner Cap

7558 Large Burner Cap

7559 Medium Flame Spreader

7560 Large Flame Spreader

7561 Medium Burner Base

7562 Large Burner Base

7569 Ignition Electrode (1200MM Lead)

7570 Ignition Electrode (900MM Lead)

7571 Ignition Electrode (600MM Lead)

7577/7376 Oven Burner Control (serial number required)

7580 7100 Manifold Weldment

7581 9100 Manifold Weldment

7590(7304)Spark Module (0+6)

7591(7404)Spark Module 0+2 (7100 only)

7917 Broiler Drawer Assembly

8200 Light Socket & Housing

8202 Oven Light Ass’y

8204 Oven Lens

8313 Curved Band - Cook Surface (9100 only)

8449 Oven Rack Support

8452 Oven Rack

8455 Base Rail Front / Side

8456 Base Rail Rear (9100 only, not shown)

8536 Closet Wrap (9100 only)

9106 Utility Drawer Frame

9141 Oven Door Frame Weldment

9147 Gas Oven Door Gasket

9237 Electronic Minute Minder

9530 Stove Top (9100 only)

9533 Valve Cover Plate (9100 only)

15211 Splash Back (7100 only)(serial number req’d)

15451 Cresting Panel (7100 only)(serial number req’d)

16071 Front Cabinet Door Panel (7100 only) - (serial

number req’d)

16601 Reservoir Front Insert Panel (7100 only) -(serial

number req’d)

45231 Splash Back (9100 only)(serial number req’d)

45451 Cresting Panel (9100 only) (serial number req’d)

46071 Front Cabinet Door Panel (9100 only) - (serial

number req’d)

91051 Drawer - Front Panel(serial number req’d)

13021 Fire Door Panel (7100 only) (serial number

req’d)

H-306 Ash Door Hinge - Pins (7100 only)

H-976 Spark Ignitor “O” ring

Please order by part number. Parts may be ordered from

your dealer or direct from Heartland Appliances Inc. Phone

factory for prices and ordering instruction. Phone 519-6505501 ask for the order desk.

31

Page 36

Model

7100 / 9100

1050 FOUNTAIN ST N. CAMBRIDGE,

ONTARIO CANADA N3H 4R7

Serial No. HGS

Natural Gas LP/Propane

Medium 8000 BTU/HR 7000 BTU/HR

Large 10000 BTU/HR 9000 BTU/HR

Oven 13500 BTU/HR 13500 BTU/HR

Manifold Pressure 4 IN. W.C. 10 IN. W.C.

Power Requirements 120 Volt 3 amps. 60 Hz

This appliance can be used with LP/Propane gas and Natural gas. The gas

appliance regulator must be set for the gas with which the appliance is used.

Surface adjacent to cook top-left (7100)................................ 1” (25mm)

Surface adjacent to cook top-right (7100) .............................0” (0mm)

Surface adjacent to cook top (9100) ..................................... 0” (0mm)

Surface adjacent to warming oven......................................... 0” (0mm)

Cook top to underside of adjacent cabinets .......................... 18”(457 mm)

Cook top to underside of cabinets......................................... 30 1/4” (768 mm)

Maximum depth of overhead cabinets ...................................13”(330 mm)

Maximum depth of counters ................................................. 24”(610 mm)

Maximum height of counters................................................. 36”(914 mm)

Rear clearance...................................................................... 0”

These symbols on the

nameplate mean the

product has been design

certified by American Gas

®

CERTIFIED

# 7285 S######

C

US

Association Laboratories

and Canadian Gas

Association Laboratories.

32

Page 37

Wiring Diagrams

Technical Data

- Voltage 120 v / 60 Hz

- Load 3 amps (model 9100)

- Load 3 amps (model 7100)

NOTE: Service amperage should be

calculated by a qualified electrician.

The maximum propane/natural gas supply

inlet must not exceed 14 inches of water

column. The minimum gas supply inlet

should be at least 5 inches of water column

for natural gas or at least 11 inches of

water column for LP gas.

NOTE: Gas services should be checked

by a qualified gas technician.

7100

9100

33

Page 38

Loading...

Loading...