Healthrider HRSY23080 User Manual

¨

USERÕS MANUAL

Model No. HRSY23080

Serial No.

The serial number is found in the

location shown below. Write the

serial number in the space above.

CAUTION

Read all precautions and instructions in this manual before using

this equipment. Save this manual for future reference.

Serial

Number

Decal

PATENT PENDING

QUESTIONS?

As a manufacturer, we are

committed to providing complete

customer satisfaction. If you

have questions, or if there are

missing or damaged parts, we

will guarantee complete satisfaction through direct assistance

from our factory.

TO AVOID UNNECESSARY

DELAYS, PLEASE CALL DIRECT

TO OUR TOLL-FREE CUSTOMER

HOT LINE. The trained technicians on our customer hot line

will provide immediate assistance, free of charge to you.

CUSTOMER HOT LINE:

1-800-999-3756

Mon.ÐFri., 6 a.m.Ð6 p.m. MST

2

Important Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Cable Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Weight Resistance Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Trouble-shooting and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Ordering Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Back Cover

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Back Cover

Note: A PART LIST/EXPLODED DRAWING and a PART IDENTIFICATION CHART are attached to the center of

this manual. Remove the PART LIST/EXPLODED DRAWING and the PART IDENTIFICATION CHART before

beginning assembly.

WARNING: Before beginning this or any exercise program, consult your physician. This is especially

important for persons over the age of 35 or persons with pre-existing health problems. Read all

instructions before using. ICON assumes no responsibility for personal injury or property damage

sustained by or through the use of this product.

Table of Contents

Important Precautions

1. It is the responsibility of the owner to ensure

that all users of the home gym system are

adequately informed of all precautions.

2. Read all instructions in this manual and in

the accompanying literature before using the

home gym system.

3. If you feel pain or dizziness at any time while

exercising, stop immediately and begin cooling down.

4. Use the home gym system only on a level

surface. Cover the floor or carpet beneath the

home gym system for protection.

5. Inspect and tighten all parts often. Replace

any worn parts immediately.

6. Make sure the cables remain on the pulleys

at all times. If the cables bind while you are

exercising, stop immediately and make sure

the cables are on all of the pulleys.

7. Always stand on a foot plate when performing an exercise that could cause the home

gym system to tip.

8. Keep hands and feet away from moving parts.

9. Keep children under the age of 12 and pets

away from the home gym system at all times.

10. The home gym system is designed to be

used by only one person at a time.

11. Always wear athletic shoes for foot protection when exercising.

12. Never release the press arms, butterfly arms,

leg lever, lat bar or ab strap while weights are

raised. The weights will fall with great force.

13. Always disconnect the lat bar or ab strap

from the home gym system when performing

an exercise that does not use these attachments.

14. The home gym system is intended for home

use only. Do not use the home gym system in

a commercial, rental or institutional setting.

15. WARNING: Never use the home gym system

without having both shrouds attached.

16. Always set the butterfly arms in the storage

position when you are using the press arms.

Likewise, store the press arms when you are

using the butterfly arms.

To reduce the risk of serious injury, read the following important

precautions before using the home gym system.

WARNING:

3

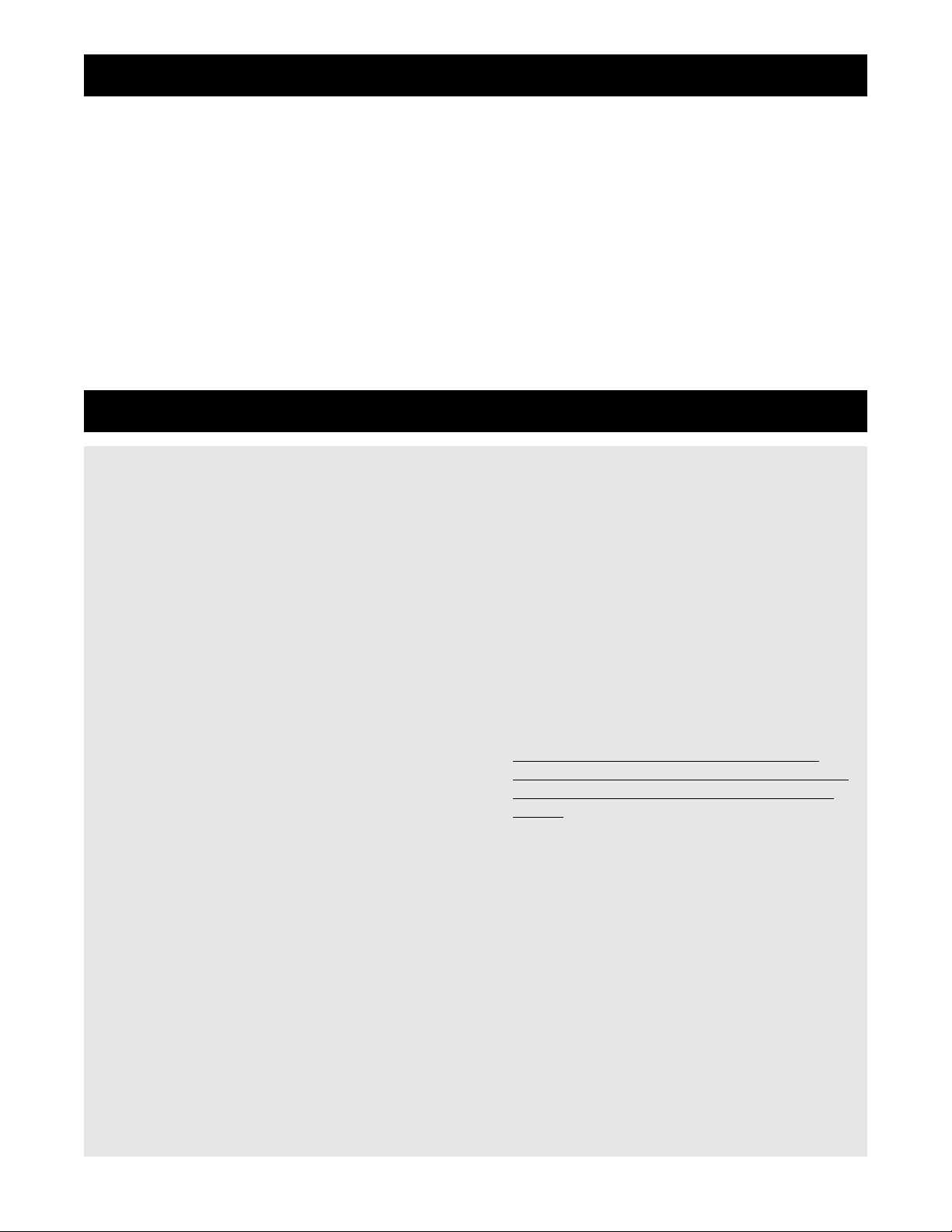

ASSEMBLED

DIMENSIONS:

Height: 81 in.

Width: 54 in.

Length: 67 in.

Low Pulley

Station

Foot Plate

Leg

Lever

Butterfly

Arm

Press Arms

Shroud

Covering

Weight Stack

Press Arm

Adjustment

Cam

Seat

Backrest

Thank you for selecting the innovative and versatile

HEALTHRIDER¨230 Home Gym System. The

HEALTHRIDER¨230 offers a unique selection of

weight stations designed to develop every major muscle group of the body. Whether your goal is to tone

your body, build dramatic muscle size and strength or

improve your cardiovascular system, the HEALTHRIDER¨230 makes it easy to achieve the results you want.

For your benefit, read this manual carefully before

using the HEALTHRIDER¨230 Home Gym System.

If you have additional questions, please call our

Customer Service Department toll-free at 1-800-9993756, Monday through Friday, 6 a.m. until 6 p.m.

Mountain Time (excluding holidays). To help us assist

you, please note the product model number and serial

number before calling. The model number is

HRSY23080. The serial number can be found on a

decal attached to the HEALTHRIDER¨230 Home Gym

System (see the front cover of this manual).

Please use the drawing below to familiarize yourself with the major parts and how they fit together.

Before You Begin

Weight Stack

Backrest

Adjustment

Knob

Press Arm

Adjustment

Knob

Adjustment

Disc

High Pulley

Station

Lat Bar

4

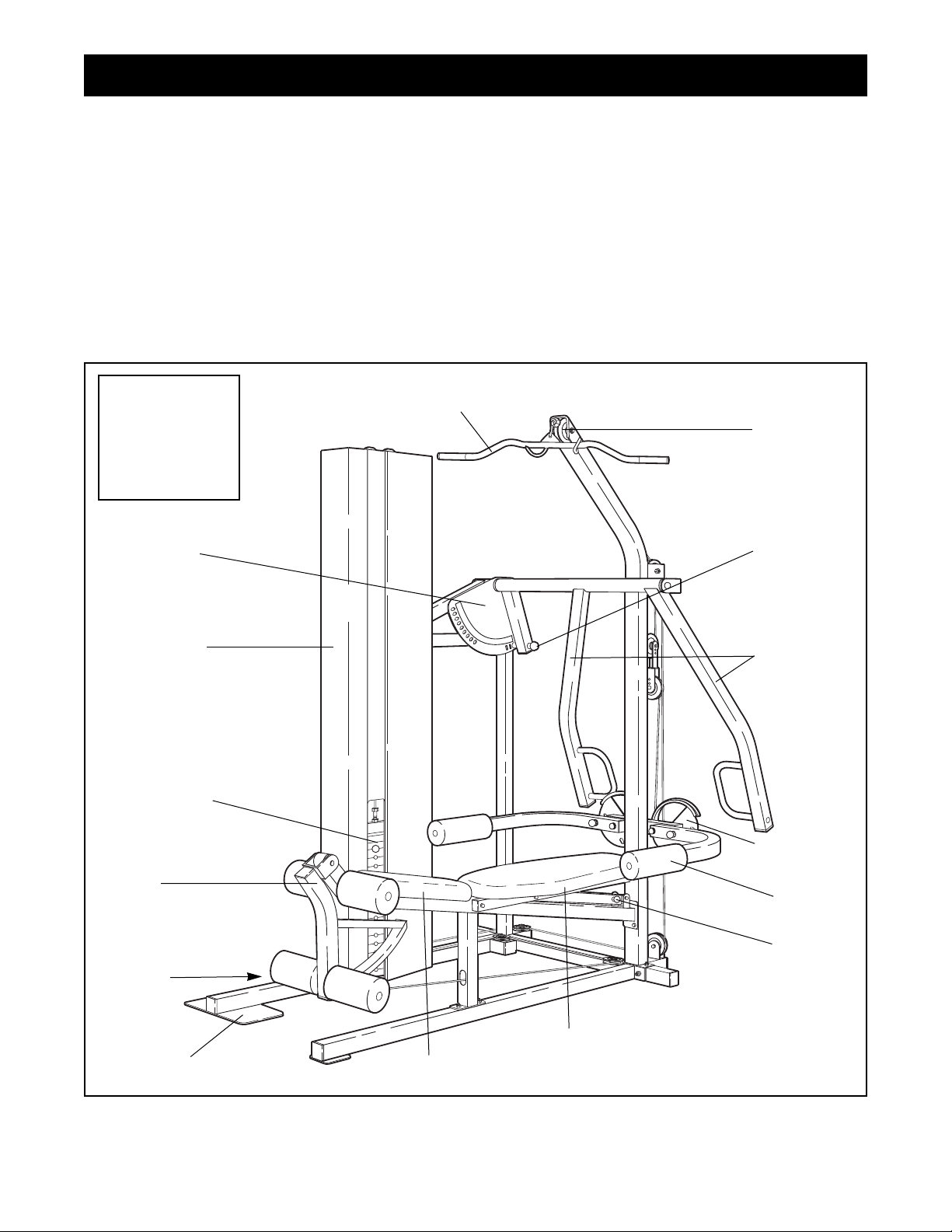

Note: This introduction will save you more

time than it takes to read it!

Identifying Parts

To help you identify the small parts used in assembly, we have included a PART IDENTIFICATION

CHART located in the center of this manual. Place

the chart on the floor or work table and use it to

quickly identify different parts as you open the packages for each step.

Note: Some small parts may have been pre-attached

for shipping. If a part is not in the parts bag, check to

see if it has been pre-attached.

Orienting Parts

As you assemble this product, be sure that all parts

are oriented as shown in the drawings.

Tightening of Parts

Tighten all parts as you assemble them, unless

instructed to do otherwise.

Lining Up the Tools

Assembly requires the following tools (not included):

¥ Two (2) adjustable wrenches

¥ One (1) standard screwdriver

¥ One (1) phillips screwdriver

¥ One (1) rubber mallet

¥ Lubricant, such as grease or petroleum jelly,

and soapy water

¥ Tape, such as clear tape or masking tape

Assembly will be more convenient if you have a

socket set, a set of open-end or closed-end wrenches

or a set of ratchet wrenches. Some assembly steps

require two people.

Giving Yourself a Good Start

Before you begin the assembly process itself, take

the time to complete the steps outlined here.

Clearing the Workspace

Clear a workspace that is large enough to hold all

parts and allow you to walk all the way around the

assembled equipment.

Unpacking the Box

To make the assembly process as smooth as possible, we have broken it into separate stages. All parts

used in each stage are found in individual packages

in the shipping box. Place all parts in a cleared area

and remove the packing materials. Do not dispose of

the packing materials until assembly is completed.

Important: Wait until you begin each assembly

stage to open the parts bag labeled for that

assembly stage.

Assembly

Making Things Easier for Yourself

Everything in this manual is designed to ensure

that the assembly of our products can be completed successfully by anyone. However, it is important to recognize that your new equipment is a

sophisticated product with many small parts. The

assembly process will take timeÑpossibly several

hours. Most people find that by setting aside plenty of time, and by deciding to make the task

enjoyable, assembly will go smoothly. You may

want to complete the process over a couple of

evenings.

The Four Stages of the Assembly Process

Frame Assembly

You will begin by assembling the base and the

upright frames that serve as the skeleton of the

equipment. The seat and all moving parts will later

be attached to the frame.

Arm Assembly

Completes the press and butterfly arms that you

operate while you are exercising.

Cable Assembly

Completes the cables and pulleys that connect the

moving arms with each other and with the weights.

This ties the different parts together and makes the

equipment function as a unit.

Seat Assembly

Completes the seat and backrest that support your

body while you are exercising.

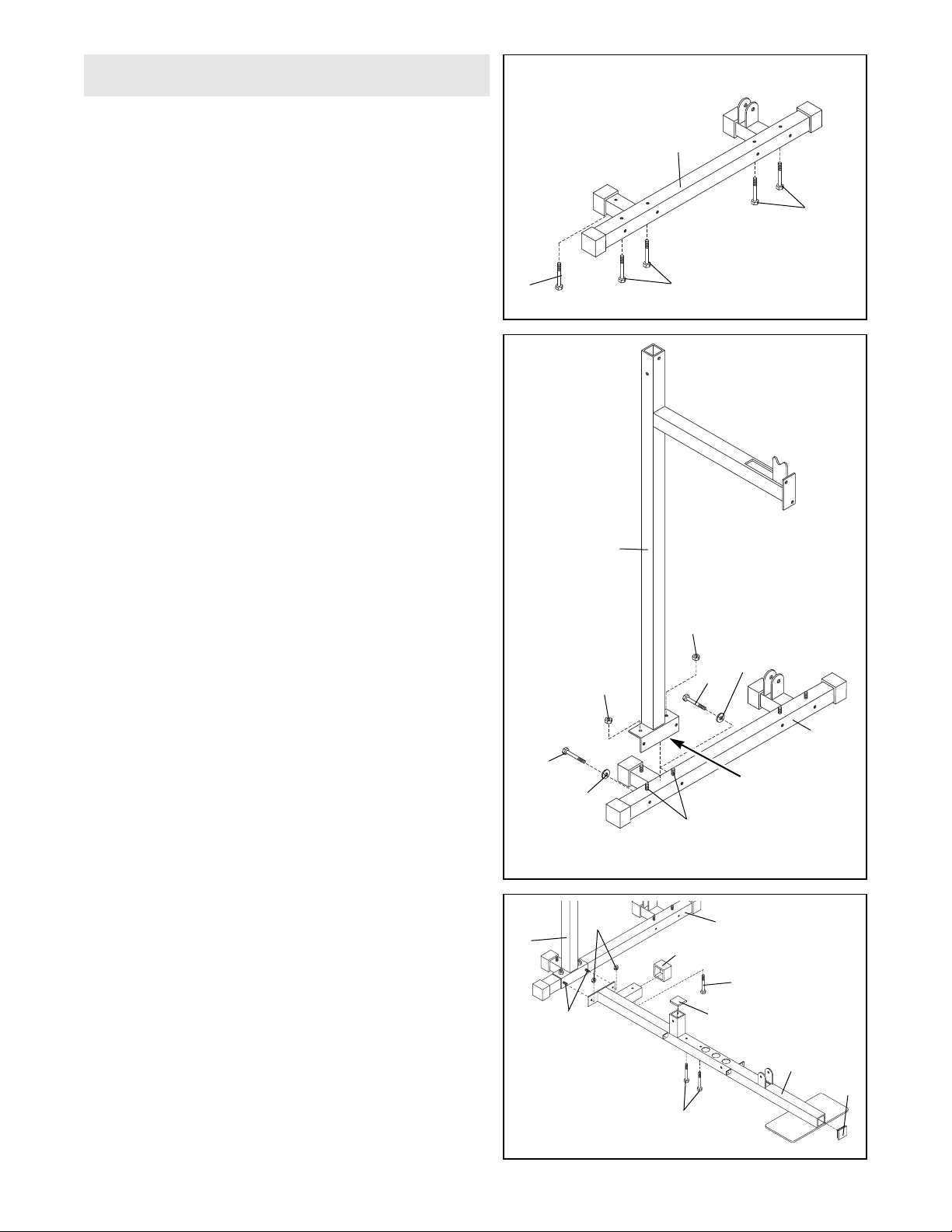

1. Before beginning, make sure that you have read

and understood the information on page 4.

Locate and open the parts bag labeled ÒFRAME

ASSEMBLY.Ó

Insert four 3/8Ó x 2 3/4Ó Carriage Bolts (45) up

through the indicated holes in the Stabilizer (4). Insert

a 3/8Ó x 3 1/2Ó Carriage Bolt (62) up through the hole

in the sidearm on the Stabilizer. Note: If the Bolts

tend to fall out, secure them by putting a small

piece of tape over the head of each Bolt. Place the

Stabilizer flat on the floor.

1

2. Place the bracket on the lower end of the Support

Upright (3) over the indicated 3/8Ó x 2 3/4Ó Carriage

Bolts (45) in the Stabilizer (4). Hand tighten two 3/8Ó

Nylon Locknuts (50) onto the Bolts. Do not tighten

the Nylon Locknuts yet.

CAUTION: Until step 3 has been performed, the

unit can easily tip over. Have one person hold the

Support Upright in position or lean it against a

wall.

Insert two 3/8Ó x 3Ó Bolts (53) with two 3/8Ó Flat

Washers (55) through the indicated holes in the

Stabilizer (4) and the bracket on the Support Upright

(3).

3. Press a 2Ó Square Inner Cap (28) into the end of the

Weight Base (5).

Press a 2Ó Square Inner Cap (28) into the end of the

riser on the Weight Base (5).

Press a 2Ó Square Cover Cap (33) onto the sidearm

on the Weight Base (5).

Insert two 3/8Ó x 2 3/4Ó Carriage Bolts (45) up through

the indicated holes in the Weight Base (5) and secure

the bolt heads with pieces of tape to prevent them

from falling out.

Insert a 3/8Ó x 3 1/2Ó Carriage Bolt (62) up through

the hole in the sidearm on the Weight Base (5) and

secure the bolt head with tape.

Place the Weight Base (5) on the floor with the holes

in the mounting bracket over the 3/8Ó x 3Ó Bolts (53)

going through the Stabilizer (4) and the bracket on

the Support Upright (3). Hand tighten two 3/8Ó Nylon

Locknuts (50) onto the Bolts. Do not tighten the

Nylon Locknuts yet.

2

3

5

Frame Assembly

45

4

62

45

53

55

45

4

53

55

Bracket

3

50

50

5

45

3

50

28

53

28

62

33

4

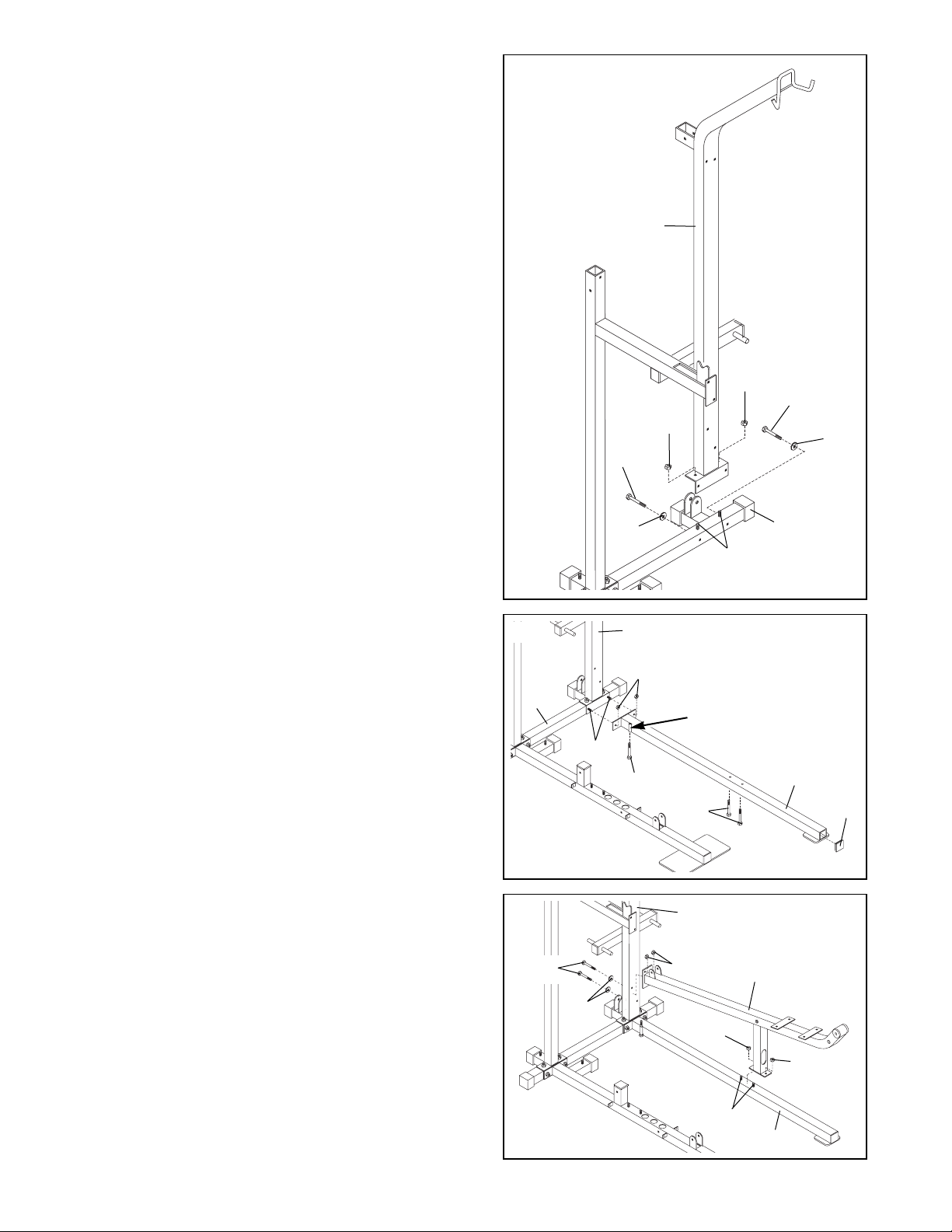

4. Place the bracket on the lower end of the Main

Upright (1) over the indicated 3/8Ó x 2 3/4Ó Carriage

Bolts (45) in the Stabilizer (4). Hand tighten two 3/8Ó

Nylon Locknuts (50) onto the Bolts. Do not tighten

the Nylon Locknuts yet.

Insert two 3/8Ó x 3Ó Bolts (53) with two 3/8Ó Flat

Washers (55) through the indicated holes in the

Stabilizer (4) and the bracket on the Main Upright (1).

4

6

5. Press a 2Ó Square Inner Cap (28) into the end of the

Seat Base (6).

Insert two 3/8Ó x 2 3/4Ó Carriage Bolts (45) up through

the indicated holes in the Seat Base (6) and secure

the bolt heads with pieces of tape to prevent them

from falling out.

Insert a 3/8Ó x 3 1/2Ó Bolt (56) up through the welded

tube on the Seat Base (6) and secure the bolt head

with tape.

Place the Seat Base (6) on the floor with the holes in

the mounting bracket over the 3/8Ó x 3Ó Bolts (53)

going through the Stabilizer (4) and the bracket on

the Main Upright (1). Hand tighten two 3/8Ó Nylon

Locknuts (50) onto the Bolts. Do not tighten the

Nylon Locknuts yet.

5

50

53

55

50

53

55

4

1

1

4

45

2845

56

6

53

50

6. Place the Seat Frame (7) onto the 3/8Ó x 2 3/4Ó

Carriage Bolts (45) in the Seat Base (6). Hand tighten

two 3/8Ó Nylon Locknuts (50) onto the Bolts. Do not

tighten the Nylon Locknuts yet.

Locate two 3/8Ó x 3Ó Bolts (53) and slide a 3/8Ó Flat

Washer (55) onto each Bolt. Insert the 3/8Ó x 3Ó Bolts

through the indicated holes in the Main Upright (1)

and the bracket on the Seat Frame (7). Hand tighten

two 3/8Ó Nylon Locknuts (50) onto the Bolts. Do not

tighten the Nylon Locknuts yet.

6

45

6

50

55

50

7

50

Welded Tube

53

1

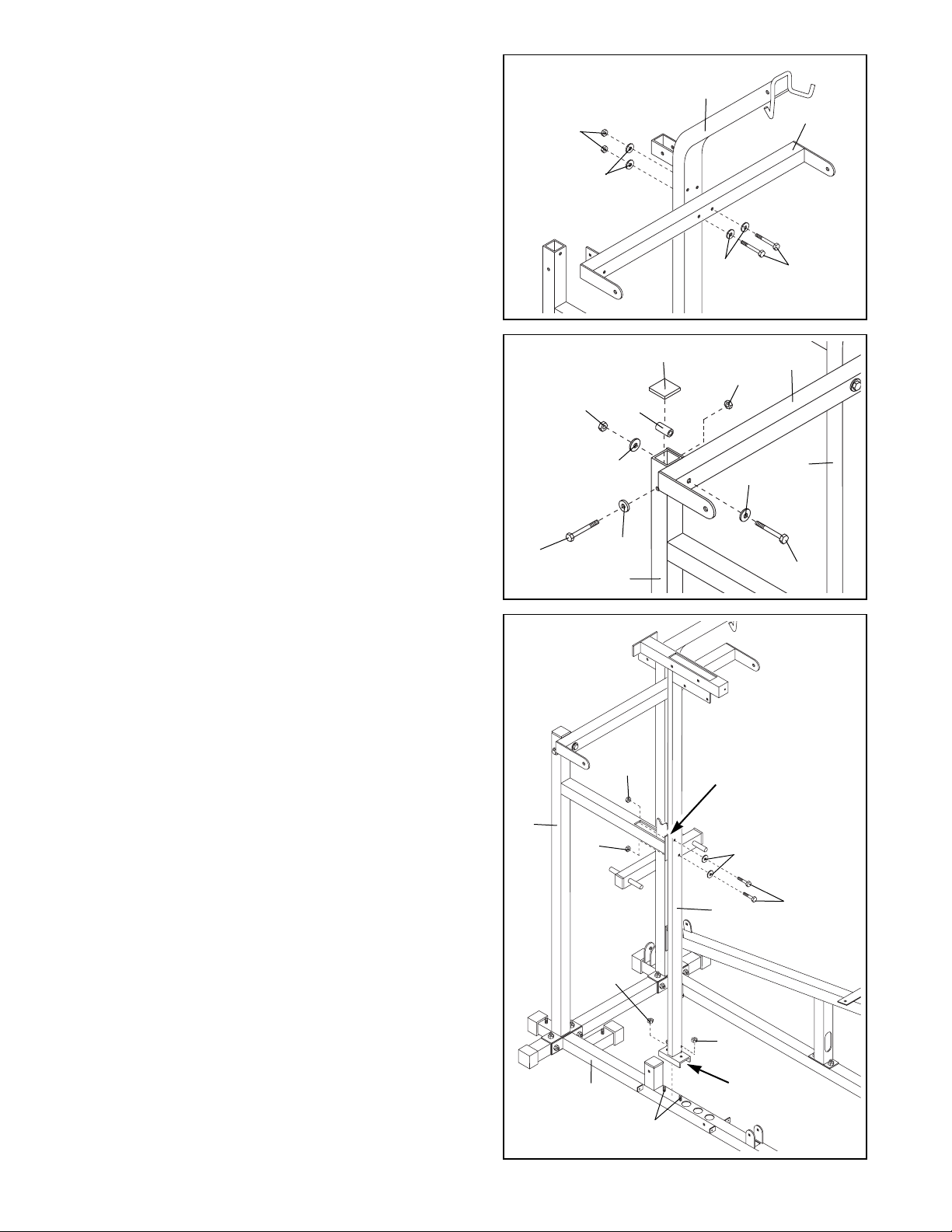

9. Place the bracket on the lower end of the Weight

Upright (2) over the indicated 3/8Ó x 2 3/4Ó Carriage

Bolts (45) in the Weight Base (5). Hand tighten two

3/8Ó Nylon Locknuts (50) onto the Bolts. Do not tight-

en the Nylon Locknuts yet.

Locate two 3/8Ó x 1 3/4Ó Bolts (57) and slide a 3/8Ó

Flat Washer (55) onto each of them. Insert the Bolts

through the indicated holes in the Weight Upright (2)

and then through the bracket on the Support Upright

(3). Secure the Bolts with two 3/8Ó Nylon Locknuts

(50).

Go back and fully tighten all Nylon Locknuts used

in steps 2 through 9.

9

7

7. Locate two 3/8Ó x 4 3/4Ó Bolts (46) and slide a 3/8Ó

Flat Washer (55) onto each of them. Insert the Bolts

through the indicated holes in the Top Frame (9) and

then through the holes in the Main Upright (1). Slide a

3/8Ó Flat Washer onto each Bolt and secure it with a

3/8Ó Nylon Locknut (50). Do not tighten the Nylon

Locknut yet.

7

8. Slide a 3/8Ó Flat Washer (55) onto a 3/8Ó x 4 3/4Ó Bolt

(46) and push the Bolt through the Top Frame (9).

Push the Bolt into the hole in the Support Upright (3)

until the tip of the Bolt is visible inside the Upright.

Slide the 1/2Ó x 1 13/16Ó Bushing (84) down into the

Upright and push the Bolt all the way through the

Bushing and the Upright. Note: Make sure you donÕt

drop the Bushing into the Upright!

Slide a 3/8Ó Flat Washer (55) onto the Bolt and

secure it with a 3/8Ó Nylon Locknut (50). Do not

tighten the Nylon Locknut yet.

Slide a 3/8Ó Flat Washer (55) onto a 3/8Ó x 2 3/4Ó Bolt

(47) and insert the Bolt through the hole in the

Support Upright (3) and the bracket on the Top Frame

(9). Hand tighten a 3/8Ó Nylon Locknut (50) onto the

Bolt. Do not tighten the Nylon Locknut yet.

8

45

5

50

3

50

50

55

2

50

57

55

50

Bracket

Bracket

1

9

55

46

28

9

50

55

55

1

55

47

3

84

50

46

8

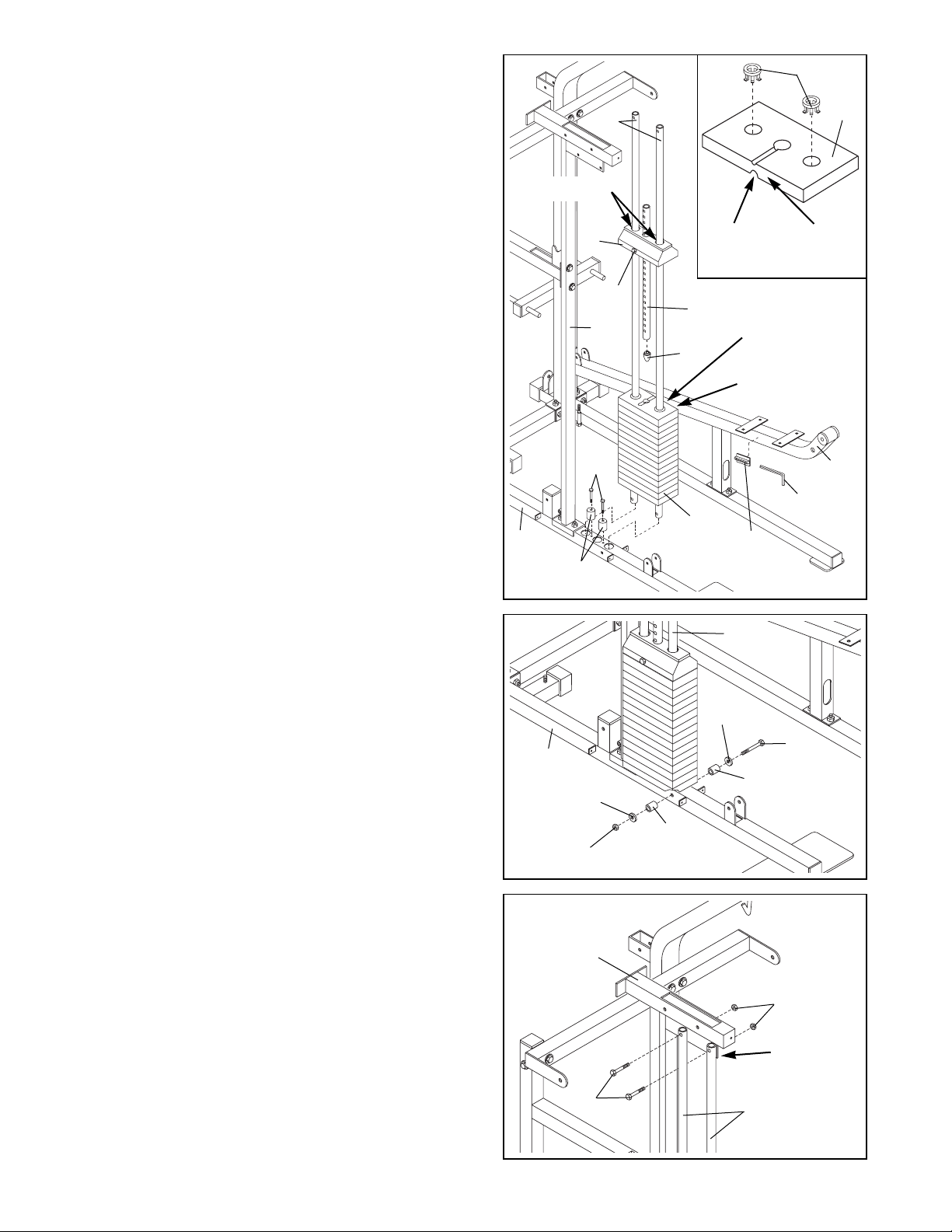

12. Attach the upper ends of the Weight Guides (15) to

the welded bracket underneath the Weight Upright (2)

with two 3/8Ó x 1 3/4Ó Bolts (57) and two 3/8Ó Nylon

Locknuts (50). Tighten, but do not overtighten, the

Nylon Locknuts.

12

11. Slide a 3/8Ó Flat Washer (55) and a 5/8Ó x 1/2Ó

Bushing (85) onto a 3/8Ó x 2 3/4Ó Bolt (47). Line up

the hole in the indicated Weight Guide (15) with the

hole in the Weight Base (5). Slide the 3/8Ó x 2 3/4Ó

Bolt through the Weight Guide and the Weight Base.

Slide a 5/8Ó x 1/2Ó Bushing (85) onto the Bolt. Secure

the Bolt with a 3/8Ó Flat Washer (55) and a 3/8Ó Nylon

Locknut (50).

11

85

85

47

5

55

55

15

57

50

2

50

15

10. Attach two Bumpers (40) to the Weight Base (5) with

two #8 x 1Ó Screws (78). Insert the two Weight Guides

(15) through the indicated holes in the Weight Base

(5).

See the inset drawing. Press two Weight Inserts (77)

into the indicated holes in each Weight (21). Make

sure the large pin groove is pointed downward, as

shown. Slide all of the included Weights (21) onto

the two Weight Guides (15). Make sure the Weights

are oriented correctly. The adjustment holes must

be turned towards the center of the unit, as

shown.

For packaging purposes, the Top Weight (16) is

mounted in the upper threaded hole in the Weight

Tube (17). Unless you have bought the Weight

Expansion Set with five extra weight plates along with

your system, the Top Weight must be moved. Use the

Allen Wrench (100) to loosen the Button Head Screw

(52) and slide the Top Weight down to the lower of

the two threaded holes in the Weight Tube, as

shown. Lubricate the insides of the holes in the Top

Weight (16). Press the Weight Tube Bumper (18) into

the indicated end of the Weight Tube (17). Slide the

Weight Tube (17) with the Top Weight (16) onto the

Weight Guides (15). Attach the Allen Wrench Holder

(79) to the indicated location on the Seat Frame (7)

Locate the decal sheet with the stickers showing the

numbers 1 through 15. Place a sticker on each

Weight (21) and the Top Weight (16) right next to the

adjustment holes (see the inset drawing). The Top

Weight must have the number 1 on it.

10

5

15

16

52

17

18

100

7

79

2

78

40

21

77

21

Large Pin

Groove

Number

Decal

Adjustment

Holes on this

side

Place Stickers

on this side

Lubricate

Welded

Bracket

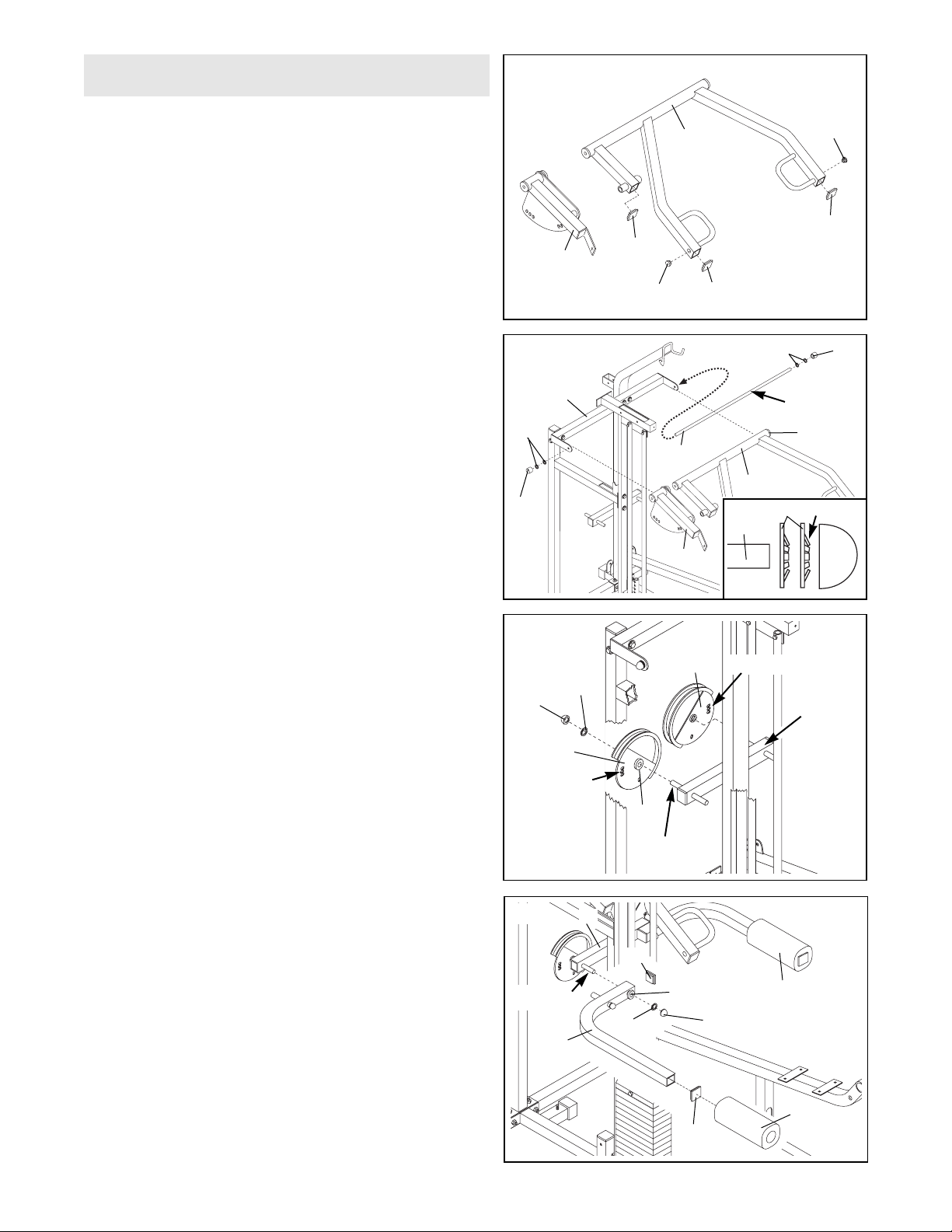

14. Tap two 1Ó Retainer Rings (32) and a 1Ó Round Cover

Cap (81) onto one end of the Press Frame Tube (34).

Lubricate the Press Frame Tube in its entire length.

Note: Use the Cover Cap to tap on the Retainer

Rings. Make sure the teeth on the Retainer Rings

bend towards the Cover Cap (see inset drawing).

Have one person lift up the Press Frame (8) while a

second person slides the indicated end of the Press

Frame Tube (34) through the bracket on the Top

Frame (9) and the pre-assembled Large Bushings

(44) in the Press Frame. Hold up the Press

Adjustment Frame (14) and slide the Press Frame

Tube through it and the bracket on the Top Frame.

Secure the Press Frame Tube with two 1Ó Retainer

Rings (32) and a 1Ó Round Cover Cap (81).

9

16. Press two 2Ó Square Inner Caps (28) into the open

ends of each Butterfly Arm (10). Wet the end of each

Arm with soapy water. Slide a Butterfly Foam Pad

(29) onto the indicated end of each Arm. Make sure a

Butterfly Bushing (88) has been pre-assembled on

each side of the Butterfly Arms.

Lubricate the indicated rod on the crossbar attached

to the Main Upright (1). Orient one Butterfly Arm (10)

as shown and slide it onto the rod. Secure the

Butterfly Arm with a 3/4Ó Retainer Ring (31) and a

3/4Ó Dome Cap (82). Make sure the teeth on the

Retainer Ring bend towards the Dome Cap as

shown above. Assemble the other Butterfly Arm (10)

on the opposite side of the crossbar. Follow the procedure described above, but orient the Butterfly Arm

as shown.

16

13. Press Arm AssemblyÑLocate and open the parts

bag labeled ÒARM ASSEMBLY.Ó

Press a 2Ó Square Inner Cap (28) into the open end

of each press arm on the Press Frame (8). Press a 1Ó

Round Inner Cap (58) into each of the indicated holes

on the press arms. Locate the Press Adjustment

Frame (14).

13

28

14

58

32

14

81

32

9

81

14

8

34

44

28

1

29

10

10

31

82

88

28

15. Butterfly Arm Assembly. Identify the Left Adjustment

Disc (26) and Right Adjustment Disc (27) by looking

at the three adjustment holes and orienting the Discs

as shown in the drawing. Make sure a Butterfly

Bushing (88) has been pre-assembled on each side

of the Adjustment Discs. Lubricate the indicated rod

on the crossbar attached to the Main Upright (1).

Slide the Right Adjustment Disc (27) onto the rod.

Secure the Adjustment Disc with a 3/4Ó Retainer Ring

(31) and a 3/4Ó Dome Cap (82). Assemble the Left

Adjustment Disc (26) in the same manner. Make sure

the teeth on the Retainer Ring bend towards the

Dome Cap as shown above.

15

82

31

26

Adjustment

Holes

Adjustment Holes

Crossbar

27

58

28

8

Arm Assembly

28

Teeth

34

81

32

88

Lubricate

Lubricate

Lubricate

Loading...

Loading...