Page 1

ZIPSTOP

ZIP LINE

BRAKE

Installation, Operation & Maintenance Manual

Models: ZS125-08 / ZSIR150-20A

NOTE TO INSTALLERS

Always Read Instructions Before Use

Leave this manual attached to the zipSTOP Brake unit. The Installation, Operation

and Maintenance manual contains information relating to the proper use of the

zipSTOP and includes all product registration and warranty information. This document may only be removed by the end user prior to operation. Ensure that this

manual is readily available to operators at all times.

Head Rush Technologies zipSTOP Zip Line Brake Installation, Operation & Maintenance Manual

P/N 01170006604

Head Rush Technologies products are covered by a number of patents, including

U.S. Patents 8,490,751; 8,851,235; 9,016,435; 8,851,235 and D654,412 & corresponding patents/applications in the USA and in other countries worldwide.

Page 2

TABLE OF CONTENTS

1. SAFETY INFORMATION 7

1.1 Symbols Used in this Manual

2. EMERGENCY ARREST DEVICE EAD CONFIRMATION 8

3. SAFETY & INFORMATION LABELS 9

3.1 Location of Safety Labels

4. WARRANTY INFORMATION 10

4.1 Warranty Conditions

4.2 Customer Responsibility

5. SPECIFICATIONS 11

5.1 Introduction

5.2 zipSTOP Brake Unit, ZS125-08

5.3 zipSTOP Brake Unit, ZSIR150-20A

5.4 zipSTOP Brake Trolley, ZS125-08 and ZSIR150-20A

6. OPERATING PRINCIPLES 15

6.1 General

7. ZIPSTOP BRAKE ASSEMBLY 16

7.1 General

7.2 Unpacking the zipSTOP

7.3 Long Term Storage

7.4 Supplied Parts

7.5 General and Additional Parts Required

7.6 Redirection Pulleys

7.7 Traveler Assembly

7.8 Minimum Hardware Requirements

7.9 Redirection Line

7.9.1 Redirection Line Specifications: ZS125-08/ZS150-20A

8. ZIPSTOP BRAKE ASSEMBLY CONFIGURATION 22

8.1 General

8.2 Setup Variables, ZS125-08/ZSIR150-20A

8.3 Rider Arrival Speed

8.4 Rider Weight

8.5 Redirection Line Ratio

8.5.1 1:1 Ratio

8.5.2 2:1 Ratio

8.6 POSSIBLE SYSTEM CONFIGURATIONS (INFORMATIVE ONLY)

8.6.1 3:1 Ratio

8.6.2 Other Configurations

8.7 Zip Line Slope

8.7.1 Positive Slope Line

8.8 Flat Line

8.9 Negative Slope Line

8.10 Calculating zipSTOP Braking Distances

8.10.1 Definition of Terms

7

9

10

10

11

12

13

14

15

16

16

17

18

18

19

19

20

20

21

22

22

23

23

23

24

25

26

26

27

27

28

28

29

29

30

www.headrushtech.com | +1-720-565-6885

3

Page 3

8.11 zipSTOP Braking Distance Charts

8.12 Configuration Notes

8.13 zipSTOP Configuration Worksheet

31

31

33

9. ZIPSTOP BRAKE ASSEMBLY INSTALLATION 34

9.1 General

9.2 Safety Precautions

9.3 Primary Anchor Point

9.4 Secondary Anchor Point

9.4.1 Position of the Secondary Anchor Point

9.5 Redirection and Support Lines

9.6 Fitting zipSTOP Brake Unit

9.7 Fitting the Brake Trolley

9.8 Fitting Type I Pulley

9.9 Fitting Type II Pulley

9.10 Fitting Redirection Line

9.11.1 1:1 Redirection Ratio

9.11.2 2:1 Redirection Ratio

34

34

35

35

36

36

37

40

42

43

43

44

46

10. OPERATION OF ZIPSTOP 49

10.1 Safety Precautions

10.2 zipSTOP Operation as a Primary Brake

10.3 zipSTOP Operation as an EAD

10.4 Landing Areas

10.5 Operation During Extreme Weather Conditions

10.6 Resetting the Brake

10.7 Operational Retraction Spring Cycle Limit

49

50

50

50

51

51

52

11. TROUBLESHOOTING 53

11.1 Before You Call

57

12. RECERTIFICATION AND MAINTENANCE 58

12.1 General

12.2 Annual Recertification

12.3 Maintenance Service Schedule

12.4 Daily Inspections

12.4.1 Safety Precautions

12.4.2 Webbing Wear

12.5 Braking Line Replacement Procedure

12.6 Brake Trolley Inspection and Maintenance

12.7 Brake Unit Casing Inspection

12.8 Webbing Line Inspection

58

58

58

59

59

60

63

65

65

66

13. BRAKING DISTANCE CHARTS 67

13.1 How to Read Braking Distance Charts

13.2 1:1 Ratio – Metric, ZSIR150-20A

13.3 1:1 Ratio – Imperial, ZSIR150-20A

67

68

68

4

www.headrushtech.com | +1-720-565-6885

Page 4

13.4 1:1 Ratio – Metric ZS125-08

13.5 1:1 Ratio – Imperial ZS125-08

13.6 2:1 Ratio – Metric, ZS125-08

13.7 2:1 Ratio – Imperial, ZS125-08

13.8 3:1 Ratio – Metric

13.9 3:1 Ratio – Imperial

69

69

70

70

71

71

14. APPENDIX A: EAD WARRANTY/REGISTRATION FORM 72

14.1 Warranty Registration Form

72

15. APPENDIX B: ACCESSORIES AND REPLACEABLE PARTS 73

15.1 Accessories and Replacement Parts

15.2 Brake Trolley Catch Accessory

15.2.1 Specifications

15.2.2 Composition

15.2.3 Mounting/Installation

15.2.4 Operation

15.2.5 zipSTOP Brake Unit Side Cover Replacement

15.2.6 zipSTOP Brake Unit Nozzle Replacement

15.2.7 Removing Nozzle Assembly

15.2.8 To Refit the Nozzle Assembly:

15.2.9 Brake Trolley Bump Stop Replacement

15.2.10 Service Life

15.3 zipSTOP Pivot Mount

15.3.1 Composition

15.3.2 Mounting

15.3.3 Installation

15.3.4 Performance

15.3.5 Service Life

15.3.6 Inspection Procedures

73

73

74

74

74

77

80

80

80

81

82

82

82

83

83

84

86

86

87

16. APPENDIX C: EXAMPLE INSPECTION LOGS 88

17. MANUFACTURER’S DETAILS 90

www.headrushtech.com | +1-720-565-6885

5

Page 5

IMPORTANT SAFETY NOTICE

Zip Lining is a Dangerous Activity

Read Before Installation & Operation

Failure by the installer or operator to heed any and all instructions, warnings and cautions for the correct

installation, operation, care and maintenance of the zipSTOP may result in serious injury or death.

The zipSTOP Brake assembly, including zipSTOP Brake Unit Model ZB125-08B and ZSIR150-20A, zipSTOP

Brake Trolley Model ZT125-17 and all associated equipment are designed and specified for use in the recreational zip line industry as components of a well designed zip line brake system. Use of the zipSTOP components for any purposes other than that intended by the manufacturer is not permitted.

The zipSTOP is designed to be utilized as a Primary Brake or Emergency Arrest Device (EAD). When using the

zipSTOP as a primary brake, the installer MUST utilize an independent EAD to protect against operator error

and third party equipment failure. Design and installation of the zip line, including the complete braking system, is the responsibility of the installer or operator.

Owners and Operators of zipSTOP devices are responsible for the safety and supervision of any person using

the zipSTOP and are required to assure that proper installation and operation procedures are followed at all

times. Proper installation requires careful design and planning using zipSTOP and non-zipSTOP components.

Owners and Operators are encouraged to seek the advice of their zip line installer or a proper engineering

professional regarding the instructions in this Manual.

These instructions must be made readily available to the operator at all times. Prior to installation and use, all

owners, installers and operators must have read and shown to have understood all instructions, labels, markings,

and safety information pertaining to the installation, operation, care, and maintenance of the zipSTOP brake, its

component parts, and all associated hardware. Failure to do so may result in equipment damage, serious injury

and death.

Page 6

1. SAFETY INFORMATION

1.1 Symbols Used in this Manual

The following safety symbols are used throughout this manual to highlight potential danger to operators and

equipment. One or more precautions may be associated with practices and procedures described within this

manual. Failure to adhere to any precautions highlighted can result in equipment damage, serious injury and/

or death.

Ensure that you read and understand all safety related procedures related to the working environment and the

task you are undertaking.

DANGER

Indicates a hazardous situation exists that, if not avoided, will result in serious injury or death.

WARNING

Indicates a potentially hazardous situation that, if not avoided, could result in serious injury or

death.

CAUTION

Indicates a potentially hazardous situation that, if not avoided, may result in injury or equipment damage.

NOTE

Indicates an action that must be taken to ensure personal safety and prevent damage to

property or equipment.

CARE FOR THE ENVIRONMENT

Take care to minimize impact on the environment when carrying out this procedure.

www.headrushtech.com | +1-720-565-6885

7

Page 7

2. EMERGENCY ARREST DEVICE (EAD) CONFIRMATION

Zip lines using the zipSTOP Brake are required to use both primary and emergency arrest devices functioning

together to arrest the motion of passengers. The EAD must engage with no input from the passenger upon

failure of the primary arrest device.

This form must be initialed by the performing EAD installation technician, signed by a separate party and attached when mailing in the Warranty Registration Form; failure to do so may void your warranty .

I have read this manual prior to zipSTOP installation and use. INITIAL:

I am aware that an approved EAD is required prior to system use. INITIAL:

I certify that an approved EAD has been correctly installed prior to system use. INITIAL:

I have inspected the installation of the EAD and certify its functionality.

SIGNED: DATE:

8

www.headrushtech.com | +1-720-565-6885

Page 8

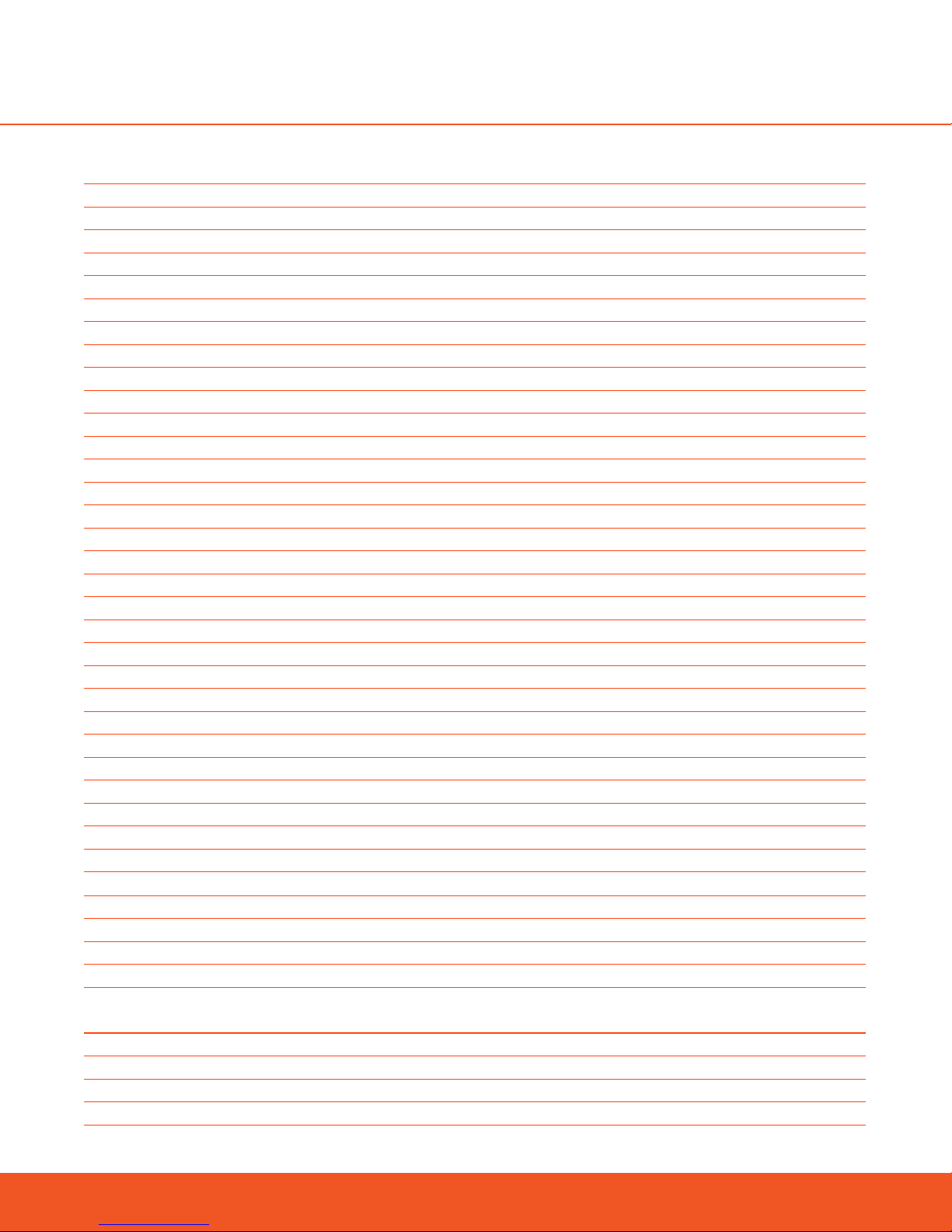

3. SAFETY & INFORMATION LABELS

Safety and Information Labels located on the zipSTOP components are not to be removed. Ensure labels are

in place and remain legible at all times.

3.1 Location of Safety Labels

www.headrushtech.com | +1-720-565-6885

Location of Labels – Brake Unit

Location of Labels – Brake Trolley

9

Page 9

4. WARRANTY INFORMATION

4.1 Warranty Conditions

Manufacturers sole warranty. The zipSTOP Brake assembly will be sold free from defects in materials and

workmanship, excluding field replaceable wear parts, for a period of one (1) year from date of purchase. This

warranty only applies to the original purchaser, and is contingent upon the owner/operator using and maintaining the device in accordance with the zipSTOP instructions, including the requirement to maintain annual

recertification as described in the Installation, Operation and Maintenance Manual.

THIS WARRANTY IS EXPRESSLY IN LIEU OF OTHER WARRANTIES, EXPRESS OR IMPLIED, AND ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE IS HEREBY EXPRESSLY EXCLUDED.

The sole remedy for breach of said warranty or for any claim in negligence or strict liability in tort is the repair

or replacement of any defective parts at the discretion of the manufacturer. Such parts claimed to be defective shall be returned to the Head Rush Technologies Service Center, transportation prepaid, for inspection by

zipSTOP to determine to its satisfaction that said part(s) are defective.

This warranty is null and void if other than genuine parts are used, or if any modifications are carried out to the

zipSTOP Brake assembly or zipSTOP components without the expressed written permission of the manufacturer. No person, Agent or Distributor is authorized to give any warranty, other than the one herein expressed,

on behalf of the zipSTOP Company or to assume for it any liability pertaining to such products. The company

makes no warranties in respect to trade accessories or component parts which are not manufactured by the

company, same being subject only to such warranties, if any, as may be made by their respective manufacturers.

4.2 Customer Responsibility

The following items are considered to be the responsibility of the Customer and, therefore, are non-reimbursable under the terms of the warranty:

Correct installation of an EAD.

Sucient unmanned testing of the entire system.

Normal maintenance/routine services.

Normal replacement of service items.

Replacements required because of abuse, misuse or incorrect operation of equipment by the installer or

operator.

Field replaceable wear parts such as the nozzle, braking line, quick links, redirection line and pulleys,

brake trolley sacrificial bump stops, and sheaves supplied as zipSTOP branded parts.

Normal wear and tear due to use and exposure.

Strict adherence to the Installation, Operation and Maintenance Manual supplied, manufacturer’s instructions

and advice given by zipSTOP service technicians is also a condition of warranty (see Appendix A: EAD Warranty/Registration Form).

10

www.headrushtech.com | +1-720-565-6885

Page 10

5. SPECIFICATIONS

5.1 Introduction

The zipSTOP Brake assembly is a controlled braking force device designed specifically for use in the zip line

industry as a Primary or EAD at the end of zip line runs. The zipSTOP caters to a range of rider weights and

approach speeds, and oers a smooth, consistent braking force for all riders. The brake is designed to be

mounted to a primary and/or secondary anchor point to slow the decent of riders on a zip line. The primary

anchor point is exactly what it sounds like; it is the main attachment point for the brake. The secondary anchor point is the support point for the redirection lines and pulleys.

The zipSTOP Brake Unit is installed at the end of the zip line, usually on or adjacent to the terminal end. A

Secondary Anchor Point is normally required upstream of the landing area to provide support for the Redirection Line pulleys. Alternately a full-length secondary cable of sucient capacity can be installed to provide

support for the Redirection Line and associated pulleys.

The design of the zipSTOP allows for simple installation, and incorporates both an advanced self-regulating

brake unit and an automatic line reset. The patented braking mechanism delivers smooth deceleration and

is designed to minimize variations in the deceleration rate and stopping distance of both children and adults.

There are no friction parts in the brake mechanism, ensuring reliability remains high while maintenance and

operating costs are kept to a minimum.

Installation, inspection, operation and maintenance must be carried out in accordance with the instructions in

this manual to protect the longevity of the zipSTOP components.

Pictures in this manual are for reference purposes in terms of geometry and proposed redirection setup

configuration only. Mandated EAD may or may not be shown.

www.headrushtech.com | +1-720-565-6885

11

Page 11

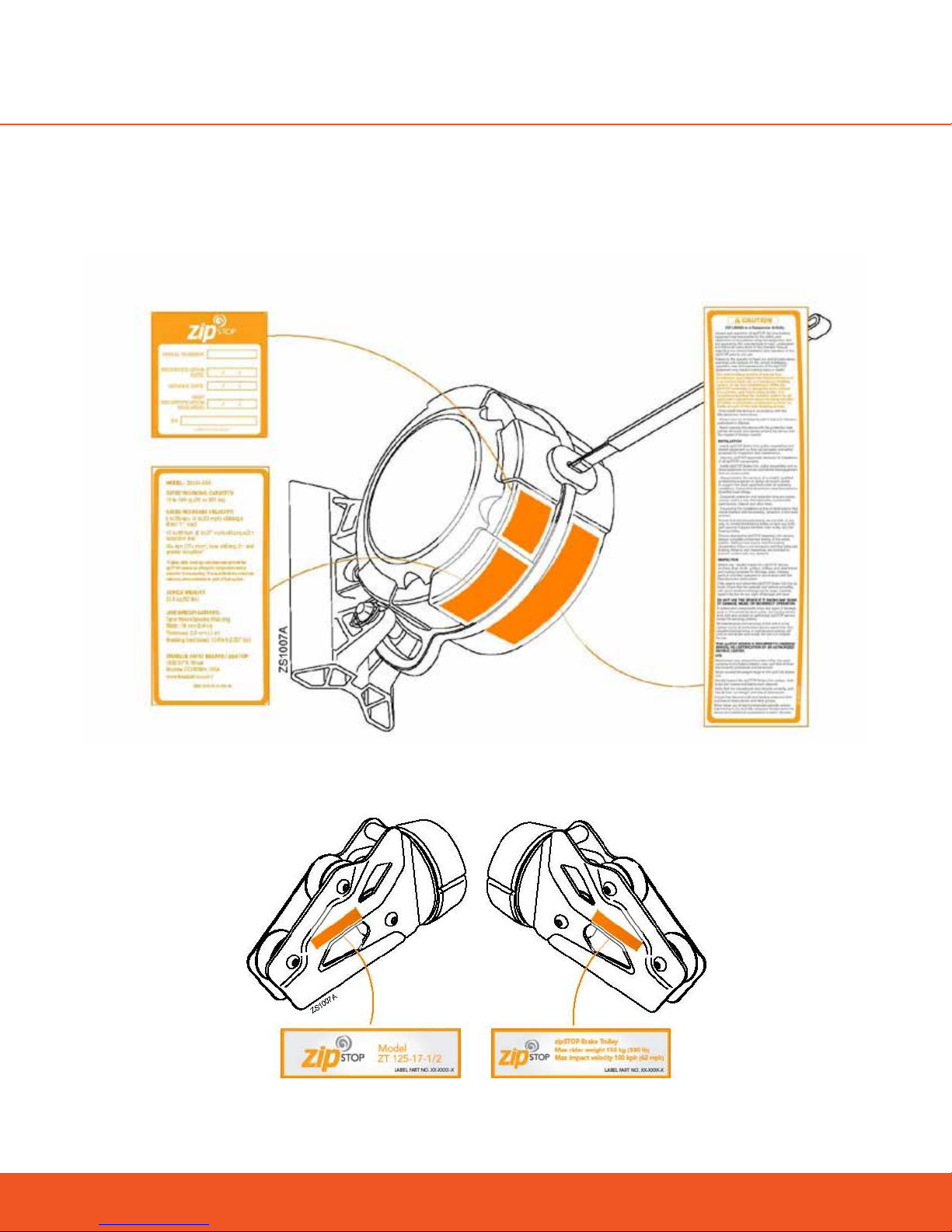

5.2 zipSTOP Brake Unit, ZS125-08

zipSTOP Mount

Top Mounting Pin

Fully Retracted - 400 mm (16”)

Side Cover

MODEL ZS 125-08B

CLASSIFICATION Zip Line Braking Device

zipSTOP Brake Unit

Nozzle Assembly

Braking Line

Pulley

DIMENSIONS 380 x 320 x 216 mm (15 x 12.6 x 8.5 in)

NET WEIGHT 23.5 kg (52 lbs)

OPERATING TEMPERATURE -10°C (14°F) to 40°C (104°F)

STORAGE TEMPERATURE -20°C (-4°F) to 60°C (140°F)

MATERIALS CASING Aluminium alloy

INTERNAL PARTS Zinc plated and stainless steel

NOZZLE Modified Acetal plastic with stainless insert

LINE 20 mm Nylon Spectra Braking Line

MAXIMUM LINE EXTENSION 12.5 m (41 ft)

RIDER WEIGHT RANGE 15 to 150 kg (33 - 330 lbs)

MAXIMUM SPEEDS 1:1 REDIRECTION RATIO 36 km/h (22 mph)

2:1 REDIRECTION RATIO 60 km/h (37 mph)

3:1 REDIRECTION RATIO* Contact Head Rush Tech

CUSTOM RATIO* Contact Head Rush Tech

*Higher speeds may be utilized with the custom Redirection Ratios, however braking distances will increase.

When planning a custom ratio, note that the automatic line reset may become compromised, requiring the

necessity for either manual reset or supplementary reset.

12

www.headrushtech.com | +1-720-565-6885

Page 12

5.3 zipSTOP Brake Unit, ZSIR150-20A

zipSTOP Mount

Top Mounting Pin

zipSTOP Brake Unit

Nozzle Assembly

Braking Line

Fully Retracted - 400 mm (16”)

Side Cover

MODEL ZSIR150-20A

CLASSIFICATION Zip Line Braking Device

DIMENSIONS 380 x 320 x 216 mm (15 x 12.6 x 8.5 in)

Pulley

NET WEIGHT 23.5 kg (52 lbs)

OPERATING TEMPERATURE -10°C (14°F) to 40°C (104°F)

STORAGE TEMPERATURE -20°C (-4°F) to 60°C (140°F)

MATERIALS CASING Aluminium alloy

INTERNAL PARTS Zinc plated and stainless steel

NOZZLE Modified Acetal plastic with stainless insert

LINE 20 mm Nylon Spectra Braking Line

MAXIMUM LINE EXTENSION 20 m (65 ft)

RIDER WEIGHT RANGE 15 to 150 kg (33 - 330 lbs)

MAXIMUM SPEEDS 1:1 REDIRECTION RATIO 60 km/h (37 mph)

ZSIR15020A THIS PRODUCT CAN ONLY BE USED WITH 1:1 REDIRECTION SETUPS

The zipSTOP IR (ZSIR150-20A) is NOT compatible with external redirection setups in any way. Installing

a redirection setup with the zipSTOP IR can create a very dangerous set of braking conditions that could

result in abnormally abrupt late braking.

www.headrushtech.com | +1-720-565-6885

13

Page 13

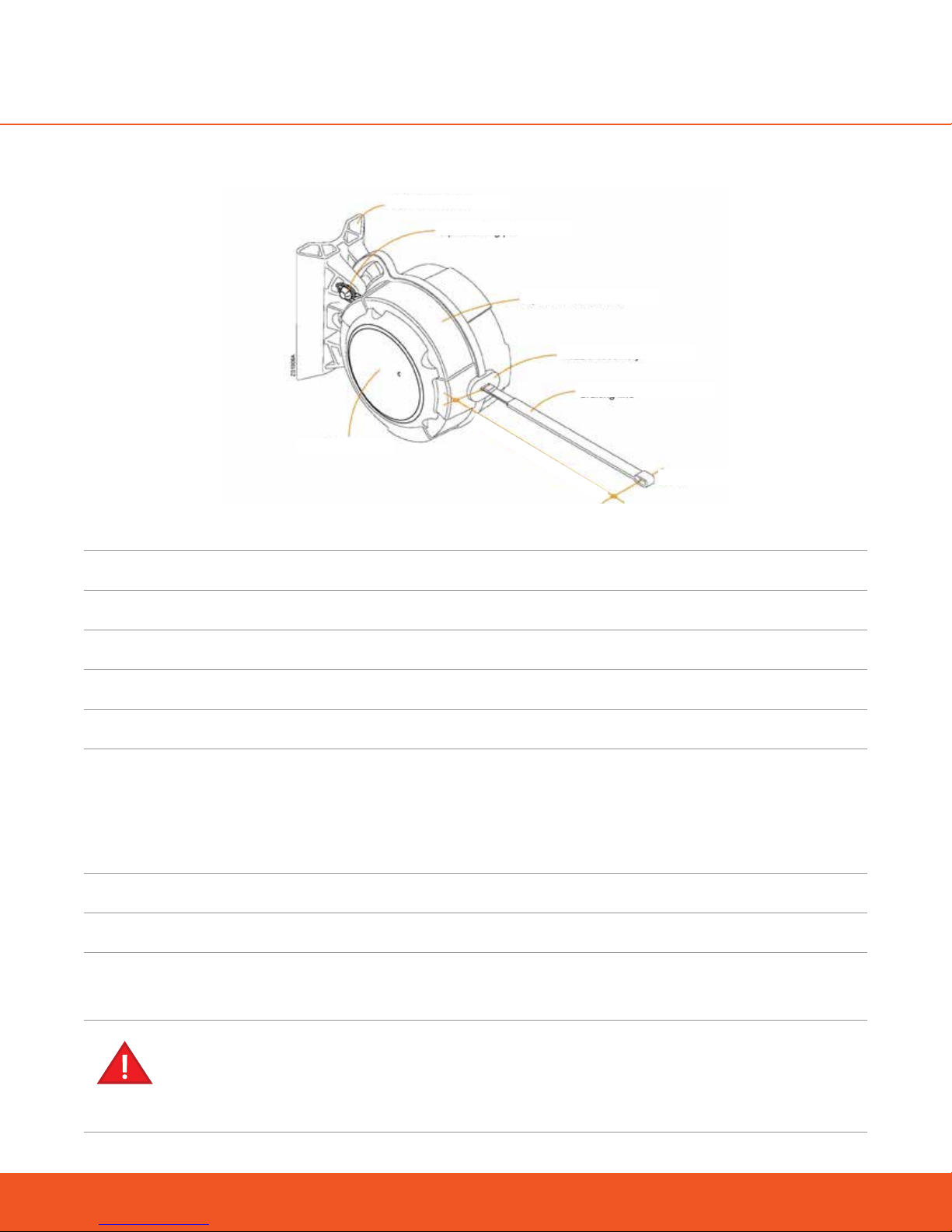

5.4 zipSTOP Brake Trolley, ZS125-08 and ZSIR150-20A

Redirection Line

Mounting Point

Upper Sheave

Lower Sheaves

MODELS ZT 125-17-1/2 – For use with 12.7 mm (½”) zip lines

ZT 125-17-3/4 – For use with 19 mm (¾”) zip lines

ZT 125-17-35/8 – For use with 15.9 mm (5/8”) zip lines

CLASSIFICATION Zip Line Brake Trolley

Bump Stops

DIMENSIONS 235 x 100 x 115 mm (9.3 x 3.9 x 4.5 in)

NET WEIGHT 1.3 kg (2.8 lbs)

MATERIALS CASING Aluminium alloy

WHEELS Steel

BUMP STOP Polyurethane

MAXIMUM SPEED 72 km/h (45 mph)

MINIMUM RIDER WEIGHT 15 kg (33 lbs)

MAXIMUM RIDER WEIGHT 150 kg (330 lbs)

14

www.headrushtech.com | +1-720-565-6885

Page 14

6. OPERATING PRINCIPLES

6.1 General

The zipSTOP Brake assembly is a controlled braking force device designed specifically for use as a Primary or

EAD at the end of zip line runs. The zipSTOP caters to a range of rider weights and approach speeds and oers

a smooth, consistent braking force for all riders. zipSTOP Brake performance relies on operators using the

correct equipment and operating the system in accordance with the instructions contained within this manual.

The zipSTOP Brake assembly consists of a zipSTOP Brake Unit, zipSTOP Brake Trolley, redirection pulleys and

associated Redirection Lines.

Pictures in this manual are for reference purposes in terms of geometry and proposed redirection setup

configuration only. Mandated EAD may or may not be shown.

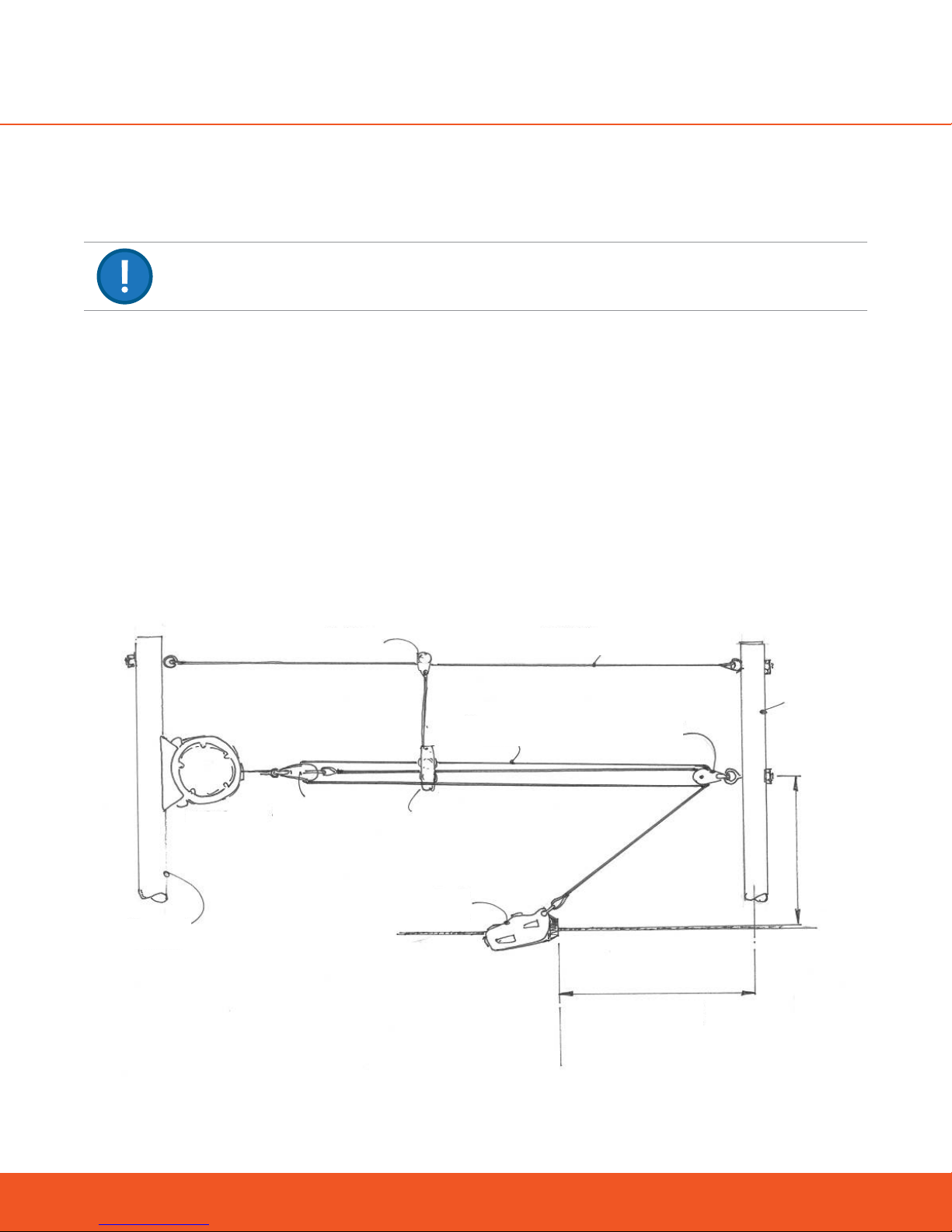

Cable Clamps &

Primary

Mount

Redirection

Line Support

Quick Links

Redirection Line

Overhead Line

Redirection Pulley

Brake Line Extension

zipSTOP Brake Line

zipSTOP Brake Unit

Arrest Zone

Typical zipSTOP Installation

Zip Line

Brake Trolley

Rest Position

The zipSTOP Brake Unit is located at the zip line terminal end, normally adjacent to the landing area. It is

connected via a redirection pulley and Redirection Line setup to the zipSTOP Brake Trolley.

The Brake Trolley is located on the zip line and when idle (zipSTOP Braking Line fully retracted) will be

positioned at the start of the rider Arrest Zone (Reset Position). The approaching rider trolley contacts

the Brake Trolley, moving it down the zip line. As the Brake Trolley moves into the Arrest Zone it extends

the Braking Line out of the zipSTOP Brake Unit via the Redirection Line. As the Braking Line extends out

of the zipSTOP Brake Unit, the eddy current brake in the unit is activated, controlling the rate of deceleration and slowing the rider in a smooth manner.

Once the load is removed from the Brake Trolley, the return mechanism in the zipSTOP Brake Unit

retracts the Braking Line, automatically returning the Brake Trolley to the start of the Arrest Zone (Reset

Position) on the zip line, ready for the next rider.

When higher Redirection Ratios are employed retraction force is reduced and a manual reset of the Brake

Trolley may be necessary.

Ensure brake is reset before rider starts down zip line, every time.

www.headrushtech.com | +1-720-565-6885

15

Page 15

7. zipSTOP BRAKE ASSEMBLY

7.1 General

The zipSTOP Brake assembly will be supplied as a kit of parts. Additional components are required to complete the braking system. Refer to Section ”Appendix B: List of Accessories and Replaceable Parts” for part

number information.

Pictures in this manual are for reference purposes in terms of geometry and proposed redirection setup

configuration only. Mandated EAD may or may not be shown.

7.2 Unpacking the zipSTOP

SAVE PACKAGING FOR REUSE

Keep all zipSTOP packaging for reuse when returning the zipSTOP Brake Unit for annual recertification.

Damages caused by shipping in improper packaging are not covered under warranty and will result in additional repair charges to the owner.

1. Upon receipt of the zipSTOP Brake Assembly Kit, inspect all parts and operation (pull out line) for signs

of shipping damage or contamination. If any components show signs of damage or mishandling, contact your zipSTOP distributor.

2. Check that all information and safety labels axed to the zipSTOP are present and legible. Refer to

Section “Location of Safety Labels”.

16

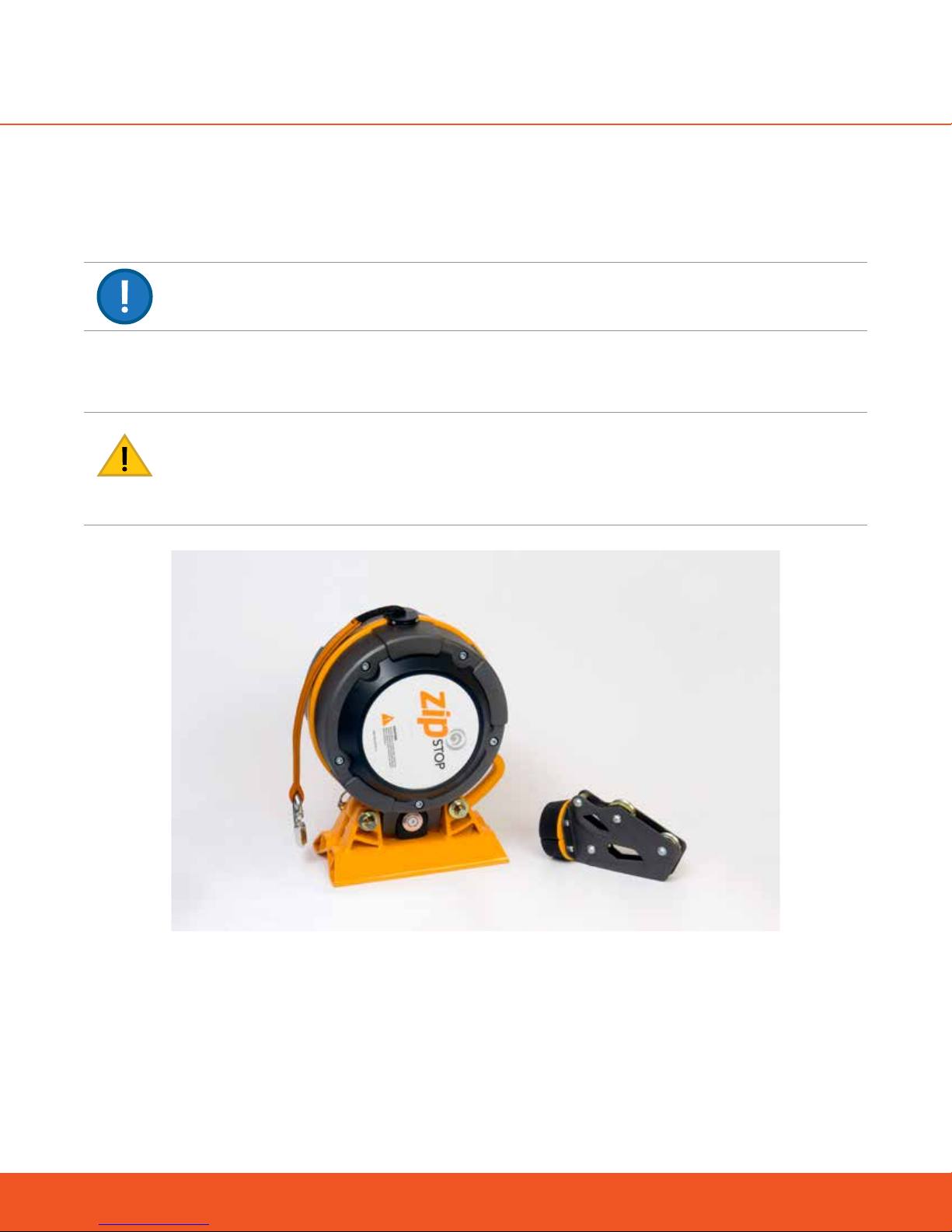

Brake Assembly Kit

www.headrushtech.com | +1-720-565-6885

Page 16

Do not use the zipSTOP after date shown here

3. Check the Certification Label on the zipSTOP Brake Unit for the ‘Next Recertification Required’ date. If

the date shown has passed or the label is missing or illegible then the zipSTOP Brake Unit must not be

put into service.

4. Register online at www.thezipshop.com/registration or fill out the Product Registration Card included

with the zipSTOP Brake Assembly Kit, and return it to your zipSTOP distributor.

5. The EAD Confirmation form and the Warranty Registration form (see Sections “Emergency Arrest Device (EAD) Confirmation” and “Warranty Registration Form” respectively) are required to be detached,

filled out, and mailed to:

Head Rush Technologies

1835 38th Street , STE C

Boulder, CO 80301

PRODUCT REGISTRATION MUST BE COMPLETED

The Product Registration must be completed, either by registering online or by filling out and returning the

Product Registration Card. This is critical for receiving product notifications and up-to-date information for

the proper use of the zipSTOP Brake assembly.

6. Read this entire Installation, Operation and Maintenance Manual supplied with the zipSTOP, and familiarize yourself with all aspects of installation, operation, care and maintenance.

7.3 Long Term Storage

If the zipSTOP Brake Unit is to be placed into storage or left unused for longer than two weeks, ensure the unit

is clean and dry and protected from the environment. Ensure the Braking Line is fully retracted into the unit.

Always store in a clean and dry environment, preferably in the original packaging

DO NOT STORE BRAKE UNIT IN A WET CONDITION

After exposure to water or damp conditions, thoroughly clean and dry the zipSTOP prior to storage. Ensure

that the zipSTOP Brake Unit is not left with a wet Braking Line retracted inside the casing as this may result

in corrosion of the unit and deterioration of the Braking Line. In a clean and dry environment, remove the

side covers and fully extend the wet Braking Line and allow to completely dry prior to storing the Brake Unit.

Ensure that debris does not enter the unit and reattach the side covers prior to storing or using the unit.

www.headrushtech.com | +1-720-565-6885

17

Page 17

When returning the zipSTOP Brake assembly to operation after an extended period of inactivity, always carry out a

ZIPSTOP

ZIP LINE

BRAKE

Installation, Operation & Maintenance Manual

Models: ZS125-08 / ZSIR150-20A

NOTE TO INSTALLERS

Always Read Instructions Before Use

Leave this manual attached to the zipSTOP Brake unit. The Installation, Operation

and Maintenance manual contains information relating to the proper use of the

zipSTOP and includes all product registration and warranty information. This document may only be removed by the end user prior to operation. Ensure that this

manual is readily available to operators at all times.

Head Rush Technologies zipSTOP Zip Line Brake Installation, Operation & Maintenance Manual

P/N 01170006604

Head Rush Technologies products are covered by a number of patents, including

U.S. Patents 8,490,751; 8,851,235; 9,016,435; 8,851,235 and D654,412 & corresponding patents/applications in the USA and in other countries worldwide.

full inspection and operational check of all components in the assembly. Refer to Section “Operation of zipSTOP” for Inspection procedures.

7.4 Supplied Parts

The following parts will be included in each Brake Assembly Kit:

1 x zipSTOP Brake Unit

1 x zipSTOP Mounting Bracket, Rattle Stop, Mounting and Lynch Pins

1 x zipSTOP Brake Trolley

zipSTOP Installation, Operation and Maintenance Manual

7.5 General and Additional Parts Required

Additional lines and equipment will be required to successfully install a zipSTOP Brake assembly within individual zip line installations. All hardware, fasteners and accessories used in the installation of zipSTOP must meet

or exceed the required loads and specifications, and must be made of materials compatible with all-season

outdoor use.

Head Rush Technologies developed specific redirection pulleys and the Gorilla rope to maximize the performance of a zipSTOP Zip Line Brake. The redirection pulleys oered by Head Rush Technologies are light-

Brake Unit Brake Unit Mounting Bracket

Brake Trolley Installation, Operation, & Maintenance Manual

18

www.headrushtech.com | +1-720-565-6885

Page 18

weight, corrosion resistant, and engineered to be virtually resistant to snagging. Head Rush Technologies also

oers the Gorilla Rope, a 6mm rope specifically designed for used as a redirection line.

7.6 Redirection Pulleys

The following parts are not supplied as part of the zipSTOP kit and may be purchased separately from your

zipSTOP distributor.

The Type I Pulley is fitted to the Secondary Anchor Point, and provides both support and a means of redirection for the Redirection Line. The Type I Pulley is required for both 1:1 and 2:1 Redirection Ratio setups.

A Type II Pulley is fitted between the zipSTOP Brake Unit and the Type I Pulley as required to provide support

and redirection for the Redirection Line and connections to the Braking Line. The Type II Pulley is only required on the 2:1 Redirection Ratio set-ups.

Example of Type I Redirection Pulley Example of Type II Redirection Pulley

7.7 Traveler Assembly

Sling

Oval Quicklink

zipSTOP Brake Line

The Traveler Assembly is a recommended support for a 2:1 ratio configuration. It is used to support the weight

of the Redirection Line and associated hardware in order to ensure that the Redirection Line does not contact

any surface other than the pulley sheaves. A sling of proper length should be used to ensure that the Braking

Line feeds straight out of the device, without twist, and centered within the Nozzle. A swivel is recommended

to ensure that the Braking Line remains free of twists.

Pulleys

Triangular Quicklink

Swivel

www.headrushtech.com | +1-720-565-6885

19

Page 19

7.8 Minimum Hardware Requirements

All required hardware is to be purchased separately. The following are minimum requirements for all hardware

used for zipSTOP installation:

DESCRIPTION SIZE QTY NOTES

Grade 4.6 (M12)

ZIPSTOP BRAKE UNIT MOUNTING

BOLTS, WASHERS & LOCKNUTS

M12 or 1/2”

3

ASTM A307 Grade A or B (1/2”)

Length to suit installation

Suitable for all-season outdoor use

TYPE I PULLEY MOUNTING

HARDWARE

CARABINERS, SNAPS, RINGS,

THIMBLES, CLEVISES

To suit To suit Suitable for all-season outdoor use

Minimum load rating 15 kN

To suit

Suitable for all-season outdoor use

7.9 Redirection Line

The Redirection Line is required to connect the zipSTOP Brake Unit to the Brake Trolley and will transfer the

braking force from the Brake Unit. The Redirection Line passes through the redirection pulleys and must meet

minimum specification. The following list provides several Redirection line options.

Head Rush Technologies developed the Gorilla Rope specifically for use as a redirection line with the zipSTOP

Zip Line Brake It features a high strength-to-weight ratio, is designed to be highly resistant to abrasion, UV

resistant, and water repellent. The 6mm Gorilla Rope maximizes performance because it is lighter, smaller in

diameter, minimizes resistance, and maximizes reliable reset.

Spectra - Spectra/Dyneema is one of the recommended materials because it has sucient strength while

minimizing size and diameter. Spectra/Dyneema is known for high strength and superior abrasion, water, and

UV resistance. The spectra line should be jacketed with an abrasion-resistant, temperature-tolerant material

to avoid possible degradation of the line due to friction. Gorilla Rope, a Head Rush Technologies product, is

designed specifically to provide high strength, a long life span, and minimal stretch for applications where a

small diameter rope is necessary. It is made for maximum durability and high performance in any application.

It is perfect for use as a reduction line with the zipSTOP Zip Line Brake but can also be used for many other

industrial or recreational applications where these qualities are critical.

Technora® - Technora, while the strongest of the synthetic fibers, is particularly sensitive to UV wear. Only

Technora core lines with UV protective jackets should be used. Technora lines are also slightly stier which

can increase retraction drag when used as a Redirection Line. The drag is usually oset by the fact that a

smaller diameter Technora line can be employed compared to another material.

Nylon and Other materials - Nylon or other materials can be used provided they meet the minimum requirements for strength, UV, and wear resistance. However, these lines may necessitate much larger diameter ropes

to attain the necessary strength which can have an adverse eect on Redirection Line performance.

20

Typical Technora Termination

www.headrushtech.com | +1-720-565-6885

Page 20

7.9.1 REDIRECTION LINE SPECIFICATIONS: ZS12508/ZSIR15020A

MAXIMUM DIAMETER 10.0 mm/0.394 in (6mm/0.236 in recommended)

MINIMUM STRENGTH 13 kN, Stretch <3% at 13 kN

STRETCH <4% at 15 kN

WEAR RESISTANCE High abrasion resistance and UV resistance

WATER RESISTANCE Dry, non-absorptive

TYPE Kernmantle or single braid construction

TYPICAL Redirection LINE EXAMPLE

ZS125-08

TYPICAL Redirection LINE EXAMPLE

ZS150-20A

ALWAYS USE THE SPECIFIED REDIRECTION LINE

Failure to utilize a Redirection Line of specified strength and quality can compromise zipSTOP brake operation, resulting in equipment damage, serious injury or death.

REDIRECTION LINE WILL BE SUBJECT TO WEAR AND ABRASION

Any Redirection Line selected for use will wear and must be replaced from time to time. Lines must be carefully inspected prior to use each day, and failure to do so may result in serious injury or death.

When selecting a Redirection line, the following considerations apply:

The line must meet the specifications described above.

A lighter, smaller diameter line is preferred, to minimize resistance and weight, and maximize reliable

reset.

A waterproof line is required. Water absorption can add significant weight, allowing the line to sag

which increases the likelihood of incomplete reset for Brake Unit and Brake Trolley.

www.headrushtech.com | +1-720-565-6885

21

Page 21

8. zipSTOP BRAKE ASSEMBLY CONFIGURATION

8.1 General

The zipSTOP Brake assembly is designed to be utilized as part of a complete zip line braking system, and can

be used for a wide range of zip line installations. The zipSTOP Brake assembly is suitable for use in both existing and new zip line installations.

Setup information contained within this manual relates only to the zipSTOP Brake assembly – The design,

installation and set-up of other components comprising the complete braking system are the responsibility of

the installer and/or operator.

COMPATIBILITY TESTING IS THE RESPONSIBILITY OF THE INSTALLER OR OPERATOR

The zipSTOP Brake is designed to work with most pulleys and zip lines but may not work with all. Compatibility is to be determined by the installer or operator based on experience and unmanned testing.

ALWAYS CARRY OUT UNMANNED TESTING TO DETERMINE ACTUAL BRAKING DISTANCE

The information contained in this manual is intended for guidance only. Calculated braking distances for

the zipSTOP Brake assembly are estimates only and may dier from actual braking distances achieved on

individual zip lines.

As there are infinite possibilities regarding participant weights and arrival speeds, line slopes and environmental

conditions, a safe and functional installation can only be achieved after careful consideration and unmanned

testing of all factors in advance of the zipSTOP installation.

The zipSTOP Brake is required to use both primary and emergency arrest devices functioning together to

arrest the motion of passengers. The EAD must engage with no input from the passenger upon failure of the

primary arrest device, and all required Confirmation and Warranty registration forms must be filled out and

returned; failure to do so may void your warranty (see Sections “Emergency Arrest Device (EAD) Confirmation”

and “Warranty Registration Form” respectively).

Pictures in this manual are for reference purposes in terms of geometry and proposed redirection setup

configuration only. Mandated EAD may or may not be shown.

8.2 Setup Variables, ZS125-08/ZSIR150-20A

A number of variables will influence the final braking distance and level of rider comfort, these include:

Rider arrival speed

Rider weight

Redirection Line Ratio (Only a 1:1 Applies with the ZSIR150-20A)

Zip line slope in the landing area

System friction

Environmental conditions (wind, rain, temperature)

Rider trolley used

22

www.headrushtech.com | +1-720-565-6885

Page 22

8.3 Rider Arrival Speed

Rider arrival speed is unique to each zip line installation and is a factor of line slope, zip line length, rider

weight, rider descent position, wind and friction. It is necessary to know the acceptable minimum and maximum rider velocities prior to configuring the zipSTOP.

8.4 Rider Weight

Suitable rider weight ranges will need to be determined by individual zip line operators. The zipSTOP Brake

unit will accommodate riders between 15 and 150 kg (33 and 330 lbs). It is necessary to know the acceptable

rider weight range before configuring the zipSTOP.

8.5 Redirection Line Ratio

The Redirection Ratio is the most influential factor in the braking characteristics of the zipSTOP. The Redirection Ratio is the ratio between the Brake Trolley travel and the zipSTOP Braking Line extension.

The Redirection Ratio is achieved by passing the Redirection Line around a series of pulleys. This alters the

ratio of Brake Trolley travel to Braking Line extension, allowing the installer to tailor the braking distances and

deceleration rates, accommodating a wide range of arrival speeds and rider weights.

ZSIR15020A THIS PRODUCT CAN ONLY BE USED WITH 1:1 REDIRECTION SETUPS

The zipSTOP IR (ZSIR150-20A) is NOT compatible with external redirection setups in any way. Installing

a redirection setup with the zipSTOP IR can create a very dangerous set of braking conditions that could

result in abnormally abrupt late braking.

Various Redirection Ratios are possible:

1:1 Ratio

MUST be used for model ZSIR150-20A

Can be used for model ZS125-08

2:1 Ratio

Can be used for model ZS125-08 only

CANNOT be used for model ZSIR150-20A

3:1 and higher ratios – contact your zipSTOP Distributor, model ZS125-08 only

The recommended configuration orients all elements (zipSTOP Brake Unit, Redirection Pulleys, Brake Trolley)

in the vertical plane.

When higher Redirection Ratios (3:1 and higher) are employed (for model ZS125-08 only), retraction force is

reduced and a manual reset of the Brake Trolley will be necessary.

ALWAYS USE THE SPECIFIED REDIRECTION LINE

Failure to utilize a Redirection Line of specified strength and quality can compromise zipSTOP brake operation, resulting in equipment damage, serious injury or death.

www.headrushtech.com | +1-720-565-6885

23

Page 23

REDIRECTION LINE WILL BE SUBJECT TO WEAR AND ABRASION

Any Redirection Line selected for use will wear and must be replaced from time to time. Lines must be carefully inspected prior to use each day, and failure to do so may result in serious injury or death.

8.5.1 1:1 RATIO

Attach zipSTOP braking line to redirection

line with a quicklink and recommended

swivel, support pulley and sling

Attach redirection pulley

to overhead line

Overhead Line

Zip Line

Brake Trolley

The 1:1 Redirection Ratio directly connects the zipSTOP Brake Unit to the zipSTOP Brake Trolley via a single

Type I Redirection Pulley. For every unit of Brake Trolley travel, the Braking Line extends an equal distance.

Characteristics of the 1:1 ratio are:

Suitable for low speeds

Strongest braking force

Short braking distances

Higher rate of rider deceleration

Maximum rider approach speed of 36 km/h (22 mph) – model ZS125-08

Maximum rider approach speed of 60 km/h (37 mph) – model ZSIR150-20A

In the case of the model ZS125-08: A 1:1 Redirection Ratio is used for zip line installations where low arrival

speeds are common. Although suitable for speeds up to 36 km/h (22 mph), typically a 1:1 ratio would be employed when approach speeds are less than 20 km/h (12 mph).

24

*EAD not shown but it is mandated*

Overhead Cable – 1:1 Redirection Ratio

www.headrushtech.com | +1-720-565-6885

Page 24

8.5.2 2:1 RATIO

redirection line with a quicklink and

recommended swivel, support pulley

Attach zipSTOP braking line to

and sling

Attach redirection pulley

to overhead line

Overhead Line

Zip Line

Brake Trolley

*EAD not shown but it is mandated*

Overhead Cable – 2:1 Redirection Ratio

The 2:1 Redirection Ratio connects the zipSTOP Brake Unit to the zipSTOP Brake Trolley via both Type I and Type

II pulleys. With a 2:1 ratio the Brake Trolley travels twice the distance that the zipSTOP Braking Line extends.

Characteristics of the 2:1 ratio are:

Suitable for medium to high speeds

Optimal combination of stopping distance, braking force and reliability in reset

Optimum rider comfort

Longer braking distances than a 1:1 setup

Overhead support line (redirection point) recommended

Maximum approach speed of 60 km/h (36 mph)

A 2:1 Ratio is used on zip line installations where medium to high approach speeds are common but a soft

stop for the rider is desired. Although suitable for approach speeds up to 60 km/h (36 mph), typically a 2:1

ratio is employed when approach speeds are less than 40 km/h (24 mph).

A 2:1 Ratio is specifically PROHIBITED in any installation of the ZSIR150-20A. Utilizing an external redirection

will lead to potentially dangerous and harmful braking dynamics.

ZSIR15020A THIS PRODUCT CAN ONLY BE USED WITH 1:1 REDIRECTION SETUPS

The zipSTOP IR (ZSIR150-20A) is NOT compatible with external redirection setups in any way. Installing

a redirection setup with the zipSTOP IR can create a very dangerous set of braking conditions that could

result in abnormally abrupt late braking.

www.headrushtech.com | +1-720-565-6885

25

Page 25

8.6 Possible Configurations (Informative Only)

8.6.1 3:1 RATIO

3:1 installation formats are a unique situation and the following information should be used to develop an

appropriate site plan.

The 3:1 ratio connects the zipSTOP unit to the braking trolley via redirection pulleys and supplementary line.

With a 3:1 ratio the braking trolley travels three meters for every meter of zipSTOP line. This will result in a longer stopping distance for the rider.

Characteristics of 3:1 ratio setup are:

Max. Approach Speed = 72 km/h.

Suitable for high arrival speed.

Softer stopping force from higher speeds

Longer stopping distances

More complex set-up.

A 3:1 ratio is commonly used on zip lines with high arrival speeds and when a longer braking distance is available. The 3:1 ratio is suitable for approach speeds up to 72 km/h (45 mph) allowing a softer stop after thrilling

high speed runs.

Primary Anchor

zipSTOP

Support Wheel

Secondary

Pulley

Redirection Line

Cable Tidy

zipSTOP

Brake Trolley

Support Line

Start of

Braking Zone

Double

Pulley

Block

Locate Secondary

Anchor Upstream

of Braking Zone

Secondary

Anchor

Line

Locate Pulley

Block Above Zip

26

www.headrushtech.com | +1-720-565-6885

Page 26

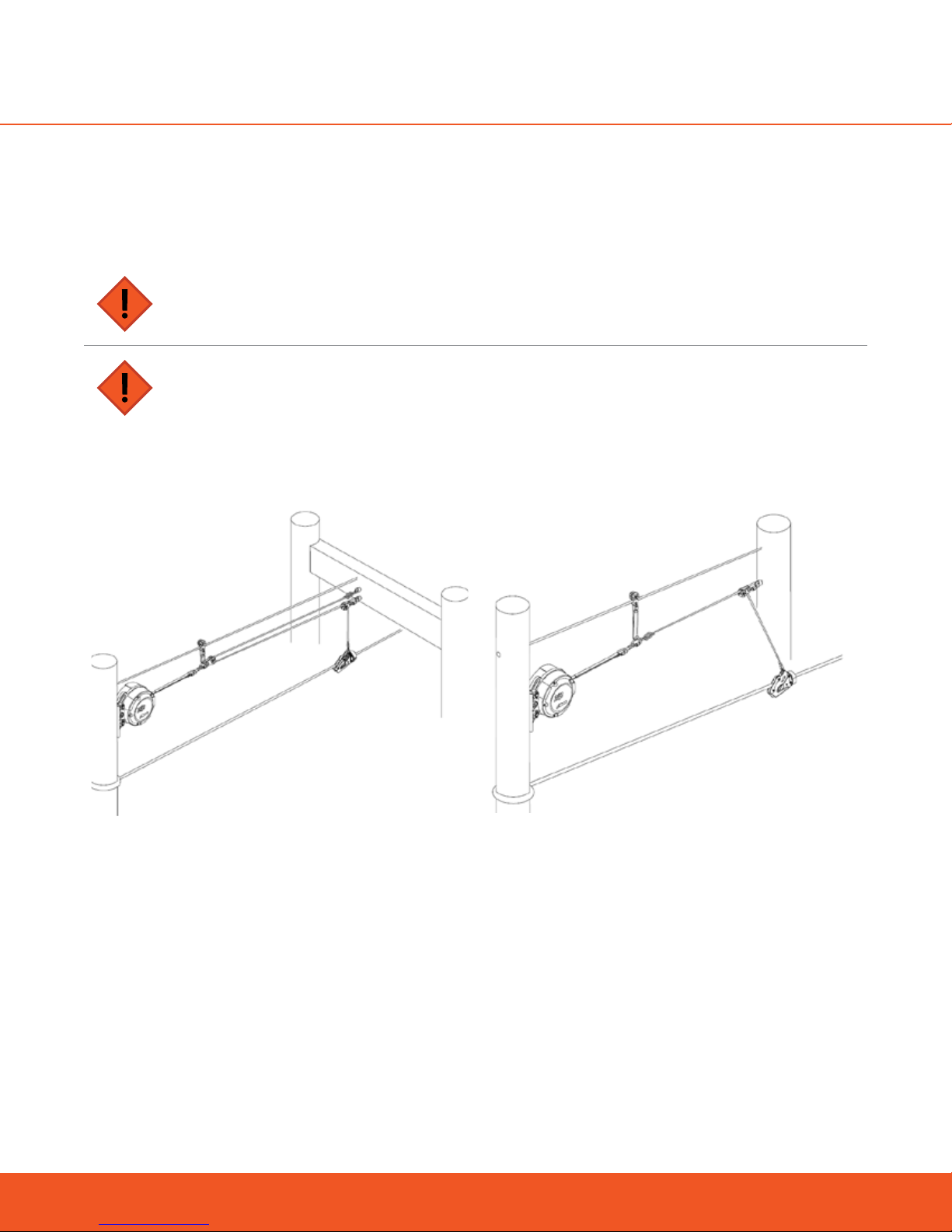

8.6.2 OTHER CONFIGURATIONS

The zipSTOP Brake assembly may be used with other zip line configurations and higher rider velocities. Configurations shown are based on a single line zip line. Dual zip lines and side-by-side configurations may also

be accommodated. Please contact your zipSTOP Distributor for information on alternate set-ups.

When higher Redirection Ratios (3:1 and higher) are employed (for model ZS125-08 only), retraction force is

reduced and a manual reset of the Brake Trolley will be necessary.

Pictures in this manual are for reference purposes in terms of geometry and proposed redirection setup

configuration only. Mandated EAD may or may not be shown.

Some examples of alternative configurations are shown below:

Beam Mounted Pulley - 2:1 Redirection Ratio

8.7 Zip Line Slope

Three zip line configurations at the end of the line are possible: flat line, positive line slope and a negative line

slope. The slope of the line will influence the braking distances as well as allowing the rider to roll slowly up or

down the line once decelerated.

www.headrushtech.com | +1-720-565-6885

Oset Redirection Pulley – 1:1 Redirection Ratio

NOTE: Oset redirection pulleys should only be used with highly

tensioned zip lines. Slack zip lines may cause binding and excessive

wear on the brake trolley.

27

Page 27

8.7.1 POSITIVE SLOPE LINE

This is the ideal configuration when designing a zip line incorporating the zipSTOP Zip Line Brake. The positive

line slope configuration equalizes the braking distance between heavy and light riders, therefore minimizing

the length needed for the arrival platform.

zipSTOP

Primary Mount

Secondary Mount

Landing Area

Brake Trolley

Minimum Braking Distance

Roll Forward

Maximum Braking Distance

Arrest Zone

Reset Position

Positive Line Slope

On positive line installations riders will decelerate within the Arrest Zone but may continue to slowly roll forward on completion of braking.

It is recommended that the platform is positioned to allow all riders to roll forward on to the platform for a

safe dismount.

8.8 Flat Line

On a flat line participants will decelerate within the Arrest Zone at the completion of braking but typically don’t

roll forward or backward.

It is recommended that the platform is positioned to allow all riders to safely dismount.

zipSTOP

Primary Mount

Secondary Mount

Landing Area

28

Brake Trolley

Minimum Braking Distance

Maximum Braking Distance

Arrest Zone

Reset

Position

Flat Line

www.headrushtech.com | +1-720-565-6885

Page 28

8.9 Negative Slope Line

On negative line installations riders will decelerate within the rider Arrest Zone and may roll backwards at the

completion of braking.

It is recommended that the platform is positioned to allow all riders to safely dismount.

zipSTOP

Primary Mount

Landing Area

Roll Back

Maximum Braking Distance

Minimum Braking Distance

Arrest Zone

Secondary Mount

Brake Trolley

Negative Line Slope

Reset

Position

8.10 Calculating zipSTOP Braking Distances

To calculate braking distances for the zipSTOP Brake assembly, follow the steps in the ‘Configuration Worksheet’ using the information contained in the ‘Braking Distance Charts’. Refer to Section “Appendix A: EAD

Warranty/Registration Form”.

ALWAYS CARRY OUT UNMANNED TESTING TO DETERMINE ACTUAL BRAKING DISTANCE

The information contained in this manual is intended for guidance only. Calculated braking distances for the zipSTOP Brake assembly are estimates only and may dier from actual braking distances achieved on individual

zip lines.

Exceeding maximum recommended line speed can cause injury to participants and damage equipment.

Before starting the zipSTOP configuration you will need to determine the rider weight range, rider arrival speed

range and preferred Redirection Ratio for the zipSTOP installation.

Information required for calculating zipSTOP braking distances:

Rider weight range

Arrival speed range

zipSTOP Redirection Line ratio

A number of other variables will aect the final performance of zipSTOP and must be taken into consideration

when designing the complete zip line braking system. These include, but are not limited to:

Line slope

EAD design

Friction

Weather Conditions (e.g. wind, rain, humidity, temperature)

Environmental factors

www.headrushtech.com | +1-720-565-6885

29

Page 29

8.10.1 DEFINITION OF TERMS

The following terms are used when configuring and installing the zipSTOP Brake assembly:

Pivot Length

Primary Mount

zipSTOP

Brake Line Extension

Buer Zone

Roll Forward

Minimum Braking Distance (BD min)

Maximum Braking Distance (BD max)

Roll Back

Landing Area

Secondary Mount

Pivot Height

Brake Trolley

Rider Arrival Speed

Maximum Arrival Speed = ASmax

Minimum Arrival Speed = ASmin

Reset

Position

Redirection LINE RATIO RR

Ratio of Brake Trolley travel to zipSTOP line extension

(LEX)

RIDER ARRIVAL SPEED

ASMAX = MAXIMUM RIDER ARRIVAL SPEED ASmax Speed at which rider enters the Arrest Zone.

ASMIN = MINIMUM RIDER ARRIVAL SPEED ASmin Determined by:

Slope of zip line

Rider size and weight

Wind speed and direction

Rider trolley rolling resistance

BRAKING DISTANCE Distance required to decelerate a rider.

BDMAX = MAXIMUM BRAKING DISTANCE

BDMIN = MINIMUM BRAKING DISTANCE

NOTE: Configurations that result in Braking distances that fall below the ‘BDmin’ line shown on the

chart are not recommended. These short braking distances may be uncomfortable for the rider and

may result in severe swinging up of rider when decelerating.

30

BDmax

BDmin

Braking distance is determined by:

Arrival speed

Rider weight

Redirection Ratio

Slope of zip line at landing area

www.headrushtech.com | +1-720-565-6885

Page 30

RIDER BRAKING RANGE BR

NOTE: Landing Area will vary depending on rider arrival speed, stopping distances and line slope.

Dierence between maximum and minimum braking distances.

RESET POSITION

BUFFER ZONE

PIVOT HEIGHT

LINE EXTENSION

RP

BZ

PH

LEX

The reset position defines the start of the Arrest

Zone and is the location on the zip line the Brake

Trolley will return to once the rider is removed.

Distance from the end of the Arrest Zone (AZ) to any

object that may impact the rider in the event the

rider overshoots the landing area.

The buer zone must include the maximum distance required for the EAD to activate and arrest a

rider.

Straight line distance between Brake Trolley and the

Type 1 Pulley. Changing pivot height will influence

the stopping distance.

Distance that zipSTOP internal Braking Line extends

from the zipSTOP Brake unit.

Min. LEX = 0.40 m (15.5”)

Max. LEX = 12.0 m (39’4”)

RIDER WEIGHT RW The weight of the rider (min and max

8.11 zipSTOP Braking Distance Charts

Charts for calculating braking distances are located at the back of this manual. These charts are to be used in

conjunction with the zipSTOP configuration worksheet to optimize the zipSTOP installation. Ensure that you

are using the correct chart for your zipSTOP model.

ALWAYS CARRY OUT UNMANNED TESTING TO DETERMINE ACTUAL BRAKING DISTANCE

The information contained in this manual is intended for guidance only. Calculated braking distances for the zipSTOP Brake assembly are estimates only and may dier from actual braking distances achieved on individual zip

lines. Exceeding maximum recommended line speed can cause injury to participants and damage equipment.

8.12 Configuration Notes

1. BDMIN LINE: BDmin line indicates the rate of deceleration that may be considered uncomfortable

and result in severe rider swing up when stopping. It is not recommended to operate the zipSTOP with

combinations of rider weights and arrival speeds that fall below the BDmin line. Operating below the

BDmin line runs the risk of rider swinging up and contacting the zip cable.

www.headrushtech.com | +1-720-565-6885

31

Page 31

2. LINE EXTENSION (LEX) – Line extension is the distance the Braking Line extends out of the zipSTOP

brake Unit. If LEX is greater than 12.0m then reduce maximum permissible approach speed (ASmax),

permissible rider weight (RWmax) or increase Redirection Ratio (RR). Exceeding 12m runs the risk of an

abrupt stop when the webbing reaches its termination as well as damage to the zipSTOP, webbing and

other equipment.

3. BUFFER ZONE (BZ) – Buer zone is the area after the Arrest Zone in which riders are safe from impacting the terminal end or any other object in the event they overshoot the landing zone. The buer zone

must include the maximum distance required for the EAD to arrest a wayward rider.

32

www.headrushtech.com | +1-720-565-6885

Page 32

8.13 zipSTOP Configuration Worksheet

Use this worksheet in conjunction with the braking distance charts at the back of this manual. Worksheet

must be completed in metric. Read the zipSTOP Brake assembly configuration notes and definitions before

completing the worksheet. Distances calculated by this worksheet are based on a flat line with no outside

influences such as wind, friction etc. Actual braking distances can vary from these values. Always determine

actual braking distances by completing unmanned test runs on final zip line installation prior to putting the

installation into operation.

1 Select Redirection Ratio and go to braking distance chart for selected Redirection Ratio.

If Redirection Ratio = 1:1, enter 1

If Redirection Ratio = 2:1, enter 2 (model ZS125-08 only)

2 Enter maximum expected rider arrival speed (ASmax) ASmax =

Enter minimum expected rider arrival speed (ASmin) ASmin =

3 Enter maximum anticipated rider weight RWmax =

4 Enter minimum anticipated rider weight RWmin =

5 Determine pivot height

Minimum pivot height = 1.0 m (40”)

6 Enter buer zone length BZ

7 Go to braking distance chart for selected Redirection Ratio and Model Number. Reference the metric

charts available on pages 60 & 62.

8 From relevant chart determine the braking distance for maximum anticipated rider

weight (RWmax) and speed

9 Add pivot height to give maximum braking distance

BDmax = BD1 + PH

RR =

PH

BD1 =

BDmax =

10 Check maximum braking distance + buer zone does not exceed maximum zipSTOP

Braking Line extension.

Line Extension (LEX) = (BDmax + BZ) / RR

LEX must be less than or equal to 12.

11 From relevant chart determine braking distance for minimum anticipated rider weight BD2 =

12 Add pivot height to give minimum braking distance.

BDmin = BD2 + PH

13 Check stopping distance is not below the ‘BDmin’ line. Distances below this line will

result in a severe deceleration for the rider

14 Calculate braking range:

BR = BDmax – Bdmin

15 Calculate Reset Point (Arrest Zone Start Point):

RP = BDmax + BZ

www.headrushtech.com | +1-720-565-6885

LEX =

(see Note 1)

BDmin =

Above BDmin line?

BR =

RP =

Y / N

33

Page 33

9. zipSTOP BRAKE ASSEMBLY INSTALLATION

9.1 General

Simply put, the zipSTOP Brake is designed to be mounted to a primary anchor point to slow the decent of

riders on a zip line. The primary anchor point is exactly what it sounds like; it is the main attachment point for

the brake. The secondary anchor point is the support point for the redirection lines and pulleys.

The zipSTOP Brake Unit is installed at the end of the zip line, usually on or adjacent to the terminal end. A

Secondary Anchor Point is normally required upstream of the landing area to provide support for the Redirection Line pulleys AND forces associated with braking. Alternately a full-length secondary cable of sucient

capacity can be installed to provide support for the Redirection Line and associated pulleys.

Pictures in this manual are for reference purposes in terms of geometry and proposed redirection setup

configuration only. Mandated EAD may or may not be shown.

9.2 Safety Precautions

ALWAYS INSTALL AN EMERGENCY ARREST DEVICE EAD

An independent arrest device is required to safely stop riders in the event of operator error or third party

equipment failure.

PROPER DESIGN AND TESTING OF THE COMPLETE BRAKING SYSTEM IS ALWAYS REQUIRED

The complete brake system for zip Lines consists of all brakes employed, including primary brake and EAD.

All braking installations that include the zipSTOP as a component of the braking system must be designed,

tested and operated according to this Installation, Operation and Maintenance Manual and proper industry

and engineering practices. Failure to do so may result in serious injury or death to participants.

Exceeding maximum recommended line speed can cause injury to participants and damage equipment.

FAILURE TO CORRECTLY INSTALL OR MAINTAIN A ZIPSTOP BRAKE ASSEMBLY MAY RESULT IN

SERIOUS INJURY OR DEATH TO PARTICIPANTS.

ALWAYS CARRY OUT UNMANNED TESTING TO DETERMINE ACTUAL BRAKING DISTANCE

The information contained in this manual is intended for guidance only. Calculated braking distances for

the zipSTOP Brake assembly are estimates only and may dier from actual braking distances achieved on

individual zip lines.

AVOID CONTACT BETWEEN RIDER AND RIDER TROLLEY AND/OR BRAKE TROLLEY

Serious injury may result if rider contacts the rider trolley or Brake Trolley during the braking phase. Always

design zipSTOP Brake assembly installation to ensure rider cannot make contact with, or have any part of

their body caught between, the rider trolley and Brake Trolley.

34

www.headrushtech.com | +1-720-565-6885

Page 34

ENSURE ALL CABLES, ATTACHMENT LINES AND PULLEYS ARE CORRECTLY ATTACHED AND

MAINTAINED TO PREVENT TANGLING, SNAGGING, BINDING AND ABRASION.

Ensure that the Redirection Line is routed cleanly and in line through the pulley system, to prevent contact

with any surface other than the pulley sheaves.

ALL STRUCTURES, SUPPORTS AND ANCHORS MUST BE EVALUATED AND DESIGNED AC

CORDING TO PROPER INDUSTRY AND ENGINEERING PRACTICES. QUESTIONS ABOUT

STRUCTURES, SUPPORTS AND ANCHORS SHOULD BE REFERRED TO YOUR ZIP LINE’S ENGI

NEER.

The act of decelerating a rider at the termination of a zip line can generate extreme loads.

9.3 Primary Anchor Point

The Primary Anchor Point provides support for the zipSTOP Brake Unit. The anchor point and associated

fittings must be of sucient strength and form to provide a secure mount and to support all applied loads

sustained during zip line operation.

Loads specified are for the zipSTOP Brake assembly installation only and do not allow for any additional equipment or other loadings applied to the primary mount or additional units attached to the same line.

The zipSTOP Brake Unit is attached to the Primary Anchor Point using three M12 or ½” fixing bolts.

Loads at Primary Anchor Point

In-line with Braking Line 6.0 kN

Right angles to Braking Line Negligible

The loads specified are applied loads for the zipSTOP Brake Unit only. These loads DO

NOT allow for additional loads applied by other equipment or structures. Ensure sucient

factor of safety is applied in the structural design of all zip line installations.

9.4 Secondary Anchor Point

The Secondary Anchor Point provides support for redirection pulleys and hardware used in the Redirection

Line setup. The design of the Secondary Anchor Point must be sucient to withstand all applied loads experienced during zip line operation.

Loads specified are for zipSTOP Brake assembly installation only and do not allow for any additional equipment or other loadings applied to the secondary mount including redirection lines for additional units.

Loads at Secondary Anchor Point

Inline with Redirection Line 11.0 kN

Right angles to Redirection Line 3.5 kN

The loads specified are applied loads for the Redirection Line and Redirection Pulley only.

These loads DO NOT allow for additional loads applied by other equipment or structures.

Ensure sucient factor of safety is applied in the structural design of all zip line installations.

www.headrushtech.com | +1-720-565-6885

35

Page 35

9.4.1 POSITION OF THE SECONDARY ANCHOR POINT

The Secondary Anchor Point is located in line with the start of the Arrest Zone (Brake Trolley Reset Point). It

provides the location for the attachment of the Type I Pulley above the zip line and also attachment of any

secondary or support lines that may be required.

Ensure the Secondary Anchor Point and any supporting structure are at least one meter above the zip line and at

a sucient distance from the zip line to prevent contact with the rider, redirection line, and other equipment.

Always install pulleys so as to prevent any tangling, snagging or binding with other lines or objects. Ensure that

the Redirection Line is routed cleanly and in line through the pulley system to prevent contact with any surface

other than the pulley sheaves.

9.5 Redirection and Support Lines

All lines must be sewn, spliced, or properly terminated.

Only use an approved termination method for all rope connections. Using a Double Figure 8 knot to terminate a Redirection Line is not recommended by Head Rush Technologies for lines with Spectra or Dyneema

sheaths. Spectra and Dyneema have low coecients of friction which can result in knots becoming untied. A

Double Figure 8 knot also reduces line strength by 20-25% when tied properly and can reduce line strength by

more if tied incorrectly.

All Redirection Lines and support lines are to be manufactured to specified strength and are to be suitable for

all-season outdoor. When installing redirection and support lines, use route lines to ensure that:

All lines are installed in such a way as to prevent loose or sagging lines, tangling, snagging or binding with

other zip line components.

Lines are to be routed to eliminate abrasion and undue wear.

All lines are laid out so as not to present a tripping or injury hazard to zip line sta or riders.

36

Typical Figure-of Eight Knot

www.headrushtech.com | +1-720-565-6885

Page 36

9.6 Fitting zipSTOP Brake Unit

The zipSTOP Brake Unit may be mounted horizontally or vertically. The mounting bracket is designed for use

with a flat or curved surface. Curved surfaces must have a minimum 150 mm (6“) diameter.

ONLY INSTALL THE ZIPSTOP BRAKE UNIT ORIENTED DIRECTLY INLINE WITH THE TYPE 1 PULLEY

The Braking Line feeds straight out of the device, without twist, and centered within the Nozzle. Accelerated Braking Line wear may occur if the line bears onto the Nozzle edge.

DO NOT REUSE SELFLOCKING NUTS

Always use new nuts, as reuse of self-locking nuts may compromise connection integrity. This type of nut

is used on the Brake Trolleys.

Fit the zipSTOP Brake Unit as follows:

INSTALLATION NOTES

Always orient the zipSTOP Brake Unit directly in line with Type I Pulley.

Always use through bolts with large washers and self locking nuts.

It is recommended that double helix spring washers are located under mounting nuts to allow for movement in

primary mount point when used on a wooden structure or use split ring washer or comparable with a rigid structure

to reduce risk of loosening due to vibration

Always mount the zipSTOP Brake Unit a sucient distance from the zip line so that Redirection Lines and pulleys do

not interfere with rider.

Once installation is complete ensure the zipSTOP Braking Line is not twisted and feeds linearly through the Nozzle.

Install the rubber RattleStop bumper

Install the RattleStop pin

INSTALL THE RATTLESTOP

www.headrushtech.com | +1-720-565-6885

37

Page 37

Install the RattleStop washers to both sides

Install the RattleStop screws to both sides.

Tighten the screws on both sides

ATTACH MOUNTING BRACKET TO PRIMARY SUPPORT

Attach the supplied mounting bracket to the primary support with three (3) M12

or ½” hex head through bolts. The bolt holes are located 100mm (3.94in) apart on

center.

Check bolt head is correctly located in the zipSTOP Brake Unit mount.

Secure with flat washers, double helix spring washers and self-locking nuts.

Torque fasteners to maximum of 15 Nm (11 ft-lb). Do not over-torque fasteners.

38

www.headrushtech.com | +1-720-565-6885

Page 38

INSTALL ZIPSTOP TO MOUNTING BRACKET

Line up zipSTOP Brake Unit with the bottom mounting hole and insert the corresponding retaining pin and lynch pin.

Swing the zipSTOP Brake Unit up and apply a small amount of pressure against

the RattleStop until upper mounting holes align.

Fit the upper mounting pin and lynch pin.

Check both lynch pins are correctly located and secure.

In order to prevent tampering, insert a padlock or bolt in place of the lynch pin.

www.headrushtech.com | +1-720-565-6885

39

Page 39

9.7 Fitting the Brake Trolley

The Brake Trolley is installed on the zip line and is used to transfer the energy of the rider to the zipSTOP Braking

Unit.

ALWAYS USE THE CORRECT BRAKE TROLLEY SIZE FOR THE ZIP LINE

Failure to use the correct size may prematurely wear the trolley or zip line.

ENSURE THAT THE ZIPSTOP BRAKING LINE IS FULLY RETRACTED INTO THE ZIPSTOP DEVICE

AT BRAKE INITIATION

If any Braking Line is extended, braking force will be increased, resulting in participant injury or damage to

the zipSTOP Brake Unit. Ensure brake trolley and zipSTOP are properly reset before every run.

NOT RECOMMENDED FOR LOW TENSION LINES WITH OFFSET REDIRECTION PULLEY

Oset redirection pulleys should only be used with highly tensioned zip lines. Slack zip lines may cause

binding and excessive wear on the brake trolley.

To fit the Brake Trolley:

INSTALLATION NOTES

Check the correct size Brake Trolley for zip line is being used.

Some disassembly is required to fit the Brake Trolley to zip line.

The Brake Trolley is installed with the Bump Stop toward the direction of rider arrival.

Ensure the two lower pulley wheels are located below the line and the single upper wheel is above the line.

Check Brake Trolley is the correct size for the zip line. Trolley size is located on

the label.

Remove Redirection Line mounting point …>>

40

www.headrushtech.com | +1-720-565-6885

Page 40

>>…Upper Sheave…>>

>>…and top half of the Bump Stop from the Brake Trolley.

Place the Brake Trolley on the zip line with the Bump Stop facing the direction

of the approaching rider.

Refit the upper half of the Bump Stop. Torque to 6 Nm (4.5 lb-ft)

Refit the Redirection Line mounting point. Torque to 15 Nm (11 lb-ft).

www.headrushtech.com | +1-720-565-6885

41

Page 41

Refit the Upper Sheave to the Brake Trolley, ensuring that all spacers are correctly positioned. Secure the upper wheel with bolt, washer and self-locking

nut. Torque to 15 Nm (11 lb-ft).

Check all fasteners are properly torqued. Do not over tighten.

Check Brake Trolley rolls smoothly on zip line.

9.8 Fitting Type I Pulley

ZSIR15020A THIS PRODUCT CAN ONLY BE USED WITH 1:1 REDIRECTION SETUPS

The zipSTOP IR (ZSIR150-20A) is NOT compatible with external redirection setups in any way. Installing

a redirection setup with the zipSTOP IR can create a very dangerous set of braking conditions that could

result in abnormally abrupt late braking.

The Type I Pulley is fitted to the Secondary Anchor Point, and provides both support and a means of redirection for the Redirection Line. The Type I Pulley is required for both 1:1 and 2:1 Redirection Ratio setups. The

Type I Pulley may be fixed horizontally or vertically to a solid surface or be clamped to a cable. The Type I

Pulley incorporates dedicated line attachment points for dead-end loops.

Fit the Type I Pulley as follows:

INSTALLATION NOTES

Always position the Type I Pulley higher than the zip line. A minimum of 1.0 meter (39.37”) is required.

Ensure the position of the pulley will not allow contact or interference between the rider and any lines or equipment.

Ensure the redirection pulley meets the load requirements as defined in this manual

Ensure the Type I pulley assembly is mounted on a load bearing surface capable of withstanding all applicable load

bearing requirements.

Ensure that the Redirection Line is routed cleanly and in line through the pulley system, to prevent contact with any

surface other than the pulley sheaves. Fixed support pulley(s) can be used to ensure that Redirection Lines are kept

free and clear.

42

www.headrushtech.com | +1-720-565-6885

Page 42

9.9 Fitting Type II Pulley

The Type II Pulley is fitted between the zipSTOP Brake Unit and the Type I Pulley as required to provide support

and redirection for the Redirection Line and connections to the Braking Line. The Type II Pulley is only required on the 2:1 Redirection Ratio set-ups.

Fit the Type II Pulley so as to ensure the position of the pulley will not allow contact or interference between

the rider and any lines or equipment

It is recommended that an overhead support line and link be used with the Type II Pulley to reduce the risk of

line entanglement and assist proper travel of pulley assembly.

Attach zipSTOP braking line to

redirection line with a quicklink and

recommended swivel, support pulley

and sling

Attach redirection

pulley to

overhead line

Overhead Line

Zip Line

9.10 Fitting Redirection Line

ONLY USE APPROVED TERMINATION METHODS FOR ALL ROPE CONNECTIONS

www.headrushtech.com | +1-720-565-6885

Brake Trolley

Double Line – 2:1 Redirection Ratio Example

43

Page 43

ENSURE THAT THE REDIRECTION LINE IS ROUTED CLEANLY & IN LINE THROUGH THE PULLEY

SETUP

Contact between Redirection Line and any surface other than the pulley sheaves must be prevented in order

to eliminate abrasion and undue wear. The redirection line must remain free and clear of all obstacles, the

Arrest Zone and rider travel path.

THE INTEGRITY OF THE REDIRECTION LINE IS PARAMOUNT TO USER SAFETY

Failure of the redirection line will result in no activation of the primary brake and may result in serious injury

or death of the rider.

THE INTEGRITY OF THE REDIRECTION LINE IS PARAMOUNT TO USER SAFETY

Failure of the redirection line may result in serious injury or death of the rider.

ENSURE THAT THE ZIPSTOP BRAKING LINE IS FULLY RETRACTED INTO THE ZIPSTOP DEVICE

AT BRAKE INITIATION

If any Braking Line is extended, braking force will be increased, resulting in participant injury or damage to

the zipSTOP Brake Unit.

ENSURE THAT THE SPECIFIED REDIRECTION LINE MEETS THE SPECIFICATIONS DESCRIBED IN

THIS MANUAL

Use of poor quality Redirection Line may lead to zip line brake failure.

Attachment of the Redirection Line will dier depending on the Redirection Ratio utilized for each zipSTOP installation.

The length of the Redirection Line must be sucient to reach between terminations with a single, continuous line.

9.11.1 1:1 REDIRECTION RATIO

Ensure the Type I pulley is securely fitted to the Secondary Anchor Point and is located higher than the adjacent zip line, and in line with the start of the Arrest Zone.

Attach zipSTOP braking line to redirection

line with a quicklink and recommended

swivel, support pulley and sling

Overhead Line

Brake Trolley

*EAD not shown but it is mandated*

Single Line with 1:1 Ratio Shown

Attach redirection

pulley to

overhead line

Zip Line

44

www.headrushtech.com | +1-720-565-6885

Page 44

INSTALLATION NOTES

Check that the Redirection Line diameter is compatible with the redirection pulley size.

Check that the Redirection Line meets the specified strength, diameter, wear resistance and UV resis-

tance requirements.

Ensure that the Redirection Line is routed cleanly and in line through the pulley system, to prevent con-

tact with any surface other than the pulley sheaves. Fixed support pulley(s) can be used to ensure that

Redirection Lines are kept free and clear. The ZSIR150-20A MUST use a 1:1 redirection line ratio.

Position the Brake Trolley at the start of the Arrest Zone (Reset Position) and temporarily

secure it at that position.

Connect the Redirection Line directly to the Brake Trolley using a proper termination

method and an optional load rated link.

If an optional load rated link is utilized, ensure the gate on the link is screwed tight and

thread lock compound is applied to prevent it from loosening over time.

Ensure the Type I pulley is correctly positioned and secure.

Pass the Redirection Line through the Type I pulley ensuring it enters the pulley from

underneath and passes over and around the sheave in the direction of the zipSTOP Brake

Unit.

Ensure zipSTOP Brake Unit is in the fully retracted position.

NOTE: Braking Line extends approximately 400 mm (16”) from Nozzle in fully retracted

position.

DO NOT TIE REDIRECTION LINE DIRECTLY TO BRAKING LINE

A quicklink or comparable must be used.

Tension the Redirection Line and connect directly to the end loop of

the zipSTOP Braking Line using both a proper termination method and

suitable locking link.

Ensure the gate on the locking link is screwed tight and thread lock

compound is applied to prevent it from loosening over time.

www.headrushtech.com | +1-720-565-6885

45

Page 45

FOLLOWING THE INSTALLATION OF THE REDIRECTION LINE

Remove temporary restraint from the Brake Trolley.

Check the Redirection Line to ensure that the Brake Trolley is in the correct Reset Position when zip-

STOP Braking Line is fully retracted.

Ensure that the Redirection Line is routed cleanly and in line through the pulley system, to prevent con-

tact with any surface other than the pulley sheaves. Fixed support pulley(s) can be used to ensure that

Redirection Lines are kept free and clear.

Tie back any loose ends and check that all lines are free and untangled.

Push the Brake Trolley down the zip line and check that no binding or interference occurs between the

Redirection Line and any other part of the zipSTOP installation.

Check that the maximum travel that can be achieved by the Brake Trolley does not exceed the full Line

Extension of zipSTOP Braking Line.

9.11.2 2:1 REDIRECTION RATIO

Attach zipSTOP braking line to

redirection line with a quicklink and

recommended swivel, support pulley

and sling

Attach redirection pulley

to overhead line

Overhead Line

Zip Line

Brake Trolley

*EAD not shown but it is mandated*

2:1 with Double Line

INSTALLATION NOTES

Check that the Redirection Line diameter is compatible with the redirection pulley size.

Check that the Redirection Line meets the specified strength, diameter, wear resistance, and UV resis-

tance standards.

When using a 2:1 ratio, it is recommended that a support cable be installed to provide support for the

Type II Pulley.

Ensure that the Redirection Line is routed cleanly and in line through the pulley system, to prevent con-

46

www.headrushtech.com | +1-720-565-6885

Page 46

tact with any surface other than the pulley sheaves. Fixed support pulley(s) can be used to ensure that

Redirection Lines are kept free and clear.

2:1 AND HIGHER RATIOS CAN ONLY BE USED WITH THE ZS12508

DO NOT use the ZSIR150-20A in 2:1 or higher configurations.

ENSURE THAT THE ZIPSTOP BRAKING LINE IS FULLY RETRACTED INTO THE ZIPSTOP DEVICE

AT BRAKE INITIATION

If any Braking Line is extended, braking force will be increased, resulting in participant injury or damage to

the zipSTOP Brake Unit. The warranty will be void.

ENSURE THAT THE SPECIFIED REDIRECTION LINE MEETS THE SPECIFICATIONS DESCRIBED IN

THIS MANUAL

Use of poor quality Redirection Line may lead to zip line brake failure.

Position the Brake Trolley at the start of the Arrest Zone (Reset Position),

and temporarily secure it at that position.

Connect the Redirection Line directly to the Brake Trolley using a proper termination method and an optional load rated link.

If a load rated link is utilized, ensure the gate on the link is screwed tight

and thread lock compound is applied to prevent it from loosening over

time.

Ensure the Type I pulley is correctly positioned and secure.

Pass the Redirection Line through the Type I pulley ensuring it passes

through the sheave in the direction of the zipSTOP Brake Unit.

Ensure zipSTOP Brake Unit is in the fully retracted position with the

Type II pulley correctly positioned and secure on the zipSTOP Braking

Line.

NOTE: Braking Line extends approximately 400 mm (16”) from Nozzle

in fully retracted position.

www.headrushtech.com | +1-720-565-6885

47

Page 47

Run the Redirection Line towards the zipSTOP Brake Unit, pass the Redirection Line around the Type II Pulley ensuring it passes through the

sheave in the direction of the Secondary Anchor Point.

Tension the Redirection Line and connect to the dedicated mounting