HEADQUARTERS DEPARTMENT OF THE ARMY 308M User manual

TM

8-6515-004-24&P

UNIT,

SUCTION

DIRECT

MAINTENANCE

(INCLUDING

APPARATUS,

TECHNICAL

SUPPORT,

REPAIR

SPECIAL

MODEL

MANUAL

AND

TOOLS

OROPHARYNGEAL

308M

GENERAL

MANUAL

PARTS

LIST)

SUPPORT

AND

APPROVED

HEADQUARTERS,

FOR

6515-01-304-6497

PUBLIC

RELEASE;

DISTRIBUTION

DEPARTMENT

IS

OF

UNLIMITED]

THE

ARMY

October

1993

I

¡SAFETY

STEPS

TO

FOLLOW

IF

SOMEONE

IS

THE

|

Do

not

try to

If

possible,

If

you

person

other

Send

After

electrical

cannot

to

safety

insulating

for

help

the

injured

shock,

immediately

VICTIM

pull

turn

off

turn

material.

as

start

or

off

OF

grab

the

the

ELECTRICAL

the

electrical

electrical

using a dry

soon

person

move

artificial

as

possible.

is

the

resuscitation.

individual.

power.

power,

wooden

free

person

pole

contact

of

a

short

SHOCK

pull,

or a dry

push,

with

distance

or

rope,

the

source

away

lift

or

the

some

of

and

TM

8-6515-004-24&P

>

№

q

Throughout

time

to

read

Procedures

this

manual

these.

which

They

must

are

are

be

observed

WARNINGS,

there

to

WARNING

to

CAUTIONS,

protect

avoid

you

and

personal

and

NOTES.

the

equipment.

injury,

and

even

Please

loss

take

of

life.

Procedures

which

Essential

must

be

equipment,

information

CAUTION

observed

to

or

long-term

NOTE

avoid

that

damage

health

should

to

equipment,

hazards.

be

remembered.

destruction

of

TM

8-6515-004-24&P

TECHNICAL

NO.

8-6515-004-248P

You

procedures,

Changes

Eguipment

Army

furnished

MANUAL

UNIT,

DIRECT

(INCLUDING

SUCTION

can

help

improve

please

to

Publications

Technical

Medical

Materiel

directly

to

SUPPORT,

MAINTENANCE

REPAIR

APPARATUS,

this

manual.

let

us

know.

and

Blank

Publications)

Agency,

you.

AND

GENERAL SUPPORT

MANUAL

PARTS

AND

OROPHARYNGEAL

MODEL

308M

6515-01-304-6497

If

you

find

any

mistakes

Mail

your

memorandum,

Forms),

located

ATTN:

or

in

SGMMA-M,

DA

Form

the

back

Frederick,

WASHINGTON,

SPECIAL

or

if

DA

Form

2028-2

of

this

manual,

MD

(Recommended

HEADQUARTERS

DEPARTMENT

TOOLS

you

know a way

2028

to:

21702-5001. A reply

OF

DC

LIST)

to

(Recommended

Changes

Commander,

THE

8

October

improve

will

ARMY

1993

to

U.S.

be

CHAPTER

Section

CHAPTER

Section

1.

1.

Il

INI.

2.

1.

|.

Il.

Iv.

V.

Vi.

Approved

HOWTOUSETHISMANUAL.........................

INTRODUCTION

General

Equipment

Principles:of

OPERATING

Preparation

Operating

‘Operating

Operation

Cleaning,

Operation

Information . ...........................,......................

for

public

TABLE

Description

Operation: . νοκ

INFORMATION

for

Operation

Information

Instructions: z à » mesmama

of

AuxiliaryEguipment

Disinfecting,

under

Unusual

release;

OF

and

Data

AND

.........................................,....

.................................................

and

Sterilizing

Conditions.

distribution

CONTENTS

........................................

αν

ες

ηο

INSTRUCTIONS

ses

cas

........................................

Procedures

.....................................

SATER

is

unlimited.

0...

sas

tes

ame

onen

aussi

CLIC

...........................

IL

TALES

Page

iv

1-1

1-3

1-8

2-1

2-1

2-3

2-5

2-6

2-7

TM

8-6515-004-24&P

CHAPTER

Section

CHAPTER

Section

APPENDIX

3.

1.

И.

IR

IV.

V.

M.

VII.

VIII.

IX.

X.

XI.

4.

1.

IL

A.

B.

ο.

Ρ.

E:

UNIT

LEVEL

General

Service

Lubrication

Preventive

Operational

Battery

Troubleshooting

Circuit

Repair

MAINTENANCE

information

Upon

Receipt

Instructions

Maintenance

Testing

Pack

Care

Descriptions

Procedures.

Ge

Maintenance

REFERENCES:

MAINTENANCE

COMPONENTS

EXPENDABLE

REPAIR

Procedures.......................................

AND

PARTS

I

of

Equipment

...........

Checks

............................

and

Recharging................

.

and

LO

Services

ces.

ο

το

ALLOCATION

OF

END

ITEM

DURABLE

AND

SPECIAL

CHART

AND

SUPPLIES

TOOLS

ο

BASIC

AND

LISTS............................

ISSUE

MATERIALS

νι

ντος...

ITEMS

LIST...

LIST

TTI

0.4.4...

44

4-1

GLOSSARY

INDEX

Figure

1-1

1-2

1-3

1-4

1-5

1-6

1-7

1-8

1-9

1-10

1-11

1-12

1-13

No.

SC

lata

Suction

Components

Rinse

Litter

Patient

CAME

ROW

Vehicle

Manufacturer

Operating

Operating

re

ita i e

apparatus

bottle

mounting

suction tube

culos

power

time

Information:

全 四 ON

lee

mg

SIINO

LIST

straps

cos

cord

..

data

plate...

limitation

Stencil...

RO

OF

ILLUSTRATIONS

Title

an

o

decal

emas

.

y

celano

eet

TSE

ca

o

as

I

al

SIT

ce

Seria

ee

ee

SII

Celine

Ia

σσ

SO

GLOSSARY-1

oo

O

ironici

INDEX-1

oa

er

.

..

$

es

o

Page

1-3

1-7

1-7

TM

8-6515-004-24&P

Figure

2-1

2-2

2-3

2-4

2-5

3-1

3-2

3-3

3-4

3-5

3-6

3-7

3-8

3-9

E-1

E-2

E-3

E-4

E-5

E-6

E-7

No.

Operating

NAQUUM

Circuit

Ice

Power

Operating

Vacuum

Operating

Schematic

Vacuum

Pumpiheadi

Vacuum

Battery

Suction

Vacuum

Manifold

Power

mode

AUDE.

breaker . .

transformer

mode

adjust

mode

diagram

pump

pump

pack:

apparatus

pump

......

transformer

Components

control

head

Mt

head

head

selector

selector

selector

cable

......

and

reo

and

coi

with

components

.....

switch.

switch

switch

manifold

ρωσ

manifold

andlaccessones

Title

.........................................

nas

ο

mate

μμ

(front)

το

inn

(front)

72.

ο

еее

ο

отл

ο

οσο.

> :

а

нее

ое

Al

se

ο

+...

Ge

Page

2-1

2-2

2-2

Table

1-1

1-2

1-3

3-1

3-2

3-3

3-4

3-5

3-6

No.

Nomenciature’

Miscellaneous

Specifications.

Transformer

Operator

Repairer

'Operatoruser

Medical

VWiringjintormation!

cross-reference

characteristics

.............

wiring

preventive

connections

preventive

troubieshootingi::

Equipment

51.

LIST

OF

Title

İlt...

......................

.

maintenance

maintenance

ve

Repairer

si

troubleshooting

eve

se

TABLES

<5.

checks

checks

ciar

ame

me не

5...

and!

and

veee

вое

ue.

cs

services.

.

.......................

rea

аль

мя

Page

ee

12

3-5

36

eee

도

alo

ao

3-12

3-13

3-32

TM

8-6515-004-24&P

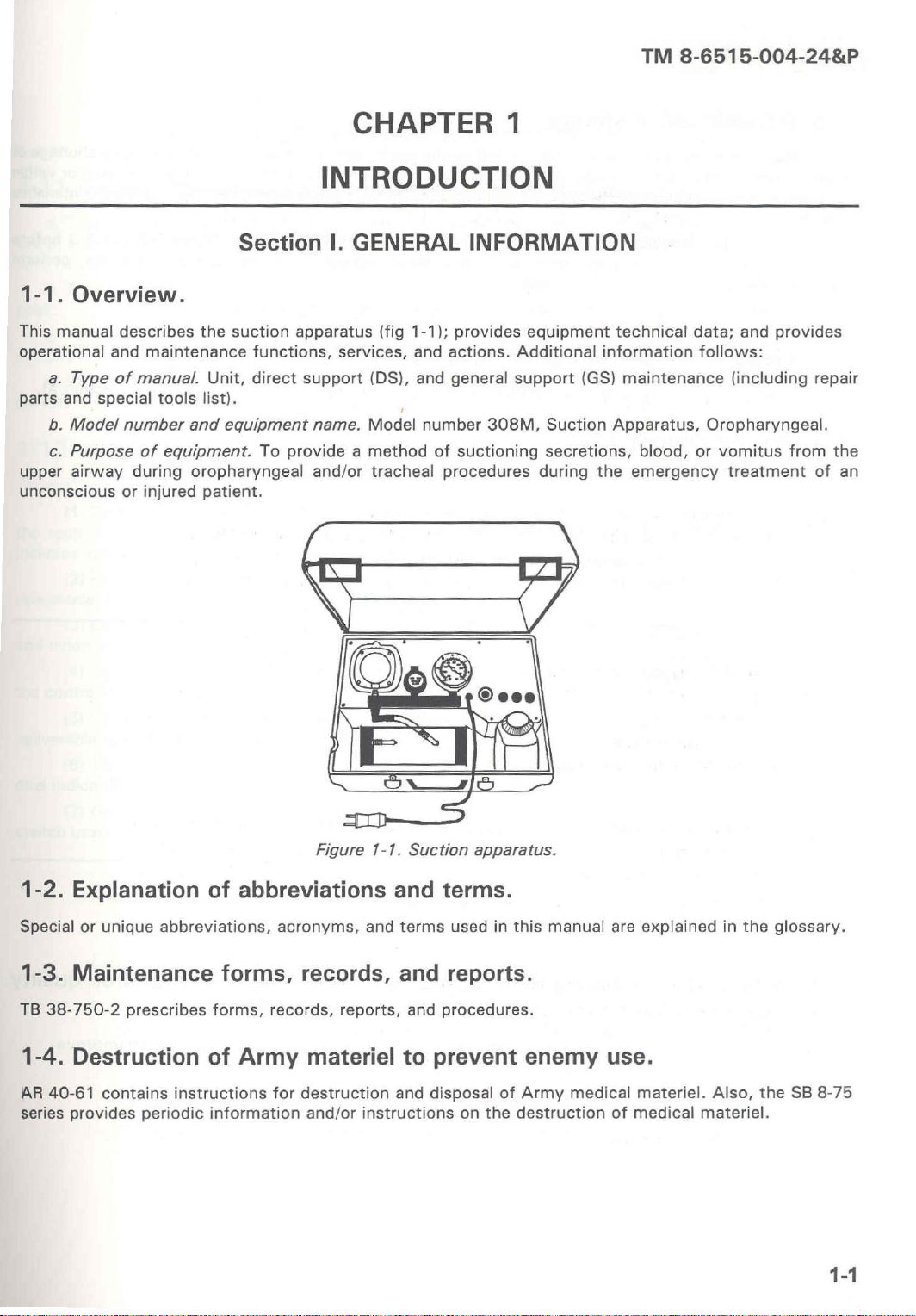

1-1.

Overview.

This

manual

operational

a.

Type

parts

and

special

b.

Model

c.

Purpose

upper

airway

unconscious

describes

and

maintenance

of

manual.

tools

number

of

equipment.

during

or

injured

Section

the

suction

functions,

Unit,

direct

list).

and

equipment

To

oropharyngeal

patient.

CHAPTER

INTRODUCTION

I.

GENERAL

apparatus

support

name.

provide a method

and/or

(fig

services,

(DS),

Model

tracheal

1-1);

and

and

number

1

INFORMATION

provides

actions.

general

of

suctioning

procedures

Additional

support

308M,

equipment

(GS)

Suction

secretions,

during

technical

information

maintenance

Apparatus,

blood,

the

emergency

data;

and

provides

follows:

(including

Oropharyngeal.

or

vomitus

treatment

from

repair

the

of

an

1-2.

Special

1-3.

TB

38-750-2

1-4.

AR

40-61

series

Explanation

or

unique

abbreviations,

Maintenance

prescribes

Destruction

contains

provides

instructions

periodic

Figure

of

abbreviations

acronyms,

forms,

forms,

of

Army

information

records,

records,

materiel

for

destruction

and/or

1-1.

and

and

terms

and

reports,

to

and

instructions

Suction

terms.

used

reports.

and

procedures.

prevent

disposal

apparatus.

in

this

of

on

the

manual

enemy

Army

medical

destruction

are

explained

use.

materiel.

of

medical

in

the

Also,

the

materiel.

glossary.

SB

8-75

1-1

TM

8-6515-004-24&P

1-5.

maintenance

the

records.

placing

PMCS

1-6.

Procedures

1-7.

TB

1-8.

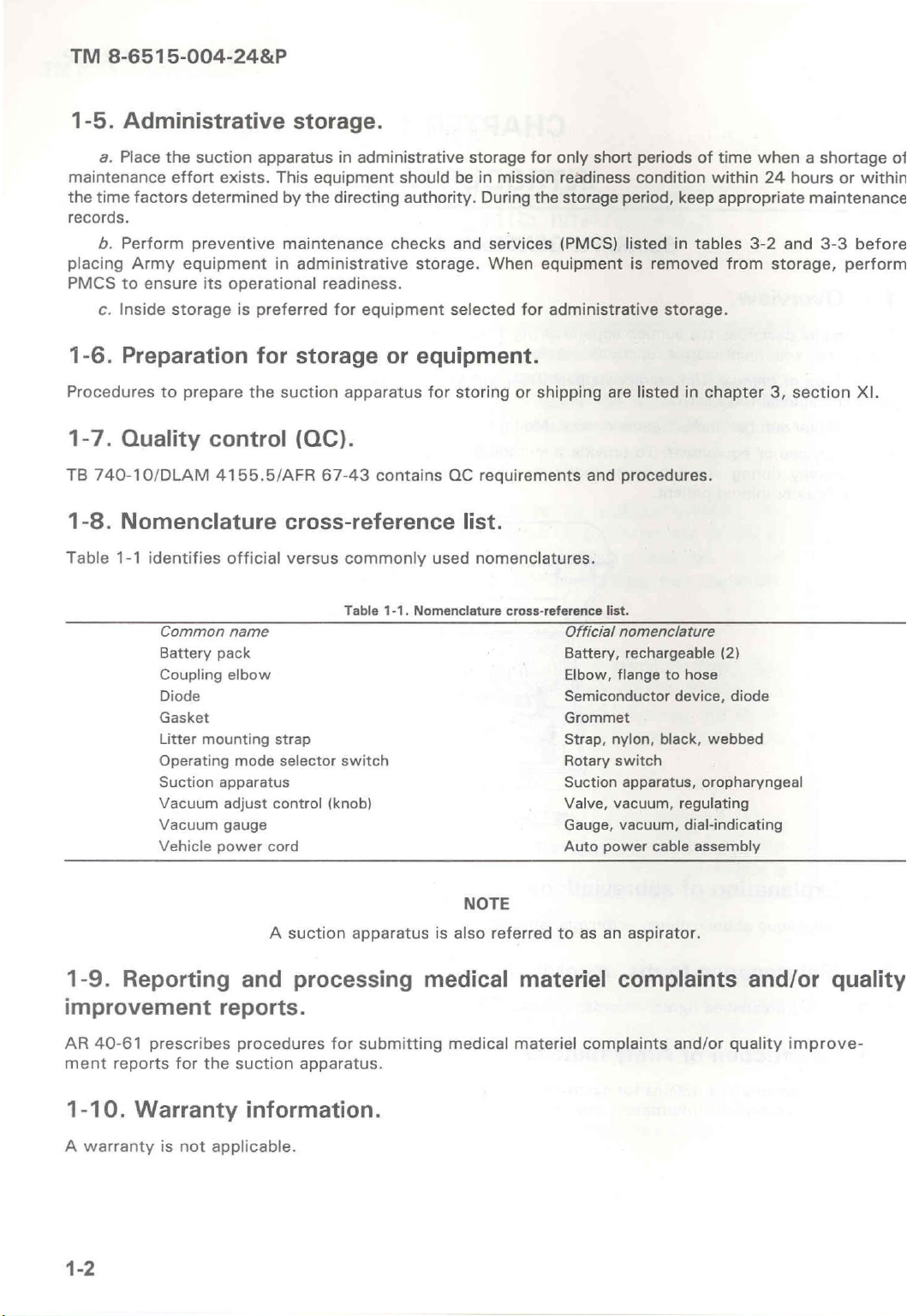

Table

Administrative

a.

Place

time

factors

b.

Perform

Army

to

c.

Inside

Preparation

Quality

740-10/DLAM

Nomenclature

1-1

the

suction

effort

determined

preventive

equipment

ensure

storage

to

prepare

its

control

identifies

Common

Battery

Coupling

Diode

Gasket

Litter

mounting

Operating

Suction

Vacuum

Vacuum

Vehicle

apparatus

exists.

This

by

maintenance

in

operational

is

preferred

for

the

suction

4155.5/AFR

cross-reference

official

name

pack

elbow

apparatus

adjust

gauge

power

mode

versus

strap

selector

control

cord

storage.

in

administrative

equipment

the

directing

checks

administrative

readiness.

for

equipment

storage

or

apparatus

should

authority.

storage.

equipment.

be

and

selected

for

storing

storage

in

mission

During

services

When

or

for

(QC).

67-43

contains

QC

requirements

list.

commonly

Table

switch

(knob) Valve,

1-1.

Nomenclature

used

nomenclatures.

cross-reference

for

only

short

readiness

the

storage

(PMCS)

equipment

administrative

shipping

are

and

list.

Official

Battery,

Elbow,

Semiconductor

Grommet

Strap,

nylon,

Rotary

Suction

Gauge,

Auto

power

periods

condition

period,

listed

procedures.

nomenclature

rechargeable

flange

switch

apparatus,

vacuum,

vacuum,

is

removed

storage.

listed

black,

cable

keep

in

in

to

hose

device,

regulating

dial-indicating

of

time

when a shortage

within

tables

chapter

webbed

oropharyngeal

assembly

24

appropriate

3-2

from

(2)

diode

hours

maintenance

and

3-3

storage,

3,

section

or

within

before

perform

XI.

of

1-9.

Reporting

improvement

AR

40-61

ment

1-10.

A

warranty

prescribes

reports

Warranty

is

for

not

A

and

reports.

procedures

the

suction

information.

applicable.

suction

apparatus

processing

for

submitting

apparatus.

NOTE

is

also

referred

medical

medical

to

as

materiel

materiel

complaints

an

aspirator.

complaints

and/or

and/or

quality

quality

improve-

TM

8-6515-004-24&P

1-11.

use

with

pack.

circuitry.

Equipment

a.

The

in

field

no

electrical

b.

The

c.

Electromagnetic

d.

The

power.

1-12.

the

includes

receptacle.

and

the

deliverable

dual

switch

Component

a.

Components

(1)

Case.

suction

storage

(2)

Power

(3)

Collection

nylon

(4)

control

(5)

“VACUUM

(6)

indicator scales

(7)

Operating

used

suction

hospital

suction

suction

The

apparatus.

cable.

It

is

permanently

tubing

Vacuum

panel

vacuum

Vacuum

to

control

Section

characteristics,

apparatus

treatment

power

apparatus

source,

interference

apparatus

and

(fig

1-2).

dual-wall,

It

includes a hinged

space

for

The

canister.

connectors.

pump.

with

gauge.

The

only

ADJUST”

level.

calibrated

mode

selector

the

Il.

EQUIPMENT

is a

self-contained

areas,

operates

includes a power

ambulances

and

aeromedical

(EMI)

accessory

high-density,

the

operating

electrical

connected

The

valved,

the

The

four

power

collection

diaphragm

black

pump

control.

round

in

millimeters

switch.

modes

metal

from

multiple

and

radio

flame-retardant

lid,

accessories.

cable

to

the

canister

head

The

black,

vacuum

and

The

of

operation.

DESCRIPTION

capabilities,

transportable

or

other

aircraft.

voltages

frequency

transformer

and

unit

patient

and

interference

to

operate

descriptions.

polyethylene

two

latches,

permits

control

consists

type

visible.

serrated

gauge,

inches

black,

The

and a movable

operation

panel.

pump

control

of

mercury.

fluted

control

of a butyrate

with

with

knob

panel

AND

features.

with

an

evacuation

frequencies

from a 230-volt

case

with a direct

cylinder,

integral

clear

with a white

knob

is

electrical

is

plastic

marked

DATA

integral

vehicles,

as

well

(RFI)

are

is

an

carrying

connection

used

to

protective

position

with

case.

It

field

as

an

controlled

source

integral

handle.

black

plastic

motor

is

regulate

marker

the

operating

is

suitable

environments

integral

component

The

located

the

cover,

battery

by

internal

of

electrical

case

to a 115-volt

end

maximum

contains

is a

modes.

for

of

also

caps,

below

rotary

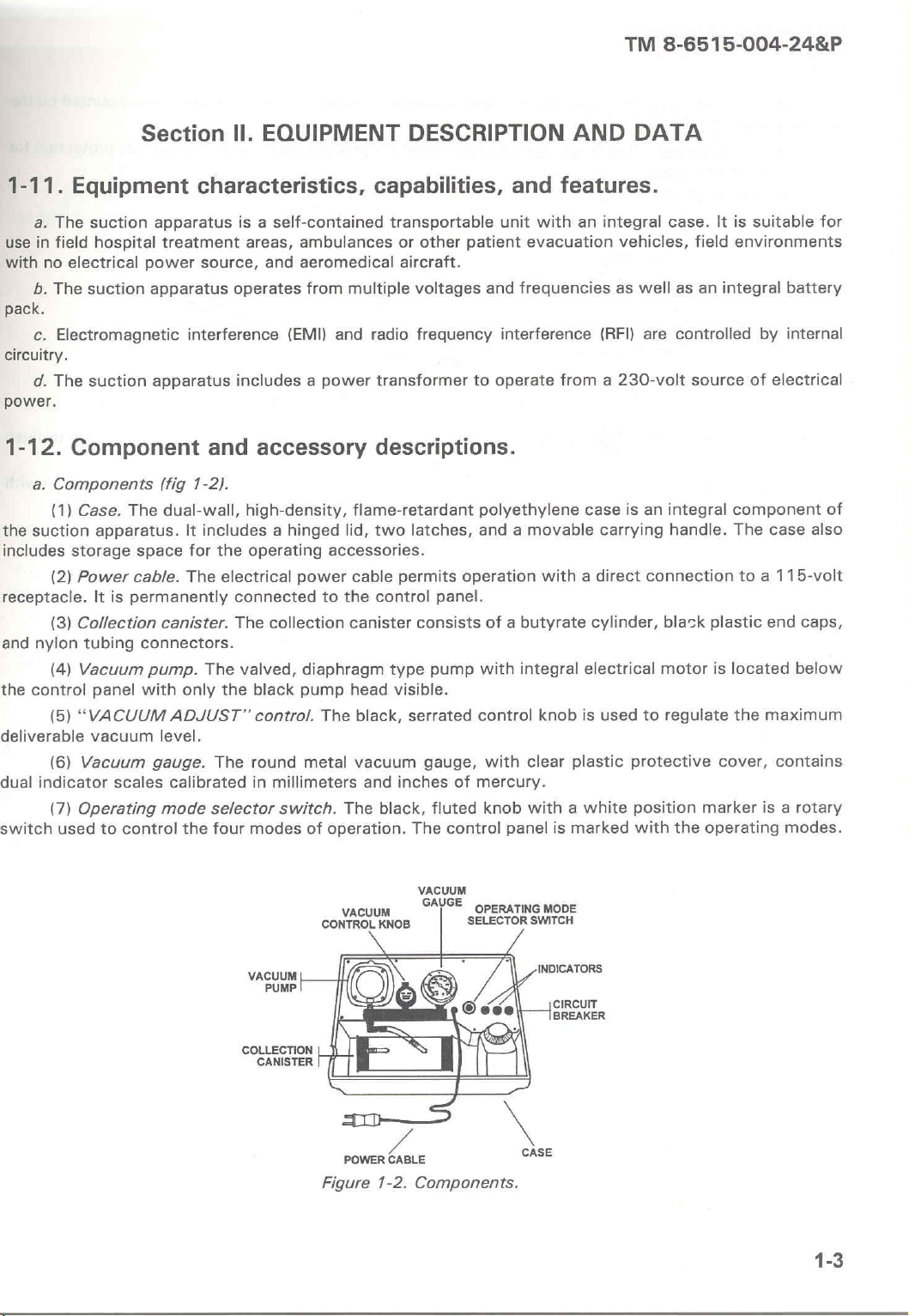

COLLECTION

CANISTER

CONTROL

Figure

VACUUM

POWER

VACUUM

KNOB

CABLE

1-2.

Components.

GAUGE

OPERATING

SELECTOR

MODE

SWITCH

INDICATORS

CIRCUIT

BREAKER

CASE

1-3

TM

8-6515-004-24&P

(8)

Indicators.

control

the

panel.

(9)

Circuit

vacuum

b.

Accessories.

pump/motor.

The

breaker.

two

The

control

black,

indicators,

button-type

which

circuit

show

breaker

green

provides

when

illuminated,

excessive

current

are

mounted

protection

on

the

for

4

the

patient

the

D-ring

a

suction

patient

to

accept

(1)

Rinse

(2)

Litter

fasteners

Figure

(3)

Patient

catheter

(4)

Catheter

suction

(5)

Tubing

(6)

Power

the

Figure

bottle

suction

mounting

1-5.

suction

tube

(fig

transformer

suction

1-3.

(fig

tube

mounted

Patient

by

qualified

(fig

1-6).

by

1-7).

apparatus

Rinse

1-3).

and

suction

straps

on

suction

tube

(fig

medical

The

qualified

The

9-inch

(fig

bottle.

The

translucent

catheter

(fig

1-4).

the

case

tube.

1-5).

sterile

medical

sterilizable

1-8).

power

which

The

two

to

secure

The

sterile

personnel

catheters,

personnel

The

step-down

cable.

Figure

plastic

tubing

rinse

bottle

may

become

black

webbed

the

suction

6-foot

to

furnished

patient

aspirate a patient.

in

to

aspirate a patient.

is

used

transformer

1-4.

Litter

holds a water/saline

clogged

nylon

apparatus

suction

two

to

assist

includes a female,

straps

Figure

tube

sizes,

in

with

to a litter.

1-6.

are

cleaning

mounting

aspirate.

are

used

Catheter.

is

used

used

the

straps.

solution

in

conjunction

in

conjunction

in

conjunction

collection

115-volt

to

flush

with

with

with

canister.

receptacle

a

aa

Figure

1-7.

Tubing.

Figure

1-8.

Power

transformer.

TM

8-6515-004-24&P

dip

The

try

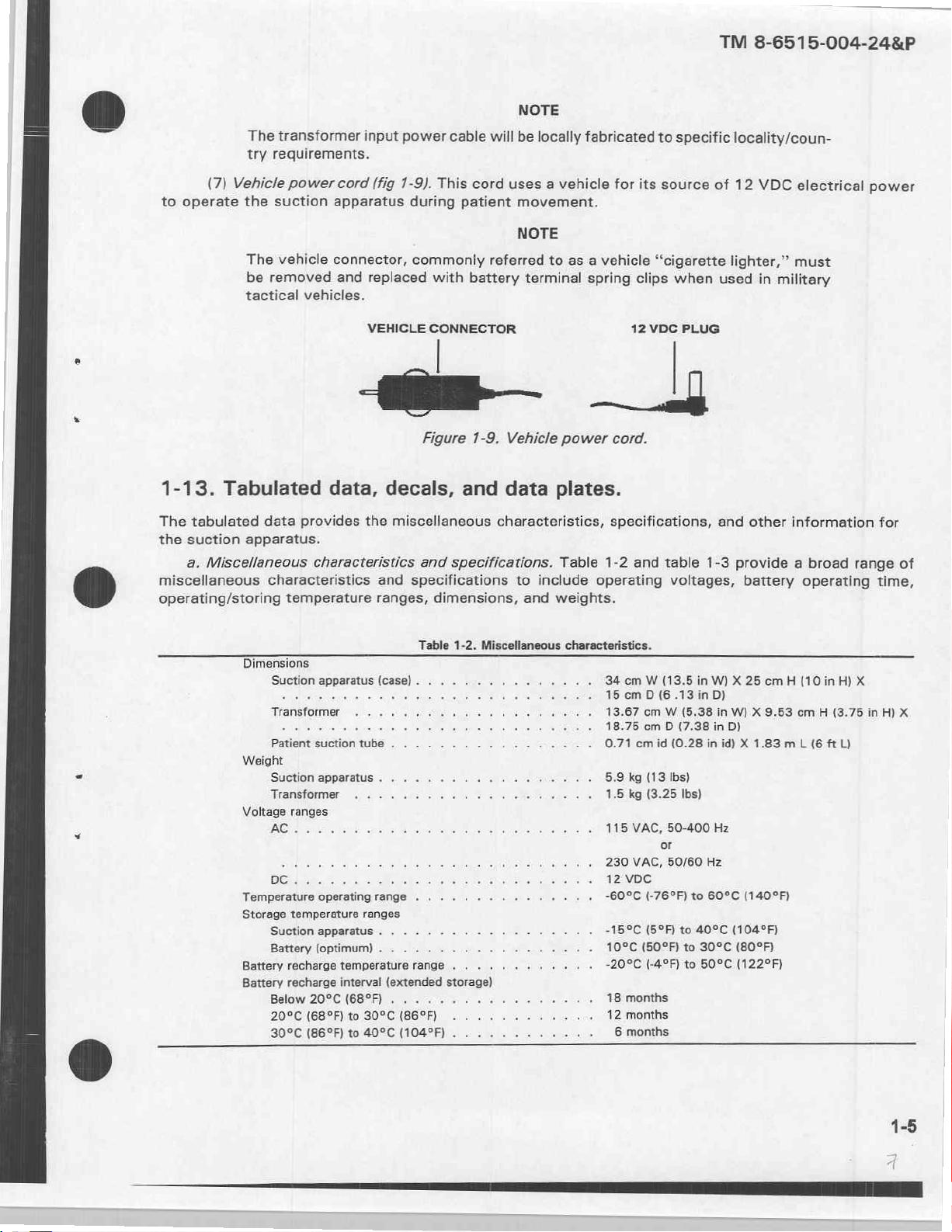

(7)

Vehicle

to

operate

the

The

be

removed

tactical

1-13.

The

the

miscellaneous

operating/storing

Tabulated

tabulated

suction

a.

apparatus.

Miscellaneous

data

characteristics

transformer

requirements.

power

suction

vehicle

cord

apparatus

connector,

and

vehicles.

om—

data,

provides

characteristics

temperature

input

power

(fig

1-9).

during

commonly

replaced

VEHICLE

Figure

decals,

the

miscellaneous

and

and

specifications

ranges,

cable

will

This

cord

patient

referred

with

battery

CONNECTOR

1-9.

and

data

characteristics,

specifications.

dimensions,

NOTE

be

locally

uses

a

vehicle

movement.

NOTE

to as a vehicle

terminal

Vehicle

power

plates.

Table

to

include

and

weights.

fabricated

for

its

spring

clips

12

_

cord.

specifications,

1-2

and

operating

to

specific

source

“cigarette

when

VDC

PLUG

table

voltages,

locality/coun-

of

12

VDC

lighter,”

used

in

military

and

other

1-3

provide a broad

battery

electrical

must

information

range

operating

power

for

of

time,

-

Table

1-2.

Dimensions

Suction

Patient

apparatus

suction

tube

(case) . .

. . . .

Miscellaneous

. .

. .

. . . . . . . . . 34

.............

characteristics.

ст W (13.5

15

cm D (6

13.67

cm W (5.38

18.75

cm D (7.38

0.71

cm

id

in

W) X 25

.13

in

D)

in

(0.28

in

cm H (10

in

W) X 9.53

D)

id) X 1.83

in

cm H (3.75

mL

(6

ft

H) X

L)

in

H)

X

Weight

Suction

Transformer

Voltage

AGA

Temperature

Storage

Suction

Battery

Battery

Battery

Below

20°C

30°C

apparatus . .

ranges

sie

eal:

qua

operating

temperature

apparatus . .

(optimum) . .

recharge

recharge

20°C

(68°F)

(86°F)

range . . . . . .

ranges

temperature

interval

(68°F) . . < <- +-

to

30°C

to

40°C

5.9

kg

1.5

М

al

hace

's

kg

115

230

12

VDC

. . . . . .

range

.............

(extended

(86°F) . .

(104°F) . . . . . . . . . . . . 6 months

storage)

+ 4 4 4 « ve

. . . . .. + + + + 12

...

ie

se

ve

-60°C

-15°C

10°C

-20°C

18

months

months

(13

Ibs)

(3.25

VAC,

50-400

or

VAC,

50/60

(-76°F)

(5°F)

(50°F)

(-49F)

Ibs)

Hz

to

60°C

to

40°C

to

30°C

to

509C

Hz

(140°F)

(104°F)

(80°F)

(1229F)

TM

8-6515-004-24&P

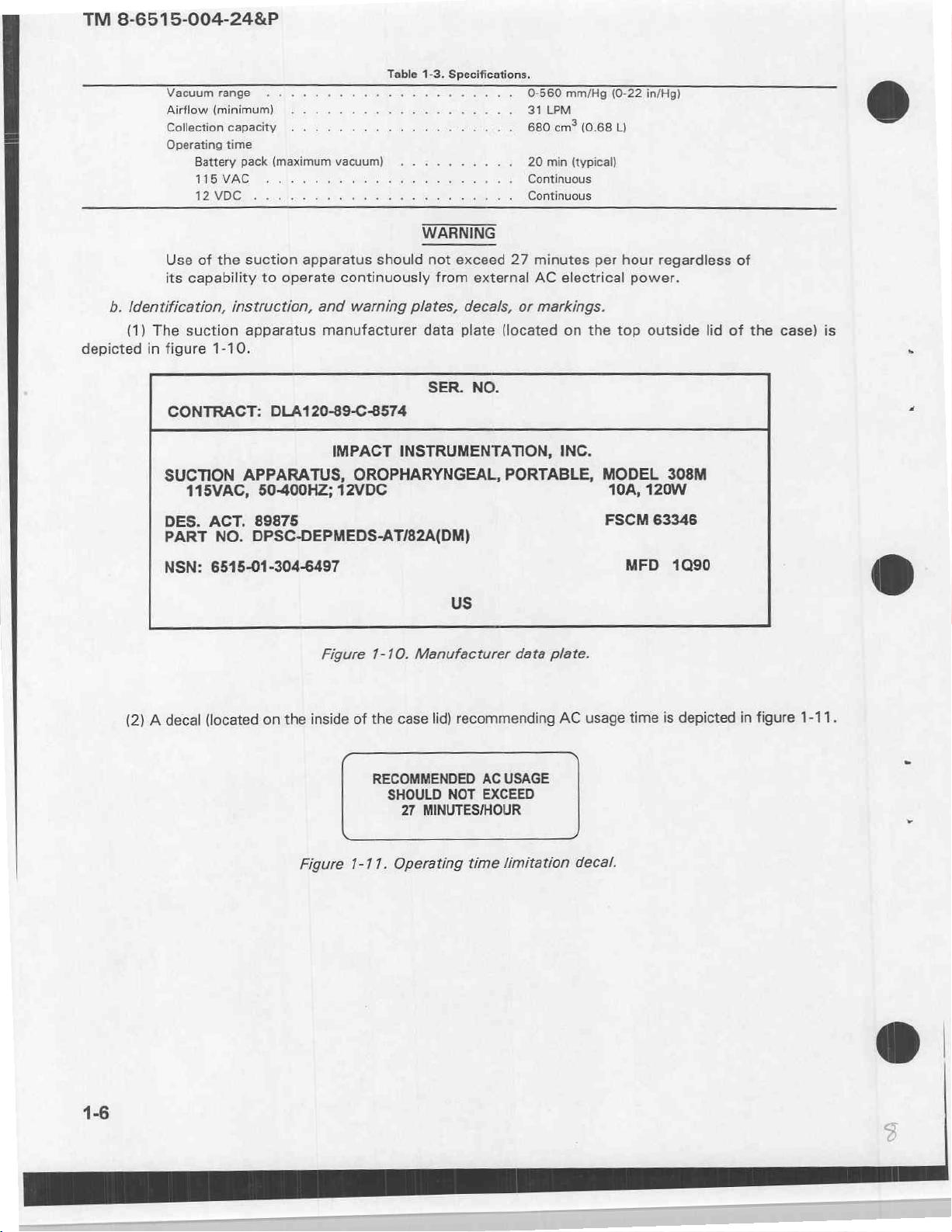

b.

depicted

Vacuum

Airflow

Collection

Operating

Use

its

Identification,

(1)

The

in

figure

CONTRACT:

SUCTION

range . ........

(minimum)

capacity

time

Battery

pack

(maximum

TIBMAC

DUO

of

the

capability

suction

1-10.

115VAC,

κ

ών

λος

suction

to

operate

instruction,

apparatus

DLA120-89-C-8574

APPARATUS,

50-400HZ;

.....

ο

vacuum)

ας

ο

apparatus

and

manufacturer

IMPACT

12VDC

Table

1-3.

ο

ο

Te

ya

eli

WARNING

should

continuously

warning

OROPHARYNGEAL,

not

plates,

data

SER.

INSTRUMENTATION,

Specifications,

0-560

31

LPM

ο

ο

as

680 cm“

20

min

=

È

Continuous

ve

exceed

from

plate

external

decals,

(located

NO.

PORTABLE,

.

Continuous

27

minutes

AC

or

markings.

mm/Hg

(0-22

(0.68

L)

(typical)

per

hour

electrical

on

INC.

the

MODEL

power.

top

10A,

in/Hg)

regardless

outside

308M

120W

lid

of

of

the

case)

is

a

<

DES.

PART

NSN:

(2) A decal

ACT.

89875

NO.

DPSC-DEPMEDS-AT/82A(DM)

6515-01-304-6497

Figure

(located

on

the

Figure

inside

of

1-11.

1-10.

Manufacturer

the

case

lid)

RECOMMENDED

SHOULD

27

Operating

NOT

MINUTES/HOUR

us

data

recommending

AC

USAGE

EXCEED

time

limitation

plate.

AC

usage

decal.

FSCM

MFD

time

63346

1090

is

depicted

in

figure

©

1-11.

TM

8-6515-004-24&P

da

è

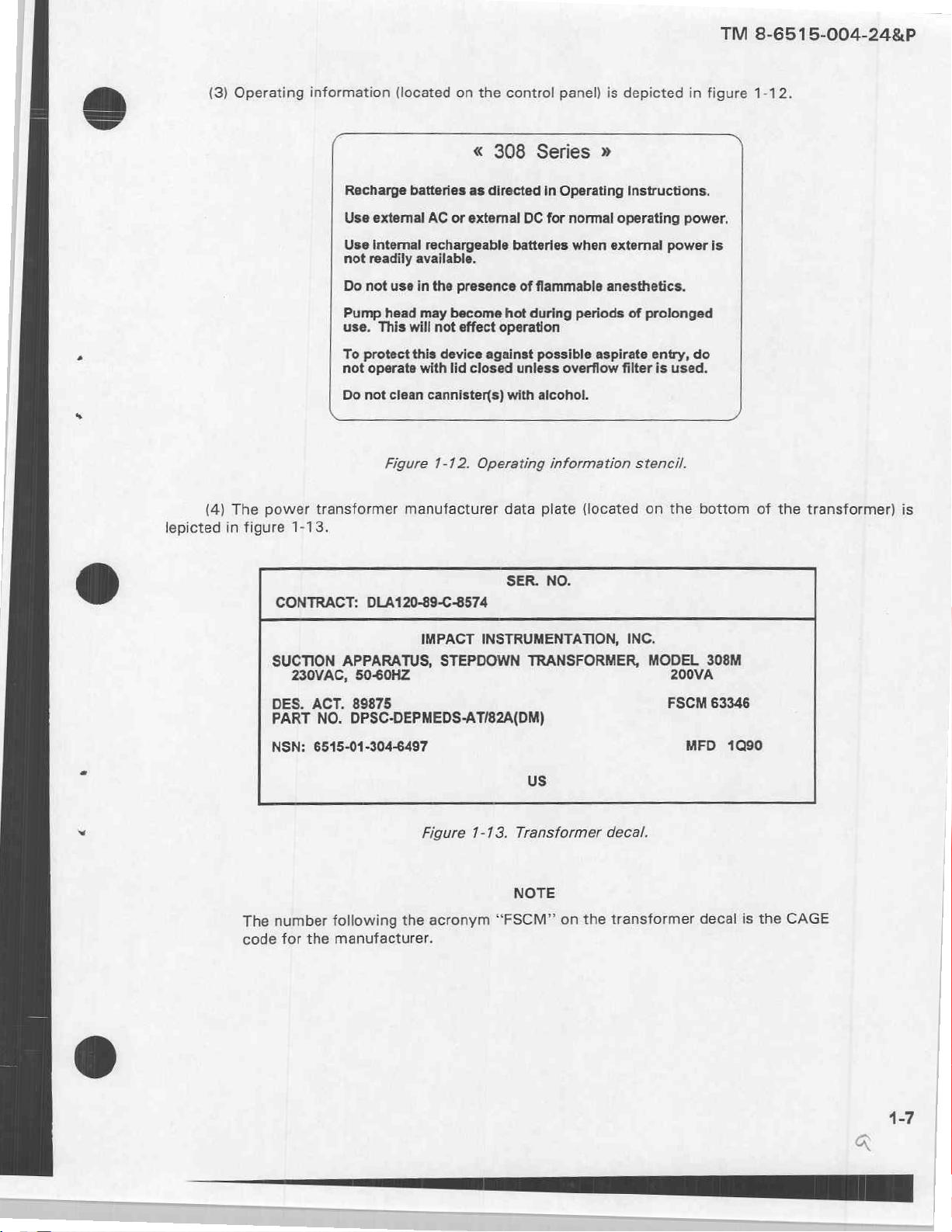

(3)

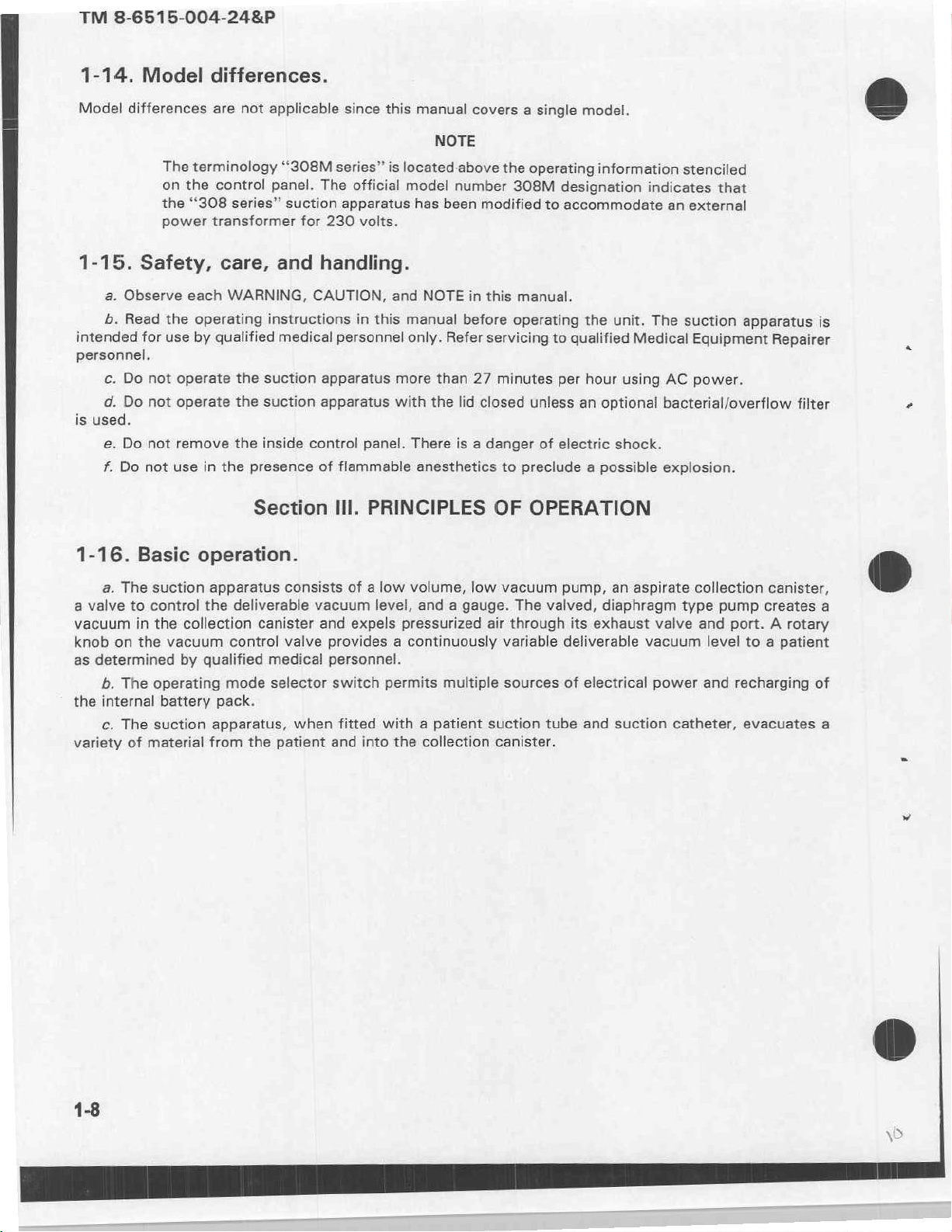

(4)

lepicted

Operating

The

power

in

figure

information

Recharge

Use

Use

not readily

Do

Pump

use.

To

not

Do

transformer

1-13.

(located

external

internal

not

use

head

This

will

protect

operate

not

clean

Figure

manufacturer

on

«

batteries

available.

in

may

this

with

as

AC

or

external

rechargeable

the

presence of

become

not

effect

device

lid

closed

cannister(s)

1-12.

the

control

308

directed

DC

batteries

flammable

hot

during

operation

against

unless

with

Operating

data

panel)

Series

in

Operating

for

normal

when

periods

possible

alcohol.

plate

aspirate

overflow

information

(located

is

depicted

»

Instructions.

operating

external

anesthetics.

of

prolonged

entry,

filter

is

stencil.

on

in

power.

power

do

used.

the

figure

is

bottom

1-12.

of

the

transformer)

is

dh

É

CONTRACT:

SUCTION

DES.

PART

NSN:

The

number

code

DLA120-89-C-8574

APPARATUS,

230VAC,

50-60HZ

ACT.

89875

NO.

DPSC-DEPMEDS-AT/82A(DM)

6515-01-304-6497

following

for

the

manufacturer.

IMPACT

Figure

the

STEPDOWN

1-13.

acronym

SER.

NO.

INSTRUMENTATION,

TRANSFORMER,

us

Transformer

NOTE

“FSCM”

on

the

INC.

MODEL,

FSCM

decal.

transformer

Fed

MFD

decal

63346

1090

is

the

CAGE

TM

8-6515-004-24&P

1-14.

Model

differences

1-15.

a.

Observe

b.

Read

intended

personnel.

c.

Do

d.

Do

is

used.

e.

Do

f.

Do

Model

The

terminology

the

on

“308

the

power

Safety,

each

the

operating

for

use

by

not

operate

not

operate

not

remove

not

use

in

differences.

are

not

applicable

“308M

control

transformer

panel.

series”

care,

WARNING,

instructions

qualified

the

suction

the

suction

the

inside

the

presence

The

suction

for

and

handling.

CAUTION,

medical

apparatus

apparatus

control

of

230

Section

since

this

series”

apparatus

is

official

volts.

and

in

this

personnel

more

with

panel.

flammable

Ill.

PRINCIPLES

manual

covers a single

NOTE

located-above

model

manual

only.

number

been

has

NOTE

There

anesthetics

before

Refer

than

the

lid

is a danger

in

27

modified

this

servicing

closed unless

model.

the

operating

308M

to

information

designation

accommodate

manual.

operating

minutes

to

preclude a possible

OF

OPERATION

to

qualified

per

of

electric

the

hour

an

indicates

unit.

Medical

using

optional

shock.

stenciled

that

external

an

The

suction

Equipment

AC

power.

bacterial/overflow

explosion.

apparatus

is

Repairer

filter

1-16.

a.

a

valve

vacuum

knob

on

as

determined

b.

the

internal

c.

variety

Basic

The

to

in

the

The

The

of

operation.

suction

control

the

collection

vacuum

by

operating

battery

suction

material

apparatus

the

deliverable

canister

control

qualified

mode

pack.

apparatus,

from

the

consists

vacuum

valve

medical

selector

when

patient

of a low

and

expels

provides a continuously

personnel.

switch

fitted

and

into

volume,

level,

and a gauge.

pressurized

permits

multiple

with a patient

the

collection

low

vacuum

air

variable

suction

canister.

The

valved,

through

sources

tube

pump,

an

diaphragm

its

exhaust

deliverable

of

electrical

and

suction

aspirate

type

valve

vacuum

power

catheter,

collection

pump

and

port. A rotary

level

to a patient

and

recharging

evacuates

canister,

creates

of

a

a

TM

8-6515-004-24&P

ab

OPERATING

2-1.

This

nance

sufficient

trained

2-2.

Scope.

manual

of

in

Assembly

a.

Assembly.

b.

Interconnections.

is

primarily

the

suction

information

specific

The

a

suctioning

No

aspiration

suction

INFORMATION

Section

intended

apparatus.

for

use

and

assembly

No

of

catheter

|.

to

provide

The

of

the

suction

techniques

interconnections.

is

required

interconnections

patients

to

the

CHAPTER

PREPARATION

information,

operating

will

collection

apparatus

and

procedures.

prior

are

require

information

to

operating

required

NOTE

the

connection

canister

2

AND

FOR

instructions,

and

on a patient.

prior

tubing

OPERATION

instructions,

the

suction

to

operating

of a patient

connector.

INSTRUCTIONS

and

Only

procedures

while

qualified

apparatus.

the

suction

valid,

medical

suction

tube

for

do

apparatus.

the

mainte-

not

provide

personnel

and

are

(bh

©

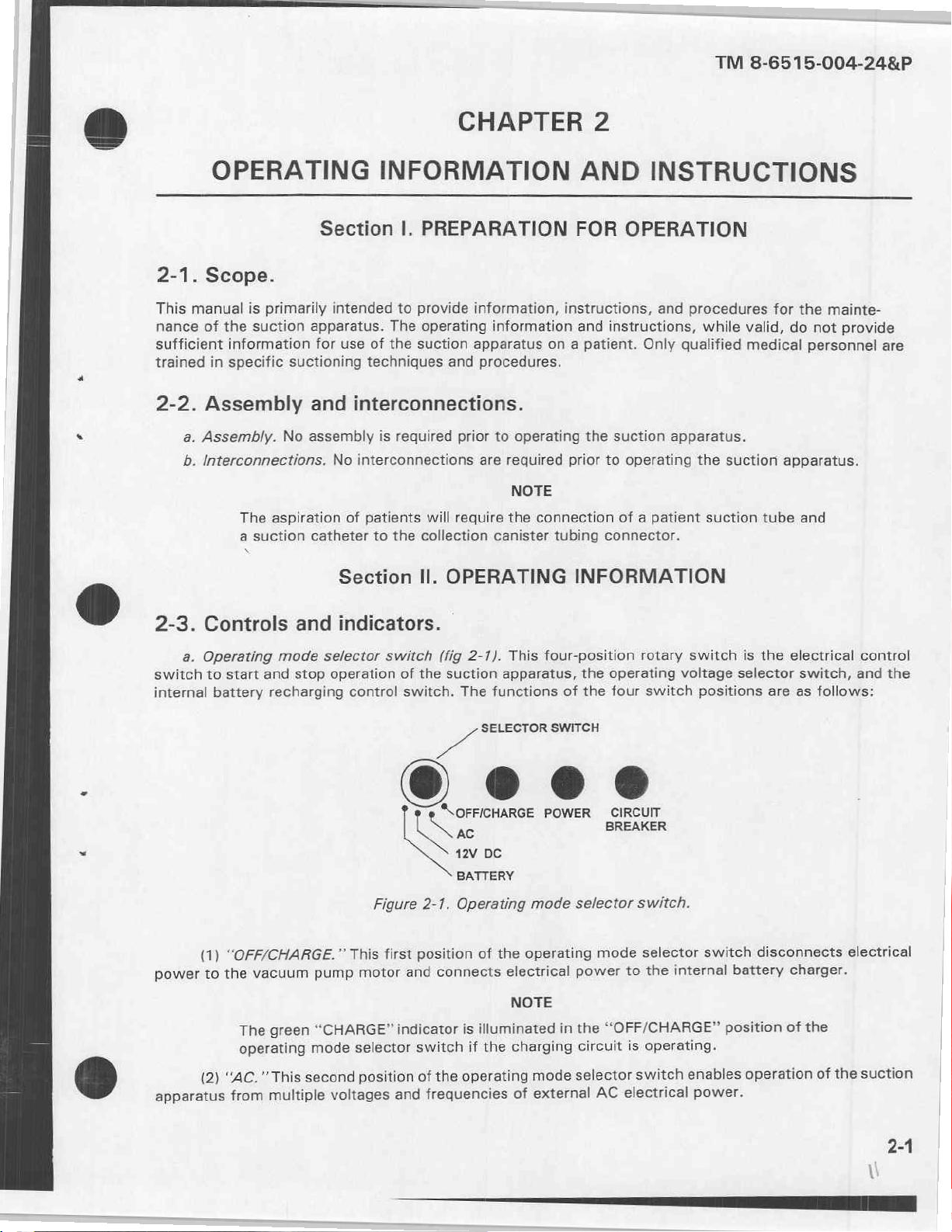

2-3.

switch

internal

power

apparatus

Controls

a.

Operating

to

battery

(1)

to

(2)

and

mode

start

and

stop

recharging

“OFF/CHARGE.”

vacuum

the

green

The

operating

second

"This

“AC,

multiple

from

Section

indicators.

selector

operation

pump

“CHARGE”

mode

voltages

control

This

motor

selector

position

switch

Figure

first

Il.

OPERATING

(fig

2-1).

of

the

suction

switch.

The

A

‘\OFFICHARGE

SS

ne

12V

BATTERY

2-1.

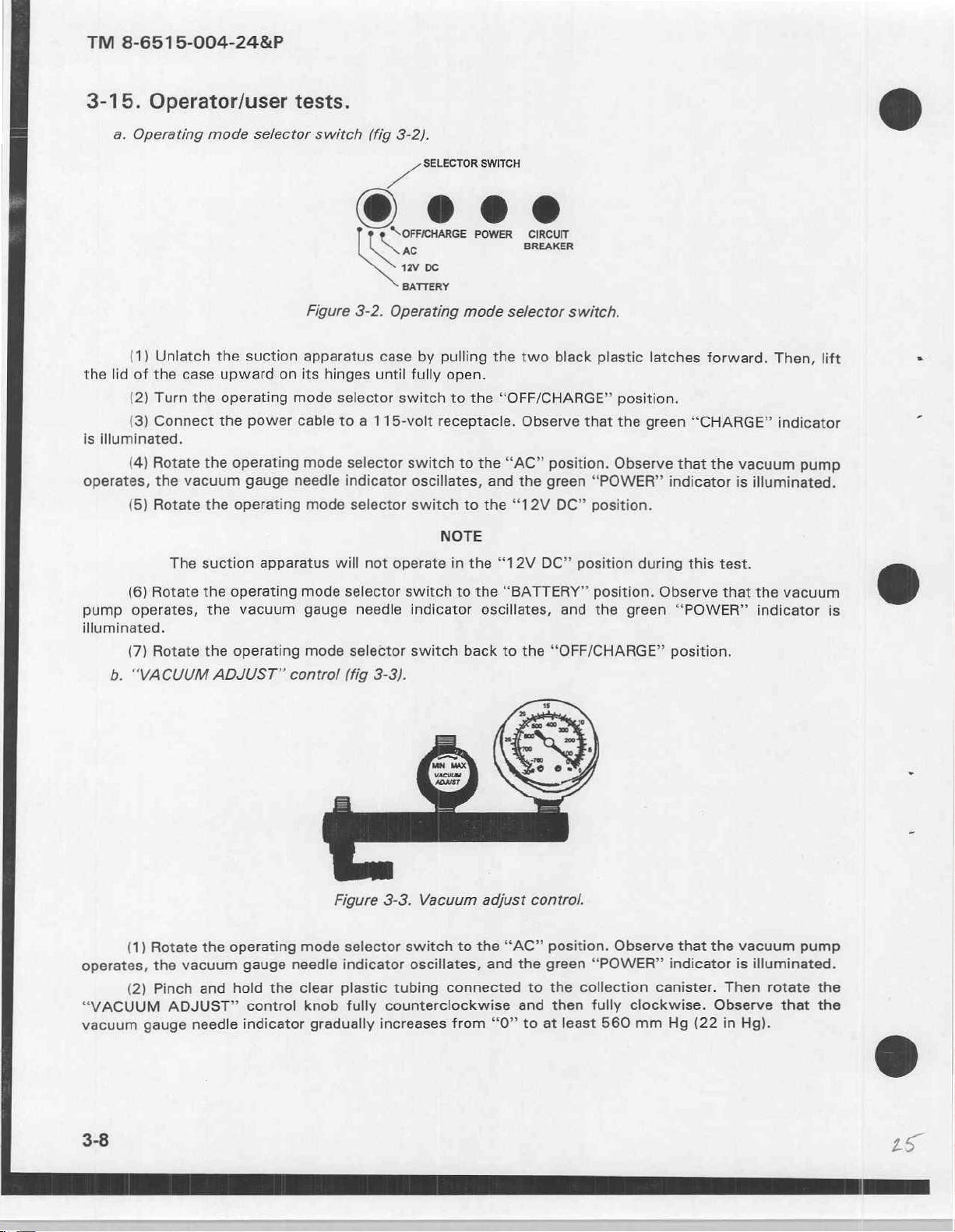

Operating

position

connects

and

indicator

switch

and

is

operating

the

of

frequencies

This

apparatus,

functions

SELECTOR

DC

mode

operating

the

of

electrical

NOTE

illuminated

charging

the

if

mode

of

INFORMATION

four-position

the

of

the

SWITCH

POWER

BREAKER

selector

mode

power

“OFF/CHARGE”

the

in

circuit

selector

external

AC

rotary

operating

four

switch

CIRCUIT

switch.

selector

internal

the

to

operating.

is

switch

electrical

switch

voltage

positions

switch

enables

power.

is

the

selector

are

disconnects

battery

position

operation

electrical

switch,

as

follows:

charger.

the

of

the

of

control

and

the

electrical

suction

TM

8-6515-004-24&P

The green

mode

(3)

“72V DC.”

suction

apparatus

The

operating

(4)

“BATTERY.”

suction

the

by

canister

vacuum

pinched

indicated

apparatus

6.

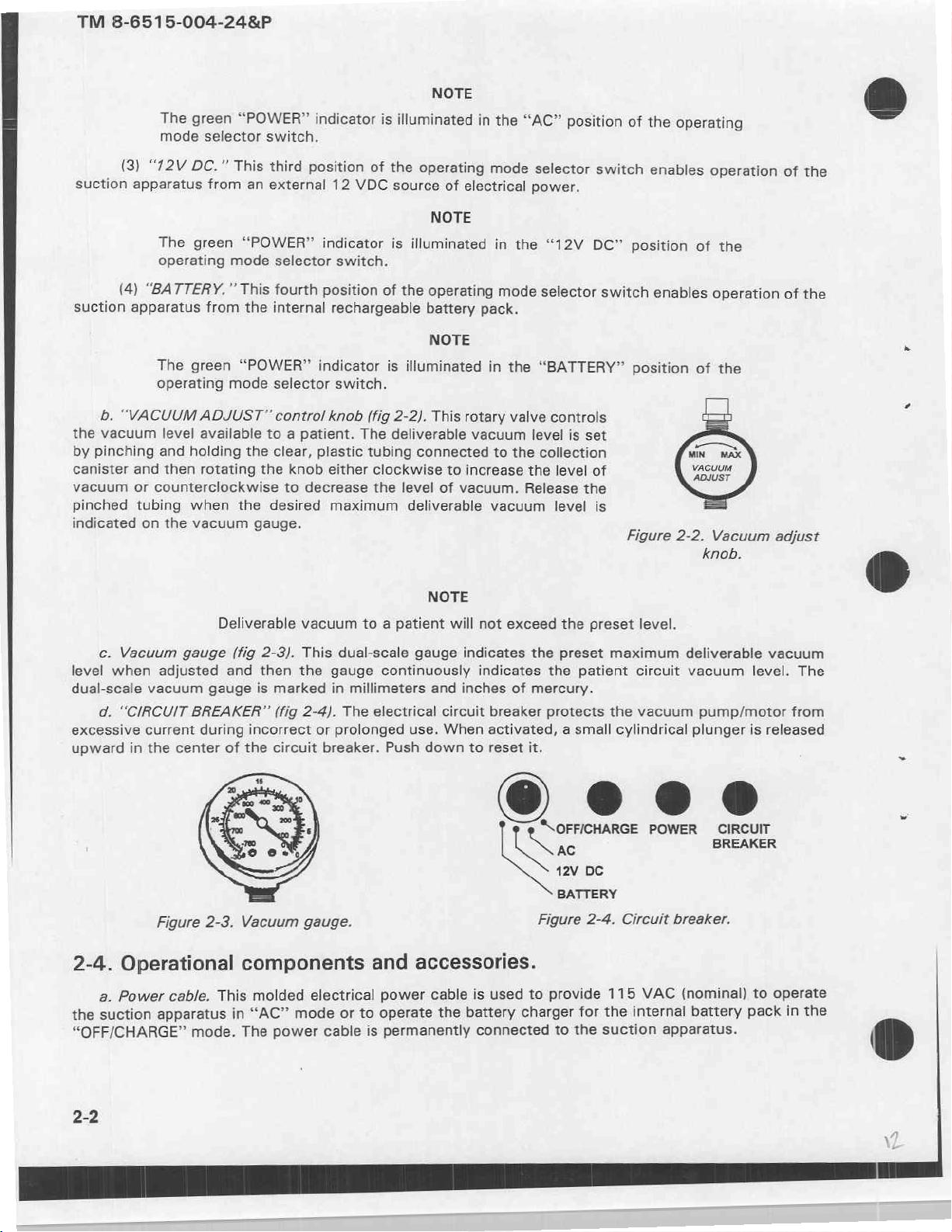

“VACUUM

vacuum

pinching

and

or

tubing

on

The green

operating

level

and

then

counterclockwise

the

selector

This

from

green

mode

This

from

mode

ADJUST”

available

holding

rotating

when

vacuum

“POWER”

switch.

third

an

external

“POWER”

selector

fourth

internal

the

“POWER”

selector

control

to a patient.

the

clear,

the

knob

to

the

desired

gauge.

indicator

position

12

VDC

indicator

switch.

position

rechargeable

indicator

switch.

knob

The

plastic

either

decrease

maximum

is

illuminated

of

the

source

is

illuminated

of

the

is

illuminated

(fig

2-2).

deliverable

tubing

connected

clockwise

the

level

deliverable

NOTE

in

operating

of

electrical

NOTE

operating

battery

pack.

NOTE

This

rotary

vacuum

to

increase

of

vacuum.

the

mode

in

the

mode

in

the

valve

to

the

vacuum

“AC”

position

selector

power.

“12V

selector

“BATTERY”

controls

level

is

collection

the

level

Release

level

switch

DC”

switch

set

of

the

is

of

the

enables

position

enables

position

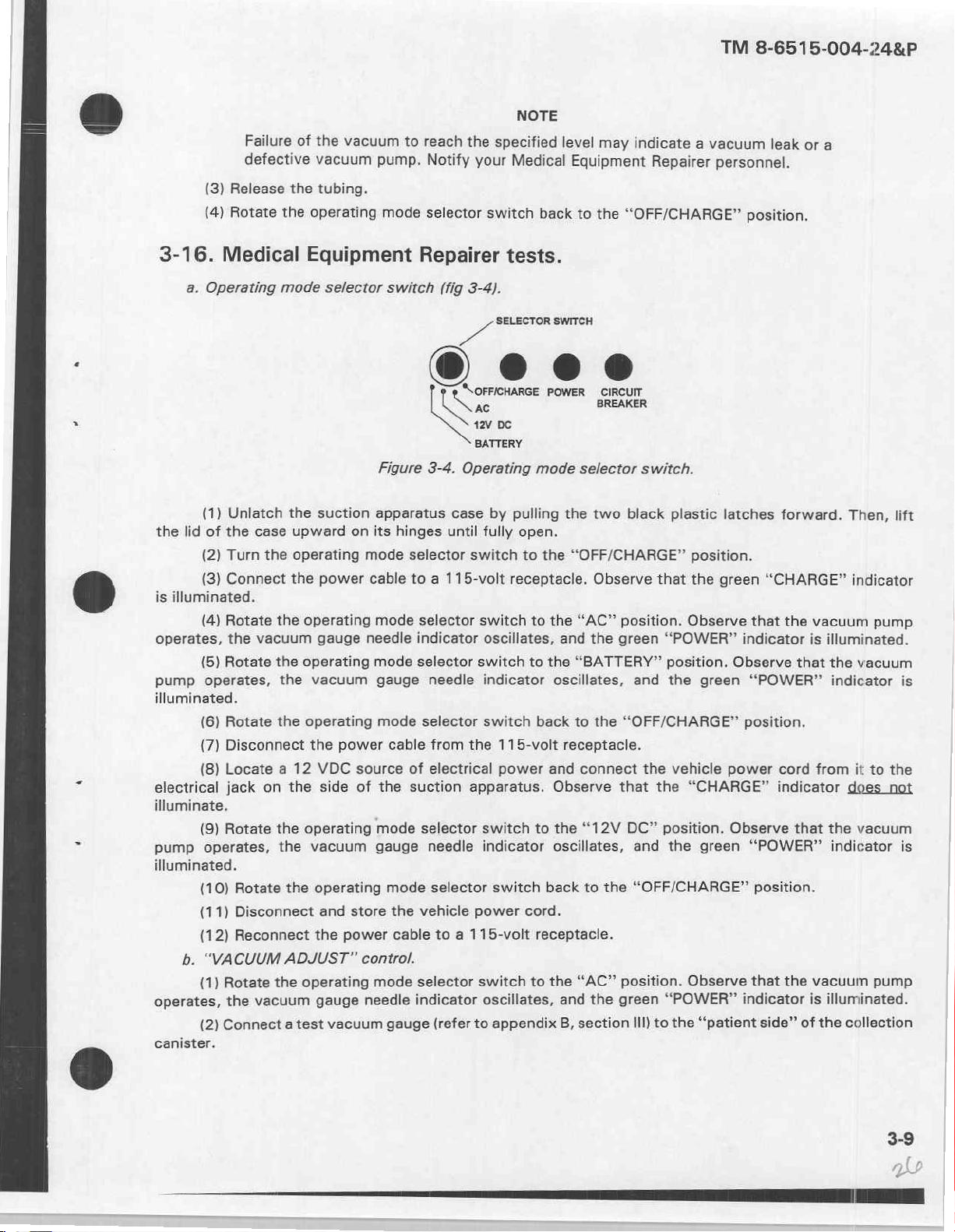

Figure

operating

operation

of

the

operation

of

the

2-2.

Vacuum

knob.

of

the

of

the

adjust

c.

Vacuum

level

when

dual-scale

d.

excessive

upward

2-4.

a.

suction

the

“OFF/CHARGE”

vacuum

“CIRCUIT

current

in

the

Operational

Power

gauge

adjusted

gauge

BREAKER”

during

center

Figure

apparatus

2-3.

cable.

mode.

Deliverable

(fig

2-3).

and

then

is

marked

(fig

incorrect

of

the

circuit

Vacuum

components

This

molded

“AC”

in

power

The

vacuum

This

dual-scale

the

gauge

in

2-4).

The

or

prolonged

breaker.

gauge.

electrical

or

mode

cable

to a patient

gauge

continuously

millimeters

electrical

use.

Push

and

accessories.

power

operate

to

permanently

is

NOTE

will

and

circuit

When

down

cable

the

not

exceed

indicates

indicates

inches

of

breaker

activated, a small cylindrical

to

reset

the

the

preset

the

mercury.

protects

it.

preset

maximum

patient

the

‘\OFFICHARGE

SN

RE

12V

DC

BATTERY

Circuit

2-4.

provide

for

the

to

115

internal

the

suction

is

used

battery

connected

Figure

to

charger

level.

circuit

vacuum

POWER

breaker.

VAC

apparatus.

deliverable

vacuum

pump/motor

plunger

level.

is

CIRCUIT

BREAKER

(nominal)

battery

to

pack

vacuum

The

from

released

operate

the

in

©

2-2

b.

operation

for

Electrical

of

jack.

the

This

two-conductor

suction

apparatus

electrical

the

in

“12V

jack

DC”

is

used

mode.

to

provide

12

TM

8-6515-004-24&P

VDC

from

an

external

source

2-5.

a.

on

its

4.

c.

d.

2-6.

a.

Unlatch

hinges

its

on

4.

follows:

(1)

(2)

(3)

c.

Ensure

d.

power.

Initial

Unlatch

hinges

Ensure

Connect

Recharge

start-up

the

until

that

the

the

Routine

the

until

Determine

hospital

Field

Do

not

hazard.

Ambulance

Litter—internal

that

Connect

either

Section

case

by

pulling

fully

open.

the

operating

power

start-up

case

fully

the

use

the

cable

internal

by

pulling

open.

location

treatment

in

or

other

battery

operating

the

power

III.

procedures.

the

two

mode

selector

to a 115-volt

battery

the

pack

procedures.

the

two

of

use

for

or

area

presence

evacuation

pack.

mode

selector

cable

or

OPERATING

black

plastic

switch

electrical

for

approximately

black

plastic

suction

the

ward—AC

WARNING

of

flammable

vehicle—DC

switch

the

vehicle

latches

latches

apparatus

electrical

(12

is

INSTRUCTIONS

forward.

is

in

the

“OFF/CHARGE”

receptacle.

16

hours.

forward.

and

power.

anesthetics

V)

in

the

power

to

electrical

“OFF/CHARGE”

cord

to

Then,

Then,

mode

the

preclude

power.

an

appropriate

lift

the

position.

lift

the

of

an

position.

lid

of

the

lid

of

the

electrical

explosion

source

case

upward

case

upward

operation

of

electrical

as

e.

Verify

in

place.

f.

Turn

required.

g.

Pinch

“VACUUM

h.

Qualified

collection

The

that

all

No

kinks

the

operating

The

vacuum

illuminate.

and

hold

ADJUST”

medical

canister

“CHARGE”

tubing

should

the

control

and

aspirate

connections

be

in

the

mode

selector

pump

clear,

will

plastic

knob

Deliverable

personnel

the

indicator

are tight

connecting

switch

start

operating

tubing

to

the

desired

vacuum

will

connect

patient.

will

illuminate

and

tubing.

to

connected

will

the

NOTE

that

either

the

NOTE

and

maximum

NOTE

not

exceed

patient

when

connected

the

black

“AC,”

the

green

to

the

deliverable

the

suction

to

collection

“12V

DC,”

“POWER”

collection

vacuum

preset

level.

tube

and a suction

115

VAC.

canister

or

“BATTERY”

indicator

canister

level.

end

caps

will

and

then

Release

catheter

are

firmly

position

rotate

the

tubing.

to

2-3

as

the

the

TM

8-6515-004-24&P

Do

operation

Do

optional

Do

power.

i.

During

collection

canister

not

block

not

operate

overflow

not

use

operation

for

or

occlude

of

the

suction

the

the

suction

of

the

potential

the

suction

safety

suction

overflow.

exhaust

apparatus.

apparatus

device

apparatus

is

apparatus,

WARNING

port

of

CAUTION

with

used.

for

more

periodically

the

the

than

vacuum

lid

27

observe

pump

of

the

minutes

case

the

to

preclude

closed

per

vacuum

hour

incorrect

unless

using

gauge

an

AC

setting

and

the

2-7.

aspiration

used

D-rings

2-8.

Procedures

patient,

Operating

a.

The

b.

Multiple

c. À standard

on a “crash

d.

Two

(located

Changing

are

a.

Pinch

b.

Rotate

gauge.

rinse

to

flush

The

when

collection

litter

to

change

as

follows:

and

the

hints.

bottle,

out a clogged

rinse

bottle

not

in

use.

hospital

cart.”

mounting

on

the

This

front

maximum

the

hold

the

“VACUUM

holding a water

patient

containing

canisters

style

collection

will

straps

and

may

afford

with

back

water

be

of

deliverable

maximum

clear,

plastic

ADJUST”

deliverable

tubing

and

saline

suction

tube

CAUTION

and

saline

connected,

canister

greater

hook-and-loop

the

should

collection

case)

to

vacuum

vacuum

connected

contro!

knob

NOTE

solution,

or

suction

solution

in

series,

be

considered

capacity

fasteners

mount

level,

to

until

the

the

the

should

should

if a large

always

catheter.

always

and

will

be

suction

level.

during

use

collection

new

setting

be

be

quantity

for

use

indicate

used

in

apparatus

of

the

canister.

is

available

tightly

of

if

aspirate

conjunction

suction

displayed

closed

aspirate

the

suction

to a litter.

apparatus

volume.

during

is

anticipated.

apparatus

with

on

the

patient

the

four

on

a

vacuum

is

c.

2-9.

Mount

Rotating

control

Release

the

Rotating

tubing

vacuum

Mounting

the

suction

the

control

knob

counterclockwise

pinched

the

“VACUUM

connected

level

to

the

suction

apparatus

knob

tubing

and

ADJUST”

to

the

collection

an

unknown

onto a litter

clockwise

increases

decreases

resume

aspirating

WARNING

control

canister,

setting.

apparatus.

by

completing

the

vacuum

the

knob,

will

the

the

level

patient.

without

change

following

of

vacuum

level.

pinching

the

procedures:

and

the

maximum

rotating

clear,

plastic

deliverable

the

the

a,

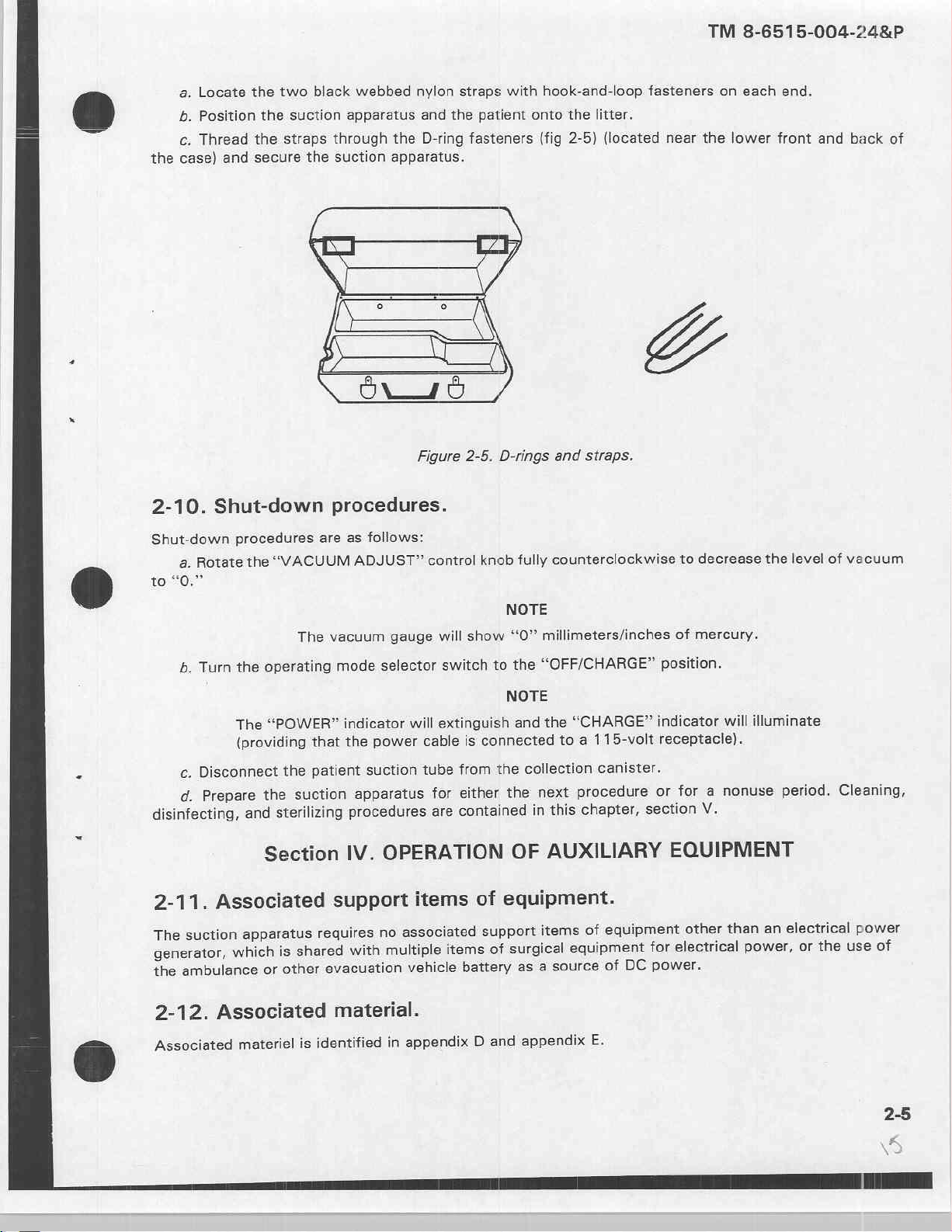

Locate

b.

Position

c.

Thread

case)

and

the

two

the

the

straps

secure

black

suction

through

the

webbed

apparatus

suction

nylon

and

the

the

D-ring

apparatus.

straps

patient

fasteners

with

hook-and-loop

onto

(fig

the

2-5)

litter.

(located

fasteners

near

the

TM

8-6515-004-24&P

on

each

end.

lower

front

and

back

of

2-10.

Shut-down

to

disinfecting,

2-11.

The

generator,

the

Shut-down

Rotate

a.

“0.”

Turn

b.

Disconnect

c.

Prepare

d.

Associated

suction

ambulance

procedures

the

The

(providing

which

“VACUUM

the

The

operating

“POWER”

the

suction

the

sterilizing

and

Section

apparatus

shared

is

other

or

procedures.

are

as

follows:

ADJUST”

vacuum

mode

that

patient

gauge

selector

indicator

power

the

suction

apparatus

procedures

OPERATION

IV.

support

with

no

multiple

requires

evacuation

Figure

will

2-5.

control

will

switch

extinguish

is

cable

from

tube

either

for

contained

are

items

associated

items

vehicle

battery

D-rings

fully

knob

NOTE

show

“O”

the

to

NOTE

and

connected

collection

the

the

OF

equipment.

of

support

surgical

of

as

and

straps.

counterclockwise

millimeters/inches

“OFF/CHARGE”

“CHARGE”

the

115-volt

a

to

canister.

procedure

next

chapter,

this

in

AUXILIARY

equipment

of

items

equipment

DC

source

a

of

decrease

to

of

mercury.

position.

indicator

receptacle).

a

for

or

section

V.

EQUIPMENT

other

electrical

for

power.

illuminate

will

nonuse

than

power,

level

the

period.

electrical

an

or

vacuum

of

Cleaning,

use

the

power

of

2-12.

Associated

Associated

materiel

material.

identified

is

appendix

in

D

and

appendix

E.

TM

8-6515-004-24&P

Section

2-13.

disinfecting,

designed

2-14.

“OFF/CHARGE”

non-abrasive

General.

a.

The

b.

Accessories

and

c.

The

Suction

a.

Cleaning.

(1)

Turn

(2)

Disconnect

(3)

Remove

(4)

Wipe

suction

collection

Do

control

V.

CLEANING,

apparatus

and/or

sterilizing

identified

manufactured

canister

apparatus.

off

the

position.

either

the

collection

the

interior

cleanser

not

with a damp

immerse

panel.

and

procedures

as

for

should

suction

the

and

the

DISINFECTING,

operating

disposable

one

use

be

apparatus

power

canister,

exterior

cloth.

suction

accessories

are

should

only.

removed

cable

or

rinse

of

the

apparatus

provided

by

the

bottle,

WARNING

in

not

be

from

the

turning

vehicle

and

suction

in a liguid

AND

should

subsequent

the

apparatus

STERILIZING

be

cleaned

case

to

operating

power

all

other

or

allow

clean

at

paragraphs.

and

reused.

facilitate

cord.

cleaning.

mode

accessories.

case

and

liguid

to

PROCEDURES

all

times.

These

selector

control

leak

panel

below

Specific

accessories

switch

using a mild,

the

cleaning,

were

to

the

δι

i

(5)

(6)

(7)

(8)

b.

Disinfecting.

it

with

c.

Sterilizing.

2-15.

a.

Cleaning.

(1)

(2)

(3)

(4)

Dry

the

suction

Reinstall

Replace

Prepare

disinfectant

the

all

the

The

Collection

Disconnect

Proceed

Connect

Dispose

Disassemble

the

of

apparatus

collection

other

accessories

suction

Disinfect

in

accordance

suction

canister.

the

tubing

slowly

9-inch

the

the

and

aspirate

collection

All

canister.

apparatus

the

suction

with

apparatus

from

carefully

section

in

tubing

with a soft

into

the

for

either

apparatus

standard

cannot

both

collection

to

prevent

tubing

of

accordance

canister

is

disposable

cloth.

case.

the

unit

be

CAUTION

both

to

with

removing

by

WARNING

next

procedure

by

wiping

procedures.

sterilized.

canister

accidentally

collection

standard

the

and

intended

or

it

with a liquid

connectors.

spilling

canister

procedures.

unit

end

two

for

one

for a nonuse

disinfectant

any

patient

connectors.

caps.

use.

period.

or

lightly

aspirate.

δν

spraying

(5)

Clean

collection

the

canister

cylinder

and

end

caps

accordance

in

with

standard

procedures.

unit

M

TM

8-6515-004-248P

dy

ーー Do

b.

procedures.

*

ec.

unit

procedures.

2-16.

not

hydrocarbon

(6)

Wipe

the

Disinfecting.

Routine

aspirate

procedures

amount

Sterilizing

(ethylene

Section

General.

clean

the

cylinder

agents.

collection

Disinfect

canister

the

disinfection

can

be

accomplished

(para

2-6)

of

disinfectant

oxide

Do

not

VI.

OPERATION

with

cylinder

collection

of

the

and

directly

(EtO)

steam

sterilize

WARNING

abrasive

and

canister

collection

using a spray

while

the

into

the

only).

Sterilize

WARNING

(autoclave)

UNDER

cleansing

end

caps

with a liquid

NOTE

canister

vacuum

collection

which

disinfectant.

pump

the

collection

the

UNUSUAL

agents,

with a soft

or

spray

does

Follow

is

operating,

canister.

canister

collection

alcohol,

cloth.

not

or

disinfectant

involve

the

routine

spray a small

in

accordance

canister.

CONDITIONS

chlorinated

using

standard

removing

start-up

with

unit

standard

The

suction

cility,

within

environment,

tive

barrier

2-17.

to

-20°C

Operating

a.

The

60°C

(-76°F

b.

The suction

to

suction

50°C

apparatus

an

ambulance

precautions

(plastic

The

protective

apparatus

to

(-4°F

is a transportable

or

other

should

sheet,

tarpaulin,

barrier

temperature

should

140°F).

apparatus

to

should

122°F).

evacuation

be

taken

etc.).

will

not

not

not

device

to

protect

interfere

range.

be

operated

be

recharged

designed

vehicle,

the

WARNING

with

when

to

operate

and with a litter.

suction

safe

operation

the

temperature

when

the

within a field

apparatus

of

temperature

When

the

by

covering

suction

is

not

medical

it

is

operated

apparatus.

within

is

not

treatment

in a wet

it

with a protec-

the

range

within

the

of

-60°C

range

fa-

of

2-7

TM

8-6515-004-24&P

3-1.

unit

personnel

checking

operator

disassembly

Overview.

a.

Unit

level

on

its

assigned

(1)

Operator

and

for

accessories,

or

maintenance.

equipment.

maintenance.

consists

frayed

cables, and

assembly

of

and

tools.

(2)

Specialist

Medical

Equipment

(a)

Scheduling

fication/certification

(b)

Performing

modules,

class

information,

services

equipment,

the

personnel

the

and

(c)

repair

(d)

(e)

(f)

in

(g)

b.

Maintenance

scope

of

will

vacuum

Operating a repair

parts

Maintaining a library

and

Conducting

Establishing

accordance

Notifying

assemblies,

the

pump

maintenance.

Repairers.

(CVC)

PCBs,

used

when

on

related

support

functions.

operator/user

perform

the

and case.

UNIT

Section

This

Responsibilities

This

equipment

stowing

replacing

of

the

end

The

and

performing

services.

unscheduled

available.

parts

medical

materials.

inspections

administrative

with

TB

38-750-2.

maintenance

or

modules.

Maintenance

are

assigned

majority

CHAPTER

LEVEL

|.

GENERAL

level

of

segment

operational

items

operator

item,

critical

This

segment

functions

PMCS,

maintenance

program

equipment.

of

technical

on

new

procedures

to

of

maintenance

MAINTENANCE

maintenance

are

stratified

of

unit

functions;

not

in

repair parts.

adjustments

of

unit

and

services

electrical

functions

to

include

manuals

or

transferred

for

battalions

functions,

unit

level

required

3

INFORMATION

is

the

responsibility

as

follows:

level

maintenance

routine

use;

Replacing

level

include—

safety

Class

(TMs),

equipment.

the

of

requirements

both

Maintenance

services

and

checking

operator

after

maintenance

inspections

with

VIII

repair

manufacturers’

control and

preventive

for

the

equipment

replacement,

of

is

like

for

parts

is

and

emphasis

parts

administration

and/or

and

corrective,

Equipment

and

performed

performed

cleaning,

loose

hardware,

will

not

or

the

performed

tests,

on

replacing

as

well

literature,

evacuating

Repairer

except

some

by a using

by

operator/user

dusting,

washing,

replacing

require

extensive

and

as

other

which

personnel.

extensive

only

by

calibration/veri-

assemblies,

commodity

repair

of

maintenance

unserviceable

are

tasks

involving

use

of

trained

parts

beyond

These

3-2.

Common

pendix

(MTOE)

3-3.

Components

Tools

B,

for

Components

and

and

tools

section

authorized

end

of

test

Ill

test

equipment

this

of

items.

item

equipment.

required

manual.

end

of

and basic

Refer

item

issue

for

your

to

and

items

level

unit

unit’s

basic

listed

are

maintenance

modified

issue

in

items.

appendix

table

the

of

organization

of

sections

C,

equipment

and

II

are listed

equipment

and

this

of

III

ap-

in

manual.

TM

8-6515-004-24&P

3-4.

Expendable

appendix

3-5.

Repair

3-6.

Special

this

3-7.

assembly

Expendable

Repair

parts

Special

tools

manual.

Unpacking

a.

Open

b.

Remove

c.

Remove

d.

Remove

and

D,

section

required

required

the

and

durable

Il

parts.

for

tools.

Section

cardboard

the

suction

the

power

the

transformer

the

two

supplies.

supplies

of

this

manual.

unit

level

for

unit

level

Il.

SERVICE

the

suction

shipping

apparatus

transformer

plastic

instruction

and

materiais

maintenance

maintenance

apparatus.

carton.

using

by

covering.

manuals.

required

are

of

UPON

the

handle

lifting

Set

Set

them

listed

the

equipment

RECEIPT

of

its

cardboard

them

aside.

for

maintenance

in

appendix

the

case.

aside.

E,

are

listed

OF

Set

packing

of

the

equipment

section

Il

in

appendix

of

EQUIPMENT

the

case

aside.

assembly.

this

E,

Remove

are

listed

manual.

section

the

in

III

of

packing

o

・

on

e.

Unlatch

its

hinges

f.

Observe

g.

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

The

nents

the

until

Verify

receipt

Vehicle

Catheter,

Catheter,

Rinse

Patient

Tubing,

Strap,

Collection

Instruction

Power

(11)

Suction

suction

how

power

may

case

fully

the

of

14

18

apparatus

be

by

open.

components

the

cord.

french.

french.

bottle.

suction

tube.

9-inch.

litter

mounting, 2 each.

canister

manuals, 2 each.

transformer.

apparatus

within

pulling the

this

following

with

fittings.

with

may

be

chest

two

and

material:

case.

NOTE

packed

and

black

accessories

into a military

not

plastic

within

latches

are

the

suction

forward.

packed

chest

into

and

operating

apparatus

Then,

the

case.

lift

the

case.

lid

compo-

of

the

case

Qi

upward

a

TM

8-6515-004-248P

3-8.

No

assembly

verify

3-9.

The

internal

dures

3-10.

a.

b.

case

with

pulling

Assembling

or

suction

that

the

black

Accessories

configuration

Do

not

for

use

accessories

Charging

battery

contained

in

Preparing

Remove

Grasp

the

the

the top

your

other

transformer

the

apparatus

collection

not

should

connect

with

the

that

the

battery

pack

of

paragraph

the

four

Phillips

section

hand.

sections

suction

interconnections

canister

reguired

be

the

patient

suction

are

furnished

the

suction

2-5.

power

screws

of

the

transformer

Then

rock

apart.

apparatus.

end

caps

are

CAUTION

for a specific

stored

to

prevent

suction

apparatus.

in

sterile

tube

pack.

apparatus

transformer

from

the

bottom

case

each

section

Set

the

transformer

are

reguired

tight

and

patient

damage

NOTE

and

suction

This

will

packaging.

will

be

for

corners

with

one

of

the

before

that

the

procedure

or

loss.

catheter

preclude

charged

use.

of

hand

and

transformer

on a work

its

operation.

canister

the

by

following

the

power

the

surface.

tubing

or

overseas

until

they

waste

bottom

case

in

You

should,

connections

voltage

are

reguired

of

disposable

the

initial

transformer.

section

opposite

of

however,

are

start-up

the

directions

proce-

transformer

tight.

while

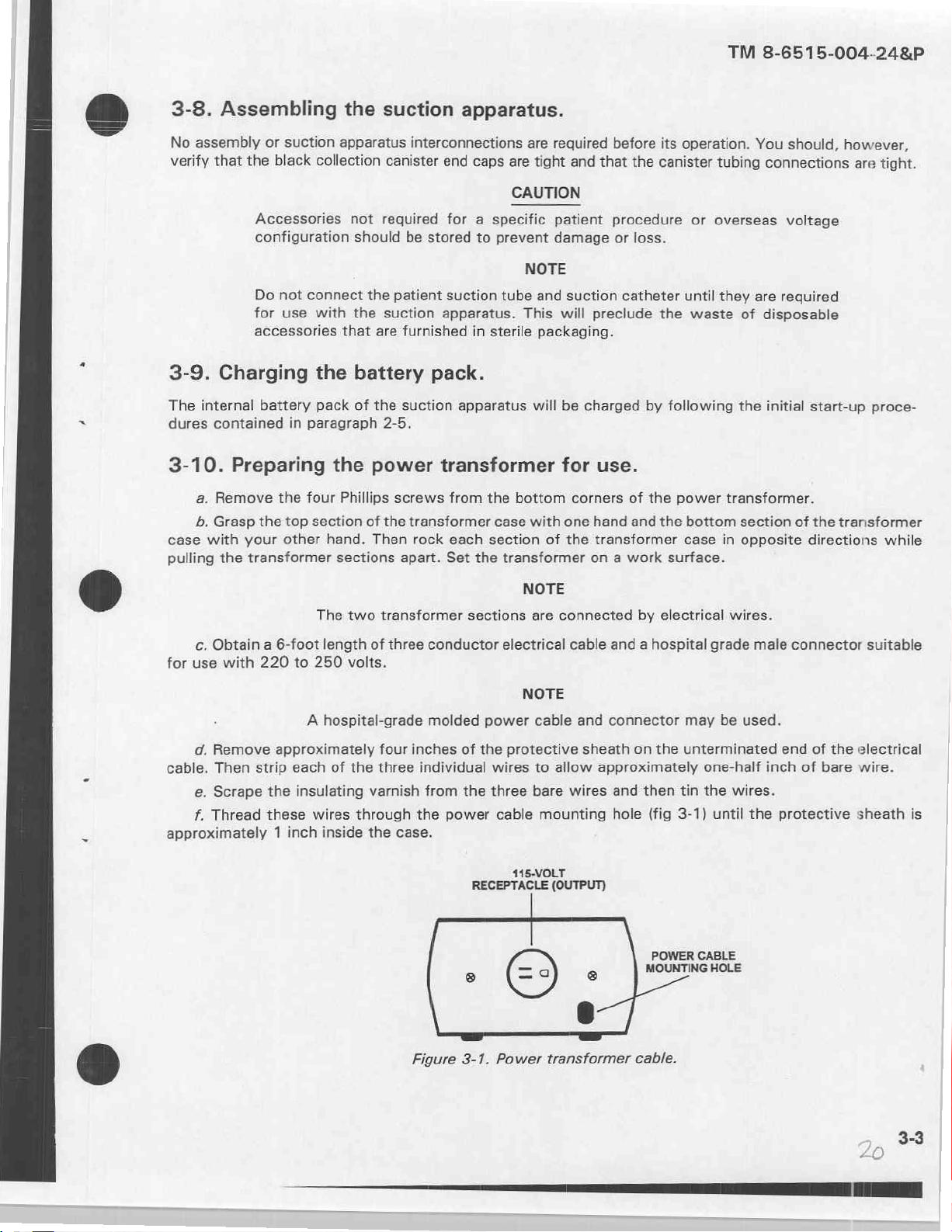

c.

Obtain a 6-foot

for

use

with

220

to

A

d.

Remove

cable.

approximately 1 inch

e.

Scrape

f.

Thread

Then

approximately

strip

each

the

insulating

these

The

two

transformer

length

250

wires

inside

of

three

volts.

hospital-grade

four

of

the

three

varnish

through

the

sections

conductor

molded

inches

individual

from

the

case.

power

electrical

power

of

the

wires

the

three

cable

RECEPTACLE

NOTE

are

connected

cable and a hospital

NOTE

cable

protective

to

allow

bare

wires

mounting

115-VOLT

(OUTPUT)

by

and

connector

sheath

on

approximately

and

hole

electrical

may

the

unterminated

then

tin

(fig

3-1)

POWER

MOUNTING

wires.

grade

be

one-half

the

wires.

until

CABLE

HOLE

male

used.

inch

the

connector

end

of

the

of

bare

protective

suitable

electrical

wire.

sheath

is

Figure

3-1.

Power

transformer

cable.

TM

8-6515-004-24&P

g.

hole

Install

until

р.

Connect

Pin

it

the

locks

power

into

the

electrical

Description

cable

place.

strain

wires

relief

to

the

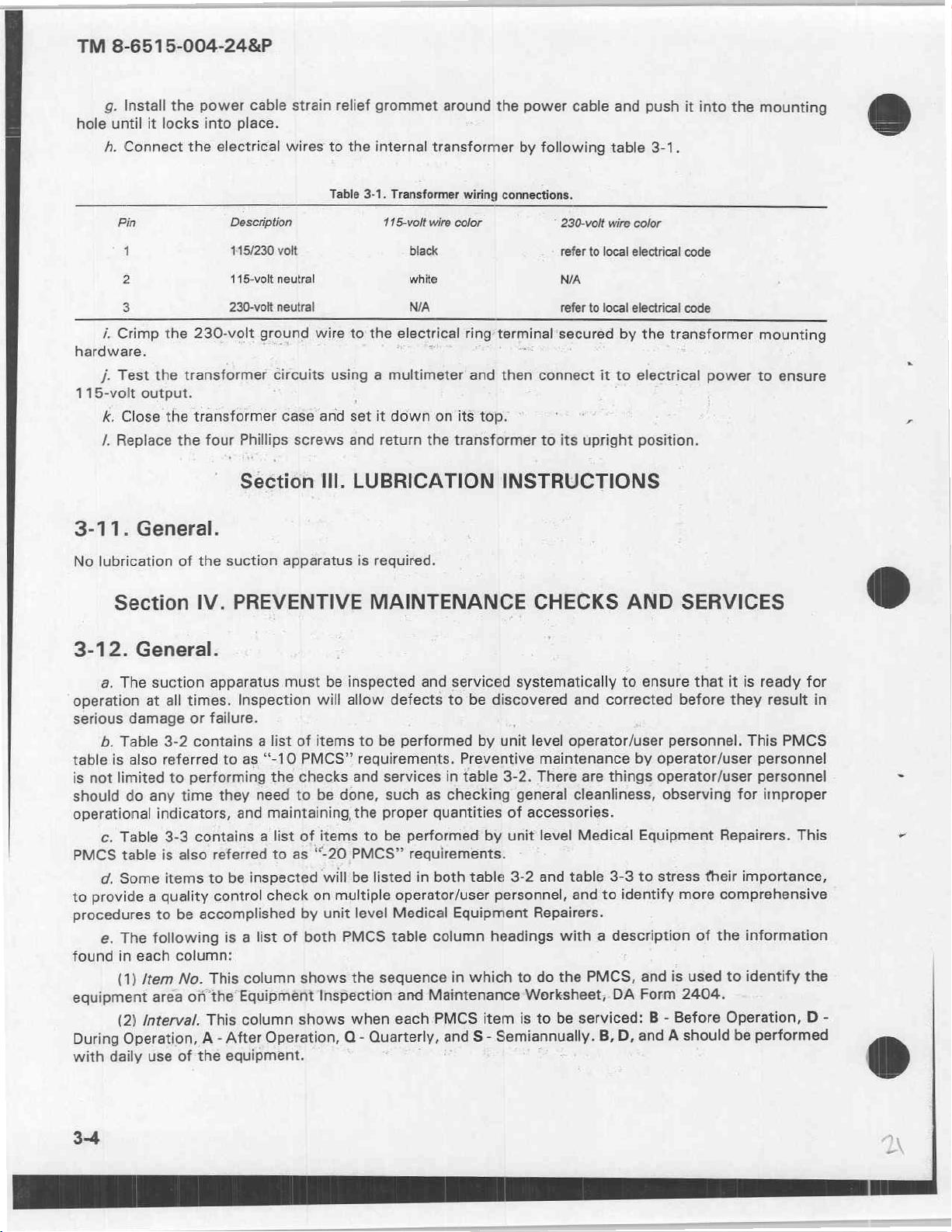

Table

grommet

internal

3-1.

Transformer

115-volt

around

transformer

wire

the

wiring

color

power

by

following

connections.

230-volt

cable

and

table

wire

color

push

3-1.

it

into

the

mounting

1

2

i.

3

Crimp

the

hardware.

j.

Test

the

115-volt

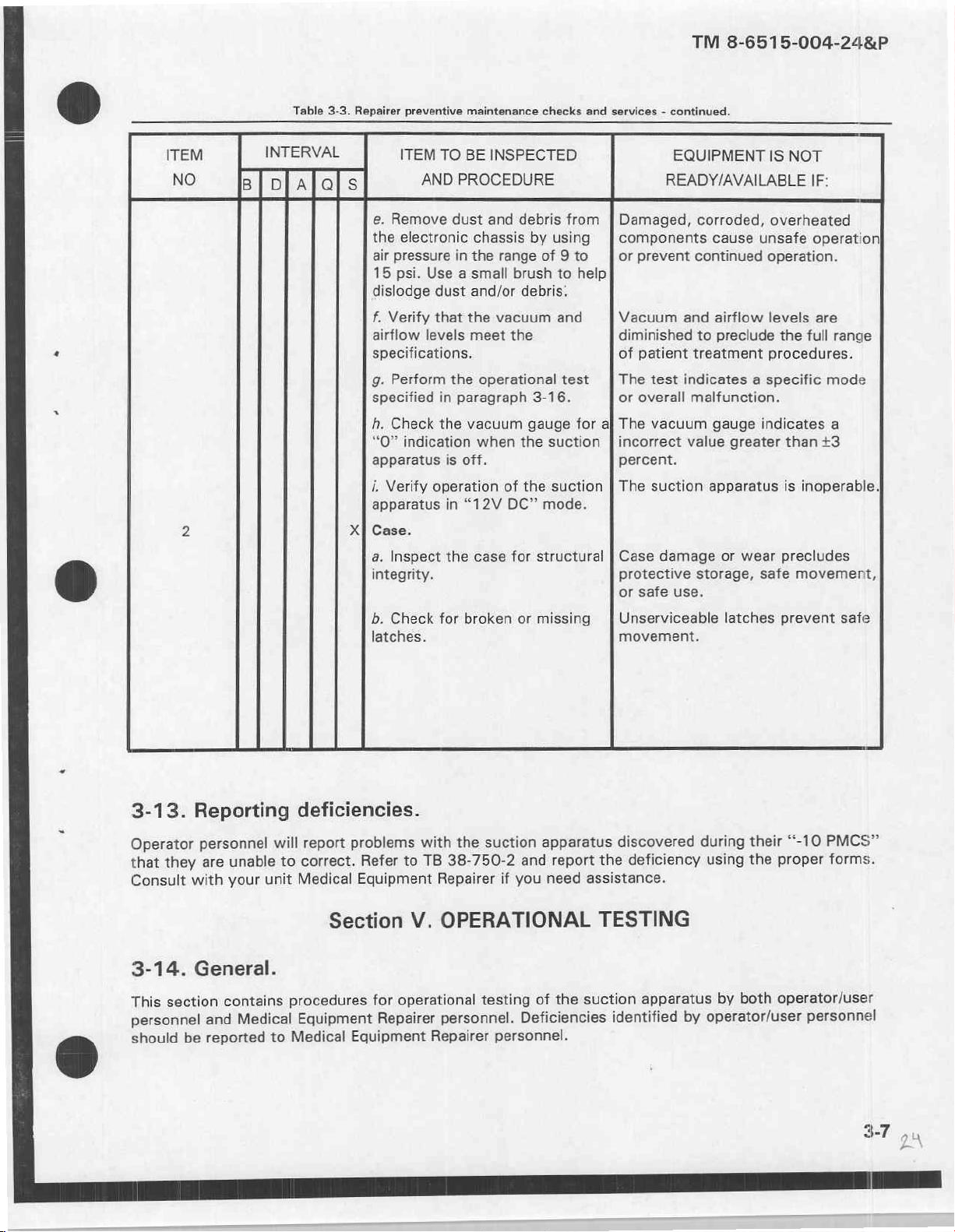

3-11.

No

output.

k.

Close

the

/.

Replace

General.

lubrication

Section

3-12.

operation

serious

table

is

should

operational

PMCS

to

procedures

found

equipment

During

with

General.

a.

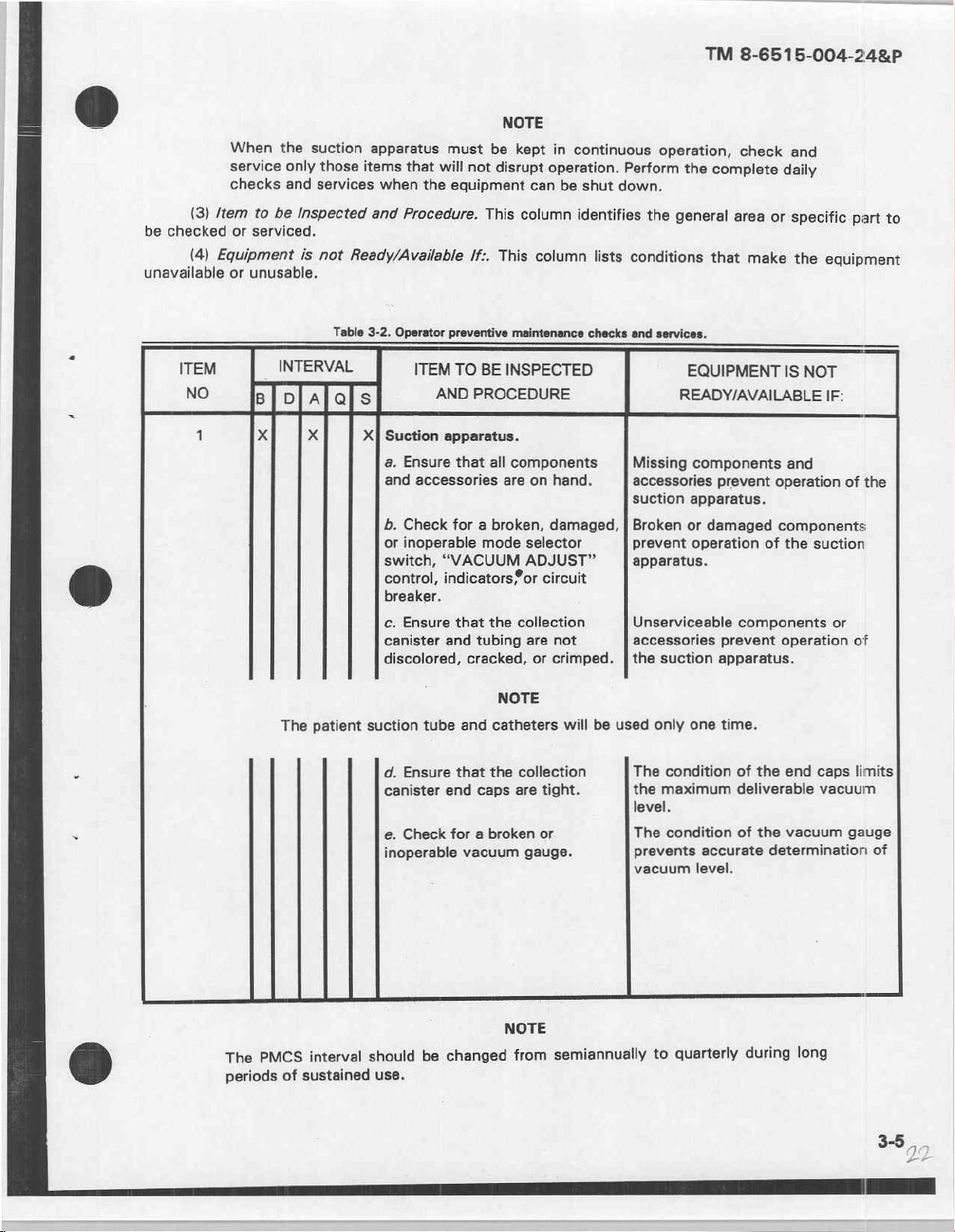

The suction

at

damage

b.

Table

3-2

is

also

referred

not

limited

do

any

indicators,

c.

Table

3-3

table

is

d.

Some

items

provide a quality

to

e.

The

following

in

each

(1)

/tem

area

Interval.

(2)

Operation,

daily

use

115/230

115-volt

230-volt

230-volt

transformer

transformer

the

four

of

the

suction

IV.

PREVENTIVE

apparatus

all

times.

or

failure.

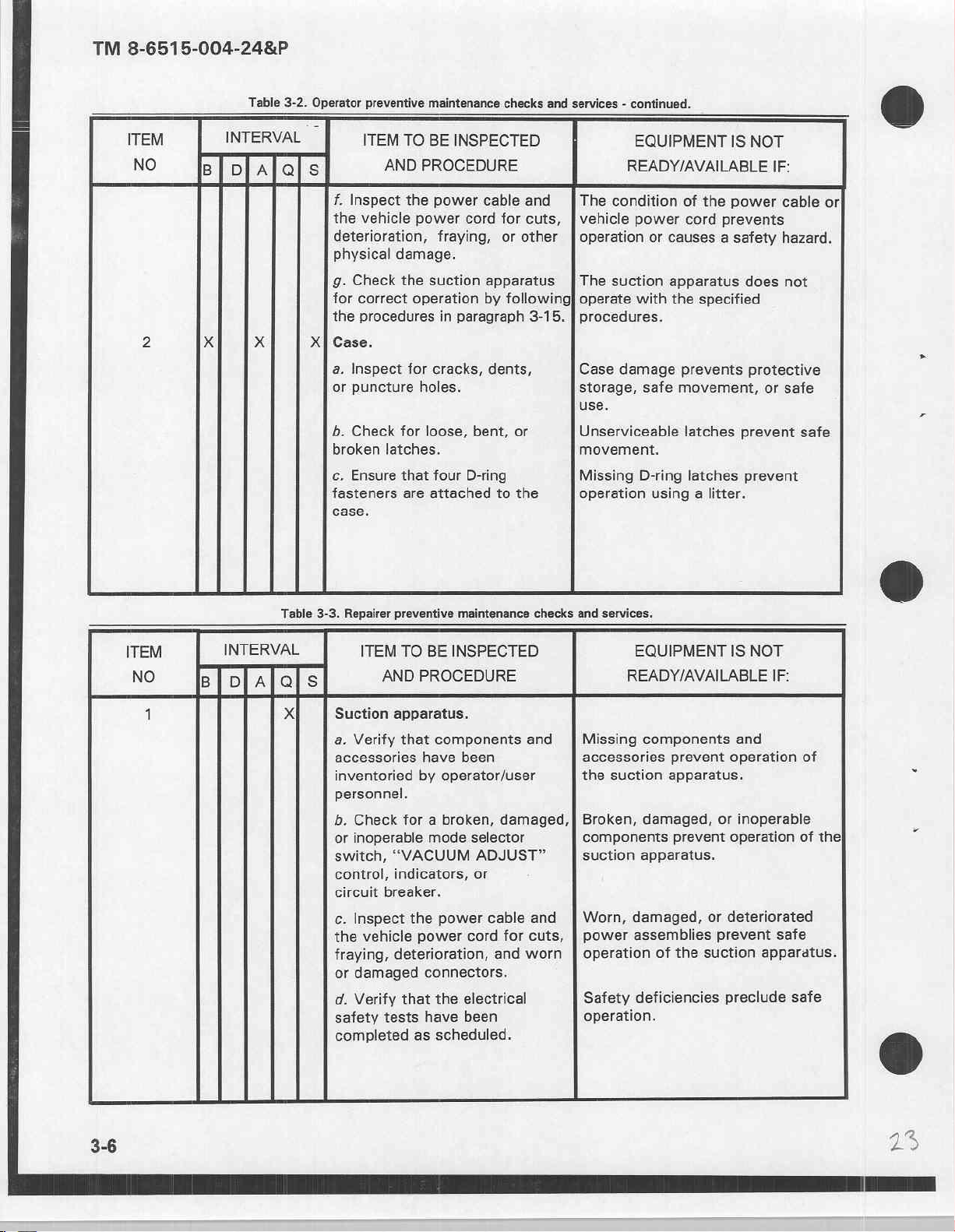

contains a list

to

to

performing

time

they

contains a list

also

referred

to

be

control

be

accomplished

is a list

column:

No.

This

the

on

This

After

-

A

of

the

equipment.

volt

neutral

neutral

ground

circuits

case

Phillips

screws

Section

apparatus

must

Inspection

of

as

“-10

PMCS”

the

checks

need

to

and

maintaining,

of

to

as

inspected

check

by

of

column

Equipment

column

shows

shows

Operation,

wire

to

the

electrical

using a multimeter

and

set

it

down

and

return

Ill.

LUBRICATION

is

required.

MAINTENANCE

be

inspected

will

allow

defects

items

to

be

requirements.

and

services

be

done,

such

the

proper

items

to

be

‘“-20

PMCS”

will

be

listed

on

multiple

unit

both

PMCS

Inspection

Q

operator/user

level

Medical

table

the

sequence

each

when

Quarterly,

-

and

black