HEADQUARTERS DEPARTMENT OF THE ARMY 306M User manual

TM

8-6515-013-14&P

TECHNICAL

OPERATOR,

GENERAL

SUPPORT

UNIT,

(INCLUDING

SPECIAL

SUCTION

PROGRAMMABLE

SUCTION-ASPIRATOR

MANUAL

DIRECT

SUPPORT,

MAINTENANCE

REPAIR

TOOLS

PARTS

LIST)

APPARATUS

INTERMITTENT

AND

MANUAL

AND

SYSTEM

APPROVED

HEADQUARTERS,

FOR

MODEL

6515-01-267-2726

PUBLIC

RELEASE;

DEPARTMENT

306M

DISTRIBUTION

OF

IS

UNLIMITED

THE

ARMY

May

1999

SAFETY

STEPS

TO

FOLLOW

IF

SOMEONE

IS

THE

VICTIM

OF

ELECTRICAL

SHOCK

Do

not

try

to

possible,

If

you

If

person

insulating

cannot

safety

to

material.

pull

turn

or

off

turn

off

using

grab

the

the

electrical

electrical

the

wooden

dry

a

individual.

power.

power,

pole

ora

pull,

push,

dry

rope,

or

or

the

lift

some

other

-

help

Send

After

shock,

artificial

for

injured

the

move

resuscitation.

soon

as

person

the

as

person

possible.

contact

free

is

short

a

of

distance

with

away

source

the

and

electrical

of

immediately

start

TM

8-6515-013-14&P

Throughout

to

read

these.

Procedures

this

manual

They

are

which

are

WARNINGS,

there

must

be

to

protect

you

WARNING

observed

to

CAUTIONS,

and

the

avoid

personal

and

NOTES.

equipment.

injury,

and

even

Please

loss

of

take

life.

time

Procedures

which

must

be

Essential

observed

long-term

information

to

avoid

damage

health

that

should

to

equipment,

hazards.

be

remembered.

destruction

of

equipment,

or

8/0

blank

TM

8-6515-013-14&P

TECHNICAL

8-6515-013-148P

NO.

You

cedures,

to

Publications

Technical

Agency,

reply

MANUAL

OPERATOR,

(INCLUDING

SUCTION

SUCTION-ASPIRATOR

can

help

improve

1423

will

please

be

let

and

Publications)

Sultan

furnished

UNIT,

SUPPORT

REPAIR

APPARATUS

this

manual.

us

know.

Mail

Blank

Forms),

located

Drive,

directly

in

Suite

to

you.

DIRECT

SUPPORT,

MAINTENANCE

PARTS

AND

SPECIAL

PROGRAMMABLE

SYSTEM,

6515-01-267-2726

If

you

find

any

mistakes

your

memorandum,

or

DA

the

back

100,

ATTN:

Form

of

2028-2

this

MCMR-MMM,

DA

(Recommended

manual

WASHINGTON,

MANUAL

MODEL

or

if

you

Form

2028

to:

U.S.

Fort

HEADQUARTERS

DEPARTMENT

DC

AND

GENERAL

TOOLS

INTERMITTENT

306M

know a way

(Recommended

Changes

Army

Medical

Detrick,

MD

to

to

Materiel

21702-5001.

OF

THE

LIST)

improve

Changes

Equipment

ARMY

pro-

A

CHAPTER

Section

CHAPTER

Section

1.

I.

Il

Ill

2.

1.

|.

Ill.

IV.

V.

VI.

Approved

ROWTEOUSETHIS

INTRODUCTION

General

Equipment

Principles

OPERATING

Preparation

Operating

Operating

Operation

Cleaning,

Operation

Information

Description

of

Operation

for

Information

Instructions . .

of

Auxiliary

Disinfecting,

Under

for

public

TABLE

MANUAE

and

INFORMATION

Operations

..

Equipment

and

Unusual

release;

OF

Data

Sterilizing

Conditions

distribution

CONTENTS

o

iui

.

AND

INSTRUCTIONS

casinos

36

is

unlimited.

dask

SEER

Procedures

.....................................

e

nee

amer

k

τος.

iv

2-1

2-8

TM

8-6515-013-14&P

CHAPTER

3.

UNIT

LEVEL

MAINTENANCE

Section

CHAPTER

Section

APPENDIX

GLOSSARY

INDEX

|.

Il

Ill

IV.

V.

VI.

VII.

Vill.

IX.

4.

L

Generalilnformationi

Service

Lubrication

Preventive

Operational

Troubleshooting....

Circuit

Repair

Storing

DIRECT

人

Maintenancs

還

MAINTENANCE

COMPONENTS

EXPENDABLE

REPAIR

Riano

Upon

Receipt

Instructions..

Maintenance

Testing.

Descriptions

Procedures.........

and

Shipping

SUPPORT

IR

..................

.

AND

rocaduros

ALLOCATION

OF

END

AND

DURABLE

PARTS

AND SPECIAL

LIST

ec

ον

of

Equipment

Checks

Procedures

GENERAL

TE

CHART

ITEM

AND

SUPPLIES

OF

ILLUSTRATIONS

on

.

and

Si

.....:.................................

SUPPORT

earn

ος

περ.

MAINTENANCE

«τοσα...

J E

et

.....................

BASIC ISSUE

TOOLS

AND

LIST

aan

ITEMS

MATERIALS

LIST

LIST

ein

....

..

.

GLOSSARY-1

net

3-1

„3-2

.

3-2

3-24

4-1

4-1

A-1

.

B-1

INDEX-1

Figure

1-1

1-2

3

1-4

1-5

2-1

2-2

2-3

2-4

3-1

3-2

3-3

3-4

E-1

E-2

E-3

E-4

E-5

E-6

E-7

No.

Suction

Components

Manufacturer

Front

(Gartassemblyi

Hose

Front

Rear

Control

Power

Suction

On/off

Suction

Front

Rear

Chassis

Heat

Heat

Battery

apparatus

and

data

panel

imprinting

interconnection

panel

controls

panel

controls

circuit

supply

level

and

one - shots

apparatus

panel

assembly

panel

assembly.

assembly

sink

sink

#1

#2

pack

Title

accessories

plate...

.

tal.

te

code

.

and

indicators

and

indicators

PCB

layout

and

charging

motor

speed

schematic...................

components

.......

alert

circuit

schematic

control

.

circuits

oe

Е

аа

Page

„+

1-1

Aa

в

人

ne

E-8

E-9

Pump

Left

assembly

and

right

sub-side

assemblies

LIST

OF

....

TABLES

TM

8-6515-013-14&P

.

E-24

.

Е-26

Table

1-1

1-2

1-3

3-1

3-2

3-3

3-4

No.

Nomenclature

Specifications

Miscellaneous

Operator

Repairer

preventive

preventive

Operator/user

Medical

Equipment

Title

cross-referencelist........................................

characteristics

maintenance

maintenance

troubleshooting

Repairer

checks

checks

and

and

troubleshooting

services

services.

. .

..

. .

..1

..

„34

58

..

3-10

Page

1-2

1-4

1-4

TM

8-6515-013-14&P

HOW

This

capabilities,

describes

The

followed

manual

must

beginning a maintenance

Use

general

subjects.

Multiple

manual.

components

familiarize

manual

the

table

subject

provides

functions,

how

to

set up,

yourself

is

arranged

by

appendixes, a glossary,

of

contents

area

figures

Words

or

and

that

words

TO

needed.

tables

USE

all

the

and

operate,

with

task.

to

are

both

that

you

by

THIS

information

characteristics

test,

and

the

entire

chapters,

help

locate

The

index

are

provided

capitalized

will

actually

an

manual

index,

the

will

MANUAL

needed

repair

sections,

chapter

help

for

and

see

of

and

locate

your

on

to

this

the

before

DA

ease

bold

the

understand

equipment.

equipment.

operating

and

paragraphs

Forms

or

section

more

in

using

are

names

equipment.

the

It

You

or

2028-2.

for

the

specific

this

of

Chapter 3 provides a systematic

equipment.

become a major

doing

anything

Only

allocation

specified

training;

perform

the

wrong

for

test,

In

this

way,

problem

checks

will

maintenance

chart

for

higher

measurement,

small

and

services

be

detected

level

your

levels

causing

of

method

defects

functions

of

maintenance

and

can

the

in

the

quickly.

maintenance.

diagnostic

of

inspecting

be

detected

equipment

same

specified

frequently

equipment;

and

servicing

early

to

fail.

Make a habit

order

Maintenance

the

in

require

each

maintenance

or

the

before

tools.

they

time

additional

and

functions

of

TM

8-6515-013-14&P

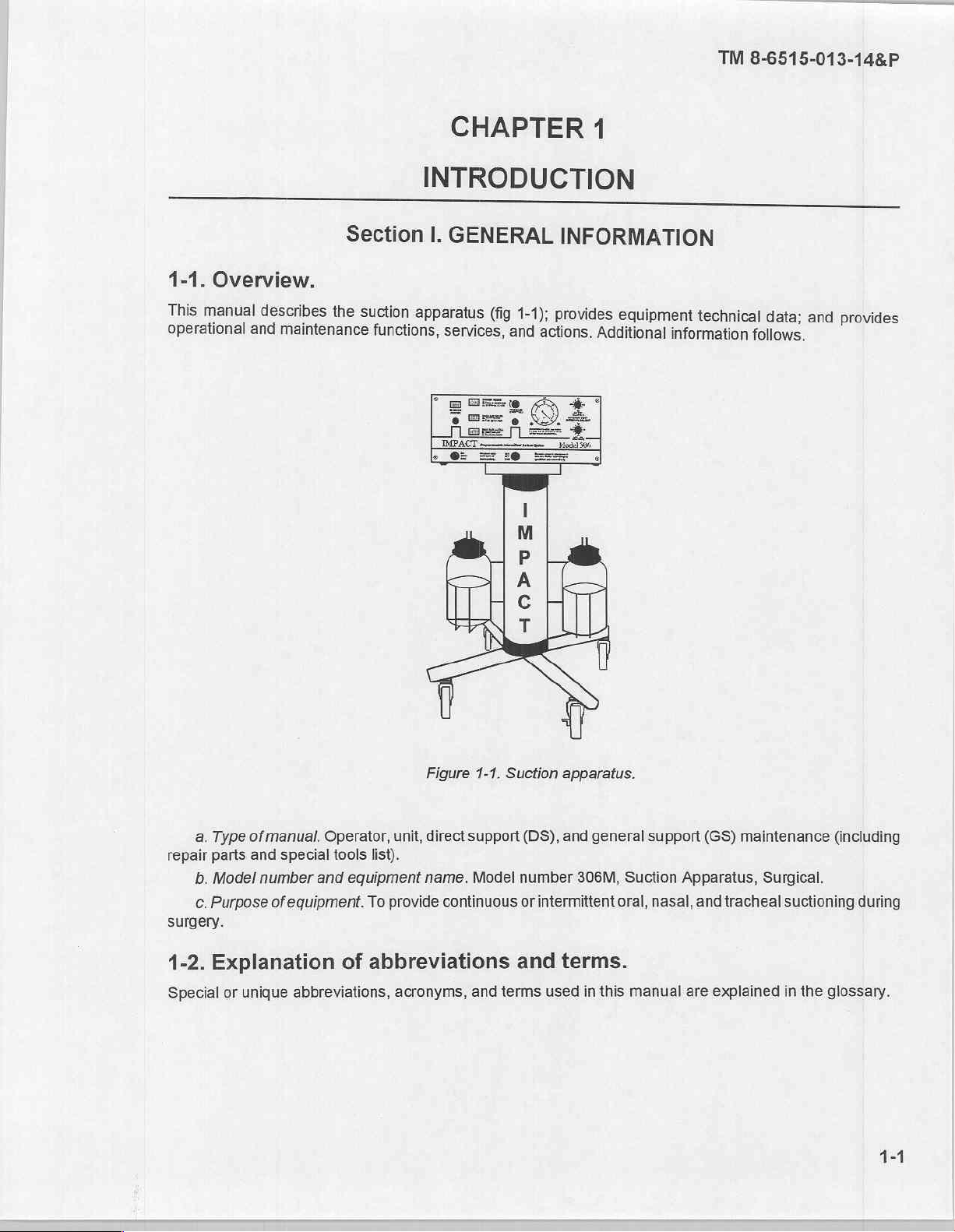

1-1.

Overview.

This

manual

operational

describes

and

maintenance

Section

the

suction

functions,

CHAPTER

INTRODUCTION

I.

GENERAL

apparatus

services,

(fig

and

INFORMATION

1-1);

provides

actions.

1

equipment

Additional

technical

information

data;

and

follows.

provides

a.

Type

repair

parts

b.

Model

c.

Purpose

surgery.

1-2.

Explanation

Special

or

ofmanual.

and

special

number

of

equipment.

unique

abbreviations,

Operator,

tools

and

equipment

To

of

unit,

list).

provide

Figure

direct

name.

1-1.

support

Model

continuous

abbreviations

acronyms,

and

Suction

(DS),

number

or

intermittent

and

terms

used

apparatus.

and

general

306M,

Suction

oral,

terms.

in

this

support

nasal,

manual

(GS)

maintenance

Apparatus,

and

tracheal

are

explained

Surgical.

suctioning

in

the

glossary.

(including

during

1-1

TM

8-6515-013-14&P

1-3.

Maintenance

a.

Reports

are

used

for

equipment

b.

Report

1-4.

Destruction

AR

40-61

series

publications

hazardous.

are

1-5.

Administrative

a,

Placement

shortage

hours

or

appropriate

b.

Perform

placing

to

Army

ensure

c.

Inside

of

contains

of

maintenance

within

maintenance

equipment

operational

its

storage

of

maintenance

packaging

instructions

provide

of

the

suction

the

time

preventive

is

preferred

forms,

and

unsatisfactory

maintenance.

and

handling

of

Army

for

destruction

periodic

information

storage.

apparatus

effort

exists.

factors

in

readiness.

as

determined

records.

maintenance

administrative

for

equipment

records,

deficiencies.

materiel

and

and/or

in

administrative

This

eguipment

by

checks

storage.

selected

and

reports.

equipment.

Fill

out

to

prevent

disposal

instructions

storage

should

the

directing

and

services

When

equipment

for

Department

and

forward

of

the

SF380

enemy

of

Army

medical

on

the

disposal

should

be

in

authority.

(PMCS)

administrative

mission

listed

is

removed

be

During

storage.

Army

(Report

use.

materiel.

of

for

short

readiness

the

in

tables

from

storage,

forms

and

of

Also,

medical

periods

condition

storage

3-1

and

procedures

Survey).

the

SB

materiel

oftime

perform

when

within

period,

3-2

8-75

that

a

24

keep

before

PMCS

1-6.

Preparation

Procedures

1-7.

Quality

AR

702-18/DLAR

procedures.

1-8.

Nomenclature

Table

1-1

identifies

Aspirator

1-9.

quality

AR

reports

Reporting

improvement

40-61

prescribes

for

the

to

prepare

the

control

4155.37/NAVSUPINST

official

Common

Suction

Vacuum

Collection

apparatus

adjust

suction

name

bottles

procedures

apparatus.

for

storage

suction

apparatus

(QC).

4410.56/AFR

cross-reference

versus

control

and

commonly

Table

1-1,

knob

processing

reports.

for

submitting

or

shipment.

for

storing

used

nomenclatures.

Nomenclature

medical

medical

or

shipping

69-10/MCO

list.

cross-reference

Official

Suction

Suction

Electronic

Collection

materiel

materiel

are

listed

4450.13

list.

nomenclature

apparatus,

apparatus,

complaints

contains

vacuum

canisters

in

chapter

surgical

surgical

regulator

3,

section

QC

requirements

(EVR)

complaints

and/or

quality

IX.

and

and/or

improvement

1-10.

A

warranty

1-2

Warranty

is

not

applicable.

information.

TM

8-6515-013-14&P

1-11.

mable

accumulated

empty

below

external

(0-8

of

the

hold the

4-12.

chassis

printed

operational

cal

control

ceptacle

porates

dual

collection

liquid,

The

nation

phobic,

maximum

fluids.

tains

length,

tubing

control.

connect

Equipment

a.

The

suction

intermittent

from

the

the

suction

b.

The

suction

115/220

c.

The

suction

in

Hg)

LOW

being

user

d.

The

unitis

same

time

e.

The

suction

unit.

Component

a.

Components

(1)

Control/pump

incorporates

circuit

(2)

Electrical

power

cable

pump/chassis,

for

Tip-resistant

(3)

four

collection

b.

Accessories.

Dual

(1)

bottles,

supplied

are

(2)

bacterial

the

of

microporous

Tubing.

(3)

3/8-in

a

1/4-in

used

An

the

Filter,

efficiency

Section

apparatus

suction

fluids

via

patient

unit

apparatus

VAC,

apparatus

VACUUM,

programmed

settable

periods.

apparatus

(fig

board

(PCB),

controls.

power

assembly,

115-volt

casters

bottles.

collection

capable

with

disposable,

prevents

filter

suction

while

The

by

id

ft

5

by

connectthe

to

corrugated

long

8-in

vacuum

inlet

Il.

EQUIPMENT

characteristics,

is a self-contained,

during

tubing

tubing

on

the

50/60

to

The

1-2).

chassis.

the

connected

is

operation.

cart.

and

each

apparatus.

membrane

disposable

ft

10

length,

to

surgery.

inserted

into

integral

is

is

and

to

provide

settings

is

and

vacuum

the

cable

hanging

The

the

bottles.

of

fluid

blocking

length,

1/4-in by

bottles,

the

into a patients

the

collection

suction

capable

Hz

power

capable

0-550

provide any

provided

of

source.

of

mmHg

on

timer

are

independent

with a castered

accessory

The

control/pump

pump,

battery

assembly.

tip-resistant

brackets

holding

suction

hydrophobic/bacterial.

The

hose

overflow

from

directly

Two

up

apparatus.

aerosol

and

filter

which

flow

the

tubing

1/4-in

1

filter,

is

pack,

the

for

reusable

to

filters

ft

andthe

also

shutoff

DESCRIPTION

capabilities,

mobile

Depending

surgical

system

cart.

operating

providing

of

periods

the

The

holding

1500

has

of

package

id

length,

user

(0-22

in

at

least

from 5 to

of

descriptions.

control

and

the

electri-

of

rear

a

into

cartincor

glass

mL

contami-

hydro-

a

with

air

aqueous

con-

1/2

1

by

clear

suction

provided

valve.

unit,

with

on

the

type

opening,

consisting

from

an internal

selectable

Hg)

HIGH

144

intermittent

60

each

other.

cart/stand

CONTROL

the

re-

ResisTANTI

TiP

。

the

of

ft

to

AND

and

integral

of

of

two

VACUUM.

seconds

with

PUMP

CART

cart,

suction

oral,

or

reusable

12

VDC

vacuum

within

The

timing

in 5 second

detachable

CHASSIS

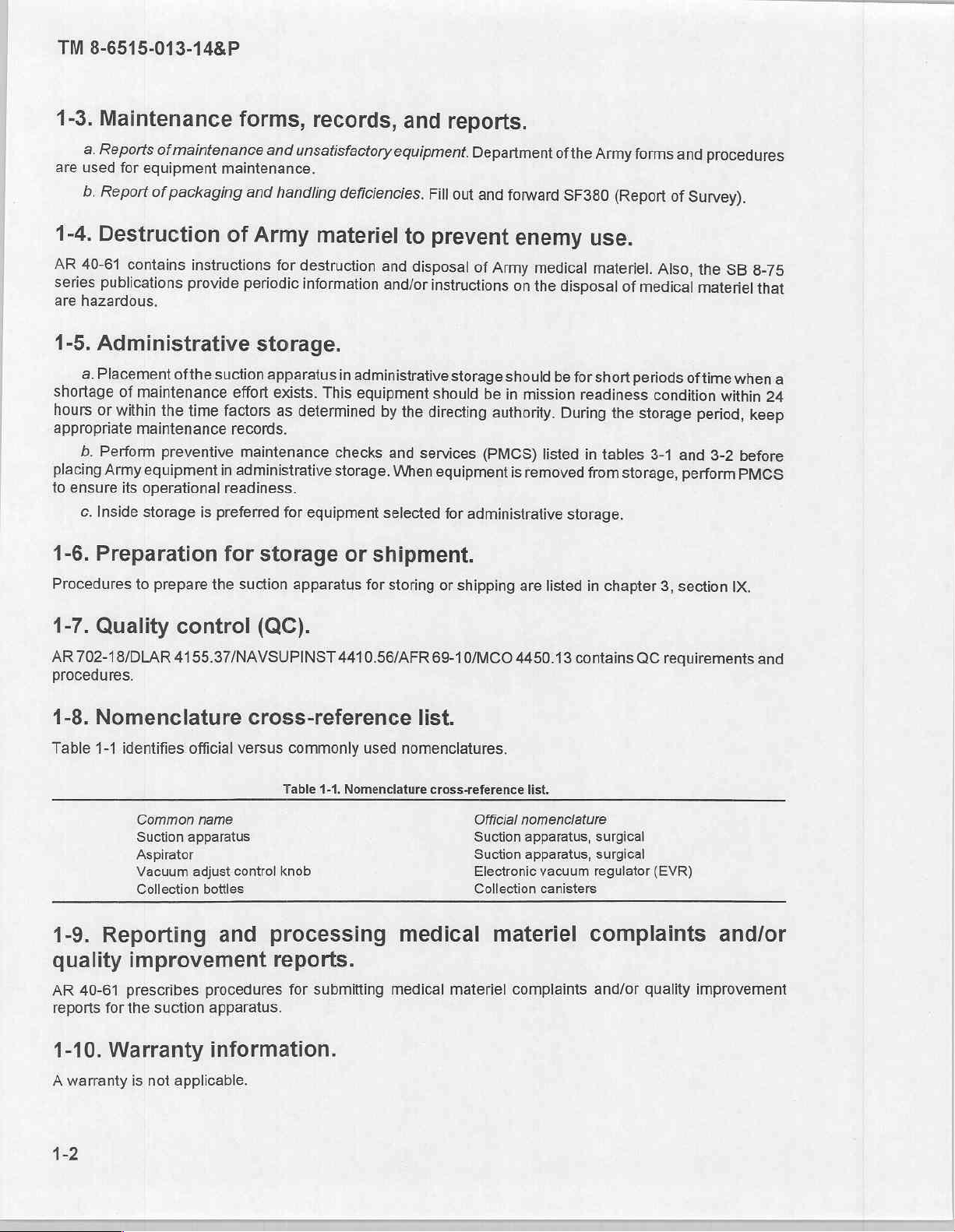

Components

Figure

1-2.

DATA

features.

capable

required,

nasal

glass

battery,

suction

cycles.

Nereo

of

the

passages.

collection

external

the

range

apparatus

increments;

mounting

POWER

and

providing

306M

bracket

program-

will

Suctioned

bottles

12

of

0-200

is

and

off

system

OVERFLOW

TUBE

QJ

FILTER

CABLE

accessories.

remove

fluids

located

VDC,

or

mmHg

capable

timer

for

to

TM

8-6515-013-14&P

1-13.

The tabulated

suction

miscellaneous

operating/storing

Tabulated

data

apparatus.

a.

Specifications

characteristics

temperature

Voltage/frequencies

Internal

Vacuum

power..

Operating

Recharge

ranges

provides

time

Continuous

Low

High

Intermittent

Free

airflow

range

Dimensions

data,

and

miscellaneous

time

.

-

decals

and

miscellaneous

characteristics.

and

specifications

ranges,

dimensions,

Table

Table

1-3.

data

characteristics,

plates.

specifications,

Table

to

include

and

1-2.

Specifications.

..115

230

12

VDC

2

VDC,

hour

-16

hours

0-200

-550

-200

4-35

Miscellaneous

operating

weights.

VAC,

50/60

VAC,

50/60

recharge

at

maximum

mmHg, + 25

mmHg, + 50

mmHg, + 25

liters

per

characteristics.

1-2

and

Hz

Hz

batteries

vacuum

mmHg

mmHg

mmHg

minute

and

other

table

1-3

voltages,

information

provide a broad

vacuum

ranges,

for

the

range

flow

of

rates,

b.

in

figure

notices

Weight.

Collection

Free

Duty

Operating

Battery

Apparatus

Identification,

suction

The

(1)

1-3.

Imprinting

(2)

are

illustrated

bottle

airflow

cycle...

range

Temperature

long

Temperature

storage

Temperature

instruction,

apparatus

(located

in

capacity

range

.

term

storage

figure

..

warning

and

manufacturer

front

the

on

1-4.

plates,

data

panel

8

cm

(7

in)

24-35

liters

per

minute

Continuous/intermittent

...-60°C

...10°C

+1

of

to

60°C

to

30°C

5°C

to

40°C

decals,

(located

plate

control/pump

the

(-76°F

(50°F

(5°F

markings.

or

on

to

140°F)

to

86°F)

to

104°F)

center

the

chassis)

rear

ofthe

providing

panel)

danger

illustrated

is

caution

and

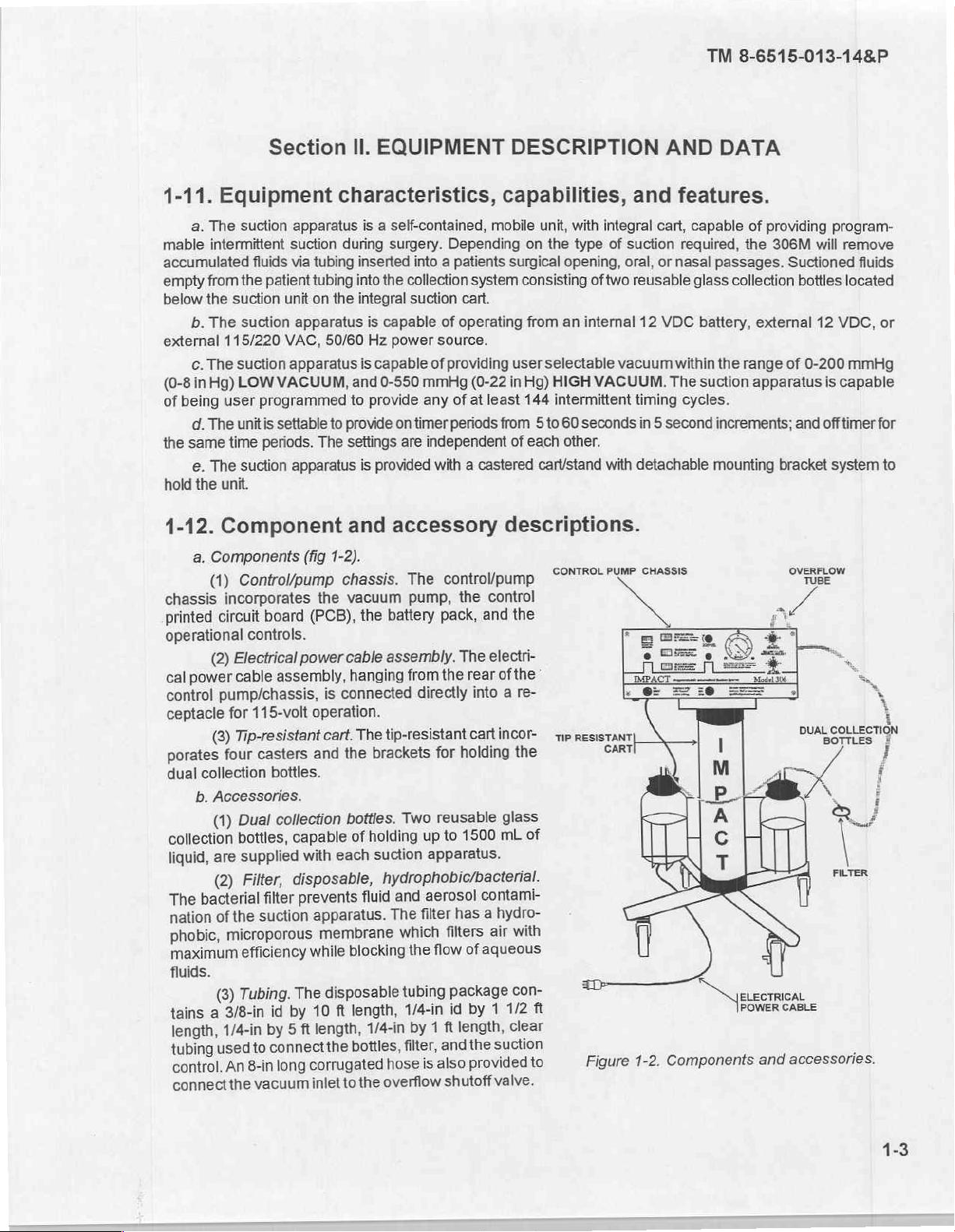

CONTRACT:

IMPACT

SUCTION

APPARATUS,

115/230VAC,

DES.

ACT.

PART

NSN:

NO.

6515-01-267-2727

SER.

NO.

DLA120-88-C-8510

INSTRUMENTATION,

SURGICAL,

50/60

HZ;

12

VDC

89875

DPSC-DEPMEDS-AT/224(DM)

INC.

MODEL

10A,

FSCM:

MFD:2088

TM

306M

120W

63346

8-6515-013-14&P

1-14.

Model

differences

1-15.

a.

Observe

b.

Read

Medical

c.

Install

d.

The

pump.

e.

Operator/user

f.

There

Replace

with

!

same

二

Model

Safety,

each

the

operating

Equipment

the

bacteria

use

of a collection

is

possible

Figure

only

fuse

of

rating.

一

一

一

differences.

are not

care,

applicable

and

WARNING,

instructions

Repairer

filter

personnel

explosion

handling.

CAUTION,

personnel.

carefully

bottle

will

hazard

一

Figure

since

in

this

to

without

not

remove

if

1-3.

Manufacturer

一

1-4.

Front

this

manual

and

manual

prevent

an

overflow

the

used

in

US

Do

covers,

qualified

一

一

panel

covers a single

NOTE

in

before

damage

shutoff

instrument

the

presence

data

plate.

not

remove

Refer

personnel

一

一

imprinting.

this

manual.

operating

to

the

filter

valve

covers.

of

flammable

equipment

servicing

一

一

model.

the

unit.

Refer

and

hoses.

may

cause

There

is a danger

anesthetics.

to

only.

一

servicing

damage

|

|

一

一

to

of

electric

to

qualified

the

vacuum

shock.

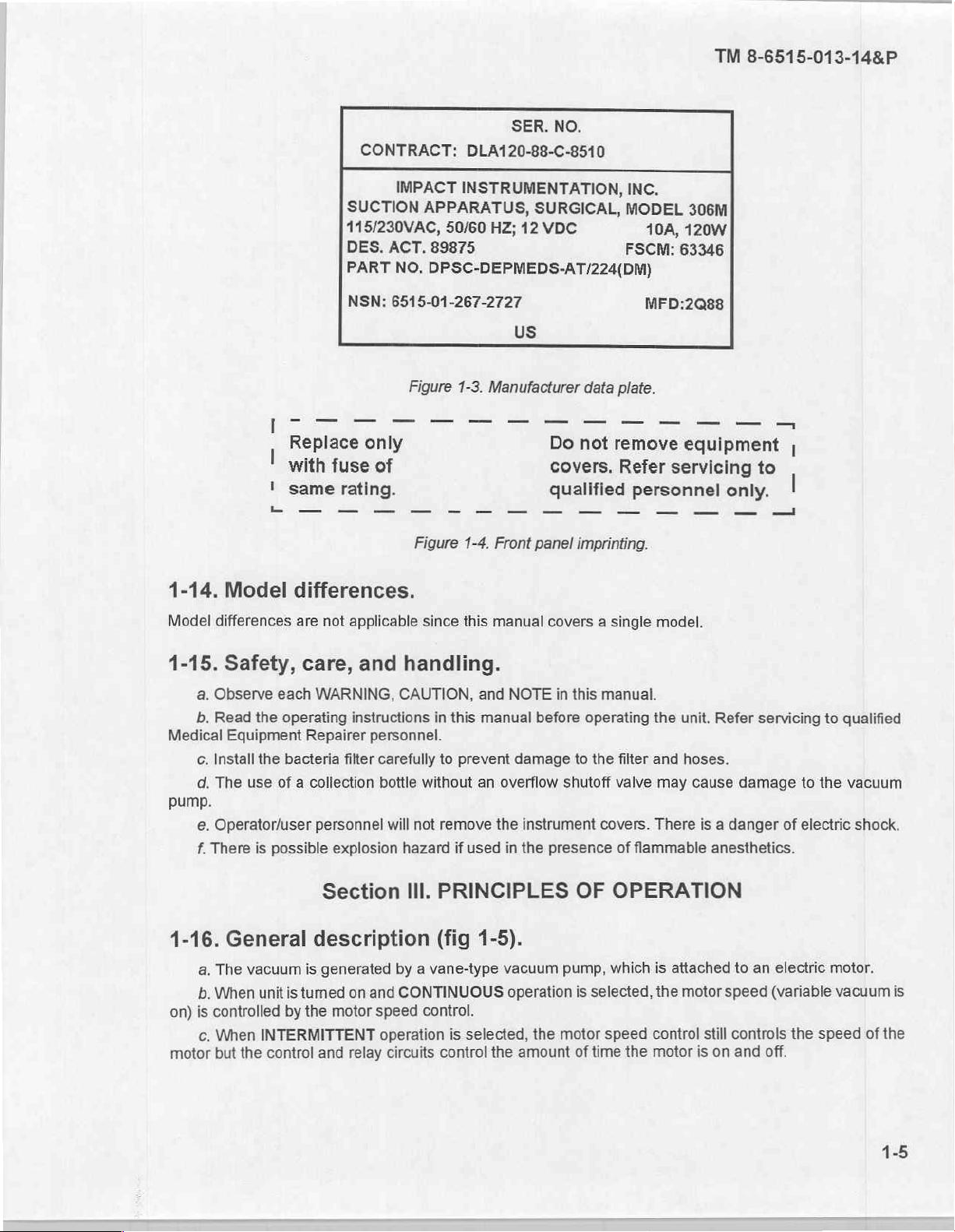

1-16.

a.

The

b.

When

on)

is

controlled

c.

When

motor

but

General

vacuum

unit

is

by the

INTERMITTENT

the

control

Section

description

is

generated

tumed

motor

and

by a vane-type

on

and

speed

operation

relay

circuits

III.

PRINCIPLES

(fig

CONTINUOUS

control.

is

selected,

control

1-5).

vacuum

operation

the

amount

the

OF

pump,

is

selected,

motor

of

time

OPERATION

which

is

attached

the

motor speed

speed

the

control

motor

still

is

on

to

an

electric

(variable

controls

and

off.

the

motor.

vacuum

speed

of

is

the

TM

8-6515-013-14&P

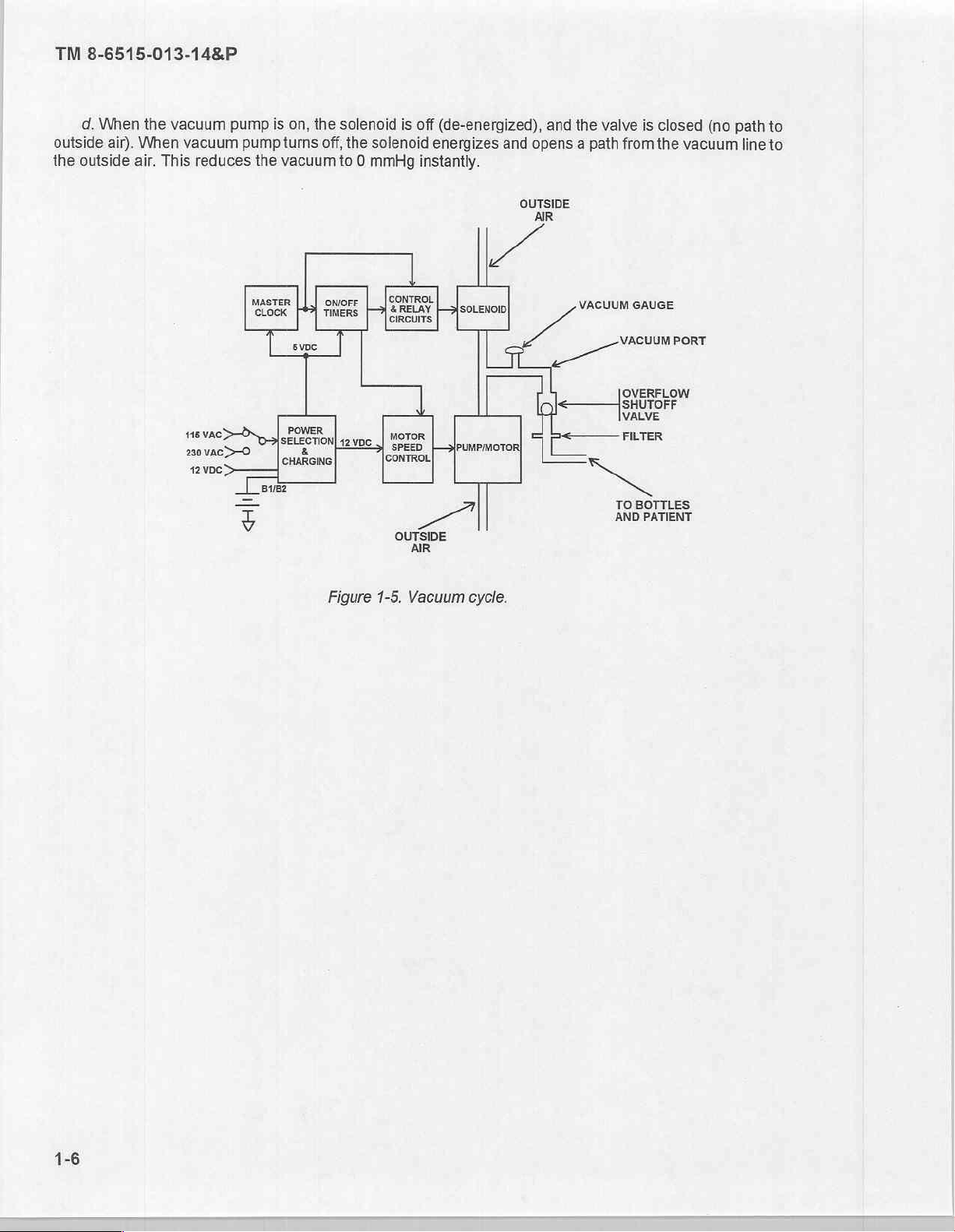

d.

When

the

outside

the

air).

outside

When

air.

vacuum

vacuum

This

pump

pump

reduces

the

is

on,

turns

vacuum

the

solenoid

off,

to 0 mmHg

the

solenoid

is

off

(de-energized),

energizes

instantly.

and

and

opens a path

OUTSIDE

AIR

the

valve

from

is

closed

the

(no

vacuum

path

line

to

to

230

Vac>—0

12000

master | [J owore

ο

8182

=>

3

ewe

POWER

a

&

CHARGING

Figure

CONTROL

|)

和

CIRCUI

[CONTROL

OUTSIDE

1-5.

Vacuum

|

AIR

soon

cycle.

VACUUM

GAUGE

VACUUM

OVERFLOW

VALVE

PORT

ое

TER

TO

BOTTLES

AND

PATIENT

TM

8-6515-013-14&P

OPERATING

2-1.

Scope.

This

manual

the

suction

mation

suctioning

2-2.

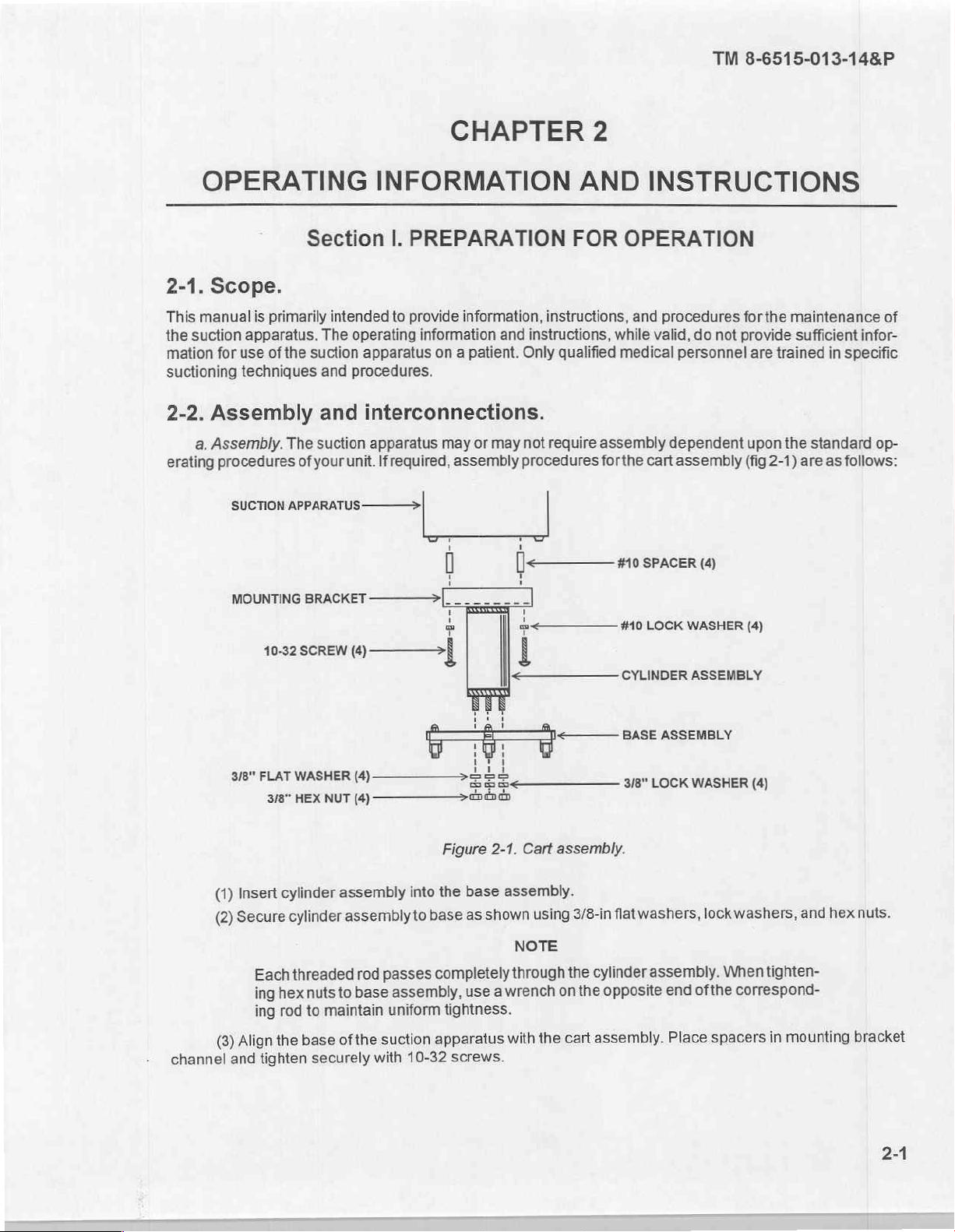

a.

erating

is

apparatus.

for

use

techniques

Assembly

Assembly.

procedures

Section

primarily

The

of

the

suction

and

and

The

suction

of

your

CHAPTER

INFORMATION

|.

PREPARATION

intended

unit.

to

provide

operating

apparatus

procedures.

information,

information

on a patient.

interconnections.

apparatus

Ifrequired,

may

assembly

or

instructions,

and

instructions,

Only

may

not

require

procedures

2

AND

FOR

while

qualified

medical

assembly

forthe

INSTRUCTIONS

OPERATION

and

procedures

valid,

do

personnel

dependent

cart

assembly

not

forthe

provide

are

upon

(fig

maintenance

sufficient

trained

the

standard

2-1)

are

as

infor-

in

specific

follows:

of

op-

(1)

(2)

(3)

channel

MOUNTING

10-32

i

3/8"

FLAT

3/8”

Insert

Secure

Each

ing

ing

Align

tighten

and

BRACKET

SCREW

À

WASHER

HEX

NUT

cylinder

cylinder

threaded

hexnuts

maintain

to

rod

base

the

securely

————>|

(4)

———>

„sla

(4)

(4)

assembly

assembly

rod

base

to

the

of

with

mě

Be

————>-

Figure

into

the

base

to

passes

uniform

suction

completely

assembly,

tightness.

apparatus

10-32

Ce

lá

EEE

endian

2-1.

base

shown

as

a

use

screws.

7

中 < 一

!

| そ ーーーーーーーー

Cart

assembly.

assembly.

using

NOTE

the

the

on

cart

through

wrench

with

CYLINDER

flat

3/8-in

cylinder

opposite

the

assembly.

#10

LOCK

3/8"

LOCK

washers,

assembly.

WASHER

ASSEMBLY

WASHER

ofthe

end

Place

washers,

lock

When

correspond-

spacers

(4)

(4)

tighten-

in

hex

and

mounting

nuts.

bracket

2-1

TM

8-6515-013-14&P

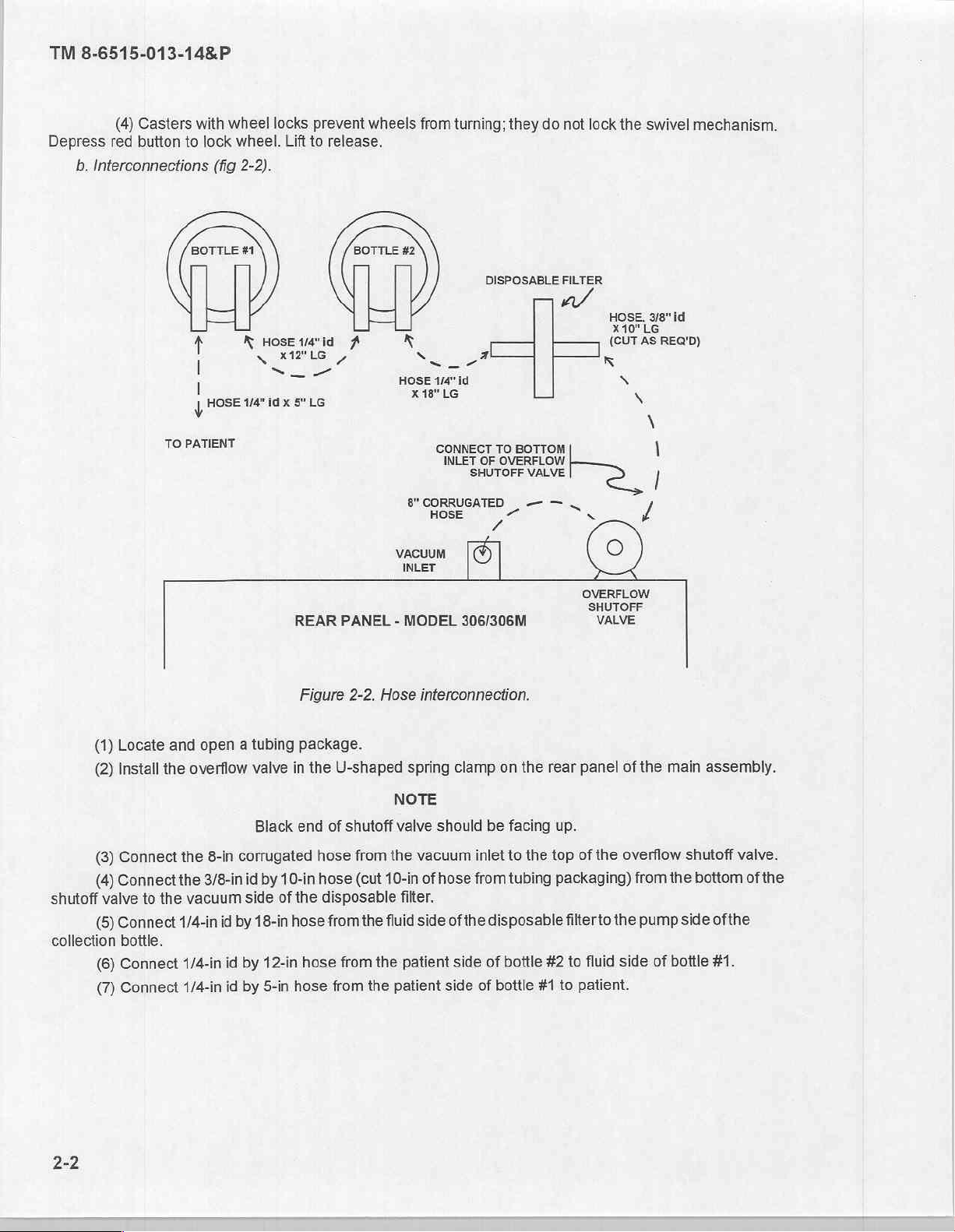

(4)

Casters

Depress

red

button

b.

Interconnections

with

to

wheel

lock

(fig

locks

wheel.

2-2).

Lift

to

prevent

release.

wheels

from

turning;

they

do

not

lock

the

swivel

mechanism.

TO

PATIENT

(SZ

т

|

I

у

Нова

K

и"

HOSE

N

>

idx

1/4"id

x12"LG

5"LG

REAR

A

ノ

PANEL - MODEL

Figure

2-2.

k

Hose

DISPOSABLE

№

N

HOSE

x18"

г

4/4"

id

LG

CONNECT

INLET

al

OF

SHUTOFF

8"

CORRUGATED | —

HOSE

VACUUM

INLET

interconnection.

©

306/306M

LJ

TO

BOTTOM

OVERFLOW

VALVE

FILTER

]

K

OVERFLOW

SHUTOFF

VALVE

HOSE

X10"

(CUT

\

3187

LG

AS

REG'D)

,

id

(1)

Locate

(2)

Install

(3)

Connect

(4)

Connect

shutoff

collection

valve

(5)

Connect

bottle.

(6)

Connect

(7)

Connect

to

and

open a tubing

the

overflow

the

8-in

the

3/8-in

the

vacuum

1/4-in

1/4-in

1/4-in

valve

Black

corrugated

id

by

side

of

id

by

18-in

id

by

12-in

id

by

5-in

package.

in

the

end

hose

10-in

hose

the

hose

hose

hose

U-shaped

NOTE

of

shutoff

from

the

(cut

10-in

disposable

from

the

fluid

from

the

from

the

patient

spring

valve

should

vacuum

of

hose

filter.

side

patient

clamp

from

of

the

side

side

inlet

on the

be

facing

to

the top

tubing

disposable

of

bottle

of

bottle

#1

rear

panel

up.

of

the

packaging)

filter

to

#2

to

fluid

to

patient.

of

the

overflow

from

the

pump

side

of

main

assembly.

shutoff

the

bottom

side

ofthe

bottle #1.

valve.

of

the

c.

Battery

(1)

(2)

battery

the

lower

(3)

(4)

3/8-in

socket

(5)

jumper

(6)

drive

handle.

(7)

(8)

installation.

Remove

The

battery

pack

to

terminals

Each

To

install

with

Install

(small

orange

Replace

Install

Replace

top

the

left,

of

bracket

the

drive

the

battery

wire)

the

the

RED

the

cover

by

pack

is

secured

sub-side

each

battery.

is

secured

battery

handle

with

is

on

two

brackets

wire

top

cover

removing

by

panel.

with

pack,

remove

or

3/8-in

battery

to

terminals

bottom

removed

the

“+”

and

the

six

screws;

two

brackets

The

other

two

#10-32

the

open

end

facing

earlier

terminal

six

screws.

three

connected

bracket

keps

four

keps

wrench

(-

and

+)

forward.

and

and

the

located

snugs

the

nuts.

nuts

securing

to

remove

toward

tighten

BLACK

along

to

battery

top

facing

the

wire

the

rear

the

main

the

keps

nuts

forward

#10-32

to

the

lip

and

chassis.

pack

to

the

brackets

and

toward

keps

nuts with a 3/8-in

“-”

terminal.

TM

8-6515-013-14&P

three

along

the

One

bracket

rear

panel

and

mentioned

brackets.

the

control

earlier.

top

edge.

snugs

the

straddles

Use

panel.

The

socket

and

the

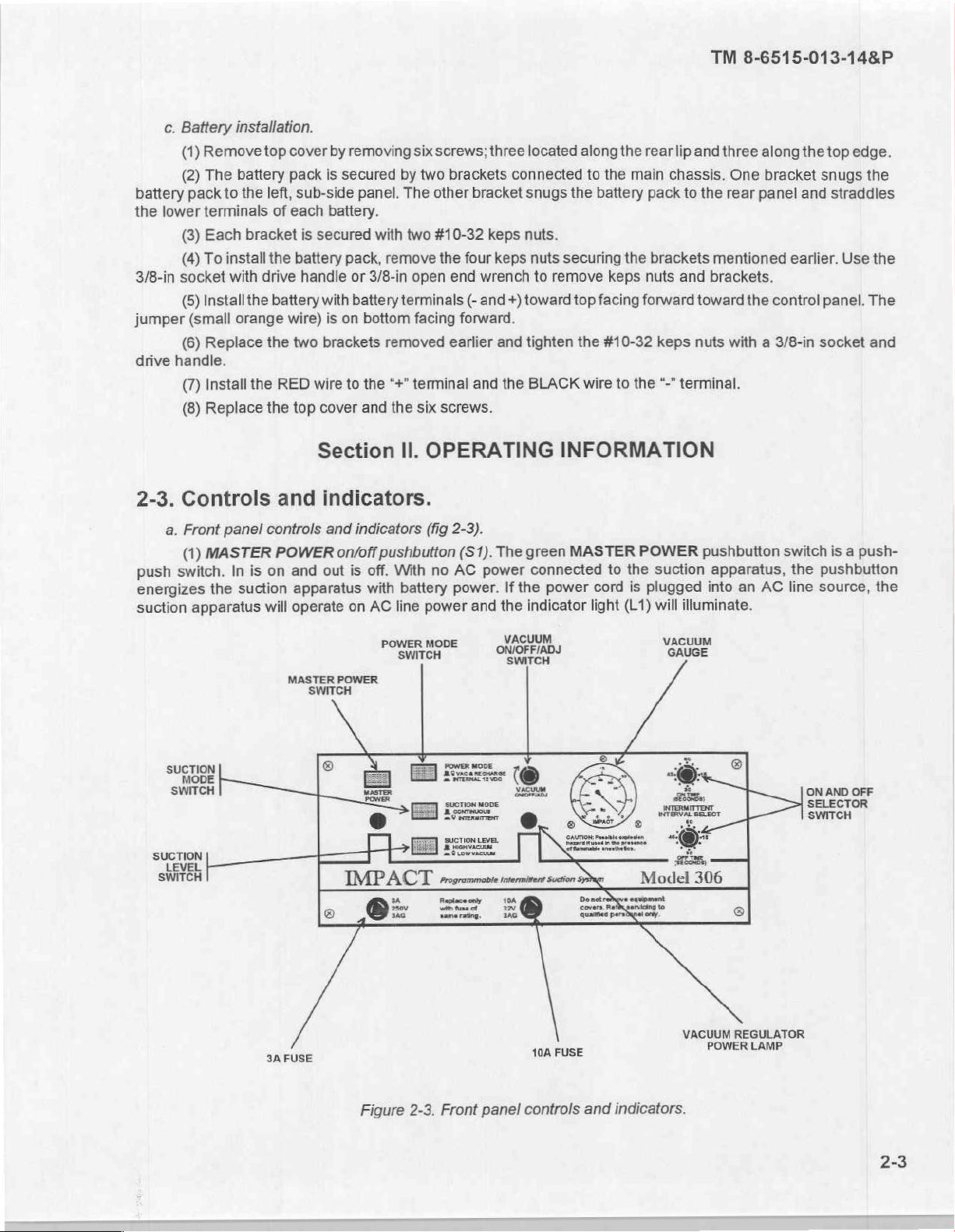

2-3.

Controls

a.

Front

(1)

push

switch.

energizes

suction

apparatus

SUCTION

MODE

SWITCH

SUCTION

LEVEL

SWITCH

panel

MASTER

In is

the

suction

LEE

Section

and

controls

POWER

on

and

apparatus

will

operate

MASTER

SWITCH

|

|

fm:

Il.

OPERATING INFORMATION

indicators.

and

indicators

on/off

out

is

on

POWER

©

IMPACT

о

ФЕ

pushbutton

off.

with

AC

的

MASTER

e

With

battery

line

POWER

SWITCH

Y

EE

æg

m

(fig

power

MODE

2-3).

(S1).

The

green

no

AC

power

connected

power.

Ss

sucTion

Er

enom

If

the

and

the

VACUUM

ONJOFF/ADJ

SWITCH

ーー

(©

а,

MODE

9

indicator

Y

oe

rrogrommoste

Fur

==

ntermirent

©

MASTER

power

à

Suction

=

to

cord

light

(L1)

POWER

the

is

plugged

о"

Model

こつ

pushbutton

suction

into

will

illuminate.

VACUUM

GAI

UGE

©+

©

gis,

ος

ss

ee

306

switch

apparatus,

an

AC

^

|

©

is a push-

the

pushbutton

line

source,

ON

AND

SELECTOR

SWITCH

the

OFF

3A

FUSE

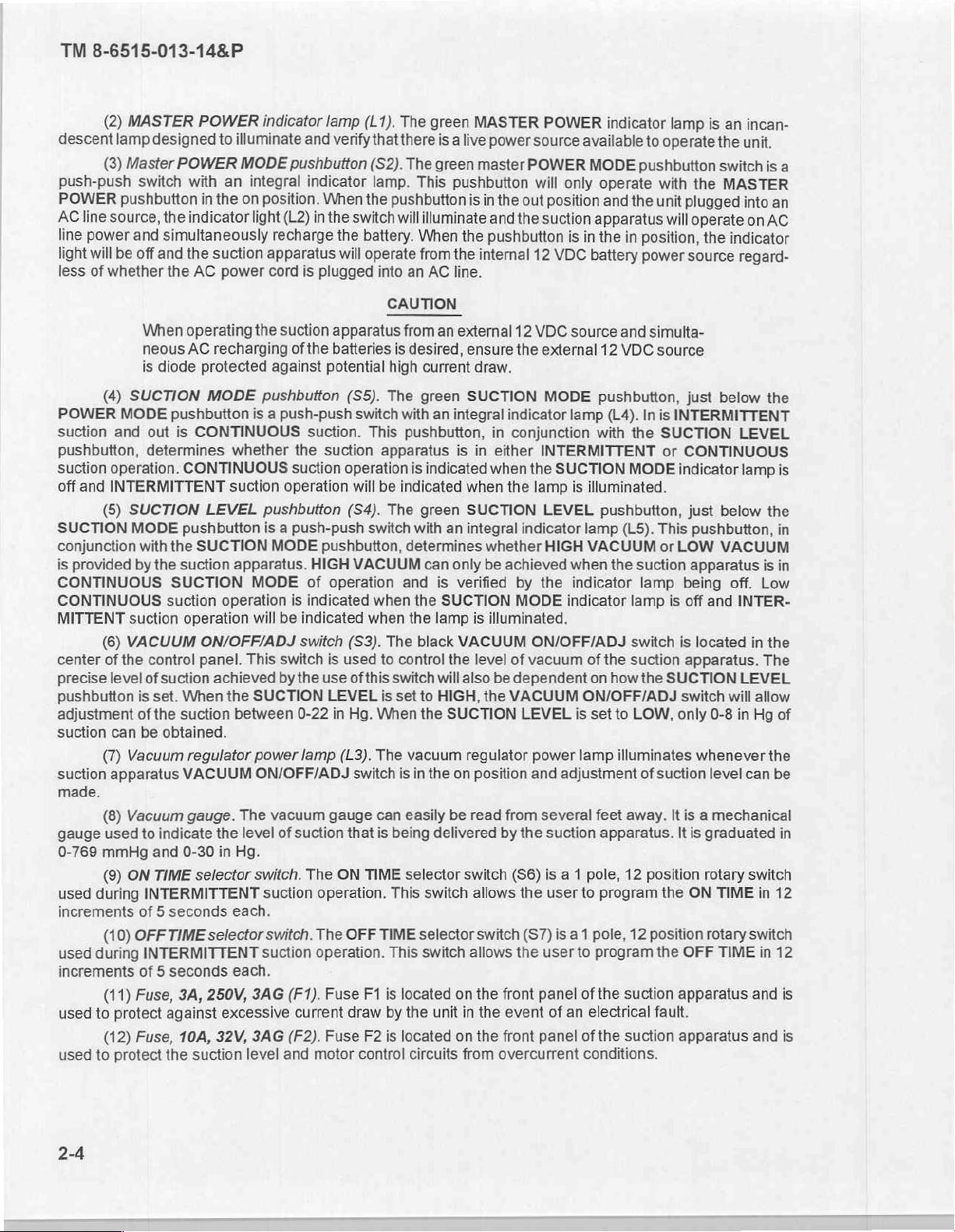

Figure

2-3.

Front

panel

AVRETE

controls

and

indicators.

VACUUM

REGULATOR

POWER

LAMP

2-3

TM

8-6515-013-14&P

(2)

MASTER

descent

push-push

POWER

AC

line

light

less

lamp

(8)

pushbutton

line

source,

power

will

be

whether

of

designed

Master

switch

and

off

and

When

neous

is

diode

(4)

SUCTION

POWER

suction

pushbutton,

suction

off

SUCTION

conjunction

is

provided

MODE

and

operation.

and

INTERMITTENT

(5)

SUCTION

out

determines

MODE

with

by

the

CONTINUOUS

CONTINUOUS

MITTENT

center

precise

pushbutton

adjustment

suction can

suction

suction

(6)

VACUUM

of

the

control

level

of

is

set.

of

the

be

(7)

Vacuum

apparatus

made.

(8)

Vacuum

gauge

used

to

0-768

mmHg

(9)

used

during

increments

(10)

used

during

increments

(11)

used

to

(12)

used

to

and

ON

TIME

INTERMITTENT

of 5 seconds

OFF

INTERMITTENT

of 5 seconds

Fuse,

protect

Fuse,

protect

POWER

to

illuminate

POWER

with

the

indicator

in

MODE

an

the

integral

on

light

simultaneously

the

suction

power

AC

the

operating

AC

protected

MODE

pushbutton

is

CONTINUOUS

the

recharging

is a push-push

whether

CONTINUOUS

suction

LEVEL

pushbutton

the

SUCTION

suction

SUCTION

suction

operation

apparatus.

MODE

operation

will

ON/OFF/ADJ

panel.

This

suction

achieved

When

suction

the

SUCTION

between

obtained.

regulator

VACUUM

gauge.

indicate

0-30

selector

power

ON/OFF/AD4J

The

the

level

in

Hg.

switch.

each.

TIME

selector

each.

3A,

250V,

3AG

against

the

10A,

32V,

suction

excessive

3AG

level

indicator

lamp

and

verify

pushbutton

indicator

position.

recharge

apparatus

cord

against

pushbutton

When

(L2)

in

the

plugged

is

suction

of

the

potential

the

will

apparatus

batteries

(S5).

suction.

the

suction

suction

operation

pushbutton

operation

(S4).

is a push-push

MODE

pushbutton,

HIGH

of

operation

is

indicated

be

indicated

switch

switch

by

the

0-22

lamp

vacuum

of

suction

suction

switch.

suction

(F1).

current

(F2).

and

(S3).

is

used

use

of

LEVEL

in

(L3).

gauge

that

The

ON

operation.

The

OFF

operation.

Fuse

draw

Fuse

motor

(L1).

that

(S2).

lamp.

the

pushbutton

switch

battery.

operate

into

CAUTION

high

The

switch

This

apparatus

will

be

The

switch

VACUUM

when

when

The

to

this

switch

is

Hg.

When

The

switch

can

is

being

TIME

This

TIME

This

F1

is

by

F2

is

control

The

green

there

is

a

live

The

green

This

pushbutton

will

illuminate

When

the

from

the

line.

AC

an

from

an

external

is

desired,

current

green

with an

integral

pushbutton,

is in

is

indicated

indicated

when

green

with

an integral

determines

can

only

and

is

verified

the

SUCTION

the

lamp

black

VACUUM

control

set

is

will

to

HIGH,

the

SUCTION

vacuum

in

the on

easily

the

also

be

delivered

selector

switch

switch allows

selector

switch

located

the

located

on

unit

in

on

circuits

from

MASTER

power

source

master

is

in

and

the

POWER

out

the

pushbutton

internal

12

12

ensure

SUCTION

the

draw.

indicator

in

conjunction

either

when

the

the

SUCTION

indicator

whether

be

achieved

by the

MODE

is

illuminated.

ON/OFF/ADJ

level

of

vacuum

be

dependent

the

VACUUM

LEVEL

regulator

position

read

power

and

from

by the

(S6)

the

switch

allows

the

the

the

(S7)

the

front

event

front

overcurrent

POWER

will

position

suction

VDC

VDC

external

MODE

available

MODE

only

operate

apparatus

is

in

the

battery

source

12

pushbutton,

lamp

indicator

and

(L4).

with

INTERMITTENT

SUCTION

lamp

is

illuminated.

LEVEL

pushbutton,

lamp

HIGH

VACUUM

when

the

indicator

indicator

of

the

on

how

ON/OFF/ADJ

is

set

to

lamp

adjustment

several

suction

is a 1

user

feet

apparatus.

pole,

to

program

isa 1 pole,

user

to

program

panel

of

the

of

an

electrical

panel

of

the

conditions.

lamp

to

operate

pushbutton

with

the

unit

plugged

will

in

position,

power

source

and

simulta-

VDC

source

just

In

is

INTERMITTENT

the

SUCTION

or

CONTINUOUS

MODE

indicator

just

(L5).

This

or

LOW

suction

lamp

being

lamp

is

off

switch

suction

illuminates

away.

the

SUCTION

LOW,

of

suction

is

apparatus.

switch

only

It

is a mechanical

It

12

position

the

12

position

the

OFF

suction

apparatus

fault.

suction

apparatus

is

an

incan-

the

unit.

switch

the

is

MASTER

into

operate

the

indicator

regard-

below

on

AC

the

LEVEL

lamp

below

the

pushbutton,

VACUUM

apparatus

and

located

is

off.

Low

INTER-

in

the

The

LEVEL

will

allow

0-8

in

Hg

whenever

level

is

graduated

rotary

ON

TIME

rotary

TIME

the

can

switch

in

switch

in

and

and

a

an

is

in

in

of

be

in

12

12

is

is

2-4

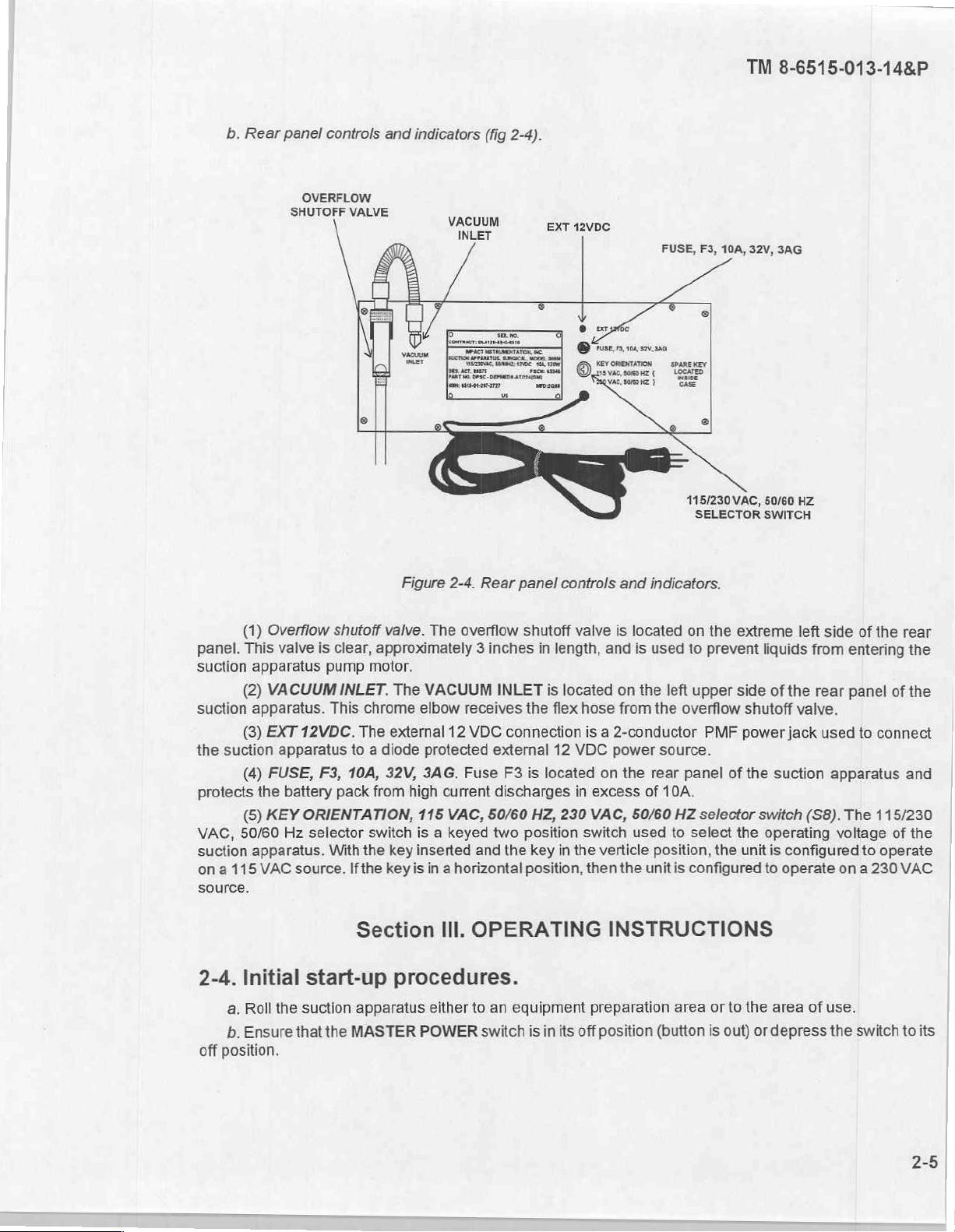

b.

Rear

panel

OVERFLOW

SHUTOFF

controls

VALVE

and

indicators

(fig

VACUUM

INLET

2-4).

EXT

12VDC

FUSE,

F3,

10A, 32V,

TM

8-6515-013-14&P

3AG

(1)

panel.

suction

suction

the

protects

VAC,

suction

This

apparatus

(2)

apparatus.

(3)

suction

(4)

(6)

50/60

apparatus.

on a 115

source.

Overflow

valve

VACUUM

EXT

12VDC.

apparatus

FUSE,

the

battery

KEY

ORIENTATION,

Hz

VAC

source.

shutoff

is

clear,

pump

INLET.

This

chrome

The

to a diode

F3,

10A,

pack

selector

With

the

Ifthe

Figure

valve.

approximately 3 inches

motor.

The

external

32V,

from

switch

key

key

2-4.

Rear

The

overflow

VACUUM

elbow

receives

12

VDC

protected

3AG.

Fuse

high

current

115

VAC,

50/60

is a keyed

inserted and

is

in a horizontal

INLET

connection

external

F3

discharges

two

the

panel

controls

shutoff

in

length,

is

located

the

flex

12

is

located

HZ,

230

position

key

in

the

position,

and

indicators.

valve

is

located

and

is

used

on

the

left

hose

from

the

is a 2-conductor

VDC

power

source.

on

the

rear

in

excess

VAC,

switch

verticle

then

50/60

used

the

of

unit

10A.

HZ

to

position,

is

115/230

VAC,

SELECTOR

on

the

extreme

to

prevent

upper

side

overflow

panel

select

configured

shutoff

PMF

power

of

the

selector

the

the

unit

50/60

HZ

SWITCH

left

liquids

switch

operating

to

from

of

the

rear

valve.

jack

suction

(S8).

is

configured

operate

side

of

the

entering

panel

used

to

connect

apparatus

The

115/230

voltage

to

on a 230

rear

the

of

the

and

of

the

operate

VAC

2-4.

a.

b.

off

position.

Initial

Roll

Ensure

start-up

the

suction

that the

Section

procedures.

apparatus

MASTER

POWER

III.

OPERATING

either

to

switch

an

equipment

is

in

INSTRUCTIONS

preparation

its

off

position

area

or

(button

to

is

the

out)

area

or

depress

of

use.

the

switch

to

2-5

its

TM

8-6515-013-14&P

Verify

jes

c.

Remove

also be

dures

power

indicator

modes.

the

patient

powered

d.

Ensure

contained

e.

Depress

source.

f.

Verify

continuous

lamp

g.

Verify

that

The

SUCTION

h.

Test

the

i.

Submerge

aspiration

j.

Remove

use

of

by

that

for

EVR

the

qualified

operating

and

external

the

coiled

by

the

the

in

paragraph

the

MASTER

power

12

electrical

internal

collection

2-2b.

POWER

operation

continuous

intermittent suction

by

adjusting

the

end

the

water

PVC

patient

MODE

of

the

into

operation

indicator

polyvinyl

the

tubing

medical

selections

VDC,

at

the

power

cable

12

VDC

batteries

bottle

assembly

switch

at

both

high

will

operates

lamp

vacuum

in

the

chloride

collection

from

the

personnel.

NOTE

at

115

back

of

assembly

or

is

to

the

on

and

low

not

illuminate

only

in

will

illuminate

high

and

(PVC)

bottle.

container

or

230

VAC,

the

unit,

and

external

in

place

position.

ranges

in

the low

in

low

ranges

patient

of

water.

connect

12

VDC.

and

assembled

The

in

each

this

mode.

vacuum

this

tubing

The

internal

rechargeable

it

to

the

in

indicator

of

the

range

lamp

in

proper

operating

mode.

in

each

ofthe

into a container

suction

apparatus

voltage.

accordance

illuminates

power

each

of

the

operating

of

is

batter-

The

with

to

operating

power

water

now

ready

unit

may

the

proce-

verify a live

modes.

and

The

power

modes.

observe

for

2-5.

Routine

Routine

start-up

assembly

2-6.

Operating

Observe

a.

unit's

standard

Observe

b.

only

bottle

Always

c.

overflows

stick.

disposable

A

д.

overflow

occurs,

brane

designed

filter.

this

start-up

procedures

and

interconnections

periodically

operating

patient.

the

would

the

the

the

use

may

valve

membrane

the

bacteria

to

patient

flow

vacuum

filter

Failure

graduation

to

ter

sultant

when

which

shutoff

retain

to

procedures.

will

follow

in

accordance

procedures.

level

the

procedures.

collection

will

In

fail

patient

of

which

final

result

risk.

which

the

shutoff

in

addition,

liquid

from

fluids

is

pump

shutoff

damage

both

is

collection

contacts

would

empty

also

overflow

permanently

and

the

initial

with

in

liquid

of

bottle

the

of

overflow

the

if

contamination

the

within

running.

provided

valve

the

hydrophobic

bottle.

aspirate,

otherwise

start-up

your

collection

the

CAUTION

prior

vacuum

protection

clear

vacuum

and

filter

This

following

or

be

procedures

units

standard

bottles

liquid

a

to

the

to

device

shut

and

tubing.

PVC

this

with

pump.

Ensure

bacterial

should

150

exhausted

and

level

patient

would

the

off

Fluids

to

unit

that

provided.

is

replaced

be

cumulative

the

into

except

operating

empty

reaching

a

pose

and

fail,

should

the

overflow

the

with

suction

protect

This

when

hours

immediate

for

differences

procedures.

accordance

in

it

1500

its

potential

bacteria

the

higher

a

drawn

be

suction

shutoff

connects

filter

discoloration

use.

of

vicinity.

involving

with

mL

risk

fil-

re-

collection

the

into

mechanism

valves

between

its

of

filter

This

NOT

DO

your

from

not

do

the

mem-

is

bypass

2-6

2-7.

Shut-down

procedures.

TM

8-6515-013-14&P

Shut-down

a,

Depress

b.

Disconnect

ο.

Dispose

procedures.

2-8.

Associated

The

suction

battery

or

erator

2-9.

Associated

Associated

Section

2-10.

fecting,

designed

General.

a.

The

and/or

b.

Accessories

and

c.

The

procedures

the

MASTER

the

of

the

Section

apparatus

operation.

material

suction

collection

is

apparatus

sterilizing

identified

manufactured

are

as

follows:

POWER

tubing

tubing

from

and

IV.

OPERATION

support

requires

no

material.

identified

V.

CLEANING,

and

procedures

as

for a one

bottle

assembly

switch

the

patient

collected

patient

items

associated

in

appendix D and

DISINFECTING,

PROCEDURES

operating

disposable

are

provided

time

should

accessories

should

use

so

the

power

to

the

collection

fluids

OF

of

equipment.

support

be

items

appendix

in

subsequent

not

only.

removed

light

is

not

bottle.

in

accordance

AUXILIARY

of

equipment

E.

AND

should

be

be

cleaned

from

the

clean

paragraphs.

or

base

lit.

with

your

EQUIPMENT

otherthan

STERILIZING

at

all

times.

reused.

These

assembly

unit's

standard

an

electrical

Specific

accessories

to

facilitate

operating

power

gen-

cleaning,

cleaning.

disin-

were

2-11.

a.

Cleaning.

(1)

(2)

(3)

(4)

(5)

b.

Disinfecting.

with

disinfectant

c.

Sterilizing.

Suction

Turn

off

the

Disconnect

Remove

Wipe

Dry

the

the

in

the

suction

The

apparatus.

suction

the

collection

suction

Disinfect

accordance

suction

apparatus

electrical

bottle

Do

not

apparatus

apparatus

the

suction

with

apparatus

by

depressing

power

cable

assembly.

allow

liquids

using a mild

with a soft

apparatus

your

unit's

cannot

the

MASTER

assembly

from

the

CAUTION

to

enter

the

control

detergent

cloth.

by

wiping

standard

be

sterilized.

with a soft

it

with a liquid

operating

POWER

electrical

system.

procedures.

switch

receptacle.

cloth.

disinfectant

to

the

or

off

position.

lightly

spraying

it

TM

8-6515-013-14&P

2-12.

Collection

a.

Cleaning.

(1)

(2)

use:

each

(3)

been

in

contact

(4)

(5)

accordance

(6)

dures.

Then

(7)

(8)

b.

Sterilizing.

the

steam

Turn

off

the

In

general,

(a)

Patient

(b)

1/4-in

The

(a)

1/4-in

(b)

3/8-in

Remove

Immerse

with

Discard

based

cracking

Dispose

the

hose

id

following

with

patient

id

id

by

the

the

your

overflow

detergents

of

of

any

immerse

Scrub

the

cap

Rinse

all

assemblies

Steam

sterilizer's

manufacturer

bottle

suction

by

by

caps

unit's

the

apparatus

following

12-in

items

can

fluids:

18-in

10-in

Lg

from

caps

and

standard

valve

the

rubber.

patient

collection

assemblies

sterilize the

assembly.

hoses

jumper

Lg

on

thoroughly

hose

be

reused

hose

between

hose

between

the

collection

those

hoses

operating

if

it

has

rubber

drainage

bottles

lightly

reusable

instructions

by

depressing

are

not

reusable

between

after

cleaning,

bottle

top

of

bottles.

not

procedures.

CAUTION

been

in

products,

fluids

in

in

the

with a nylon

in

warm

caps

and your

the

and

bottles

provided

#2

and

disposable

specified

contact

as

it

with

will

accordance

detergent

brush

water

and

and

collection

unit's

MASTER

should

be

it

bottom

filter

and

in

a(2)

above

patient

potentially

fluids.

with

solution.

in

warm

allow

them

bottles

standard

POWER

switch.

disconnected

can

be

established

of

disposable

bottom

of

in a warm

Never

lead

to

dry

your

unit's

detergent

to

dry.

for

15

operating

and

filter

overflow

detergent

use

alcohol

rotting

standard

solution.

minutes

in

procedures.

disposed

that

they

shutoff

solution

and

operating

accordance

of

after

have

valve

proce-

with

not

in

2-13.

The

mobile

Section

Unusual

suction

VI.

OPERATION UNDER

conditions.

apparatus

is

designed

to

operate

UNUSUAL

only

within a medical

CONDITIONS

treatment

facility

environment.

TM

8-6515-013-14&P

3-1.

Overview.

a.

Unit

level

maintenance.

on

its

assigned

(1)

personnel

checking

accessories,

sembly

or

(2)

Medical

Equipment

cation/certification

modules,

class

repair

tion,

and

services

in

equipment,

b.

Maintenance

scope

personnel

the

of

vacuum

equipment.

Operator

and

forfrayed

reassembly

Specialist

maintenance.

consists

cables,

and

replacing

of

maintenance.

Repairers.

(a)

Scheduling

(CVC)

(b)

Performing

or

PCBs,

(c)

parts

(d)

related

(e)

(f)

when

Operating a repair

used

Maintaining a library

materials.

Conducting

Establishing

accordance

(g)

Notifying

assemblies,

functions.

the

operator/user

will

perform

pump, PCBs,

UNIT

Section

This

level

Responsibilities

This

of

equipment

and

stowing

operator

the

end

item,

This

The

functions

and

performing

services.

unscheduled

available.

parts

on

medical

inspections

administrative

with

support

or

modules.

are

the

majority

or

equipment.

of

technical

TB

38-750-2.

maintenance

Maintenance

assigned

of

stand.

CHAPTER

LEVEL

I.

GENERAL

of

maintenance

are

segment

operational

items

not

repair

parts.

critical

adjustments

segment

and

PMCS,

maintenance

program

on

new

maintenance

electrical

to

manuals

or

transferred

procedures

battalions

functions,

to

unit

3

MAINTENANCE

INFORMATION

is

the

responsibility

stratified

of

functions;

in

Replacing

of

services

include

level

as

unit

level

use;

and

after

unit

safety

functions

Class

(TMs),

for

of

both

Maintenance

required

follows:

maintenance

routine

checking

services

operator

replacement,

level

maintenance

include—

inspections

with

VIII

repair

manufacturers’

equipment.

the

control

requirements

preventive

for

the

equipment

of

is

like

forloose

parts

will

orthe

and

emphasis

parts

and

administration

and/or

and

corrective,

Equipment

and

performed

performed

cleaning,

hardware,

not

require

extensive

is

performed

tests,

and

on

replacing

as

well

as

literature,

repair

evacuating

which

Repairer

except

some

by

a

using

unit

by

operator/user

dusting,

replacing

extensive

calibration/verifi-

use

only

washing,

operator

disas-

oftools.

by

trained

assemblies,

other

commodity

parts

informa-

of

maintenance

unserviceable

are

beyond

personnel.

tasks involving

the

These

3-2.

Tools

Common

B,

tools

section

authorized

3-3.

Components

Components

3-4.

Expendable

Expendable

appendix

D,

and

and

III

of

this

items.

of

end

and

section

test

test

equipment

manual.

item

durable

II

of

equipment.

required

Refer

to

your

of

end

item

and

basic

issue items

supplies.

supplies

this

and

manual.

for

unit

units

and

are

materials

level

maintenance

modified

basic

listed

reguired

table

of

issue

in

appendix

for

maintenance

of

the

equipment

organization

items.

C,

sections

of

the

are

and

equipment

II

and

eguipment

listed

III

of

this

are

in

appendix

(MTOE)

manual.

listed

for

in

TM

8-6515-013-14&P

3-5.

Repair

parts.

Repair

3-6.

Special

Special

manual.

3-7.

Unpacking

a.

Open

b.

Remove

©.

Open

d.

Remove

e.

Lift

f.

Open

g.

Verify

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

(14)

(15)

(16)

(17)

parts

required

for

tools.

tools

required

for

Section

the top

the

and

the

receipt

Suction

Assembly,

Hose, corrugated,

3/8-in

1/4-in

1/4-in

Maintenance

Operation

Spare

Spare

Filter,

Reusable

Holder,

Wall

Screws,

Cart

Battery

flaps

the

two

top

of

the

the

foam

roll

the

suction

small

box

of

the

apparatus.

overflow

id

by 10

id

by 1 1/2

id

by 5 ft

manuals

fuse,

type

fuse,

disposable,

collection

collection

mounting

self-tapping

for

suction

pack.

unit

level

maintenance

unit

level

maintenance

II.

SERVICE

the

suction

of

the

shipping

boxes

from

inside

large

box.

blocks

ft

and

type

from

the

apparatus

with

accessories

following:

shutoff

8-in

long.

length

of

ft

length

length

of

service

(2).

3AG,

10A,

3AG,

hydrophobic/bacterial.

canister

canister

bracket

(for

apparatus.

out

valve.

tubing,

of

tubing,

tubing,

manuals

32V

3A,

250V.

system

(2).

(for

collection

wall

are

listed

of

the

equipment

UPON

RECEIPT

apparatus.

container.

the

shipping

box and

of

the

and

remove

clear.

clear.

clear.

(2).

(2).

mounting

container.

set

them

box.

(2

bottles

canisters).

brackets)

in

aside.

the

contents.

with

appendix

are

OF

caps).

(4).

E,

section

listed

in

appendix

EQUIPMENT

Set

the

box

II

of

this

aside.

manual.

E,

section

III

of

this

3-8.

General.

No

lubrication

3-2

of

Section

the

suction

Ill.

apparatus

LUBRICATION

is

required.

INSTRUCTIONS

TM

8-6515-013-14&P

Section

3-9.

General.

a.

The

operation

damage

b.

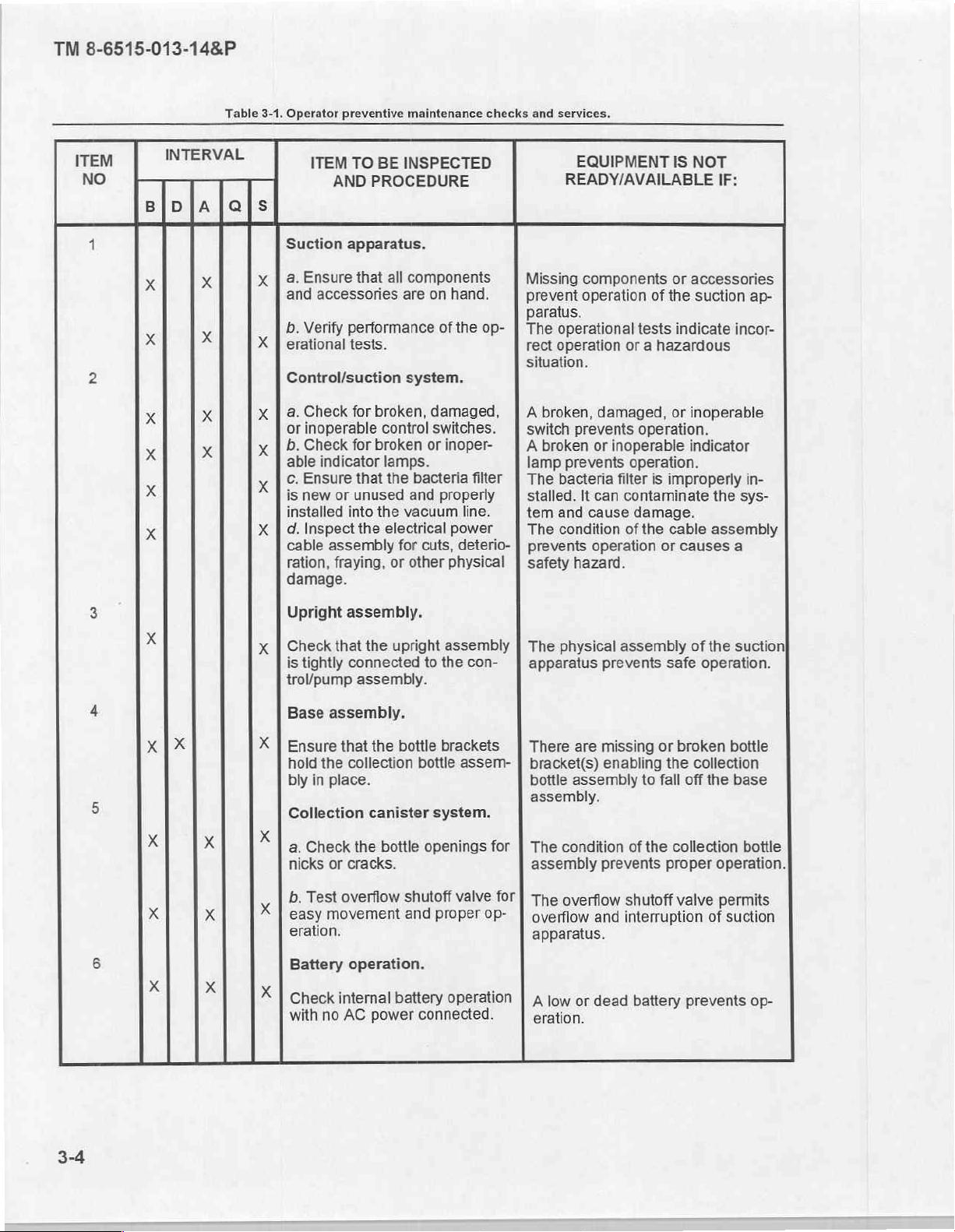

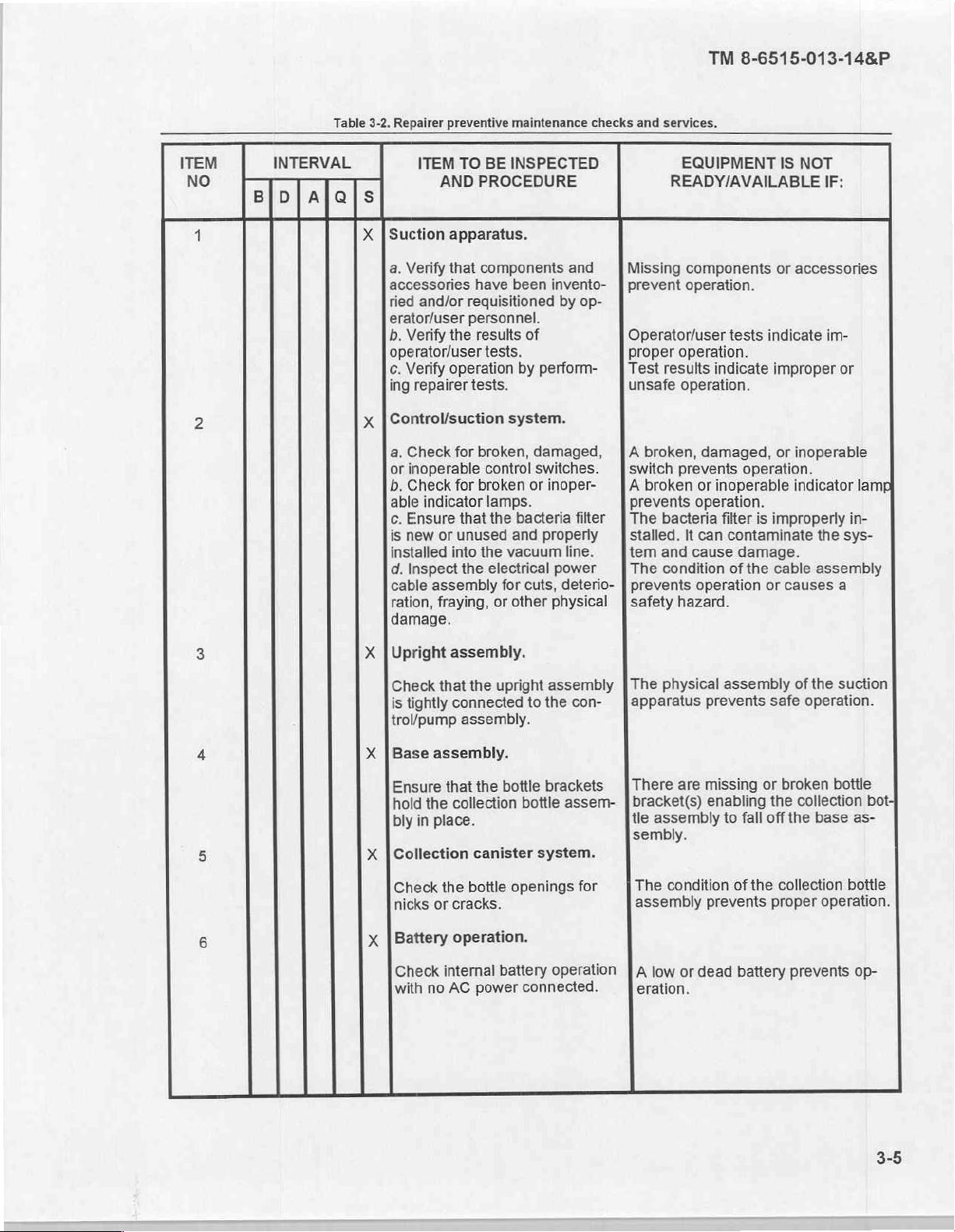

Table

table

is

also

not

limited

should

operational

PMCS

c.

Table

d.

Some

do

table

IV.

suction

at

all

times.

or

failure.

3-1

referred

to

performing

any

time

indicators,

3-2

is

also

items

provide a quality

procedures

e.

each

equipment

During

with

daily

to

be

The

following

column:

(1)

Item

number.

area

(2)

Interval.

Operation, A -

use

of

on

the

PREVENTIVE

apparatus

Inspection

contains a list

to

as “-10

they

and

contains a list

referred

to

be

control

accomplished

is a list

the

This

After

equipment.

must

will

of

PMCS"

the

checks

need

to

maintaining

of

to

as

inspected

check

on

by

of

both

This

column

Equipment

column

shows

Operation, © -

MAINTENANCE

be

inspected

allow

defects

items

to

requirements.

and

services

be

done,

the

items

to

“-20

PMCS"

will

be

listed

multiple

unit

level

PMCS

table

shows

Inspection

when

Quarterly,

and

serviced

to

be

discovered

be

performed

Preventive

in

table

such

as

checking

proper

be

quantities

performed

requirements.

in

both

table

operator/user

Medical

column

the

sequence

and

each

Equipment

headings

Maintenance

PMCS

and S -

CHECKS

systematically

and

by

unit

level

maintenance

3-1.

There

general

of

accessories.

by

unit

level

3-1

and

personnel,

Repairers.

with a description

in

which

to

do

Worksheet,

item

is

to

Semiannually.

to

corrected

operator/user

are

cleanliness,

Medical

table

and

the

be

serviced: B -

before

by

things

Equipment

3-2

to

to

identify

PMCS,

DA

B,

D,

AND

operator/user

ensure

they

personnel.

SERVICES

that

result

operator/user

observing

Repairers.

stress

their

more

comprehensive

of

the

information

and

is

used

Form

2404.

Before

and A should

it

is

ready

for

in

serious

This

PMCS

personnel

is

personnel

for

improper

This

importance,

to

identify

found

the

to

in

Operation, D -

be

performed

(3)

checked

(4)

able

or

When

ice

only

checks

Item

to

or

serviced.

Equipment

unusable.

the

suction

those

and

services

be

Inspected

is

not

apparatus

items

when

and