`

HDT –Tactical Systems Business Unit

30525 Aurora Rd

Solon, Ohio 44139-2795

Tech Support: (800) 684-6111

www.hdtglobal.com

MV60-EU Series Heaters, 220 VAC, 50-60 Hz

SHELTER HEATER

60,000 BTU Multi-fuel Shelter Heater

Operation and Maintenance Manual

MANUAL PART NUMBER: 53858

REVISION 3 – 26APRIL2011

THIS PAGE INTENTIONALLY LEFT BLANK

Operation and Maintenance Manual

Warning Summary

IMPORTANT

Be sure to read and understand this operation and maintenance manual before starting or servicing this

heater.

WARNING!

FIRE, EXPLOSION, CARBON MONOXIDE POISONING

Improper use of this heater can result in serious bodily injury due to hazards of fire and explosion, carbon

monoxide poisoning, burn and electrical shock. Do not adjust the pump pressure higher then the

recommended amount. Failure to do so can result in higher then normal heat exchanger temperatures,

which can cause the heat exchanger to fail allowing dangerous Carbon Monoxide gas to enter the shelter.

Failure to follow these instructions could cause serious injury or death.

WARNING!

FIRE, EXPLOSION

Use only Kerosene, Diesel or Number 1 Fuel Oil, or JP8 can be used for extreme cold conditions. Never

burn gasoline, naphtha, paint thinners, alcohol or other volatile fuels. Fill fuel tank or move heater only

when heater is shut off.

WARNING!

FIRE, EXPLOSION

Use only in areas free of flammable vapor or high dust content. Never use heater where gasoline, paint

thinner or other highly flammable vapors are present.

WARNING!

EXPLOSION

Fully drain and ventilate fuel tank before transporting.

3

Operation and Maintenance Manual

WARNING!

ROTATING MACHINERY

When used with thermostat, heater may start at any time. Do not open access door while heater is

running or plugged in. Remove all power prior to service.

WARNING!

SHOCK HAZARD

Use only with electrical voltage and frequency specified on model plate. Do not perform any service with

heater plugged in.

WARNING!

HIGH VOLTAGE

The ignition transformer develops 10,000 volts. Serious injury or death may occur if personnel come in

contact with high voltage lead.

WARNING!

FIRE, EXPLOSION

Do not operate heater without output duct, P/N CAH-1015, properly installed. Ensure hot air outlet is at

least 1.5 meters from combustible materials. Ensure ducts (outlet and inlet) are free from obstructions and

sharp bends. ALWAYS REMOVE STORAGE PLUG CAH-126-1 BEFORE OPERATING HEATER.

WARNING!

HOT SURFACES

Parts of the heater become very hot when operating and immediately after operating. The exhaust can

reach temperatures in excess of 1000 degrees Fahrenheit. Severe burns may occur if the heater is not

allowed to cool down properly before servicing.

4

Operation and Maintenance Manual

WARNING!

CARBON MONOXIDE POISONING

The heat exchanger must be inspected annually by qualified service personnel for leaks which could

allow dangerous carbon monoxide gas to enter the shelter. Failure to due so, could cause severe

injury or death.

5

Operation and Maintenance Manual

Table of Contents

Operation and Maintenance Manual ............................................................................................................. 1

1. System Overview, Description and Principles of Operation ............................................................... 10

1.1 System Overview .......................................................................................................................... 10

1.2 Description of Major Components ................................................................................................ 11

1.3 Controls and Indicators ................................................................................................................. 14

1.4 WARNING Labels and Data Plates .............................................................................................. 16

1.5 CAMFIRE Heater Specifications .................................................................................................. 19

1.6 Principles of Operation ................................................................................................................. 20

2. Setup and Operation of the CAMFIRE Heater ................................................................................. 25

2.1 Preparing the Heater for Operation .............................................................................................. 25

2.1.1 Unpacking .............................................................................................................................. 25

2.1.2 Installing the Exhaust Stack Extension ................................................................................. 25

2.1.3 Removing the Accessories .................................................................................................... 26

2.2 Siting Considerations .................................................................................................................... 26

2.3 Setup ............................................................................................................................................ 27

2.3.1 Attaching the Flexible Ducts .................................................................................................. 27

2.4 Before Operation Preventative Maintenance Checks and Services (PMCS)............................... 30

2.5 Fueling .......................................................................................................................................... 30

2.5.1 Fueling the Internal Tank (MV60S-EU, MV60T-EU) ............................................................. 30

2.5.2 Connecting and operating the Remote Room Thermostat ................................................... 31

2.5.3 Connecting the Power Cable ................................................................................................. 32

2.6 Final Checks Before Operation .................................................................................................... 33

2.7 Starting and Operating the Heater ................................................................................................ 33

2.7.1 Starting the Heater ................................................................................................................ 33

2.8 Refueling During Operation .......................................................................................................... 34

2.9 Shutting Down the Heater ............................................................................................................ 34

2.10 Preparing for Movement or Storage.......................................................................................... 34

2.10.1 Preparing for Movement ........................................................................................................ 34

2.10.2 Preparing the Heater for Storage .......................................................................................... 35

3. CAMFIRE Troubleshooting .................................................................................................................. 38

3.1 Introduction ................................................................................................................................... 38

3.2 Operator Level Troubleshooting ................................................................................................... 38

3.3 Safety Control Operation and Diagnostics ................................................................................... 38

3.3.1 Operator Level Malfunction Symptom Index ......................................................................... 39

3.3.2 Examining the Heater ............................................................................................................ 39

3.3.3 Test Firing the Heater ............................................................................................................ 40

3.3.4 Operator Level Troubleshooting Procedures ........................................................................ 40

3.4 Maintainer Level Troubleshooting ................................................................................................ 45

3.4.1 Test Firing .............................................................................................................................. 45

3.4.2 Maintainer Level Safety Control Operation and Diagnostics ................................................ 45

3.4.3 Maintainer Level Malfunction Symptom Index ...................................................................... 46

3.4.4 Maintainer Level Troubleshooting Procedures ...................................................................... 47

4. CAMFIRE Maintenance ....................................................................................................................... 54

4.1 Introduction ................................................................................................................................... 54

4.2 Preventive Maintenance Checks and Services ............................................................................ 54

4.2.1 Introduction ............................................................................................................................ 54

4.2.2 Removing Upper Shell .......................................................................................................... 56

4.2.3 Preventive Maintenance Checks and Services ..................................................................... 57

4.3 Special Tools, Equipment and Supplies ....................................................................................... 61

6

Operation and Maintenance Manual

4.4 System Maintenance Procedures ................................................................................................. 61

4.4.1 General .................................................................................................................................. 61

4.4.2 Remote Room Thermostat (Inspect/Test) ............................................................................. 62

4.4.3 Ignition Transformer (Inspect/Test) ....................................................................................... 63

4.4.4 Checking Motor Starting Circuits (Test) ................................................................................ 65

4.4.5 Fan Service ........................................................................................................................... 67

4.4.6 Sediment strainer Service ..................................................................................................... 68

4.4.7 Burner Head Service (Clean) ................................................................................................ 69

4.4.8 Air Pump Repair (Inspect, Test, Repair) ............................................................................... 73

4.4.9 Safety Control Circuit Testing (Test, Clean) .......................................................................... 81

4.4.10 Photocell (Test) ..................................................................................................................... 85

5. Illustrated Parts Listing......................................................................................................................... 88

6. Schematics and Wiring Diagrams ...................................................................................................... 106

7. Alphabetical Index .............................................................................................................................. 108

7

Operation and Maintenance Manual

Table of Figures

Figure 1-1. CAMFIRE Control Panel ........................................................................................................... 14

Figure 1-2. Remote Room Thermostat ....................................................................................................... 15

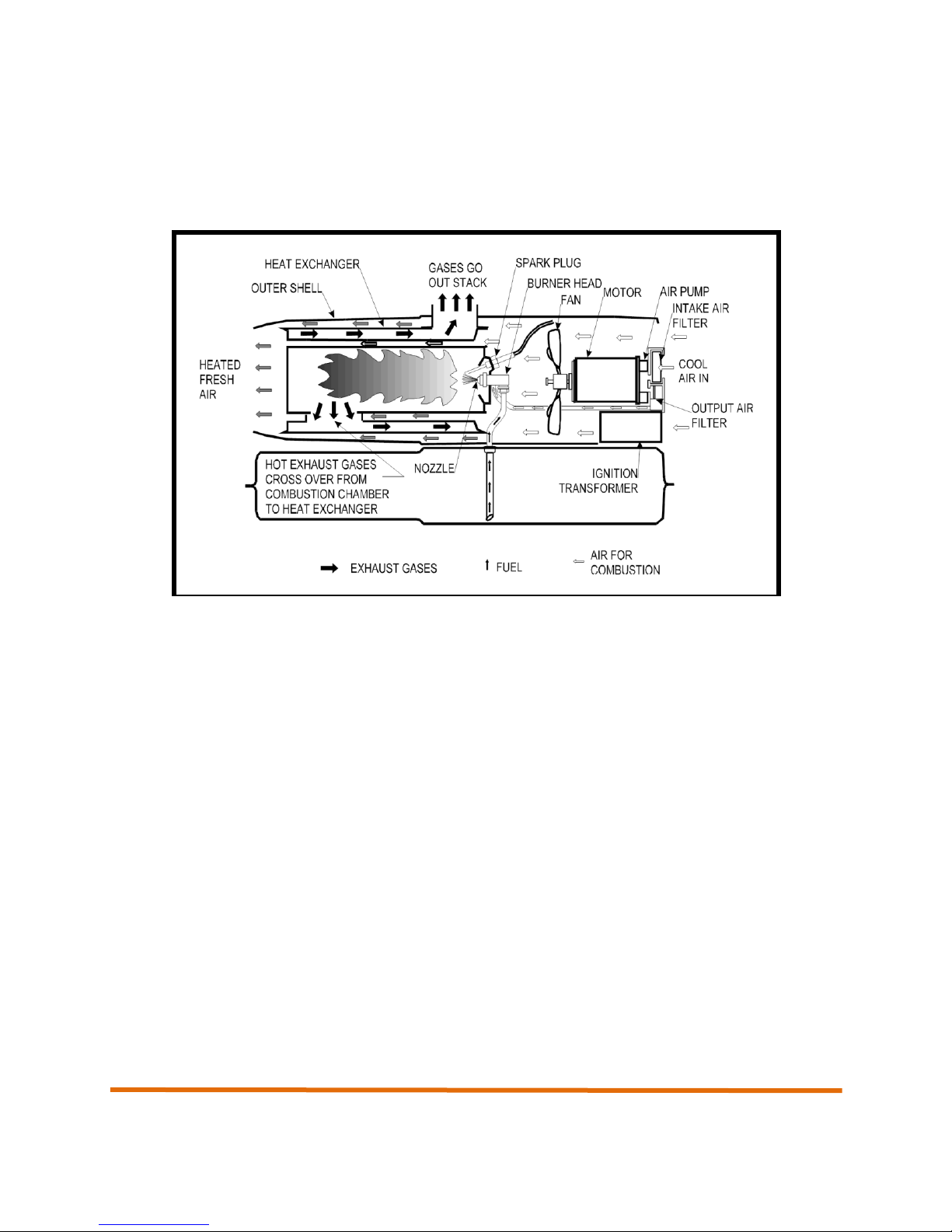

Figure 1-3. System Operational Diagram (simplified for clarity) ................................................................. 21

Figure 4-1. Camfire Maintenance Locations ............................................................................................... 56

Figure 4-2. Wiring Diagram ......................................................................................................................... 66

Figure 4-3. Location of Fan on Shaft .......................................................................................................... 67

Figure 4-4. Checking clearance of air pump rotor....................................................................................... 78

Figure 5-1. MV60-EU Labels and Accessories ........................................................................................... 88

Figure 5-2. MV60-EU FULL ASSEMBLY .................................................................................................... 90

Figure 5-3. COMBUSTION CHAMBER ASSEMBLY .................................................................................. 92

Figure 5-4. BURNER HEAD ASSEMBLY 53649 ........................................................................................ 94

Figure 5-5. MV60 CONTROL BOX-FUEL BRACKET ASSEMBLY ............................................................ 96

Figure 5-6B. CONTROL BOX ASSEMBLY ................................................................................................. 98

Figure 5-7. MOTOR/PUMP/BRACKET ASSEMBLY (53745) ................................................................... 100

Figure 5-8. MOTOR AND PUMP ASSEMBLY(53485) ............................................................................. 102

Figure 6-1. Camfire Heater Wiring Diagram ............................................................................................. 106

Figure 6-2. Camfire (MV60) Fuel Schematic ............................................................................................ 107

Table of Tables

Table 1-1. CAMFIRE Heater Warning Labels and Data Plates ................................................................. 16

Table 1-2. Camfire Heater Specifications ................................................................................................... 19

Table 2-1. Flexible Duct Usage vs. Outside Temperature .......................................................................... 27

Table 2-2. Extension Cord Size Requirements ........................................................................................... 32

Table 3-1. Operator Level Malfunction Symptom Index ............................................................................. 39

Table 3-2. Operator Level Troubleshooting Procedure .............................................................................. 40

Table 3-3. Maintainer Level Malfunction Symptom Index ........................................................................... 46

Table 3-4. Maintainer Level Troubleshooting Procedures .......................................................................... 47

Table 4-1. Camfire Heater Preventive Maintenance Checks and Services ................................................ 57

Table 5-1. MV60 Labels and Accessories .................................................................................................. 89

Table 5-2. Combustion Chamber Assembly ............................................................................................... 93

Table 5-3. Burner Head Assembly 53649 ................................................................................................... 95

Table 5-4. Control Box-Fuel Bracket Assembly .......................................................................................... 97

Table 5-5. Control Box Assembly ............................................................................................................... 99

Table 5-6. Motor/Pump/Bracket Assembly ............................................................................................... 101

Table 5-7. Motor and Pump Assembly P/N 53485.................................................................................... 103

8

Chapter 1

System Overview,

Description and

Operation and Maintenance Manual

Principles of Operation

9

Operation and Maintenance Manual

1. System Overview, Description and

Principles of Operation

1.1 System Overview

The CAMFIRE Heaters are portable, clean-air space heaters that rely on an external input of 220 VAC,

50/60 Hz, single phase power.

The heart of the heater is a heat exchanger that is supplied with air from a fan driven by a 1/4 horsepower

motor. Part of the air from the fan enters the combustion chamber where it mixes with the atomized fuel to

become a combustible mixture. The exhaust gases circulate within the heat exchanger; warming its inner

surfaces, then escape from the heater through a flue pipe adapted to the top of the heater.

The remaining air from the fan passes over and around the combustion chamber and through the heat

exchanger where it is heated, and emerges from the heater as a powerful stream of heated clean air.

The heater is provided with duct connectors at the outlet and inlet ends, allowing use either in a 100%

fresh air mode or 100% recirculation air mode.

The fuel system consists of an air pump mounted on one end of the motor shaft that forces air through

the nozzle. The moving air in the nozzle lifts the fuel from the tank by siphon action and carries it into the

combustion chamber.

Filters protect the fuel system prior to the fuel entering into the spray nozzle. The electrical control system

is protected by a push button type circuit breaker.

A safety control unit, connected to a photoelectric cell, shuts down the heater if a flame is not detected in

the combustion chamber after start up. It also has two diagnostic LEDs to help troubleshoot problems. A

”Duct Over-Heat” switch is installed as a safety measure. In the event that the outlet duct becomes

blocked, the switch will shut the heater down.

A thermostat accessory, which plugs into the electrical system of the heater, may be set to any desired

temperature. When the temperature of the surrounding air reaches the pre-set temperature, the

thermostat contacts open and cause the heater to shut down. When the air cools, the thermostat contacts

close and the heater recycles.

The heater is designed for hard use in rough environments resulting in a minimum of down time for repair

and maintenance. It is protected by roll bars to prevent damage by upset or rollover and shrouded to

protect the working portion of the heater against falling objects.

The heater can be fitted with added accessories such as wheels, skis or toboggan. A spares kit is also

available that includes filters, spark plug, and fuel regulating components.

10

1.2 Description of Major Components

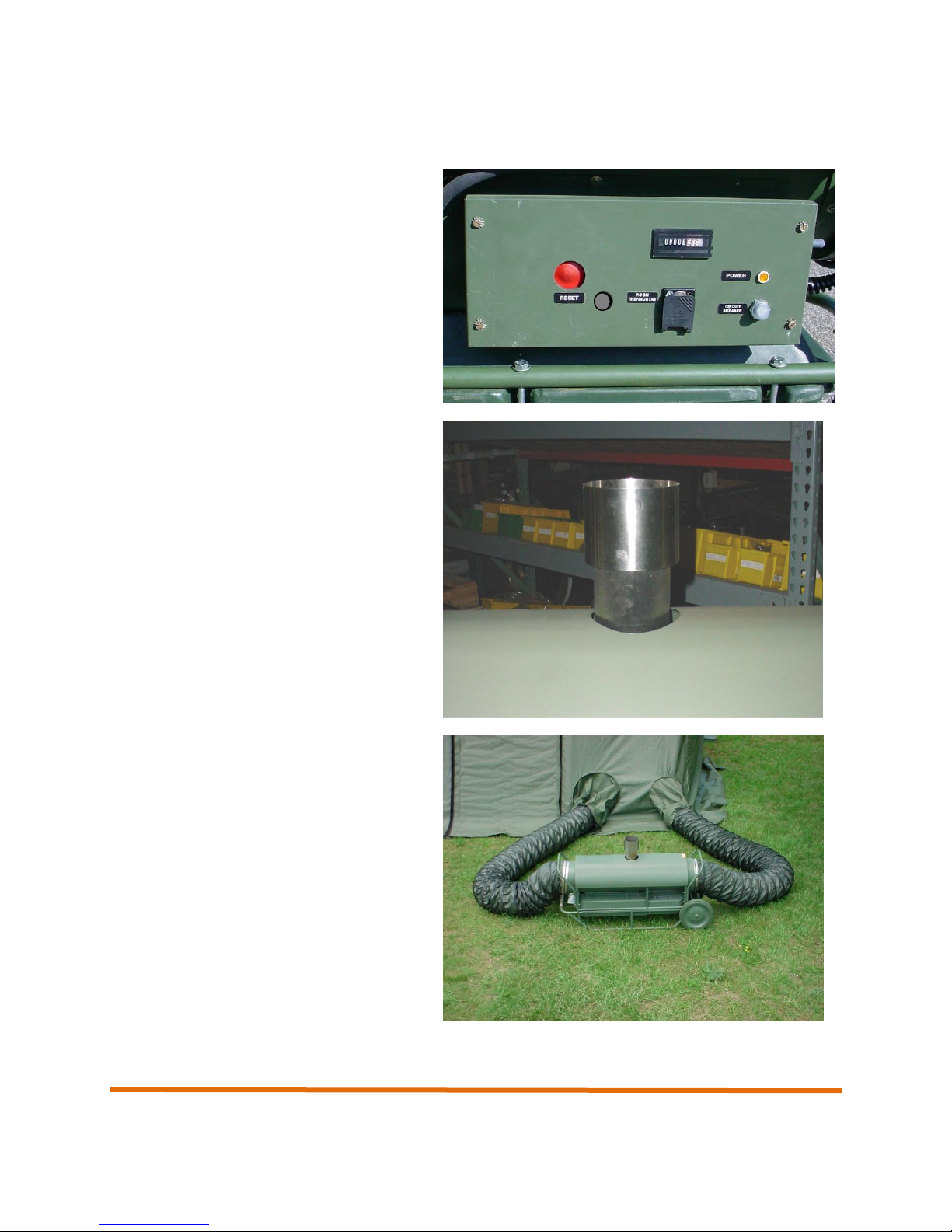

Control Panel – Contains all operation

controls for heater including power input

connector, optional remote room thermostat

connector, and hour meter.

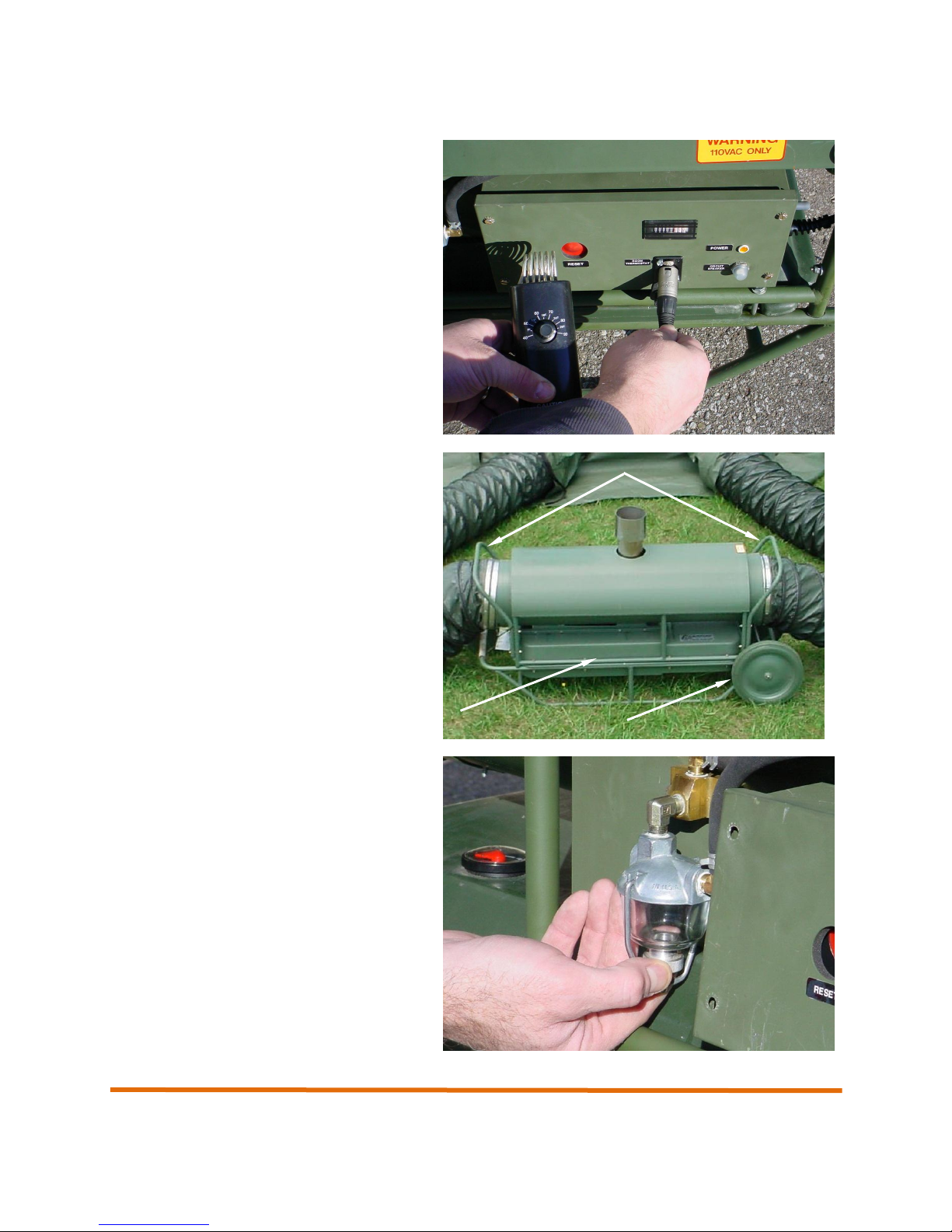

Exhaust Stack Extension– The exhaust

stack extension is installed in the exhaust

outlet on the top of the heater and acts to

direct the combustion gases away from the

heater.

An internal screen in the exhaust stack

extension acts as a spark arrester.

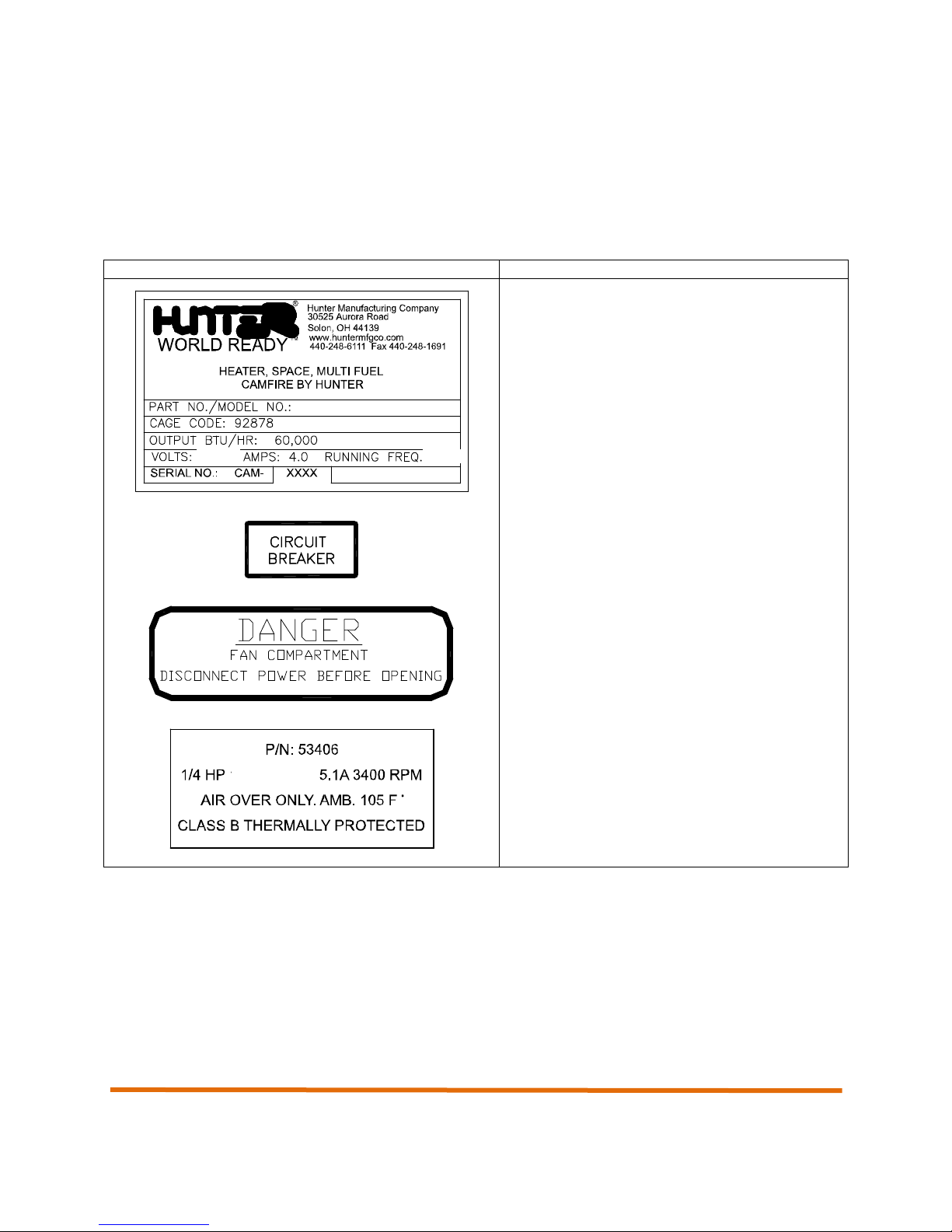

Inlet and outlet ducts – 15 foot flexible

ducts connect to the shelter duct tunnels and

circulate heated and unheated air through the

shelter.

Operation and Maintenance Manual

11

Operation and Maintenance Manual

End plug – Installs into the inlet end of the

heater and is used to house accessory items

such as the remote room thermostat.

Burner assembly – The burner assembly is

where all combustion occurs within the

Camfire heater. Atomized fuel is mixed with

air and ignited by the spark plug to create the

heat circulated through the shelter.

Power cable – A 6-foot long AC power cable

that connects the heater with a 220` VAC

power source. The power cable is wrapped

around the inlet duct adapter.

12

Operation and Maintenance Manual

Remote Room Thermostat – Permits

automatic temperature control inside a

shelter. The remote room thermostat hangs

inside the shelter and monitors the shelter

temperature. If the shelter temperature falls

below the set point on the thermostat, the

heater will start and begin supplying heat

until the set point is reached.

Roll bars, handles, and local transport

wheels* – Handles are located at either end

of the heater and permit the heater to easily

be moved into position. Roll bars are located

around the heater and act to protect the

heater from damage. Local transport wheels

(optional accessory) permit the heater to be

rolled into position.

* Local transport wheels are an optional accessory.

Sediment strainer assembly. Allows for

visual inspection of fuel for dirt and water. Is

able to be easily removed and cleaned.

13

No.

Control

Description

1

Reset

Resets the heater in the event a problem shuts the heater down or a fault

condition occurs

2

Power ON AUTO/

ON MANUAL

Turns heater power on and selects AUTO or MANUAL heat mode

3

Pilot Light

Indicates that power is supplied to the heater.

4

Thermostat Jack

Permits the connection of the remote thermostat assembly.

5

Hour meter

Displays the total number of operating hours for the heater.

6

Circuit Breaker

Protects the heater against circuit overload

7

View Port

Allows the user to view the diagnostic LEDs, for troubleshooting and repair

1

2

3

4

5

6

7

1.3 Controls and Indicators

Operation and Maintenance Manual

Figure 1-1. CAMFIRE Control Panel

14

Operation and Maintenance Manual

No.

Control

Description

1

Variable

Temperature

Control

Placed inside the shelter being heated, permits the operator to set the

desired temperature of the shelter.

2

Temperature

Sensing Coil

Located on the top of the remote room thermostat, monitors the temperature

of the shelter.

1

2

Figure 1-2. Remote Room Thermostat

15

Operation and Maintenance Manual

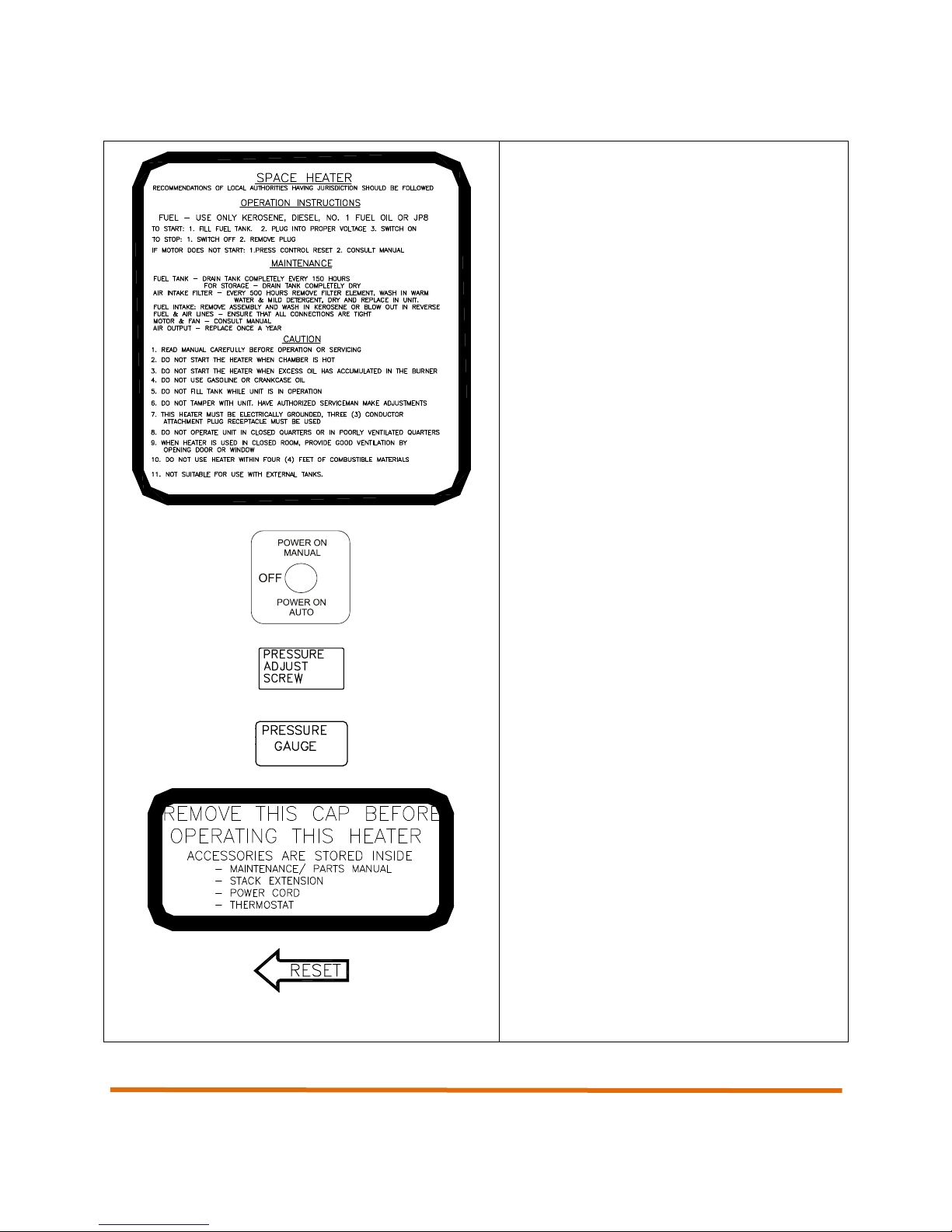

WARNING Label or Data Plate

Location/Description

Located on the side of the heater, the data plate

provides pertinent data including Model Number

and Serial Number

Located on the control panel, identifies the

circuit breaker. See section on controls and

indicators.

Located near the fan compartment, warns user

of electrical shock potential inside fan

compartment.

Located on fan assembly, label identifies part

number and performance specs of fan.

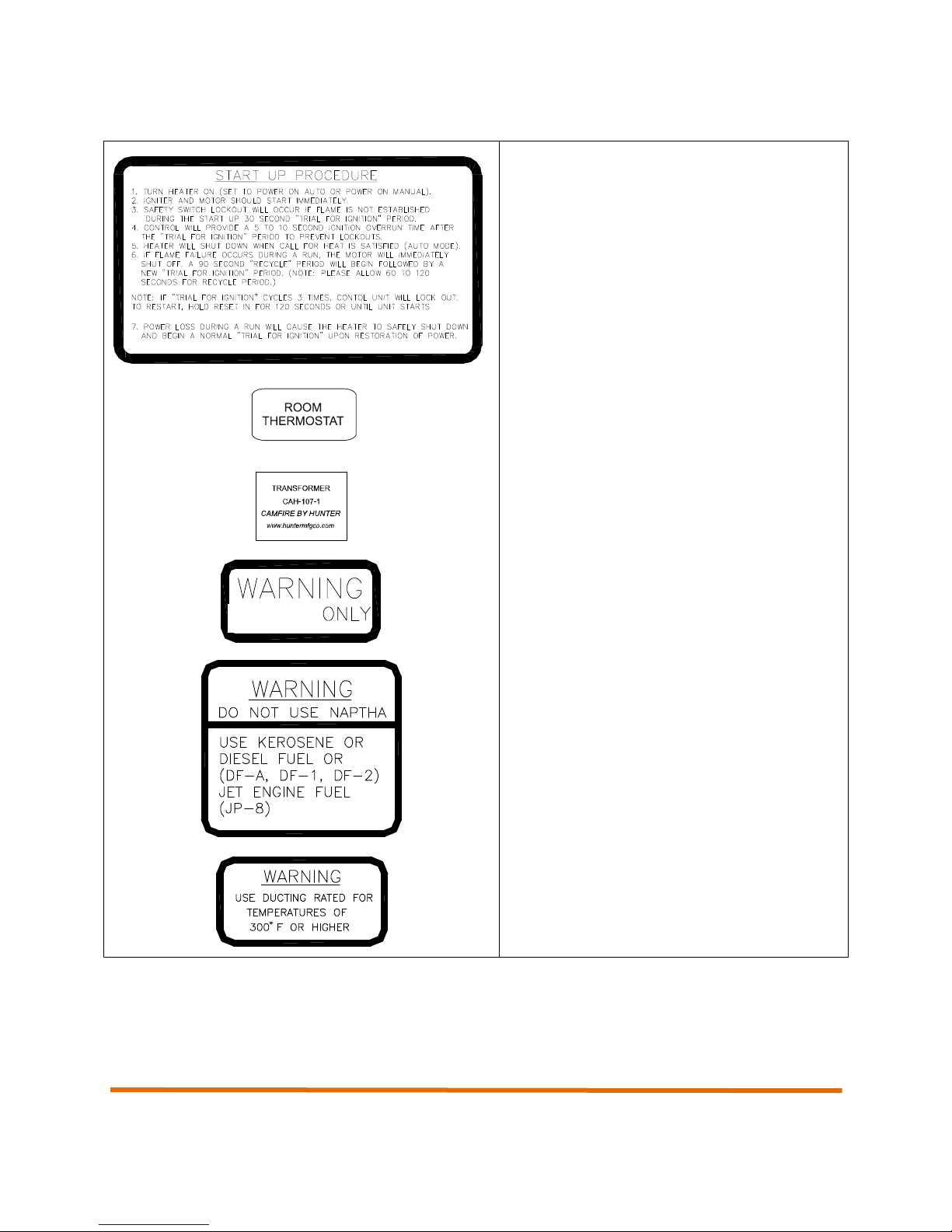

1.4 WARNING Labels and Data Plates

The following section contains a description of all WARNING labels and data plates associated with the

Camfire Heater.

Table 1-1. CAMFIRE Heater Warning Labels and Data Plates

16

Operation and Maintenance Manual

Located on side of heater, label lists the

operating procedures for the heater in

abbreviated form.

Located on the control panel, identifies power

switch.

Located inside heater near air pump, identifies

pressure adjustment screw.

Located inside heater near burner assembly,

identifies pressure gauge.

Located on end plug at end of heater, identifies

the fact that the cap must be removed before

operation. Also informs user of accessories

stored inside end plug.

Located on control panel, identifies Reset

switch.

17

Operation and Maintenance Manual

Located on side of heater, details heater startup procedures.

Located on control panel, identifies remote

ROOM THERMOSTAT.

Parts ID tag located on the ignition transformer.

Located on control panel, alerts user that only

220VAC power should be used.

Located near fuel filler cap on side of heater,

warns user against the use of naptha and

identifies all approved fuels.

Located near duct connections at end of heater.

Warns user that only approved flexible ducts

rated for temperatures of 300 degrees F or

higher can be used.

220 VAC

18

MV60S-EU, MV60T-EU,

Input Heat Rating

BTU/Hour

90,000

Output Ratings

Clean-air Output, BTU/Hour

60,000

Volume, CFM (Approximate)

600

Other Ratings

Current, starting

3.5 AMPS

Current, running

2.2 AMPS

Voltage

220 VAC

Frequency

50/60 Cycles

Fan/Pump Motor

1/4 HP

Air Pump Pressure

5.0 PSI

Fuel Nozzle

Meter Size

0.65 GPH

Spray Angle

80 DEGREES

Fuel

Kerosene, DF1, DF2,

Fuel Oil, JP8 Only

Tank Capacity

8.5 GAL

Flexible Ducts (2)

12 inch diameter

15 ft Length

Dimensions (Without Stack

Extension)

W15” L46” H25”

Weight (Without Fuel)

105 LBS

1.5 CAMFIRE Heater Specifications

Table 1-2. Camfire Heater Specifications

Operation and Maintenance Manual

19

Operation and Maintenance Manual

1.6 Principles of Operation

Fuel System

An air pump on one end of the motor shaft forces the air through the nozzle. The moving air lifts fuel from

the tank or from the remote fuel source ( AND version) by a siphon action and carries it into the

combustion chamber in a fine spray.

Air System

The air system is divided into two parts, both are supplied with air from a fan that is attached to the other

end of the motor.

Part of the air from the fan enters the combustion chamber where it mixes with the atomized fuel to

become a combustible mixture, and also mixes with the burning gases to complete the process of

combustion.

The exhaust gases from the combustion chamber circulate within the inner surfaces of the heat

exchanger. They are then ducted out of the heater through the stack adapter on its’ top and out of the

heater space through a flue pipe.

The rest of the air from the fan passes over and around the combustion chamber and through the heat

exchanger where it is heated and emerges from the front of the heater as a powerful stream of heated

fresh air, without being mixed with the products of combustion.

Ignition System

The ignition system consists of a transformer and spark plug. The transformer increases the input voltage

to a very high potential that causes an arc to be drawn between the electrodes of the spark plug. The arc

is used to ignite the fuel and air mixture within the combustion chamber.

Control System

The safety control circuit consists of a duct over heat switch, a light sensitive photocell, and a safety

control. The safety control will trip if the heater fails to ignite or the flame goes out, thereby causing the

heater to shut down. The safety control has two diagnostic LEDs which can be seen through a hole in the

front of the control panel.

The photocell is used to sense the presence of light due to the flame inside the combustion chamber. It

varies its’ electrical resistance in relation to light rays. When under the influence of light, the cell has very

low resistance. The resistance is high when little or no light strikes the light sensitive surface. The flame

sensor’s function is to control the safety control.

A ”duct over-heat” switch is located at the outlet end of the heater. This switch will shut down the heater if

the duct temperature exceeds approximately 275 deg. F.

A thermostat accessory, Part No. CAH-134-1, may be incorporated into the electrical circuit of the heater.

The thermostat can be set to any desired temperature between 35 deg. F and 95 degrees F. When the

20

Operation and Maintenance Manual

temperature of the surrounding air reaches the pre-set temperature, the thermostat contacts open and

cause the heater to shut down. When the air cools, the thermostat contacts close and the heater recycles.

A ”duct over-heat” switch is located at the outlet end of the heater. This switch will shut down the heater if

the duct temperature exceeds approximately 275 degrees F.

Figure 1-3. System Operational Diagram (simplified for clarity)

21

Operation and Maintenance Manual

22

Operation and Maintenance Manual

Chapter 2

Setup and Operation of the

CAMFIRE Heater

23

Operation and Maintenance Manual

24

Operation and Maintenance Manual

2. Setup and Operation of the CAMFIRE Heater

2.1 Preparing the Heater for Operation

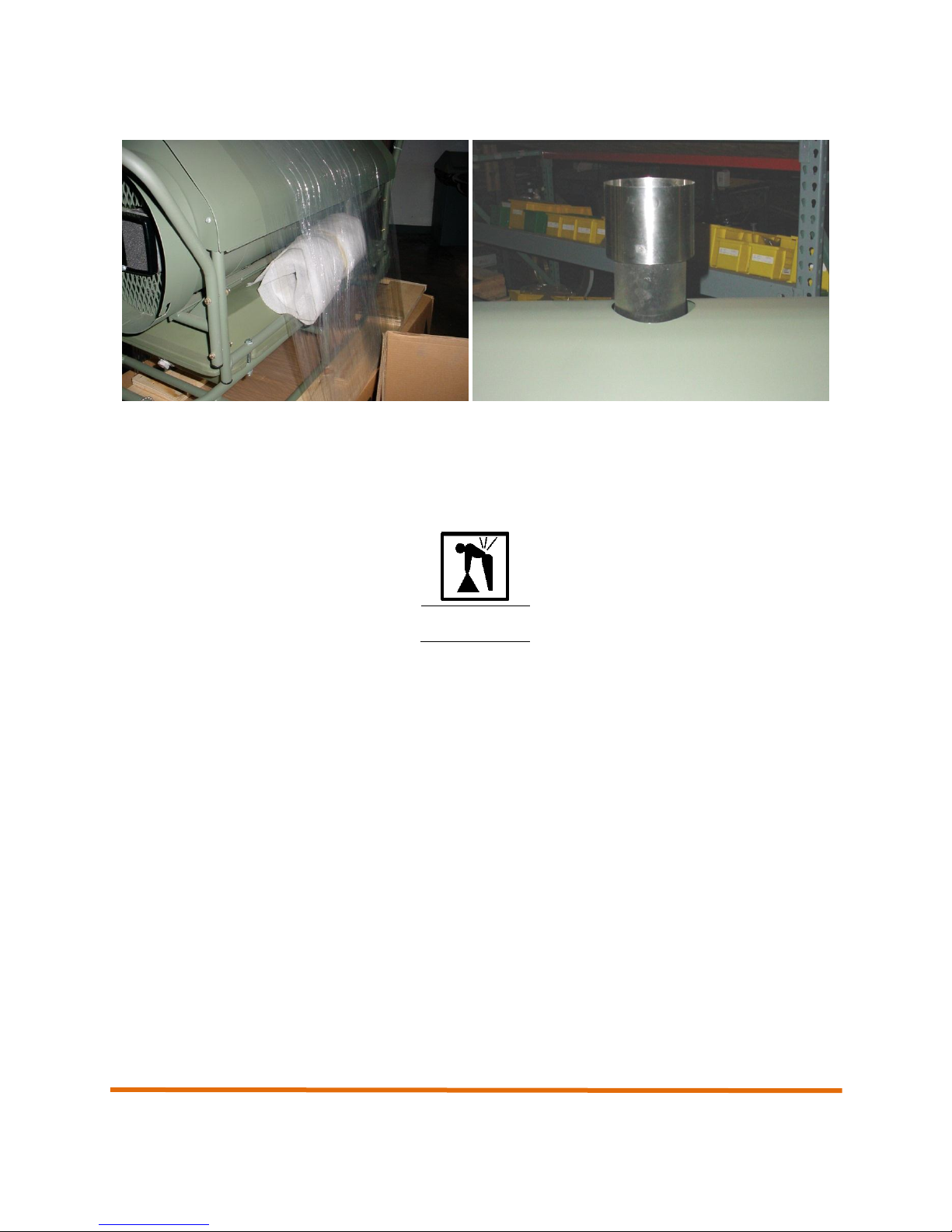

2.1.1 Unpacking

The Camfire heater is shipped mounted to a shipping pallet and wrapped in a plastic wrap material. When

unpacking the heater, remove all protective material covering the heater and remove the unit from the

shipping pallet.

2.1.2 Installing the Exhaust Stack Extension

The exhaust stack extension is wrapped in foam and packaged to the side of the heater. Unwrap the

exhaust stack extension and install on the top of the heater by engaging the exhaust stack extension into

the exhaust port at the top of the heater. Push down and seat securely.

25

Operation and Maintenance Manual

WARNING

2.1.3 Removing the Accessories

Remove the end plug by pushing in and rotating counterclockwise to release from the J-slot. Pull the end

plug to disengage it from the heater and remove the remote room thermostat. Set the thermostat aside.

2.2 Siting Considerations

The CAMFIRE heater weighs approximately 105 pounds dry weight (48 kg). A fully fueled

heater weighs 165 pounds (74.8 kg). Two persons must carry the CAMFIRE heater when

lifting or lowering the unit. Be sure to lift with legs, not back, to prevent injury.

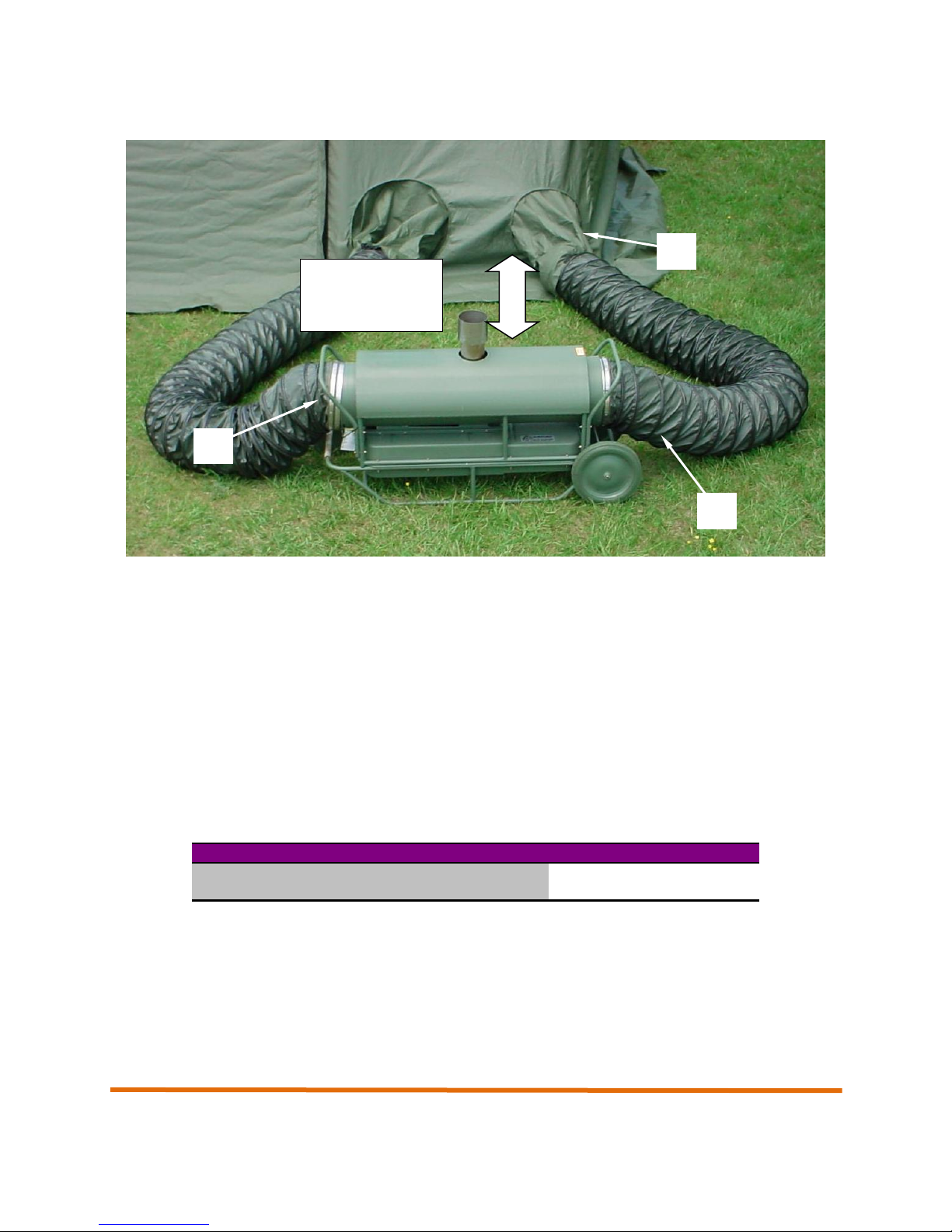

The CAMFIRE heater site location will be dictated by the location of the shelter since the heater inlet (1)

and outlet (2) ducts must be able to reach the shelter duct tunnels (3). (see photo next page)

The heater site must be as level as possible and free of combustible material (e.g. dried twigs, leaves.

etc.). If snow is present, it should be removed from the area immediately beneath and around the heater.

The site should be selected so that the heater will be positioned at least 2 feet (61 cm) from combustibles,

including the shelter wall.

26

Below 320F

Above 320F

Use Heated Air Outlet Duct Only

X

Use Air Inlet Duct and Heated Air Outlet Duct

X

Position heater

at least 2 feet

from shelter wall

1

2

3

Operation and Maintenance Manual

Positioning the Heater Outside Shelter. Place heater on the side of the shelter that has the shelter duct

tunnels. The heater should be a minimum of 2 feet (61 cm) from shelter walls. If possible, position the

heater so that the control panel faces away from the shelter wall. Position the heater so that the two

supplied 15-foot flexible ducts can be connected to the heater and the shelter duct tunnels.

2.3 Setup

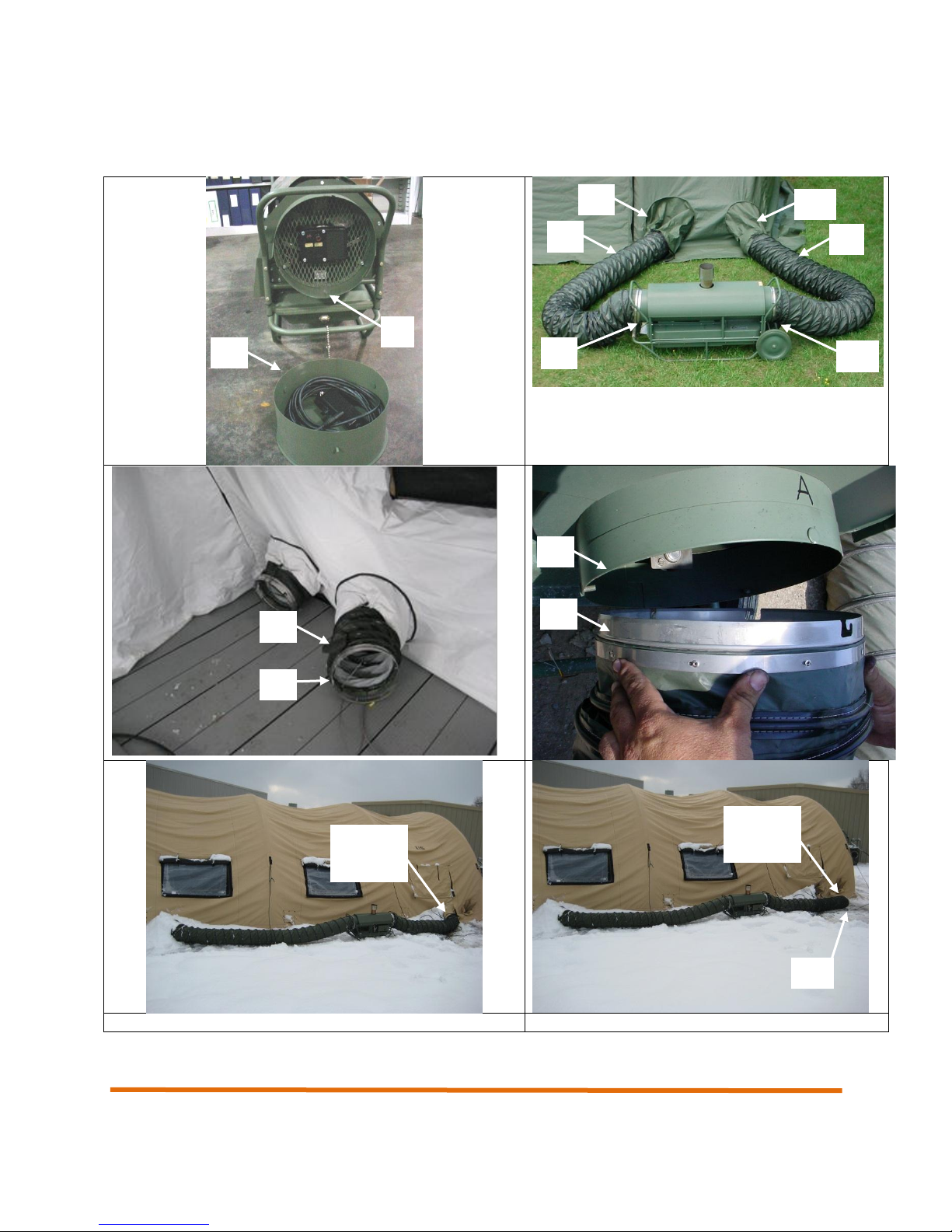

2.3.1 Attaching the Flexible Ducts

General. Two air ducts, 15 feet in length and 12 inches in diameter, connect to the inlet and outlet ends

of the heater and move air from the interior of the shelter, through the heater, and back to the interior of

the shelter. In conditions where the outside ambient temperature is above freezing, only the heated air

supply duct is used. In this way, the heater draws unheated air from the outside. Operating the heater

without input ducting in warmer temperatures allows the heater to run cooler, thus preventing safety

overheat shutdown.

Table 2-1. Flexible Duct Usage vs. Outside Temperature

27

Operation and Maintenance Manual

WARNING

Installing the Air Supply and Return Ducts (re-circulation mode). To install the heated air return and

air supply ducts (NOTE: air return duct to be installed only if outside temperatures are below freezing),

remove end plug (1) from the heater duct adapter (2) on the air inlet end of the heater by pushing in and

rotating clockwise to disengage the protruding pins on the end plug from the J-slots in the heater duct

adapter. Remove the power cable stowed inside the end plug and set aside.

During heater operation, air leaving the heated air outlet of the heater and passing

through the heated air return duct may exceed 220°F (104°C). Make sure shelter

personnel are aware of burn hazards and equipment hazards presented by the heated air

exiting the heated air duct.

CAUTION

Wear gloves whiles handling ducts. There may be sharp metal edges or burrs that could

cut you.

NOTE: The heater ducts are outfitted with J-slot, twist lock bands on each end. They can only be

attached one way. Make sure to match up the ends before attaching to the shelter. Locate the heated air

supply duct (3). Make sure inside and outside of duct are free of damage, dirt, and obstructions prior to

attachment to the heater assembly. Insert the outlet end (4) of the duct into the shelter duct tunnel (5)

closest to the heated air outlet end (6) of the heater as indicated by the label “Heated Air Outlet” on the

upper housing assembly. Make sure about 12 inches of the outlet end (4) protrude into the shelter (7) so

that the air can be directed away from the inlet properly. Secure the shelter duct tunnel tie straps. Do not

secure the straps so tightly that the air flow within the duct is restricted. Attach the end of the duct with the

J-slot bracket (8) to the duct adapter (9) on the heated air outlet end (6) of the heater. Engage the J-slot

onto the protruding pins on the inside of the duct adapter and push in fully. While pushing the duct in,

rotate the duct counterclockwise until it locks in place.

IMPORTANT

If using the heater on a shelter with a plenum, move the plenum to the side so it does not

obstruct the airflow. DO NOT ATTACH THE HEATER TO THE SHELTER PLENUM. The

heater will do a much better job of heating by blowing the heat on the floor.

Insert the end of the duct without the J-slot mounting bracket into the shelter duct tunnel (14) closest to

the air inlet end (15) of the heater as indicated by the label “Air Inlet” on the upper housing assembly.

Secure the shelter duct tunnel tie straps (16). Do not secure the straps so tightly that the air flow within

the duct is restricted. Attach the end of the duct with the pins onto the J-slots (17) to the duct adapter (18)

on the air inlet end of the heater. Engage the protruding pins onto the J-slots on the duct adapter and

push in fully. While pushing the duct in, rotate the duct counterclockwise until it locks in place.

28

Operation and Maintenance Manual

Re-circulation mode

Outside air mode (see next section)

7

1 2 5

3

4

6

8

9

14 3 15

12

Duct

shelter

Duct

shelter

inside

outside

29

Operation and Maintenance Manual

WARNING

2

3

Installing the Air Supply and Return Ducts (outside air mode) If outside temperatures are above

freezing, the inlet of the air supply duct (12) should be located outside the shelter, drawing outside air, in

accordance with Table 2-1. This helps to keep the heater from shutting down on overheat unexpectedly.

Make sure the duct is still attached to the heater as this keeps rain and snow from being drawn into the

fan compartment. Also, make sure inside and outside of duct and the grill are free of damage, dirt, and

obstructions prior to attachment to the heater assembly.

Never use gasoline in this heater. Never use JP-4. The heater is designed to run only on

DF-1, DF-2, DF.A, JP-5, and JP.8. Failure to use only authorized fuels may result in fire

or explosion.

2.4 Before Operation Preventative Maintenance Checks and Services (PMCS)

Perform the “Before Operation PMCS” on all CAMFIRE heater components as outlined in section 4.2,

prior to preparing the heater for use. All scheduled maintenance must be performed on the heater and its

associated equipment prior to use.

2.5 Fueling

2.5.1 Fueling the Internal Tank (MV60S-EU, MV60T-EU)

Remove the internal fuel tank cap (2) and fill the internal tank with an approved fuel as detailed in section

1.5 of this manual.

Install the internal fuel tank cap (2) and hand tighten securely.

Open the vent on the top of the fuel tank cap

(2).

CAUTION: For fuel tanks with a manual vent.

The fuel tank vent should always be open to

prevent pressure from building up in the fuel

tank. Only close the vent when the heat is

tilted, such as when moving the heater on its

optional wheels.

The fuel level in the tank is displayed on the

fuel gauge to the right of the fuel tank cap (3).

30

Operation and Maintenance Manual

1

2

3

4

5

2.5.2 Connecting and operating the Remote Room Thermostat

The optional remote room thermostat (1) allows the operator to control the environment inside the shelter

automatically by monitoring the temperature and subsequently controlling the heat output of the Camfire

heater. (see photo next page)

To connect the remote room thermostat (1), engage the plug (2) on the end of the cable into the

connector (3) on the control panel of the heater labeled “ROOM THERMOSTAT”. Push the plug in

securely until it clicks in position. Rotate the dial on the room thermostat fully counter clockwise so that it

does not turn on unexpectedly while setting up.

Route the thermostat control into the shelter and hang from a convenient location. Be sure to position the

control so that it is not in the direct path of the heated air outlet or the cold air at the entrance to the

shelter. You may need to try several locations in the shelter before a suitable location is found.

To use the room thermostat move the control panel switch (4) to the ON AUTO position. Adjust the dial

until the heater comes on. If the room temperature is not satisfactory, adjust the room thermostat as

necessary. NOTE: The numbers (5) on the room thermostat are for reference only. You should remember

that if the shelter temperature is too cold (or hot) simply adjust the room thermostat.

31

Operation and Maintenance Manual

LENGTH OF CORD

WIRE SIZE (AWG)

100 ft

NO. 14

200 ft

NO. 12

300 ft

NO. 10

400 ft

NO. 8

450 ft

NO. 6

2

1

2.5.3 Connecting the Power Cable

Ensure that the main power switch (1) on the Camfire heater control panel is in the OFF position.

Uncoil the power cable (2) and connect the male end of the power cable to a 220 VAC, 50/60 cycle single

phase power source with GFCI.

If an extension cord is required, ensure that it is a three wire cord and of adequate size, as listed in the

following table.

Table 2-2. Extension Cord Size Requirements

32

Operation and Maintenance Manual

WARNING

2.6 Final Checks Before Operation

1. Make sure that all the connections are secure, power, room thermostat, ducts, etc.

2. Open internal fuel tank cap and check for an adequate fuel supply. Make sure the fuel tank cap vent

is open.

3. Ensure that the power switch on the control panel is in the OFF position.

4. Plug the Camfire heater power cord into a grounded, 220 VAC power supply outlet.

5. The heater assembly is now ready for operation.

2.7 Starting and Operating the Heater

2.7.1 Starting the Heater

1. Set the toggle switch to the ON MANUAL position if the heater is not being operated with the room

thermostat control. If the room thermostat accessory is being used, set the toggle switch to the ON

AUTO position and set the dial on the room thermostat to the desired temperature. This will initiate a

“call for heat”. The heater will start immediately provided that the surrounding air is cooler than the

setting of the dial. The heater will continue to operate until the temperature of the surrounding air

reaches the dial setting. It will then shut down and cycle on when the temperature drops.

2. Safety control lockout will occur if flame is not established during the startup 15 second “trial for

ignition” period. To restart, the safety switch must be manually reset. See section 3 for details.

3. Control will provide a 5 to 10 second ignition overrun time after the “trial ignition period” to prevent

lockouts.

4. Burner will turn off when call for heat is satisfied. CAUTION: There is no post purge on this heater so

surfaces will remain hot for some time after shut down.

5. If flame failure occurs during a run, the motor will immediately shut off. A 90 second “recycle” period

will begin followed by a new “trial for ignition” period. (Please allow 60 to 120 seconds for recycle

period). Flame failure may occur due to a heater failure or, if the heater runs out of fuel.

NOTE

If trial for ignition locks out three times, control will “latch-up”. To reset, refer to section 3.

Only a qualified technician should attempt to rest the control after latch-up. The

problem that caused the malfunction must be corrected before returning the

burner to normal operation. Failure to do so may lead to fire and or damage to

equipment or personnel. (see troubleshooting)

33

Operation and Maintenance Manual

6. Power loss during a run will cause the burner to safely shut down and begin a normal trial for ignition

upon power restoration.

2.8 Refueling During Operation

The heater must not be refueled while it is operating. To refuel the heater, turn the power switch to the

OFF position. Refuel in accordance with the section entitled “Fueling the Internal Fuel Tank”.

2.9 Shutting Down the Heater

1. Move the heater switch to the OFF position.

2. If the heater is equipped with a thermostat accessory, turn the dial to the”No Heat” position.

2.10 Preparing for Movement or Storage

2.10.1 Preparing for Movement

1. To prepare the Camfire heater for movement, ensure that the heater has been shutdown in

accordance with section 2.9 and that it is completely cool.

2. Unplug the power cord from the power source as well as the Camfire control panel. Coil the power

cord around the inlet adapter.

3. Remove the remote room thermostat from the shelter (if used) and disconnect from the thermostat

connector on the control panel. Coil the remote room thermostat cable and stow it in the end plug

along with the power cable.

4. Remove the heated air outlet duct from the shelter duct tunnel. Stow the duct in a location that will

protect it from weather extremes, cuts, tears, or other damage.

5. Remove the air inlet duct (if used) from the remaining shelter duct tunnel. Stow the duct in a location

that will protect it from weather extremes, cuts, tears, or other damage.

6. Ensure that the remote room thermostat is neatly coiled inside the end plug as previously discussed.

Install the end plug in the end of the heater by aligning the pins on the end plug with the J-slots on the

heater duct housing. Push the end plug in place and rotate clockwise to lock in place. Release the

end plug.

7. Remove the stack extension and stow in a protected location along with the ducts.

34

Operation and Maintenance Manual

2.10.2 Preparing the Heater for Storage

To prepare the heater for storage, follow all procedures detailed in the previous section to prepare the

heater for movement.

In addition, drain the fuel tank and purge with an approved agent. Start the heater and run out all residual

fuel left in the system. Make sure the fuel tank vent is open. Empty the sediment strainer.

CAUTION: The fuel tank vent should always be open to prevent pressure from building up in the fuel

tank. Only close the vent when the heat is tilted, such as when moving the heater on its optional wheels.

Lubricate all hinges.

Fog the entire heater with a thin layer of WD-40 or equivalent light oil spray to protect all metal surfaces.

Store the heater in a location protected from moisture and sand.

35

Operation and Maintenance Manual

36

Chapter 3

Operation and Maintenance Manual

Troubleshooting

37

Operation and Maintenance Manual

Step

LED

Status

Description

A R

1 O O

Power ON/Standby, Control waits for Room Thermostat circuit to close or Manual

ON

2 I O

Call for heat, Room Thermostat circuit closed. The amber LED turns ON. For the

first 3 of 4 seconds, the control performs a self-test. If the photocell senses flame, the

control repeats this test until flame is no longer detected. During this time the amber

LED blinks off momentarily every 3 or 4 seconds

3 O O

Burner ON. After the self-test, the amber LED turns OFF. The igniter starts, followed

1 second later by the motor.

4 O O

TFI (trial for ignition), the photocell must detect flame within 15 seconds. After flame

is detected, the igniter stays on another 10 seconds for flame stabilization.

5 O O

RUN, the burner continues firing as long as the photocell senses flame and the

overheat does not trip.

6 O I

LOCKOUT, if the photocell does not sense flame within 15 seconds after the burner

starts, lockout occurs. The control turns the RED on constant.

To RESET, push in and hold red button for 1 second, then release.

N/A

I I LATCH-UP, If the control locks out 3 times during a single call for heat, latch-up

occurs. The control turns on both the amber and red LEDs constant.

Warning! Only a qualified technician should attempt to rest the control after

latch-up. The problem that caused the malfunction must be corrected before

returning the burner to normal operation. (see maintainer level

troubleshooting)

3. CAMFIRE Troubleshooting

3.1 Introduction

Should you encounter any problems with the operation of a heater, the chart on the following pages may

help. For each problem there is a list of ”possible causes”. The corrective action column tells you how to

correct the problem or tells you by means of a section and paragraph number where to find detailed

instructions for correcting it.

In troubleshooting, remember that the air pump is part of the fuel system because the air it supplies lifts

the fuel from the tank and pushes it through the nozzle.

NOTE

Be sure to follow all cautions and warnings. They will help you prevent damage to the

heater or injury to yourself.

3.2 Operator Level Troubleshooting

3.3 Safety Control Operation and Diagnostics

During the start-up and operation of the heater the safety control goes through several steps where it is

evaluating the controls and inputs from other safety devices such as the photocell and overheat

thermostat. On the control there are to LEDs, one amber (A) and one red (R), which are visible through a

small view port on the front of the control panel. During operations the LEDs may come on and/or blink.

The table below shows various stages of operation after the heater is switched on, and the resultant LED

status. The LED status is as follows: I=ON, O=OFF

38

Operation and Maintenance Manual

Malfunction

Troubleshooting

Procedure

Motor Does Not Start

1

Heater Will Not Ignite, But Motor Runs For A Short Time.

2

Heater Burns But Puffs Of Smoke Can Be Seen; Heater Will Not Burn Steady;

Heater Burns With Odor; Heater Smokes Continuously

3

Flames and/or Black Smoke Come Out Of Stack

4

Heater Cycles Intermittently

5

Heater starts but will not stay running, RED light is flashing on control

5

Heater Ignites But Safety Control Trips, Red LED is on constant.

6 Heater will not start, amber light is flashing on the control

7

3.3.1 Operator Level Malfunction Symptom Index

The malfunction symptom index lists common malfunctions that may occur during the operation of the

CAMFIRE Heater. Find the malfunction to be eliminated and go to the indicated troubleshooting

procedure in the next section. This index cannot list all malfunctions that may occur, all tests or

inspections needed to find the fault, or all actions required to correct the fault. If the existing malfunction is

not listed, or cannot be corrected through this troubleshooting index, notify maintenance.

For purposes of this troubleshooting section, the term operator refers to someone who has been trained

in the deployment and use of the heater but has not been trained or certified in the maintenance of the

heater beyond operator level maintenance tasks.

Table 3-1. Operator Level Malfunction Symptom Index

3.3.2 Examining the Heater

WARNING!

REMOVE ALL POWER BEFORE SERVICING THE HEATER. SEVERE INJURY COULD OCCUR

1. Check the fuel tank for sludge and water. If you find it, expect to find a dirty nozzle and/or sediment

strainer.

2. Spin the fan to be sure it turns freely. If it is stiff, look for a worn or dry bearing on the fan end of the

motor, or for binding pump rotor.

3. Check the heater for dirt and foreign materials around the pump, fan and air filters. Be sure the heater

is reasonably clean before test-firing.

4. Check the heater cord for obvious breaks or other unsafe conditions. If the cord is doubtful repair it or

replace with a new one before test firing.

39

Operation and Maintenance Manual

No.

Malfunction

Possible Cause

Corrective Action To Take

1.

Motor does not start.

A. Safety control locked out.

(see section 3.3)

1. Push and hold red reset button

for 5 seconds.

B. No power or low voltage at

heater.

1. Check that heater is plugged

in.

2. Ensure voltage at heater is the

same as indicated on heater Data

Plate located on electrical panel

cover and as indicated in the

Specifications, Section 1.5.

3. Use an extension cord of

sufficient gauge to carry the

electrical load of the heater (see

Table 2-3).

C. Thermostat (if used)

improperly set or defective.

1. Adjust thermostat to a higher

setting. If heater still does not

start, continue with Step 2.

2. Place the toggle switch on the

heater control box to the “ON

MAUNAL” position. If heater

functions properly, replace

thermostat.

D. Fan obstructed by

mechanical damage or dirt.

1. Check for bent outer shell,

damaged fan, or damaged motor

mount.

E. Defective photocell.

1. Refer the unit to maintenance

for further troubleshooting.

F. Defective safety control.

1. Refer the unit to maintenance

3.3.3 Test Firing the Heater

1. Clean the fuel tank and fill it with at least 2 gal of fuel. A minimum of 1 gal of fuel must be in the tank

in order to operate the heater.

2. Clean the air intake filter. See Section 4.4.8.

3.3.4 Operator Level Troubleshooting Procedures

Table 3-2. Operator Level Troubleshooting Procedure

40

Operation and Maintenance Manual

No.

Malfunction

Possible Cause

Corrective Action To Take

for further troubleshooting.

G. Broken rotor or carbon

blades. Pump rotor binding.

1. Refer the unit to maintenance

for further troubleshooting.

2.

Heater will not ignite, but

motor runs for a short time.

A. Fuel tank empty, wrong fuel,

water in fuel.

1. Check level of fuel in tank. A

minimum of 1 gallon is required

for proper operation.

2. Ensure fuel is of a type

indicated on the heater or listed in

the Specifications, Section 1.5.

3. Check for water in the fuel

tank. Water in the fuel will form

visible globules in the bottom of

the fuel tank.

4. If water is found, refer the unit

to maintenance.

B. Air leak at sediment strainer.

1. Check sediment strainer and

gasket for air leaks and tightness

of thumb screw that holds the

glass bowl on.

C. Defective or damaged spark

plug.

1. Refer the unit to maintenance

for further troubleshooting.

D. Defective transformer.

1. Refer the unit to maintenance

for further troubleshooting.

3.

Heater burns but puffs of

smoke can be seen; heater

will not burn steady; heater

burns with odor; heater

smokes continuously.

A. Heater running out of fuel,

wrong fuel, water in fuel.

1. Check level of fuel in tank. A

minimum of 1 gallon is required

for proper operation.

2. Ensure fuel is of a type

indicated on the heater or listed in

the Specifications, Section 1.5.

3. Check for water in the fuel

tank. Water in the fuel will form

visible globules in the bottom of

the fuel tank.

4. If water is found, refer the unit

to maintenance for repair.

B. Dirty air filters causing

reduced air pressure through

1. Ensure air intake is not

blocked.

41

Operation and Maintenance Manual

No.

Malfunction

Possible Cause

Corrective Action To Take

nozzle resulting in low fuel flow.

2. Remove and clean air filters

(see Section 4.4.8).

C. Dirty sediment strainer.

1. Remove sediment bowl and

clean.

2. Refer the unit to maintenance

for further troubleshooting.

D. Sediment strainer loose.

1. Check sediment strainer and

gasket for air leaks and tightness

of thumb screw that holds the

glass bowl on.

E. Dirty fuel nozzle.

1. Refer the unit to maintenance

for further troubleshooting.

F. Low pump output pressure

(low motor speed, worn pump,

pump out of adjustment.

CAUTION

Never use a drill, wire or other

tool to open nozzle passage

1. Ensure that no mechanical

damage to the fan blades could

be causing low motor speed.

2. If mechanical damage is

observed, refer the unit to

maintenance for further

troubleshooting.

G. Loose output airline

between pump and burner

head.

1. Tug airline at both connections

to ensure that they are tight.

H. Inlet duct is blocked

1. Check inlet duct and make sure

it is clear. Make sure test fabric or

other FOD are not blocking the

airflow.

I. Inlet screen blocked

1. Remove inlet duct and check

debris screen for FOD. Clean as

necessary.

4.

Flames and/or black

smoke come out of stack.

A. Dirty fan or air passageway

through heater blocked.

1. Ensure that debris grill is clear.

Ensure that fan is operating

properly in accordance with

Section 4.4.5.

2. Ensure air passageway

through heater is clear.

42

Operation and Maintenance Manual

No.

Malfunction

Possible Cause

Corrective Action To Take

B. Pump output too high

causing too much fuel to be

supplied.

1. Refer the unit to maintenance

for further troubleshooting.

C. Fan loose or improperly

located on shaft.

1. Refer the unit to maintenance

for further troubleshooting.

D. Bent or damaged fan.

1. Inspect fan for damage. If

damage to fan is observed, refer

the unit to maintenance for repair.

Make sure fan is not loose on the

motor shaft.

E. Inlet duct is blocked

1. Check inlet duct and make sure

it is clear. Make sure test fabric or

other FOD are not blocking the

airflow.

F. Inlet screen blocked

1. Remove inlet duct and check

debris screen for FOD. Clean as

necessary.

G Access hatch is open

1. close access hatch

5.

Heater cycles

intermittently.

A. Room Thermostat (if used)

set too low.

1. Set thermostat to a higher

temperature for more even

operation.

B. Defective thermostat (if

used).

1. Set power switch on heater

control box to “ON MAUNUAL”

position.

2. If heater runs evenly, replace

thermostat.

C. Defective electrical supply or

defective electrical

connections.

1. Ensure extension cord is in

good condition.

2. Check mechanical and

electrical soundness of all wiring

connections in the heater (see

Schematic, Section 6).

D. Defective overheat switch.

1. Refer the unit to maintenance

for further troubleshooting.

E. Unit is overheating.

1. Check ducts for obstructions,

or kinks. Straighten ducts to

promote good airflow.

2. Remove inlet duct from shelter.

43

Operation and Maintenance Manual

No.

Malfunction

Possible Cause

Corrective Action To Take

6.

Heater ignites but safety

control trips. Heater starts

but will not stay running,

The control turns the red

LED on constant,

If photocell does not sense

flame within 15 seconds after

burner starts, lockout occurs.

A. Dirty or defective photocell.

1. Lift top cover. Open access

hatch. Remove photocell from

bracket attached to burner head.

2. Inspect glass face of photocell.

If dirty, wipe with clean soft cloth

3. Replace photocell and close

access hatch. Start heater. If

problem persists, notify

maintenance.

4. Overheat, (see 5, D and E)

B. overheat switch open

1. Let unit cool down and see if

overheat resets.

2. Check ducts and inlet screen

for blockages

D. Sediment strainer loose.

1. Check sediment strainer and

gasket for air leaks and tightness

of thumb screw that holds the

glass bowl on.

D. Sediment strainer dirty.

1. Check sediment strainer for dirt

and water. Empty bowl and clean

screen.

If problem persists notify unit

maintenance

7.

Heater will not start, Amber

light flashes on control

A. photocell seeing light

1. Make sure access cover is

closed.

2. Attach return duct

3. Disconnect photocell. If heater

starts then photocell is defective.

Notify unit maintenance.

44

Operation and Maintenance Manual

Step

LED

Status

Description

A R

1 O O

Power ON/Standby, Control waits for Room Thermostat circuit to close or Manual

ON

2 I O

Call for heat, Room Thermostat circuit closed. The amber LED turns ON. For the

first 3 of 4 seconds, the control performs a self-test. If the photocell senses flame, the

control repeats this test until flame is no longer detected. During this time the amber

LED blinks off momentarily every 3 or 4 seconds

3 O O

Burner ON. After the self-test, the amber LED turns OFF. The ignitor starts, followed

1 second later by the motor.

4 O O

TFI (trial for ignition), the photocell must detect flame within 15 seconds. After flame

is detected, the igniter stays on another 10 seconds for flame stabilization.

5 O O

RUN, the burner continues firing as long as the photocell senses flame and the

overheat does not trip.

6 O I

LOCKOUT, if the photocell does not sense flame within 15 seconds after the burner

starts, lockout occurs. The control turns the RED on constant.

To RESET, push in and hold red button for 1 second, then release.

I I

LATCH-UP, If the control locks out 3 times during a single call for heat, latch-up

occurs. The control turns on both the amber and red LEDs constant. You must use

the special procedure below to reset the control after latch-up.

Warning! Only a qualified technician should attempt to rest the control after

latch-up. The problem that caused the malfunction must be corrected before

returning the burner to normal operation.

3.4 Maintainer Level Troubleshooting

3.4.1 Test Firing

1. Check and adjust the air pressure, as described in Section 4.4.8, except that fuel must be used for

test-firing.

NOTE

It is not possible to test-fire a heater properly if this adjustment cannot be made.

2. Allow the heater to run for 15 minutes. Observe its operation during the test-run.

3. After making the pressure check, adjustment, and test firing, remove the gauge and re-install the

plug. Tighten plug until sealed. Use soapy water to check for sealing. Do not tighten.

4. If any troubles show up during the test firing, refer to the troubleshooting chart to find out how to

correct them.

3.4.2 Maintainer Level Safety Control Operation and Diagnostics

During the start-up and operation of the heater the safety control goes through several steps where it is

evaluating the controls and inputs from other safety devices such as the photocell and overheat

thermostat. On the control there are tWo LEDs, one amber (A) and one red (R) which are visible through

a small view port on the front of the control panel. During operations the LEDs may come on and/or blink.

The table below, shows various stages of operation and the resultant LED status. The LED status is as

follows: I=ON, O=OFF, B=BLINK, F=FLASHING

45

Malfunction

Troubleshooting

Procedure

Motor Does Not Start

1

Heater Will Not Ignite, But Motor Runs For A Short Time.

2

Heater Burns But Puffs Of Smoke Can Be Seen; Heater Will Not Burn Steady;

Heater Burns With Odor; Heater Smokes Continuously

3

Flames and/or Black Smoke Come Out Of Stack

4

Heater Cycles Intermittently

5

Heater starts but will not stay running, RED light is flashing on control

5

Heater Ignites But Safety Control Trips, Red LED is on constant.

6 Heater will not start, amber light is flashing on the control

7

F

O

F

O

RESET from LATCH-UP Push in and hold the reset button for about 10 seconds.

The amber and red LED’s will begin to flash alternately.

After the LED's begin flashing, continue holding the reset button for about another 20

seconds. The LED's will turn off. Release the reset button and the control will restart.

(Releasing the button before the LED's turn off will cause the control to remain in

latch-up.)

Note: The 50240 control will not reset from lockout or latch-up if power is interrupted.

O F

FLAME FAILURE If the photocell loses flame signal during operation (after the TFI),

the red LED flashes. The burner shuts off within seconds. Recycle: Control waits for

65 seconds (with red LED flashing), then begins again at Self-test. Red LED goes off

3.4.3 Maintainer Level Malfunction Symptom Index

Operation and Maintenance Manual

Table 3-3. Maintainer Level Malfunction Symptom Index

46

3.4.4 Maintainer Level Troubleshooting Procedures

No.

Malfunction

Possible Cause

Corrective Action To Take

1

Motor does not start

A. Fan obstructed by

mechanical damage or dirt.

1. Replace a damaged fan. Do

not attempt to repair.

B. Defective photocell.

(see section 4.4.10)

1. Lift top cover. Open access

hatch. Remove photocell from

bracket attached to burner head.

2. Disconnect blue and white

photocell leads.

3. Connect ohmmeter test leads

to photocell leads.

4. Hold open end of photocell

towards a light source (a 60-watt

light bulb or direct sunlight). The

resistance indicated on the

ohmmeter should be low.

5. Block off light completely by

covering the open end of the

photocell. Within 10 seconds the

resistance indicated should be

high.

6. Replace photocell if there is no

change in resistance during this

procedure.

C. Defective safety control.

(see section 4.4.9)

1. Remove 4 screws holding the

control box. Pull away from the

electrical panel but do not

disconnect any electrical

connections.

2. Attach one test lead of a

voltmeter to one of the white

leads on the distribution bar. Plug

heater in and switch on. Touch

the other test lead to first the

orange wire on the left side of the

distribution bar, then to the blue

wire on the left side of the

distribution bar.

3. If one or both wires do not read

220 volts (approximately) replace

Table 3-4. Maintainer Level Troubleshooting Procedures

Operation and Maintenance Manual

47

Operation and Maintenance Manual

No.

Malfunction

Possible Cause

Corrective Action To Take

the safety control.

NOTE

After replacing the safety control,

check the ignition transformer as

follows before starting the heater.

4. Remove screen from inlet end

of heater. Disconnect the red and

white transformer leads.

5. Attach ohmmeter test leads to

the red and white transformer

leads. The ohmmeter should

indicate an open line (no

conductance).

D. Broken rotor or carbon

blades. Pump rotor binding.

(see Section 4.4.4).

1. Remove pump end cover and

pump front cover.

2. Visually inspect rotor and

blades for breakage.

3. Ensure that the rotor and

blades are free of any lubricant or

debris.

4. Check rotor with feeler gauge

for proper clearance between

rotor and pump body (see Section

4.4.4).

E. Defective run capacitor

Check capacitor near motor in

accordance with 4.4.4

2.

Heater will not ignite, but

motor runs for a short time.

A. Fuel tank empty, wrong fuel,

water in fuel.

1. Check for water in the fuel

tank. Water in the fuel will form

visible globules in the bottom of

the fuel tank.

2. If water is found, drain and

clean tank and filter. Fill with

fresh, clean fuel.

B. Defective or damaged spark

plug.

1. Remove spark plug from

burner head. Visually inspect

spark plug for cracks or worn

electrodes.

48

Operation and Maintenance Manual

No.

Malfunction

Possible Cause

Corrective Action To Take

2. Adjust spark plug gap (see

Section 4.4.3).

3. Establish a good ground

between the spark plug and the

heater. Be careful not to let any

part of your person become a

portion of the grounded circuit.

See 4.4.3

4. Start heater; observe the spark

between the plug’s electrodes. If

the ground is good and spark

does not jump between see next

troubleshooting section.

C. Defective transformer.

WARNING

To begin the transformer test, first

ensure the heater is not plugged

in. Then, when power is required,

be EXTREMELY careful when

checking the transformer. A

transformer in good condition

produces VERY HIGH VOLTAGE

at the output terminal. See 4.2.3

1. Connect the transformer lead

to a properly gapped spark plug.

The gap should be 0.050 inch,

plus or minus 0.005 inch.

2. Establish a good ground

between the spark plug and the

heater. Be careful not to let any

part of your person become a

portion of the grounded circuit.

3. Start heater; observe the spark

between the plug’s electrodes. If

the ground is good and spark

does not jump between the

electrodes, the transformer is

defective and must be replaced.

49

Operation and Maintenance Manual

No.

Malfunction

Possible Cause

Corrective Action To Take

3.

Heater burns but puffs of

smoke can be seen; heater

will not burn steady; heater

burns with odor; heater

smokes continuously.

A. Heater running out of fuel,

wrong fuel, water in fuel.

1. Check for water in the fuel

tank. Water in the fuel will form

visible globules in the bottom of

the fuel tank.

2. If water is found, drain and

clean tank and filter. Fill with

fresh, clean fuel.

3. Check fuel tank for dirt or water

B. Dirty sediment strainer.

1. Remove and clean sediment

strainer (see Section 4.4.6).

2. Replace a blocked filter screen.

C. Low pump output pressure

(low motor speed, worn pump,

pump out of adjustment.

1. Check and adjust pump output

pressure (see Section 4.4.8).

2. Repair or replace pump if

adjustment cannot be made (see

Section 4.4.8).

4.

Flames and/or black

smoke come out of stack.

A. Pump output too high

causing too much fuel to be

supplied.

1. Check and adjust pump output

pressure.

B. Fan loose or improperly

located on shaft.

1. Check and tighten hex screw

located on rear of fan hub.

2. Ensure fan is in correct location

(see Section 4.4.5).

C. Bent or damaged fan.

1. Replace a damaged fan. DO

NOT ATTEMPT TO REPAIR A

DAMAGED FAN.

5.

Heater cycles

intermittently.

Red LED flashes on the

control.

NOTE: If the photocell loses

flame signal during operation

(after the TFI), the red LED

flashes. The burner shuts off

and the Control waits for 65

seconds (with red LED

flashing), then begins again at

Selftest. Red LED goes off

A. Defective overheat switch.

1. Remove leads from overheat

switch (located at output end of

heater).

2. Using a test lead with 2

alligator clips, jump overheat

leads (white wires are low

voltage).

3. Start heater. If heater runs

properly, replace overheat switch.

50

Operation and Maintenance Manual

No.

Malfunction

Possible Cause

Corrective Action To Take

6.

Heater ignites but safety

control trips. Heater starts

but will not stay running,

The control turns the red

LED on constant,

If photocell does not sense

flame within 15 seconds after

burner starts, lockout occurs.

A. Dirty or defective photocell.

Note: make sure photocell is

aligned properly so it is pointing

towards the view port in the

burner head

1. Disconnect blue and white

photocell leads.

2. Connect ohmmeter test leads

to photocell leads.

3. Hold open end of photocell

towards a light source (a 60-watt

light bulb or direct sunlight). The

resistance indicated on the

ohmmeter should be low.

4. Block off light completely by

covering the open end of the

photocell. Within 10 seconds the

resistance indicated should be

high.

5. Replace photocell if there is no

change in resistance during this

procedure.

B. Defective overheat switch.

1. Remove leads from overheat

switch (located at output end of

heater).

2. Using a test lead with 2

alligator clips, jump overheat

leads (white wires low voltage).

3. Start heater. If heater runs

properly, replace overheat switch.

C. Dirty nozzle

1. clean or replace nozzle in

accordance with section 4.4.7

B. Dirty sediment strainer.

1. Remove and clean sediment

strainer (see Section 4.4.6).

2. Replace a blocked filter screen.

D. Low pump output pressure

(low motor speed, worn pump,

pump out of adjustment.

1. Check and adjust pump output

pressure (see Section 4.4.8).

2. Repair or replace pump if

adjustment cannot be made (see

Section 4.4.8).

51

Operation and Maintenance Manual

No.

Malfunction

Possible Cause

Corrective Action To Take

7.

Heater will not start, Amber

light flashes on control

A. photocell seeing light

1. Make sure access cover is

closed.

2. Attach return duct

3. Disconnect photocell. If heater

starts then photocell is defective.

(see section 4.4.10)

52

Chapter 4

Maintenance

Operation and Maintenance Manual

53

4. CAMFIRE Maintenance

4.1 Introduction

Maintenance consists of simple operations the user of the heater can perform to keep the heater running

and in good condition. If ordinary maintenance fails to return the heater to good operating condition, refer

to Section 3 in this manual for checking and troubleshooting. See Figure 4-1 for maintenance points.

4.2 Preventive Maintenance Checks and Services

4.2.1 Introduction

Preventive Maintenance Checks and Services (PMCS) are performed to keep the Camfire Heater in good

operating condition and ready for its primary mission. The checks are used to find, correct, and report

problems. PMCS is performed every day the Camfire Heater is in operation, and is done according to the

PMCS table provided. Pay attention to WARNING, CAUTION, and NOTE statements. A WARNING

indicates that someone could be hurt or killed. A CAUTION indicates that equipment could be damaged.

A NOTE may make your maintenance or repair task easier.

Be sure to perform scheduled PMCS. Always perform PMCS in the same order so it becomes habit.

With practice, you will quickly recognize problems with the equipment.

Use DA Form 2404, Equipment Inspection and Maintenance Worksheet, to record any discovered faults.

Do not record faults that you fix!

PMCS PROCEDURES

Table 4-1 lists inspections and care required to keep your equipment in good operating condition. It is

arranged so that you can perform before operation checks as you walk around the equipment.

Explanation of Table 1 Columns

Item Number

Indicates the reference number. When completing DA Form 2404, Equipment Inspection and

Maintenance Worksheet, include the item number for the item to check/service indicating a fault. Item

numbers appear in the order you must perform the checks/services listed.

Interval

Indicates when you must perform the procedure in the procedure column.

before - perform before equipment operation

during - perform during equipment operation

after - perform after equipment has been operated

weekly - perform every week

monthly - perform each month

hours - perform at the noted hourly interval

Item to Check/Service

Indicates the item to be checked or serviced.

Procedure

Indicates the procedure you must perform on the item listed in Item to Check/Service column. You must

perform the procedure at the time specified in the Interval column.

54

Not Fully Mission Capable If:

Indicates faults which will prevent your equipment from performing its primary mission. If you perform

procedures listed in Procedure column which show faults listed in this column, do not operate the

equipment. Follow standard procedures for maintaining the equipment or reporting equipment failure. If

you are not authorized to perform a task, notify unit maintenance.

Other special entries

Observe all special information and notes that appear in Table 4-1.

When a check/service procedure is required for both weekly and before intervals, it is not necessary to

perform the procedure twice if the equipment is operated during the weekly period.

COMMON CHECKS AND CLEANING

Cleaning

Always keep the equipment clean. Remove dirt, sand, and debris from all circuit breakers and hose

connections.

Bolts, nuts, and screws