PowerLine User Guide

PowerLine

Power-Line (PLD) User Manual

High Country Tek, Inc.

Electronic Control Solutions for the Global Fluid Power Industry

,

System Controller

User Guide

Part No:- 021-00155 RevD7 PowerLine System Controller User Guide Page | 1

PowerLine User Guide

Welcome to the High Countr y Tek Inc. ( HCT ) PowerLine system controller us er guide, and thank you for

selecting this HCT controller to use in your application

The following information is designed to allow you to connect, set-up and optimize the PowerLine module.

If you have used HCT products before, you will recognize some of the instructions and settings. For those of you

that are new to HCT, please read the direc tions with c are and be sure that if you have any ques tions regardi ng

this industry unique c ontroller, th en please contact us using one of the numbers gi ven on the back page of this

manual.

We value our customers, their experience and abilities and ask that if you would like to see any additions,

subtractions or find any errors in this publication, that you contact HCT’s customer service so that we can

correct the information and make sure that our programming community is using the latest information.

If you require urgent support, more information or would like specific programming areas clarified, you can

contact us on the customer support number at 1 530 265 3236 or E-mail us through our website at

www.hctcontrols.com

, giving details of your issue and how we can contact you.

Introduction:

This manual is designed to provide information needed for the installation and use of the Power Line Valve

Controller. Its intende d user is qualified trained s ervice personnel that under stand the hazards involved in an

electromechanical e nvironm ent. It is recomm ended that this m anual be read in its entiret y before installati on is

begun with particular attention paid to caution and safety information.

Cautions:

Changing setup val ues and limits under computer control while t he machine is operating ma y cause sudden

machine movement, whic h may lead to possible injury or death. It is strong ly recommended that an y moving

parts are disabled prior to any alignment procedure whenever possible. In any case, caution should be

exercised during any procedure and work should be completed only by qualified trained personnel.

Warranty Information:

High Country Tek Inc. Guarantees this pr oduct to be free of defects in m aterials and workm anship for a period

of one year extending f rom t he date th e unit was s hipped f rom the fac tor y. Within this t ime f rame, High Co u ntry

Tek will provide evaluation of warranted items free of charge. Warranty repair or replacement will be at the

factory’s discretion. If necessary, contact the factory for return authorization by phone (530) 265-3236, Fax

(530) 265-3275, E-Mail Service@hctcontrols.com

Service Dept., 208 Gold F lat Court, Nevad a Cit y, CA 9595 9. To hel p us ser ve you better, please ha ve the units

full Model / Part Number and Serial N umber available when c ontacting the factor y f or an y r eason . Do not return

products to the factory without prior authorization and a RMA number attached.

Part No:- 021-00155 RevD7 PowerLine System Controller User Guide Page | 2

or by writing our service department at, High Country Tek,

PowerLine User Guide

Manual Index:

Introduction: ........................................................................................................................... 2

Cautions: ............................................................................................................................................................ 2

Warranty Information: ........................................................................................................................................ 2

Manual Index: ......................................................................................................................... 3

Product Application Guidelines: ........................................................................................... 4

PowerLine flexible configurations: ....................................................................................... 5

Module Familiarity: ................................................................................................................. 6

Module Compatibility and Valve Settings: ............................................................................ 8

Module Connections: ........................................................................................................... 11

PowerLine Dimensional Information: ................................................................................. 13

Electrical Specification Overview: ...................................................................................... 14

Opto 3000: USB serial Interface .......................................................................................... 15

Software PowerLine Installation ......................................................................................... 16

System Requirements ...................................................................................................................................... 16

Using The PowerLine application ....................................................................................... 17

File ( Memory Options ): ...................................................................................................... 17

Control Logic: ....................................................................................................................... 18

Manual PWM% ................................................................................................................................................ 19

Horse Power Limiter & Anti-Stall Mode ............................................................................................................ 20

Horse Power Limiter & Anti Stall Mode with Reverse ...................................................................................... 21

Horse Power Limiter & Anti Stall with Max Command ..................................................................................... 22

Proportional Valve Driver Mode ....................................................................................................................... 23

Setup: .................................................................................................................................... 24

Help: ...................................................................................................................................... 32

Exit the program (GUI) ..................................................................................................................................... 32

Troubleshooting: .................................................................................................................. 33

Application Connection Examples: ..................................................................................... 36

Ordering Guide: .................................................................................................................... 38

Default Files and Set-up tips: .............................................................................................. 39

Valve Driver Settings: .......................................................................................................... 40

Dual Coil Valve Driver ...................................................................................................................................... 40

Command Input: .............................................................................................................................................. 40

Process Setup: ................................................................................................................................................. 41

Coil Setup: ....................................................................................................................................................... 41

Single Coil Valve Driver ................................................................................................................................... 42

Command Input Command Input: .................................................................................................................... 42

Process Setup: ................................................................................................................................................. 42

Coil Setup: ....................................................................................................................................................... 42

Horse Power Limiter & Anti-Stall Mode .............................................................................. 43

Dual Coil Driver ................................................................................................................................................ 43

Pulse Input: ...................................................................................................................................................... 43

Command Input: .............................................................................................................................................. 43

Process Setup: ................................................................................................................................................. 44

Coil Setup: ....................................................................................................................................................... 44

Anti-Stall with Max Command: ......................................................................................................................... 44

Need More Information ? ................................................................................................................................. 45

Part No:- 021-00155 RevD7 PowerLine System Controller User Guide Page | 3

PowerLine User Guide

Product Application Guidelines:

ALWAYS do the following:

• Take a few minutes to FULLY read THESE information / data sheets BEFORE starting.

• Keep High Voltage AC cables separate from Low Voltage DC signal and supply cables.

• Make sure the unit supply voltage is the same as the coils on the valve being driven !

• Ensure that you are aware of the adjustments and consequences on the electronics and hydraulics.

• Make sure you have the correct tools to do the intended job ( i.e. Opto unit, P.C., software ) e.t.c.

• ‘Isolate’ this unit from all other equipment BEFORE any form of welding takes place.

• Check ALL connections to and from this unit to ensure NO short or OPEN circuits.

• Check the units supply voltage is CORRECT, ‘ ELECTRICALLY CLEAN ’ and STABLE.

• Operate the units within specified operating temperature for best & reliable performance.

• Ensure that any unused wires / terminals are terminated safely and not shorted together.

• Use screened cables wherever possible for best immunity to external interference.

• Use cables that are capable of carrying the required voltage and current for your products and application.

• Isolate the controller if ANY form of battery charging or battery boosting takes place on the vehicle.

• Ensure ALL valve connectors are wired correctly, secure, locked and connected to correct coils.

• Observe the set-up procedures in this manual for best operational results.

• Follow and abide by local and country health & safety standards – protect yourself and others !

NEVER do the following:

• Arc Weld or Charge Batteries with this driver unit connected as damage can occur.

• Attempt to use this unit if you are unsure of electrical OR hydraulic connections or expected operation.

• Attempt to use this unit in Areas where other AC or DC coils HAVE NOT been fully suppressed.

• Use a power supply that is not rated for the correct required O/P current under full load.

• Allow wires TO or FROM the unit to short circuit ( to each other or chassis/cabinet e.t.c. ).

• Attempt to use this unit in areas of intense RF without adequate screening measures.

• Disconnect or connect wires to or from this unit unless it isolated from the power supply.

• Use this unit in temperatures that exceed those specified as operation may be effected.

• Start this unit without ensuring ALL work areas are clear of personnel !

Software Safety:

The software has been carefully written to give the user the maximum system configuration flexibility while being

transparent in operation and easy to use, even for novice system builders and operators.

To ensure safety when using the software and to prevent accidental connection to another module that is not a

PowerLine, rules have been written into the software to ensure correct operation at all times:

When the PC running the GUI is first connected to a powered PowerLine, and before any data exchange can be

allowed, a ‘Handshake’ takes place that confirms the internal software ( BIOS ) is compatible, the serial number and

the PowerLine part number. The GUI then checks to ensure that its own revision is compatible with the module

software and only then allows the PC and the module to communicate and share data.

If at any point during the process above an error or mis-match is detected, the GUI software will NOT allow

communications and will inform the user of the problem via a clear message in the ‘Status’ window.

Part No:- 021-00155 RevD7 PowerLine System Controller User Guide Page | 4

PowerLine User Guide

PowerLine flexible configurations:

The PowerLine module is ideally suited for today’s hydraulic OEM, distributor or system builder. With both

mechanical and electrica l robustness paramount in the design priority, Windows™ compatible eas y to use setup software and full CE c om pliance m eans this one p roduct can throug h , the man y configurations and featur es

available, be used across multiple platforms, markets and applications.

This units cost eff ectiveness will b ecom e quickly apparent through th e reduc tion in inven tory costs an d stock ing

needs as well as in the reduced costl y engineering time taken usually associ ated with the design to delivery

cycle.

The PowerLine has five (5) basic configurable modes of operation available within the one module.:

1) Manual control of the output current through the graphical user interface.

This mode is typically used during system start-up and commissioning. Used to prove control and

direction of motion as well as correct hoses and fittings are leak free.

2) Horse Power Limiter & Anti-Stall – automotive style prime mover protection.

Used to protect an engine from stalling by progressi vely reducing the hydraulic load either by valve or

pump control, effectively de-coupling the load from the m otor. The active nature of this m ode allows th e

machine to find the optimized work rate and still support healthy engine RPM.

2a) Horse Power Limiter & Anti-Stall with Reverse –

Ideal for system suc h as auto-feed wood chip pers or any applicat ions that need a r everse feature if the

engine starts to stall because of a forced load.

3) Horse Power Limiter & Anti-Stall with Max Command -

Used to protect an engine from stalling by progressi vely reducing the hydraulic load either by valve or

pump control, effectively de-coupl ing the load from the motor. Extra F eatures ar e provided to allo w the

user to vary the maximum command signal with a pot or joystick during Anti-Stall operations.

4) Valve Driver – Direct open loop control of single or dual coil valves or pump controls.

The last mode provi des a quick, easy method of controlling single or dual coi l valves or pum p stroker s.

This unit will drive all the m ajor O EM produc ts and can be s et eas ily to interface with a simple j o ystick or

work from an external command signal of either voltage or current.

Part No:- 021-00155 RevD7 PowerLine System Controller User Guide Page | 5

PowerLine User Guide

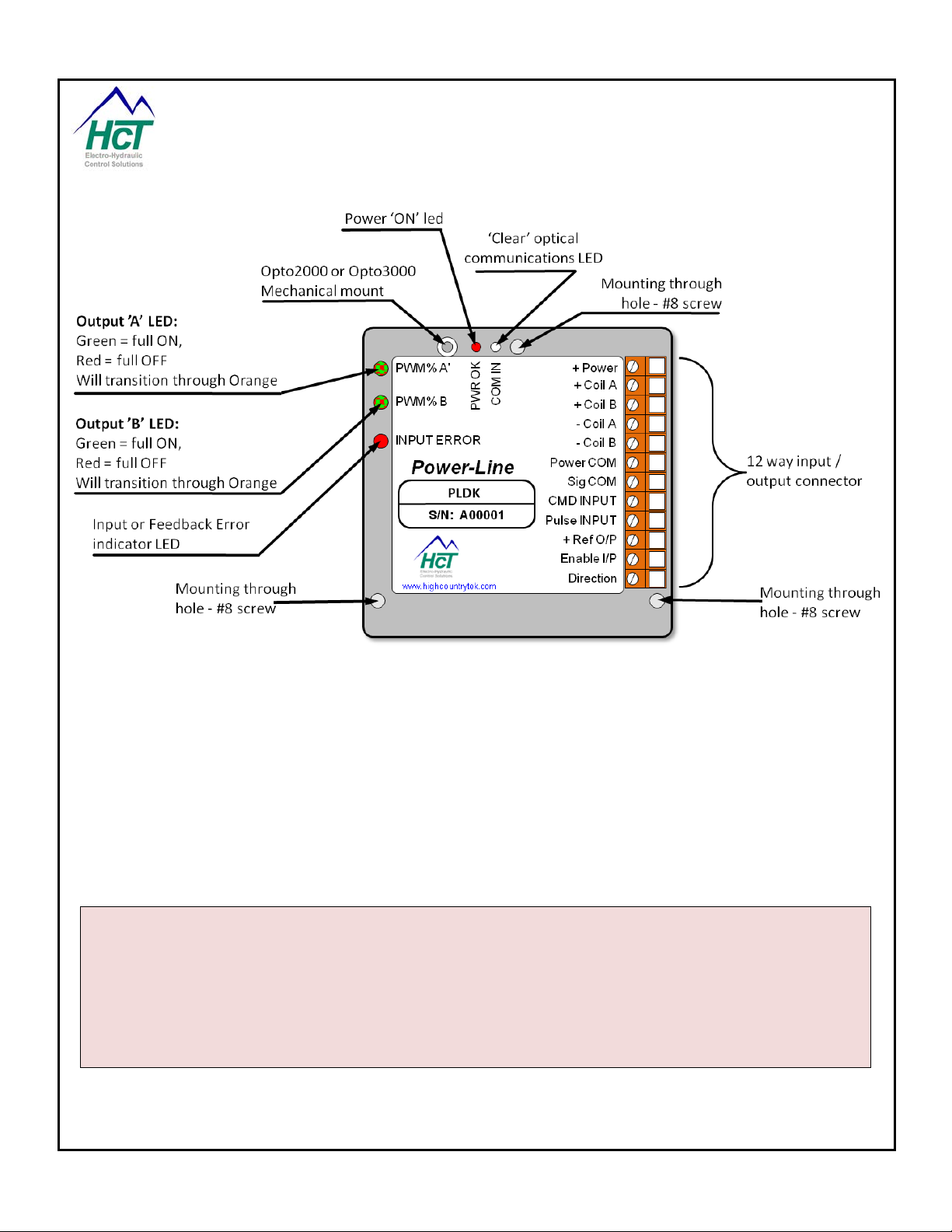

Module Familiarity:

Wiring:

Use 16 AWG wire for power and coil wiring. Use of shrouded coil connectors is always recommended.

Shielded cables ar e pr eferred for the puls e a nd c om m and in puts as these are typically low level, analog signals.

This will minimize potential cross talk between cables that are bundled or in a cable harness.

Additional noise protection can be obtained by shielding the coil and power cables. The shields should be

grounded only at the unit end of the cable.

Long cable runs with any other c ables, especiall y high voltage or those car rying switching t ype signals in close

proximity of each other should be avoided.

Take extra care to iso lat e a n y ca ble t ha t are c o nnec te d to h ig h v olt ag e AC el ect ri c m otors , varia bl e f r equency or

variable voltage drives.

Protecting the unit’s pulse input from external noise is very important and can save a lot of time in

troubleshooting.

NOTE:

The unit MUST be installed with an in-line fuse in the positive supply cable. Use only an AGC-5 fuse.

Locate the fuse as close to the power supply as possible to provide pr otection to both the wiring and

the unit. Failure to use a fuse invalidates the warranty, can be dangerous to the system and also the

PowerLine unit.

Part No:- 021-00155 RevD7 PowerLine System Controller User Guide Page | 6

PowerLine User Guide

OFF

Input or feedback signal operation is normal

-

Check command or feedback signal for

correct as required

OFF

Power Su pply below 9VDC

Increase power supply to >9VDC

ON

Power supply between 9VDC and 30VDC

NO action – normal operation

Blinking

Power supply above 30VDC

Reduce power supply to <30VDC

OFF

NO output or not in use

Check power supply or module fuse

GREEN

Respective output fully ON

-

RED

Respective output fully OFF

-

ORANGE

Respective output in transition or under control

-

output

turn power back on

circuit turn power back on

SHORT and OPEN CIRCUIT ERROR DETECTI ON:

INPUT ERROR LED blink code descriptions:

LED Condition Solution

Blinking Error detected or loss of feedback

Power LED blink code description:

LED Condition Solution

PWM% A and PWM% B Output LED blink code description:

LED Condition Solution

Flash RED 2Hz

Flash GREEN 1Hz Respective output OPEN circuited turns OFF PWM output

Respective output SHORT circuited, module turns OFF PWM

connection, signal level and polarity and

Turn OFF power and clear short circuit,

Turn OFF power and re-connect open

If power is applied to the controller while connected to an existing short circuit, the module will not detect this or

show an error led and will output PWM current equivalent to the Imax setting.

The module ( which should be protected by an AGC5 fuse as reccomended ) will be regulating and will not

damage itself in this mode, but the issue can only be diagnosed by using the GUI and observing that the current

is changing but the PWM% is only moving to a max of ~5% of max output.

If power is applied to the controller while connected to an existing open circuit, the module will not detect this or

show an error led until the PWM output is commanded to control current.

Part No:- 021-00155 RevD7 PowerLine System Controller User Guide Page | 7

PowerLine User Guide

Coil

(V)

Dither

(Hz)

Dither

(%)

PSL/V – (Size 2)

12

~450 mA

~1,160 mA

40 - 70 Hz (55)

20 - 35%

PSL/V – (Size 2)

24

~225 mA

~580 mA

40 - 70 Hz (55)

20 - 35%

PSL/V(F) – (Sizes 3 & 5)

12

~620 mA

~1,260 mA

40 - 70 Hz (55)

20 - 35%

PSL/V(F) – (Sizes 3 & 5)

24

~310 mA

~630 mA

40 - 70 Hz (55)

20 - 35%

EM 21 D(S)E

12

~50 mA

~1,200 mA

50 - 150 Hz

20 - 40%

EM 21 D(S)E

24

~25 mA

~630 mA

50 - 150 Hz

20 - 40%

EMP 21 S

12

~550 mA

~1,100 mA

50 - 150 Hz

20 - 40%

EMP 21 S

24

~240 mA

~480 mA

50 - 150 Hz

20 - 40%

EMP 21 V

12

~500 mA

~1,000 mA

50 - 150 Hz

20 - 40%

EMP 21 V

24

~200 mA

~500 mA

50 - 150 Hz

20 - 40%

EMP 21 S10

12

~40 mA

~1,300 mA

50 - 150 Hz

20 - 40%

EMP 21 S10

24

~20 mA

~650 mA

50 - 150 Hz

20 - 40%

EMP 21 V10

12

~400 mA

~1,380 mA

50 - 150 Hz

20 - 40%

EMP 21 V10

24

~200 mA

~690 mA

50 - 150 Hz

20 - 40%

EMP 31 S

12

~240 mA

~1,200 mA

50 - 150 Hz

20 - 40%

EMP 31 S

24

~120 mA

~600 mA

50 - 150 Hz

20 - 40%

EMP 31 V

12

~400 mA

~1,000 mA

50 - 150 Hz

20 - 40%

EMP 31 V

24

~200 mA

~500 mA

50 - 150 Hz

20 - 40%

EMP 31 S10

12

~150 mA

~1,200 mA

50 - 150 Hz

20 - 40%

EMP 31 S10

24

~75 mA

~600 mA

50 - 150 Hz

20 - 40%

EMP 31 V10

12

~400 mA

~1,560 mA

50 - 150 Hz

20 - 40%

EMP 31 V10

24

~200 mA

~780 mA

50 - 150 Hz

20 - 40%

EMP 41 S

12

~100 mA

~870 mA

50 - 150 Hz

20 - 40%

EMP 41 S

24

~200 mA

~1,750 mA

50 - 150 Hz

20 - 40%

EMP 41 V

12

~100 mA

~870 mA

50 - 150 Hz

20 - 40%

EMP 41 V

24

~200 mA

~1,750 mA

50 - 150 Hz

20 - 40%

PMV

12

~200 mA

~1,260 mA

60 - 150 Hz

20 - 40%

PMV

24

~100 mA

~630 mA

60 - 150 Hz

20 - 40%

PDM, PDV

12

~190 mA

~1,200 mA

50 - 150 Hz

20 - 40%

PDM, PDV

24

~110 mA

~680 mA

50 - 150 Hz

20 - 40%

PM(Z)

12

~200 mA

~1,260 mA

50 - 150 Hz

20 - 40%

PM(Z)

24

~100 mA

~630 mA

50 - 150 Hz

20 - 40%

SE - (Sizes 2 & 3)

12

~380 mA

~1,900 mA

60 - 150 Hz

20 - 40%

SE - (Sizes 2 & 3)

24

~190 mA

~950 mA

60 - 150 Hz

20 - 40%

SEH - (Sizes 2 & 3)

12

~250 mA

~1,260 mA

60 - 150 Hz

20 - 40%

SEH - (Sizes 2 & 3)

24

~130 mA

~630 mA

60 - 150 Hz

20 - 40%

SWS 2

12

~400 mA

~1,350 mA

50 - 150 Hz

20 - 40%

SWS 2

24

~260 mA

~880 mA

50 - 150 Hz

20 - 40%

V30D "V" Controller

24

~250 mA

~750 mA

80 - 100 Hz

20 - 40%

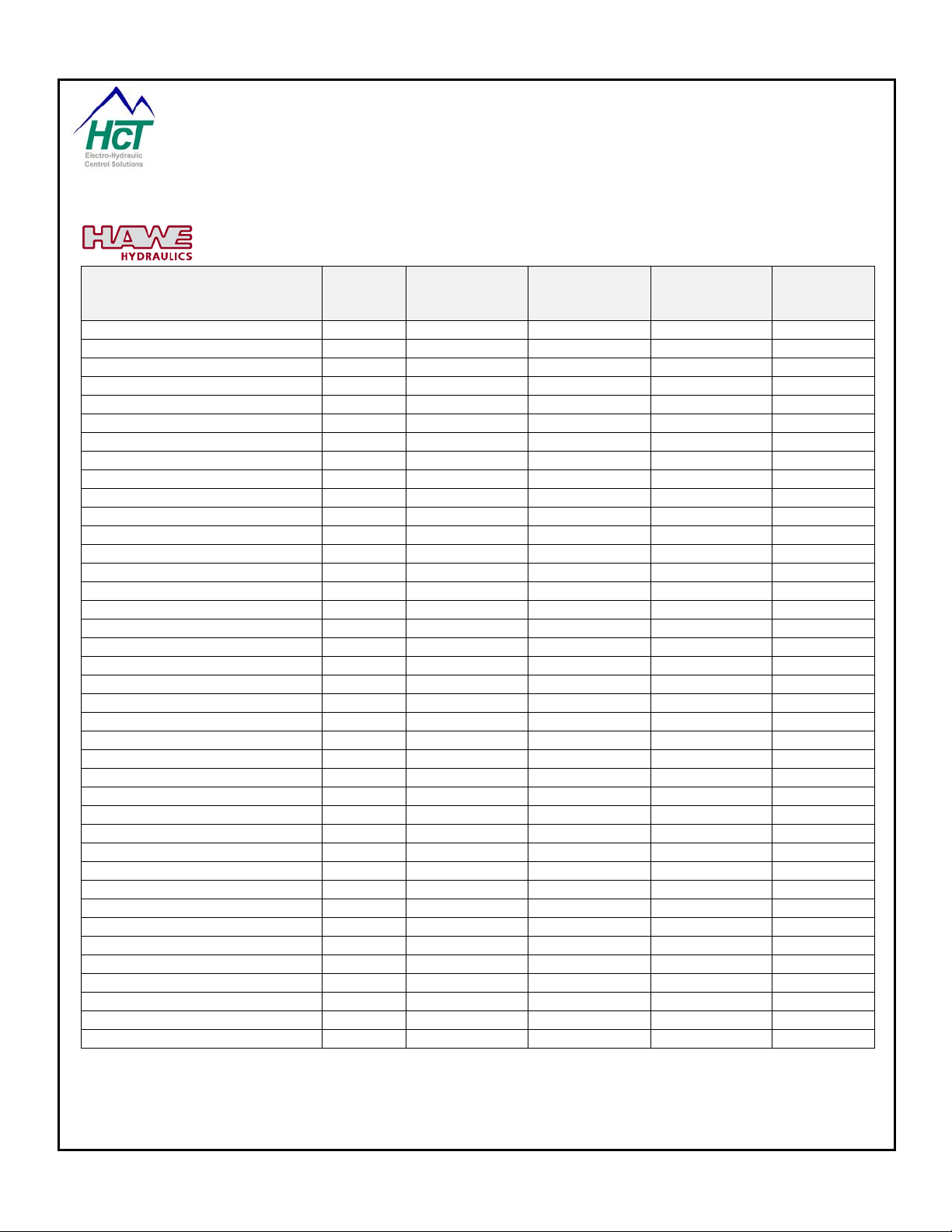

Module Compatibility and Valve Settings:

Valve Type

Voltage

IMin

(mA)

IMax

(mA)

Frequency

Amplitude

Note: Final optimized settings are valve size and system/application dependent. Consult valve manufacturer for full details

as required.

Part No:- 021-00155 RevD7 PowerLine System Controller User Guide Page | 8

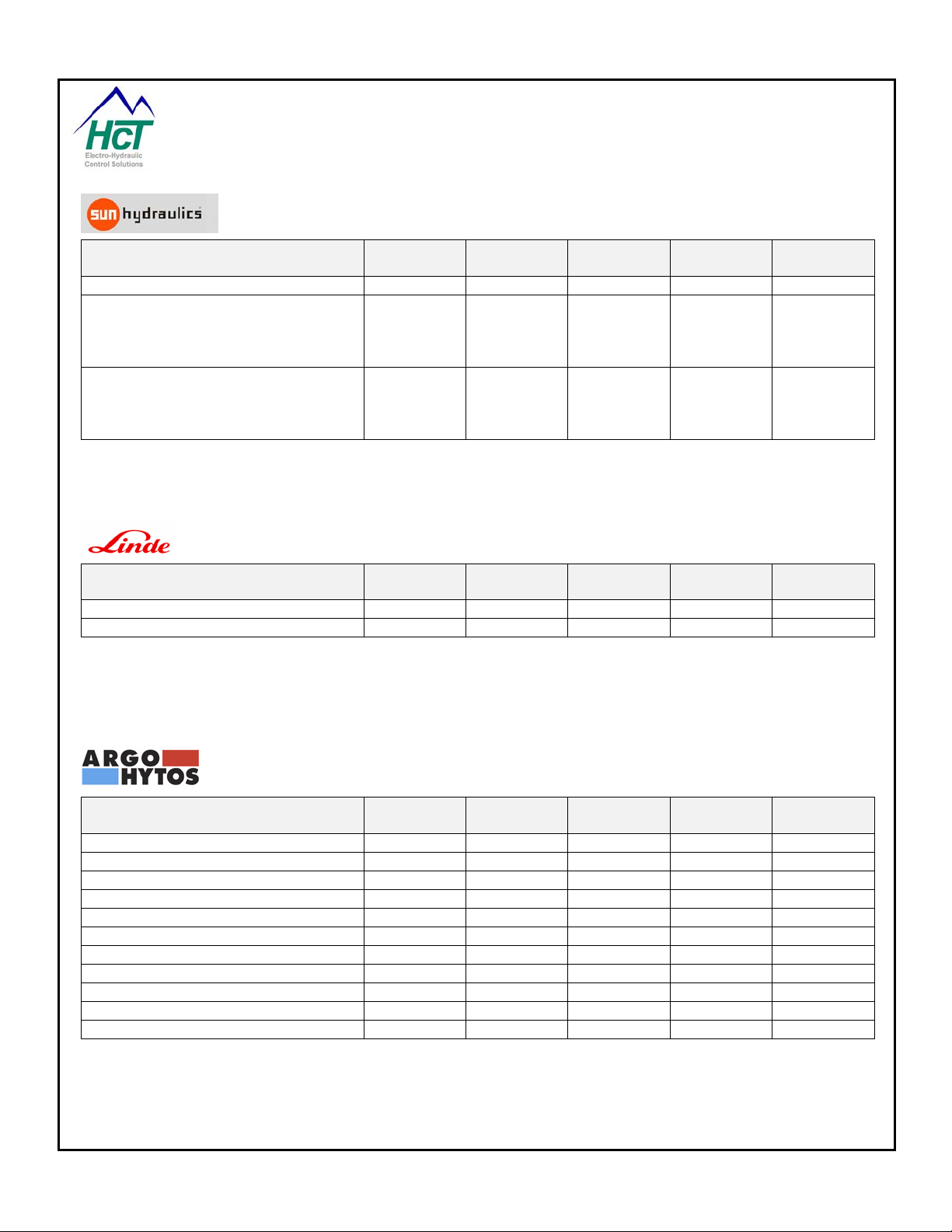

PowerLine User Guide

Coil

(V)

Dither

(Hz)

Dither

(%)

Coil

(V)

Dither

(Hz)

Dither

(%)

70 size / Proportional Coil

12

~<100

1500

~200

50 – 100

70 size / Proportional Coil

24

~<100

750

~200

50 – 100

EHPR / Proportional coil

12

~<100

~1100 -1200

~200

50 – 100

EHPR / Proportional coil

24

~<100

~550 - 600

~200

50 – 100

Dither

(Hz)

Dither

(%)

F5C

12

-

~220-250

70

50 - 100

VP01-

24

~200

~800

140

50 – 100

4VP01-

12

~250-500

~2700

250

50 – 100

4VP01-

24

~100-300

~1500

250

50 – 100

4RP01

24

~200

~800

140

50 – 100

9A – Pump stroker coil

24

~150

~350

250

50 – 100

4DP01 – single OR dual coil

12

~250

~2300-2500

250

50 – 100

4DP01 – single OR dual coil

24

~250

~1100-1300

250

50 – 100

4DP02 – single OR dual coil

12

~250

~2200-2700

100

50 – 100

4DP02 – single OR dual coil

24

~250

~1250-1500

100

50 – 100

3DP03 – single OR dual coil

12

~400

~1500-1700

250

50 – 100

3DP03 – single OR dual coil

24

~200

~550-750

140

50 – 100

3DP06 – single OR dual coil

12

~400

~1500-1700

250

50 – 100

3DP06 – single OR dual coil

24

~200

~550-750

140

50 - 100

Valve Type

Note: Final optimized settings are valve size and system/application dependent. Consult valve manufacturer for full details

as required

.

Valve Type

Note: Final optimized settings are valve size and system/application dependent. Consult valve manufacturer for full details

as required

.

Voltage

Voltage

IMin

(mA)

IMin

(mA)

IMax

(mA)

IMax

(mA)

Frequency

Frequency

Amplitude

Amplitude

Valve Type

Note: Final optimized settings are valve size and system/application dependent. Consult valve manufacturer for full details

as required

Part No:- 021-00155 RevD7 PowerLine System Controller User Guide Page | 9

.

Coil

Voltage (V)

IMin

(mA)

IMax

(mA)

Frequency

Amplitude

PowerLine User Guide

Coil

Voltage

Dither

Frequency

Dither

Amplitude

DAAL, DBAL, DLDA, DMDA, DNDA,

RBAN, RBAP

DAAL, DBAL, DLDA, DMDA, DNDA,

RBAN, RBAP

Coil

Voltage

Dither

Frequency

Dither

Amplitude

HPV – 02 – E1

12

~440 – 460

~810 - 1200

100 Hz

HPV – 02 – E1

24

~215 – 235

~410 – 600

100 Hz

Coil

Voltage

Dither

Frequency

Dither

Amplitude

PRM2-04

12

~600-700

~1700

90

0-30

PRM2-04

24

~250-270

~800

60

0-30

PRM2-06

12

~700-850

~2500

90

0-30

PRM2-06

24

~270-310

~1000

60

0-30

PVRM1-063/S

12

~250-310

~1000-1200

100

-

PP2P-06

12

~300-330

~1000-1100

150

-

PRM6-10

12

~600-700

~1900

90

0-30

PRM6-10

24

~300-400

~1100

60

0-30

PVRM3-10

12

~250-290

~1500

100

-

SR4P-B2

12

~150-210

~1000

160

SR4P-B2

24

~150-210

~750

160

Valve Type

DNDC, DTCA, DTDA, DWDA, FMDA,

FMDB, PRDL, PRDM, PRDN, PRDP,

DNDC, DTCA, DTDA, DWDA, FMDA,

FMDB, PRDL, PRDM, PRDN, PRDP,

Note: Final optimized settings are valve size and system/application dependent. Consult valve manufacturer for full details

as required

.

Valve Type

Note: Final optimized settings are valve size and system/application dependent. Consult valve manufacturer for full details

as required

.

Imin (mA) Imax (mA)

12 1150mA

24 590

Imin (mA) Imax (mA)

100 –

250Hz

dependant on

valve size

100 –

250Hz

dependant on

valve size

Valve Type

Note: Final optimized settings are valve size and system/application dependent. Consult valve manufacturer for full details

as required

.

Part No:- 021-00155 RevD7 PowerLine System Controller User Guide Page | 10

Imin (mA) Imax (mA)

PowerLine User Guide

Module Connections:

+Power ( connector terminal 1 ):

This is the main + Voltage power supply input for the module. The PowerLine controller will accept 9 to 30VDC.

NOTE:

Make sure the unit has an in-line fuse fitted to protect the system, the module and the warranty.

+Coil A ( Connector terminal 2 ):

This terminal should be connected to the ‘A’ c oils positive (+) connectio n. It is switched ON or OFF to decide

which if any coil will be driven. These terminals should not be connected to +Power.

+Coil B ( Connector terminal 3 ):

This terminal should be connected to the ‘B’ coi ls positive (+) connection. It is switched ON or OFF to decide

which if any coil will be driven. These terminals should not be connected to +Power.

-Coil A ( Connector terminal 4 ):

Both -Coil A and -Coil B are internally connected together on the card and should be connected to the negative

coil leads. These are used to sense coil current, control the internal feedback circuit that maintains and

regulates current to the coils to recover from heating effects and should never be grounded.

-Coil B ( Connector terminal 5 ):

Both -Coil A an d -Coil B ar e internall y connected tog ether on the card and sho uld be conn ected to the ne gative

coil leads. These are used to sense coil current, control the internal feedback circuit that maintains and

regulates current to the coils to recover from heating effects and should never be grounded.

Power Com ( Connector terminal 6 ):

This is the main 0 Volts ( GND ) power supply connection for the module.

Sig Com ( Connector terminal 7 ):

This terminal is internally tied to Power Common ( Power Com ) on the card. To provide the best possibl e

noise resistance Sig Com should be used as the only ground for the pulse and command sensors.

Command In ( Connector terminal 8 ):

This is the analog command input for the controller. The Graphical User Interface (GUI ) allows the user

through software to c h oos e f r om sever al se lec t abl e ra nges inclu di ng 0 to +5-Volts, 0 to +10-Volts an d +4-20mA.

There is also the f acility that lets the user choose Uni or Bi-direct ional operation by setting the inputs so their

respective mid poi nts becom e the zero cros sover poin t ( i.e. 0-5V becomes 0 – 2.5– 5) with 2.5V repres enting

NO drive to the valve coils.

This input has an impedance of 100 KOhms when ‘Voltage Mode’ is selected and is internally pulled low to allow

for error detection and avoid spurious signals if not used.

Pulse In ( Connector terminal 9 ):

This is a pro gram mable range input th at ac cept s pulses above up t o 30KHz. Puls es m us t c ros s the midpoint of

the range selected to be de tec ted a nd may exceed the r ange wit hout damage to the unit if les s tha n + / - 30-Volts

Peak. Selectable ranges include –1 to +1V, 0 to 1.25V, 0 to 2.5 V, 0 to 5 V and 0 t o 10V. A G UI software switch

is provided to allow the user to activate an internal 10KOhm pull down resistor on this input. Activation of the

pull down resistor is intended to provide loading for inductive, sourcing or open emitter sensors.

Part No:- 021-00155 RevD7 PowerLine System Controller User Guide Page | 11

PowerLine User Guide

Module Connections Cont.

NOTE:

Sinking or open collector sensors may require an external pull up resistor.

Pot Ref Out ( Connector terminal 10 ):

Pot Ref Out provides +5VDC through a 1KΩ c urrent limit resistor ( 5mA max ) and is typically us ed for local

connection to a 10K potentiometer or Joystick.

NOTE:

This output should not be used as a sensor power supply as it will not supply sufficient current.

Enable In ( Connector terminal 11 ):

This is a s inking s witch inp ut. Act ivati on is ach ieved b y pullin g the in put hig h to ei ther +5-Volts or to the module

+power supply connection.

This input nominal impedance is 10 KOhms.

NOTE:

This input is internally pulled low to prevent a floating input when deactivated or not in use.

Direction ( Connector terminal 12 ):

This is a sinking switch input that m a y be used to activate ‘Co il B’ remotely.

This innovative feature allows the user to have full resolution of the command source by choosing when to

select the coil ‘B’ drive output rather than offsetting the command input to mid-point.

Activation is achieved by pulling the input high to either +5-Volts or to the modules +power supply connection.

This input nominal impedance is 10 KOhms.

NOTE:

This input is internally pulled low to prevent a floating input when deactivated or not in use.

Part No:- 021-00155 RevD7 PowerLine System Controller User Guide Page | 12

PowerLine User Guide

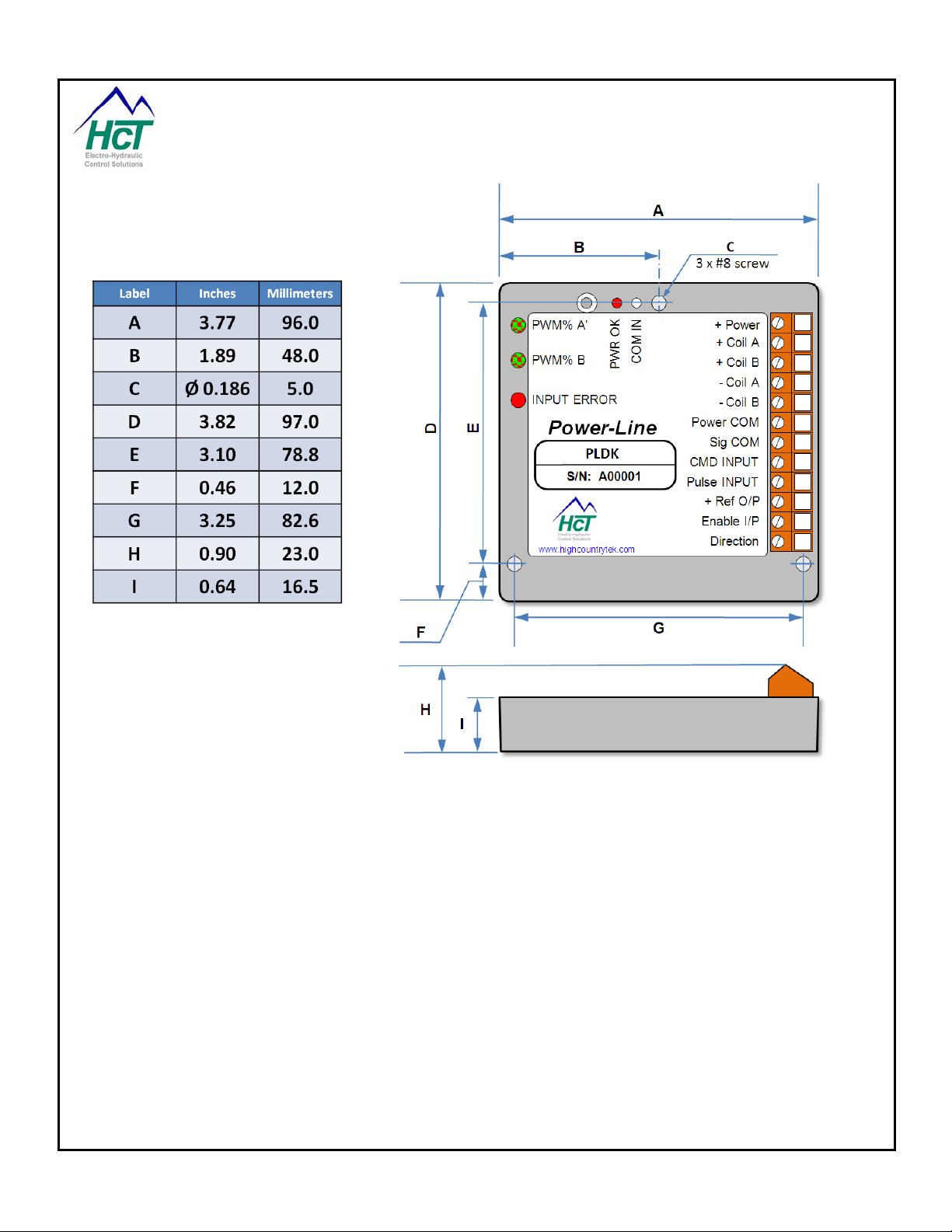

PowerLine Dimensional Information:

Housing Type:- High Country Tek unique ‘encapsulated’ block.

Housing Material:- None, solid, flameproof epoxy resin block.

Housing Color:- Black / dark Grey.

Surface Finish:- Gloss

Housing Thickness:- 12mm ( main module ) 25mm incl. Connectors.

Unit size:- See above size detail drawings.

Unit Weight:- Approx.... 400 grams ( including Encapsulation material )

Wire entry:- Via heavy duty screw type connector.

Encapsulation:- Flame Resistant, Black , Two Part Epoxy Resin.

Mounting:- Via through holed ( 3 ) suitable for No. 8 ( 5mm ) screw .

Temperature range:- - 40 to +85 degrees Centigrade ( operational )

Part No:- 021-00155 RevD7 PowerLine System Controller User Guide Page | 13

PowerLine User Guide

1 - Board Style: High Country Tek unique size and mounting.

2 - Connector Type : 12 way heavy duty scr ew termin al.

3 - Input Suppl y Vol tage: 9 – 30VDC ( absolu t e m aximum s )

4 - Input suppl y cur r ent : ~400mA quiescent + valve curr ents

5 - Input suppl y pr ot ection:

User supplied in- l ine fuse ( AGC5 )

6 - User Reference Voltage: +5VDC ( +/- 10% ) – short circuit protec t ed.

7 - User Reference Voltage curr ent: ~5mA ( Absolute maximum ) current limited.

8 - Command I nput types: DC Voltage an d pulse

9 - DCV Comma nd i nput v al ue r ange: 0 – 5VDC or 0 – 10VDC

10 - DC Current Com m and I nput Range 4 – 20mA ( 100 O hm resistor load )

11 - Puls e Comm a nd i nput v al ue r ange: 0 – 30 KHz

12 - Pulse comm and volt age range: ±0 – ±30V absolu t e m ax.

13 - Enabl e i nput value range : 0 – 5V or +m odule su pply

14 - Enabl e i nput impedance: 10 KOh m

15 - Paramet er A dj ust ment s:

All t hrou gh graphical user int er f ac e sof t ware.

16 - Coil ‘A’ c ur r ent s et t ing range: ~0 – 3000m A ( w it h curr ent feedback circuit )

17 - Coil ‘B’ curre nt se t t ing range: ~0 – 3000mA ( w it h curr ent feedback circuit )

18 - Coil ‘A’ & ‘B’ Protection: Open and short circuit det ect cir cuit.

19 - Ramp ‘A ’ max setti ng range: ~0 – 10 seconds up and down

20 - Ramp ‘B’ m ax set t i ng range: ~0 – 10 seconds up and down

21 - Dither f requency ( Hz ) range: ~0 – 250H z

22 - Dither am plitude max: ~0 – 5V Pk-Pk

23 - Process ‘P’ t er m scal e f act or r ange: 0 - 7

24 - Process ‘I ’ term scale f act or range: 0 - 7

25 - Indus t r y Com pl iance:

Designed to m eet latest CE cer t if ication stan dar ds

26 - Environmental: Totally encapsulated unit f or m echanical pr ot ect ion.

27 - IP rating: IP68 ( Modu l e only - der at e for connectors as r equired )

28 - NEMA rating: 6P ( Module on l y - derat e f or connect or s as r equired )

29 - Humidity: 95 – 100% Non con densing

30 - Stor age Tem p r ange: -60 t o + 90 Deg C ( Max )

31 - Ope r at ing temp r ange: -40 t o + 85 Deg C ( max )

Electrical Specificat ion Overview:

Part No:- 021-00155 RevD7 PowerLine System Controller User Guide Page | 14

PowerLine User Guide

Opto 3000: USB seria l Interf ace

The Opto 3000 is the newest way to interface with an y PC running

Windows™ XP® Professional and Vista Business or Ultimate, to

program or observe operation of the PowerLine module.

The unit is USB compatible c om es with all the c ab les n eede d t o star t

work immediately.

The Opto 3000 gets power f rom the PC USB por t so th e user s hould

take care to select a por t that can suppor t 5VDC output ( beware of

USB expansion hubs with m aximum load limitations ). T he unit has

TX and RX LED’s ava ilable to allow the user to observe activity on

the communications cable.

The kit has all the parts you will ne ed to connect and/or externally

power the interface as required.

To begin using the Opto 3000, Locate a free USB communications

port on your computer . Connect and s ecure one end of the s upplied

USB cable into the port of the computer, the other end into the Opto3000 connector.

Important NOTE:

The optical interface head that mechanically connects to the PowerLine module has a ‘RED mark’ on

one end - This mark should be facing towards the “PWR OK” indicator.

Part No:- 021-00155 RevD7 PowerLine System Controller User Guide Page | 15

PowerLine User Guide

Once the software has been installed, restart your computer.

Figure 1, Main Screen

Software PowerLine Installation

You are now ready to install and start the PowerLine program by Inserting the software CD and running the

‘setup.exe’ program – follow the on-screen instruction s .

After installation, the program will be found in the Start m enu group called “HCT Products“.

Before you find and run the PowerLine software program, ensure all

mechanical and electrica l connections are secure between the PC and the

Opto 3000 and that the PowerLine module is connected to a correct power

supply and turned ON.

When the software is started, and depending on your PC sof tware set-up,

the first thing it will do is to f ind the connected Opto 3000 and m ay display

the screen on the left while it is doing this operation.

After a few seconds, the a vailable Communications ( COM ) ports will sho w

up as Green. Select the port being used for communications. If you are

correct, the screen , left will disappear and the main program screen will

replace it – congrat ulations, you are now comm unicating with the PowerLine

controller.

In most instances, when us ing the Opto 3000 , the PC will detect the u nit as

soon as it is connected, and automatically select a port and start the

PowerLine user interface.

System Requirements

Windows XP Professional, Vista Business or Ultimate

256MB RAM or greater

Serial Port RS232 or USB Adapter

Opto 3000 and USB cable

• The PowerLine Graphical User Interface part

number is:- P/N: 023-00206

Part No:- 021-00155 RevD7 PowerLine System Controller User Guide Page | 16

• Ensure you have the latest version of software for

this module by contacting our customer service

and support personel if required.

• Run Setup.exe from the install CD.

• Follow the on-screen instructions as you are

prompted.

PowerLine User Guide

Using The PowerLine application

File ( Memory Options ):

Selection from Menu -> Save Temporary Memory to Permanent Memory

NOTE: It is strongly reccomended that the user cycles power to the PowerLine module after saving any

program changes to ensure that the setting alterations take place and any old setting data is erased by

the controller.

The unit stores all user programmable

settings both in tem porary and permanent

memory. The unit reads the values from

permanent memor y in the PowerLine “EEprom” into temporary memory only at

power up or when the “Res tore Tempor ary

Memory from Permanent Memory” menu

item is selected. The temporary memory

values, “settings”, are used in operation.

The PowerLine control program allows

altering the values in temporary memory,

which immediately (and temporarily)

affects the unit’s operation. The control

program also allows sav in g the p ar ameters

in temporary memory into the unit’s

permanent memory by selecting “Save

Temporary to Permanent Memory”.

Changes that are not saved will be lost

when power is turned off or if the Restore Temporary Memory from Permanent Memory is selected.

Caution: The unit does not function while settings are being saved. Use of this selection

temporarily prevents the unit from working in the system. Do not select this option while the machine

is operating.

Selection from Menu -> Save Temporary Memory to Permanent Memory & File

The control program can save and restore all unit settings to or from a file. The temporary and permanent

memory values in the un it are made to be iden tical during operations to a void confusion a bout what was s aved

or restored. When the Save Temporary Memory to Permanent Memory & a File is selected, the temporary

settings are saved t o permanent mem ory. Next, the user is prompted for a f ile name and locat ion to save the

new s ettings to. T his file can be used to program other units iden tically or act as a back up while adjusting t he

unit. This feature also allows a replacement unit to be set up identically to the original without having to

manually determine the required values for a particular installation.

Caution: Use of this selection temporarily prevents the unit from working in the sy stem.

Do not select this option while the machine is operating.

Part No:- 021-00155 RevD7 PowerLine System Controller User Guide Page | 17

PowerLine User Guide

This drop down menu allows the user to

IMPORTANT NOTE – DUAL COIL OPERATION:

Selection from Menu -> Restore Temporary Memory from Permanent Memory

Restores settings stored in permanent memory to temporary (operational) memory.

Caution: Use of this selection temporarily prevents the unit from working in the system.

Do not select this option while the machine is operating.

Selection from Menu -> Restore Temporary & Permanent

Memory from a File

When this selection is made, the user is prompted for a file

name and location from which to retrieve settings. The

restored values are placed in temporary and permanent

memory.

Caution: Use of this selection temporarily prevents the

unit from working in the system.

Do not select this option while the machine is operating.

Control Logic:

select what control mode the controller will

operate in:

1. Manual PWM control

2. Anti-Stall

(Reverse option available)

( Set-up )

3. Anti-Stall with Max Command

4. Valve Control

( Single or dual coil )

The output of either ‘A’ or ‘B’ output will go from the respective ‘I Min’ setting to ZERO (0mA ) when crossing

through command mid-point. The valve outputs do NOT jump from one I Min to the other.

Part No:- 021-00155 RevD7 PowerLine System Controller User Guide Page | 18

PowerLine User Guide

Manual PWM%

Selection from Menu -> Control Logic-> Manual PWM% Mode

This feature allows the user to manually

control the output current to coils ‘A’ and ‘B’

( PWM% ) by the using the ‘Virtual

Potentiometer’ shown colored as ‘Yellow’

on the screen to the left.

This option can be used for coil and system

setup and is ideal for troubleshooting.

NOTE for information:

The “Current = LOS Current” status message is always displayed ( not seen on this screen shot )

on the GUI when using or in this controller mode.

IMPORTANT NOTE – DUAL COIL OPERATION:

The output of either ‘A’ or ‘B’ output will go from the respective ‘I Min’ setting to ZERO (0mA ) when crossing

through command mid-point. The valve outputs do NOT jump from one I Min to the other.

Part No:- 021-00155 RevD7 PowerLine System Controller User Guide Page | 19

PowerLine User Guide

MAX

MIN

Stop RPM Slow RPM

Output

Current[A]

Figure 2 Coil Current vs. Demand in

Anti Stall Mode

Single Coil Operation

Horse Power Limiter & Anti-Stall Mode

NOTE: It is strongly reccomended that the user cycles power to the PowerLine module after saving any

program changes to ensure that the setting alterations take place and any old setting data is erased by

the controller.

Selection from Menu -> Control Logic -> Anti-Stall – Single Coil Operation

The PowerLine will adjust its outputs as a

function of the RPM of a device. Anti-stall,

or load limiting, progressively de-couples

the load as RPM decreases to avoid

stalling the prime m over ( electric motor or

engine ). T his method is typically used in

situations where the throttle of the engine

is controlled by the operator and the load

changes independently such as a

propulsion circuit. The Anti-Stall action is

used to prevent a sudden increase in load

from causing the eng ine to stall before th e

operator has a chance to increase the

throttle or decrease the load, or to

automatically adjust the load without

operator intervention.

When the prime mover RPM is less than

the STOP RPM setting, the PowerLine

outputs MIN current and the load wil l be completely rem oved. W hen the R PM is more than the SLOW RPM, the

PowerLine will output Max current. Setting the MAX current value too high can delay the start of load decoupling until an RPM less than the SLOW RPM set point has been reached.

The separation between the SLOW RPM and

STOP RPM determines how aggressively the

load is reduced. This algorithm can be used as

a continuously variable transmission controller

when connected to a variable displacement

pump or motor. Ram ps are provided to tu ne the

response time (PID constants do not affect this

process). This algorithm can caus e os c illati ons if

the ramp times are too short in some systems.

Ramps are easy to tune as there is only one

number to adjust per ramp and there are only

four independently tunable ramps. The ramps

are simply increased from zero until the

oscillation (if any) stops or the desired

smoothness is achieved. Because the ramp

settings are independent, the rate of reducing

the load can be set differently than the rate for

re-applying the load.

Part No:- 021-00155 RevD7 PowerLine System Controller User Guide Page | 20

PowerLine User Guide

RPM

PWM% A

PWM% B

100mS

Dwell

100mS

Dwell

‘STOP’

Setpoint

Output A to

ZERO

Normal RPM level

PWM% A – Full ON

PWM% B – Full OFF

Auto Reverse

Time

Ramp

PWM% A

UP setting

Ramp

PWM% B

DOWN

setting

Ramp

PWM% B

UP setting

Ramp set

by rate of

RPM

decline

‘SLOW’

Setpoint

Horse Power Limiter & Anti Stall Mode with Reverse

Selection from Menu -> Control Logic -> Anti-Stall Mode with Reverse

The PowerLine controller has a new useful

function that combines Anti-stall with a

reverse feature.

This feature will allow the user to set up the

anti-stall as normal with ‘SLOW’ and

‘STOP’ limits , with the dif ference bei ng that

if the monitored RPM reaches the ‘STOP’

limit, the controller will turn the PWM% A

output fully off , then turn the PWM% B on

to offer a reverse feature.

The ramps used for the PWM% A and

PWM% B are set in the process setup

window as shown here.

The reverse feature is turned OFF by setting the ‘Auto Reverse Time’ to 0 (ZERO) seconds.

IMPORTANT NOTE: Reverse feature ON/OFF setting

The auto reverse feature is turned ON if there is any time entered in the ‘Auto Reverse Time’ box.

The minimum reverse time is 0.5 seconds while the max is ~85 seconds.

Part No:- 021-00155 RevD7 PowerLine System Controller User Guide Page | 21

PowerLine User Guide

MAX

MIN

Stop RPM

Slow RPM

Output

Current[A]

Output

Current[B]

Command Input

Min MAX

Center

deadband

Figure 3 Coil Current V’s.

IMPORTANT NOTE – DUAL COIL OPERATION:

Horse Power Limiter & Anti Stall with Max Command

Selection from Menu -> Control Logic-> Anti Stall w Max Command

Anti Stall w Max Comm and

Anti-Stall except for the addition of the

COMMAND input that adjusts the MAX

current. The effect of the COMMAND

input is exactly the sam e as changing the

MAX current setting, with the adjustment

range of the analog input bein g the MIN to

MAX current values set b y the Opto 3000.

See the graph in figure 7. Anti Stall w

Max Command m ode can be used to give

the operator a joystick controlled load

horsepower, or load speed, adjustment in

addition to the automatic load reduction

process that prevents stalling the engine.

is the sam e as

The output of either ‘A’ or ‘B’ output will go from the respective ‘I Min’ setting to ZERO (0mA ) when

crossing through command mid-point. The valve outputs do NOT jump from one I Min to the other.

Part No:- 021-00155 RevD7 PowerLine System Controller User Guide Page | 22

Command Voltages in Anti

Stall w Max Command Mode

PowerLine User Guide

Figure A Coil Current vs. Command Voltages in

Figure B Coil Current vs. Command Voltages in

IMPORTANT NOTE – DUAL COIL OPERATION:

Proportional Valve Driver Mode

Selection from Menu -> Control Logic-> Valve Control Mode

This mode allows you to adjust the coil

current based on the c omm and input. This

method is typically used in situations

where the output current needs to be

controlled directly using a joystick.

The valve driver can operate in either dua l

coil or single coil mode. Figure A shows

the characteristics of the valve dr iver mode

in dual coil mode which is ideal for

directional valve control or for pump swash

control.

Figure 8 shows single coil characteristic

which is ideal for flow or pressure control

operation.

Valve Driver Mode with dual coils

Valve Driver Mode with single coil

The output of either ‘A’ or ‘B’ output will go from the respective ‘I Min’ setting to ZERO (0mA ) when

crossing through command mid-point. The valve outputs do NOT jump from one I Min to the other.

Part No:- 021-00155 RevD7 PowerLine System Controller User Guide Page | 23

PowerLine User Guide

NOTE:

Setup:

NOTE: It is strongly reccomended that the user cycles power to the PowerLine module after saving any

program changes to ensure that the setting alterations take place and any old setting data is erased by

the controller.

From this screen, the user has access to all of the setup sub-screens and drop downs that will enable the

configuration of the particular control logic mode that has been selected. The following pages describe the

setting available, their limits and what the effect is on the application being worked on.

Each Graphical User Interface screen may have grayed out settings or look different to the pictures

shown in this manual. This is due to the settings regarding the mode of operation and or other user

settings that may render them invalid or require them to be set to a mandatory set point.

Part No:- 021-00155 RevD7 PowerLine System Controller User Guide Page | 24

PowerLine User Guide

Pulse Input Setup:

Selection from Menu-> Pulse Input Setup

Enable Pull Down Resistor

This check box is used to enable a 10k resistor from the

pulse input to ground f or use on s ystems with open e mitter

sensors.

Pulses Per Rev

Number of pulses per revolution

LOS Current (amps) – (Loss Of Signal Current)

The user can set the coil current to drive when a loss of

signal is detected.

Feedback Selection

Used to select a voltage r ange for the Pulse Input. Pulses

must cross the midpoint of the range selected to be

detected and ma y exceed the rang e without dam age t o the

unit if less than +/- 30-Volts.

RPM Range

Use to select the bes t range for the app lication. If m ore than one range works, select the lo west range that fits

your application.

Configuration Steps:

1. Enter the number of teeth or pulses per revolution (maximum 255)

2. Enter LOS (Loss Of Signal) Current

3. Select voltage range of the pulse input under Feedback Selection

4. Select a RPM range t hat best fits the application; choose the range with the highest “lower” RPM

value that will work.

Application Tips

Inductive Pickup - Use 1 to -1v for Feedback Selection value

Hall Effect Pickup - Use 0 – 5v, or 0 – 10v for Feedback Selection value

Part No:- 021-00155 RevD7 PowerLine System Controller User Guide Page | 25

PowerLine User Guide

Command Input Setup:

Selection from Menu-> Command Input Setup

Command Error Detection

Enabled when checked disabled when

unchecked

Command Error = coils off

(active if command error detection = true)

activates when a command error is detected.

Coils turned off when checked, command

would go to “Command Error Default Volts”

when unchecked.

Command Range

Max - voltage to determine end of joystick travel

Center – Pot/joystick center point voltage

Min - voltage to determine end of joystick travel

Command Selection

0 to +5V or 0 to +10V or 4 to20mA options.

Command Error Default Volts - (active if command error detection = true) activates when a command error is

detected

If the unit senses a com mand error, th is vo ltage val ue wil l be read b y the c ard as the c omm and voltage u ntil the

error is corrected.

Command Error Limits - (active if command error detection = true)

The Command Error Limits feature will detect an d report errors on the Com mand Input that exceed the user

defined set points.

NOTE:

If the command input value is outside the High and Low values entered here, the modules outputs will

be determined by the ‘Command Input Error’ settings

These settings are used when the Command Error Detection check box has been checked.

High - Command Input Error reported when command volts are greater than High.

Low - Command Input Error reported when command volts are less than Low.

Part No:- 021-00155 RevD7 PowerLine System Controller User Guide Page | 26

PowerLine User Guide

reference volts are less than Low.

Reference Error Limits - (active if command

error detection = true)

The Reference Error Limits feature will

detect and report errors on the Command

Reference Output of the module that

exceed the user defined set points. These

settings are used when the Command

Error Detection check box has been

checked.

High - Command Input Error reported when

reference volts are greater than Hig h.

Low - Command Input Error reported when

Auto Center

The voltage from the j oystick is used during power up as the center command voltage, if it is within the Auto

Center limits set below. Check this box to enable auto center detect on power up.

Auto Center + - %

This setting is used to calc ulate how far a j oystick c an be out of the center set point in the command range. On

power up and sets limits for the Auto Center feature.

Deadband + - %

This setting installs a D eadband over the center por tion of the command voltage r ange that is plus and minus

percent from Command center. When the Command Input Voltage is in this range, the coil outputs are

disabled.

Auto Calibrate:

This feature is used to gather information about

the input command signal. The c ommand r ange,

command error limits and reference error limits

are set automaticall y. The user moves the input

command to minimum and maximum, pausing

momentarily then returns to center and presses

the Ok button. The va lues ar e the n s tored in the

controllers temporary memory. The user must

then select the “Save Temporary Memory to

Permanent Memory” menu option to

permanently save the calibration settings.

Part No:- 021-00155 RevD7 PowerLine System Controller User Guide Page | 27

PowerLine User Guide

Advanced Settings:

Selection from Menu-> Advanced Settings

Process P and I Term Scale

These values allow for scaling the P and I term scale.

These values are only editable when the controller is in

RPM Regulation Mode. These values represent the

number of times to divide the eff ect of the P or I term by

two. Therefore, larger shif t values will increasingly reduce

the effects of the P and I terms. The P s hift value can be

from 0 to 7 (default = 5). The I s hift value can be f rom 0 to

7 (default = 7). These setting should only be changed

when the use of process P, I and I time values were not

able to tune the process. (Refer to Tuning a PID controller)

NOTE:

These settings are pre-set for optimal r esponse a nd ar e onl y available with th e co rrec t password pleas e cont act

HCT factory for further information.

Part No:- 021-00155 RevD7 PowerLine System Controller User Guide Page | 28

PowerLine User Guide

Process Setup

Selection from Menu-> Process Setup

Ramp Up and Ramp Down

The units ( seconds ) are the time taken to

change from minimum output current to

maximum output current, i.e. 0 – 100%.

Smaller changes wit hin this window, will be a

ratio of this value. Com mands to chang e coils

will be delayed by the ramping process.

In RPM regulation mode, the user can adjust

the speed of the c hange in t he set p oint d ue to

changing comm and inp ut. This does not aff ec t

the speed of process regu lation at a given set

point.

In load limiting and horsepower limiting mode

the user can adjust the s peed of the chan ge in

current due to changing command input.

Process P, I and I Time

These settings are used to tune the units response to input and output changes.

The P and I values have a range of 0 to 25 5 with def au lt va lu es of P = 10 and I = 2. The Process I tim e range is

4 to 512ms, default value 50ms. The default values typically pr oduce a slow response time in the s ystem. A

detailed explanation of these settings can be found in this user guide under the heading “PID -- The Basic

Technique for Feedback Control”.

The user can adjust the process control parameters here to tune the rate and aggressiveness of the speed

change relative to feedbac k as well as system under /over shoot for the speed regulation mode. Note th at the

process setup settings, directly affect the output current value to the coil.

Minimum / Maximum RPM or Stop / Slow

The user can adjust the m inimum and maxim um RPM that is selected by the command input as it goes f rom its

minimum to maxim um value in RPM R egulation m ode. In Anti S tall m ode, this is the St op RPM and Slow RPM

set point.

Part No:- 021-00155 RevD7 PowerLine System Controller User Guide Page | 29

PowerLine User Guide

More Current = More Speed

This software selectable f eat ure al lo ws the use

of reverse acting s ingle coi l valves. W hen this

box is unchecked, the PowerLine will apply

less current to get h igher system speed. T his

feature is only available if Disable Coil B is

selected. The current, when the coil is "off",

will be the MAX current in reverse acting

mode.

Enable Active High - (active when enable 'enable'

= true)

When this box is check ed the PowerLine logic

is enabled when there is a high or > 5 VDC on

the enable input p in. When the check box is unc hecked, the unit is ena bled when there is a low or 0 volts on the

enable input pin. The unit is disabl ed when enable pin is not in the enabled state. This prevents driving the

outputs unless “More Current = More Speed” is unchec ked. If uncheck ed, disabled causes m ax current. (Note:

The 'Enable Enable' check box must be checked for enable active to operate properly)

Enable the ‘Enable’ Input

When this box is check ed the PowerLine will look at the ‘Enab le In’ input to enable the contr oller . W hen this box

is unchecked, the PowerLine is always enabled.

Enable Direction

Use of the Directi on input allows the user to use the full range ( res olution ) of the command inp ut in each

direction when applicable.

This check box enables the (Dir ection) Coil B H In input to the control ler. When selected, Coi l B will be active

when the input is pulled high.

Ramp to 0 (zero) if Disabled

This check box determ ines the units behavior w hen the enable inp ut is used and changes s tate. When this box

is checked, the ram p value and method in use with t he selected algorithm is applied to turning off the output.

When this box is unchecked, the unit immediately turns off the output.

Anti-Stall - Current to 0 (Zero)

When the input RPM is le ss than the STOP RPM, the current will sta y at MIN unless this box is checked, in

which case the current drops to zero from Imin without ramping. This option is only active in Anti-Stall mode.

Command Reverse Acting

This feature is available in “Anti Stall w Max Com mand” m ode only. When c hecked, the Comm and Volts M in in

single coil operation demands 100 percent current and Command Volts Max demands 0 percent current.

Warning: It is dangerous to do this in dual coil operation, the Center Voltage will command 100 percent output.

Part No:- 021-00155 RevD7 PowerLine System Controller User Guide Page | 30

PowerLine User Guide

IMPORTANT NOTE – DUAL COIL OPERATION:

Coil Setup

Selection from Menu-> Coil Setup

Minimum and Maximum current

The user can adjust t he minimum and maximum

current on a per coil basis. The c urr ent outpu t wil l

not be commanded outside of these r anges w hen

the coil is on. This feature is useful as it allows f or

valve ‘deadband’ to be reduced, making the

system more responsive to small commands

around the zero position or point of a command

source ( i.e. Joystick e.t.c. ). The softw are has a

limit of zero (0) for minimum and a limit of

3000mA for maximum current.

EDC ( Electronic Displacement Control ) Type Coil

This soft switch changes th e PWM frequenc y to a lower setting for use with lo w current coils to allo w for better

current regulation. Check this box when using EDC coils

Note, Adjusting the max current above recommended OEM values may damage the coil and will reduce the

resolution of the process control

Disable Coil B

This software switc h disables coil ‘B’ output. Check this box when usin g as a single co il valve or uni-direction

motor or open circuit pump.

NOTE:

Always make sure to uncheck the ‘Disable Coil B’ tick box when using a dual coil valve or bi-

directional motor or closed circuit pump.

Dither Amplitude and frequency ( Hz )

Dither is commonly used to reduce the effects of valve hysteresis and stiction. These parameters can be

adjusted to suit the hydraulic product being controlled. Optimized values can typically be found in the

manufacturers datasheets.

The output of either ‘A’ or ‘B’ output will go from the respective ‘I Min’ setting to ZERO (0mA ) when

crossing through command mid-point. The valve outputs do NOT jump from one I Min to the other.

Part No:- 021-00155 RevD7 PowerLine System Controller User Guide Page | 31

PowerLine User Guide

Help:

The ‘Help’ dropdown menu offers two

choices. The first opens a wind o w that gi ves

the user information on the controller

Application and BIOS versions as well as

contact information for High Country Tek,

Inc.

The second option ‘View Help’ will open a

PDF file of this manual to allow the user

immediate access to information regarding

the controller, application, set-up and

troubleshooting.

Software Controls:

Exit the program (GUI)

Click the ‘Exit’ button on the man screen lower right hand corner.

NOTE:

Always use this method of terminating the PowerLine PC program. This cleanly exits the program and

also releases any communications port(s) in use for other applications.

Log Data

A data-logging f eature is a vailable to log the R PM, Coil Cur rent and

RPM set point. This feature is us eful for system troubleshooting a nd

remote debugging. The Log Data button is used t o start the data

log process. The user is prom pted f or a file nam e and location af ter

the data has been co llected. The data log contai ns 250 samples.

The timer period of the data log is less than a ha lf of a minute on a

fast computer, to several m inutes on a slow computer. The log f ile

is text and may be read into a spreadsheet and graphed.

Part No:- 021-00155 RevD7 PowerLine System Controller User Guide Page | 32

PowerLine User Guide

Troubleshooting:

General Considerations

The ‘PWR OK’ LED must be steadily on, not flashing, for correct unit operation.

This LED will be off if the power supply is too low , and flashing if the power supply is to o high. Interm ittent low

power supply c onditions also cause flashing. Large noise s pikes on the power supply can cause the unit to

temporarily shut down due to over voltage.

The INPUT ERROR LED flashes if there is a fault with the COMMAND IN or PULSE IN inputs.

The PWM%A and B LED ’s are on when their co il is driven. They range f rom red ( driving 0%) throu gh green

(driving 100%). The LED ’s flash red/off for shorted coils and gre en/off for open coils. +CO IL leads shorted t o

power or ground may be interpr eted as either a short or open. -COIL leads shor ted to power or ground will be

indicated as a short or open on whichever coil is driven first.

NOTE:

The unit WILL NOT drive coils after a short or open until the controllers power is cycled or disabled

then re-enabled by the ENABLE IN signal.

The trouble-shooting m ode of Manual PW M% is avai lable to dr ive the coi ls witho ut reference t o the pu lse input.

This allows using a “Virtual Pot” on t he computer to control the coil current. Valve s election for coil A or B is

obtained though the us e of a “Soft Switch” next to the virtua l pot. Manual PWM% applies 0 to 100% of the

power supply to the selec ted coil output and does not regulate current against power supply var iations or coil

resistance changes.

Note: Care should be exercised when driving coils that are rated for lower voltages than the controllers

supply voltage ( i.e. 12V coil with 24V supp ly ). Over Drivin g a valve coil may/will da mage the coil by

overheating.

The switch inputs have on screen indicators that toggle when that switch function is enabled.

Running graphs allo ws the viewing of several i nput and outp ut signals . The PUL SE IN voltage display is useful

to verify that the pulse sensor is providing the expected voltage swing. Note that this signal does not show

pulse shapes, but does indicate the range of amplitudes detected by the unit. These graphs can also be used to

aid in tuning the dynamics of the system regulation.

A LOG button allows saving the un it settings and sampling th e inputs to the PC for later ana lysis. multiple logs

can be saved into the same file. Logs should always accompany trouble reports to the factory if possible.

Part No:- 021-00155 RevD7 PowerLine System Controller User Guide Page | 33

PowerLine User Guide

On Site Testing:

If the set up procedure does not achie ve the desire d results, doub le check the wiring and perf orm the f ollowing

tests. Record the test results.

Tools required

A PC running W indows XP and an O pto 3000 ar e required f or init ial set-up, program ming or obser vation of the

controllers operation through the RS232 port.

The PC can also be used for uploading the configured program to new PowerLine modules for series

production.

A battery operated multi-meter is always a good idea for measuring and confirming analog signals and an

oscilloscope would be useful for looking at fast moving or digital signals on the system as well as monitoring the

system power input for transients that could cause intermittent operation.

Check the power input:

The module will not function correctly unless the +POWER supply is at least 9 VDC when driving the coils.

If the supply voltage is below 9VDC , there is a risk of:

a) Module shutting down, b) Module continuously trying to reset or c) Low drive current to valves.

If the supply voltage is more than 30 VDC there is a risk of:

a) Blown in-line AGC5 fuse, b) Module internal damaged or c) Coil damage due to excessive drive voltage.

Check the control inputs:

Verify the control inputs ar e the correct polarit y an d are hooked up corr ectly to the correct m odule terminals by

monitoring their status with the PowerLine software or testing with a voltmeter or oscilloscope.

Ensure that any external control or com m and inputs have t heir respective 0V or GN D connect ed to the modules

power supply 0V or GND terminal.

Verify the coil is not shorted or open:

Disconnect the wires goi ng to the +COIL and -COIL ter minals and measure the res istance between the wires.

Verify it is in the expected Ohmic range for the type and voltage of coil being driven. Verify that ther e is no

voltage between either wire and power or ground (indicating a short circuit to either power or ground).

NOTE:

If a +COIL or -COIL is short circuited or open circuited while being driven, the controller will shut

down its outputs until the user cycles controller power or disables then re-enables the module.

Check the card at full-on and full-off:

Do not try the full on test if the power supply is higher than the coil's rated voltage.

To test the card at full on, use the control software to go to Open Loop PWM mode and set the PWM to 100%.

Full-ON - Measure the voltage ac ros s the +COIL and -COIL and from +POWER to POWER CO M. The vol t age

difference should be no more than approx. one (1) volt if the card is operating correctly.

Full-OFF - T o check the card at f ull off, Enter the GUI and go to th e ‘Manua l PWM’ sc reen and s et the PW M to

0% in open loop mode. Measure across the +COIL to -COIL voltage which should be zero volts.

Part No:- 021-00155 RevD7 PowerLine System Controller User Guide Page | 34

PowerLine User Guide

Valve not being driven to maximum:

If the card passes the "full on test" above, the problem is potentially in the system or wiring.

1. Check the controllers ‘I Max’ settings through the GUI and make sure they are correct.

2. Dry test the valves:

a. Turn off the hydraulics pump.

b. Ensure there is NO system flow or trapped pressure.

c. Make the equipment safe to work on for you and others.

d. Command the valves using GUI manual mode to maximum.

e. Measure the voltage at the power supply or battery and ensure this is at least 20% above the

specified coil voltage that you are driving ( see note 1 below )

f. If there is a d iff erenc e of >1VDC at f ull load bet ween th e m easur ement at the p ower suppl y and

at the module power input , there is excessive voltage drop in the connection wires and they

should be shortened or replaced by bigger wires( larger cross sectional area ).

g. Also check for bad 0V or ground connections as this can also cause large voltage drops.

Note 1:

Ohms Law says that when a c oil heats up in use, it increas es Ohmic resistance which de-creases the curr ent

flow. Most manufacturers coils, even when hot should still b e able to fully shift the valve 100% if their rated

voltage is supplied to them.

In some instances, a volta ge s lightl y greater th an the c oils rat ing is needed to m aintain the valve 10 0% p osition.

On a mobile applicat ion, no m inal s ystem volt age is q uoted as be ing 1 2VDC. When the alternator is runn ing, the

fully charged batter y voltage should be in the 13.8 – 1 4.3VDC region. This extra voltage should be suf ficient to

enable the valve to drive to 100%.

When an increased suppl y voltage is not a possible option, you must use a coil rated for less voltage. The

controller will have no trouble driving a 12 V coil from a 24 V supply, or a 10 V coil from a 12 V supply for

example.

If the valve shift is erratic

Electrical interference o n the command wires c onnected to the contro ller can also cause er ratic behavior if the

field is strong enough. O bserve the control inputs on th e PC GUI. If the electrical noise greater than a few

percent of full scale is noticed on an unchanging PU LSE IN or COMMAND IN input, or if the digital inputs are

‘switching’ randoml y, try changing the routing of the control wires to see if the probl em changes. The use of

shielded signal cables is strongly reccomended to a void the affects of induced input errors.

Power suppl y interference or brown-outs ( power suppl y voltage ‘dips’ as load ing increases or when starting an

engine e.t.c. ) can a lso caus e erratic beha vior. Obs erve the power supp ly on the graph on the PC GUI. If large

dips are noticed, test for a poor supply by running the card off its own fully charged battery.

Further information

Visit our website www.highcountrytek.com

for additional documentation and assistance.

Part No:- 021-00155 RevD7 PowerLine System Controller User Guide Page | 35

PowerLine User Guide

This first example shows how the controller can be used in a

This example shows how the controller can be used in a single

This example shows how the controller can be used in a Dual

IMPORTANT NOTE – DUAL COIL OPERATION:

Application Connection Examples:

single proportional valve control application.

The command is coming from a manual source, either a

potentiometer or joystick as shown here.

proportional valve control a pplic ati on.

The command is coming from a remote signal source, possibly

another machine controller

proportional valve control a pplic ati on.

The command is coming from a remote signal source,

possibly another machine controller

The output of either ‘A’ or ‘B’ output will go from the

respective ‘I Min’ setting to ZERO (0mA ) when crossing

through command mid-point. The valve outputs do NOT

jump from one I Min to the other.

Part No:- 021-00155 RevD7 PowerLine System Controller User Guide Page | 36

PowerLine User Guide

PID - The Basic Technique for Feedback Control:

The Proportional-Integral-Der ivative or “ PID” contro ller look s at the pres ent value of the err or, the integr al of the

error over a recent tim e interval, and the derivati ve of the error signal to calcu late how much of a cor rection to

apply. These calculat ions are done once ever y “I Time”, but are f ast enough t o appear to be co ntinuous to the

system. These three quantities are each multiplied by tuning constants and added together to produce the

controller output.

Error = target-feedback

Pterm = (P * error / 2^Process_P_Scale_Factor)

Iterm = (I * sum_of_error / 2^ Process_I_scale_factor)

Output = Pterm + Iterm

Note: The derivative or D term is not implemented at this time.

Tuning a PID Controller

How to best tune a PID controller depends upon how the process responds to the controller’s corrective efforts.