HCT HFS-J-Bus User Manual

Electronic Controller Solutions for the Global Fluid Power Industry

HFS-J

Hydraulic Fan Drive

High Country Tek, I nc. reserves the r ight to improve this product at any time and without

Electronic Control Sol uti ons f or t he Gl oba l Fluid Power Industry

High Country Tek, Inc.

Hydraulic Fan Drive User Guide: HFS-J

Hydraulic Fan System Controller with SAE J1939 Interface

System Controller

HFS-J User Guide

User Guide

notice. This manual may contain mistakes and printing errors. The information in this

publication is regularly c hecked and corrections mad e in the next issue. Please c heck our

Part No:- 021-00158 Rev C HFS-J Hydraulic F an System Controller User Guide Page | 1

website or contact our customer support for latest version. HCT accepts NO liability for

technical mistakes or printing errors or their consequences.

Electronic Controller Solutions for the Global Fluid Power Industry

High Country Tek, Inc. (HCT)

www.hctcontrols.com

The information in this publication is intended as a guide only, and High Country Tek, Inc. (HCT) takes NO

Hydraulic Fan System Controller with SAE J1939 Interface

HFS-J User Guide

is North America’s foremost independent designer and

producer of modular, r uggedized digital and a nalog electronic contro ller products for the f luid power

industry.

From our factor y in California, we build, test an d produce ‘speci alty’ controller s that provide s olutions

for specific everyday functions as well as our ‘DVC family’ of fully adaptable user programmable units

that can be integrated together to enable large area networked system solutions.

The modules are typically used in mobile, industrial and marine applications, but are also applied

successfully in several other growing global market segments.

Because High Country Tek has an industry unique non-repairable product protection system, with

every module e ncaps u late d in solid flame res istant material for maximum durability, electr ic a l integrit y

and complete environm ental security, we have to deliberate ly select the highest qualit y components

from our suppliers at all times, ensuring our 100% operating shipped product.

HCT is also a market leader in many applicatio n arenas, including hydraulic generator and hydraulic

fan system controls where significan t f uel, em iss ion and o peration al sav ings can be rea li zed b y using

one of the aforem ention ed spec ial t y units to optimize the applications operation.

HCT’s market neutrality and flexible product configuration approach offers dependable integration

with virtually any hydraulic OEM products for easy, simple and accurate control of valves, pumps,

sub-systems or systems.

Our best-in-class cus tomer service and product reliability is well k nown and trusted throughout the

fluid power network and we look forward to working with you in the future.

responsibility for usage and implementation in any user entered values into the provided GUI structure.

HCT strongly suggests that the user attends one of the product training courses to ensure correct and full

understanding of this information and to learn further optimized methods of control techniques.

Please contact HCT customer service to book one of the scheduled training dates or to discuss arranging a course

specific to your company needs.

Thank you for using High Country Tek Inc. Products.

Part No:- 021-00158 Rev C HFS-J Hydraulic F an System Controller User Guide Page | 2

Electronic Controller Solutions for the Global Fluid Power Industry

Hydraulic Fan System Controller with SAE J1939 Interface

Manual Index:

Introduction: ....................................................................................................................... 4

Cautions: ............................................................................................................................. 4

Warranty Information: ........................................................................................................ 4

Controller Updates: ............................................................................................................ 4

controller information. ....................................................................................................... 4

‘HFS-J’ Hydraulic Fan System Controller: ...................................................................... 5

Product Overview ............................................................................................................... 6

Product Application Guidelines: ....................................................................................... 7

Software Safety: ................................................................................................................. 7

Module Familiarity: ............................................................................................................. 8

Electrical Specificat ion Overview: .................................................................................... 9

Note: .................................................................................................................................... 9

Application Examples: ..................................................................................................... 10

Error LED code descriptions: .......................................................................................... 11

Module Connection Descriptor: ...................................................................................... 12

Serial Communications: .................................................................................................. 14

RS232 Serial Connection Cable: Part No- 999-10075 ( see page 32 of this manual ) . 14

Loading the HFS-J GUI onto Host PC: ............................................................................ 15

System Requirements ...................................................................................................... 15

Installing the HFS-J Software .......................................................................................... 15

Password Protection ........................................................................................................ 17

GUI software – Main screen (Dashboard) ....................................................................... 19

Controller Set-up: ............................................................................................................. 20

Controller Set-up Cont: .................................................................................................... 21

Controller Set-up Cont: .................................................................................................... 22

Channel controlling fan speed: ....................................................................................... 23

Data Logging: ................................................................................................................... 25

Miscellaneous Information: ............................................................................................. 27

Software Controls: ........................................................................................................... 27

Quit .................................................................................................................................... 27

Temperature Sensor Information: ................................................................................... 28

Connector Information: .................................................................................................... 28

System Accessories: ....................................................................................................... 28

Item Description: .............................................................................................................. 28

HCT P/No: .......................................................................................................................... 28

On Site Testing: ................................................................................................................ 29

HFS-J Dimensional Information: ..................................................................................... 31

HFS-J User Guide

Part No:- 021-00158 Rev C HFS-J Hydraulic F an System Controller User Guide Page | 3

Electronic Controller Solutions for the Global Fluid Power Industry

Welcome

Introduction:

Cautions:

injury

death

Warranty Information:

info@hctcontrols.com

Controller Updates:

Please check on-line at www.hctcontrols.com for the latest products, updated software and controller information.

Hydraulic Fan System Controller with SAE J1939 Interface

HFS-J User Guide

for selecting this HCT controller to use in your application.

The following information is designed to allow you to connect, set-up and optimize the HFS-J module. If you have

used HCT products before, you will recognize some of the instructions and settings. For those of you that are new to

HCT, please read the directions with care and be sure that if you have any questions regarding this industry unique

controller, then please contact us one of the numbers given on the back page of this manual.

We value our customers, their experience and abilities and ask that if you would like to see any additions,

subtractions or find any errors in this publication, that you contact HCT’s customer service so that we can correct the

information and make sure that our programming community is using the latest information.

If you require urgent support, more information or would like specific programming areas clarified, you can contact us

on the customer support number at 1 530 265 3236 or E-mail us through our website at www.hctcontrols.com

details of your issue and how we can contact you.

to the High Country Tek Inc. ( HCT ) HFS-J Hydraulic Fan Drive system controller user guide, and thank you

This manual is designed to provide information needed for the installation and use of the HFS-J Hydraulic Fan System

Controller. Its intended user is qualified trained service personnel that understand the hazards involved in an

electromechanical environment. It is recommended that this manual be read in its entirety before installation is

begun with particular attention paid to caution and safety information.

Changing setup values and limits under computer control while the machine is operating may cause sudden machine

or

movement, which may lead to possible

prior to any alignment procedure whenever possible. In any case, caution should be exercised during any procedure

and work should be completed only by qualified trained personnel.

High Country Tek Guarantees this product to be free of defects in materials and workmanship for a period of one year

extending from the date the unit was shipped from the factory. Within this time frame, High Country Tek will provide

evaluation of warranted items free of charge. Warranty repair or replacement will be at the factory’s discretion. If

necessary, contact the factory for return authorization by phone (530) 265-3236, Fax (530) 265-3275, E-Mail

or by writing our service department at, High Country Tek, Service Dept., 208 Gold Flat

Court, Nevada City, CA 95959. To help us serve you better, please have the units full Model / Part Number and Serial

Number available when contacting the factory for any reason. Do not return products to the factory without prior

authorization and a RMA number attached.

HCT continuously improve the controllers and make additional information and/or features available.

. It is strongly recommended that any moving parts are disabled

, giving

Part No:- 021-00158 Rev C HFS-J Hydraulic F an System Controller User Guide Page | 4

Electronic Controller Solutions for the Global Fluid Power Industry

‘HFS-J’ Hydraulic Fan System Controller:

High Country Tek ( HCT )

High Country Tek’s

Hydraulic Fan System Controller with SAE J1939 Interface

HFS-J User Guide

The HFS-J is the latest addition to the

family of hydraulic fan control modules. The highly

cost effective HFS-J has enough processing power and input output functionality when operating as a single control

module to support a wide range of hydraulic fan system applications. As with all of the HCT modules, the HFS-J is

packaged in a small rugged enclosure and encapsulated in flame resistant resin to withstand extreme conditions in

the harsh mobile operating environment.

The HFS-J module is ideally suited for today’s hydraulic OEM, distributor or system builder. With both mechanical and

electrical robustness paramount in the design priority, Windows™ compatible easy to use set-up software and full CE

compliance means this one product can through, the many configurations and features available, be used across

multiple platforms, markets and applications.

This units cost effectiveness will become quickly apparent through the reduction in inventory costs and stocking

needs as well as in the reduced costly engineering time taken usually associated with the design to delivery cycle.

Programming of the controller parameters and all diagnostics is done through the RS232 connector pendant. This is a

separate connector from the main power, signal and output connector so that optimization or operational observation

can be carried out without disturbing the cooling system operation. When programming, changes or observation of

the module function is required, connection can be made through a standard computer serial connection, either

directly via a 9 way ‘D’ type connector or through one of the many available USB to serial cables along with the

software program HFS-J and the HCT programming interface cable ( Part No:

999-10075) is required for

communication from the controller to a Windows™ based PC.

The HFS-J is designed to make the fan system set-up easy to configure and control. The hardware contains the

framework software where the parameters can be changed depending on the user’s needs via the PC graphical user

interface ( GUI ).

The GUI has been organized into various user screens that are logical and simple to understand. Terminology has

been used that is commonplace through the mechanical, hydraulic, mobile and fan drive industry to allow easy

configuration, set-up and running and is intended to cater for a wide range of users with varying levels of computer

familiarity.

This new version of proven controller hardware is ideally suited to equipment upgrades as well as fitment by OEM’s at

machine build time and offers all the necessary features required by today’s modern engines that use the J1939

communications standard.

The controller will take information directly from the J1939 bus for the common temperatures broadcast such as

Engine RPM, Water, Charge air and Transmission temperature making system integration very quick and easy. The

controller allows the user to also have up to 2 additional external inputs from thermistor or temperature switches as

the same time if required, these can be used as fan speed overrides if for example, the engine retarder or

air/conditioning is selected in the vehicle increasing the heat load needing to be cooled.

The HFS-J product is backed by

industry leading product reliability, easy to use software design

and market leading customer service and technical support as well as on-time delivery while the well designed and

intuitive graphical user Interface (GUI), allows you to program multiple configurable modes of operation available

within the one module.

Part No:- 021-00158 Rev C HFS-J Hydraulic F an System Controller User Guide Page | 5

Electronic Controller Solutions for the Global Fluid Power Industry

NO software experience needed to apply this controller successfully.

SAE J1455 protection

CE approved

J1939 CAN Bus communications

**

IP68 (NEMA 6P)

Compatible with all manufacturers fan system hydraulic valve and pump control products.

**J1939 Temperature Data NOTE:-

If the J1939 PGN data for temperature is NOT correct for a particular engine, HCT can change the PGN number

to one that is correct and re-issue the program code to you. Please use the contact numbers on the back page

of this manual to discuss this with our customer support personel.

Hydraulic Fan System Controller with SAE J1939 Interface

HFS-J User Guide

Product Overview

•

• Pre-written ‘Fan Drive’ software for easy, fast system configuration, development and production.

• Intuitive Graphical User Interface ( GUI ) runs on any PC with Windows® XP or newer software ( .net compatible ).

• 9 to 32VDC operation with full reverse polarity and

• Extended -40ºC ( -40ºF ) to +85ºC ( +185ºF ) controller operational temperature range.

•

•

•

J1939 temperature data hard coded for :

Engine water/coolant at PGN 65262,

Transmission Oil temperature at PGN 65272

Intake manifold/charge air Temperature at PGN 65270

• All inputs and outputs protected from shorting to ground or the power supply.

• Diagnostic LED display shows I/O status and module operation at a glance.

• ‘Blinking’ error code LED for fast on-site ‘health check’.

• System wiring and coil fault detection and alarms.

• Alarm output for integration into host system.

•

• Single Deutsch Metri-pack 150 series I/O 12 way connector for easy system wiring.

• Separate RS232 communications connector for programming, monitoring and diagnostics.

• Rugged encapsulated product withstands harsh environments found in mobile applications.

to latest international test standards.

for engine and temperature zone data Inputs

rating on module for harsh environment reliability ( connector IP rating may differ ).

.

• Non Volatile Memory maintains ALL settings without power

• Completely user configurable for setting confidentiality.

•

Part No:- 021-00158 Rev C HFS-J Hydraulic F an System Controller User Guide Page | 6

Electronic Controller Solutions for the Global Fluid Power Industry

Product Application Guidelines:

Software Safety:

Hydraulic Fan System Controller with SAE J1939 Interface

HFS-J User Guide

ALWAYS do the following:

• Take a few minutes to FULLY read THESE information / data sheets BEFORE starting.

• Keep High Voltage AC cables separate from Low Voltage DC signal and supply cables.

• Make sure the unit supply voltage is the same as the coils on the valve being driven !

• Ensure that you are aware of the adjustments and consequences on the electronics and hydraulics.

• Make sure you have the correct tools to do the intended job ( i.e. P.C., software ) e.t.c.

• ‘Isolate’ this unit from all other equipment BEFORE any form of welding takes place.

• Check ALL connections to and from this unit to ensure NO short or OPEN circuits.

• Check the units supply voltage is CORRECT, ‘ ELECTRICALLY CLEAN ’ and STABLE.

• Operate the units within specified operating temperature for best & reliable performance.

• Ensure that any unused wires / terminals are terminated safely and not shorted together.

• Isolate the controller if ANY form of battery charging or battery boosting takes place on the vehicle.

• Ensure ALL valve connectors are wired correctly, secure, locked and connected to correct coils.

• Observe the set-up procedures in this manual for best operational results.

• Follow and abide by local and country health & safety standards – protect yourself and others !

NEVER do the following:

• Arc Weld or Charge Batteries with this driver unit connected as damage can occur.

• Attempt to use this unit if you are unsure of electrical OR hydraulic connections or expected operation.

• Attempt to use this unit in Areas where other AC or DC coils HAVE NOT been fully suppressed.

• Use a power supply that is not rated for the correct required O/P current under full load.

• Allow wires TO or FROM the unit to short circuit ( to each other or chassis/cabinet e.t.c. ).

• Attempt to use this unit in areas of intense RF without adequate screening measures.

• Disconnect or connect wires to or from this unit unless it isolated from the power supply.

• Use this unit in temperatures that exceed those specified as operation may be effected.

• Start this unit without ensuring ALL work areas are clear of personnel !

The software has been carefully written to give the user the maximum system configuration flexibility while being

transparent in operation and easy to use, even for novice system builders and operators.

To ensure safety when using the software and to prevent accidental connection to another module that is not a HFSJ, rules have been written into the software to ensure correct operation at all times:

When the PC running the GUI is first connected to a powered HFS-J, and before any data exchange can be allowed, a

‘Handshake’ takes place that confirms the HFS-J internal software ( BIOS ) is compatible, the serial number and the

HFS-J part number. The GUI then checks to ensure that its own revision is compatible with the module software and

only then allows the PC and the module to communicate and share data.

If at any point during the process above an error or miss-match is detected, the GUI software will NOT allow

communications and will inform the user of the problem via a clear message in the ‘Status’ window.

Part No:- 021-00158 Rev C HFS-J Hydraulic F an System Controller User Guide Page | 7

Module Familiarity:

RS232 Communication

and programming 4 way

plug

Flame retardent epoxy

resin material for complete

IP68 ( NEMA 6P ) rating

3 x # 8 ( 5mm )

mounting holes

Industry standard 12 way

sealed Deutsch main I/O

connector

Heavy duty

cables used for

programming

harness

Controller ‘STATUS’ led –

Bi-color, indicates what

the module is doing at any

given time.

Bi-color, Controller Fault

‘Blink’ code and Fan reverse

cycle indicator LED

Full CE to latest test

standards,

J1455 ( load Dump )

and

J1939 compliance

NOTE:

effective. This feature is especially useful in the field where test equipment may not be available.

Electronic Controller Solutions for the Global Fluid Power Industry

Hydraulic Fan System Controller with SAE J1939 Interface

HFS-J User Guide

Part No:- 021-00158 Rev C HFS-J Hydraulic F an System Controller User Guide Page | 8

This module has local diagnostic capabilities by way of the two Bi-Color ( Red / Green ) LED’s mounted

on the front of the unit. These LED’s are used to show the user a variety of ‘Blink’ codes that equate to

the precise issue or error being seen by the controller, so locating and fixing an issue will be quick and

Electronic Controller Solutions for the Global Fluid Power Industry

Electrical Specification Overview:

CE

Note:

Hydraulic Fan System Controller with SAE J1939 Interface

HFS-J User Guide

1) Board Style: High Country Tek unique size and mounting.

2) Connector Type: 12 way male Deutsch DT series

3) Comms. I/O connector:

4 core umbilical cable.

4) Comms. Type: Serial data at 57.6K Baud through PC USB/Serial port.

5) Input Supply Voltage: 9 to 32VDC ( absolute maximums )

6) Input supply current: ~200mA quiescent + valve currents

7) Input supply protection: SAE J1455 & User supplied in-line fuse ( AGC5 )

8) Command Input types: SAE J1939 & 2 x external discrete thermistor/switch contact

9) Thermistor types: 2 wire Resistance variety only ( see table )

10) Thermistor Protection: Open and short circuit detection

11) Proportional valve current range: ~0 – 3000mA ( with current feedback circuit )

12) Directional valve current range: ~0 – 3000mA.

13) Output Protection: Open and short circuit detection

14) Alarm output current: ~0 – 3000mA.

15) ‘Reverse’ input signal value range: >+2.5VDC to +V module supply

16) ‘Reverse’ input signal impedance: >100K Ohm

17) Digital Input De-Bounce: 150mS ( triggered on rising edge )

18) Industry Compliance:

19) Environmental: Totally encapsulated unit for mechanical protection.

20) IP rating: IP68 ( Module only - derate for connectors as required )

21) NEMA rating: 6P ( Module only - derate for connectors as required )

22) Humidity: 95 – 100% Non-condensing

23) Storage Temp range: -60 to + 90 Deg C ( Max )

24) Operating temp range: -40 to + 85 Deg C ( max )

ALL controller and system response adjustments are made through graphical user interface software,

See ‘HFS-J Software’ section in this manual for full details.

4 way Packard MALE ( Tower ) connector on 6 inch,

certification to latest standards

Part No:- 021-00158 Rev C HFS-J Hydraulic F an System Controller User Guide Page | 9

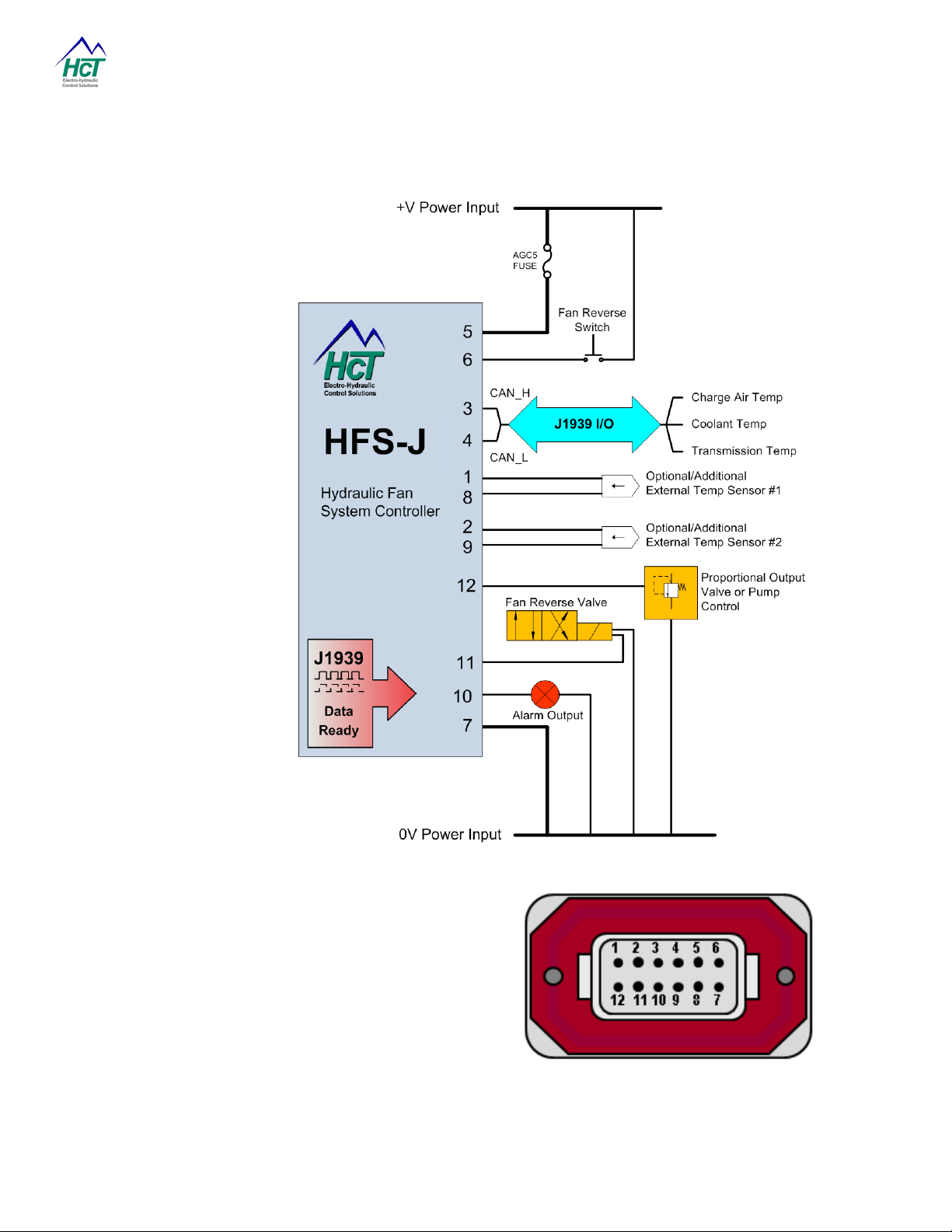

Application Examples:

NOTE:-

Controller MUST have

in-line fuse fitted by

user in +V Power Input

for system protection.

NOTE:-

Electronic Controller Solutions for the Global Fluid Power Industry

Hydraulic Fan System Controller with SAE J1939 Interface

HFS-J User Guide

View looking at 12 way male connector on

HFS - J controller - DTF15-12PB

Pin 1:- Thermistor #1 +signal input.

Pin 2:- Thermistor #2 +signal input.

Pin 3:- CAN_H Input ( J1939 )

Pin 4:- CAN_L Input ( J1939 )

Pin 5:- +Vin 9 to 32VDC Power supply Input

Pin 6:- Reverse fan input ( Momentary )

Pin 7:- 0V power input ( Common )

Pin 8:- 0V—Signal common #1

Pin 9:- 0V—Signal common #2

Pin 10:- Alarm output drive ( 3A max sourcing )

Pin 11:- Reverse valve output drive ( 3A max sourcing )

Part No:- 021-00158 Rev C HFS-J Hydraulic F an System Controller User Guide Page | 10

Pin 12:- Proportional valve output ( 3A max sourcing )

Loading...

Loading...