HCT emc-3 User Manual

emc-3 Controller Module

User Guide – Rev A

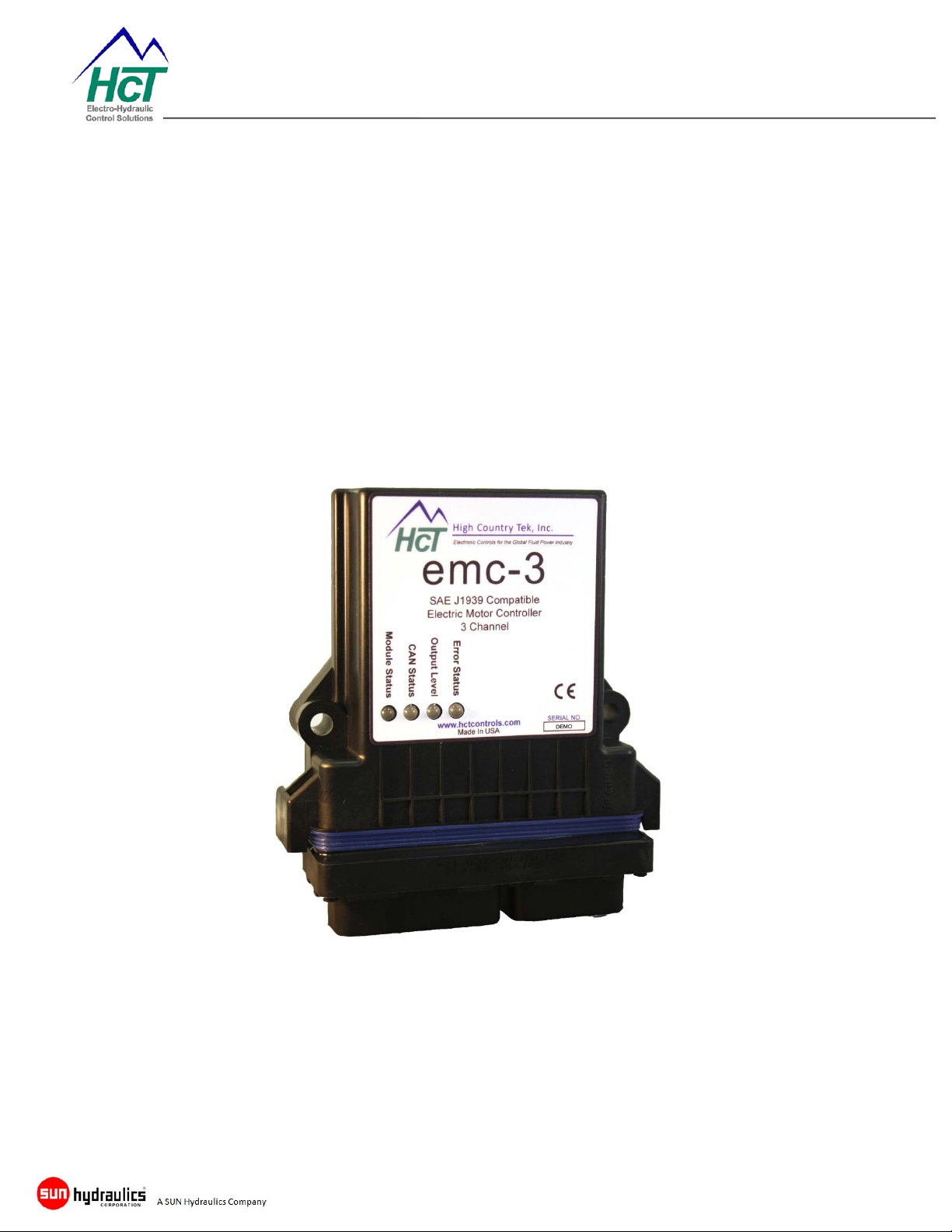

emc-3

3 array e-Fan

Electronic Controller

User Guide

High Country Tek, Inc. reserves the right to improve this product at any time and without notice. This manual

may contain mistakes and printing errors. The information in this publication is regularly checked and

corrections made in the next issue. Please check our website or contact our customer support for latest version.

HCT accepts NO liability for technical mistakes or printing errors or their consequence

Page 1 of 39

emc-3 Controller Module

User Guide – Rev A

High Country Tek, Inc. (HCT)

producer of modular, ruggedized digital and analog electronic controller products for the fluid

power industry.

From our factory in California, we build, test and produce ‘specialty’ controllers that provide

solutions for specific everyday functions as well as our ‘DVC family’ of fully adaptable user

programmable units that can be integrated together to enable large area networked system

solutions.

The modules are typically used in mobile, industrial and marine applications, but are also applied

successfully in several other growing global market segments.

Because High Country Tek has an industry unique non-repairable product protection system, with

every module encapsulated in solid flame resistant material for maximum durability, electrical

integrity and complete environmental security, we have to deliberately select the highest quality

components from our suppliers at all times, ensuring our 100% operating shipped product.

HCT is also a market leader in many application arenas, including hydraulic generator, e-Fan and

hydraulic fan system controls where significant fuel, emission and operational savings can be

realized by using one of the aforementioned specialty units to optimize the applications operation.

is North America’s foremost independent designer and

HCT’s market neutrality and flexible product configuration approach offers dependable integration

with virtually any hydraulic OEM products for easy, simple and accurate control of valves, pumps,

sub-systems or systems.

Our best-in-class customer service and product reliability is well known and trusted throughout

the fluid power network and we look forward to working with you in the future.

For our latest information, products, updates, guides and accessories, please visit us on-line at:

www.hctcontrols.com

The information in this publication is intended as a guide only, and High Country Tek, Inc. (HCT)

takes NO responsibility for usage and implementation in any user entered values into the

provided GUI structure.

HCT strongly suggests that the user attends one of the product training courses to ensu re correct

and full understanding of this information and to learn further optimized methods of control

techniques.

Please contact HCT customer service to book one of the scheduled training dates or to discuss

arranging a course specific to your company needs.

Thank you for using High Country Tek Inc. Products.

Page 2 of 39

emc-3 Controller Module

User Guide – Rev A

Introduction

The emc-3 application allows for independent control of up to three fan banks.

Each bank is controlled by any three of the seven Command Inputs.

The emc-3 is designed to drive PWM controlled fans with up to 3 Amps/Channel

by providing a High Side sourcing 100Hz PWM signal.

A normally low Alarm output notifies the user to check the fan system.

A normally low Reverse output notifies the user that the fans are in reverse.

The emc-3 has the following inputs:

3 thermistor inputs

8 configurable discreet inputs for fan diagnostics

1 discreet Ignition/Enable input

1 discreet Reverse input

1 configurable Fire Input

The emc-3 can be configured either by using the HCT Intella® PLM, or over the

SAE J1939 CAN Bus using configuration messages.

A Status message is available that will transmit all the I/O status as well as

thermistor temperatures and various program states on the SAE J1939 CAN

Bus.

Page 3 of 39

emc-3 Controller Module

User Guide – Rev A

Table of Contents

Introduction ......................................................................................................................... 3

Controller Mechanical information ..................................................................................... 6

Theory of Operation ............................................................................................................ 7

Normal Operation ....................................................................................................... 7

Wiring ......................................................................................................................... 8

Reverse Mode Operation .......................................................................................... 10

Manual Control ......................................................................................................... 11

Auto dB Test Mode ( field noise measurement ) ...................................................... 11

Inputs................................................................................................................................. 12

Command Inputs ....................................................................................................... 12

Diagnostic ( digital ) Inputs ( ALL via 30 way ) ...................................................... 13

Reverse Input ( 30 way / Pin F2 ) ............................................................................. 13

Fire Input ( 30 way / Pin G2 ) ................................................................................... 13

Ignition Input ( 30 way / Pin H2 ) ............................................................................. 13

Outputs ( all via 18 way ) .................................................................................................. 14

Output Bank Settings ................................................................................................ 14

Fan Bank Outputs ..................................................................................................... 14

Fans In Reverse Output ............................................................................................. 14

Check Fan System Output ........................................................................................ 14

Indicators........................................................................................................................... 15

Status LED ................................................................................................................ 15

Module Configuration ....................................................................................................... 16

PLM Configuration ................................................................................................... 16

SAE J1939 CAN Bus Configuration ........................................................................ 16

SAE J1939 CAN Messages .............................................................................................. 17

Appendix A, EE-Memory Configuration Codes .............................................................. 24

Appendix B, Status LED Alarm Codes ............................................................................ 25

Appendix C, Settings and Limits ...................................................................................... 26

Appendix D, Electrical Characteristics ............................................................................. 29

Appendix E, the Program Loader Monitor (PLM) ........................................................... 30

1) Introduction: ............................................................................................................ 30

2) File types & Definitions: ........................................................................................ 30

2) Connecting the PC to the DVC Family: .............................................................. 32

Page 4 of 39

emc-3 Controller Module

User Guide – Rev A

3) Starting the Program Loader Monitor: ................................................................ 33

4) Main Program Loader Monitor Screen: .............................................................. 33

6) Program Loader ..................................................................................................... 34

Frequently Asked Questions: ............................................................................................ 36

emc-3 accessories.............................................................................................................. 36

‘Wet’ Fluid Sensor Information ........................................................................................ 37

‘Dry’ Fluid Sensor Information ........................................................................................ 38

Page 5 of 39

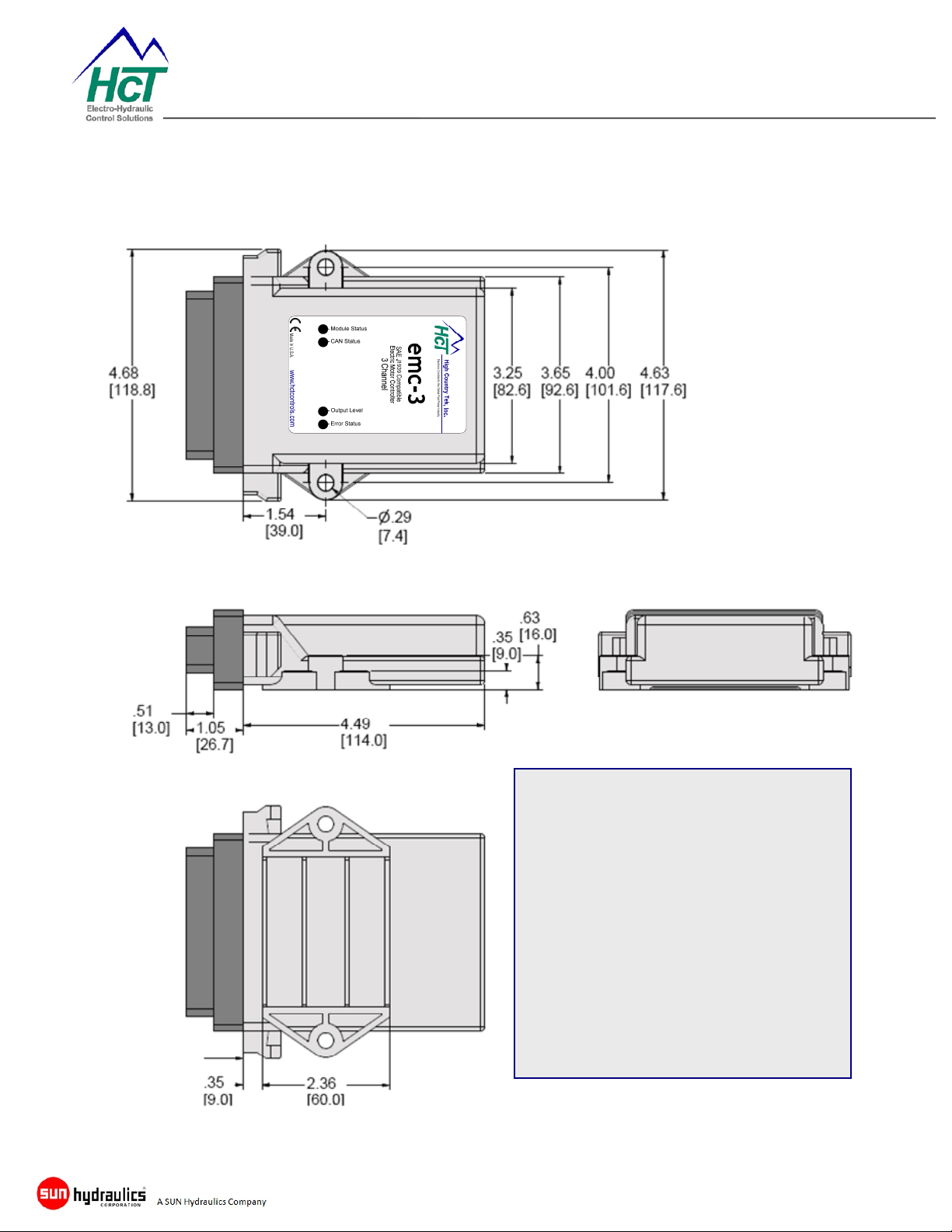

Controller Mechanical information

emc-3 Controller Module

User Guide – Rev A

IMPORTANT NOTE:

Recommended tightening torques for the

securing bolts are as follows:

For a 1/4-20 bolt, SAE Grade 5

DRY Torque: 8 Ft-Lbs

Lubricated Torque: 6.3 Ft-Lbs

Use 0.5” or 12-15mm spaces if mounted to

hot surface 9 i.e. manifold assembly )

Mount with connector facing downwards to

prevent collection of debris and liquids

Page 6 of 39

emc-3 Controller Module

User Guide – Rev A

Theory of Operation

Normal Operation

At Power On, the module will not run the fans until the Startup Delay has expired.

The Startup Delay is set by entering a value into the EE-Memory location

“Startup_Delay_Seconds” using the PLM or SAE J1939 configuration messages.

After the delay the controller will check 2 inputs before enabling the outputs:

The Minimum Engine RPM ( must exceed entered value ).

The Ignition Switch ( must be set to ON/+V to allow operataion).

If the “Engine Minimum RPM” variable is set to 0 in EE-Memory, the emc-3 is

enabled whenever the Ignition Switch is ON (≥ 3.5

If the “Engine Minimum RPM” variable is set to a value greater than 0; if the

Engine RPM read from the EEC1 message is greater than the “Minimum Engine

RPM” set point and the ignition switch is on, the emc-3 is enabled. If the module

detects the Ignition Input as “Off” (≤ 1.5

) while there is a valid Engine RPM

VDC

message detected, the Module will be enabled as required and report an Ignition

Input Error. Fans will continue to run as demanded by the current configuration.

When the emc-3 is enabled, the cooling demand is determined by the values set

in the EE-Memory for each enabled input. Each input’s demand is converted to a

percentage for comparison and the highest demand will control the fan RPM

independently for each Bank.

If the “Bank n Fan Idle Enable” is disabled (0) in the EE-Memory, and the cooling

demand is 0, the fan is set to the “Bank n Off DYCY”. If the “Bank n Fan Idle

Enable” is enabled (> 0) in EE-Memory, that Bank will run at min RPM even

when the cooling demand is 0 as long as the emc-3 is enabled. The minimum

RPM is determined by setting the “Bank n Start DYCY” in EE-Memory.

The “Minimum Fan Cycle Seconds” setting in the EE-Memory determines the

minimum amount of time that the fans must run before stopping, assuming the

fan controller is enabled. For example, if the “Minimum Fan Cycle Seconds”

were set to 20 seconds and a Fan Banks demand rose above 0, the fans on that

Bank would start. Then if the demand dropped back to 0 after 5 seconds, the

fans on that bank would be set to the “Bank n Start DYCY” for the remaining 15

seconds of the “Minimum Fan Cycle Seconds” before shutting off. The “Minimum

Fan Cycle Seconds” has no effect if the “Bank n Fan Idle Enable” is set.

VDC

).

Page 7 of 39

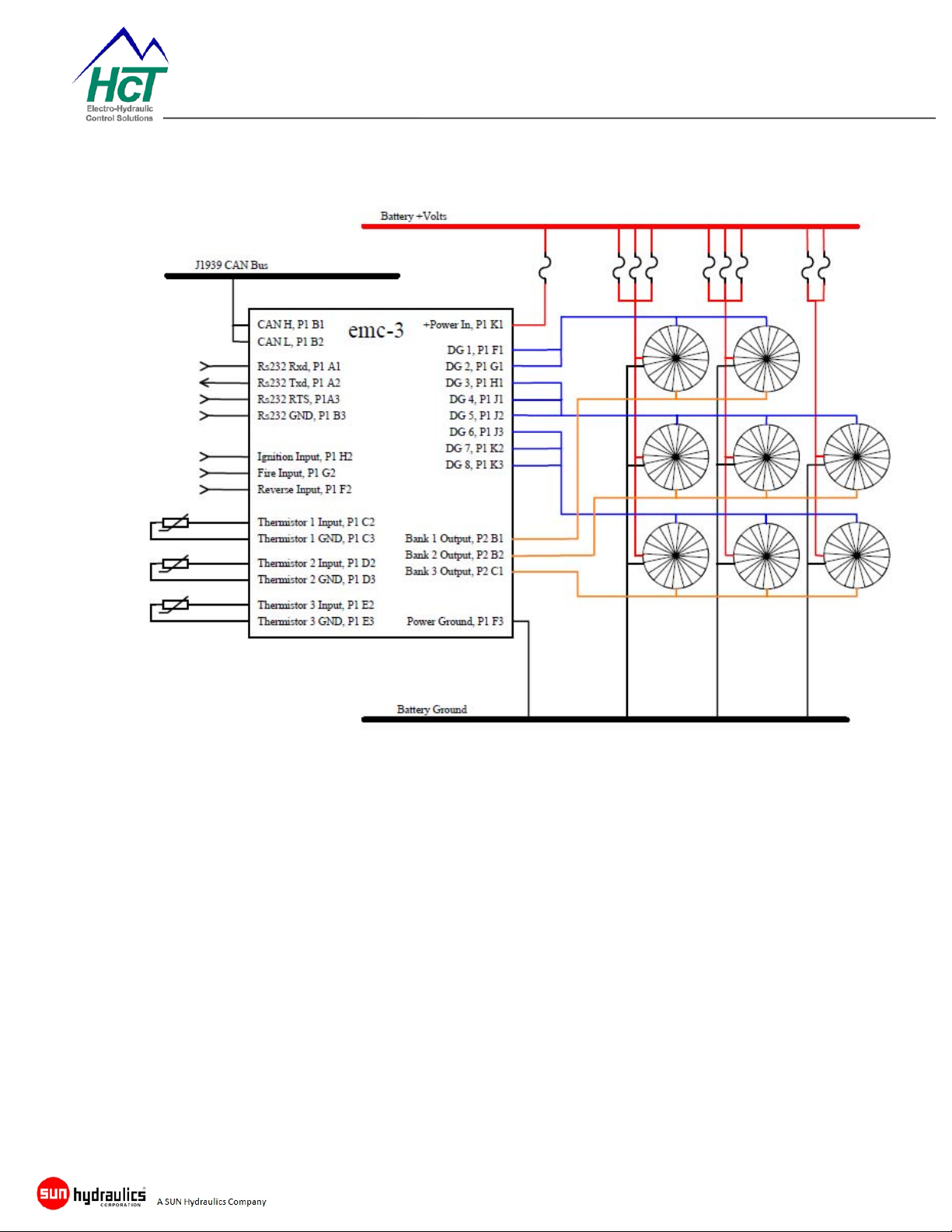

Wiring

emc-3 Controller Module

User Guide – Rev A

Page 8 of 39

emc-3 Controller Module

User Guide – Rev A

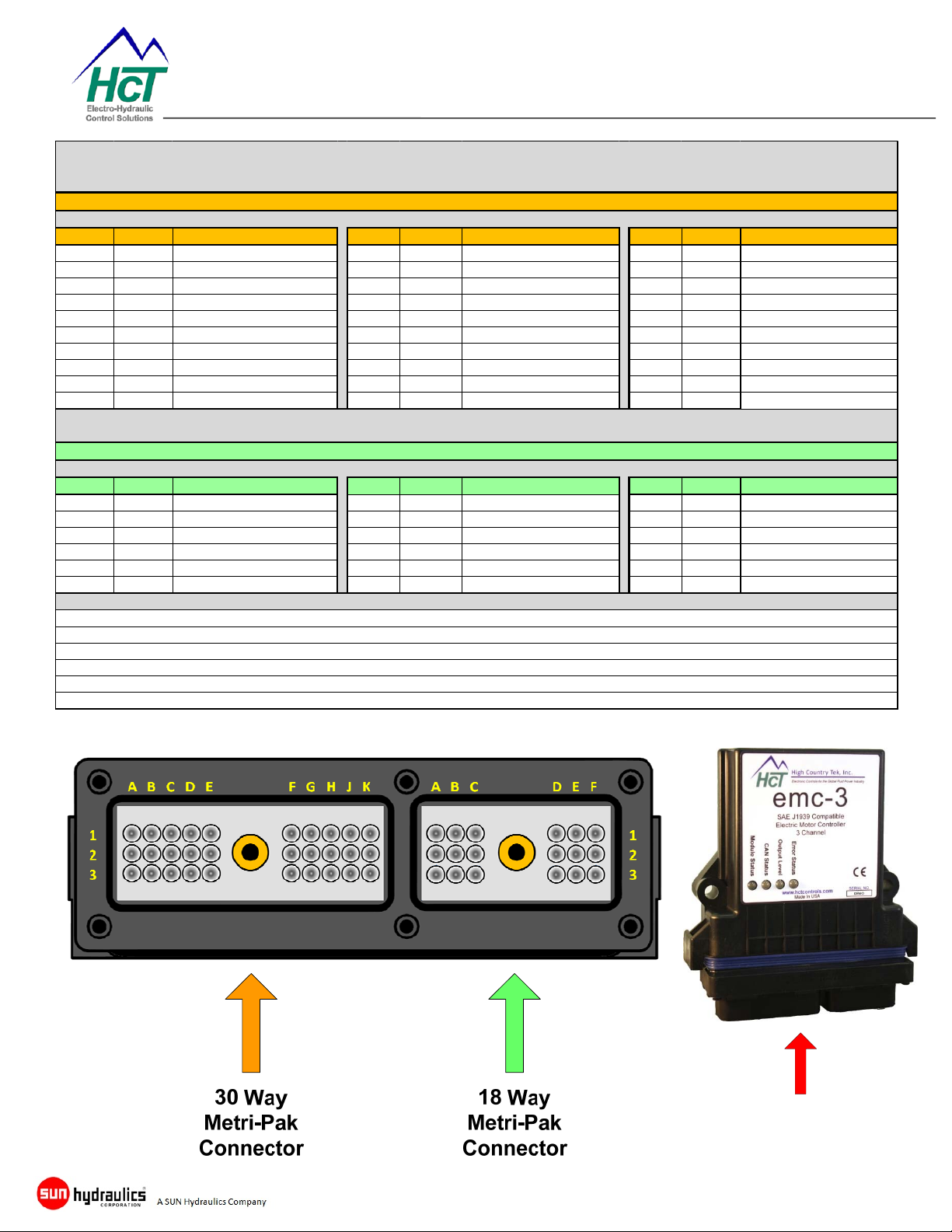

emc‐3ConnectorDesignationTables

30PinMetri‐PakConnector(Male,Plug)

PIN Name Function PIN Name Function PIN Name Function

A1 RXD ReceiveRS232Data‐Pin'A' D2 Uni‐ 2UniversalInput#2 G3 GND Ground/0V/SignalCommon

A2 TXD TransmitRS232Data‐ Pin'C' D3 GND Ground/0V/SignalCommon H1 Dig3 DigitalInput#3

A3 RTS RequestToSend‐RS 232Pin'D' E1 Vref +5Vregulateduseroutput H2 Ana3 Analoginput#3

B1 CAN‐ HCAN#1High E2 Uni‐3UniversalInput#3 H3 GND Ground/0V/SignalCommon

B2 CAN‐ LCAN#1

B3 COM 0V/COMRS232 Data‐Pin'B' F1 DIG‐1 DigitalIn put#1 J2 Dig5 DigitalInput#5

C1 CAN‐HCAN#2High F2 ANA‐1Analoginput#1 J3 Dig6 DigitalInput#6

C2 Uni‐1UniversalInput#1 F3 GND Ground/0V /SignalCommon K1 +Pwr +VSupplyPowerInput

C3 GND Ground/0V/SignalCommon G1 DIG‐2 DigitalInput#2 K2 Dig7 Digital Input#7

D1 CAN‐

PIN Name Function PIN Name Function PIN Name Function

A1 +VPwr +VSupplyPowerI nput C1 PWM‐3PWMOutputtoFanBank#3 E1

A2 +VPwr +VSupplyPowerI nput C2 HS‐4ON/Offoutput E2 NotUse d NotUse d‐

A3 NotUsed No tUse d‐ C3 NotUse d NotUse d‐ E3 NotUsed No tUse d‐

B1 PWM‐1PWMOutputtoFanBank#1 D1 HS‐ 5ON/Offoutput F1

B2 PWM‐2PWMOutputtoFanBank#2 D2 HS‐ 6ON/Offoutput F2

B3 NotUse d NotUse d‐ D3 NotUse d N ot Use d‐ F3

LCAN#2Low G2 ANA‐2Analoginput#2 K3 Dig8 DigitalInput#8

Low E3 GND Ground/0V/SignalCommon J1 Dig4 DigitalInput#4

18PinMetri‐PakConnect or( Male,Plug)

GndforDVC

GndforDVC

GndforDVC

GndforDVC

Ground/0V Common

Ground/0V Common

Ground/0V Common

Ground/0V Common

Notes:

emc‐3isdesignedtodriveupto3separatebanksofelectricfanswithlowcurrectrequirement‐ PWMcommandsignaltype inputs

emc‐3hasthecapabilityofmonitoringupto8individualfansoperationusingthedigitalON/OFFinputsDIG‐1thruDIG‐8

Use rsystemalarm,operationallogicor

safetyinputsshouldusetheanaloginputs1thu3

Connectors Viewed In

This Direction

Page 9 of 39

emc-3 Controller Module

User Guide – Rev A

Reverse Mode Operation

A Reverse Cycle may be initialized either Manually or Automatically.

initiation of a Manual Reverse Cycle is done by momentarily toggling the

Reverse Input at any time that the Ignition Switch is “On”. A Manual Reverse

Cycle Request is considered valid if the Reverse Input pulse is between 500mS

and 3.0S in duration. Pulses of less than 500mS will be ignored. Pulses lasting

longer than 3 seconds will be considered a fault and cancel the Reverse Cycle.

This prevents a shorted switch from holding the fans in reverse.

The Auto Reverse feature will initiate a reverse cycle at a period determined by

the “Auto Reverse Interval Minutes” set point. When set to 0, the Auto Reverse

Feature is disabled. When the “Auto Reverse Interval Minutes” is set, the Auto

Reverse Cycle timer is reset each time an Auto Reverse Cycle is initiated. This

means that each Auto Reverse Cycle is run within the period for the next cycle.

Valid Auto Reverse Intervals are 2 to 500 Minutes (8 hours).

NOTE:

Momentarily toggling the Reverse Input during any active Reverse Cycle will

cancel that Reverse Cycle.

Expiration of the Auto Reverse Interval Timer or toggling the Reverse Input

anytime the System is enabled will cause a reverse cycle. During a Reverse

Cycle, the following sequence takes place;

1. The “Fans in Reverse Output begins flashing at ≈ 1 Hz

2. All the fans freewheel for the period determined by the “Reverse Dwell

Seconds” set point. (all Banks set to “Bank n Off DYCY”)

3.

The Reverse signal is sent to all Fan Banks, “Bank n Reverse DYCY”

All Banks remain in Reverse for the period determined by the “Reverse

4.

Cycle Seconds” Set point.

The “Fans in Reverse Output stops flashing

5.

All fans banks resume normal operation.

6.

Page 10 of 39

emc-3 Controller Module

User Guide – Rev A

Manual Control

To manually control the Fan Banks, set “Manual Control Enable” to a number

greater than 0. Then do any one of the following;

1. Cycle power,

2. Cycle the Ignition Switch or

3. Reduce the engine RPM to less than the “Minimum Engine RPM” set point

in the EE-Memory.

Once the emc-3 has entered Manual Mode, each Banks fan speed is determined

by the “Bank n Manual DYCY” set points in the EE-Memory.

Valid settings are 0% to 100%

Auto dB Test Mode ( field noise measurement )

The Auto dB Test Mode is designed to allow users to test the noise level of the

fan banks without having to control the emc-3 from the PLM or the CAN Bus.

When the Auto dB Test Mode is activated, the Fan Banks will be set to the value

entered in the EE-Memory location “Auto dB Test Percent” for the duration

determined by the “Auto dB Test Time” set point.

To enter the Auto dB Test Mode, set the Reverse Switch to “On” and hold it, then

Cycle Power to the emc-3. When the Status LED on the emc-3 module begins to

blink (Red), release the Reverse Switch. When the test has timed out, the emc-3

resumes normal operation automatically.

Default values are;

Auto dB Test Time – 30 Seconds

Auto dB Test Percent – 70% of maximum fan speed

Page 11 of 39

emc-3 Controller Module

User Guide – Rev A

Inputs

Command Inputs

With only one exception, all command inputs have common settings:

1. Start Temp – The set point at which positive demand is calculated.

2. Max Temp – The set point for 100% demand.

3. Over Temp – The set point at which an error is reported due to over

temperature.

An Input demand is calculated as a percentage of error between the Start and

Max Temp set points.

The Exception to the above is when using the J1939 Percent Requested Fan

Speed (SPN 986) message, as an input at which point the demand for the input

(0% to 100%) is determined directly by the ECM.

Command Inputs are selected by entering their code number in the “Bank n

Control n” EE-Memory locations. Each Bank has 3 controls available for

assignment.

The available Command Inputs used to control the fans and their codes are as

follows;

Description

Code

NOTE:

1 Percent Fan Request from ECM – PGN 57344 or 57599, automatically

detected

Coolant Temp – PGN 65262

2

Manifold Temp – PGN 65270

3

Transmission Oil Temp – PGN 65272

4

Thermistor 1, Delphi HCT PN:206-00083 or 206-00084

5

Thermistor 2, Delphi HCT PN:206-00083 or 206-00084

6

Thermistor 3, Delphi HCT PN:206-00083 or 206-00084

7

1.

Any Input may be used in more than one bank.

2.

Individual J1939 CAN Messages are enabled / disabled by assigning them

to control an output.

Page 12 of 39

Loading...

Loading...