e-Fan Cooling System Controllers

with J1939 Interface

emc-1P & emc-1V

e-Fan Drive - System Controller

User Guide

High Country Tek, Inc. reserves the right to improve this product at any time and without

notice. This manual may contain mistakes and printing errors. The information in this

publication is regularly checked and corrections made in the next issue. Please check

our website or contact our customer support for latest version. HCT accepts NO liability

for technical mistakes or printing errors or their consequences.

Part No:- 021-00351 Rev 1.0 emc-1P & emc-1V e-Fan System Controller User Guide Page 1

e-Fan Cooling System Controllers

with J1939 Interface

High Country Tek, Inc. (HCT) is North America’s foremost independent designer and

producer of modular, ruggedized digital and analog electronic controller products for the fluid power

industry.

From our factory in California, we build, test and produce ‘specialty’ controllers that provide solutions

for specific everyday functions as well as our ‘DVC family’ of fully adaptable user programmable units

that can be integrated together to enable large area networked system solutions.

The modules are typically used in mobile, industrial and marine applications, but are also applied

successfully in several other growing global market segments.

Because High Country Tek has an industry unique non-repairable product protection system, with

every module encapsulated in solid flame resistant material for maximum durability, electrical integrity

and complete environmental security, we have to deliberately select the highest quality components

from our suppliers at all times, ensuring our 100% operating shipped product.

HCT is also a market leader in many application arenas, including hydraulic generator, e-Fan and

hydraulic fan system controls where significant fuel, emission and operational savings can be realized

by using one of the aforementioned specialty units to optimize the applications operation.

HCT’s market neutrality and flexible product configuration approach offers dependable integration

with virtually any hydraulic OEM products for easy, simple and accurate control of valves, pumps,

sub-systems or systems.

Our best-in-class customer service and product reliability is well known and trusted throughout the

fluid power network and we look forward to working with you in the future.

www.Hctcontrols.com

The information in this publication is intended as a guide only, and High Country Tek, Inc. (HCT) takes

NO responsibility for usage and implementation in any user entered values into the provided GUI

structure.

HCT strongly suggests that the user attends one of the product training courses to ensure correct and full

understanding of this information and to learn further optimized methods of control techniques.

Please contact HCT customer service to book one of the scheduled training dates or to di scuss arranging

a course specific to your company needs.

Thank you for using High Country Tek Inc. Products.

Part No:- 021-00351 Rev 1.0 emc-1P & emc-1V e-Fan System Controller User Guide Page 2

e-Fan Cooling System Controllers

with J1939 Interface

TableofContents

Welcome ....................................................................................................................... 4

Introduction .................................................................................................................. 4

Cautions ....................................................................................................................... 4

Warranty Information .................................................................................................. 4

Controller Updates: ..................................................................................................... 4

’emc-1P & emc-1V’ e-Fan System Controller ............................................................ 5

Product Overview ........................................................................................................ 6

Product Application Guidelines ................................................................................. 7

Software Safety ............................................................................................................ 7

emc-1P & emc-1v Electrical Specification Overview ................................................ 8

emc-1P Module Familiarity ......................................................................................... 9

emc-1P Connection Information ............................................................................... 10

emc-1V Module Familiarity ....................................................................................... 11

emc-1V Connection Information ............................................................................... 12

Error LED Code Descriptions for emc-1P & emc-1V .............................................. 13

Module Connection Descriptions ............................................................................. 14

Serial Communications ............................................................................................. 16

Loading the emc-1P or emc-1V GUI onto Host PC ................................................. 17

System Requirements ............................................................................................... 17

Controller adjustments and Monitor ........................................................................ 18

GUI Menu Options ................................................................................................................... 18

Password Protection ................................................................................................................ 19

Help ......................................................................................................................................... 20

GUI software – Main screen (Dashboard) ............................................................................... 21

Data Logging ........................................................................................................................... 22

General Settings ...................................................................................................................... 23

Unit Settings ............................................................................................................................ 23

Output Settings ........................................................................................................................ 24

Auto Reverse Settings ............................................................................................................. 24

Input Settings ........................................................................................................................... 25

Error Information Log ............................................................................................................... 27

Factory Information .................................................................................................................. 28

Temperature Sensor Information ............................................................................. 29

Main I/O connector & Accessories ........................................................................... 29

On Site Testing .......................................................................................................... 30

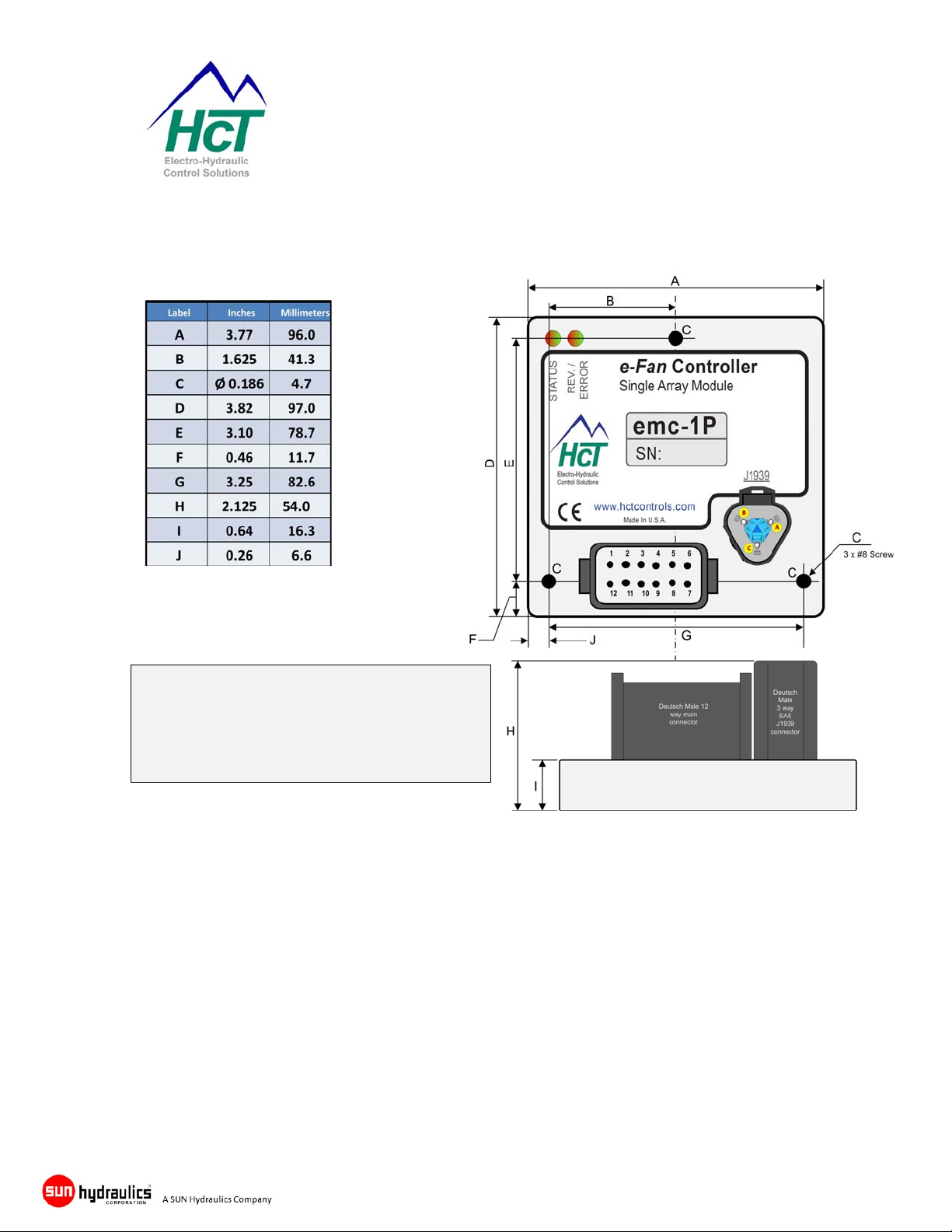

emc-1P & emc-1V Dimensional Information ............................................................ 32

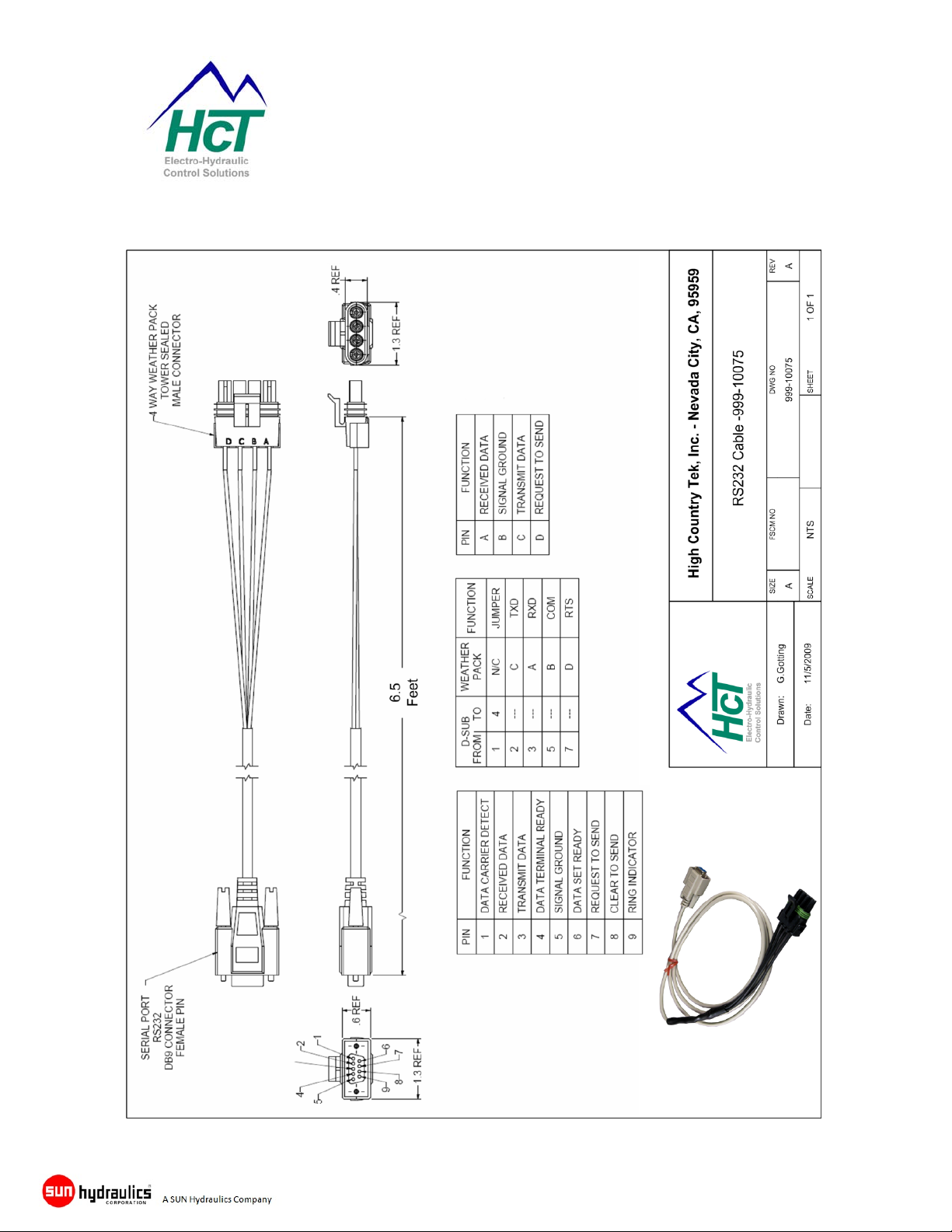

RS232 Communication Cable ................................................................................... 33

Part No:- 021-00351 Rev 1.0 emc-1P & emc-1V e-Fan System Controller User Guide Page 3

e-Fan Cooling System Controllers

with J1939 Interface

Welcome

Welcome to the High Country Tek Inc. (HCT) e-Fan cooling systems controller user guide, and thank you

for selecting this HCT controller to use in your application

The following information is designed to allow you to connect, set-up and optimize the emc-1P and emc1V modules.

If you have used HCT products before, you will recognize some of the instructions and settings. For those

of you that are new to HCT, please read the directions with care and be sure that if you have any

questions regarding this industry unique controller, then please contact us using one of the numbers

given on the back page of this manual.

We value our customers, their experience and abilities and ask that if you would like to see any additions,

subtractions or find any errors in this publication, that you contact HCT’s customer service so that we can

correct the information and make sure that our programming community is using the latest information.

If you require urgent support, more information or would like specific programming areas clarified, you can

contact us on the customer support number at 1 530 265 3236 or E-mail us through our website at

www.hctcontrols.com

, giving details of your issue and how we can contact you.

Introduction

This manual is designed to provide information needed for the installation and use of the emc-1P & emc1V e-Fan Cooling System Controllers. Its intended user is qualified trained service personnel that

understand the hazards involved in an electromechanical environment. It is recommended that this

manual be read in its entirety before installation is begun with particular attention paid to caution and

safety information.

Cautions

Changing setup values and limits under computer control while the machine is operating may cause

sudden machine movement, which may lead to possible injury or death. It is strongly recommended that

any moving parts are disabled prior to any alignment procedure whenever possible. In any case, caution

should be exercised during any procedure and work should be completed only by qualified trained

personnel.

Warranty Information

High Country Tek Guarantees this product to be free of defects in materials and workmanship for a period

of one year extending from the date the unit was shipped from the factory. Within this time frame, High

Country Tek will provide evaluation of warranted items free of charge. Warranty repair or replacement will

be at the factory’s discretion. If necessary, contact the factory for return authorization by phone (530)

265-3236, Fax (530) 265-3275, E-Mail info@hctcontrols.com

High Country Tek, Service Dept., 208 Gold Flat Court, Nevada City, CA 95959. To help us serve you

better, please have the units full Model / Part Number and Serial Number available when contacting the

factory for any reason. Do not return products to the factory without prior authorization and a RMA

number attached.

or by writing our service department at,

Controller Updates:

HCT continuously improve the controllers and make additional information and/or features available.

Please check on-line at www.hctcontrols.com

controller information.

for the latest products, updated software and

Part No:- 021-00351 Rev 1.0 emc-1P & emc-1V e-Fan System Controller User Guide Page 4

e-Fan Cooling System Controllers

with J1939 Interface

’emc-1P & emc-1V’ e-Fan System Controller

The emc-1P and emc-1V are the latest additions to the High Country Tek (HCT) family of e-Fan control

modules. These highly cost effective controllers have all the features and input output functionality that

will support a wide range and configuration of e-Fan system applications. As with all of the HCT modules,

the controller is packaged in a small rugged enclosure and encapsulated in flame resistant resin to

withstand extreme conditions in the harsh mobile operating environment.

The modules are ideally suited for today’s OEM, distributor or system builder, with both mechanical and

electrical robustness paramount in the design priority, Windows™ compatible easy to use set-up software

and full CE compliance means this one product can be used across multiple platforms, markets and

applications. This unit’s cost effectiveness will become quickly apparent through the reduction in

inventory costs and stocking needs as well as in the engineering time taken usually associated with the

design to delivery cycle.

Programming of the controller parameters and all diagnostics is done through the RS232 connector

pendant. This is a separate connector from the main or SAE J1939 connector ( as fitted on the emc-1P )

so that optimization or operational observation can be carried out without disturbing the cooling system

operation. When programming, changes or observation of the module function is required, connection

can be made through a standard computer serial connection, either directly via a 9 way ‘D’ type connector

or through an HCT approved USB to serial converter. In all cases, the HCT programming interface cable

(Part No: 999 – 10075, RS232 programming cable) is required for communication from the controller to a

Windows™ based PC.

The controller is designed to make the fan system set-up easy to configure and control. The hardware

contains the framework software where the parameters can be changed depending on the user’s needs

via the PC graphical user interface (GUI).

The GUI has been organized into various user screens that are logical and simple to understand.

Terminology has been used that is commonplace through the mechanical, hydraulic, mobile and electric

fan drive industry to allow easy configuration, set-up and running and is intended to cater for a wide range

of users with varying levels of computer familiarity.

This controller is ideally suited to equipment upgrades as well as installation by OEM’s at machine build

time and offers all the necessary features required by today’s modern engines that use the J1939

communications standard.

The controller will take information directly from the J1939 bus for the common temperatures broadcast

such as Engine Coolant, Charge air and Transmission Oil Temperature making system integration very

quick and easy. Engine RPM is also monitored by the module giving the user an option to control the

engine load during the engine start cycle. (minimum RPM setting) Additional external inputs ( 1x emc-1P

& 2x emc-1V ) from Thermistors may be used to monitor non SAE J1939 temperatures and effect the fan

operation.

The emc-1P & emc-1V products are backed by High Country Tek’s industry leading product reliability,

easy to use software design and market leading customer service and technical support as well as ontime delivery while the well designed and intuitive graphical user Interface (GUI), allows you to program

multiple configurable modes of operation available within the one module.

Part No:- 021-00351 Rev 1.0 emc-1P & emc-1V e-Fan System Controller User Guide Page 5

e-Fan Cooling System Controllers

with J1939 Interface

Product Overview

NO software experience needed to apply this controller successfully.

Pre-written ‘e-Fan Drive’ software for easy, fast system configuration, development and production.

Intuitive Graphical User Interface (GUI) runs on any PC with Windows® XP or newer software (.net

compatible).

9 – 32VDC operation with full reverse polarity and SAE J1455 protection.

CE approved to latest international test standards.

J1939 CAN Bus communications for engine and temperature zone data Inputs

**J1939 temperature data hard coded for:

SPN 109, Engine Coolant Temperature; PGN 65262,

SPN 177, Transmission Oil Temperature; PGN 65272

SPN 105, Engine Intake Manifold 1 Temperature; PGN 65270

Extended -40ºC (-40ºF) to +85ºC (+185ºF) controller operational temperature range.

All inputs and outputs are protected from shorting to ground or the power supply.

Diagnostic LEDs display I/O status and module operation at a glance.

‘Blinking’ error codes for fast on-site ‘health check’.

System wiring and coil fault detection alarms.

Configurable Alarm output for integration into host system.

IP68 (NEMA 6P) rating on module for harsh environment reliability.

Deutsch IP69K connectors for reliable and easy system wiring.

Separate RS232 communications connector for programming, monitoring and diagnostics.

Rugged encapsulated product withstands harsh environments found in mobile applications.

Non Volatile Memory maintains ALL settings without power

Completely user configurable and settings are password protected.

**J1939 PGN Address Note**

If the standard SAE J1939 PGN address for Temperatures or RPM is NOT compatible for a

particular application, HCT can change the PGN numbers as needed and re-issue personalized

program code to you. Please use the contact numbers on the back page of this manual to discuss

this with our customer support personnel.

Part No:- 021-00351 Rev 1.0 emc-1P & emc-1V e-Fan System Controller User Guide Page 6

e-Fan Cooling System Controllers

with J1939 Interface

Product Application Guidelines

ALWAYS do the following

Take a few minutes to FULLY read this manual and accompanying data sheets BEFORE starting.

Keep High Voltage AC cables separate from Low Voltage DC signal and supply cables.

Make sure the unit output voltage is compatible with the equipment being driven!

Ensure that you are aware of the adjustments and consequences for the external equipment.

Make sure you have the correct tools to do the intended job (i.e. P.C., software) etc.

‘Isolate’ this unit from all other equipment BEFORE any form of welding takes place.

Check ALL wire connections to ensure there are no unintended SHORT or OPEN circuits.

Check that the units supply voltage is CORRECT, ‘ELECTRICALLY CLEAN’ and STABLE.

Operate the units within specified operating temperature for the best and most reliable performance.

Ensure that any unused wires / terminals are terminated safely and not shorted together.

Isolate the controller if ANY form of battery charging or battery boosting takes place on the vehicle.

Ensure ALL connectors are wired correctly, secure, locked and connected.

Observe all the set-up procedures in this manual for best operational results.

Follow and abide by local and country health & safety standards – protect yourself and others!

NEVER do the following

Arc Weld or Charge Batteries with this driver unit connected as damage can occur.

Attempt to use this unit if you are unsure of electrical OR mechanical connections or expected operation.

Use a power supply that is not rated for the correct required O/P current under full load.

Allow wires TO or FROM the unit to short circuit (to each other or chassis/cabinet etc).

Attempt to use this unit in areas of intense RF fields without adequate screening measures.

Disconnect or connect wires to or from this unit unless it isolated from the power supply.

Use this unit in temperatures that exceed those specified as operation may be effected.

Start this unit without ensuring ALL work areas are clear of personnel!

Software Safety

The software has been carefully written to give the user the maximum system configuration

flexibility while being transparent in operation and easy to use, even for novice system builders and

operators.

To ensure safety when using the software and to prevent accidental connection to another module

that is not an emc-1P or emc-1V, rules have been written into the software to ensure correct

operation at all times. After program entries, cycle power, to ensure changes are accepted by

the unit.

When the PC running the GUI is first connected to a powered controller, and before any data

exchange can be allowed, a ‘Handshake’ takes place that confirms the internal software (BIOS) is

compatible with the GUI software and only then allows the PC and the module to communicate and

share data.

If at any point during the process above an error or miss-match is detected, or loss of

communication, the GUI software will indicate “OFF LINE” and NOT allow communications until the

problem is corrected.

Part No:- 021-00351 Rev 1.0 emc-1P & emc-1V e-Fan System Controller User Guide Page 7

e-Fan Cooling System Controllers

with J1939 Interface

emc-1P & emc-1v Electrical Specification Overview

Board Style ...................................................... High Country Tek unique size and mounting

Connector Type (Main) ................................... 12 way male Deutsch IP69K rated

Connector SAE J1939 ..................................... 3 way male Deutsch IP69K rated

Communication I/O connector RS232 ............ 4 way Packard MALE (Tower) connector on 6 inch Cable

Communication Type ...................................... Serial data at 57.6K Baud through PC USB/Serial port

Input Supply Voltage ....................................... 9 – 32VDC (absolute maximums)

Input supply current ......................................... ~200mA quiescent + valve currents

Input supply protection SAE J 1455 & User supplied inline

fuse (AGC5 or compatible)

Command Input type Main .............................. SAE J1939 digital date OR

Command type additional - emc-1P ................ 1 x external discrete Thermistor

Command type additional - emc-1V ................ 2 x external discrete Thermistor

Thermistor types ............................................. 2 wire Resistance variety only (see page 29)

Proportional Output Type / Range

emc-1P .................................................... PWM / 33Hz to 500Hz, 0% – 100% Duty Cycle, 0 – 3000mA

emc-1V .................................................... Voltage, 0 – 5 VDC / 0 – 50mA ( short circuit protected )

Alarm Output Type / Range ............................ Discreet Active Low or High / 0 – 3000mA

Alarm Output Protection .................................. Short protection to power and ground

‘Reverse’ input signal range ............................ +5VDC to +V module supply momentary = ON

‘Reverse’ input signal impedance ................... 20K Ohm to ground

‘Fire Event’ input signal range ......................... +5V to +V module supply Fans turn OFF

(0V normal Fan operation)

‘Fire Event’ input signal impedance ................ 100K Ohm

‘Ignition’ input signal range .............................. +5VDC to +V module supply = ON

‘Ignition’ input signal impedance ..................... 20K Ohm to ground

Digital Input De-Bounce (Hold Time) .............. 150mS (triggered on rising edge)

Reverse Indicator output Type / Range .......... Discreet Active High / 0 – 3000mA

Reverse Output Protection .............................. Short protection to power and ground

Industry Compliant .......................................... CE certification to latest standards

SAE J1455 Load Dump

Environmental ................................................. Totally encapsulated unit for mechanical protection

IP rating ........................................................... IP 69K

NEMA rating .................................................... 6P

Humidity .......................................................... 95 – 100% Non-condensing

Storage Temp range ....................................... -60 to + 90°C

Operating temp range ..................................... -40 to + 85°C

Note:

ALL controller and system response adjustments are made through graphical user interface software.

See‘emc-1P & emc-1V Software’ section in this manual for full details.

Part No:- 021-00351 Rev 1.0 emc-1P & emc-1V e-Fan System Controller User Guide Page 8

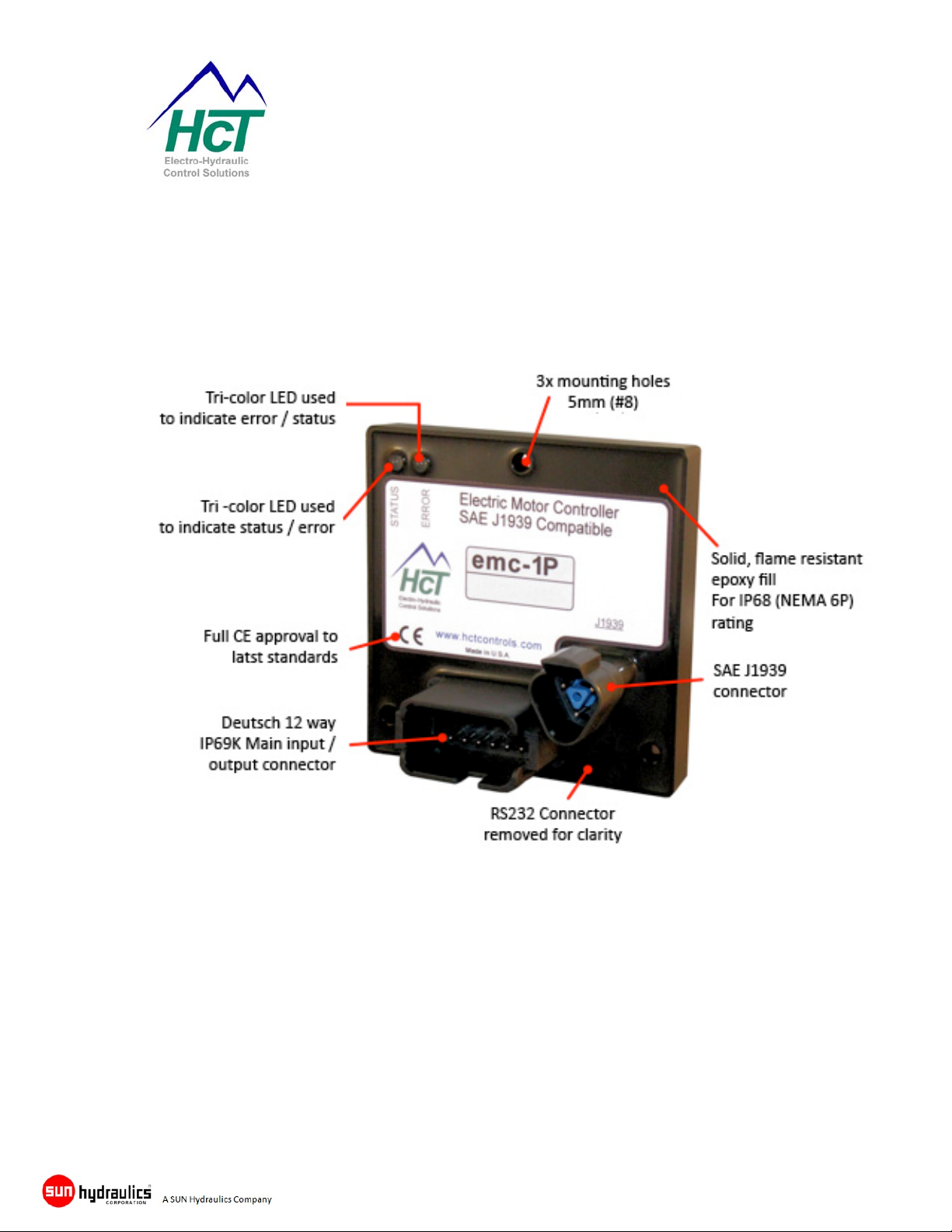

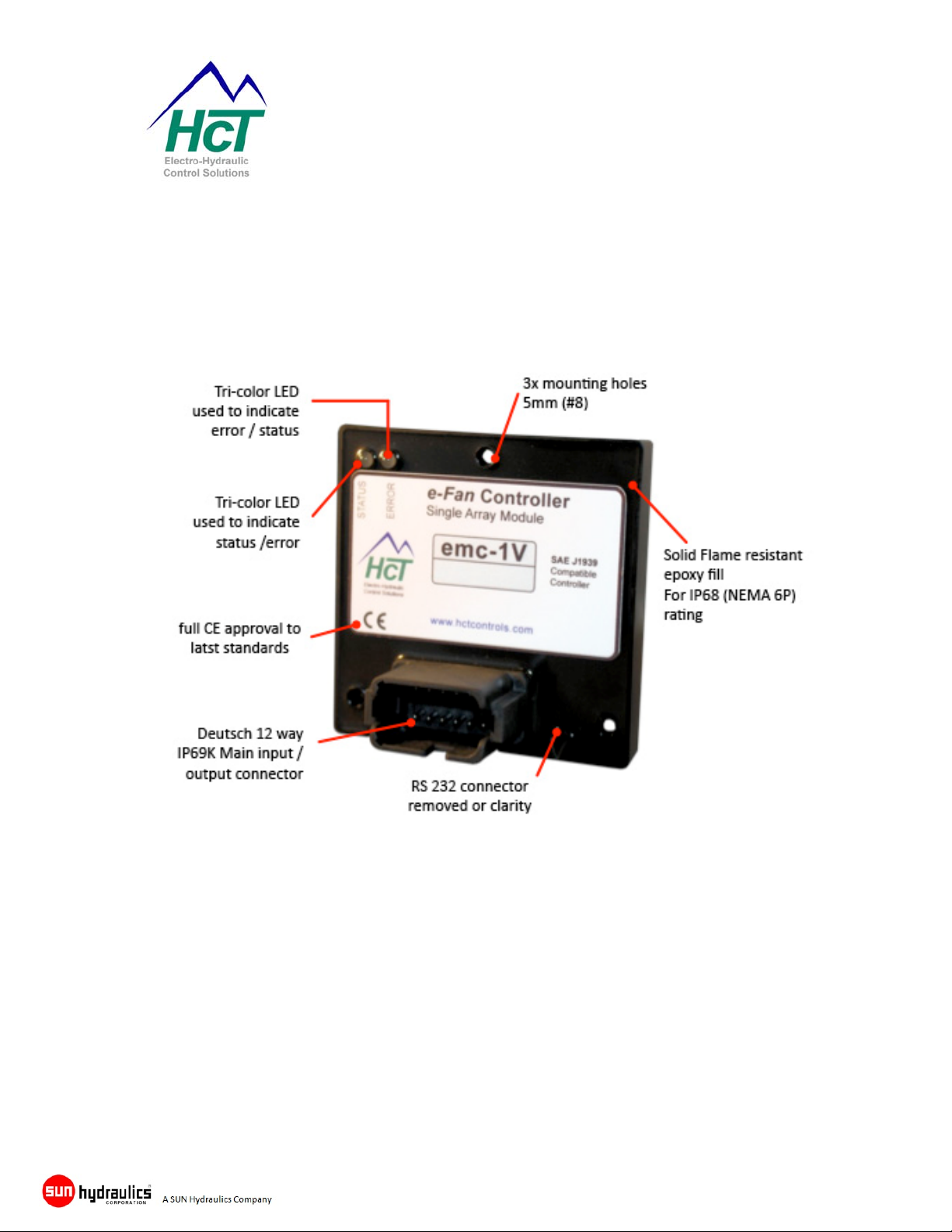

emc-1P Module Familiarity

e-Fan Cooling System Controllers

with J1939 Interface

Part No:- 021-00351 Rev 1.0 emc-1P & emc-1V e-Fan System Controller User Guide Page 9

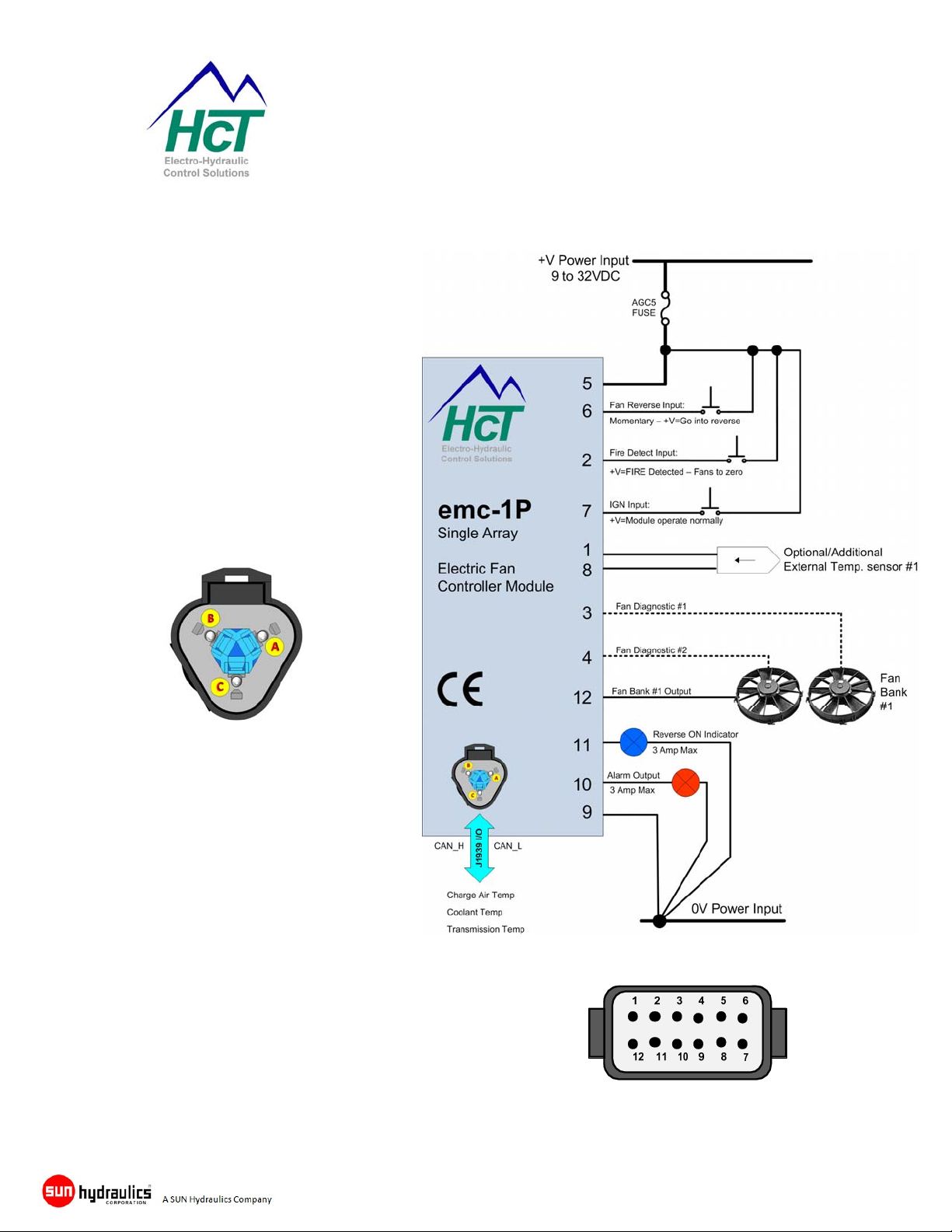

emc-1P Connection Information

NOTE:ControllerMUSThavein‐linefuse

fittedby

userinthe+VPowerInputforsystem

protection.

SAE J1939 Connections

Pin A CAN_Hi (SAE J1939)

Pin B CAN_Low (SAE J1939)

Pin C No connection

Pin 1 ................. Sensor #1 +signal input

Pin 2 ................. Fire detect input

Pin 3 ................. Fan #1 Diagnostic input

Pin 4 ................. Fan #2 Diagnostic input

Pin 5 ................. +Volts 9-32VDC input

Pin 6 ................. Reverse fan input (momentary)

Pin 7 ................. Ignition ON input

Pin 8 ................. Sensor #1 common

Pin 9 ................. Power supply return (GND)

Pin 10 ............... Alarm output (3A max sourcing)

Pin 11 ............... Reverse output (3A max sourcing)

Pin 12 ............... 0-100% PWM e-fan output

e-Fan Cooling System Controllers

with J1939 Interface

Part No:- 021-00351 Rev 1.0 emc-1P & emc-1V e-Fan System Controller User Guide Page 10

emc-1V Module Familiarity

e-Fan Cooling System Controllers

with J1939 Interface

Part No:- 021-00351 Rev 1.0 emc-1P & emc-1V e-Fan System Controller User Guide Page 11

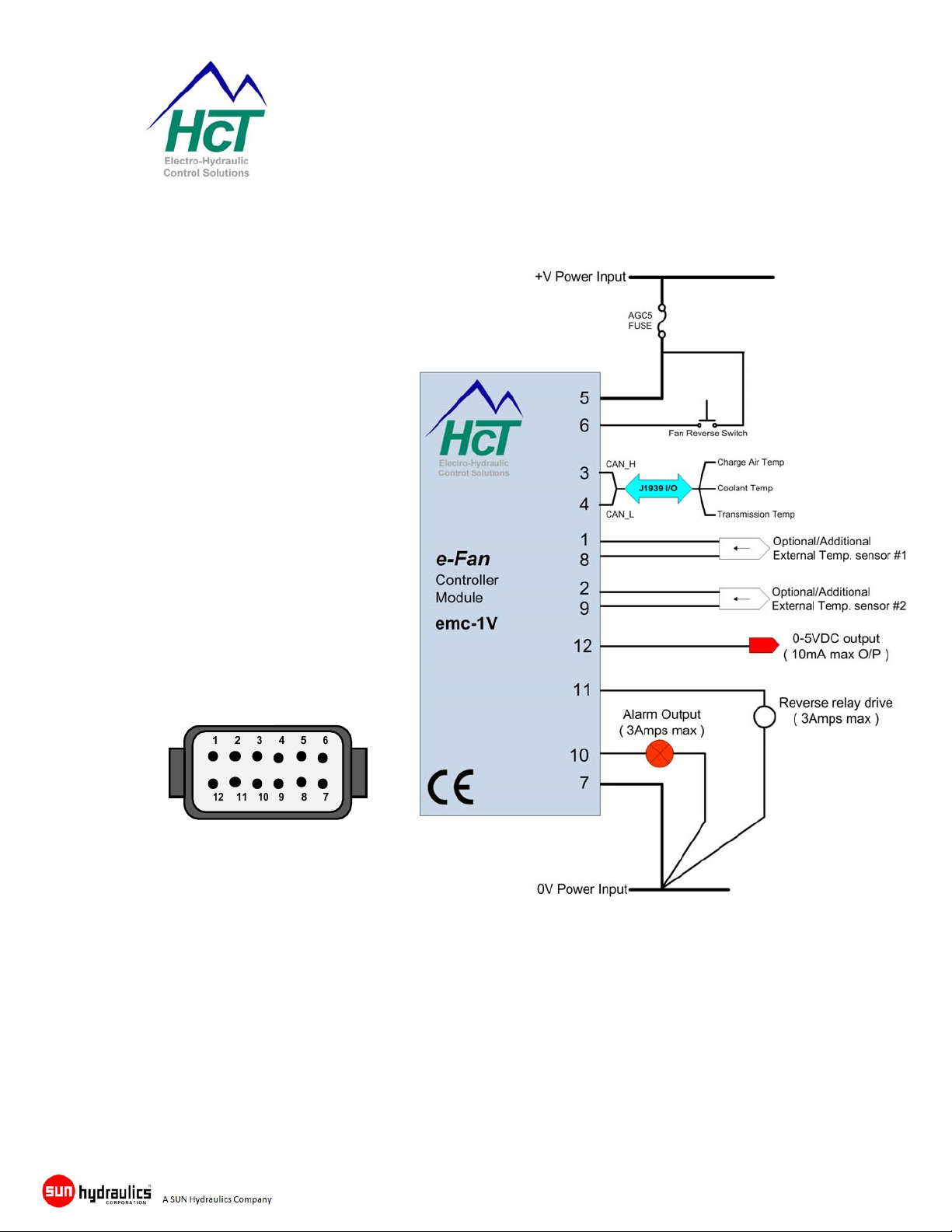

emc-1V Connection Information

NOTE:ControllerMUSThavein‐linefusefittedby

userinthe+VPowerInputforsystemprotection.

Pin 1 ....................... Sensor #1 +signal input

Pin 2 ....................... Sensor #2 +signal input

Pin 3 ....................... SAE J1939 HI input

Pin 4 ....................... SAE J1939 Low input

Pin 5 ....................... +Volts 9 to 32VDC power supply input

Pin 6 ....................... Reverse fan input (momentary)

Pin 7 ....................... Power supply return (GND)

Pin 8 ....................... Sensor #1 signal common

Pin 9 ....................... Sensor #2 signal common

Pin 10 ..................... Alarm out (3A max sourcing)

Pin 11 ..................... reverse out (3A max sourcing)

Pin 12 ..................... 0-5VDC e-fan out (10mA)

e-Fan Cooling System Controllers

with J1939 Interface

Part No:- 021-00351 Rev 1.0 emc-1P & emc-1V e-Fan System Controller User Guide Page 12

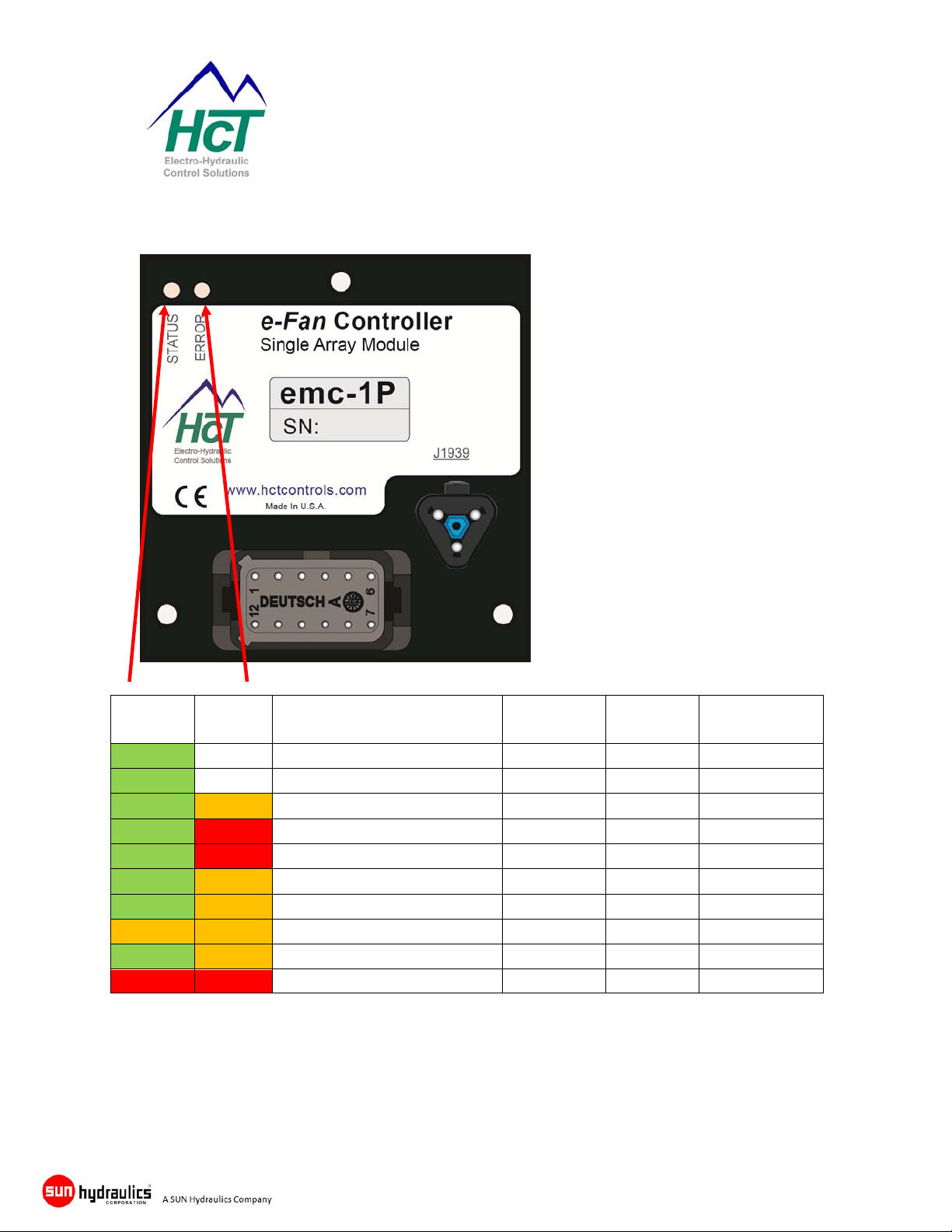

e-Fan Cooling System Controllers

Error LED Code Descriptions for emc-1P & emc-1V

Status

Led

Static off

Flashing off

Static Static

Static Static

Static Flashing

Static Flashing

Static Flashing

Static Static

Flashing Flashing

Static Static

Note:*Fireinputisavailableontheemc‐1Ponly.

Error

LED

NormalOperation

ReverseCycle

FireInputon

Thermistoropen/short

FanDiag.Error

Alarmoutshort

Reverseoutshort

CanmessageTimeout

Coolingsystemover‐temp

Moduleovertemp

Description

AlarmOut FanOut

off normal normal

off revcycle cycleOn

on off off

on maximum normal

on retry normal

off normal normal

on normal off

on maximum normal

on maximum manualonly

on normal normal

with J1939 Interface

Reverse

operation

Part No:- 021-00351 Rev 1.0 emc-1P & emc-1V e-Fan System Controller User Guide Page 13

e-Fan Cooling System Controllers

with J1939 Interface

Module Connection Descriptions

Sensor #1 Input (emc-1P & emc-1V)

This input is designed to allow non SAE J1939 connected zones to be measured if required. The input

accepts a standard NTC thermistor. This input should be referenced to the Signal Ground (0V) on the

connector. The GUI is used to select / de-select and set-up the signal from this additional input and how it

effects the fan speed control. Note: Use Pin 8 for signal ground as the reference for temperature sensor

#1.

Sensor #2 Input (emc-1V only)

This input is designed to allow non SAE J1939 connected zones to be measured if required. The input

accepts a standard NTC thermistor. This input should be referenced to the Signal Ground (0V) on the

connector. The GUI is used to select / de-select and set-up the signal from this additional input and how it

effects the fan speed control. Note: Use Pin 9 for signal ground as the reference for temperature sensor

#2.

SAE J1939 High

This is the High side of the J1939 CAN Bus communication port. The cable used should be suitable for

this type of data connection. Reference, SAE J1939/01 3.1.8, J1939/11 and J1939/31, Please observe

proper Bus protocol including correct termination.

NOTE: The emc1P & emc-1V DO NOT have terminating resistors fitted – these must be system

supplied by others.

SAE J1939 Low

This is the Low side of the J1939 CAN Bus communication port. The cable used should be suitable for

this type of data connection. Reference, SAE J1939/01 3.1.8, J1939/11 and J1939/31, Please observe

proper Bus protocol including correct termination.

NOTE: The emc1P & emc-1V DO NOT have terminating resistors fitted – these must be system

supplied by others.

Power Supply Input

This terminal is the Main +Supply Voltage input on the controller. To provide the best possible noise

resistance and current capability, this input should be taken directly to battery Positive or the power

supply +V output using a large current capacity cable. An ACG 5, ATO 5 or compatible fuse should be

installed as close as practical to the originating power source.

Range – 9 to +32VDC

Note: Failure to install a proper fuse in-line with the controller will void the

warranty.

Part No:- 021-00351 Rev 1.0 emc-1P & emc-1V e-Fan System Controller User Guide Page 14

e-Fan Cooling System Controllers

with J1939 Interface

Fan Reverse Switch Input (Momentary contact)

This is a momentary signal input and only required that the input be pulled to +5V or Supply Power

Supply for approx. 500mS to initiate the reverse sequence settings, this input is debounced in the module

software to avoid false triggers.

This input may normally be referenced to chassis ground

Fire Detect Input: (emc-1P only)

Signal input must be pulled to +5V or Supply Power by the fire event. This will turn OFF the Fans.

This is not latched and will return to normal operation when off. (0V)

Connect to PWR common 0V (GND) if not used.

Ignition Input

Ignition input must be pulled to +5V or Supply Power to enable operation.

This is not latched, emc-1 will not be enabled when off.

Power Ground Input, (0V)

This terminal is the Main Power Ground or Power Common (0V) input on the controller. To provide the

best possible noise resistance and current capability, this input should be taken directly to battery

Negative or the power supply 0V (GND) output using a large current capacity cable. DO NOT use a

connection to chassis or false operation may occur.

Alarm Output

This output can SOURCE up to 3 amps at supply voltage and can be used to connect to an audio device

or light indicator to show the systems alarm condition. This output can be set active High, or active Low.

Output is reverse polarity and short circuit protected.

Reverse Indicator Output

This output can SOURCE up to 3 amps at supply voltage and can be used to connect to an indicator or

alarm to show reverse status. This is a normally OFF, output will go to supply voltage when energized.

Output is reverse polarity and short circuit protected.

NOTE:

The Alarm and Reverse Outputs, will source a small amount of current when OFF. The

currentavailableat32voltswouldbe~500uAand~200uAat12Volts.Thissmallamountof

currentshouldbeconsideredwhendrivinghighimpedanceinputsorhighefficiencyLEDs.

Proportional Output; The function of this pin is dependent on the model in use.

emc-1P

This is a proportional Pulse Width Modulation (PWM) output that vary between 0 to 100% and can source

up to 100mA and is intended to drive the command input of a ‘Smart’ electric fan that requires a low level

PWM input for control. The PWM frequency is adjustable from 33 to 500Hz through the GUI. This output

is reverse polarity, short and open circuit protected.

emc-1V

This is a proportional 0 to 5 Volt DC output that is capable of driving up to 10mA (or loads up to 100Ω)

and is intended to drive the command input typically seen on VFD converters. This output is reverse

polarity, short and open circuit protected.

Part No:- 021-00351 Rev 1.0 emc-1P & emc-1V e-Fan System Controller User Guide Page 15

e-Fan Cooling System Controllers

with J1939 Interface

Serial Communications

Controller monitoring, health checks, diagnostics and set-up can be accessed through the supplied GUI.

This program will operate on PC using a Windows® based operating system and is password protected

to maintain module parameter integrity by only allowing authorized users to access different levels of the

controller settings.

The interface is designed to be simple to use and follows the familiar Windows® menu format with drop

down option screens to select the various options available at the user level allowed.

Explanations of the screens are covered in detail, later in this guide.

Once the PC has been connected to a ‘live’ controller, and the GUI program started, a free

communications port will be allocated and communication with the GUI will begin.

Users running a computer without a 9 pin serial port MUST use one of the following approved

RS232/USB adaptors:

Manufacturer HCTPartNumber Notes

CommFront 108-00119

After communications have been established, the user will be presented with the initial information screen

that will give all the basic information needed to assess the health of the system.

Real time graphing is available to monitor a wide range of items (selectable from a drop down list) and for

remote diagnostics, a ‘Data Log’ button will start a Windows CSV file that can be used as a monitor for

comparison to other logged charts during the system’s life or can be E-mailed to an engineering source

for interpretation of system efficiency.

Passwords protect the settings of the module at all times and are needed to make any changes to the

operational parameters.

RS232 Serial Connection Cable: Part No- 999-10075 (see page 33 of this manual)

NOTE: The 4-pin shroud Weatherpack connector from the

controller has MALE pins, therefore the mating cable

needs to terminate in a Tower Weatherpack connector with

FEMALE pins.

CE certified

RoHS compliant

Part No:- 021-00351 Rev 1.0 emc-1P & emc-1V e-Fan System Controller User Guide Page 16

e-Fan Cooling System Controllers

with J1939 Interface

Loading the emc-1P or emc-1V GUI onto Host PC

Both controllers are set-up via a common GUI interface for ease of use.

GUI P/N: 023-00264

The PC Graphical User Interface (GUI) is a self-extracting and installing program that will reside on the

chosen host PC hard drive. It is recommended that the user allow the defaults to be used for easy future

update installation, but the option is given to allow the user to choose where the program should be

located.

It is NOT recommended that this program be run from a network as it needs access to certain files

available only in the Windows directories.

To start the installation process, insert the CD ROM or if this does not work, search for the “setup.exe”

Application and ‘run’.

System Requirements

Windows XP, Vista or Windows7

256MB or greater

Serial Port RS232 or USB Adapter

RS232 Serial Cable PN: 999-10075

Part No:- 021-00351 Rev 1.0 emc-1P & emc-1V e-Fan System Controller User Guide Page 17

Controller adjustments and Monitor

e-Fan Cooling System Controllers

with J1939 Interface

After program entries cycle power to ensure changes are accepted by the unit.

GUI Menu Options

File

-> Read file or Save File

The user has two simple options available:

1) Read settings from file.

This option allows the user to search for and find preciously saved settings files (*.DAT) and to load them

into a new controller or to reset a controller to a previous version e.t.c.

2) Save settings to file.

This option allows the user to save the current settings displayed on the GUI while connected to a

controller to a file name and destination of choice for retrieval at a later time.

These *.DAT files may also be E-mailed if required to other users to duplicate settings that may have

been optimized or changed.

Part No:- 021-00351 Rev 1.0 emc-1P & emc-1V e-Fan System Controller User Guide Page 18

-> Find Controller

e-Fan Cooling System Controllers

with J1939 Interface

Will search the com ports, find the controller, and read settings. Helpful if you have lost communication

and or want to do a clean read.

Password Protection

Enter Password

Password entry is started by clicking the ‘Password’ option in the top bar of the GUI screen.

This will open a box to enter the passwords.

Level 0) - NO Password

This allows the user to view the current operational, settings, and alarms. Operator may use the help

menu and log data. Cannot change settings or load new file.

Level 1) – OEM password (supplied with unit or contact HCT)

Access at this level gives the user full viewing as above and also allows changing of all of the system

settable parameters. This includes the resetting of the OEM password. Does NOT allow resetting of

highest values recorded. This is module warranty information for HCT.

Level 2) – High Country Tek Inc. (Safety Reset) Password

This level of password overrides all other password levels and allows HCT authorized personnel to

access the module and the software when required for factory settings.

Passwords are ‘cAsE

SeNsitivE’ so ensure

you have the ‘Caps

Lock’ off if required.

Part No:- 021-00351 Rev 1.0 emc-1P & emc-1V e-Fan System Controller User Guide Page 19

Menu Option

->Help

Help

e-Fan Cooling System Controllers

with J1939 Interface

View Help

This option directs you to emc-1 manual that is part of the installation package. You may add your own

docs by adding word.doc or other .pdf files to the same folder. (c:\HCT Products\Fan Drives\emc-1)

Print Parameter

This will print all settings to your PC default printer. Or print to a text file, tab delimited. The text file may

be viewed with Notepad, Word, or Excel. You could also set your default printer to ‘Adobe PDF’ for

storage on your PC.

->Quit or EXIT

This will insure that the unit is not left in the manual mode, it will then close the GUI and release

the communication port for future use.

Part No:- 021-00351 Rev 1.0 emc-1P & emc-1V e-Fan System Controller User Guide Page 20

e-Fan Cooling System Controllers

with J1939 Interface

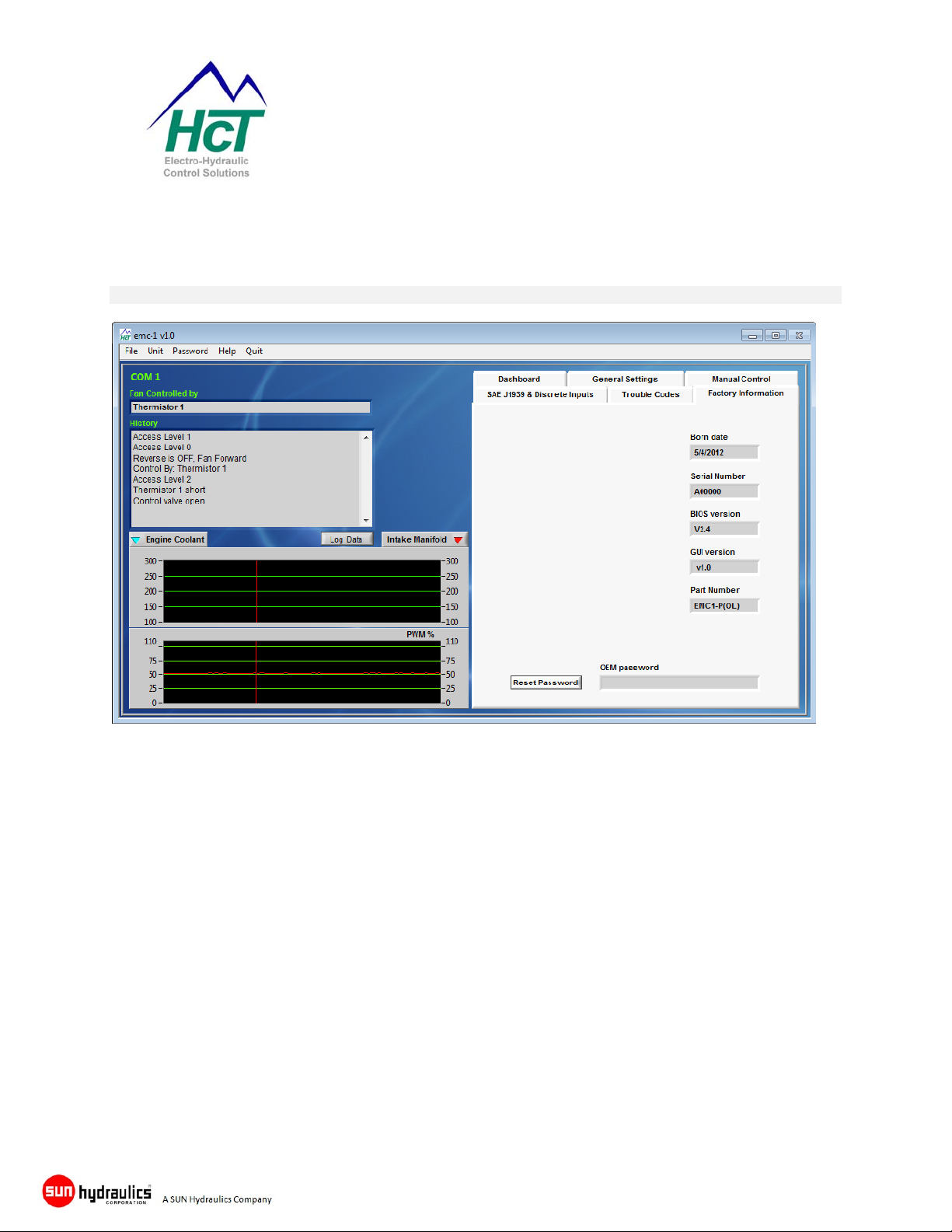

GUI software – Main screen (Dashboard)

The software has been designed such that there is NO nesting of menus so that it is easy to navigate

around the different screens without getting lost or having multiple windows open at any one time. The

five main screens are available via ‘Click Tabs’ from the ‘Dashboard’ and are:

The ‘Dashboard’ tab provides a quick user overview of the controller operation, system status and

condition of the J1939 data Bus. Error indicators change from Green (OK) to Red (error or alarm) with an

over temperature or a J1939 message timeout.

Fan Controlled by:

Displays what attribute is currently controlling the Fan.

History

Continuous updates of all changes in module operation as they happen, new changes are reported at the

top.

Graphs

There are two graphs displaying Temperature and PWM%. You may select which two Temperatures that

you want to monitor.

Each signal displayed will have a color coded individual scale on the ‘Y’ axis.

The History and Graphs are providing vital information on the operational status of the emc-1.

Part No:- 021-00351 Rev 1.0 emc-1P & emc-1V e-Fan System Controller User Guide Page 21

e-Fan Cooling System Controllers

with J1939 Interface

Data Logging

Start a data log by clicking on this button, data logging will continue until it is turned off by using the same

button now labeled “Logging Data”

Module Input Voltage

Module Internal Temperature

Proportional Valve Current

Thermistor #1 Temp I/P ( Actual )

Thermistor #2 Temp I/P ( Actual )

J1939 Coolant Temperature ( Actual )

J1939 Inlet Manifold Temperature ( Actual )

J1939 Transmission oil Temperature ( Actual

Note: you may also right click on the graph at any time to capture a window in spreadsheet format.

The file type will be saves as tab delimited file and may be viewed by any text editor or copied

directly into Excel for examination.

The user should be cautious when using this LOG function as the files can become very large if

logging is left to continue for long periods, making the files difficult to read and manage.

Experience has shown us that several smaller logs over adjacent periods are easier to

manipulate and view as graphical data.

Part No:- 021-00351 Rev 1.0 emc-1P & emc-1V e-Fan System Controller User Guide Page 22

General Settings

Selection Tab -> General Settings

e-Fan Cooling System Controllers

with J1939 Interface

On each tab changes must be ‘Applied’ to take effect. Cancel will restore values.

Unit Settings

Unit Disabled

The controller is shipped in a disabled state and should be enabled by the OEM or user by using the GUI.

Once this button is selected, the date from the enabling PC is taken and used as the ‘Born Date’ when

warranty starts.

Alarm Active High

This sets the default state of the alarm output to allow normally OFF or normally ON devices to be driven.

When enabled, the output is HIGH when alarm condition exists and LOW with NO alarm condition.

Retry Alarm and Reverse Shorts

If not checked and a short is detected on the Alarm output or the Reverse Indicator output, the software

will stop driving that circuit until a power cycle. Thus preventing damage to external hardware from high

current or overheating. This does not affect fan control.

Temperature Units

This setting selects either degrees Fahrenheit or degrees Centigrade and ripples through all the settings

that deal with temperature.

Part No:- 021-00351 Rev 1.0 emc-1P & emc-1V e-Fan System Controller User Guide Page 23

e-Fan Cooling System Controllers

with J1939 Interface

Output Settings

Refer to the requirements set by the fan manufacture for the following 3 adjustments:

1. Minimum PWM% (0-100%) output

2. Maximum PWM% (0-100%) output

3. PWM Freq ( 33-500Hz): This is the ‘dither’ or operating frequency for the PWM% output.

Minimum RPM (50-4000RPM)

This value is the engine RPM needed before the fan controller will start to operate above the minimum

system speed set by the motor pressure drop – this reduces the load on the starter motor.

NOTE: Information for this feature is taken from the J1939 Bus and cannot be used if not connected.

Start Up Delay (0-30 seconds)

Delay action is only triggered once when power is first applied to the module i.e. at key ON engine start

time. This feature is designed to reduce the load on the starter motor by holding off fan operation until the

time set has expired.

Input 0 to 30 seconds

Ramp UP & Down (0.5-30 seconds)

This will affect the output rate of change. These should be set to give smooth operation but not too long

or performance will be affected by slowing down fan speed response.

Auto Reverse Settings

Dwell Time (0-60 seconds)

This is the time that the controller allows for the fan to get to minimum speed before changing direction

when entering or leaving the reverse mode.

Time in Reverse (0-120 seconds)

Sets the duration for fan reverse operation.

Auto Reverse Time (1-1440min)

Sets the wait period between fan reverse cycles.

Disable Auto Reverse

When checked this will set the Auto Reverse Time to 0.0 and not allow the use of the setting.

Note: If J1939 messages are enabled, the RPM must be above minimum RPM setting for fans to work in

the forward or reverse direction.

With an over-temp alarm active, only the manual input will start a Reverse Cycle. Auto Reverse is

disabled.

Part No:- 021-00351 Rev 1.0 emc-1P & emc-1V e-Fan System Controller User Guide Page 24

Input Settings

Selection Tab -> SAE J1939 & Discrete Inputs

e-Fan Cooling System Controllers

with J1939 Interface

Settings do not take effect until Applied

Enable J1939

This option MUST be clicked if the unit is to understand the J19349 Bus information. If this button is NOT

clicked, all J1939 features are disabled in the controller.

Note: If J1939 messages are enabled, the RPM must be above minimum RPM setting for fans to work in

the forward or reverse direction.

Temperature settings

The emc-1 has 3 J1939 Bus messages and Thermistor inputs that can be individually enabled or disabled

as required.

Engine Coolant temperature at PGN 65262, SPN 109

Transmission Oil temperature at PGN 65272, SPN 177

Intake Manifold temperature at PGN 65270, SPN 105

Output PWM% to the fan is controlled between ‘Fan Start Temperature’ and ‘Fan max temperature’

and is a linear line between these two set values.

Fan Fault Condition

Set this for the fault condition that your fan will produce as the diagnostic input for Fan 1 or Fan 2.

Depending on the fan type it will either do nothing, Open, or will drive the input Low or High to indicate a

fault.

Set to Disabled if not used.

Part No:- 021-00351 Rev 1.0 emc-1P & emc-1V e-Fan System Controller User Guide Page 25

Sensor setup

e-Fan Cooling System Controllers

with J1939 Interface

Allows for a switch input or a thermistor input and name

for either. Name is useful in data logging and on the

Dashboard monitor.

As a Thermistor input:

Check the Thermistor box, then select profile type from

pull down menu, and enter the Start, Maximum, and

Alarm temperature values, then Apply Changes.

As a Switch input:

Check the Switch box, then select Active High or Active

Low for the input. Enter a name if desired, then Apply

Changes

Apply Changes will save to the unit and close this

window. Or Cancel Changes to close window without

applying.

Part No:- 021-00351 Rev 1.0 emc-1P & emc-1V e-Fan System Controller User Guide Page 26

Error Information Log

Selection Tab -> Alarm Condition

e-Fan Cooling System Controllers

with J1939 Interface

This page shows the user information that will help to track and where necessary, fix intermittent opens

and short circuits on any of the wires used to connect to the sensors, switches or the coils in the system.

The program shows where the error has been seen, even if the error has cleared itself.

The information can be cleared by the user with the appropriate password level by clicking the ‘Reset’

button in the Opens and Shorts section.

Highest Readings are stored permanently in the modules memory and cannot be reset by the user.

These are the maximum values seen on several key areas including the module health, and are only

overwritten by higher values.

Part No:- 021-00351 Rev 1.0 emc-1P & emc-1V e-Fan System Controller User Guide Page 27

Factory Information

Selection Tab -> Factory Information

e-Fan Cooling System Controllers

with J1939 Interface

This page allows the user to view information concerning the controller serial number, GUI Part number,

BIOS and Graphical user Interface (GUI) software versions as well as the ‘Born Date,’ which is taken from

the local PC used to activate the module.

This information should always be available when requesting support so that HCT personnel

know the level of controller with which you are working.

Part No:- 021-00351 Rev 1.0 emc-1P & emc-1V e-Fan System Controller User Guide Page 28

Temperature Sensor Information

HCT P/N: 206-00083, Wet fluid temperature sensor.

13.10

56.1

24.2 REF

Housing Type: Delphi Unique

Typical supply voltage: +5VDC

Dissi pation Con stant*: 24m W/°C

The rmal Tim e Constan t**: 17.5 to 23.5 seconds

Temperature range: -40 to +150 ºC

( operational )

NEMA/IP Rating: NEMA 6P/68

8.30 DIA

13.00

Con t act HCT cu st omer se rvice for mo re

sensor options and information

HCT P/N: 206-00084, Dry fluid temperature sensor.

Housing Type: Delphi Unique

Typical supply voltage: +5VDC

Dissipation Constant*: 18m W/°C

Thermal Time Constant**: 60seconds

Temperature range: -40 to +150 ºC

( operational )

NEMA/IP Rati ng: NEMA 6P/6 8

Main I/O connector & Accessories

e-Fan Cooling System Controllers

with J1939 Interface

Sensor Body: Brass

Connector Body: PBT 30%

Glass Filled

Hex Size: 18.9mm / 3/4”

Thread Size: 3/8’ - 18 NPTF

Thread Sealant: GM09985473

Sealing Pressure: 145kPa

Installation Torque: 20Nm

Overall Weight: 40g

Sensor Body: PEI ( polyetherim ide )

30% Glass Filled

Connector Body: PBT 30% Glass Filled

Hex Size: 18.9mm / 3/4”

Thread Size: 3/8’ - 18 NPTF

Thread Sealant: GM09985490

Sealing Pressure: 145kPa

Installation Torque: 10.8 - 16.3 Nm

Overall Weight: 13.2g

Mating connector Parts information: Complete harnesses and connector kits can be supplied by HCT.

Please contact customer service for information.

System Accessories for emc-1P and emc-1V:

Item Description: HCT P/No:

SAE J1939 connector kit for the emc-1P 999 - 10244

RS232 Communications Cable - Weatherpack 999 - 10075

emc-1Main Mating I/O connector Kit 999 - 10155

emc -1Graphical User Interface ( GUI ) replacement Disk 023 – 00264

emc -1Operating Manual 021 – 00351 (see website for latest version)

Part No:- 021-00351 Rev 1.0 emc-1P & emc-1V e-Fan System Controller User Guide Page 29

e-Fan Cooling System Controllers

with J1939 Interface

On Site Testing

If the set up procedure does not achieve the desired results, double check the wiring and perform the

following tests. Record the test results.

Tools Required:

A PC running Windows XP, Vista, or Windows7 and the correct emc-1 software are required for initial setup, programming or observation of the controllers operation through the RS232 port (directly or via a USB

to serial converter cable).

The PC can also be used for uploading the configured program to new emc-1 modules for upgrades.

A battery operated multi meter is always a good idea for measuring and confirming analog signals and an

oscilloscope would be useful for looking at fast moving or digital signals on the system.

Check the Power input: (9-32V)

If the supply voltage is below 9VDC, there is a risk of:

a) Module shutting down,

b) Module continuously trying to reset or

c) Low drive current to valves.

If the supply voltage is more than 32 VDC there is a risk of:

a) Blown in-line AGC5 fuse

b) Module shutting down.

c) Fan damage due to excessive drive voltage.

Check the Control Inputs:

Verify that any analog control inputs are the correct polarity and are hooked up correctly and to the

correct module terminals by monitoring their status with the emc-1software or testing with a voltmeter or

oscilloscope.

Ensure the J1939 Bus is terminated correctly (120 ohm resistors) and that the engine is running to ensure

good data.

Ensure that any external control or command inputs have their respective sources 0V or GND connected

to the modules power supply 0V or GND terminal.

Verify That Alarm or Reverse Indicator Loads are Not Shorted:

Disconnect the wires going to the terminals and measure the resistance between the wires. Verify it is in

the expected Ohmic range for the type and voltage of load being driven. Verify that there is no voltage

with respect to ground generated by the load and wiring.

Part No:- 021-00351 Rev 1.0 emc-1P & emc-1V e-Fan System Controller User Guide Page 30

e-Fan Cooling System Controllers

with J1939 Interface

If the e-Fan Operation is Erratic:

Electrical interference on the control lines can cause erratic behavior if it is strong enough. Observe the

control inputs on the PC. If noise greater than a few percent is noticed on an unchanging PULSE IN or

COMMAND IN input, or if the digital inputs are toggling, try changing the routing of the control wires to

see if the problem changes.

Power supply interference or brown outs can also cause erratic behavior. Observe the power supply on

the graph on the PC. If large dips are noticed, test for a poor supply by running the card off its own fully

charged battery.

Further Information:

Visit the HCT website (www.hctcontrols.com)

for additional documentation and assistance.

Part No:- 021-00351 Rev 1.0 emc-1P & emc-1V e-Fan System Controller User Guide Page 31

emc-1P & emc-1V Dimensional Information

Notes:

Mount controller as shown or with connector

facing down to avoid surface debris collecting.

Unit weight is approx. 250 grams

RS232 cable removed for clarity

RS232 cable is approx 6” long

e-Fan Cooling System Controllers

with J1939 Interface

Housing Type ........................... High Country Tek unique ‘encapsulated’ block

Housing Material ...................... None, solid, flameproof epoxy resin block

Housing Color .......................... Black / dark Grey

Surface Finish .......................... Smooth Gloss

Housing Thickness .................. 16.5mm (main module) ~41.5mm incl. Connectors

Unit Size.................................... See above size detail drawings

Unit Weight ............................... Approx. 250 grams (including Encapsulation material)

Wire Entry ................................. Industry standard 12-way Deutsch, sealed connector

Encapsulation .......................... Flame Resistant, Black, Two-Part Epoxy Resin

Mounting................................... Via through holed ( 3 ) suitable for No. 8 ( 5mm ) screw

Temperature Range ................. - 40 to +85 degrees Centigrade (operational)

Part No:- 021-00351 Rev 1.0 emc-1P & emc-1V e-Fan System Controller User Guide Page 32

RS232 Communication Cable

e-Fan Cooling System Controllers

with J1939 Interface

Part No:- 021-00351 Rev 1.0 emc-1P & emc-1V e-Fan System Controller User Guide Page 33

Mining & Exploration

Agriculture

Cranes & lifts

Refuse & Re-cycling

Construction

Off-Road vehicles

Forestry, Wood & Pulp

Reclamation & Salvage

Oil Field & Sands

Demolition Equipment

Cooling Solutions

Military Apparatus

Specialty Use

Remote Control

Power Generation

Emission Controls

Integrated Drivers

Valve & Pump Controls

e-Fan Cooling System Controllers

with J1939 Interface

Electronic Control Solutions for the Global Fluid Power Industry

HCT Product Sales and Support:

For a full list of authorized distributors worldwide, please visit:

www.hctcontrols.com/distributors/index.htm

Need more information ?

To discuss anything in this brochure, order product, get

price and delivery or schedule an application discussion

meeting, please contact your nearest HCT distributor who

will be pleased to help you.

www.hctcontrols.com

Visit our website for the latest product releases, application

ideas, literature and software downloads.

Copyright © High Country Tek, Inc. - 2012

Note: T his guide is intended for suggestion onl y and may contain mist akes and print ing errors. Users should check calcul ations and confirm pa rts selection wi ll meet system re quirements whil e complying with cust omer specific or local and state saf ety requirements at all times.

Part No:- 021-00351 Rev 1.0 emc-1P & emc-1V e-Fan System Controller User Guide Page 34

HCT and accepts NO liability for technical mistakes or printing errors, or their consequences

High Country Tek, Inc.

208 Gold Flat Court

Nevada City, CA, 95959

Tel: (1) 530 265 3236

Fax:(1) 530 265 3275

Loading...

Loading...