H&C MEDICAL DEVICES CARDIETTE Service Manual

1

CARDIETTE ®

SERVICE MANUAL

A

SSTTA

RTT 110000

R

Rev. 01 Data: 28 May 1999 Code Nr. 66500092

AFTER SALES SERVICE

2

INDEX

Foreword and special remarks page 4

Installation program page 4

Register number page 4

Aim of the manual page 5

Reference standards page 6

Special remarks page 6

1. Technical characteristics page 7

2. Apparatus description page 9

2.1 Case page 9

2.2 Battery page 9

2.3 Mother board page 9

2.4 Keyboard page 11

2.5 Paper sensors board page 11

2.6 Printer mechanical group complete with thermal head page 11

2.7 Mechanical group of the paper driving system page 11

2.8 Protection from defibrillation page 11

3. Inputs and outputs page 12

3.1 Connection to the patient input socket page 12

4. Check of the safety characteristics pag. 13

4.1 Required instruments page 13

4.2 Applied voltage test page 13

4.3 Leakage current test page 14

5. Check of the main characteristics of the electrocardiograph page 16

5.1 Required instruments page 16

5.2 Sensitivity test page 16

5.3 Test of the ECG leads page 16

5.4 Check of the paper driving system page 17

5.5 Check of the response in frequency page 18

5.6 Check of the power supply and battery recharge page 18

5.7 Technical self-test page 19

6. Detection of the damaged circuits and analysis of the page 20

main malfunctions

6.1 Introduction page 20

6.2 Purpose page 20

6.3 The apparatus does not switch on page 21

6.4 The apparatus does not correctly accept the keyboard commands page 23

6.5 Malfunctions during printing process page 24

6.6 Malfunctions during paging and paper presence signalling page 26

6.7 Malfunctions caused by defective paper driving page 28

6.8 Illustration of the power supply voltage page 30

AFTER SALES SERVICE

3

7. Disassembling and reassembling the apparatus page 31

7.1 Foreword page 31

7.2 Opening and closing the apparatus page 31

7.3 Disassembling the mother board page 31

7.4 Disassembling the battery page 32

7.5 Disassembling the keyboard page 33

7.6 Disassembling the paper driving motor group page 33

7.7 Disassembling the printer group page 33

7.8 Disassembling the paper and notch sensors card page 33

7.9 Disassembling the paper lid page 34

7.10 Disassembling and replacing the keyboard plate page 34

7.11 Mains fuses page 34

8 Calibrations page 35

8.1 General information page 35

8.2 Calibrating the sensitivity of paper and notch presence sensors page 36

8.3 Calibrating the paper speed page 36

9. General directions for maintenance page 37

9.1 Foreword page 37

9.2 Messages page 37

9.3 Inspection schedule page 38

9.4 Cleaning the thermal head page 39

10. List of spare parts page 40

10.1 General information page 40

APPENDIX A

Procedures for handling and storing electronic components sensitive

to electrostatic discharges (ESD) page 45

Ilustrated tables page 47

AFTER SALES SERVICE

4

FOREWORD AND SPECIAL REMARKS

This apparatus is a multilingual, class I (first) and CF type portable electrocardiograph with

3/6 printing channels and dual power supply (mains/battery).

The apparatus uses 130 mm wide rolls of thermosensitive paper, provided with grid.

It is supplied in two different models:

START 100 P 110 ÷ 120 Vac 220 ÷ 240 Vac

This model, in addition to recording the ECG, grants the possibility of:

− calculating the main electrocardiographic parameters with either brief or extended

report;

− recording in both manual and automatic mode, with copy possibility in printing mode 3

and/or 6 channels;

− selecting the language (Italian - English - German - French -Spanish - Russian);

− selecting the 50 -55 - 60 Hz filters;

− automatically numbering the pages by either terns or six lines groups, 1 or 2;

− inserting the user name.

START 100 H 110 ÷ 120 Vac 220 ÷ 240 Vac

This model differs from the previous one in that it features the implementation of the

interpreting program instead of the parameters calculation.

INSTALLATION PROGRAM

The access to the programming menus can be achieved in two steps.

The first one takes place by depressing the STOP key within 3 seconds after switching the

apparatus on. If the procedure has been correctly performed, all the leds relevant to the

velocity, amplitude and filters keys will blink.

In such condition the AUTO - STOP - SPEED keys shall be depressed in sequence.

The menu activation is very clearly guided on the print-outs.

For more detailed information, please refer to the “installation instructions”.

REGISTER NUMBER

The label with the apparatus identification data is placed on the movable bottom (Table

T3).

The label is subdivided into three parts:

1 - The upper part gives the seller’s data and the apparatus trademark.

2 - The middle part gives:

The model __________

the characteristics of the power supply in Volt __________

The code number __________ the frequency in Hz. ___________

The serial number __________ the absorption in Amperes ___________

CE mark __________

AFTER SALES SERVICE

5

3 - The lower part gives:

the language (or langages) ___________

the manufacturer’s identification data ___________

NOTE:

Always use the series code and the apparatus code when communicating with the Seller

or with the Assistance Service.

CE MARKING

The CE marking identification label is placed on the movable bottom and defines the type

of apparatus conformity.

CE Marking only

CE

it defines conformity to European Community Directive 89/336 relative to electromagnetic

compatibility.

CE Marking 0470

CE 0470

it defines conformity to European Community Directive 93/42 relative to the safety of

medical devices.

The number 0470 indicates the homology number of the Nemko Certified Body.

AIM OF THE MANUAL

The aim of this manual is the following:

a) to give a description of how the unit operates;

b) to give a description of the procedures necessary to carry out a complete test of the

apparatus;

c) to give a description of the procedures necessary to carry out the safety tests

according to the IEC safety regulations;

d) to identify and isolate blocks of operational breakdowns;

e) to describe the maintenance interventions necessary for a correct and long-lasting

operation of the apparatus;

f) to supply a list of spare parts.

AFTER SALES SERVICE

6

REFERENCE STANDARDS

The safety characteristics of the electromedical class apparatus are in accordance with the

regulations:

EN 60601-1: (1990) General regulations for the safety of electromedical equipments

EN 60601-1: (1990/A1-1993)

EN 60601-1: (1990/A2-1995)

EN 60601-1-2: (1993) Regulations about the electromagnetic compatibility of

electromedical equipments

IEC 601-2-25: (1993) Special safety regulations for electrocardiographs

IEC 62D(CO)6: (1978) Special regulations about the performance of the

electrocardiographs

SPECIAL REMARKS

a) Please remember that, by following the instructions outlined in this manual, the

apparatus and its accessories will be correctly and efficiently maintained and

consequently will be safer and will last longer.

b) Please remember that this service manual is only addressed to technically competent

persons.

c) Please remember that all the instrumentation described or indicated in this service

manual is necessary to correctly carry out tests, calibrations and controls of the safety

characteristics of the apparatus.

d) Please remember that whenever the apparatus is opened for inspection or assistance,

a complete control of the safety characteristics, as described in chapter 5, must be

carried out before the apparatus is returned.

e) Please remember that this apparatus has been designed using CMOS technology.

Most of the electronic components belongs to the ELECTROSTATIC SENSITIVE

DEVICES (ESD).family.

Therefore, it is necessary to follow specific working procedures.

Appendix A describes the special procedures required in the treatment of electrostatic

sensitive devices (ESD.).

The manufacturer refuses all responsibility for any damage undergone by the

apparatus caused by inadequate or non existent working procedure necessary

in treating with ESD devices

NOTE:

Transportation and packaging of the apparatus not in its original packaging or

an incorrectly packaged apparatus, frees the manufacturers of any

responsibility with regard to damages to the apparatus and its accessories thus

resulting in the annulment of the warranty.

f) H&C MEDICAL DEVICES S.p.A. reserves to itself the right to modify at any time,

and without any advance notice, the product or this manual.

g) Before starting the assistance service, please ready the entire content of this

manual.

AFTER SALES SERVICE

7

1. TECHNICAL CHARACTERISTICS

Power supply from mains Class I (first)

110..120 V~ ± 10% 50..60 Hz

220..240 V~ ± 10% 50..60 Hz

Max input 0.28 A at 110 ÷ 120V~ ± 10%

014 A at 220 ÷ 240V~ ± 10%

Mains power supply protection T 0.315 A - 250 V (5x20 mm.) fuse at 110..120 V~

T 0.16 A - 250 V (5 x 20 mm) fuse at 220..240 V~

Built-in power supply Built-in lead rechargeable battery 12V 0.8 Ah

Battery protection T 2 A - 250V (5x20mm) fuse

Applied part CF type

Protection from defibrillation Inside the apparatus

Input dynamics ± 300 mV @ 0 Hz

± 6.4 mV in the passing through band

Input impedance > 100 MΩ on each electrode

Common rejection 95 dB

Frequency response 0.05..150 Hz (-3dB) without filters

Time constant > 3.3 sec

Acquisition 12 bits

1000 samples/sec/printing channel and filters

500 samples /sec/channel during calculation phase

3.125 µV/bit resolution

Leads 12 STANDARD leads, out of which:

8 acquired - 4 reconstructed (III - aVR - aVL - aVF)

Signal memory 10 s for each lead in self-isochronous mode

Sensitivity:

manual 5 - 10 - 20 mm/mV ± 5%

automatic 3 channels printing

10 mm/mV for 0.3 ÷ 3 mV signals

5 mm/mV for signals > 3 mV

20 mm/mV for signals < 0.3 mV

6 channels printing

10 mm/mV for 0.15 ÷ 1.5 mV signals

5 mm/mV for signals > 1.5 mV

20 mm/mV for signals < 0.15 mV

Printing system Thermal printing unit 8 dot/mm

Printing useful height 108 mm

Printing channels 3 - 6

Paper driving speed 5 mm/s ± 10% 25 - 50 mm/s ± 5%

Thermo-sensitive paper DOT-CARD® 130 mm in 25 metres rolls

Filters Mains disturbancies: modified 50 - 55 - 60 Hz notch digital filter

Anti drift : 0.5 Hz, pass high and linear phase digital filter

Keyboard Membrane type, with 8 functional and numerical keys

Led 9 Function indicators

Interpreting Program HES ECG program developed by

(START 100 H) Medizinische Hochschule Hannover - Germany

Parameters calculation Developed by “lstituto di Fisiologia Clinica (C.N.R.)” in Pisa Italy

(START 100 P)

Operating mode Manual (real time acquisition)

Automatic (isochronous)

Usage mode Continuous operation

Autonomy Built-in battery: 30 minutes in the 3 channel mode

10 mm/mV

25 mm/sec.

10 Hz p.v.

Recharging time Built-in battery:

12 h 100%

Caovering protection degree IP20

4 h 80%

AFTER SALES SERVICE

8

Environmental conditions:

operation Ambient temperature: +10°C to +40°C

Relative humidity: 25% to 95% (without condensation)

Atmospheric pressure: 700 hPa to 1060 hPa

Transport and storage Ambient temperature: -10°C to +40°C

Relative humidity: 10% to 95% (without condensation)

Atmospheric pressure :500 hPa to 1060 hPa

Dimensions 247 x 69 x 262 mm. (width x height x depth)

Weight 2.4 Kg

Compliance with standards EN 60601-1: (1990)

EN 60601-1: (1990/A1-1993)

EN 60601-1: (1990/A2-1995)

General standards for the electromedical equipment safety

EN 60601-1-2: (1993)

Standards related to the electromagnetic

compatibility of electromedical equipment

IEC 601-2-25: (1993)

Special safety standards for electrocardiographs

IEC 62D(CO)6: (1978)

Special performance standards for electrocardiographs

NOTE REGARDING THE PROTECTION:

The maximum applicable voltage to inputs and outputs is the maximum value causing no

damage to the apparatus.

AFTER SALES SERVICE

9

2. APPARATUS DESCRIPTION

The apparatus consists of the following main components:

− case, internally painted with conductive and shielding paint, complete with paper lid,

plate, keyboard and serigraphs;

− sealed lead battery;

− main electronic card, hereinafter called “mother board”;

− keyboard card;

− paper sensors card;

− printer mechanical group complete with thermal head;

− mechanical group of the paper driving device

2.1 CASE

The case consists of two parts:

− the upper housing, made of polycarbonate Lexan 940, colour RAL 7035;

− the lower housing, made of ABS, colour RAL 7025.

Both parts are internally painted with conductive and shielding paint. Such lining is highly

conductive and works as a shielding both against the radio disturbances generated by the

apparatus and those externally produced, which could cause malfunctions.

The fastening columns of cards and mechanical components, as well as the PVC

insulating plates, are an integral part of the case.

SAFETY NOTE

The mentioned insulations are strictly required to guarantee the safety features of the

apparatus. If they are removed during an inspection or repair of the apparatus, they must

be exactly restored as foreseen by the design.

2.2 BATTERY

The battery is a lead sealed type accumulator having the following characteristics:

− voltage: 12 V;

− capacity: 0.8 Ah;

− dimensions: 96 x 62 x 25 mm (width - depth - height);

− weight: 350 g;

− recommended make: FIAMM-GS FG20086.

SAFETY NOTE

The battery can only be replaced with the recommended type or an equivalent one, as to

both the electic characteristics and the mechanical ones.

2.3 MOTHER BOARD

The mother board is a multilayer printed circuit card (six layers) in “fine-line” technology for

the assembly of SMD components (Surface Mounting Devices).

It houses most of the apparatus electronic circuits and may be divided in the following

sections, with reference to the electrical block diagram file name: Blok - 100.

AFTER SALES SERVICE

10

2.3.1 POWER SUPPLY FROM MAINS

The power supply from mains is a Class I type, therefore it assures the apparatus

electrical safety only if the protection earthing (yellow/green wire of the power supply

cable) is connected to a system realized in compliance with the laws in force.

The section consists of the following parts:

− separable three-wire mains cable;

− three-pin mains plug with built-in extractable fuses (table T 2);

− protection devices (VDR and PTC) and disturbances filtering devices;

− mains transformer complying with medical standards, code ET 69701082 (table T 6);

− rectifying, filtering and voltage adjustment circuits with current limiter for the recharge of

the built-in battery. Such circuits do not allow operating the apparatus without the

battery;

− connection socket with earthing functions and equipotential connection (table T 2).

The equipotential connection must be carried out according to the instructions and using

the materials listed hereunder.

Required material:

• cylindrical head, M5X10 mm type screw;

• 5 mm internal diameter washer;

• 5 mm internal diameter cable terminal;

• wire with overall resistance lower than 0.1 Ohm and 1.5 cm2 minimum section.

Instructions:

• prepare and solder the wire to the cable terminal;

• insert the washer and the cable terminal in the screw;

• fix and adequately tighten the screw in the equipotential threaded bushing.

SAFETY NOTE

The replacement of the components belonging to the mains power supply section may

only be carried out using identical components to the original ones, homologated by the

manufacturer, or else the safety features of the apparatus will be lost.

2.3.2. POWER SUPPLY TO INTERMEDIATE CIRCUITS

This section consists of a DC/DC converter and a high frequency transformer generating

the following voltages:

• 5 V to supply the control logic;

• 24 V to supply the printer thermal head;

• ± 5 V to supply the insulated part.

2.3.3. INTERMEDIATE CIRCUITS FOR CONTROL AND INTERFACING

This section includes the microprocessor system controlling the operation of the whole

apparatus and the external interfaces of the mother board, such as the keyboard and the

serial interface RS232, the analog inputs and outputs, the remote control and the auxiliary

power supply, if provided.

AFTER SALES SERVICE

11

SAFETY NOTE

The connection to the intermediate circuits, for instance through the serial interface

RS232, may be realized only and exclusively towards other medical apparatus, according

to IEC 601-1-1 standard relating to the medical systems safety. Should any doubt exist

about the compliance to the medical standards of the apparatus connected to the

intermediate circuits (e.g. a Personal Computer), make use of a galvanic de-coupling

device, that may be provided by request.

2.3.4. INSULATED PREAMPLIFIER

This section consists of a 12 channels ECG preamplifier with active control of the

reference electrode, complete with protection from the effects of defibrillation and 12 bit

analog/digital conversion circuit.

The galvanic de-coupling is performed by means of a guard zone on the printed circuit (4

mm minimum insulation) and photo-couplers (2500V rms minimum for 1 minute

insulation).

SAFETY NOTE

We strongly advise against any intervention on the components assuring the patient

insulation, such as the photo-couplers and the insulation transformer of the DC/DC

converter generating the intermediate and insulated power supplies. In case of failure

replace the mother board.

2.4 KEYBOARD

This card houses only the keys and leds required for the operation of the apparatus.

2.5 PAPER SENSORS BOARD

This card houses the sensors signalling the paper presence and the paging black notch.

2.6 PRINTER MECHANICAL GROUP COMPLETE WITH THERMAL HEAD

This group consists of the supporting plate for the printer thermal head and the mechanical

components required for its correct positioning.

A complete sparee group is provided.

2.7 MECHANICAL GROUP OF THE PAPER DRIVING SYSTEM

The group consists of the driving motor complete with support and gears.

A complete spare group is provided.

2.8 PROTECTION FROM DEFIBRILLATION

The apparatus has a built-in protection from the defibrillator discharges.

Therefore this apparatus allows the use of patient cables not protected from defibrillation

and supplied by the manufacturer.

AFTER SALES SERVICE

12

3. INPUTS AND OUTPUTS

START 100 does not allow any connection to other external apparatus.

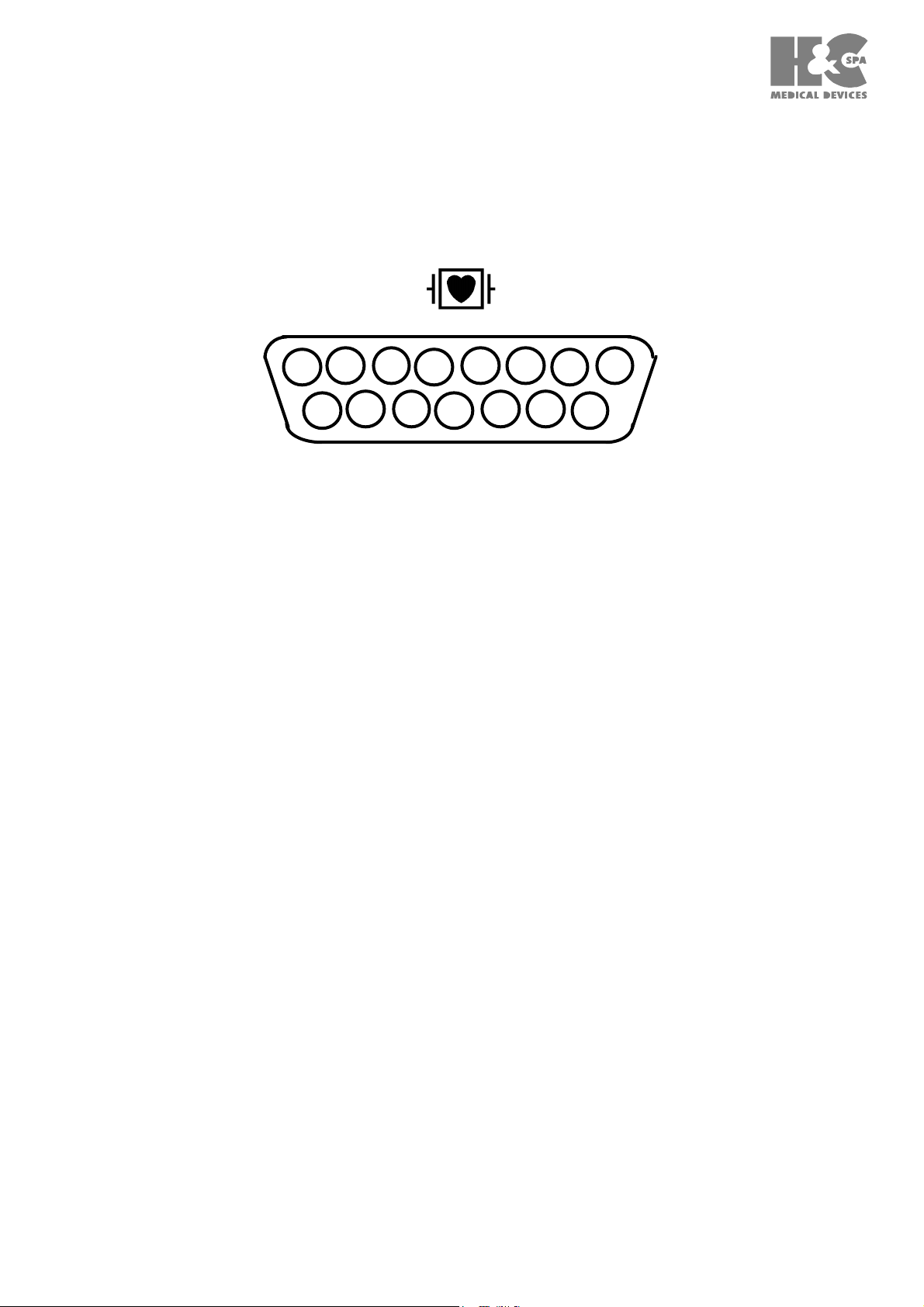

3.1 CONNECTION TO THE PATIENT INPUT SOCKET (table T2)

4

11

3

10

7

8

15 9

Socket seen from the connection side

Pin 1 = IN C2 (C2 electrode)

Pin 2 = IN C3 (C3 electrode)

Pin 3 = IN C4 (C4 electrode)

Pin 4 = IN C5 (C5 electrode)

Pin 5 = IN C6 (C6 electrode)

Pin 6 = IAGND

Pin 7 = NC (not connected)

Pin 8 = NC (not connected)

Pin 9 = IN R (R electrode)

Pin 10 = IN L (L electrode)

Pin 11 = IN F (F electrode)

Pin 12 = IN C1 (C1 electrode)

Pin 13 = NC (not connected)

Pin 14 = IN N (N electrode)

Pin 15 = NC (not connected)

The inputs have the following characteristics:

a) Sensitivity: 1 mV/5 - 10 - 20 mm depending on the selected sensitivity;

b) Input impedance higher than 100 MOhm for each electrode;

c) Input dynamic:+/- 300 mV.at 0 Hz.

+/- 6.4 mV in the passing through band;

d) The inputs are protected from defibrillation.

5

6

1314

12

1

2

AFTER SALES SERVICE

13

4. SAFETY CHARACTERISTICS CONTROL

The safety regulation expects two important tests:

a) The applied voltage test:

it verifies the insulating efficiency of the power supply circuits and those relative to the

patient connections.

b) The leakage current test:

it measures the value of the leakage currents in relation to patient safety.

NOTE:

All safety tests should be performed according to IEC 601-1 regulations(paragraphs 19-

20).

4.1 NECESSARY INSTRUMENTS

a) Insulating strength analyser:

model "U28 M" Elektrotechn. Laboratorium D - 7015 Korntal Germany or its

equivalent;

b) Leakage current analyser:

model “AMPLAID ST 10“ - Amplifon Division S.p.A. Italy, or

model METRON QA 80” Electrical Safety Analyser, or

model “BIO-TEK 601-PRO” Amplisim Division srl - Italy or its equivalents

4.2 APPLIED VOLTAGE TEST

The test should be carried out in a suitable location in accordance with safety regulations

by using the instrument 4.1 a).

This test must be carried out only in those apparatuses in which components with special

insulating characteristics have been substituted:

a) power supply transformers;

b) transformer on the TR1 voltage converter;

c) optoinsulators: FC1...FC7 of the mother board;

d) entire mother board.

4.2.1 INSULATING TEST TOWARDS MAINS POWER SUPPLY

Perform this test with the mains switch inserted (Table T2).

a) Apply the test voltage between the pins with the exclusion of the central pin in the

apparatus mains plug (Table T2) and the equipotential outlet which is connected to the

frame (ground) of the apparatus (Table T2).

b) How the performance test is carried out:

(class I electrocardiograph (first).

Apply for 10 seconds a voltage equal to 0.750 KVac, then raise it to 1.5 KVac and hold it

at this value for 1 minute.

AFTER SALES SERVICE

14

4.2.2 DECOUPLING TRANSFORMER AND OPTOINSULATOR TEST.

(CF type electrocardiograph defined by this symbol )

Perform this test with the apparatus turned off.

a) Apply the test voltage between all the Pins of the patient input outlet connector (Table

T2) and the equipotential outlet (Table T2);

b) Apply for 10 seconds a voltage equal to 1.25KVac then raise it to 2.5KVac and hold it

at this value for 1 minute.

4.2.3 IN BOTH TESTS (4.2.1 - 4.2.2)

Verify that during the test there are neither superficial nor destructive discharges.

Moderate discharges due to the back effect can be ignored, as long as they stop when the

test voltage is temporarily lowered to a lower value, which nevertheless must remain

greater than the reference voltage U (250V), as long as the discharges do not result in test

voltage drops.

4.3 LEAKAGE CURRENT TEST

THIS TEST TO BE MADE AFTER EACH OPENING FOR INSPECTION

AND/OR REPAIR USING TOOL 4.1 B AND IN ANY CASE EVERY TWO

YEAR PERIOD.

Proceed as follows:

4.3.1 Connect the electrocardiograph to the measuring instrument according to the

instructions given in its user’s manual and remember that:

a) The leakage current towards ground, is measured between the mains power supply

circuits and the ground point of the equipotential outlet (Table T2).

b) The leakage current towards the case, is measured between the mains power supply

circuits(Table T2), the equipotential outlet (Table T2) and a metallic sheet not greater

than 20 x 10 cm in size which should be pressed against the case, if composed of

insulating material.

c) The leakage current in the patient, is measured between the mains (Table T2) and the

applied part (Table T2).

The same patient cable can be used for the connection with the applied part.

d) The leakage current in the patient with mains voltage directly on the applied part (first

fault condition), is measured between the equipotential connection (Table T2) and the

applied part (Table T2).

e) The auxiliary current in the patient, is measured individually on each electrode (with

the exclusion of the black one) with respect to all the other electrodes connected

together.

4.3.2 Program the instrument according to the electrocardiograph type (CF) and class I

(first).

4.3.3 Perform the measurement according to the instructions given in the user’s manual of

the instrument itself and verify that the values of the leakage currents measured are

less than or equal to those reported in Table IV.

AFTER SALES SERVICE

15

IEC REGULATI

ONS 60601

-1

(1990)

60601 - 2 - 25 (1993)

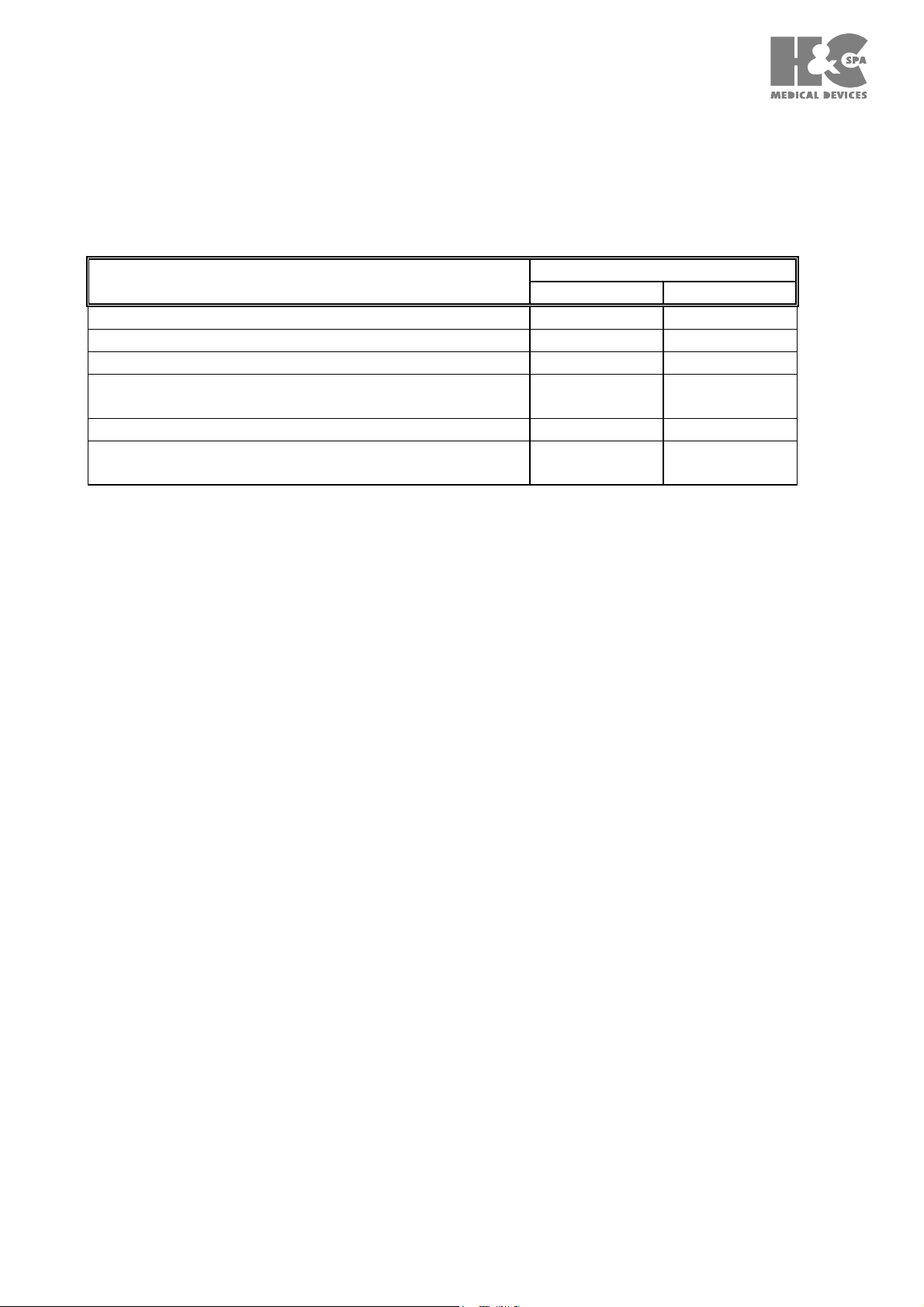

Table IV

Permanent admissible values for the leakage currents and for the auxiliary currents in the

patient in mA.

Current path

CF type

N.C. (+) S.F.C.(++)

Leakage current towards ground 0.5 1

Leakage current in the case 0.1 0.5

Leakage current in the patient 0.01 0.05

Leakage current in the patient with

----- 0.05

mains voltage in the applied part

Auxiliary current in the patient 0.01 0.05

(+) N.C. = Usual condition

(++) S.F.C. = First fault condition

AFTER SALES SERVICE

Loading...

Loading...