H.C Duke & Son Electro-Freeze Genesis Series, GEN-2080 Operator’s Manual With Illustrated Parts List

OPERATOR’S MANUAL

with Illustrated Parts List

Combination Soft Serve and

Shake Freezer

Model GEN-2080

185240— 4/15

H.C. Duke & Son, LLC. P/N 185240 April 2015 Printed In U.S.A.

Operator’s Manual

for

Electro Freeze Combination

Soft Serve and Shake

Freezer Model GEN-2080

All contents © Copyright 2015 H.C. Duke & Son, LLC., 2116 Eighth Avenue, East Moline, Illinois 61244

HC185240

i

ELECTRO FREEZE Soft Serve Model GEN-1578

SAFETY FIRST!

Follow these four steps to safety ....

1. Recognize Safety Information ....Look for

this safety alert symbol throughout this manual.

When you see this symbol on your freezer or in this

manual, be alert to the potential for personal injury.

Follow recommended precautions and safe operating

practices.

2. Understand Signal Words ....

The signal words — DANGER, WARNING and

DANGER

WARNING

CAUTION

CAUTION — are used with the safety alert symbol

(DANGER decals on the freezer may or may not

have the safety alert symbol, but the message is the

same). Decals with the words DANGER, WARNING

or CAUTION appear on the freezer. DANGER

identies the most serious hazard. Decals with the

words DANGER or WARNING are typically near

specic hazards on the freezer. General precautions

are listed on CAUTION safety decals. In this manual,

CAUTION messages with the safety alert symbol

call attention to safety messages.

ii

ELECTRO FREEZE Soft Serve Model GEN-1578

Safety

First!

SAFETY FIRST!

3. Follow Safety Instructions ....

Read and understand all safety messages in this

manual. Read and understand the decal safety

messages on your freezer. Take notice of the location

of all decals on the freezer and keep the safety decals

in good condition. Check them periodically and replace

missing, damaged or illegible safety decals. The safety

decals must remain in place and legible for the life of

the freezer. If you need new decals, use the information

and illustrations on pages v and vi of this manual to

identify the decal and contact your local Electro Freeze

Distributor — or call or write to H.C. Duke & Son, LLC.

DO NOT attempt to operate the GEN-2080 freezer until

you read and understand all safety messages and the

operating instructions in this manual.

4. Operate Safely ....

DO NOT allow untrained personnel to maintain or

service this machine. Failure to follow this instruction

may result in severe personal injury. DO NOT operate

the freezer unless all service panels and access doors

are secured with screws. DO NOT attempt to maintain

or repair the freezer until the main power supply has

been disconnected. Some freezers have more than one

disconnect switch. Contact your local Electro Freeze

Distributor for authorized service.

iii

ELECTRO FREEZE Soft Serve Model GEN-1578

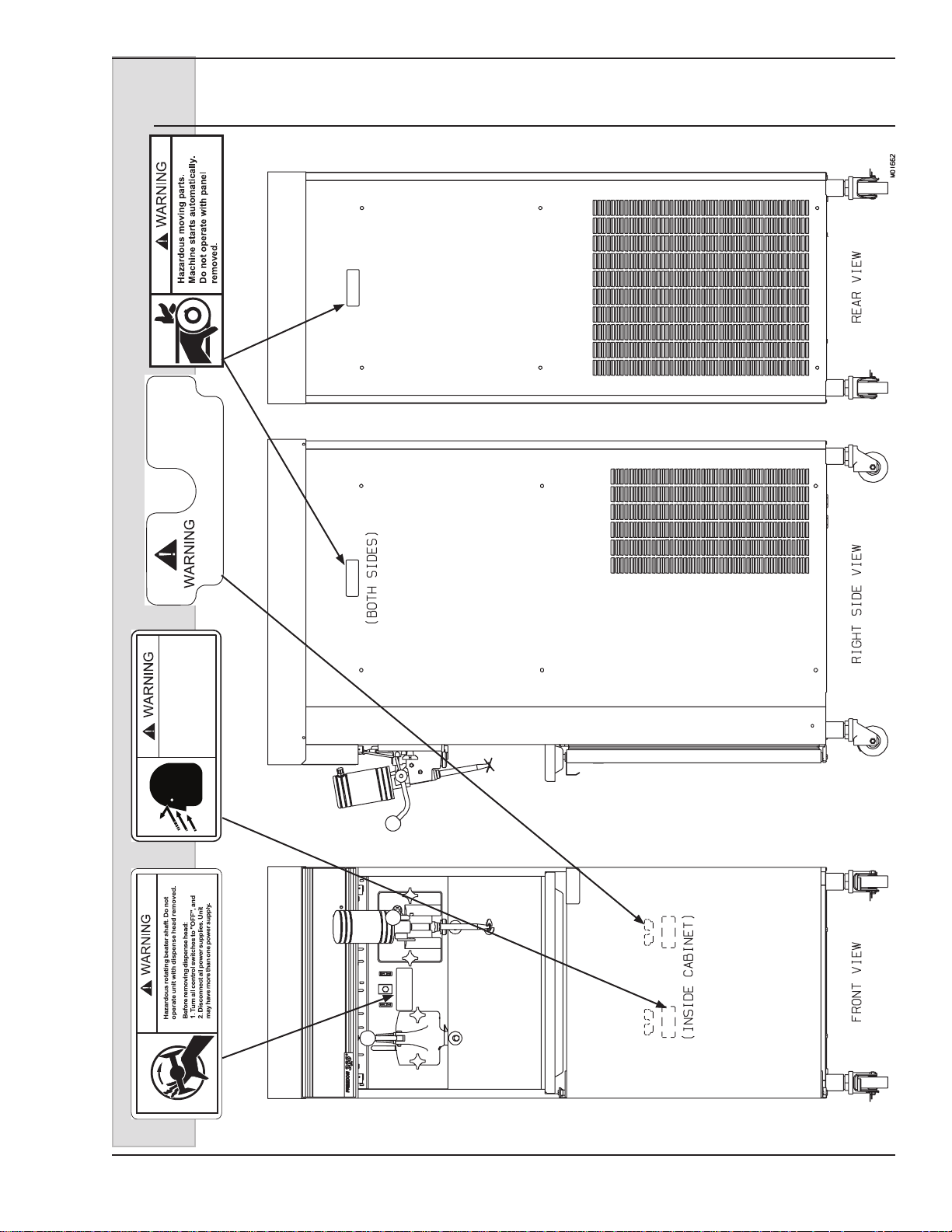

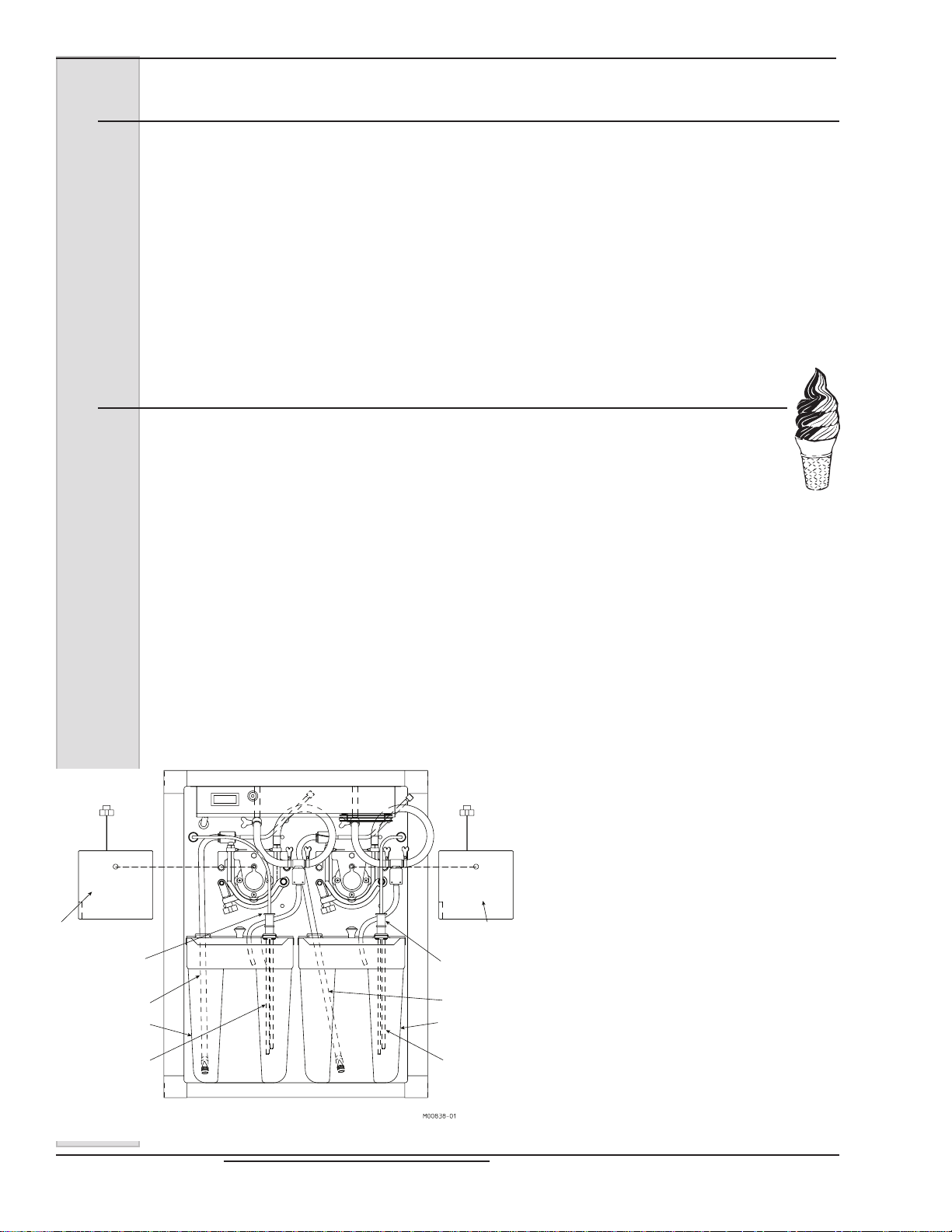

Safety Decal Locations

Do not attempt to operate the freezer

until all safety precautions and operating

instructions in this manual are read and

understood.

Take notice of all warning, caution,

instruction and information decals (or

labels) on the freezer as shown in the

gure to the right. The labels have been

put there to help maintain a safe working

environment.

The labels have been designed to withstand washing and cleaning. All labels

must remain legible for the life of the

freezer. Check labels periodically to be

sure they can be recognized as warning

labels.

If it is necessary to replace any label,

please contact your local authorized

Electro Freeze Distributor or H. C. Duke

& Son, LLC. When ready to order, you will

need to determine the (1) part number,

(2) type of label, (3) location of label, and

(4) quantity required, and include a return

shipping address.

You may contact your local authorized

Electro Freeze Distributor, as follows:

Name:

Address:

Phone:

or, for factory service assistance, contact

H. C. Duke & Son, Electro Freeze Service

Department by phone, FAX or e-mail:

Phone: (309) 755-4553

(800) 755-4545

FAX: (309) 755-9858

E-mail: service@hcduke.com

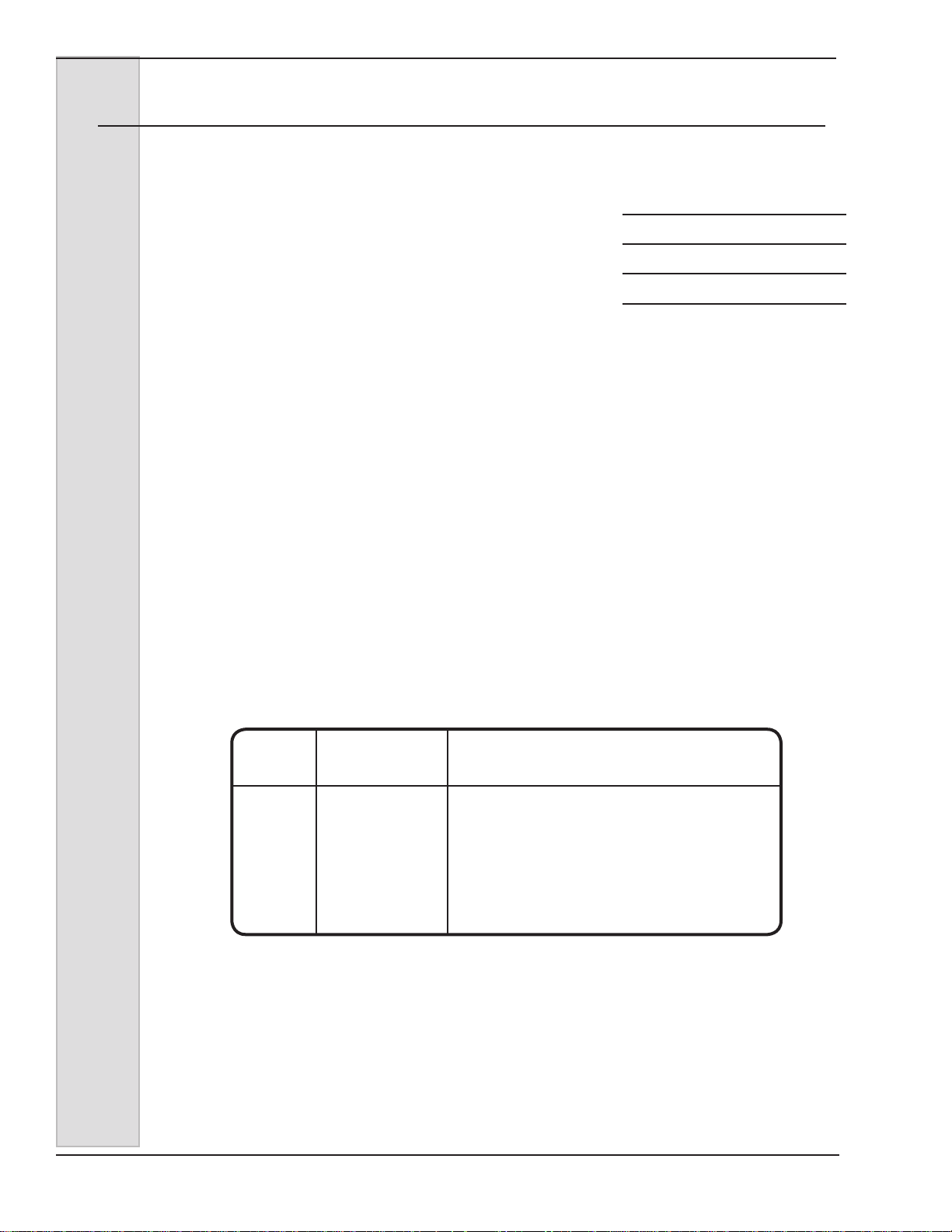

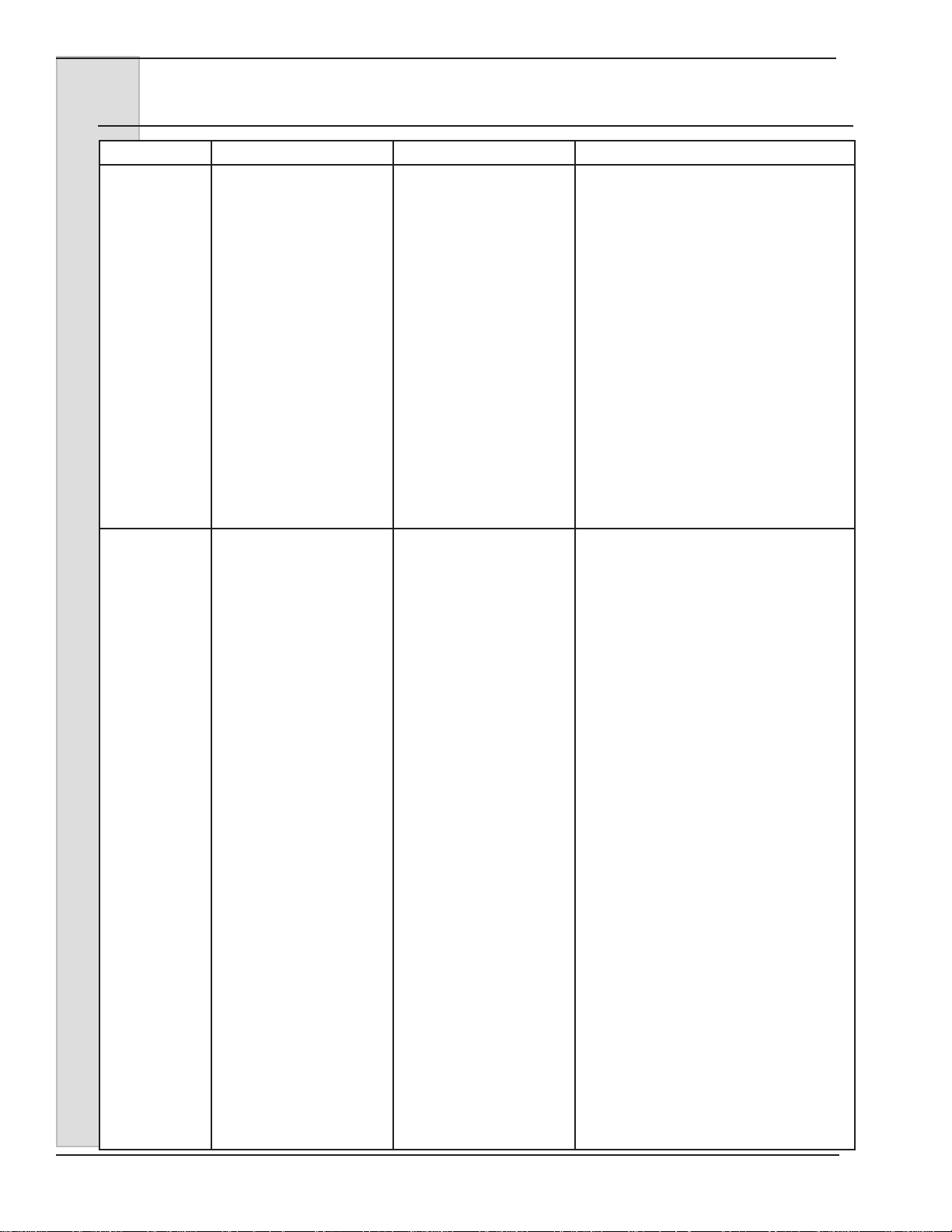

(The decals on the next page are

numbered 1, 2, 3 and 4. Those numbers

correspond to the numbers in the table

below. The table provides the part

number, description, and quantity for each

decal.)

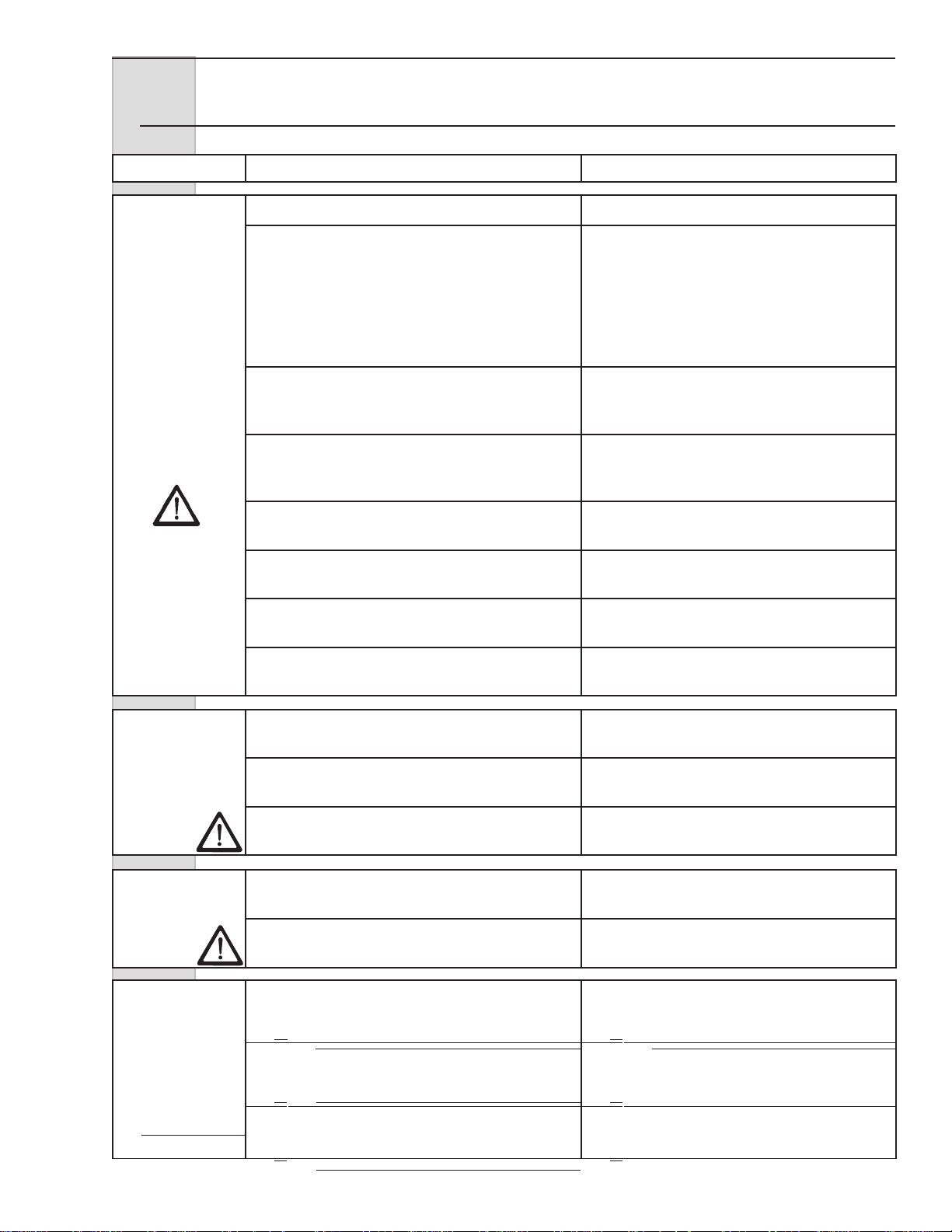

No. Part No. Description (Qty)

1 HC165025 Decal — Beater Warning (1)

2 HC165246 Decal — Pressurized System Warning (2)

3 HC165048 Decal — Warning Rotating Parts (2)

4 HC165126 Decal — Panel Removal Warning (3)

iv

ELECTRO FREEZE Soft Serve Model GEN-2080

165048

Safety Decal Locations

HC165126

4

Do not

operate

with cover

removed!

Pressurized system.

Depressurize unit

before dismantling mix

HC165048

3

transfer system.

HC165246

2

HC165025

1

185240 vii

ELECTRO FREEZE Soft Serve Model GEN-1578

Table of Contents

Safety First ................................................................................................... ii

Safety Decal Locations ................................................................................... iv

Part I

1 Introduction ......................................................................... 1

2 Note to Installer ................................................................... 1

2.1 Uncrating and Inspection ............................................................. 2

2.2 Installation .................................................................................... 2

2.3 Electrical Requirements ............................................................... 3

2.4 Electrical Connections ................................................................. 3

3 Specications ...................................................................... 4

3.1 Particulars .................................................................................... 4

3.2 Installation Date ........................................................................... 4

3.3 Data Plate .................................................................................... 5

3.4 Reference Information ................................................................. 5

3.5 Dimensions .................................................................................. 6

4 Part Names and Functions — Soft Serve ............................ 8

5 Part Names and Functions — Shake .................................. 14

6 Operator Controls ................................................................ 18

7 Operator Display Menu ................................................................. 21

8 Disassembly and Cleaning — Soft Serve ............................ 24

8.1 Cleaning Accessories ................................................................... 25

8.2 Disassembly Instructions ............................................................. 26

8.3 Cleaning Instructions ................................................................... 29

8.3.1 Cleaning & Lubricating MTS Assembly ...................................... 31

9 Disassembly and Cleaning — Shake .................................. 33

9.1 Cleaning Accessories ......................................................... 34

9.2 Disassembly Instructions ............................................................. 36

9.3 Cleaning Instructions ................................................................... 37

9.3.1 Cleaning and Lubricating MTS Assembly .................................. 39

vi

ELECTRO FREEZE Soft Serve Model GEN-1578

Table of Contents — continued

10 Assembly — Soft Serve ....................................................... 40

11 Assembly — Shake ..................................................................... 45

12 Start-up Instructions — Soft Serve ........................................... 51

12.1 Sanitizing Instructions ................................................................ 51

12.2 Priming ....................................................................................... 52

13 Start-up Instructions — Shake ............................................ 53

13.1 Sanitizing Instructions ................................................................ 54

13.2 Priming ....................................................................................... 55

14 Closing Procedures ............................................................. 56

14.1 Night Switch Operation ............................................................... 56

14.2 Draining Product ......................................................................... 56

15 Product Information ............................................................. 58

15.1 Overrun ...................................................................................... 58

15.2 Overrun Adjustment .................................................................... 59

15.3 Rerun .......................................................................................... 59

16 Routine Maintenance ........................................................... 60

17 Troubleshooting Table ......................................................... 66

18 VQM Error Codes ................................................................ 75

Part II

Model GEN-2080 Replacement Parts Manual with Illustrations ............ *

* Refer to Part II Table of Contents

vii

ELECTRO FREEZE Soft Serve Model GEN-2080

1 Introduction

The GEN-2080 Freezer is designed to

produce soft serve ice cream, ice milk,

yogurt, and similar frozen dairy products,

with a product serving temperature range

of 15 to 25°F (-9 to -4°C). It also produces

shakes with a product temperature of

26°F (-3°C). If such products are prepared

from powdered concentrate, they should

be precooled to 40ºF (4°C) prior to

introduction to the freezer. Use of other

products in this machine is considered

misuse (see Warranty).

This manual has been prepared to assist

you in the proper operation and general

maintenance of the Electro Freeze Soft

Serve and Shake Freezer Model GEN-

2080.

Your freezer will not compensate for or

correct any assembly or priming errors

made during the initial start-up. Therefore,

it is important to follow the assembly

and priming procedures detailed in this

manual.

Make sure all personnel responsible for

equipment operation completely read and

understand this manual before operating

the freezer. When properly operated and

maintained, the freezer will produce a

consistent quality product.

If you require technical assistance, please

contact your local authorized Electro

Freeze Distributor as follows:

Name:__________________________

Address: ________________________

________________________________

Phone: __________________________

For factory service assistance — contact

H. C. Duke & Son, LLC., Electro Freeze

Service Department as follows:

Phone: (309) 755-4553

(800) 755-4545

FAX: (309) 755-9858

2 Note to Installer

This freezer must be installed and serviced by an Electro Freeze Distributor or

authorized service technician.

After installation the warranty registration card must be completed and

returned to validate the warranty.

E-mail: service@hcduke.com

185240 1

ELECTRO FREEZE Soft Serve Model GEN-2080

2.1 Uncrating and Inspection

Be sure to properly support

the machine when removing

bolts and installing legs or

casters.

CAUTION

When the unit is received and while

the carrier is still present, inspect the

shipping carton for any damage that

may have occurred in transit. If the

SHOCKWATCH® label indicates red and/

or the carton is broken, torn, or punctured,

Figure 2-1 Machine Bolted to Shipping Base

note the damage on the carrier’s freight

bill and notify the carrier’s local agent

immediately.

1. Remove the carton from the

pallet, and move the machine as close as

possible to the permanent location.

2. Remove the shipping bolts on

the bottom of the freezer (gure 2-1) and

install either the legs or casters (gure

2-2).

NOTE: Screw casters

or legs all the way in

coupling, then adjust

out to level side to side

with a 1/4” slope to the

front.

Figure 2-2 Installing Mounting Legs or Casters

2.2 Installation

CAUTION

All materials and connections

must conform to local

requirements and be in

compliance with the National

Electrical Code (NEC).

2 185240

1. This freezer is designed for indoor

use and must be protected from outdoor

weather conditions.

– continued

ELECTRO FREEZE Soft Serve Model GEN-2080

2.2 Installation (continued)

2. Where codes permit, we

recommend that the freezer be installed

on casters and have exible water and

electrical connections for service and

cleaning ability.

3. All models require a minimum 6

inch (15 cm) clearance on either the side

panels or the rear panel for adequate

ventilation. Freezers designed with top air

discharge require that at least 18 inches

(45 cm) above the top panel be free of

obstructions. Anything blocking ventilation

of the freezer (including cone dispensers)

will reduce the efciency of the freezer.

4. Water cooled models will require

a 1/2 inch MPT water inlet and water

waste connection. Both condensers are

2.3 Electrical Requirements

CAUTION

To prevent accidental electrical shock, a

positive earth ground is

required.

1. Always verify electrical

specications on the data plate of each

freezer. Data plate specications (see

Figure 3-1) will always supersede the

information in this manual.

tied together so that one water inlet and

one water waste is all that is required.

The connections are found on the bottom

under the compressor mounting area

and are tagged “Water Inlet” and “Water

Waste.” A manual shut-off valve should be

installed in the water inlet line at the time

of installation. The water pressure must

be above 35 psig (241 kPa) and below

140 psig (965 kPa) for proper operation.

5. Place the freezer in the nal

location and level by adjusting the legs or

casters so that it is level side-to-side and

the front is approximately ¼ inch lower

than the rear (to allow proper drainage of

the freezing cylinder).

2. Supply voltage must be within

+ 10% of voltage indicated on the

nameplate. Also, on three-phase

systems, voltage between phases must

be balanced within 2%. (More than a 6

volt difference between any two voltage

measurements at 208-230 volts indicates

a possible imbalance.) Request your local

power company to correct any voltage

problem.

3. An easily accessible main power

disconnect must be provided for all poles

of the wiring to the freezer.

2.4 Electrical Connections

CAUTION

To prevent accidental electrical shock, a positive earth

ground is required.

1. Double freezers with two

compressors require one power supply for

each side of the freezer. Each side of the

freezer operates independently.

2. Check the data plate for fuse

size, wire ampacity and electrical

specications.

185240 3

3. Refer to the wiring diagram

provided for proper power connections.

4. Electrical connections are made in

the junction box located mid-level behind

the left side panel.

5. Use a exible connection when

permissible. All materials and connections

must conform to local codes and the

National Electrical Code.

6. For 3 phase freezers, beater shaft

rotation must be clockwise as viewed

from the front of the freezer.

ELECTRO FREEZE Soft Serve Model GEN-2080

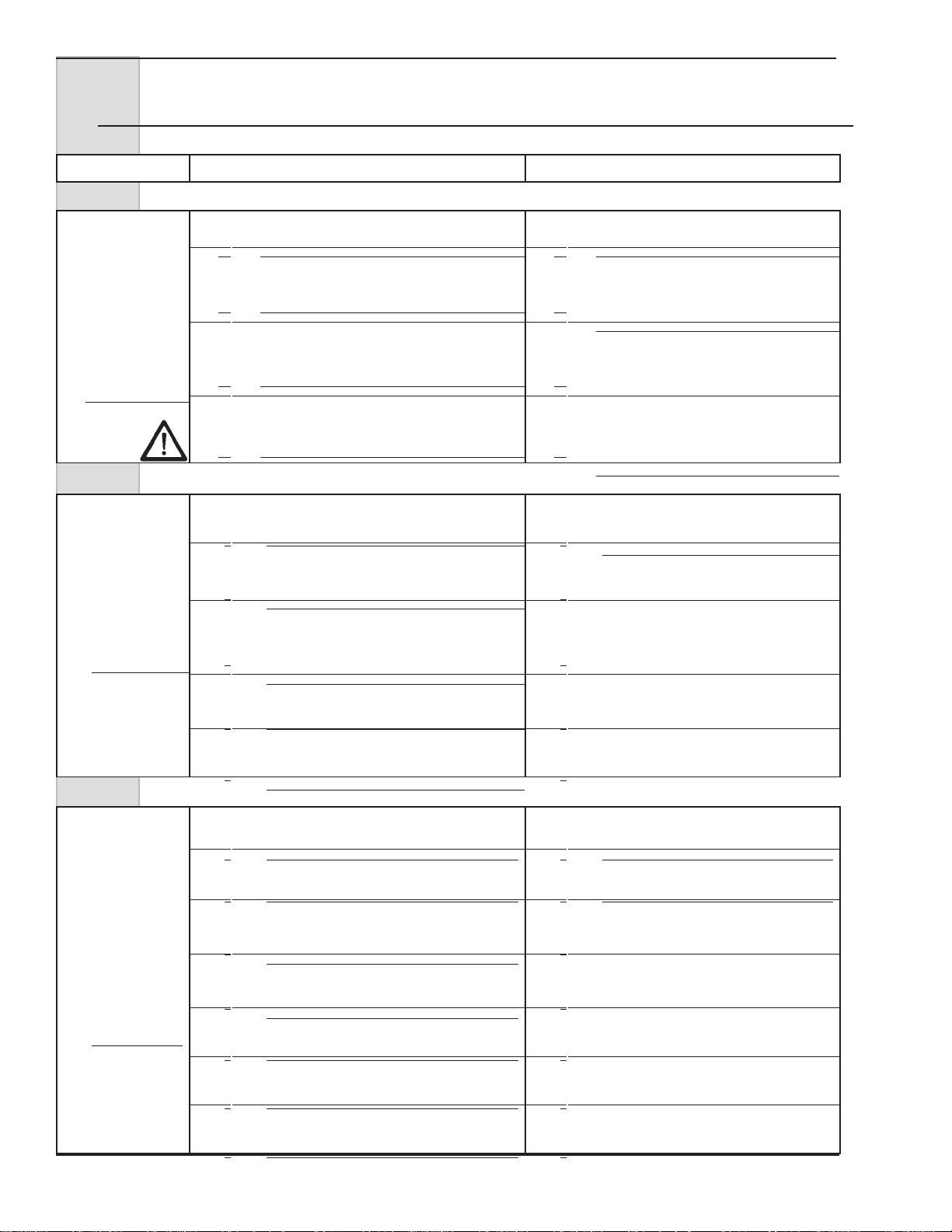

3 Specifications

3.1 Particulars

Always check and verify voltage and amperage on the data

plate located on the back panel of each freezer.

GEN-2080 Combination Soft Serve and Shake Freezer

Width (in/cm) 26 / 66

Height (in/cm) 70 / 178 (Air Cooled Models)

67.5 / 172 (Water and Air Cooled Remote Models)

Depth (in/cm) 36.5 / 93

Weight (lbs/kg) 852 / 408

Soft Serve Shake

Compressors 2 HP / 9500 BTU 2 HP 12000 BTU

1.5 kw (Motor) 1.5 kw (Motor)

2.8 kw (Cooling) 2.8 kw (Cooling)

Beater Motor 2 HP / 1.5 kw 1 .5 HP / 1.1 kw

Refrigerant 404a 404a

Charge 3.75 lb. / 1.7 kg 3.75 lb. / 1.7 kg

Mix Container 30 qts. / 28.4 L 28 qts. / 26.5 L

Cylinder 4 Qts. / 3.8 L 9 Qts. / 8.51 L

3.2 Installation Date

Fill in the date of installation, and the name, address, and phone number of the

installer in the space provided below. This information will be needed when ordering

parts or service for the GEN-2080 Freezer.

Date of installation: ___________________________________

Installed by: ___________________________________

Address: ___________________________________

___________________________________

Phone: ___________________________________

4 185240

ELECTRO FREEZE Soft Serve Model GEN-2080

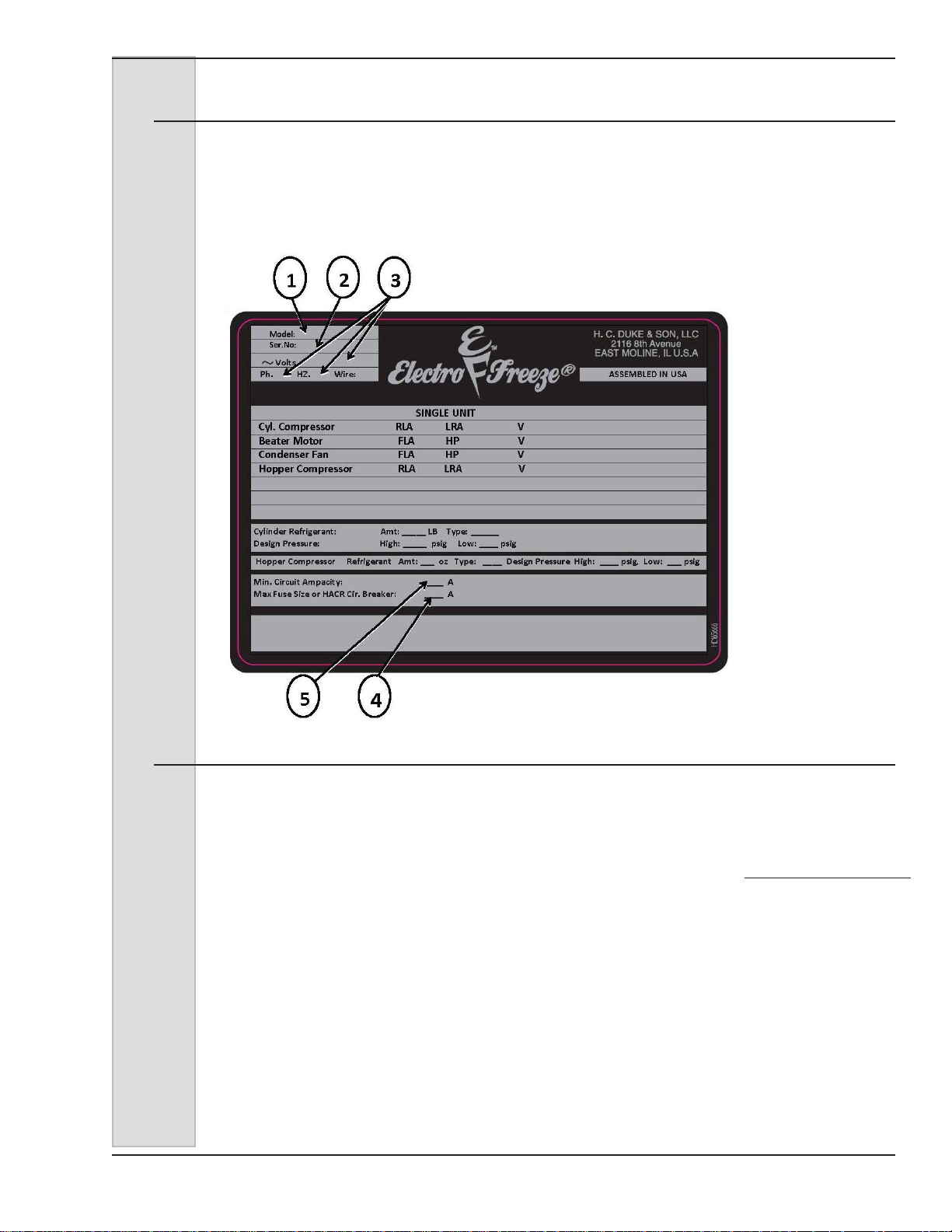

3.3 Data Plate

The data plate provides important information that the operator should record

and have available for parts ordering,

warranty and service requests.

Figure 3-1

3.4 Reference Information

Write in

Reference

Information HERE!

Fill in this information as soon as you

receive the Electro Freeze GEN-2080

Soft Serve/Shake Freezer. The item

numbers, encircled, correspond with the

call-out numbers in gure 3-1.

1.) Model Number: ________________

2.) Serial Number: ________________

3.) Electrical Spec: Voltage _________

Phase _______ Hertz _________

4.) Maximum Fuse Size: ____________

5.) Minimum Circuit Ampacity:________

185240 5

ELECTRO FREEZE Soft Serve Model GEN-2080

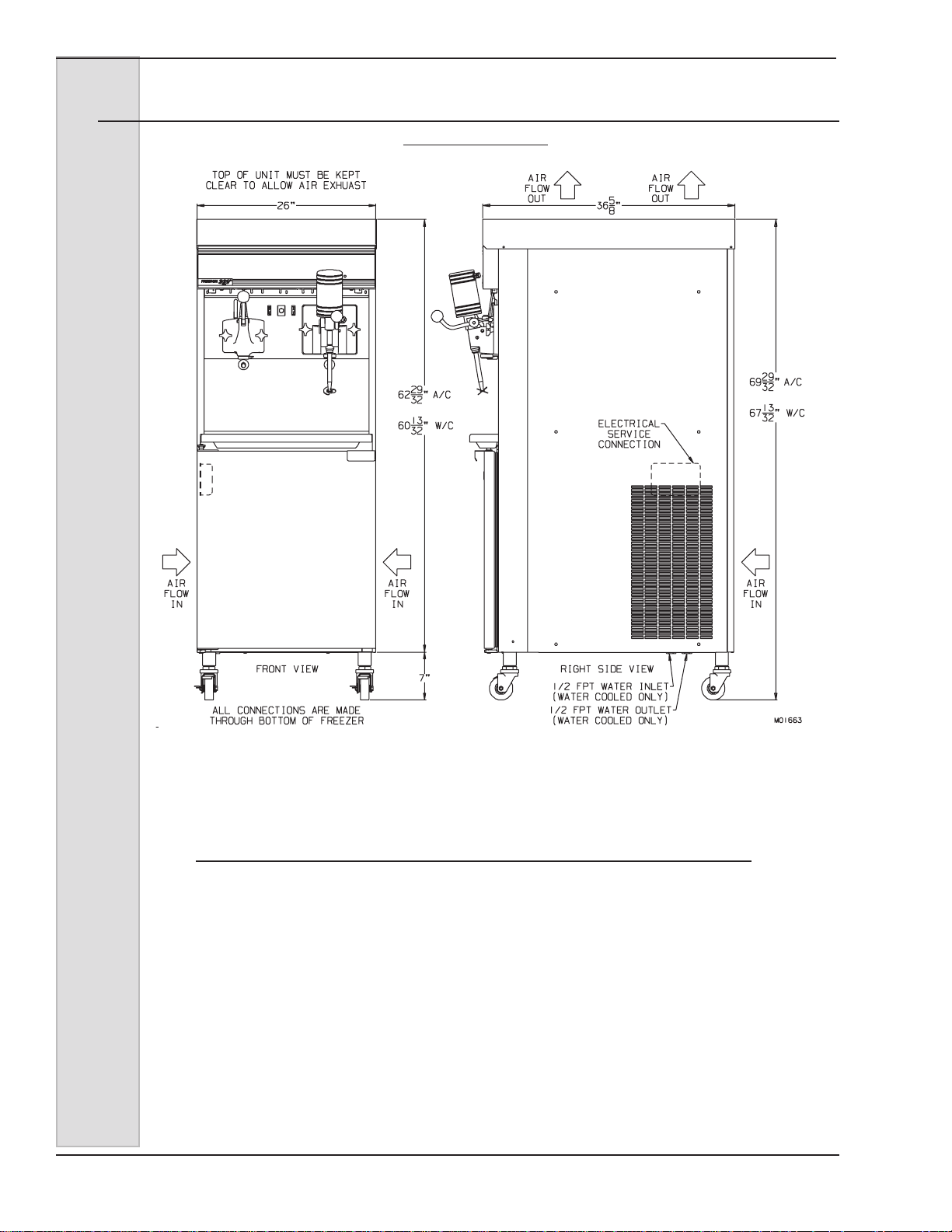

3.5 Dimensions

MODEL GEN-2080

W/C = Water Cooled Models

A/C = Air Cooled Models

ACR = Air Cooled Remote Models dimensions are the same as W/C

Figure 3-2

6 185240

ELECTRO FREEZE Soft Serve Model GEN-2080

NOTE: Combination Soft Serve/Shake

Freezers

Please note that in the following pages of this manual,

some sections relate specifically to either the “Soft

Serve” side of the freezer or the “Shake” side of the

freezer. The GEN-2080 combination freezer actually

contains two separate systems — one side provides

soft serve ice cream and the other, shakes. Although

there are some part and procedure similarities

between the shake and soft serve sides, we have

separated them to make it easier for you to find the

information you need. You may notice a duplication of

some information. Where feasible the information is

only provided once, for both sides.

Look for the Electro Freeze Cone and term “Soft

Serve” in the section header for instructions

concerning the frozen dessert side of the freezer.

Look for the Electro Freeze Shake and the term

“Shake” in the section header for instructions

concerning the shake side of the freezer.

185240 7

ELECTRO FREEZE Soft Serve Model GEN-2080

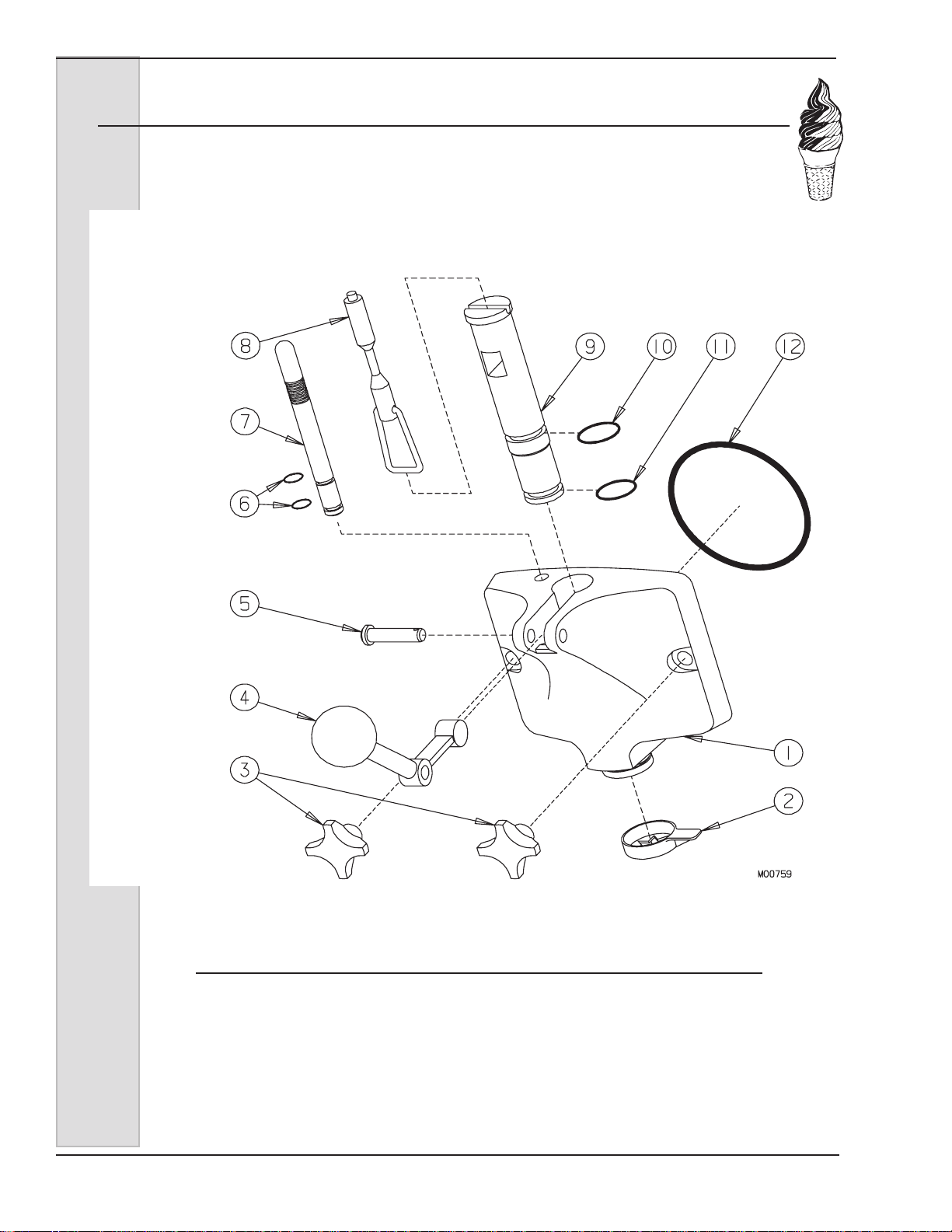

4 Part Names and Functions — Soft Serve

ROD-PLUNGER

PLUG-AIR BLEED

O-RING-PLUG

PIN-HANDLE

HANDLE-DISPENSE

KNOB-HAND

PLUNGER

O-RING-HEAD

O-RING-PLUNGER

O-RING-PLUNGER

HEADDISPENSE

Figure 4-1 Head Assembly

8 185240

NOZZLE

ELECTRO FREEZE Soft Serve Model GEN-2080

4 Part Names and Functions — Soft Serve

The following descriptions apply to gure 4-1. The number preceding the

part name corresponds to the number in the gure.

1.) HEAD: Encloses the freezing

cylinder and provides an opening for

product to be dispensed.

2.) NOZZLE: Shapes the frozen

product as it is dispensed.

3.) KNOB-HAND: Secures the

dispensing head to the freezing

cylinder.

4.) HANDLE-DISPENSE: Opens and

closes the plunger to start and stop

the ow of product from the freezer.

5.) PIN-HANDLE: Secures the handle

to the dispense head.

6.) O-RING-PLUG: Seals the air bleed

plug in the dispense head.

7.) PLUG-AIR BLEED: Seals the air

bleed opening in the head when

closed. Allows excess air to be

removed from the cylinder in the

lling process.

8.) ROD-PLUNGER: Starts the freezer

when dispensing. Must be in place

before freezer will operate.

9.) PLUNGER: Seals the product

opening in the head when closed.

Allows product to ow when open.

10.) O-RING-PLUNGER-UPPER: Seals

the plunger in the dispensing head.

Must be lubricated to seal and slide

properly.

11.) O-RING-PLUNGER-LOWER: Seals

the plunger in the dispensing head.

Must be lubricated to seal and slide

properly.

12.) O-RING-HEAD: Seals the

dispensing head to the freezing

cylinder. Must be lubricated.

185240 9

ELECTRO FREEZE Soft Serve Model GEN-2080

4 Part Names and Functions — Soft Serve

Figure 4-2 Soft Serve Beater Shaft Assembly

10 185240

ELECTRO FREEZE Soft Serve Model GEN-2080

4 Part Names and Functions — Soft Serve

The following descriptions apply to gure 4-2. The number preceding the

part name corresponds to the number in the gure.

1.) BUSHING - CYLINDER: Holds the

beater in place at the front of the cylinder. Center must be lubricated.

2.) SHAFT - ASSY. BEATER: Rotates

in the freezing cylinder, blending air

and mix as it ejects product.

3.) BLADE - SCRAPER SOFT SERVE:

Scrapes the frozen product from the

freezing cylinder wall.

Important:

Soft serve blades only have 2 holes

and are not interchangeable with the

3 hole shake blades. If the incorrect

blades are used the freezer could be

damaged.

4.) O-RING - SHAFT SEAL: Seals the

beater shaft to the shaft seal. Is

inserted into the shaft seal bushing.

Must be lubricated.

5.) WASHER - SHAFT SEAL: Holds

the shaft seal o-ring. Lightly lubricate the side opposite the cup

seal.

6.) SEAL(CUP) - BEATER SHAFT:

Seals the opening between the

freezing cylinder and the beater

shaft. Do not lubricate rubber cup

portion.

185240 11

ELECTRO FREEZE Soft Serve Model GEN-2080

AIR METER

TUBE-AIR

RETAINER-AIR TUBE

CLAMP-SOFT HOSE

HOSE-MIX BRAIDED

SUPPORT-ROLLER

BEARING

HOSE-TRANSFER

RED LINE

ROLLER-ASSY

COMPLETE

SHOE-ROLLER

CLAMP-SOFT HOSE

O-RING

PORT-AIR/MIX INLET

CLIP-TUBE RETAINER

CLAMP-SOFT HOSE

ARM-SWING CLAMP

KNOB-HAND

COVER-MTS

TUBE-ASSY

PICKUP

DUCKBILL-INLET

20

VALVEPRESSURE RELIEF

4 Part Names and Functions

Figure 4-3 Mix Transfer System (MTS)

12 185240

ELECTRO FREEZE Soft Serve Model GEN-2080

4 Part Names and Functions

The following descriptions apply to gure 4-3. The number preceding the part

name corresponds to the number in the gure.

1.) SUPPORT-ROLLER BEARING:

Holds roller assembly in place.

2.) SHOE-ROLLER: Provides an

opening to insert the mix transfer

hose. Squeezes transfer hose

against rollers.

3.) ROLLER ASSEMBL Y COMPLETE:

Squeezes mix/air through tubing to

freezing cylinder.

4.) KNOB-HAND: Locks roller shoe in

position.

5.) CLAMP-SHOE: Swings hand knob

into position over roller shoe.

6.) RETAINER-AIR TUBE: Holds air

meter tube in the “up” position.

7.) AIR METER: Regulates the amount

of air being drawn into the system.

8.) TUBE-AIR: Provides connection for

the air meter.

12.) HOSE - TRANSFER RED: Special

“red-lined” hose that is squeezed by

rollers to transfer mix to freezer.

13.) TUBE-ASSEMBLY MIX INLET:

Carries mix from mix container to

MTS.

14.) DUCKBILL: A rubber check valve

that prevents mix from falling back

into the mix container.

15.) PORT - AIR/MIX: Blends air and

mix as it ows into the transfer

hose.

16.) CLIP - TUBE RETAINER: Locks

mix pickup tube into air/mix port.

17.) O-RING: Seals the mix tube in the

air/mix port.

9.) CLAMP - ASSY. SOFT HOSE 5/8”:

Prevents mating parts from leaking.

10.) HOSE - ASSY. MIX BRAIDED:

Connecting tube between the Mix

Transfer System and the cylinder

inlet.

11.) COVER - MTS: Protection against

moving parts. Cover must be in

place for the MTS to operate.

185240 13

ELECTRO FREEZE Soft Serve Model GEN-2080

5 Part Names and Functions — Shake

Figure 5-1 Head Assembly

14 185240

ELECTRO FREEZE Soft Serve Model GEN-2080

5 Part Names and Functions — Shake

The following descriptions apply to gure 5-1. The number preceding the

part name corresponds to the number in the gure.

1.) HEAD - ASSY. W/ACTUATOR:

Encloses the freezing cylinder and

provides an opening for product to

be dispensed.

2.) BUSHING - BEATER BEARING:

Holds the beater in place at the front

of the cylinder. Must be inserted

into the head and lubricated before

assembly.

3.) O-RING - HEAD: Seals the head

to the freezing cylinder. Must be

lubricated.

4.)

and

5.) O-RINGS - PLUNGER: (UPPER &

LOWER): Seals the plunger in the

head. Must be lubricated to seal and

slide properly.

6.) PLUNGER - DISPENSING BLACK:

Seals the product opening in the head

when closed. Allows product to ow

when open.

7.) PUSH ROD - ASSY. PLUNGER

SWITCH: Starts the freezer when

dispensing. Must be in place before

freezer will operate.

12.) O-RING - PIVOT POST:

Holds the pivot post in place.

13.) HANDLE - ASSY. SPINDLE HEAD:

Opens and closes the plunger to

start and stop the ow of product

from the freezer.

14.) KEEPER - ASSY. SPINDLE: Secures the handle to the head.

15.) KNOB - HAND: Secures the head

to the freezing cylinder.

16.) O-RING - AIR RELIEF PLUG:

Seals the air relief screw in the

head.

17.) PLUG - AIR RELIEF: Seals the

air relief opening in the head when

closed. Allows excess air to be

removed from the cylinder when

lling.

18.) EXTENSION-SHAKE SPIGOT:

Product ows from the head through

the extension.

19.) O-RING-SPIGOT EXTENSION:

Seals the extension to the head.

8.) FUSE - SLO BLOW 1A: Prevents the

spindle motor from overload.

9.) SPINDLE - ASSY. FRONT MOUNT:

Mixes the shake as it is dispensed.

10.) O-RING - SPINDLE ASSY.: Holds the

spindle in place.

11.) POST - PIVOT (Optional): Holds

the handle in place when the spindle is not used.

185240 15

ELECTRO FREEZE Soft Serve Model GEN-2080

5 Part Names and Functions — Shake

Figure 5-2

16 185240

ELECTRO FREEZE Soft Serve Model GEN-2080

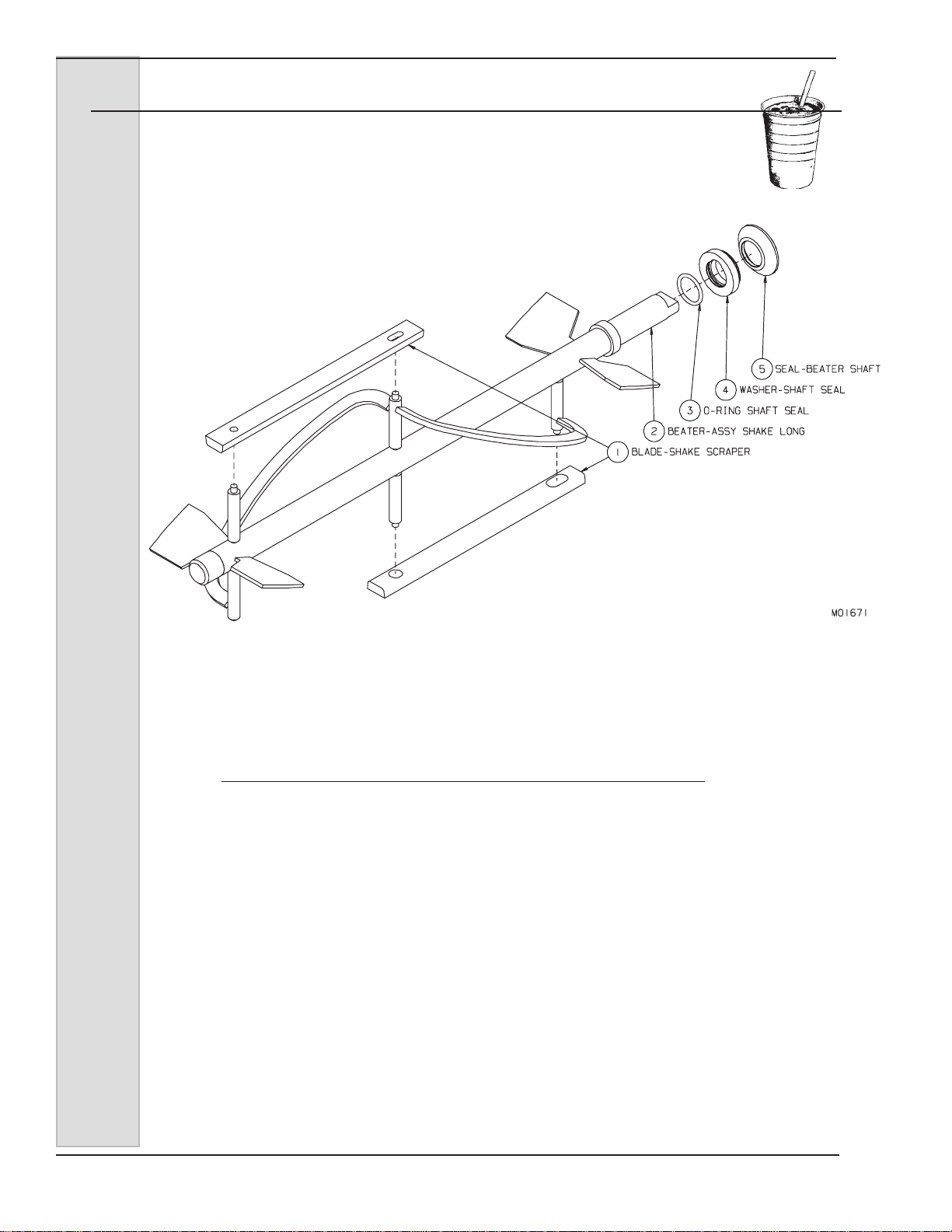

5 Part Names and Functions — Shake

The following descriptions apply to gure 5-2. The number preceding the

part name corresponds to the number in the gure.

1.) BLADE - SCRAPER: Scrapes the

frozen product from the freezing

cylinder wall.

Important:

Shake blades have 3 holes and are

not interchangeable with the 2 hole

soft serve blades. If the incorrect

blades are used the freezer could be

damaged.

2.) SHAFT - BEATER: Rotates in the

freezing cylinder, blending air and mix

and ejecting product.

3.) O-RING-SHAFT SEAL: Seals the

beater shaft to the shaft seal. Is

inserted into the shaft seal washer.

Must be lubricated.

4.) WASHER-SHAFT SEAL: Holds the

shaft seal o-ring. Lightly lubricate

the side opposite the cup seal.

5.) SEAL(CUP)-BEATER SHAFT: Seals

the opening between the freezing

cylinder and the beater shaft. Do not

lubricate rubber cup portion.

185240 17

ELECTRO FREEZE Soft Serve Model GEN-2080

L1

23

45 6789

10

2

4

L2 R1 R2

1

LEFT RIGHT

OFF

OFF

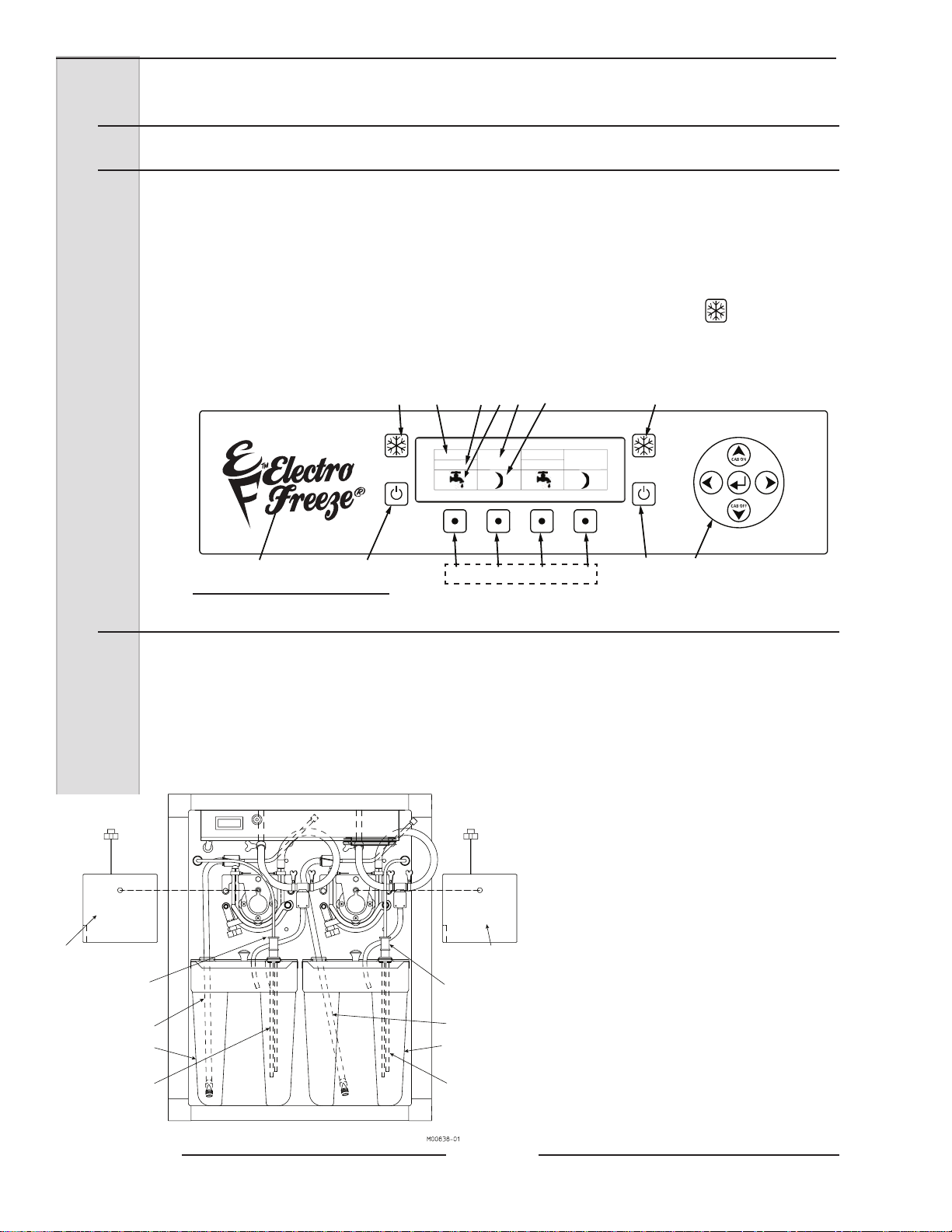

6 Operator Controls

Figure 6-1

The following paragraphs describe the

operator controls. Refer to Fig. 5-1 for

numbered items in description. Note

the left side controls operates the left

side cylinder. Operation for right side

controls is the same. The display

window has three levels of display:

Operators Menu, Technician Menu. The

last menu is restricted and reserved for

use by qualied personnel.

NOTE: The dispense head must be in

place before the freezer will operate.

CAUTION

Test operation of the head

switch prior to placing

the freezer in service.

See Section 11, Routine

Maintenance, Monthly.

1. Function Buttons (Four)

Pressing any of these buttons will activate the icon directly above in the display screen.

Left side (L1 & L2), Right Side (R1& R2).

2. OFF Key

When this symbol is pressed, the left side of unit will shut off. The beater motor and

compressor will not operate.

3. Navigation Pad (Up/Down = Cabinet ON/OFF)

Used to navigate the menu structure. Up/Down arrows are used to turn the cabinet

on/off when both cylinders are off. Used by technicians for programming and setting

changes. See Troubleshooting section for Operator accessible controls.

4. Freeze Symbol

18 185240

When this symbol is pressed, the unit will enter the automatic freeze mode. Both

the hopper and cylinder compressors will energize to refrigerate product to settings

in program. Use this button for DAY mode operation to maintain product in “ready

to serve” state.

ELECTRO FREEZE Soft Serve Model GEN-2080

6 Operator Controls (continued)

5. Left or Right side Control Indicator

Left indicates controls for left side cylinder and hopper. “Right” Indicates controls

for right side of freezer cylinder and hopper.

6. Mode of Operation Indicator

There are three primary modes of operation:

a. OFF –This is the indicator when power is applied to freezer and when

(OFF) button is pressed. In this mode, the refrigeration and beater motor

will not operate.

b. FRZ – This is the indicator when Freeze button is pressed. In this

mode, the freezer is in automatic freeze mode and both the beater motor

and refrigeration will activate as needed. Use this position for dispensing

product from freezer. Cabinet will also be refrigerated as needed to

maintain product below 41°F.

Important:

in the cylinder or hopper. The freezer will be damaged.

c. Standby – This is the indication when the Night button is pressed. In this

mode, an energy-saving feature will activate and reduce product

refrigeration. The freezer will automatically cycle to maintain temperatures

in the cylinder and cabinet below 41°F and keep product from deteriorating.

Use this position when the freezer will not be in use for periods of more

than one hour.

Important:

cleaning and sanitation procedures at the frequencies required by the

federal, state, or local regulatory agency.

Do not use the freeze position with water or sanitizer

Night/standby mode is not to be used in lieu of proper

7. Wash or Clean Mode

Press the function button directly below icon to activate clean mode. Also allows

individual activation of the mix pump & beater.

8. Information Window

This window is normally blank when unit is functioning properly. This window will

give you indication when mix in hopper is low and other error messages. Refer to

Troubleshooting Section of manual for details on error messages.

9. Standby Indicator

This is the indication when the Night button is pressed. In this mode, an energysaving feature will activate and reduce product refrigeration. The freezer will

automatically cycle to maintain temperatures in the cylinder and cabinet below 41°F and

keep product from deteriorating. Use this position when the freezer will not be in use for

periods of more than one hour.

10. Hidden Operator Menu Key

Press this key to enter the operator menu to adjust the freezers settings.

185240 19

ELECTRO FREEZE Soft Serve Model GEN-2080

LEFT RIGHT

OFF

OFF

L1

23

45 6789

10

2

4

L2 R1 R2

1

LEFT RIGHT

OFF

OFF

6 Operator Controls (continued)

11 Power Switch See Figure 6-3

In the “ON” position, power is supplied

to the beater motors. Use this position

11

to operate the freezer. Select the ”OFF”

position for disassembly and cleaning.

See Operators Display Menu for use of

this switch in recording cleaning cycles.

Figure 6-3

7 Operator Display Menus

Figure 7-1

To Enter the Operator Menu, push and hold the hidden key (11) under the F for 3 seconds

(gure 6-1).

Figure 7-2

The operator menu will show up on the screen (gure 7-2). The cursor will highlight the selected

sub-menu (i.e. Basic Setting, Actual Temps, etc.), use the Arrow Buttons to move the cursor up or

down to the desired sub-menu. Once the desired menu is highlighted, in this example we will use

Basic Settings, press the select (

Offset will be shown for left and right barrel. Use the Arrow Buttons to move the cursor to highlight

the value to be changed, once highlighted press the select button and the cursor will now be

) button to enter the sub-menu. Product Type and Temperature

blinking. While the cursor is blinking the value may now be changed using the left or right Arrow

Buttons, once you have reached the desired setting press select (

) one more time, the cursor

will now stop blinking, this indicates that the value change has been stored. Follow these steps to

change any other desired settings, once complete you may use the far right Function button to exit

the operator menu or just wait and the menu will time out and return to the Home screen.

20 185240

ELECTRO FREEZE Soft Serve Model GEN-2080

7 Operator Display Menus

Below is a list of the menu categories that are displayed upon entering the

Operator’s menu.

Operator’s Menu Options

• Basic Settings

• Actual T emps

• Event Log

• Error Log

• Lockouts

• Screen Settings

• Date/Time

• Last Clean

• Software Version

The following information explains more about each of the menu options.

Basic Settings: Information Shown

Left Barrel: nonfat, lowfat, highfat, or yogurt

Right Barrel: nonfat, lowfat, highfat, or yogurt

Temperature Offset 1-9, 5 is neutral

Actual Temps: Information Shown

Cabinet Temperature

Cylinder Temperature: Left or Right Cylinder

Event Log: Allows the operator to look at logged events i.e. power switch cycle, low

Error Log: Allows the operator to look at logged errors i.e. Barrel refrigeration

Statistics: Shows the number of starts that the compressor/compressors,

switches and beater motors have seen. Also displays the cumulative

run time in hours for compressors and beater motors.

Information Shown

On Time Left & Right Barrel

Freeze Mode Left & Right Barrel

Standby Mode Left & Right Barrel

Off Left & Right Barrel

Last PWR Fail

All PWR Fail Time

All PWR Fails

Product Type

mix, etc. The log will display the last 50 events with the newest

event at the top.

timeout, low/high refrigeration pressure, etc. The log will display the

last 50 events with the newest event at the top.

185240 21

ELECTRO FREEZE Soft Serve Model GEN-2080

7 Operator Display Menus (continued)

Spigot Left & Right Barrel

Statistics Cont.

Center Spigot

Spigot Hours Left & Right Barrel

C Spigot Hours

Comp. Starts Left & Right Barrel

Comp. Hours Left & Right Barrel

Beater Starts Left & Right Barrel

Beater Hours Left & Right Barrel

Cab Comp. Starts

Cab Comp. Hours

Pump Starts Left & Right Barrel

Pump Hours Left & Right Barrel

Lockouts: Allows the operator to lock out the clean, freeze, and night function

so that on the home screen when the button is pressed the unit will

not react.

Information Shown

Freeze Mode Y or N

Clean Mode Y or N

Standby Mode Y or N

Cab Only Mode Y or N

Cones Left 5

Screen Settings: Operator can turn on or off the following functions:

Display Cabinet Temperature Y or N

(Will or will not display Cabinet temp. on home screen)

Alternate Moon Y or N

Beep Function Y or N

(unit will or will not beep when a button is pressed)

Hide Clock Error Y or N

Date/Time: Allows user to set the Real Time Clock and current date in the unit.

Last Clean: Displays the Last time the unit has been cleaned

Software Versions: Has current software version numbers for both the U.I. and Main

board

Main ———

U.I. ————

Model GEN

Cyl Count 2

Compressors 2

Hopper Y or N

Cabinet Y or N

Product Table GEN or SLX

22 185240

ELECTRO FREEZE Soft Serve Model GEN-2080

LEFT RIGHT

OFF

OFF

Press to start Left Clean Mode

Press to start Right Clean Mode

CABINET

ON

370F

LEFT RIGHT

OFF

OFF

CABINET

ON

370F

PUMP

ON OFF

PUMP

ON OFF

BEATER

ON OFF

BEATER

ON OFF

Press to turn left

beater on

Press to turn left

pump on

Press to turn right

beater on

Press to turn right

pump on

LEFT RIGHT

ON

ON

CABINET

ON

370F

Press to enter Standby mode

7 Operator Display Menus (continued)

Cabinet Temperature Map for user adjustment. User will only see 1 through 9 but the table

below shows the differences with each number change. 6 is default setting

185240 23

ELECTRO FREEZE Soft Serve Model GEN-2080

8 Disassembly and Cleaning — Soft Serve

Safety Information

This freezer uses pressure to assure

consistent product quality. It is important

for your safety that the freezer is

depressurized slowly and completely

whenever the freezer is to be drained,

disassembled, cleaned, or serviced. The

safety instructions in this manual will

remind you when to check to make sure

the freezer is depressurized. When you

CAUTION

Make sure freezer is

depressurized before

proceeding.

see this CAUTION statement

the following steps should be taken:

It is important that the freezer

be disassembled, washed,

lubricated and sanitized before

operation.

The cleaning and sanitizing instructions

explained in this manual are required to

maintain a clean, sanitary freezer. The

freezer should be disassembled, cleaned,

reassembled, lubricated and sanitized

daily to ensure the best possible product

quality and freezer operation.

Persons assembling, cleaning or

sanitizing the freezer must rst wash

and sanitize hands and forearms with an

approved sanitizer.

1. Using the buttons L2 & R2 on the

control panel be sure both MTS pumps

are in the “OFF” position.

CAUTION

To avoid electrical shock or

contact with moving parts,

make sure the control pad

is “OFF” and that the main

power switch is “OFF”.

2. Turn the control pad “OFF” and then

turn “OFF” the main power switch.

3. Place a clean bucket under the

dispense head.

4. Slowly open the spigots, allowing

any pressurized cleaning solution or

air to escape. If there is product in

the freezer refer to Section 9, Closing

Procedures, 9.1 Draining Product.

5. Remove the spigot switch rods and

open the spigots completely.

6. Inside the refrigerated cabinet,

remove the MTS cover, loosen the shoe

clamp hand knob, swing back the shoe

clamp and swing open the roller shoe on

both mix transfer systems.

Following these steps will assure that the

system is depressurized.

24 185240

ELECTRO FREEZE Soft Serve Model GEN-2080

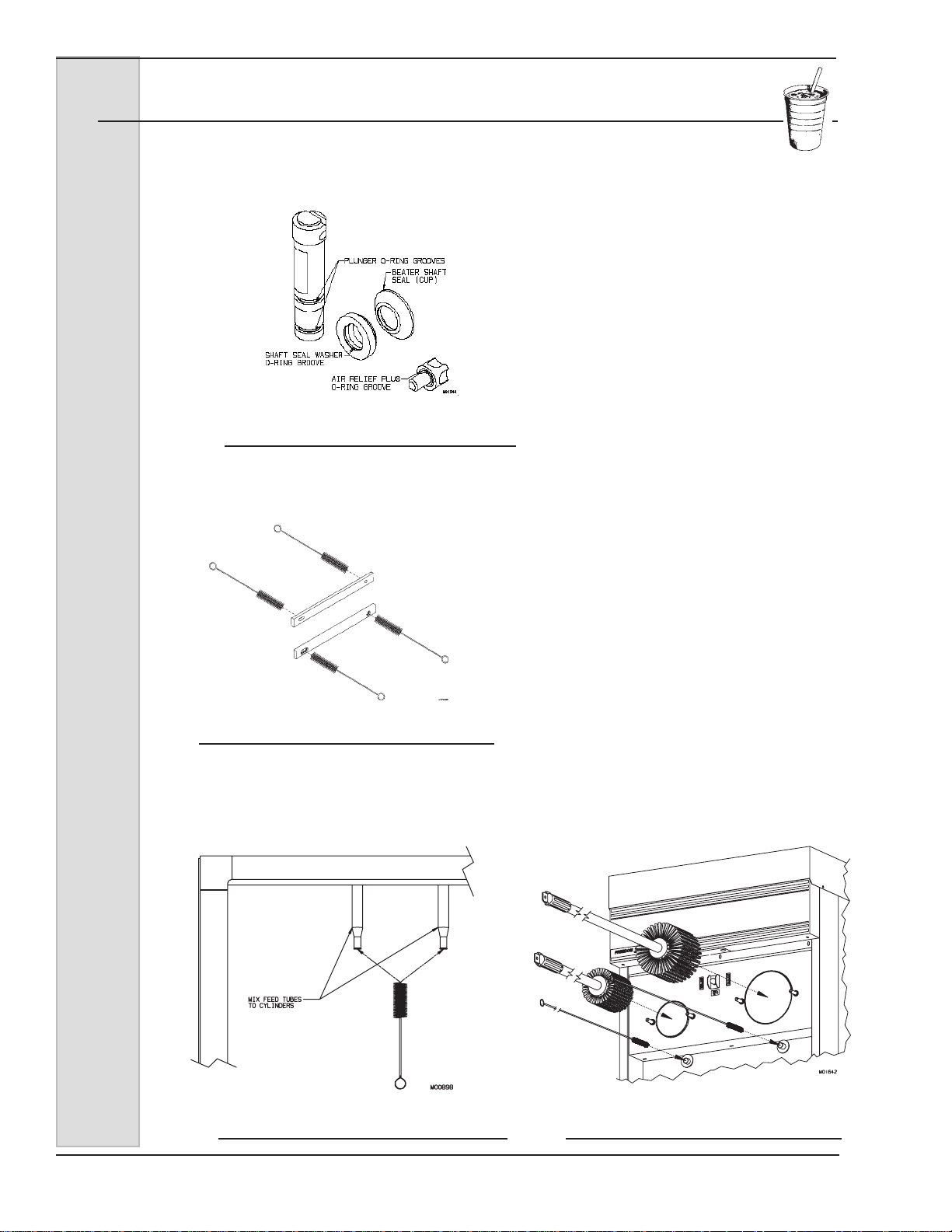

8.1 Cleaning Accessories — Soft Serve

The following accessories shipped with the freezer are necessary for cleaning,

sanitizing, and disassembly/assembly (Figure 8-1):

1.) HC158004 BRUSH: 4 inch diameter

with 36 inch handle used to clean

the shake cylinder.

2.) HC158019 BRUSH: 9/16 inch

diameter 30 inches long used to

clean drain tube, the mix feed tube

in the ceiling of the cabinet and the

pickup tube.

3.) HC158018 BRUSH: 7/16 inch

diameter 12 inches long used to

clean transfer hose, braided hose,

and the air relief opening in the

dispense head.

4.) HC158026 BRUSH: 1 inch diameter

12 inches long used to clean

the disassembled shaft seal and

bushing.

5.) HC158037 BRUSH: 1/4 inch

diameter 18-1/2 inches overall

length used to clean the air meter

hose, the small hole in the back

of the dispense head and small

parts.

6.) HC169374 TOOL - O-RING

REMOVAL: Aids in removing O-rings

from plunger, head, air relief plug,

and spindle.

7.) HC158000A LUBRICANT -

PETROL-GEL: Approved lubricant

for moving parts and O-rings.

8.) HC196103 BOTTLE, WASH:

Used to ush the hose cavity, roller

assembly and plunger.

9.) HC115530 KIT - O-RING: Contains

all O-rings and seals needing

replacement on a regular basis. (not

shown)

1

2

3

4

5

6

7

8

Figure 8-1 Cleaning Accessories

185240 25

ELECTRO FREEZE Soft Serve Model GEN-2080

8.2 Disassembly Instructions — Soft Serve

ROD-PLUNGER

PLUG-AIR BLEED

O-RING-PLUG

PIN-HANDLE

HANDLE-DISPENSE

KNOB-HAND

PLUNGER

O-RING-HEAD

O-RING-PLUNGER

O-RING-PLUNGER

HEADDISPENSE

Figure 8-2 Disassemble the Head Assembly

26 185240

NOZZLE

ELECTRO FREEZE Soft Serve Model GEN-2080

8.2 Disassembly Instructions — Soft Serve (continued)

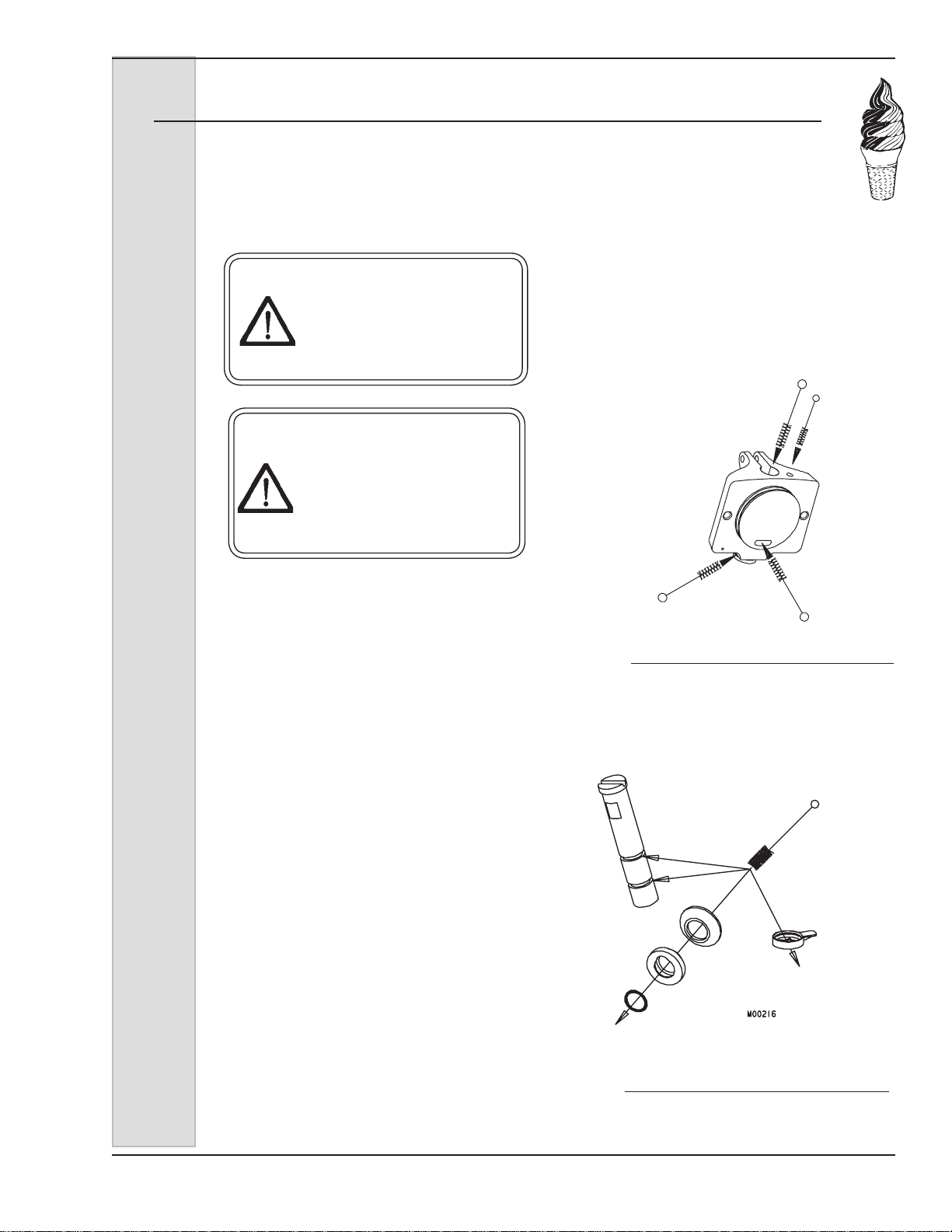

CAUTION

Make sure freezer is

depressurized before

proceeding.

CAUTION

To avoid electrical shock or

contact with moving parts,

make sure all switches are

in the “OFF” position and

that the main power source

is disconnected. Some

freezers have more than one

disconnect switch.

1. If there is product in the freezer

refer to Section 14, Closing Procedures,

14.2 Draining Product.

2. Remove the plunger rod (8, gure

8-2) by lifting up and swinging the bottom

out and down. Remove the hand knobs

(3) and pull dispensing head (1) straight

out by gently rocking the head from the

studs.

3. Remove the cylinder bushing and

beater shaft from the cylinder.

4. Remove the scraper blades and

shaft seal (gure 8-4) from the beater

shaft.

CAUTION

To prevent bacteria

growth, remove

ALL O-rings when

disassembling for

cleaning. Failure to do

so could create a health

hazard.

5. Remove drip tray and insert from

the front of the freezer. (see Replacement

Parts Manual, Panel Assembly)

6. From the front of the head remove

the air bleed plug (7, gure 8-2) and the

two plug O-rings (6).

7. Remove the handle pin (5),

handle (4), plunger (9) and nozzle (2)

from dispensing head.

8. Remove one O-ring (12) from the

head and two O-rings (10, 11) from the

plunger.

9. Remove the cup seal (gure 8-4)

and O-ring from the bushing on the shaft

seal assembly.

10. Remove mix container, cover and

low mix probe from the cabinet.

-continued

Figure 8-3 Disassemble Beater Shaft

CUP SEAL

WASHER

O-RING

Figure 8-4 Disassemble Shaft Seal

185240 27

ELECTRO FREEZE Soft Serve Model GEN-2080

8.2 Disassembly Instructions — Soft Serve (continued)

11. Remove MTS hose assemblies

from the Mix Transfer Systems as

follows (gure 8-5):

a. remove cover,

b. loosen the hand knob,

c. swing back the shoe clamp,

d. swing open the roller shoe,

e. loosen the clamp on braided

hose,

f. pull tube off cylinder inlet and

slide hose assembly out of

roller support housing.

12. Disassemble the MTS hose

assembly as shown in gure 8-6.

Figure 8-6 MTS Hose Assembly

Figure 8-5 MTS

28 185240

ELECTRO FREEZE Soft Serve Model GEN-2080

8.3 Cleaning Instructions — Soft Serve

The cleaning instructions explained in this section are procedures to

remove bacteria and maintain a clean, sanitary freezer. The freezer must

be disassembled, washed, and sanitized according to the instructions in

this manual. Always sanitize before start-up to ensure the best possible

cleanliness.

CAUTION

To prevent bacteria growth,

remove all O-rings when

cleaning. Failure to do

so could create a health

hazard.

CAUTION

Electrical shock hazard.

Do not splash water on

switches or allow water

to ow onto electrical

components inside the

machine.

NOTE: It is your responsibility to

be aware of and conform to the

requirements for meeting federal, state

and local laws concerning the frequency

of cleaning and sanitizing the freezer.

1. Prepare a three-compartment

sink for washing, rinsing, and sanitizing

parts removed from the freezer, per

applicable local health codes. Also,

prepare a clean surface to air-dry all

parts.

a. The mix container, pickup tube

assembly, hoses and probe.

b. The head plunger openings,

plunger ports, O-ring grooves, dispense

nozzle mounting rings and mix ports as

shown in gure 8-7.

Figure 8-7 Clean head ports and

openings with brush.

c. The beater shaft cup seal,

plastic washer, and O-rings, plunger

O-ring grooves and nozzle, as shown in

gure 8-8.

Important:

Do not use unapproved sanitizer

or laundry bleach. These materials

may contain high concentrations of

chlorine and will chemically attack

freezer components.

NOTE: The sanitizer should be

mixed according to the manufacturer’s

instructions to yield 100 PPM strength

chlorine solution (example: Stera Sheen

Green Label). Use warm water (100° to

110°F or 38° to 43°C) to wash, rinse, and

sanitize.

2. Wash all parts removed from the

Figure 8-8 Clean O-ring grooves,

seal and nozzle with

brush.

freezer thoroughly with dish detergent.

Clean the following parts with the

— continued

appropriate supplied brush:

185240 29

ELECTRO FREEZE Soft Serve Model GEN-2080

8.3 Cleaning Instructions — Soft Serve (continued)

d. The air bleed plug O-ring

grooves.

e. The beater shaft and the

Figure 8-9 Clean Scraper Blade Pin Holes

scraper blade pin holes as shown in gure

8-9.

3. After all parts are washed, rinse

and then place them in the sanitizing

solution. For proper sanitizing, the

parts must remain fully immersed in the

sanitizer for 5 minutes. Allow parts to airdry after sanitizing.

Do not leave parts in sanitizing

solution for more than 15 minutes.

Important:

Figure 8-10 Brush inside of cylinder mix

feed tubes.

3. After all parts are washed, rinse

and place in the sanitizing solution.

Brush the inside of all mix transfer hoses

with sanitizer. For proper sanitizing, the

parts must remain fully immersed in the

sanitizer for 5 minutes. Allow parts to airdry after sanitizing.

4. Using a warm mild dish detergent

solution thoroughly brush:

a. the mix feed tubes from the

cabinet to the cylinders (gure 8-10)

b. the inside of the cylinders

making certain to clean the back walls,

and the inside of the drain tube as shown

in gure 8-11 (dip the brush in the dish

detergent solution and force into the drain

tube until it stops - repeat until clean).

5. Wash the drip tray and insert in

the warm dish detergent solution and

rinse with clear water.

6. Wash the outside of the freezer

and the inside of the cabinet with the dish

detergent solution. Rinse with clear water.

Figure 8-11 Brush inside of cylinders and

drain tubes.

30 185240

ELECTRO FREEZE Soft Serve Model GEN-2080

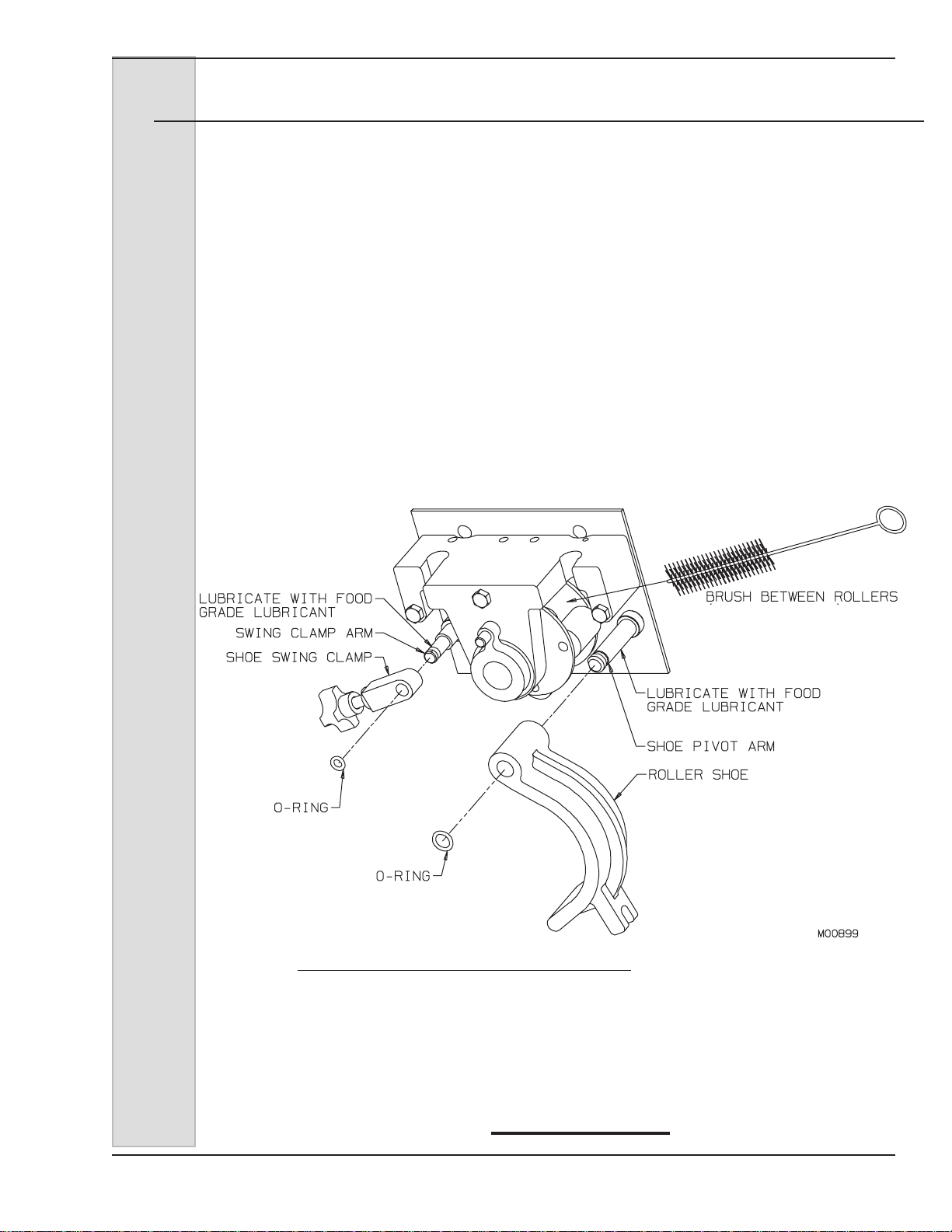

8.3.1 Cleaning and Lubricating MTS Assembly Shoe

NOTE: Clean the shoe weekly or when

necessary. Do not interchange the shoe

with any other MTS shoes.

Follow these directions for each MTS

shoe:

1. Remove the O-rings and slide the

shoe off of the pivot arm and the swing

clamp off of the clamp arm. See gure

7-12.

2. Carry to the sink, wash in mild

detergent with the brush provided and dry

thoroughly.

3. Brush in between rollers. Flush

clean with water bottle.

Important:

Do not let shoe sit in sanitizing

solution or water. Corrosion will occur

in bore.

4. Lubricate the shoe pivot arm and

the swing clamp arm with food grade

lubricant such as Petrol-Gel.

5. Reassemble the shoe and O-ring

on pivot arm.

6. Reassemble the shoe swing

clamp and O-ring on the swing clamp

arm.

Figure 8-12

Replace worn brushes. Use only Electro Freeze original

or authorized replacement parts. See Accessories parts

list in Part II of this Manual to order new brushes.

185240 31

ELECTRO FREEZE Soft Serve Model GEN-2080

9 Disassembly and Cleaning — Shake

Safety Information

This freezer uses pressure to assure

consistent product quality. It is important

for your safety that the freezer is

depressurized slowly and completely

whenever the freezer is to be drained,

disassembled, cleaned, or serviced. The

safety instructions in this manual will

remind you when to check to make sure

the freezer is depressurized. When you

CAUTION

Make sure freezer is

depressurized before

proceeding.

see this CAUTION statement

the following steps should be taken:

It is important that the freezer

be disassembled, washed,

lubricated and sanitized before

operation.

The cleaning and sanitizing instructions

explained in this manual are required to

maintain a clean, sanitary freezer. The

freezer should be disassembled, cleaned,

reassembled, lubricated and sanitized

daily to ensure the best possible product

quality and freezer operation.

Persons assembling, cleaning or

sanitizing the freezer must rst wash

and sanitize hands and forearms with an

approved sanitizer.

1. Using the buttons L2 & R2 on the

control panel be sure both MTS pumps

are in the “OFF” position.

CAUTION

To avoid electrical shock or

contact with moving parts,

make sure the control pad

is “OFF” and that the main

power switch is “OFF”.

2. Turn the control pad “OFF” and then

turn “OFF” the main power switch.

3. Place a clean bucket under the

dispense head.

4. Slowly open the spigots, allowing

any pressurized cleaning solution or

air to escape. If there is product in

the freezer refer to Section 9, Closing

Procedures, 9.1 Draining Product.

5. Remove the spigot switch rods and

open the spigots completely.

6. Inside the refrigerated cabinet,

remove the MTS cover, loosen the shoe

clamp hand knob, swing back the shoe

clamp and swing open the roller shoe on

both mix transfer systems.

Following these steps will assure that the

system is depressurized.

32 185240

ELECTRO FREEZE Soft Serve Model GEN-2080

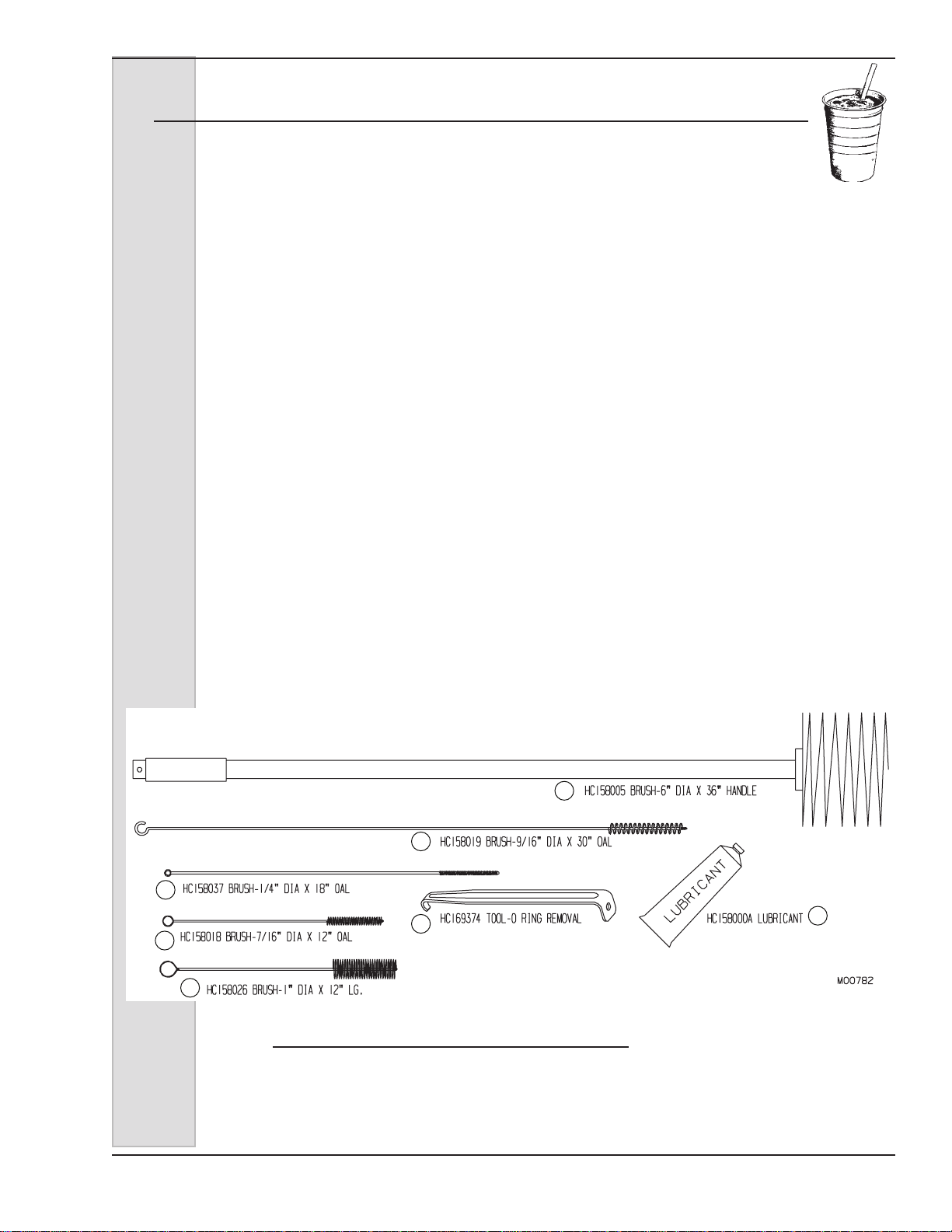

9.1 Cleaning Accessories — Shake

The following accessories shipped with the freezer are necessary for cleaning,

sanitizing, and disassembly/assembly (Figure 9-1):

1.) HC158005 BRUSH: 6 inch diameter

with 36 inch handle used to clean the

shake cylinder.

2.) HC158019 BRUSH: 9/16 inch

diameter 30 inches long used to clean

drain tube, the mix feed tube in the

ceiling of the cabinet and the pickup

tube.

3.) HC158037 BRUSH: 1/4 inch diameter

18-1/2 inches overall length used to

clean the air meter hose, the small

hole in the back of the dispense head

and small parts.

4.) HC158018 BRUSH: 7/16 inch

diameter 12 inches long used to clean

transfer hose, braided hose, and the

air relief opening in the dispense

head.

5.) HC158026 BRUSH: 1 inch diameter

12 inches long used to clean the

disassembled shaft seal and bushing.

6.) HC169374 TOOL - O-RING

REMOVAL: Aids in removing O-rings

from plunger, head, air relief plug, and

spindle.

7.) HC158000A: LUBRICANT PETROL-GEL. Approved lubricant

for moving parts and O-rings.

8.) HC116588 KIT - O-RING: Contains

all O-rings and seals needing

replacement on a regular basis.

(not shown)

1

2

3

6

4

5

7

Figure 9-1 Cleaning Accessories

185240 33

ELECTRO FREEZE Soft Serve Model GEN-2080

9.2 Disassembly Instructions— Shake

Figure 9-2 Shake Head Assembly

34 185240

ELECTRO FREEZE Soft Serve Model GEN-2080

9.2 Disassembly Instructions — Shake (continued)

SEAL-ASSY. SHAFT

1. If there is product in the freezer

refer to Section 14 Closing Procedures,

14.2 Draining Product.

2. Refer to gure 9-2. Remove the

plunger rod (7) by lifting up and swinging

CUP SEAL

WASHER

O-RING

BEATER-ASSY. SHAKE LONG

BLADE-SCRAPER

Figure 9-3 Beater Shaft Assembly

the bottom out and down.

3. Pull the keeper (11) out of the

head (1).

4. Unplug the spindle motor (8) and

lift it upward, removing it from the head.

5. Remove the handle (10) and

hand knobs (15), and then pull the head

straight out by gently rocking the head

from the studs.

CUP SEAL

WASHER

O-RING

Figure 9-4 Shaft Seal Assembly

CAUTION

Make sure freezer is

depressurized before

proceeding.

CAUTION

To avoid electrical shock or

contact with moving parts,

make sure all switches are

in the “OFF” position and

that the main power supply

is disconnected. Some

freezers have more than one

disconnect switch.

6. Remove the head bushing (2) and

the beater shaft from the cylinder.

7. Remove the scraper blades and

shaft seal from the beater shaft. Refer to

gure 9-3)

CAUTION

To prevent bacteria growth,

remove all O-rings when

cleaning. Failure to do so

could create a health hazard.

8. If you haven’t already removed

the drip tray (See Replacements Parts

Manual, Panel Assembly) and drip tray

insert from the front of the freezer, do so

now.

9. From the head remove the

plunger (6), and O-rings (4 & 5) from the

plunger.

10. Unscrew the air relief plug (13)

and o-ring (14), and head o-ring (3) from

the head.

11. Refer to gure 9-4. Remove

the cup seal and O-ring from the plastic

washer on the beater shaft seal assembly.

12. Remove mix tank, covers, and low

mix probe from inside the cabinet.

— continued

185240 35

ELECTRO FREEZE Soft Serve Model GEN-2080

9.2 Disassembly Instructions — Shake (continued)

13. Remove MTS hose assembly

from the Mix Transfer System as follows

(gure 9-5):

a. remove cover,

b. loosen the hand knob,

c. swing back the shoe clamp,

d. swing open the roller shoe,

e. loosen the clamp on braided

hose,

f. pull the braided hose off the

cylinder inlet and slide the mix transfer

hose assembly out of the roller support

housing.

14. Disassemble the MTS

hose assembly as shown in

gure 9-6.

Figure 9-5 MTS

Figure 9-6 MTS Hose Assembly

36 185240

ELECTRO FREEZE Soft Serve Model GEN-2080

9.3 Cleaning Instructions — Shake

The cleaning instructions explained in this section are procedures to remove

bacteria and maintain a clean, sanitary freezer. The shake freezer must be

disassembled, washed and sanitized according to the instructions in this

manual before start-up to ensure the best possible cleanliness.

CAUTION

Electric shock hazard.

Do not splash water on

switches or allow water

to ow onto electrical

components inside the

machine.

CAUTION

To prevent bacteria growth,

remove ALL O-rings when

cleaning. Failure to do

so could create a health

hazard.

Important:

Do not use unapproved sanitizers

or laundry bleach. These materials

may contain high concentrations of

chlorine and will chemically attack

freezer components.

NOTE: It is your responsibility to

be aware of, and conform to, the

requirements for meeting federal, state,

and local laws concerning the frequency

of cleaning and sanitizing the freezer.

1. Prepare a three-compartment sink

for cleaning, rinsing, and sanitizing parts

removed from the freezer, per applicable

health codes. Also, prepare a clean

surface to air-dry all parts.

NOTE: The sanitizer should be mixed

according to the manufacturer’s

instructions to yield 100 PPM strength

chlorine solution (example: Stera Sheen

Green Label). Make sure that sanitizer

has completely dissolved and/or is mixed

thoroughly. Use warm water (100° to

110°F or 38° to 43°C) to wash, rinse, and

sanitize.

Important:

Do not submerge the spindle motor in

water. This will damage the motor.

2. Wash all parts removed from the

freezer thoroughly with dish detergent

soap. Clean the following parts with the

appropriate supplied brush:

a. the mix tank, pickup tube

assembly, hoses and probe

b. the head, plunger, spindle, and

air relief plug openings, and all O-ring

grooves, as shown in gure 9-7.

— continued

Figure 9-7 Clean Head Openings

and Ports

185240 37

ELECTRO FREEZE Soft Serve Model GEN-2080

8.3 Cleaning Instructions — Shake (continued)

c. the shaft cup seal, plastic

washer, plunger O-ring grooves, as

shown in gure 9-8.

Figure 9-8 Clean Shaft Seal and

Plunger O-ring Grooves

d. the beater shaft and the

scraper blade pin holes, as shown in

gure 9-9.

with sanitizer. For proper

sanitizing the parts must remain fully

immersed in the sanitizer for 5 minutes.

Allow parts to air-dry after sanitizing.

4. Using a warm mild dish detergent

solution thoroughly brush:

a. the mix feed tubes from the

cabinet to the cylinders (gure 9-10)

b. the inside of the cylinders

making certain to clean the back walls,

and the inside of the drain tubes, as

shown in gure 9-11. Dip the brush in

the dish washing solution and force into

the drain tube until it stops - repeat until

clean.

5. Wash the drip tray and insert in

the warm dish detergent solution and

rinse with clear water.

6. Wash the outside of the freezer

and the inside of the cabinet with the

dish detergent solution. Rinse with clear

water.

Figure 9-9 Scraper Blade Pin Holes

3. After all parts are washed, rinse

and then place in the sanitizing solution.

Brush the inside of all mix transfer hoses

Figure 9-10 Brush inside of cylinder

mix feed tubes.

Figure 9-11 Brush the inside of the

Cylinders and Drain Tubes

38 185240

ELECTRO FREEZE Soft Serve Model GEN-2080

9.3.1 Cleaning and Lubricating MTS Assembly Shoe

NOTE: Clean the shoe weekly or when

necessary. Do not interchange the shoe

with any other MTS shoes.

Follow these directions for each MTS

shoe:

1. Remove the O-rings and slide the

shoe off of the pivot arm and the swing

clamp off of the clamp arm. See gure

8-10.

2. Carry to the sink, wash in mild

detergent with the brush provided and dry

thoroughly.

3. Brush in between rollers. Flush

clean with water bottle.

Important:

Do not let shoe sit in sanitizing

solution or water. Corrosion will occur

in bore.

4. Lubricate the shoe pivot arm and

the swing clamp arm with food grade

lubricant such as Petrol-Gel.

5. Reassemble the shoe and O-ring

on pivot arm.

6. Reassemble the shoe swing

clamp and O-ring on the swing clamp

arm.

Figure 9-10

Replace worn brushes. Use only Electro Freeze original

or authorized replacement parts. See Accessories parts

list in Part II of this Manual to order new brushes.

185240 39

ELECTRO FREEZE Soft Serve Model GEN-2080

10 Assembly — Soft Serve

Correct assembly of the freezer

is essential to prevent leakage of

the product and damage to the

freezer. To assemble the freezer

you will need an approved lubricant (such

as Petrol-Gel). Make sure all parts of

the assemblies have been washed and

sanitized before assembling.

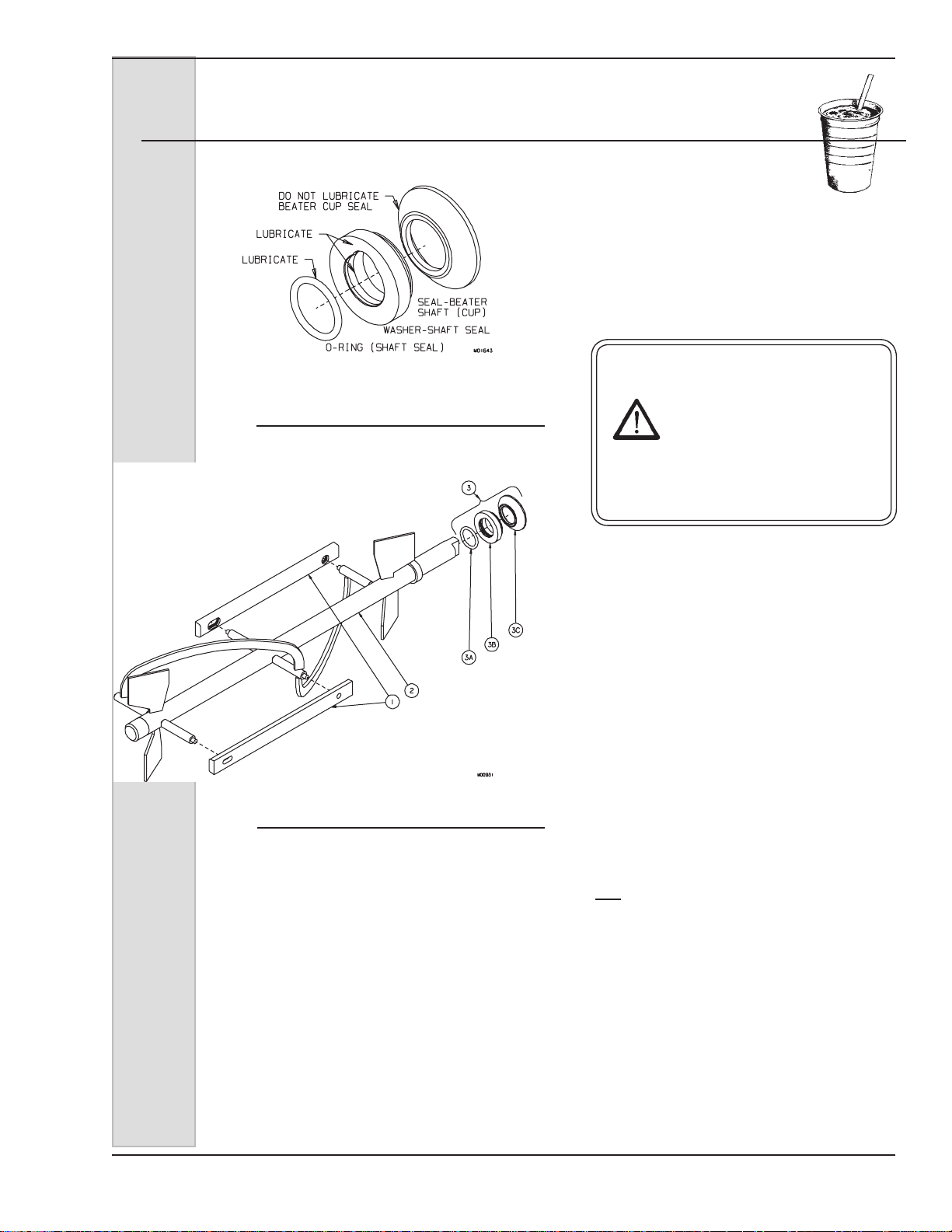

Figure 10-1 Shaft Seal Assembly

Figure 10-2 Beater Shaft Assembly

CAUTION

To avoid electrical shock or

contact with moving parts,

make sure all switches

are in the “OFF” position

and that the main power supply is

disconnected. Some freezers have

more than one disconnect switch.

1. Persons assembling the freezer

must rst wash and sanitize their hands

and forearms with an approved sanitizer.

2. To assemble the shaft seal, install

the cup seal and O-ring on the bushing

(see gure 10-1). Apply a moderate

amount of approved sanitary lubricant

(such as Petrol-Gel) to the O-ring and the

face of the plastic bushing opposite the

bell portion of the seal. Do not allow any

lubricant to come into contact with the

bell-shaped rubber portion of the seal.

3. Install the shaft seal over the rear

of the beater shaft, with the bell-shaped

portion facing the rear, as shown in gure

10-2. Remove any excess lubricant from

the beater shaft.

PROPER BLADE

INSTALLATION

IS WITH

FLAT SIDE

AGAINST

CYLINDER WALL.

Soft serve blades only have 2 holes

and are not interchangeable with the

3 hole shake blades. If the incorrect

blades are used the freezer could be

damaged.

Important:

4. Place the scraper blades on the

beater shaft, making sure the blades are

installed properly. (see gure 10-3)

Figure 10-3 Proper blade installation

— continued

40 185240

ELECTRO FREEZE Soft Serve Model GEN-2080

10 Assembly — Soft Serve

ROD-PLUNGER

PLUG-AIR BLEED

O-RING-PLUG

PIN-HANDLE

HANDLE-DISPENSE

KNOB-HAND

Figure 10-4 Soft Serve Head Assembly

5. Insert the assembled beater shaft

into the cylinder by placing the rear blade

on the bottom of the cylinder. This will

center the beater and allow alignment

with the drive coupling. Rotate the beater

assembly while pushing, until the shank

has engaged the drive shaft.

6. Lubricate the inside surface of the

head bushing and place on the end of the

beater shaft assembly by lifting the shaft

up until the bushing slides in place.

Important:

ALWAYS make sure the head bushing

is positioned on the beater shaft

properly. Operating the freezer with

a missing or badly worn bushing

will damage the beater, head and

cylinder.

7. Refer to gure 10-4 and O-ring

Chart in the Replacement Parts Section

of this manual. Install and lubricate the

O-rings (10,11) on the dispensing plunger

(9) and insert halfway into the head (1).

8. Install and lightly lubricate the

4-inch head O-ring (12).

PLUNGER

O-RING-PLUNGER

O-RING-PLUNGER

O-RING-HEAD

HEADDISPENSE

NOZZLE

9. Position the handle (4) in the head

and plunger assembly. Lock in place with

the handle pin (5).

10. Install and then lubricate O-rings

(6) on the air bleed plug (7). Insert plug in

head (1) assembly.

11. Install the dispensing head onto

the freezer by aligning the studs with the

holes in the head and sliding toward the

freezer. Tighten the hand knobs evenly,

nger-tight only.

Important:

Excessive force will damage the head.

Do not use tools to tighten.

12. Install the plunger rod (9). The

nozzle (2) will be installed on the mix

outlet at the bottom of the head after

sanitizing.

Important:

Always inspect the mix transfer hose

during assembly for wear. Do not

use tools or sharp objects to remove

hose.

185240 41

ELECTRO FREEZE Soft Serve Model GEN-2080

10 Assembly — Soft Serve (continued)

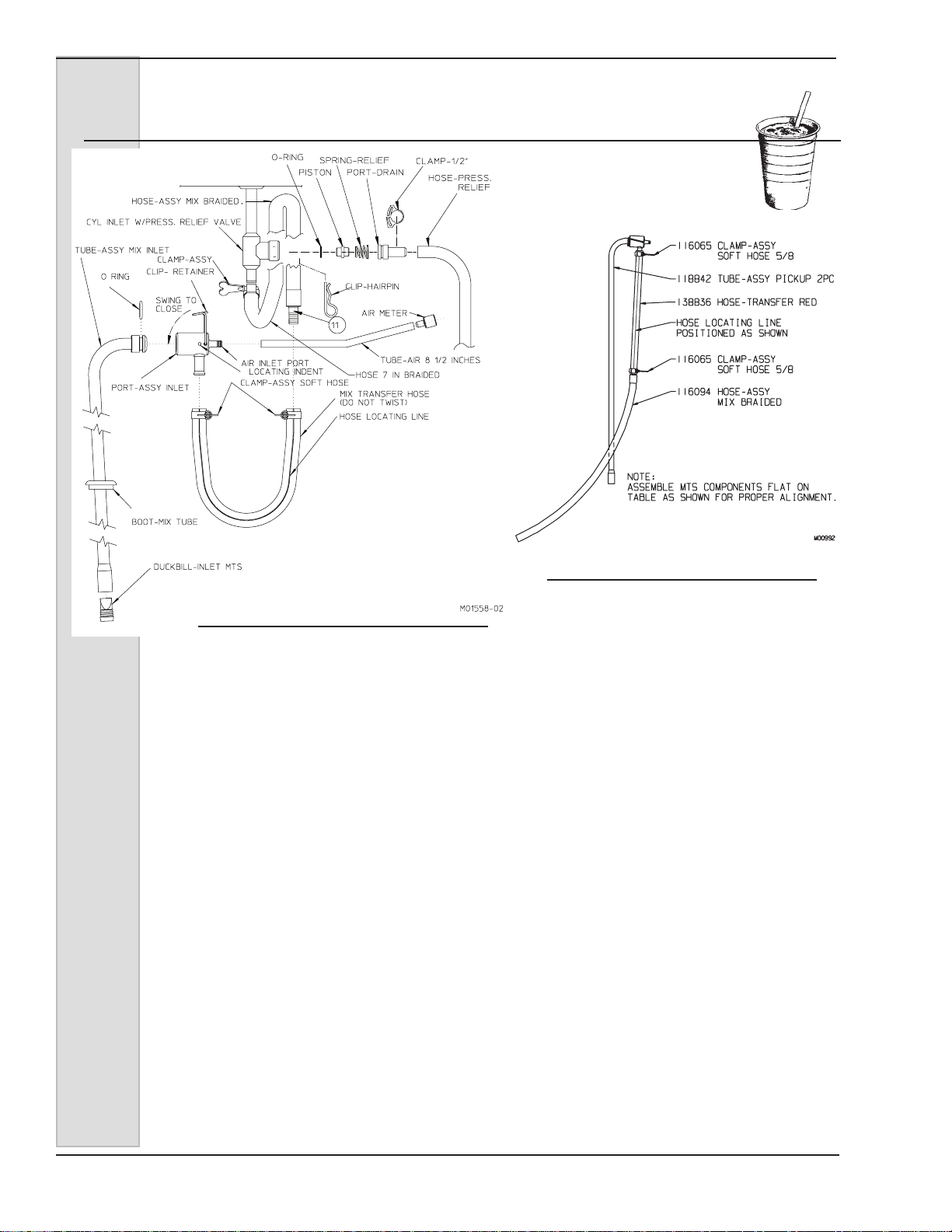

Figure 10-5 MTS Hose Assembly

Important:

Use original Electro Freeze transfer

hose only. Your freezer will not operate

properly with any other type of hose.

Never twist the transfer hose when

assembling or installing.

Important:

Replace transfer hose every 30 days.

13. Assemble the MTS hose

assembly as shown in gures 10-5 and

9-6. The transfer hose has a red locating

line. Hold the mix/air inlet port with the

transfer hose mix port on your right and

the barbed air port facing away from you.

With the locating line up, slide the mix

transfer hose onto the port aligning it with

the small locating indent. Then slide a

clamp over the hose to secure it to the

port. Finger tighten only! The thumbscrew

must lie parallel to the mix/air inlet port.

Figure 10-6 Attaching Braided Hose

clamp. Finger tighten only! The thumb

screw must lay horizontal as shown in

gure 10-6.

15. Slide the air tube over the air inlet

port and insert air meter in the opposite

end of the air tube.

16. Install o-ring on mix inlet tube

assembly and lubricate. Place the tube

assembly end into the port assembly

and swing retainer clip over to lock tube

assembly in place.

17. Install mix tube boot with at side

rst, over the tube assembly.

18. Insert the duckbill valve into the

bottom of the pickup tube. Push until the

two ribs are completely inserted.

— continued

14. Slide another clamp over the mix

transfer hose and connect to the barbed

end of the braided hose. Tighten the

42 185240

ELECTRO FREEZE Soft Serve Model GEN-2080

10 Assembly — Soft Serve (continued)

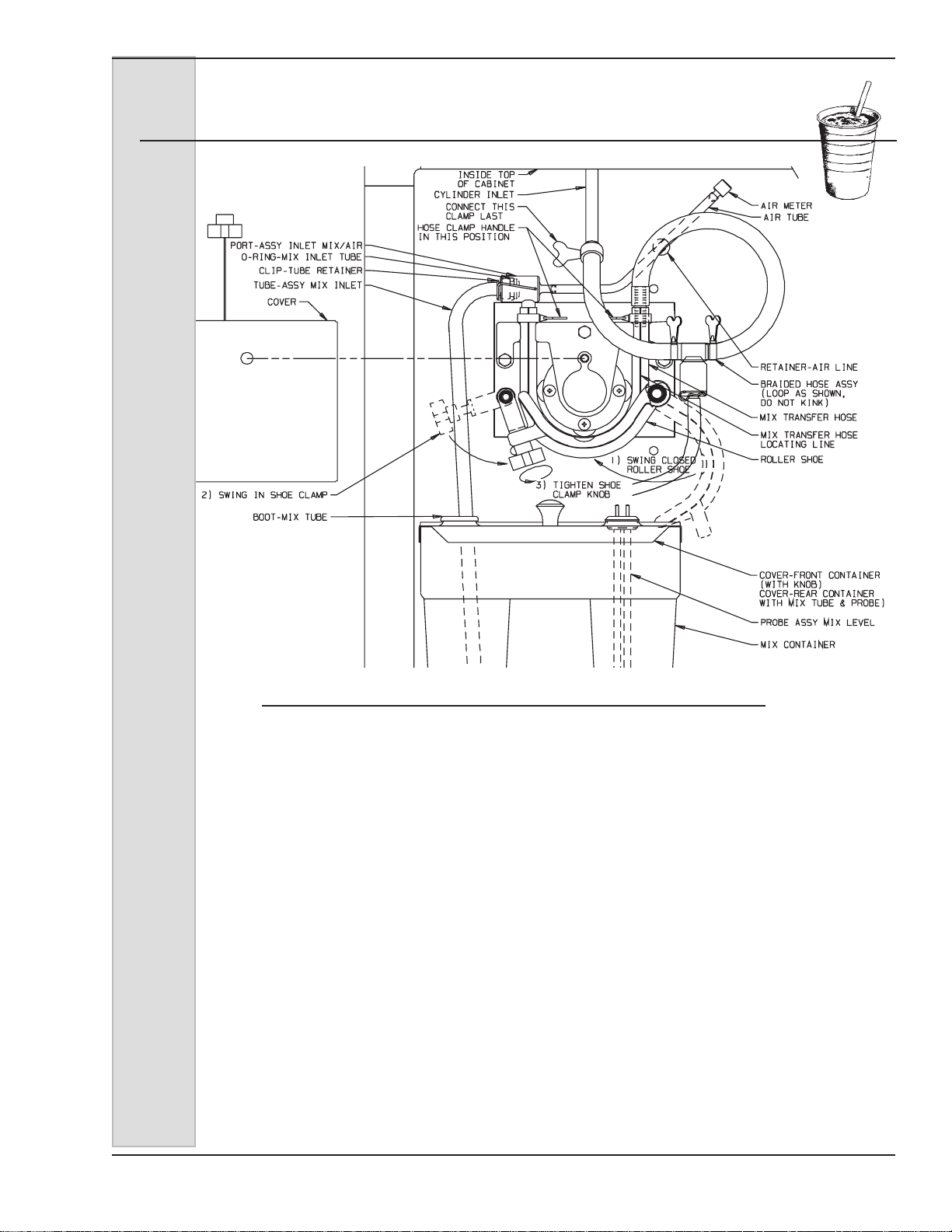

Figure 10-7 MTS

19. Refer to gure 10-7. Install the

MTS hose assembly by rst placing the

clamp next to the braided hose, above

the roller bearing support on the right side

and push hose into slot. Place the transfer

hose under the rollers. While holding the

pickup tube stretch the hose so the left

hand clamp is above the roller bearing

support and push the hose into the slot.

Important:

Do not twist the hose assembly while

installing.

20. Check to ensure the transfer

hose is straight and centered on the

roller assembly making sure the locating

line is facing out. The line should be in

the same position at the inlet and outlet

guides of the roller bearing support, as

shown in gure 10-7.

21. Swing the shoe over hose and

tighten the swing clamp hand knob in

place until it bottoms out and will not turn

any further.

22. Insert the air tube into the

retainer in the back of the cabinet.

23. Insert the MTS cover over stud

see gure 10-8. Hose clamps should

be exposed. Tighten cover knob. Hand

tighten only.

Important:

The MTS will not operate unless the

cover is installed and secured by the

hand knob.

24. Loop the braided hose towards

you and slide the hose over the cylinder

inlet tube. Tighten the clamp. Make sure

the braided hose is not twisting transfer

hose.

— continued

185240 43

ELECTRO FREEZE Soft Serve Model GEN-2080

10 Assembly — Soft Serve (continued)

CLAMP-SOFT HOSE

O-RING

PORT-AIR/MIX INLET

CLIP-TUBE RETAINER

AIR METER

TUBE-AIR

RETAINER-AIR TUBE

CLAMP-SOFT HOSE

CLAMP-SOFT HOSE

ARM-SWING CLAMP

KNOB-HAND

COVER-MTS

TUBE-ASSY

PICKUP

HOSE-MIX BRAIDED

SUPPORT-ROLLER

BEARING

HOSE-TRANSFER

RED LINE

ROLLER-ASSY

COMPLETE

SHOE-ROLLER

20

VALVEPRESSURE RELIEF

DUCKBILL-INLET

Figure 10-8 MTS and Mix Container

44 185240

ELECTRO FREEZE Soft Serve Model GEN-2080

SEAL-ASSY. SHAFT

L

11 Assembly — Shake

Figure 11-1 Shaft Seal Assembly

Correct assembly of the

freezer is essential to prevent

leakage of the product and damage to

the freezer. To assemble the freezer you

will need an approved lubricant (such

as Petrol-Gel). Make sure all parts of

the assemblies have been washed and

sanitized before assembling.

CAUTION

To avoid electrical shock or

contact with moving parts,

make sure all switches are

in the “OFF” position and

that the main power supply

is disconnected. Some

freezers have more than

one disconnect switch.

O-RING

BEATER-ASSY. SHAKE LONG

BLADE-SCRAPER

Figure 11-2 Beater Shaft Assembly

CUP SEA

WASHER

1. Persons assembling the freezer

must rst wash and sanitize their hands

and forearms with an approved sanitizer.

2. See gure 11-1. To assemble

the shaft seal, install the cup seal and

O-ring on the bushing. Apply a moderate

amount of approved sanitary lubricant

such as Petrol-Gel to the O-ring and the

face of the plastic bushing opposite the

bell portion of the seal. Do not allow any

lubricant to come into contact with the

bell-shaped rubber portion of the seal.

3. See gure 11-2. Install the shaft

seal over the rear of the beater shaft with

the bell-shaped portion facing the rear.

Important:

Shake blades have 3 holes and are

not interchangeable with the 2 hole

soft serve blades. If the incorrect

blades are used the freezer could be

damaged.

4. Place the scraper blades on the

beater shaft, making sure the blades are

installed properly.

— continued

185240 45

ELECTRO FREEZE Soft Serve Model GEN-2080

11 Assembly — Shake (continued)

5. Insert the assembled beater shaft

into the cylinder by placing one blade

on the bottom of the cylinder and gently

pushing. This will center the beater and

allow alignment with the drive shaft.

Rotate the beater assembly

while pushing, until the

shank has engaged the drive

shaft.

Figure 11-3 Shake Head Assembly

46 185240

ELECTRO FREEZE Soft Serve Model GEN-2080

11 Assembly — Shake (continued)

Figure 11-4 Head Bushing

6. See gure 11-3 and O-ring chart

in Replacement Parts section of this

manual. Install and lubricate the O-rings

on the dispensing plunger (6) and insert

into the dispense head (1), with the slot

facing the rear of the head.

7. Install and lubricate the 6-inch

O-ring (3) on the head.

8. Install and lubricate O-ring (14) on

the air relief plug (13). Then, thread the

plug into the head assembly.

9. Lubricate the inside surface of the

head bushing (2) and place in the head

assembly, making sure to line the bushing

key into the head slot, as shown in gure

10-4.

Important:

ALWAYS make sure the head bushing

is positioned in the head properly (see

gure 11-4). The head is slotted to

match the key on the bushing. Make

sure the key aligns with the slot.

Failure to install the bushing properly

in the dispensing head will damage the

beater, head and cylinder.

10. Install the dispensing head onto

the freezer by tilting the top of the head

towards you, aligning the studs with the

holes in the head, and sliding toward

the freezer. Push the head towards the

freezer, carefully rocking it into place and

aligning the beater shaft with the drive

coupling.

11. Tighten the hand knobs

simultaneously, nger-tight only.

Important:

Excessive force will damage the head.

Do not use tools to tighten.

12. Hook the handle (10) into the

slot on the plunger (6). Insert the spindle

motor (8) into the head.

13. Insert the keeper (11) through the

holes in the handle (10), spindle (8) and

head (1). Install the spigot o-ring (17) on

the head assembly and then the spigot

extension (16).

14. Plug the spindle motor cord into

the outlet provided in the bottom of the

electrical box and install the plunger rod.

— continued

185240 47

ELECTRO FREEZE Soft Serve Model GEN-2080

11 Assembly — Shake (continued)

Figure 11-5 MTS Hose Assembly

Important:

Always inspect the transfer hose

during assembly for wear. Do not use

tools or sharp objects to remove hose.

Important:

Use original Electro Freeze transfer

hose only. Your freezer will not operate

properly with any other type of hose.

Never twist the transfer hose when

assembling or installing.

Important:

Replace transfer hose every 30 days.

15. Assemble the MTS hose

assembly as shown in gures 11-5 and

11-6. The transfer hose has a red locating

line. Hold the mix/air inlet port with the

transfer hose mix port on your right and

the barbed air port facing away from you.

With the locating line up, slide the mix

transfer hose onto the port aligning it with

the small locating indent. Then slide a

clamp over the hose to secure it to the

port. Finger tighten only! The thumbscrew

must lie parallel to the mix/air inlet port.

Figure 11-6 Attaching Braided Hose

16. Slide another clamp over the mix

transfer hose and connect to the barbed

end of the braided hose. Tighten the

clamp. Finger tighten only! The thumb

screw must lay horizontal as shown in

gure 11-6.

17. Slide the air tube over the air inlet

port and insert air meter in the opposite

end of the air tube.