Page 1

Operating Manual | Bedienungsanleitung

English Deutsch

WTX110

Page 2

Hottinger Baldwin Messtechnik GmbH

Im Tiefen See 45

D-64239 Darmstadt

Tel. +49 6151 803-0

Fax +49 6151 803-9100

info@hbm.com

www.hbm.com

Mat.:

DVS: A4774-1.0 HBM: public

12.2017

Program version: ≥ Firmware Update_20160412.1.IT468E

E Hottinger Baldwin Messtechnik GmbH.

Subject to modifications.

All product descriptions are for general information only.

They are not to be understood as a guarantee of quality or

durability.

Änderungen vorbehalten.

Alle Angaben beschreiben unsere Produkte in allgemeiner

Form. Sie stellen keine Beschaffenheits- oder Haltbarkeits

garantie dar.

Page 3

Operating Manual | Bedienungsanleitung

English Deutsch

WTX110

Page 4

English

1 Safety instructions 9.......................................

2 Markings used 14...........................................

2.1 The markings used in this document 14.........................

2.2 Markings used on the device 15...............................

3 System description 17......................................

4 Installation 20..............................................

4.1 Overview of connections 20...................................

4.1.1 ADM (analog sensors) 20.....................................

4.1.2 Serial interfaces 21..........................................

4.1.3 Digital inputs/outputs 22......................................

4.1.4 Analog output 24............................................

4.2 Setup and installation 24......................................

4.3 Mains connection 25.........................................

4.4 General cable assembly 26...................................

4.5 Connection of analog SG sensors 27...........................

4.5.1 Connection cable for analog load cell 29........................

4.5.2 Saving calibration data for legal for trade applications 30..........

4.6 Serial interface connection 32.................................

4.7 USB connection 35..........................................

4.8 Ethernet TCP/IP connection 35................................

4.9 Digital inputs/outputs 36......................................

4.9.1 Overview I/O Connection 37..................................

4.9.2 Overview I/O Connection with Ethernet (Modbus-TCP) Fieldbus

coupler 38..................................................

4.10 Connection of digital inputs/outputs IO (2xDO, 2xDI) 39...........

4.11 Connection of digital inputs/outputs DIO (2xDO, 1xDI) 41.........

4.12 Connection of 15-bit analog output 43..........................

4.13 Power supply for external peripheral devices 47..................

4.14 Connection to 110 … 240 VAC 48.............................

2 A4774-1.0 HBM: public WTX110

Page 5

4.15 Connection to 12…30 VDC 50.................................

4.16 Connection to external battery 12…30 VDC 50..................

4.17 Legal for trade data storage/alibi memory 52....................

4.18 Activating the On/Off key 54..................................

5 Operator control/settings 55.................................

5.1 Service password 55.........................................

5.2 Display and control elements 56...............................

5.3 Example of entries via WTX110 display keys 59.................

5.3.1 Alphanumeric entry 59.......................................

5.3.2 Entering whole numbers 60...................................

5.3.3 Entering numbers with decimal places 62.......................

5.4 Operating the weighing functions 63............................

5.4.1 Tare functions 63............................................

5.4.2 Set / delete tare (Tare mode: Gross/Net) 63.....................

5.4.3 Automatic deletion of tare (Tare mode: Auto Clear) 64............

5.4.4 Repeated taring (Tare mode: Net=0) 65........................

5.4.5 Zeroing 66..................................................

5.4.6 Weighing 66................................................

5.4.7 Switch weight indicator to 10 times the resolution 67..............

Navigation Pilot 68..................................................

6 Service mode 69............................................

6.1 Configure interfaces (Interface) 70.............................

6.1.1 Setting the Ethernet interface (interface: Com0 (Eth)) 70..........

6.1.2 Setting the serial interface (interface: Com1 (SIM)) 71............

6.1.3 Setting the serial interface (Com6 (DWB1)) 73...................

6.2 Enter parameter (General) 73.................................

6.2.1 Continuous Out 78...........................................

6.3 Calibrate scale (Calibration) 79................................

6.4 Configuration 80.............................................

6.4.1 Configure scale (Configuration Scale) 80........................

WTX110 A4774-1.0 HBM: public 3

Page 6

6.4.2 Configure digital I/Os (Config. Digital IO) 81.....................

6.4.3 Configure analog outputs (Configuration Analog out) 81...........

6.5 Hardware test (Test) 83......................................

6.5.1 Test digital interfaces (Test: Digital IO) 83.......................

6.5.2 Test serial interfaces (Test: Serial IO) 84.......................

6.6 Reset parameter (Reset) 85...................................

6.6.1 Reset parameter (Reset Parameter) 85.........................

6.6.2 Delete legal for trade weight memory (Reset Approved Weight) 87.

6.7 Network 87.................................................

6.8 Backup/restore (Backup) 90...................................

6.8.1 Back up/ restore using USB 90................................

7 Operating modes 92........................................

7.1 Operating mode STANDARD 92...............................

7.2 Operating mode FILLER 93...................................

7.3 Operating mode COUNT 95...................................

7.4 Application examples COUNT 98..............................

7.4.1 Counting into an empty counting 98............................

7.4.2 Counting from a full container 102...............................

7.5 Operating mode CHECK 105...................................

7.6 Application examples CHECK 109..............................

8 Application 111..............................................

8.1 General setup 111............................................

8.2 Limit switches 114............................................

8.2.1 Mode: Above level (Above level) 115............................

8.2.2 Mode Below level (Below level) 116.............................

8.2.3 Mode: Outside band (Outside band) 117.........................

8.2.4 Mode: Inside band (Inside band) 118............................

8.3 Configuration Digital I/O (Digital I/O) 118.........................

8.3.1 Configuration of the digital inputs and outputs for

Application: Standard 119......................................

4 A4774-1.0 HBM: public WTX110

Page 7

8.3.2 Configuration of the digital inputs/outputs for Application: Filler 120..

8.4 Adapting print formats (Format) 122.............................

8.4.1 Standard print formats 123.....................................

8.5 Factory Defaults 127..........................................

9 Mastermode 128.............................................

10 Supervisormode 130........................................

10.1 General 130..................................................

10.2 Products 131.................................................

10.2.1 Edit/Load from USB/Save to USB 132...........................

10.2.2 <Info> 133...................................................

10.2.3 Product number (Product No.) 133..............................

10.2.4 Product (Product) 133.........................................

10.2.5 Dosing mode (Dos.mode) 133..................................

10.2.6 Tare mode (Tare mode) 135...................................

10.2.7 Emptying mode (Emptying) 135.................................

10.2.8 Optimization (Optimization) 136.................................

10.2.9 Re-dosing (Re-Dosing) 137....................................

10.2.10 Alarm (Alarm:Empty) 138......................................

10.2.11 Valve control Valve 139........................................

10.2.12 Empty weight monitoring (Empty weight) 143.....................

10.2.13 Target weight (Target weight) 144...............................

10.2.14 Empty weight (Empty weight) 144...............................

10.2.15 Minimal starting weight (Min. Start w.) 144.......................

10.2.16 Coarse flow cut-off point Crs.Fl.off 145..........................

10.2.17 Coarse flow monitoring (Crs. Monitor) 145........................

10.2.18 Fine low cut-off point (Fine fl.off) 145............................

10.2.19 Fine flow monitoring (Fine monitor) 146..........................

10.2.20 Minimum fine flow (Min.Fine fl.) 146.............................

10.2.21 Lower tolerance (Lower tol.) 147................................

10.2.22 Upper tolerance Upper tol.) 147.................................

WTX110 A4774-1.0 HBM: public 5

Page 8

10.2.23 Systematic difference (Syst.diff.) 147............................

10.2.24 Maximum dosing time (Max.dos.t(s)) 148........................

10.2.25 Tare delay (Tare delay(s)) 148..................................

10.2.26 Start fine flow before coarse flow (Start Fine(s)) 149...............

10.2.27 Coarse flow monitoring (time interval) (Cors.mon.(s)) 149..........

10.2.28 Lockout time coarse flow (Lockout crs(s)) 149....................

10.2.29 Fine flow monitoring (time interval) (Fine mon.(s)) 150.............

10.2.30 Lock out time fine flow (Lock fine(s)) 151.........................

10.2.31 Dosing delay 1 (Dos.delay1(s)) 152.............................

10.2.32 Dosing delay 2 (Dos.delay2(s)) 152.............................

10.2.33 Residual flow time (Residuals) 153..............................

10.2.34 Stabilization time (Stabilizat.(s)) 153.............................

10.2.35 Emptying time (Empt.time(s)) 153...............................

10.2.36 Number of dosing operations (No. of dosing) 154.................

10.2.37 Total weight (Total weight) 154.................................

10.2.38 Mean value of dosing results (Mean Value) 154...................

10.3 Weight Storage 155...........................................

10.3.1 Display of saved weight values 156.............................

10.3.2 Reset the "legal for trade weight memory" 156....................

10.4 Logbook (Logbook) 156........................................

10.5 Software ID 157..............................................

10.6 MAC/IP address 158..........................................

11 Calibration 159..............................................

11.1 Multiple-range 159............................................

11.2 Multi-interval weighing machine 161.............................

11.2.1 Adaptation to the weighing environment 162......................

11.2.2 Calibration and geo value setting 163............................

11.2.3 Legal for trade applications 163.................................

11.3 Select group (group 1-9) 166...................................

11.4 Scale parameters 167.........................................

11.5 Calibration 170...............................................

6 A4774-1.0 HBM: public WTX110

Page 9

11.6 Linearization 174.............................................

11.7 Zero Adjust 176..............................................

11.8 Adaptation 178...............................................

11.9 Incline Setup 181.............................................

11.9.1 Incline parameters 182........................................

11.9.2 Incline calibration 183.........................................

11.9.3 Incline linearization 184........................................

11.9.4 Incline weight 186.............................................

11.9.5 Incline Reset 186.............................................

11.10 High resolution 187...........................................

11.11 Reset parameters 187.........................................

11.12 Calculate span 189...........................................

11.13 W&M Info 191................................................

12 PanelX interface 192.........................................

13 Data transfer 193............................................

13.1 Protocol for data transfer 193...................................

14 Continuous output/HBM protocol (Cont.out) 195...............

14.1 HBM Remote protocol 196.....................................

14.2 Customized protocol 197......................................

15 Transport, maintenance and cleaning 200.....................

15.1 Transport 200................................................

15.2 Maintenance 200.............................................

15.3 Cleaning 201.................................................

15.4 Replacing the battery 202......................................

15.5 ROHSII 205..................................................

16 Interference 207.............................................

16.1 Scale error log 207............................................

16.2 Error messages 209...........................................

WTX110 A4774-1.0 HBM: public 7

Page 10

17 Geo values 212..............................................

8 A4774-1.0 HBM: public WTX110

Page 11

Safety instructions

1 Safety instructions

Intended use

The device is to be used exclusively for measurement tasks and directly

related control tasks within the application limits detailed in the specifications.

Use for any purpose other than the above is deemed to be non-designated

use.

Depending on the variant, the device operates with a power supply of either

12...30 VDC or 110...240 VAC (50...60 Hz). Note the applicable national and

international requirements according to the state of the art for the relevant

application. Changes to the integrated power supply and/or pre-wired

connection cables (applies to 110...240 AC variants) are strictly prohibited and

shall render all claims against HBM for any damage whatsoever null and void.

Device variants with 12...30 VDC power supply must be used with a shielded

connection cable.

Hardware changes to pre-wired options not described in the WTX110 manual

are not permitted. Service cases must always be processed through HBM.

Any person instructed to carry out installation, commissioning or operation of

the device must have read and understood the Operating Manual and in

particular the technical safety instructions.

In the interests of safety, the device should only be operated by qualified

personnel and as described in the Operating Manual. It is also essential to

comply with the legal and safety requirements for the application concerned

during use. The same applies to the use of accessories.

The device is not intended for use as a safety component. Please also refer to

the "Additional safety precautions" section. Proper and safe operation requires

proper transportation, correct storage, siting and mounting, and careful

operation.

WTX110 A4774-1.0 HBM: public 9

Page 12

Safety instructions

Operating conditions

S Protect the device from direct contact with water.

S Protect the device from moisture and weather such as rain or snow. The

protection class of the device (front panel after installation) is IP69K

(DIN EN 60529).

S The device is designed for use in industrial environments and conforms with

Class A in accordance with DIN EN55011.

S Do not expose the device to direct sunlight.

S Comply with the maximum permissible ambient temperatures and the

specifications regarding maximum humidity.

S The device must not be modified in terms of design or safety engineering

except with our express agreement. In particular, any repair or soldering

work on motherboards (replacement of components) is prohibited. When

exchanging complete modules, use only original parts from HBM.

S The device is supplied ex works with a fixed hardware and software

configuration. Changes can only be made within the range of possibilities

described in the corresponding documentation.

S The device is largely maintenance-free.

S Please note the following when cleaning the housing:

- Disconnect the device from all current and voltage supplies.

- Clean the housing with a soft, slightly damp (not wet!) cloth. Never use

solvent, as this could damage the label or the housing.

- When cleaning, ensure that no liquid gets into the device or connections.

S The device has a configurable On/Off key. If the key is deactivated, the

device is ready for operation immediately after the power supply network is

connected. Please read the corresponding section in the technical manual.

S The local input voltage must match the input voltage of the device.

S In accordance with national and local environmental protection and material

recovery and recycling regulations, old devices that can no longer be used

must be disposed of separately and not with normal household garbage.

10 A4774-1.0 HBM: public WTX110

Page 13

Safety instructions

S If the weighing terminal is connected via mains cable with a plug, the socket

must be located in the immediate vicinity of the device plug. If the con

nection is permanent, there must be a readily accessible isolating

mechanism present in the supply circuit.

Qualified personnel

Qualified persons means persons entrusted with the installation, fitting,

commissioning and operation of the product who possess the appropriate

qualifications for their function.

This includes people who meet at least one of the three following requirements:

S They have knowledge of the safety equipment and procedures of measure

ment and automation systems, and are familiar with them as project

personnel.

S They are operating personnel of measurement or automation systems and

have been instructed on how to handle the machinery. They are familiar

with the operation of the equipment and technologies described in this

document.

S As commissioning engineers or service engineers, they have successfully

completed the training to repair the automation systems. Moreover, they are

authorized to start up, ground and label circuits and equipment in ac

cordance with safety engineering standards.

Working safely

S The device must not be directly connected to the power supply system.

S Error messages should only be acknowledged once the cause of the error

has been eradicated and there is no further danger.

S Maintenance and repair work on an open device with the power on may

only be performed by trained personnel who are aware of the dangers

involved.

S Automation equipment and devices must be designed to ensure adequate

protection or locking against inadvertent actuation (e.g. access control,

password protection, etc.).

WTX110 A4774-1.0 HBM: public 11

Page 14

Safety instructions

S For devices operating in networks, safety precautions must be taken in

terms of both hardware and software, so that an open circuit or other inter

ruptions to signal transmission do not result in undefined states or loss of

data in the automation device.

S Following work on settings or password-protected activities, make sure that

any controls that may be connected remain in a safe condition until the

switching behavior of the device has been tested.

Additional safety precautions

Additional safety precautions to meet the requirements of the relevant national

and local accident prevention regulations must be taken in plants where

malfunctions could cause major damage, loss of data or even personal injury.

The scope of supply and performance of the device covers only a small area of

measurement technology. Before starting up the device in a system, a project

planning and risk analysis must first be implemented, taking into account all the

safety aspects of measurement and automation technology so that residual

risks are minimized. This particularly concerns personal and machine protec

tion. In the event of a fault, the relevant precautions must establish safe

operating conditions.

If this device is used as a component in a system, the system design must be

checked by qualified specialists who are familiar with the design and function of

all the individual components!

General dangers of failing to follow the safety instructions

The device is state of the art and as such is failsafe. The device may give rise

to residual dangers if it is inappropriately installed or operated.

Exercise caution when pressing the keys that control movable system parts

such as conveyor systems, flaps, etc. Before pressing these buttons, make

sure that no persons are in the danger zone of moving system parts!

The weighing terminal must not be used in a potentially explosive atmosphere.

It is the responsibility of the owner of the equipment to classify potentially ex

plosive areas (division into zones, equipment groups, temperature classes,

12 A4774-1.0 HBM: public WTX110

Page 15

Safety instructions

etc.). Local labor inspection authorities and technical inspection agencies can

be of assistance here!

The power input terminals of the device must be connected to safety extra low

voltage (12…30 V

). When connecting external components with their own

DC

power supply (e.g. serial interfaces), care must be taken to ensure that only

SELV is used in that case as well! This applies to variants with 12…30 VDC

power supply.

The weighing terminal contains a lithium battery for storing the data that is

entered. There is a risk of explosion if the battery is replaced incorrectly. It

must only be replaced with the same type of battery, or an equivalent type

recommended by the manufacturer. Dispose of used batteries in accordance

with the manufacturer's instructions.

Notices:

S All switching devices (e.g. relays and contactors) that are connected or in

the immediate vicinity must be wired to effective noise filters (RC filters,

free-wheeling diodes).

S In order to avoid static charge buildup, all metallic parts of a system must

be thoroughly grounded. Moving parts, such as portable scales on plastic

wheels, must be grounded with ground clamps or ground leads of

appropriate diameter.

WTX110 A4774-1.0 HBM: public 13

Page 16

Markings used

2 Markings used

2.1 The markings used in this document

Important instructions for your safety are specifically identified. It is essential to

follow these instructions in order to prevent accidents and damage to property.

Symbol Meaning

WARNING

CAUTION

Notice

Important

Information

Emphasis

See …

Service mode Menu names and entries are in the Consolas font

This marking warns of a potentially dangerous

situation in which failure to comply with safety re

quirements could result in death or serious physical

injury.

This marking warns of a potentially dangerous

situation in which failure to comply with safety re

quirements could result in slight or moderate physical

injury.

This marking draws your attention to a situation in

which failure to comply with safety requirements

could lead to property damage.

This marking draws your attention to important in

formation about the product or about handling the

product.

This marking draws your attention to information

about the product or about handling the product.

Italics are used to emphasize and highlight text and

identify references to sections, diagrams, or external

documents and files.

14 A4774-1.0 HBM: public WTX110

Page 17

2.2 Markings used on the device

Electrical shock

Disconnect the power plug before opening the housing.

This applies to variants with power supply

110 … 240 V

Note supply voltage

This symbol indicates that the supply voltage must be

between 12 and 30V

12…30 V

CE mark

With the CE mark, the manufacturer guarantees that the

product complies with the requirements of the relevant

EC Directives (the Declaration of Conformity can be

found on the HBM website HBM (www.hbm.com) under

HBMdoc).

.

AC

power supply.

DC

DC

Markings used

. This applies to variants with

Statutory waste disposal mark

In accordance with national and local environmental

protection and material recovery and recycling regula

tions, old devices that can no longer be used must be

disposed of separately and not with normal household

garbage.

Battery disposal

In accordance with national and local environmental pro

tection and material recovery and recycling regulations,

old batteries that can no longer be used must be

disposed of separately and not with normal household

garbage.

WTX110 A4774-1.0 HBM: public 15

Page 18

Markings used

Marking of pollutant emission limits (for deliveries to China)

Statutory mark of compliance with emission limits in

20

electronic equipment supplied to China.

16 A4774-1.0 HBM: public WTX110

Page 19

System description

3 System description

The WTX110 weighing terminal is designed for universal use, for example in

weighing, recording and dosing systems.

Depending on the device variant, either analog SG load cells or specified digital

HBM sensors and electronics can be used.

Depending on the device variant, three power supplies are available

S 12 … 30 VDC

S 110 … 240 VAC

S External battery 12 … 30VDC (battery not included)

Two stainless steel housing variants (1) table / wall-mounting or panel

mounting are available. Both variants have IP protection rating IP69K (panelframe: front).

Fig. 3.1 Desktop and wall mounting

WTX110 A4774-1.0 HBM: public 17

Page 20

System description

Fig. 3.2 Panel mounting

The WTX110 can optionally be equipped with the following hardware options:

S Communications interfaces

- Ethernet TCP/IP interface (e.g. for PanelX, printer or firmware update)

- 2 x Digital Out, 1 x Digital In

- RS485 (4 wires) (e.g. for printer)

- RS232 (e.g. for incline sensor)

- USB2.0 (e.g. for printer, keyboard or firmware update)

S Analog or digital inputs/outputs

- 2 x Digital Out, 2 x Digital In

- 1 x analog output

S Legal for trade data storage 1,000,000

18 A4774-1.0 HBM: public WTX110

Page 21

System description

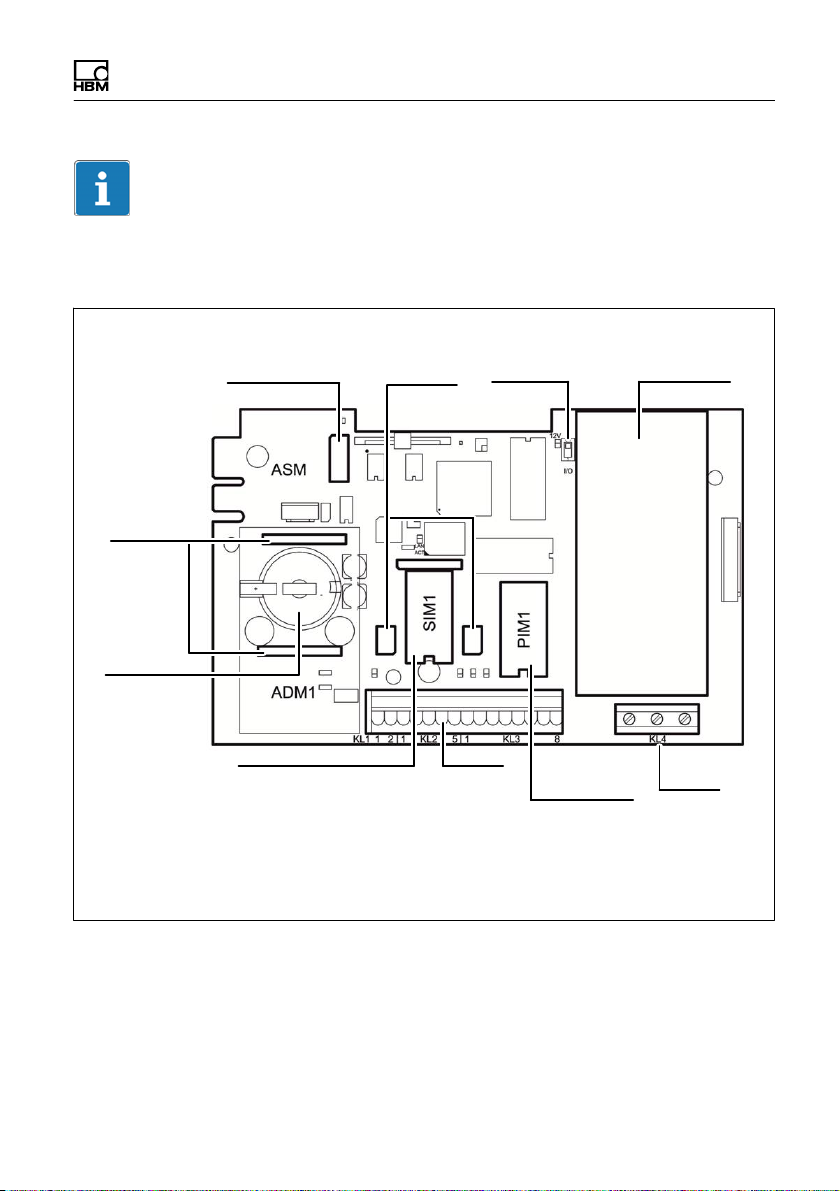

Important

Only one option can be selected at a time for communications interfaces and

analog or digital I/Os.

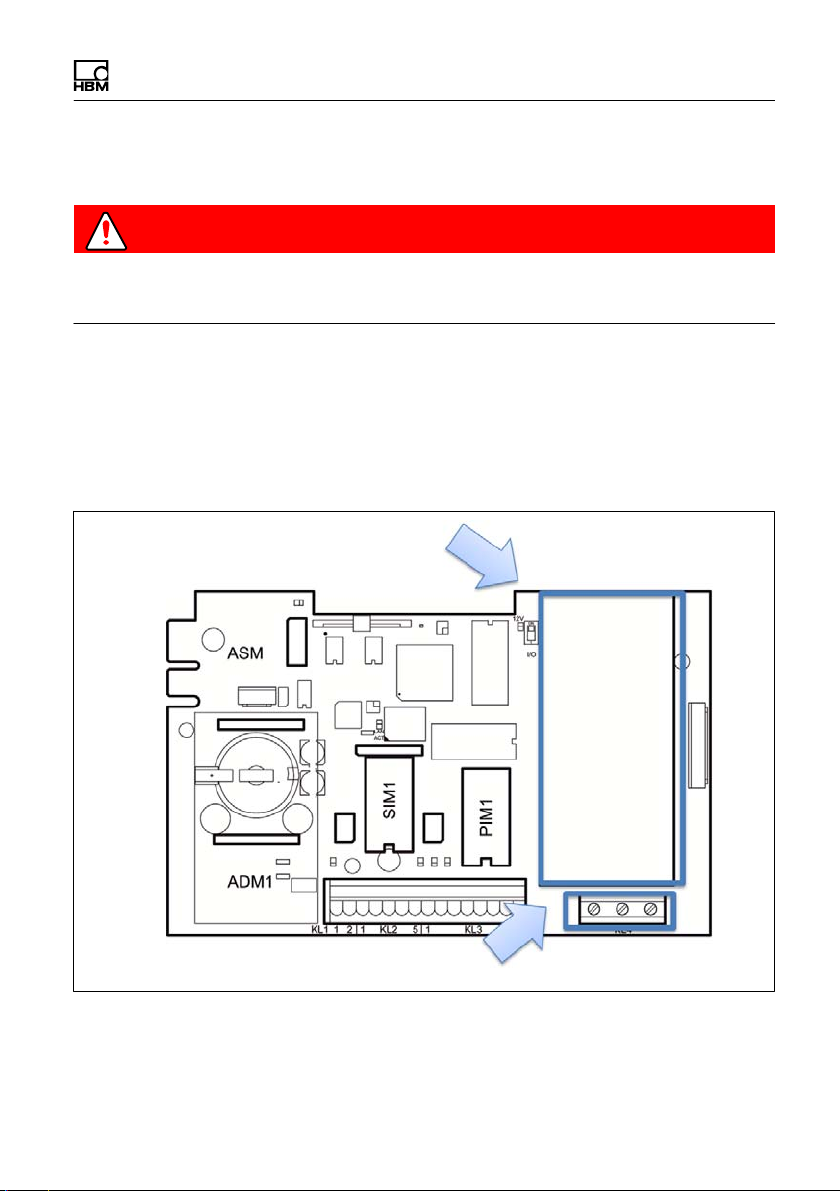

Scale

connection

of ADM,

DWB

Battery

CR2032

Slot for legal for

trade data storage

(ASM)

Slot for communications

interfaces Ethernet TCP/

IP, RS485-4, RS232

SIM USB

slot

S100 On/

Off key

Terminals

KL1-KL3 Power

Slot for analog

output or digital

I/Os PIM500,

DAU15

Power supply

12…30 VDC

110…240 AC

supply

For connecting different plug-in modules see section 4 "Installation," page 20.

WTX110 A4774-1.0 HBM: public 19

Page 22

Installation

4 Installation

4.1 Overview of connections

4.1.1 ADM (analog sensors)

ADM for analog sensors in slot ADM1

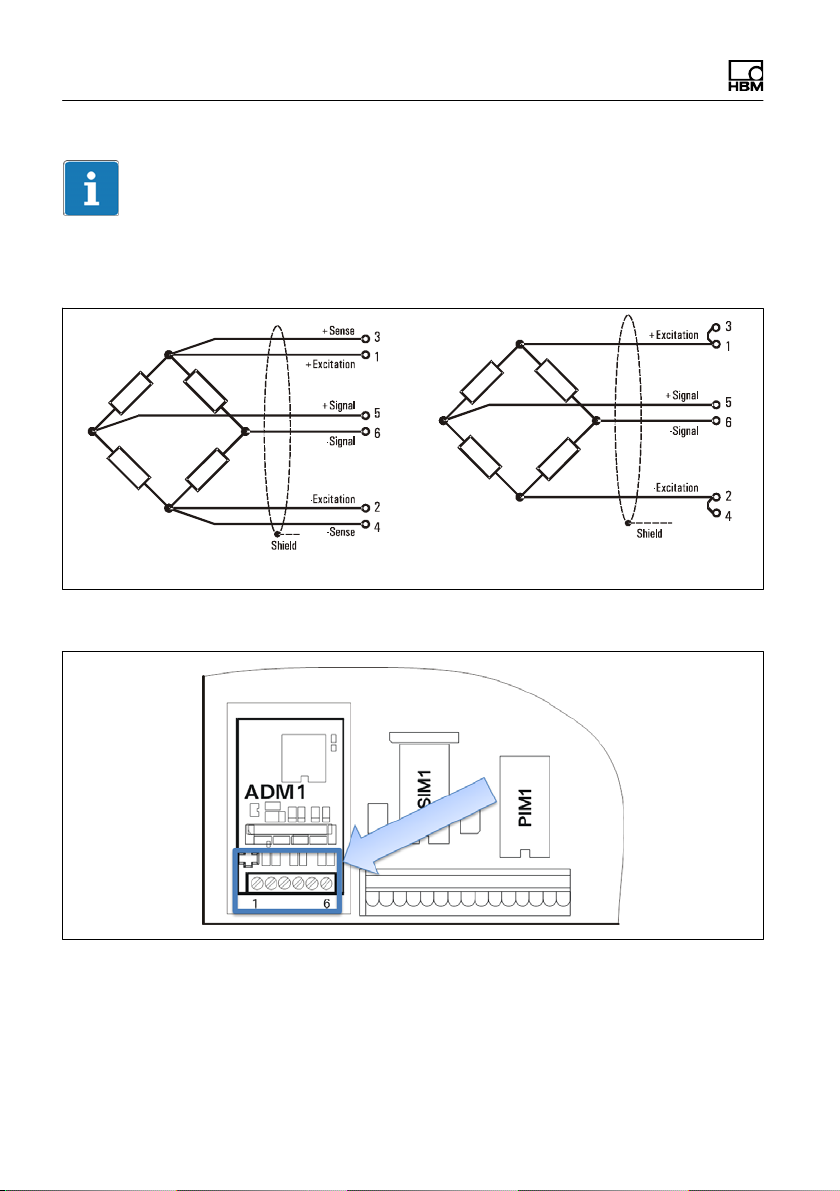

6 wires 4 wires

1 + Excitation 1 / 3 + Excitation

2 – Excitation 2 / 4 – Excitation

3 + Sense 5 + Signal

4 – Sense 6 – Signal

5 + Signal

6 – Signal

20 A4774-1.0 HBM: public WTX110

Page 23

4.1.2 Serial interfaces

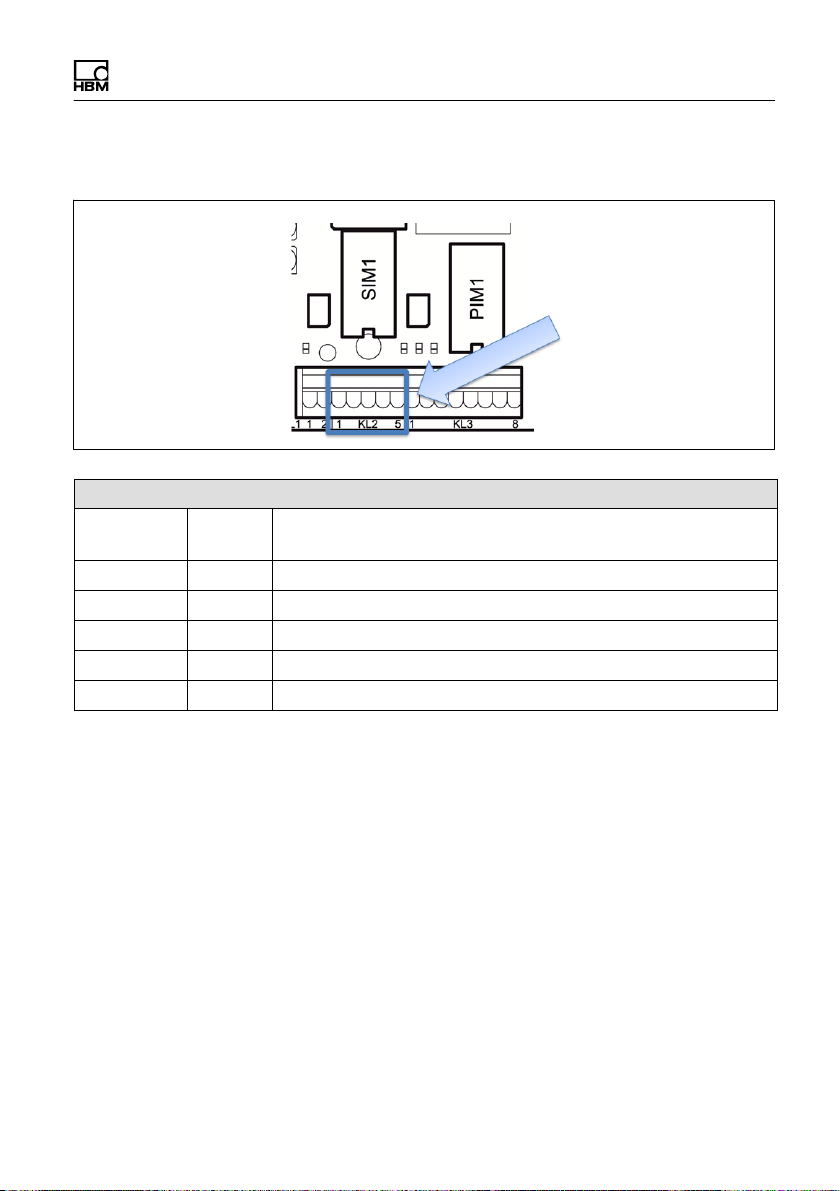

KL2: Serial interfaces RS485, RS232 in slot SIM1

ConnectionRS232 RS485 4 wires

1 TxD Tx A (Tx+)

2 RTS Tx B (Tx‒)

3 RxD Rx A (Rx+)

4 CTS Rx B (Rx‒)

5 Gnd -

Installation

WTX110 A4774-1.0 HBM: public 21

Page 24

Installation

4.1.3 Digital inputs/outputs

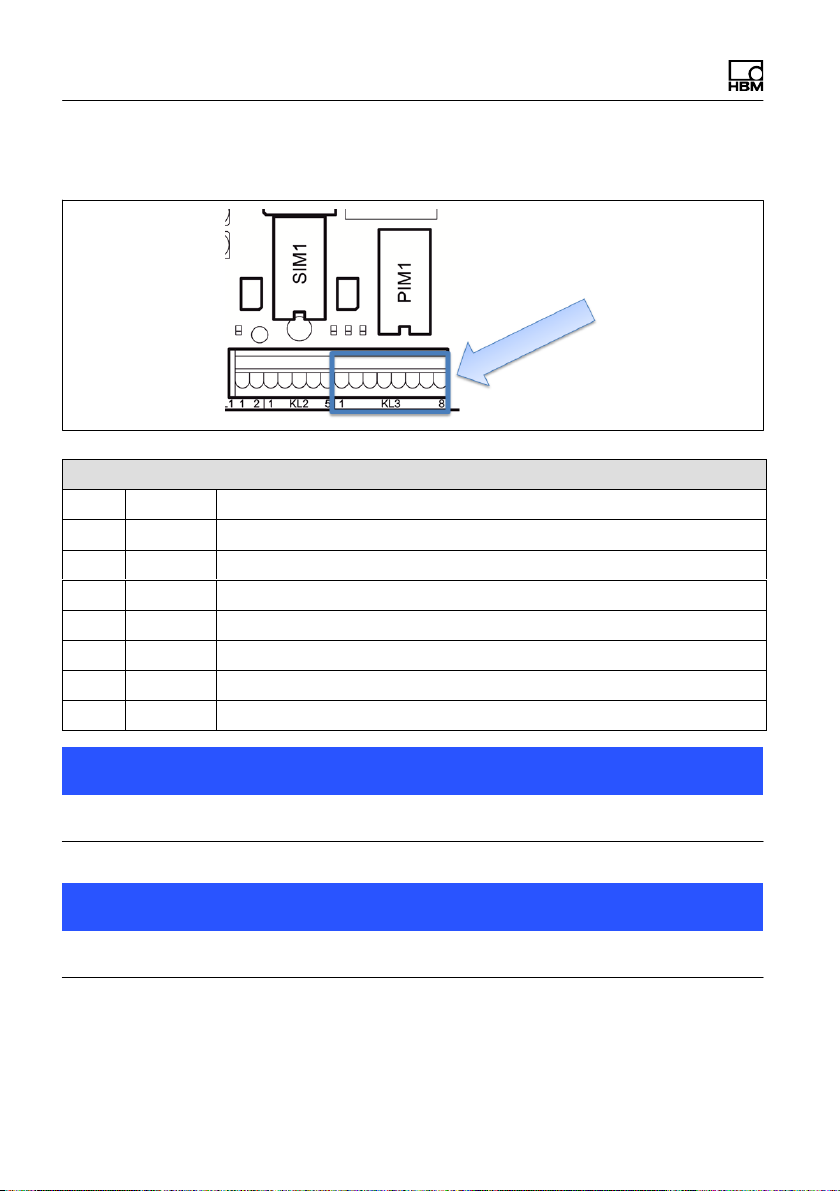

KL3: Digital inputs/outputs PIM500 in slot PIM1

1 (=0 V) Power supply for external peripheral devices (digital load cells, etc.)

2 (=+12 V) Power supply for external peripheral devices (digital load cells, etc.)

3 IN 0

4 IN 1

5 IN ‒ PIM500: for IN 0, IN 1 and OUT 0, OUT 1

6 OUT 0

7 OUT 1

8 OUT + for OUT 0, OUT 1

Notice

Load carrying capacity of outputs max. 500 mA at 12…24 VDC.

Notice

Current consumption of inputs max. 7 mA at 12…24 VDC.

22 A4774-1.0 HBM: public WTX110

Page 25

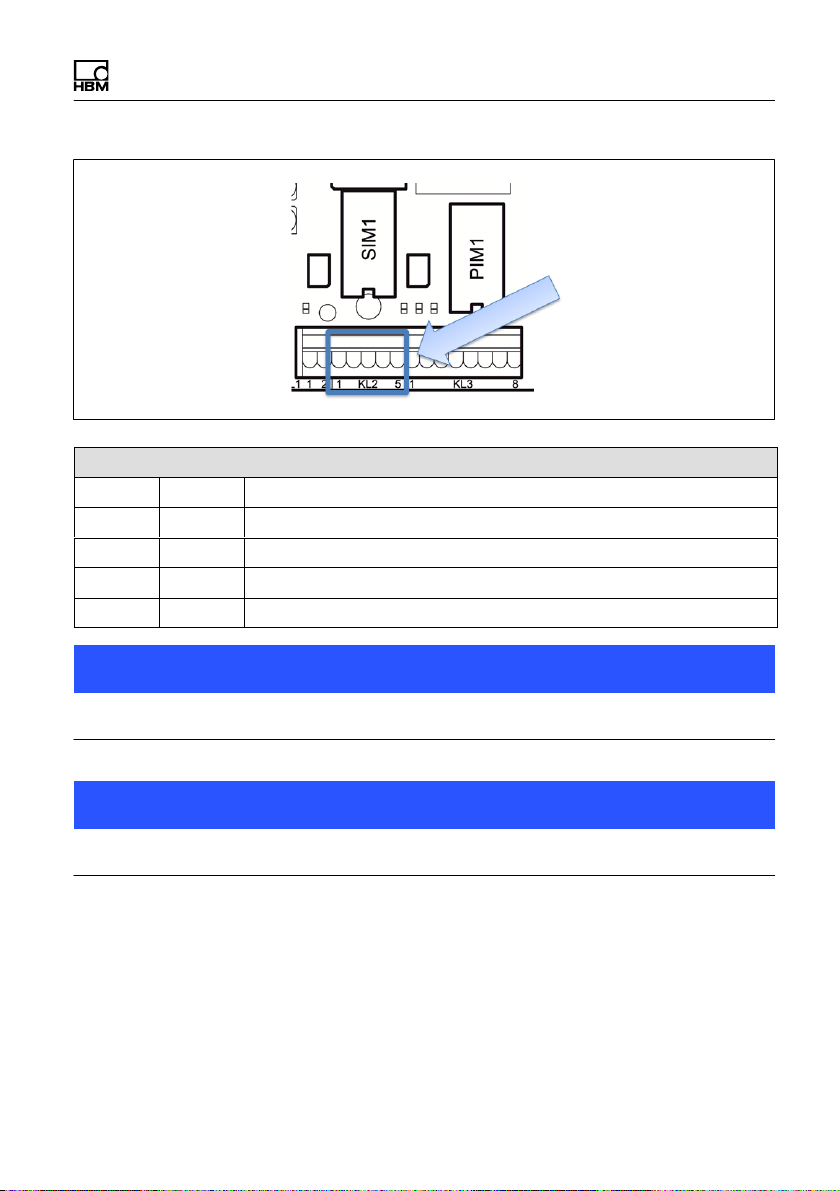

KL2: Digital inputs/outputs SIO in slot SIM1

1 OUT 0

2 OUT 1

3 OUT + For OUT 0 … OUT 1 and IN 0

4 IN 0

5 - Must stay clear

Installation

Notice

Load carrying capacity of outputs max. 100 mA at 12–24 VDC.

Notice

Current consumption of inputs max. 7 mA at 12–24 VDC.

WTX110 A4774-1.0 HBM: public 23

Page 26

Installation

4.1.4 Analog output

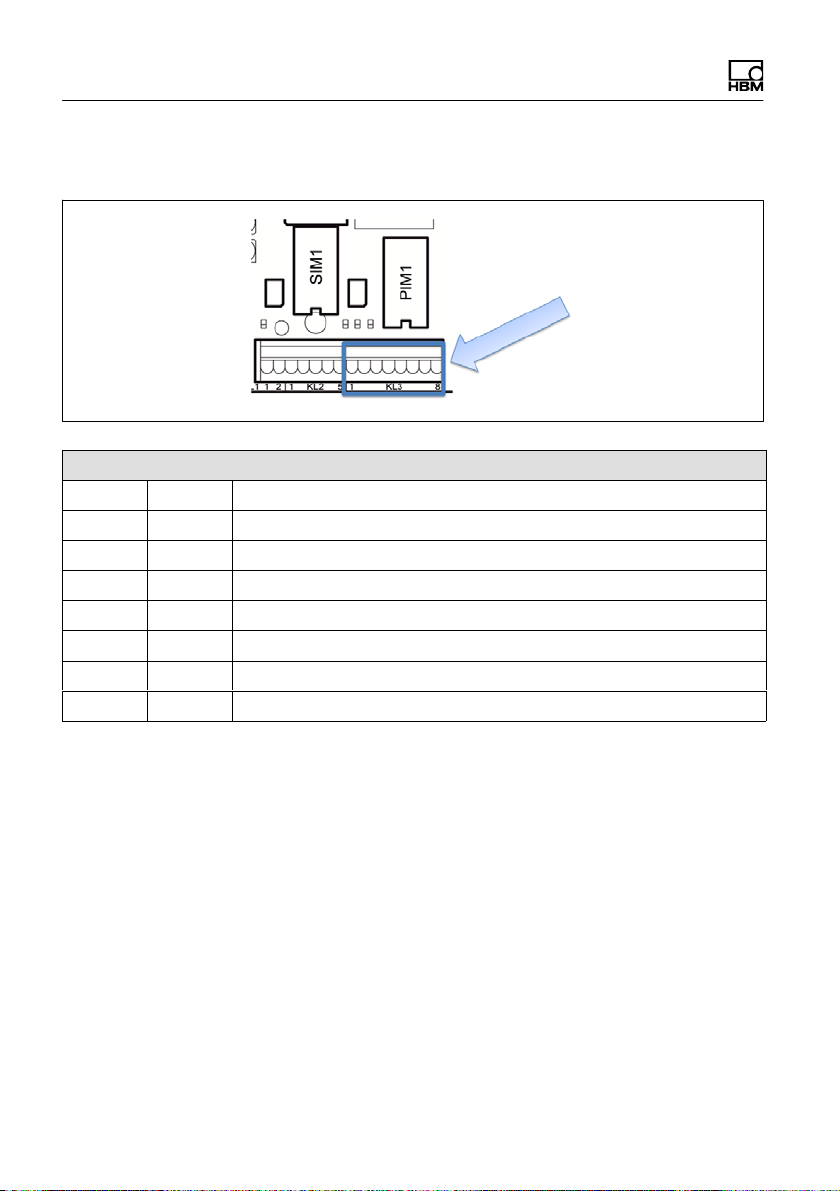

KL3: Analog output DAU15 in slot PIM1

1 2 3 I + Current output 0/4–20 mA (+)

4 I – Current output 0/4–20 mA (–)

5 6 U + Voltage output 0/2–10 V (+)

7 U – Voltage output 0/2–10 V (–)

8 -

4.2 Setup and installation

The operating temperature can be between –10 °C and +40 °C with 95 %

relative humidity (non-condensing). Avoid direct sunlight

For wall-mounting the device is first mounted on the wall and then the cables

are connected with the housing cover open.

There are six fastening clamps on the device for control cabinet mounting.

Before commissioning the housing must always be closed and screwed shut

with the hexagonal nuts included with delivery. The hexagonal nuts must be

tightened crosswise to a torque of 1.1 Nm.

24 A4774-1.0 HBM: public WTX110

Page 27

Installation

4.3 Mains connection

DANGER

Danger of death! it is absolutely necessary to read the General safety instruc

tions chapter before making the mains connection!

The WTX110 is available for connection in three variants:

S Alternating voltage systems K-WTX110-*-AC*-**-***-**-***-**

S DC voltage systems K-WTX110-*-DC/-**-***-**-***-**

S External batteries K-WTX110-*-BA/-**-***-**-***-**

Power supply

unit

Power supply

The power supply is connected to terminal 4.

WTX110 A4774-1.0 HBM: public 25

Page 28

Installation

The device power supply must not simultaneously supply machines or

equipment that cause grid interference (motors, relays, heaters, etc.). Even

brief surges or drops in the voltage supply can adversely affect how the device

functions or lead to damage. An uninterruptible power supply (UPS) or voltage

stabilizer can prevent this.

The device must be incorporated into the potential equalization of the system.

There is a threaded bolt on back for this purpose.

4.4 General cable assembly

All connection cables are directed through the bolted cable connection on the

bottom of the device to the inside of the housing.

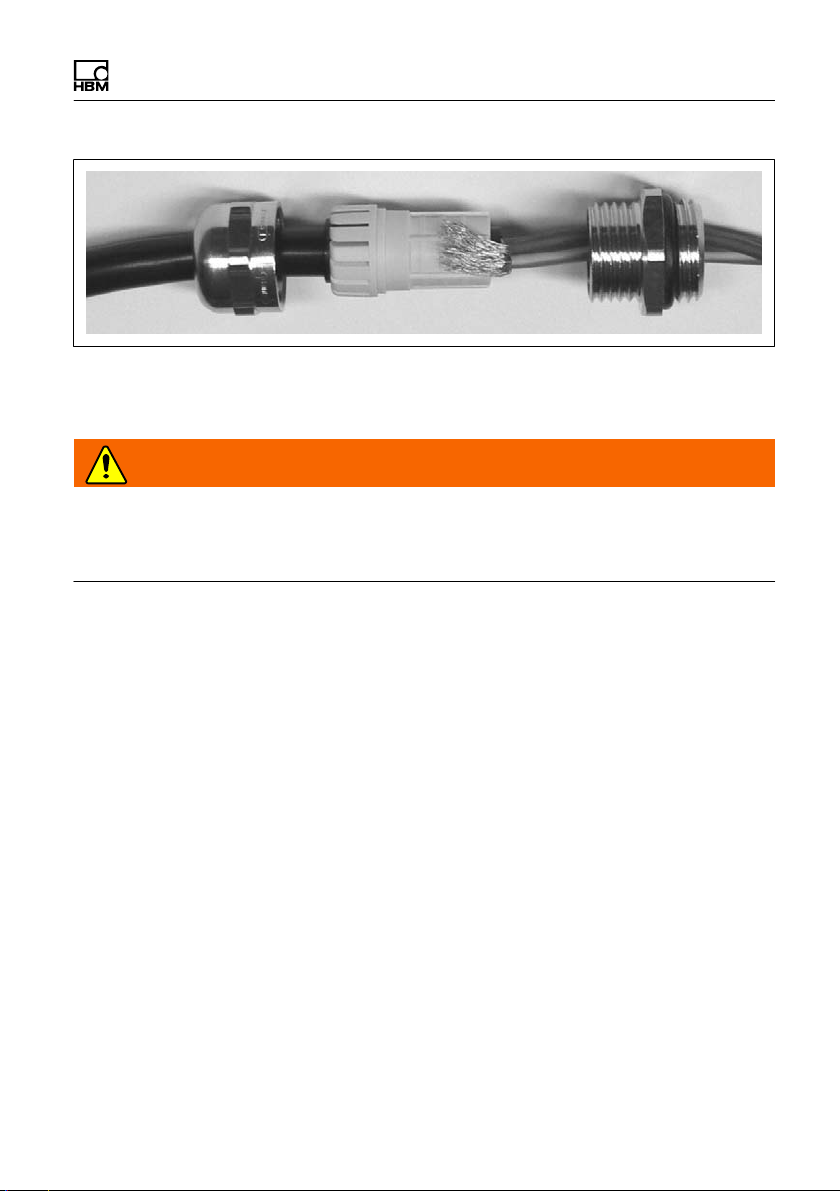

Cable sheath Shield Swivel nut Plastic

insert

Metal

housing

Check

nut

► Slide the swivel nut over the cable sheath.

► Push the plastic insert over the cable sheath until the right edge of the

insert meets the end of the cable sheath.

► Unbraid the shield and lay it as flat as possible over the right part of the

plastic insert so that the shield is conductively connected with the housing.

The shield wires must not be longer than the right part of the insert.

Otherwise the bolted cable connection no longer provides a reliable seal.

26 A4774-1.0 HBM: public WTX110

Page 29

Installation

► Guide the cable with plastic insert into the metal housing.

► Screw on the swivel nut and tighten it with a screwdriver.

WARNING

Cut the individual wires to length so that the parts conducting mains voltage

(connection cable, power supply unit) cannot touch! Use wire end ferrules for

leads with fine wires and make certain no individual wires are sticking out.

4.5 Connection of analog SG sensors

The WTX110-A permits the connection of analog SG sensors with the following

specification:

S Maximum 8 SG load cells with 350 Ω each

S Load cell impedance range 43 Ω ... 3321 Ω

S Legal for trade weight resolution 10.000 e, internal 524.000 d

S Smallest permissible input signal for legal for trade applications: 0.33 μV/e

S Sample rate 50–800 measurements / second (can be adjusted in Service

mode)

S Supply voltage for load cells: 5 V ±5 %, clocked

S Connection in 4- or 6-wire configuration

WTX110 A4774-1.0 HBM: public 27

Page 30

Installation

Tip

Use a suitable terminal box to connect multiple load cells, for example types

VKK1-4 or VKK2-8 from HBM, for wiring the load cells.

6-wire configuration of load cell 4-wire configuration of load cell

Fig. 4.1 Schematic diagram of load cell with 6- and 4-wire configuration

Fig. 4.2 Connection of an analog SG sensor in 6-wire configuration to the ADM

module

28 A4774-1.0 HBM: public WTX110

Page 31

Installation

ADM for analog sensors in slot ADM1

6 wires 4 wires

1 + Excitation 1 / 3 + Excitation

2 – Excitation 2 / 4 – Excitation

3 + Sense 5 + Signal

4 – Sense 6 – Signal

5 + Signal

6 – Signal

Connection of an analog SG sensor in 4-wire configuration to the ADM

module

To operate sensors without sense wires (4-wire mode), jumpers must be fitted

on terminal TE1 between pins 1 and 3 and 2 and 4.

4.5.1 Connection cable for analog load cell

When laying scale connecting cables (analog load receptors) please note:

S Use only suitable scale connecting cables:

WTX110 A4774-1.0 HBM: public 29

Page 32

Installation

- Keep to the rated voltages of the connecting cable.

- Double-shielded cable is advantageous (braided shield)

- The length and cross-section of the individual wires must meet the

following conditions:

Cable length (m) / cross-section (mm@) v270 (m/mm@)

- Maximum line length between load cells and weighing terminal: 200 m

S The shield of the load cell cable must be fitted across a large area all-round

in the screwed cable gland of the weighing terminal. This can be done with

all WTX110 variants. An additional connection for potential equalization is

located on the bottom of the WTX110.

S The load cells and load receptors, terminal boxes and weighing terminal

must be integrated into the equipotential bonding system. To do this,

depending on the local conditions, it may be necessary to lay a separate

equipotential bonding line with a corresponding cross-section (e.g. 16mm@).

S Use only metal terminal boxes to extend cables, and fit the shielding for

both cables in the screwed cable glands.

S Cable laid a minimum of 50 cm away from power lines. Lay cable in

grounded steel conduit, metal tubing or metal cable ducts.

S When load cells are under tension rather than compressive load, the +

and – signal connections must be swapped.

4.5.2 Saving calibration data for legal for trade applications

The calibration data can be saved on the ADM motherboard with jumper W1.

In the factory settings W1 is always set to calibration enabled!

30 A4774-1.0 HBM: public WTX110

Page 33

Installation

Calibration data saved:

Jumper set

Enable calibrating and saving: Jumper in

this position or completely removed

Information

Not removing the W1 jumper completely, or only removing it for replugging and

proceeding with care when moving the jumper is recommended to prevent the

jumper from being lost!

When setting the jumper, take care to ensure it is set on both pins to ensure

reliable calibration.

WTX110 A4774-1.0 HBM: public 31

Page 34

Installation

The position of the W1 jumper can be locked by a

weights and measures officer with thread and lead or a

seal:

A description of calibration can be found in section 11

"Calibration," page 159!

4.6 Serial interface connection

The WTX110 generally ships with the variant configuration with pre-wired

options.

RS232 or RS485 (4-wire) can be selected as serial options. The serial interface

module is always plugged into slot SIM1.

Fig. 4.3 Positioning the serial module on the WTX110 motherboard (CPU1)

32 A4774-1.0 HBM: public WTX110

Page 35

The connection is via terminal KL2 serial 1-5.

KL2: Serial interfaces RS485, RS232 in slot SIM1

Connection RS232 RS485 4 wires

1 TxD Tx A (Tx+)

2 RTS Tx B (Tx‒)

3 RxD Rx A (Rx+)

4 CTS Rx B (Rx‒)

5 Gnd -

Installation

Transfer lines connecting the serial ports must be installed so that inductive

and capacitive interference from other lines, machines or electrical devices is

ruled out. Interference on data transfer could result in delays or in the program

stopping.

To ensure optimal interference suppression of all injected frequencies, the

shield should be applied on both sides.

In the event of fluctuations in ground potential, a compensating current may

flow via the double-side shield. In this case an additional equipotential bonding

line must be laid.

WTX110 A4774-1.0 HBM: public 33

Page 36

Installation

Important

Terminal designation: Some manufacturers of components with RS485 ports

designate the terminals differently. According to the standard, the TxD+ / RxD+

port is designated 'B' and the TxD– / RxD– port 'A'.

Important

Cable: Always use twisted-pair cables! The surge impedance of the cable

should be approximately 150 W.

When laying cables for serial interfaces please note:

S Transfer lines connecting the serial ports must be installed so that inductive

and capacitive interference from other lines, machines or electrical devices

is ruled out. Interference on data transfer could result in delays or in the

program stopping.

S Self-wired cables must meet the following specification:

Shielded with twisted pairs, for example LIYCY 3 x 2 x 0.14 mm@ or LIYCY 3 x 2 x

0.25 mm@; shielded applied on both side

Cable resistance ≤ 125 Ω/km

2

Conductor cross-section ≥ 0.14 mm

Line capacitance ≤ 130 nF/km

Cable length, RS232 max. 15 m

Cable length, RS485 max. 1200 m

Characteristic impedance of RS485 approx. 150 Ω

Nominal (rated) voltage of the cable ≥ 250 V

to 200 m, ≥ 0.25 mm2 to 1200 m

34 A4774-1.0 HBM: public WTX110

Page 37

Installation

4.7 USB connection

If a WTX110 is ordered with a USB connection, the USB connection is

completely pre-wired. Devices can be connected via USB connector socket

type A on the bottom of the device.

4.8 Ethernet TCP/IP connection

If a WTX110 is ordered with an Ethernet connection, the Ethernet connection

is completely pre-wired. Devices can be connected via M-12 socket on the

bottom of the device.

An HBM connection cable can be used for the connection to local 10/100-Mbit

Ethernet networks.

S 1-KAB2129-5: Ethernet connection cable M12 plug to RJ45 plug (straight)

(5 m)

S 1-KAB2130-5: Ethernet connection cable M12 plug (90°) to RJ45 plug (5 m)

S 1-KAB2129-10: Ethernet connection cable M12 plug to RJ45 plug (straight)

(10 m)

S 1-KAB2130-10: Ethernet connection cable M12 plug (90°) to RJ45 plug

(10 m)

Information

Cable length without repeater (hub/switch) max. 80 m

WTX110 A4774-1.0 HBM: public 35

Page 38

Installation

4.9 Digital inputs/outputs

Depending on the configuration of the relevant variant, the WTX110 has a

maximum of three digital inputs and four digital outputs on the device. It is also

possible to connect up to four digital inputs and 4 digital outputs via a Modus/

TCP fieldbus coupler (for example Wago 750-342). See chapter 4.9.2.

There are two independent options available for digital I/Os, (1) IO and / or (2)

DIO

K-WTX110-*-***-**-***-IO-***-**

2x DO and 2 x DI

Information

If the IO option is selected, no additional interfaces can be used on this option!

K-WTX110-*-***-**-DIO-** -***-**

2 x DO and 1 x DI

Information

If the DIO option is selected, no additional interfaces can be used on this

option!

In the maximum configuration level no additional options such as Ethernet

TCP/IP, USB or an analog output are possible.

If a WTX110 is ordered with option "IO" and / or "DIO", the interface is

completely pre-wired. The IO option is always used in slot PIM1, DIO always in

SIM1.

36 A4774-1.0 HBM: public WTX110

Page 39

Installation

4.9.1 Overview I/O Connection

Settings at the WTX110 Config 1 Config. 2 Config. 3

Group 1

(Config.->Digital I/O)

Group 2

(Config.->Digital I/O)

Number of outputs 2 2 4

Number of inputs 1 2 3

Output 1 KL2-OUT0 KL3-OUT0 KL3-OUT0

Output 2 KL2-OUT1 KL3-OUT1 KL3-OUT1

Output 3 na na KL2-OUT0

Output 4 na na KL2-OUT1

Input 1 KL2-IN0 KL3-IN0 KL3-IN0

Input 2 na KL3-IN1 KL3-IN1

Input 3 na na KL2-IN0

Input 4 na na na

SIO

see

Tab. 4.2

Overview of terminalblocks

PIM

see

Tab. 4.1

PIM

see

Tab. 4.1

SIO

see

Tab. 4.2

WTX110 A4774-1.0 HBM: public 37

Page 40

Installation

4.9.2 Overview I/O Connection with Ethernet (Modbus-TCP) Fieldbus coupler

Settings at the WTX110 Config 4 Config. 5

Group 1

(Config.->Digital I/O)

Group 2

(Config.->Digital I/O)

Number of outputs 4* 4*

Number of inputs 4* 4*

Output 1 KL2-OUT0 MTCP-Output 1

Output 2 KL2-OUT1 MTCP-Output 2

Output 3 MTCP-Output 1 MTCP-Output 3

Output 4 MTCP-Output 2 MTCP-Output 4

Input 1 KL3-IN0 MTCP-Input 1

Input 2 KL3-IN1 MTCP-Input 2

Input 3 MTCP-Input 1 MTCP-Input 3

Input 4 MTCP-Input 2 MTCP-Input 4

PIM Modbus/TCP

Modbus/TCP -

Overview of terminalblocks

38 A4774-1.0 HBM: public WTX110

Page 41

Installation

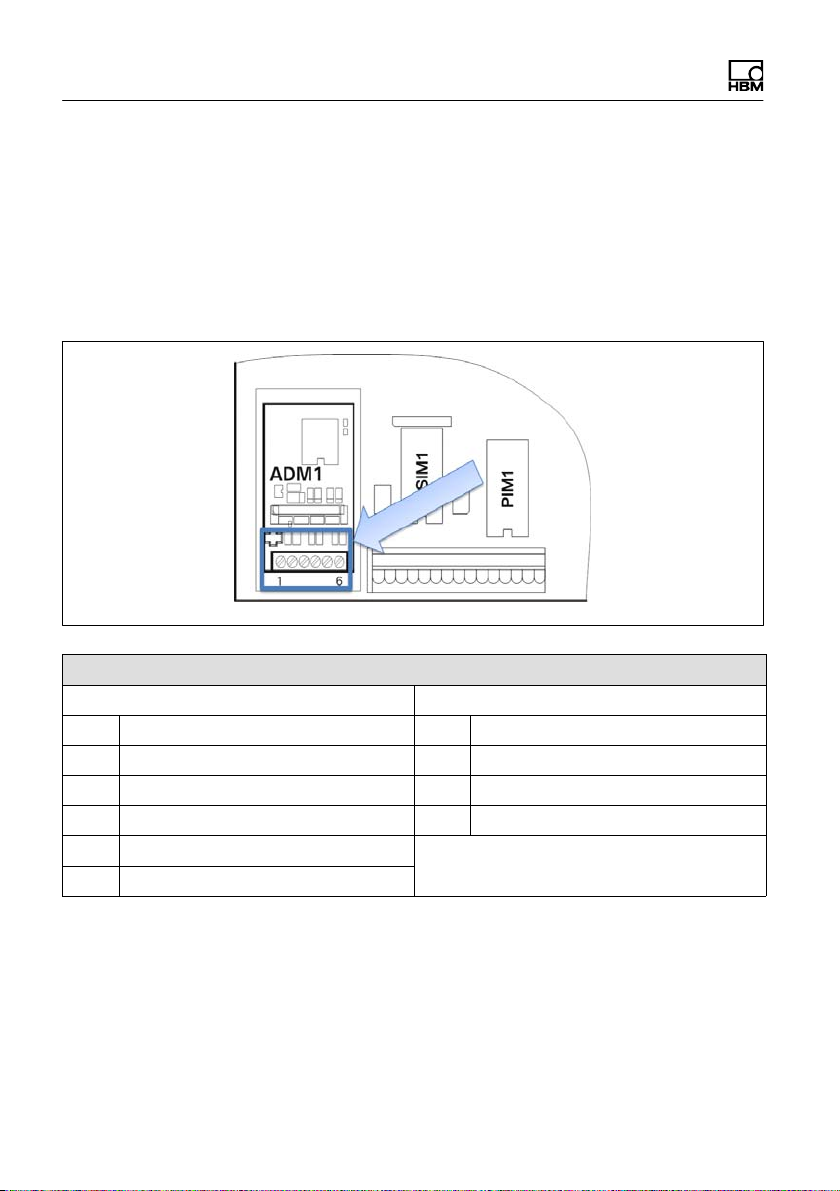

4.10 Connection of digital inputs/outputs IO (2xDO, 2xDI)

If a WTX110 is ordered with option "IO," the interface is completely pre-wired.

K-WTX110-*-***-**-***-IO-***-**

The IO option is always used in slot PIM1 and labeled with PIM500.

Notice

Load carrying capacity of outputs max. 500 mA at 12…24 VDC.

Notice

Current consumption of inputs max. 7 mA at 12…24 VDC.

Fig. 4.4 Positioning of the IO module (PIM500) on the WTX110 motherboard

WTX110 A4774-1.0 HBM: public 39

Page 42

Installation

Fig. 4.5 Connection of digital inputs/outputs to KL3

KL3: Digital inputs/outputs PIM500 in slot PIM1

1 (=0 V) Power supply for external peripheral devices (digital load cells, etc.)

2 (=+12 V) Power supply for external peripheral devices (digital load cells, etc.)

3 IN 0

4 IN 1

5 IN ‒ PIM500: for IN 0, IN 1 and OUT 0, OUT 1

6 OUT 0

7 OUT 1

8 OUT + for OUT 0, OUT 1

Tab. 4.1 KL3: Digital inputs/outputs OIM500 in slot PIM1

Notice

Maximum current consumption on KL3 (terminal 1 and 2) according to section

4.13 "Power supply for external peripheral devices".

40 A4774-1.0 HBM: public WTX110

Page 43

Installation

4.11 Connection of digital inputs/outputs DIO (2xDO, 1xDI)

If a WTX110 is ordered with option "DIO," the interface is completely pre-wired.

K-WTX110-*-***-**-DIO-**-***-**

The DIO option is always used in slot SIM1 and labeled with SIO. It has one

optically isolated input and two optically isolated outputs.

Notice

Load carrying capacity of outputs max. 100 mA at 12–24 VDC.

Notice

Current consumption of inputs max. 7 mA at 12–24 VDC.

Fig. 4.6 Positioning of the DIO module (SIO) on the WTX110 motherboard

WTX110 A4774-1.0 HBM: public 41

Page 44

Installation

The connection is via terminal KL2 serial 1-4.

KL2: Digital inputs/outputs SIO in slot SIM1

1 OUT 0

2 OUT 1

3 OUT + For OUT 0 … OUT 1 and IN 0

4 IN 0

5 - Must stay clear

Tab. 4.2 KL2: Digital inputs/outputs SIO in slot SIM1

Information

In contrast to the digital inputs of the IO module, the input of the DIO module is

inverted! A logical 1 is detected if the input is connected to ground potential.

See the schematic circuit diagram below.

42 A4774-1.0 HBM: public WTX110

Page 45

Installation

Digital output Digital input

Fig. 4.7 Schematic circuit diagram of DIO module

4.12 Connection of 15-bit analog output

If a WTX110 is ordered with option "AO," the interface is completely pre-wired.

K-WTX110-*-***-**-***-AO-***-**

Depending on the relevant variant of the device, the WTX110 is fitted with an

analog output in slot PIM1 and labeled with DAU15. A plug-on module

(DAU15) can be used to indicate gross or net weights via a 15-bit analog

output.

WTX110 A4774-1.0 HBM: public 43

Page 46

Installation

Fig. 4.8 Positioning of the AO module (DAU15) on the WTX110 motherboard

The resolution of the analog output signal (gross or net weight) is 15 bits

(32,768 increments). The output signal is active and potential-free.

The AO module (DAU15) is in Service mode/Config.Config. The Analog Out

group 'DAU15' can optionally be adjusted to 0/2…10 V or 0/4…20 mA. The

resolution of the analog output signal is 15 bits (32,768 increments). The

output signal is active and potential-free.

Information

The AO module must be always calibrated.

44 A4774-1.0 HBM: public WTX110

Page 47

Fig. 4.9 Connection of analog output to KL3

KL3: Analog output

1

2

3 I+ Current output 0/4–20 mA (+)

4 I‒ Current output 0/4–20 mA (–)

5

6 U+ Voltage output 0/2–10 V (+)

7 UI‒ Voltage output 0/2–10 V (–)

8

Installation

WTX110 A4774-1.0 HBM: public 45

Page 48

Installation

KL3

Fig. 4.10 Example of connection for current output 0/4–20 mA

500 ohms max.

KL3

500 ohms min.

Fig. 4.11 Example of connection for voltage output 0/2-10 V

46 A4774-1.0 HBM: public WTX110

Page 49

Installation

4.13 Power supply for external peripheral devices

12 V is provided on terminals KL1 (terminals 1, 2) and KL3 (terminal 1, 2) as

the power supply for peripheral devices (digital load cells, etc.).

Terminal 1 2

KL 1 0 V (=+12 V)

KL 3 0 V +12 V

Maximum current consumption

ADM installed in slot ADM1 (with up to 8 analog load cells, 350 ohms each):

Current consumption

of USB device

0…100 mA 300 mA max.

100…300 mA 200 mA max.

300…500 mA 100 mA max.

Current consumption 12 V for peripheral devices on KL1

and KL3 (total)

WTX110 A4774-1.0 HBM: public 47

Page 50

Installation

4.14 Connection to 110 … 240 VAC

All K-WTX110-*-AC*-**-***-**-***-** variants have a power supply unit for alter

nating voltages in the range from 110 V (–15 %) to 240 V (+10 %), 50/60 Hz.

The input side is protected by a safety fuse (2 A slow-blow). The mains

connection is made with the mains cable, which is connected to terminal KL4

at the time of delivery (length 2.5 m) with a VDE plug or selected mains plug.

KL4: Power supply

1 PE

2 N

3 L1

48 A4774-1.0 HBM: public WTX110

Page 51

Installation

Information

Depending on the relevant variant of the device, mains connector plugs are

available for Europe, US, UK, Switzerland, South Africa and Australia, etc.

pre-wired and having passed the relevant electrical tests.

Potential equalization is pre-wired for the housing and cover.

DANGER

Parts of the power supply unit conduct high, life-threatening voltages during

operation! A faulty power supply unit cannot be repaired! The device must be

returned to HBM!

WTX110 A4774-1.0 HBM: public 49

Page 52

Installation

4.15 Connection to 12…30 VDC

All K-WTX110-*-DC/-**-***-**-***-** variants have a power supply unit (DCB)

that operates with DC voltage in the range from 12 VDC (–15 %) to 30 VDC

(+10 %). The connection is via terminal KL4. Power supply.

KL4: Power supply

1 PA

2 0 VN

3 +V

4.16 Connection to external battery 12…30 VDC

All K-WTX110-*-BA/-**-***-**-***-** variants have a power supply unit (NTB) for

input DC voltages in the range from 12 VDC (*15 %) to 30 VDC (+10 %). The

device is suitable for connecting to an external battery. It has voltage

monitoring with automatic shut-off. The external battery is connected to

terminal KL4.

50 A4774-1.0 HBM: public WTX110

Page 53

KL4: Power supply.

1 PA

2 0 VN

3 +V

Installation

If the WTX110 is powered by an external battery, the type must be selected in

'\Service\General\Power supply.' The effect of this selection on the automatic

shut-off behavior of the terminal is as follows:

WTX110 A4774-1.0 HBM: public 51

Page 54

Installation

Parameters Type Low batt. (volts)

(flashing battery

symbol beginning at

about)

Pb12 12 V lead

rechargeable

battery

Pb24 24 V lead

rechargeable

battery

Adjust Any recharge

able battery

Line Mains operation - -

11.5 V 11 V

23 V 22 V

Adjustable Adjustable

Power off (volts)

(shutdown at about)

If there is only a little remaining capacity (Low batt) the user is alerted by a

flashing battery icon in the top right corner of the display that the rechargeable

battery must be charged.

To prevent deep discharge of the connected rechargeable battery, the terminal

automatically switches off at the set voltage (Power off). If the terminal is

turned on again with the rechargeable battery deeply discharged, a message

appears indicating 'Low Battery: Power off' and the terminal switches off again.

4.17 Legal for trade data storage/alibi memory

If a WTX110 with the ALI option was ordered, the legal for trade memory is

completely pre-wired and plugged into the ASM slot. It is used for storing the

last 1,000,000 weighing processes.

K-WTX110-*-***-**-***-**-ALI-**

52 A4774-1.0 HBM: public WTX110

Page 55

Fig. 4.12 Positioning of ALI option on the WTX110 motherboard

Installation

WTX110 A4774-1.0 HBM: public 53

Page 56

Installation

4.18 Activating the On/Off key

Fig. 4.13 Switches S100

Switch S100 on the WTX110 motherboard is used to configure the function of

the On/Off key (F1):

ON position (default) On/Off key deactivated

The weighing terminal starts immediately as soon as current

is supplied.

Position 1 On/Off key activated

The weighing terminal does not start until the On/Off key is

activated. Activating the key again turns the weighing

terminal off.

About 1 minute is required to start the device. The device shows the text:

System Startup ...

Please wait!

54 A4774-1.0 HBM: public WTX110

Page 57

Operator control/settings

5 Operator control/settings

5.1 Service password

The Service password provides access to the Service mode.

The default Service password is 324.

1 234OK

The numbers are shown on the WTX110 display by the softkeys.

The Service password cannot be changed.

WTX110 A4774-1.0 HBM: public 55

Page 58

Operator control/settings

5.2 Display and control elements

Scale no./

weighing range no.

Scale stand

still symbol

Gross weight

or net weight

(Net)

Scale no.

Maximum

load

Minimum

load

Scale interval e

division d

Tare value

Time

Fig. 5.1 WTX110 display

Electronic typeplate

(only for single and dual range/two scale division scales)

Meaning Display Description

Scale no. W1 Always 1

Maximum load For example:

Max 5000 kg

Minimum load For example:

Min 2 g

Upper weighing range limit (without addi

tive tare), adjustable In calibration mode

Lower weighing range limit

Electronic

typeplate

Net display

symbol

Unit

Operator guidance

display

Softkeys

Function keys

56 A4774-1.0 HBM: public WTX110

Page 59

Operator control/settings

DescriptionDisplayMeaning

Scale interval e /

division d

12:14 PM Time display

For example:

e=d=0.1 g

Legal for trade scale division – scale

division e and display increment

scale interval d (in most cases e is the

same as d)

Information

The electronic typeplate is hidden with the setting in 'Service

Mode\Calibration\Adaptation\Onscreen typeplate=N' or for certain types of

scales (which ones?).

Weight indicator

Meaning Display Description

Scale no. W1 Scale no. selected with the scale toggle

key

Weighing range no. W1.1 … W1.3 Partial weighing range for multi-range

weighing machines

Scale standstill

symbol

Zero symbol >0< Scale is stopped in gross zero range

Tare 7.9 g T Display of tare weight

Gross weight or net

weight

Net display symbol Net Scale is tared

Unit For example g Weight unit, adjustable in calibration

For example 1250

For example

1000.0 g Net

Weight stabilized (printing/saving

possible)

(±0.2 d)

Switch between legal for trade gross

weight / net weight with Tare key

mode

WTX110 A4774-1.0 HBM: public 57

Page 60

Operator control/settings

Entry confirmation/function selection

Normally every entry or parameter/selection function must be confirmed with

the Enter key, even if it does not appear in the text. Then the program

continues in the next step.

Softkeys

The assignment of softkeys depends on the current program step as well as

the selected application. The current assignment is displayed in the bottom line

on the screen by the function keys.

Function keys

Key Softkey Description

On/Off Turn On/Off (if S100 in position 1)

Select Scroll forward / adapt parameters, call Service mode with

vibration notice

Clr Press: Delete characters individually

Hold: Clear all places

Tare Tare (tare balance), or clear tare of tared scale (multiple

taring also possible)

+1 Selection menu options or select values in a parameter

entry (+1)

Yes Activate an option

=> Scroll by character

Zero balance Zero gross weight of scale (only in range of zero setting)

0 Append 0 in parameter entries (0)

No Deactivate an option

Return

Return to the previous program step

Confirm

Confirm the parameter entries or continue to the next

program step (Enter)

58 A4774-1.0 HBM: public WTX110

Page 61

Operator control/settings

5.3 Example of entries via WTX110 display keys

The following sections explain the operator control sequence based on the

displayed user guidance texts and the corresponding entries.

The displays are shown on the left-hand side.

The following sections present examples of the input of alphanumeric

characters and numbers.

5.3.1 Alphanumeric entry

The following explains how the character string E1c can be entered based on

the example of an FTP password entry.

Display Key Description of key function

FTP pwd:

FTP pwd:A Hold to change entry mode.

The entry switches between:

A =upper case

a =lower case

0 =numbers and special characters

FTP pwd:E Keep pressing until the desired letter appears, e.g. E

FTP pwd:EA Press to create a new digit position

FTP pwd:E0 Hold to change entry mode.

FTP pwd:E1 Hold to change entry mode,

e.g. 1

FTP pwd:E10 Press to create a new digit position

WTX110 A4774-1.0 HBM: public 59

Page 62

Operator control/settings

Description of key functionKeyDisplay

FTP pwd:E1a Hold to change entry mode.

FTP pwd:E1c Keep pressing until the desired letter appears, e.g. c

FTP pwd:E1c Apply value

Information

The CLR key is used to clear individual characters.

5.3.2 Entering whole numbers

The following explains how to enter a sequence of digits.

Here for example the sequence 123.

Display Key Description of key function

Terminal No.: 001

Terminal No.: 0

Terminal No.: 1

Terminal No.: 10

Terminal No.: 12

Clear all places

Keep pressing until the desired digit appears, e.g. 1

Press to create a new digit position

Keep pressing until the desired digit appears, e.g. 2

60 A4774-1.0 HBM: public WTX110

Page 63

Operator control/settings

Description of key functionKeyDisplay

Terminal No.: 120

Terminal No.: 123

Terminal No.: 123 Apply value

Press to create a new digit position

Keep pressing until the desired digit appears, e.g. 3

Information

The F1 key is used to clear individual characters.

WTX110 A4774-1.0 HBM: public 61

Page 64

Operator control/settings

5.3.3 Entering numbers with decimal places

The following explains how to enter a sequence of digits with decimal places.

Here for example the sequence 0.001.

Display Key Description of key function

Interval 0.321

Interval 0.000 Clear all places

Interval 0.001 Keep pressing until the desired digit appears, e.g. 1

Interval 0.010 Press to move the digit one position to the left.

Interval 0.012 Keep pressing until the desired digit appears, e.g. 2

Interval 0.120 Press to move the digit one position to the left.

Interval 0.123 Keep pressing until the desired digit appears, e.g. 3

Interval 1.230 Press to move the digit one position to the left.

Interval 1.234 Keep pressing until the desired digit appears, e.g. 4

Interval 1.234 Apply value

62 A4774-1.0 HBM: public WTX110

Page 65

Operator control/settings

5.4 Operating the weighing functions

The basic step for all processes is displaying the current continuous weight

value. In this step the basic weighing functions can be called and displayed.

A precondition for the following processes is the settings in Service mode:

'Print mode: Standard' and 'Auto Tare?=N.

See section 'Print mode' and 'Auto Tare'.

Further information is available from your supplier.

5.4.1 Tare functions

In Service mode, various tare functions can be assigned to the 'General' group.

A precondition for the following processes is the settings in Service mode:

'Print mode: Standard' and 'Auto Tare?=N.

Further information is available from your supplier.

5.4.2 Set / delete tare (Tare mode: Gross/Net)

Every time the Tare key is pressed, the display changes from Gross to Net and

back (setting 'Tare mode: Gross/Net'). This is the usual tare function, which is

suitable for most applications.

Display Key/Action Description

8.0 kg Set container in place

Tare

WTX110 A4774-1.0 HBM: public 63

Page 66

Operator control/settings

DescriptionKey/ActionDisplay

0.0 Net/kg

Delete tare

5.4.3 Automatic deletion of tare (Tare mode: Auto Clear)

The loaded scale can be tared one time. If the scale is completely unloaded,

the tare is automatically deleted and the display switches back to Gross.

This function is provided for series of weighings with identical tare weight.

Display Key/Action Description

8.0 kg Set container in place

13.0 Net/kg Article in container

-8.0 Net/kg Remove full container from the scale

64 A4774-1.0 HBM: public WTX110

Page 67

Operator control/settings

5.4.4 Repeated taring (Tare mode: Net=0)

Every time the Tare key is pressed, the scale is tared again and the display

shows the net weight. If the scale is completely unloaded, the tare is automati

cally deleted and the display switches back to Gross.

This function is used when multiple components will be weighed one after the

other in the same container.

Display Key/Action Description

8.0 kg Set container in place

0.0 Net/kg

Taring...

13.0 Net/kg 1st article in container

13.0 Net/kg

Weighing...

0.0 Net/kg

Taring...

13.0 Net/kg 2nd article in container

13.0 Net/kg

Weighing...

Tare scale (Net is displayed)

Send weight value to printer / PC

Tare scale again

Send weight value to printer / PC

WTX110 A4774-1.0 HBM: public 65

Page 68

Operator control/settings

DescriptionKey/ActionDisplay

-8.0 Net/kg Remove full container from the scale

5.4.5 Zeroing

Display Key/Action Description

0.2 kg

0.0 kg

Zeroing

Zero gross weight (only possible within the

selected range of zero setting).

5.4.6 Weighing

Display Key/Action Description

13.0 kg Article in container

13.0 kg

Weighing...

Send weight value to printer / PC

66 A4774-1.0 HBM: public WTX110

Page 69

Operator control/settings

5.4.7 Switch weight indicator to 10 times the resolution

Information

Only possible if 'Totals? = N' is set in Supervisor mode.

Display Key/Action Description

13.0 kg Gross weight display

13.0 kg

Net(X) 13.03 kg

Display of the current weight with 10 times

higher resolution.

After about 5 seconds the display

automatically disappears.

WTX110 A4774-1.0 HBM: public 67

Page 70

1 Service

Appl.

Master

2 Entry

Supervisor

Mode

Standard

WTX110 V#.#.#

< 3 seconds < 3 seconds

WTX110

Navigation Pilot

Password

Enter service

password

Com0 (Eth)

Port

Protocol

General

Date: Entry

Time: Entry

…

Brightness

Password

Baud

Databits

Parity

Ctrl.

Protcl.

Target weight

...

Filler configuration;

only available

in filler application

Com6 (DWB)Com1 (SIM1)

Baud

Databits

Parity

Ctrl.

Protcl.

Weight Storage Logbook Software IDProducts

Search Date

Id-No.

Weight not found

note: only if

ALI available

Language

Keyboard

Time Zone (1)

Time Zone (2)

Date (format only)

Time (format only)

Country Code

Decimal char.

Approval signs

Tare mode

Cont. out.

Light off (Min.)

Power off (Min.)

Power Supply

Serial No.

3_ ...

2_ ...

1_...

note: if „W1“ jumper

is in position 1

only access,

no changes possible

ID: ...

Calibrate Scale 1

Mastermode

note: alternative

access

MAC-/IP-Address

M:

IP:

only info

parameter

error protocoll,

only info

Config.

Scale

Config. Scale

Test Reset Network BackupGeneralInterface

Digital IO

Serial IO

Config.

Digital IO

Reset Service

Mode Parameters?

Reset

Approved Wgt

note: only if

ALI available

Config.

Analog out

IP

Mask

Gate

DNS

NTP

FTP pwd

PanelX access

Access number

Set PanelX password

Update SSL cert

Start auto ping

Terminal No.

Backup or

Restore

from USB

note: ETH

or USB option

required

General SetupCalibration

Application

note: after

change restart

required!

Language

LS1 – LS4 Source

LS1 – LS4 Mode

only available in

standard application

Digital IO Print FormatsLimit switches

Input 1 – 4

Output 1 – 4

Ticket Weight

Total Weight

Ticket Count

Total Count

Factory defaults

Load application

MastermodeApplicationService Mode

Mode: Info

(zero offset)

Mode: Adapt

(several

filter settings)

Map symbology

F2 F3 F4 F5

Two different possible entries

Entry field F1 button level

Subsequent field F1 button level

Related fields on F1 button level

Enter password / Unload Scale

Mastermode

F1

Click F1 button

Click respective grey button

Notes

exception: back to „Select Group 1 – 9“ with

not with the F1 button

Select Group 1 – 9

note: adapted parameters

must be saved to be valid!

ADM

HBM

None

Parameters

Single Range

One Interval

Capacity

Interval

Unit

PIM

Modbus TCP

SIO

None

2 Calibration 3 Linearization

Geo Value

Calibrate Zero?

Calibrate Load?

High Cap.

High Int.

Low Cap.

Low Int.

Unit

High Cap.

High Int.

Low Cap.

Low Int.

Unit

Non

DAU15

...

Aout 1: Mode

Aout 1: Output

Aout 1: Calibration

New Fixpoint 1? Motion Window

Triple RangeDual Range

High Cap.

High Int.

Mid Cap.

Mid Int.

Low Cap.

Low Int.

Unit

Three IntervalsTwo Intervals

High Cap.

High Int.

Mid Cap.

Mid Int.

Low Cap.

Low Int.

Unit

4 Zero Adjust 5 Adaption 6 High

Unload Scale

High Cap.

High Int.

Low Cap.

Low Int.

Unit

Motion Counter

Filter Size

Auto Zero Range

...

Incline Switch

PowerUp Zero

With Taring?

Underload

Update Rate

Three Intervals T+Two Intervals T+

High Cap.

High Int.

Mid Cap.

Mid Int.

Low Cap.

Low Int.

Unit

Resolution

Weight Reset Parameters? Calibrate Zero?

7 Reset 8 Calculation

note: only

calibration

Span

Zero (mV/V)

LC-Cap. (kg)

No. of LCs

mV/V of LC1

Quick Start Guide for Calibration Setup

1. Connect Sensor

2. go to “Calibration”\“1 Scale Parameters”

and enter load cell parameters like Capacity, Interval, Unit

3. Perform Calibration

- with Calibration Weight go to “2 Calibration”

- without Calibration Weight go to “8 Calculation Span”

4. Enter further parameters like Dual Range, Linearization, etc.

5.

Save Calibration Parameters

measure and predict with confidence

9 W&M Info1 Scale

W&M Setup ok

Page 71

Service mode

6 Service mode

To access the Service mode group select the following keys:

Menu Key Function

Standard Switch to version notice

WTX110V#.# Display the current firmware version number

Call password entry within 3 seconds

Password 324 Enter the password

1 Service mode Call Service mode

Servicemode is used to configure the weighing terminal. In addition to

configuration, Service mode includes function tests for the hardware and,

depending on the device variant (Ethernet TCP/IP, USB), the option for saving

data to a connected PC.

S Device variants for update:

- K-WTX110-A-***-**-ETH-**-***-**

- K-WTX110-A-***-**-USB-**-***-**

S The weighing terminal and connected peripheral devices may only be

configured and calibrated by qualified personnel!

S Before calling Service mode all peripherals should have been connected

and configured!

S To call Servicemode the Service password must be known.

S Inappropriate changes to settings in Service mode could result in

operational malfunctions!

WTX110 A4774-1.0 HBM: public 69

Page 72

Service mode

6.1 Configure interfaces (Interface )

For more information on the keys necessary to access this menu group, go to

the Navigation Pilot.

Information

The set values must match the setting of the corresponding peripheral devices.

6.1.1 Setting the Ethernet interface (interface: Com0 (Eth))

Menu Key Function/Secondary selection

Interface Com0 (Eth)

Com0: Port : 1234 Enter the port

Com0: Protocol AckNak Select the transfer protocol:

None Raw data only

TTY Printer control (data only)

AckNak Secure procedure with

acknowledgment

NoAck Secure procedure with

acknowledgment

→Protocol TTY selected

Com0: Codepage None Output character set:

None as per selected language

850 DOS code page 'Western Europe' for

older printers

852 DOS code page 'Central Europe'

866 DOS code page 'Russian'

Star DOS code page Star printer

70 A4774-1.0 HBM: public WTX110

Page 73

Service mode

→Protocol AckNak selected

Com0: Start char. 999 Enter the start character as a decimal value

(e.g. 2 = STX)

If you enter 0 no start character will be transferred

Com0: End char. 999 Enter the end character as a decimal value

(e.g. 3 = STX)

If you enter 0 no end character will be transferred

Com0: Checksum XOR Select checksum formation; the checksum is

transferred after the end character:

None No checksum

XOR Exclusive-Or combination

CPL Two's complement

→If start or end character entered and a checksum selected

Com0: With start N Start character is included in checksum formation

Com0: With end N End character is included in checksum formation

6.1.2 Setting the serial interface (interface: Com1 (SIM))

Menu Key Function/Secondary selection

Interface Com1 (SIM1)

Com1: Baud: 9600 Select the baud rate of the Com1 interface:

300, 600, 1200, 2400, 4800, 9600,

[19200], 38400, 57600, 115200

WTX110 A4774-1.0 HBM: public 71

Page 74

Service mode

Function/Secondary selectionKeyMenu

Com1: Data bits 8 Select the data format of the Com1 interface1:

7 7 data bits

8 8 data bits

1 stop bit is always transferred.

Com1: Parity None Select the parity for the Com1 interface:

None No parity

Even Even parity

Odd Odd parity

COM1: Contrl. None Select the send/receive control

(hardware handshake) of the Com1 interface:

XOn/Xoff Control by XON/XOFF

RTS/CTS Control with RTS/CTS

None No flow control

Notice: RTS/CTS not possible on Com2!

Com1: Protcl. None Select the transfer protocol of Com1:

None Raw data only

TTY Printer control (data only)

AckNak Secure procedure with

acknowledgment

NoAck Secure procedure with

acknowledgment

→Protocol TTY selected

Com0: Codepage None Output character set:

None ISO8869 as per selected language

850 DOS code page 'Western Europe' for

older printers

852 DOS code page 'Central Europe'

866 DOS code page 'Russian'

Star DOS code page Star printer

72 A4774-1.0 HBM: public WTX110

Page 75

Service mode

→Protocol AckNak or NoAck selected

Com1: Start char. 999 Enter the start character as a decimal value

(e.g. 2 = STX)

If you enter 0 no start character will be transferred

Com1: End char. 999 Enter the end character as a decimal value

(e.g. 3 = STX)

If you enter 0 no end character will be transferred

Com1: Checksum None Select checksum formation; the checksum is

transferred after the end character:

None No checksum

XOR Exclusive-Or combination

CPL Two's complement

→If start or end character entered and a checksum selected:

Com1: With start N Start character is included in checksum formation

Com1: With end N End character is included in checksum formation

6.1.3 Setting the serial interface (Com6 (DWB1))

Menu Key Function/Secondary selection

Interface Com6 (DWB1) K-WTX110-D-***-**-***-**-***-**

6.2 Enter parameter (General)

For more information on the keys necessary to access this menu group, go to

the Navigation Pilot.

In this menu group you can set various parameters, such as the language, time

zone, date, time, etc.

WTX110 A4774-1.0 HBM: public 73

Page 76

Service mode

Menu Key Function/Secondary selection

Language: German Select the language

German Deutsch

English Englisch

French Französisch

Polish Polnisch

Russian Russisch

…

Notice: Applies to General, Application and

Softkeys

Notice: The language can also be changed in the

Application / General Setup menu.

Country code Enter the country code of the installation location.

Required to comply with national approval

requirements. 2-character code according to

ISO-3166-2, e.g.:

DE Germany

GB Great Britain

CA Canada

NL Netherlands

Notice: Parameter protected by jumper W1.

Notice: Automatic changes are made in the

firmware depending on the country code.

Notice: If country code US or CA is selected,

parameter NTEP in the Service mode/Calibrate

Scale1/Select Group 1-9/5 Adaptation menu is

set to Y and hidden!

Keyboard: US Layout of the USB keyboard:

US = US American

GB = British

Notice: Not with Language: German

74 A4774-1.0 HBM: public WTX110

Page 77

Function/Secondary selectionKeyMenu

Time zone: CET Set the time zone:

CET Central European Time

Other time zones:

Canada, EET, EST, Etc, Europe, GB, GMT,

HST, MET, MST, Mideast, NZ, Pacific,

Singapore, UCT, US, UTC, WET, Africa,

America, Asia, Atlantic, Australia,

Brazil

Notice: For some entries the specific location

must be entered, e.g. Pacific-Asia. With Etc a

time difference from GMT can be selected.

Automatic summer/winter time switching is im

plemented according to the set zone.

Notice: After the Time Zone is changed the

current Time must be set in the

SupervisorMode/General group!

Date: DD:MM:YY Select the date format:

DD.MM.YY MM.DD.YY YY.MM.DD

DD-MM-YY MM-DD-YY YY-MM-DD

DD/MM/YY MM/DD/YY YY/MM/DD

DD.MM.YYYY MM.DD.YYYY YYYY.MM.DD

DD-MM-YYYY MM-DD-YYYY YYYY-MM-DD

DD/MM/YYYY MM/DD/YYYY YYYY/MM/DD

D = Day, M = Month, Y = Year

Notice: Day, month and years are set in

Supervisor mode/General.

Time: HH:MM Select the time format:

HH:MM HH:MM:SS

H = Hour, M = Minute, S = Second

Notice: Hour and minute are set in Supervisor

mode/General.

Service mode

WTX110 A4774-1.0 HBM: public 75

Page 78

Service mode

Function/Secondary selectionKeyMenu

Decimal char.: Dot Select the decimal separator:

Dot dot (e.g. 1.00)

Comma comma (e.g. 1,00)

Approval signs: N Print in brackets

Y The weights are printed in brackets, in

accordance with the former PTB guideline.

Example: Gross/Tare/Net

<25.45kg> / <10.00kg> / <15.45kg>

or <25.45kg> / 10.00kgPT / 15.45kgC