HBM we2111 Quick Start Manual

Quick Start Guide

English Deutsch Français

Digital Weighing Indicator

A3983-1.0 en/de/fr

WE2111

WE2111

English

1 Safety instructions 3........................................

2 Markings used 7............................................

2.1 Symbols on the device 7......................................

2.2 The markings used in this document 7..........................

3 Introduction 9..............................................

3.1 Scope of delivery 9..........................................

3.2 Application 9................................................

3.3 Operating manual 10..........................................

4 Calibration labels and sealing 11.............................

5 Mounting optional modules 12...............................

5.1 WE2111-ZCC contact assignment 15............................

5.2 WE2111-ZS contact assignment 15.............................

6 Connecting load cells 16.....................................

7 Connecting the power supply 19..............................

7.1 Connection of DC voltage 19...................................

7.2 Connection for AC voltage 20..................................

8 Connecting the interfaces 22.................................

8.1 Serial interfaces 22...........................................

8.2 Ethernet interface 24..........................................

8.3 USB interface 25.............................................

9 Mechanical installation 26....................................

10 Start-up (quick start guide) 28................................

10.1 Switching on 28..............................................

10.2 Calling the setting menu 29....................................

2 A3983-1.0 en/de/fr

WE2111

10.3 Implementing general settings (decimal places, nominal (rated)

range, unit) 29................................................

10.4 Calibration 31................................................

11 Selling on, waste disposal and environmental protection 33....

A3983-1.0 en/de/fr 3

1 Safety instructions

Proper use

The device is to be used exclusively as a component for

a scale and directly related control tasks within the

application limits detailed in the specifications. Use for

any purpose other than the above is deemed to be

non-designated use.

Everyone involved with siting, starting up, or operating

the device must have read and understood the operating

manual and in particular the technical safety instructions.

In the interests of safety, the device should only be

operated by qualified personnel and as described in the

Operating Manual. It is also essential to comply with the

legal and safety requirements for the application

concerned during use. The same applies to the use of

accessories.

The device is not intended for use as a safety

component. Please also refer to the section: "Additional

safety precautions". Proper and safe operation requires

proper transportation, correct storage, siting and

mounting, and careful operation.

WE2111

Operating conditions

S Protect the device from direct contact with water.

S Protect the device from moisture and weather such as

rain or snow. The device degree of protection is IP20

(DIN EN 60529), the front plate degree of protection

is IP66.

S Do not expose the device to direct sunlight.

S Protect the device against impact/shock loads and

strong vibrations.

4 A3983-1.0 en/de/fr

WE2111

S Comply with the maximum permissible ambient

temperatures and maximum humidity figures stated in

the specifications.

S The device must not be modified from the design or

safety engineering point of view except with our

express agreement. In particular, any repair or

soldering work on motherboards (replacement of

components) is prohibited. When exchanging

complete modules, use only original parts from HBM.

S The device is delivered from the factory with a fixed

hardware and software configuration. Changes can

only be made within the possibilities documented in

the manuals.

S The device is intended for use in industrial

environments and corresponds to Class A in

compliance with DIN EN55011.

S The device is maintenance-free.

S Please note the following points when cleaning the

housing:

- Disconnect the device from all current and voltage

supplies before cleaning it.

- Clean the housing with a soft, slightly damp (not

wet!) cloth. You should never use solvents, since

these could damage the labeling or the housing.

- When cleaning, ensure that no liquid gets into the

device or connections.

S In accordance with national and local environmental

protection and material recovery and recycling

regulations, old equipment that can no longer be used

must be disposed of separately and not with normal

household garbage, see Chapter 11, Page 34.

A3983-1.0 en/de/fr 5

WE2111

Qualified personnel

Qualified persons means persons entrusted with the

installation, fitting, commissioning and operation of the

product who possess the appropriate qualifications for

their function.

This includes people who meet at least one of the

following three requirements:

S Knowledge of the safety concepts of measurement

and automation technology is a requirement and as

project personnel, you must be familiar with these

concepts.

S As measurement or automation plant operating

personnel, you have been instructed how to handle

the machinery. You are familiar with the operation of

the equipment and technologies described in this

documentation.

S As commissioning engineers or service engineers,

you have successfully completed the training to

qualify you to repair the automation systems. They

are also authorized to activate, ground and label

circuits and equipment in accordance with safety

engineering standards.

Working safely

S The device must not be directly connected to the

power supply system. The supply voltage must be

between 12 and 24VDC. A supply with 110 to 240V

AC

is possible with the option 1-WE2111-AC.

S Error messages should only be acknowledged once

the cause of the error is removed and no further

danger exists.

S Automation equipment and devices must be designed

in such a way that adequate protection or locking

6 A3983-1.0 en/de/fr

WE2111

against unintentional actuation is provided (e.g.

access checks, password protection, etc.).

S Additional safety precautions must be taken in terms

of both hardware and software for devices working in

networks, so that a line break or other interruptions to

signal transmission do not cause undefined states or

loss of data in the automation device.

S After making settings and carrying out activities that

are password-protected, ensure that any controls that

may be connected remain in a safe condition until the

switching performance of the device has been tested.

Additional safety precautions

Additional safety precautions that meet the requirements

of the applicable national and local accident prevention

regulations must be taken in plants where malfunctions

could cause major damage, loss of data or even personal

injury.

The scope of supply and performance of the device

covers only a small area of measurement technology.

Before starting up the device in a system, a project

planning and risk analysis must first be implemented,

taking into account all the safety aspects of

measurement and automation technology so that residual

dangers are minimized. This particularly concerns

personal and machine protection. In the event of a fault,

appropriate precautions must establish safe operating

conditions.

General dangers of failing to follow the safety

instructions

The device is state of the art and as such is failsafe. The

device may give rise to residual dangers if it is

inappropriately installed and operated.

A3983-1.0 en/de/fr 7

2 Markings used

2.1 Symbols on the device

FCC certification

This mark enables the manufacturer to guarantee that

the product complies with the requirements of the FCC

(Federal Communications Commission, USA).

CE certification

The CE mark enables the manufacturer to guarantee that

the product complies with the requirements of the

relevant EC directives (the Declaration of Conformity can

be found on the HBM website (www.hbm.com) under

HBMdoc).

Statutory waste disposal mark

In accordance with national and local environmental

protection and material recovery and recycling

regulations, old devices that can no longer be used must

be disposed of separately and not with normal household

garbage. Also see Section 11 on Page 34.

WE2111

2.2 The markings used in this document

Important instructions for your safety are specifically

identified. It is essential to follow these instructions in

order to prevent accidents and damage to property.

8 A3983-1.0 en/de/fr

WE2111

Symbol Significance

Note

Important

This marking draws your attention to a situation in

which failure to comply with safety requirements

could lead to damage to property.

This marking draws your attention to important

information about the product or about handling the

product.

This marking indicates application tips or other

information that is useful to you.

Tip

Emphasis

See …

Device -> New Bold text indicates menu items, as well as dialog and

Sampling rate Bold text in italics indicates inputs and input fields in

Italics are used to emphasize and highlight text and

identify references to sections, diagrams, or external

documents and files.

window titles in the user interfaces. Arrows between

menu items indicate the sequence in which the

menus and sub-menus are called up

the user interfaces.

A3983-1.0 en/de/fr 9

3 Introduction

3.1 Scope of delivery

S Safety instructions

S WE2111 (basic device)

S USB storage device with Quick Start Guide and

The Operating Manual and the quick start guide are

available in PDF format on the HBM website

(www.hbm.com) under HBMdoc in the section Digital

weighing electronics.

3.2 Application

The WE2111 digital weighing indicator, in combination

with SG1 load cells, enables high-precision weight

measurements. In the legal for trade sector, you can set

up scales with up to 10,000 division resolution and

multi-range/multi-interval scales with up to two times

3,000 division resolution are also possible. It is possible

to connect up to 16 load cells in larger systems, use

linearization over up to 5 intermediate points and use

various filters.

WE2111

Operating Manual as PDF

The WE2111 digital transducer electronics standard

configuration includes Ethernet, USB and RS-422/485

interfaces.

The PC software WE2111 Viewer is available for simple

parameter setting. You can download the (free) software

via the HBM website in the Digital weighing electronics

area: www.hbm.com/HBM Software.

1)

Strain gages

10 A3983-1.0 en/de/fr

WE2111

Optional components

There are several optional modules and components

available for diverse application cases. However, only

certain combinations can be connected, depending on

the module.

S Power pack module 1-WE2111-AC for connection to a

power supply with 110 to 240VAC, 50 to 60Hz.

S Plug-in module 1-WE2111-ZS with 8 freely

configurable digital inputs and/or outputs.

S Plug-in module 1-WE2111-ZCC with 2 freely

configurable digital inputs and/or outputs, analog

current output (4 … 20mA) and analog voltage output

(0 … 10V).

S Plug-in module 1-WE2111-R2 with galvanically

isolated RS-232 interface.

S Plug-in module 1-WE2111-R4 with galvanically

isolated RS-485 interface.

S Table stand 1-WE2111-ZT or housing made of

stainless steel 1-WE2111-ZH.

3.3 Operating manual

This quick start guide covers the load cell connection,

power supply and the optional modules on the WE2111,

as well as an example for setting up a scale.

Further information is provided in the WE2111 Operating

Manual.

A3983-1.0 en/de/fr 11

4 Calibration labels and sealing

The WE2111 calibration is implemented digitally. The

results are saved power failsafe.

Settings that change the calibration are only possible in

the setup mode "Full" (password protection

recommended). This also changes the status of the

calibration counter and can therefore be subsequently

recognized. In addition, it is possible to restrict the

access to the Full setup mode so that access is only

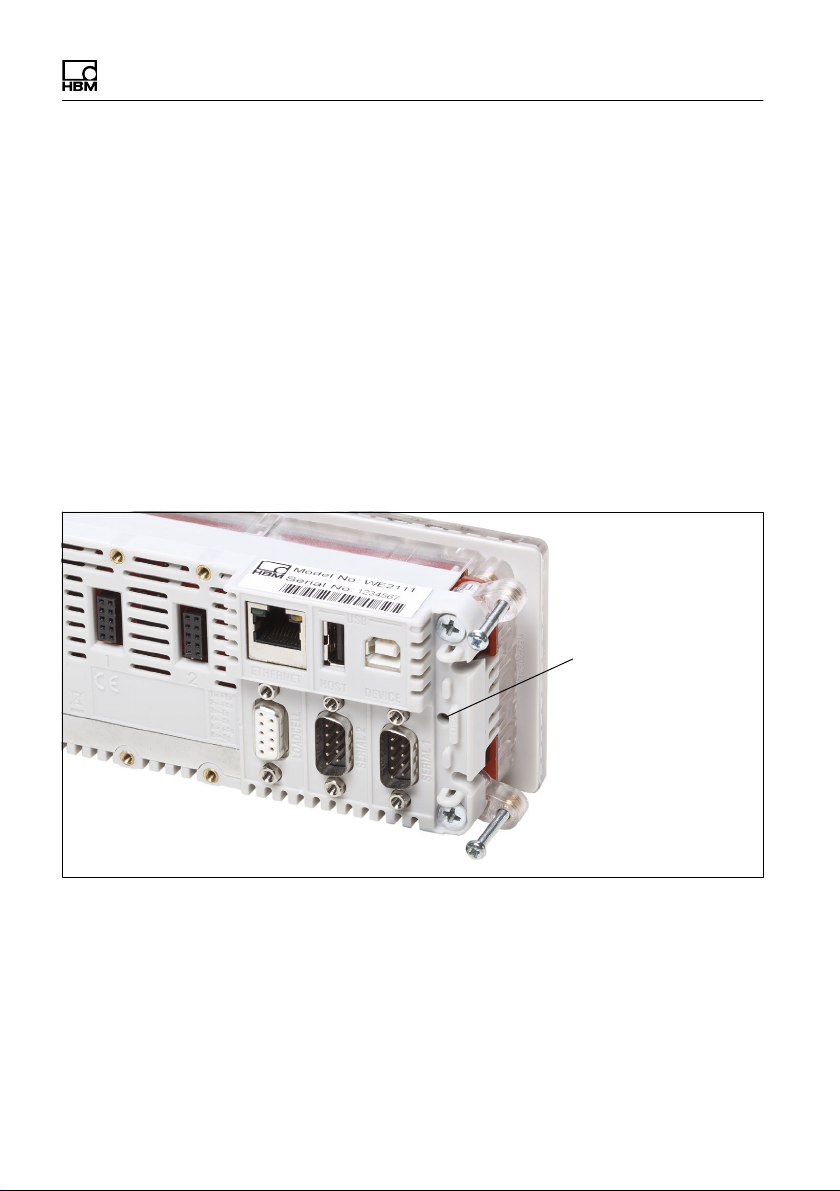

possible after the button on the rear is pressed (Fig. 4.1).

The button is covered by a panel and can be protected

by a suitable label, lead seal or seal.

WE2111

Hidden button

(cover removed)

Fig. 4.1 View from rear, fastener brackets swivelled out

12 A3983-1.0 en/de/fr

WE2111

5 Mounting optional modules

Note

A module must not be connected or removed if power is

present, otherwise the WE2111 may be destroyed.

Disconnect or switch off the voltage supply before

installation/removal.

This section describes the connection of the modules for

analog or digital inputs/outputs and the interface

modules.

The connection of the power pack module is described in

Section 7.2 on Page 21.

Important

You can only connect one of the modules WE2111-ZS or

WE2111-ZCC and only one of the modules WE2111-R2

or WE2111-R4.

A total of two modules (with power pack module) can be

connected.

A3983-1.0 en/de/fr 13

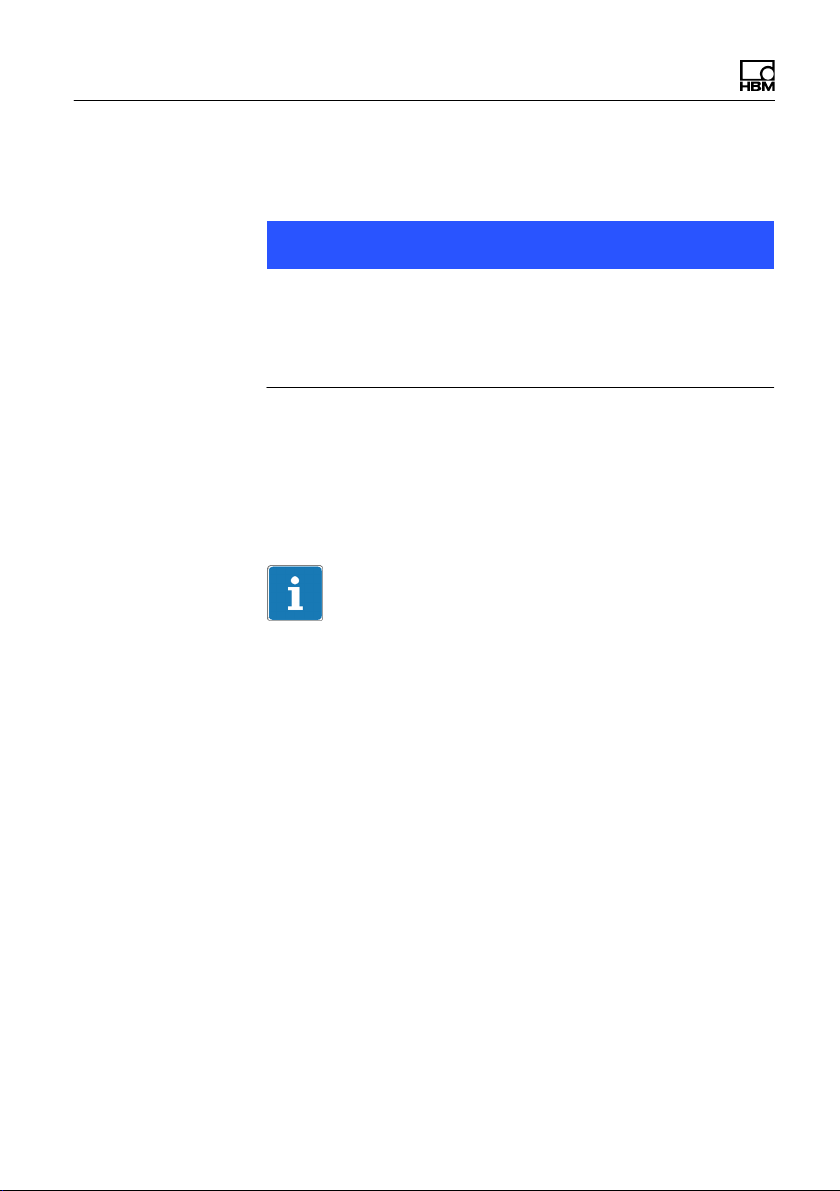

Connection sockets

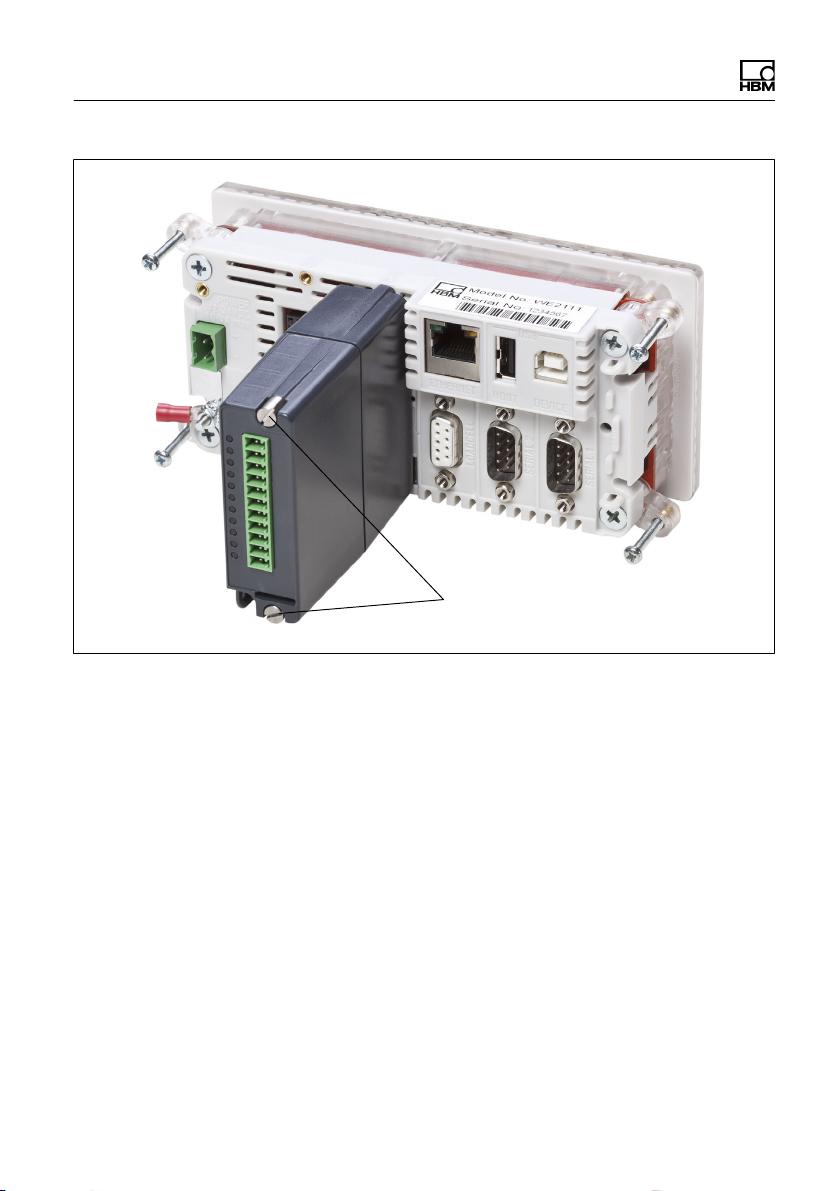

Fig. 5.1 View from rear, connection of optional modules

"

WE2111

Mounting

Mounting

Plug in the module so that the connector in the

module slides into the connector socket of the

WE2111 (Fig. 5.1). If the power pack module needs to

be mounted, you must use the right-hand connector

socket. Otherwise, either connector socket can be

used for the optional modules.

14 A3983-1.0 en/de/fr

WE2111

Fastening screws

Fig. 5.2 View from rear, connection of optional modules

"

Hand-tighten the two fastening screws for the module

(Fig. 5.2).

The module is then ready for operation.

Depending on the module type, settings may need to be

implemented, e.g. which input/output should be used and

how. Further information can be found in the Operating

Manual.

Use shielded cables for the analog outputs. The cables

for the digital inputs/outputs only need to be shielded if

the cable length exceeds 30 m.

A3983-1.0 en/de/fr 15

WE2111

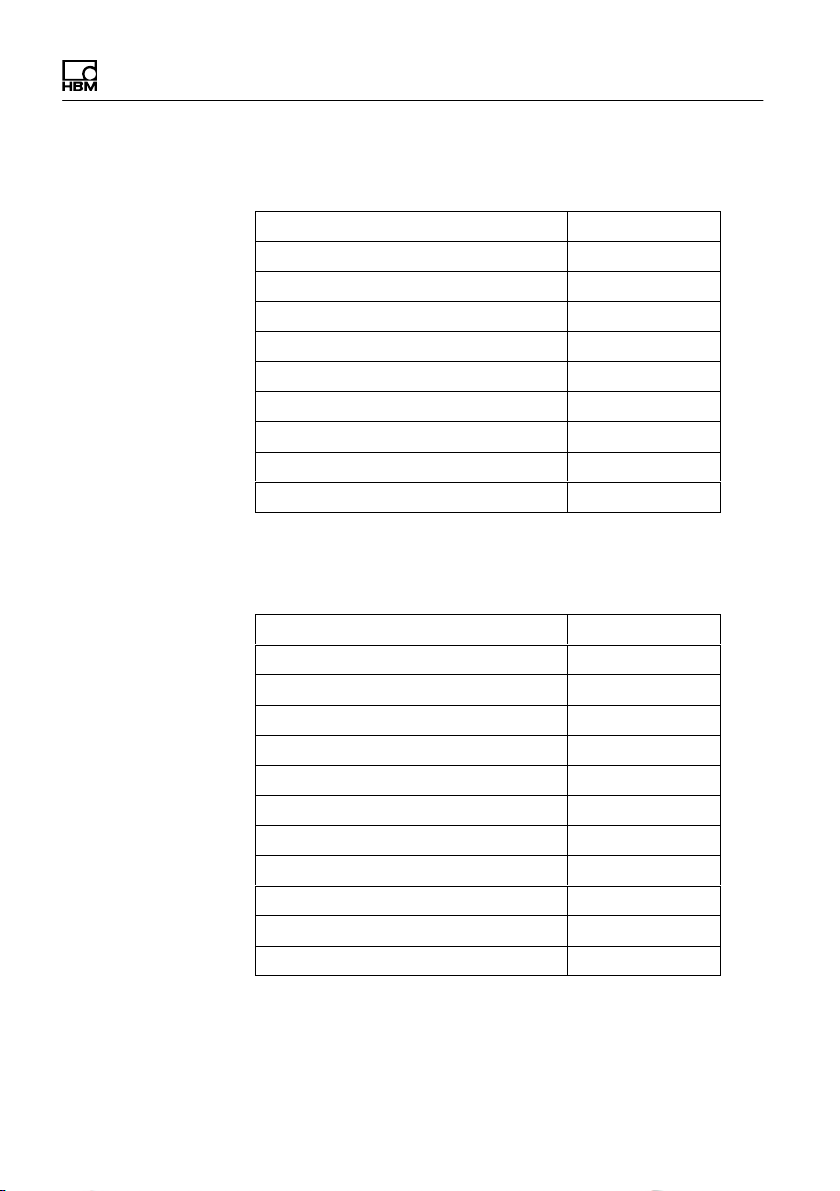

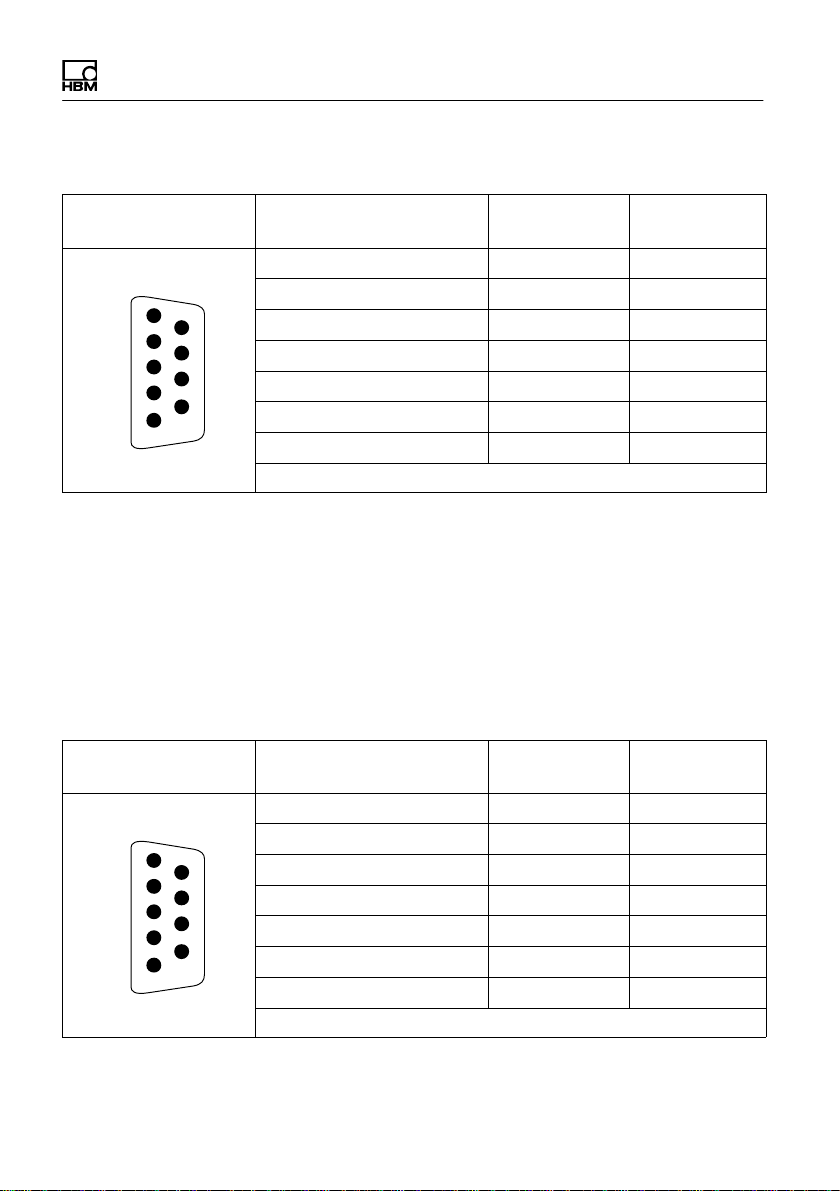

5.1 WE2111-ZCC contact assignment

Function Imprint

Current output (+), 600Ω max. IOUT+

Current output (-), 600Ω max. IOUT-

Voltage output (+), 2000Ω min. VOUT+

Voltage output (-), 2000Ω min. VOUTInput/output 1 I/O1

Input/output 2 I/O2

Common supply +U

Common supply -Ub (ground) COMCable shield SHIELD

b

COM+

5.2 WE2111-ZS contact assignment

Function Imprint

Common supply +U

Common supply -Ub (ground) COMInput/output 1 I/O1

Input/output 2 I/O2

Input/output 3 I/O3

Input/output 4 I/O4

Input/output 5 I/O5

Input/output 6 I/O6

Input/output 7 I/O7

Input/output 8 I/O8

Cable shield SHIELD

b

COM+

16 A3983-1.0 en/de/fr

WE2111

6 Connecting load cells

This section describes how to connect one or more load

cells.

You can connect a maximum of 16 SG load cells in a full

bridge circuit with a bridge resistance of 350Ω each.

Transducer excitation is implemented in the basic device

WE2111 with 5V

We recommend connecting the load cells via a suitable

junction if several load cells are connected, e.g. the HBM

model VKK2-8.

Important

Not all load cells can be connected in parallel. Refer to

the operating manual of the load cells to see if this is

possible.

For EMC reasons, a double shielded cable is

advantageous for connecting the load cell(s), e.g. HBM

model 4-3301.0071 with 3 ∗ 2 ∗ 0.14 m2.

(bridge excitation voltage).

DC

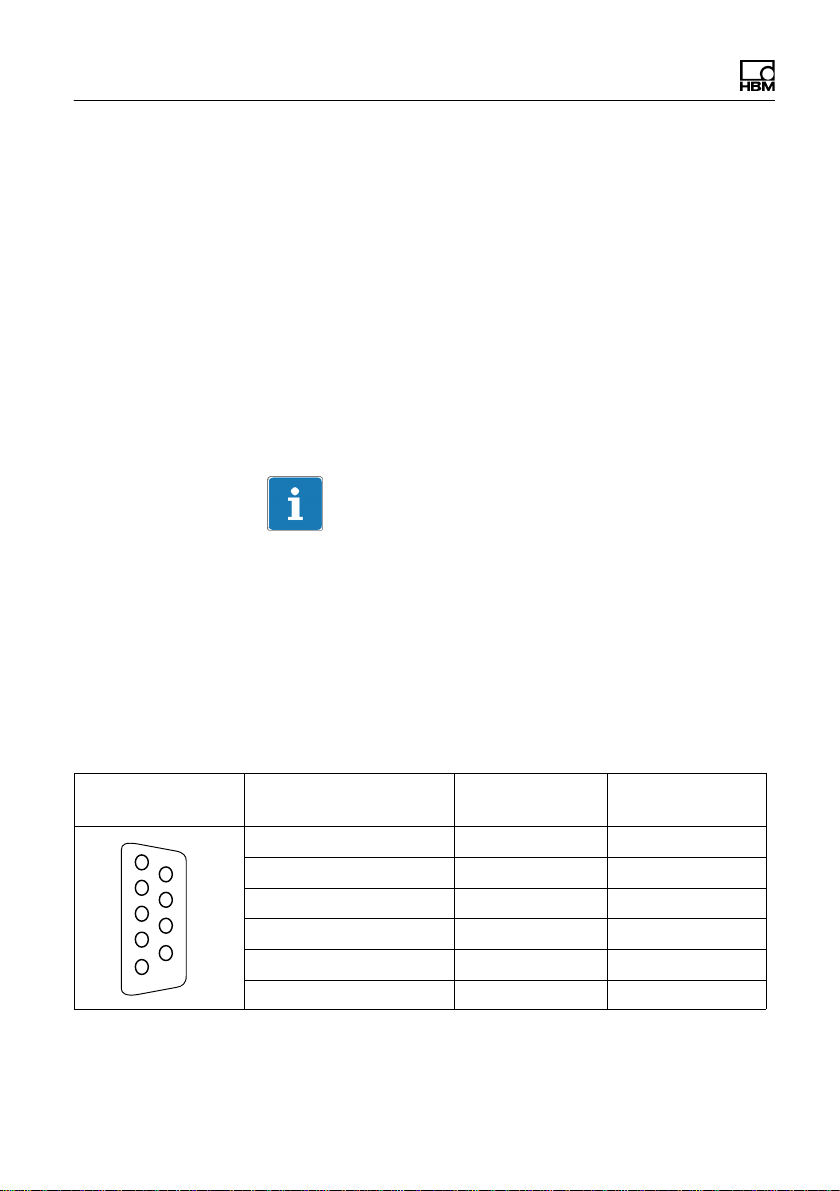

Contact assignment

Connector socket Function Contact No.

(Pin/Imprint)

Excitation voltage (+) 1 (+ Ex) BU (blue)

1

6

9

5

A3983-1.0 en/de/fr 17

Excitation voltage (-) 3 (- Ex) BK (black)

Sense lead (+) 2 (+ Sn) GN (green)

Sense lead (-) 4 (- Sn) GY (gray)

Measurement signal (+) 9 (+ Sg) WH (white)

Measurement signal (-) 8 (- Sg) RD (red)

HBM color code

Connector socket for load cell(s)

Fig. 6.1 View from rear, connection of load cell(s)

"

Connect a 9-pin D-Sub connector as shown in the

table with the connections of the load cell(s).

WE2111

Use shielded cables for the connecting cables and

connect the shield extensively to the connector

housing.

Important

If the load cell(s) are in four-wire configuration, the sense

leads must be connected to the excitation voltage with

jumpers: 2 (+) to 1 (+) and 4 (-) to 3 (-).

The sense lead inputs must not remain open otherwise

only error messages will be displayed (E00040, E00080

or E000C0).

18 A3983-1.0 en/de/fr

WE2111

Insert the six-wire connection up to the junction box if

you are using several transducers.

"

Plug the connector in the connector socket for the

load cell(s) (Fig. 6.1).

"

Hand-tighten the fastening screws of the connector.

The load cell(s) are now connected.

A3983-1.0 en/de/fr 19

7 Connecting the power supply

The WE2111 must be supplied with a controlled DC

voltage between 12 and 24V. The power pack module

WE2111-AC, which can supply 110 to 240V, is also

available as an option.

7.1 Connection of DC voltage

"

Connect the supply voltage to the connection marked

in Fig. 7.1.

Connection for 12

to 24VDC supply

WE2111

+

-

Grounding plug

Fig. 7.1 Connection of the power supply and grounding plug

The upper connection is connected with Plus, the

lower with Minus. The pin assignment is also

embossed on the housing.

20 A3983-1.0 en/de/fr

WE2111

Grounding plug

"

Connect the grounding plug (Fig. 7.1) with a

grounding point in the vicinity.

The resistance between grounding point and WE2111

must not exceed 2ohm.

The WE2111 is now ready for switch on.

7.2 Connection for AC voltage

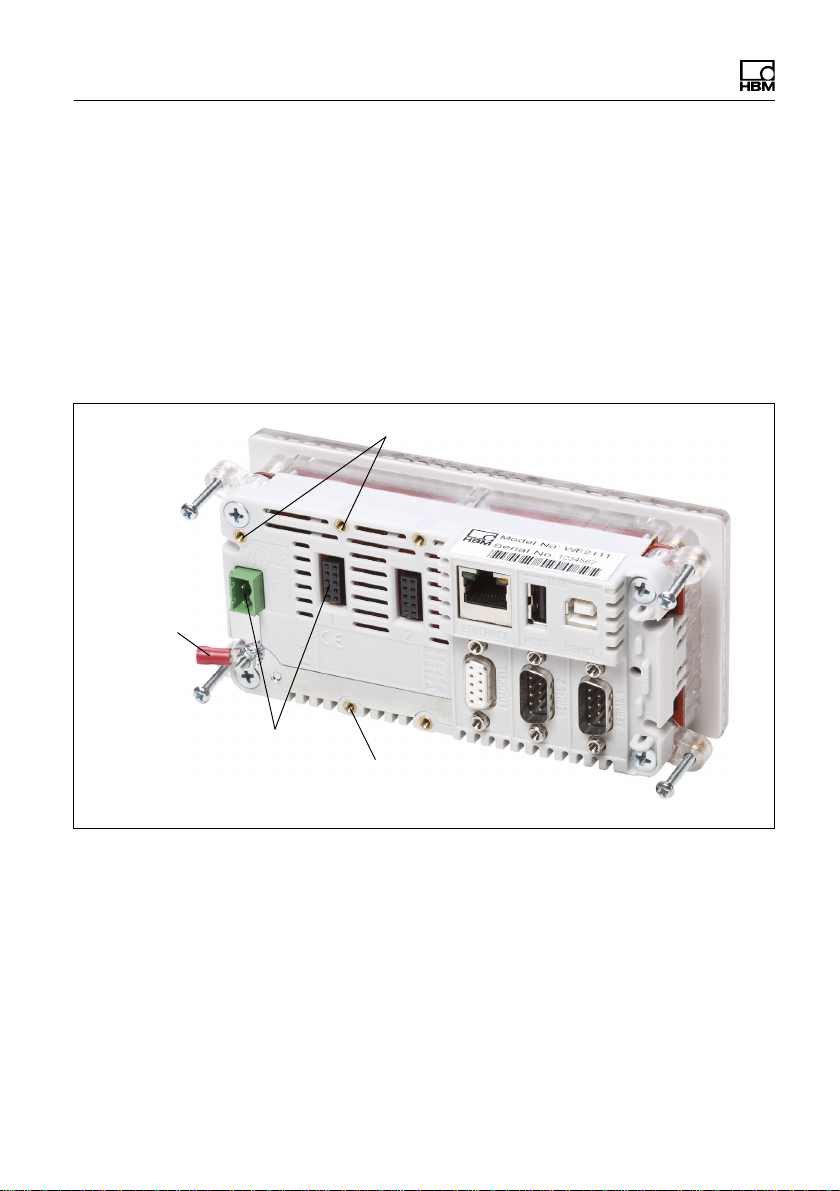

Mounting

Connector sockets

Mounting

Fig. 7.2 View from rear, connection of power pack module

"

Connect the grounding plug (Fig. 7.2) with a

grounding point in the vicinity.

The resistance between grounding point and WE2111

must not exceed 2ohm.

A3983-1.0 en/de/fr 21

Fastening screw (1)

Fastening screw (1)

(recessed)

"

Plug in the power pack module so that the connector

in the module slides into the connector socket of the

WE2111 (Fig. 7.2).

The socket for the mains connector must be at the

bottom of the module after mounting and the output

for the 12V auxiliary voltage at the top (Fig. 7.3).

WE2111

Fastening screw (1)

(recessed)

Fig. 7.3 View from rear, mounted power pack module

"

Hand-tighten the three fastening screws (1) for the

module (Fig. 7.3).

The WE2111 is now ready for switch on.

22 A3983-1.0 en/de/fr

WE2111

8 Connecting the interfaces

This section describes the pin assignments of the

interface sockets.

8.1 Serial interfaces

Note

There is a danger with long cable lengths (over 30 m)

that the bus nodes have different ground potentials. If

necessary, establish potential equalization between the

bus nodes with a separate cable.

Use a flexible cable with a cross-section of at least

10mm2 for the potential equalization.

All connections for the serial interfaces are available at

Serial 1. Serial 2 is set up for a connection of a serial

printer, the connections of both sockets are connected

internally.

A3983-1.0 en/de/fr 23

Contact assignment Serial 1

WE2111

Connector socket Function Contact No.

(Pin)

RS-232 Receive 2 RX1

RS-232 Transmit 3 TX1

5

9

6

1

RS-232 Ground 5 GND1

RS-422/485 Receive A (-) 6 RA

RS-422/485 Receive B (+) 7 RB

RS-422/485 Transmit A (-) 8 TA

RS-422/485 Transmit B (+) 9 TB

Cable shield: Attach to connector housing

If the RS-422/485 interface is not used, the inputs must

not be used. These contacts are connected through to

the second serial interface Serial 2.

The termination resistors required for the RS422/485

interface are integrated in the WE2111 and are activated

via software.

Contact assignment Serial 2

Connector socket Function Contact No.

(Pin)

RS-232 Transmit 3 TX2

RS-232 DTR Handshake 4 DTR

5

9

6

1

RS-232 Ground 5 GND2

RS-422/485 Receive A (-) 6 RA

RS-422/485 Receive B (+) 7 RB

RS-422/485 Transmit A (-) 8 TA

RS-422/485 Transmit B (+) 9 TB

Cable shield: Attach to connector housing

Abbreviation

Abbreviation

24 A3983-1.0 en/de/fr

WE2111

If the RS-422/485 interface is not used, the inputs must

not be used. These contacts are connected through to

the first serial interface Serial 1.

The termination resistors required for the RS422/485

interface are integrated in the WE2111 and are activated

via software.

8.2 Ethernet interface

The Ethernet interface enables the connection of an

Ethernet network with 10Base‐T/100Base‐TX via an

RJ45 connector.

You can assign a permanent IP address or use DHCP for

communication. The interface uses two TCP sockets for

the following purposes:

1. SER5 (Port 2222)

This interface is used by the WE2111 Viewer software

and enables bidirectional transmission of data and

commands.

2. SER6 (Port 2223)

This interface only outputs data and is used for

automatic transmission of outputs.

The ports used can be set.

A3983-1.0 en/de/fr 25

8.3 USB interface

The WE2111 has two USB interfaces:

1. USB socket, type A (slave)

This interface is for the connection of peripheral

devices such as a keyboard, USB memory stick or

USB printer.

2. USB socket, type B (host)

This interface is for the connection of a PC. You must

install a driver for operation on the PC (WE21-511) in

order to enable communication with the WE2111 as if

it were a serial interface (SER0 in the WE2111).

WE2111

26 A3983-1.0 en/de/fr

WE2111

9 Mechanical installation

Conditions on site

S Protect the device from direct contact with water.

S Protect the device from moisture and weather such as

rain or snow. The device degree of protection is IP20

(DIN EN 60529), the front plate degree of protection

is IP66.

S Do not expose the device to direct sunlight.

S Protect the device against impact/shock loads and

strong vibrations.

S Comply with the maximum permissible ambient

temperatures and maximum humidity figures stated in

the specifications.

Installation orientation

The device can be mounted in any position.

Installation

The WE2111 can either be used as a desktop device,

e.g. with the option 1-WE2111-ZT (table stand), or as a

built-in device. Mounting is identical in both cases, the

housing fits in any standard device recess as per DIN

43700 (138mm x 67mm).

"

Push the housing through the recess.

"

Swivel the four fastener brackets (1) on the corners

out by 90° to 180°, depending on the desired or

necessary fastening position (Fig. 9.1).

"

Hand-tighten the screws (2) (Fig. 9.1).

A3983-1.0 en/de/fr 27

Screw (2)

Screw (2)

WE2111

Fastener brackets (1)

Screw (2)

Fastener brackets (1)

Screw (2)

Fig. 9.1 View from rear, fastener brackets swivelled out

28 A3983-1.0 en/de/fr

WE2111

10 Start-up (quick start guide)

This section describes how to switch on the device and

what needs to be set in order to carry out weighing. The

example is based on a single-range balance for not legal

for trade operation without a password. A load cell with

10kg maximum capacity (1,000 divisions) is connected,

a 10kg weight is provided. Further information about the

various balance types and set up can be found in the

Operating Manual.

This section assumes that all necessary connections

have been made (load cell(s), power supply, etc.).

The buttons on the front panel are indicated here as

graphics with the button label, e.g.

G/N (MENU).

10.1 Switching on

for the button

"

Switch on the WE2111 power supply.

The WE2111 runs through various self-tests after

being switched on. The display initially shows bOOt,

then all segments of the display and all light displays

are activated, e.g. including the limit values and units.

The display then tests all digits from 0 to 9, i.e., the

display runs through all digits from 000000 to 999999.

Finally, the firmware version (e.g. P60c) and the

calibration counter (e.g. C00008) are displayed before

the actual measured value appears.

A3983-1.0 en/de/fr 29

10.2 Calling the setting menu

"

Press the button for several seconds.

SAFE is displayed.

"

Press the button again (briefly).

FULL is displayed.

"

Press the button.

The following are displayed in sequence: SEtUP,

firmware version (e.g. P60c), calibration counter

(e.g. C00008) and buiLd.

10.3 Implementing general settings

(decimal places, nominal (rated)

range, unit)

The display must show buiLd before the following

settings can be made.

"

Press the button twice.

WE2111

dP is displayed.

"

Press the button.

000000 is displayed.

"

Press the button until 0000.00 is displayed.

The number of decimal places is then set to two

places.

"

Press the button.

dP is displayed (decimal point).

30 A3983-1.0 en/de/fr

Loading...

Loading...