Page 1

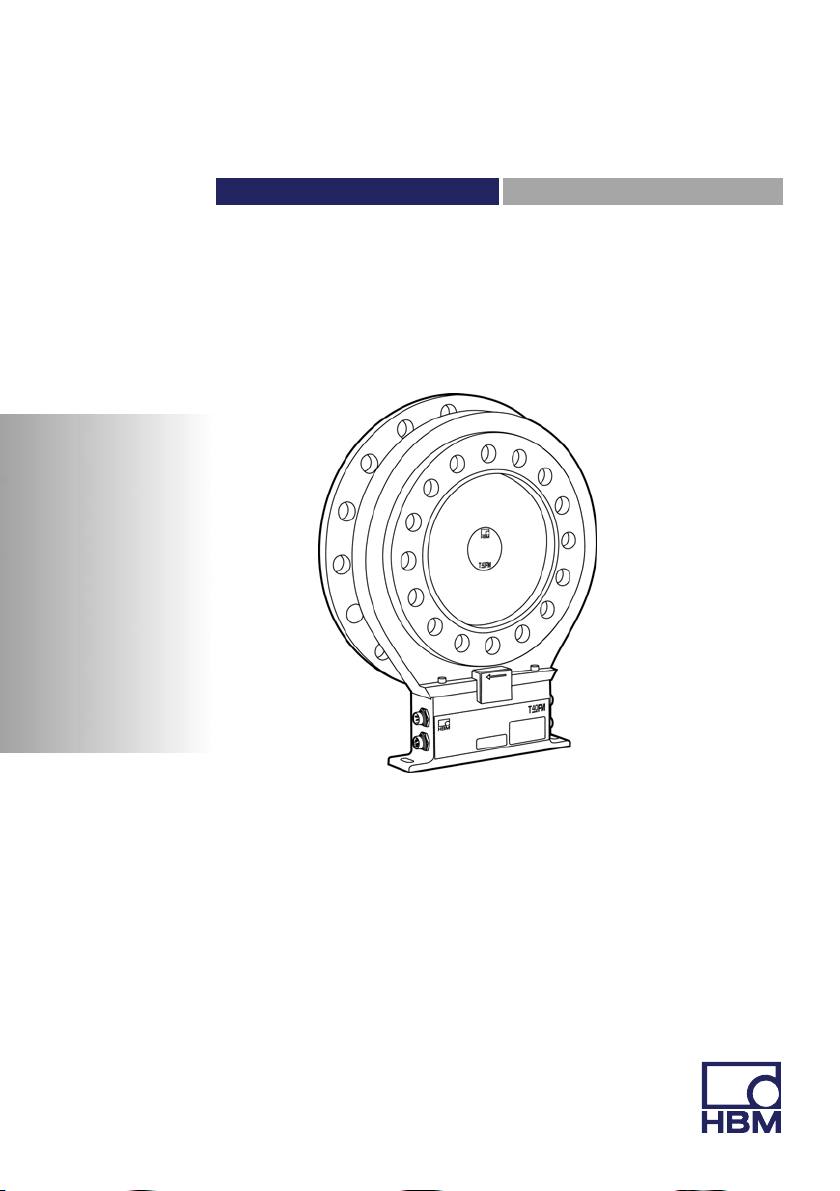

Mounting Instructions | Montageanleitung

English Deutsch

T40FM

Page 2

Hottinger Baldwin Messtechnik GmbH

Im Tiefen See 45

D-64239 Darmstadt

Tel. +49 6151 803-0

Fax +49 6151 803-9100

info@hbm.com

www.hbm.com

Mat.: 7-2001.3276

DVS: A3276-11.0 HBM: public

09.2017

E Hottinger Baldwin Messtechnik GmbH.

Subject to modifications.

All product descriptions are for general information only.

They are not to be understood as a guarantee of quality or

durability.

Änderungen vorbehalten.

Alle Angaben beschreiben unsere Produkte in allgemeiner

Form. Sie stellen keine Beschaffenheits- oder Haltbarkeits

garantie dar.

Page 3

Mounting Instructions | Montageanleitung

English Deutsch

T40FM

Page 4

English

1 Safety information 4........................................

2 Markings used 10............................................

2.1 The marking used in this document 10...........................

2.2 Symbols on the transducer 11..................................

3 Applications 12..............................................

4 Structure and Mode of Operation 13..........................

5 Mechanical installation 15....................................

5.1 Important precautions during installation 15......................

5.2 Conditions on site 16..........................................

5.3 Installation orientation 16......................................

5.4 Installation options 17.........................................

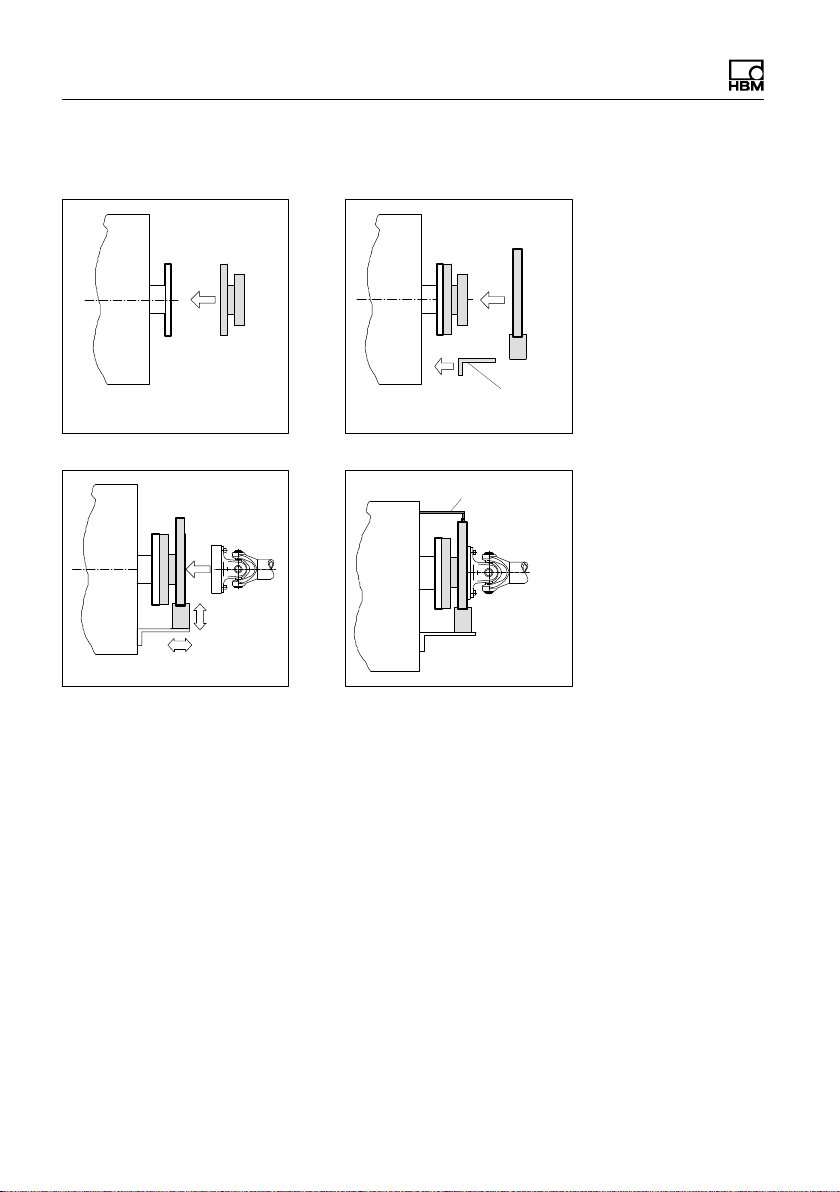

5.4.1 Installation without dismantling the antenna ring 18................

5.4.2 Installation with subsequent antenna ring mounting 19.............

5.5 Preparing for the rotor mounting 20.............................

5.6 Mounting the rotor 23..........................................

5.7 Installing the stator 26.........................................

5.8 Mounting the rotational speed flange (rotational speed measuring

system only) 30..............................................

6 Electrical Connection 33.....................................

6.1 General information 33........................................

6.2 EMC protection 33............................................

6.3 Pin Assignment 34............................................

6.4 Supply Voltage 41............................................

7 Shunt signal 43..............................................

8 Functionality testing 44......................................

8.1 Rotor status, LED A (upper LED) 44.............................

2 A3276-11.0 HBM: public T40FM

Page 5

8.2 Stator status, LED B (lower LED) 45............................

9 Loading capacity 46.........................................

10 Maintenance 47..............................................

11 Waste disposal and environmental protection 48..............

12 Dimensions 49..............................................

12.1 T40FM without speed measurement, Option 6, Code 0 49..........

12.1.1 T40FM 15kNm - 25kNm 49...................................

12.1.2 T40FM 30kNm - 50kNm 51...................................

12.1.3 T40FM 60kNm - 80kNm 53...................................

12.2 T40FM with speed measurement, Option 6, Code 1

(Code A optional) 55..........................................

12.2.1 T40FM 15kNm - 25kNm 55...................................

12.2.2 T40FM 30kNm - 50kNm 57...................................

12.2.3 T40FM 60kNm - 80kNm 59...................................

13 Order numbers, Accessories 61..............................

14 Specifications 63............................................

15 Supplementary Technical Information 73......................

T40FM A3276-11.0 HBM: public 3

Page 6

Safety information

1 Safety information

FCC Compliance & Advisory Statement about Option 7, Code S, H

Important

Any changes or modification not expressly approved in writing by by the party

responsible for compliance could void the user’s authority to operate the

device. Where specified additional components or accessories elsewhere

defined to be used with the installation of the product, they must be used in

order to ensure compliance with FCC regulations.

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference,

and (2) this device must accept any interference received, including interfer

ence that may cause undesired operation.

The FCC identifier or the unique identifier, as appropriate, must be displayed

on the device.

Model Measuring range FCC ID IC

T40S7

T40S8

T40S9

15 kNm, 20 kNm,

25 kNm

30 kNm, 40 kNm,

50 kNm

60 kNm, 70 kNm,

80 kNm

2ADAT−T40S7TOS9 12438A−T40S7TOS9

4 A3276-11.0 HBM: public T40FM

Page 7

Label example with FCC ID and IC number.

Label

Safety information

Fig. 1.1 Location of the label on the stator of the device

Model: T40S7

FCC ID: 2ADAT-T40S7TOS9

IC: 12438AT40S7TOS9

This device complies with part 15 of the FCC Rules. Operation is

subject to the following two conditions: (1) This device may not

cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause

undesired operation.

Fig. 1.2 Example of the label

T40FM A3276-11.0 HBM: public 5

Page 8

Safety information

Industry Canada for Option 7, Code S, H

This device complies with Industry Canada standard RSS210.

This device complies with Industry Canada license−exempt RSS stan

dard(s).Operation is subject to the following two conditions: (1) this device may

not cause interference, and (2) this device must accept any interference,

including interference that may cause undesired operation of the device.

Cet appareil est conforme aux norme RSS210 d’Industrie Canada.

Cet appareil est conforme aux normes d’exemption de licence RSS d’Industry

Canada. Son fonctionnement est soumis aux deux conditions suivantes : (1)cet

appareil ne doit pas causer d’interférence et (2) cet appareil doit accepter toute

interférence, notamment les interférences qui peuvent affecter son fonction

nement.

Appropriate use

The T40FM torque flange is used exclusively for torque, angle of rotation and

power measurement tasks within the load limits stipulated in the specifications.

Any other use is not appropriate.

Stator operation is only permitted when the rotor is installed.

The torque flange may only be installed by qualified personnel in compliance

with the specifications and with the safety requirements and regulations of

these mounting instructions. It is also essential to observe the applicable legal

and safety regulations for the application concerned. The same applies to the

use of accessories.

The torque flange is not intended for use as a safety component. Please also

refer to the section: "Additional safety precautions". Proper and safe operation

requires proper transportation, correct storage, siting and mounting, and careful

operation.

Load carrying capacity limits

The data in the technical data sheets must be complied with when using the

torque flange. The respective specified maximum loads in particular must never

6 A3276-11.0 HBM: public T40FM

Page 9

Safety information

be exceeded. For example, the values stated in the specifications must not be

exceeded, e.g. for

S Limit torque

S Longitudinal limit force, lateral limit force or limit bending moment

S Torque oscillation width

S Breaking torque

S Temperature limits

S Limits of the electrical load-carrying capacity.

Use as a machine element

The torque flange can be used as a machine element. When used in this man

ner, it must be noted that, to favor greater sensitivity, the transducer is not de

signed with the safety factors usual in mechanical engineering. Please refer

here to the section "Loading capacity limits" and to the specifications.

Accident prevention

According to the prevailing accident prevention regulations, once the trans

ducers have been mounted, a covering agent or cladding has to be fitted as

follows:

S The covering agent or cladding must not be free to rotate.

S The covering agent or cladding should prevent squeezing or shearing and

provide protection against parts that might come loose.

S Covering agents and cladding must be positioned at a suitable distance or

be so arranged that there is no access to any moving parts within.

S Covering agents and cladding must still be attached even if the moving

parts of the torque flange are installed outside people's movement and

working range.

The only permitted exceptions to the above requirements are if the torque

flange is already fully protected by the design of the machine or by existing

safety precautions.

T40FM A3276-11.0 HBM: public 7

Page 10

Safety information

Additional safety precautions

The torque flange cannot (as a passive transducer) implement any (safety-rel

evant) cutoffs. This requires additional components and constructive measures,

for which the installer and operator of the plant is responsible. The electronics

conditioning the measurement signal should be designed so that measurement

signal failure does not subsequently cause damage.

The scope of supply and performance of the transducer covers only a small

area of torque measurement technology. In addition, equipment planners, in

stallers and operators should plan, implement and respond to safety engineer

ing considerations in such a way as to minimize residual dangers. Pertinent

national and local regulations must be complied with.

General dangers of failing to follow the safety instructions

The torque flange corresponds to the state of the art and is reliable. Trans

ducers can give rise to residual dangers if they are incorrectly operated or inap

propriately mounted, installed and operated by untrained personnel. Every per

son involved with siting, starting-up, operating or repairing a torque flange must

have read and understood the mounting instructions and in particular the tech

nical safety instructions. The transducers can be damaged or destroyed by

non-designated use of the transducer or by non-compliance with the mounting

and operating instructions, these safety instructions or any other applicable

safety regulations (safety and accident prevention regulations), when using the

transducers. Transducers can break, particularly in the case of overloading.

The breakage of a transducer can also cause damage to property or injury to

persons in the vicinity of the transducer.

If the torque flange is not used according to the designated use, or if the safety

instructions or specifications in the mounting and operating instructions are ig

nored, it is also possible that the transducer may fail or malfunction, with the

result that persons or property may be adversely affected (due to the torques

acting on or being monitored by the torque flange).

8 A3276-11.0 HBM: public T40FM

Page 11

Safety information

Conversions and Modifications

The transducer must not be modified from the design or safety engineering

point of view except with our express agreement. Any modification shall ex

clude all liability on our part for any damage resulting therefrom.

Selling on

If the torque flange is sold on, these mounting instructions must be included

with the torque flange.

Qualified Personnel

Qualified personnel means persons entrusted with siting, mounting, starting up

and operating the product, who possess the appropriate qualifications for their

function.

This includes people who meet at least one of the three following requirements:

1. Knowledge of the safety concepts of automation technology is a require

ment and as project personnel, you must be familiar with these concepts.

2. As automation plant operating personnel, you have been instructed how to

handle the machinery. They are familiar with the operation of the equipment

and technologies described in this documentation.

3. As system startup engineers or service engineers, they have successfully

completed the training to qualify them to repair the automation systems. You

are also authorized to ground and label circuits and equipment and place

them in operation in accordance with safety engineering standards.

T40FM A3276-11.0 HBM: public 9

Page 12

Markings used

2 Markings used

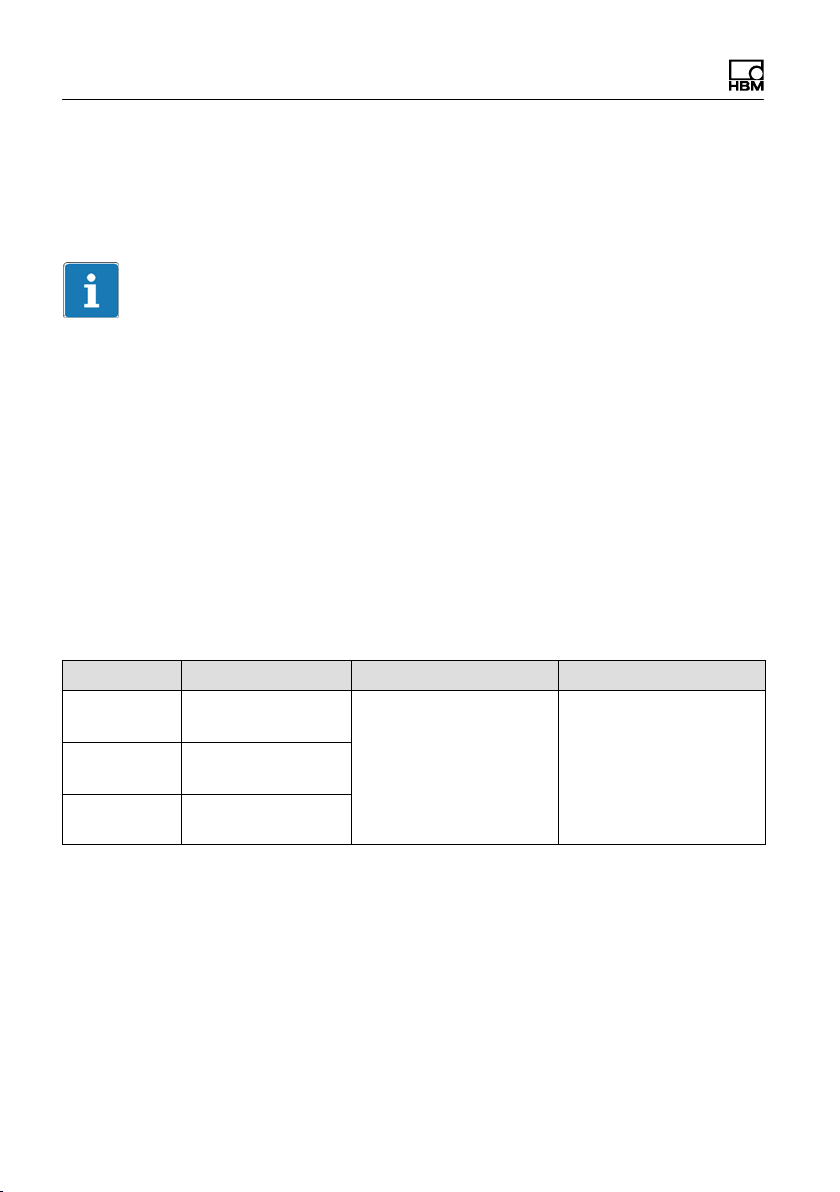

2.1 The marking used in this document

Important instructions for your safety are specifically identified. It is essential to

follow these instructions in order to prevent accidents and damage to property.

Symbol Significance

WARNING

CAUTION

Note

Important

Tip

Information

Emphasis

See …

This marking warns of a potentially dangerous situ

ation in which failure to comply with safety require

ments can result in death or serious physical injury.

This marking warns of a potentially dangerous situ

ation in which failure to comply with safety require

ments can result in slight or moderate physical injury.

This marking draws your attention to a situation in

which failure to comply with safety requirements

could lead to damage to property.

This marking draws your attention to important in

formation about the product or about handling the

product.

This marking indicates application tips or other in

formation that is useful to you.

This marking draws your attention to information

about the product or about handling the product.

Italics are used to emphasize and highlight text and

identify references to sections, diagrams, or external

documents and files.

10 A3276-11.0 HBM: public T40FM

Page 13

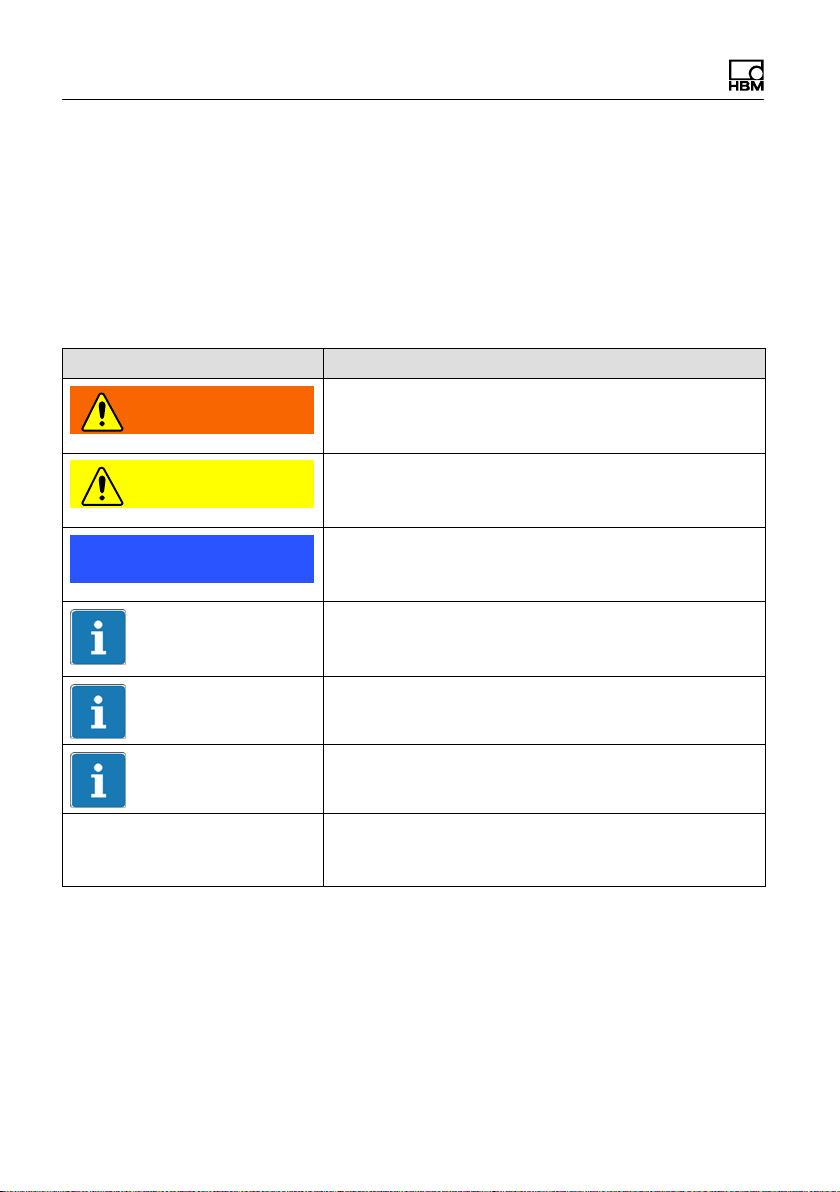

2.2 Symbols on the transducer

CE mark

The CE mark enables the manufacturer to guarantee that

the product complies with the requirements of the relev

ant EC directives (the Declaration of Conformity can be

found on the HBM website at www.hbm.com under HBM

doc).

Label example

Markings used

Model: T40S7

FCC ID: 2ADAT-T40S7TOS9

IC: 12438AT40S7TOS9

This device complies with part 15 of the

FCC Rules. Operation is subject to the

following two conditions: (1) This device

may not cause harmful interference, and

(2) this device must accept any interfer

ence received, including interference that

may cause undesired operation.

Label example with FCC ID and IC number. Location of

the label on the stator device.

Statutory waste disposal mark

The electrical and electronic devices that bear this sym

bol are subject to the European waste electrical and elec

tronic equipment directive 2002/96/EC. The symbol indic

ates that, in accordance with national and local

environmental protection and material recovery and re

cycling regulations, old devices that can no longer be

used must be disposed of separately and not with normal

household garbage, see also Chapter 11, Page 48.

T40FM A3276-11.0 HBM: public 11

Page 14

Applications

3 Applications

The T40FM torque flange measures static and dynamic torques on stationary

and rotating shafts. Test beds can be extremely compact because of the com

pact design of the transducer. This offers a very wide range of applications.

The T40FM torque flange is reliably protected against electromagnetic interfer

ence. It has been tested according to harmonized European standards and/or

complies with US and Canadian standards. The product carries the CE mark

and/or FCC label.

12 A3276-11.0 HBM: public T40FM

Page 15

Structure and Mode of Operation

4 Structure and Mode of Operation

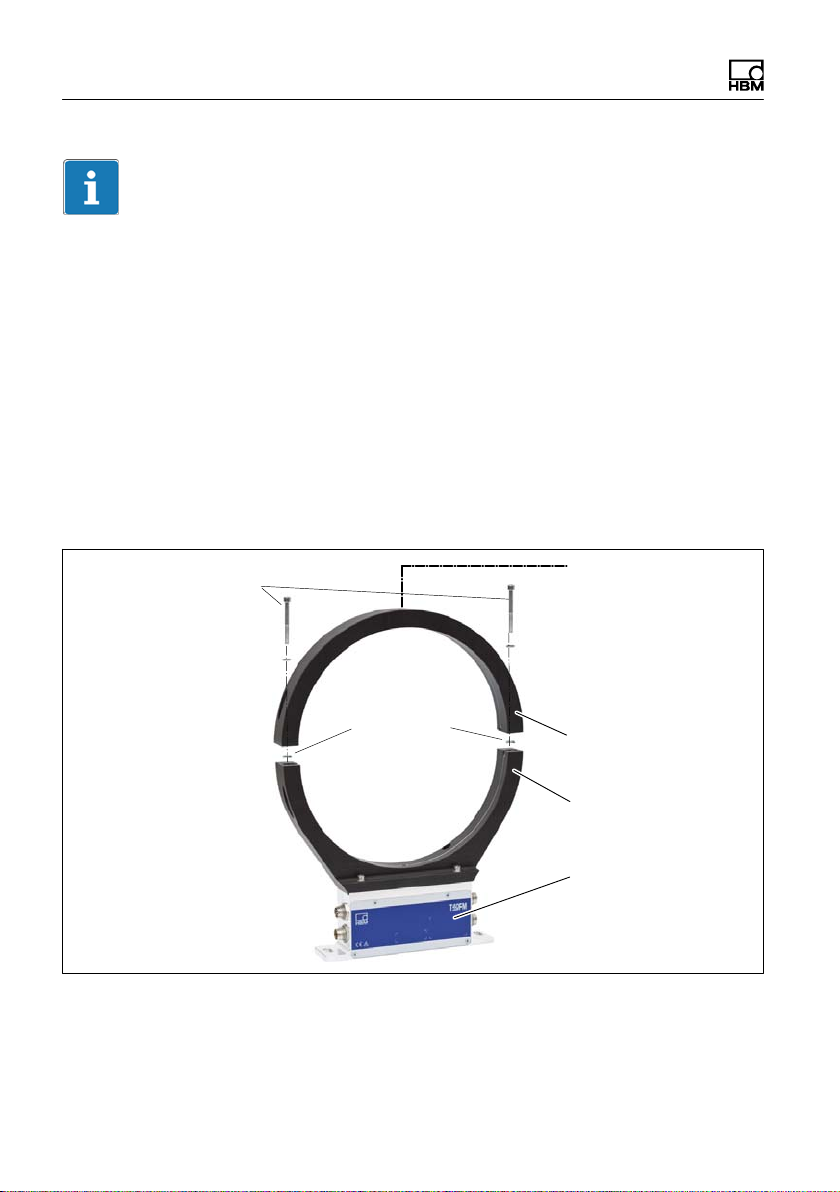

The torque flange consists of two separate parts: the rotor and the stator. The

rotor comprises the measuring body and the signal transmission elements.

Strain gauges (SGs) are installed on the measuring body. The rotor electronics

for transmitting the bridge excitation voltage and the measurement signal are

located centrally in the flange. The transmitter coils for contactless transmission

of excitation voltage and measurement signal are located on the measuring

body's outer circumference. The signals are sent and received by a separable

antenna ring. The antenna ring is mounted on a housing that contains the elec

tronics for voltage adaptation and the signal conditioning.

Connector plugs for the torque and rotational speed signals, the voltage supply

and digital output, are located on the stator. The antenna segments (ring)

should be mounted concentrically around the rotor (see Chapter 5).

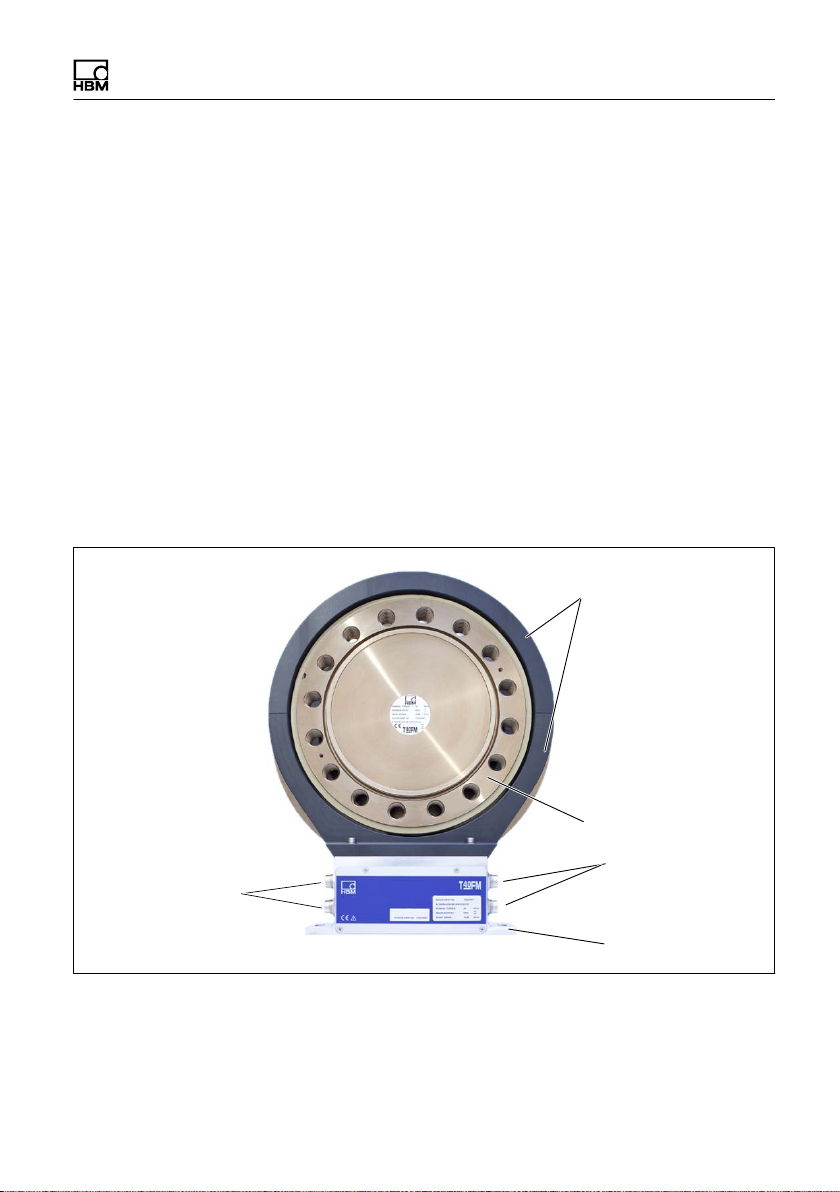

Antenna segments

Rotor

Connector plugs

Connector plugs

Identification plate

Fig. 4.1 Mechanical construction without a rotational speed measuring system,

Option 6, Code 0

Stator housing

T40FM A3276-11.0 HBM: public 13

Page 16

Structure and Mode of Operation

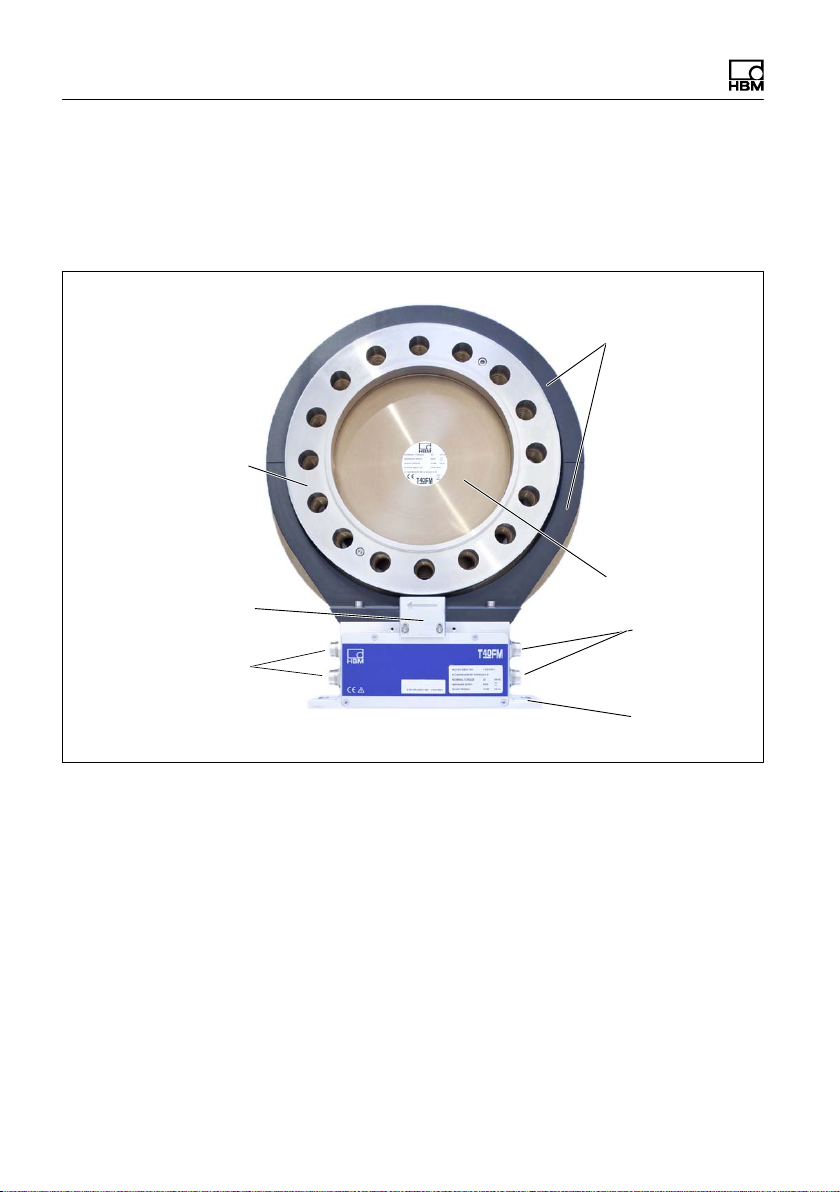

The rotational speed sensor is mounted on the stator in Option 6 with a rota

tional speed measuring system. The customer mounts the rotational speed disc

between the measuring body and customer flange. The rotational speed is

measured magnetically with an AMR sensor and magnetic tape.

Antenna segments

Rotational speed disc

Sensor head for

measuring rotational

speed

Connector plugs

Identification plate

Rotor

Connector

plugs

Stator

housing

Fig. 4.2 Mechanical construction with a speed measuring system, Option 6, Code 1

14 A3276-11.0 HBM: public T40FM

Page 17

Mechanical installation

5 Mechanical installation

5.1 Important precautions during installation

Notice

A torque flange is a precision measuring element and therefore needs careful

handling. Dropping or knocking the transducer may cause permanent damage.

Make sure that the transducer cannot be overloaded, including while it is being

mounted.

S Handle the transducer with care.

S Check the effect of bending moments, critical rotational speeds and natural

torsional vibrations, to prevent the transducer being overloaded by reson

ance sharpness.

S Make sure that the transducer cannot be overloaded.

WARNING

There is a danger of the transducer breaking if it is overloaded. This can cause

danger for the operating personnel of the system in which the transducer is in

stalled.

Implement appropriate safety measures to avoid overloads and to protect

against resulting dangers.

S Use a threadlocker (medium strength, e.g. LOCTITE) to glue the screws into

the counter thread to exclude prestressing loss due to screw slackening, in

the event of alternating loads.

S Comply with the mounting dimensions to enable correct operation.

T40FM A3276-11.0 HBM: public 15

Page 18

Mechanical installation

An appropriate shaft flange enables the T40FM torque flange to be mounted

directly. It is also possible to mount a joint shaft or relevant compensating ele

ment directly on the rotor (using an intermediate flange when required). Under

no circumstances should the permissible limits specified for bending moments,

lateral and longitudinal forces be exceeded. Due to the T40FM torque flange's

high torsional stiffness, dynamic shaft train changes are kept to a minimum.

Important

Even if the unit is installed correctly, the zero point adjustment made at the fact

ory can shift by up to approx. 0.5% of the characteristic value. If this value is

exceeded, we advise you to check the mounting conditions. If the residual zero

offset when the unit is removed is greater than 1% of the sensitivity, please

send the transducer back to the Darmstadt factory for testing.

5.2 Conditions on site

The T40FM torque flange must be protected against coarse dirt particles, dust,

oil, solvents and moisture.

There is wide ranging compensation for the effects of temperature on the out

put and zero signals of the transducer (see Chapter 14 "Specifications"). If

there are no static temperature ratios, for example, because of the temperature

differences between the measuring body and the flange, the values given in the

specifications can be exceeded. In this case, ensure static temperature ratios

by cooling or heating, depending on the application. As an alternative, check if

thermal decoupling is possible, e.g. by means of heat radiating elements such

as multiple disc couplings.

5.3 Installation orientation

The torque flange can be installed with any orientation.

With clockwise torque, the output frequency is 60 … 90 kHz for Option 5, code

DU2 (Option 5, code SU2: 10 … 15kHz; Option HU2: 240 … 360kHz). In con

junction with HBM amplifiers or when using the voltage output, a positive output

16 A3276-11.0 HBM: public T40FM

Page 19

Mechanical installation

signal (0 V …+10 V) is present. In the case of the rotational speed measuring

system, an arrow is attached to the stator housing to clearly define the direction

of rotation: if the measurement flange turns in the direction of the arrow, con

nected HBM measuring amplifiers deliver a positive output signal.

5.4 Installation options

There are basically two options for mounting the torque flange: with or without

dismantling the antenna ring. We recommend mounting as described in

Chapter 5.4.1. If mounting in accordance with Chapter 5.4.1 is not possible,

(e.g. in the case of subsequent stator replacement), you will have to dismantle

the antenna ring. It is essential in this case to comply with the notes on assem

bling the antenna segments (see Chapter 5.4.2).

T40FM A3276-11.0 HBM: public 17

Page 20

Mechanical installation

5.4.1 Installation without dismantling the antenna ring

Mounting supplied by

customer

1. Install rotor 2. Install stator

Support supplied by customer

3. Finish shaft train installation

4. Fit support

18 A3276-11.0 HBM: public T40FM

Page 21

Mechanical installation

5.4.2 Installation with subsequent antenna ring mounting

1. Install rotor

Washers

3. Dismantle antenna segment

Support supplied by customer

Fan-type

lock

washers

4. Fit support

2. Install shaft train

4. Install antenna segment

T40FM A3276-11.0 HBM: public 19

Page 22

Mechanical installation

5.5 Preparing for the rotor mounting

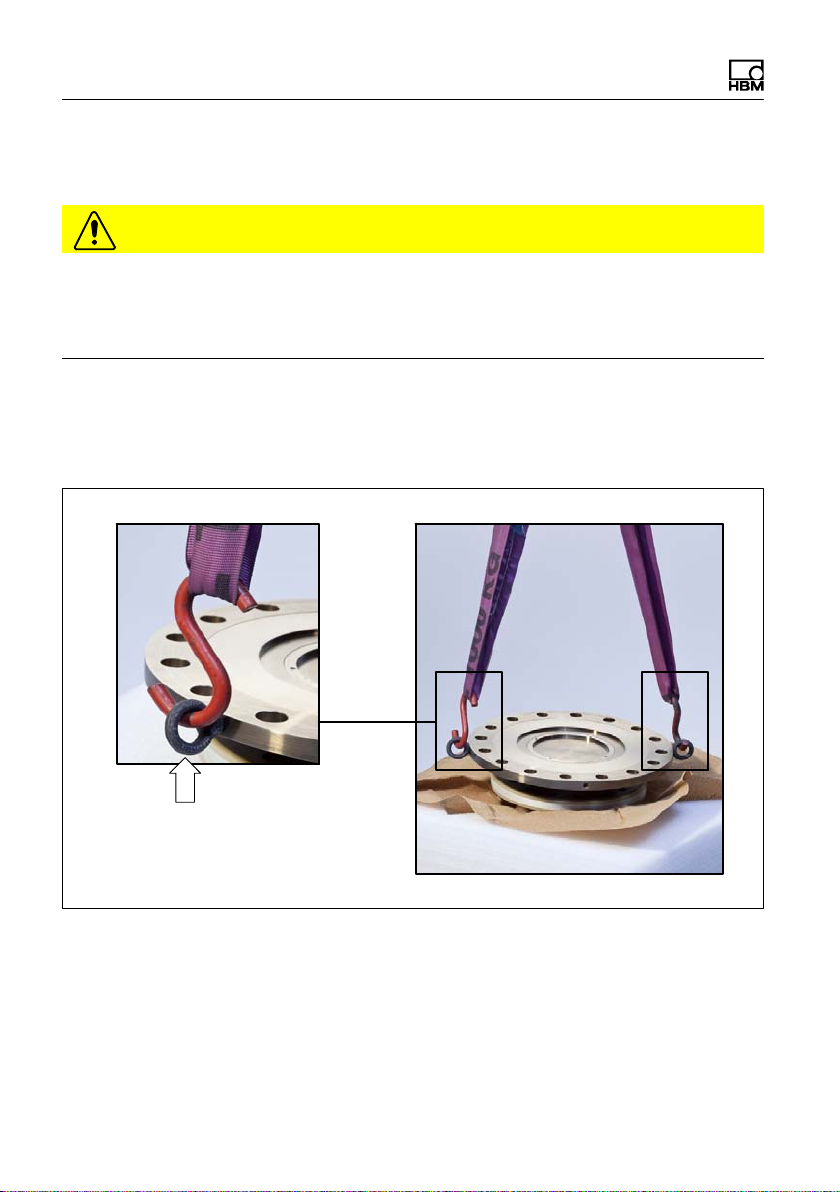

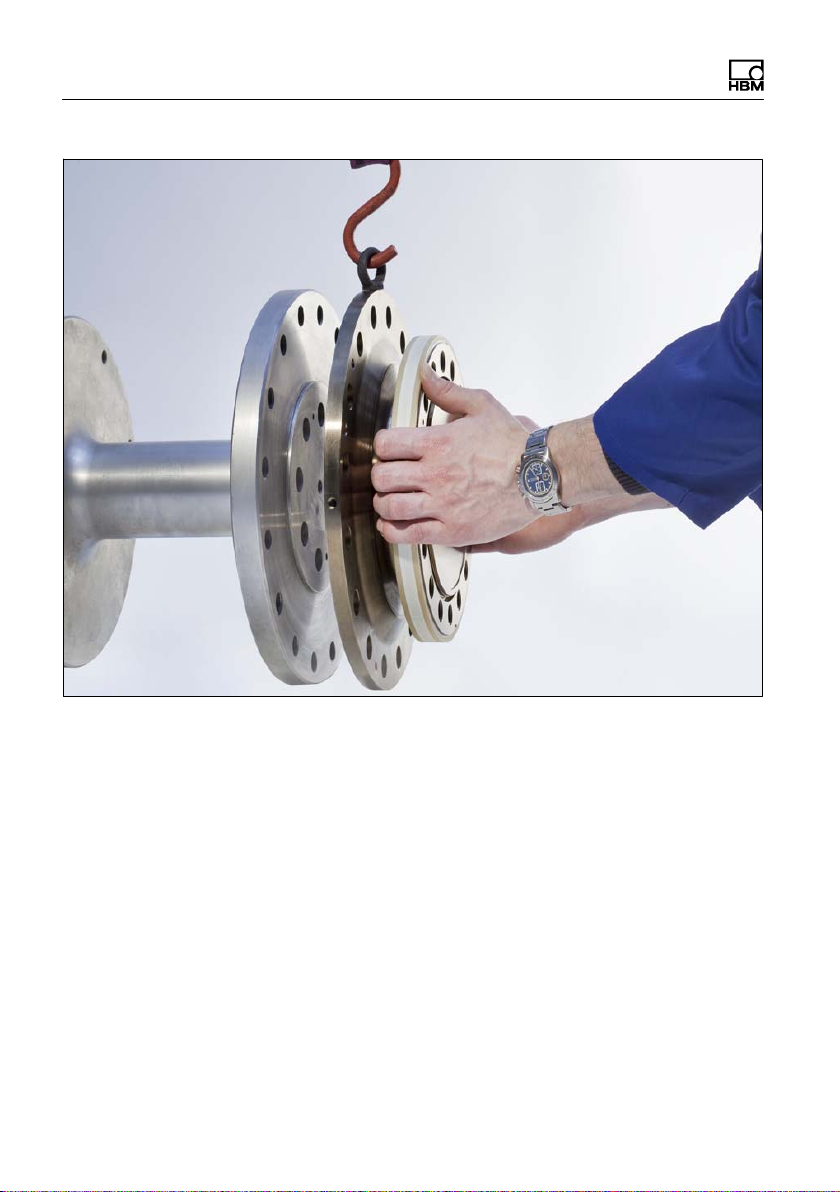

CAUTION

The rotor is very heavy (depending on measuring range: 18kg … 39kg)!

Use a crane or other suitable lifting equipment to lift it out of its packaging and

install it.

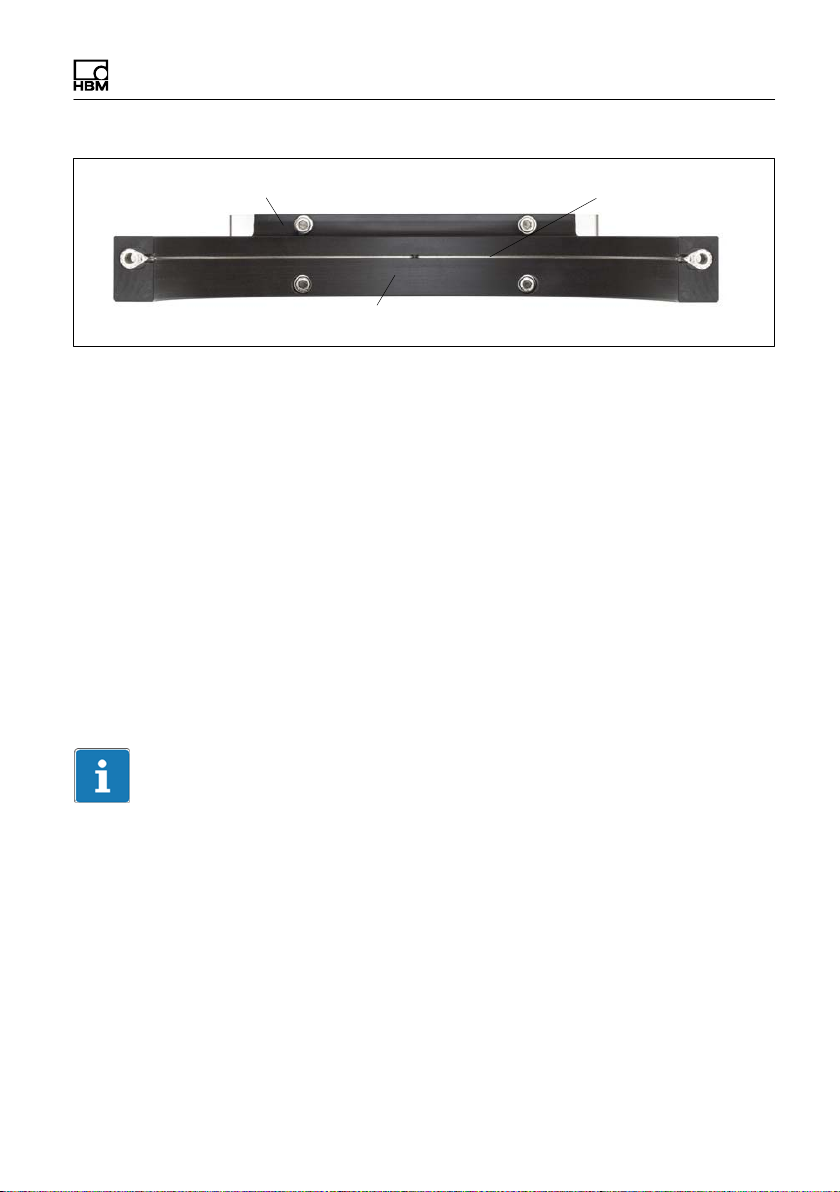

Two eye bolts are screwed into the rotor as transport and mounting aids. Hook

the lifting equipment to these eye bolts as this ensures that the rotor is lifted

horizontally out of the packaging (see Fig. 5.1).

Transport and mounting eye bolts

Fig. 5.1 Transport and mounting eye bolts on the rotor

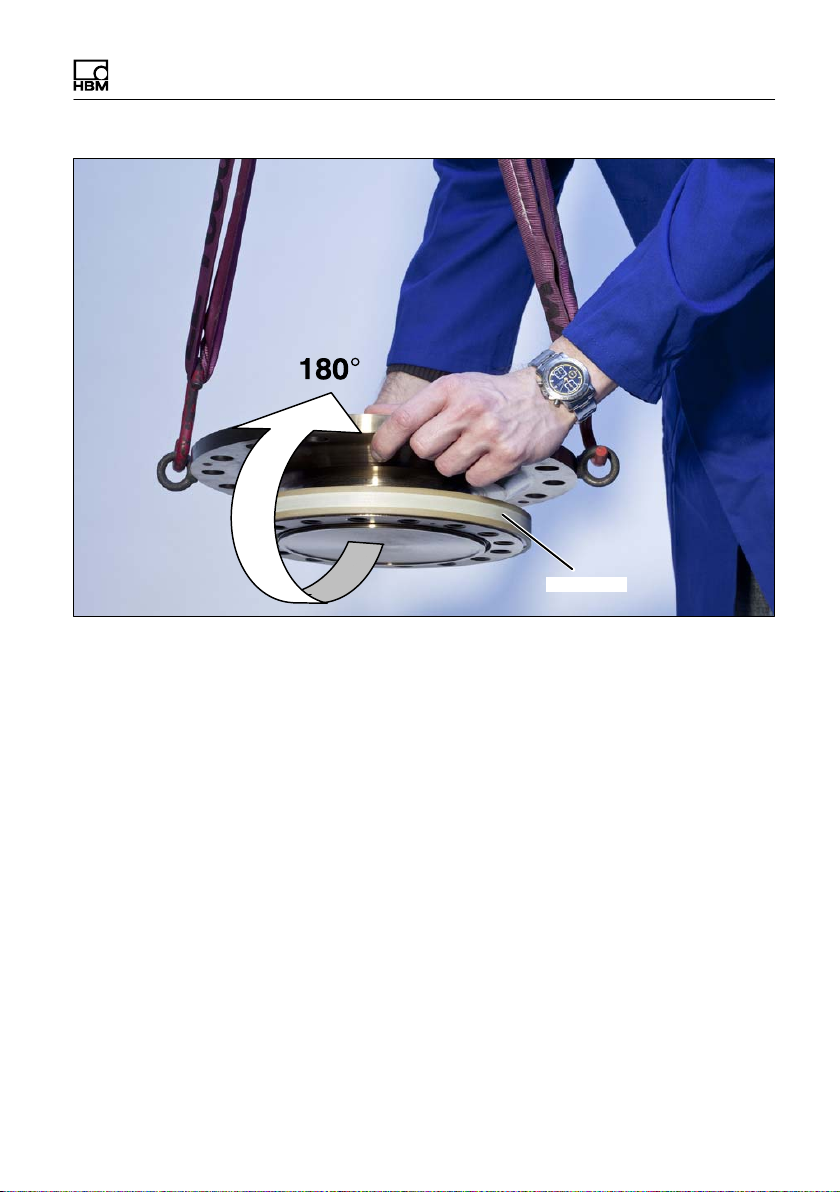

1. Lift the rotor out of the packaging, rotate horizontally by 180_, so that flange

B is pointing upwards (see Fig. 5.1).

20 A3276-11.0 HBM: public T40FM

Page 23

Fig. 5.2 Rotating the rotor

Mechanical installation

Flange B

2. Place the rotor carefully onto a clean and stable table.

3. If the rotor is to be installed horizontally as shown in Fig. 5.3, remove one

mounting eye bolt. Both mounting eye bolts can initially remain in the flange

for vertical installation.

T40FM A3276-11.0 HBM: public 21

Page 24

Mechanical installation

Fig. 5.3 Rotor installation (horizontal)

4. Clean the plane faces of the transducer flange and the counter flange.

For safe torque transfer, the faces must be clean and free from grease. Use

a piece of cloth or paper soaked in solvent. Make sure that no solvent drips

into the inside of the transducer and that the transmitter coils are not dam

aged during cleaning.

5. Fasten the lifting equipment to the mounting eye bolt(s).

6. Carefully lift up the rotor and move it to the mounting position (see Fig. 5.1).

22 A3276-11.0 HBM: public T40FM

Page 25

Mechanical installation

5.6 Mounting the rotor

Tip

Usually the rotor type plate is no longer visible after installation. This is why we

include with the rotor additional stickers with the important characteristics,

which you can attach to the stator or any other relevant test-bench compon

ents. You can then refer to them whenever there is anything you wish to know,

such as the shunt signal. To explicitly assign the data, the identification number

and the size are engraved on the rotor flange, where they can be seen from

outside.

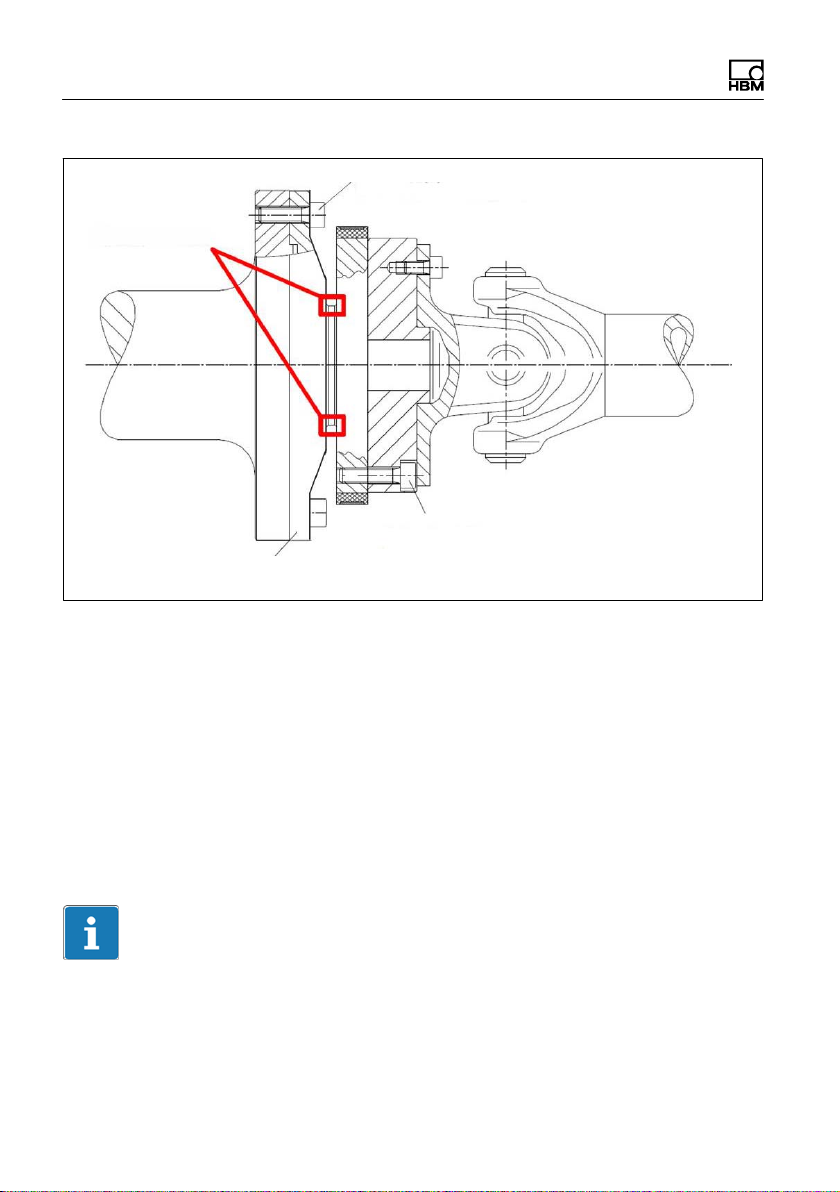

Notice

Make sure during installation that you do not damage the measuring zone

marked in Fig. 5.4 by using it to support tools or knocking tools against it when

tightening screws, for example. This can damage the transducer and produce

measurement errors, or even destroy the transducer.

1. Prior to installation, clean the plane faces of the transducer flange and the

counter flange.

For safe torque transfer, the faces must be clean and free from grease. Use

a piece of cloth or paper soaked in solvent. When cleaning, make sure that

you do not damage the transmitter winding.

T40FM A3276-11.0 HBM: public 23

Page 26

Mechanical installation

Measuring zone

Flange A

Fig. 5.4 Bolted rotor connection

Hexagon socket screw (Z)

DIN EN ISO 4762 (10.9)

Fastening bolt (10.9);

note maximum thread reach Y!

2. For the connection of flange A (see Fig. 5.4), use DIN EN ISO 4762

property class 10.9 hexagon socket screws of a suitable length (dependent

on the connection geometry, see Tab. 5.1 on Page 25).

We recommend fillisterhead screws DIN EN ISO 4762, blackened, smooth

headed, permitted size and shape variance in accordance with DIN ISO

4759, Part 1, product class A.

3. Fasten all screws with the specified torque (Tab. 5.1 on Page 25).

4. Now remove the eye bolt(s) used for transportation and mounting.

Important

Keep them in a safe place for future dismounting.

24 A3276-11.0 HBM: public T40FM

Page 27

Mechanical installation

5. There are relevant tapped holes on flange B for continuing the shaft train

mounting. Again use screws of property class 10.9 and tighten them with

the prescribed torque, as specified in Tab. 5.1, Page 25.

Important

Use a threadlocker (medium strength, e.g. LOCTITE) to glue the screws into

the counter thread to exclude prestressing loss due to screw slackening, in the

event of alternating loads.

Notice

Comply with the maximum screw-in depth as per Tab. 5.1, Page 25. Otherwise

significant measurement errors may result from torque shunt, or the transducer

may be damaged.

Measuring

range

kNVm Z

15

20

25

30

40

50

60

70

80

1)

DIN EN ISO 4762; black/oiled/m

Tab. 5.1 Fastening screws

Fastening screws Maximum thread

reach Y of screws

in flange B

1)

M18

M20 40 560

M22 45 760

Property class mm NVm

30 400

10.9

=0.125

tot

Prescribed

tightening

moment

T40FM A3276-11.0 HBM: public 25

Page 28

Mechanical installation

Important

Dry screw connections can result in different and higher friction factors (see

VDI 2230, for example). This means a change to the required tightening mo

ments.

The required tightening moments can also change if you use screws with a sur

face or property class other than that specified in Tab. 5.1, as this affects the

friction factor.

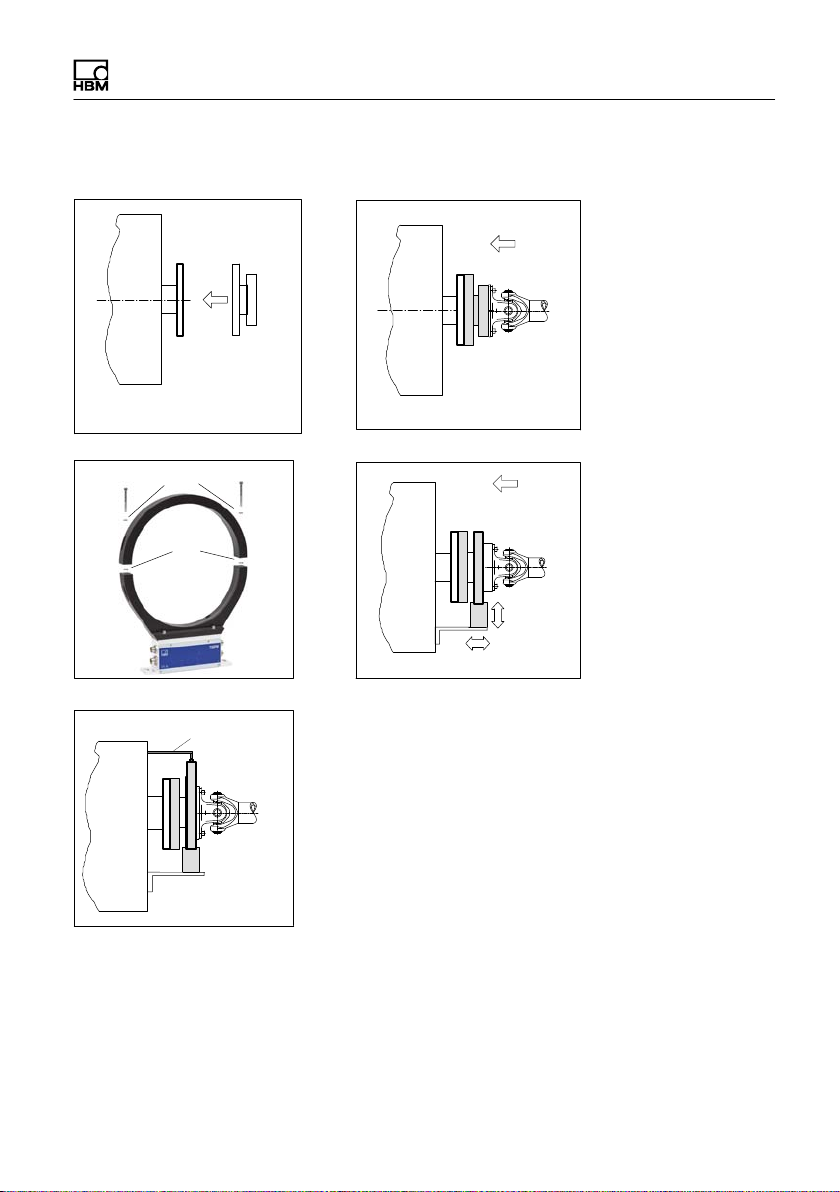

5.7 Installing the stator

On delivery, the stator has already been installed and is ready for operation.

The upper antenna segment can be separated from the stator, for example, for

maintenance or to facilitate stator mounting.

Antenna segment screws

with washers (M5)

Fan-type lock

washers

Fig. 5.5 Bolted connection of the antenna segments on the stator

M5 hole for fixing the

antenna segment

upper

Antenna segments

lower

Stator housing

26 A3276-11.0 HBM: public T40FM

Page 29

Mechanical installation

Stator housing

Lower antenna segment

Fig. 5.6 Stator housing and lower antenna segment with antenna wire

Antenna wire

1. Undo and remove the bolted connections (M5) on the upper antenna seg

ment.

There are fan-type lock washers between the antenna segments: make sure

that they do not get lost.

2. Use an appropriate mounting base to install the stator housing in the shaft

train, so that there is sufficient opportunity for horizontal and vertical adjust

ments. Do not fully tighten the bolts yet.

3. Now use two hexagon socket screws to mount the upper antenna segment

removed in Point 1 on the lower antenna segment.

Make sure that the two fan-type lock washers are inserted between the an

tenna segments (these ensure that there is a defined contact resistance)!

Important

To make sure that they function perfectly, the fan-type lock washers (A5.3-FST

DIN 6798 ZN/galvanized) must be replaced after the bolted antenna connection

has been loosened three times.

4. Now tighten all the bolted antenna segment connections with a tightening

torque of 5 N⋅m.

5. Then align the antenna to the rotor in such a way that the antenna encloses

the rotor more or less coaxially and the antenna wire in the axial direction

has the same position as the center of the transmitter winding on the rotor.

T40FM A3276-11.0 HBM: public 27

Page 30

Mechanical installation

Fig. 5.7 Alignment of the rotor with the stator

6. Now fully tighten the bolted stator housing connection.

Prevention of axial stator oscillation

Depending on the operating conditions, the stator may be induced to oscillate.

This effect is dependent on:

S the rotational speed,

S the antenna diameter (depends in turn on the measuring range),

S the design of the machine base.

Important

To prevent this axial oscillation, the antenna ring requires additional support by

the customer. There is a socket (with an M5 internal thread) on the upper an

tenna segment, which can be used for a suitable clamping device (see

Fig. 5.8). If this is the case, the cable plug also needs some support, as shown

in the construction example in Fig. 5.9.

28 A3276-11.0 HBM: public T40FM

Page 31

Mechanical installation

Fig. 5.8 Construction example for supporting the antenna ring

Fig. 5.9 Construction example for connector terminals (for two plugs)

T40FM A3276-11.0 HBM: public 29

Page 32

Mechanical installation

5.8 Mounting the rotational speed flange (rotational speed measuring system only)

The rotational speed disc (intermediate flange) is ready-mounted on the rotor at

the factory, with two (M4) screws.

Rotational speed disc

M4 fixing screws

Sensor head

for measuring

rotational

speed

Sensor head

for reference

signal

Fig. 5.10 Torque transducer with rotational speed measurement, optional reference

signal, Option 6, Code A

Notice

The two (M4) screws are only used to fix the rotational speed disc. The meas

urement flange and the attached speed measuring system may therefore be

rotated only after mounting.

30 A3276-11.0 HBM: public T40FM

Page 33

Mechanical installation

Important

The speed measuring system uses a magnetic measuring principle. In applica

tions where high magnetic field strengths can occur, e.g. eddy-current brakes,

implement suitable measures to ensure that the maximum permissibly mag

netic field strength cannot be exceeded (see Chapter 14 "Specifications",

Page 63).

Stator alignment (rotational speed measuring system, optionally with

reference signal)

The rotational speed measuring system is correctly aligned when the stator is

precisely aligned for torque measurement. A reduction in the distance between

the sensor head and magnetic ring can in some cases improve the signal qual

ity when the rotor is centrally positioned in the stator. To do this, loosen both

screws on the sensor head and push the sensor head in parallel as marked

with the arrows in Fig. 5.11.

The sensor for recording the reference signal is permanently set and must not

be adjusted.

T40FM A3276-11.0 HBM: public 31

Page 34

Mechanical installation

Do not adjust

Sensor head

screws

Fig. 5.11 Torque transducer with speed disc and sensor head, and reference signal

(optional), Option 6, Code A

32 A3276-11.0 HBM: public T40FM

Page 35

Electrical Connection

6 Electrical Connection

6.1 General information

S With extension cables, make sure that there is a proper connection with

minimum contact resistance and good insulation.

S All cable connectors or swivel nuts must be fully tightened.

Important

Transducer connection cables from HBM with plugs attached are identified in

accordance with their intended purpose (Md or n). When cables are shortened,

inserted into cable ducts or installed in control cabinets, this identification can

get lost or become concealed. So the cables must be marked beforehand, just

in case.

6.2 EMC protection

Important

The transducers are EMC-tested in accordance with EC directives and identi

fied by CE certification. However, you must connect the shield of the connec

tion cable on the shielding electronics enclosure in order to achieve EMC pro

tection for the measuring chain.

Special electronic coding methods are used to protect the purely digital signal

transmission between the transmitter head and the rotor from electromagnetic

interference.

The cable shield is connected with the transducer housing. This encloses the

measurement system (without the rotor) in a Faraday cage when the shield is

laid flat at both ends of the cable. With other connection techniques, an

EMCproof shield should be applied in the wire area, and this shielding should

T40FM A3276-11.0 HBM: public 33

Page 36

Electrical Connection

also be connected extensively (also see HBM Greenline Information, brochure

i1577).

Electrical and magnetic fields often induce interference voltages in the measur

ing circuit. Therefore:

S Use shielded, low-capacitance measurement cables only (HBM cables fulfill

both conditions).

S Only use plugs that meet EMC guidelines.

S Do not route the measurement cables parallel to power lines and control

circuits. If this is not possible, protect the measurement cable with e.g. steel

conduit.

S Avoid stray fields from transformers, motors and contact switches.

S Do not ground the transducer, amplifier and indicator more than once.

S Connect all the devices in the measuring chain to the same protective earth

conductor.

S In the case of interference due to potential differences (compensating cur

rents), the connections between supply voltage zero and housing ground

must be broken at the amplifier and a potential equalization line established

between the stator housing and the amplifier housing (copper conductor, at

least 10 mm

2

wire crosssection).

S Should differences in potential between the machine rotor and stator, be

cause of unchecked leakage, for example, cause interference, this can usu

ally be overcome by connecting the rotor definitively to ground, e.g. with a

wire loop. The stator must be connected to the same (ground) potential.

6.3 Pin Assignment

The stator housing has two 7-pin plugs, an 8-pin plug and a 16-pin plug.

The supply voltage connections and shunt signal connections of plugs 1 and 3

are each electrically interconnected, but are protected against compensating

currents by diodes. There is also a self-resetting fuse (multifuse) to protect the

supply voltage connections against overload by the stator.

34 A3276-11.0 HBM: public T40FM

Page 37

Electrical Connection

Assignment for plug 1 - Supply voltage and frequency output signal

61

Device plug

5

72

3

4

Top view

KAB153 KAB149 KAB178

Plug

Assignment Color

pin

code

D‐SUB‐

plug

pin

Torque measurement signal (frequency

1

output; 5 V

Supply voltage 0 V;

2

2),3

)

wh 13 5

bk 5 -

3 Supply voltage 18 V to 30 V bu 6 -

Torque measurement signal (frequency

4

output; 5 V

Measurement signal 0 V; symmetrical

5

2),3

)

rd 12 10

gy 8 6

6 Shunt signal trigger 5 V to 30 V gn 14 15

Shunt signal 0 V

7

gy 8 -

Shielding connected to housing ground

1)

Bridge between 4 + 9

2)

RS-422 complementary signals; with cable lengths exceeding 10 m, we recommend using a

termination resistor R = 120 ohms between the (wh) and (rd) wires.

3)

RS‐422: pin 1 corresponds to A, pin 4 corresponds to B.

1)

HD‐SUB‐

plug

pin

T40FM A3276-11.0 HBM: public 35

Page 38

Electrical Connection

Notice

Torque flanges are only intended for operation with a DC supply voltage. They

must not be connected to older HBM amplifiers with square-wave excitation.

This could destroy the connection board resistors or cause other faults in the

amplifiers.

36 A3276-11.0 HBM: public T40FM

Page 39

Electrical Connection

Assignment for plug 2 - Rotational speed measurement system

2

5

3

4

Device plug

8

1

Top view

6

7

KAB154 KAB150 KAB179

Plug

Assignment Color

pin

Rotational speed measurement signal

1

(pulse string, 5 V; 0°)

code

2)

rd 12 10

D-SUB-

plug pin

2 Not in use bl - -

Rotational speed measurement signal

3

(pulse string, 5 V; 90° phase shifted)

2)

gy 15 8

4 Not in use bl - 5 Not in use vi - -

Rotational speed measurement signal

6

(pulse string, 5 V; 0°)

Rotational speed measurement signal 2)

7

(pulse string, 5 V; 90° phase shifted)

8 Operating voltage zero bk/bl

2)

wh 13 5

gn 14 7

3)

8 6

Shielding connected to housing ground

1)

Bridge between 4 + 9

2)

RS-422 complementary signals; with cable lengths exceeding 10 m, we recommend using a

termination resistor of R = 120 ohms.

3)

KAB163/KAB164: color code brown (bn)

1)

HD-SUB-

plug pin

T40FM A3276-11.0 HBM: public 37

Page 40

Electrical Connection

Assignment for plug 2 - Rotational speed measurement system with

reference signal

2

5

3

4

Device plug

8

1

Top view

6

7

KAB164 KAB163 KAB181

Plug

Assignment Color

pin

Rotational speed measurement signal

1

(pulse string, 5 V)

2 Reference signal (1 pulse/revolution, 5 V)

Rotational speed measurement signal

3

(pulse string, 5 V; 90° phase shifted)

4 Reference signal (1 pulse/revolution, 5 V)

code

2)

2)

rd 12 10

2)

bl 2 3

gy 15 8

2)

bl 3 2

D-SUB-

plug pin

5 Not in use vi - -

Rotational speed measurement signal

6

(pulse string, 5 V; 0°)

Rotational speed measurement signal

7

(pulse string, 5 V; 90° phase shifted)

8 Operating voltage zero bl

2)

2)

wh 13 5

gn 14 7

3)

8 6

Shielding connected to housing ground

1)

Bridge between 4 + 9

2)

RS-422 complementary signals; with cable lengths exceeding 10 m, we recommend using a

termination resistor of R = 120 ohms.

3)

KAB163/KAB164: color code brown (bn)

1)

HD-SUB-

plug pin

38 A3276-11.0 HBM: public T40FM

Page 41

Electrical Connection

Pin 1

Pin 6

Pin 3

Pin 7

Pin 2

Pin 4

Fig. 6.1 Rotational speed signals at plug 2 (rotational speed in the direction of the

arrow)

T40FM A3276-11.0 HBM: public 39

Page 42

Electrical Connection

Pin 1

Pin 6

Pin 3

Pin 7

Pin 2

Pin 4

Fig. 6.2 Rotational speed signals at plug 2 (rotational speed against the direction of

the arrow)

40 A3276-11.0 HBM: public T40FM

Page 43

Electrical Connection

Assignment for plug 3 - Supply voltage and voltage output signal

61

5

72

3

4

Plug pin Assignment Color code

1

2

3 Supply voltage 18 V to 30 V DC bl

4 Torque measurement signal (voltage output; ±10 V) rd

5 Not in use gy

6 Shunt signal trigger 5 V to 30 V gn

7

Device plug

Top view

Torque measurement signal

(voltage output; 0 V)

Supply voltage 0 V;

Shunt signal 0 V;

Shielding connected to housing ground

wh

bk

gy

Assignment for plug 4

TMC - only for connection to the TIM 40 Torque Interface Module within HBM.

6.4 Supply Voltage

The transducer must be operated with a separated extra-low voltage (supply

voltage 18 … 30 V

). You can supply one or more torque flanges within a test

DC

bench at the same time. Should the device be operated on a DC voltage net

1)

, additional precautions must be taken to discharge excess voltages.

work

1)

Distribution system for electrical energy with greater physical expansion (over several test

benches, for example) that may possibly also supply consumers with high nominal (rated)

currents.

T40FM A3276-11.0 HBM: public 41

Page 44

Electrical Connection

The information in this Chapter relates to the self-contained operation of the

T40FM without HBM system solutions.

The supply voltage is electrically isolated from signal outputs and shunt signal

inputs. Connect a separated extra-low voltage of 18 V … 30 V to pin 3 (+) and

pin 2 (

KAB 8/00-2/2/2 and the appropriate sockets (see Accessories). The cable can

be up to 50m long for voltages ≥24V, otherwise it can be up to 20m long.

If the permissible cable length is exceeded, you can feed the supply voltage in

parallel over two connection cables (plugs 1 and 3). This enables you to double

the permissible length. Alternatively, install an on-site power supply.

The instant you switch on, a current of up to 4 A may flow and this may switch

off power packs with electronic current limiters.

) of plugs 1 or 3. We recommend that you use HBM cable

Important

42 A3276-11.0 HBM: public T40FM

Page 45

Shunt signal

7 Shunt signal

The T40FM torque flange delivers an electrical shunt signal that can be activ

ated from the amplifier for measuring chains with HBM components. The trans

ducer generates a shunt signal of about 50% of the nominal (rated) torque; the

precise value is specified on the type plate. After activation, adjust the amplifier

output signal to the shunt signal supplied by the connected transducer, to adapt

the amplifier to the transducer.

Information

The transducer should not be under load when the shunt signal is being meas

ured, as the shunt signal is mixed additively.

Triggering the shunt signal

Applying a separated extra-low voltage of 5 … 30 V to pins 6 (+) and 7 (

plug 1 or 3, triggers the shunt signal.

The nominal (rated) voltage for triggering the shunt signal is 5 V (triggering at U

> 2.5 V), but when voltages are less than 0.7 V, the transducer is in measuring

mode. The maximum permissible voltage is 30 V, current consumption at nom

inal (rated) voltage is approx. 2 mA and at maximum voltage, approx. 18 mA.

The voltage for triggering the shunt signal is electrically isolated from the supply

and measuring voltage.

Tip

The shunt signal can be triggered by the amplifier or via the operating software

in HBM system solutions.

T40FM A3276-11.0 HBM: public 43

) at

Page 46

Functionality testing

8 Functionality testing

You can check the functionality of the rotor and the stator from the LEDs on the

stator.

LED A, rotor status

LED B, stator status

Fig. 8.1 LEDs on the stator housing, Option 7, Code S and FCC option

Important

Once the supply voltage is applied, the torque transducer needs up to a further

4 seconds to be ready for operation.

8.1 Rotor status, LED A (upper LED)

Color Significance

Green (pulsating) Internal rotor voltage values ok

Flashing orange Rotor and stator mismatched (an increasing flashing

frequency indicates the degree of misalignment)

=> Correct the rotor/stator alignment

44 A3276-11.0 HBM: public T40FM

Page 47

Functionality testing

SignificanceColor

Pulsating orange Rotor status cannot be defined

=> Correct the rotor/stator alignment

If the LED still pulsates orange, it is possible that there is a

hardware defect. The measurement signals reflect the level of

the fault.

Red (pulsating) Rotor voltage values not ok.

=> Correct the rotor/stator alignment

If the LED still pulsates red, it is possible that there is a

hardware defect. The measurement signals reflect the level of

the fault.

Pulsating means that the LED goes dark for about 20 ms every second (sign of

life), making it possible to detect that the transducer is functioning.

8.2 Stator status, LED B (lower LED)

Color Significance

Green

(permanently lit)

Green, intermittently

orange.

Numerous

synchronization

defects:

Measurement signal transmission and internal stator voltages

ok

Orange until end of defective transmission if y5 incorrect

measured values are transmitted in succession. The

measurement signals reflect the level of the defect status for

the duration of the transmission defect + for approx. another

3.3ms.

permanently orange

Orange

(permanently lit)

Permanently disrupted transmission, the measurement

signals reflect the level of the fault. (f

= 0 Hz, U

out

= defect

out

level).

=> Correct the rotor/stator alignment.

Red

(permanently lit)

Internal stator defect, the measurement signals reflect the

level of the fault (f

= 0 Hz, U

out

= defect level).

out

T40FM A3276-11.0 HBM: public 45

Page 48

Loading capacity

9 Loading capacity

Nominal torque can be exceeded statically up to the limit torque. If the nominal

torque is exceeded, additional irregular loading is not permissible. This includes

longitudinal forces, lateral forces and bending moments. Limit values can be

found in Chapter 14 "Specifications" on Page 63.

Measuring dynamic torque

The torque flange can be used to measure static and dynamic torque. The fol

lowing apply to the measurement of dynamic torque:

S The T40FM calibration performed for static measurements is also valid for

dynamic torque measurements.

S The natural frequency f

pends on the moments of inertia J

of the mechanical measuring arrangement de

0

and J2 of the connected rotating masses

1

and the torsional stiffness of the T40FM.

Use the equation below to approximately determine the natural frequency f

the mechanical measuring arrangement:

f

= natural frequency in Hz

f0+

1

· cT·

2p

Ǹ

ǒ

J

1

)

Ǔ

J

2

1

1

0

J2= mass moment of inertia in kg⋅m

J

1,

c

= torsional stiffness in N⋅m/rad

T

2

S The permissible mechanical vibration bandwidth (peak-peak) can also be

found in the specifications.

of

0

46 A3276-11.0 HBM: public T40FM

Page 49

Maintenance

Nominal (rated) torque M

a %

+ M

nom

0

- M

nom

as

nom

Vibration bandwidth

Vibration bandwidth

Fig. 9.1 Permissible dynamic loading

10 Maintenance

The T40FM torque flanges are maintenance-free.

200% oscillation

Time t

Vibration bandwidth

width

T40FM A3276-11.0 HBM: public 47

Page 50

Waste disposal and environmental protection

11 Waste disposal and environmental protection

All electrical and electronic products must be disposed of as hazardous waste.

The correct disposal of old equipment prevents ecological damage and health

hazards.

Statutory waste disposal mark

The electrical and electronic devices that bear this sym

bol are subject to the European waste electrical and elec

tronic equipment directive 2002/96/EC. The symbol indic

ates that, in accordance with national and local

environmental protection and material recovery and re

cycling regulations, old devices that can no longer be

used must be disposed of separately and not with normal

household garbage.

As waste disposal regulations may differ from country to country, we ask that

you contact your supplier to determine what type of disposal or recycling is leg

ally applicable in your country.

Packaging

The original packaging of HBM devices is made from recyclable material and

can be sent for recycling. Store the packaging for at least the duration of the

warranty. In the case of complaints, the torque flange must be returned in the

original packaging.

For ecological reasons, empty packaging should not be returned to us.

48 A3276-11.0 HBM: public T40FM

Page 51

Dimensions

12 Dimensions

12.1 T40FM without speed measurement, Option 6, Code 0

12.1.1 T40FM 15kNm - 25kNm

Dimensions in mm (1 mm = 0.03937)

Dimensions without tolerances, per

DIN ISO 2768-mk

Mounting dimensions

Outer rotor Ø

Inner stator Ø

for axial locking

T40FM A3276-11.0 HBM: public 49

Page 52

Dimensions

T40FM 15kNm - 25kNm, continued

Internal centering

Rotor

Rotor flange (thread

reach)

Stator

Center of gravity

External centering

Partial sections cut

A-A

Dimensions without tolerances, per DIN ISO 2768-mk

Dimensions in mm (1 mm = 0.03937)

Alignment plane rotor - stator

Outer rotor Ø

50 A3276-11.0 HBM: public T40FM

Page 53

12.1.2 T40FM 30kNm - 50kNm

Dimensions in mm (1 mm = 0.03937)

Dimensions without tolerances, per DIN ISO 2768-mk

Mounting dimensions

Dimensions

Outer rotor Ø

Inner stator Ø

for axial locking

T40FM A3276-11.0 HBM: public 51

Page 54

Dimensions

T40FM 30kNm - 50kNm, continued

Dimensions in mm (1 mm = 0.03937)

Dimensions without tolerances, per DIN ISO 2768-mk

Rotor

Rotor flange (thread reach)

Stator

Alignment plane rotor - stator

Center of gravity

Internal centering

External centering

Outer rotor Ø

Partial sections cut

A-A

52 A3276-11.0 HBM: public T40FM

Page 55

12.1.3 T40FM 60kNm - 80kNm

Dimensions in mm (1 mm = 0.03937)

Dimensions without tolerances, per

DIN ISO 2768-mk

Mounting dimensions

Dimensions

Outer rotor Ø

Inner stator Ø

for axial locking

T40FM A3276-11.0 HBM: public 53

Page 56

Dimensions

T40FM 60kNm - 80kNm, continued

Dimensions in mm (1 mm = 0.03937)

Dimensions without tolerances, per DIN ISO 2768-mk

Rotor

Rotor flange (thread reach)

Stator

Alignment plane rotor - stator

Center of gravity

Internal centering

External centering

Outer rotor Ø

Partial sections cut

A-A

54 A3276-11.0 HBM: public T40FM

Page 57

Dimensions

12.2 T40FM with speed measurement, Option 6, Code 1 (Code A optional)

12.2.1 T40FM 15kNm - 25kNm

Dimensions in mm (1 mm = 0.03937)

Dimensions without tolerances, per

DIN ISO 2768-mk

Mounting dimensions

Outer rotor Ø

Inner stator Ø

Only Option 6,

Code A

for axial locking

T40FM A3276-11.0 HBM: public 55

Page 58

Dimensions

T40FM 15kNm - 25kNm, continued

Dimensions in mm (1 mm = 0.03937)

Dimensions without tolerances, per DIN ISO 2768-mk

Rotor

Rotor flange (thread reach)

Rotational speed flange

Stator

Alignment plane rotor - stator

Internal centering

Center of gravity

External centering

Rotational speed flange

Outer rotor Ø

Outer rotational speed flange Ø

Partial sections cut

A-A

56 A3276-11.0 HBM: public T40FM

Page 59

12.2.2 T40FM 30kNm - 50kNm

Dimensions in mm (1 mm = 0.03937)

Dimensions without tolerances, per

DIN ISO 2768-mk

Mounting dimensions

Dimensions

Outer rotor Ø

Inner stator Ø

Only Option 6,

Code A

for axial locking

T40FM A3276-11.0 HBM: public 57

Page 60

Dimensions

T40FM 30kNm - 50kNm, continued

Dimensions in mm (1 mm = 0.03937)

Dimensions without tolerances, per DIN ISO 2768-mk

Rotor

Rotor flange (thread reach)

Rotational speed flange

Stator

Alignment plane rotor - stator

Center of gravity

Internal centering

External centering

Rotational speed flange

Outer rotor Ø

Outer rotational speed flange Ø

Partial sections cut

A-A

58 A3276-11.0 HBM: public T40FM

Page 61

12.2.3 T40FM 60kNm - 80kNm

Dimensions in mm (1 mm = 0.03937)

Dimensions without tolerances, per

DIN ISO 2768-mk

Mounting dimensions

Dimensions

Outer rotor Ø

Inner stator Ø

Only Option 6,

Code A

for axial locking

T40FM A3276-11.0 HBM: public 59

Page 62

Dimensions

T40FM 60kNm - 80kNm, continued

Dimensions in mm (1 mm = 0.03937)

Dimensions without tolerances, per DIN ISO 2768-mk

Rotor

Rotor flange (thread reach)

Rotational speed flange

Stator

Center of gravity

Internal centering

Alignment plane rotor - stator

External centering

Rotational speed flange

Outer rotor Ø

Outer rotational speed flange Ø

Partial sections cut

A-A

60 A3276-11.0 HBM: public T40FM

Page 63

Order numbers, Accessories

13 Order numbers, Accessories

Order no.

K-T40FM [only with Option 2 = MF/ST]

Code Option 1: Measuring range up to

015R 15 kN·m [only with Option 2 = MF/RO]

020R 20 kN·m [only with Option 2 = MF/RO]

025R 25 kN·m [only with Option 2 = MF/RO]

030R 30 kN·m [only with Option 2 = MF/RO]

040R 40 kN·m [only with Option 2 = MF/RO]

050R 50 kN·m [only with Option 2 = MF/RO]

060R 60 kN·m [only with Option 2 = MF/RO]

070R 70 kN·m [only with Option 2 = MF/RO]

080R 80 kN·m [only with Option 2 = MF/RO]

Code Option 2: Component

MF Measurement flange, complete

RO Rotor

ST Stator

Code Option 3: Accuracy

S Standard

G Linearity deviation including hysteresis <±0,05%

Code Option 4: Adjustment

M Metric (N·m)

Code Option 5: Electrical configuration [only with Option 2 = MF/RO]

SU2 10 kHz ±5 kHz and ±10 V outp. signal, 18…30V DC supply volt.

DU2 60 kHz ±30 kHz and ±10 V outp. signal, 18…30V DC supply volt.

HU2 240 kHz ±120 kHz and ±10 V outp. sign., 18…30V DC sup. volt.

Code Option 6: Rotational speed measuring system

0 Without rotational speed measuring system

1 Magnetic rot. speed meas. system: 1024 pulses/revolution

A Magnetic rot. speed meas. sys. (1024 pulses/rev.) and ref.

Code Option 7: Customized modification

S No customer-specific modification

Nominal speed depending on measuring range

H

4500 rpm to 8000 rpm

= PREFERENCE Types

K-T40FM - 0 3 0 R - M F - S - M - D U 2 - 0 - S

T40FM A3276-11.0 HBM: public 61

Page 64

Order numbers, Accessories

Accessories, to be ordered separately

Article Order no.

Connection cable for torque output

Torque connection cable, 423 - D-Sub 15P, 6m 1-KAB149-6

Torque connection cable, 423 - free ends, 6m 1-KAB153-6

Connection cable for rotational speed output

Speed connection cable, 423 - D-Sub 15P, 6m 1-KAB150-6

Speed connection cable, 423 - free ends, 6m 1-KAB154-6

Speed with reference pulse connection cable, 423 8 pin - D-Sub 15P,6m1-KAB163-6

Speed with reference pulse connection cable, 423 8 pin - free ends,

6m

TMC connection cable

Connection cable TIM40/TMC, 6m 1-KAB174-6

Cable sockets

423G-7S, 7 pin (straight) 3-3101.0247

423W-7S, 7-pin (angular) 3-3312.0281

423G-8S, 8-pin (straight) 3-3312.0120

423W-8S, 8-pin (angular) 3-3312.0282

Connection cable, by the meter (min. order quantity: 10 m, price per meter)

Kab8/00-2/2/2 4-3301.0071

1-KAB164-6

62 A3276-11.0 HBM: public T40FM

Page 65

Order numbers, Accessories

14 Specifications

Type T40FM

Accuracy class 0.1

Nominal (rated) torque M

nom

Nominal (rated) rotational speed

Optional

Torque measuring system, frequency output

Nominal (rated) sensitivity (nom

inal (rated) signal range between

torque = zero and nominal (rated)

torque)

Option SU2 kHz 5

Option DU2 kHz 30

Option HU2 kHz 120

Sensitivity tolerance (deviation of

the actual output quantity at M

nom

from the nominal (rated) sensitivity)

Non-linearity incl. hysteresis, re

lated to the nom. (rated) sensitivity

For a max. torque in range:

Between 0% v. M

v. M

nom

> 20% of M

M

nom

> 60% of M

M

nom

nom

nom

and 20%

nom

and 60% of

and 100% of

Relative standard deviation of re

producibility (variability),

as per DIN 1319, related to the vari

ation of the output signal

Load resistance kΩ >2

kNVm 15 20 25 30 40 50 60 70 80

rpm

rpm

6000

8000

4000

6000

% "0.2

% <"0.03 (optional <"0.015)

% <"0.065 (optional <"0.035)

% <"0.1 (optional <"0.05)

% <"0.05

3000

4500

T40FM A3276-11.0 HBM: public 63

Page 66

Order numbers, Accessories

Nominal (rated) torque M

nom

Output signal at zero torque

Option SU2 kHz 10

Option DU2 kHz 60

Option HU2 kHz 240

Nominal (rated) output signal

(RS-422, 5 V symmetrical)

At positive nominal (rated)

kHz 15

torque, Option SU2

At positive nominal (rated)

kHz 90

torque, Option DU2

At positive nominal (rated)

kHz 360

torque, Option HU2

At negative nominal (rated)

kHz 5

torque, Option SU2

At negative nominal (rated)

kHz 30

torque, Option DU2

At negative nominal (rated)

kHz 120

torque, Option HU2

1

Maximum modulation range

Option SU2 kHz 2.5 ... 17.5

Option DU2 kHz 15 ... 105

Option HU2 kHz 60 ... 420

Maximum bandwidth (-3dB)

Option SU2 kHz 1

Option DU2 kHz 3

Option HU2 kHz 6

Group delay

Option SU2 μs <400

Option DU2 μs <220

Option HU2 μs <150

807060504030252015kNVm

64 A3276-11.0 HBM: public T40FM

Page 67

Order numbers, Accessories

Nominal (rated) torque M

nom

Temperature effect per 10 K in

the nominal (rated) temperature

range

on the output signal, related to

% <"0.1

the actual value of the signal

span

on the zero signal, related to

% <"0.05

the nominal (rated) sensitivity

Long-term drift over 48 h at refer

%

≤0.03

ence temperature, related to the

nominal (rated) sensitivity

Torque measuring system, voltage output

Nominal (rated) sensitivity (span

V 10

between torque = zero and nominal

(rated) torque)

Sensitivity tolerance (deviation of

the actual output quantity at M

nom

% "0.2

from the nominal (rated) sensitivity)

Non-linearity including hyster

esis, related to the nominal (rated)

sensitivity

For a max. torque in range:

Between 0% v. M

v. M

nom

> 20% of M

M

nom

> 60% of M

M

nom

nom

nom

Relative standard deviation of re

and 20%

nom

and 60% of

and 100% of

% <"0.03 (optional <"0.015)

% <"0.065 (optional <"0.035)

% <"0.1 (optional <"0.05)

% <"0.05

peatability (variability),

per DIN 1319, relative to the vari

ation of the output signal

Output signal at zero torque V 0

Nominal output signal

807060504030252015kNVm

T40FM A3276-11.0 HBM: public 65

Page 68

Order numbers, Accessories

Nominal (rated) torque M

At positive nominal (rated)

nom

kHz 10

807060504030252015kNVm

torque

At negative nominal (rated)

kHz -10

torque

Maximum modulation range

invalid measured value

2

V

V

"12

13 ... 15

Load resistance kΩ >10

Residual ripple

3)

mV <40 (peak-to-peak)

Temperature effect per 10 K in

the nominal (rated) temperature

range

on the output signal, related to

%

≤0.2

the actual value of the signal

span

on the zero signal, relative to

% <"0.15

the nominal (rated) sensitivity

Long-term drift over 48 h at refer

% <"0.03

ence temperature, related to the

nominal (rated) sensitivity

Rotational speed measuring system

Measurement system Magnetic, via AMR sensor (Anisotropic

Resistive Effect) and magnetized

plastic ring with embedded steel ring

Magnetic poles 158 186 204

Maximum positional variation of

"50 angular seconds

the poles

Output signal V 5 V symmetrical (RS-422);

2 square-wave signals, approx. 90_

phase-shifted

Pulses per revolution 1024

Minimum rotational speed for

rpm

0

sufficient pulse stability

66 A3276-11.0 HBM: public T40FM

Page 69

Order numbers, Accessories

Nominal (rated) torque M

Pulse tolerance

4)

Maximum permissible output fre

nom

degrees

< "0.05

kHz 420

quency

Group delay μs < 150

Radial nominal (rated) distance

mm 1.6

between sensor head and mag

netic ring

(mechanical distance)

Working distance range between

sensor head and magnetic ring

Max. permissible axial displace

ment of the rotor to the stator

mm 0.4 … 2.5

5)

mm "1.5

6)

Hysteresis of reversal in the case

of relative vibrations between

rotor and stator

Torsional vibration of the rotor

Horizontal stator vibration dis

degrees

< approx. 0.2

mm < approx. 0.5

placement

Load resistance

7)

kΩ ≥2

Magnetic load limit (damage to

rotors)

Remanent flux density mT >100

Coercive field strength kA/m >100

Permissible magnetic field

kA/m <0.1

strength for signal deviations

Application limitations

Reference temperature °C +23

Nominal temperature range °C +10 … +70

Operating temperature range

8)

°C -20 … +85

Storage temperature range °C -40 … +85

Permissible ambient humidity

807060504030252015kNVm

T40FM A3276-11.0 HBM: public 67

Page 70

Order numbers, Accessories

Nominal (rated) torque M

Relative humidity / no condens

nom

% 5 ... 95

807060504030252015kNVm

ation

Reference signal measuring system (zero index)

Measurement system Magnetic, with Hall sensor and magnet

Output signal V 5 V symmetrical (RS 422)

Pulses per revolution 1

Minimum rotational speed for

rpm 2

sufficient pulse stability

Pulse width, approx.

Pulse tolerance

9)

degrees

degrees

0.088

<"0.05

Group delay μs <150

Axial nominal (rated) distance

mm 2.0

between sensor head and

magnetic ring (mechanical

distance)

Working distance range between

mm 0.4 … 2.5

sensor head and magnetic ring

Max. permissible axial

mm "1.5

displacement of the rotor to the

10)

stator

Load limits

11)

Limit torque kN⋅m 32 60 110

Max. limit load of measuring

12)

body

kN⋅m 100 200 350

Breaking torque (static) kN⋅m >100 >200 >350

Longitudinal limit force (static) kN 60 120 240

Lateral limit force (static) kN 80 160 240

Limit bending moment (static) N⋅m 6000 12000 24000

Oscillation width per DIN 50100

(peaktopeak)

13)

kN⋅m 30 32 60 100

68 A3276-11.0 HBM: public T40FM

Page 71

Order numbers, Accessories

Nominal (rated) torque M

Protection class, as per

nom

IP 54

EN 60529 (rotor/stator)

Shunt

Nominal (rated) trigger voltage V 5

Trigger voltage limit V 36

Calibration signal on V

Calibration signal off V

Tolerance of the shunt signal, re

lated to M

at reference temp.

nom

min

min

%

>2.5

<0.7

<"0.05

Energy supply

Nominal (rated) supply voltage

V

DC

18 ... 30

(separated extralow voltage

(SELV))

Rated current consumption

In measuring mode A <1 (typ. 0.3 at 20 V supply voltage)

In startup mode A <4 (typ. 2) for max. 50μs

Nominal (rated) power consump

W <10 (typ. 6)

tion

Maximum cable length m 50

General information

EMC

Emission

(per FCC 47 Part 15, Subpart C)

Emission

(per EN 61326-1, Section 7)

RFI field strength Class B

Immunity from interference,

as per EN 61326-1, EN 61326-2-3

Electromagnetic field (AM) V/m 10

Magnetic field A/m 100

Electrostatic discharge (ESD)

807060504030252015kNVm

T40FM A3276-11.0 HBM: public 69

Page 72

Order numbers, Accessories

Nominal (rated) torque M

nom

Contact discharge kV 4

Air discharge kV 8

Fast transients (burst) kV 1

Impulse voltages (surge) kV 1

Conducted interference V 10

Mechanical shock

14)

,

as per EN 60 068-2-72

Quantity n 1000

Duration ms 3

Acceleration (half sine) m/s

2

Vibrational stress in 3

directions

14)

,

as per EN 60068-2-6

Frequency range Hz 10 ... 2000

Duration h 2.5

Acceleration (amplitude) m/s

2

Mechanical data

Torsional stiffness c

T

kN⋅m/

32050 63260 106200

rad

Torsion angle at M

nom

degrees

807060504030252015kNVm

650

200

0.036

0.045

0.027

0.036

0.045

0.033

0.027

0.038

Stiffness in the axial direction cakN/mm 1380 1710 2280

Stiffness in the radial direction crkN/mm 3900 5080 6170

Stiffness during the bending mo

ment round a radial axis c

b

Maximum deflection at longitud

kN⋅m/

94 188 290

deg.

mm <0.05 <0.08 <0.12

inal limit force

Additional maximum radial devi

mm <0.05 <0.05 <0.05

ation at lateral limit force

70 A3276-11.0 HBM: public T40FM

0.043

Page 73

Order numbers, Accessories

Nominal (rated) torque M

nom

Additional maximum plumb/par

allel deviation at limit bending

moment

Balance quality level, as per

DIN ISO 1940

Mechanical data

Permissible max. limits for relat

ive shaft vibration (peak-peak)

15)

Undulations in area of connection

flange, based on ISO7919-3

Normal operation (continuous

operation)

Start and stop operation/reson

ance ranges (temporary)

Mass moment of inertia

of rotor J

v

(around the rotary axis; does not

take flange bolts into account)

Without rotational speed meas

uring system

With rotational speed measuring

system

Proportional mass moment of in

ertia for the transmitter side

(side of the flange with external

centering)

Without rotational speed meas

uring system

With rotational speed measuring

system

Permissible eccentricity of the ro

tor (radially) to the center point of

the stator (without rotational speed

measuring system)

mm <0.5 <0.7

G 6.3

μm

μm

kg⋅m

kg⋅m

% of J

% of J

s

(p*p)

s

(p*p)

2

0.20 0.46 0.75

2

0.22 0.51 0.81

28 23 26

v

37 30 32

v

+

+

9000

Ǹ

n

13200

Ǹ

n

(n in rpm)

(n in rpm)

mm " 2

807060504030252015kNVm

T40FM A3276-11.0 HBM: public 71

Page 74

Order numbers, Accessories

Nominal (rated) torque M

Permissible axial displacement

nom

mm " 2

between rotor and stator (without ro

tational speed measuring system)

16)

Weight

Rotor without speed measuring

kg 18 28 39

system

Rotor with rotational speed

kg 20 32 42

measuring system

Stator kg 1.8 2.1 3.0

1)

Output signal range in which there is a repeatable correlation between torque and output signal.

2)

Output signal range in which there is a repeatable correlation between torque and output signal.

3)

Signal frequency range 0.1 to 10kHz.

4)

At nominal (rated) conditions.

5)

The pulse tolerance improves with reduced distance and vice versa.

6)

The data refers only to a central axial alignment. Deviations lead to a change in pulse tolerance.

7)

Note the necessary termination resistances as per RS-422.

8)

Heat conductance via the stator base plate necessary over 70°C. The temperature of the base

plate must not exceed 85°C.

9)

At nominal (rated) conditions.

10)

The data refers only to a central axial alignment. Deviations lead to a change in pulse tolerance.

11)

Each type of irregular stress (bending moment, lateral or longitudinal force, exceeding nominal

(rated) torque) can only be permitted up to its specified limit, provided none of the others can

occur at the same time. If this condition is not met, the limit values must be reduced. If 30% of

the limit bending moment and lateral limit force occur at the same time, only 40% of the

longitudinal limit force is permissible and the nominal (rated) torque must not be exceeded. The

effects of permissible bending moments, longitudinal and lateral forces on the measurement

result are ≤±1% of the nominal (rated) torque. The load limits only apply for the nominal (rated)

temperature range. At temperatures <10°C, the load limits must be reduced by approx. 30%

(strength reduction).

12)

The data refer to static loading of the measuring body; note the bolted connection!

13)

The nominal (rated) torque must not be exceeded.

14)

The antenna ring and connector plug must be fixed.

15)

The influence of radial run-out deviations, eccentricity, defects of form, notches, marks, local

residual magnetism, structural inhomogeneity or material anomalies needs to be taken into

account and isolated from the actual undulation.

16)

Above the nominal (rated) temperature range ±1.5 mm.

807060504030252015kNVm

72 A3276-11.0 HBM: public T40FM

Page 75

Supplementary Technical Information

15 Supplementary Technical Information

Axial and radial run-out tolerances

0.02 AB

0.02 AB

Internal centering

Flange B

Flange A

Hardness 47 ±2 HRC

0.8

Surface quality of the axial and radial run-out tolerances (A, B and

AB)

0.02

AB

A

To ensure that the torque flange retains its characteristics once it is installed,

we recommend that the customer also chooses the specified form and position

tolerances, surface quality and hardness for the connections provided.

T40FM A3276-11.0 HBM: public 73

Page 76

Supplementary Technical Information

74 A3276-11.0 HBM: public T40FM

Page 77

Mounting Instructions | Montageanleitung

English Deutsch

T40FM

Page 78

Deutsch

1 Sicherheitshinweise 4......................................

2 Verwendete Kennzeichnungen 11.............................

2.1 Auf dem Aufnehmer angebrachte Symbole 11....................

2.2 In dieser Anleitung verwendete Kennzeichnungen 12..............

3 Anwendung 13..............................................

4 Aufbau und Wirkungsweise 14...............................

5 Mechanischer Einbau 16.....................................

5.1 Wichtige Vorkehrungen beim Einbau 16.........................

5.2 Bedingungen am Einbauort 17..................................

5.3 Einbaulage 17................................................

5.4 Einbaumöglichkeiten 18.......................................

5.4.1 Einbau mit nicht demontiertem Antennenring 19..................

5.4.2 Einbau mit nachträglicher Montage des Antennenrings 20..........

5.5 Rotormontage vorbereiten 21...................................

5.6 Montage des Rotors 24........................................

5.7 Montage des Stators 27.......................................

5.8 Montage des Drehzahlflansches (nur Drehzahlmesssystem) 33.....

6 Elektrischer Anschluss 35....................................

6.1 Allgemeine Hinweise 35.......................................

6.2 EMV‐Schutz 35...............................................

6.3 Steckerbelegung 36...........................................

6.4 Versorgungsspannung 43......................................

7 Shuntsignal 45..............................................

8 Funktionsprüfung 46........................................

8.1 Rotorstatus, LED A (obere LED) 46.............................

8.2 Statorstatus, LED B (untere LED) 48............................

2 A3276-11.0 HBM: public T40FM

Page 79

9 Belastbarkeit 49.............................................

10 Wartung 50..................................................

11 Entsorgung und Umweltschutz 51............................

12 Abmessungen 52............................................

12.1 T40FM ohne Drehzahlmessung, Option Option 6, Code 0 52.......

12.1.1 T40FM 15kNm - 25kNm 52...................................