Page 1

Mounting Instructions

Montageanleitung

Torque flange

Drehmoment‐Messflansch

T40B

A3452-5.0 en/de

Page 2

English Page 3 - 43.................................................

Deutsch Seite 45 - 85...............................................

Dimensions/Abmessungen Page/Seite 87 - 1 16......................

Page 3

T40B

3

Contents Page

English

Safety instructions 5..............................................

1 Markings used 8...............................................

1.1 Symbols on the transducer 8................................

1.2 The markings used in this document 8........................

2 Application 9..................................................

3 Structure and mode of operation 10..............................

4 Mechanical installation 13.......................................

4.1 Important precautions during installation 13....................

4.2 Conditions on site 14........................................

4.3 Installation orientation 14....................................

4.4 Installation options 14.......................................

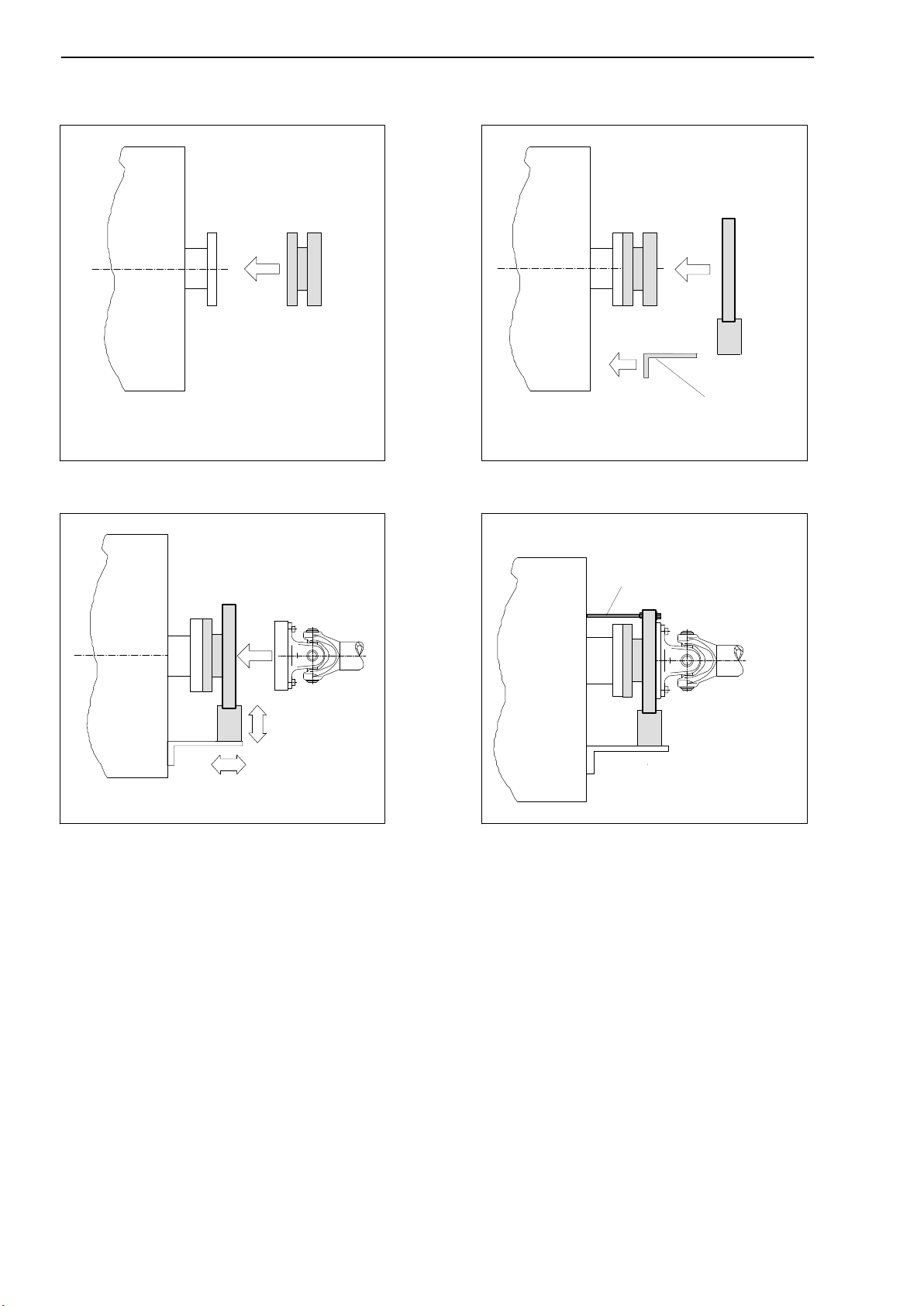

4.4.1 Installation without dismantling the antenna ring 15........

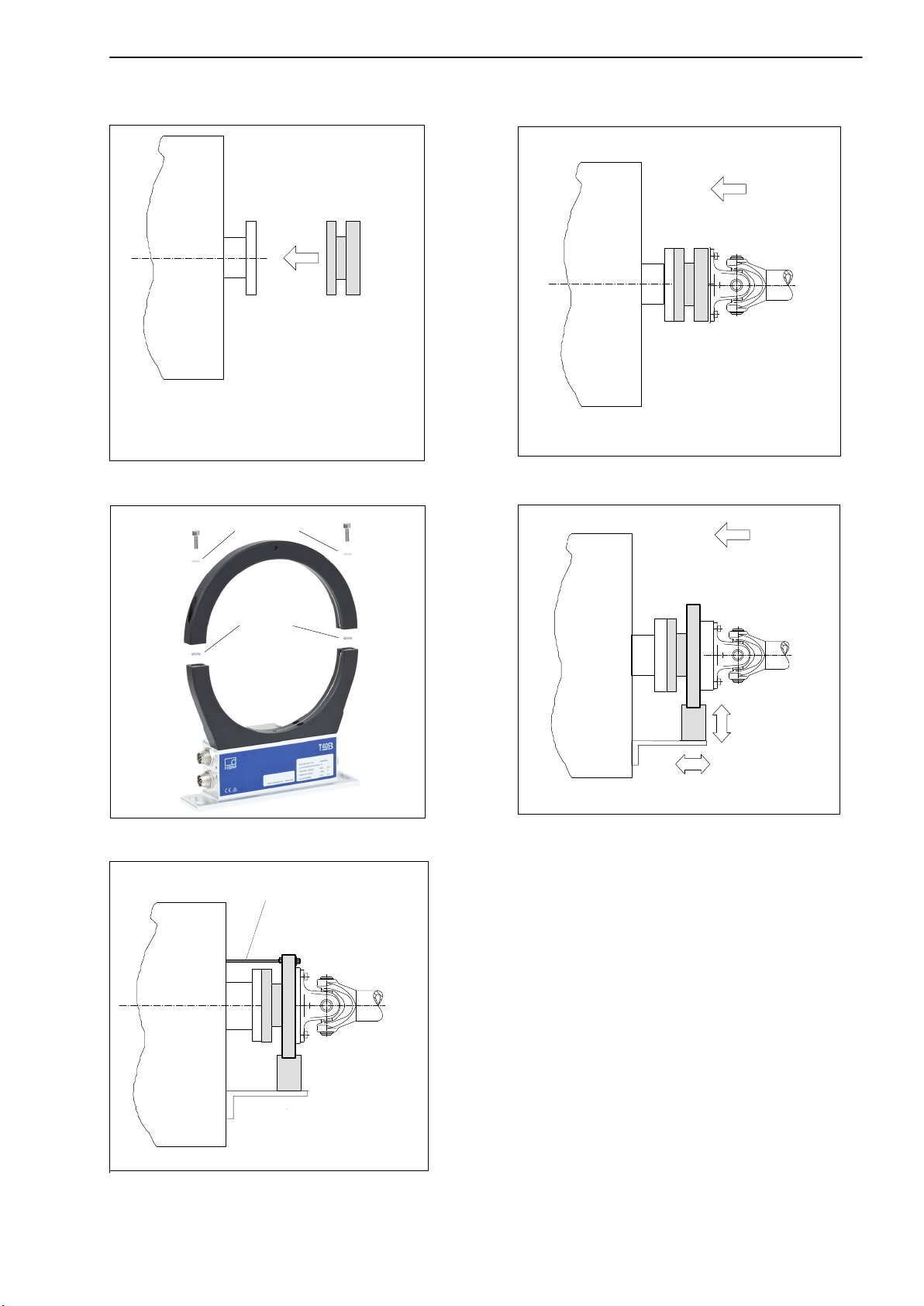

4.4.2 Installation with subsequent stator mounting 16...........

4.5 Mounting the rotor 17.......................................

4.6 Installing the stator 19.......................................

4.7 Rotational speed measuring system, reference signal (optional) 24

5 Electrical connection 26.........................................

5.1 General information 26......................................

5.2 EMC protection 26..........................................

5.3 Connector pin assignment 27................................

5.4 Supply voltage 30..........................................

6 Shunt signal 31.................................................

7 Functional testing 32............................................

7.1 Rotor status, LED A (upper LED) 32..........................

7.2 Stator status, LED B (lower LED) 33..........................

8 Load‐carrying capacity 34.......................................

9 Maintenance 35.................................................

10 Waste disposal and environmental protection 35..................

11 Ordering numbers, accessories 36...............................

12 Specifications 37...............................................

13 Supplementary technical information 44..........................

A3452-5.0 en/de HBM

Page 4

4

T40B

Safety instructions

Appropriate use

The T40B torque flange is used exclusively for torque, angle of rotation and

power measurement tasks within the load limits stipulated in the specifications. Any other use is not the designated use.

Stator operation is only permitted when the rotor is installed.

The torque flange may only be installed by qualified personnel in compliance

with the specifications and with the safety requirements and regulations of

these mounting instructions. It is also essential to observe the applicable legal

and safety regulations for the application concerned. The same applies to the

use of accessories.

The torque flange is not intended for use as a safety component. Please also

refer to the section: “Additional safety precautions". Proper and safe operation

requires proper transportation, correct storage, siting and mounting, and careful operation.

Load‐carrying capacity limits

The data in the technical data sheets must be complied with when using the

torque flange. In particular, the respective maximum loads specified must

never be exceeded. The values stated in the specificationsmust not be

exceeded, for example, for

limit torque,

longitudinal limit force, lateral limit force or limit bending moment,

torque oscillation width,

breaking torque,

temperature limits,

the limits of the electrical load‐carrying capacity.

Use as a machine element

The torque flange can be used as a machine element. When used in this

manner, it must be noted that, to favor greater sensitivity, the transducer is not

designed with the safety factors usual in mechanical engineering. Please refer

here to the section “Load‐carrying capacity limits" and to the specifications.

Accident prevention

According to the prevailing accident prevention regulations, once the transducers have been mounted, a covering agent or cladding has to be fitted as

follows:

The covering agent or cladding must not be free to rotate.

A3452-5.0 en/deHBM

Page 5

T40B

5

The covering agent or cladding should prevent squeezing or shearing and

provide protection against parts that might come loose.

Covering agents and cladding must be positioned at a suitable distance or

be so arranged that there is no access to any moving parts within.

Covering agents and cladding must still be attached even if the moving

parts of the torque flange are installed outside people's movement and

working range.

The only permitted exceptions to the above requirements are if the torque

flange is already fully protected by the design of the machine or by existing

safety precautions.

Additional safety precautions

The torque flange cannot (as a passive transducer) implement any (safety‐rel

evant) cutoffs. This requires additional components and constructive measures for which the installer and operator of the plant is responsible. The layout

of the electronics conditioning the measurement signal should be such that

measurement signal failure does not cause damage.

The scope of supply and performance of the transducer covers only a small

area of torque measurement technology. In addition, equipment planners,

installers and operators should plan, implement and respond to safety engineering considerations in such a way as to minimize residual dangers. Pertinent national and local regulations must be complied with.

General dangers of failing to follow the safety instructions

The torque flange corresponds to the state of the art and is fail‐safe. Transducers can give rise to residual dangers if they are incorrectly operated or

inappropriately mounted, installed and operated by untrained personnel.

Every person involved with siting, starting‐up, operating or repairing a torque

flange must have read and understood the mounting instructions and in particular the technical safety instructions. The transducers can be damaged or

destroyed by non‐designated use of the transducer or by non‐compliance with

the mounting and operating instructions, these safety instructions or any other

applicable safety regulations (BG safety and accident prevention regulations),

when using the transducers. Transducers can break, particularly in the case of

overloading. The breakage of a transducer can also cause damage to property or injury to persons in the vicinity of the transducer.

If the torque flange is not used according to the designated use, or if the

safety instructions or specifications in the mounting and operating instructions

are ignored, it is also possible that the transducer may fail or malfunction, with

the result that persons or property may be adversely affected (due to the

torques acting on or being monitored by the torque flange).

A3452-5.0 en/de HBM

Page 6

6

T40B

Conversions and modifications

The transducer must not be modified from the design or safety engineering

point of view except with our express agreement. Any modification shall

exclude all liability on our part for any damage resulting therefrom.

Selling on

If the torque flange is sold on, these mounting instructions must be included

with the torque flange.

Qualified personnel

Qualified personnel means persons entrusted with siting, mounting, starting‐

up and operating the product, who possess the appropriate qualifications for

their function.

This includes people who meet at least one of the three following requirements:

- Knowledge of the safety concepts of automation technology is a requirement and as project personnel, you must be familiar with these concepts.

- As automation plant operating personnel, you have been instructed how to

handle the machinery. You are familiar with the operation of the equipment

and technologies described in this documentation.

- As system startup engineers or service engineers, you have successfully

completed the training to qualify you to repair the automation systems. You

are also authorized to activate, ground and label circuits and equipment in

accordance with safety engineering standards.

A3452-5.0 en/deHBM

Page 7

T40B

1 Markings used

1.1 Symbols on the transducer

Symbol:

Meaning: Read and note the data in this manual

7

Symbol:

Meaning: CE mark

The CE mark enables the manufacturer to guarantee that the product complies with the requirements of the relevant EC directives (the Declaration of

Conformity can be found on the HBM website at www.hbm.com under

HBMdoc).

1.2 The markings used in this document

Important instructions for your safety are specifically identified. It is essential

to follow these instructions in order to prevent accidents and damage to property.

Symbol Significance

This marking warns of a potentially

dangerous situation in which failure to

comply with safety requirements can result

in death or serious physical injury.

This marking warns of a potentially

CAUTION

NOTE

Important

Tip

A3452-5.0 en/de HBM

dangerous situation in which failure to

comply with safety requirements can result

in slight or moderate physical injury.

This marking draws your attention to a

situation in which failure to comply with

safety requirements can lead to damage to

property.

This marking draws your attention to

important information about the product or

about handling the product.

This marking indicates application tips or

other information that is useful to you.

Page 8

8

SignificanceSymbol

This marking draws your attention to

information about the product or about

handling the product.

Emphasis Italics are used to emphasize and highlight

texts.

T40B

2 Application

The T40B torque flange measures static and dynamic torques on stationary

and rotating shafts. Test beds can be extremely compact because of the short

construction of the transducer. This offers a very wide range of applications.

The T40B torque flange is reliably protected against electromagnetic interference. It has been tested with regard to EMC according to the relevant

European standards, and carries the CE mark.

A3452-5.0 en/deHBM

Page 9

T40B

9

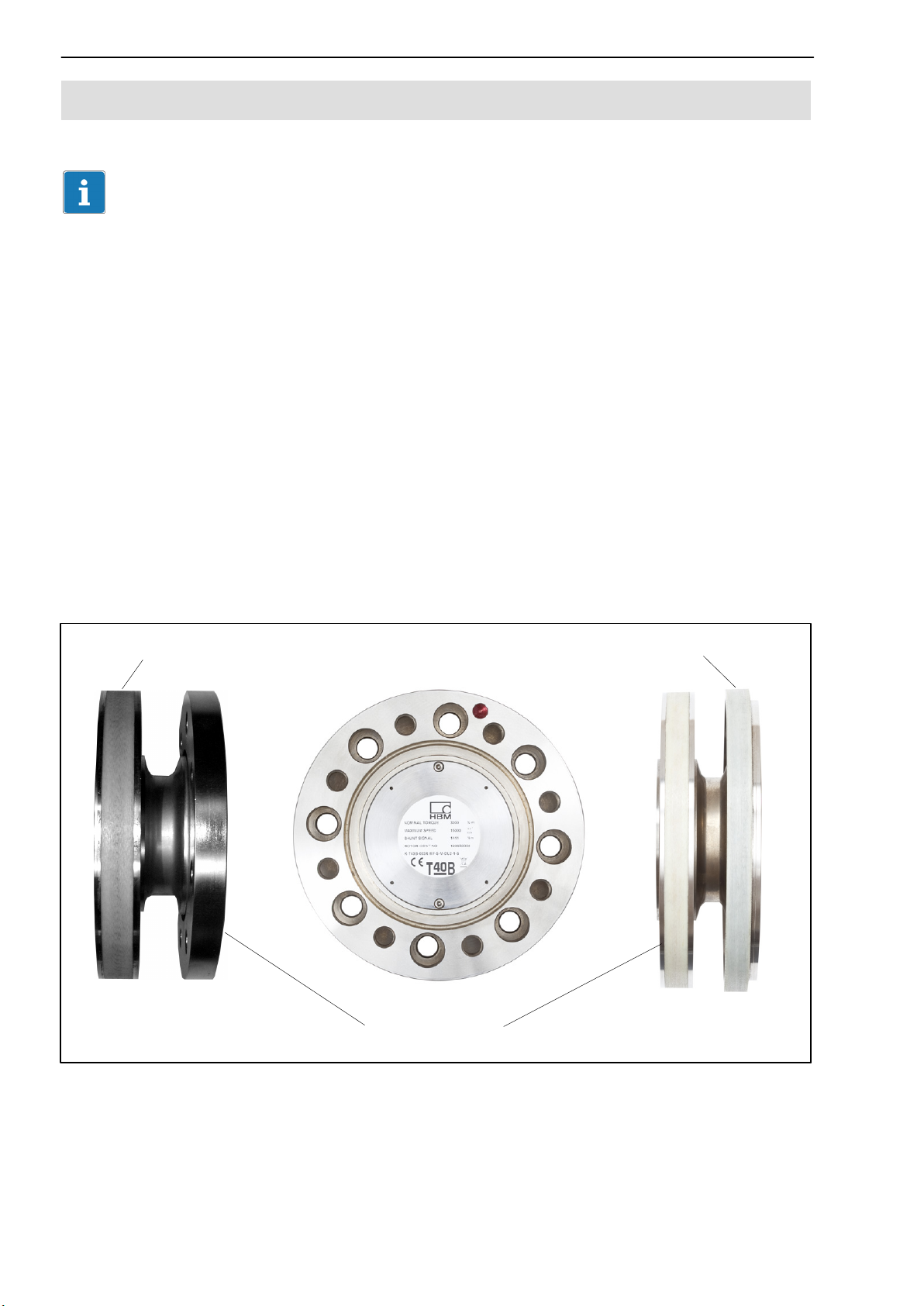

3 Structure and mode of operation

The torque flange consists of two separate parts: the rotor and the stator. The

rotor comprises the measuring body and the signal transmission elements.

Strain gauges (SGs) are installed on the measuring body. The rotor electronics for transmitting the bridge excitation voltage and the measurement signal

are located centrally in the flange. The transmitter coils for contactless transmission of excitation voltage and measurement signal are located on the

measuring body's outer circumference. The signals are sent and received by

a separable antenna ring. The antenna ring is mounted on a housing that contains the electronics for voltage adaptation and the signal conditioning.

Connector plugs for the torque and speed signals, the voltage supply and

digital output, are located on the stator. The antenna segments (ring) should

be mounted more or less concentrically around the rotor (see chapter 4).

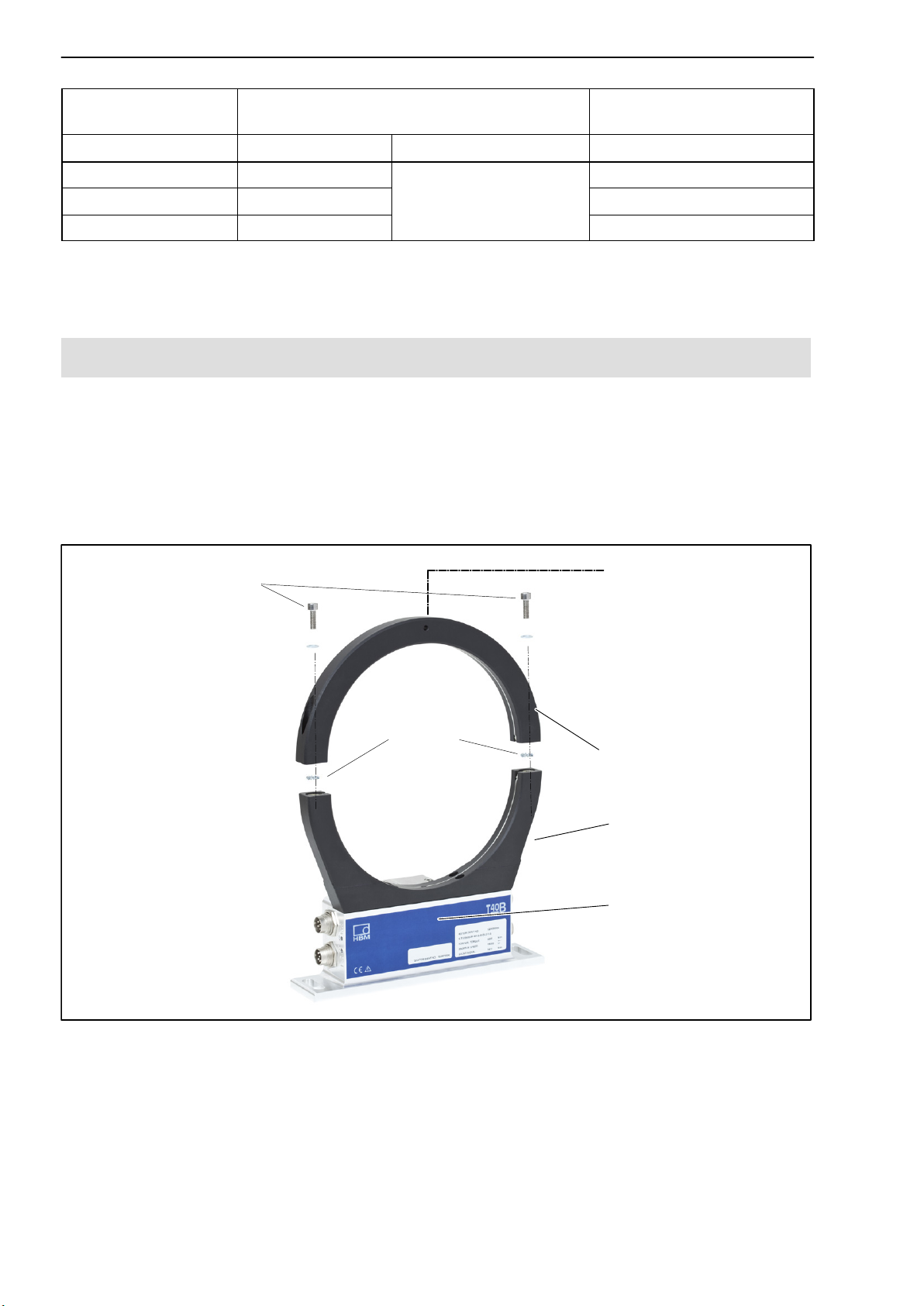

Connector plugs

Antenna segments

Rotor

Connector plugs

Stator housing

Type plate

Fig. 3.1: Mechanical construction without a rotational speed measuring system

The speed sensor is mounted on the stator in Option 6 with a rotational speed

measuring system. The rotational speed is measured magnetically via an

AMR sensor and a magnetic ring. The magnetic ring for measurement of rotational speed is welded to the flange.

A3452-5.0 en/de HBM

Page 10

10

Antenna segments

Magnetic ring for measuring

rotational speed

Sensor head for measuring

rotational speed

Connector plugs

T40B

Rotor

Connector plugs

Stator housing

Type plate

Fig. 3.2: Mechanical construction with a rotational speed measuring system

In the version with a rotational speed measuring system, the transducer can

also be fitted with a sensor head for a reference signal (zero index) for measuring the angle of rotation. The magnet to be used for this is located on the

inner surface of the flange. The sensor head for sampling the reference signal

is located in the bracket above the speed sensor.

A3452-5.0 en/deHBM

Page 11

T40B

Sensor head for measuring

rotational speed

Connector plugs

Stator housing

11

Rotor

Antenna segments

Magnetic ring for

measuring rotational

speed

Sensor head for

the reference

signal

Connector plugs

Type plate

Fig. 3.3: Mechanical construction with rotational speed measuring system and

sensor for the reference signal (zero index)

A3452-5.0 en/de HBM

Page 12

12

T40B

4 Mechanical installation

4.1 Important precautions during installation

NOTE

A torque flange is a precision measuring element and therefore needs careful

handling. Dropping or knocking the transducer may cause permanent damage. Make sure that the transducer cannot be overloaded, even while it is

being mounted.

Handle the transducer with care.

Check the effect of bending moments, critical rotational speeds and natural

torsional vibrations, to prevent the transducer being overloaded by

resonance sharpness.

Make sure that the transducer cannot be overloaded.

WARNING

There is a danger of the transducer breaking if it is overloaded. This can

cause danger for the operating personnel of the system in which the

transducer is installed.

Implement appropriate safety measures to avoid overloads and to protect

against resulting dangers.

If alternating loads are expected, use threadlocker (medium strength, e.g.

LOCTITE No. 242) to glue the screws into the counter thread to exclude

prestressing loss due to screw slackening.

Comply with the mounting dimensions to enable correct operation.

An appropriate shaft flange enables the T40B torque flange to be mounted dir-

ectly. It is also possible to mount a joint shaft or relevant compensating element directly on the rotor (using an intermediate flange when required). Under

no circumstances should the permissible limits specified for bending

moments, lateral and longitudinal forces be exceeded. Due to the T40B

torque flange's high torsional stiffness, dynamic shaft train changes are kept

to a minimum.

A3452-5.0 en/deHBM

Page 13

T40B

13

Important

Even if the unit is installed correctly, the zero point adjustment made at the

factory can shift by up to approx. 2% of the sensitivity. If this value is

exceeded, we advise you to check the mounting conditions. If the residual

zero offset when the unit is removed is greater than 1% of the sensitivity,

please send the transducer back to the Darmstadt factory for testing.

4.2 Conditions on site

The T40B torque flange must be protected against coarse dirt particles, dust,

oil, solvents and humidity.

There is wide ranging compensation for the effects of temperature on the output and zero signals of the transducer (see “Specifications" section). If there

are no static temperature ratios, for example, because of the temperature differences between the measuring body and the flange, the values given in the

specifications can be exceeded. In this case, ensure static temperature ratios

by cooling or heating, depending on the application. As an alternative, check if

thermal decoupling is possible, e.g. by means of heat radiating elements such

as multiple disc couplings.

4.3 Installation orientation

The torque flange can be installed with any orientation.

With clockwise torque, the output frequency is 60 90 kHz for Option 5,

Code DU2 (Option 5, Code SU2: 10 15 kHz; Option HU2: 240 360kHz).

In conjunction with HBM amplifiers or when using the voltage output, a positive output signal (0 V +10 V) is present. In the case of the rotational speed

measuring system, an arrow is attached to the stator housing to clearly define

the direction of rotation. If the measurement flange turns in the direction of the

arrow, connected HBM measuring amplifiers deliver a positive output signal.

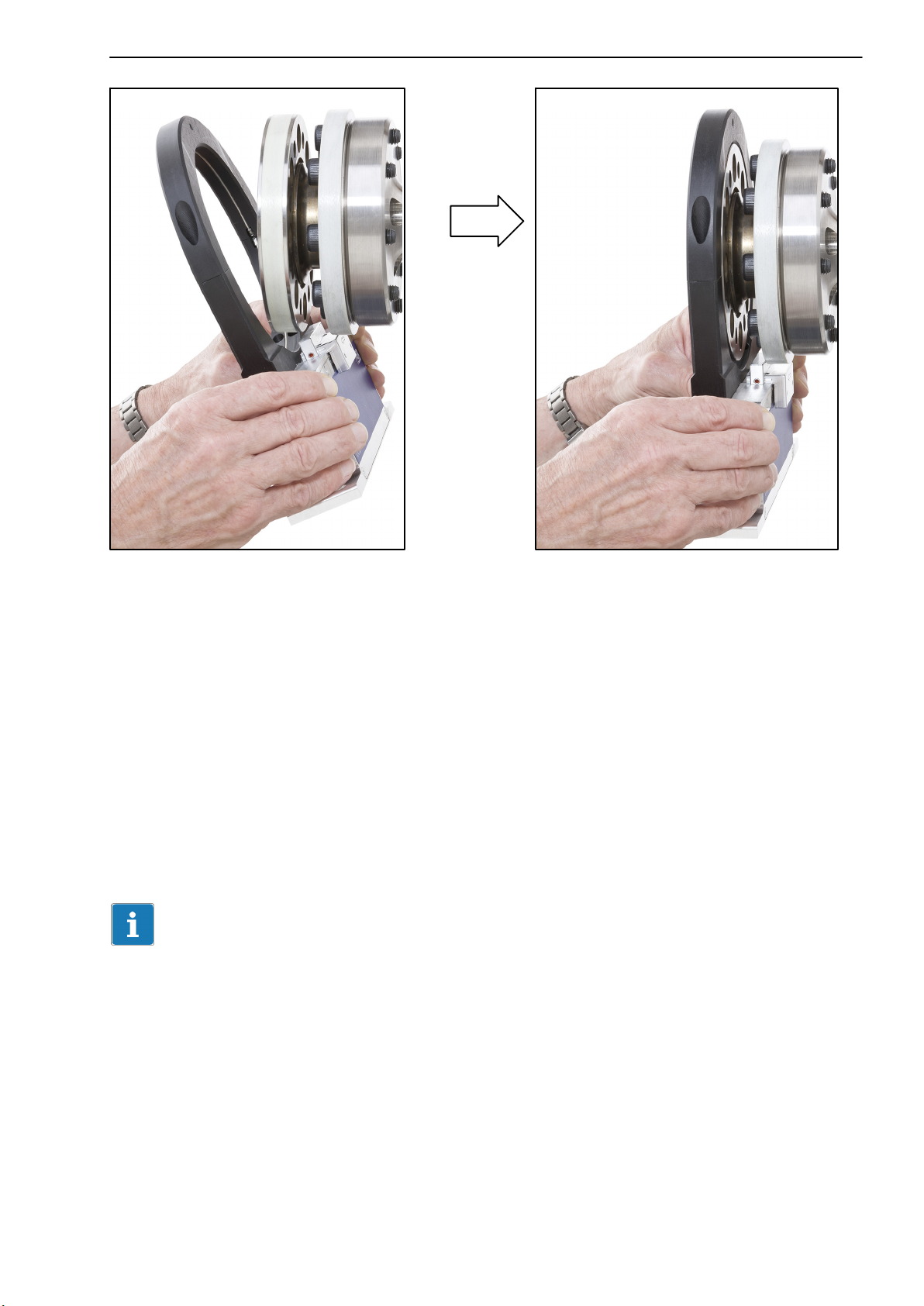

4.4 Installation options

There are basically two options for mounting the torque flange: with or without

dismantling the antenna ring. We recommend mounting as described in

Chapter 4.4.1. If mounting in accordance with Chapter 4.4.1 is not possible,

(e.g. in the case of subsequent stator replacement), you will have to dismantle

the antenna ring. It is essential in this case to comply with the notes on

assembling the antenna segments (see Chapter 4.4.2).

A3452-5.0 en/de HBM

Page 14

14

4.4.1 Installation without dismantling the antenna ring

T40B

1. Install rotor

3. Finish installation of shaft run

2. Install stator

4. Mount support

Customer

Support supplied by customer

mounting

A3452-5.0 en/deHBM

Page 15

T40B

4.4.2 Installation with subsequent stator mounting

15

1. Install rotor

Washers

Fan‐type lock

washers

3. Dismantle antenna segment

Support supplied by customer

2. Install shaft train

4. Install antenna segment

4. Mount support

A3452-5.0 en/de HBM

Page 16

16

T40B

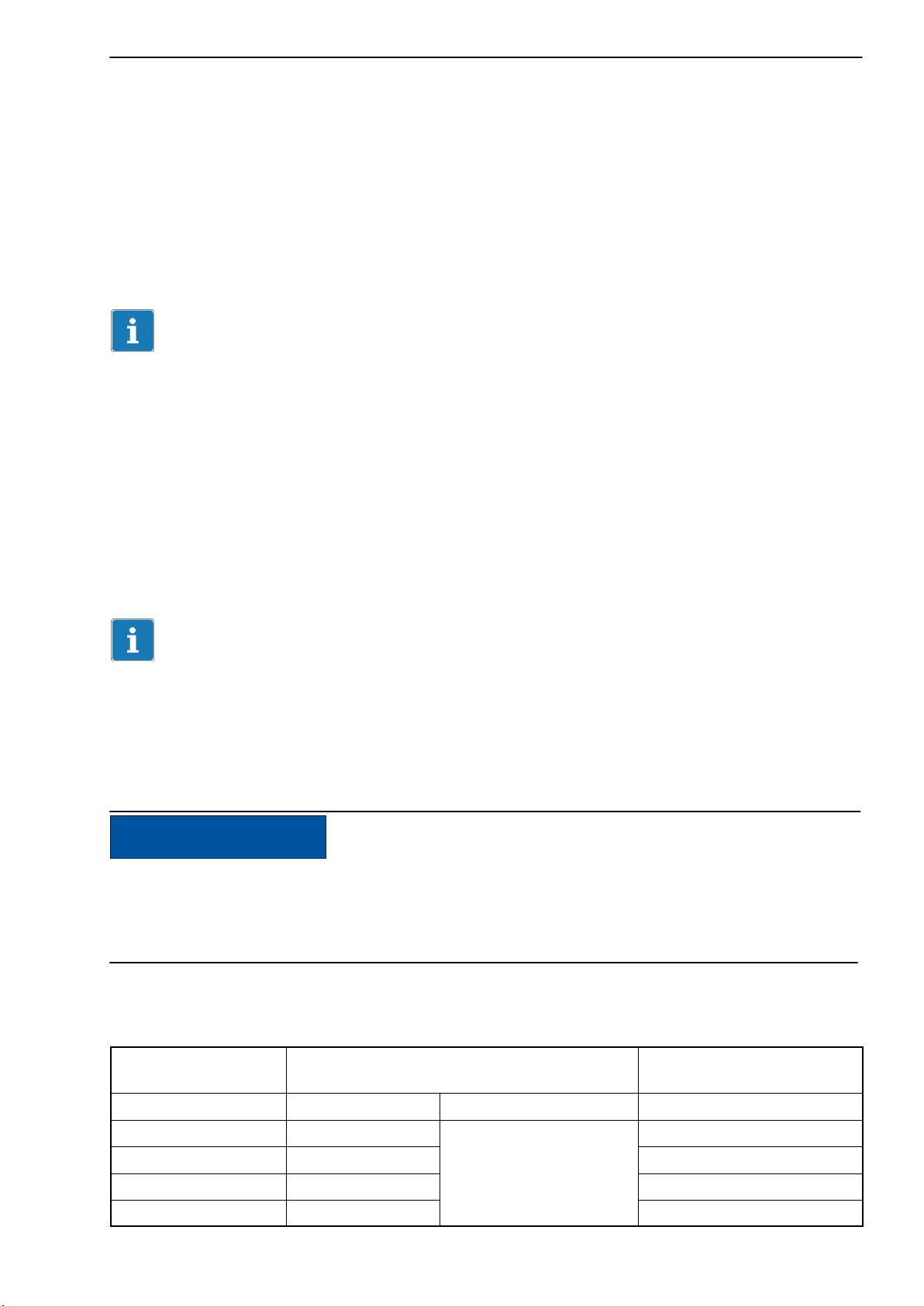

4.5 Mounting the rotor

Tip

Usually the rotor type plate is no longer visible after installation. This is why

we include with the rotor additional stickers with the important characteristics,

which you can attach to the stator or any other relevant test‐bench components. You can then refer to them whenever there is anything you wish to know,

such as the shunt signal. To explicitly assign the data, the identification number and the size are engraved on the rotor flange, where they can be seen

from outside.

1. Prior to installation, clean the plane faces of the transducer flange and the

counter flange.

For safe torque transfer, the faces must be clean and free from grease.

Use a piece of cloth or paper soaked in solvent. When cleaning, make sure

that you do not damage the transmitter winding or the rotational speed

measuring system.

Transmitter winding

Rotational speed measuring system

Without rotational speed

measuring system

Fig. 4.1: Bolted rotor connection

Flange plane faces

With rotational speed

measuring system

A3452-5.0 en/deHBM

Page 17

T40B

17

2. For the bolted rotor connection (see Fig. 4.1), use six or eight DIN EN ISO

4762 hexagon socket screws of the property class stated in Table 4.1, in a

suitable length (dependent on the connection geometry, see Table 4.1 on

page 18).

We recommend DIN EN ISO 4762 socket head cap screws, blackened,

smooth‐headed, permitted size and shape variance in accordance with DIN

ISO 4759, Part 1, product class A.

Important

If alternating loads are expected, use threadlocker (medium strength, e.g.

LOCTITE No. 242) to glue the screws into the counter thread to exclude

prestressing loss due to screw slackening.

3. Fasten all screws with the specified torque (Table 4.1 on page 18).

4. There are eight tapped holes on the rotor for the further mounting of the

shaft run. Also use screws of property class 10.9 or 12.9 and fasten them

with the torque specified in Table 4.1.

Important

If alternating loads are expected, use threadlocker (medium strength, e.g.

LOCTITE No. 242) to glue the screws into the counter thread to exclude

prestressing loss due to screw slackening.

NOTE

Comply with the maximum thread reach as per Table 4.1. Otherwise significant measurement errors may result from torque shunt, or the transducer may

be damaged.

Measuring range Fastening bolts Prescribed tightening

moment

NVm Z

200 M8

500 M10 67

1 k M10 67

2 k M12 115

A3452-5.0 en/de HBM

1)

Property class NVm

34

10.9

Page 18

18

T40B

Measuring range Prescribed tightening

NVmNVmProperty classZ

3 k M12

5 k M14 220

10 k M16 340

Fastening bolts

moment

1)

135

12.9

Table 4.1: Fastening bolts

1)

DIN EN ISO 4762; black/oiled/m

= 0.125

tot

4.6 Installing the stator

On delivery, the stator has already been installed and is ready for operation.

The upper antenna segment can be separated from the stator, for example,

for maintenance or to facilitate stator mounting.

If your application does not require the stator to be dismantled, proceed as

described in points 2, 5, and 6.

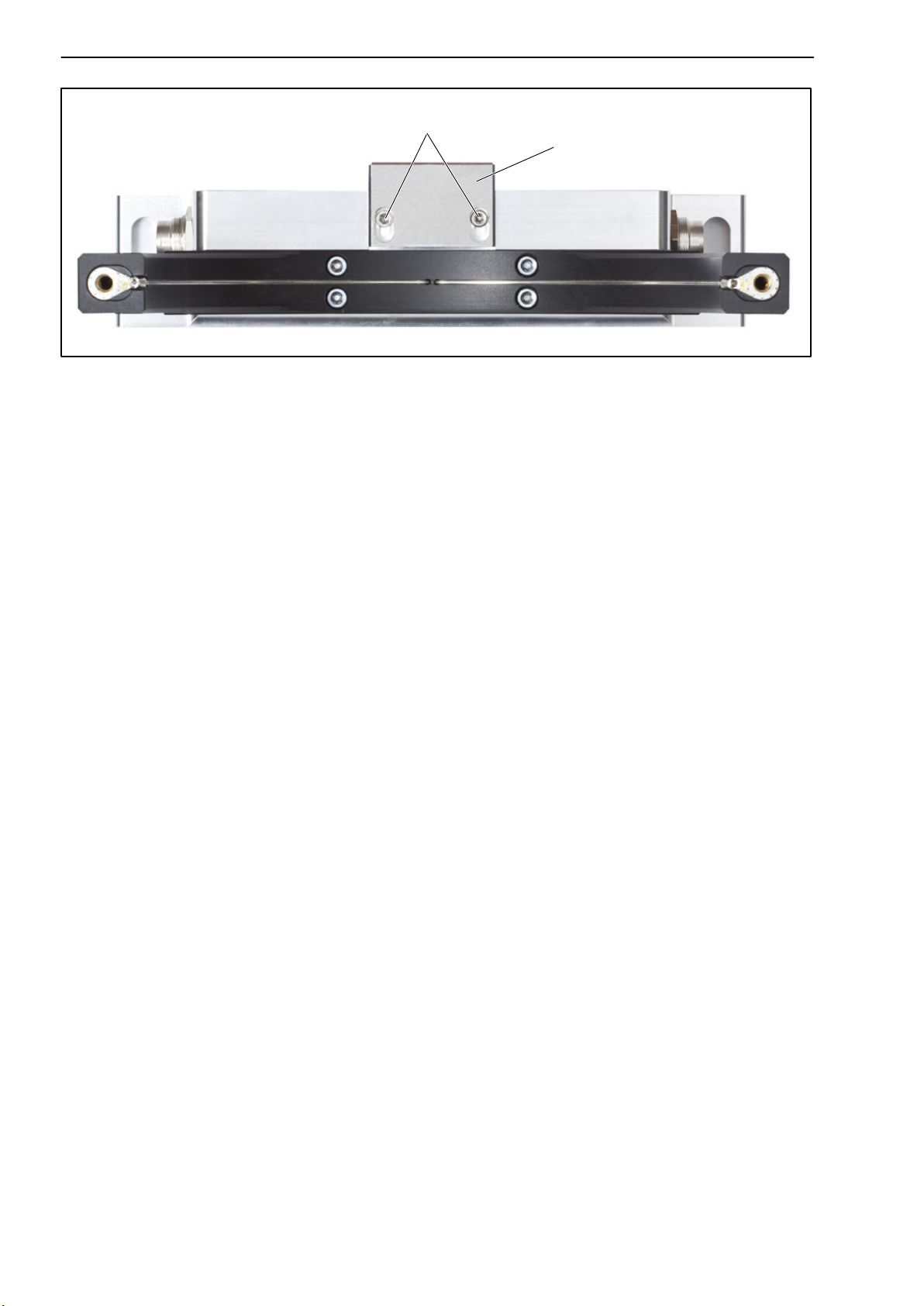

Antenna segment bolts

with washers (M5)

Fan‐type lock washers

Hole for fixing the

antenna segment,

diameter 4.2 or

5.2mm, depending

on maximum

capacity

upper

antenna segments

lower

Stator housing

Fig. 4.2: Bolted connection of the antenna segments on the stator

A3452-5.0 en/deHBM

Page 19

T40B

19

T40B without a rotational speed measuring system

T40B with a rotational speed measuring system

Sensor head for measuring rotational speed

Stator housing

Antenna wire

Lower antenna segment

Fig. 4.3: Stator housing and lower antenna segment with antenna wire

1. Undo and remove the bolted connections (M5) on the upper antenna segment.

There are fan‐type lock washers between the antenna segments: make

sure that they do not get lost.

2. Use an appropriate mounting base to install the stator housing in the shaft

train so that there is sufficient opportunity for horizontal and vertical adjustments. Do not fully tighten the bolts yet.

3. Now use two hexagon socket screws to mount the upper antenna segment

removed in Point 1 on the lower antenna segment.

Make sure that the two fan‐type lock washers are inserted between the antenna

segments (these ensure that there is a defined contact resistance)!

Important

To make sure that they function perfectly, the fan‐type lock washers (A5,

3-FST DIN 6798 ZN/galvanized) must be replaced after the bolted antenna

connection has been loosened three times.

4. Now tighten all antenna‐segment bolted connections with a tightening

torque of 5 Nm.

A3452-5.0 en/de HBM

Page 20

20

T40B

5. Rotational speed measurement without a sensor for the reference signal

(zero index):

Then align the antenna to the rotor in such a way that the antenna

encloses the rotor more or less coaxially and the antenna wire in the

axial direction has the same position as the center of the transmitter

winding on the rotor.

To make this alignment easier, the antenna segment and the transmitter

winding on flange B have the same width. Please comply with the permissible alignment tolerances stated in the specifications.

Fig. 4.4: Alignment of the rotor with the stator (without a reference signal

sensor)

Rotational speed measurement with a sensor for the reference signal (zero

index):

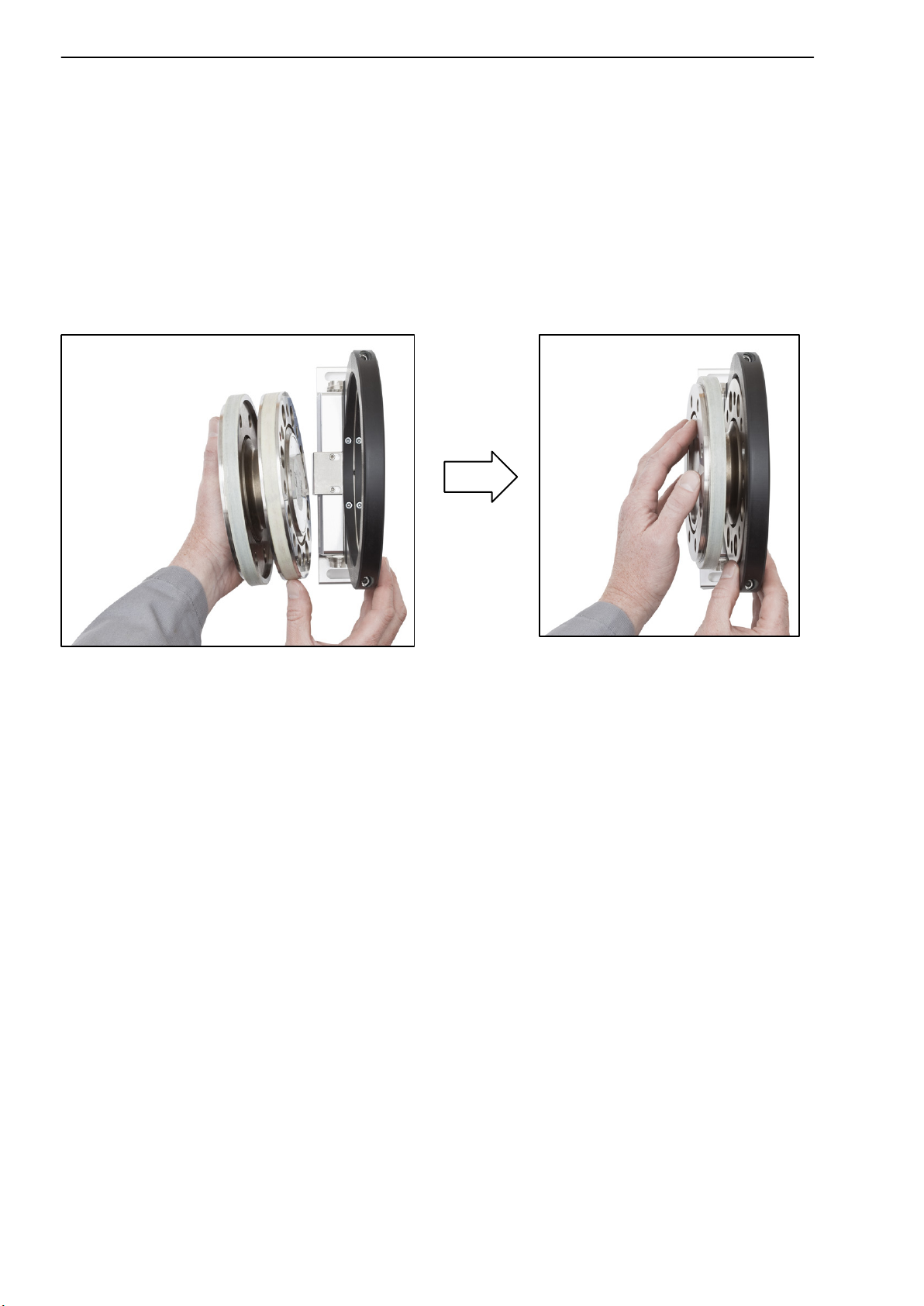

Tilt the stator slightly (see Fig. 4.5, left), so that the bracket with the

sensor head for the reference signal (zero index) is between the two

flanges. Now tip the stator over the rotor until the antenna ring completely covers the flange with the transmitter winding (see Fig. 4.5, right).

A3452-5.0 en/deHBM

Page 21

T40B

21

Fig. 4.5: Alignment of the rotor with the stator (with a reference signal sensor)

6. Now fully tighten the bolted stator housing connection.

Prevention of stator axial oscillation

Depending on the operating conditions, the stator may be induced to oscillate.

This effect is dependent on:

the rotational speed,

the antenna diameter (depends in turn on the measuring range),

the design of the machine base.

Important

To prevent this axial oscillation, the antenna ring requires additional support

by the customer. There is a socket (with an M5 internal thread) on the upper

antenna segment, which can be used for a suitable clamping device (see

Fig. 4.6).

If this is the case, the cable plug also needs some support, as shown in the

construction example in Fig. 4.7.

A3452-5.0 en/de HBM

Page 22

22

T40B

Fig. 4.6: Construction example for supporting the antenna ring

Fig. 4.7: Construction example for plug clamps (for two plugs)

A3452-5.0 en/deHBM

Page 23

T40B

23

4.7 Rotational speed measuring system, reference signal (optional)

The optional rotational speed measuring system (also with the additional reference signal and zero index option) is integrated into the transducer at the

factory, so no installation is required.

Magnetic ring for rotational

speed measurement

Sensor head for the

reference signal

Sensor head for rotational

speed measurement

Fig. 4.8: Torque transducer with rotational speed measurement and reference sig-

nal

Rotational speed measuring system sensor head alignment

If the stator is accurately aligned for torque measurement, the rotational

speed measuring system and the sensor for the reference signal (zero index)

are also correctly aligned. So the two Allen screws on the sensor head

(Fig. 4.9) must not be loosened.

Important

You must not change the position of the sensor head.

A3452-5.0 en/de HBM

Page 24

24

Never loosen the screws!

Sensor head for rotational

speed measurement

T40B

Fig. 4.9: Torque transducer with sensor head for rotational speed measurement

A3452-5.0 en/deHBM

Page 25

T40B

25

5 Electrical connection

5.1 General information

With cable extensions, make sure that there is a proper connection with

minimum contact resistance and good insulation.

All cable connectors or swivel nuts must be fully tightened.

Important

Transducer connection cables from HBM with plugs attached are identified in

accordance with their intended purpose (Md or n). When cables are

shortened, inserted into cable ducts or installed in control cabinets, this identification can get lost or become concealed. So the cables must be marked

beforehand, just in case.

5.2 EMC protection

Important

The transducers are EMC‐tested in accordance with EC directives and identified by CE certification. However, you must connect the shield of the connection cable on the shielding electronics enclosure in order to achieve EMC protection for the measuring chain.

Special electronic coding methods are used to protect the purely digital signal

transmission between the transmitter head and the rotor from electromagnetic

interference.

The cable shield is connected with the transducer housing. This encloses the

measurement system (without the rotor) in a Faraday cage when the shield is

laid flat at both ends of the cable. With other connection techniques, an

EMC-proof shield should be applied in the wire area and this shielding should

also be connected extensively (also see HBM Greenline Information, brochure

i1577).

Electrical and magnetic fields often induce interference voltages in the measuring circuit. Therefore:

Use shielded, low‐capacitance measurement cables only (HBM cables ful-

fill both conditions).

Only use plugs that meet EMC guidelines.

A3452-5.0 en/de HBM

Page 26

26

T40B

Do not route the measurement cables parallel to power lines and control cir-

cuits. If this is not possible, protect the measurement cable withsteel conduits,

for example.

Avoid stray fields from transformers, motors and contact switches.

Do not ground the transducer, amplifier and indicator more than once.

Connect all devices in the measuring chain to the same protective earth

conductor.

In the case of interference due to potential differences (compensating cur-

rents), the connection between supply voltage zero and housing ground

must be broken at the amplifier and a potential equalization line established

between the stator housing and the amplifier housing (copper conductor, at

2

least 10 mm

wire cross-section).

Should differences in potential occur between the machine rotor and stator

because of unchecked leakage, for example, this can usually be overcome

by connecting the rotor definitively to ground, e.g. with a wire loop. The

stator must be connected to the same (ground) potential.

5.3 Connector pin assignment

The stator housing has two 7‐pin connectors, an 8‐pin connector and a 1‐pin

connector.

The supply voltage connections and shunt signal connections of connectors 1

and 3 are each electrically interconnected, but are protected against compensating currents by diodes. There is also an automatically resetting fuse

(multifuse) to protect the supply connections against overload by the stator.

A3452-5.0 en/deHBM

Page 27

T40B

Assignment for connector 1:

Supply voltage and frequency output signal.

27

Connector

pin

Device plug

61

5

72

3

4

Top view

1)

RS-422 complementary signals; with cable lengths exceeding 10 m, we recommend

1

2 Supply voltage 0 V; bk 5

3 Supply voltage 18 V 30 V bu 6

4

5

6 Shunt signal trigger 5 V 30 V gn 14

7 Shunt signal 0 V; gy 8

Assignment Color

code

Torque measurement signal

(frequency output; 5 V

Torque measurement signal

(frequency output; 5 V

Measurement signal 0 V;

symmetrical

Shielding connected to housing ground

1),2)

) wh 13

1),2)

) rd 12

gy 8

using a termination resistor R = 120 ohms between the (wh) and (rd) wires.

2)

RS-422: Pin 1 corresponds to A, Pin 4 corresponds to B.

Sub‐D

connector

pin

NOTE

Torque flanges are only intended for operation with a DC supply voltage. They

must not be connected to older HBM amplifiers with square‐wave excitation.

This could destroy the connection board resistors or cause other faults in the

amplifiers.

A3452-5.0 en/de HBM

Page 28

28

Assignment for connector 2:

Rotational speed output signal, reference signal (optional).

T40B

Connector

Assignment

pin

1)

1)

1)

1)

1)

1)

Device plug

2

5

3

4

8

1

6

7

Top view

1

Rotational speed measurement signal

(pulse string, 5 V; 0)

2 Reference signal (1 pulse/revolution, 5V)

3

Rotational speed measurement signal

(pulse string, 5 V; 90phase shifted)

4 Reference signal (1 pulse/revolution, 5V)

5 Not in use

6

7

Rotational speed measurement signal

(pulse string, 5 V; 0)

Rotational speed measurement signal

(pulse string, 5 V; 90phase shifted)

8 Operating voltage zero

Shielding connected to housing ground

1)

RS-422 complementary signals; with cable lengths exceeding 10 m, we recommend

using a termination resistor of R = 120 ohms.

Assignment for connector 3:

Supply voltage and voltage output signal.

Device plug

61

72

5

3

4

Top view

Connector

pin

1 Torque measurement signal (voltage output; 0 V )

2

3 Supply voltage 18 V 30 V DC

4

5 Not in use

6 Shunt signal trigger 5 V 30 V

7 Shunt signal 0 V;

Assignment

Supply voltage 0 V;

Torque measurement signal (voltage output; "10 V)

Shielding connected to housing ground

Assignment for connector 4:

TMC - only for connection to the TIM 40 Torque Interface Module within HBM.

A3452-5.0 en/deHBM

Page 29

T40B

29

5.4 Supply voltage

The transducer must be operated with a separated extra‐low voltage (nominal

(rated) supply voltage 18 30 V

flanges within a test bench at the same time. Should the device be operated

1)

on a DC voltage network

, additional precautions must be taken to discharge

excess voltages.

The information in this section relates to the self‐contained operation of the

T40B, without HBM system solutions.

The supply voltage is electrically isolated from signal outputs and shunt signal

inputs. Connect a separated extra‐low voltage of 18 V 30 V to pin 3 (+) and

). You can supply one or more torque

DC

pin 2 (

) of connectors 1 or 3. We recommend that you use HBM cable KAB

8/00-2/2/2 and the appropriate sockets (see Accessories). The cable can be

up to 50 m long for voltages 24 V, otherwise it can be up to 20 m long.

If the permissible cable length is exceeded, you can supply the voltage in parallel over two connection cables (connectors 1 and 3). This enables you to

double the permissible length. Alternatively, install a power supply on site.

Important

The instant you switch on, a current of up to 4 A may flow and this may switch

off power supplies with electronic current limiters.

1)

Distribution system for electrical energy with greater physical expansion (over several test benches, for

example) that may possibly also supply consumers with high nominal (rated) currents.

A3452-5.0 en/de HBM

Page 30

30

T40B

6 Shunt signal

The T40B torque flange delivers an electrical shunt signal that can be activated from the amplifier in measuring chains with HBM components. The transducer generates a shunt signal of about 50% of the nominal (rated) torque;

the precise value is specified on the type plate. After activation, adjust the

amplifier output signal to the shunt signal supplied by the connected transducer to adapt the amplifier to the transducer.

The transducer should not be under load when the shunt signal is being

measured, as the shunt signal is mixed additively.

Triggering the shunt signal

Applying a separated extra‐low voltage of 5 30 V to pins 6 (+) and 7 (

connector 1 or 3 triggers the shunt signal.

The nominal (rated) voltage for triggering the shunt signal is 5 V (triggering at

U > 2.5 V), but when voltages are less than 0.7 V, the transducer is in measuring mode. The maximum permissible voltage is 30 V, current consumption

at nominal (rated) voltage is approx. 2 mA and at maximum voltage, approx.

18 mA. The voltage for triggering the shunt signal is electrically isolated from

the supply and measuring voltage.

) at

Tip

The shunt signal can be triggered by the amplifier or via the operating software in HBM system solutions.

A3452-5.0 en/deHBM

Page 31

T40B

7 Functional testing

You can check the functionality of the rotor and the stator from the LEDs on

the stator.

LED A, rotor status

LED B, stator status

31

Fig. 7.1: LEDs on the stator housing

7.1 Rotor status, LED A (upper LED)

Color Significance

Green (pulsating) Internal rotor voltage values ok

Rotor and stator mismatched (an increasing flashing

Flashing orange

Pulsating orange

Red (pulsating)

frequency indicates the degree of misalignment)

=> Correct the rotor/stator alignment

Rotor status cannot be defined

=> Correct the rotor/stator alignment

If the LED still pulsates orange, it is possible that there is a

hardware defect. The measurement signals reflect the level of

the defect status.

Rotor voltage values not ok.

=> Correct the rotor/stator alignment

If the LED still pulsates red, it is possible that there is a

hardware defect. The measurement signals reflect the level of

the defect status.

Pulsating means that the LED goes dark for about 20 ms every second (sign

of life), making it possible to detect that the transducer is functioning.

A3452-5.0 en/de HBM

Page 32

32

7.2 Stator status, LED B (lower LED)

Color Significance

T40B

Green

(permanently lit)

Green, intermittently

orange.

Numerous

synchronization defects:

permanently orange

Orange

(permanently lit)

Red

(permanently lit)

Measurement signal transmission and internal stator voltages ok

Orange until end of defective transmission if y5 incorrect

measured values in sequence are transmitted. The

measurement signals reflect the level of the defect status for the

duration of the transmission defect + for approx. another 3.3 ms.

Permanently disrupted transmission, the measurement signals

reflect the level of the defect status. (f

= 0 Hz, U

out

= defect

out

level).

=> Correct the rotor/stator alignment.

Internal stator defect, the measurement signals reflect the

level of the defect status (f

= 0 Hz, U

out

= defect level).

out

A3452-5.0 en/deHBM

Page 33

T40B

33

8 Load‐carrying capacity

Nominal (rated) torque can be exceeded statically up to the limit torque. If the

nominal (rated) torque is exceeded, additional irregular loading is not permissible. This includes longitudinal forces, lateral forces and bending moments.

Limit values can be found in the “Specifications" chapter (Chapter 12,

page

Measuring dynamic torque

The torque flange can be used to measure static and dynamic torque. The following rule applies to the measurement of dynamic torque:

The T40B calibration performed for static measurements is also valid for

36).

dynamic torque measurements.

The natural frequency f

depends on the moments of inertia J

of the mechanical measuring arrangement

0

and J2 of the connected rotating

1

masses and the torsional stiffness of the T40B.

Use the equation below to approximately determine the natural frequency f

the mechanical measuring arrangement:

f0+

1

· cT·

Ǹ

2p

ǒ

f

)

1

Ǔ

J

2

1

J

1

0

J

c

= natural frequency in Hz

J2= mass moment of inertia in kgm

1,

= torsional stiffness in Nm/rad

T

2

The permissible mechanical oscillation width (peak‐to‐peak) can also be

found in the specifications.

Nominal (rated) torque M

+ M

nom

nom

as a %

of

0

Oscillation width

- M

nom

Oscillation width

0

Time t

Oscillation width

200% oscillation width

Fig. 8.1: Permissible dynamic loading

A3452-5.0 en/de HBM

Page 34

34

T40B

9 Maintenance

T40B torque flanges are maintenance‐free.

10 Waste disposal and environmental protection

All electrical and electronic products must be disposed of as hazardous

waste. The correct disposal of old equipment prevents ecological damage and

health hazards.

Symbol:

Meaning: Statutory waste disposal mark

The electrical and electronic devices that bear this symbol are subject to the

European waste electrical and electronic equipment directive 2002/96/EC.

The symbol indicates that, in accordance with national and local environmental protection and material recovery and recycling regulations, old devices

that can no longer be used must be disposed of separately and not with normal household garbage.

As waste disposal regulations may differ from country to country, we ask that

you contact your supplier to determine what type of disposal or recycling is

legally applicable in your country.

Packaging

The original packaging of HBM devices is made from recyclable material and

can be sent for recycling. Store the packaging for at least the duration of the

warranty. In the case of complaints, the torque flange must be returned in the

original packaging.

For ecological reasons, empty packaging should not be returned to us.

A3452-5.0 en/deHBM

Page 35

T40B

11 Ordering numbers, accessories

35

Accessories, to be ordered separately

Article Order no.

Connection cable, set

Torque connection cable, Binder 423 - 15‐pin D-Sub, 6 m 1-KAB149-6

Torque connection cable, Binder 423 - 7‐pin, free ends, 6 m 1-KAB153-6

Rotational speed connection cable, Binder 423 - 15‐pin D-Sub, 6 m 1-KAB150-6

Rotational speed connection cable, Binder 423 - 8‐pin, free ends, 6 m 1-KAB154-6

Rotational speed connection cable, reference signal, Binder 423 - 15‐pin D-Sub, 6 m 1-KAB163-6

Rotational speed connection cable, reference signal, Binder 423 - 8‐pin, free ends, 6 m 1-KAB164-6

TMC connection cable, Binder 423 - 16‐pin, free ends, 6 m 1-KAB174-6

Cable sockets

423G-7S, 7 pin (straight) 3-3101.0247

423W-7S, 7 pin (angle) 3-3312.0281

423G-8S, 8‐pin (straight) 3-3312.0120

423W-8S, 8‐pin (angle) 3-3312.0282

Connection cable, by the meter (min. order quantity: 10 m, price per meter)

Kab8/00-2/2/2 4-3301.0071

A3452-5.0 en/de HBM

Page 36

36

T40B

12 Specifications

Type T40B

Accuracy class 0.05

Torque measuring system

Nominal (rated) torque M

nom

Nominal (rated) rotational speed rpm 20000 15000 12000 10000

Non‐linearity including hysteresis, relative to

the nominal (rated) sensitivity

Frequency output %

Voltage output %

Relative standard deviation of repeatability

per DIN 1319, relative to the variation of the

output signal

Frequency output %

Voltage output %

Temperature effect per 10 K in nominal

(rated) temperature range

on the output signal, relative to the actual

value of the signal spread

Frequency output

Voltage output %

on the zero signal, relative to the nominal

(rated) sensitivity

Frequency output

Voltage output %

Nominal (rated) sensitivity (spread between

torque = zero and nominal (rated) torque)

Freq. output 10kHz / 60kHz / 240kHz

Voltage output

Sensitivity tolerance (deviation of the actual

output quantity at M

from the nominal (rated)

nom

sensitivity)

Output signal at torque = zero

Frequency output kHz 10/60/240

Voltage output V 0

Nominal (rated) output signal

Frequency output

with positive nominal (rated) torque kHz

with negative nominal (rated) torque kHz

Voltage output

with positive nominal (rated) torque V +10

with negative nominal (rated) torque V -10

1)

Option 5, 10"5 kHz (code SU2)

2)

Option 5, 60"30 kHz (code DU2)

3)

Option 5, 240"120 kHz (code HU2)

4)

RS-422 complementary signals, note termination resistor .

Nm 200 500

kNm 1 2 3 5 10

<"0.03

<"0.03

<"0.03

<"0.03

%

"0.05

"0.2

%

"0.05

"0.1

kHz

V

5/30/120

10

"0.1

15

1)

/ 90

2)

/ 360

3)

(5 V symmetrical 4))

1)

5

(5 V symmetrical

/ 30

2)

/ 120 3)

4)

)

A3452-5.0 en/deHBM

Page 37

T40B

37

Nominal (rated) torque M

nom

Nm 200 500

kNm 1 2 3 5 10

Load resistance

Frequency output k 2

Voltage output k 10

Longterm drift over 48 h

Frequency output

%

Voltage output %

Measurement frequency range, -3 dB kHz 11) / 32) / 6

t"0.03

t"0.03

3)

Group delay s t4001) / t2202) / t150

Residual ripple

Voltage output

Maximum modulation range

Frequency output

5)

6)

mV t40

2.5 17.5

kHz

1)

/ 15 105

60 420

3)

Voltage output V -12 +12

Energy supply

Nominal (rated) supply voltage (separated

extra‐low DC voltage)

V 18 30

Current consumption in measuring mode A < 1

Current consumption in startup mode A < 4 (typ. 2) 50 s

Nominal (rated) power consumption W < 10

Maximum cable length m 50

Shunt signal approx. 50 % of M

Tolerance of the shunt signal, relative to

M

nom

Nominal (rated) trigger voltage

Trigger voltage limit

Shunt signal ON

Shunt signal OFF

5)

Signal frequency range 0.1 to 10 kHz

6)

Output signal range in which there is a repeatable correlation between torque and output signal.

%

V

V

V

V

<"0.05

<"0.05

5

36

min. 2.5

max. 0.7

nom

3)

2)

/

A3452-5.0 en/de HBM

Page 38

38

T40B

Rotational speed measuring system

Nominal (rated) torque M

nom

Nm 200 500

kNm 1 2 3 5 10

Measurement system Magnetic, via AMR sensor

(Anisotropic Resistive Effect) and

magnetized plastic ring with

embedded steel ring

Magnetic poles 72 86 108 126 156

Maximum position deviation of the poles

"50 angular seconds

Output signal V 5 V symmetrical (RS-422);

2 square wave signals approx. 90

phase shifted

Pulses per revolution 1024

Minimum rotational speed for sufficient pulse

stability

Pulse tolerance

7)

rpm 0

degrees

<"0.05

Maximum permissible output frequency kHz 420

Group delay s <150

Radial nominal (rated) distance between

sensor head and magnetic ring (mechanical

distance)

mm 1.6

Working distance range between sensor head

and magnetic ring

mm 0.4 2.5

Max. permissible axial displacement of the

rotor to the stator

8)

mm

"1.5

Hysteresis of reversal in the case of relative

vibrations between the rotor and the stator

Torsional vibration of the rotor degrees approx. 0.2

Horizontal stator vibration displacement mm approx. 0.5

Magnetic load limit

Remanent flux density mT 100

Coercive field strength kA/m 100

Permissible magnetic field strength for signal

deviations

Load resistance

7)

At nominal (rated) conditions.

8)

The data refers only to a central axial alignment. Deviations lead to a change in pulse tolerance.

9)

Note the termination resistors required in accordance with RS-422.

9)

kA/m 0.1

k 2

A3452-5.0 en/deHBM

Page 39

T40B

Reference signal measuring system (zero index)

Measurement system Magnetic, via Hall sensor and magnet

Output signal V 5 V symmetrical (RS‐422)

Pulses per revolution 1

Minimum rotational speed for sufficient

pulse stability

Pulse width, approx. degrees 0.088

Pulse tolerance

10)

Group delay s <150

Axial nominal (rated) distance between

sensor head and magnetic ring (mechanical

distance)

Working distance range between sensor

head and magnetic ring

Max. permissible axial displacement of the

rotor to the stator

10)

At nominal (rated) conditions.

11)

The data refers only to a central axial alignment. Deviations lead to a change in pulse tolerance.

11)

rpm 2

degrees

<"0.05

mm 2.0

mm 0.4 2.5

mm

"1.5

39

A3452-5.0 en/de HBM

Page 40

40

General information

Nominal (rated) torque M

nom

EMC

Emission (per EN 61326-1, Section 7)

RFI field strength - Class B

Immunity from interference (EN

61326-1, Table 2)

Electromagnetic field (AM) V/m

Magnetic field A/m

Electrostatic discharge (ESD)

Contact discharge kV

Air discharge kV

Fast sweeps (burst) kV

Impulse voltages (surge) kV

Conducted interference (AM) V

Degree of protection per EN60529 IP 54

Reference temperature C

Nominal (rated) temperature range C

Operating temperature range C

Storage temperature range C

Mechanical shock per

EN60068-2-27

12)

Number n

Duration ms

Acceleration (half sine) m/s

Vibrational stress in 3 directions per

EN60068-2-6

12)

Frequency range Hz 10 2000

Duration h 2.5

Acceleration (amplitude) m/s

Load limits

Limit torque, relative to M

Breaking torque, relative to M

Longitudinal limit force

Lateral limit force

Limit bending moment

13)

15)

15)

15)

nom

14)

nom

14)

Oscillation width per DIN 50100

(peak‐to‐peak)

12)

The antenna ring and connection plug must be fixed in place.

13)

Each type of irregular stress (bending moment, lateral or longitudinal force, exceeding nominal (rated)

torque), can only be permitted up to its specified load limit, provided none of the others can occur at the

same time. If this condition is not met, the limit values must be reduced. If 30% of the limit bending

moment and lateral limit force occur at the same time, only 40% of the longitudinal limit force is permissible and the nominal (rated) torque must not be exceeded. The permissible bending moments, longitudinal forces and lateral forces can affect the measurement result by approx. 0.3% of the nominal (rated)

torque. The load limits only apply for the nominal (rated) temperature range. At temperatures t 10C,

load limits are expected to reduce by up to 30%, because there is an increased reduction in toughness as

temperatures fall.

14)

With static loading.

15)

Static and dynamic.

16)

The nominal (rated) torque must not be exceeded.

16)

Nm 200 500

kNm 1 2 3 5 10

10

100

4

8

1

1

10

23

+10 +70

-20 +85

-40 +85

1000

3

2

2

650

200

% 200 160

% > 400 > 320

kN 10 13 19 30 35 60 80

kN 2 4 5 9 10 12 18

Nm 100 200 220 560 600 800 1200

Nm 400 1000 2000 4000 4800 8000 16000

T40B

A3452-5.0 en/deHBM

Page 41

T40B

Mechanical values

Nominal (rated) torque

M

nom

Torsional stiffness c

Torsion angle at M

T

nom

Stiffness in the axial

direction c

a

Stiffness in the radial

direction c

r

Stiffness with bending

moment round a radial

axis c

b

Maximum deflection at

longitudinal limit force

Additional max. radial

deviation at lateral limit

force

Additional plumb/parallel

deviation at limit bending

moment

(with j d

)

B

Balance quality level per

DIN ISO 1940

Max. limits for relative

shaft vibration

(peak‐to‐peak)

17)

Undulation in the

connection flange area

following ISO 7919-3

Normal operation

(continuous operation)

Start and stop operation/

resonance ranges

(temporary)

Mass moment of inertia

of the rotor J

v

without rotational speed

measuring system

with magn. rotational

speed measuring system

Proportional mass

moment of inertia for the

transmitter side (side of

the flange with external

centering)

without rotational speed

measuring system

with magn. rotational

speed measuring system

17)

The influence of radial deviations, eccentricity, defects of form, notches, marks, local residual magnetism,

structural inhomogeneity or material anomalies needs to be taken into account and isolated from the

actual undulation.

Nm 200 500

kNm 1 2 3 5 10

kNm/rad 360 745 1165 2515 3210 5565 14335

degrees 0.032 0.038 0.049 0.046 0.054 0.051 0.040

kN/mm 540 450 580 540 570 760 960

kN/mm 315 560 860 1365 1680 2080 2940

kNm/

degrees

3.6 4.2 5.9 9 9.3 20.2 45.5

mm <0.04 <0.05 <0.06 <0.08 <0.09

mm <0.02

mm <0.06 <0.11 <0.09 <0.18

<0.19 <0.14 <0.12

G 2.5

m

m

kgm

kgm

% of J

% of J

s

(p p)

s

(p p)

2

0.0017 0.0039 0.0128 0.0292 0.0771

2

0.0022 0.0048 0.0145 0.0146 0.0333 0.0872

62 59 54 53 54

v

48 48 48 47 48

v

+

+

9000

Ǹ

n

13200

Ǹ

n

(n in rpm)

(n in rpm)

41

A3452-5.0 en/de HBM

Page 42

42

T40B

Nominal (rated) torque

M

nom

Nm 200 500

kNm 1 2 3 5 10

Max.permissible static

eccentricity

of the rotor (radially) to the

center point of the stator

without rotational speed

measuring system

mm

Permissible axial

displacement between

rotor and stator

18)

without rotational speed

measuring system

mm

Weight

Rotor without rotational

speed measuring system

Rotor with magn.

kg

1.1

rotational speed

measuring system

Stator

18)

Above the nominal (rated) temperature range: 1.5mm.

kg

kg

1.3

1.1

1.9

2.1

1.1

"2

"2

3.8

4.1

1.1

3.9

4.1

1.1

6.5

6.9

1.2

10.9

11.7

1.3

A3452-5.0 en/deHBM

Page 43

T40B

13 Supplementary technical information

Axial and radial run‐out tolerances

B

Axial run‐out AB

Radial run‐out AB

Internal centering

Hardness 46 to 54 HRC

Surface quality of the axial and radial

0.8

run‐out surfaces (A, B and AB)

Measuring range (NVm) Axial run‐out tolerance (mm) Radial run‐out tolerance

200 0.01 0.01

500 0.01 0.01

1 k 0.01 0.01

2 k 0.02 0.02

3 k 0.02 0.02

5 k 0.02 0.02

10 k 0.02 0.02

A

(mm)

43

To ensure that the torque flange retains its properties once it is installed, we

recommend that the customer also chooses the specified form and position

tolerances, surface quality and hardness for the connections provided.

A3452-5.0 en/de HBM

Page 44

44

T40B

A3452-5.0 en/deHBM

Page 45

T40B

45

Inhalt Seite

Deutsch

Sicherheitshinweise 46.............................................

1 Verwendete Kennzeichnungen 49................................

1.1 Auf dem Aufnehmer angebrachte Symbole 49..................

1.2 In dieser Anleitung verwendete Kennzeichnungen 49............

2 Anwendung 50.................................................

3 Aufbau und Wirkungsweise 51...................................

4 Mechanischer Einbau 54........................................

4.1 Wichtige Vorkehrungen beim Einbau 54.......................

4.2 Bedingungen am Einbauort 55...............................

4.3 Einbaulage 55.............................................

4.4 Einbaumöglichkeiten 55.....................................

4.4.1 Einbau mit nicht demontiertem Antennenring 56...........

4.4.2 Einbau mit nachträglicher Montage des Stators 57........

4.5 Montage des Rotors 58......................................

4.6 Montage des Stators 60.....................................

4.7 Drehzahlmesssystem, Referenzimpuls (optional) 65.............

5 Elektrischer Anschluss 67.......................................

5.1 Allgemeine Hinweise 67.....................................

5.2 EMV‐Schutz 67............................................

5.3 Steckerbelegung 68.........................................

5.4 Versorgungsspannung 71....................................

6 Shuntsignal 72.................................................

7 Funktionsprüfung 73............................................

7.1 Rotorstatus, LED A (obere LED) 73...........................

7.2 Statorstatus, LED B (untere LED) 74..........................

8 Belastbarkeit 75................................................

9 Wartung 76.....................................................

10 Entsorgung und Umweltschutz 76................................

11 Bestellnummern, Zubehör 77....................................

12 Technische Daten 78............................................

13 Ergänzende technische Informationen 85.........................

A3452-5.0 en/de HBM

Page 46

46

T40B

Sicherheitshinweise

Bestimmungsgemäße Verwendung

Der Drehmoment‐Messflansch T40B ist für Drehmoment‐, Drehwinkel‐ und

Leistungs‐Messaufgaben im Rahmen der durch die technischen Daten spezi

fizierten Belastungsgrenzen konzipiert. Jeder andere Gebrauch ist nicht

bestimmungsgemäß.

Der Betrieb des Stators ist nur mit montiertem Rotor zulässig.

Der Drehmoment‐Messflansch darf nur von qualifiziertem Personal ausschließlich entsprechend der technischen Daten unter Beachtung der

Sicherheitsbestimmungen und Vorschriften dieser Montageanleitung eingesetzt werden. Zusätzlich sind die für den jeweiligen Anwendungsfall geltenden

Rechts‐ und Sicherheitsvorschriften zu beachten. Sinngemäß gilt dies auch

bei Verwendung von Zubehör.

Der Drehmoment‐Messflansch ist nicht zum Einsatz als Sicherheitsbauteil

bestimmt. Bitte beachten Sie hierzu den Abschnitt „Zusätzliche Sicherheitsvorkehrungen“. Der einwandfreie und sichere Betrieb setzt sachgemäßen

Transport, fachgerechte Lagerung, Aufstellung und Montage sowie sorgfältige

Bedienung voraus.

Belastbarkeitsgrenzen

Beim Einsatz des Drehmoment‐Messflanschs sind die Angaben in den

technischen Datenblättern unbedingt zu beachten. Insbesondere dürfen die

jeweils angegebenen Maximalbelastungen keinesfalls überschritten werden.

Nicht überschritten werden dürfen z.B. die in den technischen Daten angegebenen Werte für

Grenzdrehmoment,

Grenzlängskraft, Grenzquerkraft oder Grenzbiegemoment,

Schwingbreite des Drehmoments,

Bruchdrehmoment,

Temperaturgrenzen,

die Grenzen der elektrischen Belastbarkeit.

Einsatz als Maschinenelemente

Der Drehmoment‐Messflansch kann als Maschinenelemente eingesetzt

werden. Bei dieser Verwendung ist zu beachten, dass der Aufnehmer zu

Gunsten einer hohen Messempfindlichkeit nicht mit den im Maschinenbau

üblichen Sicherheitsfaktoren konstruiert wurde. Beachten Sie hierzu den

Abschnitt „Belastbarkeitsgrenzen“ und die technischen Daten.

A3452-5.0 en/deHBM

Page 47

T40B

47

Unfallverhütung

Entsprechend den einschlägigen Unfallverhütungsvorschriften der Berufsgenossenschaften ist nach der Montage des Aufnehmers vom Betreiber eine

Abdeckung oder Verkleidung wie folgt anzubringen:

Abdeckung oder Verkleidung dürfen nicht mitrotieren.

Abdeckung oder Verkleidung sollen sowohl Quetsch‐ und Scherstellen

vermeiden als auch vor evtl. sich lösenden Teilen schützen.

Abdeckungen und Verkleidungen müssen weit genug von den bewegten

Teilen entfernt oder so beschaffen sein, dass man nicht hindurchgreifen

kann.

Abdeckungen und Verkleidungen müssen auch angebracht sein, wenn die

bewegten Teile des Drehmoment‐Messflanschs außerhalb des Verkehrs‐

und Arbeitsbereiches von Personen installiert sind.

Von den vorstehenden Forderungen darf nur abgewichen werden, wenn der

Drehmoment‐Messflansch schon durch den Aufbau der Maschine oder be

reits vorhandene Schutzvorkehrungen ausreichend gesichert ist.

Zusätzliche Sicherheitsvorkehrungen

Der Drehmoment‐Messflansch kann (als passiver Aufnehmer) keine

(sicherheitsrelevanten) Abschaltungen vornehmen. Dafür bedarf es weiterer

Komponenten und konstruktiver Vorkehrungen, für die der Errichter und

Betreiber der Anlage Sorge zu tragen hat. Die das Messsignal verarbeitende

Elektronik ist so zu gestalten, dass bei Ausfall des Messsignals keine Folgeschäden auftreten können.

Der Leistungs‐ und Lieferumfang des Aufnehmers deckt nur einen Teilbereich

der Drehmoment‐Messtechnik ab. Sicherheitstechnische Belange sind vom

Anlagenplaner/Ausrüster/Betreiber so zu planen, zu realisieren und zu verantworten, dass Restgefahren minimiert werden. Die jeweils existierenden nationalen und örtlichen Vorschriften sind zu beachten.

Allgemeine Gefahren bei Nichtbeachten der Sicherheitshinweise

Der Drehmoment‐Messflansch entspricht dem Stand der Technik und ist

betriebssicher. Von dem Aufnehmer können Gefahren ausgehen, wenn er von

ungeschultem Personal oder unsachgemäß montiert, aufgestellt, eingesetzt

und bedient werden. Jede Person, die mit Aufstellung, Inbetriebnahme,

Betrieb oder Reparatur eines Drehmoment‐Messflanschs beauftragt ist, muss

die Montageanleitung und insbesondere die sicherheitstechnischen Hinweise

gelesen und verstanden haben. Bei nicht bestimmungsgemäßem Gebrauch

des Aufnehmers, bei Nichtbeachtung der Montage‐ und Bedienungsanleitung,

dieser Sicherheitshinweise oder sonstiger einschlägiger Sicherheitsvorschriften (Unfallverhütungsvorschriften der BG) beim Umgang mit dem Aufnehmer, kann der Aufnehmer beschädigt oder zerstört werden. Insbesondere

A3452-5.0 en/de HBM

Page 48

48

T40B

bei Überlastungen kann es zum Bruch des Aufnehmers kommen. Durch den

Bruch können darüber hinaus Sachen oder Personen in der Umgebung des

Aufnehmers zu Schaden kommen.

Wird der Drehmoment‐Messflansch nicht seiner Bestimmung gemäß eingesetzt oder werden die Sicherheitshinweise oder die Vorgaben der Montage‐

oder Bedienungsanleitung außer Acht gelassen, kann es ferner zum Ausfall

oder zu Fehlfunktionen des Aufnehmers kommen, mit der Folge, dass (durch

auf den Drehmoment‐Messflansch einwirkende oder durch diesen überwachte

Drehmomente) Menschen oder Sachen zu Schaden kommen können.

Umbauten und Veränderungen

Der Aufnehmer darf ohne unsere ausdrückliche Zustimmung weder konstruktiv noch sicherheitstechnisch verändert werden. Jede Veränderung

schließt eine Haftung unsererseits für daraus resultierende Schäden aus.

Veräußerung

Bei einer Veräußerung des Drehmoment‐Messflanschs ist diese

Montageanleitung dem Drehmoment‐Messflansch beizulegen.

Qualifiziertes Personal

Qualifiziertes Personal sind Personen, die mit Aufstellung, Montage, Inbetriebsetzung und Betrieb des Produktes vertraut sind und die über die ihrer

Tätigkeit entsprechende Qualifikationen verfügen.

Dazu zählen Personen, die mindestens eine der drei folgenden Voraussetzungen erfüllen:

- Ihnen sind die Sicherheitskonzepte der Automatisierungstechnik bekannt

und Sie sind als Projektpersonal damit vertraut.

- Sie sind Bedienungspersonal der Automatisierungsanlagen und im

Umgang mit den Anlagen unterwiesen. Sie sind mit der Bedienung der in

dieser Dokumentation beschriebenen Geräte und Technologien vertraut.

- Sie sind Inbetriebnehmer oder für den Service eingesetzt und haben eine

Ausbildung absolviert, die Sie zur Reparatur der Automatisierungsanlagen

befähigt. Außerdem haben Sie eine Berechtigung, Stromkreise und Geräte

gemäß den Normen der Sicherheitstechnik in Betrieb zu nehmen, zu erden

und zu kennzeichnen.

A3452-5.0 en/deHBM

Page 49

T40B

49

1 Verwendete Kennzeichnungen

1.1 Auf dem Aufnehmer angebrachte Symbole

Symbol:

Bedeutung: Angaben in dieser Anleitung nachlesen und berücksichtigen

Symbol:

Bedeutung: CE‐Kennzeichnung

Mit der CE‐Kennzeichnung garantiert der Hersteller, dass sein Produkt den

Anforderungen der relevanten EG‐Richtlinien entspricht (die Konformitätser

klärung finden Sie auf der Website von HBM www.hbm.com unter HBMdoc).

1.2 In dieser Anleitung verwendete Kennzeichnungen

Wichtige Hinweise für Ihre Sicherheit sind besonders gekennzeichnet. Beachten Sie diese Hinweise unbedingt, um Unfälle und Sachschäden zu

vermeiden.

Symbol Bedeutung

Diese Kennzeichnung weist auf eine mögliche gefährliche Situation hin, die – wenn

die Sicherheitsbestimmungen nicht beachtet werden – Tod oder schwere Körperverletzung zur Folge haben kann.

Diese Kennzeichnung weist auf eine mög-

liche gefährliche Situation hin, die – wenn

VORSICHT

HINWEIS

Wichtig

Tipp

A3452-5.0 en/de HBM

die Sicherheitsbestimmungen nicht beachtet werden – leichte oder mittlere Körperverletzung zur Folge haben kann.

Diese Kennzeichnung weist auf eine

Situation hin, die – wenn die Sicherheitsbestimmungen nicht beachtet werden –

Sachschäden zur Folge haben kann.

Diese Kennzeichnung weist auf wichtige

Informationen zum Produkt oder zur Handhabung des Produktes hin.

Diese Kennzeichnung weist auf Anwendungstipps oder andere für Sie nützliche

Informationen hin.

Page 50

50

BedeutungSymbol

Diese Kennzeichnung weist auf Informationen zum Produkt oder zur Handhabung

des Produktes hin.

Betonung Hervorhebungen im Text sind mit kursiver

Schrift gesetzt.

T40B

2 Anwendung

Der Drehmoment‐Messflansch T40B erfasst statische und dynamische Drehmomente an ruhenden oder rotierenden Wellen. Der Aufnehmer ermöglicht

durch seine kurze Bauweise äußerst kompakte Prüfaufbauten. Dadurch

ergeben sich vielfältige Anwendungen.

Gegen elektromagnetische Störungen ist der Drehmoment‐Messflansch T40B

zuverlässig geschützt. Er ist nach den einschlägigen europäischen Normen

auf EMV‐Verhalten geprüft und mit der CE‐Kennzeichnung versehen.

A3452-5.0 en/deHBM

Page 51

T40B

51

3 Aufbau und Wirkungsweise

Der Drehmoment‐Messflansch besteht aus zwei getrennten Teilen, dem Rotor

und dem Stator. Der Rotor setzt sich zusammen aus dem Messkörper und

den Signal‐Übertragungselementen.

Auf dem Messkörper sind Dehnungsmessstreifen (DMS) installiert. Die Rotor-

elektronik für die Brückenspeisespannungs‐ und Messsignalübertragung ist

zentrisch im Flansch angeordnet. Der Messkörper trägt am äußeren Umfang

die Übertragerspulen für die berührungslose Übertragung von Speisespannung und Messsignal. Die Signale werden von einem teilbaren Antennenring

gesendet bzw. empfangen. Der Antennenring ist auf einem Gehäuse befestigt, in dem die Elektronik für die Spannungsanpassung sowie die Signalaufbereitung untergebracht sind.

Am Stator befinden sich Anschlussstecker für das Drehmoment‐ und das

Drehzahlsignal, die Spannungsversorgung und den digitalen Ausgang. Die

Antennensegmente (der Antennenring) müssen konzentrisch um den Rotor

montiert werden (siehe Kapitel 4).

Anschlussstecker

Antennensegmente

Rotor

Anschlussstecker

Statorgehäuse

Typenschild

Abb. 3.1: Mechanischer Aufbau ohne Drehzahlmesssystem

Bei der Option 6 mit Drehzahlmesssystem ist auf dem Stator der Drehzahlsensor montiert. Die Drehzahlmessung erfolgt magnetisch mittels

A3452-5.0 en/de HBM

Page 52

52

T40B

AMR‐Sensor und Magnetring. Der Magnetring für die Drehzahlerfassung ist

auf dem Flansch aufgeschweißt.

Antennensegmente

Magnetring für

Drehzahlmessung

Rotor

Sensorkopf für

Drehzahlmessung

Anschlussstecker

Anschlussstecker

Statorgehäuse

Typenschild

Abb. 3.2: Mechanischer Aufbau mit Drehzahlmesssystem

Bei der Ausführung mit Drehzahlmesssystem kann der Aufnehmer zusätzlich

mit einem Sensorkopf für einen Referenzimpuls (Null‐Index) zur Drehwinkel

messung versehen werden. Hierbei befindet sich der dazu verwendete

Magnet auf der Innenseite des Flansches. Der Sensorkopf zur Abtastung des

Referenzimpulses befindet sich in dem Bügel oberhalb des Drehzahlsensors.

A3452-5.0 en/deHBM

Page 53

T40B

53

Rotor

Antennensegmente

Magnetring für

Drehzahlmessung

Sensorkopf für

Drehzahlmessung

Anschlussstecker

Statorgehäuse

Typenschild

Sensorkopf für

Referenzimpuls

Anschlussstecker

Abb. 3.3: Mechanischer Aufbau mit Drehzahlmesssystem und Sensor für Refe-

renzimpuls (Null‐Index)

A3452-5.0 en/de HBM

Page 54

54

T40B

4 Mechanischer Einbau

4.1 Wichtige Vorkehrungen beim Einbau

HINWEIS

Ein Drehmoment‐Messflansch ist ein Präzisions‐Messelement und verlangt

daher eine umsichtige Handhabung. Stöße oder Stürze können zu

permanenten Schäden am Aufnehmer führen. Sorgen Sie dafür, dass auch

bei der Montage keine Überlastung des Aufnehmers auftreten kann.

Behandeln Sie den Aufnehmer schonend.

Prüfen Sie den Einfluss von Biegemomenten, kritischen Drehzahlen und

Torsionseigenschwingungen, um eine Überlastung des Aufnehmers durch

Resonanzüberhöhungen zu vermeiden.

Stellen Sie sicher, dass der Aufnehmer nicht überlastet werden kann.

WARNUNG

Bei einer Überlastung des Aufnehmers besteht die Gefahr, dass der Aufnehmer bricht. Dadurch können Gefahren für das Bedienpersonal der

Anlage auftreten, in die der Aufnehmer eingebaut ist.

Treffen Sie geeignete Sicherungsmaßnahmen zur Vermeidung einer Überlastung und zur Sicherung gegen sich daraus ergebende Gefahren.

Kleben Sie die Verbindungsschrauben mit einer Schraubensicherung

(mittelfest, z.B. LOCTITE Schraubensicherung Nr. 242) in das

Gegengewinde ein, um einen Vorspannverlust durch Lockern

auszuschließen, falls Wechsellasten zu erwarten sind.

Halten Sie die Montagemaße unbedingt ein, um einen einwandfreien

Betrieb zu ermöglichen.

Der Drehmoment‐Messflansch T40B kann über einen entsprechenden Wellenflansch direkt montiert werden. Am Rotor ist auch die direkte Montage einer Gelenkwelle oder entsprechender Ausgleichselemente (bei Bedarf über

Zwischenflansch) möglich. Die zulässigen Grenzen für Biegemomente, Quer‐

und Längskräfte dürfen jedoch in keinem Fall überschritten werden. Durch die

hohe Drehsteifigkeit des Aufnehmers T40B werden dynamische Veränderungen des Wellenstrangs gering gehalten.

A3452-5.0 en/deHBM

Page 55

T40B

55

Wichtig

Auch bei korrektem Einbau kann sich der im Werk abgeglichene Nullpunkt bis

zu ca. 2% vom Kennwert verschieben. Wird dieser Wert überschritten, empfehlen wir, die Einbausituation zu prüfen. Ist der bleibende Nullpunktversatz

im ausgebauten Zustand größer als 1% vom Kennwert, senden Sie den Aufnehmer bitte zur Prüfung ins Werk Darmstadt.

4.2 Bedingungen am Einbauort

Der Drehmoment‐Messflansch T40B muss vor grobem Schmutz, Staub, Öl,

Lösungsmitteln und Feuchtigkeit geschützt werden.

Der Aufnehmer ist in weiten Grenzen gegen Temperatureinflüsse auf das

Ausgangs‐ und Nullsignal kompensiert (siehe Kapitel „Technische Daten“).

Liegen keine stationären Temperaturverhältnisse vor, z.B. durch Temperaturunterschiede zwischen Messkörper und Flansch, können die in den technischen Daten spezifizierten Werte überschritten werden. Sorgen Sie in diesen

Fällen je nach Anwendungsfall durch Kühlung oder Heizung für stationäre

Temperaturverhältnisse. Prüfen Sie alternativ, ob eine Temperaturentkopplung

möglich ist, z.B. durch Wärme abstrahlende Elemente wie Lamellenkupplungen.

4.3 Einbaulage

Die Einbaulage des Drehmoment‐Messflanschs ist beliebig.

Bei Rechtsdrehmoment (im Uhrzeigersinn) beträgt die Ausgangsfrequenz bei

Option 5, Code DU2 60 90 kHz (Option 5, Code SU2: 10 15kHz; Option

HU2: 240 360kHz). In Verbindung mit Messverstärkern von HBM oder bei

Nutzung des Spannungsausgangs steht ein positives Ausgangssignal (0 V

+10 V) an. Beim Drehzahl‐Messsystem ist zum eindeutigen Bestimmen der

Drehrichtung auf dem Statorgehäuse ein Pfeil angebracht: Dreht der Messflansch in Pfeilrichtung, liefern angeschlossene HBM‐Messverstärker ein positives Ausgangssignal.

4.4 Einbaumöglichkeiten

Prinzipiell haben Sie zwei Möglichkeiten, den Drehmoment‐Messflansch zu

montieren: mit oder ohne Zerlegen des Antennenringes. Wir empfehlen die

Montage nach Kapitel 4.4.1. Ist eine Montage nach Kapitel 4.4.1 nicht möglich

(z.B. bei nachträglichem Wechsel des Stators), müssen Sie den Antennen-

A3452-5.0 en/de HBM

Page 56

56

T40B

ring zerlegen. Beachten Sie hierbei unbedingt die Hinweise zum Zusammenbau der Antennensegmente (siehe Kapitel 4.4.2).

4.4.1 Einbau mit nicht demontiertem Antennenring

Kundenseitige

Befestigung

1. Rotor montieren

3. Wellenstrang fertigmontieren

2. Stator montieren

Kundenseitige Abstützung

4. Abstützung montieren

A3452-5.0 en/deHBM

Page 57

T40B

4.4.2 Einbau mit nachträglicher Montage des Stators

57

1. Rotor montieren

Unterlegscheiben

Fächerscheiben

3. Antennensegment demontieren

Kundenseitige Abstützung

2. Wellenstrang montieren

4. Antennensegment montieren

4. Abstützung montieren

A3452-5.0 en/de HBM

Page 58

58

T40B

4.5 Montage des Rotors

Tipp

Nach der Montage ist in der Regel das Rotor‐Typenschild verdeckt. Deshalb

liegen dem Rotor zusätzliche Klebeschilder mit den wichtigen Kenndaten bei,

die Sie auf den Stator oder andere relevante Prüfstandskomponenten aufkleben können. Sie können dann jederzeit die für Sie interessanten Daten

ablesen, z.B. das Shuntsignal. Für die eindeutige Zuordnung der Daten ist

am Rotorflansch von außen sichtbar eine Identifikationsnummer und die Baugröße eingraviert.

1. Reinigen Sie vor dem Einbau die Flanschplanflächen des Aufnehmers und

der Gegenflansche.

Die Flächen müssen für eine sichere Drehmomentübertragung sauber und

fettfrei sein. Benutzen Sie mit Lösungsmittel angefeuchtete Lappen oder

Papier. Achten Sie beim Reinigen darauf, dass die Übertragerwicklung

oder das Drehzahlmesssystem nicht beschädigt werden.

Übertragerwicklung

Drehzahlmesssystem

ohne Drehzahl-

messsystem

Abb. 4.10: Verschraubung des Rotors

Flanschplanflächen

mit Drehzahl-

messsystem

A3452-5.0 en/deHBM

Page 59

T40B

2. Verwenden Sie für die Verschraubung des Rotors (siehe Abb. 4.10) sechs

bzw. acht Innensechskantschrauben DIN EN ISO 4762 der

Festigkeitsklasse nach Tabelle 4.1 in geeigneter Länge (abhängig von der

Anschlussgeometrie, siehe Tabelle 4.1 auf Seite 60).

Wir empfehlen Zylinderschrauben DIN EN ISO4762, geschwärzt, glatter

Kopf, zulässige Maß‐ und Formabweichung nach DIN ISO4759, Teil1, Produktklasse A.

59

Wichtig

Kleben Sie die Verbindungsschrauben mit einer Schraubensicherung (mittelfest, z.B. LOCTITE Schraubensicherung Nr. 242) in das Gegengewinde ein,

um einen Vorspannverlust durch Lockern auszuschließen, falls Wechsellasten

zu erwarten sind.

3. Ziehen Sie alle Schrauben mit dem vorgeschriebenen Drehmoment an

(Tabelle 4.1 auf Seite 60).

4. Am Rotor befinden sich zur weiteren Montage des Wellenstranges sechs

bzw. acht Gewindebohrungen. Verwenden Sie ebenfalls Schrauben der

Festigkeitsklasse 10.9 bzw. 12.9 und ziehen Sie diese mit dem vorgeschriebenen Moment nach Tabelle 4.1 an.

Wichtig