Page 1

Torque Transducers

T32 FNA

Operating manual

Electrical

measurement

of mechanical

quantities

HBM Mess- und Systemtechnik GmbH

B 23.T32FNA.10 e

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Page 2

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Page 3

3

T32FNA

Contents Page

Safety instructions 4..............................................

1 General description, field of application 7........................

2 Construction and function 8.....................................

2.1 Construction 8..............................................

2.1.1 Torque measurement system 9..........................

2.1.2 Speed measurement system 10..........................

3 Installation 12...................................................

3.1 General hints 12..............................................

3.2 Precautions 12...............................................

3.3 Mounting 12.................................................

3.3.1 Mounting with curved tooth couplings 14...................

3.4 Fixing of the housing 15.......................................

3.5 Mounting position 16..........................................

3.6 Limits of application 17........................................

4 Electrical connections 19........................................

4.1 Connection plugs and cables 19................................

4.2 Instruments that can be connected 20...........................

5 Calibration signal 20.............................................

6 Load limits 21...................................................

7 Maintenance 22..................................................

8 T echnical Data 23................................................

9 Dimensions 26..................................................

10Copy of Declaration of Conformity 27.............................

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Page 4

4

T32FNA

Safety instructions

Appropriate use

The T32 FNA Torque Transducer may be used for torque-measurement and

directly related control and regulation tasks, only. Any other use is not appropriate.

To ensure safe operation, the transducer may only be used according to the

specifications given in this manual. When using the transducer, the legal and

safety regulations for the respective application must also be observed. The

same applies if accessories are used.

The transducer is no safety element in the sense of appropriate use. Prerequisites for correct and safe transducer operation are appropriate transportation,

storage, installation and mounting, and careful operation.

General dangers in the case of non-observance of the safety instructions

The transducer complies with the state of the art and is operationally reliable.

If the transducer is used and operated inappropriately by untrained personnel,

residual dangers might develop.

Any person charged with transducer installation, operation, maintenance or

repair must in any case have read and understood the operating manual and

the notes on safety, in particular.

Residual dangers

The transducer’s scope of performance and supply covers a part of the torque

measuring-technology, only. The plant designer/constructor/operator must in

addition design, realize and take responsibility for the torque measuring-system’s safety such that potential residual dangers are minimized. The respective regulations must in any case be observed. Residual dangers regarding

the torque measuring-system must be specified explicitly.

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Page 5

5

T32FNA

In this manual, the below symbols are used to refer to residual dangers:

Symbol:

DANGER

Meaning:

Maximum danger level

Warns of an imminently dangerous situation in which failure to comply with

safety requirements will result in death or serious physical injury.

Symbol:

WARNING

Meaning:

Potentially dangerous situation

Warns of a potentially dangerous situation in which failure to comply with

safety requirements can result in death or serious physical injury.

Symbol:

CAUTION

Meaning:

Potentially dangerous situation

Warns of a potentially dangerous situation in which failure to comply with

safety requirements could result in damage to property or some form of

physical injury.

Symbol:

Note

Means that important information about the product or its handling is being

given.

Symbol:

Meaning:

CE mark

The CE mark enables the manufacturer to guarantee that the product complies with the requirements of the relevant EC guidelines (see Declaration of

Conformity at the end of this document).

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Page 6

6

T32FNA

Reconstruction and modifications

HBM’s express consent is required for modifications regarding the transducer’s construction and safety. HBM does not take responsibility for damage resulting from unauthorized modifications.

Qualified personnel

The transducer may be used by qualified personnel, only; the technical data

and the special safety regulations must in any case be observed. When using

the transducer, the legal and safety regulations for the respective application

must also be observed. The same applies if accessories are used.

Qualified personnel means: personnel familiar with the installation, mounting,

start-up and operation of the product, and trained according to their job.

Prevention of accidents

According to the prevailing regulation to prevent accidents a cover has to be

fitted after the mounting of the torque transducers T32 FNA as follows:

the cover must be stationary

the cover shall avoid any danger of squeezing and provide

protection against parts that might come loose

the cover shall be installed at a minimum distance from moving

pats or shall be of a nature that a hand cannot be put through

the cover shall be fitted even if moving parts are installed outside

the usual access area of persons.

Above regulations could only be disregarded if there is already sufficient

protection of machine parts owing to the design of the machine or due to other

precautions.

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Page 7

7

T32FNA

1 General description, field of application

Mechanical power transmission through rotating machine parts often requires

extensive investigations of machine parts that transmit or generate power.

Furthermore, continuous monitoring is often required. This, in turn, makes it

necessary to have transducers to sense the physical quantities torque and

speed of rotation.

The torque transducers type T32 FNA from HBM which are without sliprings

and bearings, provide torque sensing as well as speed measurement. The

torque transducers are suitable to determine static as well as dynamic torque

in stationary and rotating shafts. Speed of rotation can be determined as well

as the sense of rotation. The multiplication of both factors gives the shaft

power.

Torque transducers are available for nominal torque ratings from 50 Nm up to

25 kNm. The maximum speed rating is 20000 min

-- 1*)

, depending on the ac-

tual type.

A frequency modulation system with non-contacting, inductive transfer of the

signal and the excitation voltage provides a system for the sensing of static

and dynamic torque which is free from wear and maintenance.

Owing to the bearing-free design preventive maintenance and lubrication is

not required. Friction losses and heating will not occur.

The field of use of the T32 FNA is to measure the required power or the efficiency, or applications on process control as well as continuous monitoring of

machines.

*)Type series of 50 Nm, 100 Nm and 200 Nm rated torque

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Page 8

8

T32FNA

2 Construction and function

2.1 Construction

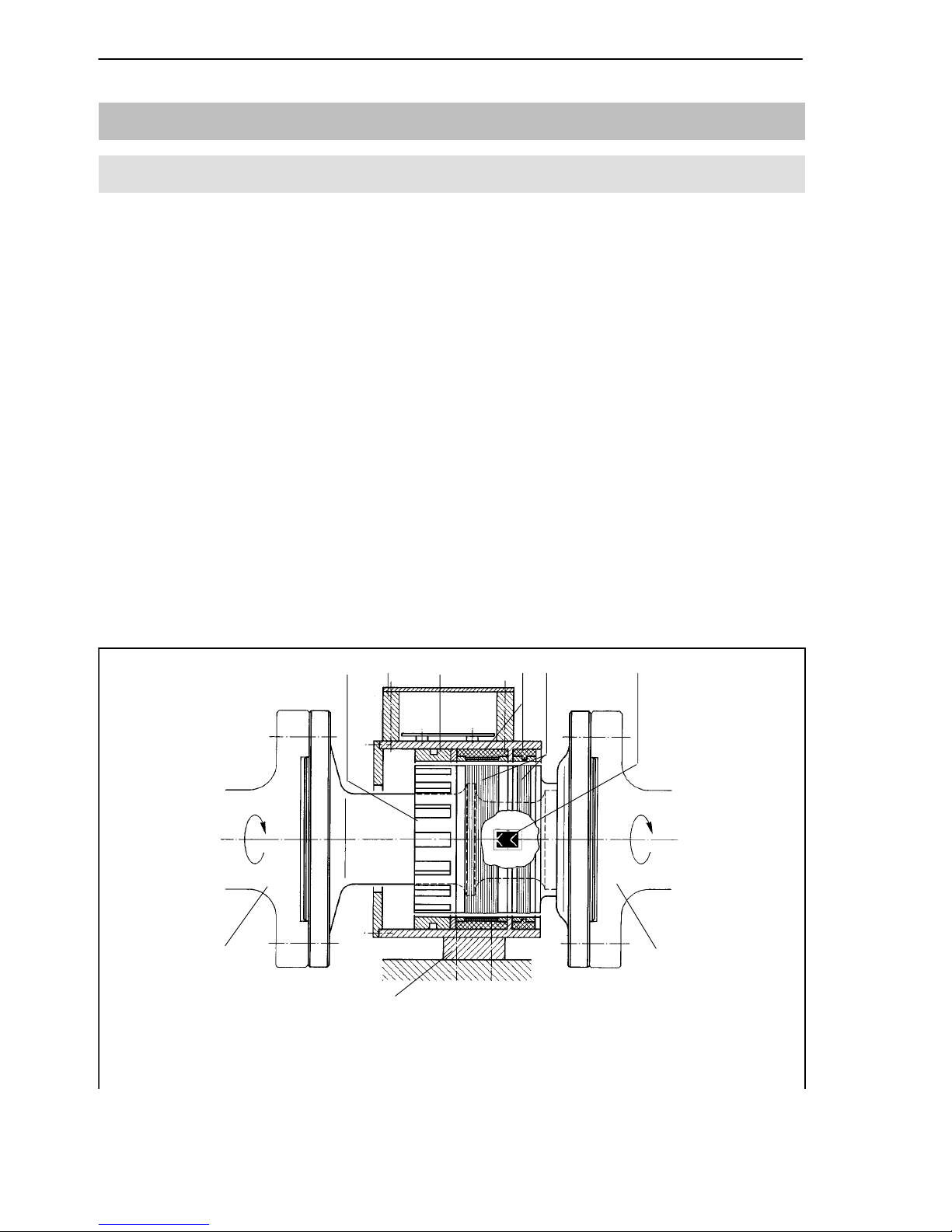

The schematic design of a torque transducer is given in Fig. 2.1. The torque

transducer consists of a measurement body which is screwed to the measurement object by means of two flanges.

The hollow shaft which forms the measurement body is equipped with strain

gauges. Inside the hollow shaft there is the electronic circuitry for the bridge

excitation voltage and for the transmission of the measurement signals. Furthermore, the shaft housing is equipped with 30 teeth for speed measurement

and with transmission elements for the inductive transmission of the supply

voltage onto the measurement body as well as elements for capacitive transmission of measured values from the shaft to the housing of the torque transducer.

The rotor, consisting of the actual measurement body and the two flanges, is

fitted to the housing by two spindle bearings. The housing also contains preamplifiers for the torque signal and for the speed signal, as well as two inductive proximity detectors which serve to detect the speed and the sense of rotation. The housing also carries the connection plugs for the measurement

cables.

1. Toothed wheel (speed measuring system)

5. Inductive voltage transmission (coils)

6. Strain gauge application

2. Connection box

3. Inductive pick--ups

4. Inductive voltage transmission

7. Mounting plate

Flange A Flange B

12 3 45 6

8

8

8. Shaft ends of the object

7

Stator:Rotor:

Fig. 2.1: Mechanical construction

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Page 9

9

T32FNA

Stator and rotor part are not connected by ball bearings. To ensure concentric positioning of the rotor part in the housing three fixing elements are provided at both ends which serve as safeguard during transport and as mounting aid. They enable to adjust the radial and axial play between rotor and

stator part of the torque transducer. After mounting the torque transducer the

fixing elements must be removed.

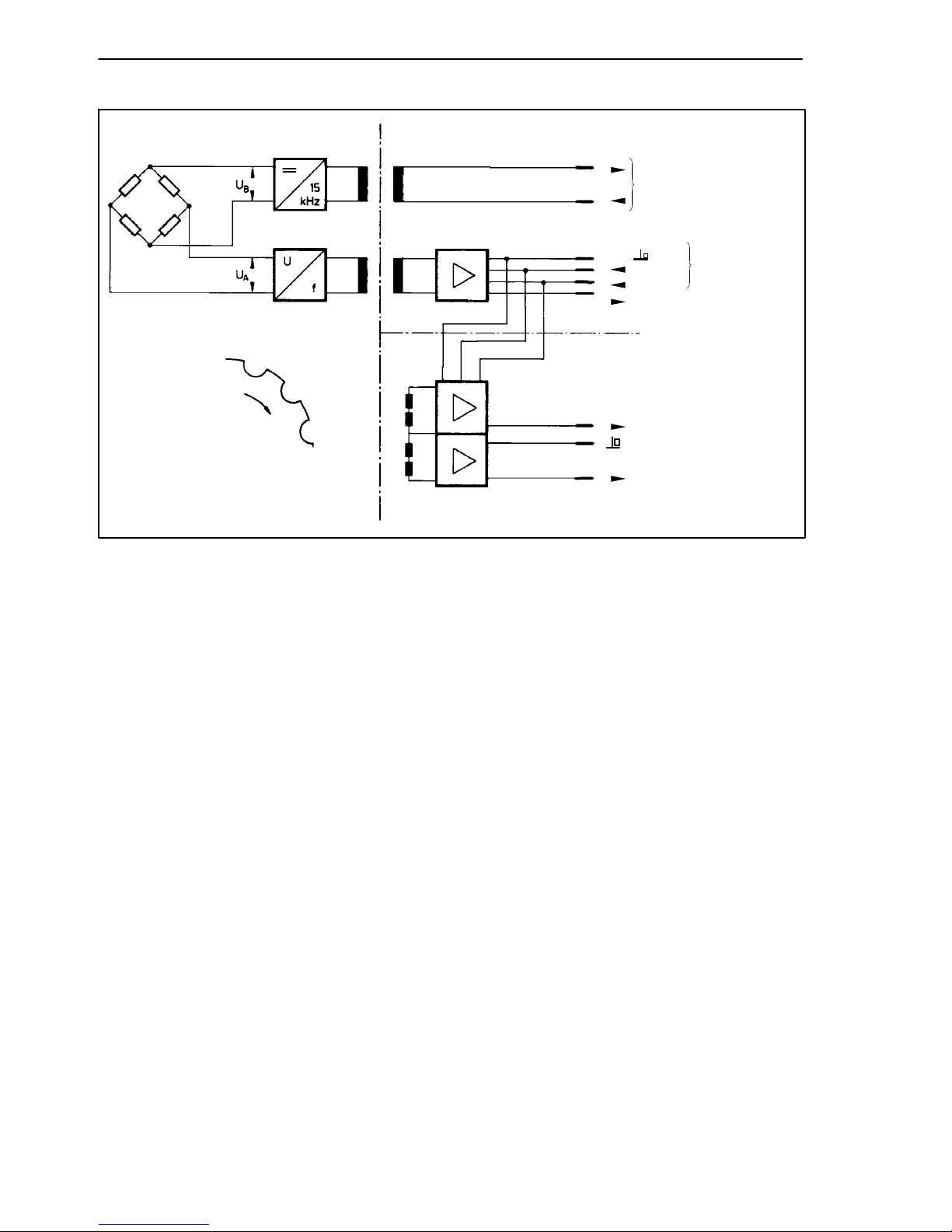

2.1.1 Torque measurement system

In the torque transducers T32 FNA there are strain gauges for torque measurement mounted on the rotor in the direction of the main stress. They are

connected as a Wheatstone bridge so that only torque will unbalance the

bridge. Temperature effects are also compensated by means of further balancing elements. Additional axial and lateral forces as well as bending moments

within the permitted limits will have only a slight influence (see section ”8.

Technical Data”).

A 15kHz voltage of 54V peak-to-peak for bridge excitation is transmitted by

inductive means. The frequency-to-voltage converter in the rotor forms out of

this a stable bridge excitation voltage. The torque acting on the sensing element deforms it and also the strain gauges. The strain gauges change their

resistance proportional to the strain thus detuning the Wheatstone bridge. The

output voltage of the bridge which is proportional to the torque is then fed to a

voltage-to-frequency converter. This, in turn, produces pulses through integration, the frequency of which is proportional to the bridge output voltage. The

pulses are inductively transmitted to the stator. They are then transformed in a

preamplifier into a pulse frequency of 12V peak-to-peak in the frequency

range from 5kHz to 15kHz. In the no-load state the output signal is 10kHz.

Depending on the sense of the torque the output signal at the ”MD” plug will

be either 15kHz or 5kHz at rated torque.

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Page 10

10

T32FNA

6 Supply voltage

for rotor

7 15kHz, 54V/74V

1

2 --15V

3+15V

4 ”MD”-output signal

5/15kHz.....

4 Speed signal 25 V

1

7 Speed signal 25 V

Rotor Stator

Pre--amplifier

”MD” and ”n”

Plug ”MD”

Plug ”n”

Fig. 2.2: Schematic circuit diagram

2.1.2 Speed measurement system

The rotor carries a toothed wheel with 15 teeth for the determination of speed.

On the stator there are evenly distributed, four inductive pick-ups. During one

revolution of the rotor 15 voltage pulses are produced the frequency of which

is proportional to speed. The pick-ups are displaced in such a way that two

pulse trains appear with a phase shift of 90. The phase shift serves as the information on the sense of rotation of the shaft.

A pre-amplifier serves to transform the two pulse trains into square waves of

25V peak-to-peak. The speed proportional square wave is available at the ”n”

plug for further processing.

Experience has shown that smooth, vibration-free running and a concentric

rotor are essential for accurate measurement of speed.

Vibration is permitted up to a maximum vibration amplitude falling with in-

creasing speed (see Fig. 2.3, Curve A).

If there is static eccentricity of the stator to the rotor, the possible maximum

vibration amplitude displacement (relative vibration displacement is reduced.

Curves B, C and D are examples of this relationship for eccentricities of

0.5 mm, 1 mm and 2 mm.

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Page 11

11

T32FNA

Note: The limit values given for the speed measurement system are not identical to the physical stress limits for the system which can be considerably

lower.

A: Concentric stator and rotor

B: Static eccentricity 0,5 mm

C: Static eccentricity 1,0 mm

D: Static eccentricity 2,0 mm

Relative vibration amplitude (peak--to--peak) in

mm

Speedninrev/min

Fig. 2.3: Maximum permitted vibration amplitude

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Page 12

12

T32FNA

3 Installation

3.1 General hints

- The torque transducers are screwed to the free shaft ends or to the couplings via flanges at both ends. Dimensions of connections see section

”9. Dimensions”.

- Align shaft ends precisely. In order to avoid mechanical overloading HBM

recommend to use couplings at both sides. Thus adverse loadings as

bending moments, lateral and axial forces will be excluded and cannot act

on the torque transducer.

- Stator and rotor are not mechanically connected. The stator should be fixed

to an external support construction by means of the mounting plate.

The support should be designed in such a way that the permitted mechanical tolerances are maintained. Axial and radial displacements with respect

to the rotor should only occur within the specified limits (see Technical

Data)

3.2 Precautions

The torque transducers T32 FNA are protected to IP 54 according to

EN 60 529. Torque transducers shall be protected against coarse dirt particles, dust, oil, solvents and humidity.

3.3 Mounting

The torque transducers T32 FNA may be mounted in a train of shafts without

couplings. However, it is imperative that error loads due to deviations from

plane running, smooth running and concentricity shall have no effect on the

torque transducer. Contact HBM, if details on the permissible radial and angular displacement of the transducers are required.

Since this is very difficult to realise HBM recommend to mount T32 FNA

torque transducers with intermediate couplings e.g. tooth couplings.

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Page 13

13

T32FNA

For the selection of suitable couplings the following criteria should be applied:

- Couplings should be dimensioned in accordance with the torque and speed

hat are expected.

- When estimating the possible loads one should take care of acceleration

and deceleration moments as well as the passing through critical speeds of

rotation. Periodic peaks of torque could be considerably higher than the average calculated from nominal power and speed. If the coupling is overdimensioned as well as the torque transducer this will bring safety against

mechanical overloading.

- Couplings should be selected so that any additional force or moment is

within the ratings, or cannot act on the torque transducer.

- Couplings can be self centering. Angular displacements, parallel and axial

shifts shall be cancelled.

- Mounting surfaces for the connection of the coupling housing shall be clean

and free from grease.

- Stability class and fastening torque for nuts and bolts to be used in the two

connecting flanges:

Nominal

torque

T32 FNA

Cheese-head screw*)as

machined, lubricated

m

tot

= 0.125

Hexagon nut as ma-

chined, lubricated

m

tot

= 0.125

Screws and

nuts per

flange evenly

distributed

Tighten-

ing

torque

50 Nm M 6 x 25 DIN 912-12.9 M 6 DIN 934-12 4 16 Nm

100 Nm M 6 x 25 DIN 912-12.9 M 6 DIN 934-12 4 16 Nm

200 Nm M 6 x 25 DIN 912-12.9 M 6 DIN 934-12 8 16 Nm

500 Nm M 10 x 35 DIN 912-10.9 M 10 DIN 6924-10 5 67 Nm

1kNm M 10 x 35 DIN 912-10.9 M 10 DIN 6924-10 10 67 Nm

2kNm M 10 x 35 DIN 912-10.9 M 10 DIN 6924-10 15 67 Nm

10 kNm M 16 x 50 DIN 912-10.9 M 16 DIN 6924-10 18 290 Nm

25 kNm M16x1.5x50DIN

912-12.9

M16x1.5 DIN

934-12

18 360 Nm

*)

The screw length belongs to the combination T32 FNA-Tacke GLB-Curved Tooth CouplingsÊ

The information given above applies under the following conditions:

Surface condition of the flanges in the area of the friction fit surfaces and of the contact surface of scre-

whead or nuts R

A

3.2mm.

Flange material: steel, tensile strength

900N/mm

2

.

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Page 14

14

T32FNA

Arrangement of the screws [-] on t he flange:

T32 FNA 50Nm ... 200Nm

T32 FNA 500Nm ... 2 kNm

T32 FNA 10 kNm ... 25 kNm

3.3.1 Mounting with curved tooth couplings

Selfcentering curved tooth couplings made by Messrs. Tacke are proved in

combination with HBM torque transducers. They are torsionally stiff and take

care of the introduction even of dynamic torque to the torque transducer in the

correct way. In addition, angular displacement and parallel or axial shift are

compensated with small restoring force.

HBM can supply suitable couplings that are well matched to the type of torque

transducer and the intended use. Special requirements of the customer are

taken care of and the shaft connections are made to the specified dimensions.

The torque transducer and the coupling housing are assembled at HBM and

are dynamically balanced (balancing quality level G 2.5). Therefore, the

mounted assembly should not be disassembled again. If this cannot be

avoided one should mark all parts in such a way that they can be assembled

afterwards in exactly the same way. Upon reassembly, the original balancing

quality can only be obtained by renewed balancing.

Coupling hubs are balanced individually and the keyways are made after balancing. Further information will be found in the various data sheets provided

by HBM.

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Page 15

15

T32FNA

3.4 Fixing of the housing

The stator housing is fitted around the rotor without bearings or without any

mechanical connection. When delivered there are fixing elements at the sides

of the stator that serve as safeguard during transport and as mounting aid for

radial and axial positioning and ensure that stator and rotor axes are properly

aligned.

Important:

- The fixing elements must be screwed in during mounting and dismounting,

and during transportation of the torque transducer. This prevents any damage to the signal transmitting devices on the stator and rotor.

- During operation fixing elements must be removed!

Follow these points when mounting:

(see section ”9. Dimensions”)

- The T32 FNA shall be mounted in the train of shafts as delivered so that

the mounting plane of the stator is seated on the prepared support plane

without play or stress. The two connection flanges shall be connected to

the shaft ends or couplings respectively.

- Any possible height difference shall be adjusted by shims. Screw in fixing

screws; do not yet t ighten to avoid jamming of the fixing elements.

- Mark position of the stator or adjust respective stops.

- Remove fixing elements from the torque transducer.

- Check dimension Z (see section ”9. Dimensions”).

- Tighten fixing screws. Stator must stay in marked position or at stops. Ro-

tor must rotate freely.

- Check if radial and axial tolerances are kept.

- Check smooth running of the torque transducer, beginning with low speeds.

In the case of elastically suspended machines larger radial and axial movements may occur. If the occurring movements exceed the permitted limits of

2.5mm, or 3mm resp. one must take care that the stator can follow the motions of the rotor, or the motions shall be properly decoupled.

If couplings are mounted a possible axial and radial play should be considered as well.

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Page 16

16

T32FNA

3.5 Mounting position

The T32 FNA can be mounted in any position. If mounted with couplings the

relevant restrictions of the couplings shall be observed regarding slanted or

vertical operation.

For the determination of the sense of rotation the following holds:

An arrow is marked on the stator for the unambiguous determination of the

sense of rotation. If the torque transducer rotates in the direction of the ar-

row the connected amplifier outputs a positive signal (0...+10 V).

For the determination of the sense of the torque the following holds:

If clockwise torque is applied the output frequency is 10...15 kHz. In conjunction with HBM amplifiers there will be a positive output signal (0...+10 V).

Fig. 3.1: Direction of torque

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Page 17

17

T32FNA

3.6 Limits of application

The nominal speed of the torque transducer is given on the type plate. It refers to the permitted continuous speed of the torque transducer when installed

and represents the maximum load due to the kinetic energy of rotation that

the transducer can tolerate.

Practical experience has shown that the running smoothness of the torque

transducers is very dependent on the overall construction of the testbed.

Thus, vibration can occur whose amplitude may be influenced by the mass of

the resonating housing and foundation, the stiffness of the bearings or supports and the proximity of resonance. Since HBM can have no responsibility

for such factors, diagram 1 shows the stated limit values of maximum deflection of the relative shaft vibration s

max

in relation to the speed for T32 FNA

torque transducers.

- Transducers without couplings

- The maximum speed is the nominal speed given on the type plate.

- The torque transducer supplied has been tested on a testbed and fulfils the

requirements of diagram.

- Transducers with couplings

- With GLB couplings: nominal speed as for torque transducer according to

diagram 1.

- With SBG couplings: the maximum speed is the lower rated speed of the

couplings being used (see section ”8. Technical Data”)

- The vibration characteristics of the combined torque transducer and coupling supplied by HBM have been tested on a testbed and fulfil the requirements of diagram 1.

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Page 18

18

T32FNA

In the diagram shown, the maximum permitted vibration amplitude s is plotted

against the speed.

The maximum values must not be exceeded during normal operation. They refer only to the

T32 FNA torque transducer and not to any connected machinery. s

max

is defined accordingly

to DIN 45670 and VDI 2059.

Speed in rev/min

m mMax. vibration amplitude in

Measuring planes

Diagram 1: Vibration amplitude versus the speed

Using a T32 FNA torque transducer in conjunction with SBG curved-tooth

couplings allows the advantages of the T32 FNA to be utilized for low speeds

in combination with cheap couplings. In this combination the continuous

speeds are lower than with the GLB curved-tooth couplings normally used.

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Page 19

19

T32FNA

4 Electrical connections

4.1 Connection plugs and cables

The type T32 FN / T32 FNA torque transducers differ only in the type of connector:

T32FN MS 3102A16S--1P............

T32FNA Binder 423...........

The two 7-pole instrument plugs Binder 423 (MS 3102 A 1 6S--1 P for

T32 FN) mounted at the housing are marked ”MD” for the torque signal and

”n” for the speed signal.

1 Operating voltage zero <WH>

Plug MD

2 Preamplifier supply voltage (--15V) <BK>

g

3 Preamplifier supply voltage (+15V) <BU>

61

4 Torque output signal (12Vpp; 5...15kHz) <RD>

5 72

43

5 Not connected

4

3

6 Rotor supply voltage (54V/74Vpp; 15kHz) <GN>

7 Rotor supply voltage (0V) <GY>

1 Operating voltage zero <WH>

Pl

u

g

n

2 Not connected

P

lug

n

3 Not connected

4 Rotation rate signal (25Vpp; 15 pulses/revolution) <RD>

61

5 72

5 Not connected

43

6 Not connected

7

Rotation rate signal (25Vpp; 15 puls./rev.);

phase shifted by 90 <GY>

The lead screen is laid flat on the connector case. This means that the complete measurement system is enclosed in a Faraday cage, reducing any electromagnetic interference.

With interference caused by potential differences (equalisation currents) the

system zero-voltage and the housing ground should be isolated from one

another and a potential equalisation conductor located between the housings

of the transducer and the amplifier (flexible stranded wire, 10 mm

2

conductor

cross-section).

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Page 20

20

T32FNA

4.2 Instruments that can be connected

The basic requirements for the trouble-free operation of torque transducers

are:

- Adequate power supply for the non-contact telemetry

- Supply for the preamplifier built into the transducer

HBM has various amplifiers available for numerous applications and these

can supply the transducers and process the torque and torque-proportional

signals. The connection details can be found in the operating manual for the

relevant electronic measurement system.

5 Calibration signal

The torque transducers T32 FNA deliver an additive electrical calibration signal that can be called from the amplifier.

When pressing a push button on the front panel of the amplifier the supply

voltage is increased from 54V to 74V. The torque transducer responds with

the output of a calibration signal of approximately 12.5kHz

50% of the rated

torque. The precise value is given on the nameplate of the T32 FNA. The amplifier has to be adjusted to the precise calibration signal of the connected unloaded torque transducer in order to achieve calibration of the measurement

chain.

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Page 21

21

T32FNA

6 Load limits

The nominal torques may be exceeded statically by max. 50 %. Within the

nominal torque exceeded, no additional irregular loads such as longitudinal

and transverse forces and bending moments are permissible. The limit values

are specified in the chapter ”8. Technical Data”.

Measurement of static and dynamic torque

Torque transducers T32 FNA are suitable for the measurement of static and

dynamic torques. When dynamic torque is measured one should note the following:

- The static calibration of the T32 FNA is also valid for dynamic torque measurements.

Note: The frequency of dynamic torque must not exceed the natural frequency of the mechanical measuring installation.

- The natural frequency f

o

of the mechanical measuring installation depends

on the moments of inertia J

1

and J2of the coupled rotating masses and de-

pends on the torsional stiffness c

T

of the T32 FNA.

The natural frequency of the arrangement can be calculated with the following

equation:

f

0

1

2¶

·cT·

Æ

1

J

1

1

J

2

É

¯

f

0

= natural frequency of the

measurement arrangement (Hz)

J

1,J2

= mass moment of inertia of

the connected rotating masses (kgm

2

)

c

T

= torsional stiffness of the torque

transducer (Nm/rad)

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Page 22

22

T32FNA

- The amplitudes (peak-to-peak) must never exceed 70 % of the nominal

torque for the specific type, even with oscillating torque. In all cases the

amplitudes must lie within the load range limits of -- M

N

and + MN.

+MN100

-M

N

100

50

50

0

45

25

70% M

N

Range

Nominal torque MNin %

Upper torque limit

Lower torque limit

Fig. 6.1: Amplitudes of dynamic torque

7 Maintenance

Torque transducers type T32 FNA are maintenance-free owing to their design

without bearings and with non-contacting transfer of the energising voltages

and of the measured signal.

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Page 23

23

T32FNA

8 Technical Data

Accuracy class 0.3 0.2 0.1

Torque measuring system

Nominal torque M

N

Nm

kNm

50 100 200 500

1 2 10 25

Measuring system

Excitation voltage -- and measuring signal

transmission

strain gauge full bridge

Inductive

Excitation voltage

Square-wave voltage (peak-to-peak)

Current consumption

Frequency

V

mA

kHz

54 5%

800 5%

approx. 15

Voltage for preamplifier V -15/0/+15

Preamplifier, max. current consumption mA -20/0/+20

Calibration signal, value given on name

plate

approx. 50 % von M

N

Tolerance of calibration signal

relatedtoM

N

% < 0,05

Release of calibration signal

Current consumption

V

mA

80 5%

1000 5%

Torque output signal pulse train

Nominal torque output signal

with positive M

N

with negative M

N

Load resistance

kHz

kHz

kW

15 (12V peak-to-peak)

5 (12V peak-to-peak)

2

Nominal sensitivity (nominal signal span

between torque = zero and nominal torque)

kHz 5

Sensitivity tolerance (deviation of the actual signal span to the nominal signal span at

M

N

) % < 0.1

Temperature error per 10 K at nominal temperature range of

output signal, related to the actual value

of signal span

% < 0.1

zero signal, related to the nominal sensitivity

% < 0.1 < 0.05

Linearity deviation including hysteresis,

related to the nominal sensitivity

% <0.3 < 0.2 < 0.1

Relative standard deviation of the reproducibility according to DIN 1319

% < 0.03

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Page 24

24

T32FNA

Speed measuring system

Nominal torque Nm

kNm

50 100 200 500

1 2 10 25

Measuring system brushless, inductive

Output signal for speed pulse train

Pulse voltage (peak-to-peak)

between plug contacts 1 and 4

between plug contacts 7 and 1

Load resistance

V

kW

25

15 pulses per revolution

15 pulses per revolution, displaced by 90

5

Minimum speed min

-- 1

2

Mechanical Data

Nominal temperature range C +10...+60

Service temperature range C -- 10 ... + 60

Storage temperature range C -- 50 ... + 70

Load limits

Torque limit, related to M

N

Destruction torque, related to M

N

%

%

150

> 300

Lateral limit force

1)

Axial limit force

1)

Bending limit moment

1)

N

kN

Nm

50

1.3

6

100

2.5

12

190

5

23

410

7

60

1.1k

14

115

1.6k

27

230

5.7k

100

1 150

14k

200

2.8k

Vibration amplitude to DIN 50 100 (peakto-peak)

Nm 35 70 140 350 700 1.4k 7k 17.5k

Mechanical impact test2)degree of preci-

sion according to IEC 68-2-27-1987

Number

Duration

Acceleration

n

ms

m/s

2

1000

3

500

Vibration stressing test2), degree of precision according to IEC 68-2-6-1985

Frequency range

Duration

Acceleration

Hz

h

m/s

2

5-65

1.5

50

Torsional stiffness c

T

kNm/rad 10.5 19.5 34.3 142 242 369 2910 6480

Torsion angle at M

N

grad 0.27 0.29 0.33 0.2 0.24 0.31 0.19 0.22

Mass moment of inertia (axially) gm

2

1.85 16 149 154

Nominal speed (without coupling) min--1 20 000 15 000 11 000

Nominal speed3)with

SBG-Coupling min

-- 1

3000

GLB-Coupling min

-- 1

20 000 15 000 10000 7600

1) Each type of irregular stress can only be permitted with its given limit value (bending moment, side load or

axial load, exceeding the nominal speed) if none of the others can occur. Otherwise the limit values must

be reduced. If for instance 30% of the bending moment and also 30% of the side load are present, only

40% of the axial load are permitted, provided that the nominal torque is not exceeded. With maximum additional loading, measuring errors of the order of 1% of the nominal torque can occur.

2) The technical data did not change after impact and vibrational stressing test.

3) The maximum permissible continuous speed for the T32 FNA-coupling mounted and balanced by HBM

given on the plate.

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Page 25

25

T32FNA

Nominal torque Nm

kNm

50 100 200 500

1 2 10 25

Quality grade4)according to VDI 2060 G2.5

Permissible residual unbalance per unit

weight of inertial body per plane

gnm/kg 0.5 0.7 0.8

Weight

Rotor kg 2.5 7.1 7.2 7.3 31.6 32

Stator kg 2.8 3 11

Total kg 5.3 10.1 10.2 10.3 42.6 43

Protection class accordingtoEN60529 IP 54

Maximum permissible static eccentricity of

the rotor (radially)

(centering with fixing elements)

mm 2.5 2.0 3

Maximum permissible amplitude (peak-topeak) of the rotor

with speed measurement

with torque measurement

mm

mm

2.5

5)

5

Permissibleaxial displacement between

shaft and housing

(centering with fixing elements)

mm 3

4) The balance quality grades include the coupling housing if it has been mounted on the shaft by HBM.

5) Accurate measurement of speed depends on the relation between the static eccentricity and the maximum

vibration amplitude of the rotor (see para. ”2.1.2 Speed measurement system”).

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Page 26

26

T32FNA

9 Dimensions

Flange A Flange B

Plug for speed

measuring signal

and indication of

direction

Plug for torque

measuring signal

Permissible deviation

of pitch5’

Dimensions without tolerances to DIN 7168-m

Transport locking

device and

mounting accessory

Type plate

Mounting surface

Z

Nominal

Dimensions in mm

torque

A B

--0.005

C D E F

0,1

G H J K L M N

50 to 200Nm 90 60 84 70 107 72 6 8.5 15 38 76 M5 8

500Nm to 2kNm 157

0.2

100 102 80 124 130 17 13 22 38 90.5 M8 12

10 to 25 kNm 235 140 122 80 216 196 33.5 18.5 60 80 90 M8 14

Nominal

Dimensions in mm

torque

O

-- 0. 5P-- 0. 2

Q R S T

H12

U V W X Y Z

50 to 200Nm 161.5 66.5 87.5 105 69 6.4 70 30 45 8x45 58.8 28

500Nm to 2kNm 171.5 75 96 105 69 10.5 70 54 24 15x24 67 17

10 to 25 kNm 244.6 123 140.8 105 69 17 130 110 20 18x20 113 42.6

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Page 27

27

T32FNA

10 Copy of Declaration of Conformity

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Page 28

28

T32FNA

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Page 29

29

T32FNA

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Page 30

30

T32FNA

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Page 31

31

T32FNA

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Page 32

HOTTINGER BALDWIN MESSTECHNIK

HBM Mess- und Systemtechnik GmbH

Postfach 10 01 51, D-64201 Darmstadt

Im Tiefen See 45, D-64293 Darmstadt

Tel.: +49/ 61 51/ 8 03-0; Fax: 89 48 96;

www.hbm.de

Modifications reserved.

All details describe our products in general

form only.They are not to be understood as

express warranty and do not constituteany

liability whatsoever.

IM--D 10.98 -- POD

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Loading...

Loading...