Page 1

Mounting Instructions

Digital

Torque Transducer

T12

A1979-7.1 en

Page 2

Page 3

T12

3

Contents Page

Contents

Safety instructions 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Scope of supply 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Operation 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Application 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Signal flow 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Structure and mode of operation 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Mechanical installation 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Conditions on site 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Mounting position 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Installing the slotted disc (speed measuring system only) 15. . . . . .

6.4 Installing the rotor 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 Fitting the protection against contact (option) 19. . . . . . . . . . . . . . . .

6.6 Installing the stator 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.1 Preparing with the mounting kit (included among the items

supplied) 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.2 Aligning the stator 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.3 Stator installation over the protection against contact

(option) 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7 Optical speed/angle of rotation measuring system (option) 31. . . . .

Axial alignment 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Radial alignment 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 LED status display 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Measuring mode operation 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Rotor clearance setting mode operation 34. . . . . . . . . . . . . . . . . . . . .

7.3 Speed measuring system setting mode operation 34. . . . . . . . . . . .

8 Electrical connection 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 General hints 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Shielding design 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 Connector pin assignment 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 Supply voltage 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.1 Supply voltage for self‐contained operation 40. . . . . . . . . . . .

9 Shunt signal 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A1979-7.1 en HBM

Page 4

4

10 Loading capacity 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 Measuring dynamic torque 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11 TEDS 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1 Content of the TEDS memory as defined in IEEE 1451.4 44. . . . . .

12 Maintenance 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1 Cleaning the speed measuring system 50. . . . . . . . . . . . . . . . . . . . . .

13 Specifications 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14 Dimensions 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.1 Rotor dimensions 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T12

14.2 Stator dimensions 100 N

system (in mm) 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.3 Stator dimensions 100 N

system (in mm) 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.4 Stator dimensions 100 N

system (in mm) 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.5 Stator dimensions 100 N

contact (in mm) 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.6 Stator dimensions 100 N

contact (in mm) 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.7 Stator dimensions 500 N

contact (in mm) 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.8 Stator dimensions 2 kN

⋅m ... 10 kN⋅m with protection against

contact (in mm) 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.8.1 Dimensions cover plates 100 N

⋅m ... 200 N⋅m with speed measuring

⋅m ... 200 N⋅m with speed measuring

⋅m ... 10 kN⋅m with speed measuring

Vm ... 200 NVm with protection against

Vm ... 200 NVm with protection against

Vm ... 1 kNVm with protection against

⋅m ... 200 kN⋅m69. . . . . . . . .

14.8.2 Dimensions cover plates 500 N

⋅m ... 10 kN⋅m70. . . . . . . . . .

14.9 Mounting dimensions 70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15 Additional technical information 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.1 Radial and axial run‐out tolerances 71. . . . . . . . . . . . . . . . . . . . . . . . .

16 Delivery status 72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17 Order numbers 76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18 Accessories 77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A1979-7.1 enHBM

Page 5

T12

5

Safety instructions

Use in accordance with the regulations

The T12 digital torque transducer is used exclusively for torque, rotational

speed, angle of rotation and power measurement tasks and control and

adjustment tasks directly connected thereto. Use for any additional purpose

shall be deemed to be not in accordance with the regulations.

Stator operation is only permitted with an installed rotor.

In the interests of safety, the transducer should only be operated as described

in the operating manual. It is also essential to observe the appropriate legal

and safety regulations for the application concerned during use. The same

applies to the use of accessories.

Each time, before starting up the transducer, you must first run a project plan

ning and risk analysis that takes into account all the safety aspects of automa

tion technology. This particularly concerns personal and machine protection.

The transducer is not a safety element within the meaning of its use as

intended. Proper and safe operation of these transducers require proper

transportation, correct storage, assembly and mounting and careful operation.

This is a Class A product. In a domestic environment this product may cause

radio interference in which case the user may be required to take adequate

measures.

General dangers of failing to follow the safety instructions

The transducer corresponds to the state of the art and is fail‐safe. The

transducer can give rise to remaining dangers if it is inappropriately installed

and operated by untrained personnel.

Everyone involved with the installation, commissioning, maintenance or repair

of the transducer must have read and understood the operating manual and in

particular the technical safety instructions.

Remaining dangers

The scope of supply and performance of the transducer covers only a small

area of torque measurement technology. In addition, equipment planners,

installers and operators should plan, implement and respond to the safety

engineering considerations of torque measurement technology in such a way

as to minimize remaining dangers. Prevailing regulations must be complied

with at all times. Reference must be made to remaining dangers connected

with torque measurement technology.

A1979-7.1 en HBM

Page 6

6

In this Mounting instructions remaining dangers are pointed out using the

following symbols:

T12

Symbol:

Meaning: Maximum danger level

Warns of an imminently dangerous situation in which failure to comply with

safety requirements will result in death or serious physical injury.

Symbol:

Meaning: Potentially dangerous situation

Warns of a potentially dangerous situation in which failure to comply with

safety requirements can result in death or serious physical injury.

Symbol:

DANGER

WARNING

CAUTION

Meaning: Dangerous situation

Warns of a potentially dangerous situation in which failure to comply with

safety requirements could result in damage to property or some form of

physical injury.

Symbols for using advices and helpful information:

Symbol:

Means that important information about the product or its handling is being

given.

Symbol:

Meaning: CE mark

NOTE

The CE mark enables the manufacturer to guarantee that the product com

plies with the requirements of the relevant EC directives (the declaration of

conformity is available at http://www.hbm.com/HBMdoc).

A1979-7.1 enHBM

Page 7

T12

7

Symbol:

Meaning: Statutory marking requirements for waste disposal

National and local regulations regarding the protection of the environment and

recycling of raw materials require old equipment to be separated from regular

domestic waste for disposal.

For more detailed information on disposal, please contact the local authorities

or the dealer from whom you purchased the product.

Conversions and modifications

The transducer must not be modified from the design or safety engineering

point of view except with our express agreement. Any modification shall

exclude all liability on our part for any damage resulting therefrom.

Qualified personnel

The transducer must only be installed and used by qualified personnel, strictly

in accordance with the specifications and with safety requirements and

regulations. It is also essential to observe the appropriate legal and safety

regulations for the application concerned during use. The same applies to the

use of accessories.

Qualified personnel means persons entrusted with the installation, fitting,

commissioning and operation of the product who possess the appropriate

qualifications for their function.

Prevention of accidents

According to the prevailing accident prevention regulations, once the T12

digital torque transducer has been mounted, a cover or cladding has to be

fitted as follows:

• The cover or cladding must not be free to rotate.

• The cover or cladding should avoid squeezing or shearing and provide

protection against parts that might come loose.

• Covers and cladding must be positioned at a suitable distance or so

arranged that there is no access to any moving parts within.

• Covers and cladding must also be attached if the moving parts of the

torque flange are installed outside peoples' movement and operating

range.

A1979-7.1 en HBM

Page 8

8

T12

CAUTION

The protection against contact option, to prevent accidental contact,

must not be used as protection against bursting parts.

The only permitted exceptions to the above requirements are if the various

parts and assemblies of the machine are already fully protected by the design

of the machine or by existing safety precautions.

Warranty

In the case of complaints, a warranty can only be given if the torque

transducer is returned in the original packaging.

A1979-7.1 enHBM

Page 9

T12

1 Scope of supply

• Digital torque transducer (rotor and stator)

• T12 Mounting Instructions

• Quick Start Guide for installing the T12 Assistant control software

• T12 system CD

• Mounting kit

• Test report

• Options:

- Speed measuring system, comprising optical rotational speed sensor and

speed kit (slotted disc, screwdriver, screw locking device, screws)

- Protection against contact

- Mounted coupling

9

2 Operation

The supplied T12 system CD contains the "T12 Assistant" control software.

You can use this software to:

• monitor the correct installation of the torque transducer

• set the signal conditioning (zero balance, filters, scaling)

• protect your settings or load the factory settings

• display and evaluate the measured values

Notes on installing the T12 Assistant on your PC can be found in the "T12

Assistant Control Software" Quick Start Guide. (pdf file on T12 system CD

and part of the “Setup Toolkit for T12" accessory).

Notes on the operation of the T12 Assistant can be found in the program's

online Help, which is called with function key F1 or via the menu bar.

For more information about connecting to fieldbus systems, please refer to the

“T12‐CAN bus/PROFIBUS" operating manual (pdf file on T12 system CD).

A1979-7.1 en HBM

Page 10

10

T12

3 Application

The T12 digital torque transducer records static and dynamic torque at

stationary or rotating shafts measures rotational speed or angle of rotation,

including indication of the direction of rotation, and computes the power. It is

designed for:

• highly dynamic torque measurements when testing the performance and

functionality of engines and compound sets

• high‐resolution speed and angle of rotation measurements

• fast, dynamic performance measurements on engine and transmission test

rigs and roll test stands

Designed to work without bearings and with contactless digital signal

transmission, the torque measuring system is maintenance‐free.

The torque transducer is supplied for nominal (rated) torques of 100 N⋅m to

10 kN⋅m. Depending on the nominal torque, maximum speeds of up to

18 000 rpm

are permissible.

The T12 torque transducer is reliably protected against electromagnetic inter

ference. It has been tested with regard to EMC according to the relevant

European standards, and carries the CE mark.

A1979-7.1 enHBM

Page 11

T12

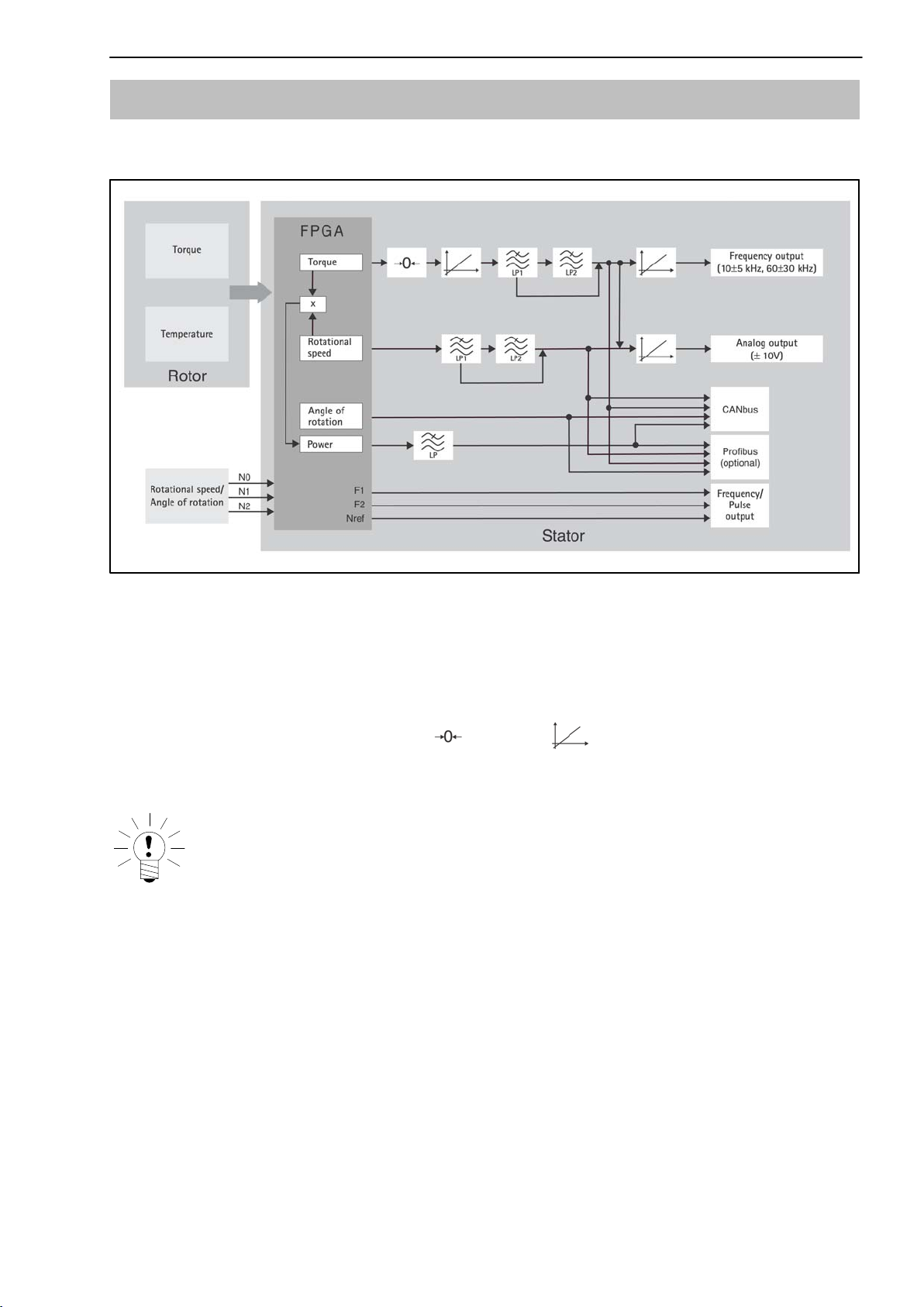

4 Signal flow

Low pass LP1: 0.05 Hz ... 4000 Hz

Low pass LP2: 0.05 Hz ... 100 Hz

Low pass LP: 0.1 Hz ... 80 Hz

11

Fig. 4.1: Signal flow diagram

The torque and the temperature signal are already digitized in the rotor and

transmission is therefore noise‐free.

The torque signal can be zeroed

, scaled (2‐point scaling) and

filtered via two low passes (LP1 and LP2). A further scaling of the frequency

output and the analog output is then possible.

NOTE

Scaling at position

(see Fig. 4.1) changes the internal calibration of

the torque transducer.

The speed signal can be filtered and also scaled for the analog output.

The angle of rotation signal, the performance signal (low pass filter LP) and

the temperature signal are only available on the fieldbusses.

The torque signal and the speed signal can be filtered via two low passes

connected in series, with the filter outputs also being available separately.

The scaled, unfiltered torque signal is used to calculate power. The resultant,

highly‐dynamically calculated power signal is filtered via a further low pass.

A1979-7.1 en HBM

Page 12

12

T12

For settings over 100 Hz (torque low‐pass filter 1 only), phase delay

compensation is run for the angle of rotation signal. This ensures that torque

and angle of rotation values that are measured simultaneously are also output

simultaneously.

For rotational speed and angle of rotation, two pulse series with a shift of 90°

are available as RS‐422 compatible signals.

A1979-7.1 enHBM

Page 13

T12

13

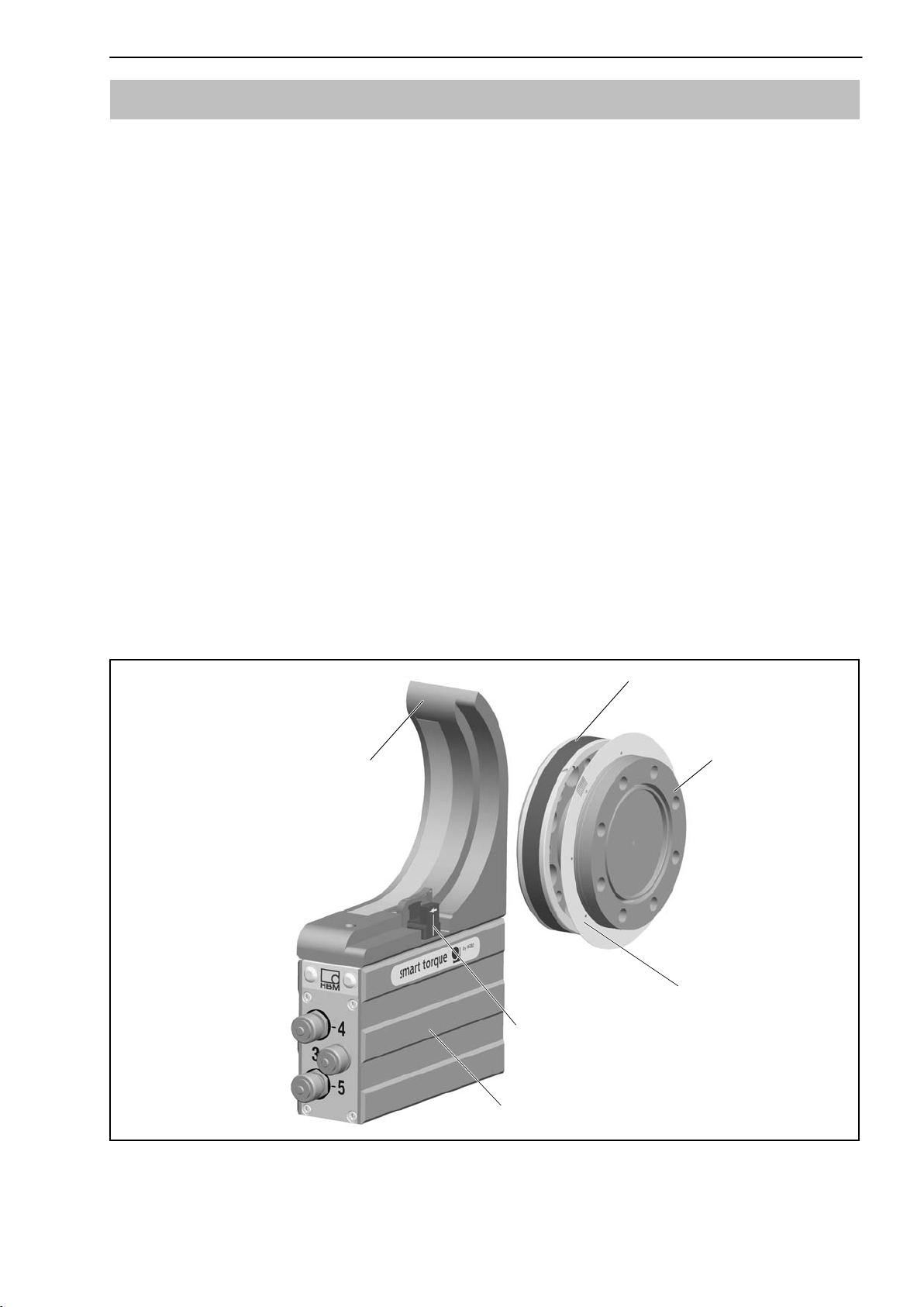

5 Structure and mode of operation

The torque transducer comprises two separate parts: the rotor and the stator.

Strain gages (SGs) for torque measurement have been installed on the rotor.

Carrier frequency technology (19.2 kHz carrier frequency) is used for

analyzing the SG and temperature signal. The rotor temperature is measured

at two measuring points and averaged.

The electronics for transmitting the bridge excitation voltage and the

measurement signal is located centrally in the rotor. The coils for the

noncontact transmission of excitation voltage and measurement signal are

located on the rotor's outer circumference of side A. The signals are sent and

received by a transmitter head. The transmitter head is mounted on the stator,

which houses the electronics for voltage adaptation and signal conditioning.

Connectors for inputs and outputs (for the connector pin assignment, see

chapter 8.3) are located on the stator. The transmitter head encloses the rotor

over a segment of about 120° and should be mounted concentrically around

the rotor (see chapter 6).

In the case of the speed measuring system option, the speed sensor is

mounted on the stator, the customer attaches the associated slotted disc on

the rotor. The optical speed measurement works on the infrared transmitted

light principle.

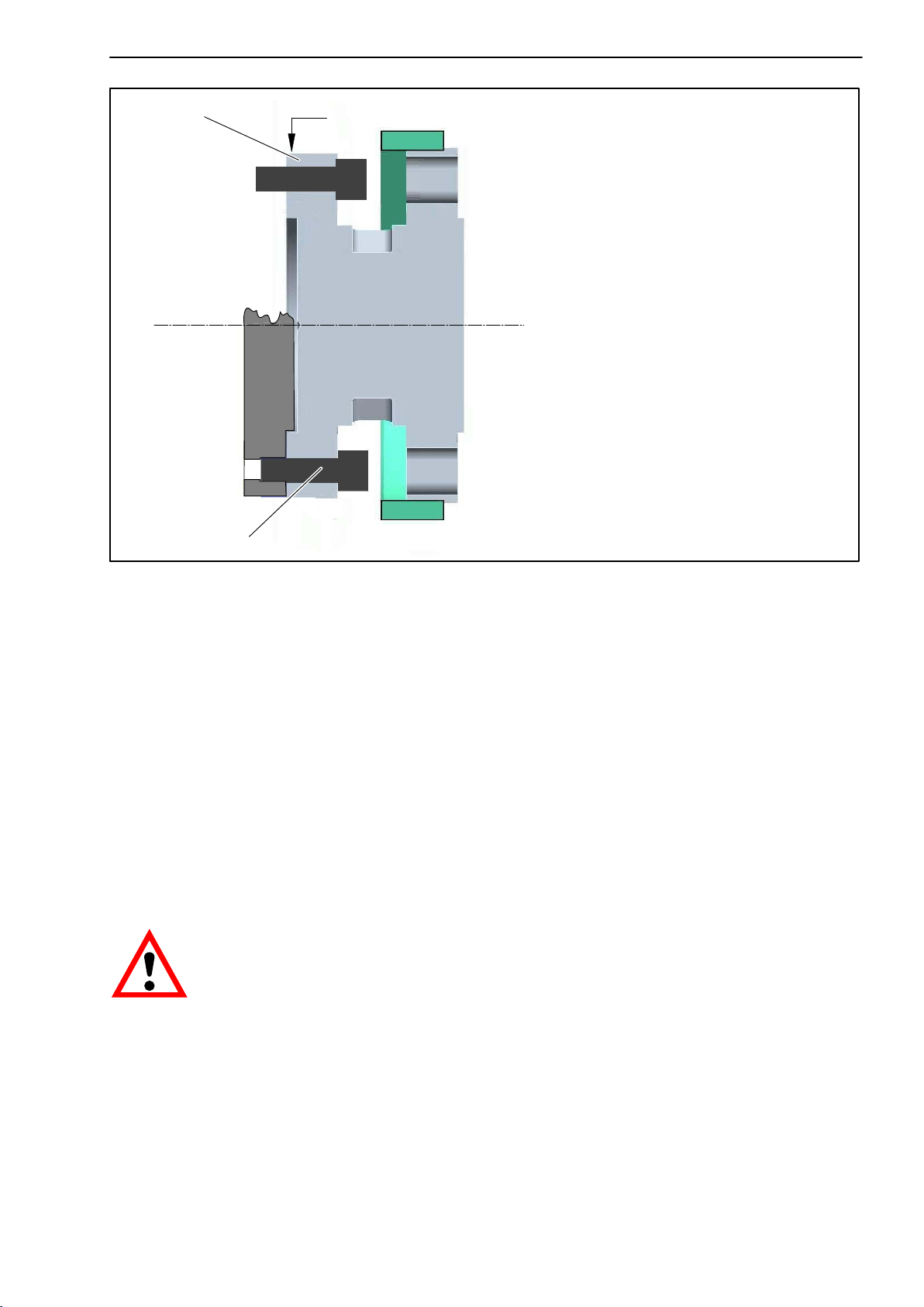

Side A

Transmitter head

Stator

Side B

Rotor

Slotted disc (option)

Speed sensor (option)

Housing

Fig. 5.1: Mechanical structure, exploded view

A1979-7.1 en HBM

Page 14

14

T12

6 Mechanical installation

WARNING

Handle the torque transducer carefully. The transducer might suffer

permanent damage from mechanical shock (e.g. dropping), chemical

effects (e.g. acids, solvents) or thermal effects (e.g. hot air, steam).

With alternating loads, you should glue the rotor connection screws into

the counter thread with a screw locking device (medium strength) to

exclude prestressing loss due to screw slackening.

The T12 torque transducer can be mounted directly with a relevant shaft

flange. It is also possible to directly mount a joint shaft or relevant compensat

ing element on opposite flange (using an intermediate flange when required).

Under no circumstances must the permissible limits specified for bending

moments, transverse and longitudinal forces be exceeded. Due to the torque

transducer's high torsional stiffness, dynamic changes on the shaft run are

minimized.

CAUTION

Check the effect on speeds and natural torsional oscillations critical to

bending, to prevent the transducer being overloaded by increases in

resonance.

6.1 Conditions on site

The T12 torque transducer is protected to IP54 according to EN 60529.

Protect the transducer from coarse dirt, dust, oil, solvents and moisture.

During operation, the prevailing safety regulations for the security of

personnel must be observed (see "Safety instructions").

There is wide ranging compensation for the effects of temperature on the

output‐ and zero signals of the T12 torque transducer (see specifications on

page 51). This compensation is carried out at static temperatures. This

guarantees that the circumstances can be reproduced and the properties of

the transducer can be reconstructed at any time.

If there are no static temperature ratios, for example, because of the temper

ature differences between flange A and flange B, the values given in the spe

cifications can be exceeded. Then for accurate measurements, you must

A1979-7.1 enHBM

Page 15

T12

15

ensure static temperature ratios by cooling or heating, depending on the

application. As an alternative, check thermal decoupling, by means of heat

radiating elements such as multiple disc couplings.

6.2 Mounting position

The transducer can be mounted in any position. With clockwise torque, the

output frequency is 10...15 kHz (Option 4, Code DF1/DU2: 60 kHz ... 90 kHz).

In conjunction with HBM amplifiers or when using the voltage output, a

positive output signal (0 V to +10 V) is present.

With counterclockwise torque, the output frequency is 5 kHz...10 kHz (Option

4, Code DF1/DU2: 30 kHz ... 60 kHz).

In the case of the speed measuring system, an arrow is attached to the head

of the sensor to clearly define the direction of rotation. When the transducer

rotates in the direction of the arrow, a positive speed signal is output.

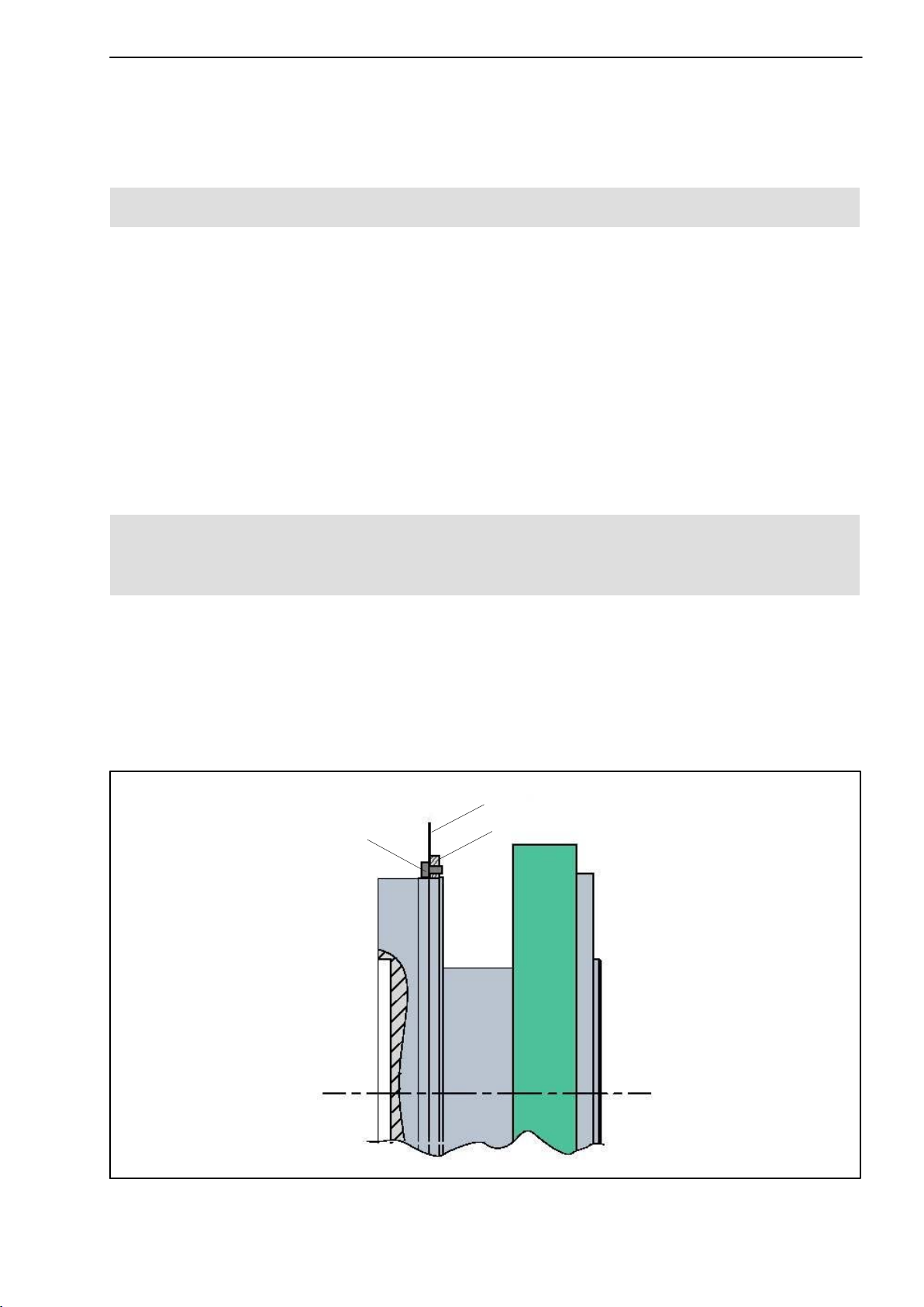

6.3 Installing the slotted disc (speed measuring system

only)

To prevent damage to the speed measuring system's slotted disc during

transportation, it is not mounted on the rotor. Before installing the rotor in the

shaft run, the customer must attach it to the mounting ring. The mounting ring

and the associated speed sensor are already fitted at the factory.

The requisite screws, a suitable screwdriver and the screw locking device are

included in the list of components supplied.

Slotted disc

Fastening screw

Mounting ring

Fig. 6.1: Installing the slotted disc

A1979-7.1 en HBM

Page 16

16

CAUTION

When carrying out installation work, be careful not to damage the

slotted disc!

Installation sequence

1. Push the slotted disc onto the mounting ring and align the screw holes.

2. Apply some of the screw locking device to the screw thread and tighten

the screws (tightening torque < 0.15 N⋅m).

6.4 Installing the rotor

T12

NOTE

In general, the rotor identification plate is no longer visible after

installation. This is why we include with the rotor additional stickers

with the important ratings, which you can attach to the stator or any

other relevant test‐bench components. You can then refer to them

whenever there is anything you wish to know, such as the shunt signal.

Data can also be accessed through T12 Assistent.

To explicitly assign the data, the identification number and the

measuring range are specified on the rotor where they can be seen from

outside.

A1979-7.1 enHBM

Page 17

T12

17

Fig. 6.2: Screw connections, flange B

1. Prior to installation, clean the plane surfaces of the transducer flange and

the counter flange. For safe torque transfer, the surfaces must be clean

and free from grease. Use a piece of cloth or paper soaked in solvent.

When cleaning, make sure that you do not damage the transmitter coils.

2. For the flange A screw connections, use hexagon‐socket screws DIN EN

ISO 4762 of property class 10.9 (measuring range 3 kN@m ... 10 kN@m:

12.9) of the appropriate length (depending on the connection geometry,

see Table 6.1).

We recommend fillister‐head screws DIN EN ISO 4762 or similar,

blackened, smoothheaded, permitted size and shape variance in

accordance with DIN ISO 4759, Part 1, product class A.

WARNING

With alternating load: Use a screw locking device (e.g. LOCTITE no. 242)

to glue the screws into the counter thread to exclude prestressing loss

due to screw slackening.

3. First tighten all the screws crosswise with 80% of the prescribed tightening

torque (Table 6.1), then tighten again crosswise, with the full tightening

torque.

A1979-7.1 en HBM

Page 18

18

4. There are relevant tapped holes on flange A for continuing the shaft run

mounting. Again use screws of property class 10.9 (measuring range of

3 kN@m ... 10 kN@m: 12.9) and tighten them with the prescribed torque, as

specified in Table 6.1.

Flange A

Fastening screw Z

T12

Fastening screw Z

Fig. 6.3: Screw connections, flange A

NOTE

Even if mounted correctly, the zero point adjusted at the factory may be

offset by up to 3 %. If this value has been exceeded, we recommend to

check the mounting conditions. If the remaining zero point offset is

greater than 1 % after dismounting, please send your transducer to our

factory in Darmstadt for evaluation.

CAUTION

With alternating loads, use a screw locking device to glue the

connecting screws into place. Guard against contamination from

varnish fragments.

A1979-7.1 enHBM

Page 19

T12

19

Measuring range

(NVm)

100 / 200 M8

500 M10 67

1 k M10 67

2 k M12 115

3 k M12

5 k M14 220

10 k M16 340

Fastening screws

(Z)

1)

Fastening screws

Property class

10.9

12.9

Prescribed

tightening torque

(NVm)

34

135

Table 6.1: Fastening screws

1)

DIN EN ISO 4762; black/oiled/m

= 0.125

tot

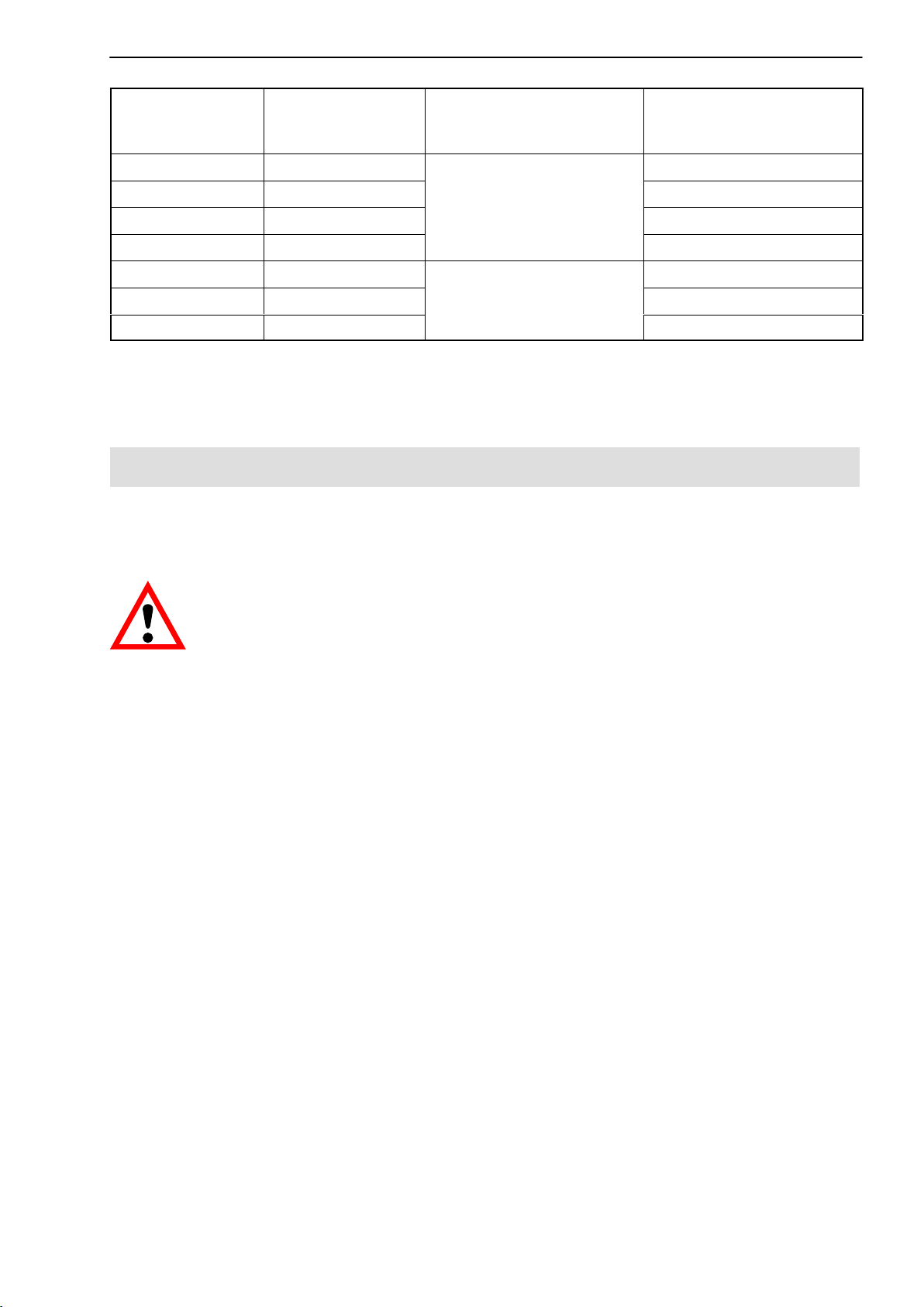

6.5 Fitting the protection against contact (option)

The protection against contact comprises two side parts and four covers. It is

screwed onto the stator housing.

CAUTION

Use threadlocker (e.g. LOCTITE 242) for locking all connecting screws.

1. Remove the side cover plates on the stator housing (see Fig. 6.4.)

A1979-7.1 en HBM

Page 20

20

T12

Cover plate

Cover plate

Fig. 6.4: Cover plates on the stator housing

2. For 500 N@m - 3 kN@m measuring ranges and retrospective protec

tion against contact orders only: The tapped holes for the stop screws

are partly covered by the attached film. Make a semicircular cutout in the

film here, at least 6 mm in radius (e.g. with a cutter, see Fig. 6.5).

Now remove the threaded pins from the tapped holes on both sides of the

stator.

Threaded pin

Fig. 6.5: Cut out the film

A1979-7.1 enHBM

Page 21

T12

21

3. For 5 kN@m and 10 kN@m measuring ranges only: remove the threaded

pins from the tapped holes on both sides of the stator. Screw the spacing

bolt into the tapped hole on the side of the speed sensor (see Fig. 6.6).

Threaded pin

Spacing bolt

1

2

Fig. 6.6: Fitting the spacing bolt (for 5 kN@m and 10 kN@m only)

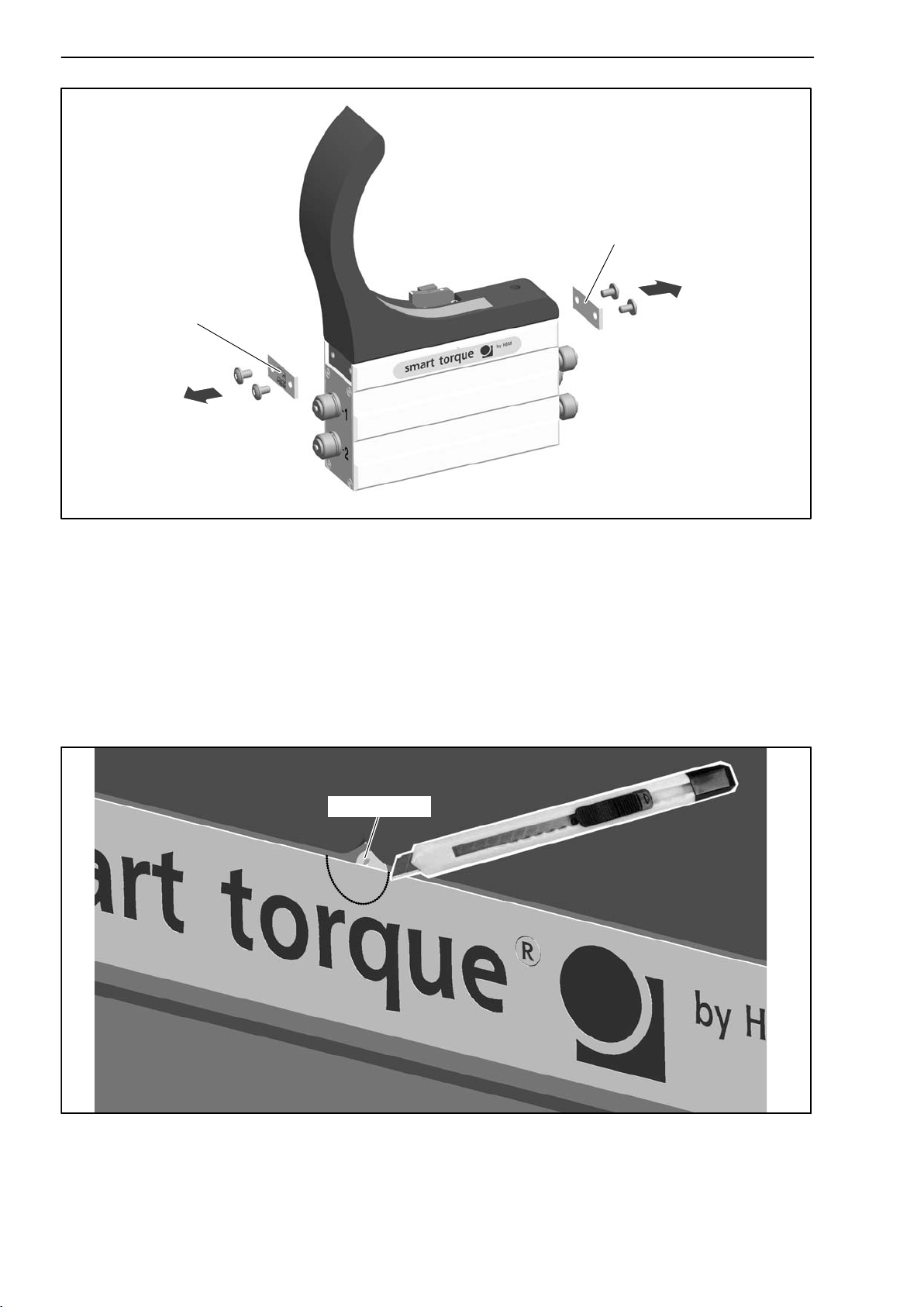

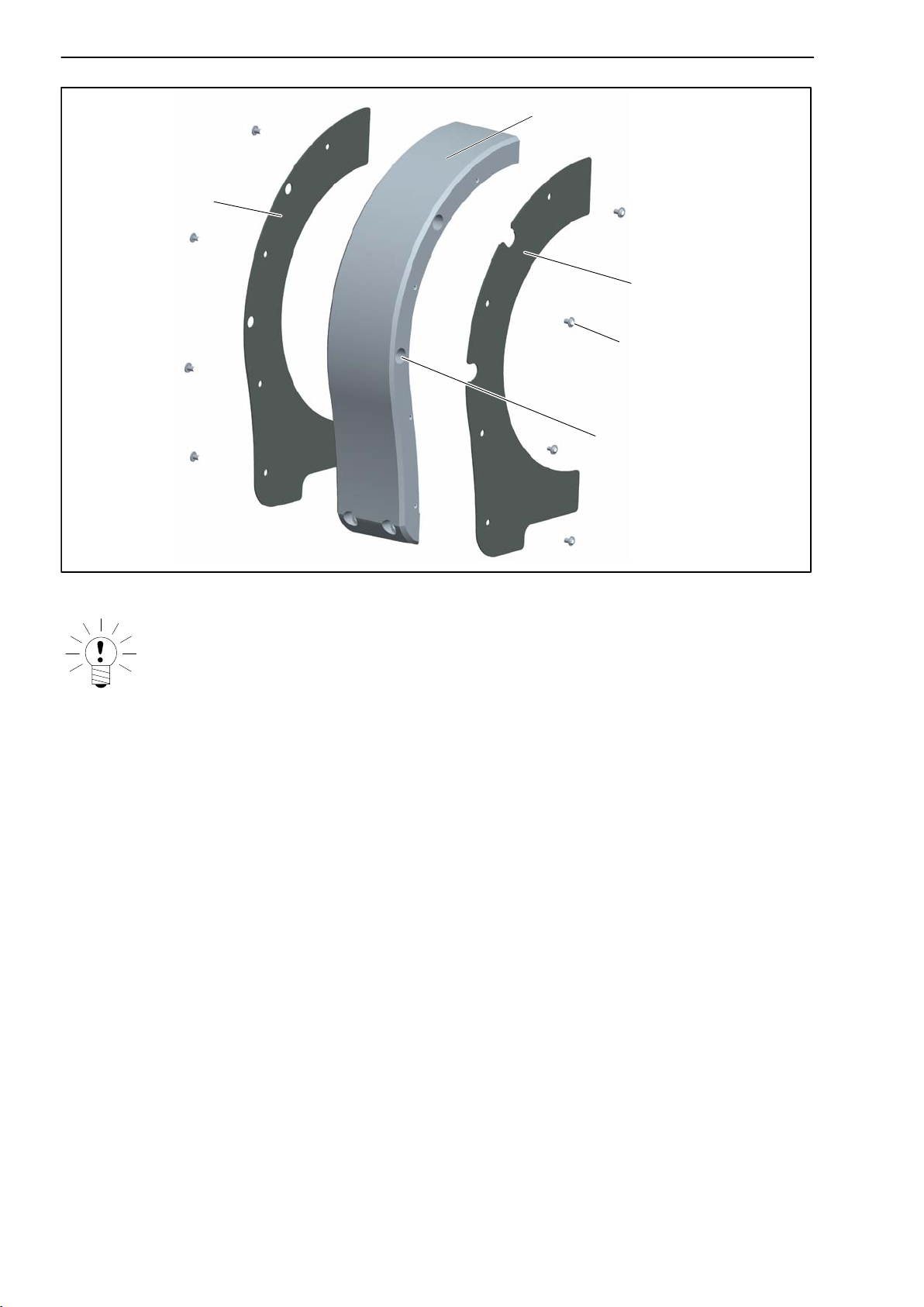

4. Screw the covers onto the side parts (use hexagon socket, 2 AF; tigh

tening torque M

= 1 N@m). It is essential to fit the cover with the cutouts

A

onto the side with the countersinks (see Fig. 6.7).

A1979-7.1 en HBM

Page 22

22

Cover with holes

T12

Side part

Cover with cutouts

2 AF

Countersink

Fig. 6.7: Fit the covers

NOTE

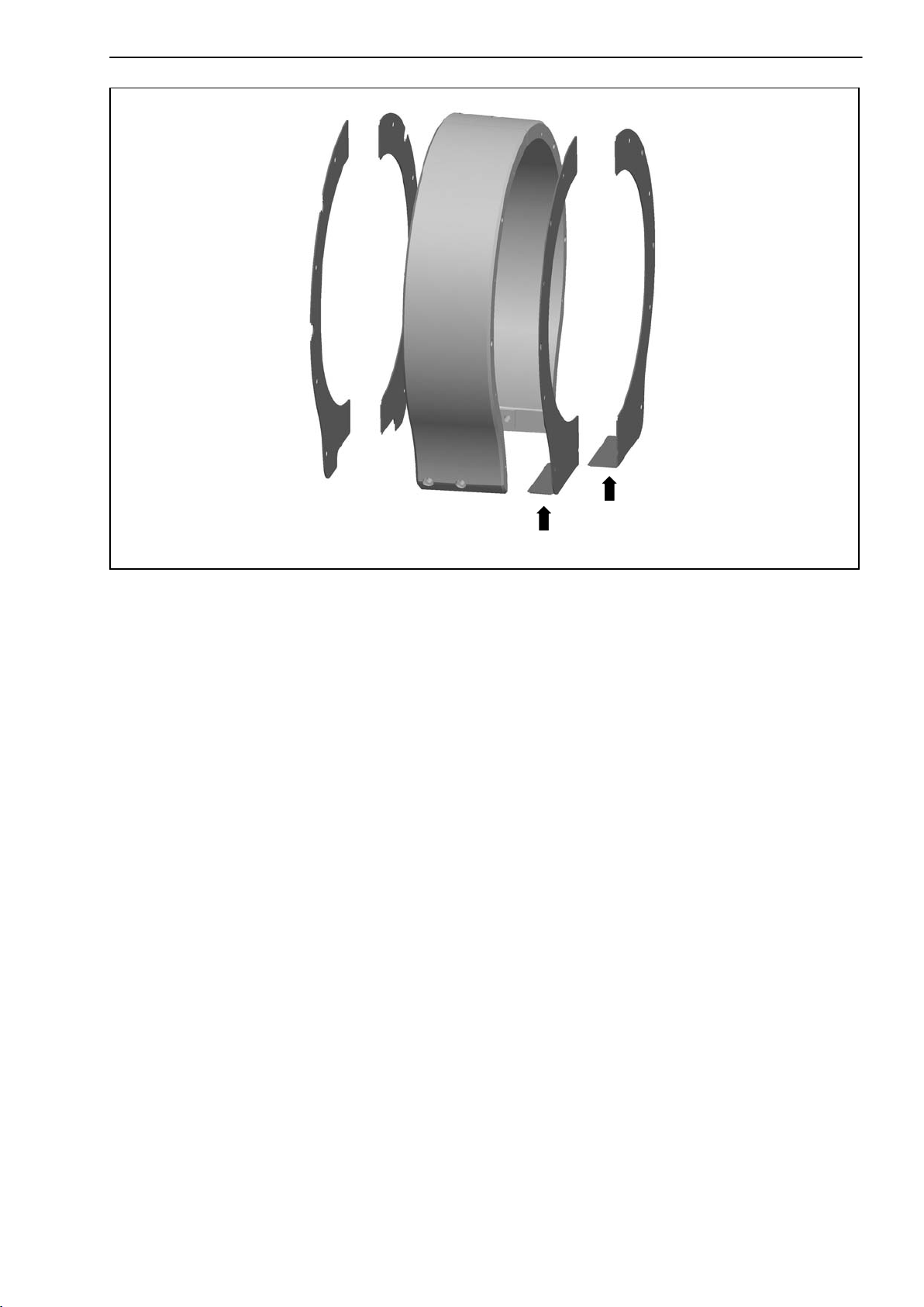

With the 5 kN@m and 10 kN@m measuring ranges, the cover plates of the

speed sensor side are angled at the bottom and must be fitted as shown

in Fig. 6.8.

A1979-7.1 enHBM

Page 23

T12

23

Fig. 6.8: Angled cover plates (for 5 kN@m and 10 kN@m measuring ranges)

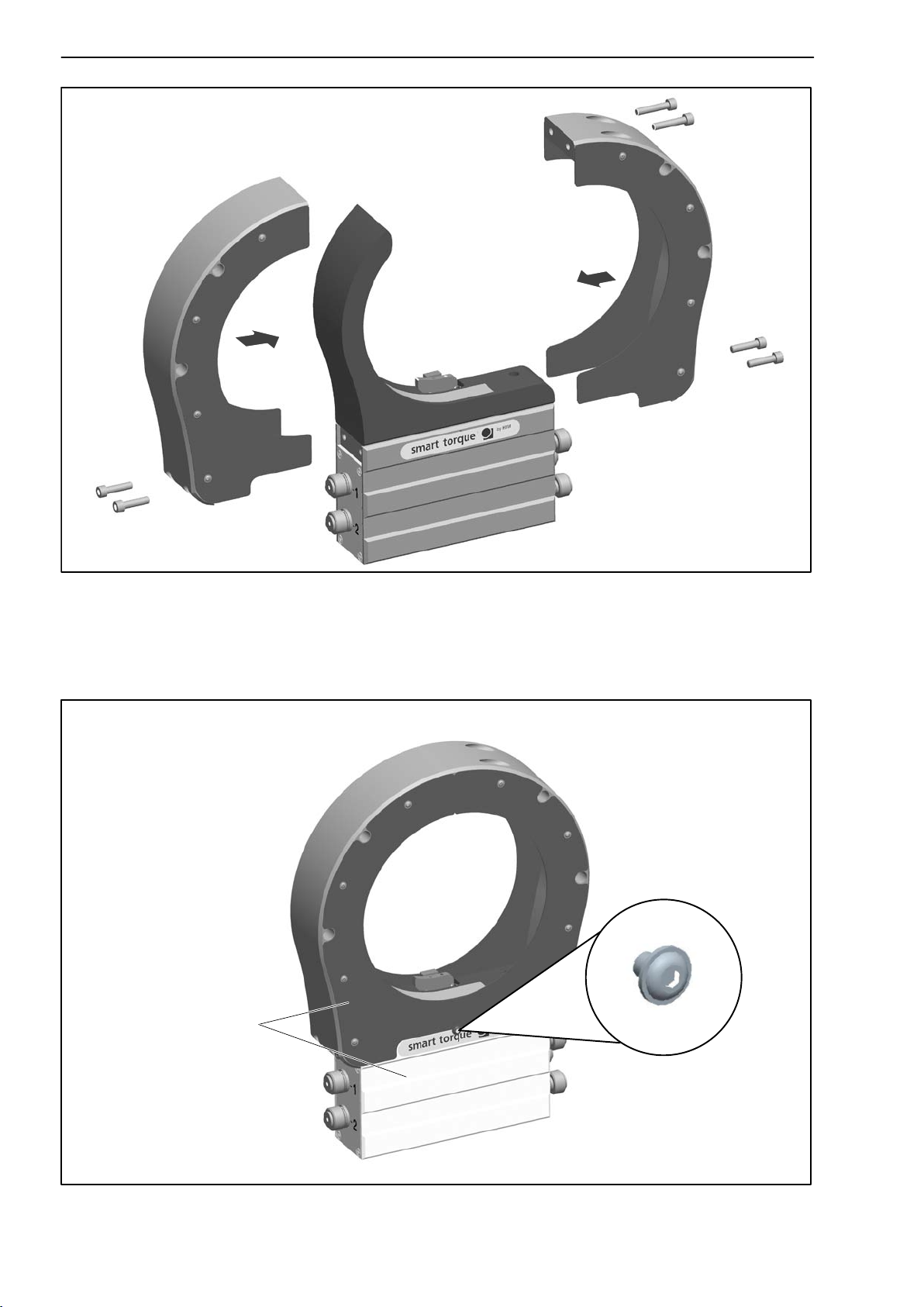

5. Fasten the preassembled side parts on the stator housing, each with two

M6 x 25 hexagon‐socket screws (5 AF). Tighten the screws hand‐tight.

6. Apply some of the screw locking device to the screw threads and screw

the side parts together, hand‐tight (2 M6 x 30 hexagon‐socket screws;

5 AF).

A1979-7.1 en HBM

Page 24

24

T12

M6 x 30

M6 x 25

M6 x 25

Fig. 6.9: Fit the halves of the protection against contact

7. Align the protection against contact in such a way that its end face is par

allel to the stator housing.

Stop screw (on

both sides)

Parallel surfaces

Fig. 6.10: Check for parallelism

A1979-7.1 enHBM

Page 25

T12

25

8. Now tighten all the screws with a tightening torque M

of 14 N@m.

A

9. Screw in the stop screws of the covers with a tightening torque of 2 N@m.

6.6 Installing the stator

On delivery, the stator has already been installed and is ready for operation.

There are four tapped holes on the base of the stator housing for mounting

the stator. Externally, two with a metric M6 thread, internally, two with a UNF

1/4" thread (closed with a plastic threaded pin).

For installation with metric thread, we recommend using two

DIN EN ISO 4762

10.9 of the appropriate length (depending on the connection geometry; not

included among the components supplied; tightening torque = 14 N@m).

NOTE

fillister‐head screws with hexagon sockets of property class

Provide a possibility for adjustment (e.g. slotted holes) for aligning

stator and rotor.

The stator can be mounted radially in any position (for example, "upside

down" installation is possible). You can also install the stator over the

protection against contact (option), see chapter 6.6.3.

maximum screw-in depth 10

maximum screw-in depth

+1

Fig. 6.11: Mounting holes in the stator housing (viewed from below)

With 5 kN⋅m and 10 kN⋅m torque transducers, we recommend supporting the

stator at the protection against contact in addition. Fig. 6.10 shows an exam

ple of how to fix an angle bracket using a bolt (A) or a threaded rod (B).

Please note that in this case the cover plates cannot be installed.

A1979-7.1 en HBM

Page 26

26

T12

A

B

∅6,6

∅11

Section through the countersink in the protection

against contact

Fig. 6.12: Supporting the stator with an angle bracket (5 kN⋅m and 10 kN⋅m)

6.6.1 Preparing with the mounting kit (included among the items sup

plied)

The supplied mounting kit contains self‐adhesive spacers, to make it easier

for you to align the stator to the rotor.

Use the spacers to align the rotor and the stator radially and axially.

Remove the

protective film

Fig. 6.13: Mounting kit spacer

A1979-7.1 enHBM

Page 27

T12

27

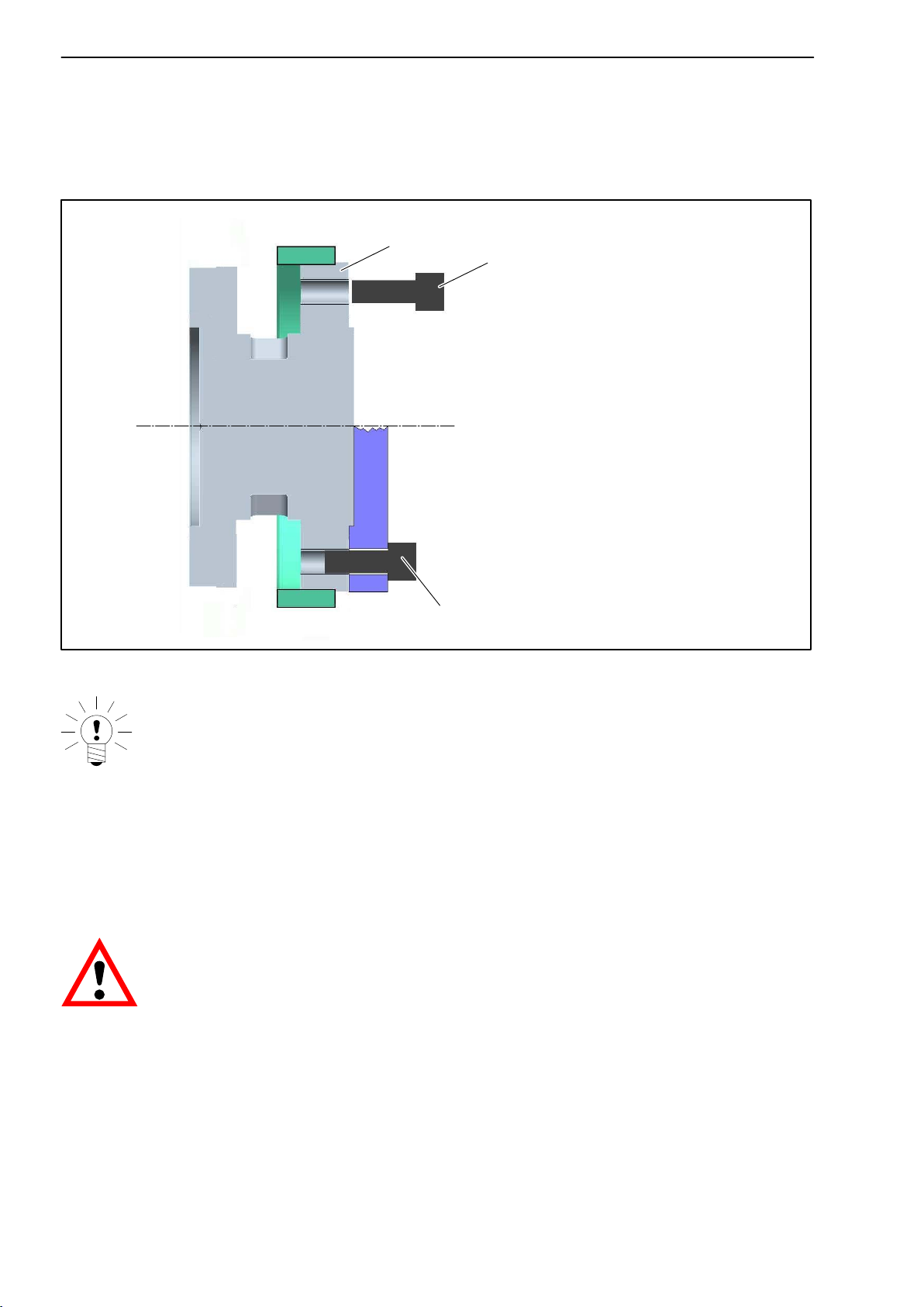

Radial alignment with spacers

The spacers should preferably be attached to the transmitter head, offset by

90°, as shown in Fig. 6.14. If your stator is equipped with a speed measuring

system, you must either shorten the spacers to an appropriate length or bond

them on a slightly staggered manner next to the speed measuring system.

90°

Spacers

Fig. 6.14: Radial position of the spacers

A1979-7.1 en HBM

Page 28

28

T12

Axial alignment with spacers

The red line on the spacers is used for axial alignment. Align the spacer in

such a way that the outer edge of the transmitter head is in line with the red

line (see Fig. 6.15).

Outer edge of

transmitter head

Red line

Fig. 6.15: Axial position of the spacers

Now remove the protective film and attach the spacer to the transmitter head,

as described.

CAUTION

Remove the spacers after installation.

6.6.2 Aligning the stator

1. Position the stator on an appropriate base plate in the shaft run, so that

there are sufficient opportunities for horizontal and vertical adjustments to

be made.

2. Should there be any misalignment in height, compensate for this by

inserting adjusting washers.

3. Initially, the fastening screws should only be hand‐tight.

4. Use the spacers to radially align the stator to the rotor.

A1979-7.1 enHBM

Page 29

T12

29

5. Use the spacers to axially align the stator to the rotor. The rotor should be

in line with the edge of the red spacer, see Fig. 6.16.

Transmitter rotor

Alignment line

Spacer

Fig. 6.16: Axial alignment to the rotor

6. Connect the power line (connector 1 or connector 3). Notice the LED to

the right of connector 4. The stator is correctly aligned, when the LED

successively

• flashes red for about 10 seconds

• flashes yellow for about 10 seconds

• then stays permanently green (CAN bus) or yellow or green

(PROFIBUS).

NOTE

When data are being exchanged via the CAN bus or the PROFIBUS, the

LED flashes green.

You can also use the T12 Assistant to check for the correct alignment. The

LED must stay green in the "Rotor clearance setting mode".

7. Now fully tighten the fastening screws (tightening torque: 14 N@m).

8. Remove the spacers, by first removing the adhesive strip and then the red

plastic strip.

A1979-7.1 en HBM

Page 30

30

9. Make sure that the air gap between the rotor and stator is free from

electrically conductive and other foreign matter.

6.6.3 Stator installation over the protection against contact (option)

You can also axially flange the stator over the protection against contact

(material: aluminum). Holes are provided in the side parts of the protection

against contact for this purpose. For this mounting, we recommend

fillister‐head screws M6 with hexagon sockets in accordance with

DIN EN ISO 4762; black/oiled/m

=0.125, of the appropriate length.

tot

T12

Fig. 6.17: Mounting holes in the protection against contact

A1979-7.1 enHBM

Page 31

T12

b

2

b

8

Customer adaptation

∅6.6

∅11

Measuring range Dimensions in mm

31

100 N⋅m ... 3 kN⋅m 56 43

5 kN⋅m 78 65

10 kN⋅m 86 73

Table 6.2: Mounting hole dimensions

b

2

b

8

Fig. 6.18: Face‐mounting on the engine shielding

6.7 Optical speed/angle of rotation measuring system

(option)

As the stator with the optical speed sensor only partially encloses the slotted

disc, if there is sufficient space available for installation, you can subsequently

move the stator tangentially over the ready‐mounted rotor.

For perfect measuring mode, the slotted disc of the speed measuring system

must rotate at a defined position in the sensor pickup.

A1979-7.1 en HBM

Page 32

32

T12

Axial alignment

There is a mark (orientation line) in the sensor pickup for axial alignment

(orientation line). When installed, the slotted disc should be exactly above this

orientation line. Divergence of up to "2 mm is permissible in measuring

mode (total of static and dynamic shift).

Slotted disc

Flange B

Orientation lines

Sensor pickup

Fig. 6.19: Position of the slotted disc in the speed sensor

Radial alignment

The rotor axis and the optical axis of the speed sensor must be along a line at

right angles to the stator platform. A conical machined angle (or a colored

mark) in the center of flange A and a vertical marker line on the sensor pickup

serve as aids to orientation.

A1979-7.1 enHBM

Page 33

T12

Centering point for aligning

the rotor

33

Marking

Fig. 6.20: Alignment marks on rotor and stator

Connect the power line (connector 1).

Switch the LED display mode of the T12 Assistant to "optical speed system"

setting mode and turn the rotor. Notice the LED to the right of connector 4;

this must stay green if the setting is correct (also see chapter 7.3).

CAUTION

Angle of rotation measurement is not suitable for static and quasi‐static

applications!

A1979-7.1 en HBM

Page 34

34

T12

7 LED status display

The LED in the stator housing (next to male device connector 4) has three

display modes: Standard (measuring mode), rotor clearance setting mode and

optical speed system setting mode.

7.1 Measuring mode operation

LED color Significance

Flashing green (fast) SDO Transfer taking place

Flashing green CAN Device has Operational status

Green For PROFIBUS option only: Data Exchange taking place

Flashing yellow (slow) Rotor communication taking place

Yellow For PROFIBUS option only: Searching for the baud rate or parameteriz

ation or configuration taking place or no Data Exchange taking place

Flashing red Overflow for measured value (amplifier input, measured value Ovfl.),

frequency or analog output

Red Error situation

1)

When PROFIBUS option exists: Messages to the PROFIBUS take precedence over messages to the CAN

bus.

1)

1)

7.2 Rotor clearance setting mode operation

LED color Significance

Green Rotor‐Stator alignment is OK

Yellow Rotor‐Stator alignment is borderline

Red Rotor‐Stator alignment is not OK

7.3 Speed measuring system setting mode operation

LED color Significance

Green The position of the two sensors is OK, the signals (F1/F2) are 90° or

270° phase‐shifted and can be correctly evaluated

Yellow The phase relation of the two sensor signals is not optimum, there is a

variation of 10° to 30°

Red The phase relation of the two sensor signals is not correct, there is a

variation of more than 30°

For more information on setting mode, look in the T12 Assistant online Help.

A1979-7.1 enHBM

Page 35

T12

35

8 Electrical connection

8.1 General hints

Detailed instructions for connecting the T12 to the CAN bus or the PROFIBUS

can be found in the "T12‐CAN bus/PROFIBUS" Internet description (in pdf

format) on the T12 system CD.

To make the electrical connection between the torque transducer and the

measuring amplifier, we recommend using shielded, low‐capacitance

measurement cables from HBM.

With cable extensions, make sure that there is a proper connection with

minimum contact resistance and good insulation. All plug connections or

sleeve nuts must be properly tightened.

Do not route the measurement cables parallel to power lines and control

circuits. If this cannot be avoided (in cable pits, for example), maintain a

minimum distance of 50 cm and also draw the measurement cable into a steel

tube.

Avoid transformers, motors, contactors, thyristor controls and similar

stray‐field sources.

CAUTION

Transducer connection cables from HBM with attached connectors are

identified in accordance with their intended purpose (Md or n). When

cables are shortened, inserted into cable ducts or installed in control

cabinets, this identification can get lost or become concealed. If this is

the case, it is essential for the cables to be re‐labeled!

NOTE

Cables and connectors for connections 1, 2 and 3 are compatible with

the T10FS torque flange.

8.2 Shielding design

The cable shielding is connected in accordance with the Greenline concept.

This encloses the measurement system (without a rotor) in a Faraday cage. It

is important that the shield is laid flat on the housing ground at both ends of

the cable. Any electromagnetic interference active here does not affect the

A1979-7.1 en HBM

Page 36

36

T12

measurement signal. Signal transmission between transmitter head and rotor

is purely digital and special electronic coding methods are used to protect

from electromagnetic interference.

In the case of interference due to potential differences (compensating

currents), supply voltage zero and housing ground must be disconnected on

the amplifier and a potential equalization line established between the stator

2

housing and the amplifier housing (copper conductor, 10 mm

wire cross

section).

If potential differences arise between the rotor and the stator on the machine,

perhaps due to unchecked leakage, and this causes interference, it can usu

ally be overcome by connecting the rotor directly to ground, for instance by a

wire loop. The stator should be fully grounded in the same way.

8.3 Connector pin assignment

Assignment for connector 1:

Supply voltage and frequency output signal.

Binder 423

61

5

72

3

4

Top view

Con

nector

pin

1 Torque measurement signal (frequency

2 Supply voltage 0 V; bk 5

3 Supply voltage 18 V ... 30 V bu 6

4 Torque measurement signal (frequency out

5

6 Shunt signal activation 5 V...30 V and TEDS

7

Assignment Color

output; 5 V

put; 5 V

Measurement signal 0 V;

for torque

Shunt signal 0 V;

Shielding connected to enclosure ground

1)

)

1)

) rd 12

symmetrical

Sub‐D

code

wh 13

connector

gy 8

gn 14

gy 8

pin

1)

Complementary signals RS‐422; for cable lengths of 10 m and longer, we recommend to

use a termination resistor R=120 ohms between wires (wh) and (rd).

CAUTION

Torque transducers are only intended for operation with a DC supply

voltage (separated extra‐low voltage), see page 36.

A1979-7.1 enHBM

Page 37

T12

Assignment for connector 2: Speed measuring system

37

Binder 423

Connector

pin

Assignment Color

code

Sub‐D

connector

pin

1 Speed measurement signal (pulse string,

1)

5 V

; 0°)

2

7

6

1

8

3

4

5

2

3 Speed measurement signal (pulse string,

4 No function bk

5

No function

1)

5 V

; 90°phase shifted) gy

TEDS for rotational speed

rd 12

bu

vt

6 Speed measurement signal (pulse string,

1)

5 V

Top view

; 0°)

7

8

Speed measurement signal (pulse string,

1)

5 V

; 90°phase shifted)

Measurement signal 0 V;

wh 13

gn

2)

bk

Shielding connected to enclosure ground

1)

Complementary signals RS‐422; for cable lengths of 10 m and longer, we recommend to use

a termination resistor R=120 ohms between wires (rd) and (wh) as well as (gy) and (gn).

2)

Wire color brown (br) with Kab 163 and Kab 164

2

15

3

9

14

8

Assignment for connector 2: Speed measuring system with reference pulse

Binder 423

pin

1 Speed measurement signal (pulse string,

2

Connector

7

6

1

8

3

4

5

2

3 Speed measurement signal (pulse string,

4 Reference signal (1 pulse/rev., 5 V1)) bk 3

5

6 Speed measurement signal (pulse string,

7

Top view

1)

Complementary signals RS‐422; for cable lengths of 10 m and longer, we recommend to use

8

a termination resistor R=120 ohms between wires (rd) and (wh); (bu) and (bk); (gy) and (gn).

2)

Wire color brown (br) with Kab 163 and Kab 164

Assignment Color

code

rd 12

1)

5 V

; 0°)

Reference signal (1 pulse/rev., 5 V1))

1)

5 V

; 90°phase shifted)

2)

TEDS for speed

1)

5 V

; 0°)

bu 2

gy

vt 9

wh 13

Speed measurement signal (pulse string,

1)

5 V

; 90°phase shifted)

Measurement signal 0 V;

gn

bk

2)

Shielding connected to enclosure ground

Sub‐D

connector

pin

15

14

8

A1979-7.1 en HBM

Page 38

38

Assignment for connector 3:

Supply voltage and voltage output signal.

T12

Binder 423

61

72

5

3

4

Top view

Connector

pin

1

2

3 Supply voltage 18 V to 30 V DC

4

5 No function

6 Shunt signal activation 5 V...30 V and TEDS for torque

7

Assignment

Torque speed measurement signal (voltage output; 0 V )

or speed measurement signal (0V)

Supply voltage 0 V;

Torque speed measurement signal (voltage output; "10 V)

or speed measurement signal ("10 V)

Shunt signal 0 V;

Shielding connected to enclosure ground

CAUTION

Do not use cable KAB 149 to connect the voltage output signal at AP01i

to ML01B of the MGCplus system! This cable is only suitable for the

frequency output signal connection.

NOTE

The analog output is designed as a monitoring output. The power

transmission of the torque transducer can cause interference on the

connected cable of up to 40 mV at 13.56 MHz. This interference can be

suppressed by connecting a 100 nF capacitor in parallel, directly at the

connected measuring device.

A1979-7.1 enHBM

Page 39

T12

Assignment for connector 4:

CAN bus standard; A‐coded, black washer

39

Binder 713

(M12x1)

5

Top view

12

43

Connector

pin

1 Shielding -

2

3 CAN ground -

4 CAN HIGH‐dominant high wh

5

Assignment Color

No function

CAN LOW‐dominant low

Shielding connected to enclosure ground

Assignment for connector 5:

CAN bus, second device connector; A‐coded, black washer

Binder 713

(M12x1)

12

Connector

pin

1 Shielding -

Assignment Color

code

-

bu

code

5

Top view

2

3 CAN ground -

4 CAN HIGH‐dominant high wh

43

5

No function

CAN LOW‐dominant low

Shielding connected to enclosure ground

Assignment for connector 5:

PROFIBUS (Option); B‐coded, violet washer

Binder 715

(M12x1)

5

Top view

12

43

Connector

pin

1 5 V (typ. 50 mA)

2

3 PROFIBUS ground

4 PROFIBUS B

5

Assignment

PROFIBUS A

Schielding

Shielding connected to enclosure ground

-

bu

A1979-7.1 en HBM

Page 40

40

T12

8.4 Supply voltage

The transducer has to be operated with a separated extra‐low voltage

(18 ... 30 V DC supply voltage) which normally supplies one or several con

sumer loads in a test bench. If the transducer is to be operated in a DC

1)

voltage network

voltages.

8.4.1 Supply voltage for self‐contained operation

The notes in this section relate to the self‐contained operation of the T12

without HBM system solutions.

The supply voltage is electrically isolated from signal outputs and shunt signal

inputs.

Connect a separated extra‐low voltage of 18 V...30 V to pin 3 (+) and pin 2

) of connectors 1 or 3. We recommend that you use HBM cable

(

KAB 8/00-2/2/2 and the relevant female Binder connectors, that at nominal

(rated) voltage (24 V) can be up to 50 m long and in the nominal voltage

range, 20 m long (see Accessories, Page 77). If the permissible cable length

is exceeded, you can supply the voltage in parallel over two connection

cables (males connectors 1 and 3). This enables you to double the

permissible length. Alternatively an on‐site power pack should be installed.

, additional measures have to be taken for discharging over

If you feed the supply voltage through an unshielded cable, the cable must be

twisted (interference suppression). We also recommend that a ferrite element

should be located close to the connector on the cable, and the stator should

be grounded.

CAUTION

The instant you switch on, a current of up to 4 A may flow and this may

switch off power packs with electronic current limiters.

1)

Distribution system of major size (e. g. including several test benches) for electrical power which may also

supply consumer loads with high nominal (rated) currents.

A1979-7.1 enHBM

Page 41

T12

41

9 Shunt signal

The T12 torque transducer supplies an electrical shunt signal, at either 50 %

or 10 % of the nominal (rated) torque, as selected. Activate this function via

the T12 Assistant or the shunt signal activation on connector 1 or connector 3

(see chapter 8.3). The shunt signal selected last in the T12 Assistant will then

be activated.

NOTE

Due to the internal singal processing, activation of the shunt signal may

be delayed by about 5 seconds.

To obtain stable conditions, the shunt signal should only be activated once the

transducer has been warming up for 15 minutes.

To enable the values of the test report to be reproduced, the bonndary condi

tions of comparability (e. g. mounting conditions) have to be reproduced.

NOTE

When measuring the shunt signal, the transducer should not be loaded,

because the signal is applied in addition.

The shunt signal is automatically deactivated after about 5 minutes.

A1979-7.1 en HBM

Page 42

42

T12

10 Loading capacity

Nominal (rated) torque can be exceeded statically up to the limit torque. If the

nominal torque is exceeded, additional irregular loading is not permissible.

This includes longitudinal forces, lateral forces and bending moments. Limit

values can be found in the "Specifications" section, Page 51.

10.1 Measuring dynamic torque

The torque transducer is suitable for measuring static and dynamic torques.

The following applies to the measurement of dynamic torque:

• The T12 calibration run for static measurements is also valid for dynamic

torque measurements.

• The natural frequency f

the moments of inertia J

of the mechanical measuring system depends on

0

and J2 of the connected rotating masses and the

1

T12's torsional stiffness.

Use the equation below to approximately determine the natural frequency f

0

of

the mechanical measuring system:

f0+

1

· cT·

2p

Ǹ

ǒ

f

)

1

Ǔ

J

2

1

J

1

0

J

c

= natural frequency in Hz

J2= mass moment of inertia in kg⋅m

1,

= torsional stiffness in N⋅m/rad

T

2

• The maximum vibration bandwidth is 200 % (measuring ranges 3 kN@m ...

10 kN@m: 160 %) of the typical nominal (rated) torque for the T12 (see the

specifications, Page 51). The vibration bandwidth must fall within the load

range designated by the upper and lower maximum torques. The same

also applies to transient resonance points.

Upper maximum

torque 100 %

0

Lower maximum

torque 100 %

Fig. 10.1: Permissible dynamic loading

Vibration bandwidth

200 % M

(3 kNm ... 10 kN@m:

160 %)

nom

A1979-7.1 enHBM

Page 43

T12

43

11 TEDS

TEDS (Transducer Electronic Data Sheet) allows you to store the transducer

data (characteristic values) in a chip, that can be read out by a connected

measuring device.

There are two TEDS blocks in the T12 digital torque transducer:

• TEDS 1 (torque): A choice of voltage sensor or frequency sensor/pulse

sensor

• TEDS 2 (speed/angle of rotation): Frequency sensor/pulse sensor

The data are written automatically into the TEDS blocks by the T12 Assistant,

when the parameters are stored. The same menu is used to select whether

the device should be presented as a voltage sensor or as a frequency sensor

or as a frequency or pulse sensor.

the conversion factors for the various engineering units.

A template is also stored, which provides

The T12 is a transducer, that is to say, the T12 does not read the TEDS

blocks, it only writes them. (We therefore strongly advise against editing the

values with the HBM TEDS Editor, for example!)

To read out the data and thus the parameterization of an MGC amplifier (such

as the ML60B or ML01B with AP01i), the relevant connection board is

connected to the T12 via cable KAB149 (torque) or KAB163 (speed).

You must then run the "TEDS" command in the MGC amplifier.

The MGC amplifier reads the data from the T12 TEDS block and parameters

are assigned accordingly.

You can also read the TEDS block data with the TEDS Editor.

CAUTION

To ensure that the data of the TEDS blocks correspond to the properties

of the T12 torque transducer, you must not overwrite the information

from the MGC.

For more information on TEDS, look in the T12 Assistant online Help.

A1979-7.1 en HBM

Page 44

44

T12

11.1 Content of the TEDS memory as defined in IEEE 1451.4

The information in the TEDS memory is organized into areas, which

are prestructured to store defined groups of data in table form.

Only the entered values are stored in the TEDS memory itself. The amplifier

firmware assigns the interpretation of the respective numerical values. This

places a very low demand on the TEDS memory. The memory content is

divided into three areas:

Area 1:

An internationally unique TEDS identification number (cannot be changed).

Area 2:

The base area (basic TEDS), to the configuration defined in standard

IEEE1451.4. The transducer type, the manufacturer and the transducer serial

number are contained here.

Example:

TEDS content for the T12/1 kN@m transducer

TEDS

Manufacturer HBM (31)

Model

Version letter

Version number 2 first point of stator ident. no.

Serial number 7 first point of stator ident. no.

T12 (15)

A

Area 3:

Data specified by the manufacturer and the user are contained in this area.

The “Value" column of the following table gives example values for a

T12/1kN⋅m torque transducer from HBM.

Torque

For the measured quantity torque, HBM has already described the template

“Frequency/Pulse Sensor" and the template “High Voltage Output Sensor".

A1979-7.1 enHBM

Page 45

T12

Template: Frequency/Pulse Sensor

Parameter Value Unit Requi

red

user

rights

Transducer Electrical

Signal Type

Minimum Torque 0.000 N@m CAL

Maximum Torque 1000 N@m CAL

Pulse Measurement Type Frequency

Pulse

Sensor

ID

45

Explanation

The physical measured quant

ity and unit are defined when

the template is created, after

which they cannot be changed.

Minimum Electrical

Value

Maximum Electrical Value 15000 Hz CAL

Mapping Method Linear

Discrete Signal Type Bipolar ID

Discrete Signal Amplitude 4 V

Discrete Signal Configu

ration

Transducer Response

Time

Excitation Level nom 24 V

Excitation Level min 18 V

Excitation Level max 30 V

Excitation Type DC

Excitation Current draw 0,5 A

Calibration Date 1-Nov-2006 CAL Date of the last calibration or

Calibration Initials HBM or PTB CAL Initials of the calibrator or calib

Calibration Period

(Days)

Measurement location ID 0 USR Identification number for the

10000 Hz CAL

Single

0 secon

ds

0 days CAL Time before recalibration, cal

The difference between these

values is the nominal (rated)

sensitivity.

creation of the test certificate (if

no calibration carried out), or of

the storage of the TEDS data (if

only nominal (rated) values

from the data sheet were

used).Format: day-monthyear.Abbreviations for the

months: Jan, Feb, Mar, Apr,

May, Jun, Jul, Aug, Sep, Oct,

Nov, Dec.

ration laboratory concerned.

culated from the date specified

under Calibration Date.

measuring point.Can be

assigned according to the

application. Possible values: a

number from 0 to 2047.

A1979-7.1 en HBM

Page 46

46

Template: High Level Voltage Sensor

Parameter Value Unit Requi

red

user

rights

Minimum Torque 0,000 N@m CAL

Maximum Torque 1000 N@m CAL

T12

Explanation

The physical measured quant

ity and unit are defined when

the template is created, after

which they cannot be changed.

Minimum Electrical Value 0 V CAL

Maximum Electrical Value 10 V CAL

Discrete Signal Type Bipolar ID

Discrete Signal Amplitude 5 V

Discrete Signal Single

Transducer Response

Time

Excitation Level nom 24 V

Excitation Level min 18 V

Excitation Level max 30 V

Excitation Type DC

Excitation Current draw 0,5 A

Calibration Date 1-Nov-2006 CAL Date of the last calibration or

Calibration Initials HBM or PTB CAL Initials of the calibrator or calib

Calibration Period (Days) 0 days CAL Time before recalibration, cal

Measurement Location ID 0 USR Identification number for the

0

The difference between these

values is the nominal (rated)

sensitivity.

creation of the test certificate (if

no calibration carried out), or of

the storage of the TEDS data (if

only nominal (rated) values

from the data sheet were

used).Format: day-monthyear.Abbreviations for the

months: Jan, Feb, Mar, Apr,

May, Jun, Jul, Aug, Sep, Oct,

Nov, Dec.

ration laboratory concerned.

culated from the date specified

under Calibration Date.

measuring point.Can be

assigned according to the

application. Possible values: a

number from 0 to 2047.

A1979-7.1 enHBM

Page 47

T12

Speed measuring sytem/Angle of rotation

For the measured quantity rotational speed/angle of rotation, HBM has

already described the template “Frequency/Pulse Sensor".

Template: Frequency/Pulse Sensor

Parameter Value Unit Requi

red

user

rights

Transducer Electrical

Signal Type

Minimum Frequency 0,000 Hz CAL

Maximum Frequency 108,000k Hz CAL

Pulse Measurement Type Frequency

Minimum Electrical Value 0 Hz CAL

Maximum Electrical Value 108,000k Hz CAL

Mapping Method Linear

Discrete Signal Type Bipolar ID

Discrete Signal Amplitude 4 V

Discrete Signal Configu

ration

Transducer Response

Time

Excitation Level nom 24 V

Excitation Level min 18 V

Excitation Level max 30 V

Excitation Type DC

Excitation Current draw 0,5 A

Calibration Date 1-Nov-2006 CAL Date of the last calibration or

Calibration Initials HBM or PTB CAL Time before recalibration, cal

Calibration Period

(Days)

Pulse

Sensor

Double

phase plus

zero index

0 secon

ds

0 days CAL Time before recalibration, cal

ID

Explanation

The physical measured quant

ity and unit are defined when

the template is created, after

which they cannot be changed.

creation of the test certificate (if

no calibration carried out), or of

the storage of the TEDS data (if

only nominal (rated) values

from the data sheet were

used).Format: day-monthyear.Abbreviations for the

months: Jan, Feb, Mar, Apr,

May, Jun, Jul, Aug, Sep, Oct,

Nov, Dec.

culated from the date specified

under Calibration Date.

culated from the date specified

under Calibration Date.

47

A1979-7.1 en HBM

Page 48

48

Template: Frequency/Pulse Sensor

Parameter Value Unit Requi

red

user

rights

Measurement location ID 0 USR Identification number for the

Transducer Electrical

Signal Type

Minimum Frequency 0,000E+000 degreesCAL

Maximum Frequency 3,6E+002 degreesCAL

Pulse Measurement Type Count

Minimum Electrical Value 0,0 Imp CAL

Maximum Electrical Value 360 Imp CAL

Mapping Method Linear

Discrete Signal Type Bipolar ID

Discrete Signal Amplitude 4 V

Discrete Signal Configu

ration

Transducer Response

Time

Excitation Level nom 24 V

Excitation Level min 18 V

Excitation Level max 30 V

Excitation Type DC

Excitation Current draw 0,5 A

Calibration Date 1-Nov-2006 CAL Date of the last calibration or

Pulse

Sensor

Double

phase plus

zero index

0 secon

ds

ID

Explantion

measuring point.Can be

assigned according to the

application. Possible values: a

number from 0 to 2047.

The physical measured quant

ity and unit are defined when

the template is created, after

which they cannot be changed.

The difference between these

values is the nominal (rated)

sensitivity.

creation of the test certificate (if

no calibration carried out), or of

the storage of the TEDS data (if

only nominal (rated) values

from the data sheet were

used).Format: day-monthyear.Abbreviations for the

months: Jan, Feb, Mar, Apr,

May, Jun, Jul, Aug, Sep, Oct,

Nov, Dec.

T12

A1979-7.1 enHBM

Page 49

T12

Template: Frequency/Pulse Sensor

Parameter Value Unit Requi

red

user

rights

Calibration Initials HBM or PTB CAL Time before recalibration, cal

Calibration Period

(Days)

Measurement location ID 0 USR Identification number for the

0 days CAL Time before recalibration, cal

Explantion

culated from the date specified

under Calibration Date.

culated from the date specified

under Calibration Date.

measuring point.Can be

assigned according to the

application. Possible values: a

number from 0 to 2047.

49

A1979-7.1 en HBM

Page 50

50

T12

12 Maintenance

The T12 torque transducer without speed measuring system is mainten

ance‐free.

12.1 Cleaning the speed measuring system

During operation and depending on the ambient conditions, the slotted disc of

the rotor and the associated stator sensor optics can get dirty. This becomes

noticeable:

• In transducers with a reference pulse, when an increment error is displayed

in the "Speed signal" status in the T12 Assistant

• In transducers without a reference pulse, when there are cyclic intrusions

into the speed signal

Remedy:

1. Use compressed air (up to 6 bar) to clean the slotted disc.

2. Carefully clean the optical system of the sensor with a dry or

spirit‐impregnated cotton bud or cloth.

CAUTION

Do not use any other solvent for cleaning the sensor optic.

Fig.12.1: Cleaning points on the speed sensor

A1979-7.1 enHBM

Page 51

T12

13 Specifications

Type T12

Accuracy class 0.03

Torque measuring system

Nominal (rated) torque M

nom

for reference only kft‐lb 75 150 375 750 1,500 2,250 3,750 7,500

Nominal (rated) sensitivity (range

between torque = zero and M

nom

)

Frequency output 10 kHz/60 kHz

Voltage output

Sensitivity tolerance (deviation of

the actual output quantity at M

nom

from the nominal (rated) sensitivity)

Fieldbusses

Frequency output

Voltage output

Output signal at torque = zero

Frequency output 10 kHz/60 kHz

Voltage output

Nominal (rated) output signal

Frequency output

with positive nominal (rated)

torque 10 kHz/60 kHz

with negative nominal (rated)

torque 10 kHz/60 kHz

Voltage output with

positive nominal (rated) torque

negative nominal (rated) torque

Low‐pass filter LP1

Low‐pass filter LP2

Load resistance

Frequency output

Voltage output

Long‐term drift over 48 h

Voltage output

Measurement frequency range

Frequency output/Voltage output

Group delay time (Low pass LP1:

4 kHz)

Frequency output 10 kHz/60 kHz

Voltage output

Scale range

Frequency output/Voltage output

Resolution

Frequency output 10 kHz/60 kHz

Voltage output

Residual ripple

Voltage output

1)

RS‐422 complementary signals, observe terminating resistance.

2)

Factory settings TP1=1,000 Hz; TP2=1 Hz.

N⋅m 100 200 500

kN⋅m 1 2 3 5 10

kHz

V

%

%

%

kHz

V

kHz

kHz

V

V

Hz

Hz

kΩ

kΩ

mV

Hz

Hz

ms

ms

%

Hz

mV

mV

15/90 (5 V symmetric1))

5/30 (5 V symmetric

0.05 ... 4,000 (4

0.05 ... 100 (4

0 ... 4,000 (-1 dB)

0 ... 6,000 (-3 dB)

10 ... 1,000 (of M

5/30

10

"0.05

"0.05

"0.1

10/60

0

1)

)

+10

-10

th

order Bessel, -1 dB)

th

order Bessel, -1 dB)

≥ 2

≥ 10

"3

320/250

500

)

nom

0.03/0.25

0.33

3

51

2)

2)

A1979-7.1 en HBM

Page 52

52

T12

Nominal (rated) torque M

nom

kN⋅m 1 2 3 5 10

for reference only kft‐lb 75 150 375 750 1,500 2,250 3,750 7,500

Temperature influence per 10 K in

the nominal (rated) temp. range

on the output signal, related to the

actual value of signal span

N⋅m 100 200 500

Fieldbusses

Frequency output

Voltage output

%

%

%

"0.03

"0.03

"0.1

on the zero signal, related to the

nominal (rated) sensitivity

Fieldbusses

Frequency output

Voltage output

Maximum modulation range

Frequency output 10 kHz/60 kHz

Voltage output

3)

%

%

%

kHz

V

"0.02 ("0.01 optional)

"0.02 ("0.01 optional)

"0.1

4 ... 16/24 ... 96

-10.2 ... +10.2

Power supply

Nominal (rated) supply voltage

(separated extra low voltage)

V

(DC)

18 ... 30

Current consumption in meas.

mode

A < 1 (typ. 0.5)

Current consumption in start‐up

mode

A < 4

Nominal (rated) power

consumption

Maximum cable length

W

m

< 18

50

Linearity deviation including hys

teresis, related to the nominal

(rated) sensitivity

Fieldbusses

Frequency output 10 kHz/60 kHz

Voltage output

%

%

%

"0.02 ("0.01 optional)

"0.02 ("0.01 optional)

"0.05

Rel. standard deviation of the

repeatability, per DIN1319, related

to variation of the output signal

Fieldbusses/frequency output % "0.01

voltage output % "0.03

Shunt signal 50 % of M

or 10 % of M

nom

nom

Tolerance of shunt signal related

to M

nom

% "0.05

Nominal trigger voltage V 5

Limit trigger voltage V 36

Shunt signal on V min. >2.5

Shunt signal off V max. <0.7

Max. switch-on period min user‐defined

Update rate CAN bus kHz 4.8 (and binary division ratios (2-64))

3)

Output signal range with a repeatable relationship between torque and output signal.

A1979-7.1 enHBM

Page 53

T12

Low pass filter LP1, LP2, LP

Low‐pass filter frequency output

th

4

order Nominal

(rated)

value f

(Hz)

4,000 4,000 6,000 0.32 0.25

2,000 2,015 3,418 0.4 0.33

1,000 1,029 1,866 0.48 0.41

500 505 852 0.74 0.67

200 202 340 1.52 1.45

100 101 177 2.27 2.2

50 50 88 4.22 4.15

20 25 44 8.12 8.05

10 12.5 22 15.9 15.9

0.5 0.8 1.38 248 248

0.2 0.2 0.34 992 992

0.1 0.1 0.17 1,980 1,980

0.05 0.05 0.08 3,960 3,960

Low‐pass filter voltage output

th

4

order Nominal

(rated)

value f

(Hz)

4,000 4,000 6,000 0.25

2,000 2,015 3,418 0.3

1,000 1,029 1,866 0.41

500 505 852 0.67

200 202 340 1.45

100 101 177 2.2

50 50 88 4.15

20 25 44 8.05

10 12.5 22 15.9

0.5 0.8 1.38 248

0.2 0.2 0.34 992

0.1 0.1 0.17 1,980

0.05 0.05 0.08 3,960

f

g

(-1 dB)

c

(Hz)

f

g

(-3 dB)

(Hz)

Group delay

time

10 kHz"5 kHz

(ms)

Group delay

time

60 kHz"30 kHz

(ms)

5 6.25 11 31.5 31.5

2 3.1 5.5 62.3 62.3

1 1.6 2.75 124 124

f

g

(-1 dB)

c

(Hz)

f

g

(-3 dB)

(Hz)

Group delay time

(ms)

5 6.25 11 31.5

2 3.1 5.5 62.3

1 1.6 2.75 124

53

A1979-7.1 en HBM

Page 54

54

T12

Nominal (rated) torque

M

nom

N⋅m 100 200 500

kN⋅m 1 2 3 5 10

for reference only kft‐lb 75 150 375 750 1,500 2,250 3,750 7,500

Speed measuring system/measuring system for angle of rotation

Optical, by means of infrared light and metallic slotted

disc

Num

Mechanical increments

ber

360 720

Positional tolerance of the

increments

mm "0.05

Tolerance of the slot width mm "0.05

Pulses per rotation

(adjustable)

Num

ber

360; 180; 90; 60; 45; 30 720; 360;

180; 120;

90; 60

Pulse frequency at nominal

(rated) speed n

Option 3, Code L

Option 3, Code H

nom

4)

4)

kHz 90 72 120

kHz 108 96 168

Minimum speed for

sufficient pulse stability

rpm 2

Group delay time μs < 5 (typ. 2.2)

Hysteresis of reversing the

direction of rotation with

relative vibrations between

rotor and stator

Torsional vibrations

of the rotor

Degree

< approx. 2

Radial vibration amplitudes

of the stator

mm

< approx. 2

Permitted degree of soiling,

in the optical path of the sen

sor fork (lenses, slotted disc)

%

< 50

Swirl influence on the zero

point, through mounted in

crement disc, related to

nominal (rated) torque

Option 3, Code L

Option 3, Code H

4)

4)

Output signal

frequency/pulse output

%

%

V

<0.05

<0.08

<0.03

<0.04

<0.03

<0.03

<0.02

<0.02

55) symmetric; 2 square wave signals

approx. 90° phase shifted

<0.01

<0.01

Load resistance kΩ ≥ 2

4)

See page 76

5)

RS‐422 complementary signals, observe terminating resistances.

A1979-7.1 enHBM

Page 55

T12

55

Nominal (rated) torque M

for reference only kft‐lb 75 150 375 750 1,500 2,250 3,750 7,500

Rotational speed

Fieldbusses

Resolution rpm 0.1

System accuracy (at torsional

vibrations of max. 3 % with double

speed frequency)

Max. speed deviation at nominal

(rated) speed (100 Hz‐filter)

Voltage output

Measuring range V " 10

Resolution mV 0.33

Scale range % 10 ... 1,000

Overmodulation limits V " 10.2

Load resistance kΩ > 10

Linearity error % < 0.03

Temperature effect per 10 K in the

nominal (rated) temperature range

on the output signal, related to the

actual value of signal span

on the zero signal % < 0.03

Residual ripple mV < 3

Low‐pass filter (4

Cut‐off frequencies (-1 dB) LP1

Cut‐off frequencies (-1 dB) LP2

Update rate CAN bus kHz 4.8 (and binary division ratios (2-64))

th

nom

order)

N⋅m 100 200 500

kN⋅m 1 2 3 5 10

ppm 150

rpm 1.5

% < 0.03

HzHz1,000; 500; 200; 100; 50; 20; 10; 5; 2; 1; 0.5; 0.2;

0.1; 0.05

100; 50; 20; 10; 5; 2; 1; 0.5; 0.2; 0.1; 0.05

A1979-7.1 en HBM

Page 56

56

T12

Nominal (rated) torque M

nom

kN⋅m 1 2 3 5 10

for reference only kft‐lb 75 150 375 750 1,500 2,250 3,750 7,500

Angle of rotation

Accuracy De

N⋅m 100 200 500

gree

1 (typ. 0.1)

Resolution De

gree

0.01

Correction of the phase delay

deviation between torque LP1 and

angle of rotation for filter frequen

cies

Hz 4,000; 2,000; 1,000; 500; 200; 100

Measuring range De

gree

0 ... 360 (singleturn) up to "1,440 (multiturn)

Power

Measurement frequency range Hz 80 (-1 dB)

Resolution W 1

Full scale value W

P

max

+ M

nom

@ n

nom

@

p

30

[M

[n

nom

nom

] in N⋅m

] in rpm

Temperature effect per 10 K in the

nominal (rated) temperature range

on the power signal, related to the

full scale value

% "0.05@n/n

nom

Linearity deviation including hys

teresis, related to the full scale value

% "0.02@n/n

nom

Sensitivity tolerance (deviation of

the actual signal span of the power

signal related to the full scale value)

Low‐pass filter (1

st

order)

Cut-off frequencies

% "0.05

Hz

100; 10; 1; 0.1

Meas.

Measuring range CAN bus

val

600

ues /s

A1979-7.1 enHBM

Page 57

T12

Temperature signal rotor

Nominal (rated) torque M

nom

for reference only kft‐lb 75 150 375 750 1,500 2,250 3,750 7,500

Accuracy K 1

Measurement frequency range Hz 5 (-1 dB)

Resolution K 0.1

Physical unit - °C

Sampling rate Measured

Fieldbusses

CAN bus

Protocol - CAN 2.OB, CAL/CANopen compatible

Sampling rate Measured

Hardware bus link per ISO 11898

Baud rate kBit/s 1000 500 250 125 100

Maximum line length m 25 100 250 500 600

Connection

Profibus DP

Protocol - Profibus DP Slave, per DIN 19245‐3

Baudrate MBaud max. 12

Profibus ident no. - 096C (hex)

Input data, max. Byte 152

Output data, max. Byte 40

Diagnosis data Byte 18 (2@4 byte module diagnosis)

Connection - 5‐pole, M12x1, B‐coding, potential separated from

Update rate PROFIBUS

6)

Configuration entries

v 2 Measured

v 4

v 8

v 12

v 16

u 16 150

Limit value switch (on fieldbusses only)

Number - 4 for torque, 4 for rotational speed

Reference level -

Hysteresis % 0 ... 100

Setting accuracy Digit 1

Response time

(LP1= 4,000 Hz)

TEDS (Transducer Electronic Data Sheet)

Number - 2

TEDS 1 (torque) - Optional voltage sensor or frequency sensor

TEDS 2

(rotational speed/angle of rot.)

6)

With simultaneously activated CAN‐PDOs, the profibus update rate is reduced. With PDO output rate di

vider: v4 by factor 2; .v2 by factor 4; 1 by factor 8.

N⋅m 100 200 500

kN⋅m 1 2 3 5 10

values /s

values /s

max. 4,800 (PDO)

40

5‐pole, M12x1, A‐coding per CANopen DR‐303‐1

-

V1.3, potential separ. from supply and meas. mass

supply and measuring mass

4,800

values /s

2,400

1,200

600

300

Torque LP1 or LP2

Rotational speed LP1 or LP2

ms typ. 3

- Frequency‐/pulse sensor

57

A1979-7.1 en HBM

Page 58

58

General data

Nominal (rated) torque M

nom

for reference only kft‐lb 75 150 375 750 1,500 2,250 3,750 7,500

EMC

EME (Emission per EN61326-1,

table 3)

RFI voltage

RFI performance

RFI field strength

Immunity from interference

(EN61326‐1, table A.1)

Electromagnetic field (AM) V/m 10

Magnetic field A/m 30

ESD

Contact discharge kV 4

Air discharge kV 8

Burst kV 1

Surge kV 1

Line‐conducted disturbance

(AM)

Degree of protection per

EN60529

Weight, approx. Rotor kg 1.1 1.8 2.4 4.9 8.3 14.6

Stator kg 2.3 2.4 2.5 2.6

Reference temperature °C [°F] +23 [73.4]

Nominal (rated) temperature

range

Service temperature range °C [°F] -10 ... +60 [+14 ... +140]

Storage temperature range °C [°F] -20 ... +70 [−4 ... +158]