Page 1

Operating manual

Measuring amplifier in

desktop housing

SCOUT55

A0236-5.9 en

Page 2

Page 3

Scout 55

3

Contents Page

Safety instructions 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Introduction 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Scope of supply 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 General 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Block diagram 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Connections 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Factory settings 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Changing the factory settings 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1 Setting the analogue output signal 13 . . . . . . . . . . . . . . . . . . . .

2.2.2 Choosing the operating mode for synchronisation 13 . . . . . .

2.3 Connecting the voltage supply 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.1 Changing the mains voltage selection/replacing the fuse 14 .

2.3.2 Device mounting 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Transducer connection 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 Analogue output 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 Control inputs / outputs 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7 Synchronisation 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

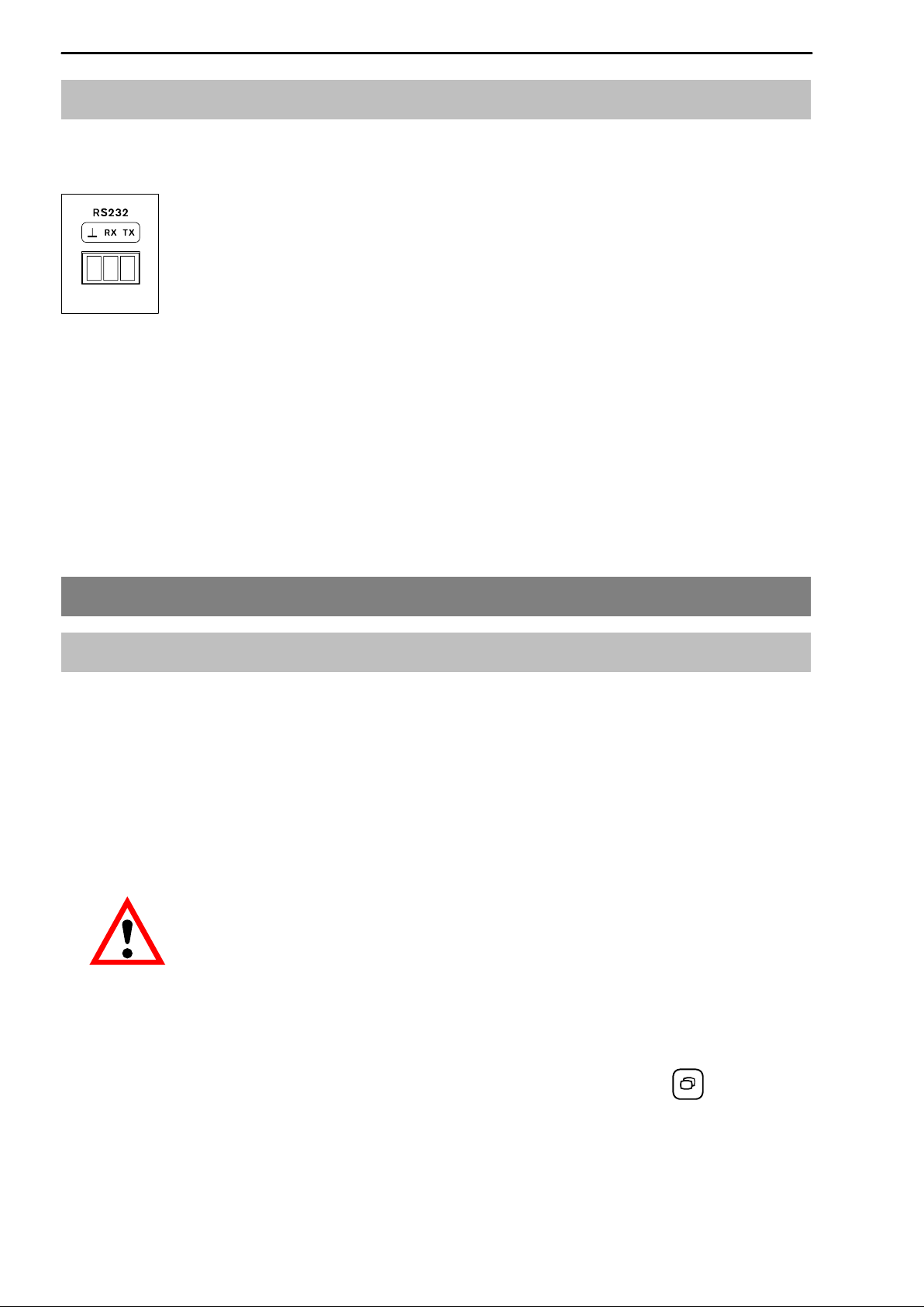

2.8 Connecting the serial interface 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Setting up and operation 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Commissioning and factory settings 20 . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Control concept and functional overview 27 . . . . . . . . . . . . . . . . . . . . .

3.3 Button functions in measuring mode 28 . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 Querying and setting limit values in measuring mode 28 . . . .

A0236-5.9 en

HBM

Page 4

4

3.4 Button functions in programming mode 30 . . . . . . . . . . . . . . . . . . . . . .

3.4.1 Changing from “Measuring” mode to

“Programming” mode 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.2 Programming 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.3 Switching from “Programming” operating mode to

“Measuring” operating mode 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Overview of all groups and parameters 33 . . . . . . . . . . . . . . . . . . . . . .

3.5.1 Setting all parameters 34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.2 Dialogue 37 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.3 Load/Save in parameter set (PARAM. SET) 37 . . . . . . . . . . . .

3.5.4 Adaptation 37 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scout 55

3.5.5 Calibration (CALIBR.) 40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.6 Limit values 1...4 (LIMITVAL.1...4) 41 . . . . . . . . . . . . . . . . . . . .

3.5.7 Set peak value store (PV STORE) 42 . . . . . . . . . . . . . . . . . . . .

3.5.8 Inputs and outputs (IN/OUT) 44 . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.9 Additional functions (ADD. FUNCT) 47 . . . . . . . . . . . . . . . . . . .

4 Example 49 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Error messages 58 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Keyword index 59 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HBM A0236-5.9 en

Page 5

Scout 55

Safety instructions

SCOUT55 can be operated either at 230 VAC or 110 VAC, 48...60 Hz mains

voltage.

For adapting the device to the mains voltage, please see chapter 2.3.1 in the

operating manual.

Before connecting the device, make sure that the mains voltage and current

type specified on the name plate correspond to the mains voltage and current

type at the site of installation and that the current circuit used is sufficiently

safe.

An earthed socket must be used for the mains plug (protection class I and II).

Do in no case use the device when the mains line has suffered damage.

Do in any case switch off the device before opening it; disconnect the mains

plug.

5

The device complies with the safety requirements of DIN EN 61010-part1

(VDE 0411-part1); protection class I. The device has a mains switch. Ensure

that it is easily accessible at any time.

The supply connection, as well as the signal and sense leads, must be

installed in such a way that electromagnetic interference does not adversely

affect device functionality (HBM recommendation: ”Greenline shielding

design”, downloadable from the Internet at http://www.hbm.com/Greenline).

Automation equipment and devices must be covered over in such a way that

adequate protection or locking against unintentional actuation is provided

(such as access checks, password protection, etc.).

When devices are working in a network, these networks must be designed in

such a way that malfunctions in individual nodes can be detected and shut

down.

Safety precautions must be taken both in terms of hardware and software, so

that a line break or other interruptions to signal transmission, such as via the

bus interfaces, do not cause undefined states or loss of data in the

automation device.

Appropriate use

The SCOUT55 with the connected transducers may be used for measurement

and directly related control and regulation tasks, only. Any other use is not

appropriate. To ensure safe operation, the transducer may only be used

according to the specifications given in this manual. It is also essential to

comply with the legal and safety requirements for the application concerned

during use. The same applies to the use of accessories.

HBMA0236-5.9 en

Page 6

6

Scout 55

Each time, before starting up the equipment, you must first run a project

planning and risk analysis that takes into account all the safety aspects of

automation technology. This particularly concerns personal and machine

protection.

Additional safety precautions must be taken in plants where malfunctions

could cause major damage, loss of data or even personal injury. In the event

of a fault, these precautions establish safe operating conditions.

This can be done, for example, by mechanical interlocking, error signaling,

limit value switches, etc.

Conditions on site

Protect desktop devices from moisture or atmospheric influences such as

rain, snow, etc.

Protect the device from direct sunlight. Ensure sufficient ventilation.

General dangers in the case of non-observance of the safety

instructions

The SCOUT55 complies with the state of the art and is operationally reliable.

If the device is used and operated inappropriately by untrained personnel,

residual dangers might develop.

Any person charged with device installation, operation, maintenance or repair

must in any case have read and understood the operating manual and the

safety instructions, in particular.

Residual dangers

The SCOUT55’s scope of performance and supply covers part of the

measuring-technology, only. The plant designer/constructor/operator must in

addition design, realise and take responsibility for the measuring-system’s

safety such that potential residual dangers are minimized. The respective

regulations must in any case be observed. Residual dangers regarding the

measuringsystem must be specified explicitly.

After making settings and carrying out activities that are password-protected,

you must make sure that any controls that may be connected remain in safe

condition until the switching performance of the amplifier system has been

tested.

HBM A0236-5.9 en

Page 7

Scout 55

In this manual, the following symbols are used to point out residual dangers:

7

Symbol:

Meaning: Maximum danger level

Warns of an imminently dangerous situation in which failure to comply with

safety requirements will result in death or serious bodily injury.

Symbol:

Meaning: Dangerous situation

Warns of a potentially dangerous situation in which failure to comply with

safety requirements can result in death or serious bodily injury.

Symbol:

Meaning: Potentially dangerous situation

Warns of a potentially dangerous situation in which failure to comply with

safety requirements could result in damage to property or some form of

bodily injury.

DANGER

WARNING

CAUTION

HBMA0236-5.9 en

Page 8

8

Symbols pointing out notes on use and waste disposal as well as useful

information:

Scout 55

Symbol:

Points out that important information about the product or its handling is being

given.

Symbol:

Meaning: CE mark

The CE mark enables the manufacturer to guarantee that the product complies with the requirements of the relevant EC directives (the declaration of

conformity is available at http://www.hbm.com/HBMdoc).

Symbol:

Meaning: Statutory marking requirements for waste disposal

National and local regulations regarding the protection of the environment and

recycling of raw materials require old equipment to be separated from regular

domestic waste for disposal.

NOTE

For more detailed information on disposal, please contact the local authorities

or the dealer from whom you purchased the product.

Safe operation

Do only quit error messages if the reason for the error has been eliminated

and there is no more danger.

Reconstruction and modifications

HBM’s express consent is required for modifications regarding the

SCOUT55’s construction and safety. HBM does not take responsibility for

damage resulting from unauthorized modifications.

In particular, repair and soldering works on the boards are prohibited. If

complete componentry is replaced use original HBM components, only.

The product is delivered from the factory with a fixed hardware and software

configuration. Changes can only be made within the possibilities documented

in the manuals.

HBM A0236-5.9 en

Page 9

Scout 55

Qualified personnel

The device may be used by qualified personnel, only; the technical data and

the special safety regulations must in any case be observed. When using the

device, the legal and safety regulations for the respective application must

also be observed. The same applies if accessories are used.

Qualified personnel means: personnel familiar with the installation, mounting,

start-up and operation of the product, and trained according to their job.

This includes people who meet at least one of the three following

requirements:

− Knowledge of the safety concepts of automation technology is a

requirement and as project personnel, you must be familiar with these

concepts.

− As automation plant operating personnel, you have been instructed how to

handle the machinery and are familiar with the operation of the equipment

and technologies described in this documentation.

9

− As commissioning engineers or service engineers, you have successfully

completed the training to qualify you to repair the automation systems.

You are also authorized to activate, to ground and label circuits and

equipment in accordance with safety engineering standards.

Maintenance and cleaning

SCOUT55 devices are maintenance-free. Please note the following points

when cleaning the housing:

− Withdraw the mains plug from the socket before carrying out any cleaning.

− Clean the housing with a soft, slightly damp (not wet!) cloth. You should on

no account use solvent, since it may damage the labelling on the front

panel and the indicator box.

− When cleaning, ensure that no liquid gets into the device or connections.

HBMA0236-5.9 en

Page 10

10

1 Introduction

1.1 Scope of supply

D Device with mounting frame / carrying handle

D 1 male cable connector DB-15P, order no.: 3.3312−0182

D 1 mains cable

D 1 male terminal strip connector 3−pin (interface)

D 2 male terminal strip connectors 9−pin (control inputs/outputs)

D 1 Operating Manual Part1; 1 Operating Manual Part2

D 1 cable Kab3−3301.0104

Scout 55

HBM A0236-5.9 en

Page 11

Scout 55

11

1.2 General

The SCOUT 55 measuring amplifier is suitable for recording and processing

measured values from passive transducers.

The essential features:

D Transducers that can be connected: S.G. full and half bridges, inductive full

and half bridges, piezoresistive and potentiometric transducers, LVDT

D 10-digit alphanumeric display

D Using the touch-sensitive keypad

D 2 peak value stores for maximum and minimum values, as well as

envelope and instantaneous value

D 4 limit switches

D RS232 serial interface for connecting a computer or a printer

D Parameter memory for saving up to 8 complete data sets

D Control inputs and outputs (potential-separated through optical couplers)

D Manageable housing with mounting frame / carrying handle

All the commands needed for device setup over the serial interface and for

querying the measured values are listed and described in a separate

Operating Manual document “Operating the SCOUT 55 by Computer”.

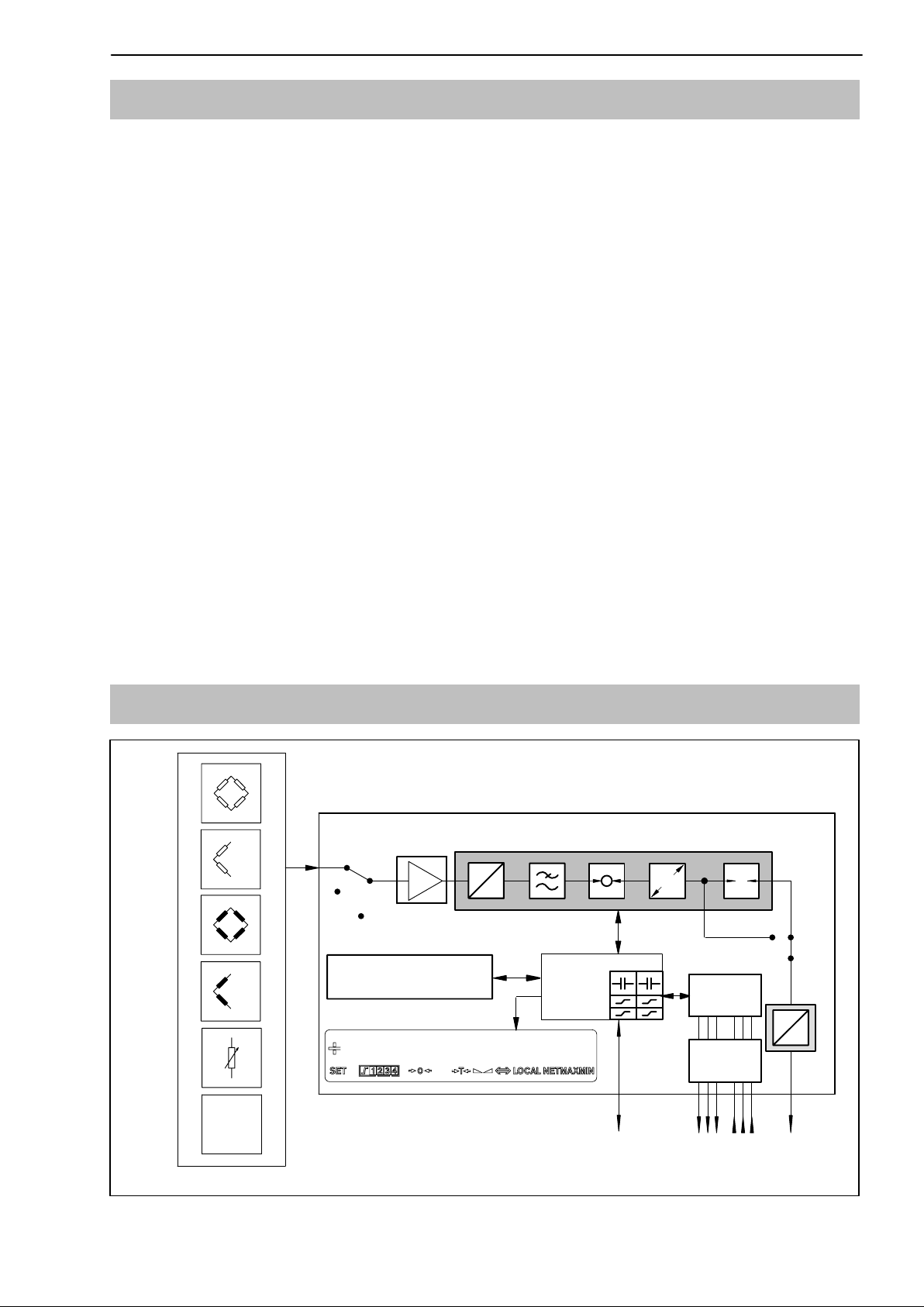

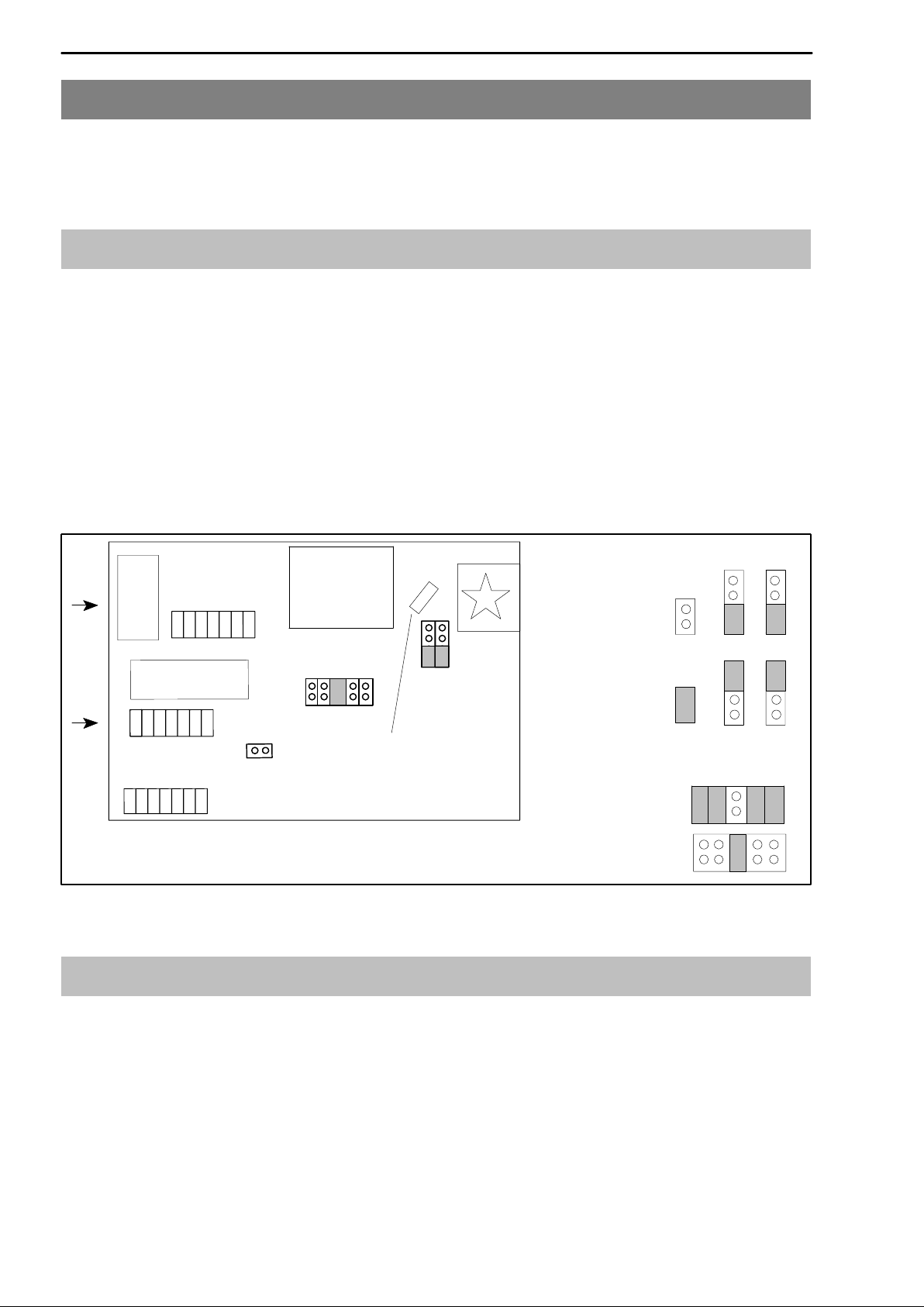

1.3 Block diagram

Measure

Zero

parameter memory

Connectable transducer

Cal.

data set 1...8

127,533 KN

A

D

CPU

E

T

control

signal

D

A

optical

coupler

LVDT

Fig. 1.1: SCOUT 55 block diagram

RS232

...

5 outputs/

6 inputs

U

A/IA

HBMA0236-5.9 en

Page 12

12

Scout 55

2 Connections

Observe the safety instructions before commissioning the device.

2.1 Factory settings

Before operating the device, check the parameters set at the factory and note

that the elements for selecting the analogue output signal (current/voltage

output) and for setting synchronisation, are located on the motherboard.

The factory settings are given below:

D Mains voltage: 230 V / 50...60 Hz or 115 V / 50..60 Hz, depending on order

D Analogue output: output voltage "10 V

D Synchronisation: master

IC

Frontsite

ST100: for attaching spare bridges

ST9 and ST10: for options

ST9

IC

ST10

ST13

ST100

Transformer

ST11

Fuses (slow-blowing)

ST15

ST14

Fig. 2.1: Location of jumpers on motherboard

2.2 Changing the factory settings

Master/Slave setting:

Master:

ST13

Slave:

ST13 ST14 ST15

Analogue output:

Current

ST11

Voltage

ST11

ST14 ST15

To change the factory settings, proceed as follows:

1 Switch off the device and take out the mains cable. Remove all the plug

connections on the back panel.

2 Loosen the four screws on the cover of the housing and remove the cover.

3 Change whichever setting is relevant to you with the aid of the jumpers, by

following Fig. 2.1

4 Screw the cover of the housing back in position.

HBM A0236-5.9 en

Page 13

Scout 55

13

2.2.1 Setting the analogue output signal

Select the analogue output signal (voltage or current) by replugging jumpers

ST11 (see Fig. 2.1). Choose between "20 mA or 4...20 mA in the control

dialogue.

2.2.2 Choosing the operating mode for synchronisation

To synchronise several devices, set one device as the Master. All the other

devices should then set to Slave. The “Master” and “Slave” selections are

made with jumpers ST13, ST14 and ST15 (see Fig. 2.1).

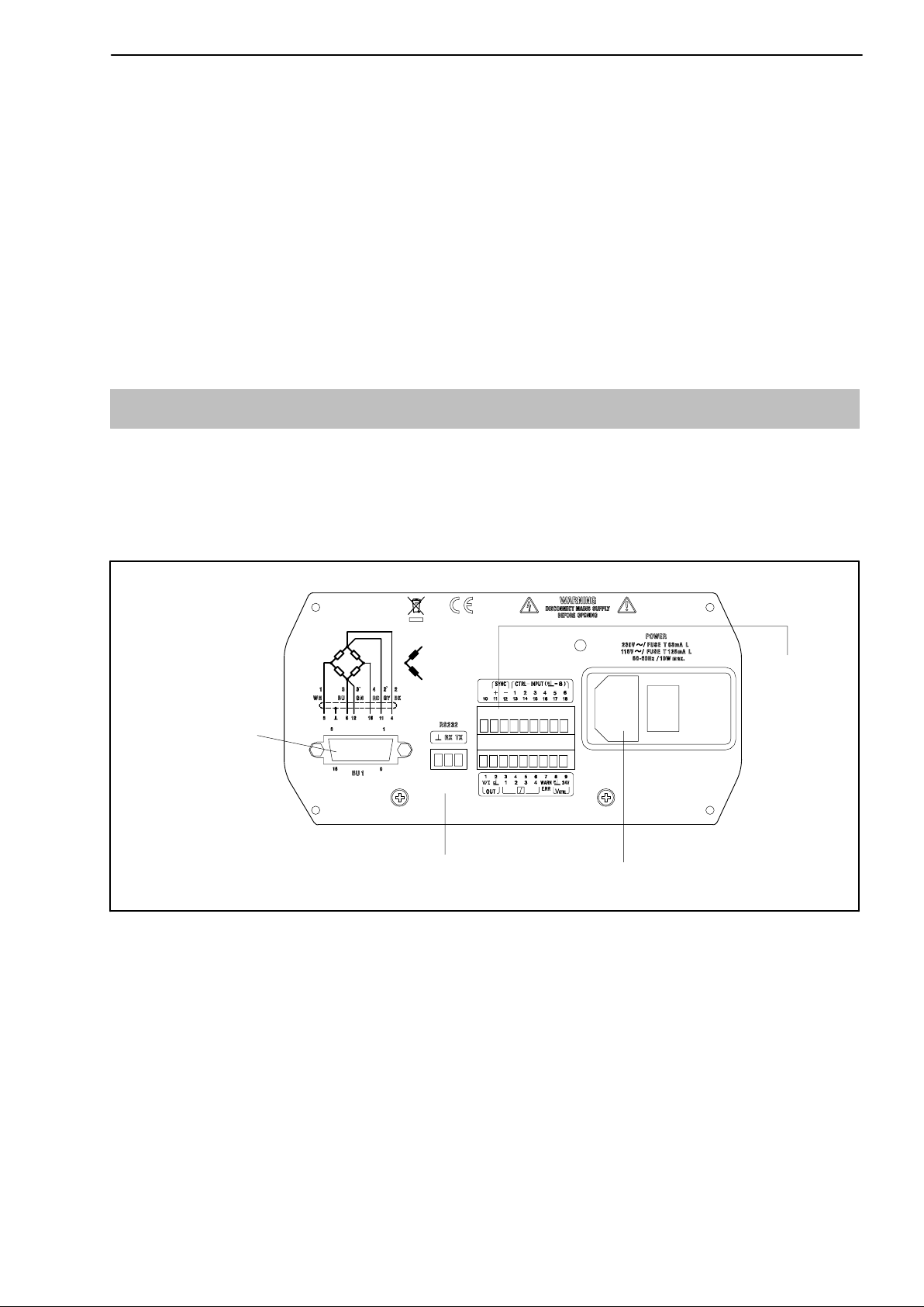

2.3 Connecting the voltage supply

Check that the mains voltage of the device (details on the back of the device)

matches the supply voltage. If this is not the case, change the device setup as

described under 2.3.1 .

transducer

connection

(15-pin

female

connector)

Fig. 2.2: Back of the device

interface port

mains connection

synchro-

nisation

analogue

output

5 outputs/

6 inputs

An inlet connector for non-heating devices is provided for connecting the

mains cable. The requisite mains power supply cable is included in the list of

components supplied.

Country-specific versions are available as accessories.

HBMA0236-5.9 en

Page 14

14

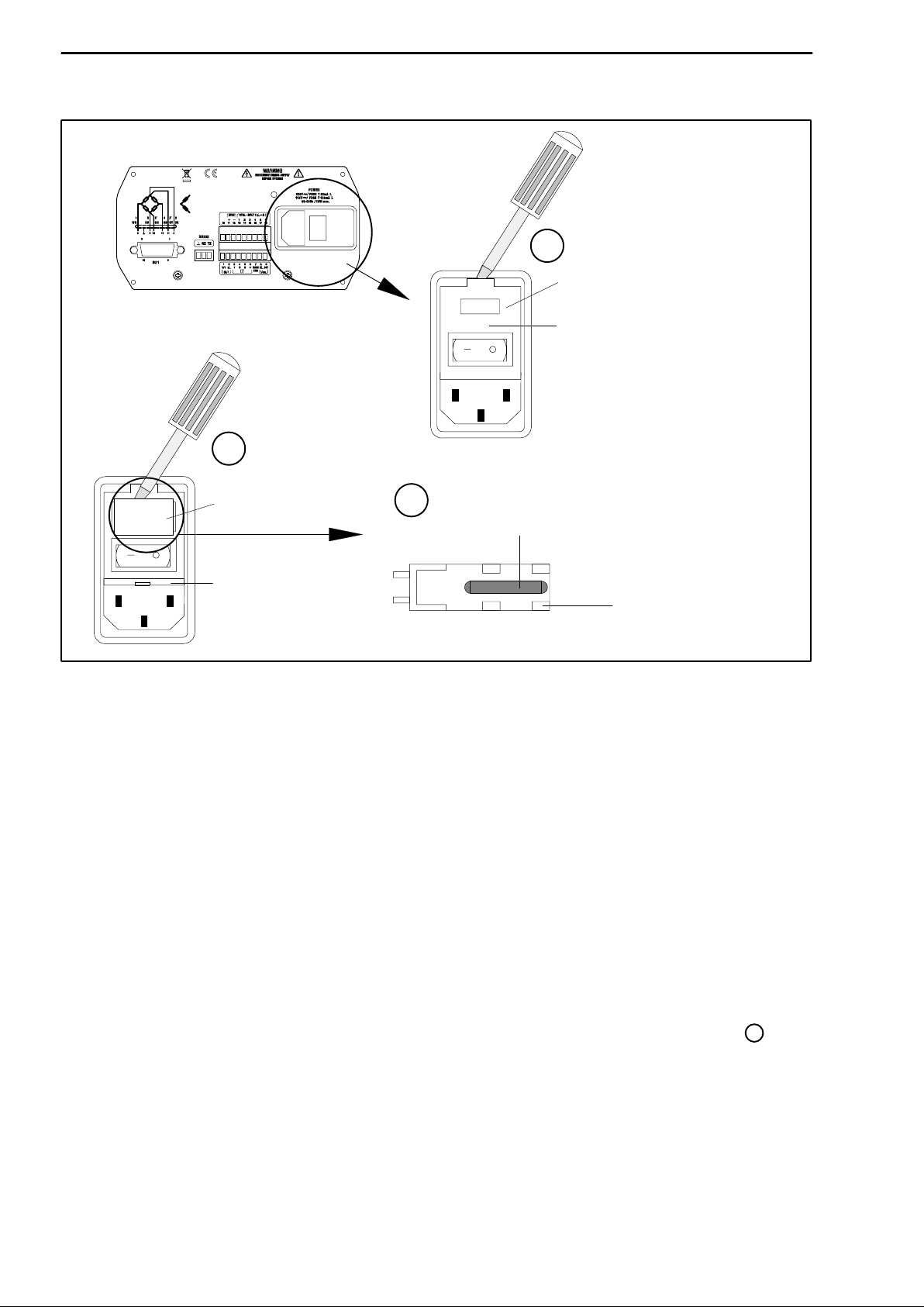

2.3.1 Changing the mains voltage selection/replacing the fuse

1

window

230V

cover

2

Scout 55

230V

PRSR

115V

fuse holder

cover open

3

replace fuse(s)

230 V: T63mA L

115 V: T125mA L

fuse holder

Fig. 2.3: Back of device: choosing mains voltage, replacing fuses

The mains voltage currently selected (e.g. 230 V) is shown in the “window”.

Adapting the mains voltage:

Switch off the device and take out the mains cable.

1 Lever the lid off and fold it aside

2 Remove the fuse holder

− Fit the fuse holder to correspond to the required mains voltage (comply

with the nominal current of the fine-wire fuse)

− Close the cover

2

The chosen mains voltage can be seen in the “window” (selection here

:

230 V).

HBM A0236-5.9 en

Page 15

Scout 55

Replacing the fuses:

Switch off the device and take out the mains cable.

1 Lever off the cover and fold it forward

2 Take out the fuse holder

3 Replace the fuses

− Fit the fuse holder, paying attention to the correct mains voltage (the

chosen value can be seen in the “window”).

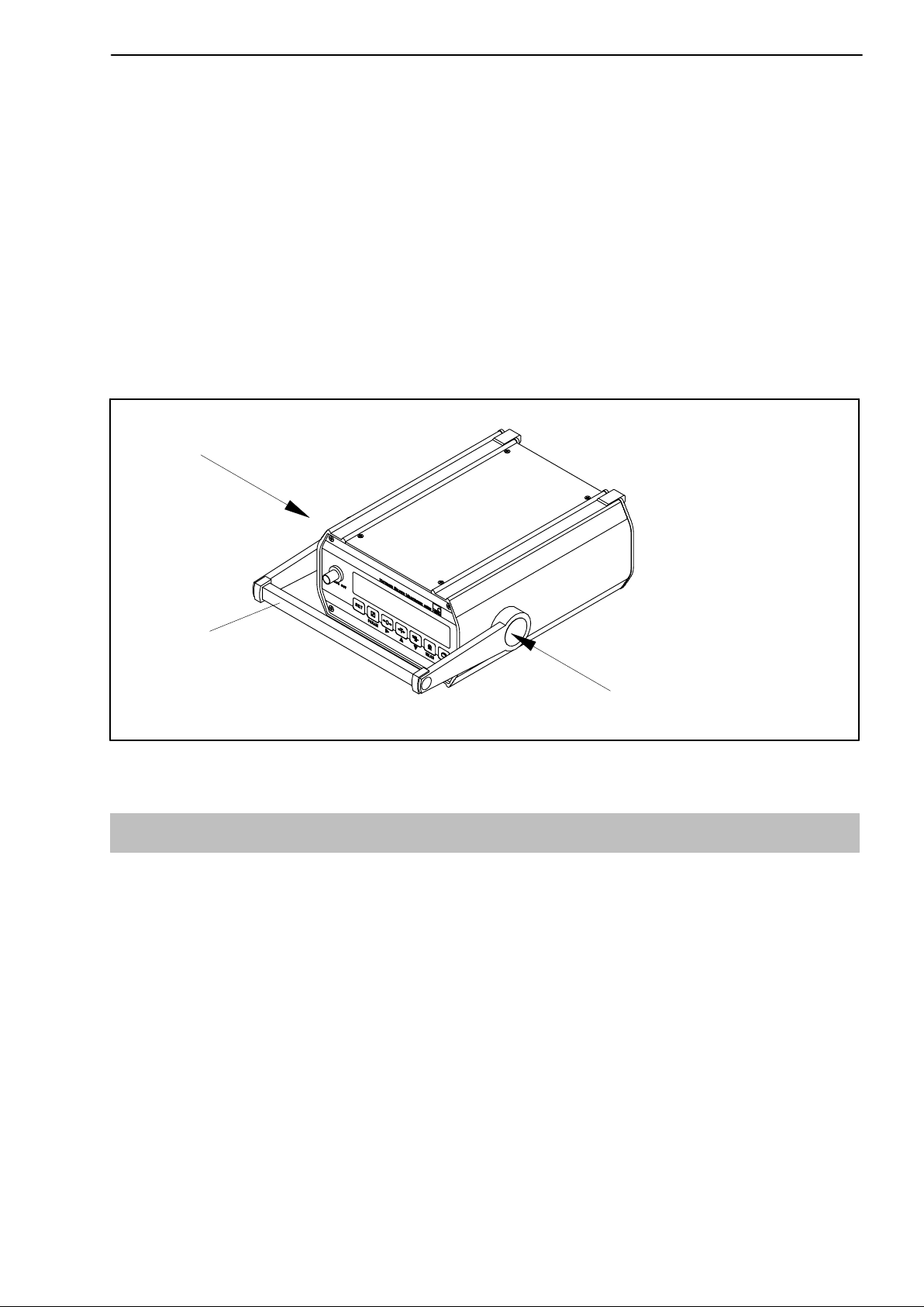

2.3.2 Device mounting

15

mounting frame and

carrying handle

Fig. 2.4: SCOUT 55 mounting

press (on both sides) and

fold down the handle

2.4 Transducer connection

The following transducer types can be connected to the SCOUT 55:

D S.G. full and half bridge transducers

D Inductive half and full bridge transducers

D Potentiometric and piezoresistive transducers

D LVDT (Linear Variable Differential Transformer)

A 15−pin socket on the back panel of the housing, labelled BU1, is used for

connection.

HBMA0236-5.9 en

Page 16

16

Scout 55

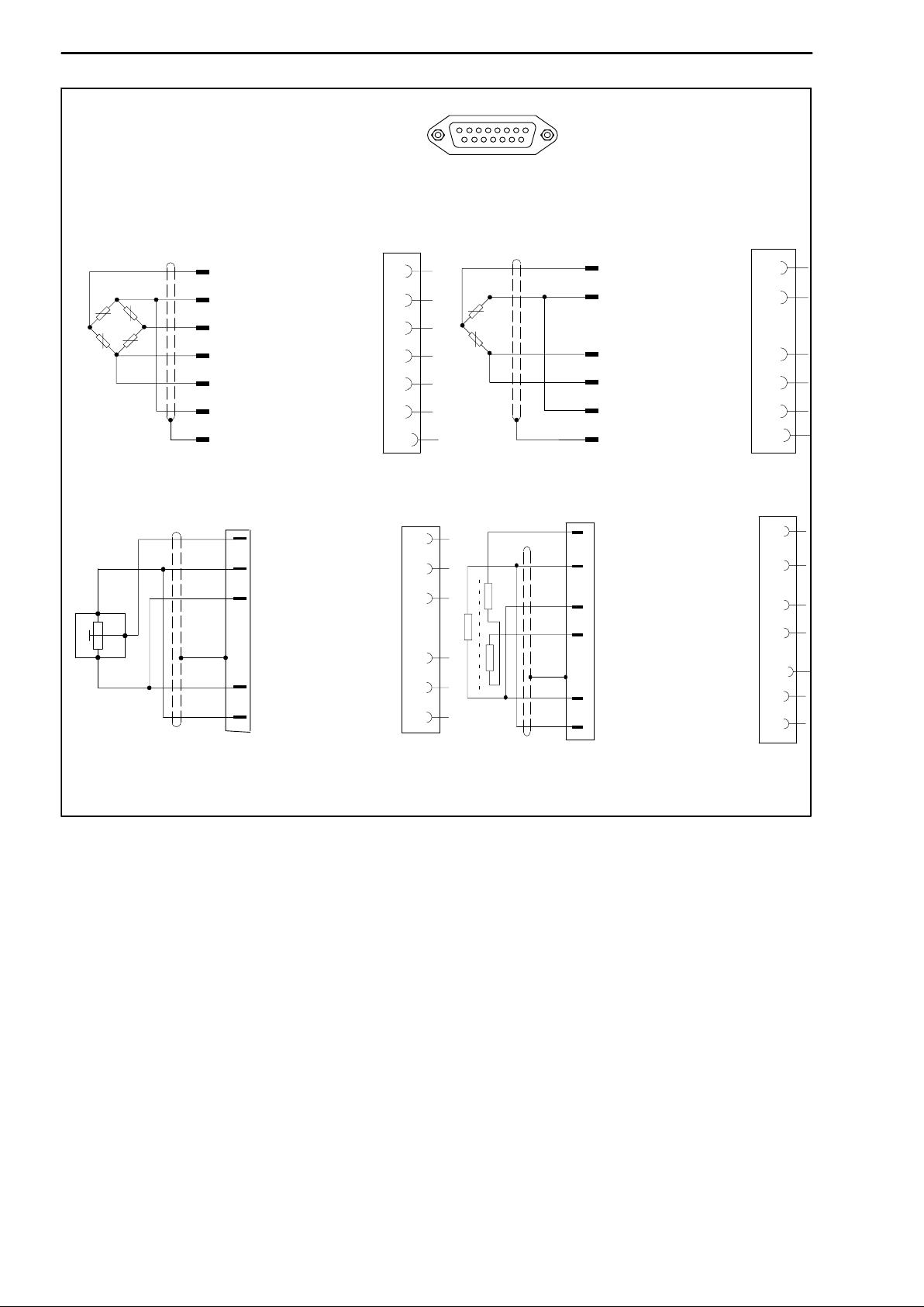

BU 1

Transducer connection socket

S.G. and inductive full bridges

piezoresistive transducers

WH

Measurement signal (+)

BK

Voltage (−)

RD

Measurement signal (−)

BU

Voltage (+)

GN

Sensor circuit (+)

GY

Sensor circuit (−)

YE

Cable shielding

potentiometric transducer

Measurement

signal (+)

Voltage (−)

8

5

15

6

13

12

Case

8

15

1

9

S.G. and inductive half bridges

Measurement

WH

signal (+)

BK

Voltage (−)

BU

Voltage (+)

GN

Sensor circuit (+)

GY

Sensor circuit (−)

YE

Cable shielding

8

5

6

13

12

Case

LVDT-transducer

8

5

Measurement signal (+)

Voltage (−)

8

5

2

1

3

Voltage (+)

Cable shielding

Sensor circuit (+)

Sensor circuit (−)

6

Case

13

12

Voltage (+)

Measurement signal (−)

Cable shielding

Sensor circuit(+)

Sensor circuit(−)

15

Case

13

12

Wire colours: WH= white; BK= black; BU= blue; RD= red; YE= yellow; GN= green;

GY= gray

Fig. 2.5: Connecting various transducers

6

HBM A0236-5.9 en

Page 17

Scout 55

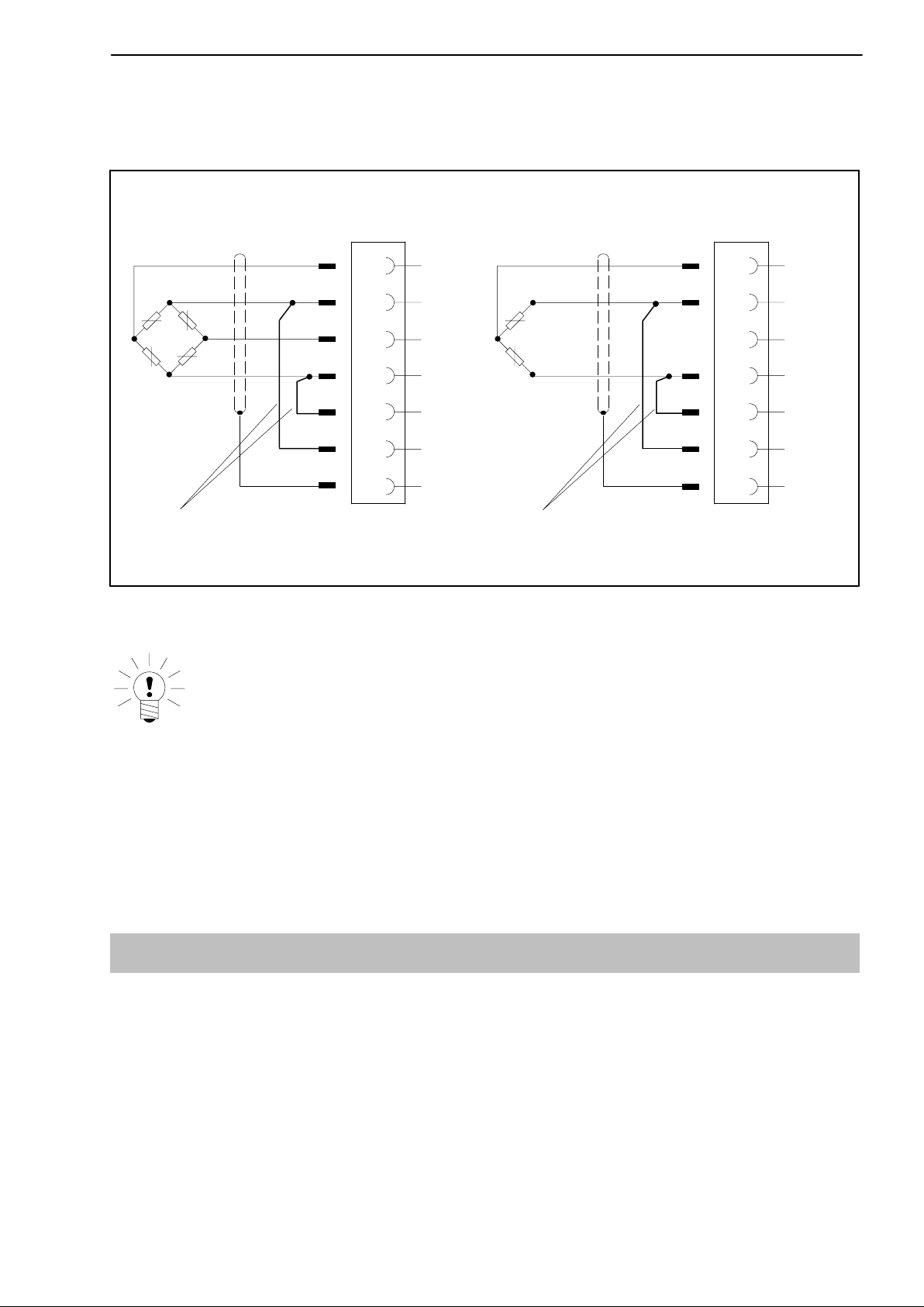

When connecting a transducer with a four-wire cable, you must connect the

sensor circuits with the relevant bridge excitation circuit in the male cable

connector (pin 5 with pin 12 and pin 6 with pin 13).

17

Four-wire connection: full bridge

WH

BK

RD

BU

YE

feedback bridges in the transducer cable plug

Wire colours: WH= white; BK= black; BU= blue; RD= red; YE= yellow; GN= green; GY= gray

8

5

15

6

13

12

Case

Four-wire connection: half bridge

WH

BK

BU

GN

GY

YE

8

5

15

6

13

12

Case

Fig. 2.6: Transducer connection in four-wire technique

NOTE

To connect the transducers, use HBM standard cable. If you use another

shielded, low-capacitance measurement cables, connect the shielding of

the transducer cable to the connector housing, in accordance with HBM

Greenline information (see http://www.hbm.com/Greenline). This

guarantees EMC protection.

2.5 Analogue output

The analogue output signal is available as voltage ("10 V) or as current

("20 mA or 4.. 20 mA) at terminals 1 and 2. The output voltage is also

available at the BNC connector (female) on the front of the device (see

Fig. 2.8.)

To choose current or voltage, use the jumpers on the amplifier motherboard,

as described in Chapter 2.1.

HBMA0236-5.9 en

Page 18

18

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Scout 55

Pin

1

2

Output signal (ground)

3

4

5

6

7

8

9

External supply voltage

ББББББББ

Function

Output signal (V/I)

LIMITVAL.1

LIMITVAL.2

LIMITVAL.3

LIMITVAL.4

Warning

Ground

24V=

Pin

10

11

12

13

14

15

16

17

18

БББББББ

Fig. 2.7: Output pin assignment

Function

no function

Synchronisation (+)

Synchronisation (−)

Remote1 (...)

Remote2 (...)

Remote3 (...)

Remote4 (...)

Remote5 (...)

Remote6 (...)

Analogue output BNC-

connector (female)

(parallel to PIN 1)

SET

Fig. 2.8: BNC connector (female) on the front of the device

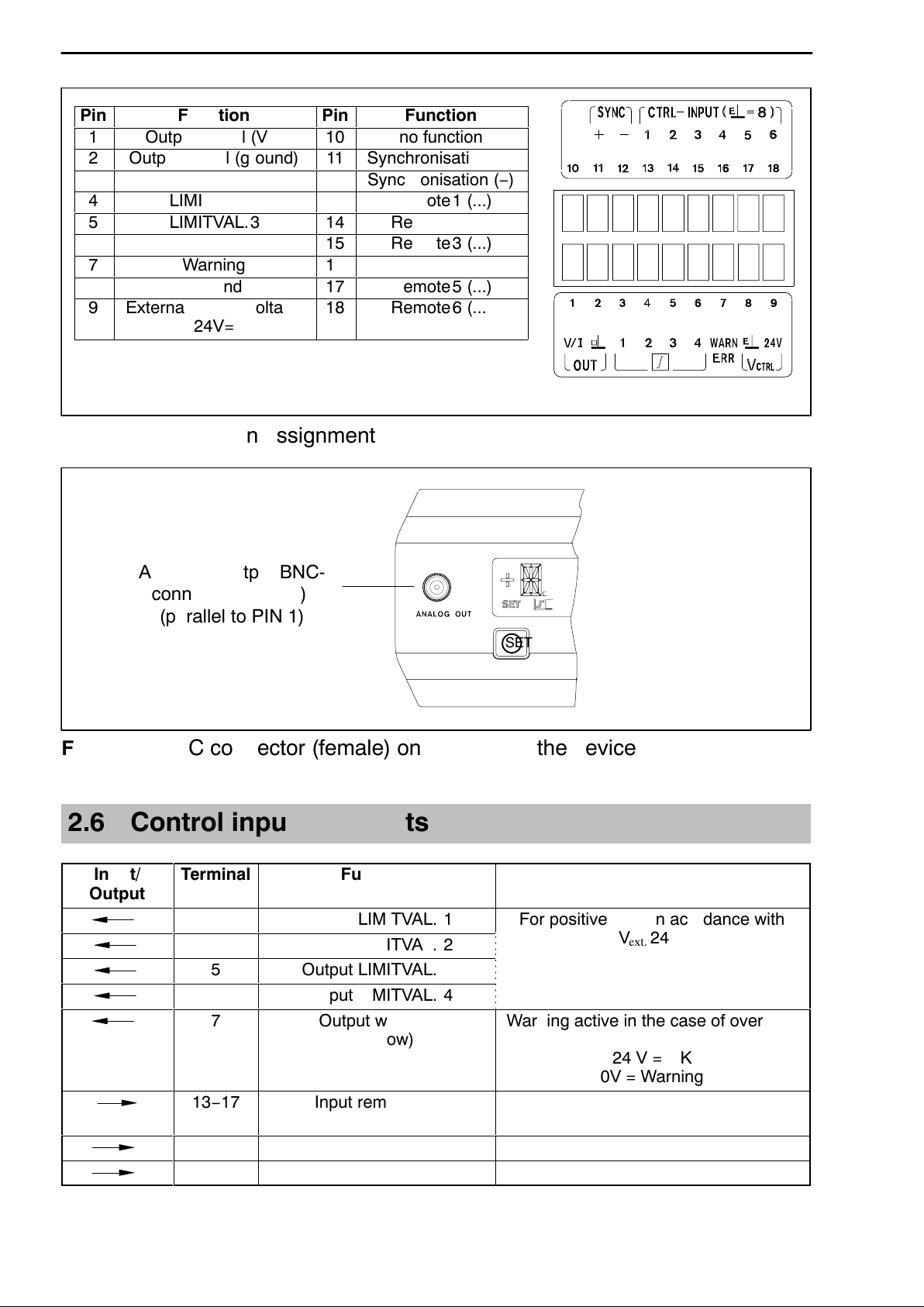

2.6 Control inputs / outputs

Input/

Output

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁÁÁÁ

Terminal

ÁÁ

3

4

5

6

7

ÁÁ

ÁÁ

13−17

8

9

Function

БББББББББ

Output LIMITVAL. 1

Output LIMITVAL. 2

Output LIMITVAL. 3

Output LIMITVAL. 4

Output warning

БББББББББ

БББББББББ

БББББББББ

(overflow)

Input remote1−6

(function selectable)

Ground

External supply voltage

ББББББББББББ

For positive logic in acordance with

ББББББББББББ

ББББББББББББ

ББББББББББББ

V

Warning active in the case of overflow,

ББББББББББББ

ББББББББББББ

ББББББББББББ

Autocal and MOTION OUT

24 V = OK

0V = Warning

see table on Page 45

V

V

ext.

ext.

ext.

24 V

0 V

24 V

HBM A0236-5.9 en

Page 19

Scout 55

19

SCOUT 55 PLC

6

9

8

max. 0.5A

24V*

0V

external supply voltage of the

relay

max. 0.5A

24V*

0V*

control outputs

Fig. 2.9: Output assignments

* The control inputs and outputs are available at the terminal strip socket

(9−pin) and are potential-separated by optical couplers. The control outputs

must be supplied with an external voltage (ground

and 24 V).

If the mains voltage is switched off, there is a power failure, or the mains

fuse blows, all the control outputs are reset to 0V (V

ext.

).

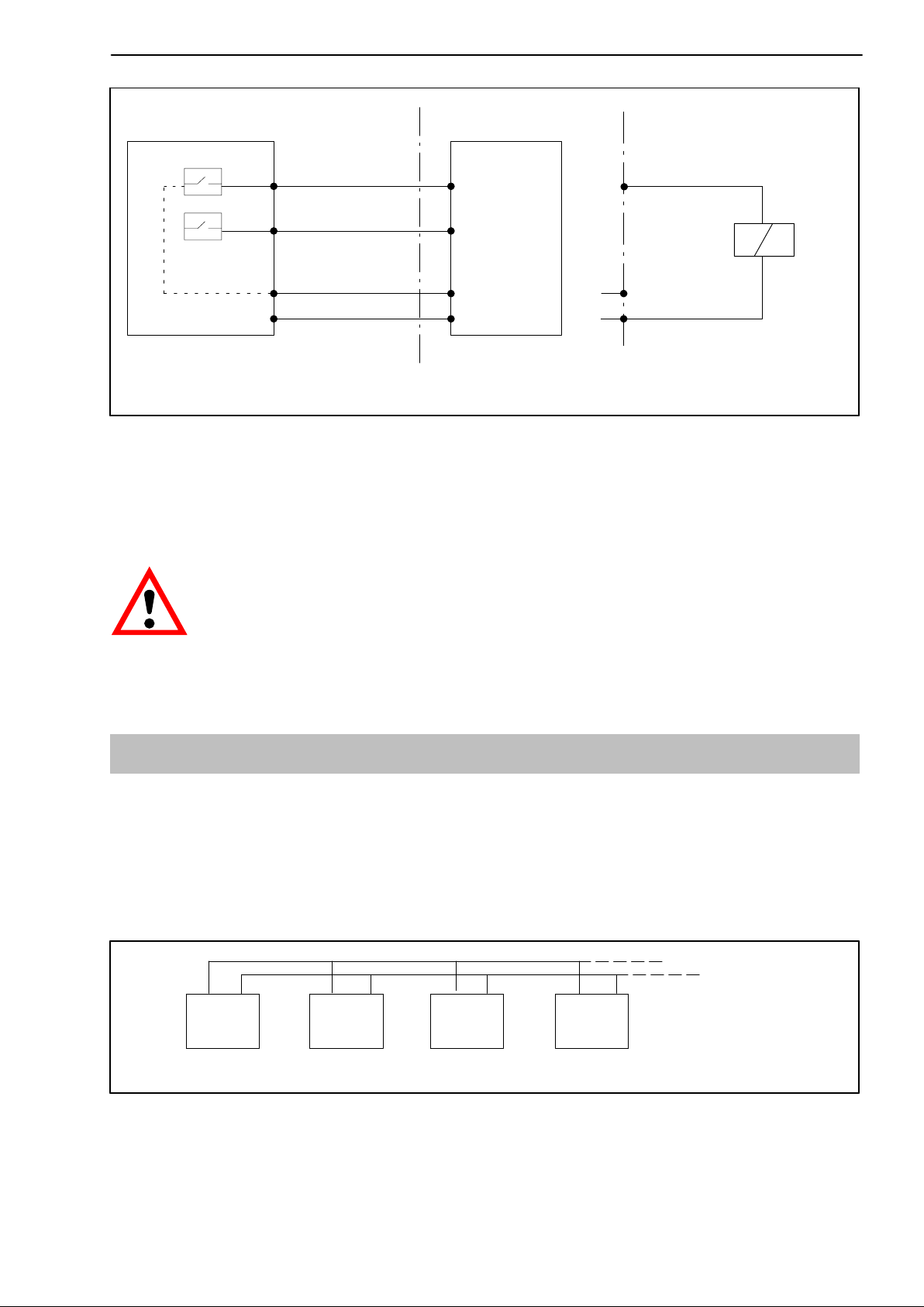

2.7 Synchronisation

If several devices are used right next to one another or if their cables run

parallel, the devices should be synchronised. To achieve this, one device

must be set to Master and all the others (max. seven) to Slave. The setup with

jumpers on the amplifier motherboard is described in Chapter 2.2.2 . As well

as these settings, the devices must be linked together for synchronisation.

11 12 11 12 11 12 11 12

Master Slave Slave Slave

Device 1 Device 2 Device 3 Device 4 (...max. 7)

Fig. 2.10: Terminal connections for synchronisation

HBMA0236-5.9 en

Page 20

20

Scout 55

2.8 Connecting the serial interface

On the back of the device, there is an RS232 serial interface for connecting a

computer or a terminal.

When connecting a printer, a simple line printer needing no

more than 4 seconds to print a line is sufficient. The printout

has 12 columns. This corresponds to a line length of 132

characters. Select the measured values to be printed as

described in Chapter 3.5.9.

When connecting a computer, it is possible to enter into dialogue with the

SCOUT 55.

You can use control commands to make all the device settings and query the

measured values. An overview of the interface commands has been compiled

in another part of the Operating Manual “SCOUT 55, Part2: Operation by

computer or terminal”.

3 Setting up and operation

3.1 Commissioning and factory settings

Some of the steps you need to take to commission your measurement chain

(amplifier and transducer) are listed below, so that you can carry out an initial

function test of all components. The description basically covers adapting the

SCOUT 55 to the transducer type used. We also warn about certain errors

which can typically occur during commissioning.

D Follow the steps given in the previous Chapter to connect the mains cable

and the transducer to the measuring amplifier.

Please observe the safety instructions

D Turn on the power switch.

D The device runs a function test and is then in measuring mode. The factory

settings are active.

D Check the choice of output signal shown on the display. Use

the gross signal (no labelling in the display)

HBM A0236-5.9 en

to select

Page 21

Scout 55

21

NOTE

If the error message CALERR. appears here, the following can be the

causes:

− no six-wire feedback connected

− incorrect transducer/sensor connection

− no transducer/sensor connected

Remedy:

Switch off the device. Connect the transducer properly. Switch the device

back on. If the error message OVFL B, OVFL N appears, you must adapt the

measuring amplifier to your transducer type. The steps to take for each

amplifier are described below.

D To get from measuring mode to device setup mode, press

SET

for about

2s. “DIALOG” will appear in the display.

D Follow the examples given below to adjust the device according to the

connected transducer type.

Transducer types:

S.G. force transducer:

Adaptation:

Transducer type: Full bridge

Excitation: 2.5 V

Input: 4 mV/V

Calibration:

Unit, nominal value/

decimal point: 20,000 kN

Measuring range: 2 mV/V

Inductive displacement transducers:

Adaptation:

Transducer type: Half bridge

Excitation: 1.0 V

Input: 10 mV/V

Calibration:

Unit, nominal value/

decimal point: 20,000 mm

Measuring range: 10 mV/V

HBMA0236-5.9 en

Page 22

22

Piezoresistive transducers:

Adaptation:

Transducer type: Half bridge

Excitation: 2.5 V

Input: 400 mV/V

Calibration:

Unit, nominal value/

decimal point: 30,000 BAR

Measuring range: 200 mV/V

Potentiometric transducers:

Adaptation:

Transducer type: Half bridge

Excitation: 1 V

Input: 1000 mV/V

Scout 55

Calibration:

Unit, nominal value/

decimal point 10,000 mm

Measuring range: 1000 mV/V

HBM A0236-5.9 en

Page 23

Scout 55

23

Key to symbols

Group

Parameter

old setting

new value

MEAS. MODE

SET

DIALOG

PAR

press for 2 sec

select number

change value

LANGUAGE

ENGLISH

DEUTSCH

SET

Language

press once

ADAPTATION

Continued on next page

transducer adaptation

HBMA0236-5.9 en

Page 24

24

Scout 55

S.G. force

transducer

(= factory settings)

PAR

TRANSDUCER

LVDT

FULL BRG.

PAR

Inductive

displacement

transducer

Transducer type

Piezoresistive transducer Potentiometric

transducer

HALF BRG.HALF BRG.

HALF BRG.

EXCITATION

1V

2.5 VOLT

PAR

INPUT

400mV/V

4 mV/V

Setting the excitation voltage

1.0 VOLT

Input signal

10 mV/V

2.5 VOLT

400mV/V

1.0 VOLT

1000mV/V

SET

CALIBR.

press once

change group

Amplifier adjustment

Continued on next page

HBM A0236-5.9 en

Page 25

Scout 55

25

S.G. force

transducer

(= factory settings)

PAR

UNIT

....

Measured quantity unit

kN

PARPAR

Inductive

displacement

transducer

....

mm

Piezoresistive

transducer

....

BAR

Potentiometric

transducer

....

mm

NOM. VALUE

....

20000 kN

PAR

dEc.P

RANGE

....

2,00000 mV/V

Nominal value input

....

20000 mm

....

30000 BAR

....

10000 mm

Press four times (skip decimal point, digit step, zero value)

Range

....

10 mV/V

....

200 mV/V

....

1000 mV/V

HBMA0236-5.9 en

Page 26

26

Scout 55

Switch to measuring mode

SET

Press for 2s

SAVE

SET

The settings are saved in parameter set 1 and the device switches to

measuring mode.

You can now run an initial function test.

NOTE

The settings are only power fail safe once they have been saved under

one of the parameter sets.

HBM A0236-5.9 en

Page 27

Scout 55

3.2 Control concept and functional overview

The control concept makes a distinction between two types of button

functions:

− keys that are operative during measuring mode and

− keys effective in programming mode.

Measured

value display,

parameter

presentation

27

Button row

operating

SET

Change

operating

mode/ choose

group

SET

Change

mode

Set

limit

values

Parameter

selection

Measuring mode

TareZero

Programming

Display of

set value/

choice of

number

CL

CL

Clear

stores

Selection buttons

Change parameter/

numeric value

Print

Switch

display

Input

signal

measurement

Confirm

Key to symbols:

Sign

Limit switches (come

on when operating,

flash in setup mode)

flashes in programming mode

Zero done (only comes

on if the zero value is not

000000mV/V)

standstill

indication

Tare done (only

comes on if the

contents of the

tare buffer are not

000000)

interface

activ

Keyboard

operation

only

Signal indicator

HBMA0236-5.9 en

Page 28

28

3.3 Button functions in measuring mode

Key Meaning

Scout 55

SET

CL

Change from Measuring mode to Programming mode (and vice

versa) by pressing

for approx. 2s.

Set the limit values LV1...4 (see from Page 41)

The additional parameters of the limit switches such as

hysteresis, direction etc., are unchanged. The limit value

function can be activated in the LIMITVAL.1...4 menu

(see Page 41).

Zeroing the measurement chain (also possible by remote).

The signal at the input is applied as the zero point.

Taring the measured value (also possible by remote).

The current measured value is applied as the tare value.

Deletes the contents of the peak value store (also possible by

remote). This function applies to all peak value stores (Min,

Max, Peak-to-Peak).

Output of measured values and parameters over the RS-232

interface (also possible by remote).

For possible print parameters, see “Additional function” starting

on Page 47.

Only those parameters (PRINT xxx) selected in additional

functions will be printed.

Switches the measured value display between:

Gross value no marking in the display

Net value (=gross minus tare) “NET” is displayed

Minimum value “MIN” is displayed

Maximum value “MAX” is displayed

Peak-to-peak value “MAXMIN” is displayed

3.3.1 Querying and setting limit values in measuring mode

You have several options available when choosing the limit values (in

measuring mode):

a: Numerical value entry for limit values

b: Apply input signal as limit value

c: Fast search (keep arrow keys pressed for several seconds)

HBM A0236-5.9 en

Page 29

Scout 55

29

MEAS. MODE

LV1 LEVEL (LIMITVAL.1)

The current limit value is displayed.

Numerical value entry for

limit values (LV1 LEVEL)

Proceed in the same way for LV2 to LV4

Save changes power

fail safe

Apply input signal

as limit value

MEA

S

SET

Press for 2 sec,

SAVE is displayed

SAVE DONE is displayed

Fast run

Keep pressed

SET

LV1 to LV4 are saved power fail safe;

the device switches to measuring mode

HBMA0236-5.9 en

Page 30

30

Scout 55

3.4 Button functions in programming mode

In this operating mode, you can make all the settings for using the amplifier in

your application. The parameters are collected into groups.

Meaning of the keys:

SET

PAR

MEAS

Change mode (press for 2 sec), select group (e.g. CALIBR.)

Parameter selection (e.g. NOM. VALUE)

Display last value set.

Select desired number.

Changes the number in ascending order.

Changes the number in descending order.

Apply measured value.

Confirms input/modification

3.4.1 Changing from “Measuring” mode to “Programming” mode

SET

Press for 2s

DIALOG

HBM A0236-5.9 en

Page 31

Scout 55

3.4.2 Programming

Typical programming mode operations

31

Selecting the value/parame-

ter from a given table (exam-

ple DIALOG-LANGUAGE)

SET

DIALOG

PAR

**

LANGUAGE

Entering a numerical value as

a parameter (example CAL-

IBR./

RANGE)

SET

CALIBR.

PAR

RANGE

Apply a signal produced by the

transducer when a defined load-

ing occurs

SET

CALIBR.

PAR

*

MEAS

ENGLISH

DEUTSCH

Only possible when setting the zero value, the measuring range

*

and the limit values

see page 37

* *

. . . .mV/V

0.60000 mV/V

. . . .mV/V

2.000 mV/V

HBMA0236-5.9 en

Page 32

32

Scout 55

3.4.3 Switching from “Programming” operating mode to “Measuring”

operating mode

When the parameters are changed, you will be asked whether the modified

parameters are to be saved power fail safe.

SET

Press for 2s

SAVE

SET

Not saved power fail safe

SAVE DONE

SET

Measuring mode Measuring mode

Saved power fail safe in

current parameter set

NOTE

The settings are only power fail safe once they have been saved under

one of the parameter sets.

HBM A0236-5.9 en

Page 33

3.5 Overview of all groups and parameters

PARAM

Parameters

SET

Groups

DIALOG PARAM. SET ADAPTATION CALIBR. LIMITVAL.1...4 PV STORE IN/OUT ADD. FUNCT.

LANGUAGE RECALL TRANSDUCER UNIT ENABLE ENABLE SOURCE UA P34

PASSWORD SAVE ? EXCITATION NOM. VALUE SOURCE PVS1 MODE UA SERIAL No.

BUTT. LVS

BUTT. ZERO AUTOCAL STEP LEVEL ENVELOPE CONTACT 1 PARITY

BUTT. TARE

BUTT. PVS MOTION CNT RANGE LOGIC CONTACT 3 COMM. ADDR

BUTT. PRINT MOTION DIG TARE VALUE LV BUTT

BUTT. SIGN MOTION OUT SET SET CONTACT 5

1)

SET

SET

INPUT

FILTER ZERO VALUE HYSTERESIS SET CONTACT 2 STOPBITS

SET CONTACT 6 PRINT MAX

DEC. POINT SWITCH DIR. PVS2 INPUT SIGN. BAUDRATE

CONTACT 4

REMOTE PRINT MIN

SET PRINT PP

PRINT.GROSS

PRINT NET

PRINT LVS

PRINT OVERL

PRINT PAR.

ZERO/TARE

SET

1)

a0236−5.9 en SCOUT 55

Use

SET

to next group

33

Page 34

3.5.1 Setting all parameters

2sec

SET

Password

00000

34

SCOUT 55

+0000 CODE

_ _ _ _

continue with

DIALOG

Enter password

+

press twice

NOYES

DIALOG

PARAM

LANGUAGE

PASSWORD

BUTT. LVS

BUTT. ZERO

BUTT. TARE

BUTT. PVS

BUTT. PRINT

BUTT. SIGN

SET

DEUTSCH

ENGLISH

FRANCAIS

ITALIANO

ESPANOL

+0000 CODE

0000

ENABLED

LOCKED

Groups

PARAM. SET

PARAM

RECALL

SAVE ?

SET

to next

group

adaptation

PARASET 1

PARASET 2

PARASET 3

PARASET 4

PARASET 5

PARASET 6

PARASET 7

PARASET 8

FACT. SETUP

PARASET 1

PARASET 2

PARASET 3

PARASET 4

PARASET 5

PARASET 6

PARASET 7

PARASET 8

FACT. SETUP

a0236-5.9 en

SET

to next

group

Parameter values

Select parameter

SET

Flashes if parameter value can

be edited

Confirm input:

Back to measuring mode

press

SET

2sec

Page 35

SCOUT 55

parameter set

groups

PV STORE

ADAPTATION

PARAM

TRANSDUCER

EXCITATION

INPUT

AUTOCAL

FILTER

MOTION CNT

MOTION DIG

FULL BRG.

HALF BRG.

LVDT

2.5 VOLT

1.0 VOLT

4 mV/V

40 mV/V

400 mV/V

OFF

ON

ONCE

400 HZ BE

200 HZ BE

100.0 HZ BE

40.0 HZ BE

20.0 HZ BE

10.0 HZ BE

5.0 HZ BE

2.5 HZ BE

1.25 HZ BE

0.5 HZ BE

0.2 HZ BE

0.1 HZ BE

0.05 HZ BE

500 HZ BU

200.0 HZ BU

80.0 HZ BU

40.0 HZ BU

20 HZ BU

10 HZ BU

5.0 HZ BU

+000 MEAS

+000 000 V

CALIBR.

PARAM PARAM

UNIT

NOM. VALUE

DEC. POINT

STEP

ZERO VALUE

RANGE

TARE VALUE

SET

to next

group

+010 000 V

FIX

.000

FIX

1

2

5

10

20

50

100

200

500

+0.00000mV/V

+2,0000mV/V

+000,000 V

G

KG

T

KT

TON

LB

OZ

N

KN

BAR

mBAR

PA

PAS

HPAS

KPAS

PSI

mm

mm

cm

m

INCH

Nm

KNm

FTLB

INLB

mm/m

M/S

M/SS

%

‰

PPM

S

MP

MN

mV/V

V

A

mA

LIMIT VALUE*) 1...4

SWITCH DIR.

HYSTERESIS

ENABLE

SOURCE

LEVEL

LOGIC

LV BUTT

SET

to next

group

OFF

OFF

ON

ON

GROSS.VALUE

NET VALUE

PVS1 MAX

PVS2 MIN

PVS3 PP

LOWER

HIGHER

+000,000 V

+000,000 V

ACTIVE.HIGH

ACTIVE.LOW

ENABLED

LOCKED

MOTION OUT

SET

OFF

ON

to next

group

*)

Query and set limit values in measuring mode, see Page 28

35

a0236-5.9 en

Page 36

36

LIMITVAL.1...4

PV STORE

PARAM

ENABLE

PVS 1 INPUT

PVS 2 INPUT

ENVELOPE +000. 000 S

SET

to next

group

PVS OFF

PVS ON

GROSS.VALUE

NET VALUE

GROSS.VALUE

NET VALUE

IN/OUT

SOURCE UA

MODE UA

INPUT SIGN.

CONTACT 1

CONTACT 2

CONTACT 3

CONTACT 4

CONTACT 5

CONTACT 6

REMOTE

Groups

GROSS.VALUE

NET VALUE

PVS1 MAX

PVS2 MIN

PVS3 PP

10 VOLT

UA OFF

MEAS.SIGNAL

ZEROSIGNAL

CAL SIGNAL

GROSS / NET

NO FUNCT.

AUTOCAL

TARE

PVS1 INST

PVS1 HOLD

PVS2 INST

PVS2 HOLD

ZEROING

PRINT

PARACODE 1

PARACODE 2

PARACODE 3

BUTTON.LOCK

ON

OFF

ADD. FUNCT.

PARAMPARAM

P34

SERIAL NO.

BAUDRATE

PARITY

STOPBITS

COMM. ADDR

PRINT.GROSS

PRINT NET

PRINT MAX

PRINT MIN

PRINT PP

PRINT LVS

PRINT OVERL

SCOUT 55

9600 BAUD

4800 BAUD

2400 BAUD

1200 BAUD

600 BAUD

300 BAUD

EVEN PAR.

NO PAR.

ODD PAR.

1 STOPBIT

2 STOPBIT

+00 ADDR

ON

OFF

a0236-5.9 en

SET

to next

group

PRINT PAR.

ZERO/TARE

SET

START

SAVE OFF

SAVE ON

DIALOG

Page 37

Scout 55

37

3.5.2 Dialogue

Select language (LANGUAGE)

Factory settings: DEUTSCH

You can choose the following languages:

German (DEUTSCH), English (ENGLISH), French (FRANCAIS),

Italian (ITALIANO), Spanish (ESPANOL)

3.5.3 Load/Save in parameter set (PARAM. SET)

The current device amplifier settings can be saved power fail safe in eight

parameter sets

and later queried.

When switching from the programming operating mode to measuring mode,

you will be asked whether or not the change is to be saved. This is described

in Chapter 3.4.3 .

Parameter sets can also be activated/recalled by remotes (PARACODE1...2,

see Chapter 3.5.8).

RECALL: Parameter set 1 (parameter set 1...8) and factory

setting (FACT. SETUP) are loaded

SAVE: Save as parameter set 1...8

3.5.4 Adaptation

TRANSDUCER:

Depending on the type of transducer, you can choose between the following

bridge types:

Selectable bridge types

*)

No distinction is made here between transducers with strain gauges and inductive transducers

Full bridge

*)

Half bridge

*)

LVDT

HBMA0236-5.9 en

Page 38

38

EXCITATION:

The excitation voltage for the transducer is selected.

Scout 55

Selectable excitation voltages

1 V 2.5 V

INPUT:

Depending on which excitation voltage is chosen, the input range

(approximate measuring range) can be selected for the transducer type.

Input range UB = 2.5 V UB = 1 V

I "4 mV/V "10 mV/V

II "40 mV/V "100 mV/V

III "400 mV/V "1000 mV/V

AUTOCAL:

Depending on the application and on the stability requirement, you can start

an autocalibration cycle. This lets you correct zero point and full scale value

drift and the long-term constancy of the measuring amplifier.

Possible settings:

ON Autocalibration switched on

OFF Autocalibration switched off

ONCE

Autocalibration is run once, as soon as you confirm it with

Autocalibration stays on/off, depending on the state previously

selected.

CAUTION

If you need the analogue output signal for continuous monitoring, you

must switch autocalibration off.

Reason: no measured values are recorded during the autocalibration

cycle. This produces a “monitoring gap” (interval approx. 5 min.,

duration approx. 1s), which is undesirable if not dangerous during

production processes.

HBM A0236-5.9 en

Page 39

Scout 55

FILTERS:

Different low-pass filters (characteristics and cut-off frequencies) can be

selected:

Characteristics

Bessel (BE)

(Hz)

0.05 18.75 5.0 1200

0.1 37.5 10 1200

0.2 75 20 1200

0.5 300 40 1200

1.25 600 80 1200

2.5 1200 200 1200

5.0 1200

10 1200

Sampling rate

(measured

values per sec)

*)

Butterworth (BU)

(Hz)

Sampling rate

(measured values

per sec)

*)

39

20 1200

40 1200

100 1200

200 1200

*) see motion count (MOTION CNT)

MOTION CNT (motion count)

To activate the motion count, you must set the number of measurements.

During these measurements, the measured value must fall within the given

tolerance for “standstill” to be reported. (for sampling rate, see table on

Page 39).

Settings

+000 MEAS Motion count switched off

+255 MEAS Maximum possible number of measurements

MOTION DIG

Input of tolerance field in digits in display units.

000110 kN

MOTION OUT

Output of motion count status (control output terminal 7; warning).

Possible settings:

OFF The motion count status is not output over WARNING

ON WARNING active, if no standstill or device error

HBMA0236-5.9 en

Page 40

40

Scout 55

Display

units

t

24V

Warning

0V

Fig. 3.1: Effect of the motion count

3.5.5 Calibration (CALIBR.)

UNIT

You can select the following units:

Selectable unit

Tolerance field (MOTION DIG)

Time

Standstill

(number of measurements

within time interval t)

N S cm

OZ PPM mm

LB ‰ mm

TON % PSI

KT M/SS KPAS

T M/S HPAS

KG mm/m PAS

G INLB PA

V FTLB mBAR

mV/V KNm BAR

MN Nm KN

MP INCH A

−−−− m mA

NOM. VALUE

You can adjust the nominal value. Specify the nominal value including the

desired decimal places.

Examples:

a. You want to measure in a pressure range between 0 and 1000.00 bar.

Enter nominal value: 100000

b. With a 50 kg load cell you want to display the measured value with 3

decimal places.

Enter nominal value: 50000

HBM A0236-5.9 en

Page 41

Scout 55

DEC. POINT

Changes the position of the decimal point.

41

Selectable positions

.0000 0.000 00.00 000.0 0000

For above example a: .00

for above example b: .000

STEP

You can choose the step or the digit step.

Selectable steps

1 2 5 10 20 50 100 200 500 1000

ZERO VALUE

The maximum zero balance range matches the particular maximum

measuring range in the following table.

RANGE:

Sets a full scale value (unit mV/V). If this value lies outside the input range,

the minimum or maximum possible value is accepted.

Input range Range at UB = 2.5V Range at UB = 1V

I "0.2...4 mV/V "0.5...10 mV/V

II "2...40 mV/V "5...100 mV/V

III "20...400 mV/V "50...1000 mV/V

TARE VALUE:

You can specify a tare value (in display units) (net value = gross value minus

tare value).

3.5.6 Limit values 1...4 (LIMITVAL.1...4)

The parameters for setting the limit values are combined in a group for each

limit value. The status of the limit switches is shown on the display and carried

out over the control outputs.

The function of the limit switches and their parameters are shown in the

following diagram:

Over limit

Below limit

LV1 ACTIVE.HIGH

LV2 ACTIVE.HIGH

24V

0V

24V

0V

Gr1

Switching on

Switching on

Gr2

Switching off

switching level

Hysteresis value

Switching off

Hysteresis value

switching level

Fig. 3.2: Limit value functions and parameters

HBMA0236-5.9 en

Page 42

42

ENABLE

Scout 55

OFF

ON

Disable individual limit switches

Enable individual limit switches

SOURCE

Limit value evaluated.

GROSS.VALUE

NET VALUE

PVS1 MAX

PVS2 MIN

PVS3 PP

SWITCH DIR.

Store for maximum values

Store for minimum values

Store for peak-to-peak value

Gross

Net

Specify the switch direction or the working direction here (see Fig. 3.2).

HIGHER

LOWER

Switch-on level greater than switch-off level for rising measured value

Switch-off level greater than switch-on level for falling measured value

LEVEL

The level is set in display units (e.g. 2,000kg).

HYSTERESIS

The hysteresis value prevents “fluttering” of the limit switches upon reaching

the switching threshold. Hysteresis is the difference between the activation

and deactivation thresholds.

The value is set in display units, e.g. 0.200kg.

LOGIC

You can change the output logic of the remotes as required. The following

allocation was made:

ACTIVE.HIGH

ACTIVE.LOW

Switched on = High

Switched off = Low

Switched on = High

Switched off = Low

3.5.7 Set peak value store (PV STORE)

Two peak value stores are available to you for monitoring processes. The

following allocation has been made:

PVS1

PVS2

HBM A0236-5.9 en

Store for maximum values

Store for minimum values

Page 43

Scout 55

Use key to display Max/Min values in measure mode.

An additional value is determined arithmetically.

43

PVS3

Store for peak-to-peak value

Linking with PVS1 regarding control functions and envelope.

Both can be operated as peak value stores or as instantaneous value stores.

The choice of operating mode is made with the remotes (see Page 45).

PVS1 INST

PVS1/Hold

PVS2 INST

PVS2/Hold

Instantaneous value or peak value for SP1

Run / Hold mode for SP1

Instantaneous or peak value for PV2

Run / Hold-Modus für SP2

The following diagram shows the function of the remotes:

Measurement signal

Vi,

V

o

Course of the

store value

t

Function

Operating mode

Peak-value (PVS1)

HoldRun Run

Current value

Hold

Fig. 3.3: Function of the remotes shown in the example of PVS1, peak value

and instantaneous value storage (also applies to PVS2 and PVS3).

If the stores are operated as peak value stores, it is possible to display an

envelope function by enabling and setting a discharge rate. This discharge

rate affects all peak value stores.

Discharge rate: too highDischarge rate: too lowDischarge rate: good

Fig. 3.4: Envelope function

HBMA0236-5.9 en

Page 44

44

You can set the following parameters:

ENABLE:

You can enable or lock the peak value stores.

Scout 55

PVS ON

PVS OFF

peak-value memory/buffer/store locked

Enable peak value store

PVS1 INPUT:

Choice of input signal for peak value store PVS1.

GROSS.VALUE NET VALUE

PVS2 INPUT:

Choice of input signal for peak value store PVS2.

GROSS.VALUE NET VALUE

ENVELOPE CURVE:

You can choose the discharge rate of the envelope function for both the peak

value stores. The specification corresponds to a time in ms.

00000 s

000.100 to 060.000 s

envelope function off

envelope function on

3.5.8 Inputs and outputs (IN/OUT)

In this menu, you can make the required settings for the SCOUT 55 input

signal, the analogue output and the remotes.

SOURCE UA:

The following signals can be specified as the source of the analogue signal:

GROSS.VALUE

NET VALUE

PVS1 MAX

PVS2 MIN

PVS3 PP

Store for maximum values

Store for minimum values

Store for peak-to-peak value

Gross

Net

HBM A0236-5.9 en

Page 45

Scout 55

45

MODE UA:

Depending on the analogue signal you select, the following options are

possible:

Display Meaning

UA OFF −

0 TO 20mA Output "20 mA

4 TO 20MA Output +4.. 20 mA

UA OFF −

10 VOLT Output +/− 10 V

NOTE

The current output or voltage output selection is made using jumpers on

the amplifier motherboard. The procedure is described on Page 45.

INPUT SIGN.:

For test purposes, a calibration signal and a zero signal can be displayed

instead of the measurement signal. You can choose the following input

signals:

MEAS.SIGNAL

CAL SIGNAL *

ZEROSIGNAL *

*)

To display the measurement signal, you must return to measuring mode.

)

)

The display corresponds to 50 % of the current full scale value

Measuring mode

Internal zero point

CONTACT 1...6:

Remotes are available on the connector strip for controlling SCOUT 55

functions. The pin assignment or allocation of the remotes is freely

configurable. No function is defined for the remotes at the factory.

HBMA0236-5.9 en

Page 46

46

Functions Level 0V Level 24V

NO FUNCT. no function (factory setting)

AUTOCAL Autocalibration ON Autocalibration OFF

TARE For the transition 0V − 24 V, the tare value is adopted

Scout 55

PVS1 INST Peak value operating mode for

PV1

PVS1/HOLD Store contents PV1 and PV3 are

updated

PVS2 INST Peak value operating mode for

PV2

PVS2/HOLD Store contents PV2 are

updated

ZEROING For the transition 0V − 24 V, the current instantaneous input signal is

adopted as the zero value

PRINT A printout is triggered over the

GROSS/NET Gross at analogue output Net at analogue output

PARACODE 1 External selection of parameter sets and binary coded

PARACODE 2

PARACODE 3

BUTTON.LOCK ENABLED LOCKED

(see following table)

Instantaneous value operating

mode for PV1

Store contents PV1 and PV3 are

frozen

Instantaneous value operating

mode for PV2

Store contents PV2 are

frozen

interface

inputs

PARAM. SET PARACODE

3 21

1 0 0 0

2 0 0 1

3 0 1 0

4 0 1 1

5 1 0 0

6 1 0 1

7 1 1 0

8 1 1 1

REMOTE

Device control through remotes can be locked or enabled.

ON

OFF

no display Operating using keyboard and remotes

LOCAL Keyboard operation only

HBM A0236-5.9 en

Page 47

Scout 55

47

3.5.9 Additional functions (ADD. FUNCT)

P_ _:

In order to provide better support should you experience technical problems,

the firmware status is indicated by this parameter. If you have any questions

for our service department or HBM branch, giving the existing firmware

version will enable us to provide effective support.

Example: P34 Software version P34

SERIAL NO:

Display the serial number of the device.

BAUDRATE:

You can choose between the following values as the baud rate for the serial

interface.

Selectable baud rates

300 600 1200 2400 4800 9600

PARITY:

The following settings are possible:

Selectable parity

EVEN PAR. ODD PAR. NO PAR.

STOPBITS:

The following settings are possible:

1 STOPBIT

2 STOPBIT

COMM. ADDR*:

Input the device address.

Selectable device addresses 00 to 31

*)

Address selectable only for RS485 version; for RS232, set address to 1

PRINT.GROSS:

Output the gross value over the serial interface.

OFF/ON

PRINT NET:

Output the net value over the serial interface.

OFF/ON

HBMA0236-5.9 en

Page 48

48

PRINT MAX:

Output the maximum value over the serial interface.

OFF/ON

PRINT MIN:

Output the minimum value over the serial interface.

OFF/ON

PRINT PP:

Output the MIN/MAX value over the serial interface.

OFF/ON

PRINT LVS:

Scout 55

Output limit switch states over serial interface.

OFF/ON

PRINT OVERL

Adjust repetition rate. Heading comprising the source of the measured value

and the unit.

0 = no heading (measured value only)

1 = Heading always

10 = Heading every 10 times etc.

PRINT PAR.:

Output all the parameters.

START

NOTE

The chosen print functions (apart from PRINT PAR) are run in measuring

mode (by pressing

HBM A0236-5.9 en

or by remote contact).

Page 49

Scout 55

49

ZERO/TARE:

Any change to the tare value or the zero value made by keys (green) or

remotes, is automatically stored in the current parameter set. This protection

can be switched on or off:

SAVE OFF

SAVE ON

4 Example

The following example uses a measurement task to show you the functionality

of the device and the required settings.

Problem definition:

The forming process in a press is to be monitored in order to obtain uniform

product quality. The maximum force exerted by the press is to be recorded in

each cycle. To guarantee the production process, this maximum force must

fall between the lower (F1) and upper (F2) force limit.

Solution:

The force characteristic measured with an S.G. force transducer (e.g.

C9B/10kN; 1 mV/V) is amplified and evaluated by the SCOUT 55. The peak

value store (maximum) is used to record the maximum force and it is

evaluated with two limit switches with regard to the lower and upper limits. An

additional limit switch is provided for overload protection (emergency shut

down) of the machine.

A PLC takes over the control of the process. As well as the control commands

for the press, it gives the SCOUT 55 a start signal to begin the pressing cycle

and once the process has finished, logically links the limit switch outputs to

the “Good/Bad evaluation”.

The start signal from the PLC clears the contents of the peak value store

through the SCOUT 55 control input. To prevent unintentional modifications,

during measurement, only the “Display signal selection” button is enabled for

the machine operator on site.

The parameter setups are protected against unauthorised modification by a

password.

Device control through the remotes (remote control) must be activated.

HBMA0236-5.9 en

Page 50

50

Wiring diagram:

Scout 55

SCOUT 55 PLC

8/9

Limit3

5

C9B/10kN

PVS1

CONTACT 1 / PVS1 INST

Limit1

Limit2

3

4

13

Serial interface for document printer, host computer, PLC, etc.

Power supply

0 / 24V

Emergency

shutdown

press

Logical

evaluation of

limit values 1

and 2

START

Timing diagram:

Switching state

Start signal from the

PLC (Control 1)

Limit3

Limit2

Limit1

Limit1

Limit2

Contents

of PVS1

Force

characteristic

1

0

1

0

24V

0

PLC evaluation

“ Good ”

HBM A0236-5.9 en

Page 51

Scout 55

Using the PLC to evaluate the limit value message:

Good Reject

Limit1 1 0 1

Limit2 1 1 0

Choose the following settings:

Limit1 Checks whether the lower force limit has been reached.

The input signal is the output of the peak value store

(maximum value). If limit LV1 is exceeded, a High signal is

generated. A positive switch direction must be set with

positive output logic.

Limit2 Checks whether the upper force limit has been reached.

The input signal is the output of the peak value store

(maximum value). If limit LV2 is exceeded, a Low signal is

generated. A positive switch direction must be set with

positive output logic.

51

Limit3 Checks whether the maximum load limit of the machine is

exceeded (emergency shutdown function). The input signal

is the gross measured value. If limit LV3 is exceeded, a

High signal is generated. A positive switch direction must

be set with positive output logic.

PVS1 Records the maximum peak value of the force

characteristic. Must be enabled, the envelope function must

be deactivated. The input signal is the gross measured

value. PVS1 is cleared with remote 1 by switching to

instantaneous value.

Remote 1 Clears the contents of the peak value store. The function

PVS1 INST must be selected. The remote must be

activated.

HBMA0236-5.9 en

Page 52

52

Scout 55

Key to symbols

Group

Parameter

Programming mode

old setting

new value

MEAS. MODE

SET

PAR

press for 2 sec

Dialogue

select number

change value

LANGUAGE

ENGLISH

DEUTSCH

PAR

HBM A0236-5.9 en

Page 53

Scout 55

53

SET

Change group

press twice

ADAPTATION

PAR

TRANSDUCER

LVDT

FULL BRG.

PAR

Transducer

type

Change group

Amplifier adjust-

ment

_ _ _ _

100Hz BE

SET

CALIBR.

PAR

press once

EXCITATION

1V

2.5VOLT

PAR

INPUT

400mV/V

4mV/V

Setting the

excitation

voltage

Input signal

Nominal value input

(display range)

UNIT

....

N

PAR

PAR

dEc.P

NOM. VALUE

Measured

quantity unit

PAR

FILTER

press twice

Signal filter

selection

....

006000N

Continued on next page

HBMA0236-5.9 en

Page 54

54

Scout 55

PAR

DEC. POINT

0000

.

PAR

dEc.P

STEP

Decimal

point input

Digit step input

dEc.P

RANGE

....

00,60000 mV/V

SET

LIMITVAL.1

PAR

Range

Transducer signal

in accordance

with the desired

display range

Change group

Set limit switches

1...4

000000

000005

PAR

ZERO VALUE

MEAS

000000 N

00,0007

Zero value in mV/V

ENABLE

OFF

ON

PAR

SOURCE

NET VALUE

GROSS.VALUE

Limit switch locked

or enabled

Limit value of

different signal

sources

PAR

HBM A0236-5.9 en

Page 55

Scout 55

PAR

55

SWITCH DIR.

LOWER

HIGHER

PAR

LEVEL

dEc.P

0100

+003500 N

Effective direction

Limit value 1

PAR

LOGIC

ACTIVE.LOW

ACTIVE.HIGH

PAR

LV BUTT

Remotes logic

Limit switch

button function

PAR

dEc.P

HYSTERESIS

....

+000005 N

Hysteresis

value input

NET VALUE

ENABLED

SET

Set limit switches 2, 3

and 4 accordingly

HBMA0236-5.9 en

Page 56

56

Change group

SET

press once

SET

Change group

Scout 55

PV STORE

PAR

ENABLE

PVS OFF

PVS ON

PAR

PVS 1 INPUT

Adjusting peak

value stores

Peak value store

locked or enabled

Input signal

choice, store 1

IN/OUT

PAR

SOURCE UA

NET VALUE

GROSS.VALUE

PAR

MODE UA

dEc.P

I/Os

Signal sources

selectable

Set output

signals

NET VALUE

GROSS.VALUE

HBM A0236-5.9 en

OFF

10VOLT

PAR

Page 57

Scout 55

57

INPUT SIGN.

ZEROSIGNAL

MEAS.SIGNAL

PAR

CONTACT 1

NO FUNCT.

PVS1 INST

Input signals

Pin assignment of

remotes 1...6

SET

SAVE

SAVE DONE

SET

press for 2 sec

Query, whether changes

press once

Measuring mode

are to be saved

Save changes

HBMA0236-5.9 en

Page 58

58

5 Error messages

Error message Cause Remedy

FIX The given value cannot be altered.

Example: For unit V and mV/V, the

nominal value setting is fixed at

10,000

OVFL B Gross value overflow

OVFL N Net value overflow

Scout 55

CAL.ERR incorrect transducer/

sensor connection:

No transducer/sensor connected

No six-wire feedback connected

Measuring bridge connected

incorrectly (e.g. full bridge set, but

half bridge connected)

OUTOFRANGE The value chosen for measuring

range, zero point value, nominal

value or tare value cannot be set,

as it exceeds the permissible limits.

DATA ERROR A transmission error occurred when

saving the parameters

Connect the transducer properly.

Switch device off and then back

on again.

The device sets the maximum or

minimum value automatically, as

soon as the error message has

been acknowledged by

“ENTER”.

HBM A0236-5.9 en

Page 59

SCOUT 55

6 Keyword index

59

A

adaptation, 37

aditional functions, 47

autocalibration, 38 , 46

B

baud rate, 47

BNC−connector (female), 18

C

calibration, 40

control inputs− and outputs, 19

D

decimal point, 41

G

gross, 28

gross signal, 20

gross value, 42

H

hysteresis, 41 , 42

I

inductive displacement transducer, 24

inductive transducers, 15

input signal, 44 , 45

inputs/outputs, 44

J

digit step, 41

E

envelope function, 44

error message, 58

F

factory settings, 12 , 20

load/save, 37

filters, 39

four wire technique, 17

full scale value, 41

fuses, 15

jumpers, 12

L

language selection, 37

limit switches, 28

limit value, disable/enable, 42

limit values, 28

setting in measuring mode, 28

logic, 18

LVDT, 15

M

mains voltage selection, 14

Master/Slave, 12

measurement example, 49

measuring mode, 27 , 30 , 32

motion count, tolerance zone, status, 39

HBMA0236-5.9 en

Page 60

60

SCOUT 55

N

net, 28

net value, 42

O

output logic of the remotes, 42

output signal, 44

P

parameter, save, 32

parameter set, 46

load/save, 37

parameters, 33

setting, 34

parity, 47

peak value store, 28 , 42

enable, lock, 44

piezoresistive transducer, 15 , 24

potentiometric transducer, 15 , 24

programming, 31

programming mode, 27 , 30 , 31 , 32

S

S.G. force transducer, 24

S.G. transducers, 15

serial interface, 20

SET, 28

setting parameters, 34

step, 41

stop bit, 47

switch direction, 42

synchronisation, 13 , 19

T

tare value, 41

taring, 28

transducer connection, S.G.-full-and half

bridges, inductive full- and half bridges,

potentiometric transducers, piezoresistive transducers, LVDT, 15

transducer types, S.G.-force transducer,

inductive displacement transducers,

piezoresistive transducers, potentiometric transducers, 21

R

remote, 46

remotes, 43 , 45

replacing the fuse, 14

RS−232 interface, 28

V

voltage output selection, 17

voltage supply, 13

Z

zero balance, 28

HBM A0236-5.9 en

Page 61

Page 62

Page 63

Page 64

pp

Modifications reserved.

All details describe our products in general form only.They are

not to be understood as express warranty and do not constitute

any liability whatsoever.

7-2002.0674

A0236-5.9 en

Hottinger Baldwin Messtechnik GmbH

Postfach 10 01 51, D-64201 Darmstadt

Im Tiefen See 45, D-64293 Darmstadt

Tel.: +49 6151 803-0 Fax: +49 6151 8039100

Email: su

ort@hbm.com Internet: www.hbm.com

Loading...

Loading...