Page 1

Mounting Instructions | Montageanleitung |

Notice de montage

English Deutsch Français

PW15iA

Page 2

Hottinger Baldwin Messtechnik GmbH

Im Tiefen See 45

D-64239 Darmstadt

Tel. +49 6151 803-0

Fax +49 6151 803-9100

info@hbm.com

www.hbm.com

Mat.: 7-2002.4359

DVS: A4359-1.0 HBM: public

1.2016

E Hottinger Baldwin Messtechnik GmbH.

Subject to modifications.

All product descriptions are for general information only.

They are not to be understood as a guarantee of quality or

durability.

Änderungen vorbehalten.

Alle Angaben beschreiben unsere Produkte in allgemeiner

Form. Sie stellen keine Beschaffenheits- oder Haltbarkeits

garantie dar.

Sous réserve de modifications.

Les caractéristiques indiquées ne décrivent nos produits

que sous une forme générale. Elles n'impliquent aucune

garantie de qualité ou de durablilité.

Page 3

Mounting Instructions | Montageanleitung |

Notice de montage

English Deutsch Français

PW15iA

Digital Load Cell

Page 4

English

1 Safety instructions 4........................................

2 Markings used 8............................................

2.1 Symbols on the transducer 8..................................

2.2 The markings used in this document 8..........................

3 Structure and mode of operation 10...........................

3.1 Layout 11....................................................

3.2 Signal conditioning 12.........................................

3.3 Adaptive interference suppression 13............................

3.4 Inputs and outputs 14.........................................

3.4.1 Trigger function 14............................................

3.4.2 Filling and dosing 15..........................................

3.4.3 Limit value function 15.........................................

3.4.4 Extreme value functions 15....................................

4 Conditions on site 16........................................

4.1 Protection against corrosion 16.................................

4.2 Deposits 17..................................................

5 Mechanical installation 18....................................

5.1 Important precautions during installation 18......................

5.2 Mounting and load application 19...............................

5.3 Dimensions 21...............................................

6 Electrical connection 22......................................

6.1 Cable laying 22...............................................

6.2 Pin assignment 22............................................

6.3 Supply voltage 24.............................................

6.4 Digital inputs 25..............................................

6.5 Digital outputs 26.............................................

2 A4359-1.0 HBM: public PW15iA

Page 5

7 Interfaces 27................................................

7.1 RS‐485 4‐wire interfaces (UART) 27............................

7.2 CANopen interface 29.........................................

7.3 DeviceNet interface 30........................................

8 Operation via software 32....................................

9 Waste disposal and environmental protection 32..............

PW15iA A4359-1.0 HBM: public 3

Page 6

Safety instructions

1 Safety instructions

Appropriate use

Transducers of the PW15iA type series are designed

solely for technical weighing applications within the appli

cation limits detailed in the specifications. Any other use

is not appropriate.

Any person instructed to carry out installation, commis

sioning or operation of the transducer must have read

and understood the Operating Manual and in particular

the technical safety instructions.

In the interests of safety, the transducer should only be

operated by qualified personnel and as described in the

Operating Manual. It is also essential to comply with the

legal and safety requirements for the application con

cerned during use. The same applies to the use of

accessories.

The transducer is not intended for use as a safety com

ponent. Please also refer to the "Additional safety pre

cautions" section. Proper and safe operation requires

proper transportation, correct storage, siting and mount

ing, and careful operation.

Operating conditions

S Please observe the allowed maximum values stated

in the specifications for:

- Limit load

- Limit load at max. eccentricity

- Limit lateral loading

- Breaking loads

- Temperature limits

4 A4359-1.0 HBM: public PW15iA

Page 7

Safety instructions

- Limits of electrical loading capacity

S Please note that when several transducers are

installed in a scale, there is not always an even distri

bution of load on the individual transducers.

S The transducers can be used as machine elements.

When used in this manner, it must be noted that, to

favor greater sensitivity, the transducer is not

designed with the safety factors usual in mechanical

engineering.

S The design or safety engineering of the transducer

must not be modified without our express permission.

S The transducer is maintenance-free.

S In accordance with national and local environmental

protection and material recovery and recycling regula

tions, old transducers that can no longer be used

must be disposed of separately and not with normal

household garbage, see Section 9, Page 32.

Qualified personnel

Qualified persons means persons entrusted with the

installation, fitting, commissioning and operation of the

product who possess the appropriate qualifications for

their function.

This includes people who meet at least one of the three

following requirements:

S Knowledge of the safety concepts of measurement

and automation technology is a requirement and as

project personnel, they must be familiar with these

concepts.

S As measurement or automation plant operating per

sonnel, they have been instructed how to handle the

machinery. They are familiar with the operation of the

PW15iA A4359-1.0 HBM: public 5

Page 8

Safety instructions

equipment and technologies described in this docu

mentation.

S As commissioning engineers or service engineers,

they have successfully completed the training to qual

ify them to repair the automation systems. They are

also authorized to activate, ground and label circuits

and equipment in accordance with safety engineering

standards.

Working safely

S The transducer must not be directly connected to the

power supply system. The supply voltage must be

between 12 and 30VDC.

S Error messages should only be acknowledged once

the cause of the error is removed and no further dan

ger exists.

S Maintenance and repair work on an open device with

the power on may only be carried out by trained per

sonnel who are aware of the dangers involved.

S Automation equipment and devices must be designed

in such a way that adequate protection or locking

against unintentional actuation is provided (e.g.

access checks, password protection, etc.).

S For those devices operating in networks, safety pre

cautions must be taken both in terms of hardware and

software, so that a line break or other interruptions to

signal transmission do not cause undefined states or

loss of data in the automation device.

S After making settings and carrying out activities that

are password-protected, ensure that any controls that

may be connected remain in a safe condition until the

switching performance of the device has been tested.

6 A4359-1.0 HBM: public PW15iA

Page 9

Safety instructions

Additional safety precautions

Additional safety precautions to meet the requirements of

the relevant national and local accident prevention regu

lations must be taken in plants where malfunctions could

cause major damage, loss of data or even personal

injury.

The scope of supply and performance of the transducer

covers only a small area of measurement technology.

Before starting up the transducer in a system, a project

planning and risk analysis must first be implemented,

taking into account all the safety aspects of measure

ment and automation technology so that residual risks

are minimized. This particularly concerns personal and

machine protection. The transducers cannot implement

any safety-relevant cutoffs. In the event of a fault, the

relevant precautions must establish safe operating condi

tions.

General dangers of failing to follow the safety

instructions

The transducer corresponds to the state of the art and is

failsafe. The transducer may give rise to residual dangers

if it is inappropriately installed or operated.

PW15iA A4359-1.0 HBM: public 7

Page 10

Markings used

2 Markings used

2.1 Symbols on the transducer

CE mark

The CE mark enables the manufacturer to guarantee that

the product complies with the requirements of the rele

vant EC directives (the Declaration of Conformity can be

found on the HBM website (www.hbm.com) under

HBMdoc).

Statutory waste disposal mark

In accordance with national and local environmental pro

tection and material recovery and recycling regulations,

old devices that can no longer be used must be disposed

of separately and not with normal household garbage.

Also see Section9, Page 32.

2.2 The markings used in this document

Important instructions for your safety are specifically

identified. It is essential to follow these instructions in

order to prevent accidents and damage to property.

Symbol Significance

WARNING

Notice

8 A4359-1.0 HBM: public PW15iA

This marking warns of a potentially dangerous situa

tion in which failure to comply with safety require

ments can result in death or serious physical injury.

This marking draws your attention to a situation in

which failure to comply with safety requirements can

lead to damage to property.

Page 11

Emphasis

See …

Important

Information

Markings used

SignificanceSymbol

This marking draws your attention to important infor

mation about the product or about handling the prod

uct.

This marking draws your attention to information

about the product or about handling the product.

Italics are used to emphasize and highlight text and

identify references to sections, diagrams, or external

documents and files.

PW15iA A4359-1.0 HBM: public 9

Page 12

Structure and mode of operation

3 Structure and mode of operation

PW15iA digital load cells are part of the family of elec

tronics developed by HBM for static and dynamic weigh

ing processes. The measuring element is a steel loaded

member to which strain gages (SG) are applied. The SG

are arranged so that two are stretched and the other two

compressed when a load acts on the load cell. The

PW15iA digitally conditions the signals and delivers a

fully-filtered, scaled and digitized output signal for direct

connection to bus systems or PCs via the RS‐485 inter

face, CANopen, or DeviceNet. Measuring element and

electronics are housed in a single enclosure. The digital

load cells can be quickly and easily matched to a particu

lar system by various parameters, and they work with an

internal data rate of up to 1200 measurements per sec

ond.

The inbuilt digital inputs and outputs allow event-driven

weight determination, e.g. for checkweigher applications

or dosing controls. The digital outputs can be configured

by software command, and can be used to control coarse

flow and fine flow in dosing valves, for example.

The PanelX PC software is available to facilitate parame

ter settings, to display dynamic measurement signals and

for comprehensive frequency analysis of the dynamic

system.

This document describes the installation and functions of

the digital load cell. The commands for the interfaces can

be found in the online documentation for the PanelX pro

gram.

10 A4359-1.0 HBM: public PW15iA

Page 13

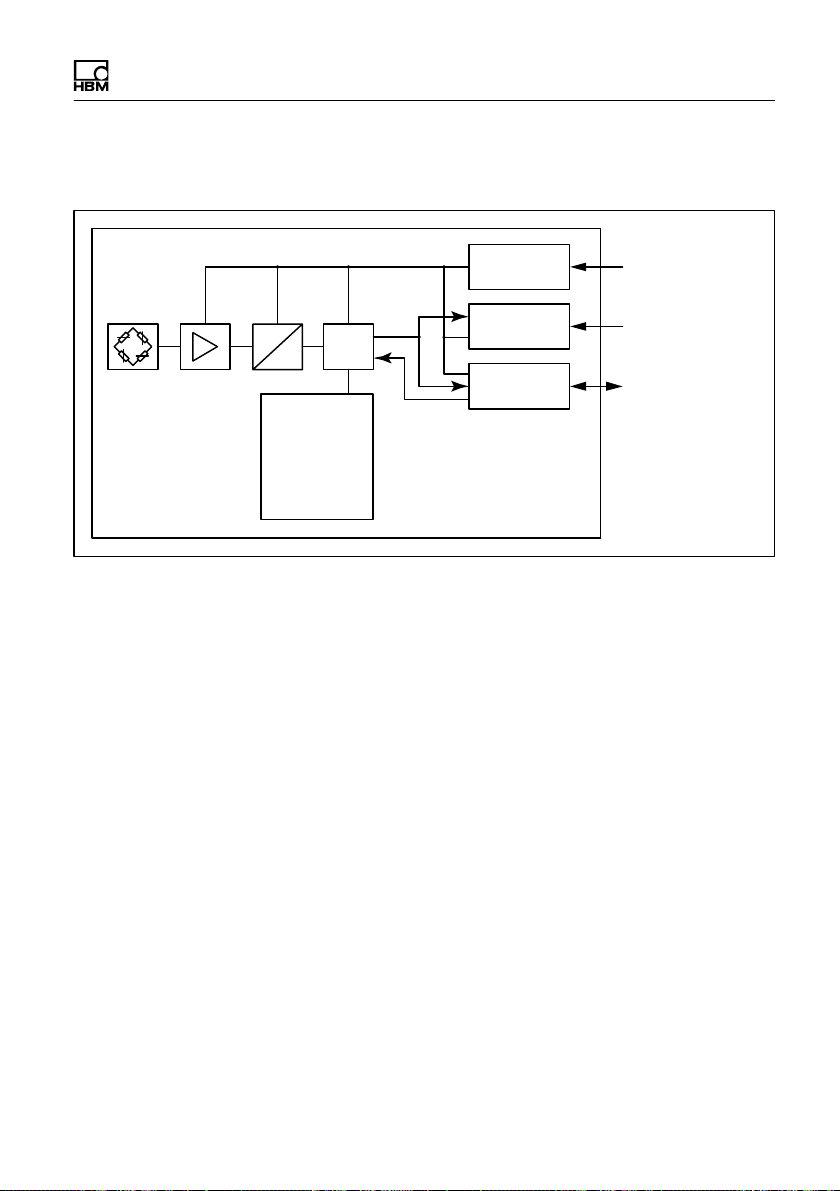

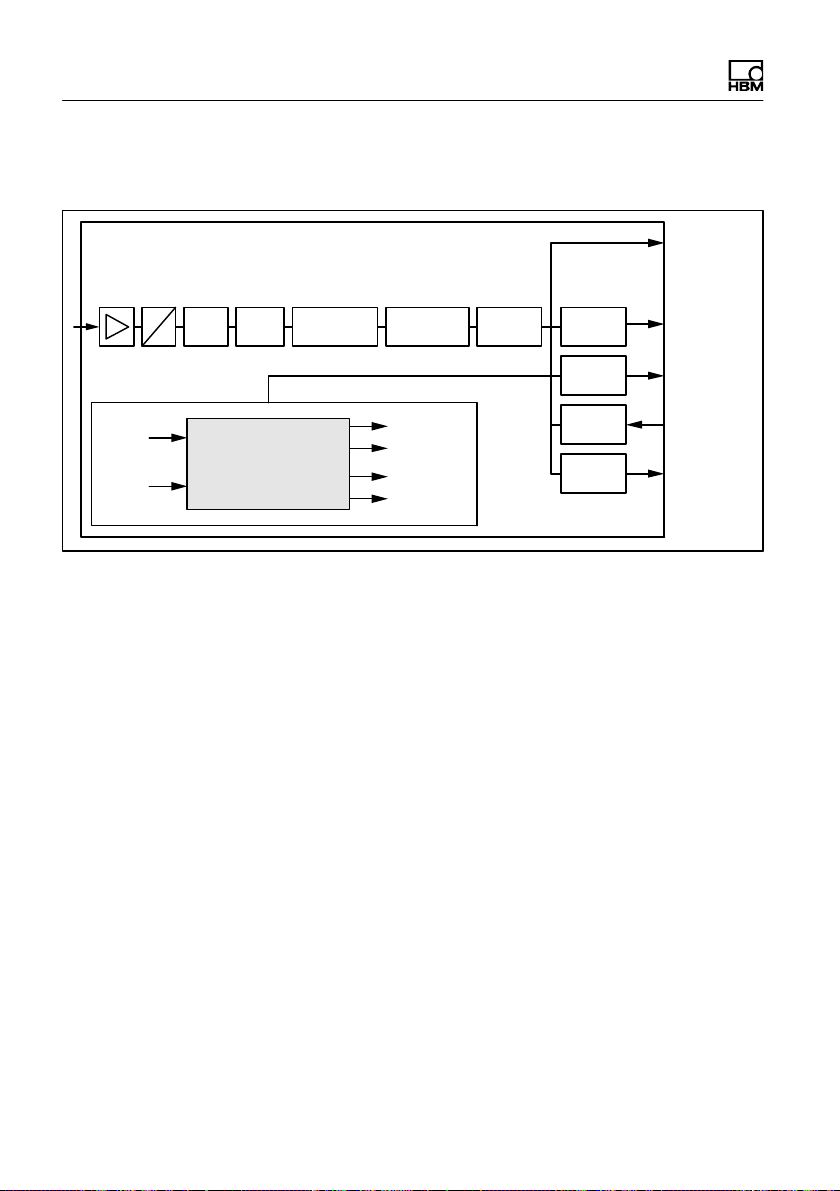

3.1 Layout

Structure and mode of operation

PW15iA

A

D

EEPROM

Linearization

Serial number

Digital filter

Data rate

Sensitivity

Zero value

Voltage

control

Interface

μP

I/Os

Supply

voltage UB/GND

Interface

RS-485/CANopen

IO

Trigger,

Stop Dosing

Fig. 1.1 Block diagram

The analog measuring element signal is amplified, fil

tered, and digitized in the A/D converter. This measure

ment signal is conditioned (filtering, analysis) in the

microprocessor, and transmitted via the interface.

Depending on the configuration, the inputs and outputs

can both control the processing and trigger valves, for

example, subject to the signal. All the parameters can be

stored power failsafe.

The digital load cells have switchable inputs or outputs:

They can use a maximum of 2 inputs or 2 outputs, or one

input and one output.

Detailed information on setting the different functions can

be found in the online help of the PanelX program.

PW15iA A4359-1.0 HBM: public 11

Page 14

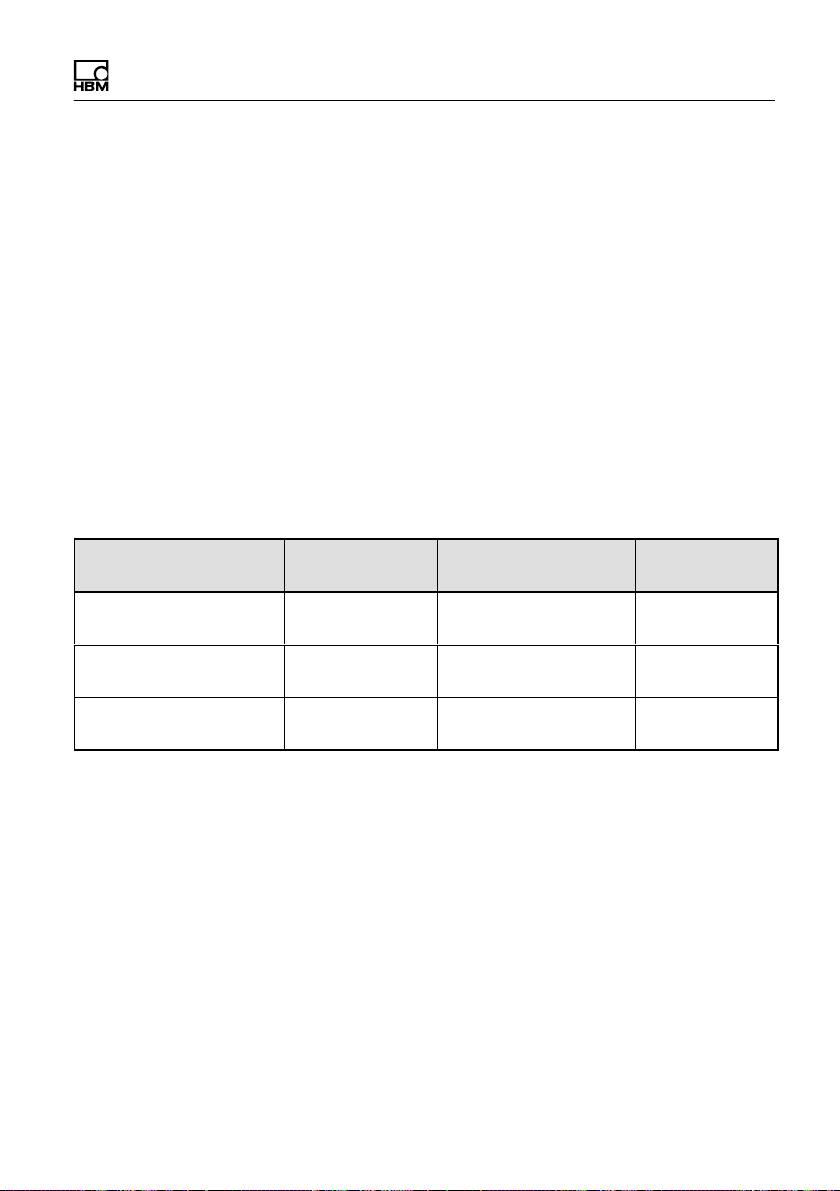

Structure and mode of operation

3.2 Signal conditioning

RUN

BRK

FMD

ASF ICR

A

D

Data

Filter Tare

rate

Dosing control

Fig. 1.2 Signal conditioning

Digitization is followed by filtering, using digital filters

adjusted by the software. The ICR command changes

the output rate (measured values per second).

SZA

SFA

Working

standard

calibr.

NOV, RSN

LDW, LWT LIC

User-defined

scaling

Coarse Flow

Fine Flow

Ready

Alarm

Linearization

TAV, TAS

Min/

Max

Trigger

Limit

values

PVA

IMD

LIV

Gross

measured

value

Net

measured

value

Extreme

values

Trigger/

Stop

Limit

values

In the working standard calibration of the electronics (on

delivery), 0 mV/V corresponds to zero and the maximum

capacity is either 1,000,000digits (NOV≠0), or

5,120,000digits (NOV=0). The two parameters LDW and

LWT give you the opportunity to adapt the characteristic

curve to meet your requirements (scale curve) and you

can use the NOV command to standardize the measured

values to the required scaling value (e.g. 3000d).

Detailed information can be found in the command docu

mentation and in the online help for the PanelX program.

You also have the opportunity to

S switch from gross to net signals,

12 A4359-1.0 HBM: public PW15iA

Page 15

Structure and mode of operation

S activate an automatic zero on start up function,

S activate an automatic zero tracking function,

S linearize the scale curve with a third order polynomial,

S activate various digital filters. Available filters include

those with cut-off frequencies below 1Hz, fast-settling

filters for dynamic measurements, notch filters and

mean value filters.

Use MSV? to read out the current measured value. The

format of the measured value (ASCII or binary) is set

with the COF command. You can also use the COF com

mand to activate automatic measurement output. The

measured values are transmitted in the following format,

subject to the COF command:

Output format Input signal Output when NOV=0 Output when

Binary, 2 chars. (INT) 0 … maximum

capacity

Binary, 4 chars. (LONG) 0 … maximum

capacity

ASCII 0 … maximum

capacity

0 … 20,000digits 1 … NOV

0 … 5,120,000digits 1 … NOV

0 … 1,000,000digits 1 … NOV

NOV>0

3.3 Adaptive interference suppression

Whatever the mode of operation, you can use the ADF

command to activate automatic interference suppression

with adaptive filters. Interference frequencies are auto

matically found during measurement and suppressed by

comb filters and averaging. The maximum filter settling

time can be limited with the TMA command.

PW15iA A4359-1.0 HBM: public 13

Page 16

Structure and mode of operation

3.4 Inputs and outputs

The two I/Os can be used either as inputs or outputs.

You can also set different switching levels (TTL or PLC)

for the inputs. On delivery, both I/Os are set as inputs

with a TTL level. Specify the function of the I/Os as

inputs with commands IM1 and IM2, and the function as

outputs with OM1 and OM2.

Notice

The electronics must be operated with a supply voltage

of between 12 and 30V. Incorrect connections between

the supply and interface cables or the digital inputs/out

puts can cause irreversible damage.

So you must check the correct assignment of the con

nections before switching on for the first time.

3.4.1 Trigger function

In Trigger mode (command IMD1), the electronics have

four different trigger functions available:

S Pre-triggering by level

S Pre-triggering by external (digital) signal

S Post-triggering by level

S Post-triggering by external (digital) signal

Gross or net values can be used as input values. The

filter settling time can be optimized by the actual elec

tronics (command AST).

14 A4359-1.0 HBM: public PW15iA

Page 17

Structure and mode of operation

3.4.2 Filling and dosing

The electronics include full dosing control (command

IMD2). As many as 32 parameter sets can be stored in

the EEPROM for different applications. But you can still

change the dosing parameters yourself during dosing.

Digital outputs can be used to control coarse and fine

flow, for example. The PanelX software includes detailed

instructions for setting the different parameters.

3.4.3 Limit value function

In Standard and Trigger modes (command IMD), the

electronics allow as many as four limit values to be moni

tored (command LIV). Gross or net values, the trigger

result, or the extreme values (Min/Max) are available to

you as input signals. Use the measurement status to

read out the status, either simultaneously with the mea

sured values (command MSV?) or separately (command

RIO?).

3.4.4 Extreme value functions

The electronics include a peak value function (Minimum

and Maximum, command PVS), that monitors either the

gross or net values, as required. Use command PVA to

read out the values and use command CPV to reset the

peak values.

PW15iA A4359-1.0 HBM: public 15

Page 18

Structure and mode of operation

4 Conditions on site

Series PW15iA transducers are hermetically encapsu

lated and are therefore very insensitive to the influence of

moisture and humidity. The transducers achieve protec

tion classes IP68 (test conditions: 100 hours under 1m

water column) and IP69K (water at high pressure, steam

cleaning), as per DIN EN60529

transducers must be protected against the lasting effects

of moisture and humidity.

Important

Note that when using a steam cleaner, the conditions

stated in EN 60529 under degree of protection IP69K

such as max. pressure, max. temperature, etc., must be

met.

4.1 Protection against corrosion

1)

. Nevertheless, the

The transducer must be protected against chemicals that

could attack the steel of the housing and base plate, or

the cable.

1)

When connector plug of the same protection class is fitted.

16 A4359-1.0 HBM: public PW15iA

Page 19

Structure and mode of operation

Notice

Acids and all substances that release ions also attack

stainless steels and their seam welds.

The resultant corrosion can cause the transducer to fail.

If this is the case, you must provide appropriate means of

protection.

4.2 Deposits

Dust, dirt and other foreign matter must not be allowed to

accumulate sufficiently to divert some of the measuring

force onto the housing, thus distorting the measured

value (force shunt).

Do not use hard or pointed objects when cleaning the

gap between load application and housing, or between

mounting plate and housing.

PW15iA A4359-1.0 HBM: public 17

Page 20

Structure and mode of operation

5 Mechanical installation

5.1 Important precautions during installation

S Handle the transducer with care.

S Welding currents must not be allowed to flow over the

transducer. If there is a risk that this might happen,

you must provide a suitable low-ohm connection to

electrically bypass the transducer. HBM provides the

highly flexible EEK ground cable for this purpose, for

example. It can be screwed on above and below the

transducer.

S Make sure that the transducer cannot be overloaded.

WARNING

There is a danger of the transducer breaking if it is over

loaded. This can cause danger for the operating person

nel of the system in which the transducer is installed.

Implement appropriate safety measures to avoid over

loads or to protect against the resulting dangers.

Notice

The length of the fastening screws must not exceed the

maximum thread reach of 10mm, as otherwise the trans

ducer could be damaged.

18 A4359-1.0 HBM: public PW15iA

Page 21

Structure and mode of operation

Notice

The transducers are precision measuring elements, and

need to be handled carefully. Dropping or knocking the

transducer may cause permanent damage. Make sure

that the transducer cannot be overloaded, including while

it is being mounted.

5.2 Mounting and load application

Before installing several digital load cells into an installa

tion with a bus system, take the following into account:

S The printed production number (type plate) is required

for setting up data communication. If the type plate

can no longer be seen after installation, the numbers

of each transducer should be noted beforehand. This

enables different addresses to be assigned during

initial operation.

S Alternatively, before connection to the bus system,

you can connect each transducer individually with a

PC, in order to set different addresses (see ADR

command in online help).

Mount the transducer on a clean surface with a flatness

better than 0.1 mm. You can integrate overload protec

tion with an M6x0.5 fine-thread screw.

To minimize off-center load errors and torques, load

should be applied in the center of the platform.

PW15iA A4359-1.0 HBM: public 19

Page 22

Structure and mode of operation

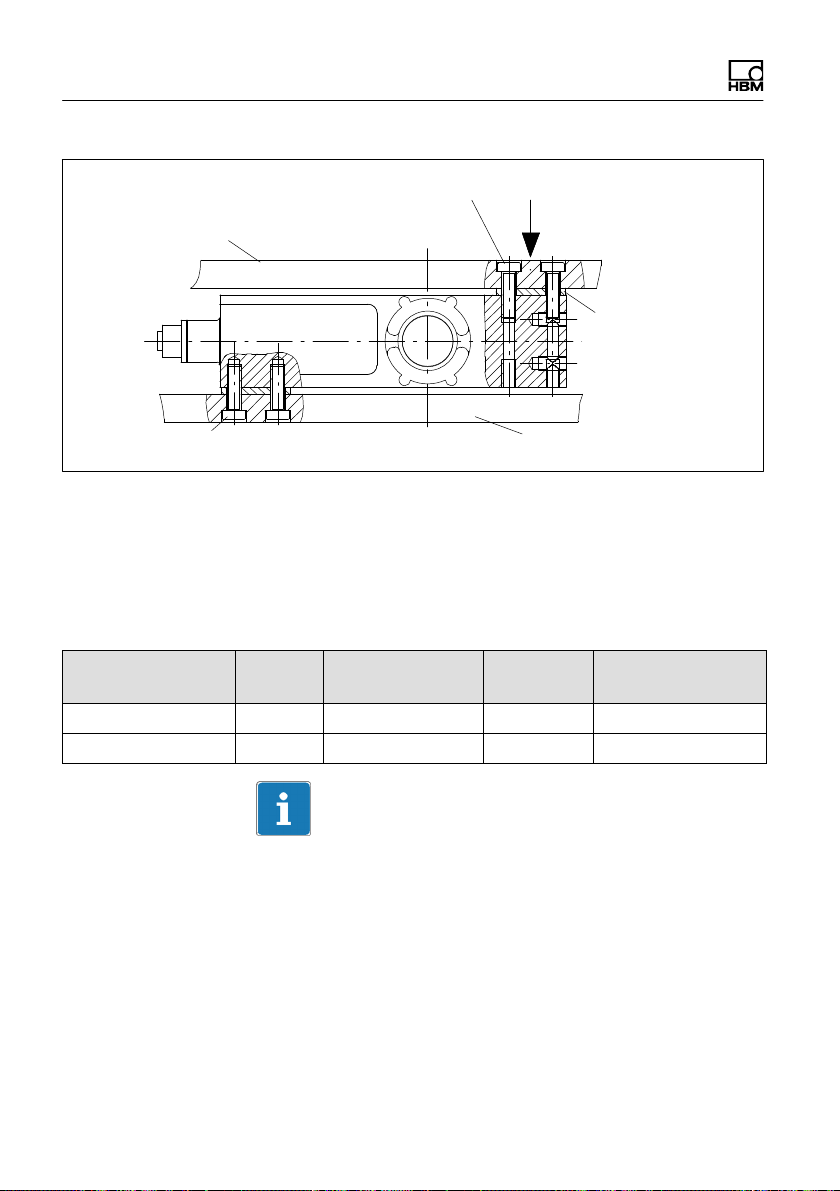

Connection to load application

Platform

(not included in the scope of supply)

Loading direction

Platform center

Load application

(customer construction)

Connection to the mounting plate

(not included in the scope of supply)

Mounting plate

Fig. 3.1 Mounting

Secure the load cell in the mounting holes. A platform for

load application can be mounted on top. The screws and

tightening torques to be used are given in the table

below:

Mounting Thread Min. property

class

On mounting plate M6 10.9 10N @ m 10mm

On load application M6 10.9 10N @ m 10mm

Tightening

torque

Max. thread reach

Important

The unevenness of the surface at the connecting faces

must be no worse than 0.1mm.

20 A4359-1.0 HBM: public PW15iA

Page 23

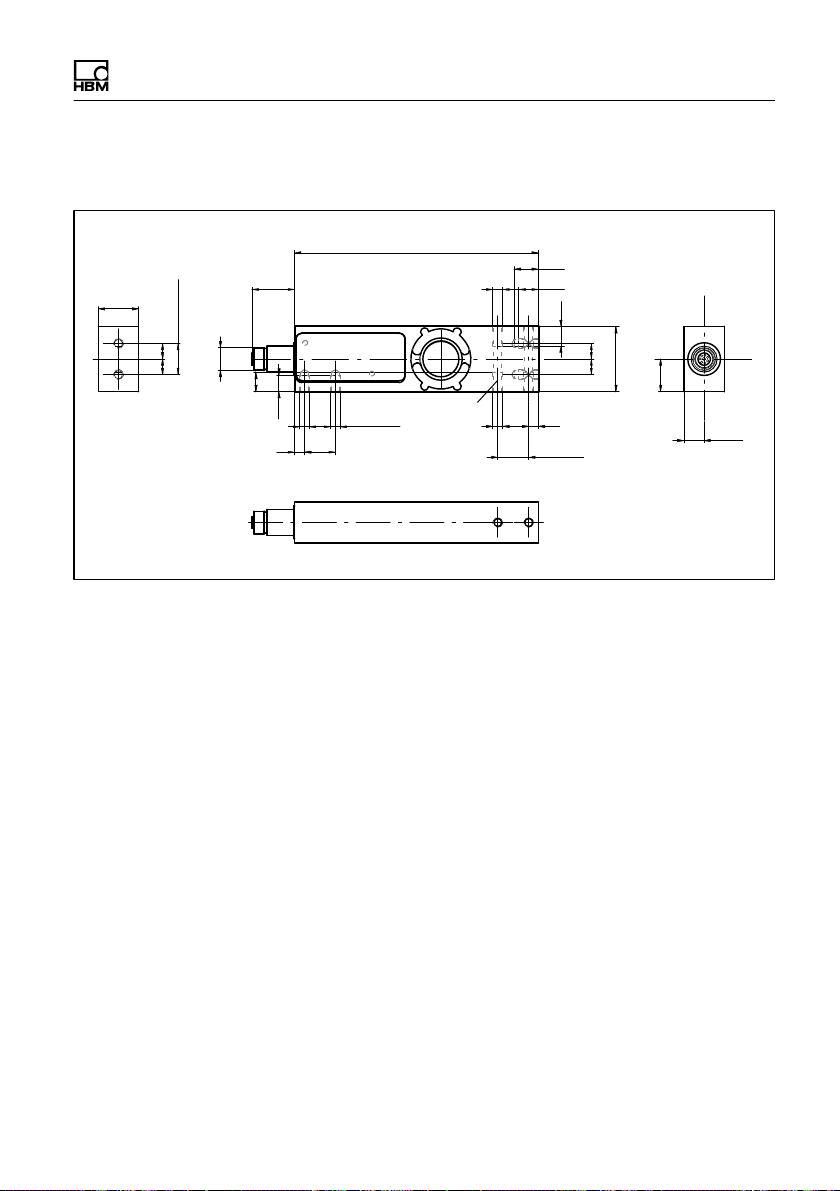

5.3 Dimensions

Structure and mode of operation

25

= =

19.1±0.2

26.2

M14

12

10

19

6

Fig. 3.2 Dimensions

M6 (2x)

150

M6 (6x)

M6x0.5

(1x)

15

12

12

6

19±0.2

= =

40

20

12.5

PW15iA A4359-1.0 HBM: public 21

Page 24

Structure and mode of operation

6 Electrical connection

Notice

Electronic components are sensitive to electrostatic dis

charge (ESD). So you must discharge your own static

electricity before touching the connector plugs.

6.1 Cable laying

Position the connection cable so that any condensation

or moisture that may occur at the cable can drip off

(loop). It must not be allowed to reach the transducer.

Also make sure that it is not possible for humidity or

moisture to get into the cables through open ends, thus

preventing damage to the cable sheath.

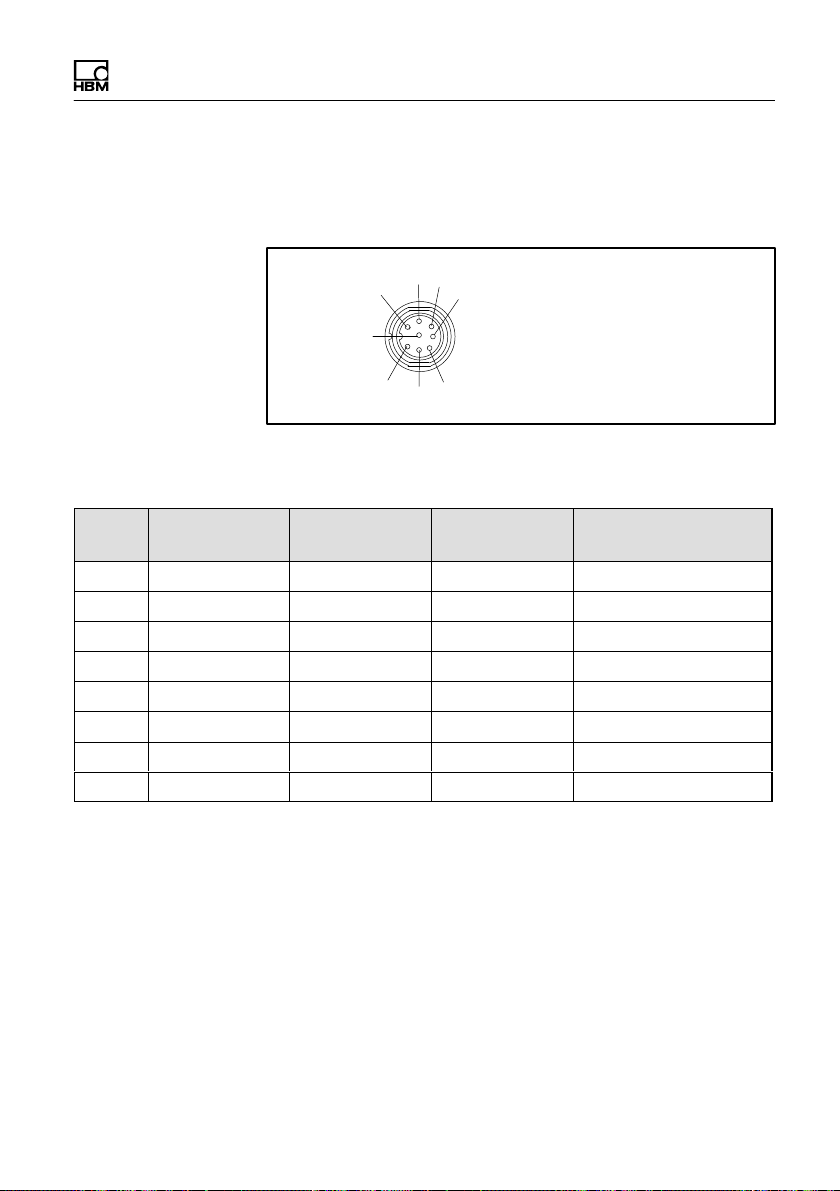

6.2 Pin assignment

Notice

The electronics must be operated with a supply voltage

of between 12 and 30V. Incorrect connections between

the supply and interface cables or the digital inputs/out

puts can cause irreversible damage.

So you must check the correct assignment of the con

nections before switching on for the first time.

The digital load cell comes supplied with an M12 8‐pin

device socket with internal thread. An M14x1 external

22 A4359-1.0 HBM: public PW15iA

Page 25

Structure and mode of operation

thread for connecting HBM cables 1-173-3-1 or 1-173-6-1

is also available. These cables also have protection class

IP69K.

3

2

8

4

5

1

Fig. 4.1 Connector plug with M12 internal thread, the M14

external thread is not shown here

Pin RS-485 CANopen DeviceNet Color code for con

1 GND GND GND White

2 I/O 2 I/O 2 I/O 2 Brown

3 RA CAN High IN CAN High IN Green

4 I/O 1 I/O 1 I/O 1 Yellow

5 RB CAN Low IN CAN Low IN Gray

6 TB CAN Low OUT CAN Low OUT Pink/black

7 TA CAN High OUT CAN High OUT Blue

8 12 … 30V 12 … 30V 12 … 30V Red

6

7

nection cable

Suitable connection cables can be found in the HBM data

sheet "Cables with a plug", B3644.

Please note:

S The housing of the PW15iA is connected to the cable

shield by the connector socket. To obtain an EMCcompliant connection (EMC = electromagnetic com

patibility), the shield of this cable must be connected

to the housing of the connected device or to ground

PW15iA A4359-1.0 HBM: public 23

Page 26

Structure and mode of operation

potential. A direct, low-ohm contact must be made

with the shield, via EMC-compliant PG cable glands,

for example.

S Should it be necessary, a separate cable can be used

to establish potential equalization between the digital

load cell and the (PC/PLC) master (grounding con

cept). You must not use the cable shield for this

potential equalization.

S Use shielded, low-capacitance cables only for all con

nections (interface, power supply and additional

devices) - (HBM measurement cables meet these

requirements).

S Electrical and magnetic fields often induce interfer

ence voltages in the measurement electronics. Do not

route the measurement cables parallel to power lines

and control circuits. If this is not possible, protect the

measurement cable (with steel conduits, for example).

Avoid stray fields from transformers, motors and con

tact switches.

6.3 Supply voltage

Regulated DC voltage of +12 … +30V is required to

operate the electronics and serial communication.

Voltage source requirements

S The supply voltage must be sufficiently smoothed

(RMS value minus residual ripple > 12 V).

S The electronics have a low-loss controller with a

power consumption of 3 W during operation. The cur

rent consumption is therefore dependent on the level

of the supply voltage:

24 A4359-1.0 HBM: public PW15iA

Page 27

Structure and mode of operation

Power demand in A

S When switched on, the electronics briefly consume a

current of approx. 0.15 A. To ensure a safe start-up,

the power supply must be able to provide this current

without a limit being triggered. This is particularly

important when supplying several PADs from one

power supply. In contrast, the sustained loading is

calculated from the formula shown above.

S Connection to a wide-ranging supply network is not

permitted as this often causes interfering voltage

peaks to be induced. Instead, a local supply must be

provided for the electronics (even when grouped).

S The supply voltage must be insulated from the shield

potential. A connection from GND to the housing is

not required, but the max. potential difference must be

no more than 7 V.

S The supply voltage ground wire (GND) is also used as

the reference potential for the interface signals and

the digital inputs/outputs.

S In layouts with several digital load cells, the supply

can run together with the RS-485 bus lines in a 6-pin

cable (with HBM junction boxes, for example). Ensure

that there is sufficient wire cross-section provided, as

some cable sections will conduct the supply current

for all the connected electronics.

=

3 W

Voltage in V

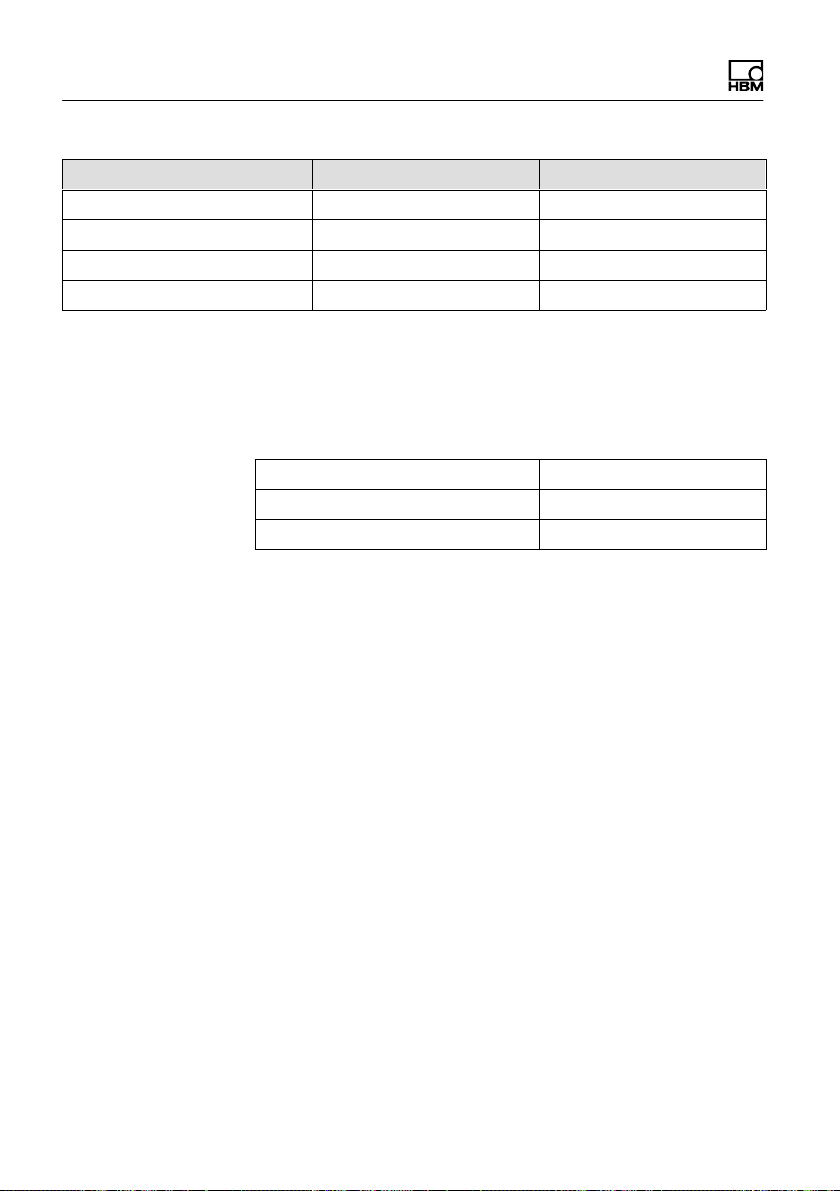

6.4 Digital inputs

You can select the switching threshold for the digital

inputs with the SPL command. Note the different levels

for High and Low, according to the setting.

PW15iA A4359-1.0 HBM: public 25

Page 28

Structure and mode of operation

SPL0 (default setting) SPL1 (PLC level) Explanation

>4V >10V High level

<1V <6V Low level

GND GND Reference potential

70kΩ 9kΩ Input resistance

6.5 Digital outputs

The following applies for the digital outputs:

Supply voltage +12 ... +30 V

Max. current per output <0.5A

Max. current for all outputs <1A

26 A4359-1.0 HBM: public PW15iA

Page 29

7 Interfaces

Interfaces

The ground reference for all the interface signals is

based on the supply voltage ground (GND). GND (0V) of

the excitation voltage must therefore also be connected,

but you must not connect GND to the shield. Use a sepa

rate line to connect the node digital ground to the power

supply GND (0V).

Use a shielded cable as the interface cable. The shield

should always be connected to the housing at both ends.

Important

Before installing several digital load cells into an installa

tion with a bus system, take the following into account:

The printed production number (type plate) is required for

setting up data communication. If the type plate can no

longer be seen after installation, the numbers of each

digital load cell should be noted beforehand. This enables

different addresses to be assigned during initial opera

tion.

Alternatively, before connection to the bus system, you

can connect each digital load cell individually with a PC,

in order to set different addresses (see ADR command in

the online help).

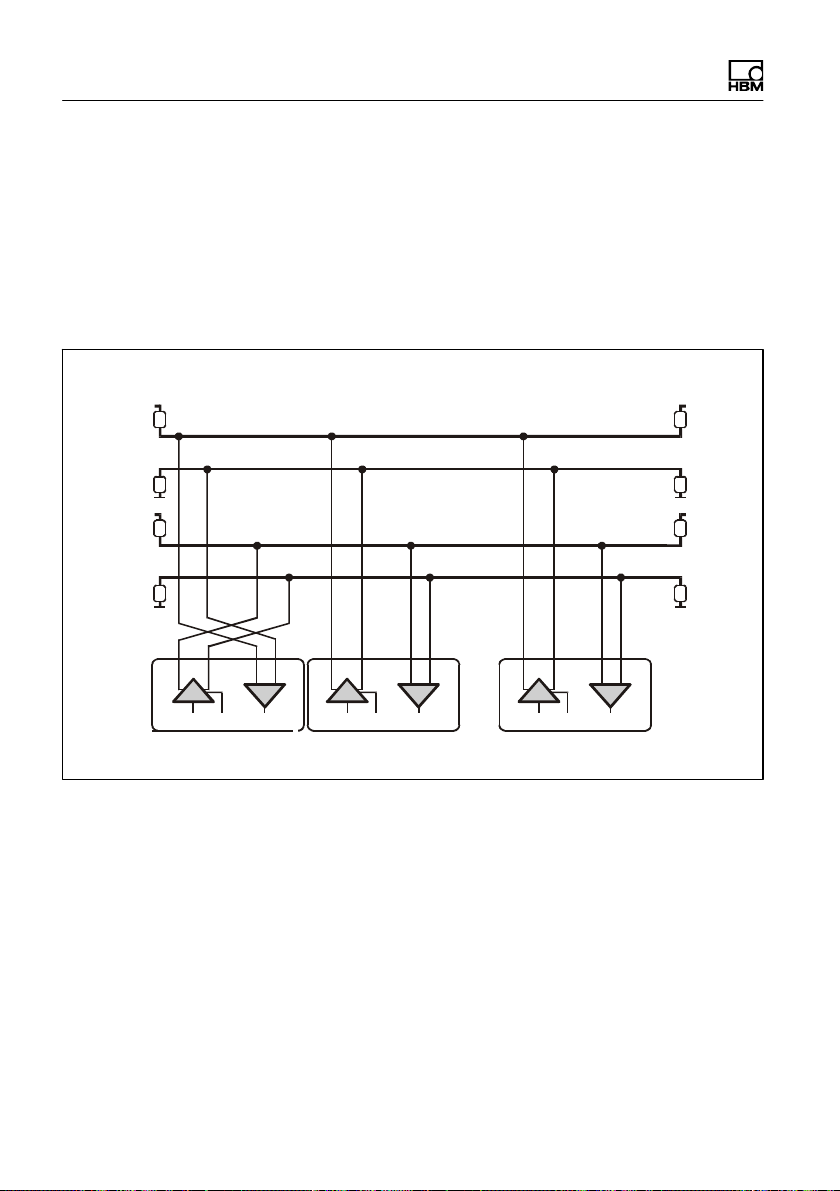

7.1 RS‐485 4‐wire interfaces (UART)

The PW15iA comes supplied with an RS-485 interface.

Bit rates of 1200 to 115,200 baud can be set for the inter

face.

Either a single digital load cell can be connected via the

RS485 interface, or you can set up a bus system to con

PW15iA A4359-1.0 HBM: public 27

Page 30

Interfaces

nect as many as 90 digital load cells to an RS-485 inter

face. All the load cells are connected in parallel on a line,

the total length of the line can be as much as 500m. The

software uses the different addresses to differentiate

between the load cells. If the control computer only has

an RS-232 interface, an interface converter is required

(e.g. from HBM, ordering no.: 1-SC232/422B).

Bus termination

+5 V

500 Ω

500 Ω

+5 V

500 Ω

500 Ω

TB TA

T

TxD

PC = Master Node 1 Node 90

Bus termination

500 Ω

500 Ω

500 Ω

500 Ω

RB RA

R

RxD

RB RA

R

on/off

TB

TA

RB

RA

RxD

TB TA

T

on/off

TxD

RB RA

R

RxD

...

TB TA

T

on/off

TxD

Fig. 5.1 Connecting several nodes to a PC via an RS‐485

4‐wire bus

The correct assignment of the transmit and receive lines

can be seen in Fig. 5.1 (bus line Ra to Ta of the con

verter, etc.). The PW15iA already includes bus termina

tion resistors (line termination), that can be activated with

the software command STR. So no additional bus termi

nation resistors are required for RS-485.

+5 V

+5 V

28 A4359-1.0 HBM: public PW15iA

Page 31

Interfaces

7.2 CANopen interface

The interface design follows the CiA DS301 CANopen

standard. The address on delivery is 63.

The CAN bus is set up as a 2‐wire line (CANH and

CANL) (see ISO11898).

Important

You must connect bus termination resistors (each 120W)

at the start and at the end of the bus. The electronics do

not contain a bus termination resistor for CANopen.

Bus termination Bus termination

IN

Master Node 1 Node X

CAN H

CAN L

OUT

Fig. 5.2 CAN bus wiring

IN

OUT

120 W120 W

IN

...

OUT

The bus wiring structure was chosen to minimize the

length of the stub lines. To make wiring simpler, the con

nections for CANH (High) and CANL (Low) are dupli

cated. This means that at a node, you can connect the

lines of the previous one and the lines to the next node to

PW15iA A4359-1.0 HBM: public 29

Page 32

Interfaces

separate connectors. The connectors are linked internally

(bridged), to keep these stub lines as short as possible.

Baud rate and bus cable lengths

The table below gives the maximum cable lengths for

CANopen, subject to the baud rate:

Baud rate in kBits/s 10 20 50 125 250 500 800 1000

Max. cable length inm5000 2500 1000 500 250 100 50 25

The max. cable length is the total line length, calculated

from the length of all the stub lines per node (bus nodes)

and the line length between the nodes. The length of the

stub lines per node is limited, and depends on the baud

rate being used (see CAN bus documentation). In the

electronics, you can set the internal interconnection stub

lines to zero. If you are only using one connection pair

(only CANIN or only CANOUT), the cable length corre

sponds to the stub line length.

Explanations of CANopen communication can also be

found in the online help.

7.3 DeviceNet interface

The DeviceNet interface is based on ISO 11898 and has

been standardized in EN 50325. The hardware is based

on CANopen, so you also need to read through the infor

mation on the CANopen interface. The constraints are

different, however, compared to CANopen. The interface

design follows the DeviceNet specification Release 2.0

ODVA. The load cell address on delivery is 63.

30 A4359-1.0 HBM: public PW15iA

Page 33

Interfaces

Important

You must connect bus termination resistors (each 120W)

at the start and at the end of the bus. The electronics do

not contain a bus termination resistor for DeviceNet.

You should only activate the resistors at the ends of the

bus system. If you activate more than 2 termination resis

tors, or they are not located at the ends, only limited

communication will be possible (bus errors) or it will no

longer work at all.

All the lines refer their level to GND. GND (0V) of the

excitation voltage must therefore also be connected, but

you must not connect GND to the shield. Use a separate

line to connect the node digital ground to the power sup

ply GND (0V). Connect the cable shields extensively to

the connector plug housings.

PW15iA A4359-1.0 HBM: public 31

Page 34

Operation via software

8 Operation via software

When required, download the PanelX software for

parameterization and visualization from the HBM web

site: http://www.hbm.com/software

& AED weighing electronics" area).

("FIT digital load cells

9 Waste disposal and environmental protection

All electrical and electronic products must be disposed of

as hazardous waste. The correct disposal of old equip

ment prevents ecological damage and health hazards.

The electrical and electronic devices that bear this sym

bol are subject to the European waste electrical and elec

tronic equipment directive 2002/96/EC. The symbol indi

cates that, in accordance with national and local

environmental protection and material recovery and recy

cling regulations, old devices that can no longer be used

must be disposed of separately and not with normal

household garbage.

As waste disposal regulations may differ from country to

country, we ask that you contact your supplier to deter

mine what type of disposal or recycling is legally applica

ble in your country.

Packaging

The original HBM packaging is made from recyclable

material and can be sent for recycling. Store the packag

ing for at least the duration of the warranty.

For ecological reasons, empty packaging should not be

returned to us.

32 A4359-1.0 HBM: public PW15iA

Page 35

Mounting Instructions | Montageanleitung |

Notice de montage

English Deutsch Français

PW15iA

Digitale Wägezelle

Page 36

Deutsch

1 Sicherheitshinweise 4......................................

2 Verwendete Kennzeichnungen 8.............................

2.1 Auf dem Aufnehmer angebrachte Symbole 8....................

2.2 In dieser Anleitung verwendete Kennzeichnungen 8..............

3 Aufbau und Wirkungsweise 10...............................

3.1 Aufbau 11...................................................

3.2 Signalverarbeitung 12.........................................

3.3 Adaptive Störunterdrückung 13.................................

3.4 Ein‐ und Ausgänge 14.........................................

3.4.1 Triggerfunktion 14............................................

3.4.2 Füllen und Dosieren 15........................................

3.4.3 Grenzwertfunktion 15..........................................

3.4.4 Extremwertfunktionen 15......................................

4 Bedingungen am Einbauort 16...............................

4.1 Korrosionsschutz 16..........................................

4.2 Ablagerungen 17.............................................

5 Mechanischer Einbau 18.....................................

5.1 Wichtige Vorkehrungen beim Einbau 18.........................

5.2 Montage und Lasteinleitung 19.................................

5.3 Abmessungen 21.............................................

6 Elektrischer Anschluss 22....................................

6.1 Kabelverlegung 22............................................

6.2 Anschlussbelegung 22.........................................

6.3 Versorgungsspannung 24......................................

6.4 Digitale Eingänge 26..........................................

6.5 Digitale Ausgänge 26..........................................

2 A4359-1.0 HBM: public PW15iA

Page 37

7 Schnittstellen 27.............................................

7.1 RS‐485‐4‐Leiter‐Schnittstellen (UART) 27........................

7.2 CANopen‐Schnittstelle 29......................................

7.3 DeviceNet‐Schnittstelle 30.....................................

8 Bedienung über Software 32.................................

9 Entsorgung und Umweltschutz 32............................

PW15iA A4359-1.0 HBM: public 3

Page 38

Sicherheitshinweise

1 Sicherheitshinweise

Bestimmungsgemäße Verwendung

Die Aufnehmer der Typenreihe PW15iA dürfen aus

schließlich für wägetechnische Anwendungen im

Rahmen der durch die technischen Daten spezifizierten

Einsatzgrenzen verwendet werden. Jeder andere Ge

brauch ist nicht bestimmungsgemäß.

Jede Person, die mit Aufstellung, Inbetriebnahme oder

Betrieb des Aufnehmers beauftragt ist, muss die

Bedienungsanleitung und insbesondere die sicherheits

technischen Hinweise gelesen und verstanden haben.

Zur Gewährleistung eines sicheren Betriebes darf der

Aufnehmer nur von qualifiziertem Personal und nach den

Angaben in der Bedienungsanleitung betrieben werden.

Bei der Verwendung sind zusätzlich die für den jeweiligen

Anwendungsfall erforderlichen Rechts‐ und Sicherheits

vorschriften zu beachten. Sinngemäß gilt dies auch bei

der Verwendung von Zubehör.

Der Aufnehmer ist nicht zum Einsatz als Sicherheits

komponente bestimmt. Bitte beachten Sie hierzu den

Abschnitt „Zusätzliche Sicherheitsvorkehrungen“. Der

einwandfreie und sichere Betrieb setzt sachgemäßen

Transport, fachgerechte Lagerung, Aufstellung und

Montage sowie sorgfältige Bedienung voraus.

Betriebsbedingungen

S Beachten Sie insbesondere die in den technischen

Daten angegebenen maximal zulässigen Werte für:

- Grenzlast

- Grenzlast bei max. Exzentrizität

- Grenzquerbelastung

4 A4359-1.0 HBM: public PW15iA

Page 39

Sicherheitshinweise

- Bruchlasten

- Temperaturgrenzen

- Grenzen der elektrischen Belastbarkeit

S Beachten Sie, dass beim Einbau mehrerer Aufnehmer

in eine Waage die Lastverteilung auf die einzelnen

Aufnehmer nicht immer gleichmäßig ist.

S Die Aufnehmer können als Maschinenelemente einge

setzt werden. Beachten Sie bei dieser Verwendung,

dass die Aufnehmer zu Gunsten einer hohen Mess

empfindlichkeit nicht mit den im Maschinenbau übli

chen Sicherheitsfaktoren konstruiert wurden.

S Der Aufnehmer darf ohne unsere ausdrückliche Zu

stimmung weder konstruktiv noch sicherheitstech

nisch verändert werden.

S Der Aufnehmer ist wartungsfrei.

S Nicht mehr gebrauchsfähige Aufnehmer sind gemäß

den nationalen und örtlichen Vorschriften für Umwelt

schutz und Rohstoffrückgewinnung getrennt von regu

lärem Hausmüll zu entsorgen, siehe Abschnitt 9, Seite

32.

Qualifiziertes Personal

Qualifizierte Personen sind Personen, die mit Aufstel

lung, Montage, Inbetriebsetzung und Betrieb des Produk

tes vertraut sind und über die ihrer Tätigkeit entspre

chende Qualifikationen verfügen.

Dazu zählen Personen, die mindestens eine der drei fol

genden Voraussetzungen erfüllen:

S Ihnen sind die Sicherheitskonzepte der Mess‐ und

Automatisierungstechnik bekannt und sie sind als

Projektpersonal damit vertraut.

PW15iA A4359-1.0 HBM: public 5

Page 40

Sicherheitshinweise

S Sie sind Bedienpersonal der Mess‐ oder Automatisie

rungsanlagen und sind im Umgang mit den Anlagen

unterwiesen. Sie sind mit der Bedienung der in dieser

Dokumentation beschriebenen Geräte und Technolo

gien vertraut.

S Sie sind Inbetriebnehmer oder für den Service einge

setzt und haben eine Ausbildung absolviert, die sie

zur Reparatur der Automatisierungsanlagen befähigt.

Außerdem haben sie die Berechtigung, Stromkreise

und Geräte gemäß den Normen der Sicherheitstech

nik in Betrieb zu nehmen, zu erden und zu kennzeich

nen.

Sicherheitsbewußtes Arbeiten

S Der Aufnehmer darf nicht unmittelbar an das Strom

versorgungsnetz angeschlossen werden. Die Versor

gungsspannung darf 12 bis 30VDC betragen.

S Fehlermeldungen dürfen nur quittiert werden, wenn

die Ursache des Fehlers beseitigt ist und keine Ge

fahr mehr existiert.

S Wartungs‐ und Reparaturarbeiten am geöffneten

Gerät unter Spannung dürfen nur von einer ausge

bildeten Person durchgeführt werden, die sich der

vorliegenden Gefahr bewusst ist.

S Geräte und Einrichtungen der Automatisierungstech

nik müssen so verbaut werden, dass sie gegen unbe

absichtigte Betätigung ausreichend geschützt bzw.

verriegelt sind (z.B. Zugangskontrolle, Passwort

schutz o.Ä.).

S Bei Geräten, die in Netzwerken arbeiten, müssen

hard‐ und softwareseitig Sicherheitsvorkehrungen ge

troffen werden, damit ein Leitungsbruch oder andere

Unterbrechungen der Signalübertragung nicht zu un

6 A4359-1.0 HBM: public PW15iA

Page 41

Sicherheitshinweise

definierten Zuständen oder Datenverlust in der Auto

matisierungseinrichtung führen.

S Stellen Sie nach Einstellungen und Tätigkeiten, die

mit Passworten geschützt sind, sicher, dass evtl. an

geschlossene Steuerungen in einem sicheren Zu

stand verbleiben, bis das Schaltverhalten des Gerätes

geprüft ist.

Zusätzliche Sicherheitsvorkehrungen

Bei Anlagen, die aufgrund einer Fehlfunktion größere

Schäden, Datenverlust oder sogar Personenschäden

verursachen können, müssen zusätzliche Sicherheitsvor

kehrungen getroffen werden, die den Anforderungen der

entsprechenden nationalen und örtlichen Unfallverhü

tungsvorschriften genügen.

Der Leistungs‐ und Lieferumfang des Aufnehmers deckt

nur einen Teilbereich der Messtechnik ab. Vor der Inbe

triebnahme des Aufnehmers in einer Anlage ist daher

eine Projektierung und Risikoanalyse vorzunehmen, die

alle Sicherheitsaspekte der Mess‐ und Automatisierungs

technik berücksichtigt, so dass Restgefahren minimiert

werden. Insbesonders betrifft dies den Personen‐ und

Anlagenschutz. Die Aufnehmer können keine sicherheits

relevanten Abschaltungen vornehmen. Im Fehlerfall

müssen entsprechende Vorkehrungen einen sicheren

Betriebszustand herstellen.

Allgemeine Gefahren bei Nichtbeachten der

Sicherheitshinweise

Der Aufnehmer entspricht dem Stand der Technik und ist

betriebssicher. Von dem Aufnehmer können Restgefah

ren ausgehen, wenn er unsachgemäß eingesetzt oder

bedient wird.

PW15iA A4359-1.0 HBM: public 7

Page 42

Verwendete Kennzeichnungen

2 Verwendete Kennzeichnungen

2.1 Auf dem Aufnehmer angebrachte Symbole

CE-Kennzeichnung

Mit der CE‐Kennzeichnung garantiert der Hersteller, dass

sein Produkt den Anforderungen der relevanten

EG‐Richtlinien entspricht (die Konformitätserklärung

finden Sie auf der Website von HBM (www.hbm.com)

unter HBMdoc).

Gesetzlich vorgeschriebene Kennzeichnung zur

Entsorgung

Nicht mehr gebrauchsfähige Altgeräte sind gemäß den

nationalen und örtlichen Vorschriften für Umweltschutz

und Rohstoffrückgewinnung getrennt von regulärem

Hausmüll zu entsorgen. Siehe auch Abschnitt9, Seite

32.

2.2 In dieser Anleitung verwendete Kennzeichnungen

Wichtige Hinweise für Ihre Sicherheit sind besonders ge

kennzeichnet. Beachten Sie diese Hinweise unbedingt,

um Unfälle und Sachschäden zu vermeiden.

8 A4359-1.0 HBM: public PW15iA

Page 43

Symbol Bedeutung

WARNUNG

Hinweis

Wichtig

Diese Kennzeichnung weist auf eine mögliche

gefährliche Situation hin, die – wenn die Sicherheits

bestimmungen nicht beachtet werden – Tod oder

schwere Körperverletzung zur Folge haben kann.

Diese Kennzeichnung weist auf eine Situation hin,

die – wenn die Sicherheitsbestimmungen nicht

beachtet werden – Sachschäden zur Folge haben

kann.

Diese Kennzeichnung weist auf wichtige Informa

tionen zum Produkt oder zur Handhabung des Pro

duktes hin.

Diese Kennzeichnung weist auf Informationen zum

Produkt oder zur Handhabung des Produktes hin.

Information

Hervorhebung

Siehe …

Kursive Schrift kennzeichnet Hervorhebungen im

Text und kennzeichnet Verweise auf Kapitel, Bilder

oder externe Dokumente und Dateien.

Verwendete Kennzeichnungen

PW15iA A4359-1.0 HBM: public 9

Page 44

Aufbau und Wirkungsweise

3 Aufbau und Wirkungsweise

Die digitalen Wägezellen PW15iA gehören zur Familie

der von HBM entwickelten Elektroniken für statische und

dynamische Wägeprozesse. Das Messelement ist ein

Verformungskörper, auf dem Dehnungsmessstreifen

(DMS) angebracht sind. Die DMS sind so angeordnet,

dass zwei von ihnen gedehnt und die zwei anderen

gestaucht werden, wenn auf die Wägezelle eine Last ein

wirkt. Die PW15iA bereitet die Signale digital auf und

liefert ein komplett gefiltertes, skaliertes und digi

talisiertes Ausgangssignal zum direkten Anschluss an

Bussysteme oder PCs über die RS‐485‐Schnittstelle,

CANopen oder DeviceNet. Messelement und Elektronik

sind in einem gemeinsamen Gehäuse untergebracht. Die

digitalen Wägezellen lassen sich über verschiedene

Parameter einfach und schnell an das jeweilige System

anpassen und arbeiten intern mit einer Messrate von bis

zu 1200 Messungen pro Sekunde.

Die eingebauten digitalen Ein-/Ausgänge ermöglichen die

ereignisgesteuerte Gewichtswertbildung, z.B. für Kon

trollwaagen-Anwendungen oder Dosiersteuerungen. Die

per Softwarebefehl konfigurierbaren digitalen Ausgänge

können Sie z.B. zum Steuern von Grobstrom und

Feinstrom bei Dosierventilen verwenden.

Zur einfachen Einstellung aller Parameter, zur Darstel

lung dynamischer Messsignale und zur umfassenden

Frequenzanalyse des dynamischen Systems steht Ihnen

die PC‐Software PanelX zur Verfügung.

Dieses Dokument beschreibt die Montage und die

Funktionen der digitalen Wägezelle. Die Befehle für die

Schnittstellen finden Sie in der Online‐Dokumentation

zum Programm PanelX.

10 A4359-1.0 HBM: public PW15iA

Page 45

3.1 Aufbau

Aufbau und Wirkungsweise

PW15iA

A

D

EEPROM

Linearisierung

Seriennummer

Digitalfilter

Messrate

Empfindlichkeit

Nullwert

Spannungs-

regler

Schnittstelle

μP

I/Os

Versorgungsspannung UB/GND

Schnittstelle

RS-485/CANopen

IO

Trigger,

Stopp Dosieren

Abb. 1.1 Blockschaltbild

Das analoge Signal des Messelements wird verstärkt,

gefiltert und im A/D-Wandler digitalisiert. Dieses Mess

signal wird im Mikroprozessor verarbeitet (Filterung, Aus

wertung) und über die Schnittstelle ausgegeben. Die Einoder Ausgänge können dabei je nach Konfiguration

sowohl die Verarbeitung steuern als auch abhängig vom

Signal die Ansteuerung von z.B. Ventilen vornehmen.

Alle Parameter können netzausfallsicher gespeichert

werden.

Die digitale Wägezelle besitzt umschaltbare Ein- oder

Ausgänge: Sie können maximal 2 Eingänge oder 2 Aus

gänge oder jeweils einen Eingang und einen Ausgang

verwenden.

Detaillierte Angaben zur Einstellung der verschiedenen

Funktionen finden Sie in der Online‐Hilfe des Programms

PanelX.

PW15iA A4359-1.0 HBM: public 11

Page 46

Aufbau und Wirkungsweise

3.2 Signalverarbeitung

FMD

ASF ICR

A

D

RUN

BRK

Mess-

Filter Tarieren

Dosiersteuerung

rate

Werkskali-

brierung

Abb. 1.2 Signalverarbeitung

Nach der Digitalisierung erfolgt die Filterung durch per

Software einstellbare Digitalfilter. Mit dem Befehl ICR

ändern Sie die Ausgaberate (Messwerte pro Sekunde).

SZA

SFA

NOV, RSN

LDW, LWT LIC

Anwenderskalierung

Grobstrom

Feinstrom

Fertig

Alarm

Linearisierung

TAV, TAS

Min/

Max

Trigger

Grenz-

werte

PVA

IMD

LIV

BruttoMesswert

NettoMesswert

Extremwerte

Trigger/

Stopp

Grenzwerte

In der Werkskalibrierung der Elektronik (Auslieferungszu

stand) entspricht 0mV/V Null und die Nennlast entspricht

wahlweise 1.000.000digit (NOV≠0), oder 5.120.000digit

(NOV=0). Sie haben die Möglichkeit, mit dem Parameter

paar LDW und LWT die Kennlinie ihren Anforderungen

(Waagenkennlinie) entsprechend anzupassen und die

Messwerte über den Befehl NOV auf den gewünschten

Skalierungswert (z.B. 3000d) zu normieren. Ausführli

che Angaben finden sie in der Befehlsdokumentation und

in der Onlinehilfe des Programms PanelX.

Sie haben außerdem die Möglichkeit

S von Brutto‐ auf Netto-Signal umzuschalten,

12 A4359-1.0 HBM: public PW15iA

Page 47

Aufbau und Wirkungsweise

S eine automatische Einschalt-Null-Funktion zu

aktivieren,

S eine automatische Zerotracking-Funktion zu

aktivieren,

S eine Linearisierung der Waagenkennlinie mit einem

Polynom 3. Ordnung vorzunehmen,

S verschiedene Digitalfilter zu aktivieren. Es stehen

Filter mit Grenzfrequenzen unter 1Hz und schnell

einschwingende Filter für dynamische Messungen

sowie Notch- und Mittelwertfilter zur Verfügung.

Lesen Sie den aktuellen Messwert über MSV? aus. Das

Format des Messwertes (ASCII oder binär) stellen Sie

über den Befehl COF ein. Sie können auch eine automa

tische Messwertausgabe über den Befehl COF

aktivieren. Die Messwerte werden je nach COF-Befehl in

folgendem Format ausgegeben:

Ausgabeformat Eingangssignal Ausgabe bei NOV=0 Ausgabe bei

NOV>0

Binär 2 Zeichen (INT) 0 … Nennlast 0 … 20.000digit 1 … NOV

Binär 4 Zeichen (LONG) 0 … Nennlast 0 … 5.120.000digit 1 … NOV

ASCII 0 … Nennlast 0 … 1.000.000digit 1 … NOV

3.3 Adaptive Störunterdrückung

Unabhängig vom Betriebsmodus können sie mit dem

Befehl ADF eine automatische Störunterdrückung mit

adaptiven Filtern aktivieren. Dabei werden während der

Messung automatisch Störfrequenzen gesucht und über

Kammfilter und gleitende Mittelwertbildung unterdrückt.

Die maximale Filtereinschwingzeit kann dabei mit dem

Befehl TMA begrenzt werden.

PW15iA A4359-1.0 HBM: public 13

Page 48

Aufbau und Wirkungsweise

3.4 Ein‐ und Ausgänge

Sie können die beiden I/Os sowohl als Eingang als auch

als Ausgang verwenden. Zusätzlich können Sie für die

Eingänge verschiedene Schaltpegel (TTL oder SPS) ein

stellen. Im Auslieferungszustand sind beide I/Os als Ein

gänge mit TTL-Pegel eingestellt. Die Funktion der I/Os

als Eingänge legen Sie mit den Befehlen IM1 und IM2

fest, die Funktion als Ausgänge mit OM1 und OM2.

Hinweis

Die Elektronik muss mit einer Versorgungsspannung zwi

schen 12 und 30V betrieben werden. Unzulässige Ver

bindungen zwischen Versorgungs‐ und Schnittstellen

leitungen oder den digitalen Ein-/Ausgängen können

irreversible Schäden zur Folge haben.

Kontrollieren Sie daher vor dem ersten Einschalten die

korrekte Zuordnung der Anschlüsse.

3.4.1 Triggerfunktion

Die Elektronik verfügt im Betriebsmodus Trigger (Befehl

IMD1) über vier verschiedene Triggerfunktionen:

S Pre-Triggerung über Pegel

S Pre-Triggerung über externes (digitales) Signal

S Post-Triggerung über Pegel

S Post-Triggerung über externes (digitales) Signal

Als Eingangswerte können Sie Brutto- oder Nettowerte

verwenden. Die Filtereinschwingzeit kann von der

Elektronik selbst optimiert werden (Befehl AST).

14 A4359-1.0 HBM: public PW15iA

Page 49

Aufbau und Wirkungsweise

3.4.2 Füllen und Dosieren

Die Elektronik enthält eine komplette Dosiersteuerung

(Befehl IMD2). Dazu lassen sich bis zu 32 Parameter

sätze für unterschiedliche Anwendungen im EEPROM

speichern. Sie können jedoch selbst während des

Dosierens noch Dosierparameter ändern. Die digitalen

Ausgänge können z.B. zur Steuerung von Grob- und

Feinstrom verwendet werden. Die Software PanelX ent

hält eine ausführliche Anleitung zur Einstellung der ver

schiedenen Parameter.

3.4.3 Grenzwertfunktion

Die Elektronik ermöglicht in den Betriebsmodi Standard

und Trigger (Befehl IMD) die Überwachung von bis zu

vier Grenzwerten (Befehl LIV). Als Eingangssignale

stehen Ihnen Brutto‐ oder Nettowert, das Triggerergebnis

oder die Extremwerte (Min/Max) zur Verfügung. Lesen

Sie den Status über den Messwertstatus aus, entweder

gleichzeitig mit Messwerten (Befehl MSV?) oder separat

(Befehl RIO?).

3.4.4 Extremwertfunktionen

Die Elektronik enthält eine Spitzenwertfunktion (Minimum

und Maximum, Befehl PVS), die wahlweise Brutto‐ oder

Nettowerte überwacht. Lesen Sie die Werte über den

Befehl PVA aus und setzen Sie die Spitzenwerte über

den Befehl CPV zurück.

PW15iA A4359-1.0 HBM: public 15

Page 50

Aufbau und Wirkungsweise

4 Bedingungen am Einbauort

Die Aufnehmer der Serie PW15iA sind hermetisch

gekapselt und deshalb sehr unempfindlich gegen

Feuchteeinwirkung. Die Aufnehmer erreichen die Schutz

klassen IP68 (Prüfbedingungen: 100 Stunden unter 1m

Wassersäule) und IP69K (Wasser bei Hochdruck,

Dampfstrahlreinigung) nach DIN EN60529

sollten die Aufnehmer gegen dauerhafte Feuchteeinwir

kung geschützt werden.

Wichtig

Beachten Sie bei einer Reinigung mit Dampfstrahler die

in EN 60529 unter der Schutzart IP69K genannten

Bedingungen wie max. Druck, max. Temperatur usw.

4.1 Korrosionsschutz

1)

. Trotzdem

Der Aufnehmer muss gegen Chemikalien geschützt

werden, die den Stahl des Gehäuses bzw. der Boden

platte oder das Kabel angreifen.

Hinweis

Säuren und alle Stoffe, die Ionen freisetzen, greifen auch

nichtrostende Stähle und deren Schweißnähte an.

Die dadurch auftretende Korrosion kann zum Ausfall des

Aufnehmers führen. Sehen Sie in diesem Fall entspre

chende Schutzmaßnahmen vor.

1)

Bei montiertem Anschlussstecker gleicher Schutzklasse.

16 A4359-1.0 HBM: public PW15iA

Page 51

Aufbau und Wirkungsweise

4.2 Ablagerungen

Staub, Schmutz und andere Fremdkörper dürfen sich

nicht so ansammeln, dass sie einen Teil der Messkraft

auf das Gehäuse umleiten und dadurch den Messwert

verfälschen (Kraftnebenschluss).

Verwenden Sie beim Reinigen des Spalts zwischen Last

einleitung und Gehäuse bzw. Montageplatte und

Gehäuse keine harten oder spitzen Gegenstände.

PW15iA A4359-1.0 HBM: public 17

Page 52

Aufbau und Wirkungsweise

5 Mechanischer Einbau

5.1 Wichtige Vorkehrungen beim Einbau

S Behandeln Sie den Aufnehmer schonend.

S Es dürfen keine Schweißströme über den Aufnehmer

fließen. Sollte diese Gefahr bestehen, so müssen Sie

den Aufnehmer mit einer geeigneten niederohmigen

Verbindung elektrisch überbrücken. Hierzu bietet z.B.

HBM das hochflexible Erdungskabel EEK an, das

oberhalb und unterhalb des Aufnehmers ange

schraubt wird.

S Stellen Sie sicher, dass der Aufnehmer nicht

überlastet werden kann.

WARNUNG

Bei einer Überlastung des Aufnehmers besteht die

Gefahr, dass der Aufnehmer bricht. Dadurch können

Gefahren für das Bedienpersonal der Anlage auftreten, in

die der Aufnehmer eingebaut ist.

Treffen Sie geeignete Sicherungsmaßnahmen zur

Vermeidung einer Überlastung oder zur Sicherung gegen

sich daraus ergebende Gefahren.

Hinweis

Die Länge der Befestigungsschrauben darf die maximale

Einschraublänge von 10mm nicht überschreiten, da

sonst der Aufnehmer beschädigt werden kann.

18 A4359-1.0 HBM: public PW15iA

Page 53

Aufbau und Wirkungsweise

Hinweis

Die Aufnehmer sind Präzisions‐Messelemente und

verlangen daher eine umsichtige Handhabung. Stöße

oder Stürze können zu permanenten Schäden am Auf

nehmer führen. Sorgen Sie dafür, dass auch bei der

Montage keine Überlastung des Aufnehmers auftreten

kann.

5.2 Montage und Lasteinleitung

Beachten Sie vor dem Einbau mehrerer digitaler Wäge

zellen in eine Anlage mit Bussystem:

S Die aufgedruckte Fertigungsnummer (Typenschild)

wird für die Einrichtung der Datenkommunikation

benötigt. Falls das Typenschild nach dem Einbau

nicht mehr zugänglich ist, sollten Sie die Nummern

aller Aufnehmer notieren. Damit ist eine Zuteilung ver

schiedener Adressen bei der ersten Inbetriebnahme

möglich.

S Alternativ können Sie vor dem Anschluss an das Bus

system jeden Aufnehmer einzeln mit einem PC ver

binden, um unterschiedliche Adressen einzustellen

(siehe ADR-Befehl in der Online-Hilfe).

Montieren Sie den Aufnehmer auf einer sauberen Fläche

mit einer Ebenheit von besser als 0,1 mm. Eine Überlast

sicherung können Sie mit einer Feingewindeschraube

M6x0.5 integrieren.

Um Eckenlastfehler und Momente zu minimieren, sollten

Sie die Lasteinleitung in der Mitte der Plattform vorsehen.

PW15iA A4359-1.0 HBM: public 19

Page 54

Aufbau und Wirkungsweise

Befestigung an Lasteinleitung

Plattform

(nicht im Lieferumfang enthalten)

Belastungsrichtung

Mitte Plattform

Lasteinleitung

(Konstruktion

durch Kunden)

Befestigung an Montageplatte

(nicht im Lieferumfang enthalten)

Montageplatte

Abb. 3.1 Montage

Befestigen Sie die Wägezelle an den Montagebohrun

gen. Eine Plattform zur Lasteinleitung kann auf der Ober

seite montiert werden. Die folgende Tabelle enthält die

zu verwendenden Schrauben und Anzugsmomente.

Befestigung Gewinde Min. Festigkeits

klasse

An Montageplatte M6 10.9 10N @ m 10mm

An Lasteinleitung M6 10.9 10N @ m 10mm

Anzugs

moment

Max. Einschraub

tiefe

Wichtig

Die Unebenheit der Oberfläche an den Verbindungsflä

chen darf nicht schlechter als 0,1mm sein.

20 A4359-1.0 HBM: public PW15iA

Page 55

5.3 Abmessungen

Aufbau und Wirkungsweise

25

= =

19,1±0,2

26,2

M14

12

10

6

M6 (2x)

19

Abb. 3.2 Abmessungen

150

M6 (6x)

M6x0.5

(1x)

15

12

12

6

19±0,2

= =

40

20

12,5

PW15iA A4359-1.0 HBM: public 21

Page 56

Aufbau und Wirkungsweise

6 Elektrischer Anschluss

Hinweis

Elektronische Bauteile sind empfindlich gegen elektrosta

tische Aufladung (ESD, Electro‐Static Discharge). Leiten

Sie daher statische Aufladungen von sich ab, bevor Sie

Anschlussstecker berühren.

6.1 Kabelverlegung

Legen Sie Anschlusskabel so, dass eventuell am Kabel

entstandenes Kondenswasser oder Feuchtigkeit

abtropfen kann (Schlaufe). Es darf nicht zum Aufnehmer

hingeleitet werden. Sorgen Sie auch dafür, dass keine

Feuchtigkeit am offenen Kabelende eindringen kann und

eine Beschädigung des Kabelmantels verhindert wird.

6.2 Anschlussbelegung

Hinweis

Die Elektronik muss mit einer Versorgungsspannung zwi

schen 12 und 30V betrieben werden. Unzulässige Ver

bindungen zwischen Versorgungs‐ und Schnittstellen

leitungen oder den digitalen Ein-/Ausgängen können

irreversible Schäden zur Folge haben.

Kontrollieren Sie daher vor dem ersten Einschalten die

korrekte Zuordnung der Anschlüsse.

22 A4359-1.0 HBM: public PW15iA

Page 57

Aufbau und Wirkungsweise

Die digitale Wägezelle wird mit einer 8‐poligen Geräte

buchse M12 mit Innengewinde ausgeliefert. Zusätzlich

steht ein Außengewinde M14x1 zum Anschluss der

Kabel 1-173-3-1 oder 1-173-6-1 von HBM zur Verfügung.

Diese Kabel besitzen ebenfalls die Schutzklasse IP69K.

3

2

8

4

5

1

Abb. 4.1 Anschlussstecker mit M12‐Innengewinde, das

M14-Außengewinde ist hier nicht eingezeichnet

Pin RS-485 CANopen DeviceNet Farbcode für

1 GND GND GND Weiß

2 I/O 2 I/O 2 I/O 2 Braun

3 RA CAN High IN CAN High IN Grün

4 I/O 1 I/O 1 I/O 1 Gelb

5 RB CAN Low IN CAN Low IN Grau

6 TB CAN Low OUT CAN Low OUT Rosa/schwarz

7 TA CAN High OUT CAN High OUT Blau

8 12 … 30V 12 … 30V 12 … 30V Rot

6

7

Anschlusskabel

Geeignete Anschlusskabel finden Sie im Datenblatt

„Kabel mit Stecker“, B3643, von HBM.

Bitte beachten Sie

S Das Gehäuse der PW15iA ist über die Anschluss

buchse mit dem Kabelschirm verbunden. Für einen

EMV‐gerechten Anschluss (EMV = Elektro‐Magne

PW15iA A4359-1.0 HBM: public 23

Page 58

Aufbau und Wirkungsweise

tische Verträglichkeit) muss der Schirm dieses Kabels

mit dem Gehäuse des angeschlossenen Gerätes bzw.

dem Erdpotential verbunden werden. Der Schirm ist

direkt und niederohmig zu kontaktieren, z.B. durch

EMV‐gerechte PG‐Durchführungen.

S Falls die Notwendigkeit besteht, stellen Sie über eine

gesonderte Leitung den Potenzialausgleich zwischen

der digitalen Wägezelle und dem Master (PC/SPS)

her (Erdungskonzept). Für diesen Potenzialausgleich

dürfen Sie nicht den Leitungsschirm verwenden.

S Verwenden Sie für alle Verbindungen (Schnittstelle,

Versorgung und Zusatzeinrichtungen) nur abge

schirmte, kapazitätsarme Kabel (Messkabel von HBM

erfüllen diese Bedingungen).

S Elektrische und magnetische Felder verursachen oft

eine Einkopplung von Störspannungen in die Mess

elektronik. Legen Sie die Messkabel nicht parallel zu

Starkstrom‐ und Steuerleitungen. Falls das nicht mög

lich ist, schützen Sie das Messkabel (z.B. durch

Stahlpanzerrohre). Meiden Sie Streufelder von Trafos,

Motoren und Schützen.

6.3 Versorgungsspannung

Für den Betrieb der Elektronik und der seriellen Kom

munikation wird eine geregelte Gleichspannung von +12

... +30 V benötigt.

Anforderungen an die Spannungsquelle

S Die Versorgungsspannung muss ausreichend geglät

tet sein (Effektivwert abzgl. Restwelligkeit > 12 V).

S Die Elektronik verfügt über einen verlustarmen

Regler, der im Betrieb eine Leistung von 3 W auf

24 A4359-1.0 HBM: public PW15iA

Page 59

Aufbau und Wirkungsweise

nimmt. Die Stromaufnahme ist daher von der Höhe

der Versorgungsspannung abhängig:

Strombedarf in A

S Die Elektronik nimmt im Einschaltmoment kurzzeitig

einen Strom von ca. 0,15 A auf. Um einen sicheren

Anlauf zu gewährleisten, muss die Versorgung diesen

Strom bereitstellen können, ohne dass eine

Begrenzung anspricht. Dies ist insbesondere bei der

Versorgung mehrerer Elektroniken durch ein einziges

Netzteil zu beachten. Die Dauerbelastung ergibt sich

dagegen aus der oben angegebenen Formel.

S Der Anschluss an ein weitläufiges Versorgungsnetz

ist nicht zulässig, weil dadurch oft störende

Spannungsspitzen eingekoppelt werden. Sehen Sie

statt dessen eine lokale Versorgung für die

Elektroniken (auch mehrere gemeinsam) vor.

S Die Versorgungsspannung ist gegenüber dem

Schirmpotenzial isoliert. Eine Verbindung von GND

mit dem Gehäuse ist nicht erforderlich, die Potenzial

differenz darf jedoch maximal 7 V betragen.

S Der Masseleiter der Versorgungsspannung (GND)

dient auch als Bezugspotential für die Schnittstellensi

gnale und die digitalen Ein-/Ausgänge.

=

3 W

Spannung in V

S Bei Aufbauten mit mehreren digitalen Wägezellen

kann die Versorgung gemeinsam mit den

RS‐485‐Busleitungen in einem 6‐poligen Kabel verlegt

werden (z.B. mit HBM‐Klemmenkästen). Achten Sie

dabei auf einen ausreichenden Leiterquerschnitt, da

einige Kabelabschnitte den Versorgungsstrom für alle

angeschlossenen Elektroniken führen.

PW15iA A4359-1.0 HBM: public 25

Page 60

Aufbau und Wirkungsweise

6.4 Digitale Eingänge

Sie können die Schaltschwelle für die digitalen Eingänge

mit dem Befehl SPL umschalten. Beachten Sie je nach

Einstellung die unterschiedlichen Pegel für High and Low.

SPL0 (Voreinstellung) SPL1 (SPS-Pegel) Erläuterung

>4V >10V High-Pegel

<1V <6V Low-Pegel

GND GND Bezugspotenzial

70kΩ 9kΩ Eingangswiderstand

6.5 Digitale Ausgänge

Für die digitalen Ausgänge gilt:

Versorgungsspannung +12 ... +30 V

Max. Strom pro Ausgang <0,5A

Max. Strom für alle Ausgänge <1A

26 A4359-1.0 HBM: public PW15iA

Page 61

7 Schnittstellen

Als Bezugsmasse aller Schnittstellensignale wird die

Masse der Versorgungsspannung verwendet (GND).

GND (0V) der Speisespannung muss deshalb ebenfalls

verbunden werden, Sie dürfen aber GND nicht mit dem

Schirm verbinden. Verwenden Sie eine separate Leitung,

um die digitale Masse der Teilnehmer mit GND (0 V) der

Stromversorgung zu verbinden.

Verwenden Sie für das Schnittstellenkabel eine

geschirmte Leitung. Der Schirm sollte immer an beiden

Enden mit dem Gehäuse verbunden sein.

Beachten Sie vor dem Einbau mehrerer digitalen Wäge

zellen in eine Anlage mit Bussystem:

Die aufgedruckte Fertigungsnummer (Typenschild) wird

für die Einrichtung der Datenkommunikation benötigt.

Falls das Typenschild nach dem Einbau nicht mehr

zugänglich ist, sollten Sie die Nummern aller digitalen

Wägezellen notieren. Damit ist eine Zuteilung verschie

dener Adressen bei der ersten Inbetriebnahme möglich.

Alternativ können Sie vor Anschluss an das Bussystem

jede digitale Wägezelle einzeln mit einem PC verbinden,

um unterschiedliche Adressen einzustellen (siehe

ADR‐Befehl in der Online‐Hilfe).

Schnittstellen

Wichtig

7.1 RS‐485‐4‐Leiter‐Schnittstellen (UART)

Die PW15iA kann mit einer RS‐485‐ Schnittstelle

geliefert werden. Für die Schnittstelle sind Bitraten von

1200 bis 115.200 Baud einstellbar.

PW15iA A4359-1.0 HBM: public 27

Page 62

Schnittstellen

Über die RS-485-Schnittstelle kann entweder eine ein

zelne digitale Wägezelle angeschlossen werden oder Sie

können durch einen Aufbau als Bussystem bis zu 90 digi

tale Wägezellen an eine RS-485‐Schnittstelle

anschließen. Dabei sind alle Wägezellen an einer Leitung

parallel geschaltet, die Gesamtlänge der Leitung darf

dabei bis zu 500m betragen. Die Unterscheidung zwi

schen den Wägezellen erfolgt per Software durch die

unterschiedlichen Adressen. Besitzt der Steuerrechner

nur eine RS‐232‐Schnittstelle, ist ein Schnittstellenkon

verter (z.B. von HBM, Bestell‐Nr.: 1‐SC232/422B)

erforderlich.

Busabschluss

+5 V

500 Ω

500 Ω

+5 V

500 Ω

500 Ω

TB TA

T

TxD

TB

TA

RB

RA

RB RA

R

on/off

PC = Master Teilnehmer 1 Teilnehmer 90

RxD

TB TA

T

on/off

TxD

RB RA

R

RxD

...

TB TA

T

on/off

TxD

RB RA

R

RxD

Abb. 5.1 Anschluss mehrerer Teilnehmer an einen PC über

RS‐485‐4‐Leiter‐Bus

Die richtige Zuordnung von Sende‐ und Empfangslei

tungen ist in Abb. 5.1 dargestellt (Busleitung Ra an Ta

Busabschluss

500 Ω

500 Ω

500 Ω

500 Ω

+5 V

+5 V

28 A4359-1.0 HBM: public PW15iA

Page 63

Schnittstellen

des Konverters etc.). Die PW15iA enthält bereits Bus

abschluss‐Widerstände (Leitungsabschluss), die mit dem

Softwarebefehl STR aktiviert werden können. Zusätzliche

Busabschlusswiderstände sind daher bei RS-485 nicht

notwendig.

7.2 CANopen‐Schnittstelle

Die Schnittstelle ist nach CANopen‐Standard CiA DS301

ausgeführt. Die Adresse bei Auslieferung ist 63.

Der CAN‐Bus ist als 2‐Draht‐Leitung (CANH und CANL)

aufgebaut (siehe ISO11898).

Wichtig

Sie müssen am Anfang und am Ende des Busses Bus

abschluss‐Widerstände (je 120W) anschließen. Die

Elektroniken enthalten keinen Busabschluss‐Widerstand

für CANopen.

Busabschluss Busabschluss

IN

Master Teilnehmer 1 Teilnehmer X

CAN H

CAN L

OUT

Abb. 5.2 Busverdrahtung CAN-Bus

IN

OUT

...

120 W120 W

IN

OUT

PW15iA A4359-1.0 HBM: public 29

Page 64

Schnittstellen

Die Struktur der Busverdrahtung wurde so gewählt, dass

die Länge der Stichleitungen minimiert wird. Um die Ver

drahtung zu vereinfachen, sind die Anschlüsse für

CANH (High) und CANL (Low) doppelt ausgelegt. Sie

können daher an einem Teilnehmer die Leitungen vom

vorherigen und die Leitungen zum nächsten Teilnehmer

an separaten Anschlüssen anschließen. Die Anschlüsse

sind intern verbunden (gebrückt), um diese Stich

leitungen so kurz wie möglich zu halten.

Baudrate und Bus‐Kabellänge

Als maximale Kabellänge in Abhängigkeit von der Bau

drate gilt für CANopen:

Baudrate in kBit/s 10 20 50 125 250 500 800 1000

Max. Kabellänge in m 5000 2500 1000 500 250 100 50 25

Die max. Kabellänge ist die Gesamtleitungslänge, die

sich aus der Länge aller Stichleitungen pro Knoten (Bus

teilnehmer) und der Leitungslänge zwischen den Knoten

errechnet. Die Länge der Stichleitungen pro Knoten ist

begrenzt und von der verwendeten Baudrate abhängig

(siehe CAN-Bus-Dokumentation). Bei den Elektroniken

können Sie die Stichleitungslänge der internen Ver

schaltung zu Null setzen. Falls Sie nur ein Anschlusspaar

verwenden (nur CANIN oder nur CANOUT), entspricht

die Kabellänge der Stichleitungslänge.

Erläuterungen zur CANopen‐Kommunikation finden Sie

auch in der Online‐Hilfe.

7.3 DeviceNet‐Schnittstelle

Die DeviceNet-Schnittstelle basiert auf ISO 11898 und

wurde in EN 50325 standardisiert. Die Hardware basiert

auf CANopen, lesen Sie daher auch die Informationen

30 A4359-1.0 HBM: public PW15iA

Page 65

Schnittstellen

zur CANopen-Schnittstelle durch. Allerdings gibt es ver

schiedene Einschränkungen gegenüber CANopen. Die

Schnittstelle ist nach DeviceNet‐Spezifikation, Release

2.0 ODVA, ausgeführt. Die Adresse der Wägezelle bei

Auslieferung ist 63.

Wichtig

Sie müssen am Anfang und am Ende des Busses Bus

abschluss‐Widerstände (je 120W) anschließen. Die

Elektroniken enthalten keinen Busabschluss‐Widerstand

für DeviceNet.

Sie dürfen die Widerstände nur an den Enden des Bus

systems aktivieren. Falls Sie mehr als 2 Abschlusswider

stände aktivieren oder sich diese nicht an den Enden

befinden, funktioniert die Kommunikation nur einge

schränkt (Busfehler) oder gar nicht mehr.

Alle Leitungen beziehen ihre Pegel auf GND. GND (0V)

der Speisespannung muss deshalb ebenfalls verbunden

werden, Sie dürfen aber GND nicht mit dem Schirm ver

binden. Verwenden Sie eine separate Leitung, um die

digitale Masse der Teilnehmer mit GND (0V) der Strom

versorgung zu verbinden. Verbinden Sie die Kabel

schirme flächig mit den Gehäusen der Anschlussstecker.

PW15iA A4359-1.0 HBM: public 31

Page 66

Bedienung über Software

8 Bedienung über Software

Laden Sie bei Bedarf die Software PanelX zur Parame

trierung und Visualisierung von der Website von HBM

herunter: http://www.hbm.com/software

Digitale Wägezellen & AED Wägeelektroniken“).

9 Entsorgung und Umweltschutz

Alle elektrischen und elektronischen Produkte müssen

als Sondermüll entsorgt werden. Die ordnungsgemäße

Entsorgung von Altgeräten beugt Umweltschäden und

Gesundheitsgefahren vor.

Elektrische und elektronische Geräte, die dieses Symbol

tragen, unterliegen der europäischen Richtlinie

2002/96/EG über elektrische und elektronische Altgeräte.

Das Symbol weist darauf hin, dass nicht mehr