HBM MVD2555 Operating Manual

Operating manual

Measuring amplifier for

instrument panel mounting

MVD2555

A0104-5.6 en

MVD2555

3

Contents Page

Safety instructions 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Introduction 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Scope of supply 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 General 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Block diagram 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Mounting 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Pre-installation notes, factory settings 10 . . . . . . . . . . . . . . . . . . . . .

2.2 Changing the factory settings 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1 Setting the analogue output signal 11 . . . . . . . . . . . . . . . .

2.2.2 Choosing the operating mode for synchronization 11 . . .

2.2.3 Replacing the fuses 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Installing the amplifier in a panel-frame 12 . . . . . . . . . . . . . . . . . . . .

3 Connections 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Connecting the voltage supply 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Connecting transducers 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Analogue output 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Control inputs / outputs 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Synchronization 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 Setting the reading angle of the display 18 . . . . . . . . . . . . . . . . . . . .

3.7 Connecting the serial interface 18 . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Setting up and operation 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Commissioning and factory settings 19 . . . . . . . . . . . . . . . . . . . . . . .

4.2 Control concept and functional overview 26 . . . . . . . . . . . . . . . . . . .

4.3 Button functions in measuring mode 27 . . . . . . . . . . . . . . . . . . . . . .

4.3.1 Querying and setting limit values in

measuring mode 28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HBMA0104-5.6 en

4

4.4 Button functions in programming mode 29 . . . . . . . . . . . . . . . . . . . .

4.4.1 Changing from ”Measuring” operating mode

to ”Programming” 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.2 Programming 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.3 Switching from ”Programming” mode to ”Measuring” 32 .

4.5 Overview of all groups and parameters 33 . . . . . . . . . . . . . . . . . . . .

4.5.1 Setting all parameters 34 . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.2 Dialogue 37 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.3 Load/Save in parameter set (PARAM. SET) 38 . . . . . . . .

4.5.4 Adaptation 38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.5 Calibration (CALIBR.) 41 . . . . . . . . . . . . . . . . . . . . . . . . . . .

MVD2555

4.5.6 Limit switches 1 ... 4 (LIMITVAL.1 ... 4) 42 . . . . . . . . . . . . .

4.5.7 Set peak value store (PV STORE) 44 . . . . . . . . . . . . . . . . .

4.5.8 Inputs and outputs (IN/OUT) 46 . . . . . . . . . . . . . . . . . . . . . .

4.5.9 Additional functions (ADD. FUNCT) 48 . . . . . . . . . . . . . . .

5 Example 51 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Error messages 60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Specifications 61 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Keyword index 65 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HBM A0104-5.6 en

MVD2555

Safety instructions

Before connecting the device, make sure that the mains voltage and current

type specified on the name plate correspond to the mains voltage and current

type at the site of installation and that the current circuit used is sufficiently

safe.

An earthed socket must be used for the mains plug (protection class I and II).

Do in no case use the device when the mains line has suffered damage.

Do in any case switch off the device before opening it; disconnect the mains

plug.

Built-in devices may only be used in the appropriate housing.

The device complies with the safety requirements of DIN EN 61010-part1

(VDE 0411-part1); protection class I.

5

Due to the fact that the device has not been equipped with a proper

mains switch, the connected supply cable may not be connected to

mains directly. According to a VDE recommendation these devices must

be equipped with a switching device (e.g. with a mains switch) that can

be disconnected from mains supply.

Appropriate use

The MVD2555 with the connected transducers may be used for measurement

and directly related control and regulation tasks, only. Any other use is not

appropriate. To ensure safe operation, the transducer may only be used

according to the specifications given in this manual. It is also essential to

comply with the legal and safety requirements for the application concerned

during use. The same applies to the use of accessories.

Conditions on site

Protect desktop devices from moisture or atmospheric influences such as

rain, snow, etc.

Protect the device from direct sunlight.

HBMA0104-5.6 en

6

General dangers in the case of non-observance of the safety

instructions

The MVD2555 complies with the state of the art and is operationally reliable. If

the device is used and operated inappropriately by untrained personnel,

residual dangers might develop.

Any person charged with device installation, operation, maintenance or repair

must in any case have read and understood the operating manual and the

safety instructions, in particular.

Residual dangers

The MVD2555’s scope of performance and supply covers part of the

measuring-technology, only. The plant designer/constructor/operator must in

addition design, realise and take responsibility for the measuring-system’s

safety such that potential residual dangers are minimized. The respective

regulations must in any case be observed. Residual dangers regarding the

measuringsystem must be specified explicitly.

MVD2555

After making settings and carrying out activities that are password-protected,

you must make sure that any controls that may be connected remain in safe

condition until the switching performance of the amplifier system has been

tested.

In this manual, the following symbols are used to point out residual dangers:

Symbol:

Meaning: Maximum danger level

Warns of an imminently dangerous situation in which failure to comply with

safety requirements will result in death or serious bodily injury.

Symbol:

DANGER

WARNING

Meaning: Dangerous situation

Warns of a potentially dangerous situation in which failure to comply with

safety requirements can result in death or serious bodily injury.

HBM A0104-5.6 en

MVD2555

Symbol: CAUTION

Meaning: Potentially dangerous situation

Warns of a potentially dangerous situation in which failure to comply with

safety requirements could result in damage to property or some form of

bodily injury.

Symbols pointing out notes on use and waste disposal as well as useful

information:

7

Symbol:

Points out that important information about the product or its handling is being

given.

Symbol:

Meaning: CE mark

The CE mark enables the manufacturer to guarantee that the product

complies with the requirements of the relevant EC directives (the declaration

of conformity is available at http://www.hbm.com/HBMdoc).

Symbol:

Meaning: Statutory marking requirements for waste disposal

National and local regulations regarding the protection of the environment and

recycling of raw materials require old equipment to be separated from regular

domestic waste for disposal.

NOTE

For more detailed information on disposal, please contact the local authorities

or the dealer from whom you purchased the product.

HBMA0104-5.6 en

8

Safe operation

Do only quit error messages if the reason for the error has been eliminated

and there is no more danger.

Reconstruction and modifications

HBM’s express consent is required for modifications regarding the MVD2555’s

construction and safety. HBM does not take responsibility for damage

resulting from unauthorized modifications.

In particular, repair and soldering works on the boards (replacement of

components except for EPROMS) are prohibited. If complete componentry is

replaced use original HBM components, only.

Qualified personnel

The device may be used by qualified personnel, only; the technical data and

the special safety regulations must in any case be observed. When using the

device, the legal and safety regulations for the respective application must

also be observed. The same applies if accessories are used.

MVD2555

Qualified personnel means: personnel familiar with the installation, mounting,

start-up and operation of the product, and trained according to their job.

Maintenance and cleaning

MVD2555 devices are maintenance-free. Please note the following points

when cleaning the housing:

- Withdraw the mains plug from the socket before carrying out any cleaning.

- Clean the housing with a soft, slightly damp (not wet!) cloth. You should on

no account use solvent, since it may damage the labelling on the front

panel and the indicator box.

- When cleaning, ensure that no liquid gets into the device or connections.

HBM A0104-5.6 en

MVD2555

1 Introduction

1.1 Scope of supply

D Device with front frame

D 2 fastening straps

D 1 male cable connector DB-15P, order no.: 3.3312-0182

D 1 3-pin terminal strip connector (mains connection)

D 1 3-pin terminal strip connector (interface)

D 2 9-pin terminal strip connectors (control inputs/outputs)

D 1 Operating Manual Part1; 1 Operating Manual Part 2

1.2 General

9

The panel-frame measuring amplifier MVD2555 for instrument panel

mounting (in accordance with DIN43700) is suitable for recording and

processing measured values from passive transducers in the industrial test

bench engineering sector and for monitoring production processes.

The essential features:

D Transducers that can be connected: S.G. full and half bridges, inductive full

and half bridges, piezoresistive and potentiometric transducers, LVDT

D 10-digit alphanumeric display

D Touch-sensitive keypad control; individual buttons can be locked

D 2 peak value stores for maximum and minimum values, as well as

envelope and instantaneous value

D 4 limit switches

D RS232 or RS485 serial interface for connecting a computer or a printer

D Parameter memory for saving up to 8 data sets

D Control inputs and outputs (potential-separated through optical couplers)

D The MVD 2555-RS485 version can be operated together with other

MVD2555s (at a common RS485 bus)

All the commands needed for device setup over the serial interface and for

querying the measured values are listed and described in a separate

Operating Manual document ”Operating the MVD2555 by Computer” .

HBMA0104-5.6 en

10

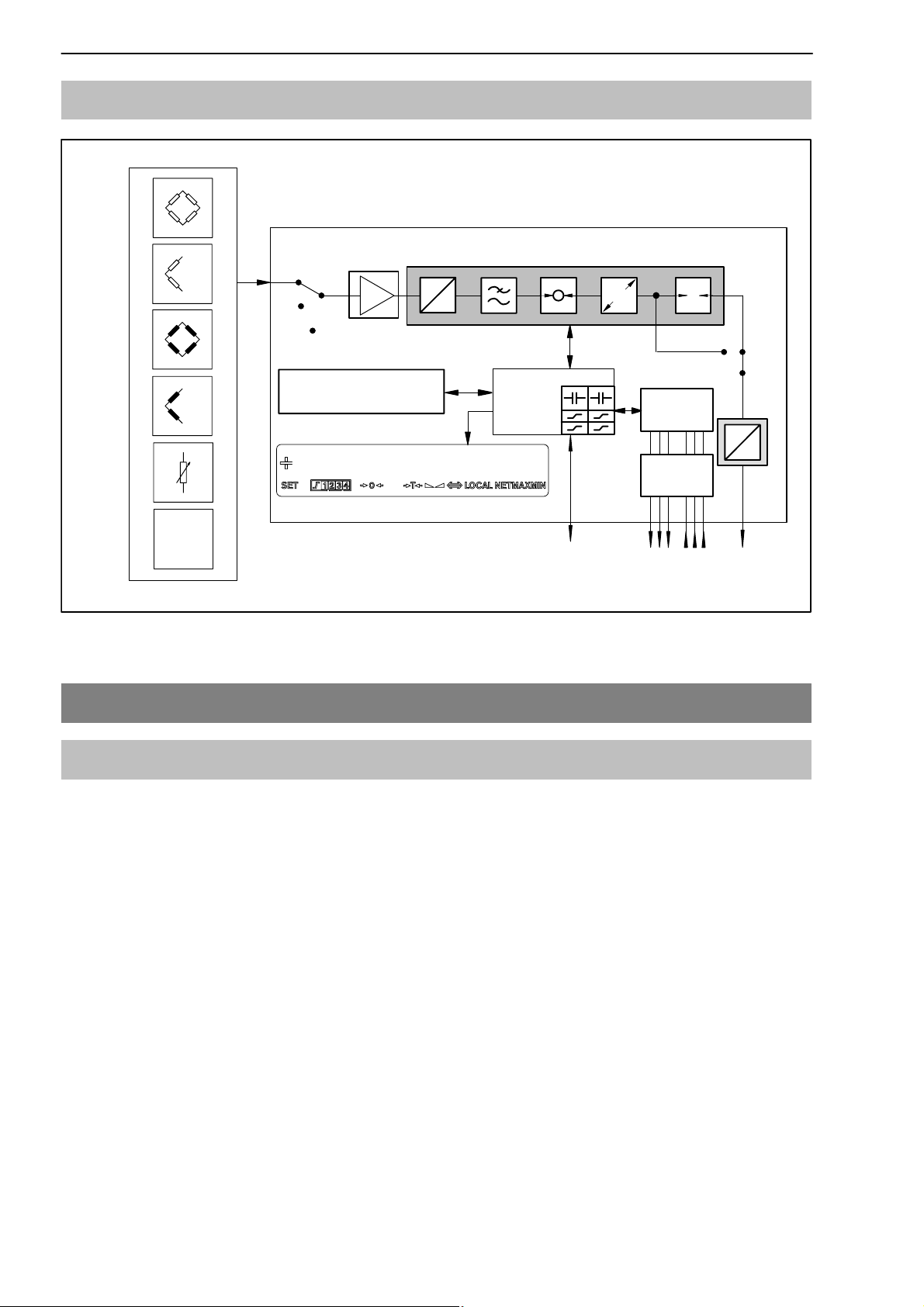

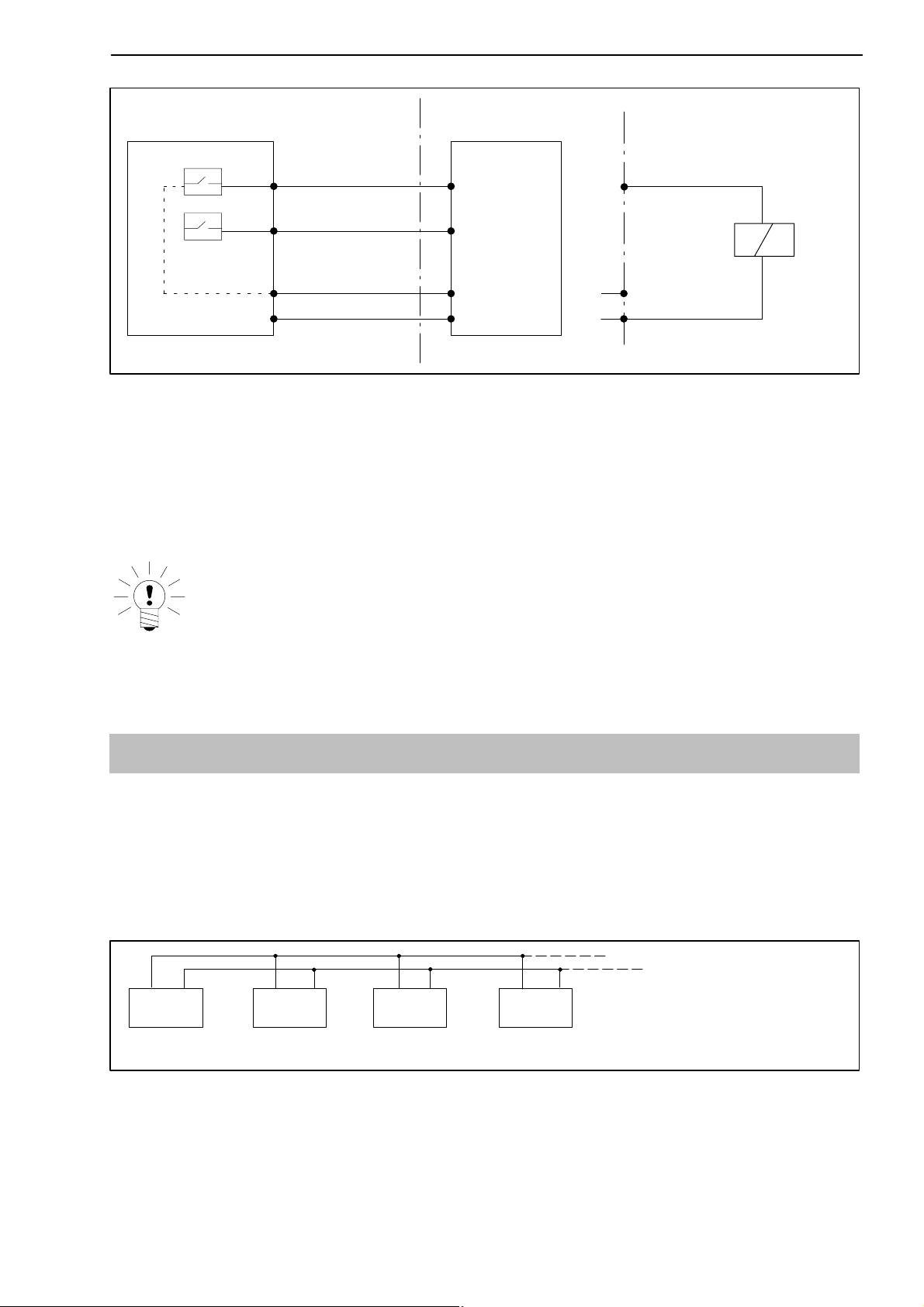

1.3 Block diagram

MVD2555

Measure

Zero

Cal.

Parameter memory

Data set 1...8

Connectable transducer

LVDT

Fig. 1.1 MVD2555 block diagram

2 Mounting

A

D

CPU

127,533 KN

PK-232 or

PK-485

E

Control

signals

Optical

coupler

5 outputs/

6 inputs

T

D

A

...

UA/IA

2.1 Pre-installation notes, factory settings

Before installing the device, check the parameters set at the factory, as the

elements for selecting the analogue output signal (current/voltage output) and

for setting synchronization, are located on the motherboard.

The factory settings are given below:

D Mains voltage: 230 V / 50 ... 60 Hz or 115 V / 50 ... 60 Hz, depending on

order

D Analogue output: output voltage "10 V

D Synchronization: Master

HBM A0104-5.6 en

MVD2555

11

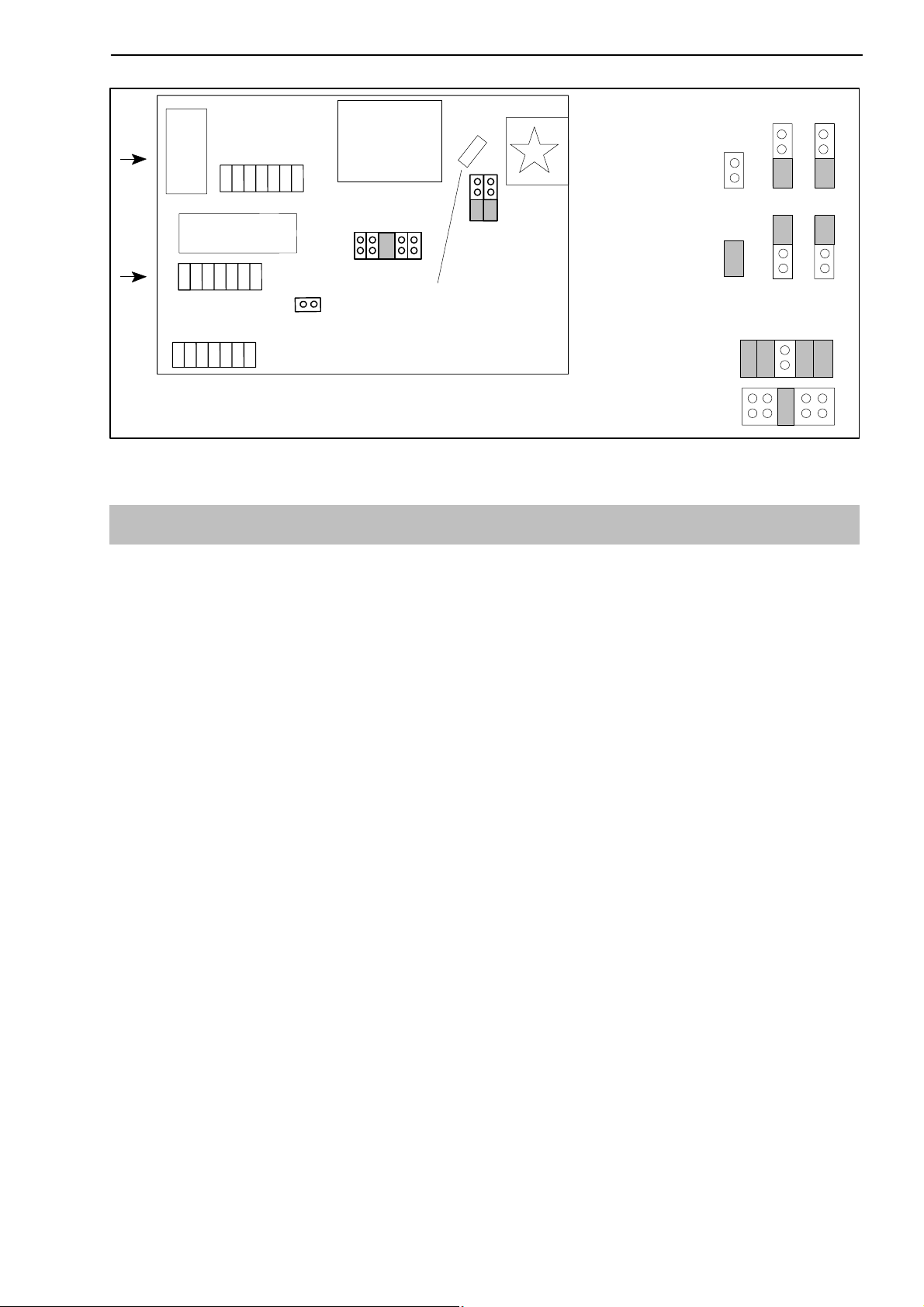

Master/Slave setting:

IC

Frontsite

ST100: for attaching spare bridges

ST9 and ST10:for options

ST9

IC

ST10

ST13

ST100

Transformer

ST11

Fuses (slow-blowing)

ST15

ST14

Fig. 2.1: Location of jumpers on motherboard

2.2 Changing the factory settings

To change the factory settings, proceed as follows:

Master:

Slave:

Current

Voltage

ST13

ST13 ST14 ST15

Analogue output:

ST11

ST11

ST14 ST15

D Loosen the four screws at the back of the housing.

D Carefully extract the back panel of the housing backward, with the

motherboard attached, until the jumper arrangement is accessible. You can

place a screwdriver between the connection board and the housing and

lever out the back panel.

D By following the diagram, change whichever setting is relevant to you with

the aid of the jumpers.

2.2.1 Setting the analogue output signal

To make the analogue output signal setting (voltage or current), use jumpers

ST11. Choose between "20 mA or 4 ... 20 mA in the control dialogue.

2.2.2 Choosing the operating mode for synchronization

To synchronize several devices, set one device as the Master. All the other

devices should then set to Slave. To make the ”Master” and ”Slave”

selections, use jumpers ST13, ST14 and ST15.

2.2.3 Replacing the fuses

To replace the fuse, remove the back panel of the housing as described. The

fuse (230 V/T63mA L; 115 V/T125mA L) will then be accessible on the

motherboard (see Fig. 2.1).

HBMA0104-5.6 en

12

MVD2555

2.3 Installing the amplifier in a panel-frame

The MVD2555 is designed to be installed in panel-frames, in accordance with

DIN43700.

Installation steps:

D Remove the fastening strap.

D Insert the housing into the cutout in the panel-frame from the front.

D Hang up the fastening strap on both sides and fasten it to the cutout with

the two threaded rods.

D Then connect the supply voltage and the transducer,

as shown in chapter 3.

partial section, front panel

+1

138

fastening strap

plastic frame

Fig. 2.2: Housing with fastening components

threaded rod

68

+0.7

HBM A0104-5.6 en

MVD2555

13

3 Connections

CAUTION

Before commissioning the device, please observe the safety instructions.

3.1 Connecting the voltage supply

Check that the mains voltage of the device (details on the back of the device)

matches the supply voltage. If this is not the case, please contact the appropriate HBM branch or HBM representative.

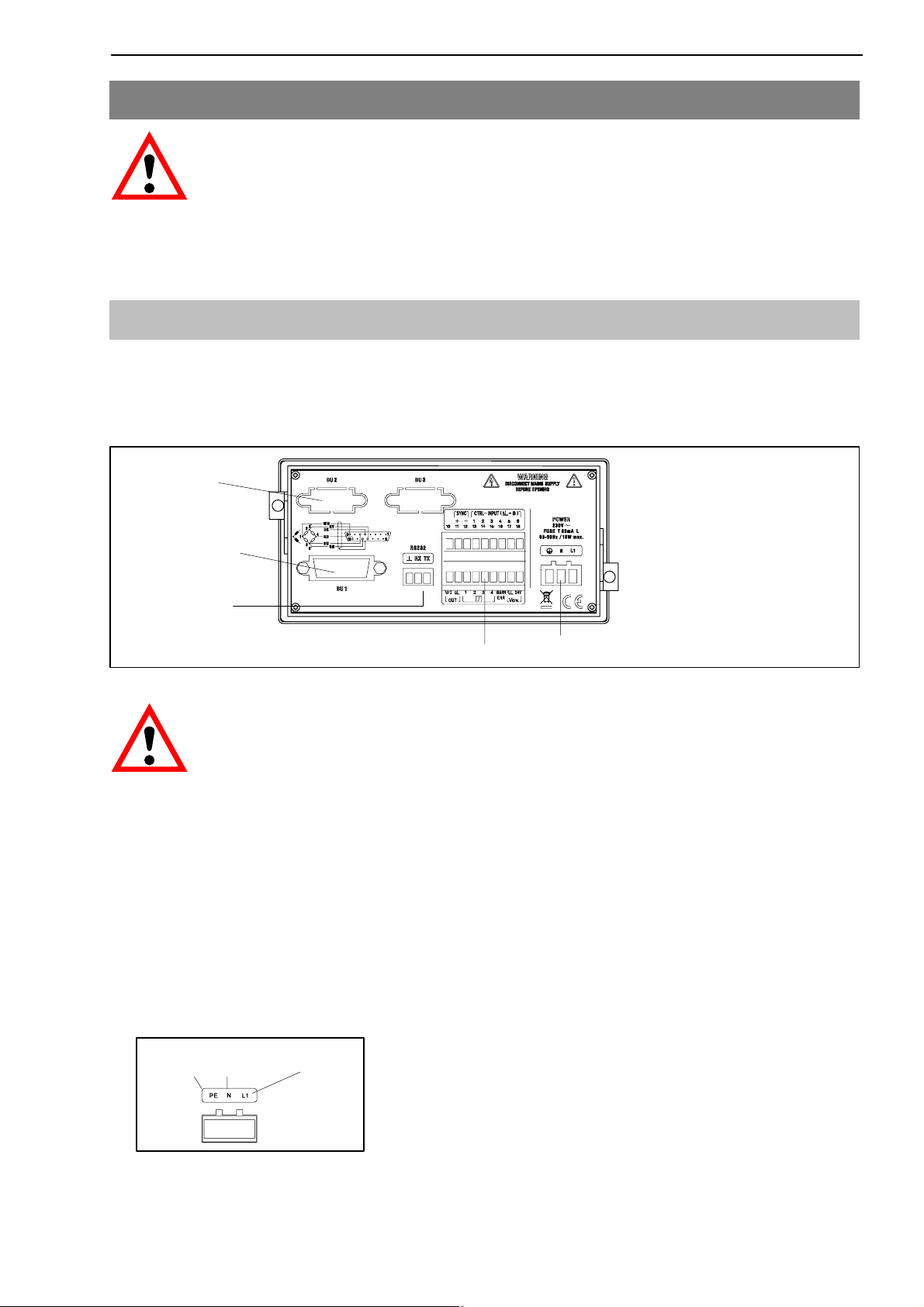

interface port

PK485

transducer

connection

(15-pin D-Sub

connector)

interface port

PK232

terminal strip for control inputs/outputs

terminal strip for mains connection

Fig. 3.1 Back of the device

CAUTION

As the device does not have a separate power switch, do not connect

the power cable directly to the mains. According to the VDE guideline,

there must be a switching device to disconnect the device from the

mains.

Connecting the mains cable:

D The cable must not be connected to the mains !

D Twist the wire ends of the mains cable and fit the end sleeves for strands

D Screw the wire ends to the terminal strip connector (3-pin)

earthed

conductor

neutral

Fig. 3.2: Pin assignment of the terminal strip connector (3-pin)

phase

D Plug the terminal strip connector (3-pin) into the mains connection socket

HBMA0104-5.6 en

14

MVD2555

3.2 Connecting transducers

The following transducer types can be connected to the device:

D S.G. full and half bridge transducers

D Inductive full and half bridge transducers

D Potentiometric and piezoresistive transducers

D LVDT (Linear Variable Differential Transformer)

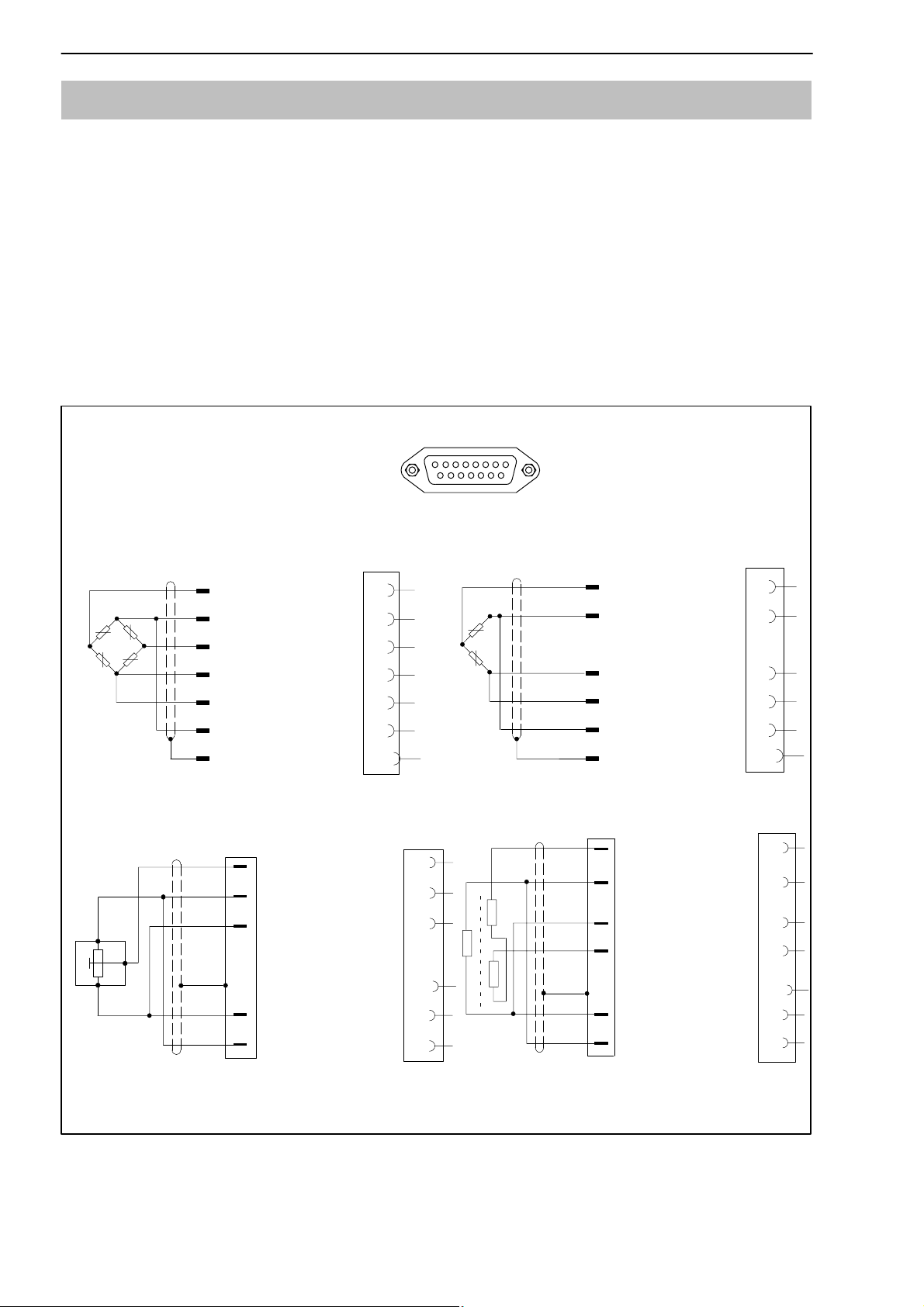

The connection is made using a 15-pin D-Sub connector on the back panel

of the housing, labelled BU1 (cable end connector: DB-15P,

Order No. 3-3312-0182).

BU 1

Transducer

connection socket

S.G. and inductive full bridges, piezoresistive transducers

Measurement

WH

signal (+)

BK

Voltage (-)

RD

Measurement

signal (-)

BU

Voltage (+)

GN

Sensor circuit (+)

GY

Sensor circuit (-)

YE

Cable shielding

Potentiometric transducer

Measurement

signal (+)

Voltage (-)

2

1

3

Voltage (+)

Cable shielding

Sensor circuit (+)

Sensor circuit (-)

8

5

15

6

13

12

Case

8

5

6

Case

13

12

8

15

1

9

S.G. and inductive half bridges

Measurement

WH

signal (+)

BK

Voltage (-)

BU

Voltage (+)

GN

Sensor circuit (+)

GY

Sensor circuit (-)

YE

Cable shileding

LVDT transducer

Measurement

signal (+)

Voltage (-)

Voltage (+)

Measurement

signal (-)

Cable shielding

Sensor circuit (+)

Sensor circuit (-)

8

5

6

13

12

Case

8

5

6

15

Case

13

12

Wire colors: WH= white; BK= black; BU= blue; RD= red; YE= yellow; GN= green; GY= gray

Fig. 3.3: Connecting different transducers

HBM A0104-5.6 en

MVD2555

15

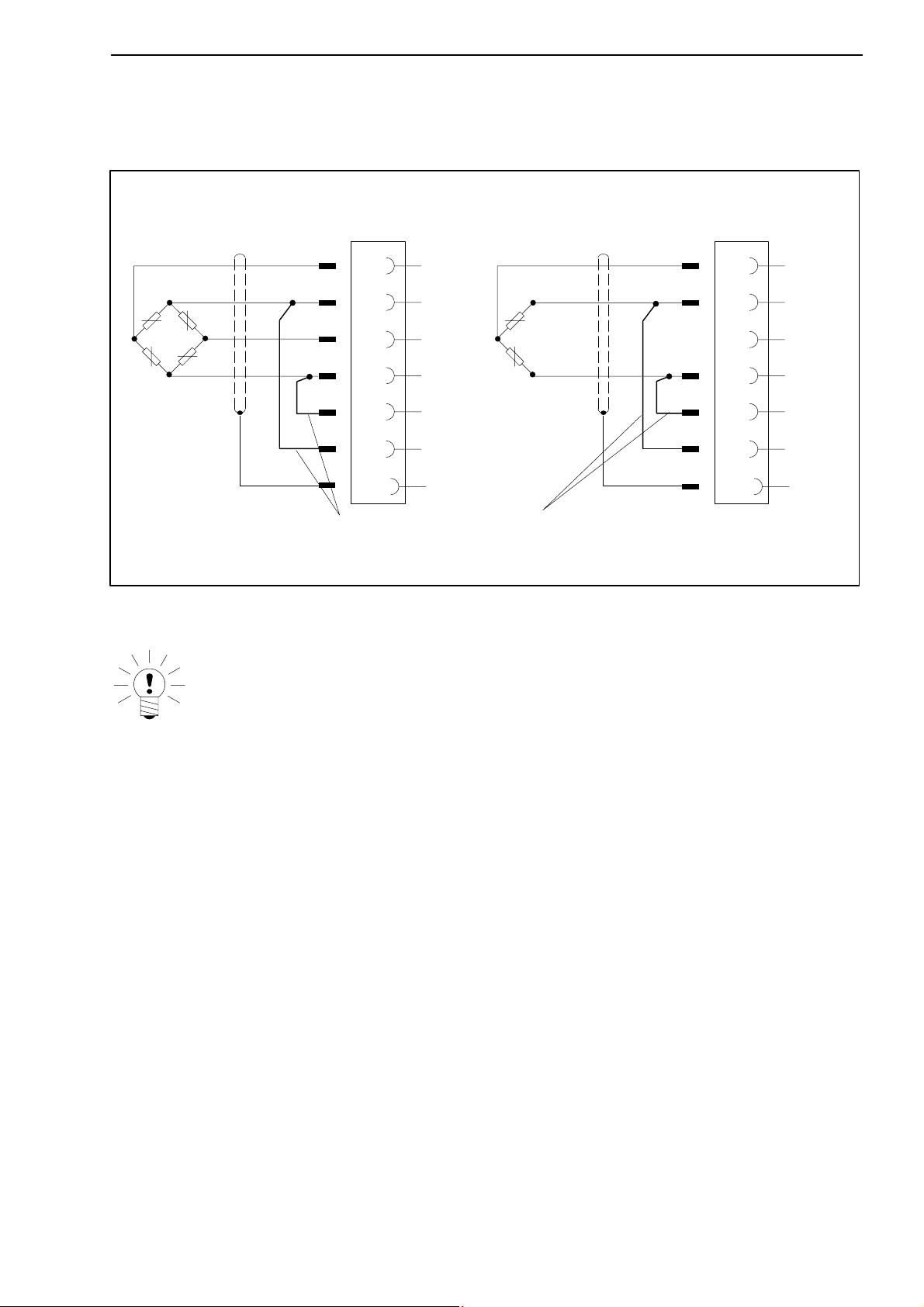

When connecting a transducer using four-wire technique, you must connect

the sensor circuits with the relevant bridge excitation circuit in the male cable

connector (pin 5 with pin 12 and pin 6 with pin 13).

Four-wire connection: full bridge

WH

BK

RD

BU

YE

Feedback bridges for four-wire connection

Wire colors: WH= white; BK= black; BU= blue; RD= red; YE= yellow; GN= green; GY= gray

8

5

15

6

13

12

Case

Four-wire connection: half bridge

WH

BK

BL

GN

GY

YE

Case

Fig. 3.4: Transducer connection in four-wire technique

8

5

15

6

13

12

NOTE

To connect the transducers, use HBM standard cable. If you use another

shielded, low-capacitance measurement cables, connect the shielding

of the transducer cable to the connector housing, in accordance with

HBM Greenline information (see http://www.hbm.com/Greenline). This

guarantees EMC protection.

HBMA0104-5.6 en

16

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

MVD2555

3.3 Analogue output

The analogue output signal is available as voltage ("10 V) or as current

("20 mA or 4 ... 20 mA) at terminals 1 and 2.

To choose current or voltage, use the jumpers on the amplifier motherboard,

as described in Chapter 2.1.

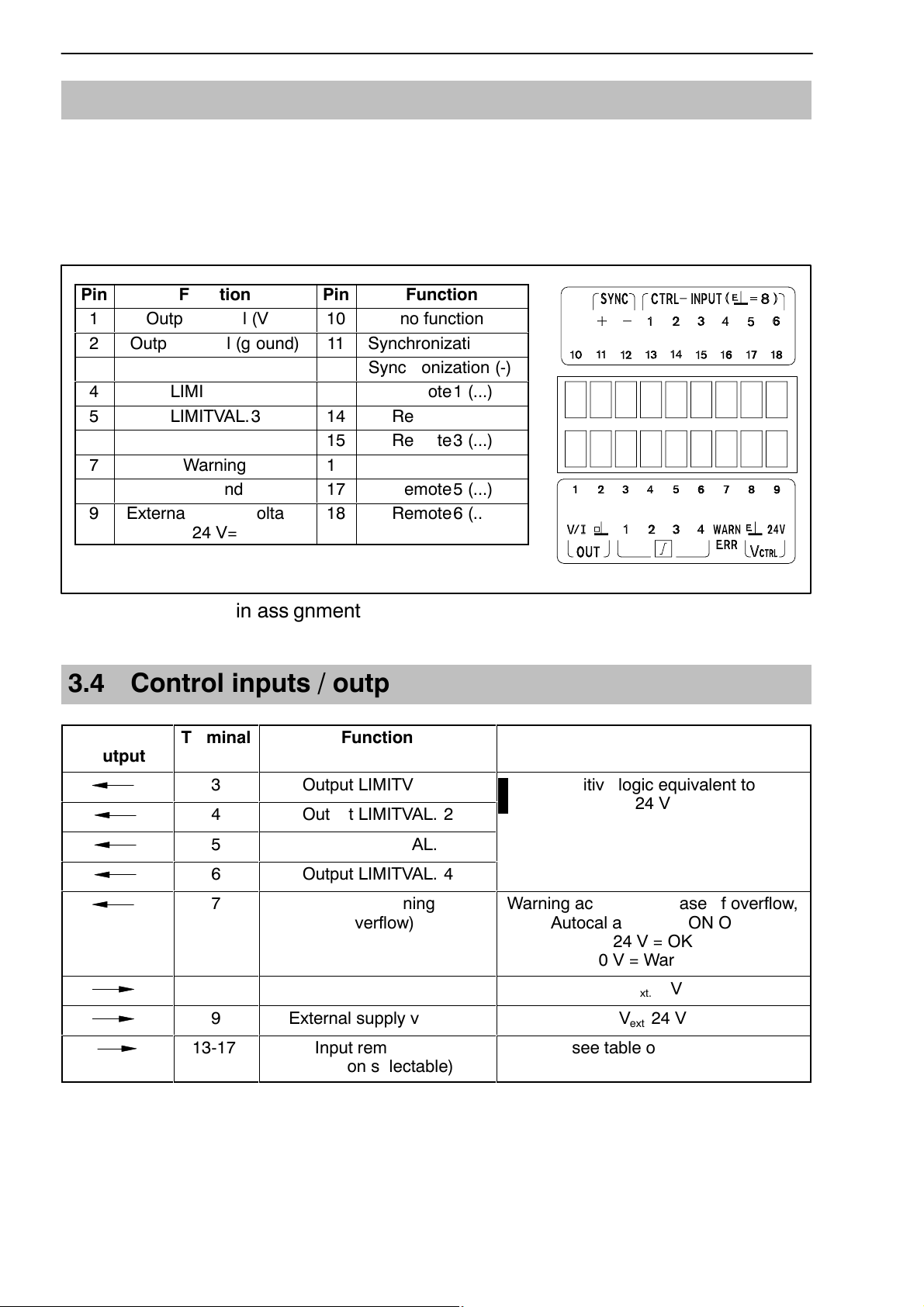

Pin

1

2

Output signal (ground)

3

ББББББББ

4

5

6

7

8

9

External supply voltage

Function

Output signal (V/I)

LIMITVAL.1

LIMITVAL.2

LIMITVAL.3

LIMITVAL.4

Warning

Ground

Pin

10

11

12

13

14

15

16

17

18

no function

Synchronization (+)

Synchronization (-)

БББББББ

Remote1 (...)

Remote2 (...)

Remote3 (...)

Remote4 (...)

Remote5 (...)

Remote6 (...)

24 V=

Fig. 3.5: Output pin assignment

3.4 Control inputs / outputs

Input/

Output

ÁÁÁÁ

Terminal

ÁÁ

Function

БББББББББ

Function

ББББББББББББ

3

4

ÁÁÁÁÁÁÁ

5

6

7

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁÁÁÁ

ÁÁ

ÁÁ

8

9

13-17

ÁÁÁÁÁÁÁ

Output LIMITVAL. 1

Output LIMITVAL. 2

Output LIMITVAL. 3

БББББББББ

Output LIMITVAL. 4

Output warning

БББББББББ

БББББББББ

БББББББББ

(overflow)

Ground

External supply voltage

Input remote1-6

БББББББББ

(function selectable)

With positive logic equivalent to V

ext.

24 V

ББББББББББББ

Warning active in the case of overflow,

ББББББББББББ

ББББББББББББ

Autocal and MOTION OUT

24 V = OK

0 V = Warning

V

0 V

ББББББББББББ

ext.

V

24 V

ext.

see table on Page 47

ББББББББББББ

HBM A0104-5.6 en

MVD2555

17

MVD2555

7

3

9

8

max. 0.5 A

24 V*

0 V*

PLC

Relay

max. 0.5 A

24 V*

0 V*

Fig. 3.6: Output assignments

The control inputs and outputs are available at the terminal strip socket

(9-pin) and are potential-separated by optical couplers.

* The control outputs and inputs must be supplied with an external voltage

(ground and 24 V).

NOTE

When the mains voltage is disconnected or fails and when the mains

fuse blows, all the control outputs are set to 0 V (V

ext.

).

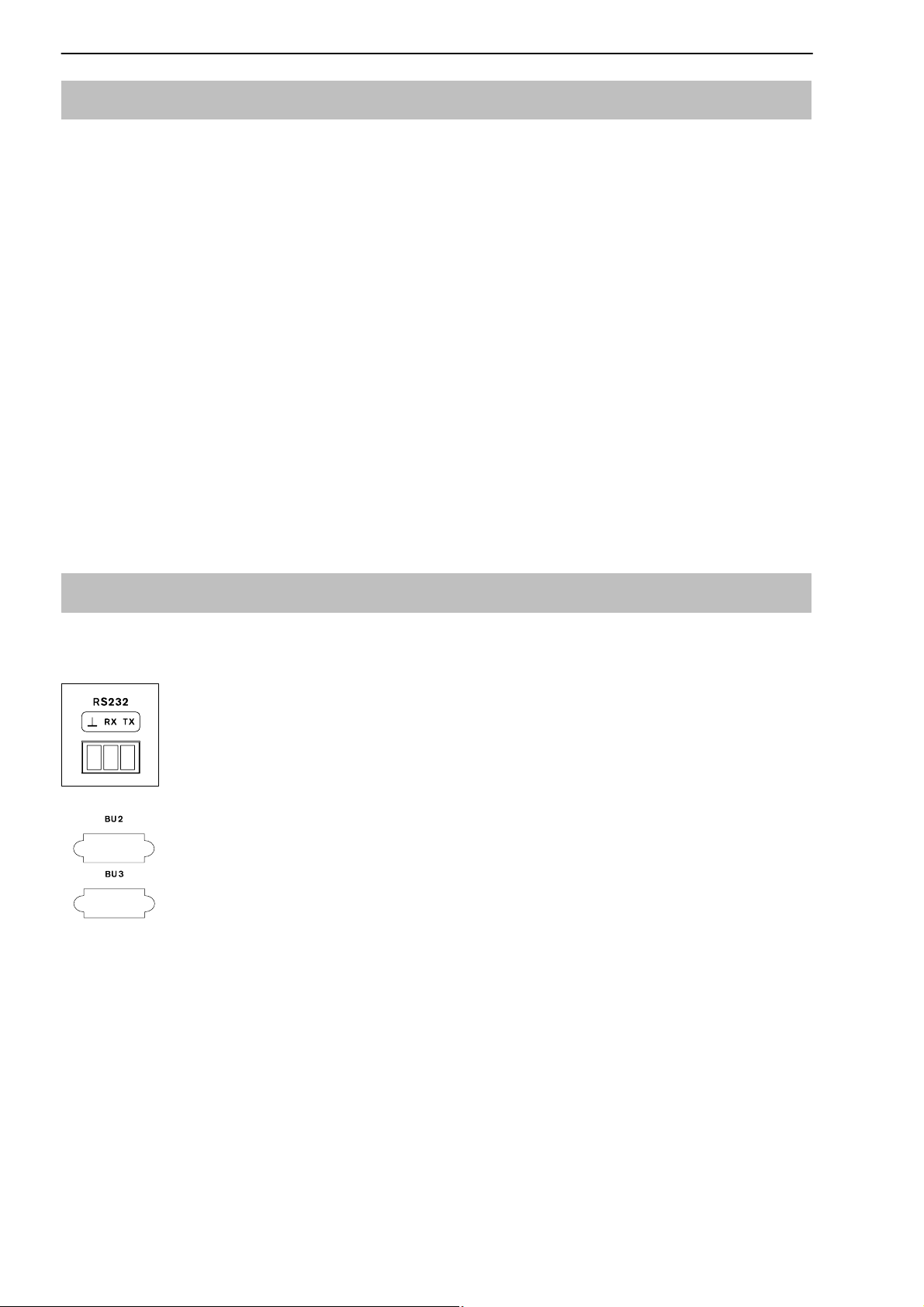

3.5 Synchronization

If several devices are used right next to one another or if their cables run parallel, the devices should be synchronized. To achieve this, one device is set to

Master and all the others (max. seven) to Slave. The setup with jumpers on

the amplifier motherboard is described in Chapter 2.1. As well as these settings, the devices must be linked together for synchronization.

11 12 11 12 11 12 11 12

Master Slave Slave Slave

Device 1 Device 2 Device 3

Device 4 (...max. 7)

Fig. 3.7: Terminal connections for synchronization

HBMA0104-5.6 en

18

MVD2555

3.6 Setting the reading angle of the display

Depending on the mounting position, it may be possible to adjust the reading

angle. A potentiometer is used for this limited adjustment. The potentiometer

is located behind the keyboard under the display. To set a new viewing angle,

proceed as follows:

D Remove the plastic frame of the display from the housing.

D Carefully lever out the keyboard (e.g. with the aid of a screwdriver).

D Use a screwdriver to turn the potentiometer and set the optimum reading

angle.

D Put back the keyboard. Make sure that the plug is correctly threaded at the

bottom edge of the keyboard. Quickly test the keyboard by pressing a key.

If it functions correctly, you can continue.

D Insert and tighten the fastening screws.

D Push the plastic frame back on the housing.

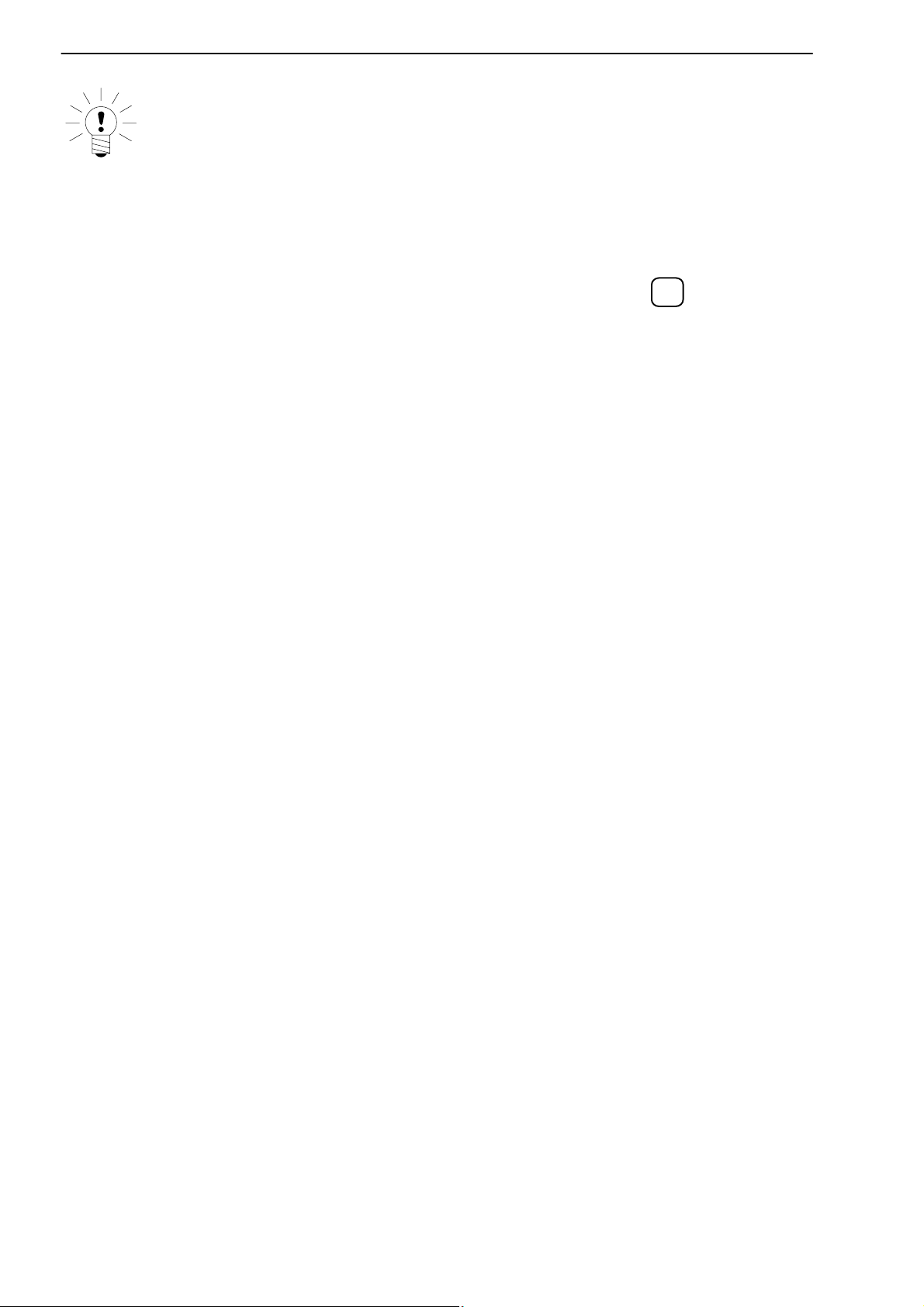

3.7 Connecting the serial interface

PK232-interface:

On the back of the device, there is anRS232 or RS485 serial

interface for connecting a computer or a terminal. The

PK485-interface is brought out at sockets Bu2 and Bu3.

When connecting a printer, a simple line printer needing no

RS485

When connecting a computer, it is possible to enter into dialogue with the

MVD2555. You can use control commands to make all the device settings and

query the measured values. An overview of the interface commands has been

compiled in another part of the Operating Manual ” Operating the MVD2555

by computer ”.

more than 4 seconds to print a line is sufficient. The printout

has 12 columns. This corresponds to a line length of 132

characters. Select the measured values to be printed as

described in Chapter 4.4.11.

HBM A0104-5.6 en

MVD2555

19

4 Setting up and operation

4.1 Commissioning and factory settings

Some of the steps you need to take to commission your measurement chain

(panel-frame amplifier and transducer) are listed below, so that you can carry

out an initial function test of all components. The description basically covers

adapting the MVD2555 to the transducer type to be used. We also warn about

certain errors which can typically occur during commissioning.

D Follow the steps given in the previous chapter to connect the mains cable

and the transducer to the measuring amplifier.

Please observe the safety instructions!

D Turn on the power switch.

D The device runs a function test and is then in measuring mode. Duration

of the function test: 1.5 s (if autocalibration is enabled, approx. 2.5 s).

During the function test, the warning output stays at 0 V. The factory

settings are active.

D Check the choice of output signal shown on the display. Use

the gross signal (no labelling in the display).

NOTE

If the error message CALERR. appears here, this can have the following

causes:

- No six-wire feedback connected

- Incorrect transducer/sensor connection

to select

- No transducer/sensor connected

Remedy:

Switch off the device. Connect the transducer properly. Switch the de-

vice back on.

HBMA0104-5.6 en

20

MVD2555

NOTE

If the error message “OVFL B, OVFL N,” appears, you must adjust the

amplifier for your type of transducer. The steps to take for each amplifier

are described below.

D To get from measuring mode to device setup mode, press

SET

for about

2 s. ”DIALOG” will appear in the display.

D Follow the examples given below to adjust the device to the connected

transducer type.

HBM A0104-5.6 en

MVD2555

Transducer types:

S.G. force transducer:

Adaptation: Example

Transducer type: Full bridge/2 mV/V=20 kN

Excitation: 2.5 V

Input: 4 mV/V

Calibration: Unit, nominal value/decimal point: 20.000 kN

Measuring range: 2 mV/V

Inductive displacement transducer:

Adaptation: Example

Transducer type: Half bridge, 10 mV/V

(80 mV/V)

Excitation: 1.0 V

Input: 10 mV/V (100 mV/V)

21

Calibration: Unit, nominal value/decimal point: 20.000 mm

Measuring range: 10 mV/V (80 mV/V)

Piezoresistive transducer:

Adaptation: Example

Transducer type: Half bridge

Excitation: 2.5 V

Input: 400 mV/V

Calibration: Unit, nominal value/decimal point: 30.000 bar

Measuring range: 200 mV/V

Potentiometric transducer:

Adaptation: Example

Transducer type: Half bridge

Excitation: 1 V

Input: 1000 mV/V

Calibration: Unit, nominal value/decimal point: 10.000 mm

Measuring range: 1000 mV/V

HBMA0104-5.6 en

Loading...

Loading...