Page 1

Operating manual

Measurement amplifier

for panel mounting

MVD2510

A0125-4.0 en

Page 2

Page 3

MVD2510

Contents Page

1 Safety instructions 5..........................................

2 Scope of supply 11.............................................

3 Introduction 11.................................................

3.1 General 11.................................................

3.2 Block diagram 12............................................

4 Mounting 12...................................................

4.1 Read before mounting, factory setups 12.......................

4.2 Change factory setups 13....................................

4.2.1 Adjust analogue output signal 14.........................

3

4.2.2 Fuse replacement 14...................................

4.3 Insert unit plug-in strip 15.....................................

4.4 Install amplifier on control cabinet 16...........................

5 Electrical connection 17........................................

5.1 Connect voltage supply 17...................................

5.2 Connect transducers 19......................................

5.3 Analogue output, Control inputs/outputs 21.....................

6 Adjustments and operation 22..................................

6.1 Start-up and factory setups 22................................

6.2 Device operation and survey of keyboard functions 24...........

6.3 Functions in Measure mode 25................................

6.3.1 Adjust limit-value levels in the Measure mode 26...........

6.4 Programming mode 28.......................................

6.4.1 Change from the ”Measure” to the ”Programming” mode 29..

6.4.2 Programming 30.......................................

Operation in the Programming mode 30.........................

6.4.3 Change from the ”Programming” to the ”Measure” mode 31..

6.5 Information on groups and parameters 32......................

6.5.1 Dialog (dIAL) 32.......................................

A0125-4.0 en HBM

Page 4

4

1

MVD25

6.5.2 Load/Save in parameter set (PArA) 33....................

6.5.3 Calibration (CAL) 34....................................

6.5.4 Limit values (Li1, Li2) 35................................

6.5.5 Inputs and outputs (I_O) 37..............................

6.5.6 Additional function (InFO) 38............................

7 Example 39....................................................

8 Displays and ex-works settings 51...............................

9 Error messages 52.............................................

10 Keyword index 53..............................................

A0125-4.0 enHBM

Page 5

MVD2510

1 Safety instructions

Appropriate use

The MVD2510 with the connected transducers may be used for measurement

and directly related control and regulation tasks, only. Any other use is not

appropriate. To ensure safe operation, the transducer may only be used

according to the specifications given in this manual. It is also essential to

comply with the legal and safety requirements for the application concerned

during use. The same applies to the use of accessories.

Each time, before starting up the equipment, you must first run a project

planning and risk analysis that takes into account all the safety aspects of

automation technology. This particularly concerns personal and machine

protection.

Additional safety precautions must be taken in plants where malfunctions

could cause major damage, loss of data or even personal injury. In the event

of a fault, these precautions establish safe operating conditions.

5

This can be done, for example, by mechanical interlocking, error signaling,

limit value switches, etc.

WARNING

Due to the fact that the device has not been equipped with a proper mains

switch, the supply cable must not be connected directly to the mains. VDE

guidelines require that the device can be disconnected from the mains via a

switching device (double-break disconnector). It is essential that the disconnector is labeled accordingly and easy to access and operate by the user.

Before connecting the device, make sure that the mains voltage and current

type specified on the name plate correspond to the mains voltage and current

type at the site of installation and that the current circuit used is sufficiently

safe.

Devices designed for panel mounting may only be operated in an EMC-tested

control cabinet. (see page LEERER MERKER).

The device complies with the safety requirements of DIN EN 61010-part1

(VDE 0411-part1); protection class I.

HBMA0125-4.0 en

Page 6

6

General dangers in the case of non-observance of the safety

instructions

The MVD2510 complies with the state of the art and is operationally reliable. If

the device is used and operated inappropriately by untrained personnel,

residual dangers might develop.

Any person charged with device installation, operation, maintenance or repair

must in any case have read and understood the operating manual and the

safety instructions, in particular.

Conditions on site

− Protect the device from direct contact with water.

− Protect the PMX system from moisture and humidity or weather conditions

such as rain, snow, etc. The degree of protection per EN 60529 standard is

IP 40 (device as a whole); IP51 (front, membrane keypad)

− Do not expose the device to direct sunlight.

MVD2510

− Please observe the permissible maximum ambient temperatures stated in

the specifications.

− The permissible relative humidity at 31 °C is 95 % (non condensing); linear

reduction to 50 % at 40 °C.

− It is safe to operate the MVD2510 system up to a height of 2000 m.

− Mounting in an EMC-tested control cabinet with line filter (see page

LEERER MERKER).

Maintenance and cleaning

MVD2510 devices are maintenance-free. Please note the following points

when cleaning the housing:

− Withdraw the mains plug from the socket before carrying out any cleaning.

− Clean the housing with a soft, slightly damp (not wet!) cloth. You should on

no account use solvent, since it may damage the labelling on the front

panel and the indicator box.

− When cleaning, ensure that no liquid gets into the device or connections.

Residual dangers

The MVD2510’s scope of performance and supply covers part of the

measuring-technology, only. The plant designer/constructor/operator must in

addition design, realise and take responsibility for the measuring-system’s

safety such that potential residual dangers are minimized. The respective

regulations must in any case be observed. Residual dangers regarding the

measuringsystem must be specified explicitly.

HBM A0125-4.0 en

Page 7

MVD2510

Product liability

In the following cases, the protection provided for the device may be ad

versely affected. Liability for device functionality then passes to the operator:

− The device is not used in accordance with the operating manual.

− The device is used outside the field of application described in this

Chapter.

− The operator makes unauthorized changes to the device.

Warning signs and danger symbols

Important instructions for your safety are specifically identified. It is essential

to follow these instructions in order to prevent accidents and damage to prop

erty.

7

Safety instructions are structured as follows:

SIGNAL WORD

Type of danger

Consequences of non-compliance

Averting the danger

− Warning sign: draws your attention to the danger

− Signal word: indicates the severity of the danger

(see table below)

− Type of danger: mentions the type or source of the danger

− Consequences: describes the consequences of non-compliance

− Defense: indicates how the danger can be avoided/bypassed

HBMA0125-4.0 en

Page 8

8

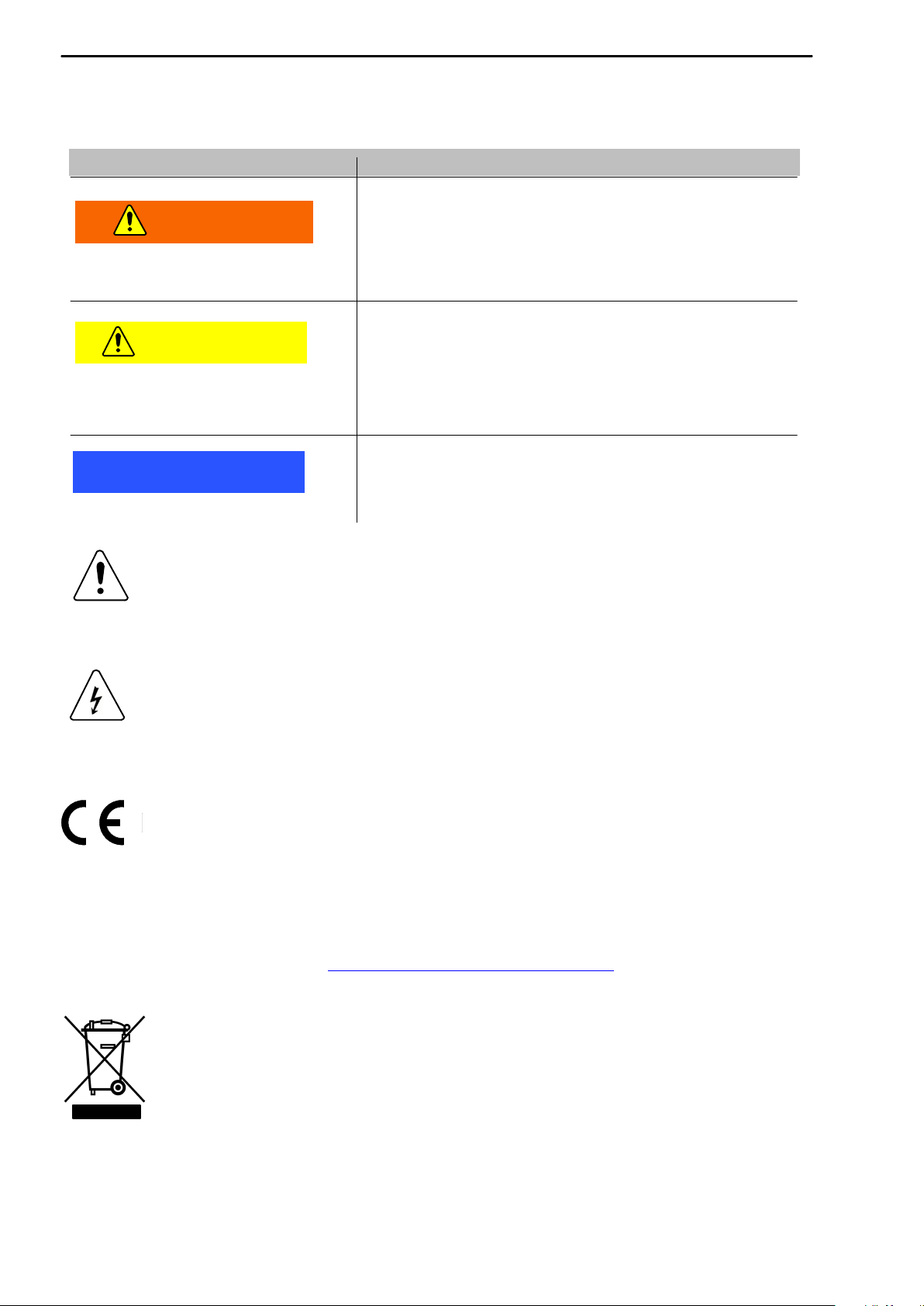

Danger class according to ANSI

Warning sign, signal word Significance

This marking warns of a potentially dangerous

WARNING

CAUTION

NOTE

situation in which failure to comply with safety

requirements can result in death or serious

physical injury.

This marking warns of a potentially dangerous

situation in which failure to comply with safety

requirements can result in slight or moderate

physical injury.

This marking draws your attention to a situation in

which failure to comply with safety requirements

could lead to damage to property.

MVD2510

On the module

Meaning: Take details in the operating manual into account

On the module

Meaning: Disconnect mains supply before opening

On the module

Meaning: CE mark

The CE mark is used by the manufacturer to declare that the product com

plies with the requirements of the relevant EC directives (the Declaration of

Conformity can be found at http://www.hbm.com/HBMdoc

).

On the module

Meaning : Statutory waste disposal mark

The electrical and electronic devices that bear this symbol are subject to the

European Waste Electrical and Electronic Equipment Directive 2002/96/EC.

HBM A0125-4.0 en

Page 9

MVD2510

The symbol indicates that the device must not be disposed of as household

garbage.

In accordance with national and local environmental protection and material

recovery and recycling regulations, old modules that can no longer be used

must be disposed of separately and not with normal household garbage.

If you need more information about waste disposal, please contact your local

authorities or the dealer from whom you purchased the product.

As waste disposal regulations within the EU may differ from country to coun

try, we ask that you contact your supplier as necessary.

Working safely

Note

9

Due to the fact that the device has not been equipped with a proper mains

switch, the supply cable must not be connected directly to the mains. VDE

guidelines require that the device can be disconnected from the mains via a

switching device (double-break disconnector). It is essential that the

disconnector is labeled accordingly and easy to access and operate by the

user.

The supply connection, as well as the signal and sense leads, must be

installed in such a way that electromagnetic interference does not adversely

affect device functionality (HBM recommendation: ”Greenline shielding

design”, downloadable from the Internet at http://www.hbm.com/Greenline

).

Automation equipment and devices must be covered over in such a way that

adequate protection or locking against unintentional actuation is provided

(such as access checks, password protection, etc.).

When devices are working in a network, these networks must be designed in

such a way that malfunctions in individual nodes can be detected and shut

down.

Safety precautions must be taken both in terms of hardware and software, so

that a line break or other interruptions to signal transmission, such as via the

bus interfaces, do not cause undefined states or loss of data in the

automation device.

HBMA0125-4.0 en

Page 10

10

MVD2510

Reconstruction and modifications

HBM’s express consent is required for modifications regarding the MVD2510’s

construction and safety. HBM does not take responsibility for damage

resulting from unauthorized modifications.

In particular, repair and soldering works on the boards are prohibited. If

complete componentry is replaced use original HBM components, only.

The product is delivered from the factory with a fixed hardware and software

configuration. Changes can only be made within the possibilities documented

in the manuals.

Qualified personnel

Qualified personnel means persons entrusted with siting, mounting, starting

up and operating the product, who possess the appropriate qualifications for

their function (qualified electrician, or by someone with electrical training un

der the supervision of a qualified electrician).

This device is only to be installed and used by qualified personnel strictly in

accordance with the specifications and with the safety rules and regulations

which follow.

This includes people who meet at least one of the three following require

ments:

− Knowledge of the safety concepts of automation technology is a

requirement and as project personnel, you must be familiar with these

concepts.

− As automation plant operating personnel, you have been instructed how to

handle the machinery and are familiar with the operation of the equipment

and technologies described in this documentation.

− As commissioning engineers or service engineers, you have successfully

completed the training to qualify you to repair the automation systems.

You are also authorized to activate, to ground and label circuits and

equipment in accordance with safety engineering standards.

It is also essential to comply with the legal and safety requirements for the ap

plication concerned during use. The same applies to the use of accessories.

Important

The safety instructions are also included in paper format with the product

("Documentation and Safety instructions PMX" A3260-2.0).

HBM A0125-4.0 en

Page 11

MVD2510

2 Scope of supply

The scope of supply includes:

D MVD2510 device with two threaded fastening screws

D MVD2510 operating manual incl. a questionnaire

D 15-pin D-plug for transducer connection

D Unit plug-in strip

D 1 terminal-strip plug (9 pins) for connection of the control inputs and

outputs, 1 terminal-strip plug (3 pins) for mains connection

3 Introduction

11

3.1 General

The MVD2510 amplifier for panel mounting (to DIN 43 700) enables

measurements from strain-gauge transducers used for industrial weighing

(not legal for trade) applications to be acquired and processed.

Main characteristics:

D Transducers that may be connected: S/G full bridges

D 4 1/2-digit LED display ("19999 Digits) and various special characters

D Operation via foil-type keyboard; single keys can be locked

D 2 limit-value switches

D Control inputs and outputs (electrically isolated by optocouplers)

HBMA0125-4.0 en

Page 12

12

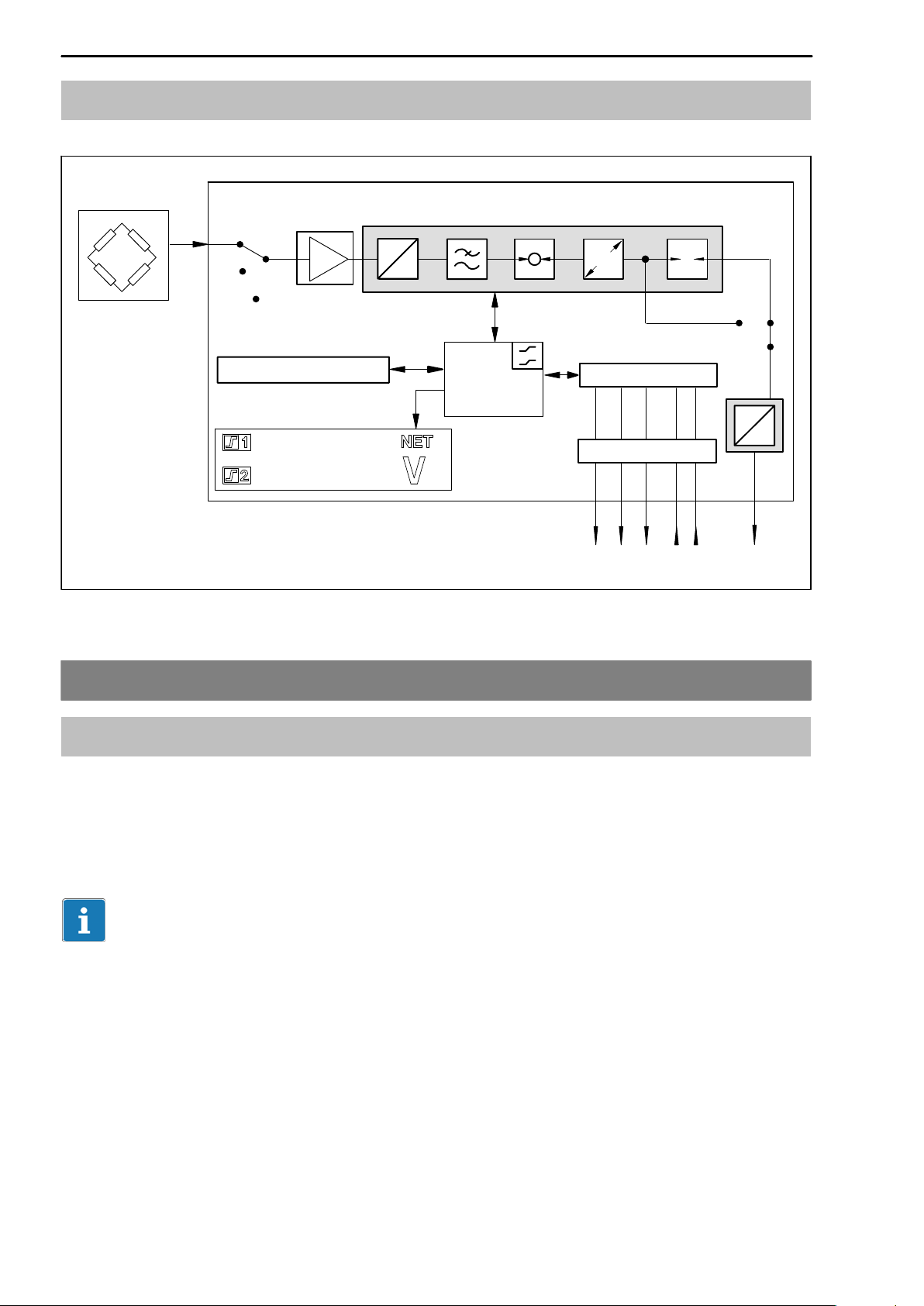

3.2 Block diagram

Measure

MVD2510

Zero

Cal.

Transducers that

may be connected

Parameter memory

+18.750

Fig. 3.1 MVD 2510 block diagram

4 Mounting

A

D

CPU

E

Control signals

Optocoupler

3 out-/2 inputs

T

D

A

UO/I

O

4.1 Read before mounting, factory setups

Before installing the MVD2510 panel amplifier, check the parameters that

have been adjusted at the factory, because the elements required for the

selection of the analogue output signal (current/voltage output) are located on

the board.

Important

The device must be mounted in an EMC-tested control cabinet with line filter

(see page LEERER MERKER).

Factory setup:

D Mains voltage: 230 V / 50...60 Hz or 115 V / 50..60 Hz according to your

order

D Analogue output: Output voltage "10 V

HBM A0125-4.0 en

Page 13

MVD2510

13

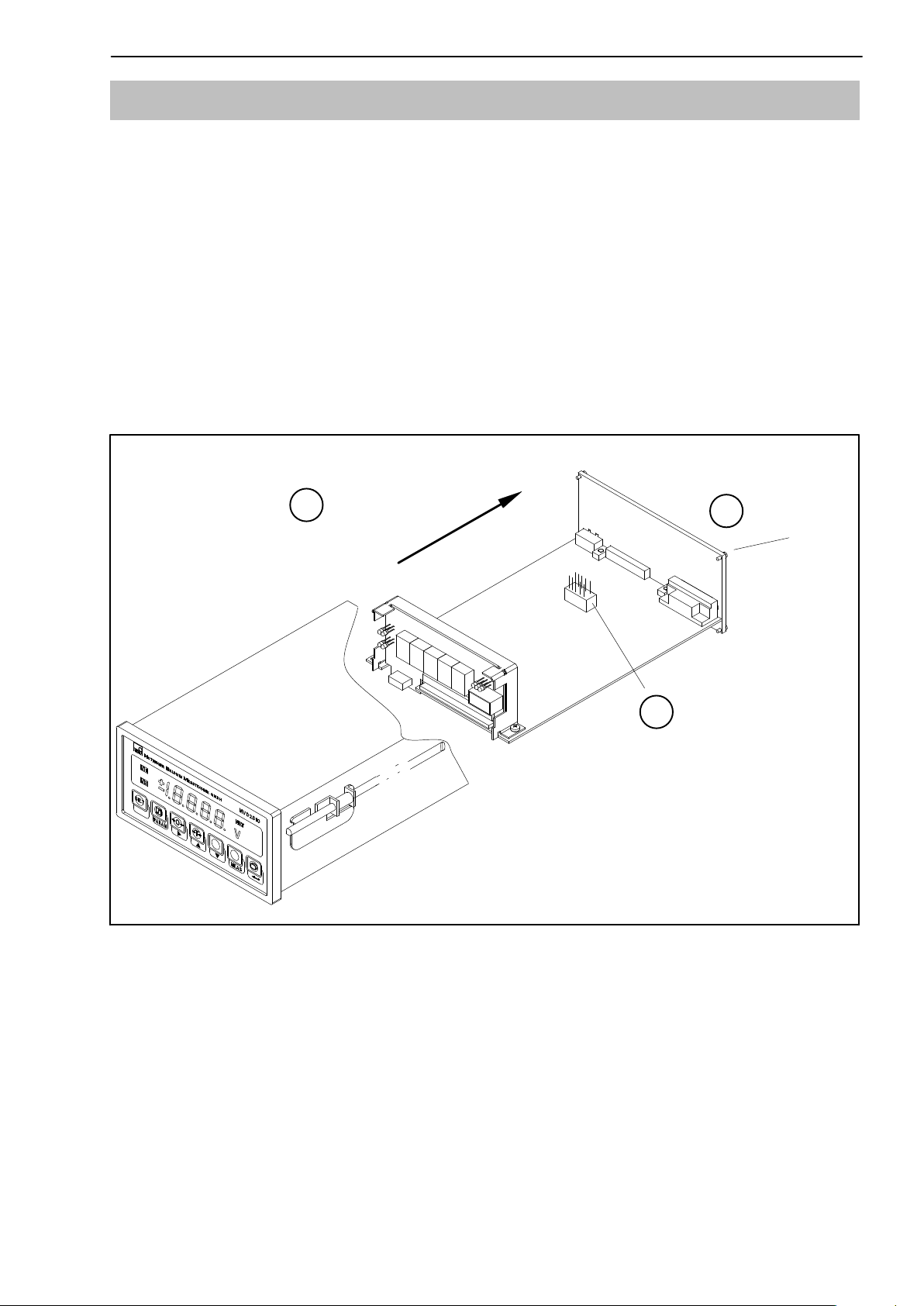

4.2 Change factory setups

Select analogue output signal

To change the factory setup proceed as follows:

1 Slacken the four screws on the housing rear.

2 Carefully pull off to the back the housing rear and the board until the jumper

arrangement is accessible. For this purpose, introduce a screw driver

between connection plate and housing to lift off the device back panel.

3 Use the plug bridges to change the desired setups according to

Fig. 4.2.

4 Insert housing rear and fasten with screws.

2

Pull

backwards

1

Plug-on jumpers ac-

3

cording to fig. 3

Slacken

screws (4x)

Fig. 4.1: Change factory setup

HBMA0125-4.0 en

Page 14

14

MVD2510

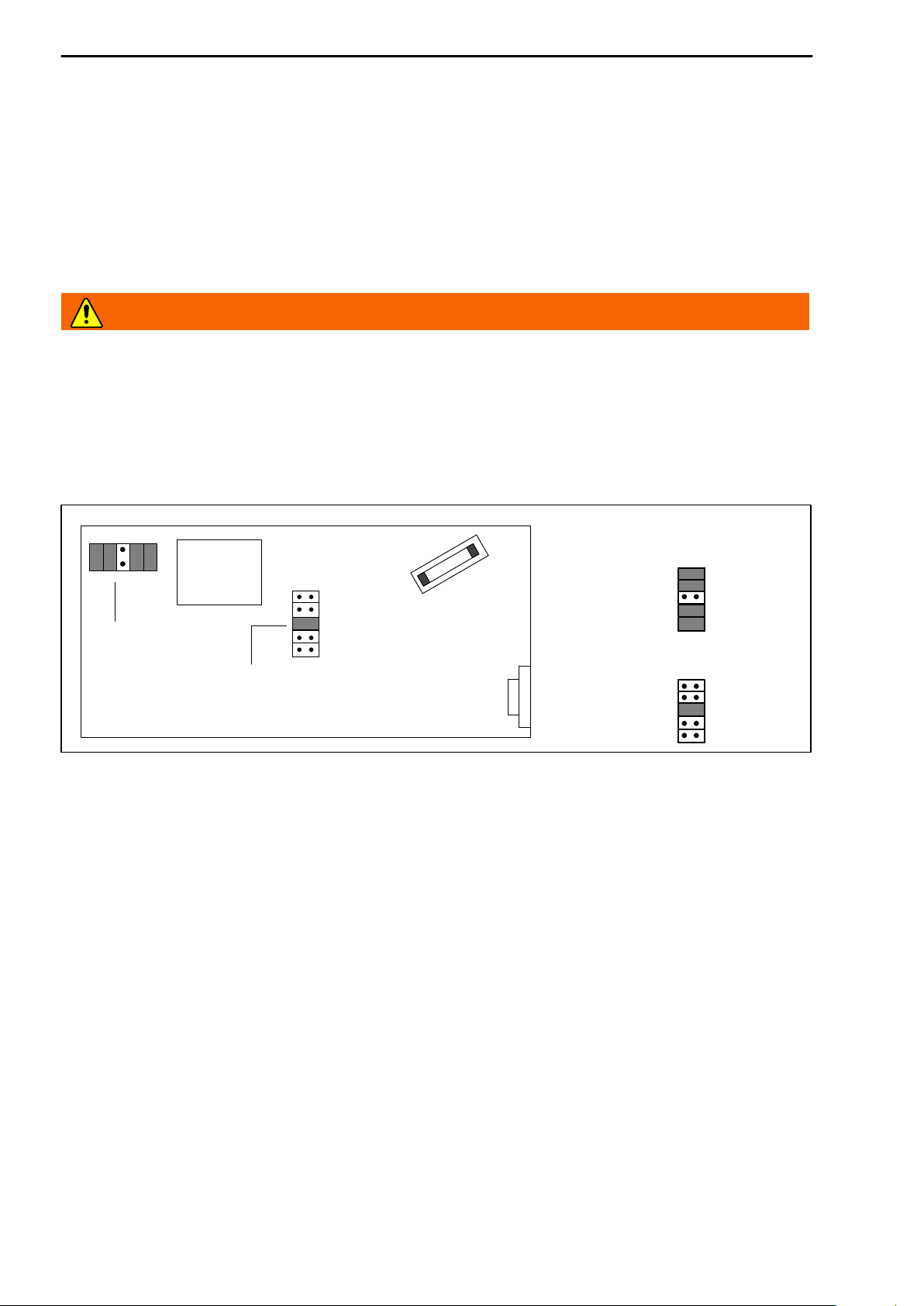

4.2.1 Adjust analogue output signal

Change the position of jumper ST5 to select the analogue output signal

(voltage or current), see Fig. 4.2. Enter the dialog mode to select "20 mA or

4...20 mA respectively.

4.2.2 Fuse replacement

WARNING

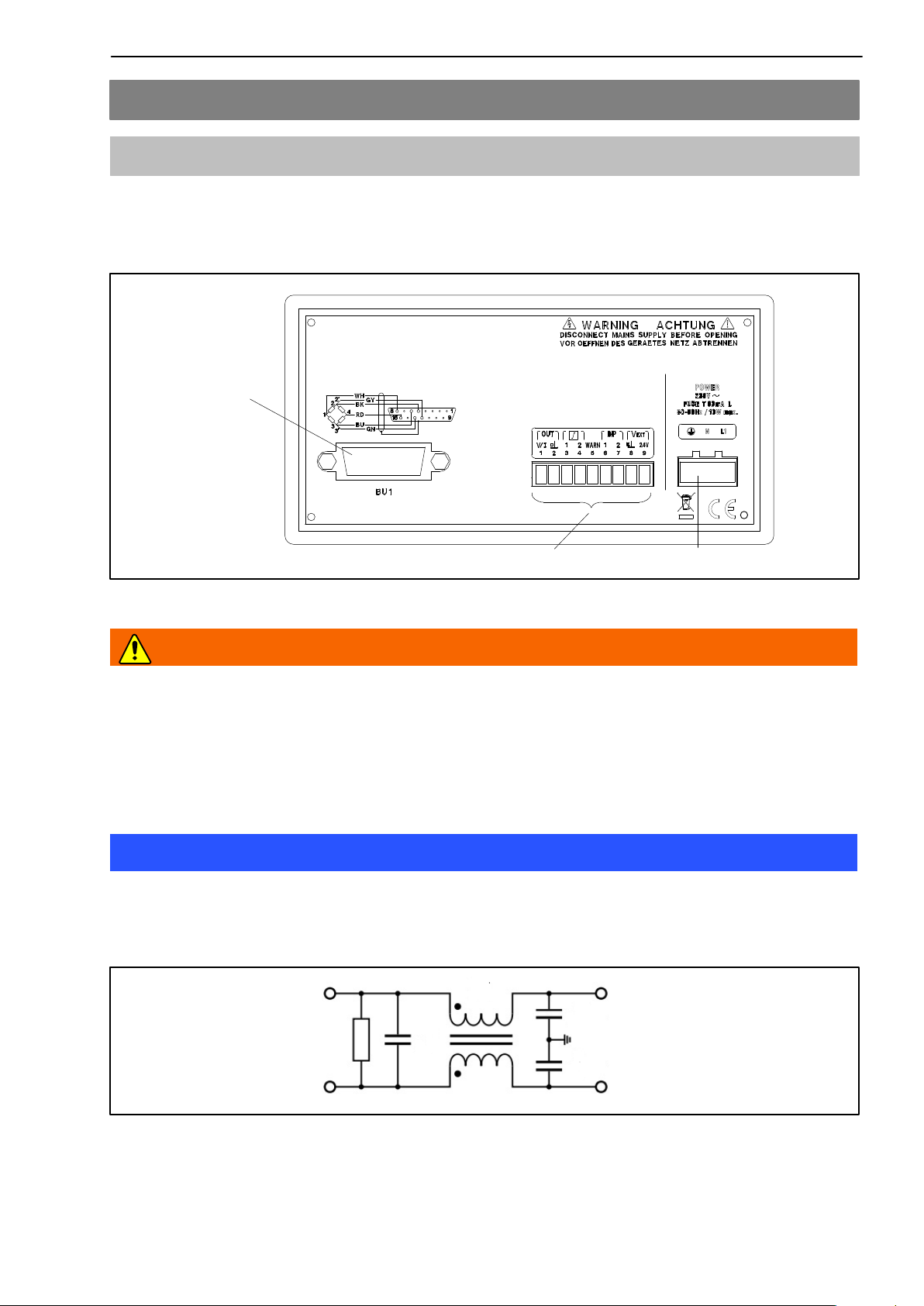

Disconnect the device from the mains supply before opening the MVD2510.

To replace the fuse you have to take off the device rear as described above.

Then, the fuse (230 V/100 mA; 115 V/200 mA) on the board will be accessible

(lift off transparent cap).

Transformer

Fuse

Spare jumpers

Jumper

Fig. 4.2: Position of the jumper and fuse on the board

Analogue output:

Current

ST5

Voltage:

ST5

HBM A0125-4.0 en

Page 15

MVD2510

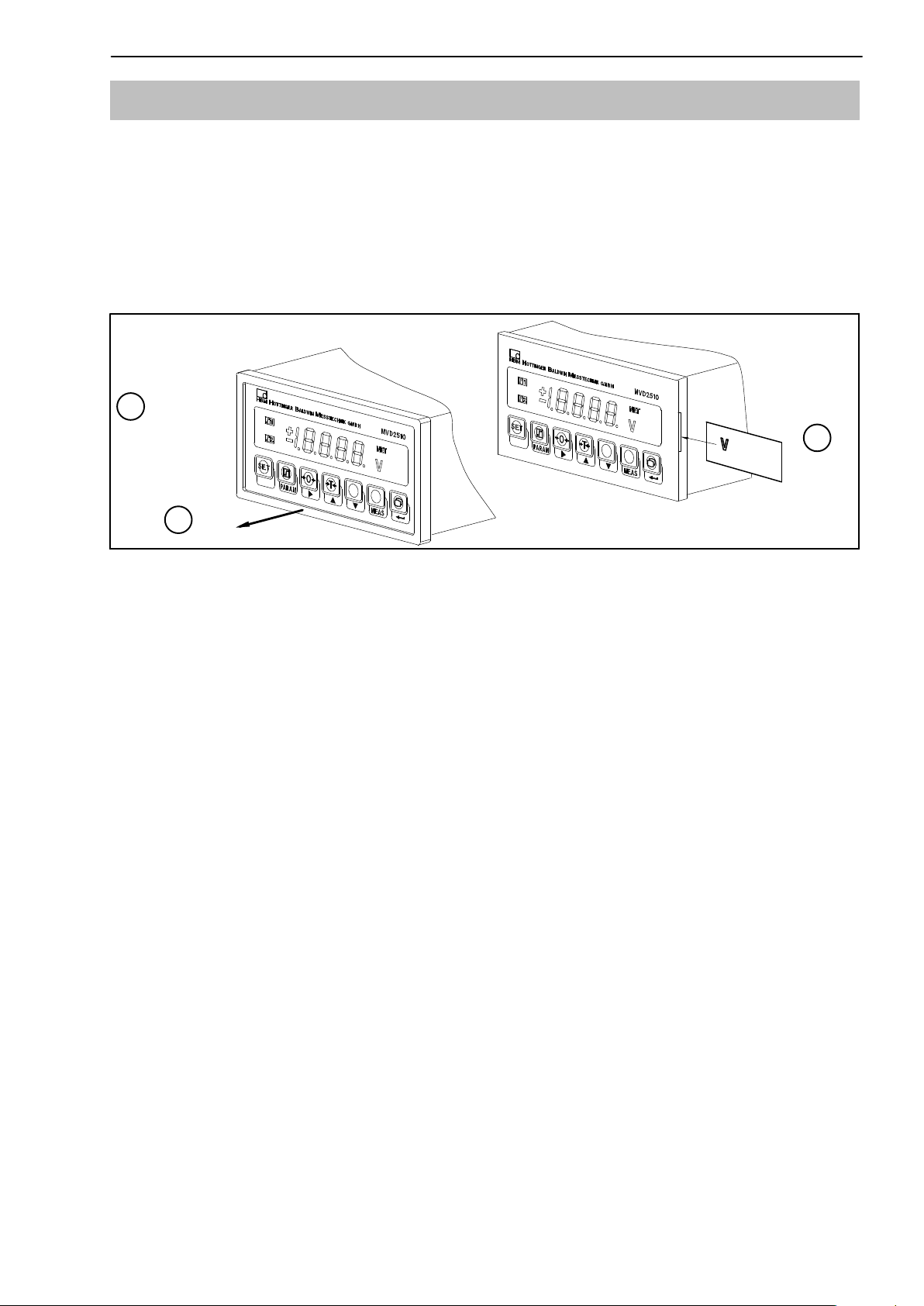

4.3 Insert unit plug-in strip

The unit for display is defined by ready-made plug-in strips that are supplied

with the device.

1 Remove the display’s plastics frame.

2 Insert the required strip into the appropriate cutout.

3 Re-install the plastics frame on the housing.

Insert

unit plug-in strip

1

15

Remove/reinstall

plastics frame

3

2

HBMA0125-4.0 en

Page 16

16

MVD2510

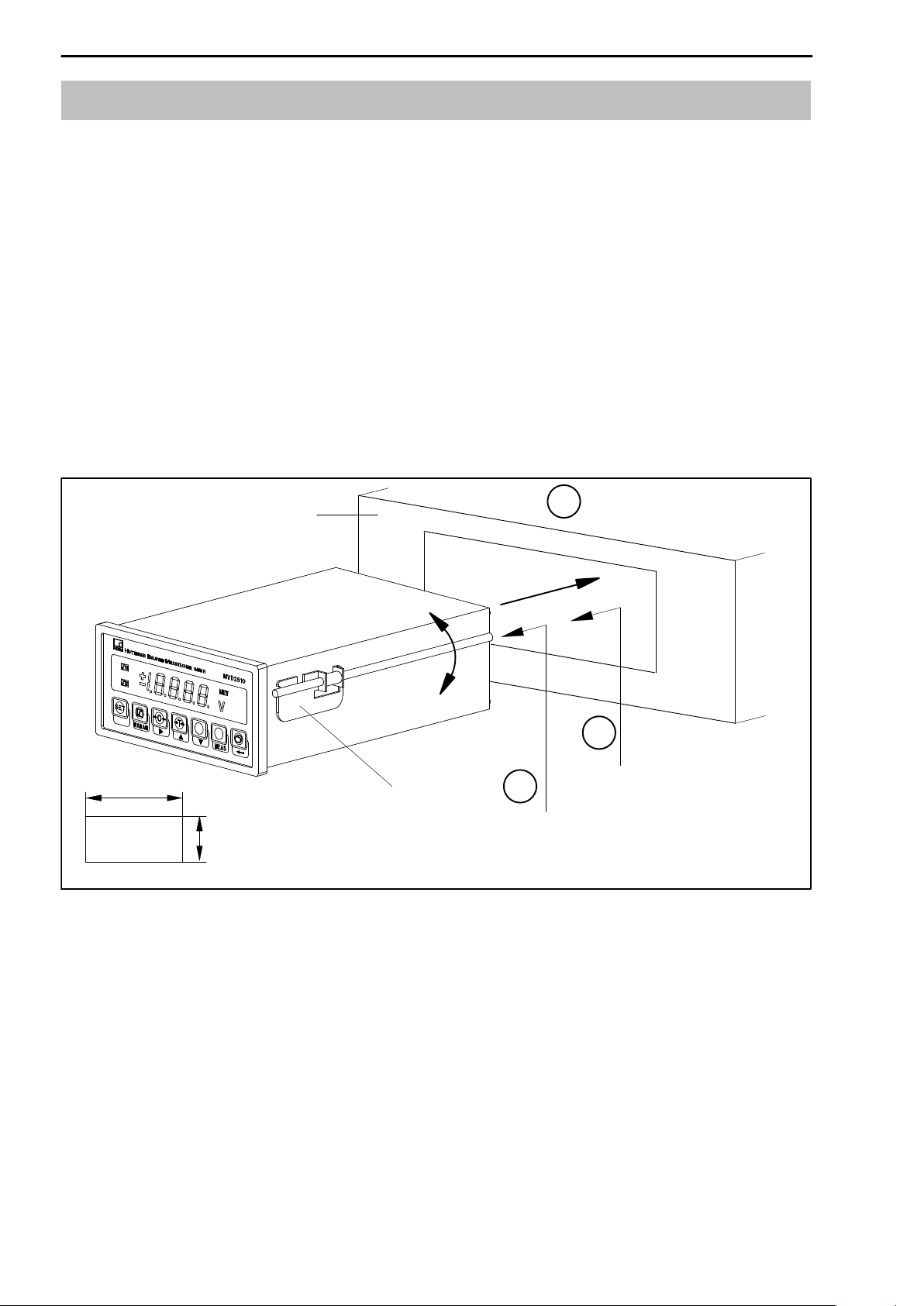

4.4 Install amplifier on control cabinet

The MVD2510 has been designed for panel mounting according to

DIN43 700.

Install amplifier on panel:

1 Turn fastening bow downwards and remove it from housing.

2 Insert housing into panel cutout from the front.

3 Hook in fastening bow on both sides, turn upwards and screw-fasten with

the two threaded rods on the cutout.

4 Then connect the supply voltage to the transducer as described in

chapter 4.

Panel

+1

138

Fastening bow

+0.7

68

Front panel cutout

Fig. 4.3 Install housing on panel

2

1

Hook out

threaded rod

Insert housing into panel

cutout

3

Hook in fastening bow

and screw fasten

HBM A0125-4.0 en

Page 17

MVD2510

5 Electrical connection

5.1 Connect voltage supply

Compare the device’s mains voltage (specified on device rear) to the supply

voltage. If they are not identical, contact your HBM representative.

Transducer-

Transducerconnection

connection

(15-pin D-plug)

(15-pin D-plug)

17

9-pin terminal-strip socket

Fig. 5.1: Device rear

3-pin terminal-strip socket

WARNING

Due to the fact that the device has not been equipped with a proper mains

switch, the connected supply cable may not be connected to mains directly.

According to a VDE recommendation the device must be equipped with a

switching device that can be disconnected from the mains supply.

Note

Ensure that the device is installed in an EMC-tested control cabinet and

connected to a suitable mains filter, e.g. a single-stage filter,

1 ampere with the following structure:

LINE LOAD

HBMA0125-4.0 en

Page 18

18

MVD2510

Mounting of the line filter:

Make sure that the line filter is laid out flat on the inside of the control cab-

inet and that the connecting cables are led directly to the filter’s input connectors.

The filter is laid out flat on the control cabinet.

The contact area needs to be clean and blank.

For more information please refer to the mounting instructions provided by the

manufacturer of the control cabinet.

Connect mains cable:

D Connection to the power supply may only be made in the de−ener-

gized state !

D Use end sleeves for the mains cable’s core ends or twist them.

D Screw the core ends onto the terminal-strip connector (3 pins)

Protective

earth wire

Fig. 5.2: Assignment of terminal strip connector (3−pole)

Neutral

wire

Phase

D Connect terminal-strip connector (3 pins) to mains-connection socket

Note

It is essential that the cables are suitable for the mains voltage. Between the

connectors of the nine- and three-pin terminals, appropriate measures need to

be taken to prevent disturbance voltages. Ensure separate cable routing

between sensor connector (A), signal output (B) and voltage supply (C).

A

HBM A0125-4.0 en

B

C

Page 19

MVD2510

19

5.2 Connect transducers

The MVD2510 enables S/G full-bridge transducers to be connected via a

15-pin D-plug designated BU1 on the housing rear. See the below figures for

the connection diagram.

Six-wire connection

WH

BK

RD

BU

GN

GY

YE

Four-wire connection

WH

BK

RD

BU

8

5

15

6

13

12

Hous

8

5

15

6

Meas. signal (+)

Bridge excitation voltage (−)

Meas. signal (−)

Bridge excitation voltage (+)

Sensor line (+)

Sensor line (−)

.

Cable screen

Use HBM standard cable for transducer

connection. When using other screened,

low-capacitance cable types connect the

transducer cable screen to the plug housing

according to the HBM Greenline information,

thus ensuring optimum EMC protection.

NOTE

BU 1

Transducer

connection-socket

8

15

1

9

13

12

YE

Feed-back bridges in the transducer

Cable-core colours: WH= white; BK= black; BU= blue; RD= red; YE=yellow; GN= green;

GY= grey

Hous

.

Fig. 5.3 Transducer connection

HBMA0125-4.0 en

Page 20

20

Transducer 1

Transducer 2

.

.

.

4 transducers

maximum

ye

ye

gy

gy

gn

gn

bu

bu

rd

rd

bk

bk

wh

wh

MVD2510

Route the two cable

cores together as

close as possible to

the transducer

wh

bk

rd

bu

gn

8

5

15

6

13

gy

80 ... 5000

ye

12

Geh

Cable core colours: wh=white; bk=black; bu=blue; rd=red; ye=yellow; gn=green;

gy=grey.

Fig. 5.4: Connection of parallel−wired transducers

.

HBM A0125-4.0 en

Page 21

MVD2510

21

5.3 Analogue output, Control inputs/outputs

The analogue output signal is present at terminals 1 and 2 as voltage ("10 V)

or current (0..."20 mA or +4...+20 mA).

Use the plug bridges (jumpers) on the amplifier board to select current/voltage

as described in chapter 3.2.1.

Refer to the below table

for the terminals 1 to 9

Analogue output signal

Input/Out-

put

Terminal

1

2

3

4

5

6

7

8

9

Function

Output signal (V/I)

Output signal (ground)

Output limit-value1

Output limit-value2

Output Warning (Overflow)

Input control-contact1

(Function selectable)

Input control-contact2

(Function selectable)

Ground (control outputs)

Supply voltage (control

outputs)

"10 V,"20 mA; +4.. 20 mA

With positive logic corresponding to

24 V

V

ext.

Warning active for overflow and

autocal.

24 V = OK

0 V = Warning

see table on page 38

V

0 V

ext.

V

24...30 V*

ext.

Note

The connections of the analog output voltage or current must be shielded .

and the shielding must be connected to an EMC-tested control cabinet.

The connection cables of the I/Os (Warning, LIV 1/2, INP 1/2, Ground, V

ext.

must not be longer than 30 m and may be laid only inside closed buildings.

)

HBMA0125-4.0 en

Page 22

22

MVD2510

MVD2510 PLC

3

9

8

Fig. 5.5: Output configuration

max. 0,5 A

4

24 V*

0 V

External supply voltage for control

Relay

max. 0,5 A

24 V*

0 V

outputs

WARNING

The control inputs and outputs on the terminal-strip socket (9 pins) are electrically isolated by optocouplers. The control outputs must be supplied with an

external DC voltage (ground and 24 V) and must have protective separation

from the mains (safety extra low voltage as per EN 61140 and IEC 61140 respectively; safety transformers as per EN 6155826 and IEC 6155826 respectively).

6 Adjustments and operation

6.1 Start-up and factory setups

Below we have listed some steps to be taken before starting up your

measuring system (panel amplifier and transducer) and to enable a first

functional test for all components to be made. This section mainly describes

the adaptation of the MVD2510 to the transducer type used. In addition, some

errors are mentioned that typically occur during device start-up.

D Install the device on your panel (see page 16)

D Proceed as described in chapter 4 to connect the mains cable and the

transducer to the panel amplifier.

CAUTION

Observe the safety instructions!

HBM A0125-4.0 en

Page 23

MVD2510

D Connect the device to mains via an external switching device (mains

switch).

D The device makes a functional test and then enters measure mode. The

factory setups are activated.

Ex-works setting: The measurement range is set to a sensitivity of 2 mV/V

and a display full−scale value of 10000 digits (see table on page 51).

SET

D Press

. The ex-works setting is loaded.

Note

If the OFL error message is displayed, this may have the below reasons:

23

− No six-wire feedback line connected

− Transducer/sensor not connected correctly

− No transducer/sensor connected

Remedy: Switch device off. Connect the transducer correctly. Switch device

on again.

D Use the

key to select the gross signal (NET is not displayed).

The device is now ready for operation. Carry out your settings, following

Chapters 5 and 6.

HBMA0125-4.0 en

Page 24

24

MVD2510

6.2 Device operation and survey of keyboard functions

The operating concept differentiates between two types of key functions:

− keys that are effective during the measurement mode and

− keys that are effective in the programming mode.

Each function key for Measure mode can be locked individually to prevent

undesired key operation (see page 33).

Here also, a password may be entered to prevent undesired modifications.

Interchangeable

unit symbols

Measurement

display,

Parameter

display

Mode line

SET

Change

operating

mode

SET

Adjust

limit-

value level

Measure mode

TareZero

Programming mode

MVD2510

Change

display

Change

operating

mode (2sec)/

Select group

HBM A0125-4.0 en

Parameter

selection

Display

adjusted

value/Select

digit

parameters/Change

Select

digit

Measure

input

signal

Confirm

Page 25

MVD2510

6.3 Functions in Measure mode

If necessary, all keys/functions in Measure mode may be locked to prevent

unauthorized manipulation.

Key Meaning

25

SET

Permits to change from the Measure to the Programming mode

(and vice versa) when pressed for about 2 sec.

Enables the limit-value levels (LIV1, LIV2) to be adjusted (see

next page). The other limit-value parameters such as hysteresis,

direction etc. are not changed. To enable changes to the

limit-value level use LIV1,2/(b.Li) key (see page 33).

Is used for system zero-balance (also possible with control

contact).The signal present at the input is taken as zero point.

Starts taring(also possible with control contact).

The currently present measurement is used as tare value.

Changes measurement display between:

Gross value no display identification

Net value ”NET” is displayed

HBMA0125-4.0 en

Page 26

26

6.3.1 Adjust limit-value levels in the Measure mode

There are two possibilities for the selection of the limit-value level:

a) Enter numerical value for limit-value levels (Li)

Li1L (Limit value 1)

The limit-value level entered last will

be displayed.

The first number flashes. If LOCK appears, the limit level is blocked.

Adjust the desired value

MVD2510

Save changes buffered against mains

failure

Confirm

Li2L (Limit value 2)

The limit-value level entered last will

be displayed.

The first number flashes. If LOCK appears, the limit level is blocked.

Adjust the desired value

Confirm

Do not save changes buffered against

mains failure

SET

SET

HBM A0125-4.0 en

Press 2 sec,

STOR will be displayed

dOnE will be displayed

Li1L and Li2L are saved buffered against mains

failure; the device changes to the Measure mode

SET

SET

Press 2 sec,

STOR will be displayed

The device changes

to the Measure mode

Page 27

MVD2510

b) Accept signal present at the input as limit-value level

Li1L (Limit value 1)

The limit-value level entered last will

be displayed.

27

Save changes buffered against mains

failure

MEAS

The signal present at the input will be

displayed

Confirm. The applied input signal is

accepted as the limit level.

Li1L (Limit value 2)

The limit-value level entered last will

be displayed.

MEAS

The signal present at the input will be

displayed

Confirm. The applied input signal is

accepted as the limit level.

Do not save changes buffered against

mains failure

SET

SET

Press 2 sec,

STOR will be displayed

dOnE will be displayed

Li1L and Li2L are saved buffered against mains

failure; the device changes to the Measure mode

SET

SET

Press 2 sec,

STOR will be displayed

The device changes

to the Measure mode

HBMA0125-4.0 en

Page 28

28

MVD2510

6.4 Programming mode

In the Programming mode and 2 are flashing alternately.

This Operating mode enables all amplifier setups required for your application

to be made. The parameters are grouped and codes are used for the group

names.

Meaning of the keys:

Change operating mode, select group (e.g. CAL)

SET

PAR

Parameter selection (e.g. INdc)

The below three keys enable numerical values to be displayed

or entered.

To display the value adjusted last. Press the key to select the

desired digit.

To change the digit in ascending sequence.

To change the digit in descending sequence.

Measures input signal.

MEAS

Confirms entry/change.

HBM A0125-4.0 en

Page 29

MVD2510

6.4.1 Change from the ”Measure” to the ”Programming” mode

29

D Press

SET

for approx. 2 s.

The device changes from the ”Measure” to the ”Programming” mode if the

password is 0000. This applies for the factory setup; dIAL will be displayed.

If a password has already been entered (different from 0000), then CodE

appears in the display on changing to ”Program”, i.e. the password is demanded.

Entering present password:

CodE is shown in the display.

D Press

D Enter the valid password (four−figure number) with

2x, the first number flashes

D Use to confirm.

Upon entry of an unknown password, the device is reset to Measure mode.

With the correct password, the first parameter group dIAL will be displayed.

HBMA0125-4.0 en

Page 30

30

6.4.2 Programming

Operation in the Programming mode

a) Select the value/parameter from a predefined table (Example

dIAL-LAnG)

MVD2510

D Use

D Use

D Press

SET

to select the group dIAL.

PAR

to select the parameter LAng

. The currently adjusted parameter will be displayed (e.g.

dEut).

D Use

and to select the new parameter (e.g. EnGL). The

parameter change is signalled by display flashing.

D Use

to confirm.

b) Enter a numerical value as parameter (Example CAL-rnGE)

SET

D Use

D Use

to select CAL.

PAR

to select the parameter rnGE

D Press

displayed.

D Press

digit.

D Use

D Use

. The measuring range in mV/V selected last will be

until the first digit is flashing; press again to select the next

and to adjust the desired value.

to confirm.

HBM A0125-4.0 en

Page 31

MVD2510

c) Accept transducer signal at defined load (Example CAL-rnGE)

31

D Use

SET

PAR

D Use

D Press

displayed.

MEAS

D Press

D Press

digit.

D Use

and to adjust the desired measuring range

(predefined load).

D Use

to confirm. The measuring range in mV/V selected last will

be displayed.

to select CAL.

to select the parameter rnGE

. The measuring range in mV/V selected last will be

(display with the selected unit).

until the first digit is flashing; press again to select the next

The setup procedure as described in c) is only permissible for the

adjustment of zero value, measuring range and limit-value levels.

6.4.3 Change from the ”Programming” to the ”Measure” mode

When changing parameters the device queries whether the changed parameters should be saved buffered against mains failure.

D Press

SET

for about 2 sec.

The device displays STOR to determine if the change is to be saved or not:

Save change: Press

. dOnE will be displayed. Press

SET

. The device

changes to Measure mode.

Do not save change: Press

SET

. The device changes to Measure mode.

CAUTION

The settings are only saved buffered against mains failure when they have

been saved under one of the parameter sets.

HBMA0125-4.0 en

Page 32

32

6.5 Information on groups and parameters

MVD2510

PAR

diAL

(Dialog)

LAnG

Language

COdE

Password

b.Li

Parameters

Taste GW

SET

(Parameter

Zero/Tare

PArA

set)

rEcA

Load

Store

Save

Au.St

value

CAL

(Calibra-

tion)

INdc

Nominal

value

dEc.P

Dec.point

StEP

Digit step

Groups

Li.1

(Limit

value 1)

Enable

Source

Direction

FrEE

Sour

dIr

Li.2

(Limit

value 2)

I−O

(Input/Out-

put)

A.SIG

Output

signal

U_I

U/I

tESt

Test

InFO

(Addi-

tional

function)

P_ _

Firmware

PXX

b.ZEr

Zero key

b.tAr

Tare key

b.SIG

Signal

key

6.5.1 Dialog (dIAL)

Select language (LAnG)

zEro

Zero value

rnGE

Measuring

range

tArA

Tare value

FILt

Filter

Li.Le

Level

HYSt

Hysteresis

LoGc

Logic

bu.Li

Limit-value key

rE.1

Contact 1

rE.2

Contact 2

L_r

Remote

control

The below dialog languages are selectable:

dEUt German

ENGL English

FrAN French

HBM A0125-4.0 en

Page 33

MVD2510

33

Set password (CodE)

When changing from Measure to Program, the password is demanded (see

page 29).

The password guards against unauthorised MVD2510 operation. Parameters

can only be changed when the valid password is entered. A change of password is possible if the old password is known.

coDE Function

0000 no password; factory setup

001 ... 9999 password adjusted

Enable/lock keys (b.Li, b.ZEr, b.tAr, b.SIG)

LIV key (b.Li): may be enabled (FrEE) or locked (LOCK)

Zero key (b.ZEr): may be enabled (FrEE) or locked (LOCK)

Tare key (b.tAr): may be enabled (FrEE) or locked (LOCK)

SIGN key (b.SIG): may be enabled (FrEE) or locked (LOCK)

6.5.2 Load/Save in parameter set (PArA)

The device setups (factory setup or parameter set 1) can be stored in an

EPROM that is protected from power failure and can be loaded if required.

When changing from Programming to Measure with changed parameters

there is a prompt asking if the changed parameters are to be stored.

rECA: To load parameter set 1 (PAr.1) or factory setup (SEtu)

Stor: To save parameter set 1 (PAr.1)

Au.St: Zero value/Tare value OFF or ON:

OFF Zero and tare values are lost during a mains failure

ON Zero and tare values are also retained during a mains failure

HBMA0125-4.0 en

Page 34

34

MVD2510

6.5.3 Calibration (CAL)

Nominal value (INdc)

The transducer’s full scale can be adjusted (Scale range "19999). A full

scale value (e.g. 10.000 KN) is assigned to an input-signal range, e.g. 2 mV/V.

Decimal point (dEc.P)

The decimal-point position is changed.

Selectable positions

.0000 0.000 00.00 000.0 0000

Step width (StEP)

Here, the step width or the digit step can be selected.

Selectable step widths

1 2 5 10 20 50 100 200 500 1000

Zero value (zEro)

A value for the measuring system’s zero balance is adjusted (unit mV/V).

Possible input: From "0.2 ... 3.8 mV/V.

Meas. range(rnGE)

A full-scale value (unit mV/V) can be adjusted. If the adjusted value is not

within the input range, the minimum or maximum permissible value will be adjusted:

Possible input: From "0,2 ... 3,8 mV/V.

Tare value (tArA)

A tare value (related to full-scale) can be defined.

Example: Displayed value 10.000 kg is tared to 5.000 kg.

Filter (FILt)

Various low-pass filters (Bessel characteristic) can be selected.

Filter frequency (Hz)

HBM A0125-4.0 en

0,05 1,0

0,1 2,0

0,2 5,0

0,5

Page 35

MVD2510

6.5.4 Limit values (Li1, Li2)

The parameters for limit-value adjustment are grouped for each limit value.

The limit values’ state is indicated on the display and transmitted via control

outputs.

The below figure illustrates the limit values’ function and the parameters:

Li1

Direction POS

Switch on

Switch off

Switching level

Hysteresis value

35

Direction NEG

Li1 Logic POS

Li2 Logic POS

Switch on

Li2

24 V

0 V

24 V

0 V

Switch off

Hysteresis value

Switching level

Fig. 6.1: Functions and parameters for the limit values

Enable/Lock limit values (FrEE)

The limit values can be enabled (EIn) or locked (AUS) individually.

OFF

ON

Inhibit limits individually

Inhibit limits individually

Source (Sour)

Limit value weighting:

groS

nET

Gross value

Net value

Direction (dIr)

Here, the switching direction or the operating direction is specified (see

Fig. 6.1).

POS

nEG

positive Switch−on threshold higher than switch−off threshold for

increasing measurement

negative Switch−off threshold higher than switch−on threshold for

decreasing measurement

HBMA0125-4.0 en

Page 36

36

MVD2510

Level (PEGL)

The level is adjusted in display units (e.g. 2.000 kg).

Hysteresis (HYSt)

The hysteresis is entered to prevent a ”fluttering” of the limit-value switch

when the switching threshold is reached. The hysteresis results from the

differential between switch-on and switch-off threshold.

A value is set in display units, e.g. 0.200 kg.

Output logic (LoGc)

The control contacts’ output logic can be modified as desired. The below

definition is valid:

POS

NEG

positive Switch on = High

Switch off = Low

negative Switch off = High

Switch on = Low

Limit-value key (buLi)

A limit-value-level modification with

(LOCK).

can be enabled (FrEE) or locked

HBM A0125-4.0 en

Page 37

MVD2510

6.5.5 Inputs and outputs (I_O)

This menu enables the setups required for the MVD2510 input signal, the

analogue output and the control contacts to be made.

Output signal(A.SIG)

The output signal weighting:

37

groS

nET

Gross value

Net value

Analogue signal (U_I)

Note

Use jumpers on the amplifier board to select current output or voltage output.

Refer to page 14 for a description of the procedure.

Depending on the selected analogue signal the below options are possible:

Display Meaning

Current

Off OFF −

On 0_20 "20 mA output

4_20 +4.. 20 mA output

Voltage

Off OFF −

On 10 U "10 V output

MVD input signal (tESt)

This function is used to check the internal calibration and zero signals.

The following input signals can be selected:

MES.S

CAL.S

zER.S

Measuring signal Measure mode

Calibration signal A calibration signal (50 %) is connected to the input

Zero signal Ground is connected to the input

HBMA0125-4.0 en

Page 38

38

MVD2510

Control contact 1..2 (rE.1 /rE.2)

You have contacts available on terminals 6 and 7 on the terminal strip socket

(9−pole) for the control of some MVD2510 functions. The control contacts

may be assigned as desired. The factory setup for the contacts is ”No function”.

Function Display Level 0 V/24 V

no function - - - No function (factory setup)

Tare tArA Upon transition 0 V - 24 V tare value is stored

Set zero zEro Upon transition 0 V - 24 V the current input signal is stored as

zero value

Lock

keyboard

bu.Lo 0 V: keyboard not locked; 24 V: keyboard locked

Remote control (StEU)

Remote control can be enabled (ON) or locked (OFF).

OFF

ON

Operation only via keyboard

Operation via keyboard and contacts

6.5.6 Additional function (InFO)

Firmware (P--)

To support you in the case of technical problems, this parameter includes the

firmware version. Please specify the firmware version when contacting our

service department.

Example: P 10 Firmware version P10

HBM A0125-4.0 en

Page 39

MVD2510

7 Example

The below example uses a measurement task to show the device functions

and the required setups.

Measurement task: Filling a container

Containers are filled by weighing on a platform weighing machine. The platform is fitted with a load cell with a measurement range of 100 kg (corresponding to 2 mV/V). The weight of the platform itself is not known, but it is

less than 10 kg. The empty weight of the container is about 10 kg. The containers are placed singly on the platform, tared and filled with 52 kg.

Balancing

Weighing machine adjustment with a partial weight of 50 kg

Platform weighing range (display full−scale value): 80 kg.

39

Number step: 1

Filter setting: 2 Hz

Limits

The container is filled with a net weight of 52 kg (Set value of Li1). If 2 kg

(Limit Li2) is undercut, a signal is produced that there is no container on the

weighing machine (referred to gross value).

The hysteresis for both limits is 0.5 kg.

Changes to the Li1 limit threshold should be able to be carried out by the op-

erator using the direct key

ons.

Other details

In order to prevent unauthorised changing of the parameters, the access to

the settings is only possible with a password (e.g. 1510).

The net signal should be available as an analogue signal (4...20 mA).

Changing of the zero point via the keyboard should not be possible.

. Limit 2 should not be changed for safety reas-

Taring is carried out via the external Control Contact 1 or with

second contact has no function. Remote control is not provided. The zero

point and tare values should be saved buffered against mains failure.

. The

HBMA0125-4.0 en

Page 40

40

MVD2510

Explanation of symbols

Group

Parameter

Select number

old setting

new value

SET

Press 2 sec

Password query (see page 29)

Dialogue

Change value

CodE

0000

1510

PAR

Password

HBM A0125-4.0 en

Page 41

MVD2510

41

PAR

b.ZEr

FrEE

LOCKED

PAR

b.tAr

LOCKED

FrEE

Zero key

Tare key

SET

PAR

Au.St

OFF

ON

Changing group

Parameter set

Zero/Tare value

HBMA0125-4.0 en

Page 42

42

MVD2510

INdc

10000

8000

SET

PAR

Changing group

Calibration

Nominal value

PAR

PAR

dEc.P

dEc.P

0000

0000

00.00

PAR

dEc.P

StEP

Dec.point

Digit step

0100

0001

HBM A0125-4.0 en

Page 43

MVD2510

43

PAR

0.135

00.00

0.200

nuLL

Zero value

Load removed from weighing machine

Zero value in mV/V (old)

MEAS

Full scale value in kg (new)

Zero value in mV/V (new)

PAR

rnGE

Measuring range

2.000

80.00

50.00

1.600

Weighing machine loaded with partial load of 50 kg

Measuring range in mV/V (old)

MEAS

Display value in kg (new) as

set under INdc

Partial load value in

kg

Display in mV/V referred to nominal value

HBMA0125-4.0 en

Page 44

44

MVD2510

PAR

dEc.P

FILt

1.0

2.0Hz

SET

PAR

Filter

Changing group

Vimit value 1

dEc.P

FrEE

OFF

ON

Enable/Lock

HBM A0125-4.0 en

Page 45

MVD2510

PAR

PAR

45

qUEL

GROSS

nET

PAR

dIr

nEG

POS

Gross/Net

Switching direction

PAR

Li.Le

10.00

52.00

Limit value 1

HBMA0125-4.0 en

Page 46

46

PAR

PAR

dEc.PqUEL

dEc.PHYSt

0000

0.50

PAR

MVD2510

Hysteresis

LoGc

NEg

POS

PAR

bu.Li

LOCKED

FrEE

Control cantacts

output logic

Change via Lim key

HBM A0125-4.0 en

Page 47

MVD2510

47

SET

PAR

dEc.P

FrEE

OFF

ON

PAR

Changing group

Limit value 2

Enable/Lock

dEc.PqUELdEc.PSour

GROSS

nET

PAR

dIr

POS

nEG

Gross/Net

Switching direction

HBMA0125-4.0 en

Page 48

48

MVD2510

PAR

PEGL

00.00

02.00

PAR

HYSt

0000

00.50

Limit value 2

Hysteresis

PAR

LoGc

NEG

POS

Control cantacts

output logic

HBM A0125-4.0 en

Page 49

MVD2510

49

PAR

bu.Li

LOCKED

FrEE

SET

PAR

Change via Lim key

Changing group

Input/Output

dEc.PA.SIG

GROSS

nET

PAR

dEc.P

U_I

0-20mA

4-20mA

Outpit signal

Analog signal

NOTE

Use plug bridges on the

amplifier board to select

current output or voltage

output. Refer to page 14 for a

description of the procedure.

HBMA0125-4.0 en

Page 50

50

MVD2510

PAR

tESt

CAL.S

MES.S

PAR

rE.1

- - - -

tArA

Input signal

Control contact 1

OFF

ON

PAR

L_r

SET

Remote control

Press 2 sec

HBM A0125-4.0 en

Page 51

MVD2510

8 Displays and ex-works settings

Display Meaning Factory setup

dIAL Operating dialogue

LanG Dialog-Language dEut

CodE Password 0000

b.Li Limit value key FrEE

b.ZEr Zero key FrEE

b.tAr Tare key FrEE

b.SIG Signal key FrEE

PArA Parameter set

rEcA Parameter set or factory setup SeTU

Store Store Parameter set PAr.1

51

Au.St Zero value and Tare value OFF

CAL Calibration

INdc Nominal value 10.000

dEc.P Decimal point 0.000

StEP Step width 0001

zEro Zero value 0.000 mV/V

rnGE Measuring range 2.000 mV/V

tArA Tare value 0.000

FILt Filter 5.0 Hz

Li1/Li2 Limit values 1, 2 Li1 Li2

FrEE Enable OFF

Sour Source of Input signal GROSS

dIr Switching direction POS nEG

PEGL Level in display unit 10.000 -10.000

HYSt Hysteresis 1.000

LoGc Control contacts output logic POS

bu.Li Limit value key FrEE

HBMA0125-4.0 en

Page 52

52

I_O Input/Output signals

A.SIG Source of Output signal GROSS

U_I Analog signal 10 V

tEST Input signals MES.S

rE.1 Control contact 1, 2 ---

L_r Remote control ---

InFO Additional functions

P__ Firmware

9 Error messages

MVD2510

Error message Reason Remedy

LOCKED The specified value cannot

be changed.

OFL Transducer/sensor not

connected properly:

No transducer/sensor

connected

No six-wire feedback line

connected

Fehl Transmission error upon

storage

1---- Display value exceeded,

amplifier not yet overloaded

Knfl Setup does not match

hardware setup

Key is locked Enable key in

No key reaction

Enable limit-value change

Connect the transducer

properly. Switch off device

and switch it on again.

-

-

Check and adapt current/

voltage setup

dIAL

b.Li

HBM A0125-4.0 en

Page 53

MVD2510

10 Keyword index

53

A

Accept transducer signal, 31

Adaptation to transducer, 39

Additional function , 38

Adjust limit−value levels, in the Measure

mode, 26

Analogue output, Current, Voltage, 14, 21

Analogue signal , 37

B

Balancing, 39

C

Calibration , 34

Change, factory setup, 13

changing parameters, 31

Error message, 23

Example for measurement, 39

F

Factory seting, 51

Factory setup, 12, 22

load/save, 33

Filter, 34

Firmware, 38

Full scale, 34

Function key , 24

fuse, Position on the board, 14

G

Gross, 23, 25, 37

Gross value, 35

Connection, 18

four−wire technique, 19

Parallel connection, 19

S/G full brige, 19

six−wire technique, 19

Control contact , 38

Control inputs, Configuration, 22

Control outputs, Configuration, 22

Current output, Select, 14

current output , select, 37, 49

D

Decimal point , 34

Device rear, 17

E

Enable/lock, keys , 33

H

Hysteresis, 35

Hysteresis , 36

I

Input signal, 37

Inputs/Outputs , 37

Install amplifier on panel, 16

L

Level , 36

Limit value, 35

Limit−value key , 36

Limit−value level, Change, 36

Limit−value levels , 25

Enable/Lock , limit values , 35

Enter numerical value, 30

Entering present password, 29

Limits, 39

Logic, 21

Logik, 35

HBMA0125-3.0 en

Page 54

54

MVD2510

M

Measure mode, 29, 31

Measure mode , 25

N

Net, 25, 37

Net value, 35

Nominal value , 34

O

Operating concept, 24

Output logic , of the control contacts, 36

Output signal, 37

P

Panel, Installation, 16, 22

panel mounting , 11

Parallel connection, 19

Parameter set, Load/Save, 33

Password, 29, 33

Password , 24

Programming mode, 29, 30, 31

R

Remote control , 38

S

S/G full bridges, Connect, 19

Select language , 32

Select parameters, 30

SET, 25, 28

Start−up , 22

Step width , 34

Switching direction, 35

T

Tare value , 33, 34

Taring, 25

Terminal, 9−pin terminal−strip socket, 21

Terminal allocation, 21

Terminal−strip connector, 18

Terminal−strip socket, 18, 38

plug bridges , 37, 49

plug−bridge arrangement, 13

Plug−bridges

Position on the board, 14

Select current/voltage, 14

Plug−in strips, 15

Programming, 28, 30

V

Voltage output, select, 14, 37, 49

Z

Zero balance, 25

Zero value, 33, 34

HBM A0125-3.0 en

Page 55

MVD2510

55

HBMA0125-3.0 en

Page 56

E Hottinger Baldwin Messtechnik GmbH. All rights reserved.

Subject to modifications.

All product descriptions are for general information only. They are not to be under

stood as a guarantee of quality or durability.

Hottinger Baldwin Messtechnik GmbH

Im Tiefen See 45 S 64293 Darmstadt S Germany

Tel. +49 6151 803−0 S Fax: +49 6151 803−9100

Email: info@hbm.com S www.hbm.com

measure and predict with confidence

A0125−4.0 en 7−2002.0480

Loading...

Loading...