Page 1

Operating manual

Two−channel

Amplifier

Module MP85

A0897-3.4 en

Page 2

Page 3

PME-MP85

3

Content Page

Safety instructions 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Introduction 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Scope of supply and accessories 8 . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 General 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Valuable information about PME MP85 documentation 9 . . . . . . . .

2 Commissioning 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Philosophy of operation 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1 Settings on the device 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.2 Overview of all groups and parameters 14 . . . . . . . . . . . . . . . . .

2.1.3 Configuring parameters on the device 15 . . . . . . . . . . . . . . . . . .

2.2 Configuring the hardware 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1 Voltage supply / Transducer 16 . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.2 Connecting the CAN adapter (LPT and USB) 17 . . . . . . . . . . . .

2.3 Installing the PME Assistant software 18 . . . . . . . . . . . . . . . . . . . . . . .

2.3.1 System requirements 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Starting the software and setting up 19 . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.1 Using the LPT interface 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.2 Using the USB interface 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Switch settings / Replacing the battery 22 . . . . . . . . . . . . . . . . . . . . . . . .

4 MP85/MP85DP mounting/disassembly (schematic diagrams) 24 . . .

4.1 Linking several modules 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Connections 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 MP85 functional overview 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 MP85DP functional overview 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Supply voltage and control inputs/outputs 28 . . . . . . . . . . . . . . . . . . . .

5.3.1 External supply voltage for control outputs 29 . . . . . . . . . . . . . .

5.3.2 Reference potential for control inputs 29 . . . . . . . . . . . . . . . . . . .

5.4 Transducer 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.1 Transducers with carrier frequency excitation 30 . . . . . . . . . . . .

5.4.2 Active encoders 33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 CAN interface 35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6 Profibus interface (MP85DP only) 36 . . . . . . . . . . . . . . . . . . . . . . . . . . .

A0897−3.4 en HBM

Page 4

4

PME-MP85

6 Communication with the control system 37 . . . . . . . . . . . . . . . . . . . . . .

6.1 Timing of the test operations 37 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Transducer test 39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Zero balance 39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 Parameter set switching 40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Error messages/operating status (LED) 41 . . . . . . . . . . . . . . . . . . . . . . .

8 Specifications 43 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Declaration of conformity 49 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 Keyword index 51 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A0897−3.4 enHBM

Page 5

PME-MP85

5

Safety instructions

Appropriate use

The MP85/MP85DP module and its connected transducers are to be used

exclusively for measurement tasks and directly related control tasks. Use for

any purpose other than the above shall be deemed to be not in accordance

with the regulations.

To ensure safe operation, the device may only be operated in accordance with

the information given in the Operating Manual. It is also essential to comply

with the legal and safety requirements for the application concerned during

use. The same applies to the use of accessories.

The device must not be connected directly to the mains supply. The

supply voltage may be 18 to 30 V.

General dangers of failing to follow the safety instructions

The MP85/MP85DP module corresponds to the state of the art and is

fail−safe. The device may give rise to further dangers if it is inappropriately

installed and operated by untrained personnel.

Any person instructed to carry out installation, commissioning, maintenance or

repair of the device must have read and understood the Operating Manual

and in particular the technical safety instructions.

Conditions on site

Protect the device from direct contact with water (IP20).

Maintenance and cleaning

The MP85/MP85DP module is maintenance-free. Please note the following

points when cleaning the housing:

− Before cleaning, disconnect the devices from the power supply.

− Clean the housing with a soft, slightly damp (not wet!) cloth. You should

never use solvent, since this could damage the labelling on the front panel

and the display.

− When cleaning, ensure that no liquid gets into the device or connections.

Remaining dangers

The scope of supply and list of components provided with the MP85/MP85DP

cover only part of the scope of measurement technology. In addition,

equipment planners, installers and operators should plan, implement and

respond to the safety engineering considerationsof measurement technology

in such a way as to minimize remaining dangers. Prevailing regulations must

be complied with at all times. There must be reference to the remaining

dangers connected with measurement technology.

A0897−3.4 en HBM

Page 6

6

Any risk of residual dangers when working with the MP85/MP85DP is pointed

out in this introduction by means of the following symbols:

PME-MP85

Symbol:

Meaning: Dangerous situation

Warns of a potentially dangerous situation in which failure to comply with

safety requirements can result in death or serious physical injury.

Symbol:

Meaning: Potentially dangerous situation

Warns of a potentially dangerous situation in which failure to comply with

safety requirements could result in damage to property or some form of

physical injury.

Symbols indicating application notes and useful information:

Symbol:

WARNING

CAUTION

NOTE

Indicates that important information is given about the product or how to

handle it.

Symbol:

Meaning: CE mark

With the CE mark, the manufacturer guarantees that his product complies

with the requirements of the relevant EC guidelines (see Declaration of

conformity at the end of this operating manual).

Working safely

Error messages must only be acknowledged when the cause of the error has

been removed and no further danger exists.

The instrument complies with the safety requirements of DIN EN 61010, Part

1 (VDE 0411, Part 1) protection class I.

The device must be mounted on a supporting rail connected to the protective

earth potential. Make sure, that at this spot both the supporting rail and the

MP85/MP85DP module are free from dirt and other foreign material.

To guarantee adequate immunity from interference, the buses (CAN and in

the case of MP85DP, Profibus DP) should be run with shielded and twisted

2-wire lines. The transducer lines should also be run using shielded cables.

A0897−3.4 enHBM

Page 7

PME-MP85

The shield of each transducer cable should be connected at the PME end by

as short a line as possible (t5 cm) and a blade connector (4.8 mm;

“Faston”).

The lines to connect the power supply and the digital control inputs and

outputs only need to be shielded if the cable length exceeds 30 m or if the

lines are installed outside closed buildings.

When connecting the lines (clip on and pull off clamps) and when replacing

the MMC, measures must be taken against electrostatic discharge to prevent

damage to the electronics.

The MP85/MP85DP module should be operated at a separated extra−low

voltage (SELV) (supply voltage 18 − 30 V DC) that usually supplies one or

more consumers within a control panel.

1)

If the device is operated on a direct voltage network

, additional precautions

must be taken to discharge excess voltages.

7

Conversions and modifications

The MP85/MP85DP module must not be modified from the design or safety

engineering point of view except with our express agreement. Any

modification shall exclude all liability on our part for any resulting damage.

In particular, any repair or soldering work on motherboards is prohibited.

When exchanging complete modules, use only original parts from HBM.

Qualified personnel

This instrument is only to be installed and used by qualified personnel strictly

in accordance with the technical data and with the safety rules and regulations

which follow. It is also essential to comply with the legal and safety

requirements for the application concerned during use. The same applies to

the use of accessories.

Qualified personnel means persons entrusted with the installation, assembly,

commissioning and operation of the product who possess the appropriate

qualifications for their function.

Maintenance and repair work on an open device with the power on must only

be carried out by trained personnel who are aware of the danger involved.

1)

Distribution system for electrical power with greater spatial expansion (e.g. via several control panels) that

may possibly even supply consumers with high nominal (rated) currents.

A0897−3.4 en HBM

Page 8

8

1 Introduction

1.1 Scope of supply and accessories

Scope of supply:

D 1 module MP85 or MP85DP

D 4 plug−in type screw terminals, coded

1x CAN, 6−pin Order no.: 3.3312−0250

2x transducers, 8−pin Order no.: 3.3312−0299

1x I/O 1, 8−pin Order no.: 3.3312−0301

in addition, for MP85:

1x I/O 2, 8−pin Order no.: 3.3312−0301

D ribbon cable connector 10−pin

D 1 Operating Manual module MP85/MP85DP

PME-MP85

Accessories:

D multimedia card (MMC), e.g. Sandisk (www.sandisk.com)

D standard ribbon cable, 10−pin, grid 1.27 mm

1.2 General

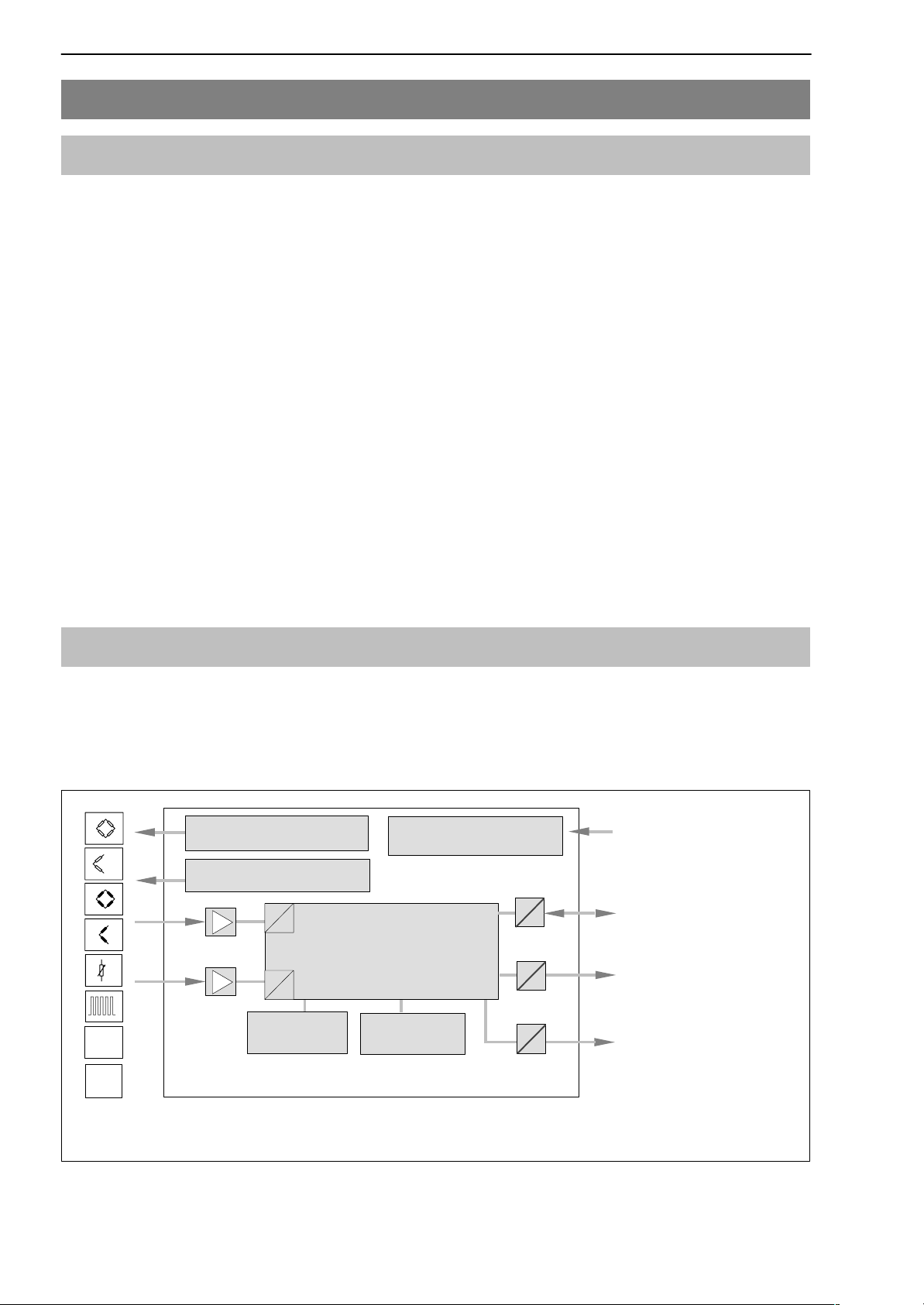

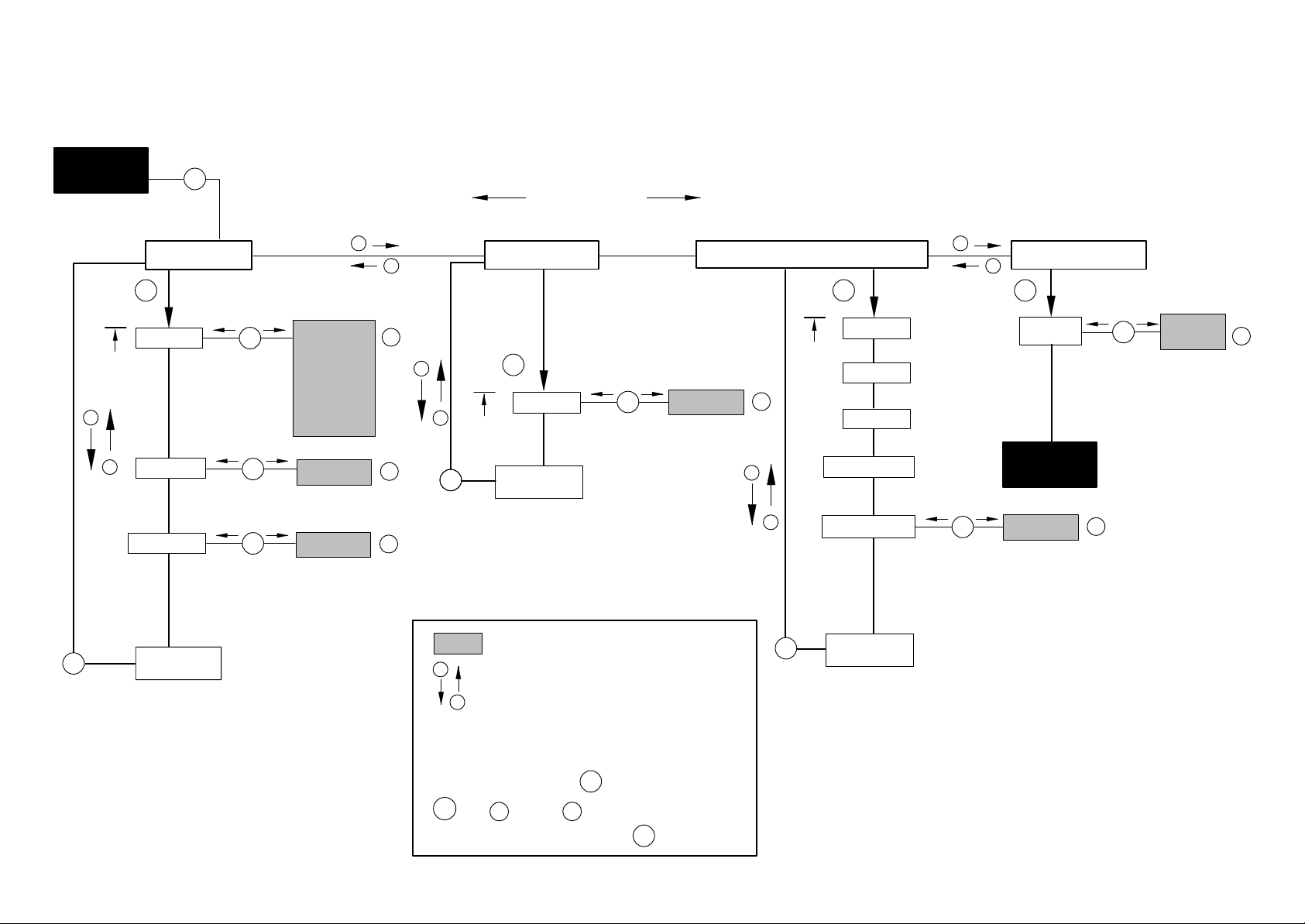

The MP85/MP85DP module from the PME product line is a two−channel

measuring amplifier suitable for connecting the transducers of a great variety

of technologies. In the case of the MP85DP, there is also a Profibus interface

available for CAN-Interface.

Carrier-frequency

excitation voltage 4.8 kHz

Supply for active transducer

5V or 24V

A

D

Intelligent signal conditioning

and powerful algorithms for

A

press-fit monitoring

D

Voltage supply,

electrically isolated

µP

24 V

Control inputs and

control outputs

CANopen

interface

"10V

SSI

Keyboard &

display

MP85 / MP85DP

MMC memory

card

Fig. 1.1: Block diagram of the MP85/MP85DP module

Profibus DP

interface

(for MP85DP)

A0897−3.4 enHBM

Page 9

PME-MP85

The PME Assistant provides a simple user interface under MS-Windows for

parameterizing the modules.

The PME Assistant is the sole means of parameterizing and setting up

the MP85/MP85DP module (described in the Online Help).

To do this you need an LPT → CAN or USB → CAN interface converter, that

has to be ordered separately (1−PMESETUP; 1−PMESETUP-USB).

The software allows you to set all the device parameters apart from the one

for the CAN-BUS interface used for setup.

The software also allows you to set up the other devices of the PME family.

1.3 Valuable information about PME MP85 documentation

MP85 documentation comprises

9

• this Operating Manual,

which describes mainly the configuration of the hardware (transducer,

device and PC with the software).

• the Online Help of the PME Assistant

which describes how to use the software to set up the device

• a separate Operating Manual for the MP85DP with a CAN object index,

CAN interface description and Profibus communication

A0897−3.4 en HBM

Page 10

10

PME-MP85

2 Commissioning

To prepare the MP85 measurement system for a measurement task, the

following conditions must be met or the relevant steps taken:

• You need a PME module MP85 or MP85DP and the PME Assistant,

including software

• The hardware must be configured (transducer, device, PC with the

software) (from Page 16)

• The PME Assistant software must be installed (from Page 18)

• To connect the PME module to a PC, you need a CAN adapter (from Page

17)

− PCAN parallel interface LPT to CAN or

− PCAN USB to CAN or

− PCAN card (PCI or ISA) to CAN

• The PME module must be connected to the CAN adapter

• Once you have started the software, you can set up the PME module with

the PME Assistant (Online Help) (Page 19)

A0897−3.4 enHBM

Page 11

PME-MP85

2.1 Philosophy of operation

2.1.1 Settings on the device

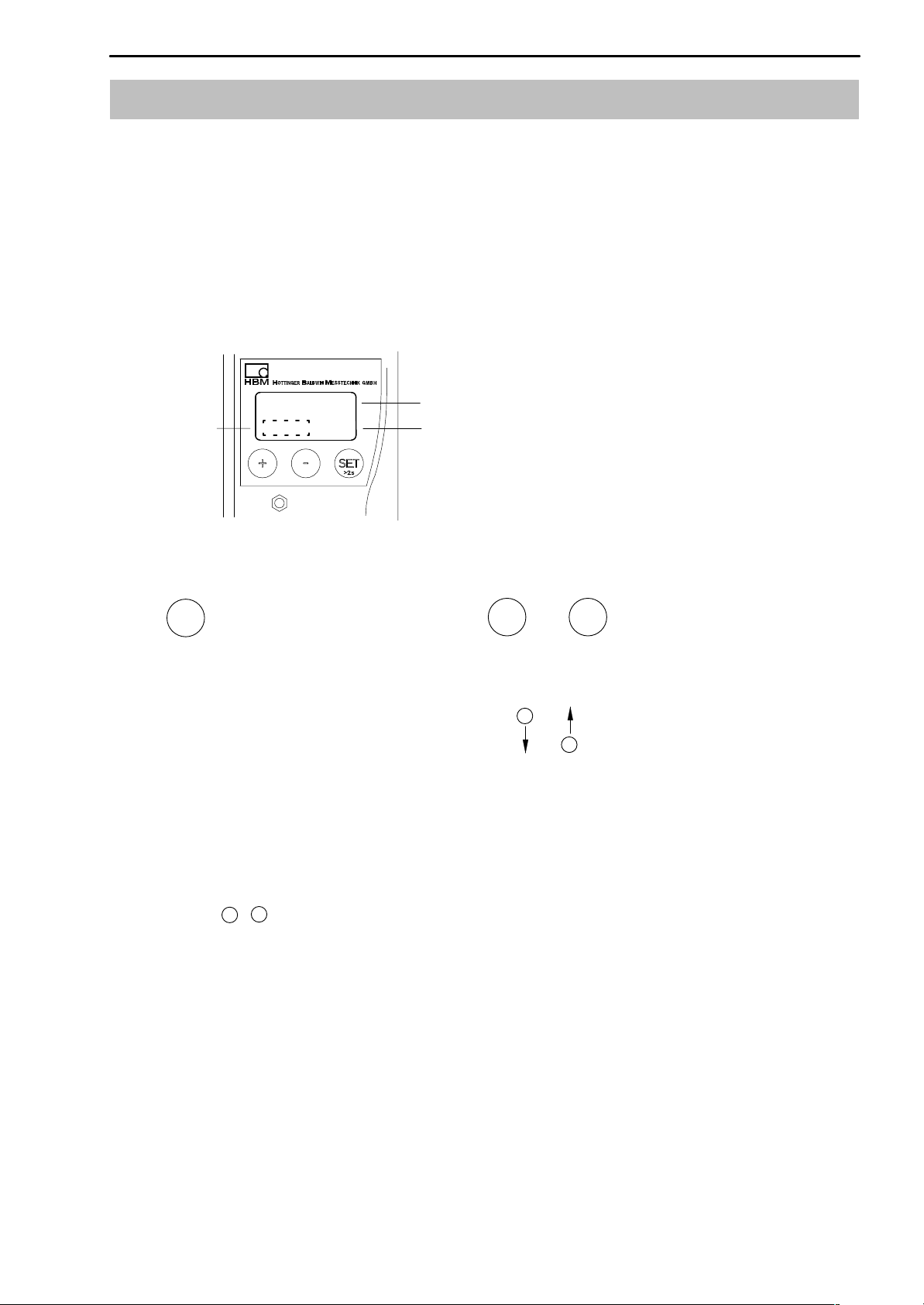

The display of the MP85/85DP shows you the measured value and status

information.

The device is actually set up by means of the “PME Assistant” software

(described in Online Help).

Display in measuring mode:

11

−18.0024

status field

!

kg

x

Function of the keys:

SET

1. Switch from measuring mode to

input mode

2. Choose the first parameter within

the group.

3. Confirm your Input

4. Back to measuring mode (press for

2 secs.)

measured value

unit

+

Select

Parameters/Group

+

−

−

↑

↓

Flashes in the status field if the parameter value can be edited

−

Keys :

+

Keep key pressed − value runs continuously

Short press of the key − advance one value at a time

A0897−3.4 en HBM

Page 12

12

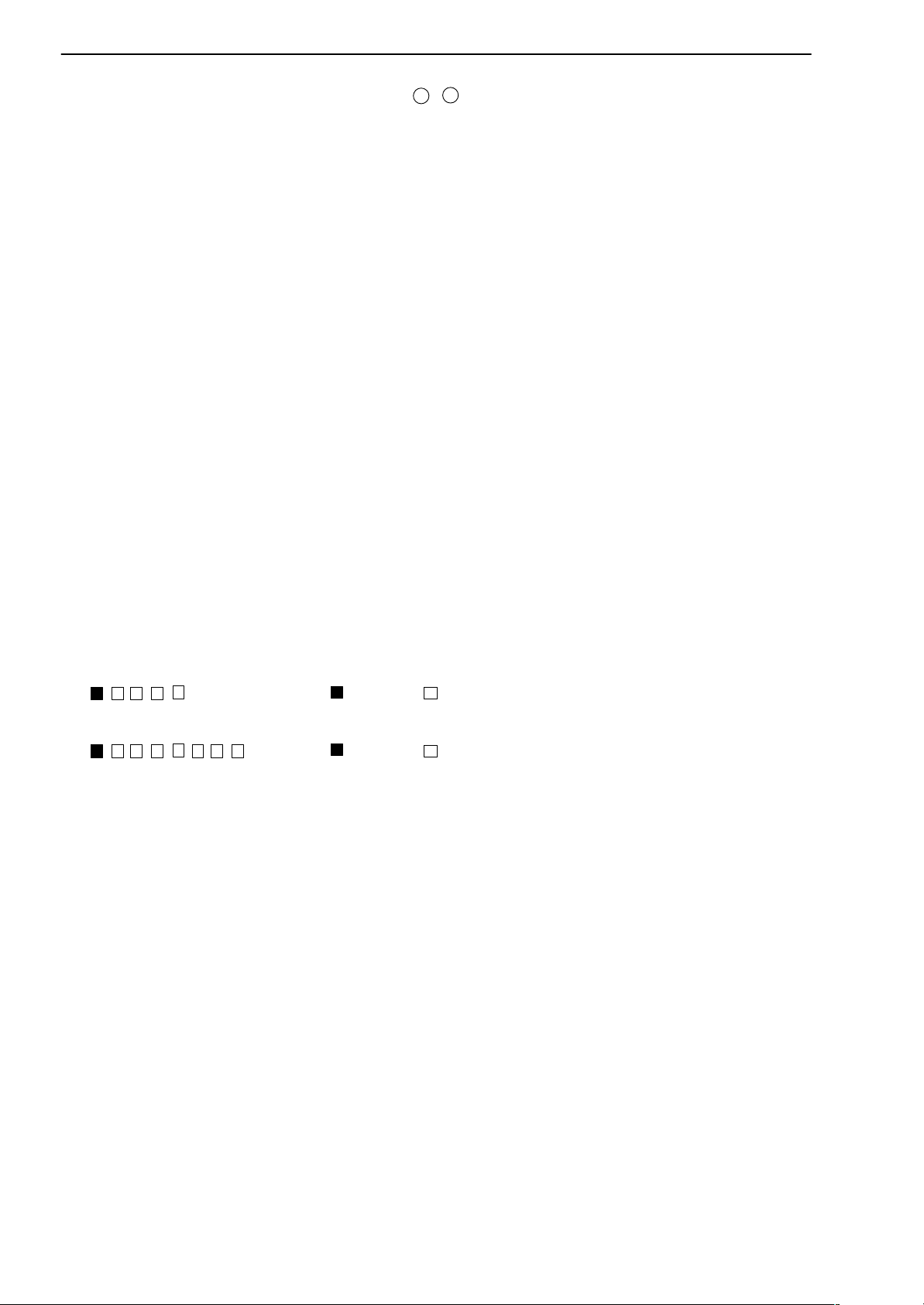

−

During measurement you can press

1. Measured values

• MVx measured value channel x

• MVy measured value channel y

2. Process status, “ProcStat”

• Alarm the last process was finished via the alarm window

• OK the last process was OK

• Not OK the last process was not OK

• Started a process has been started and not yet finished

+

− to view in the display:

PME-MP85

3. Status of the digital inputs and outputs

The MP85 has 5 inputs and 8 outputs.

The MP85DP has 1 input and 4 outputs.

• Input

set, not set

• Output

set, not set

4. Profibus status

BD_SEAR (baud rate search)

WT_PARM (waiting for parameterization)

WT_CONF (waiting for configuration)

DATA_EX (cyclical data traffic)

ERROR (bus error)

A0897−3.4 enHBM

Page 13

PME-MP85

5. MMC-DisplayState (MMCState)

Display Explanation

notinuse No data storage on MMC

with any other display: data storage on MMC

no MMC There is no MMC in the device

Init... The MMC is initialized automatically after insertion

SET ³ STOP MMC ready for storing. Press SET to reset to Stop state.

Then the MMC can be removed.

Storing Data is written to the MMC. Upon completion of data sto-

rage, the state changes to “Ready”; SET ³ STOP is displayed.

Stopped Before removing the MMC from the device,

you must press the SET key to close all files

and write the FAT.

13

The message “MMC Disk Closed” or in case of an error

“MMC DiskClose Err” is displayed for a short time.

Then the MMC changes to the “Stopped” state and can be

removed from the device.

If there is no more free memory available on the MMC, the

status automatically changes to “Stopped”.

The only way to exit this state is to remove the MMC from

the device. Afterwards, there will be an automatic reinitialization.

5. Error types

During measurement, the character ! in the status field (whilst in measuring

mode) indicates a module error.

−

+

The errors are displayed one after the other (obtainable by using

).

• ERROR x (related to screw terminal SENSOR X)

• ERROR y (related to screw terminal SENSOR Y)

SENSOR X

SENSOR Y

Possible error messages are summarized in

Chapter 7 ”Error messages”,

Page 41.

A0897−3.4 en HBM

Page 14

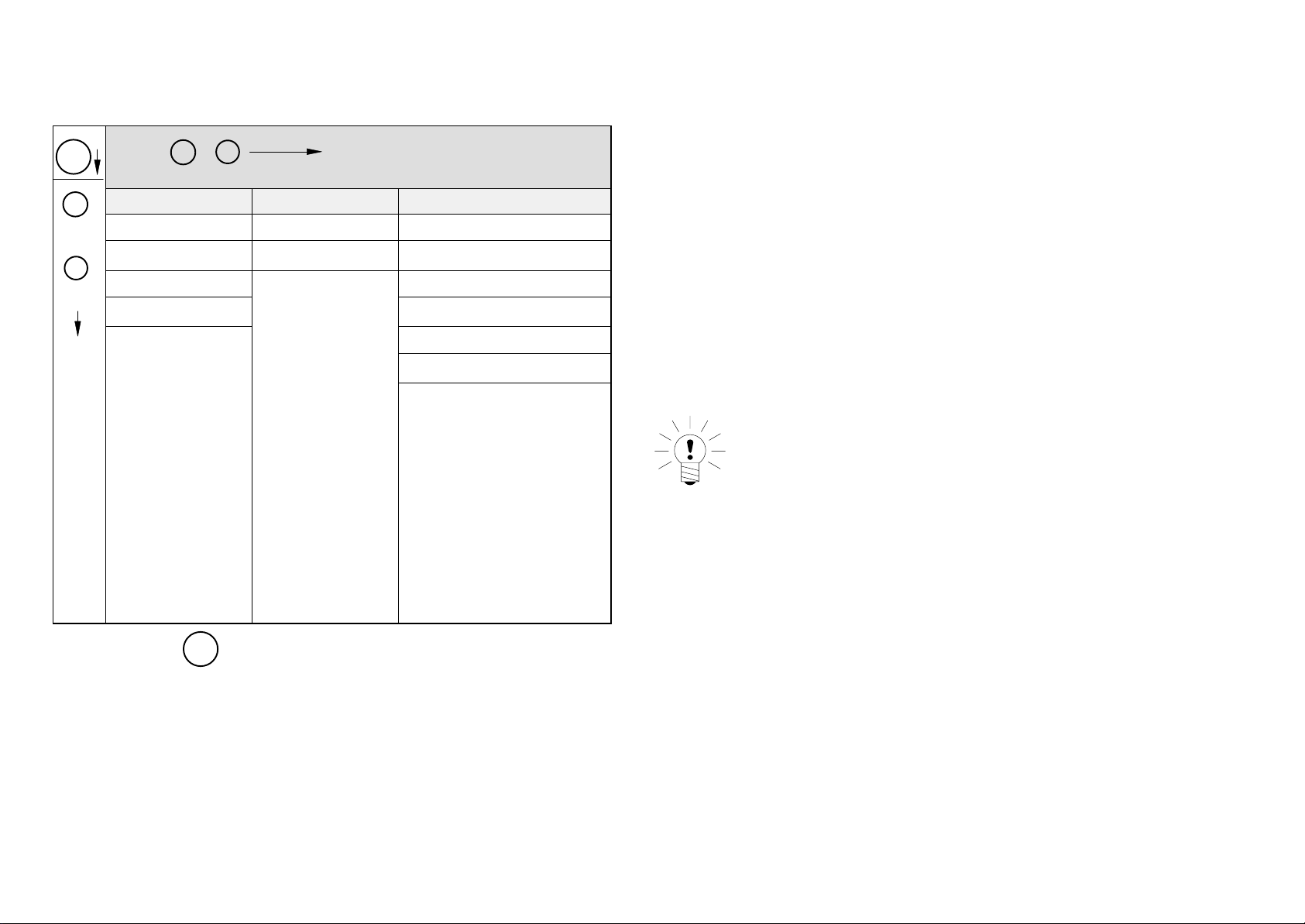

2.1.2 Overview of all groups and parameters

+

SET

+

Up

−

Down

CAN-BUS PROFIBUS ADDITIONAL FUNCTION

Baud rate Address AmplType

Address

OutpR. ms SrNo

MAINGRP

−

Overview of parameters

Groups

MAINGRP

Explanation of parameters:

Load MMC:

Allows you to load a parameter set that has already been

stored on the MMC using the PME Assistant.

PrgVers

HW vers

Load MMC

MAINGRP

We recommend to format the MMC from time to time

for optimizing MMC access times.

MAINGRP with

A0897−3.4 en HBM

SET

back to Group

14

Page 15

2.1.3 Configuring parameters on the device

Measured

value

+

−

2sec

SET

Groups

10kB

20kB

50kB

100kB

+

−

+/-

+

PROFIBUS

SET

ADDITIONAL FUNCTION

AmplTyp

e

PrgVers

CAN bus

SET SET SET

Baud rate

SET

↑

↓

125kB

Address

OutpR. ms

SET

SET

250kB

500kB

1000kB

↑

1−127

↓

↑

↓

000

+/-

+/-

−

SETSET

Address

back

MAINGRP

SET

↑

3 − 123

↓

+/-

SrNo

+

−

HW vers

Load MMC

+

SET

−

Measured

value

↑

↓

MEAS MODE

Save ?

0 − 39

+/-

SET

Yes

↑

↓

No

+/-

SET

back

MAINGRP

A0897−3.4 en HBM

Parameter values

+

Select Parameters

−

↑

↓

Flashes if the parameter value can be edited

SET

Confirm your Input

+/-

=

+ −

or

Back to measuring mode:

Print

SET

2sec

SET

back

MAINGRP

15

Page 16

16

PME-MP85

2.2 Configuring the hardware

2.2.1 Voltage supply / Transducer

• Connect the power supply cable and the transducer to the module

(Chapters 5.3 and 5.4).

CAUTION

Be sure to comply with the safety instructions!

• Activate the power supply.

• The device will run a self-test (approx. 10 secs) and will then, if working

properly, be in measuring mode. During the self-test, the control

outputs stay at 0V.

If ! appears in the display or the status LED shows red, please consult

Chapter 7 ”Error messages”.

• Connecting the bus system

To find out how to connect several devices to a CAN bus, refer to Chapter 5.5.

How to set up the CAN address and the baud rate is described in Chapter

2.1.3.

NOTE

A0897−3.4 enHBM

Page 17

PME-MP85

17

2.2.2 Connecting the CAN adapter (LPT and USB)

To enable PME devices to communicate with the PC, you first have to link the

device to the PC.

1. Connecting LPT to CAN (parallel interface)

• Switch off the PC and attach the LPT to CAN adapter to the parallel

interface port of the PC.

Unfortunately it is not possible to operate a printer from this parallel

interface at the same time. You need a second parallel interface.

• Attach the cable on the adapter between the male connector of the PS2

mouse and the female connector of the PC. This cable is needed to supply

power for the adapter. Alternatively you can attach this power supply cable

between the keyboard connector and the relevant PC socket.

• Attach the CAN connector cable to the MP85 to the adapter.

• Activate the PC.

2. Connecting USB to CAN

First install the PME Assistant.

• Attach the USB to CAN adapter to a free USB interface on your PC.

• The PC will immediately detect the adapter (Plug and Play).

A floppy disk is supplied with the adapter. It includes the driver required for

installation.

A0897−3.4 en HBM

Page 18

18

PME-MP85

2.3 Installing the PME Assistant software

2.3.1 System requirements

To operate the PME Assistant software you need a PC with the following

prerequisites:

− min. processor requirement, Intel Pentium 400 MHz or equivalent

− Windows 95 or higher, Windows NT Version 4.0 or later, Service Pack 3,

Windows 2000

− Internet Explorer 5.0 or higher

− RAM

− 32 MByte for Windows 95/98

− 64 MByte for Windows NT and Windows Millennium

− 128 MByte for Windows 2000 or later

− Graphics card with min. resolution 800 x 600 pixels

− min. 10 MBytes memory available on the hard disk

− Microsoft or 100 % compatible mouse

− configured default printer

− LPT or USB interface

The following fonts must be installed:

− Arial (TT)

− Courier

− MS Sans Serif

− Times New Roman (TT)

− Wingdings

A0897−3.4 enHBM

Page 19

PME-MP85

2.4 Starting the software and setting up

Interface mode

Opens the

Setup window

19

The factory settings

of the interface

CAN bus scan for

connected PME

modules

Fig. 2.1: Startup window

2.4.1 Using the LPT interface

• Start the PME Assistant program and in the startup window, enter the

interface details.

To configure the LPT interface, perform the following steps:

1. In the <Schnittstellentyp> dropdown list box, select the mode PCAN

Dongle Std.

2. Enter the port address of the parallel interface in the <LPT Adresse (hex)>

text box.

NOTE

Under Windows 2000, open System from the Control Panel and click the

Device Manager button on the Hardware tab. Use Connections " Printer

connection to display the available hardware. Double-click on an entry

to open a dialog box to display the requisite information.

3. Select the interrupt of the parallel interface from the <LPT Interrupt>

dropdown list box.

This interrupt must not be used for other devices.

A0897−3.4 en HBM

Page 20

20

NOTE

Under Windows 2000, make sure that an interrupt is used for the

interface: display the properties for the printer connection

(double-click). On the Connection settings tab, each Use interrupt

assigned to the connection must be activated and the interrupt to be

used (interrupt request) must be entered on the Resources tab.

This interrupt must only be used from this interface, double assignment

by a second device, for example, an audio card, is not permissible.

4. In the <CAN−Baudrate> dropdown list box, select the baud rate to be set

for the connected PME modules.

If you do not know the setting, you can use the keyboard of a PME module

to query it (see Page 2.1.1 ).

PME-MP85

The baud rate must be the same for all the PME modules connected to

the CAN bus. The factory setting is 1000 kB.

5. Click the <Scan> button.

In a few seconds, the addresses of the connected PME modules will be

listed in the <CAN−ID> dropdown list box in the Devices area.

6. Select a module and click on <SET>. This opens the Setup window (see

Online Help).

You can now use the PME Assistant software to set up the MP85.

This is described in the Online Help.

NOTE

A0897−3.4 enHBM

Page 21

PME-MP85

2.4.2 Using the USB interface

To configure the USB interface, perform the following steps:

• Start the PME Assistant program and in the startup window, enter the

interface details.

1. In the <Interface type> dropdown list box, select the mode PCAN USB

2. In the <CAN-Baudrate> dropdown list box, select the baud rate to be set

for the connected PME modules.

If you do not know the setting, you can use the keyboard of a PME module

to query it (see Page 2.1.1 ).

NOTE

21

The baud rate must be the same for all the PME modules connected to

the CAN bus. The factory setting is 1000 kB.

5. Click the <Scan> button.

In a few seconds, the addresses of the connected PME modules will be

listed in the <CAN-ID> dropdown list box in the Devices area.

6. Select a module and click on <SET>. This opens the Setup window (see

Online Help).

You can now use the PME Assistant software to set up the MP85.

This is described in the Online Help.

A0897−3.4 en HBM

Page 22

22

PME-MP85

3 Switch settings / Replacing the battery

Modifying the supply voltage for active encoders

Use switch S1 to toggle the supply voltage for active encoders between the

internal 5V supply and the external 24V supply. This is the only changeover

that the housing has to be open for.

NOTE

Switch S1 must be set/modified before fitting the PME.

To set switch S1, proceed as shown in Fig. 3.1.

1

Unscrew the

cover

Switch S1 for the supply

voltage of active encoders

2

S1

5V

(int)

24V

(ext)

Fig. 3.1: Opening the housing, position of switch S1 (schematic diagram)

Terminating resistance

The CAN terminating resistance is activated/deactivated by switch S2 (see

Fig. 3.2).

S2

Toggle switch S2 for the

terminating resistance

ON OFF

Fig. 3.2: Switch for the CAN bus terminating resistance (schematic diagram)

A0897−3.4 enHBM

Page 23

PME-MP85

23

Replacing the battery

The MP85 has a realtime clock which is fed by a type CR2032 lithium battery.

This can be removed from the battery holder and replaced at the point shown

in Fig. 3.3. The battery should be replaced approx. every 5 years.

NOTE

When replacing the battery, you must remove the MP85/MP85DP from

the DIN rail.

1

Battery

for realtime

clock

Unscrew the

cover

2

Fig. 3.3: Opening the housing, position of the battery (schematic diagram)

CAUTION

Check the polarity of the battery

Battery position

−

+

Fig. 3.4: Correct battery position

A0897−3.4 en HBM

Page 24

24

4 MP85/MP85DP mounting/disassembly

(schematic diagrams)

PME-MP85

Fig. 4.1: Mounting on a support rail

Fig. 4.2: Disassembly

CAUTION

The support rail must lie on protective-conductor potential .

A0897−3.4 enHBM

Page 25

PME-MP85

4.1 Linking several modules

Ribbon cable connector

Subsequent devices will be

linked via this connector.

1.

3.

25

Color coding at

Pin 1

2.

58 mm

recommended distance

for the ribbon cable

connectors

Fig. 4.3: Connecting the ribbon cable

Up to four MP85/MP85DP modules can be linked via a ribbon cable. This

cable ensures local connection of the supply voltage, the CAN bus and

synchronization of the carrier frequency between modules.

A0897−3.4 en HBM

Page 26

26

5 Connections

WARNING

Before starting the device, read the safety instructions.

5.1 MP85 functional overview

Local connection of CAN bus, supply voltage and synchronization between

modules

Screw terminal 1:

Voltage supply and CAN bus, synchronization

PME-MP85

LED 1

LED 2

Screw terminal 3:

1 potential-separated control input

(24 V level) incl. input ground,

4 potential-separated control outputs

(24 V level), injection of external supply

for control outputs or incremental or

SSI encoders

Screw terminal 2: (same assignment as

screw terminal 1)

CAN adapter for PC/laptop connection,

parameterization via CAN bus

Two line LC display

Control keys

Multi Media Card (MMC) module

Screw terminal 4:

4 potential-separated control inputs

(24 V level, related to input ground

screw terminal 3)

4 potential-separated control outputs

(24 V level, supply via screw terminal 3)

Screw terminal 5:

Transducer connection channel x

including transducer excitation

Cable shield connection for

transducers

Screw terminal 6:

Transducer connection channel y

including transducer excitation

A0897−3.4 enHBM

Page 27

PME-MP85

5.2 MP85DP functional overview

Local connection of CAN bus, supply voltage and synchronization between

modules

Screw terminal 1:

Voltage supply and CAN bus, synchronization

27

LED 1

LED 2

Screw terminal 3:

1 potential-separated control input

(24 V level) incl. input ground,

4 potential-separated control outputs

(24 V level), injection of external

supply for control outputs or

incremental or SSI encoders

Screw terminal 2: (same assignment as

screw terminal 1)

CAN adapter for PC/laptop connection,

parameterization via CAN bus

Two line LC display

Control keys

Multi Media Card (MMC) module

Connection 4:

9-pin sub-D female connector

for Profibus DP connection

Screw terminal 5:

Transducer connection channel x

including transducer excitation

Cable shield connection for

transducers

Screw terminal 6:

Transducer connection channel y

including transducer excitation

A0897−3.4 en HBM

Page 28

28

PME-MP85

5.3 Supply voltage and control inputs/outputs

Four (MP85) or three (MP85DP) connectable screw terminals are available for

connecting the supply and the control inputs/outputs.

Connecting the voltage

supply:

The MP85/MP85DP module must be connected to an

external supply voltage of 18−30 V (24 V

D The wire ends of the voltage supply must be provided with

D Attach the wire ends to screw terminal 1.

D Insert the screw terminal in the top socket.

D Activate the voltage supply.

Screw terminal 2

(CAN adapter; assignment as

screw terminal 1)

WARNING

end sleeves for strands.

Labeling

nom

CAN

0 V

LH

).

24 V

SYNC

Screw terminal 1

Screw terminal 3

(control inputs/outputs)

Out 1

Out 2

Out 3

Out 4

0V

24V

IN 1

IN

IN = digital input OUT = digital output

CAUTION

1

2

OUT

3

4

0V

24V

1

IN

If there is a power failure at the MP85/MP85DP module, all

the control outputs will be set to 0 V.

Screw terminal 4 (MP85 only)

(voltage supply CAN bus,

synchronization)

(control inputs/outputs)

Out 5

Out 6

Out 7

Out 8

IN 2

IN 3

IN 4

IN 5

5

6

OUT

7

8

2

3

IN

4

5

Fig. 5.1: Screw terminal assignment

The screw terminals are coded so that there will be no confusion when

attaching them to the sockets. Sockets are equipped with coding tabs, screw

terminals 1 and 2 with coding pins.

In the case of screw terminals 3 and 4, the coding lugs are broken off. Screw

terminals 3 and 4, 5 and 6, each have different grid dimensions.

A0897−3.4 enHBM

Page 29

PME-MP85

5.3.1 External supply voltage for control outputs

Example: PLC connection

29

Module MP85/MP85DP

OUT3

OUT1

24 V*

0 V*

Screw terminal 3

max. 0.5 A

PLC

Relay

max. 0.5 A

24 V

0 V*

Fig. 5.2: Connection to a PLC

Control outputs are available at screw terminals 3 and 4 and are electrically

isolated from the internal supply voltage:

• at screw terminal 3: control outputs 1 − 4

• at screw terminal 4: control outputs 5 − 8 (MP85 only)

)

*

Control outputs must be supplied with an external voltage (ground and

24V) via screw terminal 3.

5.3.2 Reference potential for control inputs

Control inputs are available at screw terminals 3 and 4 and are electrically

isolated from the internal supply voltage and from the control outputs.

• at screw terminal 3: control input 1

• at screw terminal 4: control inputs 2 − 5 (MP85 only)

For control inputs, it is necessary to connect an external reference potential

(

IN ) to which the control input signals relate.

A0897−3.4 en HBM

Page 30

30

PME-MP85

5.4 Transducer

2 transducers can be independently connected at screw terminals 5 and 6.

5.4.1 Transducers with carrier frequency excitation

In “carrier frequency amplifier” mode, the following transducer types can be

connected:

Screw terminals 5 and 6

for transducer connection

SENSOR X

18

SENSOR Y

18

S.G. and inductive full bridges,

piezoresistive transducers

WH

Measurement

signal (+)

BK

Excitation voltage (−)

RD

Measurement

signal (−)

BU

Excitation voltage (+)

GN

Sensor circuit (+)

GY

Sensor circuit (−)

YE

Cable shield

MP85

1

2

6

4

5

3

Hous.

MP85DP

S.G. and inductive half bridges

WH

Measurement

signal (+)

BK

Excitation

voltage (−)

BU

Excitation

voltage (+)

GN

Sensor circuit (+)

GY

Sensor circuit (−)

YE

Cable shield

1

2

4

5

3

Hous.

Potentiometric transducer *

Measurement

signal (+)

Excitation

voltage (−)

2

1

3

Excitation

voltage (+)

Cable shield

Sensor circuit (+)

Sensor circuit (−)

)

1

2

4

Hous.

5

3

LVDT transducer

Measurement

signal (+)

Excitation

voltage (−)

Excitation

voltage (+)

Measurement

signal (−)

Cable shield

Sensor circuit (+)

Sensor circuit (−)

1

2

4

6

Hous.

5

3

Cable core colors:

WH= white; BK= black; BU= blue; RD= red; YE= yellow; GN= green; GY= gray

Fig. 5.3: Connection of different transducers in “carrier frequency amplifier” mode

*)Function halfbridge

A0897−3.4 enHBM

Page 31

PME-MP85

31

When connecting a transducer in four-wire technology, the sensor circuits

must be linked to the relevant bridge excitation circuit (pin 3 with pin 2 and pin

1)

5 with pin 4)

.

Four-wire connection:

Full bridge

WH

BK

RD

BU

YE

Hous

1

2

6

4

5

3

.

Four-wire connection:

Half bridge

WH

BK

BU

GN

GY

YE

Hous

1

2

6

4

5

3

.

Feedback bridges for four-wire technology

Cable core colors: WH= white; BK= black; BU= blue; RD= red; YE= yellow; GN= green; GY= gray

Fig. 5.4: Transducer connection in four-wire technology

NOTE

To connect the transducers, use standard cable from HBM or another

shielded, low-capacitance measurement cable. Connect the shield of

each transducer cable via the shortest possible lead (t5 cm) and a

blade connector (4.8 mm; “Faston”) to the right of screw terminal 6. This

ensures EMC protection.

1)

For cable lengths >50 m, instead of feedback bridges, a resistance with half the value of the bridge

resistance (RB/2) must be activated at the transducer. If the transducers are calibrated in a six-wire circuit,

the resistances must be activated directly into the sensor circuit.

A0897−3.4 en HBM

Page 32

32

Synchronization:

Synchronization is advisable for carrier-frequency fed transducers if

D the transducer cables of several devices are installed side by side

D the measuring points are close together and unshielded

Synchronisation prevents carrier frequency differences leading to disturbing

superpositions.

PME-MP85

When synchronizing several modules, one device has to be declared the

master. The remaining devices must be set to slave (use Setup).

Synchronization between modules should always − even if you are working

without a CAN bus − be effected with the ribbon cable.

NOTE

A0897−3.4 enHBM

Page 33

PME-MP85

33

5.4.2 Active encoders

In “incremental encoder, SSI transducer or direct voltage encoder” mode, the

following transducer types can be connected:

MP85

MP85DP

Pulse counter, incremental transducer (symmetric signals)

Ground

Ground

o

o

f1, 0

f1, 0

o

o

f2, 90

f2, 90

Transducers with SSI interface (symmetric signals)

Measurement signal F1 (+), 0°

Measurement signal F1 (−), 0°

Cable shield

Measurement signal F2 (+), 90°

Measurement signal F2 (−), 90°

Zero index, Ix (+)

Zero index, Ix (−)

Supply voltage +5 V/+24 V

Ground

Clock, Cl (+)

7

6

1

Hous.

5

3

4

2

8

7

6

Clock, Cl (−)

Cable shield

Data, D (+)

Data, D (+)

Supply voltage +5 V/+24 V

DC voltage sources ("10V)

Measurement signal (+)

U

Measurement signal (−)

Cable shield

Fig. 5.5: Connecting active encoders

1

Hous.

5

3

8

5

3

Hous.

A0897−3.4 en HBM

Page 34

34

PME-MP85

A supply voltage is available at screw terminals 5 and 6, pins 7 and 8 for

feeding incremental transducers and transducers with an SSI interface.

Switch S1 is used to toggle between an internal and an external supply. The

device has to be opened to do this. (see Chapter 3).

• Transducer supplied from the MP85/MP85DP:

Transducer supply voltage 5V "10 %, 150 mA max. (for both channels

together). The supply is then not electrically isolated from the

measurement system.

• Transducer supplied from an external power pack:

At screw terminal 3, pins 5 and 6, a voltage between 10 − 30 V

24 V

) including ground is applied. A current of max. 300 mA (for both

DC

(nominal

DC

channels together) can then be drawn at transducer terminals 5 and 6.

This external supply voltage is electrically separated from the signal ground

and at the same time feeds the digital control outputs.

Screw terminal 3

GND_int 5 V_int

GND_ext

24 V_ext

5

6

S1

78

Screw terminal 5

GND +5 V / 24 V

Screw terminal 6

78

Fig. 5.6: Supplying active encoders (schematic diagram)

A0897−3.4 enHBM

Page 35

PME-MP85

35

5.5 CAN interface

The CAN bus is connected via screw terminal 1. A maximum of 32 CAN

nodes can be connected in one bus segment (under CANopen specification).

The CAN bus needs a terminating resistance of 120 Ω in the first and last bus

nodes. The bus line must have no more than two terminating resistances. A

terminating resistance is integrated in the MP85DP module and is activated

by toggle switch S2.

Low High

1st device

Fig. 5.7: Connecting the CAN interface

CAN low

CAN connection

as per Fig. 5.7

First device in

the bus line

Switch in the

terminating resistance

here (toggle switch)

Do not switch in the

terminating resistance

CAN high

Last device in

the bus line

Switch in the

terminating resistance

here (toggle switch)

Fig. 5.8: CAN bus mode with several modules (max. 32 according to the standard)

NOTE

If the first or last device in the bus line is not a PME module, a 120 W

resistance must be switched in to each of these external devices.

A0897−3.4 en HBM

Page 36

36

PME-MP85

5.6 Profibus interface (MP85DP only)

On the front panel of the MP30DP is a 9-pin D-sub connection socket for the

Profibus connection.

GND

9

RS485-A

5

RS485-RTS

RS485-B

Vcc (5V)

6

1

Profibus

connection socket

Fig. 5.9: Profibus connection in accordance with standard

Installation:

• Connect the MP85DP module to the 24 V supply voltage and set the

required Profibus address via the keyboard or the Setup program.

• Connect the Profibus cable to the MP85DP module. Ensure that a

terminating resistance is connected to the first and last Profibus unit (the

housing of the Profibus connector usually contains a sliding switch for this

purpose).

Example:

Profibus

connector

First device in

the bus line

sliding switch of Profibus connector

to ”Resistance ON” . . . .

Fig. 5.10: Profibus operation

PLC

Profibus

connector

Last device in

the bus line

sliding switch of Profibus connector

to ”Resistance ON”

A0897−3.4 enHBM

Page 37

PME-MP85

37

6 Communication with the control system

All the diagrams relate to a positive logic.

6.1 Timing of the test operations

a.) Storing curves and results without data loss

The below diagrams apply, if you choose the “without data loss” storage method and want to save curves and/or results on the MMC or externally via

CAN. The READY signal is not reset to 1 until the device is ready to save data

for the next process.

NOTE

Before starting a new measurement, the READY bit must have been reset to 1.

Start/Stop Input

Ready

Running

Result valid

External stop

The READY signal is

not reset to 1 until

there has been an

external stop.

External stop or end condition

occurred

Process in order

State undefined

Once the evaluation time

has expired, you can

Initialisization typ. 25 ms

Data acquisition running

Time until stop

Offline evaluation

Data storage

A0897−3.4 en HBM

read off result 0 or 1 at

the output.

Only if “Result valid” = 1,

the process result (Process in order) is valid.

Page 38

38

PME-MP85

b.) Process optimized storage of curves and results

The below diagrams apply, if you choose the “Process optimized storage” storage method and want to save curves and/or results on the MMC or externally

via CAN. In contrast to the “Storing without data loss” method, the READY signal can be reset to 1 even if the device is not yet ready to save new data.

Consequently the results and curve files might not be transmittes if you start a

new measurement immediately. This method should only be chosen if extremely fast processes must be monitored and the results and curves are merely

used for random sample checks.

NOTE

Before starting a new measurement, the READY bit must have been reset to 1.

Start/Stop Input

Ready

Running

Result valid

External stop

The READY signal is

not reset to 1 until

there has been an

external stop.

External stop or end condition occurred

Process in order

Initialisization typ. 25 ms

Data acquisition running

State undefined

Time until stop

Offline evaluation

Once the evaluation time

has expired, you can

read off result 0 or 1 at

the output.

Only if “Result valid” = 1,

the process result (Process in order) is valid.

Data storage

A0897−3.4 enHBM

Page 39

PME-MP85

6.2 Transducer test

Transducer test timing diagram

39

min. 5 ms

Input

Transducer test

Output transducer test result

6.3 Zero balance

Zero balance timing diagram

min. 5 ms

Inputs

Zeroing

1

0

typically 10 ms

1

0

Input

START

Settling time e.g. for

100 Hz filter: 20 ms

A0897−3.4 en HBM

Page 40

40

6.4 Parameter set switching

PME-MP85

Inputs

Switchover occurs when the level changes

Load parameter set

bit 0 − bit 4

Output Busy

typically 500 ms

Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Active parameter set

0 0 0 0 0 Factory settings

0 0 0 0 1 1

0 0 0 1 0 2

0 0 0 1 1 3

0 0 1 0 0 4

0 0 1 0 1 5

0 0 1 1 0 6

0 0 1 1 1 7

0 1 0 0 0 8

0 1 0 0 1 9

0 1 0 1 0 10

0 1 0 1 1 11

0 1 1 0 0 12

0 1 1 0 1 13

0 1 1 1 0 14

0 1 1 1 1 15

1 0 0 0 0 16

1 0 0 0 1 17

1 0 0 1 0 18

1 0 0 1 1 19

1 0 1 0 0 20

1 0 1 0 1 21

1 0 1 1 0 22

1 0 1 1 1 23

1 1 0 0 0 24

1 1 0 0 1 25

1 1 0 1 0 26

1 1 0 1 1 27

1 1 1 0 0 28

1 1 1 0 1 29

1 1 1 1 0 30

1 1 1 1 1 31

A0897−3.4 enHBM

Page 41

PME-MP85

7 Error messages/operating status (LED)

Depending on the display mode, various error messages can appear in the

display instead of the measured value.

Error message Cause Remedy

TransdErr. Input signal overflow

Transducer not connected

Transducer wrongly connected

Amplifier not adapted to transducer

type

No sensor circuits connected

Connect transducer

See pin assignment

Connect sensor circuits

41

ADC ovfl. Input signal of the A/D converter too

high

Grs ovfl. Gross value overflow Reduce display by one decimal

Scal.Err Input characteristic too steep Modify input characteristic

Flash error An error occurred when reading out

the Flash EOROM.

An error occurred at the CAN bus Check whether there are termi-

CAN bus error

Initial calibr. error No valid initial calibration values Start again, send PME to the

CAN Tx No PDO request on bus Check CAN bus configuration

Adjust hardware measuring

range

place

This can be a one-off read error,

please repeat the operation. If

the error occurs again, please

contact HBM Service.

nating resistances or whether a

channel is faulty. Then switch the

devices back on. If this does not

help, connect one device at a

time to the CAN bus to ascertain

which device is faulty.

manufacturer (HBM)

A0897−3.4 en HBM

Page 42

42

PME-MP85

Operating status MP85 / MP85DP:

The LEDs show the operating status (ready to take measurements, overflow

etc.) of the device.

With the MP85DP, however, the Profibus status is displayed instead of the

CAN status (as is the case with the MP85).

LED 1

LED 2

Operating status:

LED1 (OK / NOK)

Operating status LED Red LED Yell LED Green LED Flashes

Initialization during start-up x

Alarm x x

Process starts x x

OK x

Not OK x

LED2 (Status)

MP85 LED Red LED Yell LED Green LED Flashes

Initialization during start-up x

EE_InCalErr x

CANOFF x

No synchronization signal x

Scale error x

MMC error x

Overload x x

LCD Err x x

CAN communitation x x

PreOperational x

Operational x

MP85DP LED Red LED Yell LED Green LED Flashes

Status: Error x

Status: BD_SEAR, WT_PARM, WT_CONF x

Status: DATA_EX x

A0897−3.4 enHBM

Page 43

PME-MP85

8 Specifications

Type MP85 / MP85DP

Accuracy class 0.1

43

Supply voltage V

DC

24; Potential separation from measuring

system (typically 500 V

Permitted supply voltage range V 18...30

Power consumption

MP85, typically

MP85DP, typically

MP85 / MP85DP, max.

Backing battery for realtime clock

W

W

W

10

Years 5

7

9

(CR2032), typical lifetime

Operating modes, independently adjustable for both channels

Carrier-frequency amplifier

Carrier frequency kHz 4.8 "1 %

Excitation voltage V

rms

2.5 "5 %

Attachable process quantity transducer

S.G., half and full bridges

Inductive half and full bridges, LVDTs

Potentiometric transducer

Ω

mH

Ω

170 − 2000

4 − 160

170 − 2000

Input sensitivity Measuring range (mV/V)

4 100 1000

mV/V 0.2 − 4 3.5 − 100 50 − 1000

Transducer cable length, max. m 500

DC

.)

Scale range, max. Digits 999999, at 10 % of input measuring

range

Scale range, min. Digits 100, at 100 % of input measuring range

Maximum permitted common-mode

voltage

V "5,5

Common-mode rejection

0 − 60

0 − 1000

0 − 4800

dB

dB

dB

u120

u96

u50

Linearity deviation % t0.03

Noise voltage typically Measuring range (mV/V)

4 100 1000

0 - 1 Hz

0 − 10 Hz

0 − 100 Hz

0 − 1000 Hz

µV/V

µV/V

µV/V

µV/V

pp

pp

pp

pp

0.1

0.25

1

2

2.5

6

25

50

25

60

250

500

Sampling rate, max. 1/s 2400

A0897−3.4 en HBM

Page 44

44

Measurement frequency range

adjustable

Low pass 4th order with Bessel

characteristic

Nomin

al

(rated)

value

fc (Hz)

1000 980 1400 0.550 0.260 4

,

0.05 0.049 0.081 3750 4280 0

−1dB

off 790 1200 0.450 0.290 3

500 440 690 0.860 0.510 1.5

200 190 320 1.6 1.11 1.5

100 100 160 2.9 2.13 1.3

50 51 83 4.6 4.24 1

20 25 41 8.2 8.36 1

10 13 21 15.5 16.8 0

5 6.1 10.3 30.2 33.4 0

2 3.1 5.2 60 67 0

1 1.6 2.6 119 137 0

0.5 0.79 1.30 240 272 0

0.2 0.19 0.32 950 1070 0

0.1 0.09 0.16 2500 2170 0

−3dB

(Hz)

(Hz)

Phase

delay

(ms)

PME-MP85

Rise

time

(ms)

Over-

shoot

Shunt calibration mV/V 1"3%

Effect of operating voltage

on zero point

on sensitivity

Effect of 10 K change in ambient

% f.s.

% f.s.

Measuring range (mV/V)

t0.01

t0.01

temperature

4 100 1000

on zero point full bridge

on zero point half bridge

on sensitivity

Long-term drift over 48 h(meas. range

µV/V

µV/V

%

1

10

0.05

20

40

0.05

µV/V 2

200

200

0.05

4 mV/V; 0.5 h after powering up)

DC-voltage transducer

Attachable process quantity transducer DC-voltage transducer, voltage sources

Nominal (rated) measuring range V "10

(%)

Input signal range V "10.5

Scale range, max. Digits 999999, at 10 % of input measuring range

Scale range, min. Digits 100, at 100 % of input measuring range

Internal resistance of the signal source kΩ v1

Maximum permitted common-mode

V 2

voltage

Measurement frequency range,

Hz 0.05 − 1000

adjustable (-1 dB)

Filter characteristics Bessel, 4th order

Linearity deviation % t0.03

Sampling rate max. 1/s 2400

A0897−3.4 enHBM

Page 45

PME-MP85

Incremental encoder

Attachable process quantity transducer Incremental encoder (up/down counter

with zero index signal)

Voltage supply 5 V, max. 150 mA or 24 V

max. 300 mA

Dual-channel mode Time division multiplex method

Inputs (F1 ("), F2 ("), Ix (")) Differential inputs (RS422)

Input level

LOW level

HIGH level

Each line to measurement earth, max.

Hysteresis, typically V 0.07

Maximum permitted common-mode

voltage

Input impedance, typically kΩ 12

Detection of direction of rotation Via "90o phase-shifted signal F2

Input range pulse counting Imp 0 − 999999

V

V

V

V −7 ... +12

t0.8

u2

"14

45

Maximum pulse rate Imp/s 1 000 000

Gap between two consecutive edges

F1("), F2(")

Scale range, max. Digits 20 for 1 pulse

Scale range, min. Digits 1 for 10,000 pulses

Measurement frequency range,

adjustable (-1 dB)

Sampling rate max. 1/s 2400

SSI transducer

Attachable process quantity transducer Disp. and angle transducer with SSI inter.

Power supply 5 V, max. 150 mA; 24 V, max. 300 mA

Dual-channel mode Time division multiplex method

Data inputs D (") Differential input (RS422)

Input level, data input D (")

LOW level

HIGH level

Each line to measurement earth, max.

Hysteresis V 0.07

Maximum permitted common-mode

voltage

Clock output Cl (")

Differential output voltage Cl("), without

load, max.

Differential output voltage Cl("), RL= 50

Ohm, min.

Common-mode output voltage on Cl

("), max.

ns u400

Hz 0.05 − 1000

V

V

V

V −7 ... +12

Differential output (RS422)

V

V

V 3

t0,8

u2

"14

5.8

2

Short-circuit current, clock outputs

Cl ("), typically

A0897−3.4 en HBM

mA 100

Page 46

46

Resolution, single turn Bits 12, 13

Resolution, multi turn Bits 24, 25

Scale range, max. Digits 20 for 1 pulse

Scale range, min. Digits 1 for 10,000 pulses

PME-MP85

Measurement frequency range,

Hz 0.05 − 1000

adjustable (-1 dB)

Sampling rate, max. 1/s 1200

Baud rates kBaud 100, 200, 500, 1000

Coding Gray Code

General specifications

Limit switches

Number 4 per channel

Reference level Gross

Hysteresis % 1 ... 100

Adjustment accuracy Digit 1

Response time, typically (fc=1000 Hz) ms t2

Control outputs

Number 4 (MP85DP) / 8 (MP85)

Nominal voltage, external power supply V

DC

24

Permitted supply voltage range V 10 − 30

Maximum output current per output A 0.5

Short-circuit current, typically

. = 24 V, RLt 0.1 Ohm)

(U

ext

A 0.8

Short-circuit period Unlimited

Isolation voltage, typically V

DC

500

Control inputs

Number 1 (MP85DP) / 5 (MP85)

Input voltage range LOW V 0 − 5

Input voltage range HIGH V 10 − 30

Input current, typically (HIGH level = 24V) mA 12

Isolation voltage, typically V

DC

500

CAN interface

Sampling rate, max. 1/s 1200

Protocol CAN 2.0B, CANopen compatible

Hardware bus link to ISO 11898

Baud rates

Maximum cable lengths

Kbit/sm1000 500 250 125 100 50 20 10

25 100 250 500 600 1000 10001000

Terminating resistance Connectable by switch

Connection Terminals

Parameter memory (Flash) 31 plus factory settings

A0897−3.4 enHBM

Page 47

PME-MP85

Multimedia card (memory card on Flash base)

47

Usable types M-

bytes

Data transmission rate, typically K-byte

/s

File system DOS

Display

Type Two line, 8 character alphanumeric, LCD

Keyboard Touch-sensitive keypad with three keys

Temperature range

Nominal temperature range

Operating temperature range

Storage temperature range

Degree of protection IP20

Dimensions mm 55 x 146 x 156

Weight, approx. g 800

Profibus DP interface (MP85DP only)

o

C 0 − 50

o

C −20 ... +50

o

C −20 ... +70

8, 16, 32, 64

8

Protocol Profibus DP slave, as per DIN 19245−3

Baud rate, max. MBaud 12

Node address 3 − 123, can be set via keyboard

Profibus ID number Hex 699

Configuration data byte 5

Parameter data, max. byte 6 (+7DP standard)

Parameter assignment (asynchronous) to DPV1 standard

Input data, max. byte 142

Output data, max. byte 40

Inputs update rate ms 1 (for 4 measured values)

Outputs update rate ms t10, on zeroing, limit values

Diagnosis data byte 48

Profibus connection 9-pin sub-D (DIN19245-3),

potential-separated from power supply

and signal ground

A0897−3.4 en HBM

Page 48

48

Specifications for analysis unit

PME-MP85

Max. number of data triples

4000 (auto. data reduction)

(channel x); (channel y); (time)

Sampling rate, max. Hz 2400

Analysis

Max. number of analysis windows 9

Type of window Oblique or straight

Analysis methods per window Plot analysis

Mean value of x or y analysis in window

x coordinates for tolerance windows absolute or relative to the start position, or

relative to the end position

Y coordinates for tolerance windows absolute or

relative to F

of tolerance window 2

min

or

relative to F

of tolerance window 2

max

Stop conditions External stop signal

Target value y + decay time

Target value x + decay time

Standstill recognition

Number of independent parameter sets 31

Switching parameter sets, max. ms 500

Duration of offline evaluation straight

ms 15 + 0.15/data pair in window

window

Duration of offline evaluation oblique

ms 15 + 0.3/data pair in window

window

Statistics (for each parameter set, separately)

Maximum number of fitting processes 4 x 10

Number of histogram classes for 2

, x

values (x

max

min

, y

max

, y

min

)

9 per tolerance window

9

A0897−3.4 enHBM

Page 49

PME-MP85

9 Declaration of conformity

49

A0897−3.4 en HBM

Page 50

50

PME-MP85

A0897−3.4 enHBM

Page 51

PME-MP85

10 Keyword index

51

A

active encoders, 22 , 33

active parameter set, 40

C

CAN bus, 15 , 26 , 27 , 35

connecting, 26 , 27

CAN interface, 35

CANopen, 35

CANopen interface, connecting, 35

coding pin, 28

coding tab, 28

commissioning, 10

configuring parameters, 15

connecting

bus system, 16

CAN adapter, 17

CAN adapters, 9

CAN interface, 35

LPT to CAN, 17

supply voltage, 28

transducers, 30 , 33

USB to CAN, 17

D

DC voltage source, 33

declaration of conformity, 49

digital input, 28

digital inputs, 12

digital output, 28

disassembly, 24

display mode, 13

dongle, 19

E

error message, 41

F

feedback bridges, 31

four−wire technology, 31

I

interface, connecting, 35

interface converter, 9

connecting the bus system, 16

connecting transducers, 30

active encoders, 33

S.G. full and half bridges, inductive full

and half bridges, potentiometric, piezoelectric, LVDT, 30 , 33

transducers with CF excitation, 30

connection, pulse counter, incremental

transducer, symmetric, 33

control inputs, 26 , 27

control inputs and outputs, 26 , 27

control outputs, 26 , 27

A0897−3.4 en

L

LED, 42

LPT interface, 19

M

measured value channel x, measured va-

lue channel y, 12

MMC load, 14

MMC−State, 13

mounting, 24

multimedia card, 8

HBM

Page 52

52

PME-MP85

P

parameters, 14

configuring, 15

PLC connection, 29

PME Assistant, 18

power failure, 28

process status, 12

Profibus interface, 36

Profibus status, 12

R

replacing the battery, 22 , 23

ribbon cable, 32

S

screw terminal assignment, 28

self−test, 16

supply voltage, 28

synchronization, 26 , 27 , 32

T

terminating resistance, 22 , 35

Test timing, 39

U

USB interface, 21

V

voltage supply, 26 , 27 , 28

screw terminal, 26 , 27

voltage supply, CAN bus, synchroniza-

tion, control inputs, control outputs, 26

, 27

Z

Zero balance, 39

HBM

A0897−3.4 en

Page 53

PME-MP85

53

A0897−3.4 en

HBM

Page 54

54

PME-MP85

HBM

A0897−3.4 en

Page 55

Page 56

pp

A0897−3.4 en

Modifications reserved.

All details describe our products in general form only.They are

not to be understood as express warranty and do not constitute

any liability whatsoever.

Hottinger Baldwin Messtechnik GmbH

Postfach 10 01 51, D-64201 Darmstadt

Im Tiefen See 45, D-64293 Darmstadt

Tel.: +49/61 51/ 8 03-0; Fax: +49/61 51/ 8039100

E−mail: su

ort@hbm.com www.hbm.com

Loading...

Loading...