Page 1

Operating Manual

Twin-channelAmplifiers

Modules

MP85A, MP85ADP

FASTpress

MP85A-S, MP85ADP-S

EASYswitch

A2392−5.0 en

Page 2

Page 3

MP85A process controller

3

Contents Page

Contents

Safety information 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Introduction 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Scope of supply and accessories 10. . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 General information 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 About this documentation 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

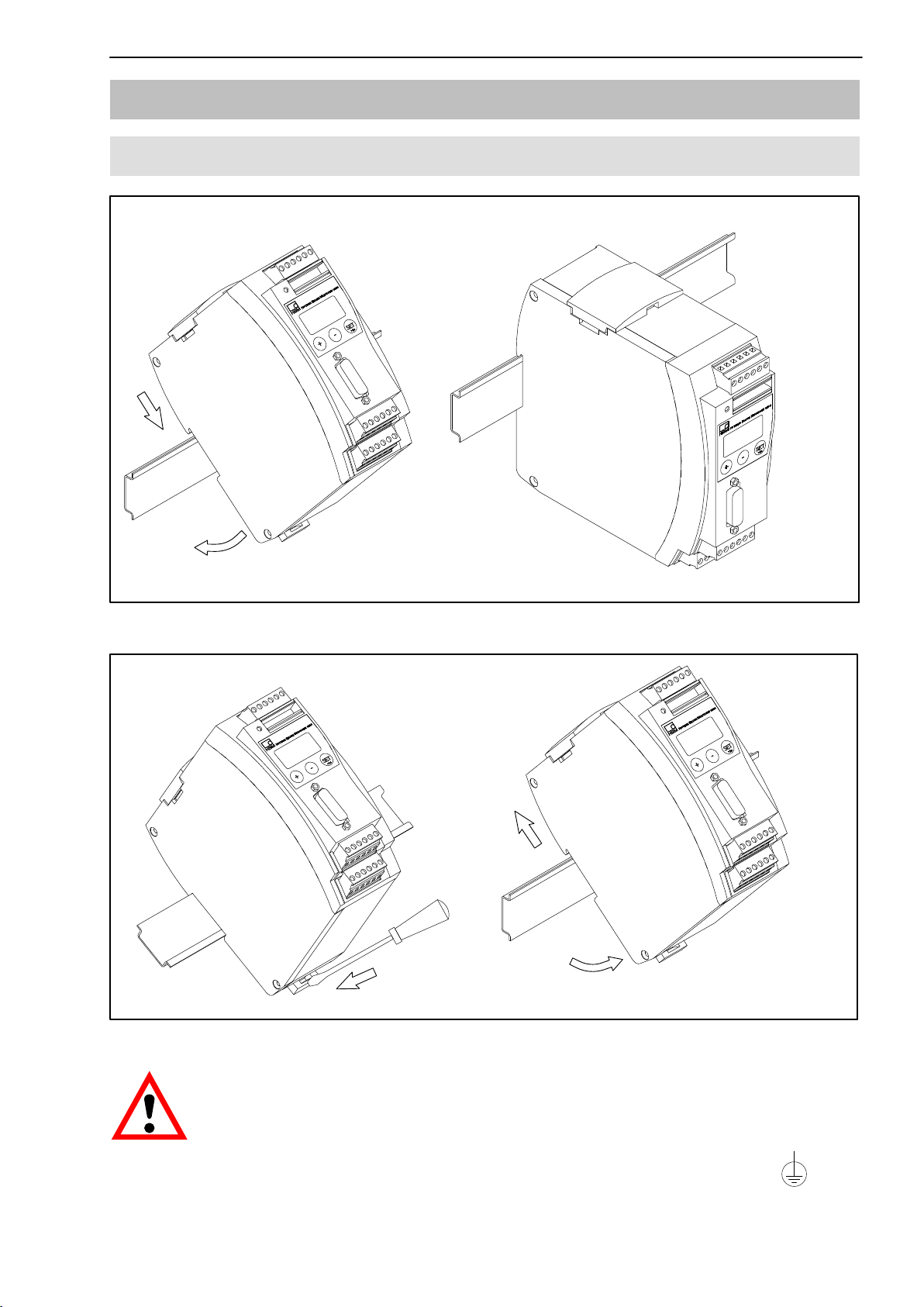

2 MP85A(DP)(-S) installation/removal (basic diagrams) 13. . . . . . . . . . .

2.1 Mechanical installation 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Connecting several devices 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Electrical connection 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Overview of MP85A/MP85A-S functions 15. . . . . . . . . . . . . . . . . . . .

3.2 Overview of MP85ADP/MP85ADP-S functions 16. . . . . . . . . . . . . . .

3.3 Supply voltage and control inputs/outputs 17. . . . . . . . . . . . . . . . . . .

3.3.1 External supply voltage for control outputs 18. . . . . . . . . . . . .

3.3.2 Reference potential for control inputs / switch check inputs . .

18

3.4 Transducer 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.1 Synchronization of carrier frequencies 19. . . . . . . . . . . . . . . .

3.4.2 SGs, displacement transducers, potentiometric and LVDT

sensors 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.3 Incremental, SSI and DC sensors 22. . . . . . . . . . . . . . . . . . . .

3.4.4 Piezoelectric measurement chains 24. . . . . . . . . . . . . . . . . . .

3.5 TEDS-transducers (electronic data sheet) 27. . . . . . . . . . . . . . . . . . .

3.5.1 TEDS connection 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.2 Parameterization with TEDS 27. . . . . . . . . . . . . . . . . . . . . . . . .

3.6 Interfaces 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.1 Ethernet interface 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.2 CAN interface 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.3 PROFIBUS interface (MP85ADP/MP85ADP-S only) 31. . . .

4 Switch settings / Replacing the battery 33. . . . . . . . . . . . . . . . . . . . . . . .

5 Starting up/Setting up mode 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Operation 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.1 Device settings, measured values, process status,

PROFIBUS, memory cards, error types, firmware update,

device backup 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.2 Overview of all groups and parameters 42. . . . . . . . . . . . . . . .

A2392−5.0 en HBM

Page 4

4

MP85A process controller

5.1.3 Setting parameters on the device 44. . . . . . . . . . . . . . . . . . . . .

5.2 Hardware setup 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 Voltage supply / transducers 45. . . . . . . . . . . . . . . . . . . . . . . . .

5.2.2 Establishing the Ethernet connection 46. . . . . . . . . . . . . . . . .

5.2.3 Connecting the CAN adapter (USB) 47. . . . . . . . . . . . . . . . . .

5.3 Installing the PME Assistant software 47. . . . . . . . . . . . . . . . . . . . . . .

5.4 PME Assistant operation 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.1 Using the Ethernet interface 48. . . . . . . . . . . . . . . . . . . . . . . . .

5.4.2 Using the USB interface 49. . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 Automatic version recognition 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6 Firmware update 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7 Offline operation 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Methods of measurement 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Data reduction 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Classification 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Monitoring limit values in real time 53. . . . . . . . . . . . . . . . . . . . . . . . .

6.4 Masking out external tolerances 54. . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 Evaluation criteria 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6 Measurement programs (parameter sets) 58. . . . . . . . . . . . . . . . . . .

7 Switch checker with MP85A(DP)-S EASYswitch 60. . . . . . . . . . . . . . . .

7.1 Switch check 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Haptic check 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Communication with a control system 63. . . . . . . . . . . . . . . . . . . . . . . . .

8.1 MP85A process controller in machine control 63. . . . . . . . . . . . . . . .

8.2 Test process sequence over time 65. . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 Transducer test 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 Zero balance 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5 Simulation of digital outputs 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6 Parameter sets (measurement programs) 69. . . . . . . . . . . . . . . . . . .

8.7 Evaluation/storage process times 71. . . . . . . . . . . . . . . . . . . . . . . . . .

8.8 Process data storage/production data management 73. . . . . . . . . .

9 Display-and control options 76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 DT85 control and display terminal 76. . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 FASTpress Suite software 77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 Error messages/operating state (LED display) 79. . . . . . . . . . . . . . . . . .

11 Technical support 83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A2392−5.0 enHBM

Page 5

MP85A process controller

5

Safety information

This operating manual applies to the devices

• MP85A

• MP85ADP

• MP85A-S

• MP85ADP-S

The designation MP85A process controller will be used for all devices in this

manual. If text/data refers only to specific devices, this will be clearly indicated

in the text and one of the above designations used.

• Use shielded, low-capacitance HBM cables only.

Intended use

The MP85A process controller is to be used exclusively for measurement

tasks and directly related control tasks. Use for any purpose other than the

above is deemed to be non-designated use. In the interests of safety, the

device should only be operated as described in the Operating Manuals. It is

also essential to comply with the legal and safety requirements for the application concerned during use. The same applies to the use of accessories.

Each time, before commissioning the device, you must first run a project planning and risk analysis that takes into account all the safety aspects of automation technology. This particularly concerns personal and machine protection.

Additional safety precautions must be taken in plants where malfunctions

could cause major damage, loss of data or even personal injury. In the event

of a fault, these precautions must establish safe operating conditions.

This can be done, for example, by mechanical interlocking, error signaling,

limit value switches, etc.

The MP85A process controller must not be connected directly to the

mains. The supply voltage must be 18 − 30 V.

General dangers of failing to follow the safety instructions

The MP85A process controller corresponds to the state of the art and is

failsafe. The device may give rise to residual dangers if it is inappropriately

installed and operated by untrained personnel.

Any person instructed to carry out installation, commissioning, maintenance or

repair of the device must have read and understood the Operating Manual

and in particular the technical safety instructions.

Conditions at the place of installation

A2392−5.0 en HBM

Page 6

6

Protect the device from direct contact with water (IP20).

Maintenance and cleaning

The MP85A process controller is maintenance-free. Please note the following

points when cleaning the housing:

− Before cleaning, disconnect the device from the power supply.

− Clean the housing with a soft, slightly damp (not wet!) cloth. You should

never use solvent, since this could damage the labeling on the front panel

and the display.

− When cleaning, ensure that no liquid gets into the device or connections.

Residual risks

The scope of supply and performance of the MP85A process controller covers

only a small area of measurement technology. In addition, equipment planners, installers and operators should plan, implement and respond to the

safety engineering considerations of measurement technology in such a way

as to minimize remaining dangers.

Prevailing regulations must be complied with at all times. There must be reference to the remaining dangers connected with measurement technology. After

making settings and carrying out activities that are password-protected, you

must make sure that any controls that may be connected remain in safe

condition until the switching performance of the measurement system has

been tested.

Any risk of remaining dangers when working with the MP85A.process

controller is pointed out in these instructions by means of the following

symbols:

MP85A process controller

Symbol:

Meaning: Dangerous situation

Warns of a potentially dangerous situation in which failure to comply with

safety requirements can lead to death or serious physical injury.

Symbol:

Meaning: Possibly dangerous situation

Warns of a potentially dangerous situation in which failure to comply with

safety requirements could lead to damage to property and slight or moderate

physical injury.

WARNING

CAUTION

A2392−5.0 enHBM

Page 7

MP85A process controller

Symbols for application instructions and useful information:

7

Symbol:

Means that important information about the product or its handling is being

given.

Symbol:

Meaning: Statutory waste disposal mark

In accordance with national and local environmental protection and material

recovery and recycling regulations, old devices that can no longer be used

must be disposed of separately and not with normal household garbage. If

you need more information about waste disposal, please contact your local

authorities or the dealer from whom you purchased the product.

Symbol:

Meaning: CE mark

NOTE

The CE mark enables the manufacturer to guarantee that the product

complies with the requirements of the relevant EC directives (the Declaration

of Conformity can be found at http://www.hbm.com/HBMdoc).

Working safely

Error messages should only be acknowledged once the cause of the error is

removed and no further danger exists.

The device complies with the safety requirements of DIN EN 61010 Part 1

(VDE 0411 Part 1).

The device must be mounted on a DIN support rail connected to grounded

conductor potential. Both the support rail and the MP85A process controller

must be free of paint, varnish and dirt at the point of installation.

To ensure adequate immunity from interference, the bus cables (CAN and for

MP85ADP, PROFIBUS DP) must be shielded, twisted-pair lines. The transducer cables must also be shielded. The shield of each transducer cable must

be connected at the MP85A process controller via as short a line as possible

(t5 cm) and a flat connector (4.8 mm; “Faston”).

The power supply and digital control input and output connection cables only

need to be shielded if the cables are longer than 30 m or are routed outside

closed buildings.

A2392−5.0 en HBM

Page 8

8

MP85A process controller

When connecting cables (fitting and extracting terminals) and when changing

the MMC/SD Card, measures must be taken to prevent electrostatic

discharge which could damage the electronics.

The MP85A process controller must be operated with a separated extra-low

voltage (18 … 30 V DC supply voltage), which usually supplies one or more

consumers within a control cabinet.

1)

Should the device be operated on a DC voltage network

, additional precau-

tions must be taken to discharge excess voltages.

Conversions and modifications

The MP85A process controller must not be modified from the design or safety

engineering point of view except with our express agreement. Any modification shall exclude all liability on our part for any damage resulting therefrom.

In particular, any repair or soldering work on motherboards is prohibited.

When exchanging complete modules, use only original parts from HBM.

The device is delivered from the factory with a fixed hardware and software

configuration. Changes can only be made within the possibilities documented

in the manuals.

Qualified personnel

Qualified personnel means persons entrusted with siting, mounting, starting

up and operating the product, who possess the appropriate qualifications for

their function.

This device is only to be installed and used by qualified personnel strictly in

accordance with the specifications and with the safety rules and regulations

which follow.

This includes people who meet at least one of the three following requirements:

• Knowledge of the safety concepts of automation technology is a require-

ment and as project personnel, you must be familiar with these concepts.

• As automation plant operating personnel, you have been instructed how to

handle the machinery and are familiar with the operation of the equipment

and technologies described in this documentation.

• As commissioning engineers or service engineers, you have successfully

completed the training to qualify you to repair the automation systems. You

are also authorized to activate, ground and label circuits and equipment in

accordance with safety engineering standards.

1)

Distribution system for electrical energy with greater physical dilatation (over several control cabinets, for

example) that may possibly also supply consumers with high nominal (rated) currents.

A2392−5.0 enHBM

Page 9

MP85A process controller

It is also essential to comply with the legal and safety requirements for the

application concerned during use. The same applies to the use of

accessories.

Maintenance and repair work on an open device with the power on must only

be carried out by trained personnel who are aware of the dangers involved.

9

A2392−5.0 en HBM

Page 10

10

1 Introduction

1.1 Scope of supply and accessories

Scope of supply:

• 1 MP85A or MP85ADP, MP85A-S or MP85ADP-S

• 4 plug-in screw terminals, coded

Phoenix order number HBM order number

MP85A process controller

1x voltage supply and CAN,

6-pin

2x transducers, 8-pin MCVW 1.5/8-ST-3.81 GY 3-3312.0422

1x I/O 1, 8-pin MC 1.5/8-ST-3.5 GY 3-3312.0421

MV STBW 2.5/6-ST-5.08 GY 3-3312.0426

Additionally for MP85A or MP85A-S:

Phoenix order number HBM order number

1x I/O 2, 8-pin MC 1.5/8-ST-3.5GY 3-3312.0421

• Extra spring for enclosure assembly (included in the pack)

• Flat ribbon cable female connector, 10-pin

• 1 FASTpress Suite system CD with:

free PME Assistant setup software

Online Help with Tricks & Tips

Quick Reference Guide for beginners

• PME-Assistant PLUS (demo-version software-add-on modules) with:

EASYsetup (user administration) and EASYteach (statistical process

analysis)

• MP85A Toolkit (demo version):

Function module kit for creating separate interfaces on operator panels via

Ethernet under Windows XP, Windows CE and WindowsMobile

• EASYmonitor CE:

Production software (demo-version, for operation on Touch-Panels under

Windows CE)

• INDUSTRYmonitor (demo version):

Production software for operation on Touch-Panels with max. 12 MP85A

process controllers

A2392−5.0 enHBM

Page 11

MP85A process controller

Accessories:

• DT85: 1/4” VGA b/w display for visualization and parameterization of

several MP85A.process controllers via the CAN interface

• Memory card: MMC or SD Card, e.g. Transcend (www.transcend.de), no

SDHC (High Capacity), SDXC (eXtended Capacity), SecureMMC or

equivalent cards

• Standard flat ribbon cable, 10-pin, 1.27 mm pitch

• Ethernet crossover cable, 2 m, (1-KAB239-2)

1.2 General information

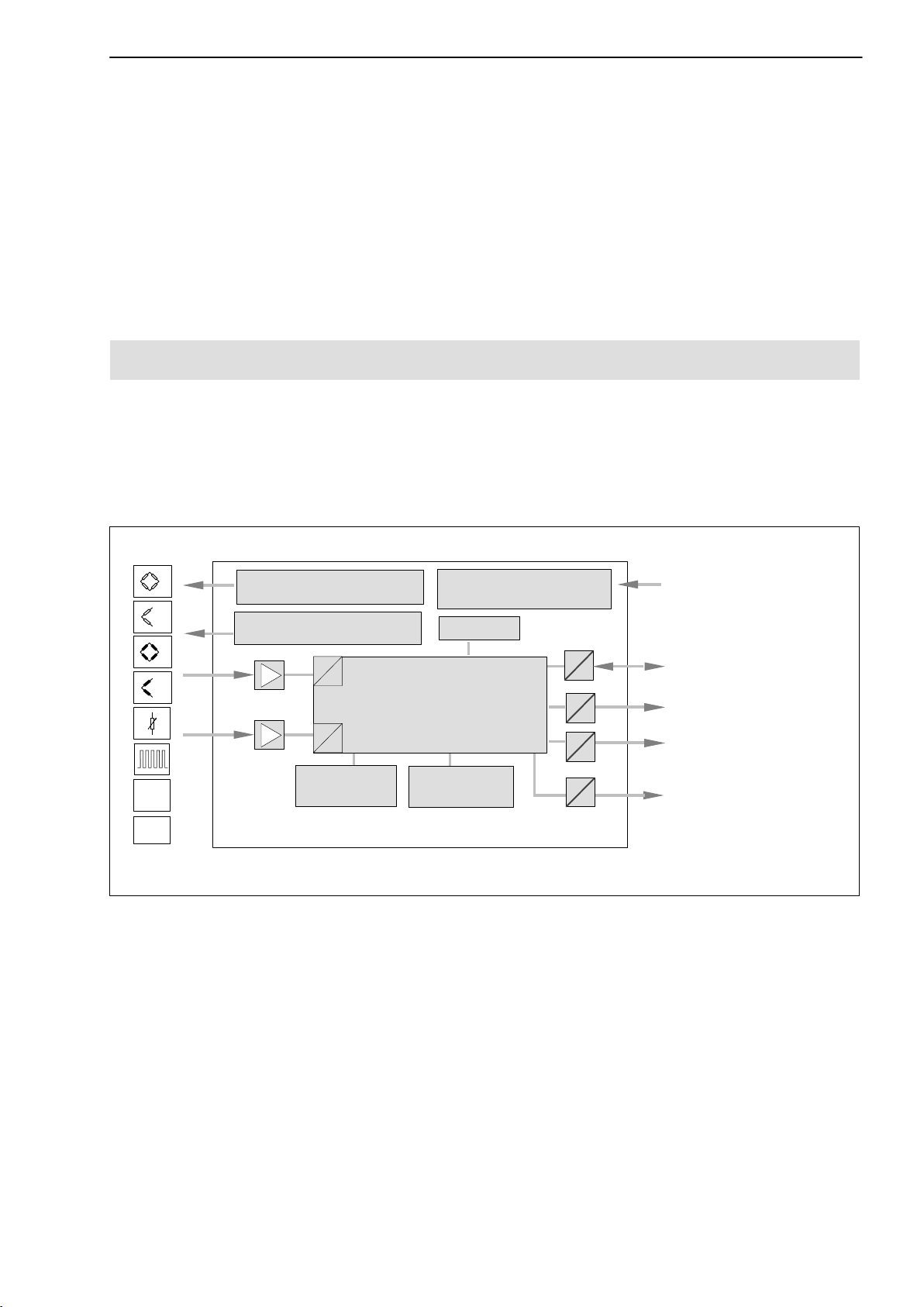

The MP85A process controller from the PME product line is a twin-channel

amplifier, suitable for connecting transducers of different technologies. The

MP85ADP and MP85ADP-S also have a PROFIBUS interface in addition to

the ETHERNET and CAN interfaces.

11

"10V

SSI

Carrier-frequency bridge

excitation voltage 4.8 kHz

Power supply for active

transducers 5 V or 24 V

A

D

Intelligent signal conditioning

and powerful algorithms for

A

D

Keyboard and

display

monitoring fitting

memory card

MP85A(DP)/MP85A(DP)-S

Voltage supply,

electrically isolated

EEPROM

MMC/SD

μP

24 V

Control inputs and

outputs, or switch test

inputs

CANopen interface

Ethernet interface

PROFIBUS DP interface

(for MP85ADP and

MP85ADP-S)

Fig. 1.1: Block diagram of the MP85A process controller

The PME Assistant provides a simple and free user interface for device parameterization under MS Windows.

This needs an Ethernet (crossover) cable (order no. 1-KAB2392) for direction

connection to a PC or a USB → CAN interface converter (when using a CAN

interface), which must be ordered separately (order number: 1-PMESETUPUSB).

All device parameters can be set with this software. The Ethernet or CAN bus

interface is set directly at the device.

Other devices in the PME product family can also be set up with this software

(MP01 ... MP70).

A2392−5.0 en HBM

Page 12

12

MP85A process controller

1.3 About this documentation

MP85A process controller documentation comprises

− this operating manual, which mainly describes setting up the hardware

(transducer, device and PC with software).

− PME Assistant online Help and add-on software modules

describing device setup and function via software

− a separate operating manual with an object dictionary and an interface

description for Ethernet, CAN and PROFIBUS communication

− a quick start guide for fast commissioning of the MP85A process controller

and all software modules

− a quick start guide for the whole FASTpress suite, i.e. for all software

modules and the MP85A process controller

A2392−5.0 enHBM

Page 13

MP85A process controller

2 MP85A(DP)(-S) installation/removal (basic diagrams)

2.1 Mechanical installation

13

Fig. 2.1: Mounting on a DIN rail

Fig. 2.2: Removal

CAUTION

The DIN rail must be connected to grounded conductor potential .

A2392−5.0 en HBM

Page 14

14

MP85A process controller

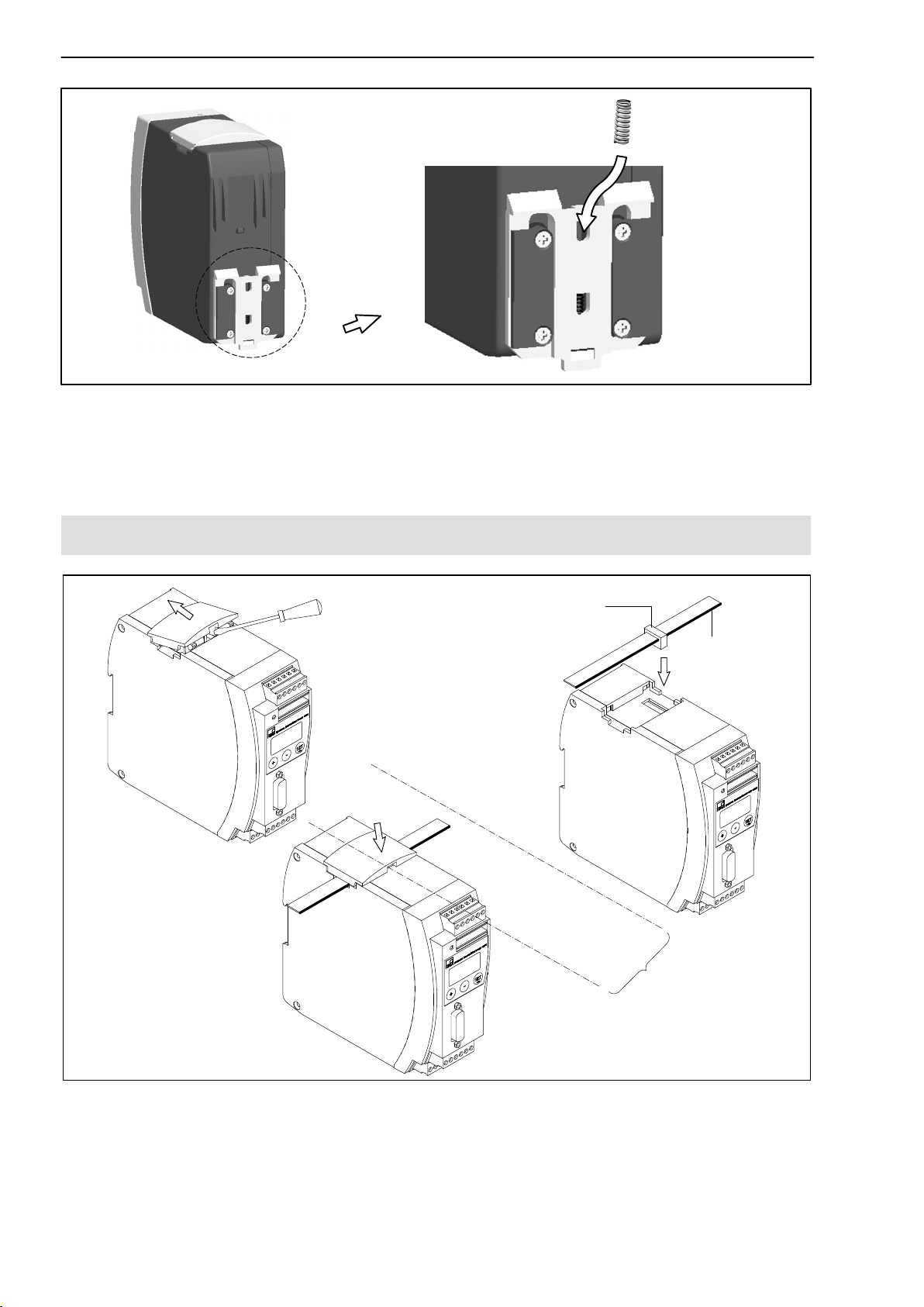

Fig. 2.3: Fitting a second spring for a more stable MP85A process controller

mounting on the DIN rail

2.2 Connecting several devices

Flat ribbon cable female connector

Subsequent devices are

interconnected via this

connector.

1.

3.

Color-coding on

Pin 1

2.

58 mm

Recommended gap for

flat ribbon cable female

connectors

Fig. 2.4: Connecting the flat ribbon cable

Up to four MP85A process controllers can be connected via one flat ribbon

cable. This cable takes care of local supply voltage, CAN bus connection and

carrier frequency synchronization between the devices.

A2392−5.0 enHBM

Page 15

MP85A process controller

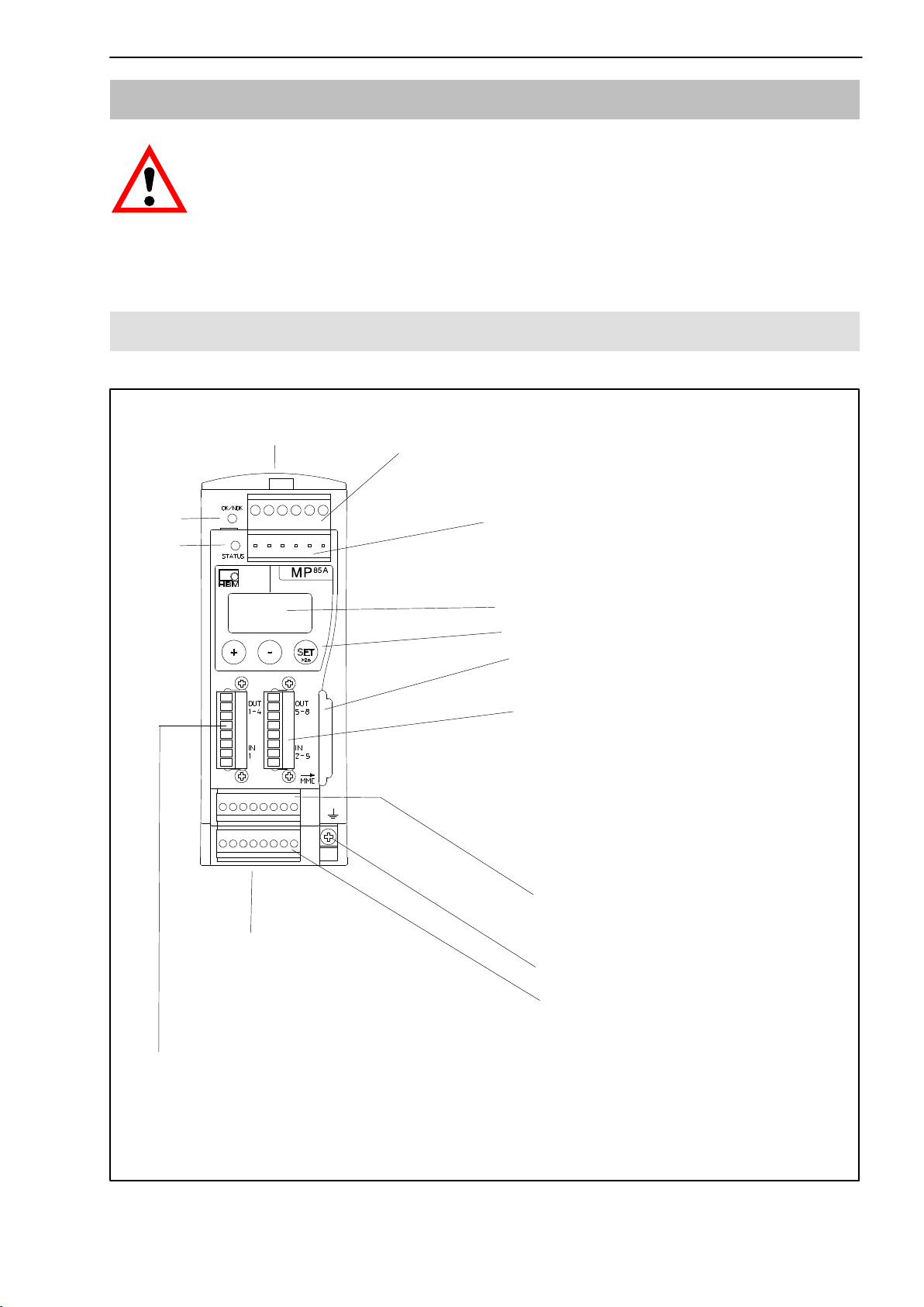

3 Electrical connection

WARNING

Comply with the safety instructions before starting up the device.

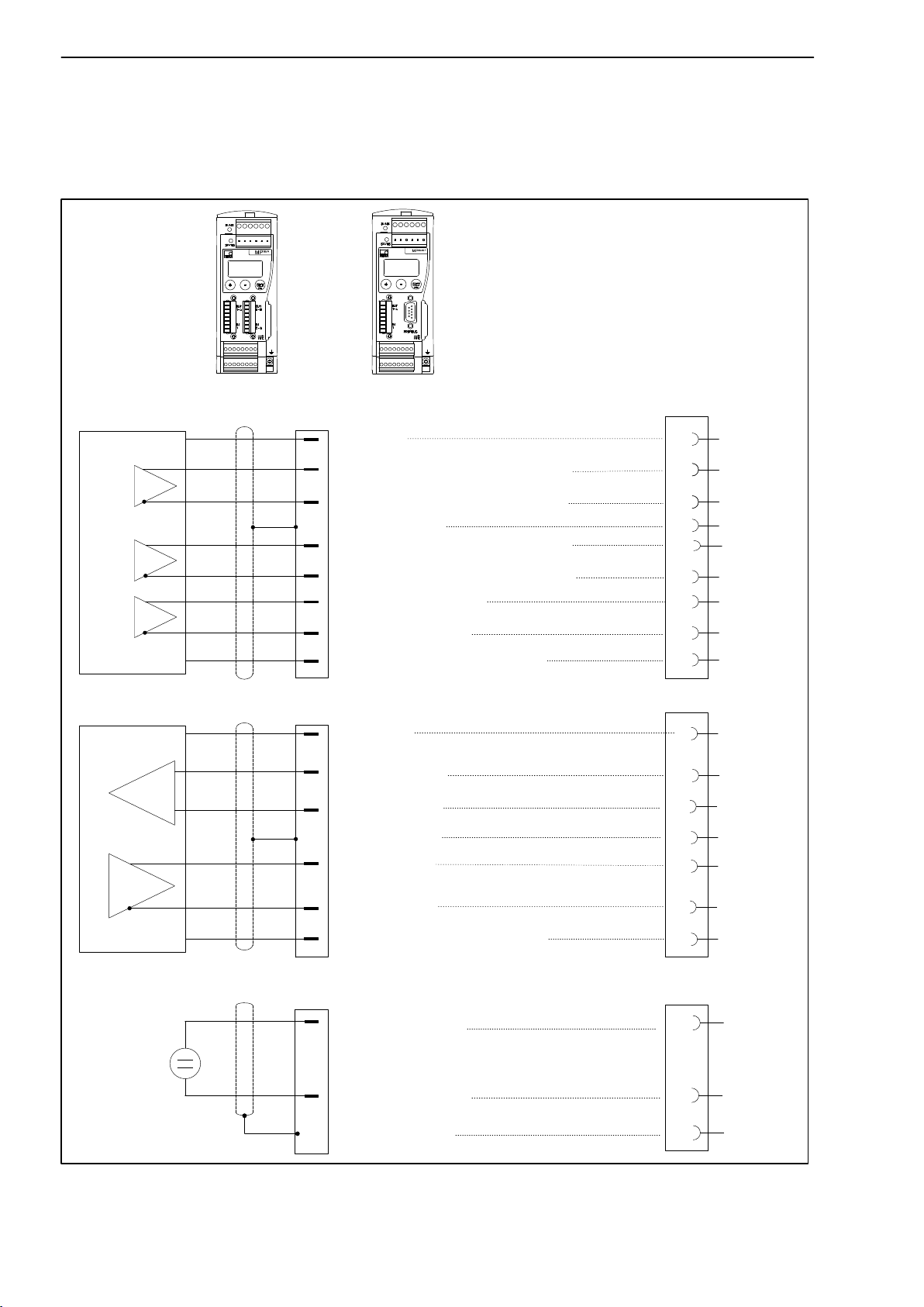

3.1 Overview of MP85A/MP85A-S functions

Local connection of CAN bus, supply voltage and synchronization between

modules

LED 1

LED 2

Screw terminal 1:

Voltage supply and CAN bus,

synchronization

Screw terminal 2: (same assignment as

screw terminal 1)

CAN adapter for PC/laptop connection,

parameterization via CAN bus

2-line LC display

Control keys

Module for MultiMediaCard (MMC) /

SD Card

15

Screw terminal 4:

4 electrically isolated control input or

switch-check inputs (24 V level,

relative to input ground screw terminal

3)

4 electrically isolated control outputs

(24 V level, power supply via screw

terminal 3)

Screw terminal 5:

Transducer connection channel x

Connection 7:

RJ45 socket for Ethernet

connection (see Page 46)

Screw terminal 3:

1 electrically isolated control input or switch test input (24 V level) incl. input

ground,

4 electrically isolated control outputs (24 V level), external supply feed for

control outputs and incremental or SSI transducers

including transducer excitation

Cable shield connection for

transducers

Screw terminal 6:

Transducer connection channel y

including transducer excitation

A2392−5.0 en HBM

Page 16

16

MP85A process controller

3.2 Overview of MP85ADP/MP85ADP-S functions

Local connection of CAN bus, supply voltage and synchronization between modules

Screw terminal 1:

Voltage supply and CAN bus,

synchronization

LED 1

LED 2

Screw terminal 2: (same assignment as

screw terminal 1)

CAN adapter for PC/laptop connection,

parameterization via CAN bus

2-line LC display

Control keys

Module for MultiMediaCard

(MMC) / SD Card

Connection 4:

9-pin sub-D socket for

PROFIBUS DP

connection

Screw terminal 5:

Transducer connection channel x

including transducer excitation

Cable shield connection for

Connection 7:

RJ45 socket for Ethernet

connection (see Page 46)

Screw terminal 3:

1 electrically isolated control input or switch test input (24 V level) incl. input

ground,

4 electrically isolated control outputs (24 V level), external supply feed for

control outputs and incremental or SSI transducers

transducers

Screw terminal 6:

Transducer connection channel y

including transducer excitation

A2392−5.0 enHBM

Page 17

MP85A process controller

17

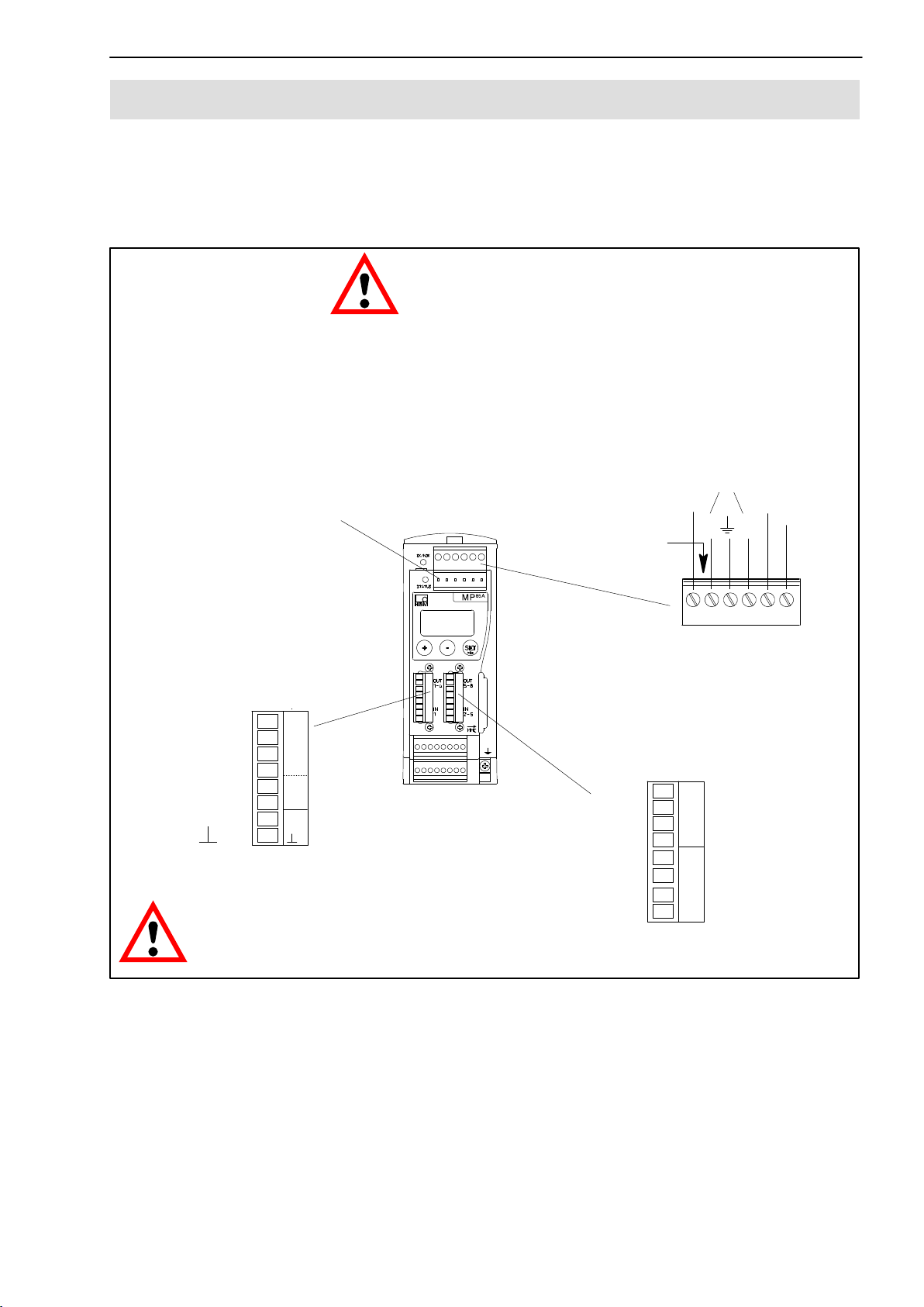

3.3 Supply voltage and control inputs/outputs

Four (MP85A/MP85A-S) or three (MP85ADP/MP85ADP-S) plug-in screw

terminals are available for connecting the power supply and the control inputs

and outputs. Control input/output functionality can be freely assigned with the

PME Assistant (menu: Digital inputs/outputs).

Connecting the power

supply:

The MP85A process controller must be connected to an

external supply voltage of 18−30 V (24 V

D Attach wire end sleeves to the voltage supply wire ends.

D Screw the wire ends to screw terminal 1.

D Insert the screw terminal into the top socket.

D Switch on the voltage supply.

Screw terminal 2

(CAN adapter; assignment as for

screw terminal 1)

WARNING

Labeling

nom

CAN

0 V

LH

).

24 V

SYNC

Screw terminal 3

(control inputs/outputs,

switch test inputs)

Out 1

Out 2

Out 3

Out 4

0 V

24 V

IN 1

IN

IN = digital input OUT = digital output

CAUTION

1

2

OUT

3

4

0V

24V

1

IN

Should the mains power fail in the MP85A process controller,

Screw terminal 4 (MP85A(-S))

(control inputs/outputs, switch test inputs)

Out 5

Out 6

Out 7

Out 8

Screw terminal 1

(CAN bus voltage supply,

synchronization)

5

6

OUT

7

8

IN 2

IN 3

IN 4

IN 5

2

3

IN

4

5

all control outputs will be set to 0 V.

Fig. 3.1: Screw terminal assignment

The screw terminals are coded to stop them being fitted into the wrong

socket. The sockets have coding tabs, screw terminals 1 and 2 have coding

pins.

The coding lugs are broken off for screw terminals 3 and 4. The contact

spacing is also different in each case for screw terminals 3 and 4, as well as 5

and 6.

A2392−5.0 en HBM

Page 18

18

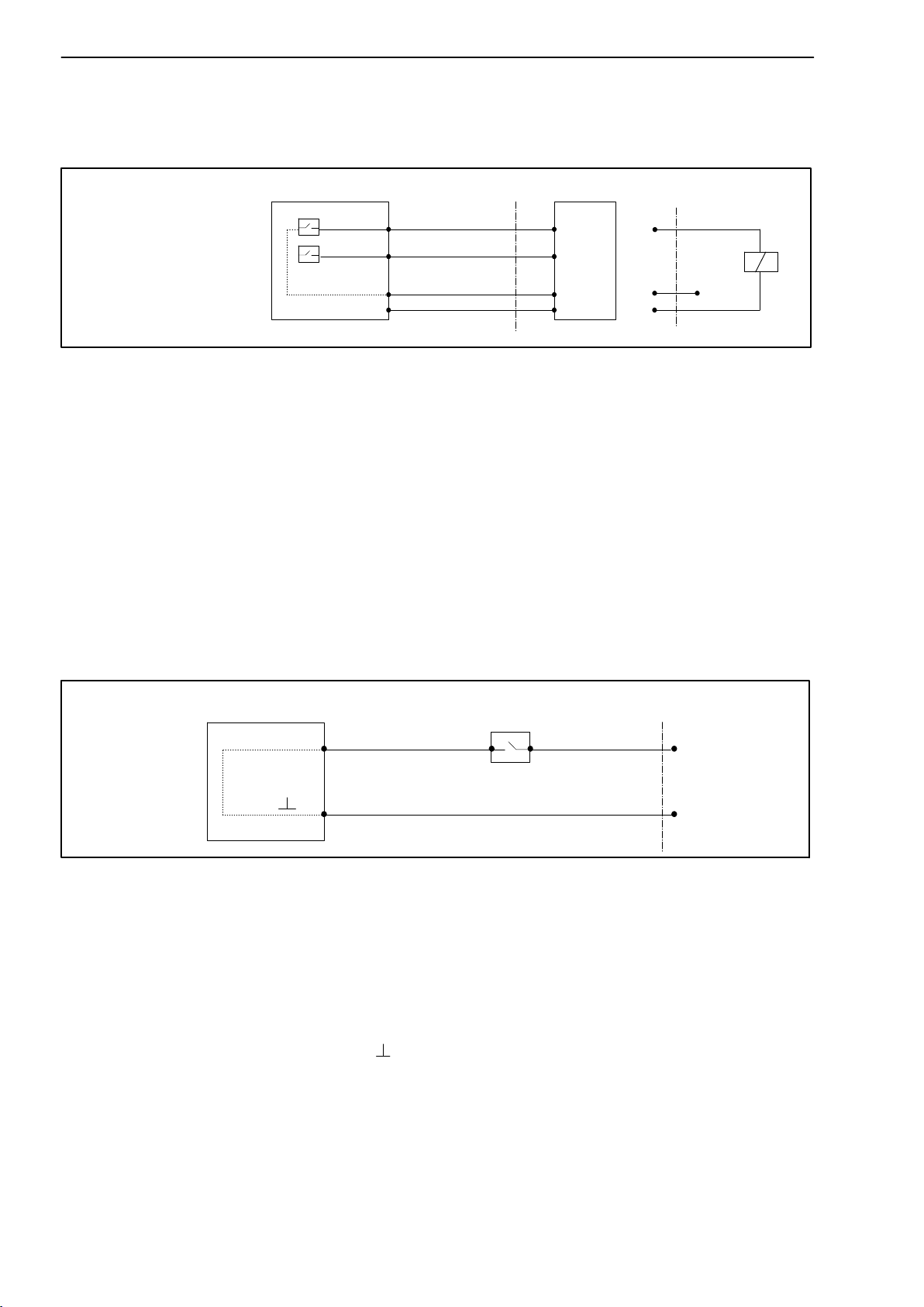

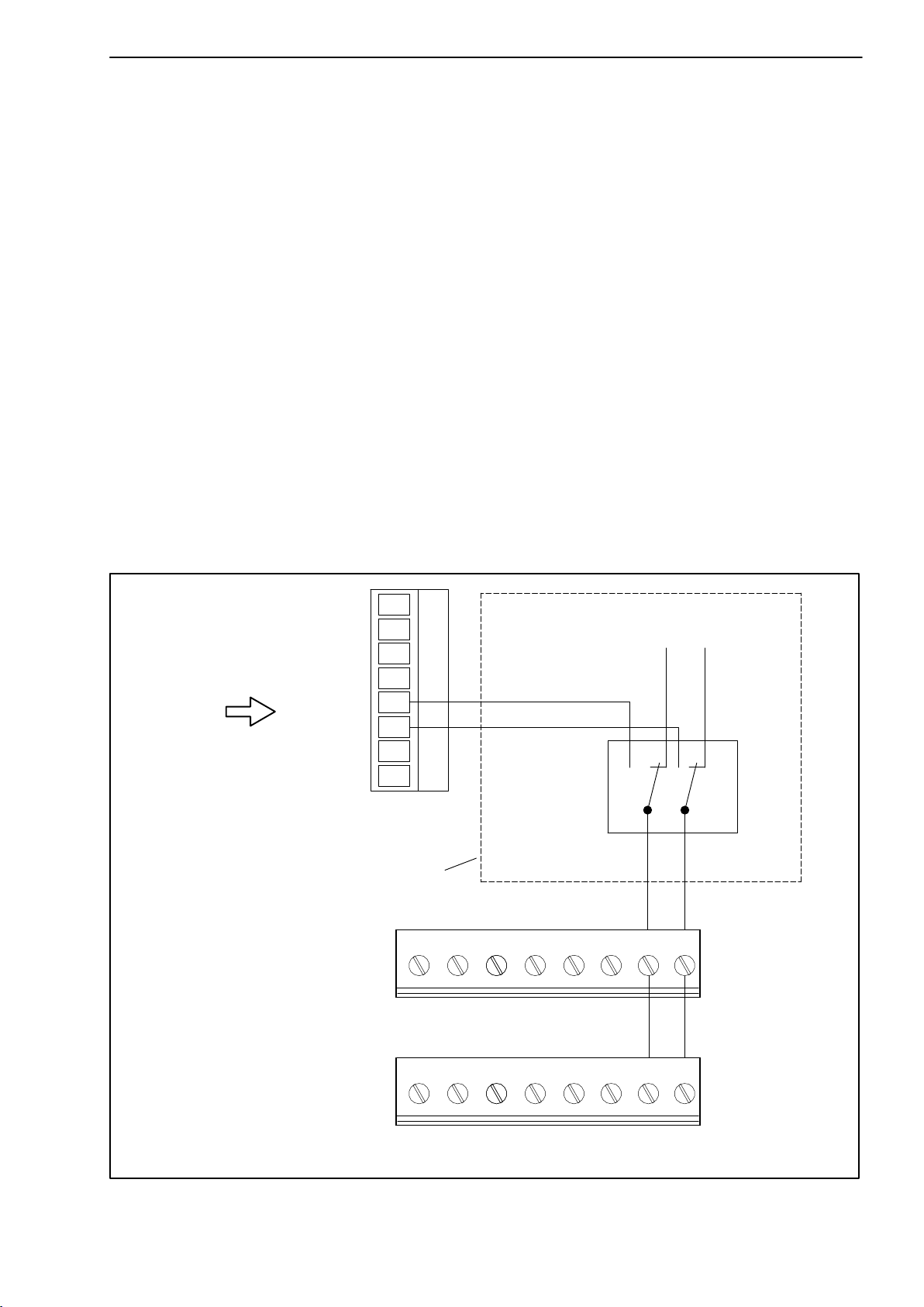

3.3.1 External supply voltage for control outputs

Example: PLC connection (p-switched)

MP85A process controller

MP85A process controller

Screw terminal 3

OUT3

OUT1

24 V*

0 V*

max. 0.5 A

PLC

Relay

max. 0.5 A

24 V

0 V*

Fig. 3.2: Connection to a PLC

The control outputs are available at screw terminals 3 and 4 and are electrically isolated from the internal supply voltage:

• at screw terminal 3: control outputs 1...4

• at screw terminal 4: control outputs 5...8 (MP85A(-S) only)

)

*

The control outputs must be supplied with an external voltage (ground and

24 V) via screw terminal 3. This external voltage is electrically isolated

from the measurement ground.

3.3.2 Reference potential for control inputs / switch test inputs

MP85A process controller

Screw terminal 3

IN 3

IN

Fig. 3.3: Connection of control input / switch test input

Switch event / test specimen

24 V (10 ... 30 V)

0 V

The control inputs are available at screw terminals 3 and 4 and are electric-

ally isolated from the internal supply voltage and from the control outputs.

• at screw terminal 3: control input 1

• at screw terminal 4: Control inputs 2...5 (MP85A/MP85A-S only)

An external reference potential (

IN ), to which the control input signals relate,

must be connected for the control inputs.

The MP85A process controller digital inputs are flank controlled by

transition from 0V to control voltage (e. g. 24V). The set digital input

function is only implemented once with the rising flank. The subsequent

permanent application of the control voltage does not cause a further

action.

A2392−5.0 enHBM

Page 19

MP85A process controller

19

3.4 Transducer

Two transducers can be connected to screw terminals 5 and 6, independently

of one another. The two measurement channels are parameterized using the

PME Assistant (menu: Transducer).

3.4.1 Synchronization of carrier frequencies

Synchronization prevents interferences occurring due to small differences in

the carrier frequencies of the individual amplifiers, i.e that amplifiers disturb

each other.

Synchronization is advisable for transducers with carrier frequency excitation

when

D the transducer cables of several devices run side by side

D the measuring points are unshielded and are close together

Even if devices work without a CAN bus, the flat ribbon cable should always

be used for synchronization between them, see Section 2.2 on Page 14.

WARNING

To synchronize several devices, declare one device as master and set all

other devices as slaves. Setting is implemented via the PME Assistant

program (menu: Basic settings −> Hardware synchronization).

A2392−5.0 en HBM

Page 20

20

MP85A process controller

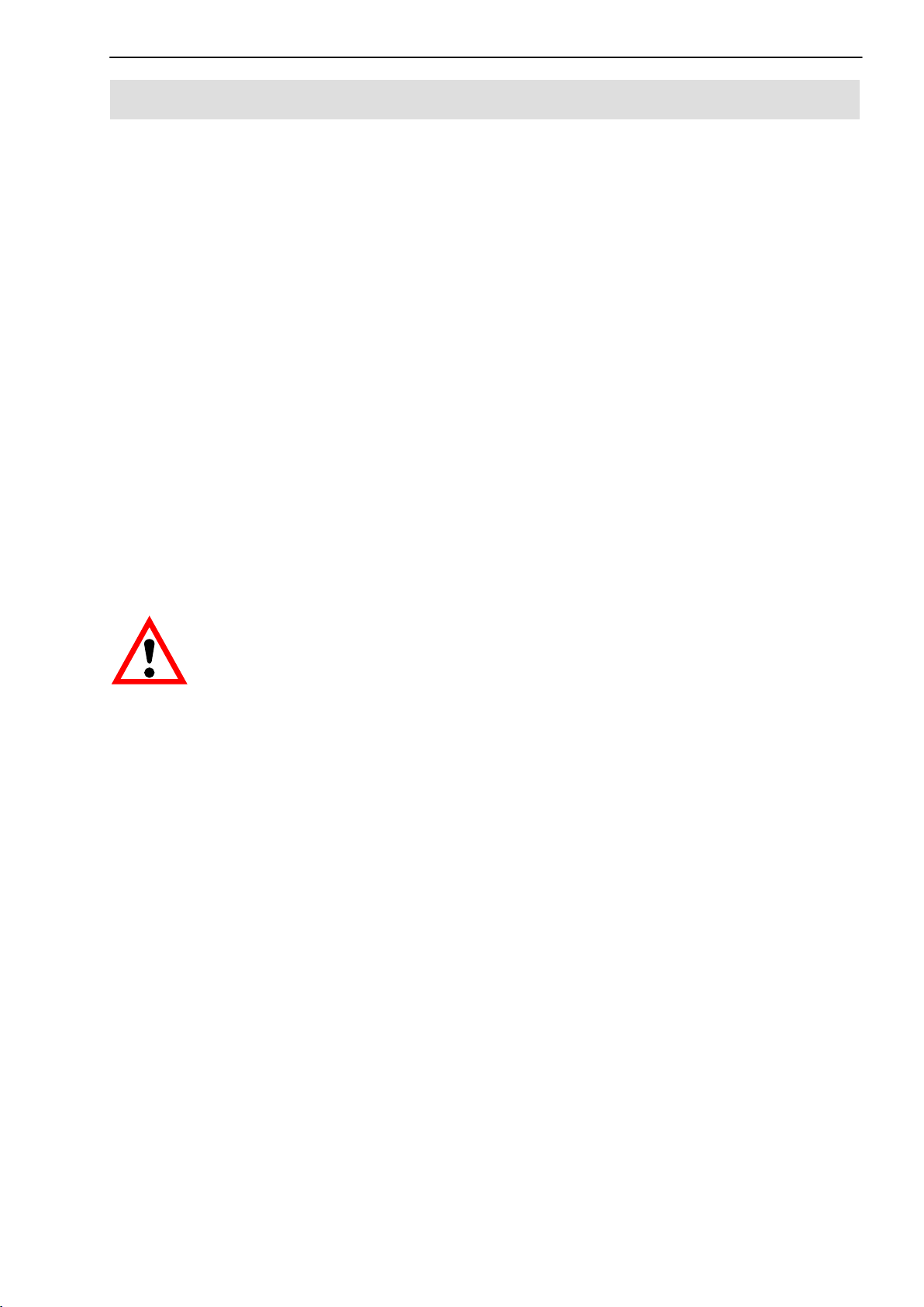

3.4.2 SGs, displacement transducers, potentiometric and LVDT sensors

In “carrier-frequency amplifier” mode, the following transducer types can be

connected:

Screw terminals 5 and 6

for transducer connection

SENSOR X

18

SENSOR Y

18

SG and inductive full bridges,

piezoresistive transducers

wh

Measurement signal (+)

bk

Bridge excitation

voltage (−)

rd

Measurement signal (−)

bu

Bridge excitation

gn

voltage (+)

Sense lead (+)

gy

Sense lead (−)

ye

Cable shield

MP85A(-S)

1

2

6

4

5

3

Hsg.

MP85ADP(-S)

SG and inductive half bridges

wh

Measurement

signal (+)

bk

Bridge excitation

voltage (−)

bu

Bridge excitation

voltage (+)

gn

Sense lead (+)

gy

Sense lead (−)

ye

Cable shield

1

2

4

5

3

Hsg.

Potentiometric transducers

Measurement

signal (+)

Bridge excitation

2

1

3

voltage (−)

Bridge excitation

voltage (+)

Cable shield

Sense lead (+)

Sense lead (−)

*)

1

2

4

Hsg.

5

3

LVDT transducer

Measurement

signal (+)

Bridge excitation

voltage (−)

Bridge excitation

voltage (+)

Measurement

signal (−)

Cable shield

Sense lead (+)

Sense lead (−)

1

2

4

6

Hsg.

5

3

Cable color code:

wh= white; bk= black; bu= blue; rd= red; ye = yellow; gn= green; gy= gray

*)

half bridge function

Fig. 3.4: Connecting different transducers in “carrier-frequency amplifier” mode

When connecting a transducer in four-wire configuration, the sense lines must

be connected to the appropriate bridge excitation circuit (Pin 3 with Pin 2 and

Pin 5 with Pin 4). With cable lengths >50 m, a resistor with half the value of

the bridge resistance (RB/2) must be connected instead in each sense lead of

the transducer.

A2392−5.0 enHBM

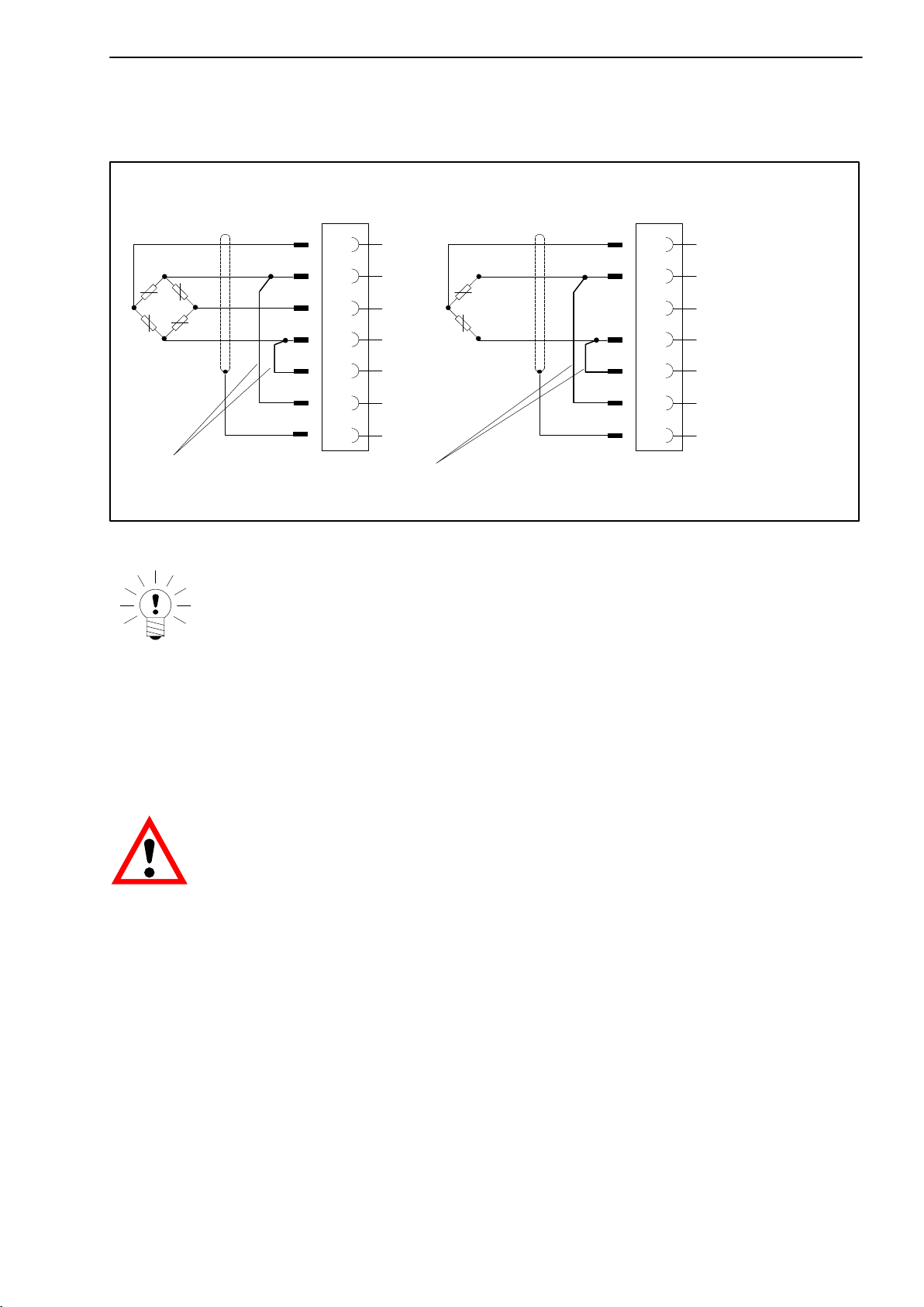

Page 21

MP85A process controller

If the transducers are calibrated in a six-wire circuit, resistors must be activated directly into the sense lead if cable lengths are >50 m.

21

Four-wire connection:

full bridge

wh

bk

rd

bu

ye

1

2

4

5

3

Hsg

6

.

Four-wire connection:

half bridge

wh

bk

bu

gn

gy

ye

1

2

6

4

5

3

Hsg

.

Feedback bridges for four-wire configuration

Cable color code: wh= white; bk= black; bu= blue; rd= red; ye = yellow; gn= green; gy=

gray

Fig. 3.5: Transducer connection in a four-wire-configuration

NOTE

Use standard HBM cables or other shielded, low-capacitance measurement cables for connecting the transducers. Connect the shield of each

transducer cable via as short a line as possible (t5 cm) and a flat

connector (4.8 mm; “Faston”) on the right next to screw terminal 6.

Otherwise EMC protection is not ensured.

CAUTION

Line break detection

MP85A process controllers have line break detection for the connected transducers.

The excitation voltage lines and the measurement signal leads are monitored.

With sense leads, a wire break is only reported as a fault if both lines are

broken; with measurement signal leads and excitation voltage leads, the

break of a single line is also reported as a fault. When a single wire breaks in

a sense lead, the measured value displayed is too high.

This also means that if the connection is faulty (for example, when full bridges

or half bridges are connected in four-wire configuration and the feedback

bridges are missing) an error message appears (display: Transducer error).

A2392−5.0 en HBM

Page 22

22

MP85A process controller

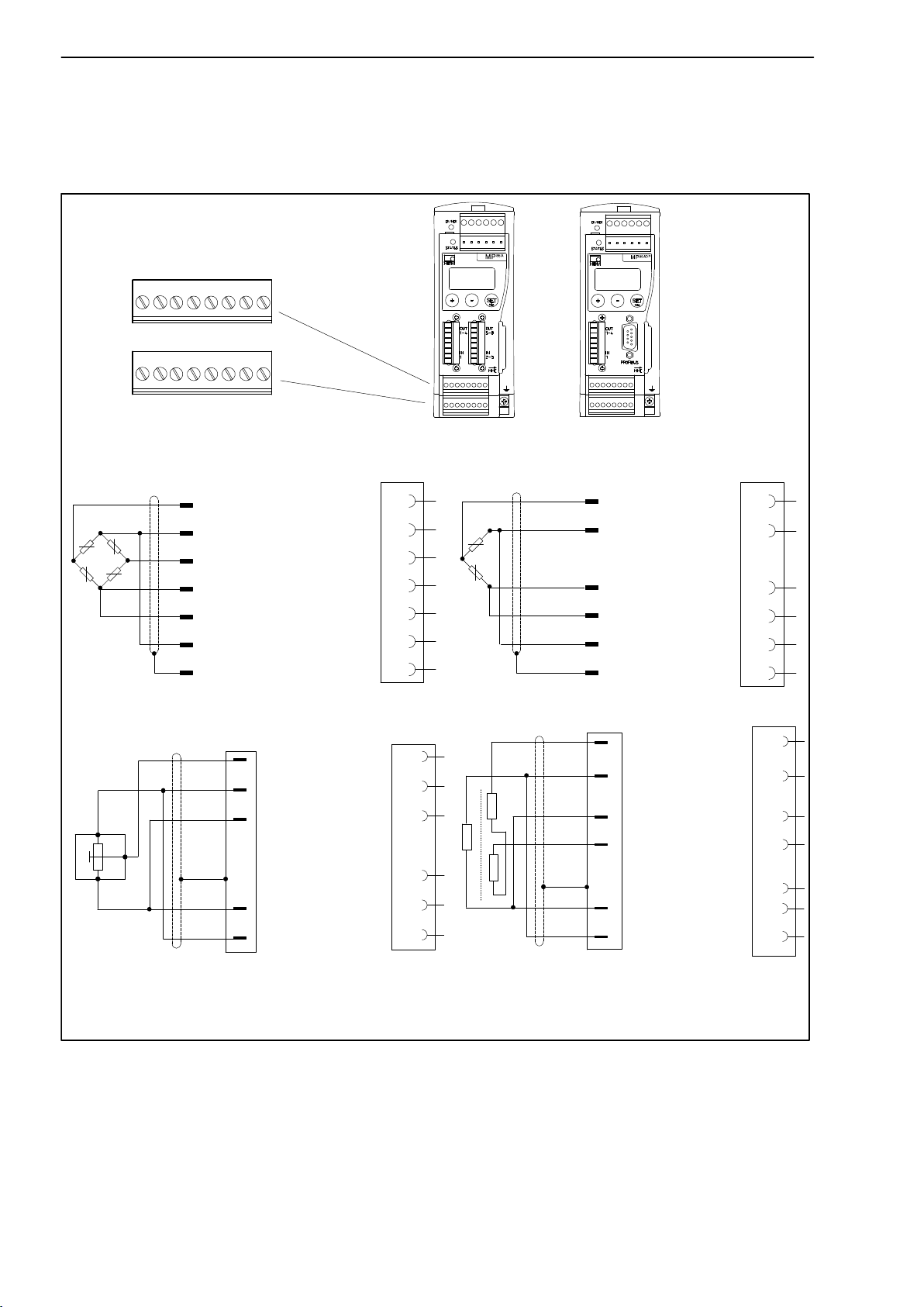

3.4.3 Incremental, SSI and DC sensors

In “Incremental encoder, SSI transducer or DC voltage transducer” mode, the

following transducer types can be connected:

MP85A(-S)

MP85ADP(-S)

Pulse counters, incremental transducers (symmetrical signals, TTL level, 5V)

Ground

f1, 0

f1, 0

f2, 90

f2, 90

o

o

o

o

Measurement signal F1 (+), 0°

Measurement signal F1 (−), 0°

Cable shield

Measurement signal F2 (+), 90°

Measurement signal F2 (−), 90°

Zero index, Ix (+)

Zero index, Ix (−)

Supply voltage +5 V/+24 V

Hsg.

7

6

1

5

3

4

2

8

Transducers with an SSI interface (symmetrical signals, TTL level, 5V)

Ground

Clock, Cl (+)

Clock, Cl (−)

Cable shield

Data, D (+)

Data, D (−)

Supply voltage +5 V/+24 V

DC voltage sources ("10 V)

U

Measureme

nt signal (+)

Measureme

nt signal (−)

Cable shield

7

6

1

Hsg.

5

3

8

5

3

Hs

g.

Fig. 3.6: Active transducer connection

A2392−5.0 enHBM

Page 23

MP85A process controller

23

A supply voltage is available at screw terminals 5 and 6, pins 7 and 8 for

feeding incremental encoders, transducers with an SSI interface and sensors

with voltage signal.

An internal or external power supply can be selected via switch S1. The

device must be open to do this (see Chapter 4).

• Transducer supplied from MP85A process controller:

Transducer supply voltage 5 V "10%, 150 mA max. (for both channels

together). The power supply is then not electrically isolated from the meas-

urement system.

• Transducer supplied from an external power pack:

At screw terminal 3, pins 5 and 6, a voltage of between 10 … 30V

DC

(nominally 24VDC), is supplied, including ground. A current of max. 300 mA

(for both channels together) can then be drawn at screw terminals 5 and 6,

pins 7 and 8.

This external supply voltage is electrically isolated from the measurement

ground and simultaneously feeds the digital control outputs.

Screw terminal 3

GND_int 5 V_int

external

power

supply

GND_ext

24 V_ext

5

6

S1

Internal MP85A

connection

78

Screw terminal 5

GND +5 V (int) / 24 V (ext.)

Screw terminal 6

78

Fig. 3.7: Active transducer power supply (basic diagram)

A2392−5.0 en HBM

Page 24

24

MP85A process controller

CAUTION

The differential signal of the measurement signal and the zero index signal must each be minimum 1.2 V.

The voltage to measurement ground must not exceed 14 V in any line. If

necessary, the voltage must be reduced via a voltage divider.

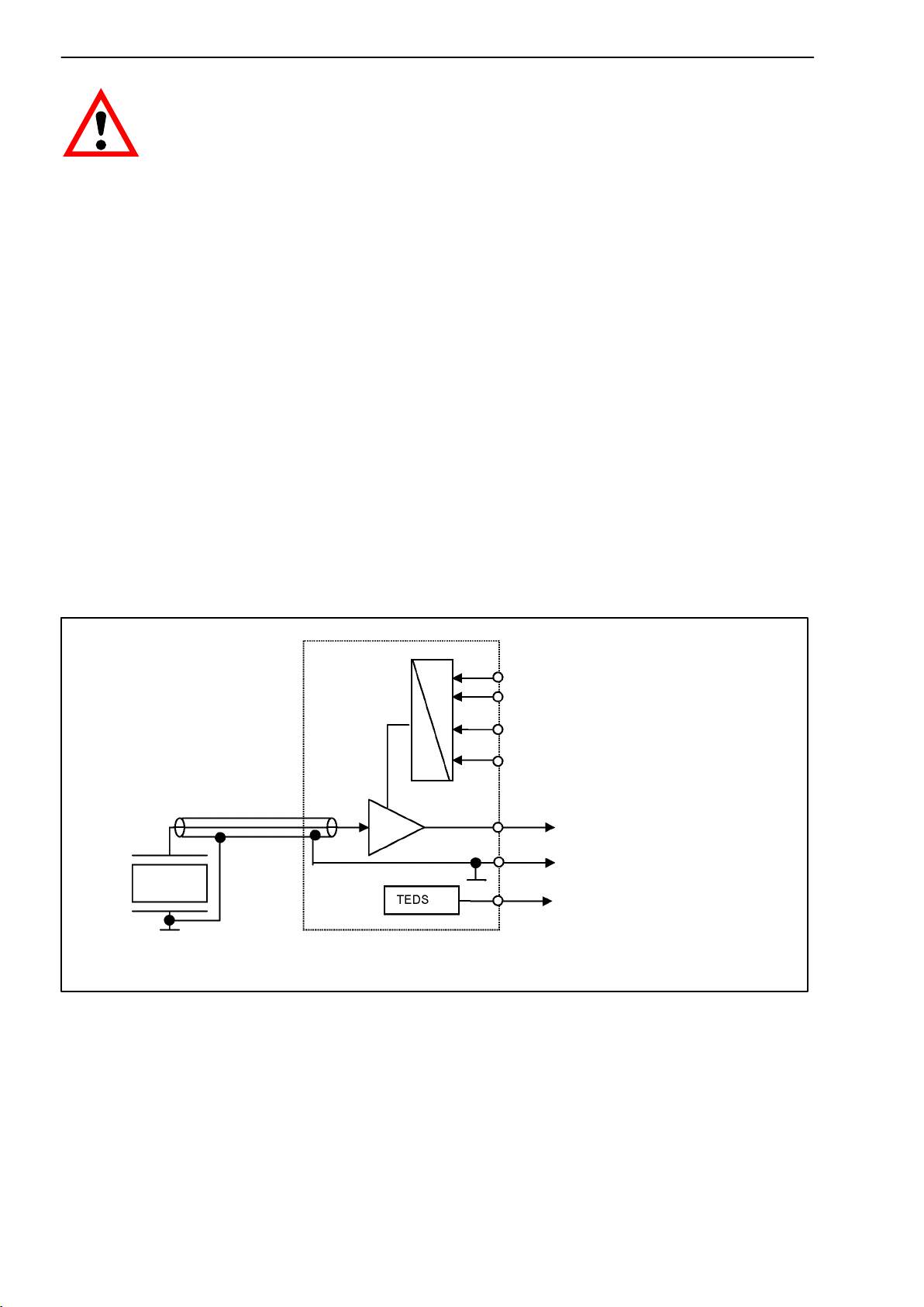

3.4.4 Piezoelectric measurement chains

The inline charge amplifier model CMA or CMD is required for operating

piezoelectric sensors on the MP85A process controller. The charge amplifier

is supplied externally with 24 VDC and is available from Pin 7 and 8 of the

screw terminals 5 and 6 of the MP85A process controller (see Chapter 3.4.3,

Active sensors, Fig. 3.7).

Internal or external voltage in the MP85A process controller can be selected

via switch S1. The device must be opened to do this (see Chapter 4) and the

switch S1 set to “24V external”.

Supply voltage

Piezoelectric

force transducer

CMA charge amplifier

18 to 30 V

0 V

DC

RANGE 1 / RANGE 2

MEASURE / RESET

Output voltage

−10 ... +10 V

0 V

DC

TEDS

DC

DC

Fig. 3.8: Block diagram of the piezoelectric measurement chain

The MP85A process controller measurement channel must be set to 10 V

(PME Assistant menu: Transducer). A reset on the charge amplifier must be

carried out before starting a measurement (Pin 3) MEASURE / RESET. With

an input voltage of 0 V at PIN 3, the charge amplifier is in the measurement

A2392−5.0 enHBM

Page 25

MP85A process controller

25

mode MEASURE. If a voltage of 24 V is present at PIN 3, the charge amplifier

switches to RESET.

TIP:

The reset signal can be generated externally or via the MP85A process

controller. To do this, the process signal “Reset piezo sensor” must be set to a

digital output of the MP85A process controller (PME Assistant, menu: Digital

outputs, circuit logic: positive).

TEDS:

The charge amplifiers have TEDS functionality for the voltage input which is

available in MP85A process controller from hardware version V1.07. When

operating without TEDS, the measurement ground (charge amplifier, Pin 6)

must be connected directly to Pin 3 of the MP85A process controller. The

yellow cable (TEDS) is therefore not required.

The charge amplifier has a measuring range selection RANGE1 / RANGE2.

Selection is via Pin 2 of the charge amplifier. The switching signal can be

supplied by an external control or the digital inputs of the MP85A process

controller. If a voltage of 0 V is present at Pin 2, measuring range 1 (100%

F

) is active at the charge amplifier.

nom

TIP:

The CMA charge amplifier gives you the option to zoom into a second measuring range (20% of the nominal (rated) force = 100% output span). A voltage

of 24 V

must be applied at PIN 2 for this.

DC

The changed measuring range must also be set in the MP85A process

controller, either automatically via the TEDS function or using the scaling

option of the input channel.

A2392−5.0 en HBM

Page 26

26

MP85A process controller

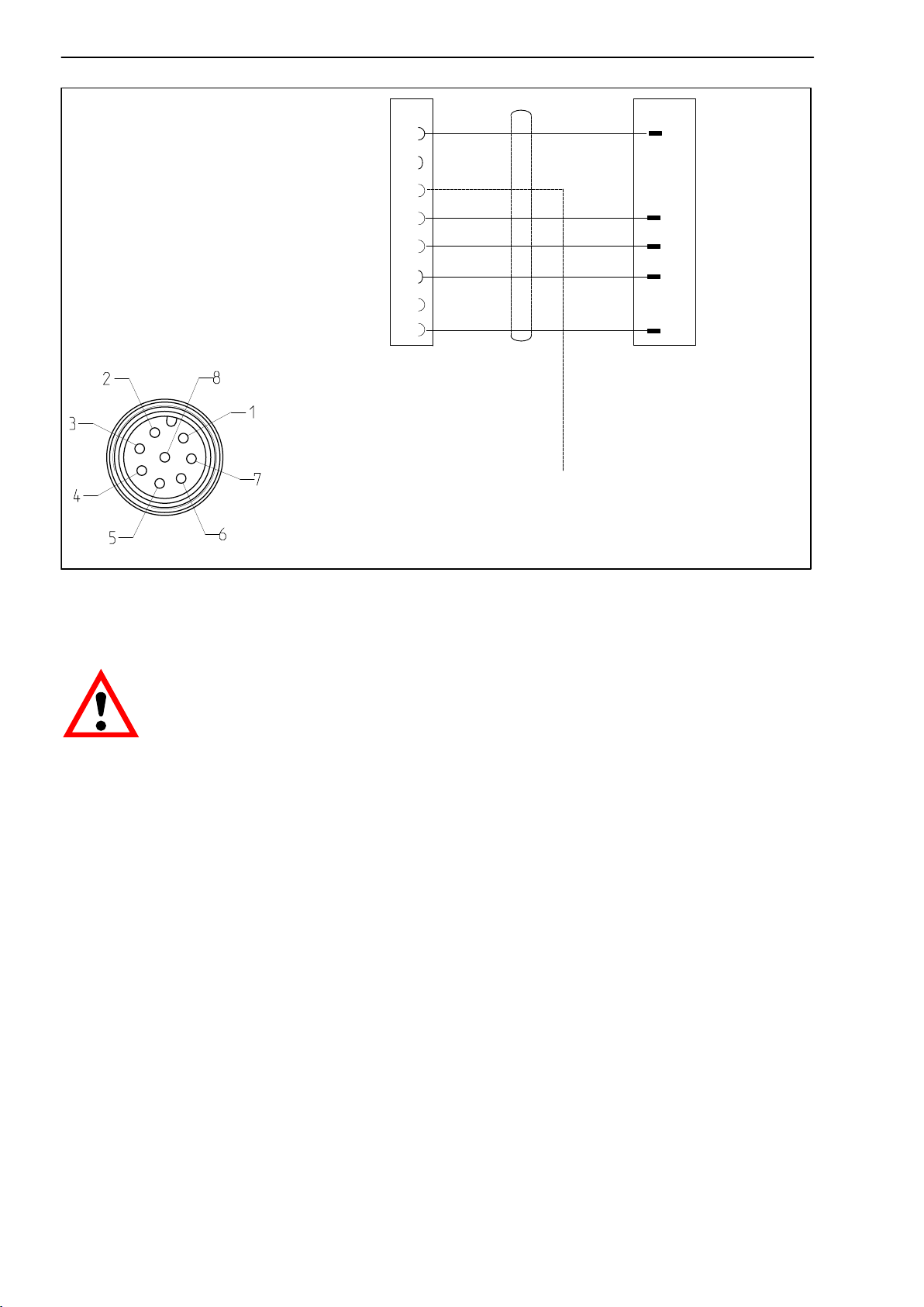

Supply voltage 0 V (GND).....

RANGE 1 / RANGE 2 (CMA only).....

MEASURE / RESET.....

TEDS.....

Output signal −10 ... +10 V.....

Measurement ground.....

Do not assign !.....

Supply voltage 18 to 30 V DC

M12 x 1, 8-pin

1)

Operating on a SELV circuit (separated extra-low voltage)

1)

1

2

3

4

5

6

7

8

.....

CMA/CMD

MP85A process controller digital OUT (Reset piezo

sensor); screw terminal 3 or 4 (output)

white

yellow

gray

pink

red

MP85A process controller

Sensor x/y

(Screw terminals 5 and 6)

7

3

5

2

8

Fig. 3.9: Connection of the piezoelectric charge amplifier CMA/CMD

CAUTION

After RESET, the charge amplifier output is set to zero, but this does not

mean that the machine generating the force is force-free. Make sure that

the force transducer is not overloaded, even though the output signal is

still in the −10 − +10 V range.

Once all the force is removed, a negative voltage signal is present with

the value of the voltage output for a RESET, without having to RESET

again.

Detailed information can be found in the operating manual “PACEline

piezoelectric force measurement chain CMC”.

A2392−5.0 enHBM

Page 27

MP85A process controller

27

3.5 TEDS-transducers (electronic data sheet)

3.5.1 TEDS connection

TEDS stands for “Transducer Electronic Data Sheet”. Transducers with electronic data sheets as per standard IEEE 1451.4 can be connected to the

MP85A process controller. This enables the automatic setting of the measuring amplifier: The transducer characteristics (electronic data sheet) are read

and translated into own settings and measurement can then start. A six-wire

configuration must be used for TEDS to be connected.

Fig. 3.10: MP85A process controller with TEDS technology

3.5.2 Parameterization with TEDS

If a transducer with TEDS, containing the parameterization data for a sensor,

is connected, this can be used to parameterize the MP85A process controller

automatically.

When the MP85A process controller is activated, it automatically detects

whether a TEDS is connected. When the transducer is replaced in the activated state, the new TEDS is also detected automatically.

To monitor TEDS functionality and to protect scaling from manual intervention, check the boxes in the TEDS dialog box in the PME Assistant

(menu: TEDS). TEDS functions can be enabled individually for each

channel. Using TEDS for piezoelectric measurement chains is described

in Section 3.4.4 .

NOTE

A2392−5.0 en HBM

Page 28

28

Set up with the PME Assistant

In the PME Assistant, choose the desired conversion unit from the selection

menu in the “TRANSDUCER” area. If instead you want to use the unit stored

in the TEDS directly, deactivate this function in the TEDS dialog box.

When the TEDS is activated, its scaling data will be read out and converted to

the required physical unit. Should the unit stored in the TEDS and the

required conversion unit be incompatible because they describe different

quantities (e.g. torque transducer connected, conversion unit is “N”), an error

message is generated and scaling does not take place.

If a scaling error is reported once the TEDS is activated, the reason may be

that the value range specified by the two characteristic curve points is so

great or so small, that the measured values cannot be displayed with the set

decimal places.

You then need to adapt the number of decimal places in the “Amplifier” area. It

may possibly help to change to a different power of ten, such as “N” to “kN”.

MP85A process controller

The PME Assistant displays this information for each channel in the “TEDS”

area with the “TEDS error status”. For an accurate analysis, it is advisable to

display the data stored in the TEDS. You need the TEDS Editor and suitable

hardware, e.g. the HBM TEDSdongle, to connect the sensors.

The data for the minimum and maximum bridge excitation voltage in the

TEDS is also checked.

If, instead of using the PME Assistant, you are parameterizing directly e.g. by

bus command, you must use Object 2122 to set the required conversion unit

before activating TEDS.

The available units match the selection list provided by the PME Assistant.

CAUTION

If several transducers are connected to an MP85A amplifier input in

parallel, their TEDS data cannot not be used as neither the error-free

reading out of parallel connected TEDS is ensured nor can a summation

of the individual parameters take place. In this case, ensure that the

fields in the TEDS dialog are not activated for the channels concerned.

3.6 Interfaces

Use the PME Assistant to set up and parameterize the device via the Ethernet

or CAN interfaces. In automatic applications, the devices are integrated into

the machine control via fieldbus interfaces.

A2392−5.0 enHBM

Page 29

MP85A process controller

3.6.1 Ethernet interface

An RJ45 socket for Ethernet connection is located underneath the MP85A

process controller as standard.

RJ45

29

Fig. 3.11: Ethernet connection

The device can also be integrated into an existing Ethernet network. It

supports speeds of 10 Mbit/s and 100 Mbit/s. The transmission speed is automatically adapted to the existing network. Category 5 or higher cables must

be used for this. This enables line lengths of 100 m to be implemented.

Fig. 3.12: Integrating the MP85A process controller into an existing Ethernet

network

Notes on operation in an Ethernet network

In order to avoid network problems, you should check the following points

before connection to an Ethernet network:

• Are the connected device addresses unique, i.e. no identical IP addresses?

A2392−5.0 en HBM

Page 30

30

MP85A process controller

• Does the network have sufficient reserves for the transmission of the

planned data or could the network load become too great?

• Are there nodes that could load the network through broadcasts, i.e. data

sent to all nodes?

In order to avoid disturbance of measurement operation by other network

nodes, you can also operate the devices in a separate network disconnected

from your company network. Connection to the company network would only

be necessary if external access to the measurement devices themselves is

necessary. If access to the generated data alone is required, you can implemented this with a PC connected between the networks − linked via one

network card to the devices and via a second network card to the company

network.

If the device is to be connected to the company network, we recommend the

use of a “Managed Switch” as these (higher quality) devices are by experience less susceptible to disturbances. The network with the measuring instruments and any PCs integrated in this network is then connected to the

company network via the Switch.

In order to achieve the best possible separation between the network with the

measuring instruments and the remaining company network, you can also use

a router that separates both networks and only transmits messages between

the two networks when necessary.

3.6.2 CAN interface

The CAN bus is connected via screw terminal 1. A maximum of 32 CAN

nodes can be connected in one bus segment (in accordance with the

CANopen specification).

The CAN bus needs a termination resistor of 120 Ω

node

. The maximum number of termination resistors the bus cable can have

on the first and last bus

is two. The MP85A process controller has an integrated termination resistor,

which is activated by toggle switch S2.

Low High

Device 1

Fig. 3.13: CAN interface connection

A2392−5.0 enHBM

Page 31

MP85A process controller

31

CAN-High

CAN connection

as per Fig. 3.13

CAN-Low

First device in

the bus cable

Connect the termination

resistor here (toggle

switch)

Do not connect the

termination resistor

Last device in

the bus cable

Connect the

termination resistor

here (toggle switch)

Fig. 3.14: CAN bus mode with several transducers (max. 32 as per standard)

NOTE

If the first or last device in the bus cable is not a PME device, a 120 W re-

sistor must be connected to each of these external devices.

The baudrate of all devices must be identical to that of the CAN master.

The baudrate must be reduced for greater line lengths according to the

CAN specifications.

3.6.3 PROFIBUS interface (MP85ADP/MP85ADP-S only)

On the front of the MP85ADP(-S) is a 9 pin D-Sub connecting socket for the

PROFIBUS connection.

GND

9

RS485-A

5

RS485-RTS

RS485-B

Vcc (5 V)

6

1

PROFIBUS

connection socket

Fig. 3.15: PROFIBUS connection as per standard

A2392−5.0 en HBM

Page 32

32

MP85A process controller

Installation:

• Connect the MP85ADP(-S) to a 24 V supply voltage and use the keyboard

or the Setup program to set the required PROFIBUS address.

• Connect the PROFIBUS line to the MP85ADP(-S). Make sure that termina-

tion resistors are connected on the first and last PROFIBUS nodes (there is

usually a slide switch on the housing of the PROFIBUS plug for this).

Example:

PROFIBUS plug PROFIBUS plug

First device in

the bus cable

PROFIBUS connector slide switch set to

“Resistor ON”

Fig. 3.16: PROFIBUS operation

Last device in

the bus cable

PROFIBUS connector slide

switch set to

“Resistor ON”

A2392−5.0 enHBM

Page 33

MP85A process controller

33

4 Switch settings / Replacing the battery

Changing the supply voltage for the active transducers

Use switch S1 to select either an internal 5 V supply or an external 24 V

supply as the supply voltage for the active transducers. The factory setting

is 5 V internal sensor supply voltage.

NOTE

The housing needs to be opened for this switchover. Therefore a change

must be made before the MP85A(DP) is mounted.

To set switch S1, proceed as shown in Fig. 4.1.

1

Unscrew the

cover

Switch S1 for the active

transducer supply voltage

2

S1

5 V

(int)

24 V

(ext)

Fig. 4.1: Opening the housing; position of switch S1 (basic diagram)

Example:

ON

12

34

5

means

6

Fig. 4.2: Switch convention

Termination resistor

The CAN termination resistor is activated and deactivated with switch S2

(see Fig. 4.3).

A2392−5.0 en HBM

Page 34

34

S2

ON OFF

MP85A process controller

Toggle switch S2 for the

termination resistor

Fig. 4.3: Switch for the CAN bus termination resistor (basic diagram)

Replacing the battery

The MP85A process controller has a real-time clock, which is fed by a

CR2032-type lithium battery. It can be removed from the battery holder and

replaced at the point shown in Fig. 4.4. The battery should be replaced about

every five years.

NOTE

The MP85A process controller must be removed from the DIN rail to

replace the battery.

1

Battery

for the

real-time clock

Unscrew the

cover

Fig. 4.4: Opening the housing; battery position (basic diagram)

2

CAUTION

Make sure that the battery is the right way round

A2392−5.0 enHBM

Page 35

MP85A process controller

Battery position

−

+

Fig. 4.5: Correct battery position

35

The buffer battery is only required for the device-internal real-time clock.

The device functions are not affected by the battery.

However, the time is also saved with the curve and results files. The correct time and data should therefore be set in the device (PME Assistant:

menu: Basic settings).

There is no automatic summer/winter time switchover.

A2392−5.0 en HBM

Page 36

36

MP85A process controller

5 Starting up/Setting up mode

To prepare the MP85A process controller for a measurement task, the

following requirements must be met and the relevant steps taken:

• You require an MP85A process controller and either the PME Assistant or

INDUSTRYmonitor program.

• The hardware must be set up: Transducer, MP85A process controller, PC

with software (from Section 5.2).

• The software must be installed (from Section 5.3)

To connect the MP85A process controller to a PC, you need:

− for Ethernet operation (Section 5.2.2 ):

• Ethernet crossover cable

− for CAN interface operation:

• CAN adapter (Section 5.2.3 ), either PCAN USB-to-CAN or PCAN card

(PCI or ISA)

The MP98A process controller must be connected to a PC via the Ethernet

cable or the CAN adapter. Once you have launched the software, you can set

up the MP85A process controller with the PME Assistant (Section 5.4).

In order not to invalidate subsequent statistics while in set up mode, the PME

Assistant (menu: Data storage) can be used to temporarily switch off the statistics processing.

TIP:

Detailed instructions are included in the PME Assistant Online Help. To call

the Help, the PME Assistant must be installed. For a quick guide to operating

the measurement system, refer to the FASTpress Suite quick start guide.

A2392−5.0 enHBM

Page 37

MP85A process controller

37

External

display

terminal

(option)

Sensors

Fig. 5.1: System configuration with the MP85A process controller

5.1 Operation

5.1.1 Device settings, measured values, process status, PROFIBUS,

memory cards, error types, firmware update, device backup

The MP85A process controller device display shows the measured values

and status information for measurement channels, process status, digital

inputs/outputs and parameter set backup; devices with PROFIBUS interface

also display the PROFIBUS status.

You can switch between individual displays and menus with the device

keyboard.

Use the device menu to set the Ethernet, CAN bus or PROFIBUS addresses.

In addition, a menu is available for device identification (serial number, firmware and hardware version, etc.) and for backing up the 31 Flash parameter

sets.

All other device settings are software set via the PME Assistant or the

INDUSTRYmonitor.

A2392−5.0 en HBM

Page 38

38

• Display in measuring mode:

MP85A process controller

Measured value

Unit

Status field

−18.0024

x

!

kg

• Function of the keys:

SET

1. Changing from measuring mode to

input mode

2. Choose the first parameter within

the group.

3. Confirm the entry

4. Return to measuring mode (press

for 2 seconds)

↑

Flashes in the status field if the parameter value can be edited

+

Selecting the

parameter/group

+

−

−

• Keys

Keep key pressed − Value runs continuously

Short key press − Advance by single value

During measurement, if you press

−

+

−

+

, the following will be displayed:

1. Measured values

• MVx Measured value for channel x

• MVy Measured value for channel y

2. Process status, “ProcStat”

• Alarm The last process was terminated via the alarm window

• O K The last process was OK

• N O K The last process was not OK

• Started A process has been started and not yet finished

3. Status of the digital inputs and outputs

The MP85A(-S) has 5 inputs and 8 outputs.

The MP85ADP(-S) has 1 input and 4 outputs.

• Input

set not set

A2392−5.0 enHBM

Page 39

MP85A process controller

39

• Output

set not set

4. PROFIBUS status (MP85ADP and MP85ADP-S only)

BD_SEAR (baudrate search)

WT_PARM (waiting for parameterization)

WT_CONF (waiting for configuration)

DATA_EX (cyclic data traffic)

ERROR (bus error)

5. Status of memory card (MMC/SD Card)

The optional memory card can be used if necessary to store measurement

curves, measurement results and even parameter sets (measurement

programs).

You can use either an SD card or a MultiMediaCard (MMC) up to 2 GB. The

PME Assistant (menu: Data storage) can be used to select what should be

saved and which medium (memory card or PC).

Up to 300,000 measurement curves can be stored on a memory card with 1

GB storage capacity. In addition, up to 31 parameter sets in XML format and

up to 1000 parameter sets in binary format can be stored.

Parameter sets in XML format can be loaded into the -device via the front

panel keyboard. Binary parameter sets can be selected using the PME

Assistant or the interface.

CAUTION

Only use standard MMC cards, not SecureMMC, MMCplus

TM

bile

, SDHC (SD High Capacity), SDXC cards (SD eXtended Capacity)

TM

, MMCmo-

or equivalent cards. The data transmission speed is not increased, but

incompatibility problems could occur. MMC or SD cards must be formatted with FAT16, not with NTFS, otherwise they will not be recognized by

the MP85A process controller. If necessary, reformat the card.

The MMC/SD card should be defragmented or reformatted at regular intervals

to optimize the access times.

A2392−5.0 en HBM

Page 40

40

MP85A process controller

Display Significance

unused

No memory card

Init...

SET ³ STOP

Saving

Stopped

No data should be saved to the memory card.

Data should be saved to the memory when anything else appears

on the display.

The device has no memory card inserted.

The memory card is initialized automatically on insertion.

The memory card is ready for storage. Pressing SET changes the

status to STOP. The memory card can then be removed.

Data are being written to the memory card. Once writing is complete, the status changes to “Ready”; SET ³ STOP appears on

the display.

Before removing the memory card from the device, you must

press the SET key. This will close all the files and write the

FAT.

The display briefly shows the message “MMC/SD Disk Closed” or,

in the case of error, “MMC DiskClose Err”. The MMC/SD card then

switches to the “Stopped” status and can be removed from the device. If there is no more space left on the memory card, it automatically switches to the “Stopped” status. This status can only be left

when the memory card is removed from the device. Re-initialization then follows automatically.

6. Kinds of error

During measurement, the ! character in the status field (in measuring mode)

indicates an MP85A process controller error.

−

+

Errors are displayed successively (can be reached using

).

− ERROR x (relative to the SENSOR X screw terminal)

− ERROR y (relative to the SENSOR Y screw terminal)

SENSOR X

SENSOR Y

TIP:

The relevant device status is clearly displayed with an error overview in the

PME Assistant “Status overview” dialog. Open the dialog via the “Status”

button in the Measured value display window.

The meaning of the displays and possible corrective measures for error

messages are listed in the online help (use F1 to call the Help). Further valuable tips and setting assistants can be found in the FAQ section.

A2392−5.0 enHBM

Page 41

MP85A process controller

41

Status

NOTE

The possible error messages are summarized in Chapter 10, “Error messages”.

7. Firmware update (F-Update)

To update the firmware, use the program PME Update. A description of the

procedure can be found in the online help. The program can be used to

transfer a new firmware version to several devices simultaneously. In order

not to conflict with the processing of a process (no measurements or evaluations can be implemented during an update), you can specific from firmware

version 2.22 or higher that the firmware update is only implemented on the

device following manual confirmation (F-Update: Permitted!). If confirmation

does not occur within 15 minutes, no changes are made to the firmware.

The firmware update program is available on the System CD or can be downloaded from the HBM website.

We recommend saving the device settings (device backup) before any

updates.

8. Device backup

All MP85A process controller settings can be saved to MMC/SD card via the

integrated keyboard and then, e.g. transferred to another MP85A process

controller.

Using the device menu, all 31 Flash parameter sets, including all interface

settings of the MP85A process controller, can be saved to the memory card

A2392−5.0 en HBM

Page 42

42

MP85A process controller

as a backup (“S-Status Save”) and reloaded into the MP85A process

controller where necessary. When loading, you can select whether loading

should take place without interface parameters (“S-Status Restore”) or with

interface parameters (“S-Status Load-Com”), see Chapter 5.1.3. Confirm the

action by pressing the SET button. Progress is displayed as a % display in the

device display.

CAUTION

No measurements or evaluations are implemented during a device

backup and the response times of the device to the software or controllers take longer!

5.1.2 Overview of all groups and parameters

SET

+

Up

−

Down

+

−

CAN-BUS ETHERNET PROFIBUS ADD. FUNCTION

Baudrate MAC address Address

Address IP-Adr.1

MNGRP

Parameter overview

Groups

Ampl.Type

(amplifier type)

MNGRP

IP-Adr.2

IP-Adr.3

IP-Adr.4 SD/MMCLo

SubNetM1

(subnet mask)

SubNetM2

SubNetM3

SubNetM4

IPGatew1

IPGatew2

PrgVers

(firmware version)

SrNo

(serial number)

HW vers.

(hardware version)

MNGRP

SYSTEM-STATE

Backup Save

Backup Restore

Backup Load-Com

MNGRP

IPGatew3

IPGatew4

MNGRP

A2392−5.0 enHBM

Page 43

MP85A process controller

43

MNGRP: with

SET

, back to main group

SD/MMCLo:

Gives you the option of loading a parameter set (XML format only) that has

previously been stored on the MMC/SD card with the PME Assistant or

+

INDUSTRYmonitor. Use keys

and − to select the required parameter set.

IP gateway:

From firmware version 2.20, the gateway address can be entered for crosssegment device access in the Ethernet network.

System-state:

From firmware version 2.22, you can save the MP85A process controller

settings to an MMC/SD card or e.g. load them into another MP85A process

controller. “S-Status Restore” restores all settings, “S-Status Load-Com”

restores all settings except the addresses (CAN/Ethernet/PROFIBUS).

A2392−5.0 en HBM

Page 44

44

5.1.3 Setting parameters on the device

Measured

value

SET

2 secs

MP85A process controller

Groups

SET

CAN bus

SET

Baudrate

SET

↑

10kB

20kB

50kB

100 kb

+

−

PROFIBUS

ETHERNET

MAC address

+/−

SET

+

IP-Adr.1

125 kb

250 kb

+

−

Address

SET

500 kb

1000 kb

↑

1−127

+/−

−

SET

Address

Back to Main

GRP

↑

3−123

SET

+/−

IP-Adr.2

IP-Adr.3

IP-Adr.4

SubNetM1

+

SubNetM2

Back to Main

GRP

−

Parameter values

+

Select parameter

−

SubNetM3

SubNetM4

IPGatew1

IPGatew2

Flashes, if parameter value

↑

can be edited

Confirm entry:

+/−

=

+ −

or

SET

Back to measuring mode:

press

SET

2 secs

SET

IPGatew3

IPGatew4

Back to Main

GRP

A2392−5.0 enHBM

Page 45

MP85A process controller

45

Groups

ADD. FUNCTION

SET SET

Ampl.Type

PrgVers

+

−

SET

SrNo

HW vers.

SD/MMCLo

(ad)

Back to Main

GRP

+

MEAS. MODE

−

Save?

Meas. value

SET

↑

↓

0 − 31

SET

+/−

+

Yes

↑

No

SYSTEM-STATE

−

+/−

+

−

SET

Backup

Save

Backup

Restore

Backup

Load-Com

Back to Main

GRP

5.2 Hardware setup

5.2.1 Voltage supply / transducers

• Connect the power supply cable and the transducers to the module

(Sections 3.3 and 3.4).

CAUTION

Comply with the safety instructions!

• Switch on the power supply.

• The device runs a self-test (about 10 secs) and then, if this functions

properly, it is in measuring mode. During the self-test, the control

outputs stay at 0 V.

A2392−5.0 en HBM

Page 46

46

MP85A process controller

NOTE

If ! appears on the display or the status LED glows red, an error has occurred. Please refer to Chapter 10 “Error messages”.

• Connecting the bus system

To find out how to connect several devices to a bus, refer to Sections 2.2

(Page 14) and 3.6 (Page 28). Note that devices must be synchronized for

error-free operation.

5.2.2 Establishing the Ethernet connection

For an MP85A process controller to communicate with the PC, the device

must be connected to the PC. Use an Ethernet crossover cable (1-KAB239-2)

for direct connection. The connection (RJ45 socket) is located underneath the

MP85A process controller. When operating several devices in an Ethernet

network, we recommend the use of industrial Ethernet switches.

RJ45

As a minimum, category 5 cables with a maximum line length of 100 meters

are used for this.

Further information on connection setup and interface settings can be

found in the operating manual “CAN/PROFIBUS/Ethernet MP85ADP

FASTpress interface descriptions”.

A2392−5.0 enHBM

Page 47

MP85A process controller

47

5.2.3 Connecting the CAN adapter (USB)

• Should the PC not have its own CAN bus interface, you can use the CAN

to USB adapter (1-PMESETUP-USB).

• Plug the USB to CAN adapter into a free USB interface on your PC.

• Your PC will detect the adapter (Plug and Play).

A CD is included with the adapter. This CD contains the installation drivers

which are automatically installed during the installation of the PME

Assistant and when the USB to CAN adapter is connected.

5.3 Installing the PME Assistant software

The PME Assistant is installed using the supplied system CD. The latest

version can also be found on the HBM website: www.hbm.com −> Support −>

Software-/Firmware-Downloads.

System requirements

To run the PME Assistant software, you need a PC that meets the following

requirements:

• Intel Pentium 2 GHz processor or equivalent

®

• Windows

2000, Windows®XP ,Windows Vistat or Windows® 7

• Microsoft Internet Explorer 6.0 (or higher)

• RAM:

®

• 256 MByte for Windows

• 512 MByte for Windows

• 2 GByte for Windows Vistat or Windows

2000

®

XP

®

7

• Graphics card with a resolution of 1024 x 768 pixels

• 20 MByte free memory on the hard drive

• The NTFS file system is necessary if you are recording numerous proces-

ses and therefore more than 65,000 files may be generated on the PC during a test.

• Microsoft or 100% compatible mouse

• Suitable standard printer

• Interface: USB-CAN interface from PEAK or Ethernet interface

• The following fonts must be installed: Arial (TT), Courier, MS Sans Serif,

Small Fonts, Tahoma, Times New Roman (TT), Verdana and Wingdings.

®

The fonts are normally installed with Windows

A2392−5.0 en HBM

.

Page 48

48

MP85A process controller

NOTE

The minimum requirements listed above are sufficient if you are only

connecting one device. Suitable, more powerful PC hardware and more

main memory are necessary if you also wish to transfer result and curve

files from several devices to PC.

Further information can be found in the quick start guide “FASTpress

Suite”.

5.4 PME Assistant operation

Interface

type

Opens the

Setup window

192 168 169 10

Factory settings

for the interface

Scanning the bus

for connected PME

modules

Fig. 5.2 Start window

5.4.1 Using the Ethernet interface

Launch the PME Assistant program and enter the required interface connection in the Start window:

• In the Interface field, select “TCP/IP”. The PME Assistant now gives you

the option of using the preset IP address or setting a new one.

• The address cannot be assigned automatically via DHCP. So you must

make sure that the IP address of the MP85A process controller differs

from the address of the network being used in max. one segment.

A2392−5.0 enHBM

Page 49

MP85A process controller

49

• In the subnet mask, a zero must be set in this position. All other

segments in the subnet mask must be set to 255.

• Now use the “Add IP to device list” button to transfer the IP address of

the MP85A process controller to the device list.

Alternatively, you can also press the “Scan” button to run a bus scan. In

this case, all the devices found will be displayed in the device list.

• If several MP85A process controllers are connected to the Ethernet

network via a switch, for example, make sure that each address has only

been used once. If you do not know the settings, you can query them via

the MP85A process controller keyboard (see Chapter 5.1.2).

• Use the “Start” button to launch the PME Assistant. The MP85A process

controller automatically sets the transmission speed to 10 Mbit or 100

Mbit.

5.4.2 Using the USB interface

Launch the PME Assistant program and take the following steps to configure

the USB interface:

• In the Interface field, select “CAN”. The PME Assistant now gives you the

option of selecting the CAN network to be used.

• The baudrate in the CAN network must be the same. In the delivery

condition, the baudrate of the MP85A process controller is set to 1 MBit/s.

• If you select “Use as standard”, this network will be chosen automatically

the next time the system starts up.

• If several MP85A process controllers are connected to the CAN network,

make sure that each address has only been used once. If you do not

know the settings, you can query them via the MP85A process controller

keyboard (see Chapter 5.1.2).

• Click the “Scan” button. The PME Assistant now searches for devices

connected to the CAN network and includes them in the device list.

• Use the “Start” button to launch the PME Assistant.

A2392−5.0 en HBM

Page 50

50

5.5 Automatic version recognition

MP85A process controller

If MP85A process

controllers are recognized

that use a firmware not fully

supported by your version

of the PME Assistant, the

following message appears:

The firmware of the device can be determined via the display of the MP85A,

PME Assistant or the INDUSTRYmonitor program.

The latest PME Assistant is always compatible with all MP85A(DP)-(S)

devices.

The latest software and firmware versions can be found on the HBM website:

www.hbm.com −> Support −> Software-/Firmware-Downloads.

NOTE

5.6 Firmware update

The firmware update program is installed using the supplied system CD. The

latest program and firmware versions can also be found on the HBM website:

www.hbm.com −> Support −> Software-/Firmware-Downloads.

New functions are often implemented via firmware and can then be loaded

into existing devices.

A2392−5.0 enHBM

Page 51

MP85A process controller

NOTE

The device settings remain unchanged if the firmware is updated. However,

we recommend that all settings be saved via the PME Assistant to the PC

before an update.

51

Simultaneous update of several devices can be selected.

In order not to conflict with the processing of a process (no measurements or

evaluations can be implemented during an update), you can specific from

firmware version 2.22 or higher that the firmware update is only implemented

on the device following manual confirmation (F-Update: Permitted!). If

confirmation does not occur within 15 minutes, no changes are made to the

firmware.

5.7 Offline operation

In offline operation, the PME Assistant can be used without a connected

MP85A process controller to create a device setting (parameter set) and save

it in XML format to PC. The device setting can later be transferred to the

MP85A process controller.

The offline mode is started as follows:

− Open the PME Assistant and select the “Offline” interface.

− Select the required device type from the device list.

− Start the Assistant with the “Start” button.

The device settings can now be made without any connected MP85A process

controllers. In the “Save/Load parameters” menu, the settings can be saved to

PC or existing settings loaded for viewing and further processing.

A2392−5.0 en HBM

Page 52

52

MP85A process controller

6 Methods of measurement

A measurement start/stop can be implemented manually with the PME

Assistant in individual operation, externally via a digital input or via the field

bus interfaces.

When measurement starts, the measured quantities acquired by the sensors

are written as an x/y value pairs with a time stamp to the internal MP85A

process controller memory and rated as OK or NOK by means of defined

windows, an envelope curve or a tolerance band. In addition, limit value

monitoring can be included in the evaluation. The last measurement curve in

each case can also be instantly plotted and displayed. All processes can be

stored in the background, independently of this display.

6.1 Data reduction

y=f(x)

A measurand Y (force) is recorded and rated as a function of a measurand x

(displacement). The measurement points are also given a time stamp.

Advantage: Intelligent data reduction. Curve points are only generated when

there is a sufficiently large change to x or y. The values nx and ny are user-

selectable.

Fig. 6.1: Force/displacement-driven process curve determination

y=f(t)

A measurand on channel y is recorded as a function of time.

Advantage: There is no need for the X sensor (the displacement sensor on a

press, for example).

Condition: Reproducible feedrates, as otherwise the curve that depends on

them would be shortened or lengthened.

A2392−5.0 enHBM

Page 53

MP85A process controller

Fig. 6.2: Time-driven process curve determination

53

6.2 Classification

Classifying X or Y

Measured quantities on channel X, such as length, thickness and diameter or

channel Y, such as force, weight, torque, etc., can be divided into 5 groups

per window. This means that e.g. springs can be automatically sorted by

spring rate.

y

max

y

min

Fig. 6.3: Classifying the measurands of a tolerance window

NOTE

Statistics and classification can only be used when using the 31 Flash para-

meter sets, not with memory card or PC parameter sets.

6.3 Monitoring limit values in real time

A total of eight limit values can be assigned and monitored in real time for

channels X and Y. A switching signal of choice can be allocated to each limit

value. This allows a press, for example, to be switched over from “fast” to

“slow”. The circuit logic can also be inverted.

A2392−5.0 en HBM

Page 54

54

MP85A process controller

6.4 Masking out external tolerances

The MP85A process controller can suppress external tolerances, such as

those caused by the differing positioning heights of workpiece holders, e.g.

when the pin being press-fitted is touched. Displacement is set to zero at this

time and a second relative axis is drawn to which the coordinates of the evaluation elements now refer.

Reference point

Dynamic zero point, relative to the force trigger.

When the reference point is reached, displacement is set

to zero. The windows now relate to this zero point.

Fig. 6.4: Reference points for X relative reference of evaluation elements

6.5 Evaluation criteria

The MP85A process controller has different window types to allow a universal