Page 1

Operating manual

Bedienungsanleitung

Manuel d’emploi

Profibus-Interface

MP60DP

A0623-6.1 en/de/fr

Page 2

English Page 3 − 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Deutsch Seite 21 − 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Français Page 39 − 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 3

PME−MP60DP

3

Contents Page

1 Introduction 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 How to connect to a PLC 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Configuring and assigning parameters 6 . . . . . . . . . . . . . . . . . . . . . . .

3 Installation 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Connections 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Pin assignment 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Operation via the keyboard 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Expanded menus 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Setup for Profibus 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Parameter assignment 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Configuration 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.1 Defining your own configuration combinations 15 . . . . . . . . . . .

6.3 Cyclical data exchange 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.1 Inputs (from MP55IBS to the PLC) 16 . . . . . . . . . . . . . . . . . . . . .

6.3.2 Outputs (from the PLC to MP55IBS) 18 . . . . . . . . . . . . . . . . . . .

6.4 Diagnosis 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HBMA0623−6.1 en/de/fr

Page 4

4

PME−MP60DP

1 Introduction

This Operating Manual describes only those functions which differ from the

MP60. The features of the MP60DP correspond to those of the MP60.

The MP60DP carrier−frequency measurement module has been expanded to

include a Profibus interface. The features on the CAN−interface remain the

same; the object directory is expanded to include some parameters for the

Profibus connection.

The Profibus connection is made using a 9−pin sub−D connector (conforming

to standard) on the front panel next to the transducer port.

DP protocol is used on the Profibus.

The following are communicated:

− the measured values (gross, net, peak values)

− the status of the limit switches

− control bits for taring, zeroing, peak value store control and changing the

parameter set, and

− optionally, the limit values

HBM A0623-6.1 en/de/fr

Page 5

PME−MP60DP

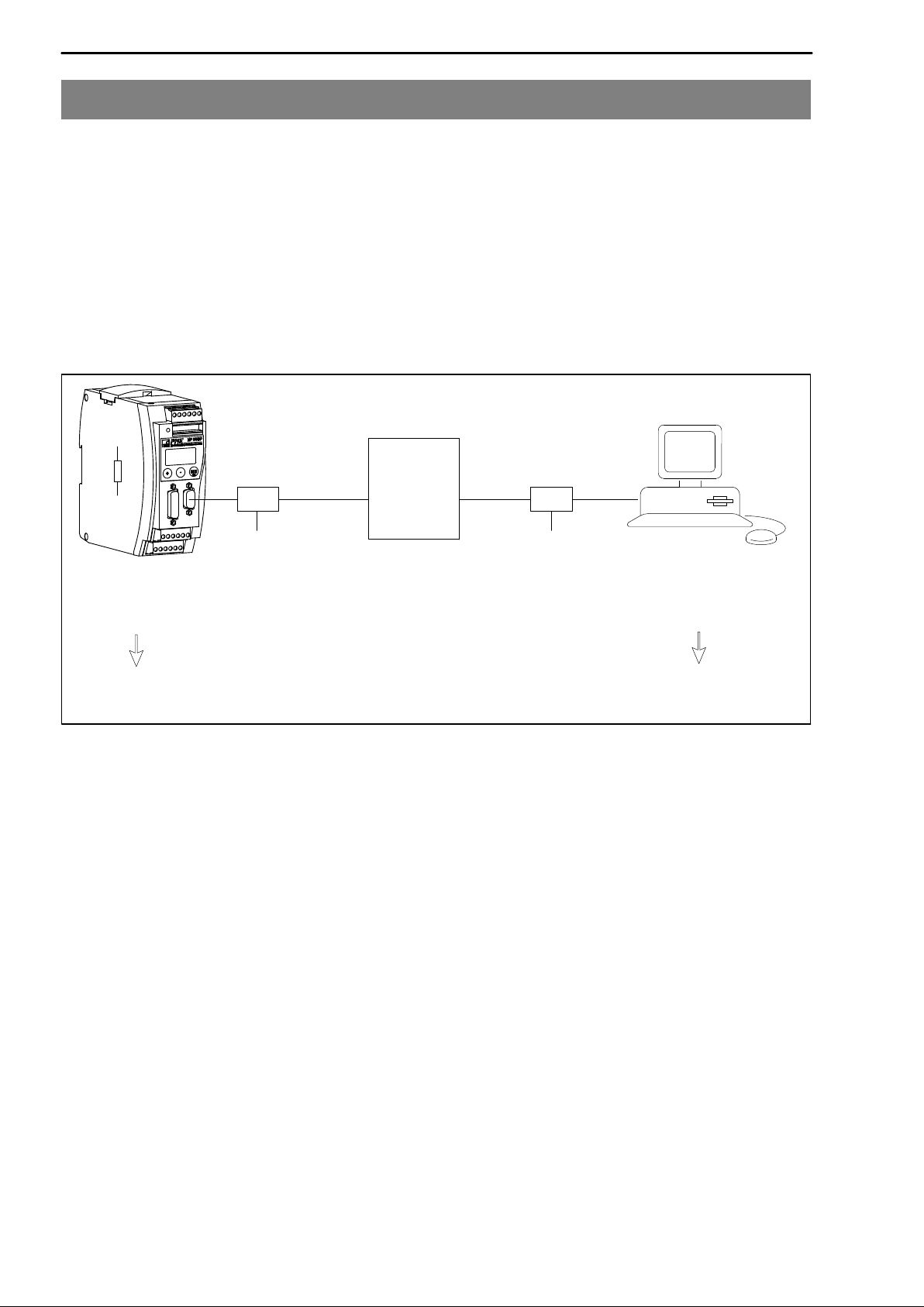

2 How to connect to a PLC

The steps in successfully connecting to the Profibus:

1. Physically connect the device to the Profibus (see page 8 and page 9)

2. Configure the device parameters, see page 12 (can also be carried out

using HBM‘s “PME-Assitent“ software).

3. Configure the Profibus message and set up its parameters with the aid of a

configuration tool (such as Step7) and GSE files, or manually as shown in

chapter 6.2.

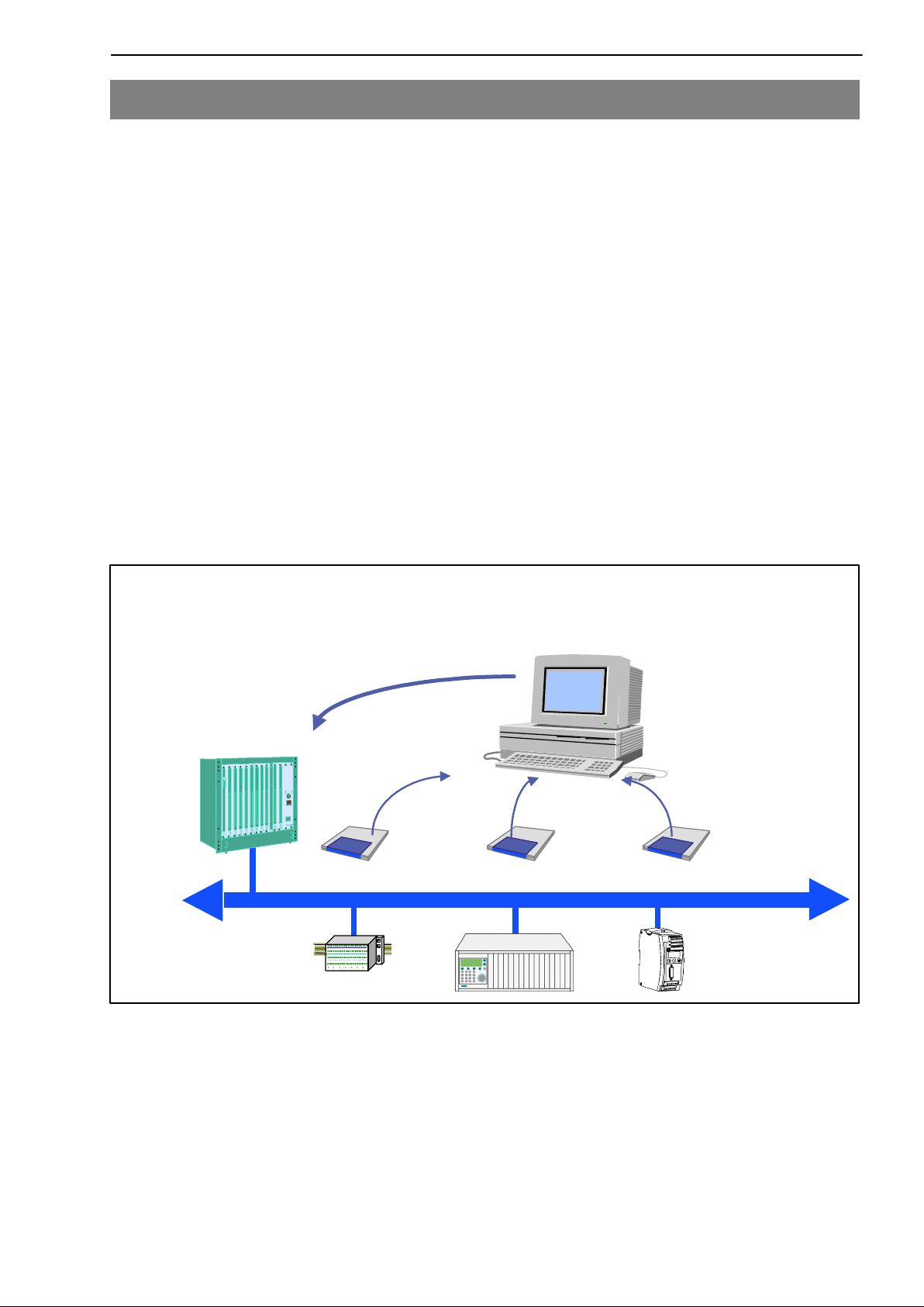

A GSE file describes the properties of a Profibus node in standardized form.

The configuration tool uses it to define which data held on individual bus

nodes will be exchanged on the Profibus.

5

A default GSE file for PME modules is supplied with the device (on system

CD: hbmxxx.gsd = German version; hbmxxxgse = English version).

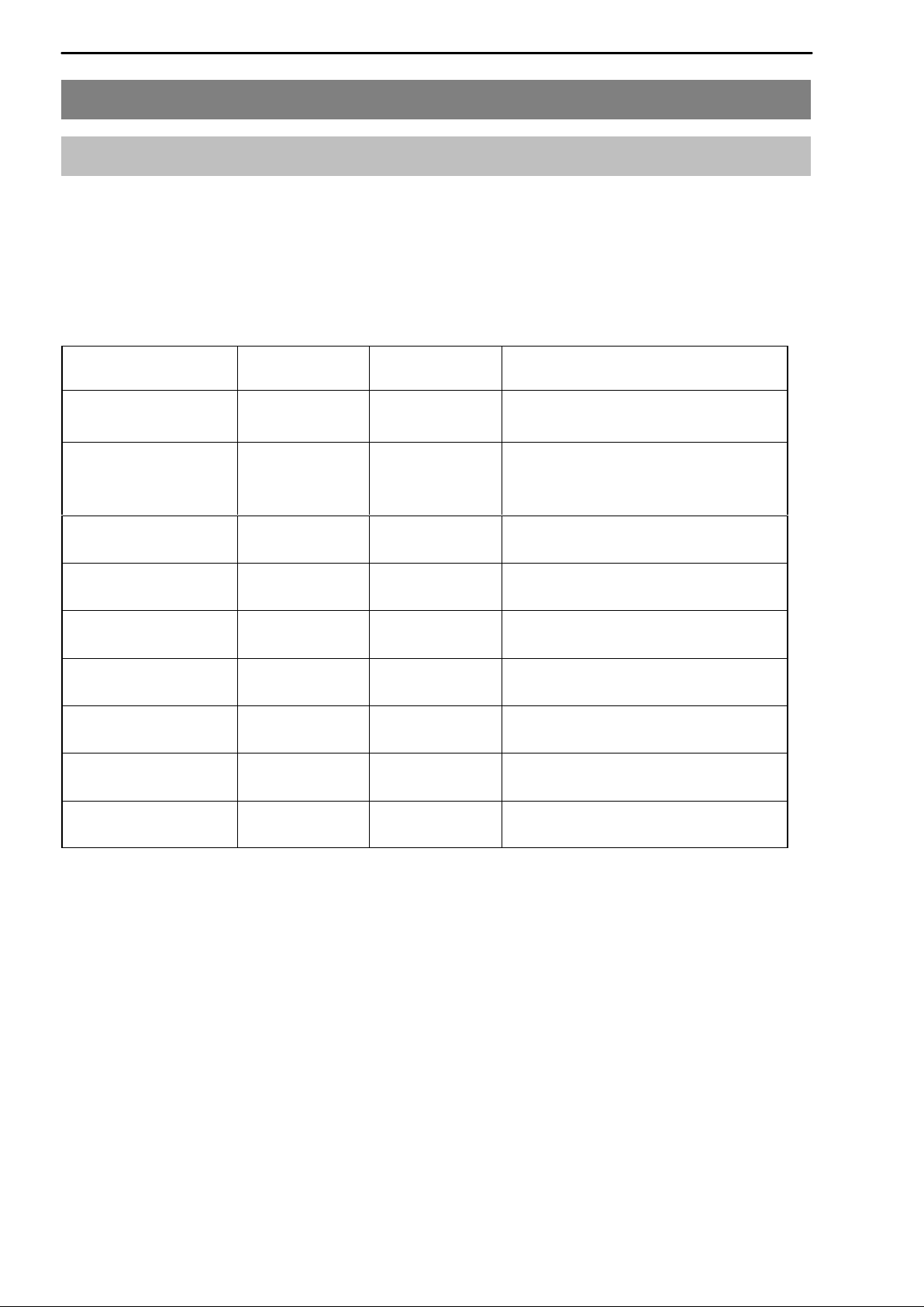

Profibus

configurator

System configuration

PLC

Electronic device data sheets (GSE files)

GSE

PROFIBUS−DP

Fig. 2.1: Configuration with the aid of GSE files

HBMA0623-6.1 en/de/fr

Page 6

6

PME−MP60DP

2.1 Configuring and assigning parameters

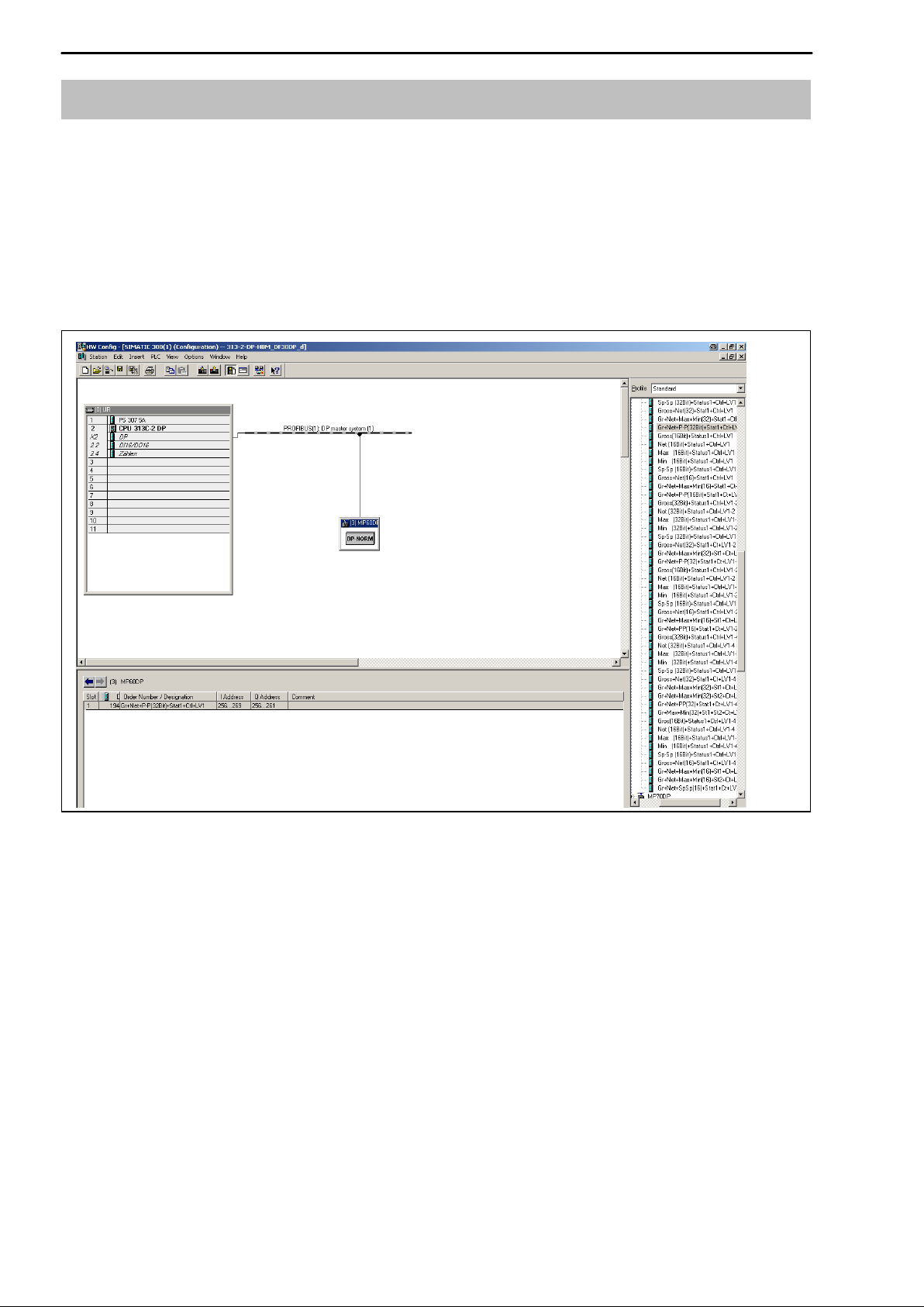

• Start your configuration program (e.g. Step7; if you have no configuration

program, proceed to chapter 6.2)

• Load the HBM GSD file (PME system CD incl. GSD/GSE files for PME)

• Add an HBM device (Hardware catalog)

• From the hardware catalog choose the configuration you want on the

Profibus.

Fig. 2.2: Hardware configuration

HBM A0623-6.1 en/de/fr

Page 7

PME−MP60DP

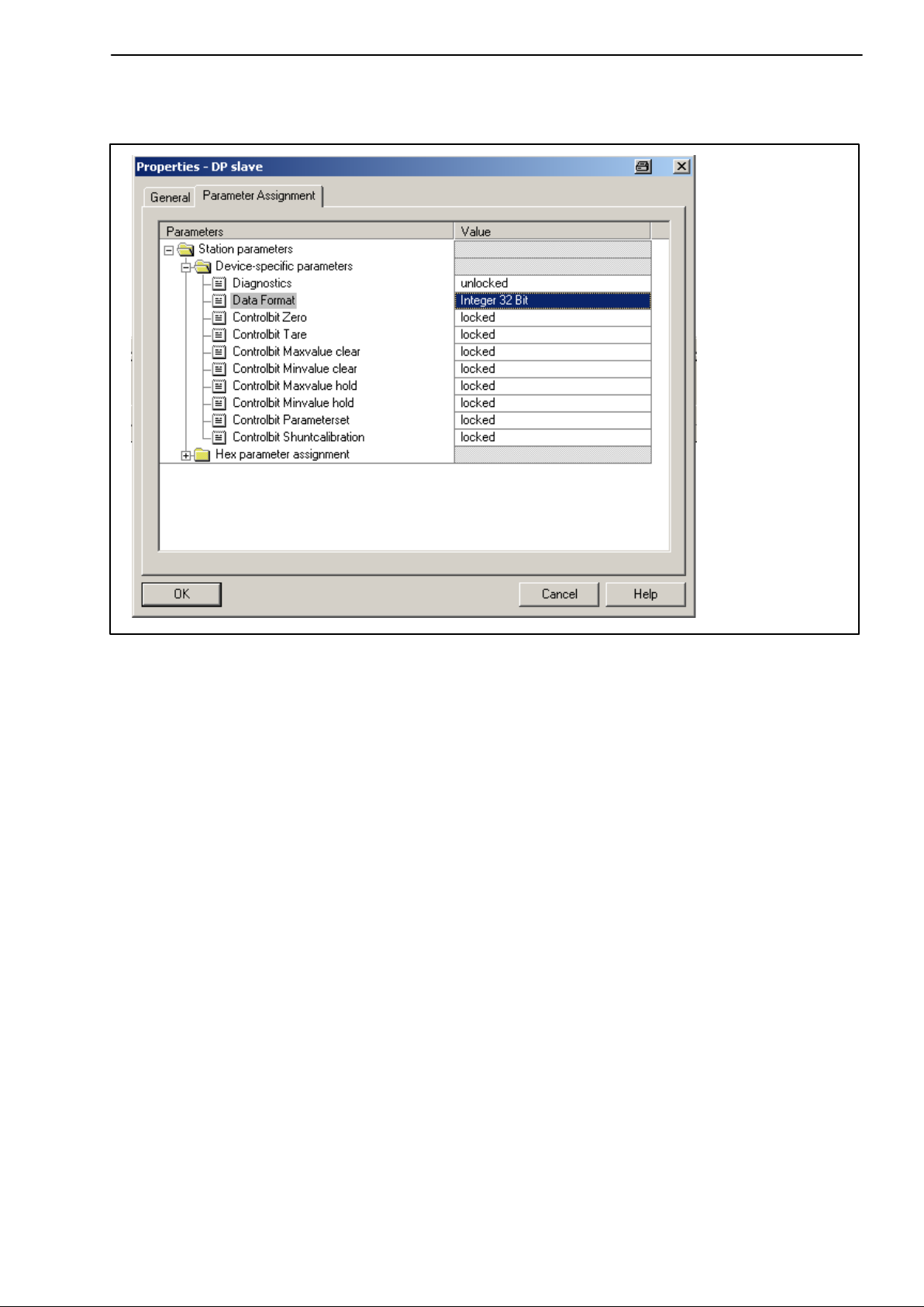

• Double-click on the configured entries to open the properties window and

select the required parameters.

7

Fig. 2.3: Setting parameters

Notes for users of the Simatic S7 PLC:

• To download consistent data of 3 bytes or over 4 bytes, use special

function modules SFC14 to read and SFC15 to write.

• In the case of the S7 3xx a maximum of 32 bytes of consistent data can be

downloaded.

To find out the meaning of the status bits and control word bits please refer to

the tables in chapter 6.3.

HBMA0623-6.1 en/de/fr

Page 8

8

PME−MP60DP

3 Installation

• Connect the MP60DP module to a 24 V supply voltage.

• Connect the Profibus cable to the MP60DP module. Ensure that a

terminating resistance is connected to the first and last Profibus unit (the

housing of the Profibus connector usually contains a sliding switch for this

purpose).

Example:

PLC

Profibus

connector

First device in

the bus line

sliding switch of Profibus connector to

”Resistance ON” .

Fig. 3.1: Profibus operation

Profibus

connector

Last device in

the bus line

sliding switch of Profibus

connector to ”Resistance ON”

HBM A0623-6.1 en/de/fr

Page 9

PME−MP60DP

4 Connections

Warning

Please note the safety instructions before commissioning the device.

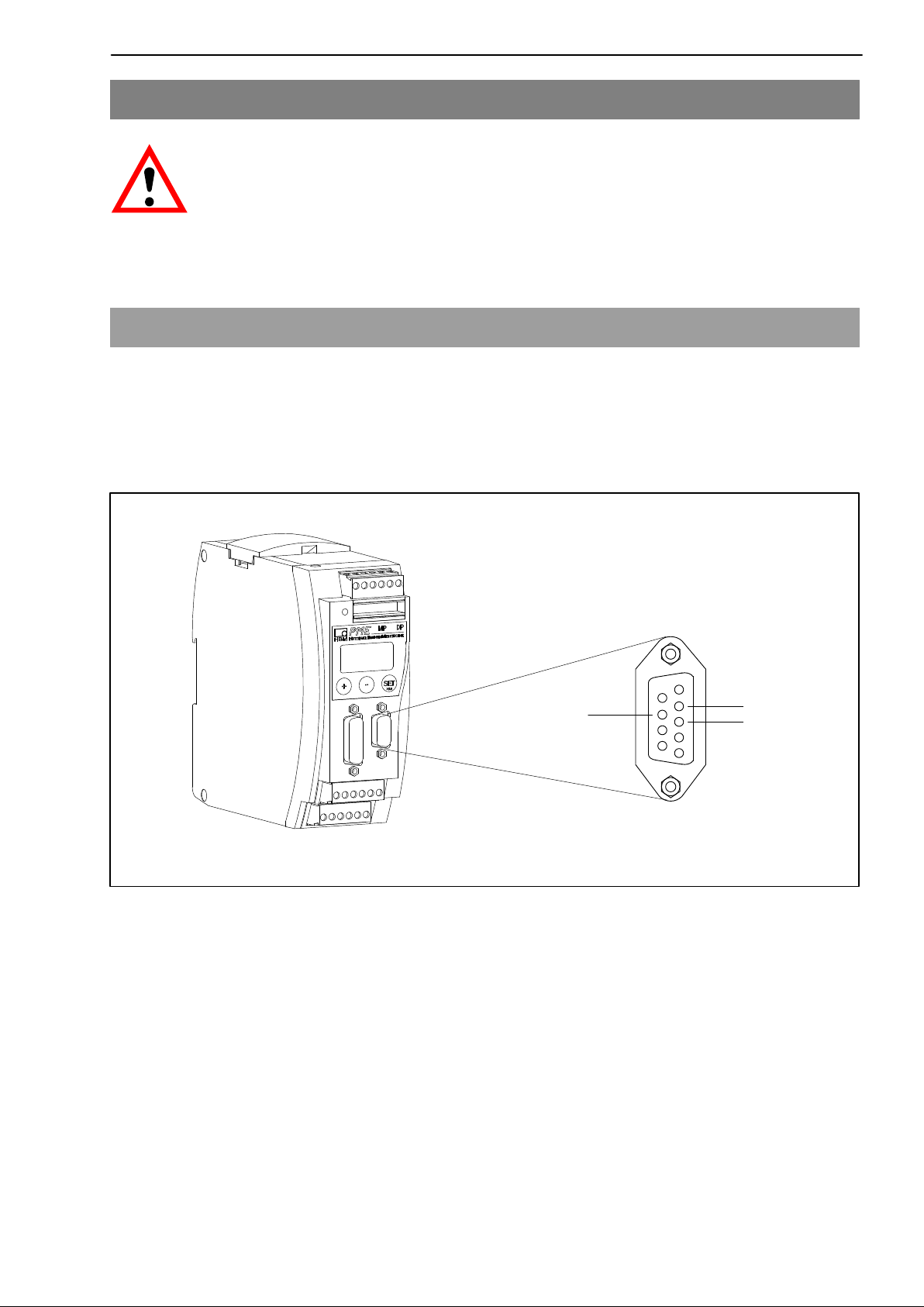

4.1 Pin assignment

For the pin assignment of the MP60DP module please refer to the Operating

Manual “PME industrial measurement electronics with MP60/MP07 module

field bus link”. On the front panel of the MP60DP is an additional 9−pin D-sub

connection socket for the Profibus connection.

9

6

0

9

RS485-A

Vcc (5V)

6

Fig. 4.1: Profibus connection in accordance with standard

Profibus

connection

socket

GND

5

RS485-RTS

1

RS485-B

HBMA0623-6.1 en/de/fr

Page 10

10

PME−MP60DP

5 Operation via the keyboard

−

During measurement you can press

the display (e.g. mV; V; Out,In; error messages).

Next to the status message “ERROR” the display shows the status of the

Profibus DP connection. One of the following status messages is displayed in

each case:

BD_SEAR (baud rate search)

WT_PARM (waiting for parameter)

WT_CONF (waiting for configuration)

DATA_EX (cyclical data communication)

ERROR (bus error)

+

− to view the status messages in

The LED shows the operating status (ready to take measurements, overflow

etc.) of the MP60DP. Instead of the CAN status (as with the MP60), however,

the Profibus status is displayed.

Operating status:

LED

colour

Green Steady light DATA_EX status

Yellow Steady light BD_SEAR, WT_PARM, WT_CONF status

Red Steady light ERROR status

Status Meaning

Profibus status

The representation of the other operating statuses is the same as that of the

MP60.

HBM A0623-6.1 en/de/fr

Page 11

PME−MP60DP

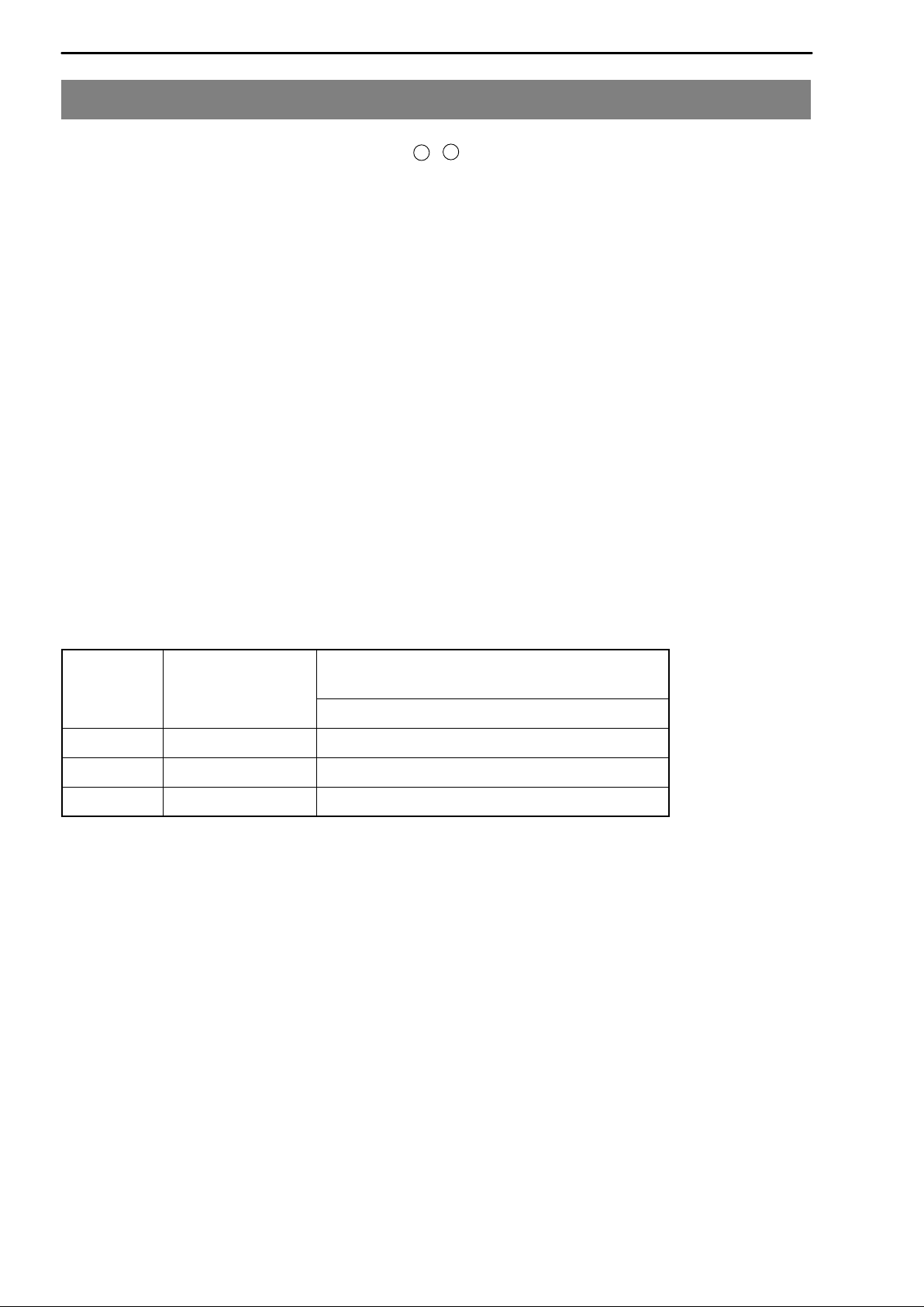

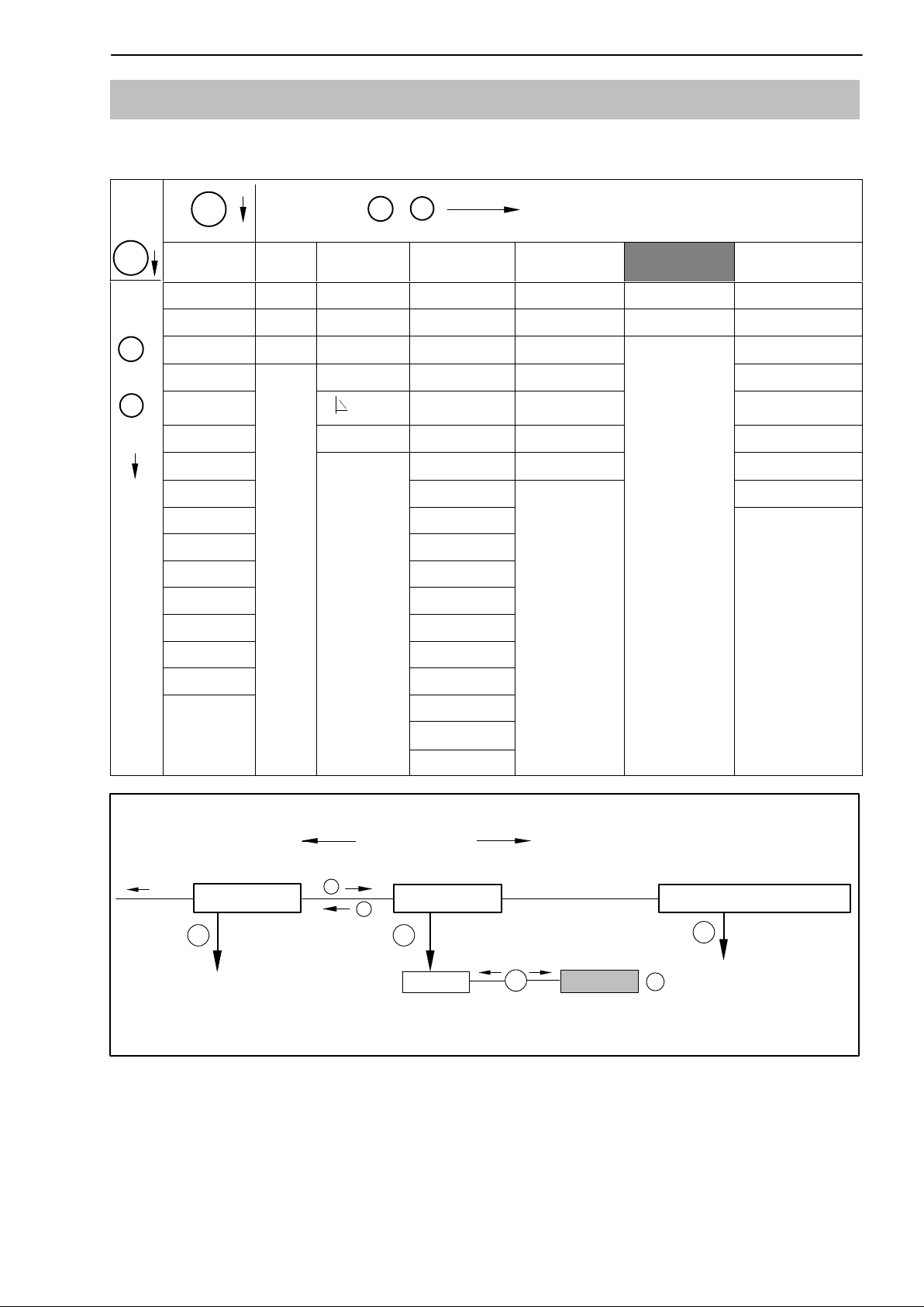

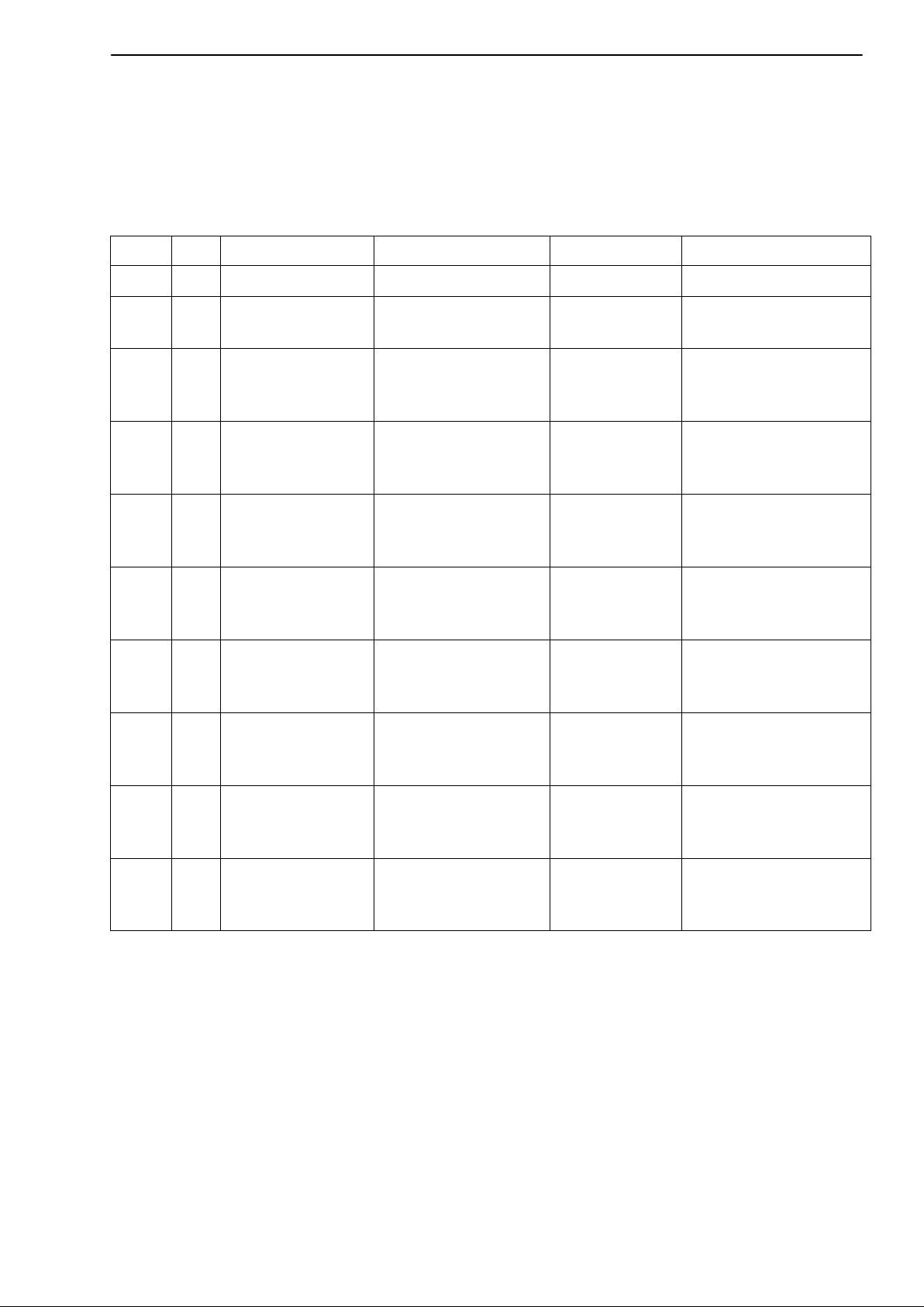

5.1 Expanded menus

New “Profibus” group in set-up mode:

−

SET

+

11

Groups

SET

+

Up

−

Down

DIALOGUE ... PEAK STORE IN/OUT CAN-BUS PROFIBUS

Password Operatn. Output1 Baud rate Address AmplType

PassStat InputMin ModeOut1 Address MAINGRP PrgVers

Language

I.DataS ClearPkV ModeOut2 Output

I.Displ.

I.Transd MAINGRP ModeOut3 PDO-Frmt SNo

I.Meas Output4

I.Condit ModeOut4 MAINGRP

I.Analog Zeroing

I.LimVal Tare

I.PStore PkMomMax

I.I/O PkHldMax

I.CAN PkMomMin

I.AddFnc PkHldMin

MAINGRP ParaCo1

InputMax

kN/s

1)

Output2 Profile >0<Rf kNm

Output3 OutR. ms Keyboard

MAINGRP

ADDITION

FUNCTION

HW synchr

HW vers.

1)

ParaCo2

Overview of parameters

InpFunc

MAINGRP

Groups

In/Out

CAN-bus

SET

+

PROFIBUS

−

SET

Address

Fig. 5.1: Setting up the Profibus address

SET

↑

↓

3 − 123

ADDITIONFUNCTION

SET

+/−

HBMA0623-6.1 en/de/fr

Page 12

12

PME−MP60DP

6 Setup for Profibus

6.1 Parameter assignment

The amplifier parameters are set via the keyboard or CAN−interface, as on

the MP60. The Profibus DP parameter assignment telegram defines some

parameters for the DP communication. If you use Profibus parameter

assignment tools which are able to evaluate the GSD files of GSD revision 1,

the following parameters are available for selection:

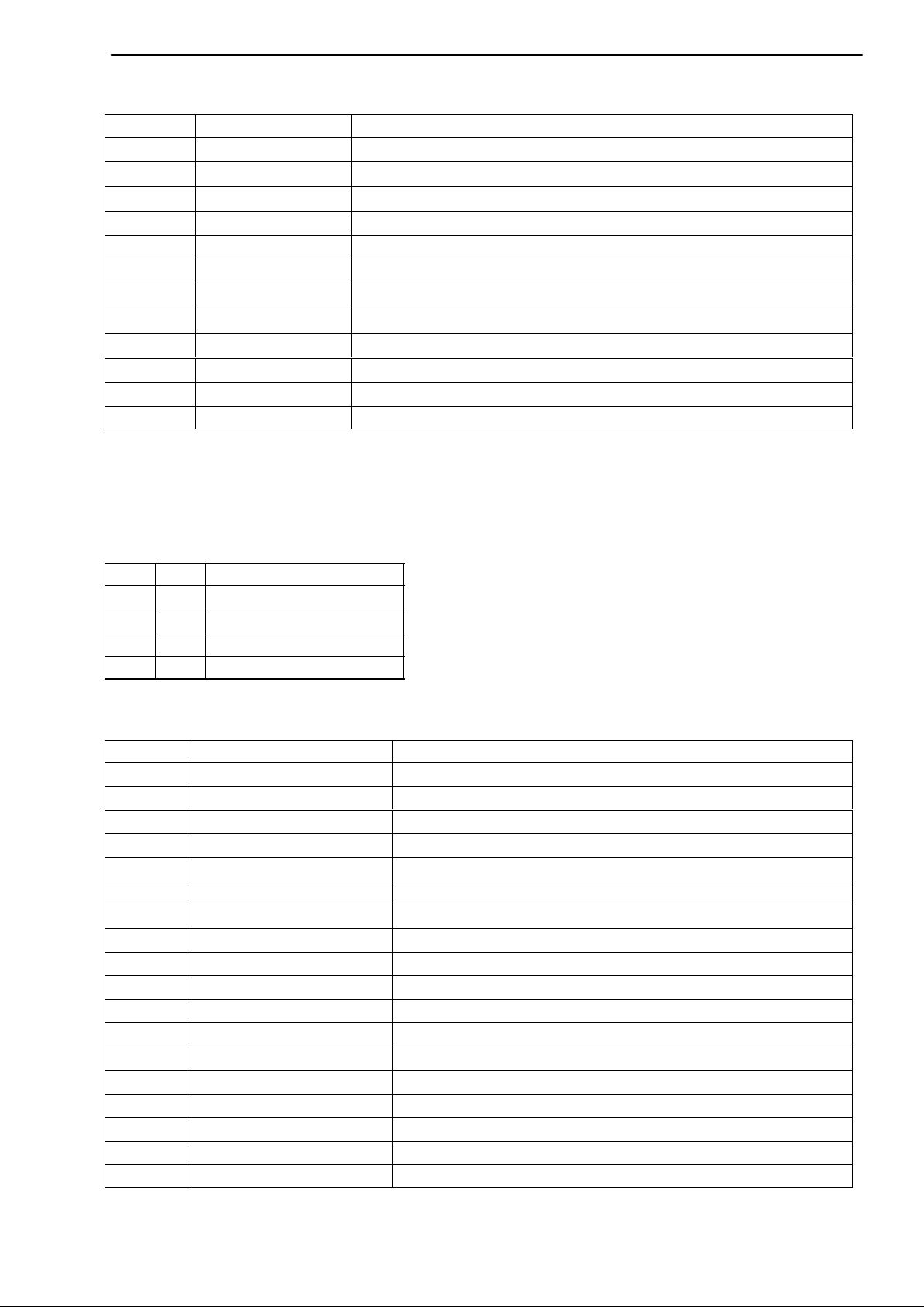

Parameter name Available

values

Diagnosis disabled

released

Data format integer 16 bits

integer 32 bits

floating point

Zeroing control bit disabled

released

Taring control bit disabled

released

Clear maximum

control bit

Clear minimum

control bit

Hold maximum

control bit

Hold minimum

control bit

disabled

released

disabled

released

disabled

released

disabled

released

Default Meaning

released release of external diagnosis

integer 16 bits defines the coding format for

measured values

disabled releases function for control of

output control word

disabled releases function for control of

output control word

disabled releases function for control of

output control word

disabled releases function for control of

output control word

disabled releases function for control of

output control word

disabled releases function for control of

output control word

Parameter set

control bit

disabled

released

disabled releases function for control of

output control word

Tab 6.1: Meaning of the parameters

The data format set applies to all the measured values exchanged in the

cyclical data communication. The definition of the decimal places for the

formats integer 16 bits and integer 32 bits is adopted from the module setting

(display, CAN−bus) (e.g. when 3 decimal places is specified, 2.0 mm is

communicated as integer value 2000). The choice of data format also affects

the length of the input data (integer 16 bits = 1 word per analogue value,

integer 32 bits and floating = 2 words per analogue value).

HBM A0623-6.1 en/de/fr

Page 13

PME−MP60DP

13

The targeted operation of the required control bits in the control word allows

you to secure all the functions not required against accidental operation in the

event of an error; otherwise, for example, the zero point set could be lost.

If you are using older parameter assignment tools the parameter values will

have to be converted to decimal or hexadecimal values:

Octet Bits Parameter name Available values Default Meaning

0 0..7 reserved 0 0 do not change

1)

1−2 all Diagnosis 0 = disabled

0xffff = released

3 all Data format 0 = integer 16 bits

1 = integer 32 bits

2 = floating point

5 0 Zeroing control

bit

5 1 Taring control bit 0 = disabled

5 4 Control bit

Delete maximum

5 5 Control bit

Delete minimum

5 6 Control bit

Hold maximum

0 = disabled

1 = released

1 = released

0 = disabled

1 = released

0 = disabled

1 = released

0 = disabled

1 = released

released release of external

diagnosis

integer 16 bits defines the coding

format for measured

values

disabled releases function for

control of output

control word

disabled releases function for

control of output

control word

disabled releases function for

control of output

control word

disabled releases function for

control of output

control word

disabled releases function for

control of output

control word

5 7 Control bit

Hold minimum

4 0−1 Parameter set

control bits

0 = disabled

1 = released

0 = disabled

3 = released

disabled releases function for

disabled releases function for

Tab 6.2: Contents of the parameter assignment message

1)

changed by your parameter assignment tool in certain circumstances

control of output

control word

control of output

control word

HBMA0623-6.1 en/de/fr

Page 14

14

PME−MP60DP

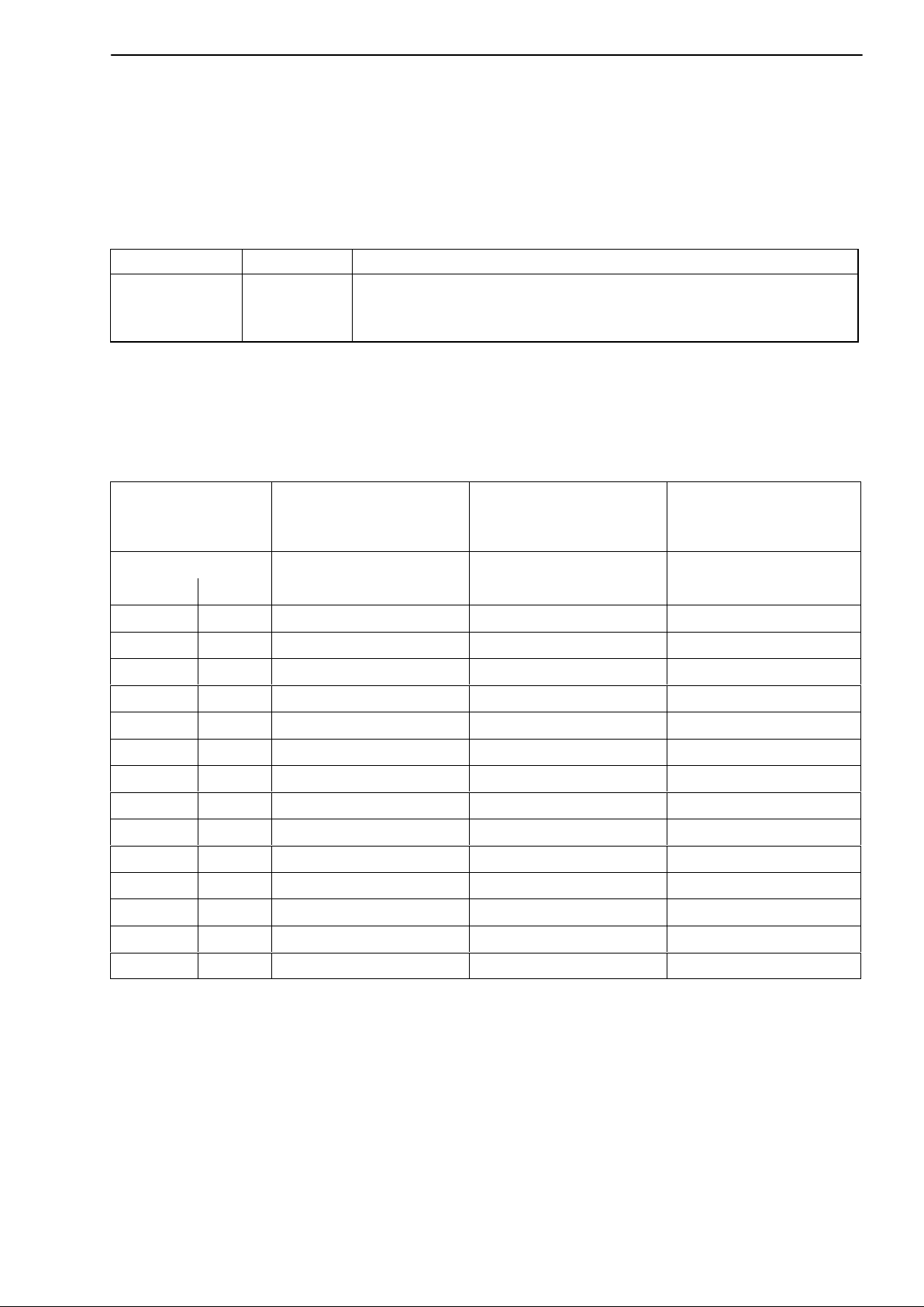

6.2 Configuration

The configuration defines which data content is exchanged in the cyclical data

communication. The following data is available for selection:

Input values:

Name Meaning Length

Gross gross measured value 1 or 2

words

Net net measured value (gross minus tare value) 1 or 2

words

Max contents of the maximum store 1 or 2

words

Min contents of the minimum store 1 or 2

words

Pk−Pk peak−to−peak, difference between max and min 1 or 2

words

Status1 status word with status of the limit switches and gen. error

bits

Status2 double status word with differentiated error flagging 2 words

1 word

Output values:

Name Meaning Length

Control word control word for triggering taring, zeroing, clearing the peak

value store, parameter set selection, etc.

Limit1 level at which limit switch 1 responds 1 or 2

Limit2 level at which limit switch 2 responds 1 or 2

Limit3 level at which limit switch 3 responds 1 or 2

Limit4 level at which limit switch 4 responds 1 or 2

1 word

words

words

words

words

The formats of the cyclically communicated data content are specified in detail

in chapter 6.3. The measured values are offered optionally as a 16-bit integer,

32-bit integer or 32 bit float. The values are always scaled to physical size

with the number of decimal places of your choice. Information on whether the

16 bit format or a 32 bit format is used and on the number of decimal places is

defined in the parameter assignment message.

Typical combinations are predefined in the GSD file. If you require other

combinations you can expand the GSD file accordingly using the following

specifications.

HBM A0623-6.1 en/de/fr

Page 15

PME−MP60DP

15

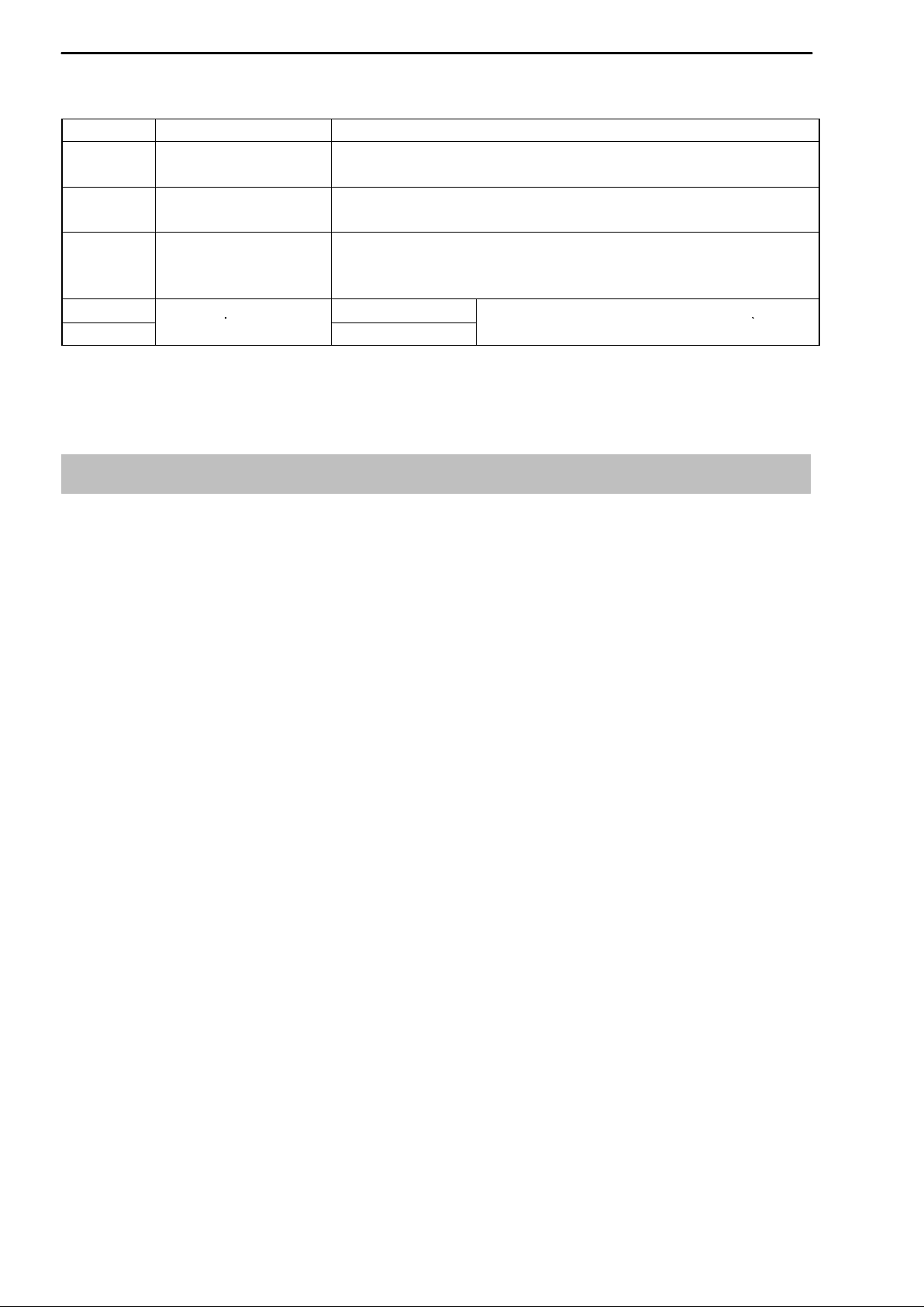

6.2.1 Defining your own configuration combinations

Only one configuration entry is available. The special identification format

(special format) must be used for this. The manufacturer−specific data

specifies the contents and thus also the length of the input data and is 2 bytes

in length.

CFG entry no. Meaning Contents

0 channel 1 special format with inputs and outputs, maximum 9 words

output, maximum 13 words input, 2 bytes comment length

(data)

The following input and output data can be configured for the cyclical data

communication. The choice of which data is actually transferred is

communicated via the manufacturer−specific data of the special identification

format.

Configuration

manufacturer−

specific data

Byte no. Bit no. (words) (words)

0 0 1(2) Gross

0 1 1(2) Net

0 2 1(2) Max

0 3 1(2) Min

0 4 1(2) Peak−to−peak

0 5 1 Status1

0 6 2 Status2

1 0 1 Control word

1 1 1(2) Limit value level 1

1 2 1(2) Limit value level 2

1 3 1(2) Limit value level 3

Length of cyclical data

inputs

Length of cyclical data

outputs

Contents of cyclical

data

Input values:

Output values:

1 4 1(2) Limit value level 4

Tab 6.3: Selecting the data content via the manufacturer−specific data

The length of the input data is the sum of all the data lengths selected for the

communication in words. When selecting the 32 bit format and the float format

for measured values, the length values in brackets must be used.

HBMA0623-6.1 en/de/fr

Page 16

16

p

(

PME−MP60DP

The configuration telegram thus has the following format:

CFG byte Meaning Permitted values for CFG (hex.)

1 header 0xC2 (inputs and outputs, 2 bytes manufacturer−specific

data)

2 length of outputs 0x40 − 0x48 (1 to 9 words of outputs) or

0xC0 − 0xC8 (1 to 9 words of outputs with consistency)

3 length of inputs 0xC0 − 0xCC or

0x40 − 0x7C (1 to 13 words of inputs with/without

consistency)

4

5

Tab 6.4: Contents of the configuration telegram

user−specific data

Input data

Output data

selection of the data content (see

Tab 6.3)

When using the 32 bit formats data consistency must always be set.

6.3 Cyclical data exchange

Depending on the configuration, the following data content is exchanged:

6.3.1 Inputs (from MP55IBS to the PLC) Measured values

Measured values can be communicated in various forms of representation.

The forms of representation available for selection are floating (2 words, 32

bit), 16 bit fixed point number (1 word, 16 bit integer in two’s complement,

decimal place must be known to the reader) or 32 bit fixed point number (2

words, 32 bit integer in two’s complement, decimal place must be known to

the reader). For conversion of the values to fixed point representation the

number of decimal places in the module parameter assignment (display,

CAN−bus) is used as a basis.

HBM A0623-6.1 en/de/fr

Page 17

PME−MP60DP

Status 1

Bits Name Meaning

0 Ovfl measured values overflow

1 AOutOvfl analogue output overflow

2 ScalErr scaling defective

3 EEPROMErr EEPROM (parameter set) defective

4 Limit1 status of limit switch 1

5 Limit2 status of limit switch 2

6 Limit3 status of limit switch 3

7 Limit4 status of limit switch 4

8 PAR1 active parameter set bit 1

9 PAR2 active parameter set bit 1

10..14 res reserved

15 MViO Measured value in order 1) (if bit 0,2,3=0)

Tab 6.5: Contents of status 1

1)

Meaning of MViO:

NOR operation of: MesswOvfl, SkalErr, EEPROMErr.

MesswOvfl is the OR operation of ADCOvfl, HardwOvfl, GrossOvfl, NetOvfl

17

The parameter set number is coded in 2 bit binary:

Bit 8 Bit 9 Parameter set no.

0 0 1

1 0 2

0 1 3

1 1 4

Status 2

Double status word 2 returns detailed error flagging.

Bits Name Meaning

0 HardwOvfl hardware overflow

1 ADCOvfl ADC overflow

2 GrossOvfl gross signal overflow

3 NetOvfl net signal overflow

4 AOutOvfl analogue output overflow

5 MaxOvfl maximum overflow

6 MinOvfl minimum overflow

7 NegOvfl overflow in negative direction

8 Limit1 status of limit switch 1

9 Limit2 status of limit switch 2

10 Limit3 status of limit switch 3

11 Limit4 status of limit switch 4

12 ScalInError scaling input invalid

13 ScalOutError scaling output invalid

14 GainError nominal value exceeded

15 InitError works calibration defective

16 TransducerError transducer error

17..31 res reserved

Tab 6.6: Contents of status 2

HBMA0623-6.1 en/de/fr

Page 18

18

PME−MP60DP

6.3.2 Outputs (from the PLC to MP55IBS) Limit values

Limit values are displayed in the same format as the measured values (16 bit

integer, 32 bit integer or floating format). The operating direction and

hysteresis remain unchanged and are set via the operating panel or the

CAN−bus.

Control word

Bits Name Meaning

0 ZERO 0−1 autom. triggers zeroing

1 TAR 0−1 triggers taring

2 SHUNT SHUNT ON / OFF

3 res reserved

4 CLRMAX 0−1 clears the MAX peak value store

5 CLRMIN 0−1 clears the MIN peak value store

6 HOLDMAX 1: freeze MAX peak value store

7 HOLDMIN 1: freeze MIN peak value store

8 PAR1 parameter set selection bit 1

9 PAR2 parameter set selection bit 2

10..15 res reserved

Tab 6.7: Contents of control word

HBM A0623-6.1 en/de/fr

Page 19

PME−MP60DP

19

6.4 Diagnosis

The MP60DP module makes a device diagnosis available as an external

diagnosis which can be released via the parameter assignment diagram.

The external diagnosis is 4 bytes long. The first byte contains the identification

character for the version number. The second byte contains the identification

character for device diagnosis. In the third and fourth bytes one bit each is

reserved for various fault causes.

Octet Bits Value Meaning

0 0..7 c1 version 1

1 0..7 4 length of device diagnosis is 4 bytes in total

2 0 0

1

2 1 ADC overflow

2 2 0

1

2 3 0

1

2 4 0

1

2 5 0

1

2 6 0

1

2 7 res

3 0..3 res

3 4 0

1

3 5 0

1

scaling of input characteristics defective

scaling of output characteristics defective

hardware overflow

gross overflow

net overflow

analogue output overflow

maximum overflow

minimum overflow

3 6 0

1

3 7 0

1

4 0 0

1

4 1...7 res

nominal value exceeded

works calibration defective

transducer error

Tab 6.8: Contents of diagnosis

HBMA0623-6.1 en/de/fr

Page 20

20

PME−MP60DP

HBM A0623-6.1 en/de/fr

Page 21

PME−MP60DP

21

Inhalt Seite

1 Einführung 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Leitfaden für den Anschluss an SPS 23 . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Konfigurieren und Parametrieren 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Installieren 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Anschließen 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Anschlussbelegung 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Bedienen über Tastatur 28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Erweiterte Menüs 29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Einstellungen für Profibus 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Parametrierung 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Konfiguration 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.1 Definition eigener Konfigurations-Kombinationen 33 . . . . . . . .

6.3 Zyklischer Datenaustausch 34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.2 Ausgänge (von der SPS an den MP60DP gesendet) 35 . . . . .

6.4 Diagnose 36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HBMA0623-6.1 en/de/fr

Page 22

22

PME−MP60DP

1 Einführung

In dieser Bedienungsanleitung werden nur diejenigen Funktionen beschrieben, die vom MP60 abweichen. Die Funktionalität des MP60DP entspricht der

des MP60.

Das Frequenz-Messmodul MP60DP ist um eine Profibus-Schnittstelle ergänzt

worden. Die Funktionalität auf der CAN-Schnittstelle bleibt erhalten; das Objektverzeichnis wird um einige Parameter der Profibus-Kopplung erweitert.

Der Profibus-Anschluss erfolgt über einen 9poligen Sub-D-Steckanschluss

(Normkonform) auf der Front neben dem Aufnehmeranschlussstecker.

Auf dem Profibus wird das Protokoll DP verwendet.

Übertragen werden:

− die Messwerte (Brutto, Netto, Spitzenwerte)

− der Zustand der Grenzwertschalter

− Steuerbits für Tarieren, Nullstellen, Spitzenwertspeichersteuerung, Parame-

tersatzumschaltung und

− optional die Grenzwertpegel

HBM A0623-6.1 en/de/fr

Page 23

PME−MP60DP

23

2 Leitfaden für den Anschluss an SPS

Die Schritte zur erfolgreichen Anbindung an den Profibus:

1. Mechanischer Anschluss des Gerätes an den Profibus (siehe Seite 26 und

Seite 27).

2. Parameter am Gerät einstellen, siehe Seite 30 (kann auch mit der HBMSoftware “PME-Assistent” erfolgen).

3. Konfiguration und Parametrierung des Profibus-Telegrammes mit einem

Konfigurationswerkzeug (z.B. Step7) und GSD-Dateien oder manuell nach

Kapitel 6.2.

Eine GSD-Datei beschreibt die Eigenschaften eines Profibus-Teilnehmers in

standardisierter Form. Sie wird vom Konfigurationswerkzeug dazu benutzt,

festzulegen, welche Dateninhalte der einzelnen Busteilnehmer auf dem Profibus ausgetauscht werden.

Eine Standard-GSD (hbmxxx.gsd = deutsch; hbmxxxgse = englisch) für PMEModule wird mit dem Gerät (System-CD) ausgeliefert.

Profibus

Konfigurator

Systemkonfiguration

SPS

Elektronische Gerätedatenblätter (GSD-Dateien)

GSD

PROFIBUS−DP

Abb. 2.4: Konfiguration mit GSD-Dateien

HBMA0623-6.1 en/de/fr

Page 24

24

PME−MP60DP

2.1 Konfigurieren und Parametrieren

• Starten Sie Ihr Konfigurationsprogramm (z.B. Step7; besitzen Sie kein Konfigurationsprogramm, verfahren Sie nach Kapitel 6.2).

• Laden Sie die HBM-GSD-Datei (PME-System-CD).

• Fügen Sie ein HBM-Gerät hinzu (Hardwarekatalog).

• Wählen Sie aus dem Hardwarekatalog die Konfiguration, die Sie auf dem

Profibus benötigen.

Abb. 2.5: Hardware-Konfiguration

HBM A0623-6.1 en/de/fr

Page 25

PME−MP60DP

• Öffnen Sie durch Doppelklicken der konfigurierten Einträge das Eigenschaftsfenster und wählen Sie die gewünschten Parameter aus.

25

Abb. 2.6: Parameter einstellen

Hinweise für Nutzer der SPS Simatic S7:

• Zum Übertragen konsistenter Daten von 3 Byte oder über 4 Byte müssen

Sie den Sonderfunktionsbaustein SFC14 zum Lesen und SFC15 zum

Schreiben benutzen.

• Bei der S7 3xx können maximal 32 Byte konsistente Daten übertragen werden.

Die Bedeutung der Bits von Status und Steuerwort entnehmen Sie den

Tabellen in Kapitel 6.3.

HBMA0623-6.1 en/de/fr

Page 26

26

PME−MP60DP

3 Installieren

• Modul MP60DP an 24 V Versorgungsspannung anschließen und über die

Tastatur oder das Setup-Programm die gewünschte Profibus-Adresse einstellen.

• Schließen Sie die Profibus-Leitung an das Modul MP60DP an. Achten Sie

darauf, dass am ersten und letzten Profibus-Teilnehmer ein Abschlusswiderstand von zugeschaltet ist (am Gehäuse des Profibus-Steckers befindet sich hierzu üblicherweise ein Schiebeschalter).

Beispiel:

SPS

Profibus-Stecker Profibus-Stecker

Erstes Gerät in

der Busleitung

Schiebeschalter des Profibus-Steckers auf

“Widerstand EIN”

Abb. 3.2: Profibus-Betrieb

Letztes Gerät in

der Busleitung

Schiebeschalter des ProfibusSteckers auf “Widerstand EIN”

HBM A0623-6.1 en/de/fr

Page 27

PME−MP60DP

27

4 Anschließen

WARNUNG

Beachten Sie vor der Inbetriebnahme des Gerätes die

Sicherheitshinweise.

4.1 Anschlussbelegung

Die Anschlussbelegungen des Moduls MP60DP entnehmen Sie bitte der Bedienungsanleitung “Industrielle Messelektronik PME mit Feldbusanbindung

Modul MP60/MP07”. Auf der Frontseite des MP60DP befindet sich eine zusätzliche 9polige D-Sub-Anschlussbuchse für den Profibus-Anschluss.

6

0

Abb. 4.2: Profibus-Anschluss nach Norm

RS485-A

Vcc (5V)

9

6

Profibus-

Anschluss-

buchse

GND

5

RS485-RTS

1

RS485-B

HBMA0623-6.1 en/de/fr

Page 28

28

PME−MP60DP

5 Bedienen über Tastatur

−

Während des Messens können Sie sich − durch Drücken von

Display die Statusmeldungen ansehen (z.B. mV; V; Ausg,Eing; Fehlermeldungen).

Im Anschluss an die Statusmeldung “FEHLER” zeigt das Display den Status

der Profibus-DP-Verbindung. Jeweils eine der folgenden Statusmeldungen

wird dargestellt:

BD_SEAR (Baudratensuche)

WT_PARM (Warten auf Parameter)

WT_CONF (Warten auf Konfiguration)

DATA_EX (Zyklischer Datenverkehr)

+

− im

ERROR (Bus-Fehler)

Die LED zeigt die Betriebszustände (Messbereit, Overflow etc.) des MP60DP

an. Statt des CAN-Zustandes (wie beim MP60) wird jedoch der ProfibusZustand angezeigt.

Betriebszustand:

LED-Farbe Zustand Bedeutung

Profibus-Zustand

Grün Leuchtet stetig Zustand DATA_EX

Gelb Leuchtet stetig Zustände BD_SEAR, WT_PARM, WT_CONF

Rot Leuchtet stetig Zustand ERROR

Die Darstellung der anderen Betriebszustände entspricht denen des MP60.

HBM A0623-6.1 en/de/fr

Page 29

PME−MP60DP

HPTGRP

HPTGRP

5.1 Erweiterte Menüs

Neue Gruppe “Profibus” im Einstellbetrieb:

−

SET

+

29

Gruppen

SET

+

Up

−

Down

DIALOG ... SPITZWRT EIN/AUSG CAN-BUS PROFIBUS ZUSATZFUNKTION

Passwort Freigabe Ausgang1 Baudrate Adresse Verst Typ

PassStat Eing.Min Mode Aus1 Adresse HPTGRP PrgVers

Sprache

E.ParaS SpLöschn Mode Aus2 Ausgabe HW Synchr

E.Anzeig

E.Aufneh

E.Einmes Ausgang4

E.Aufber Mode Aus4 HPTGRP

E.Analog Nullst.

E.Grnzw Tarier.

E.Spitzw SpMomMax

E.E/A SpHltMax

E.CAN SpMomMin

E.Zusatz SpHltMin

HPTGRP ParaCod1

Eing.Max

kN/s

HPTGRP

1)

Ausgang2 Profil >0<Rf kNm

Ausgang3 AusgR. ms Tastatur

Mode Aus3 PDO-Frmt SNr

HW-Vers.

ParaCod2

1)

Übersicht der Parameter

EingFkt.

Gruppen

Ein/Ausg

CAN-Bus

SET

Abb. 5.2: Profibus-Adresse einstellen

+

PROFIBUS

−

SET

Adresse

SET

↑

↓

3 − 123

ZUSATZ-FUNKTION

SET

+/−

HBMA0623-6.1 en/de/fr

Page 30

30

PME−MP60DP

6 Einstellungen für Profibus

6.1 Parametrierung

Die Verstärkerparameter werden wie beim MP60DP über Tastatur oder CANSchnittstelle eingestellt. Das Profibus-DP-Parametriertelegramm legt einige

Parameter für die DP-Übertragung fest. Wenn Sie Profibus-Parametriertools

verwenden, die GSD-Files der GSD-Revision 1 verwerten können, stehen

folgende Parameter zur Auswahl:

Parameter-Name mögliche

Werte

Diagnose gesperrt

freigegeben

Datenformat Integer 16 Bit

Integer 32 Bit

Floating Point

Steuerbit Null-

stellen

Steuerbit Tarieren gesperrt

Steuerbit Maximum

löschen

Steuerbit Minimum

löschen

Steuerbit Maximum

halten

Steuerbit Minimum

halten

gesperrt

freigegeben

freigegeben

gesperrt

freigegeben

gesperrt

freigegeben

gesperrt

freigegeben

gesperrt

freigegeben

Default Bedeutung

freigegeben Freigabe der externen Diagnose

Integer 16 Bit Festlegung des Kodierungsfor-

mats für Messwerte

gesperrt gibt Funktion für Steuerung über

Ausgangssteuerwort frei

gesperrt gibt Funktion für Steuerung über

Ausgangssteuerwort frei

gesperrt gibt Funktion für Steuerung über

Ausgangssteuerwort frei

gesperrt gibt Funktion für Steuerung über

Ausgangssteuerwort frei

gesperrt gibt Funktion für Steuerung über

Ausgangssteuerwort frei

gesperrt gibt Funktion für Steuerung über

Ausgangssteuerwort frei

Steuerbit Parame-

tersatz

gesperrt

freigegeben

gesperrt gibt Funktion für Steuerung über

Ausgangssteuerwort frei

Tab. 6.1. Bedeutung der Parameter

Das eingestellte Datenformat gilt für alle im zyklischen Datenverkehr ausgetauschten Messwerte. Die Angabe der Nachkommastellen für die Formate Integer 16 Bit und Integer 32 Bit wird aus der Modul-Einstellung (Display, CANBus) übernommen (z.B. 2.0 mm wird bei Vorgabe von 3 Nachkommastellen

als Integer-Wert 2000 übertragen). Die Wahl des Datenformats hat auch Auswirkungen auf die Länge der Eingangsdaten (Integer 16 Bit = 1 Wort pro Analogwert, Integer 32 Bit und Float = 2 Worte pro Analogwert).

HBM A0623-6.1 en/de/fr

Page 31

PME−MP60DP

31

Die gezielte Freigabe der benötigten Steuerbits im Steuerwort bietet die Möglichkeit, alle nicht benötigten Funktionen im Fehlerfall gegen eine ungewollte

Auslösung abzusichern, da sonst z.B. der einmal eingestellte Nullpunkt verloren gehen könnte.

Falls Sie ältere Parametriertools einsetzen, müssen die Parameterwerte in

Dezimal- oder Hexadezimalwerte umgerechnet werden:

Octet Bit Parameter-Name mögliche Werte Default Bedeutung

0 0..7 reserviert 0 0 nicht verändern

1)

1−2 alle Diagnose 0 = gesperrt

0xffff = freigegeben

3 alle Datenformat 0 = Integer 16 Bit

1 = Integer 32 Bit

2 = Floating Point

5 0 Steuerbit

Nullstellen

5 1 Steuerbit

Tarieren

5 4 Steuerbit

Maximum

löschen

5 5 Steuerbit

Minimum

löschen

5 6 Steuerbit

Maximum halten

0 = gesperrt

1 = freigegeben

0 = gesperrt

1 = freigegeben

0 = gesperrt

1 = freigegeben

0 = gesperrt

1 = freigegeben

0 = gesperrt

1 = freigegeben

freigegeben Freigabe der exter-

nen Diagnose

Integer 16 Bit Festlegung des Ko-

dierungsformats für

Messwerte

gesperrt gibt Funktion für

Steuerung über Aus-

gangssteuerwort frei

gesperrt gibt Funktion für

Steuerung über Aus-

gangssteuerwort frei

gesperrt gibt Funktion für

Steuerung über Aus-

gangssteuerwort frei

gesperrt gibt Funktion für

Steuerung über Aus-

gangssteuerwort frei

gesperrt gibt Funktion für

Steuerung über Aus-

gangssteuerwort frei

5 7 Steuerbit

Minimum halten

5 0−1 Steuerbits

Parametersatz

0 = gesperrt

1 = freigegeben

0 = gesperrt

3 = freigegeben

Tab. 6.2. Inhalt des Parametrier-Telegramms

1)

wird u.U. von Ihrem Parametriertool sebständig verändert

gesperrt gibt Funktion für

Steuerung über Aus-

gangssteuerwort frei

gesperrt gibt Funktion für

Steuerung über Aus-

gangssteuerwort frei

HBMA0623-6.1 en/de/fr

Page 32

32

PME−MP60DP

6.2 Konfiguration

Die Konfiguration legt fest, welche Dateninhalte im zyklischen Datenverkehr

ausgetauscht werden. Für die Auswahl stehen folgende Daten zur Verfügung:

Eingangswerte:

Bezeichnung Bedeutung Länge

Brutto Brutto-Messwert 1 oder 2

Worte

Netto Netto-Messwert (Brutto abzüglich Tara-Wert) 1 oder 2

Worte

Max Inhalt des Maximum-Speichers 1 oder 2

Worte

Min Inhalt des Minimum-Speichers 1 oder 2

Worte

Sp−Sp Spitze-Spitze, Differenz zwischen Max und Min 1 oder 2

Worte

Status1 Statuswort mit Zustand der Grenzwertschalter u. allg. Fehler-

bits

Status2 Status-Doppelwort mit differenzierter Fehlerkennzeichnung 2 Worte

1 Wort

Ausgangswerte:

Bezeichnung Bedeutung Länge

Steuerwort Steuerwort zur Auslösung von Tarierung, Nullstellen, löschen

der Spitzenwertspeicher, Parametersatzauswahl etc.

GW1 Pegel, bei dem Grenzwertschalter 1 anspricht 1 oder 2

GW2 Pegel, bei dem Grenzwertschalter 2 anspricht 1 oder 2

GW3 Pegel, bei dem Grenzwertschalter 3 anspricht 1 oder 2

GW4 Pegel, bei dem Grenzwertschalter 4 anspricht 1 oder 2

1 Wort

Worte

Worte

Worte

Worte

Die Formate der zyklisch übertragenen Dateninhalte werden im Detail im

Kapitel 6.3 angegeben. Die Messwerte werden wahlweise als 16-Bit Integer,

32-Bit Integer oder 32 Bit Float angeboten. Die Werte sind immer auf physikalische Größe skaliert mit wählbarer Nachkommastellenzahl. Die Angaben, ob

das 16 Bit oder ein 32 Bit-Format verwendet wird, sowie die Anzahl der Nachkommastellen wird im Parametrier-Telegramm festgelegt.

Im GSD-File sind typische Kombinationen vordefiniert. Wenn Sie andere

Kombinationen benötigen, können Sie anhand der folgenden Spezifikationen

das GSD-File entsprechend erweitern.

HBM A0623-6.1 en/de/fr

Page 33

PME−MP60DP

33

6.2.1 Definition eigener Konfigurations-Kombinationen

Es steht nur ein Konfigurations-Eintrag zur Verfügung. Bei diesem muss das

spezielle Kennungsformat (Spezialformat) verwendet werden. Die herstellerspezifischen Daten spezifizieren die Inhalte und damit auch die Länge der

Eingabedaten und haben eine Länge von 2 Byte.

CFG-Eintrag

Nr.

0 Kanal 1 Spezialformat mit Ein- und Ausgabe, maximal 9 Worte Aus-

Bedeutung Inhalt

gabe, maximal 13 Worte Eingabe, 2 Byte Kommentarlänge

(Daten)

Folgende Ein- und Ausgangsdaten können für den zyklischen Datenverkehr

konfiguriert werden. Die Auswahl, welche Daten tatsächlich übertragen werden, wird über die herstellerspezifischen Daten des speziellen Kennungsformats mitgeteilt.

Konfiguration

herstellerspez.

Daten

Byte-Nr. Bit-Nr. (Worte) (Worte)

0 0 1(2) Brutto

0 1 1(2) Netto

Länge zyklische Daten

Eingänge

Länge zyklische Daten

Ausgänge

Inhalt zyklische Daten

Eingangswerte:

0 2 1(2) Max

0 3 1(2) Min

0 4 1(2) Spitze-Spitze

0 5 1 Status1

0 6 2 Status2

Ausgangswerte:

1 0 1 Steuerwort

1 1 1(2) Grenzwertpegel 1

1 2 1(2) Grenzwertpegel 2

1 3 1(2) Grenzwertpegel 3

1 4 1(2) Grenzwertpegel 4

Tab. 6.3. Auswahl der Dateninhalte über die herstellerspezifischen Daten

Die Länge der Eingangsdaten ergibt sich als Summe aller für die Übertragung

ausgewählter Datenlängen in Worten. Bei Auswahl des 32-Bit Formats sowie

des Float-Formats für Messwerte müssen die Längenwerte in Klammern verwendet werden.

HBMA0623-6.1 en/de/fr

Page 34

34

p

(

Das Konfigurationstelegramm hat damit folgendes Format:

PME−MP60DP

CFG-

Byte

1 Kopf 0xC2 (Ein- und Ausgaben, 2 Byte herstellerspez. Daten)

2 Länge Ausgaben 0x40...0x48 (1 bis 9 Worte Ausgaben) oder

3 Länge Eingaben 0xC0 ... 0xCC oder

4

5

Bedeutung Erlaubte Werte für CFG (Hex)

0xC0...0xC8 (1 bis 9 Worte Ausgaben mit Konsistenz)

0x40..0x7C (1 bis 13 Worte Eingaben mit / ohne Konsi-

stenz)

benutzerspezifische

Daten

Eingangsdaten

Ausgangsdaten

Auswahl der Dateninhalte (siehe

Tab. 6.3.)

Tab. 6.4. Inhalt des Konfigurationstelegramms

Bei Verwendung der 32-Bit-Formate ist unbedingt Datenkonsistenz einzustellen.

6.3 Zyklischer Datenaustausch

Abhängig von der Konfiguration werden folgende Dateninhalte ausgetauscht:

6.3.1 Eingänge (vom MP60DP an die SPS geliefert)

Messwerte

Messwerte können in unterschiedlicher Darstellung übertragen werden. Zur

Auswahl stehen Float (2 Worte, 32Bit), 16 Bit Festpunktzahl (1 Wort, 16 Bit Integer im Zweierkomplement, Kommastelle muss der lesenden Stelle bekannt

sein) oder 32 Bit Festpunktzahl (2 Worte, 32 Bit Integer im Zweierkomplement, Kommastelle muss der lesenden Stelle bekannt sein). Für die Umrechnung der Werte in die Festpunktdarstellung wird die Anzahl der Nachkommastellen in der Modulparametrierung (Display, CAN-Bus) zugrundegelegt.

Status 1

Bit Name Bedeutung

0 MesswOvfl Messwerte übersteuert

1 AOutOvfl Analogausgang übersteuert

2 SkalErr Skalierung fehlerhaft

3 EEPROMErr EEPROM (Parametersatz) fehlerhaft

4 GW1 Zustand Grenzwertschalter 1

5 GW2 Zustand Grenzwertschalter 2

6 GW3 Zustand Grenzwertschalter 3

7 GW4 Zustand Grenzwertschalter 4

8 PAR1 aktiver Parametersatz-Bit 1

9 PAR2 aktiver Parametersatz-Bit 2

10..14 res reserviert

15 MWiO Messwert in Ordnung1) (wenn Bit 0,2,3=0)

Tab. 6.5. Inhalt Status 1

1)

Bedeutung von MWiO:

Negierte ODER-Verknüpfung von: MesswOvfl, SkalErr, EEPROMErr.

MesswOvfl ist die Oder-Verknüpfung von ADCOvfl, HardwOvfl, GrossOvfl, NetOvfl

HBM A0623-6.1 en/de/fr

Page 35

PME−MP60DP

Die Parametersatznummer ist in 2 Bit binär kodiert:

Bit 8 Bit 9 Parametersatz-Nr

0 0 1

1 0 2

0 1 3

1 1 4

Status 2

Das Status-Doppelwort 2 liefert eine detailliertere Fehlerkennzeichung.

Bit Name Bedeutung

0 HardwOvfl Übersteuerung Hardware

1 ADCOvfl ADC übersteuert

2 GrossOvfl Bruttosignal übersteuert

3 NetOvfl Nettosignal übersteuert

35

4 AOutOvfl Analogausgang übersteuert

5 MaxOvfl Maximum übersteuert

6 MinOvfl Minimum übersteuert

7 NegOvfl Übersteuerung in negative Richtung

8 GW1 Zustand Grenzwertschalter 1

9 GW2 Zustand Grenzwertschalter 2

10 GW3 Zustand Grenzwertschalter 3

11 GW4 Zustand Grenzwertschalter 4

12 SkalInError Skalierung Eingang ungültig

13 SkalOutError Skalierung Ausgang ungültig

14 GainError Nennwert überschritten

15 UrcalError Werkskalibrierung fehlerhaft

16 TransducerError Aufnehmerfehler

17..31 res reserviert

Tab. 6.6. Inhalt Status 2

6.3.2 Ausgänge (von der SPS an den MP60DP gesendet) Grenzwerte

Grenzwertpegel werden im selben Format wie die Messwerte dargestellt (16

Bit Integer, 32 Bit Integer oder Float-Format). Die Schaltrichtung und Hysterese bleiben unverändert und werden über das Bedienfeld oder den CAN-Bus

eingestellt.

HBMA0623-6.1 en/de/fr

Page 36

36

Steuerwort

Bit Name Bedeutung

0 NULL 0−1 löst autom. Nullstellen aus

1 TAR 0−1 löst Tarierung aus

2 SHUNT Shunt EIN / AUS

3 res reserviert

4 CLRMAX 0−1 löscht den Spitzenwertspeicher MAX

5 CLRMIN 0−1 löscht den Spitzenwertspeicher MIN

6 HOLDMAX 1: Spitzenwertspeicher MAX einfrieren

7 HOLDMIN 1: Spitzenwertspeicher MIN einfrieren

8 PAR1 Parametersatz-Auswahl Bit 1

9 PAR2 Parametersatz-Auswahl Bit 2

10..15 res reserviert

Tab. 6.7. Inhalt Steuerwort

PME−MP60DP

6.4 Diagnose

Das Modul MP60DP stellt als externe Diagnose eine Geräte-Diagnose zur

Verfügung, die über das Parametrier-Diagramm freigegeben werden kann.

Die externe Diagnose hat eine Länge von 4 Byte. Das erste Byte enthält die

Kennung für die Versionsnummer. Das zweite Byte enthält die Kennung für

Geräte-Diagnose. Im dritten und vierten Byte wird für verschiedene Fehlerursachen je ein Bit reserviert.

HBM A0623-6.1 en/de/fr

Page 37

PME−MP60DP

Octet Bit Wert Bedeutung

0 0..7 c1 Version 1

1 0..7 4 Länge der Gerätediagnose ist insgesamt 4 Byte

37

2 0 0

1

2 1 ADC übersteuert

2 2 0

1

2 3 0

1

2 4 0

1

2 5 0

1

2 6 0

1

2 7 res

3 0..3 res

3 4 0

1

3 5 0

1

Skalierung Eingangskennlinie fehlerhaft

Skalierung Ausgangskennlinie fehlerhaft

Hardware übersteuert

Brutto übersteuert

Netto übersteuert

Analogausgang übersteuert

Maximum übersteuert

Minimum übersteuert

3 6 0

1

3 7 0

1

4 0 0

1

4 1...7 res

Nennwert überschritten

Werkskalibrierung fehlerhaft

Aufnehmer-Fehler

Tab. 6.8. Inhalt Diagnose

HBMA0623-6.1 en/de/fr

Page 38

38

PME−MP60DP

HBM A0623-6.1 en/de/fr

Page 39

PME−MP60DP

39

Sommaire Page

1 Introduction 40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Mémento pour le raccordement à l’API 41 . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Configuration et paramétrage 42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Installation 44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Branchement 45 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Affectation des connexions 45 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Commande via clavier 46 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Menus étendus 47 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Réglages du Profibus 48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Paramétrage 48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Configuration 50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.1 Définir ses propres combinaisons de configuration 51 . . . . . . .

6.3 Echange cyclique de données 52 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.1 Entrées (du MP55IBS à l’API) 52 . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.2 Sorties (de l’API au MP55IBS) 54 . . . . . . . . . . . . . . . . . . . . . . . .

6.4 Diagnostic 55 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HBMA0623-6.1 en/de/fr

Page 40

40

PME−MP60DP

1 Introduction

Dans ce manuel d’emploi ne sont décrites que les fonctions qui diffèrent de

celles du MP60. Les fonctions du MP60DP sont identiques à celles du MP60.

Le module de mesure de fréquence MP60DP comporte en complément une

interface Profibus. Les fonctions de l’interface CAN sont identiques ; l’index

des objets est étendu de quelques paramètres concernant le couplage

Profibus.

Le branchement Profibus s’effectue à l’aide d’une connexion Sub−D 9 pôles

(conforme à la norme) située sur la partie avant à côté de la fiche de

raccordement du capteur.

Le Profibus s’utilise avec le protocole DP.

Les paramètres transmis sont:

− les valeurs (brutes, nettes, crêtes)

− état des bascules à seuils

− bits de contrôle pour le tarage, la mise à zéro, la commande des mémoires

crêtes, la commutation des blocs de paramètres et

− en option, les niveaux seuils.

HBM A0623-6.1 en/de/fr

Page 41

PME−MP60DP

41

2 Mémento pour le raccordement à l’API

Les étapes pour un raccordement avec succès au Profibus :

1. Raccordement physique de l’appareil au Profibus (cf. page 44 et page 45)

2. Ajuster l’adresse Profibus à l’appareil, cf page 6 (peut aussi être effectué à

l’aide du logiciel HBM “PME-Assistant“).

3. Configuration et paramétrage du télégramme Profibus à l’aide d’un outil de

configuration (p. ex. Step7) et des fichiers GSD ou manuellement selon

chapitre 6.2.

Un fichier GSD décrit les propriétés d’un participant Profibus sous une forme

standardisée. L’outil de configuration utilise ce fichier pour déterminer le type

de données échangées par les participants au sein du réseau Profibus.

Un fichier GSD standard (hbmxxx.gsd = deutsch; hbmxxxgse = englisch) pour

les modules PME est fourni avec l’appareil (CD de système).

Configurateur

Profibus

API

Configuration du réseau

GSD

Bases de données équipements (fichiers GSD)

PROFIBUS−DP

Fig. 2.7: Configuration à l’aide de fichiers GSD

HBMA0623-6.1 en/de/fr

Page 42

42

PME−MP60DP

2.1 Configuration et paramétrage

• Lancez votre programme de configuration (p. ex. Step7; si vous ne

disposez pas d’un programme de configuration, procédez comme décrit

dans chapitre 6.2)

• Chargez le fichier GSD HBM (CD système PME incl. fichiers GSD/GSE pour

PME)

• Ajoutez un équipement HBM (catalogue hardware)

• Sélectionnez dans le catalogue hardware la configuration dont vous avez

besoin sur Profibus.

Fig. 2.8 : Configuration hardware

HBM A0623-6.1 en/de/fr

Page 43

PME−MP60DP

• En double-cliquant sur les paramètres de configuration, activez la fenêtre

des caractéristiques et sélectionnez les paramètres désirés.

43

Fig. 2.9: Définir les paramètres

Remarques pour les utilisateurs de l’API Simatic S7 :

• Pour la transmission de données cohérentes d’une longueur de 3 ou 4

octets, vous devez utiliser les blocs de fonction spéciaux SFC14 pour la

lecture et SFC15 pour l’écriture.

• Le système S7 3xx permet la transmission de données cohérentes d’une

longueur maximale de 32 octets.

Pour la signification des bits des mots d’état et de contrôle, veuillez vous

reporter aux tableaux du chapitre 6.3.

HBMA0623-6.1 en/de/fr

Page 44

44

PME−MP60DP

3 Installation

• Raccorder le module MP55DP à la tension d’alimentation 24 V.

• Connecter le câble Profibus au module MP55DP. Veiller à ce que le

premier et le dernier participant du Profibus soit équipé d’une résistance de

terminaison (à cet effet, le boîtier du connecteur Profibus est, en général,

muni d’un interrupteur à coulisse).

Exemple :

API

Connecteur

Profibus

Premier

appareil dans

la ligne bus

Interrupteur à coulisse du connecteur

Profibus en position “Résistance ACTIVE”

Fig. 3.3 : Fonctionnement Profibus

Connecteur

Profibus

Dernier appareil

dans la ligne bus

Interrupteur à coulisse du

connecteur Profibus en

position “Résistance ACTIVE”

HBM A0623-6.1 en/de/fr

Page 45

PME−MP60DP

45

4 Branchement

AVERTISSEMENT

Avant de mettre l’appareil en fonction, veuillez consulter les consignes

de sécurité.

4.1 Affectation des connexions

Afin de connaître l’affectation des connexions du module MP60DP, veuillez

consulter le manuel d’emploi ”Electronique de mesure industrielle avec liaison

bus de terrain module MP55”. La façade du MP60DP comporte une prise de

connexion D−Sub 9 pôles supplémentaire pour la connexion du Profibus.

6

0

9

RS485-A

Vcc (5V)

6

Fig. 4.3: Connexion du Profibus conformément à la norme

Prise de

connexion

Profibus

GND

5

RS485-RTS

1

RS485-B

HBMA0623-6.1 en/de/fr

Page 46

46

PME−MP60DP

5 Commande via clavier

−

Pendant la mesure, vous pouvez − en appuyant sur

les messages d’état (par ex. mV; V; Sortie, Entrée; messages d’erreur).

Le message d’état “ERREUR” entraîne l’affichage de l’état de la connexion

DP Profibus. Un des messages d’état suivants est alors affiché:

BD_SEAR (recherche vitesse en Bauds)

WT_PARM (en attente de paramètres)

WT_CONF (en attente de configuration)

DATA_EX (circulation de données cyclique)

ERROR (erreur de bus)

+

− consulter à l’écran

La DEL indique les états de fonctionnement (prêt à mesurer, surcharge, etc.)

du MP60DP. Cependant, au lieu de l’état CAN (comme pour le MP60), c’est

ici l’état du Profibus qui est indiqué.

Etat de fonctionnement:

Couleur

DEL

Vert Allumé en continu Etat DATA_EX

Jaune Allumé en continu Etats BD_SEAR, WT_PARM, WT_CONF

Rouge Allumé en continu Etat ERREUR

Etat Signification

Etat Profibus

La représentation des autres états de fonctionnement est identique à celle du

MP60.

HBM A0623-6.1 en/de/fr

Page 47

PME−MP60DP

5.1 Menus étendus

Nouveau groupe “Profibus” en mode de paramétrage :

−

SET

+

Groupes

47

SET

+

Haut

−

Bas

DIALOGUE ...

MotPasse Libérer Sortie1 Vitesse Adresse TypeAmpl

StatMPas E.CrtMin ModeSor1 Adresse GRP PRINC VersLog

Langue

ParaPr.E Effac.MC ModeSor2 Transfert

Affich.E

Captr.E GRP PRINC ModeSor3 PDO-Frmt NoSr

Mes. E Sortie4

Adaptn.E ModeSor4 GRP PRINC

Analog.E Reg.Zero

Seuil.E Tarage

MCrete.E CrMaInst

Ent/Srt.E CrMaHold

CAN.E CrMiInst

FntCom.E CrMiHold

GRP PRINC ParaCo 1

MEMOIRE

CRETE

E.CrtMax

kN/s

ENTR./SORT. CAN-BUS PROFIBUS FONCT. COMPL

Sortie2 Profil >0<Rf kNm

1)

Sortie3 VitTrans ms Clavier

GRP PRINC

Hard Synchr

Vers.Hard

1)

ParaCo 2

FoncEntr

Vue d’ensemble des paramètres

GRP PRINC

Groupes

Entr./Sort.

Bus CAN

SET

+

PROFIBUS

−

SET

Adresse

Fig. 5.3: Paramétrer l’adresse Profibus

SET

↑

↓

3 − 123

FONCT. COMPL

SET

+/−

HBMA0623-6.1 en/de/fr

Page 48

48

PME−MP60DP

6 Réglages du Profibus

6.1 Paramétrage

Comme pour le MP60, les paramètres de l’amplificateur sont configurables

via le clavier ou l’interface CAN. La liste des paramètres DP du Profibus

détermine certains paramètres pour la transmission DP. Si vous utilisez un

outil de paramétrage pour Profibus capable de manipuler les fichiers GSD de

la GSD−révision 1, les paramètres suivants sont disponibles:

Nom du paramètre Valeurs valables Valeur par

défaut

Diagnostic inactif

Format des

données

Virgule flottante

Bit de contrôle

mise à zéro

Bit de contrôle

tarage

Bit de contrôle

suppr. valeur max.

Bit de contrôle

suppr. valeur min.

Bit de contrôle

garder valeur max.

Bit de contrôle

garder valeur min.

actif

16 bits Entier

32 bits Entier

inactif

actif

inactif

actif

inactif

actif

inactif

actif

inactif

actif

inactif

actif

actif Activation du diagnostic externe

16 bits

Entier

inactif active la fonction pour commande

inactif active la fonction pour commande

inactif active la fonction pour commande

inactif active la fonction pour commande

inactif active la fonction pour commande

inactif active la fonction pour commande

Signification

Définition du format de codage des

valeurs

par mot de commande de sortie

par mot de commande de sortie

par mot de commande de sortie

par mot de commande de sortie

par mot de commande de sortie

par mot de commande de sortie

Bit de contrôle bloc

de paramètres

inactif

actif

inactif active la fonction pour commande

par mot de commande de sortie

Tab 6.9: Signification des paramètres

Le format de données sélectionné est valable pour toutes les valeurs

échangées par circulation de données cyclique. Pour les formats 16 bits

Entier et 32 bits Entier, le nombre de positions après la virgule est identique à

celui qui est défini dans les paramètres du module (écran, bus CAN), par ex.

dans le cas où 3 positions après la virgule sont sélectionnées 2.0 mm sont

transmis comme valeur Entier 2000). Le choix du format des données influe

également sur la longueur des données à l’entrée (16 bits Entier = 1 mot par

valeur analogiq, 32 bits Entier et Flottante = 2 mots par valeur analogiq).

HBM A0623-6.1 en/de/fr

Page 49

PME−MP60DP

49

En activant de manière ciblée les bits de contrôle nécessaires, il est possible

d’éviter − en cas d’erreur − un déclenchement involontaire des fonctions non

requises, et ainsi d’éviter la perte du point zéro préalablement défini.

Si vous utilisez d’anciens outils de paramétrage, les valeurs des paramètres

doivent être converties en valeurs décimales ou hexadécimales:

Octet Bit Nom du

paramètre

0 0..7 réservé 0 0 Ne pas modifier

1−2 tous Diagnostic 0 = inactif

3 tous Format des

données

5 0 Bit de contrôle

mise à zéro

5 1 Bit de contrôle

tarage

5 4 Bit de contrôle

Suppr. val.

max.

Valeurs valables Valeur par

défaut

actif Activation du

0xffff = actif

0 = 16 bits Entier

1 = 32 bits Entier

2 = virgule flottante

0 = inactif

1 = actif

0 = inactif

1 = actif

0 = inactif

1 = actif

16 bits Entier Définition du format

inactif Active la fonction

inactif Active la fonction

inactif Active la fonction

Signification

diagnostic externe

de codage des

valeurs

pour commande par

mot de commande

de sortie

pour commande par

mot de commande

de sortie

pour commande par

mot de commande

de sortie

1)

5 5 Bit de contrôle

Suppr. val.

min.

5 6 Bit de contrôle

Garder val.

max.

5 7 Bit de contrôle

Garder val.

min.

4 0−1 Bits de

contrôle bloc

de paramètres

0 = inactif

1 = actif

0 = inactif

1 = actif

0 = inactif

1 = actif

0 = inactif

3 = actif

inactif Active la fonction

inactif Active la fonction

inactif Active la fonction

inactif Active la fonction

Tab 6.10: Contenu de la liste des paramètres

1)

est modifié automatiquement, le cas échéant, par votre outil de paramétrage

pour commande par

mot de commande

de sortie

pour commande par

mot de commande

de sortie

pour commande par

mot de commande

de sortie

pour commande par

mot de commande

de sortie

HBMA0623-6.1 en/de/fr

Page 50

50

PME−MP60DP

6.2 Configuration

La configuration détermine les contenus de données à échanger durant la

circulation de données cyclique. Les données suivantes peuvent être

sélectionnées:

Valeurs d’entrée:

Désignation Signification Longueur

Brute Valeur mesurée brute 1 ou 2

mots

Nette Valeur mesurée nette (brute moins tare) 1 ou 2

mots

Max Contenu de la mémoire valeur maximum 1 ou 2

mots

Min Contenu de la mémoire valeur minimum 1 ou 2

mots

Cr−Cr Crête−crête, différence entre valeur max. et valeur min. 1 ou 2

mots

Etat1 Mot d’état avec état des bascules à seuil et bits d’erreur généraux 1 mot

Etat2 Double mot d’état avec indication d’erreur détaillée 2 mots

Valeurs de sortie:

Désignation Signification Longueur

Mot de

contrôle

Seuil1 Niveau de déclenchement de la bascule à seuil 1 1 ou 2

Seuil2 Niveau de déclenchement de la bascule à seuil 2 1 ou 2

Seuil3 Niveau de déclenchement de la bascule à seuil 3 1 ou 2

Seuil4 Niveau de déclenchement de la bascule à seuil 4 1 ou 2

Mot de contrôle pour lancer le tarage, mettre à zéro,

supprimer les mémoires crêtes, sélectionner le bloc de

paramètres, etc.

1 mot

mots

mots

mots

mots

Les formats des contenus de données échangées cycliquement sont indiqués

plus en détail dans le chapitre 6.3. Les valeurs mesurées sont indiquées au

choix sous la forme 16 bits Entier, 32 bits Entier ou 32 bits Flottante. Les

valeurs sont toujours échelonnées par rapport aux grandeurs physiques, et le

nombre de positions après la virgule peut être sélectionné. Le type de format

(16 bits ou 32 bits) ainsi que le nombre de positions après la virgule sont

déterminés dans la liste des paramètres. Des combinaisons typiques sont

prédéfinies dans le fichier GSD. Pour ajouter d’autres combinaisons, étendre

le fichier GSD à l’aide des indications ci−après.

HBM A0623-6.1 en/de/fr

Page 51

PME−MP60DP

51

6.2.1 Définir ses propres combinaisons de configuration

Un seul enregistrement de configuration est disponible. Pour ce faire, il

convient d’utiliser le format d’identification spécial (format spécial). Les

données propres au fabricant spécifient les contenus et donc la longueur des

données saisies. Elles ont une longueur de 2 octets.

Inscr. CFG No. Signification Contenu

0 Voie 1 Format spécial comportant entrée et sortie − 9 mots max.

sortie − 13 mots max. entrée − longueur du commentaire

(données) 2 octets

Les données d’entrée et de sortie suivantes peuvent être configurées pour la

circulation de données cyclique. La sélection des données réellement

échangées est notifiée par les données spécifiques au fabricant du format

d’identification spécial.

Configuration

des données spécif.

au fabricant

No. octet No. bit (mots) (mots)

0 0 1(2) Brute

0 1 1(2) Nette

0 2 1(2) Max

0 3 1(2) Min

0 4 1(2) Crête−crête

0 5 1 Etat1

0 6 2 Etat2

1 0 1 Mot de contrôle

1 1 1(2) Niveau seuil 1

1 2 1(2) Niveau seuil 2

Longueur des

données

cycliques Entrées

Longueur des

données cycliques

Sorties

Contenu des données

cycliques

Valeurs d’entrée:

Valeurs de sortie:

1 3 1(2) Niveau seuil 3

1 4 1(2) Niveau seuil 4

Tab 6.11: Sélection des contenus des données à l’aide des données spécifiques au

fabricant

La longueur des données d’entrées est égale à la somme des longueurs de

données (en mots) choisies pour la transmission. Si un des formats 32 bits ou

flottante est choisi pour les valeurs mesurées, il faut utiliser les longueurs

indiquées entre parenthèses.

HBMA0623-6.1 en/de/fr

Page 52

52

pq

()

Ainsi, la liste de configuration a le format suivant:

PME−MP60DP

Octet

CFG

1 En−tête 0xC2 (entrées et sorties, 2 octets de données spécif. au

2 Longueurs des

3 Longueur des

4

5

Signification Valeurs valables pour CFG (Hex)

fabric.)

0x40...0x48 (1 à 9 mots sorties) ou

données de sortie

données d’entrées

Données

spécifiques à

l’utilisateur

0xC0...0xC8 (1 à 9 mots sorties avec cohérence)

0xC0 ... 0xCC ou

0x40..0x7C (1 à 13 mots entrées avec / sans cohérence)

Données

d’entrées

Données de sortie

Sélection des contenus de données

(cf. Tab 6.11)

Tab 6.12: Contenu de la liste de configuration

Si vous utilisez le format 32 bits, sélectionnez impérativement la cohérence

de données.

6.3 Echange cyclique de données

Selon la configuration, les contenus de données suivants sont échangés:

6.3.1 Entrées (du MP55IBS à l’API)

Valeurs

Les valeurs peuvent être transmises sous des formes de représentation

différentes. Les formats disponibles sont: Flottante (2 mots, 32 bits), 16 bits

chiffre à virgule fixe (1 mot, 16 bits Entier dans le complément de deux,

l’appareil effectuant la lecture doit connaître la position de la virgule) ou 32

bits chiffre à virgule fixe (2 mots, 32 bits Entier dans le complément de deux,

l’appareil effectuant la lecture doit connaître la position de la virgule). Pour

convertir les valeurs en une représentation à virgule fixe, le nombre des

positions après la virgule est celui qui est déterminé dans le paramétrage du

module (écran, bus CAN).

HBM A0623-6.1 en/de/fr

Page 53

PME−MP60DP

Etat 1

Bit Nom Signification

0 Zero Valeurs surchargées

1 DepVal Sortie analogique surchargée

2 DepAnlg Erreur d’échelonnage

3 ErrCadr Erreur d’EEPROM (bloc de paramètres)

4 Seuil1 Etat de la bascule à seuil 1

5 Seuil2 Etat de la bascule à seuil 2

6 Seuil3 Etat de la bascule à seuil 3

7 Seuil4 Etat de la bascule à seuil 4

8 PAR1 Bit actif du bloc de paramètres 1

9 PAR2 Bit actif du bloc de paramètres 2

10..14 res réservé

15 MWiO Valeur de mesure OK

Tab 6.13: Contenu état 1

1)

Signification de MWiO:

Opération NON OU de: MesswOvfl, SkalErr, EEPROMErr.

MesswOvfl est l’opération OU de ADCOvfl, HardwOvfl, GrossOvfl, NetOvfl

1)

(si Bit 0,2,3=0)

53

Le numéro du bloc de paramètres est codé de façon binaire dans 2 bits:

Bit 8 Bit 9 Numéro du bloc de

paramètres

0 0 1

1 0 2

0 1 3

1 1 4

Etat 2

Le double mot d’état 2 fournit une identification d’erreurs plus détaillée:

Bit Nom Signification

0 Dep Mater Surcharge matériel

1 DepADC ADC surchargé

2 DepBru Signal brut surchargé

3 DepNet Signal net surchargé

4 DepAnlg Sortie analogique surchargée

5 DepMax Valeur maximum surchargée

6 DepMin Valeur minimum surchargée

7 DepNeg Surcharge vers valeurs négatives

8 Seuil1 Etat de la bascule à seuil 1

9 Seuil2 Etat de la bascule à seuil 2

10 Seuil3 Etat de la bascule à seuil 3

11 Seuil4 Etat de la bascule à seuil 4

12 ErrCadrE Echelonnage entrée non valable

13 ErrCadrS Echelonnage sortie non valable

14 ErrGain Dépassement valeur nominale

15 ErrCafln Calibrage par défaut erroné

16 ErrCapt Erreur de capteur

17..31 res réservé

Tab 6.14: Contenu état 2

HBMA0623-6.1 en/de/fr

Page 54

54

PME−MP60DP

6.3.2 Sorties (de l’API au MP55IBS)

Seuils

Les niveaux seuils sont représentés dans le même format que les valeurs

mesurées (16 bits Entier, 32 bits Entier ou Flottante). La direction de

commutation et l’hystérésis ne sont pas modifiées ; elles sont programmées

via le bloc de commande ou le bus CAN.

Mot de contrôle

Bit Nom Signification

0 Zero 0−1 déclenche autom. mise à zéro

1 Ta r 0−1 déclenche tarage

2 SHUNT SHUNT ON /OFF

3 res réservé

4 EffaceMax 0−1 efface la mémoire crête MAX

5 EffaceMin 0−1 efface la mémoire crête MIN

6 GardeMax 1: garder mémoire crête MAX

7 GardeMin 1: garder mémoire crête MIN

8 PAR1 Sélection bloc de paramètres, bit 1

9 PAR2 Sélection bloc de paramètres, bit 2

10..15 res réservé

Tab 6.15: Contenu mot de contrôle

HBM A0623-6.1 en/de/fr

Page 55

PME−MP60DP

6.4 Diagnostic

En tant que diagnostic externe, le module MP60DP offre un diagnostic de

l’appareil qui peut être activé par le diagramme de paramétrage.

Le diagnostic externe a une longueur de 4 octets. Le premier octet contient

l’identification du numéro de version. Le deuxième octet contient

l’identification du diagnostic de l’appareil. Dans les troisième et quatrième

octet, les différentes causes d’erreur sont indiquées chacune par un bit.

Octet Bit Valeur Signification

0 0..7 c1 Version 1

1 0..7 4 La longueur du diagnostic de l’appareil est de 4 octets au

total.

55

2 0 0

1

2 1 ADC surchargé

2 2 0

1

2 3 0

1

2 4 0

1

2 5 0

1

2 6 0

1

2 7 res

3 0..3 res

3 4 0

1

3 5 0

1

Erreur d’échelonnage de la caractéristique d’entrée

Erreur d’échelonnage de la caractéristique de sortie

Matériel surchargé

Brute surchargée

Nette surchargée

Sortie analogique surchargée

Valeur maximum surchargée

Valeur minimum surchargée

3 6 0

1

3 7 0

1

4 0 0

1

4 1...7 res

Dépassement valeur nominale

Calibrage par défaut erroné

Erreur de capteur

Tab 6.16: Contenu du diagnostic

HBMA0623-6.1 en/de/fr

Page 56

Modifications reserved.

All details describe our products in general form only.They are

not to be understood as express warranty and do not constitute

any liability whatsoever.

Änderungen vorbehalten.

Alle Angaben beschreiben unsere Produkte in allgemeiner Form.

Sie stellen keine Beschaffenheits- oder Haltbarkeitsgarantie im

Sinne des §443 BGB dar und begründen keine Haftung.

Document non contractuel.

Les caractéristiques indiquées ne décrivent nos produits que

sous une forme générale. Elles n’établissent aucune assurance

formelle au terme de la loi et n’engagent pas notre responsabilité.

7−2001.0431

A0623−6.1 en/de/fr

Hottinger Baldwin Messtechnik GmbH

Postfach 10 01 51, D-64201 Darmstadt

Im Tiefen See 45, D-64293 Darmstadt

Tel.: +49 6151 803-0 Fax: +49 6151 8039100

Email: support@hbm.com Internet: www.hbm.com

Loading...

Loading...