Page 1

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

Instra

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

REMOTE INSPECTION

View

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Page 2

Operating manual

PME industrial

measurement

electronics linked

to a field bus

MP55 module

A0563-5.6 en

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 3

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 4

PME-MP55

3

Contents Page

Safety instructions 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Introduction 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 List of components and accessories supplied 7 . . . . . . . . . . . . . . . .

1.2 Introduction 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Choose amplifier settings with the aid of DIP switches 8 . . . . . . . . .

3 Fitting/removing the MP55 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Linking several modules 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Connections 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Functional overview of the MP55 14 . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Supply voltage and remote contact I/Os 15 . . . . . . . . . . . . . . . . . . . . .

4.2.1 External supply voltage for the control I/Os 16 . . . . . . . . . . . . . .

4.3 Transducers 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 CAN-interface 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Synchronisation 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Setting up and operation (MP55) 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Operating principles 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Commissioning 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Overview of all groups and parameters 25 . . . . . . . . . . . . . . . . . . . . . .

5.3.1 Set up all parameters 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Declaring the significant parameters 30 . . . . . . . . . . . . . . . . . . . . . . . . . .

7 CAN interface description 38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Introduction 38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Cyclical data transmission 38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Parameter assignment 39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 Object directory: communications profile section

as defined in CANopen (CiA-DS301) 41 . . . . . . . . . . . . . . . . . . . . . . . .

7.5 Object directory: manufacturer-specific objects 44 . . . . . . . . . . . . . . .

7.6 Manufacturer-specific objects in FLOAT data format 53 . . . . . . . . . . .

7.7 Examples 55 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Error messages/operating status (LED) 57 . . . . . . . . . . . . . . . . . . . . . . .

9 Specifications 60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 Keyword index 63 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

HBMA0563-5.6 en

Page 5

4

PME-MP55

Safety instructions

Use in accordance with the regulations

The MP55 module and its connected transducers are to be used exclusively

for measurement tasks and directly related control tasks. Use for any additional purpose shall be deemed to be not in accordance with the regulations.

In the interests of safety, the instrument should only be operated as described

in the User Manual. It is also essential to observe the appropriate legal and

safety regulations for the application concerned during use. The same applies

to the use of accessories.

The device must not be connected directly to the mains supply. The

maximum permissible supply voltage is 18...30 V.

General dangers of failing to follow the safety instructions

The MP55 module corresponds to the state of the art and is safe to operate.

The instrument can give rise to further dangers if it is inappropriately installed

and operated by untrained personnel.

Everyone involved with the installation, commissioning, maintenance or repair

of the instrument must have read and understood the User Manual and in particular the technical safety instructions.

Conditions on site

Protect the device from direct contact with water (IP20).

Maintenance and cleaning

The MP55 module is maintenance-free. Please note the following points when

cleaning the housing:

- Before cleaning, disconnect the devices from the power supply.

- Clean the housing with a soft, slightly damp (not wet!) cloth. You should

never use solvent, since this could damage the labelling on the front panel

and the display.

- When cleaning, ensure that no liquid gets into the device or connections.

HBM A0563-5.5 en

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 6

PME-MP55

5

Residual dangers

The scope of supply and list of components provided with the MP55 cover

only part of the scope of measurement technology. In addition, equipment

planners, installers and operators should plan, implement and respond to the

safety engineering considerations of measurement technology in such a way

as to minimise residual dangers. Prevailing regulations must be complied with

at all times. There must be reference to the residual dangers connected with

measurement technology.

Any risk of residual dangers when working with the MP55 is pointed out in this

introduction by means of the following symbols:

Symbol:

WARNING

Meaning: Dangerous situation

Warns of a potentially dangerous situation in which failure to comply with

safety requirements can lead to death or serious physical injury.

Symbol:

CAUTION

Meaning: Possible dangerous situation

Warns of a possibly dangerous situation in which failure to comply with safety

requirements can cause damage to property or lead to some form of physical

injury.

Symbol:

NOTE

Means that important information about the product or its handling is being

given.

Symbol:

Meaning: CE mark

The CE mark enables the manufacturer to guarantee that the product com-

plies with the requirements of the relevant EC directives (the declaration of

conformity is available at http://www.hbm.com/support/dokumentation).

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

HBMA0563-5.5 en

Page 7

6

PME-MP55

Working safely

Error messages should only be acknowledged if the cause of the error is removed and no further danger exists.

The instrument complies with the safety requirements of DIN EN 61010,

Part 1 (VDE 0411, Part 1).

To ensure adequate immunity from interference, use only Greenline shielded

ducting (place the shield of the transducer cable onto the connector housing).

The MP55 module must be operated with an extra-low safe voltage (supply

voltage 18 to 30 V DC).

Conversions and modifications

The MP55 module must not be modified from the design or safety engineering

point of view except with our express agreement. Any modification shall exclude all liability on our part for any damage resulting therefrom.

In particular, any repair or soldering work on motherboards is prohibited.

When exchanging any modules, only original HBM parts must be used.

Qualified personnel

This instrument is only to be installed and used by qualified personnel strictly

in accordance with the technical data and with the safety rules and regulations

which follow. It is also essential to comply with the appropriate legal and

safety regulations for the application concerned during use. The same applies

to the use of accessories.

Qualified personnel means persons entrusted with the installation, assembly,

commissioning and operation of the product who possess the appropriate

qualifications for their function.

Maintenance and repair work on an open device with the power on must only

be carried out by trained personnel who are aware of the dangers involved.

HBM A0563-5.5 en

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 8

PME-MP55

1 Introduction

1.1 List of components and accessories supplied

List of components supplied:

D 1 MP55 module

D 3 x 6-pin terminal plugs, coded

Order No.: 3.3312-0251 (terminal plug 3);

3.3312-0252 (terminal plug 4); 3.3312-0250 (terminal plug 1)

D 10-pin ribbon cable jack-connector

D 1 User Manual for the MP55 module

Accessories:

D 15-pin Sub-D connector for transducer, Order No.: 3.3312-0182

7

D Standard ribbon cable, 10pin, 1.27 mm pitch

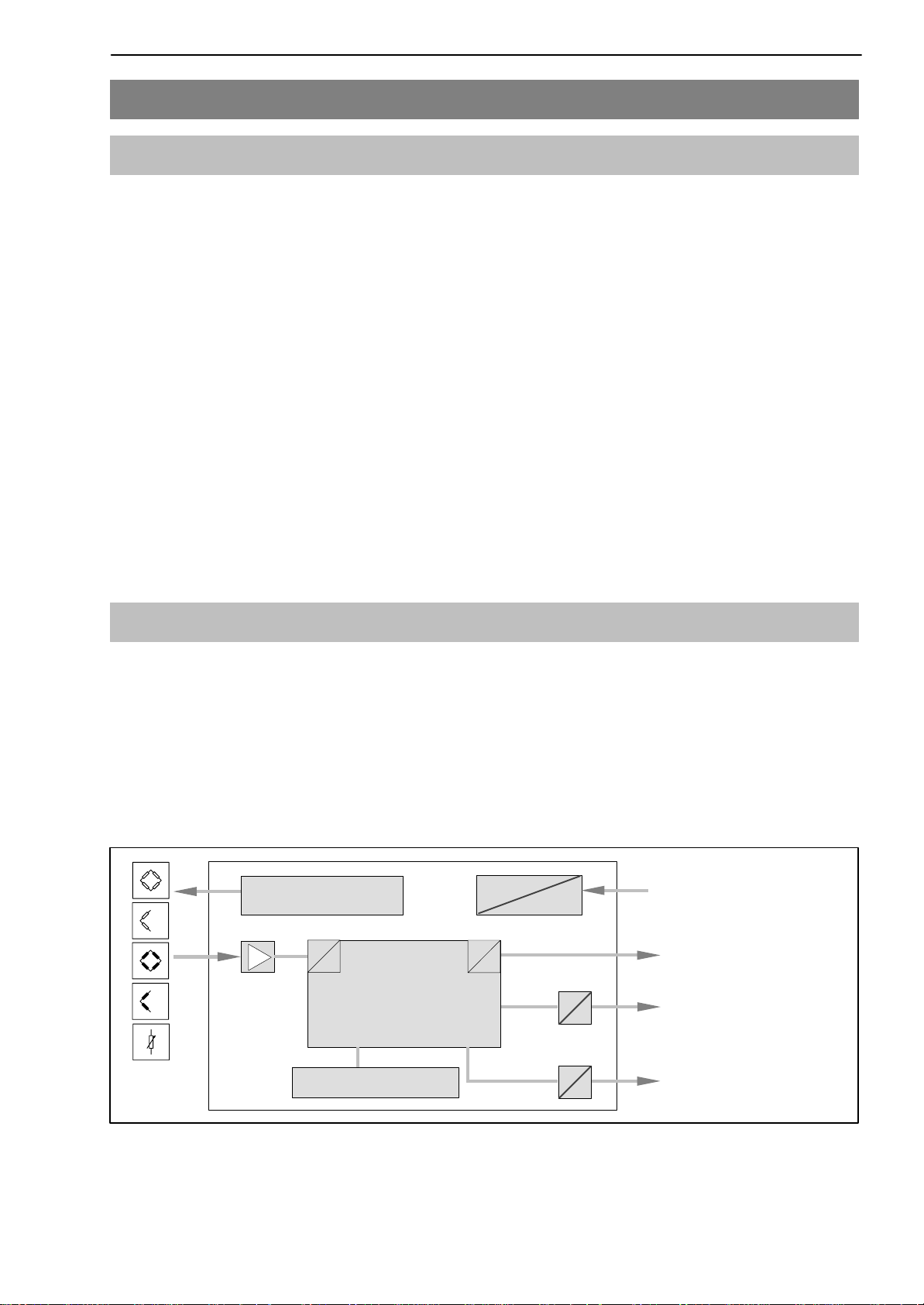

1.2 Introduction

The MP55 module from the PME product line is a carrier-frequency amplifier,

and is ideal for connecting the widest possible technological varieties of force,

pressure, torque and displacement transducers as well as load cells. The

MP55 module is set up, and its parameters are assigned, using either the keyboard and display or the PME Assistent. The PME Assistent provides an easy

operator interface under MS-Windows and this is used for assigning parameters to modules (as described in the ”PME Assistant” online help).

Carrier-frequency

transducer excitation

A

D

Smart signal condi-

tioning, e.g. limit va-

lue switch

µP

DC

DC

D

A

Supply voltage

24 V

Analogue output

Control I/Os

MP55

Keyboard & display

Fig. 1.1: Block diagram of the MP55 module

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

CANopen interface

HBMA0563-5.5 en

Page 9

8

PME-MP55

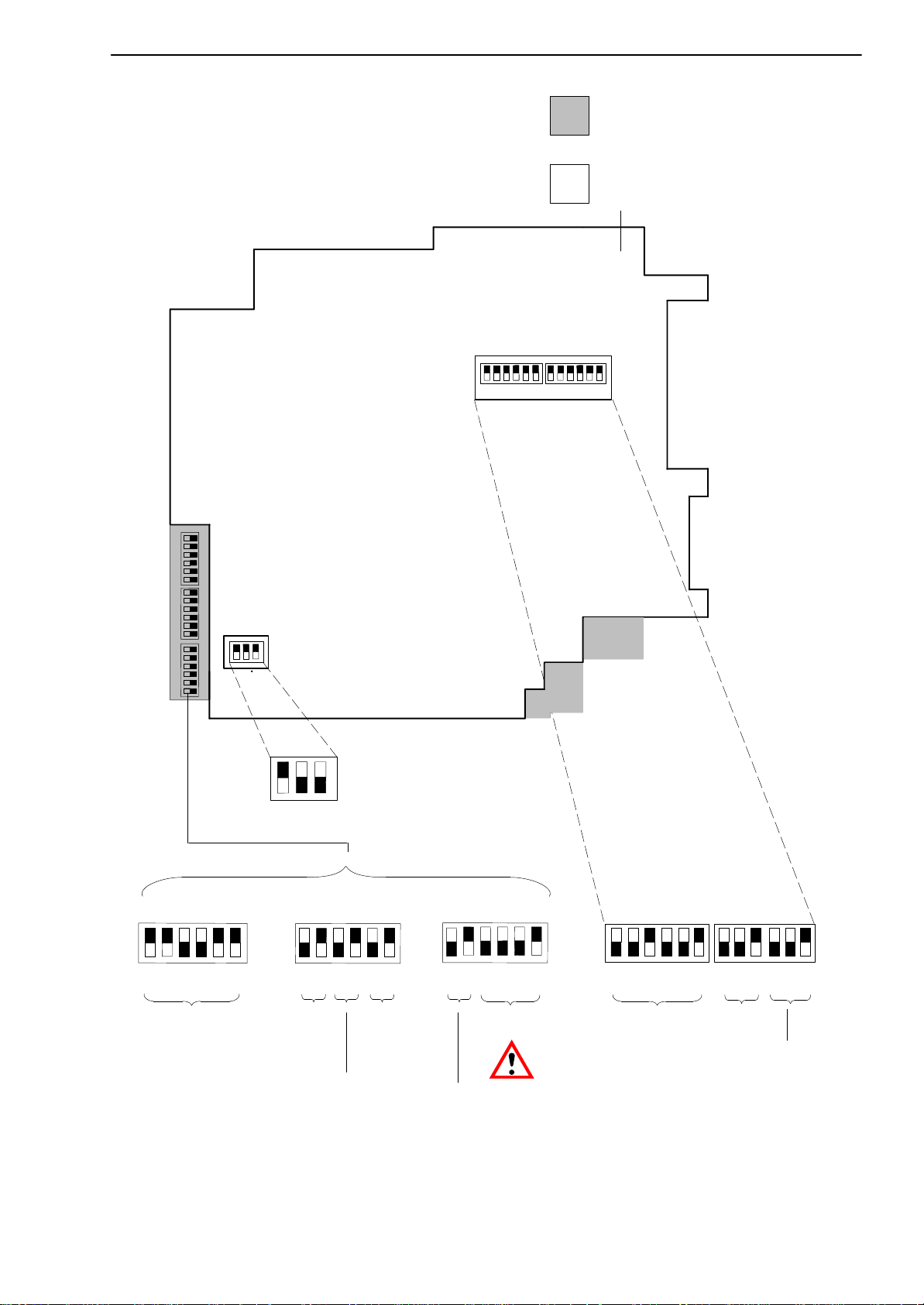

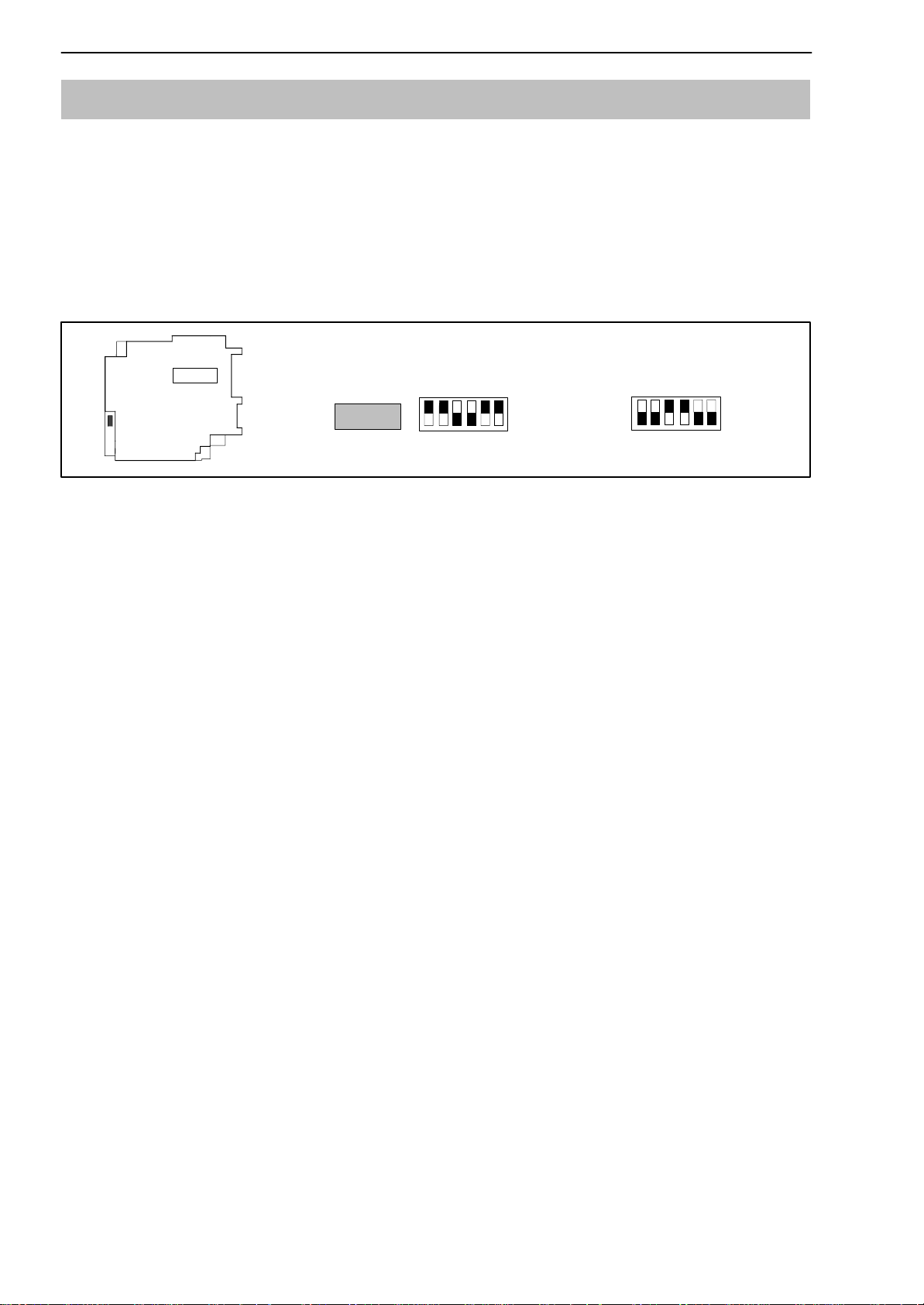

2 Choose amplifier settings with the aid of DIP switches

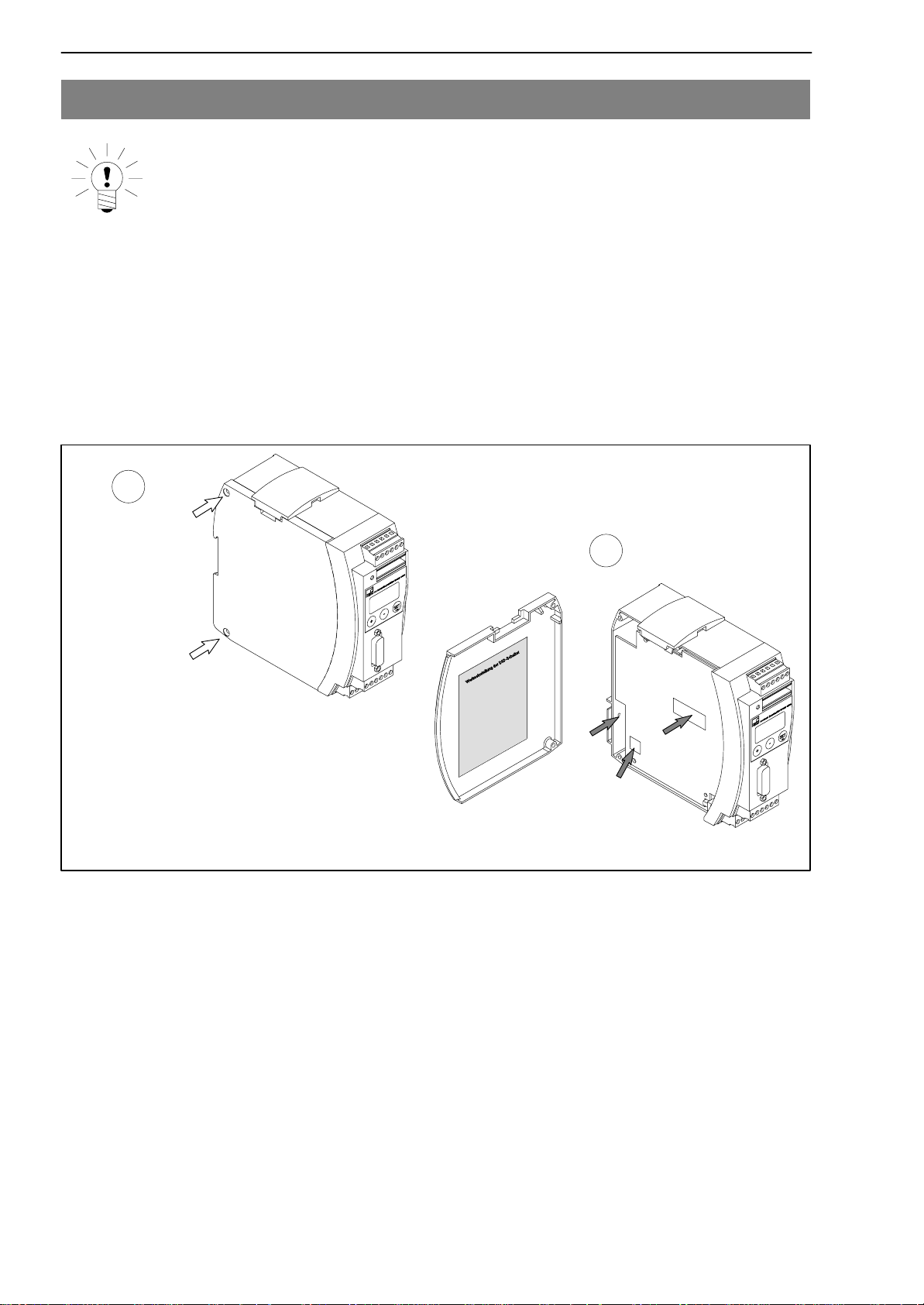

NOTE

The DIP switches must be set up/changed before the PME is fitted.

Various settings are defined with DIP switches and can be read out via the

display (see chapter 5.3). These are the settings for

bridge excitation voltage, effective range, bridge type, analogue output,

master/slave, terminating bus impedance, edge steepness

To set up the DIP switches proceed as shown in Fig. 2.1.

1

Unscrew the

cover

Fig. 2.1: Open the housing; position of the DIP switches

S10

S11

S12

2

S1/S2

S5

HBM A0563-5.5 en

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 10

PME-MP55

9

Factory settings:

ON ON ON

1

2

3

S10

S11

S12

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

ON

2

3

1

S5

S2

ON ON

123456 12 3456

S1

Lower

board:

Upper

board:

S10, S11 and

S12 and S5

S1 and S2

ON

1

S10

2

34

Master/

Slave

ON

Analogue output

123

S11

ON ON

5

6

12

Analogue

output

34

5

Bridge ex-

citation

voltage

Input

range

6

Bridge

type

S12

1

23

45

6

Amplifier type

Switch positions

must not be changed!

WARNING

S2

ON ON

S1

123456 123456

Bridge ex-

citation vol-

tage

Bridge

type

Input

range

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

HBMA0563-5.5 en

Page 11

10

PME-MP55

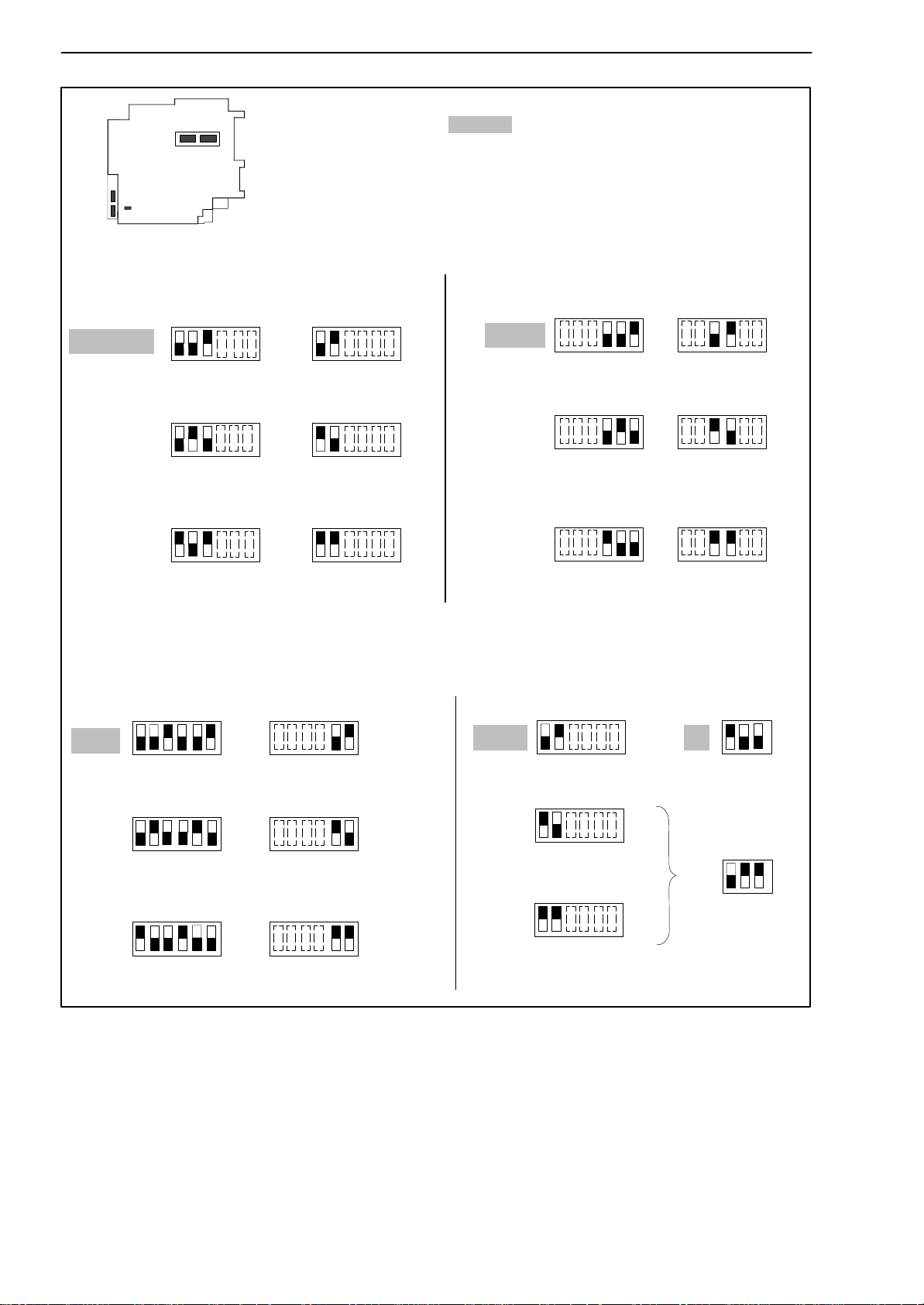

S11

S12

Full bridge

Half bridge

LVDT

S5

S2 S1

Bridge type

ON

123456

ON

123456

ON

123456

Factory setting:

1)

ON

S1

123456

ON

S1

123456

ON

S1

123456

S12

S12

S12

3 mV/V

Switch pos. I

50 mV/V

Switch pos. II

500 mV/V

Switch pos. III

Input range*)

ON

S1

123456

ON

S1

123456

ON

S1

123456

2)

ON

S11

123456

ON

S11

123456

ON

S11

123456

See Tab. 1.1 on the opposite page

3)

S11

"10 V

"20 mA

Analogue output

ON

S11

123456

ON

S11

123456

5 V

2.5 V

Bridge excitation voltage

ON

123456

ON

1234 56

ON

S2

123456

ON

S2 S11

123456

mA

ON

ON

1 V

123456

ON

S2 S11

123456

4...20 mA

S11

123456

Fig. 2.2: Setting up an amplifier

1)

Check this in the display under the TRANSDUCER group, parameter ”Trans.type”; see page 25

2

) Check this in the display under the TRANSDUCER group, parameter ”Input”; see page 25

3)

Check this in the display under the TRANSDUCER group, parameter ”Excitation”; see page 25

4)

Check this in the display under the ANALOG OUTPUT group, parameter ”ModeUa”, see page 25

*)

mV/V values by reference to 5 VUB (see table Tab. 1.1 on the following page)

V

4)

ON

S5

123

ON

S5

123

HBM A0563-5.5 en

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 12

PME-MP55

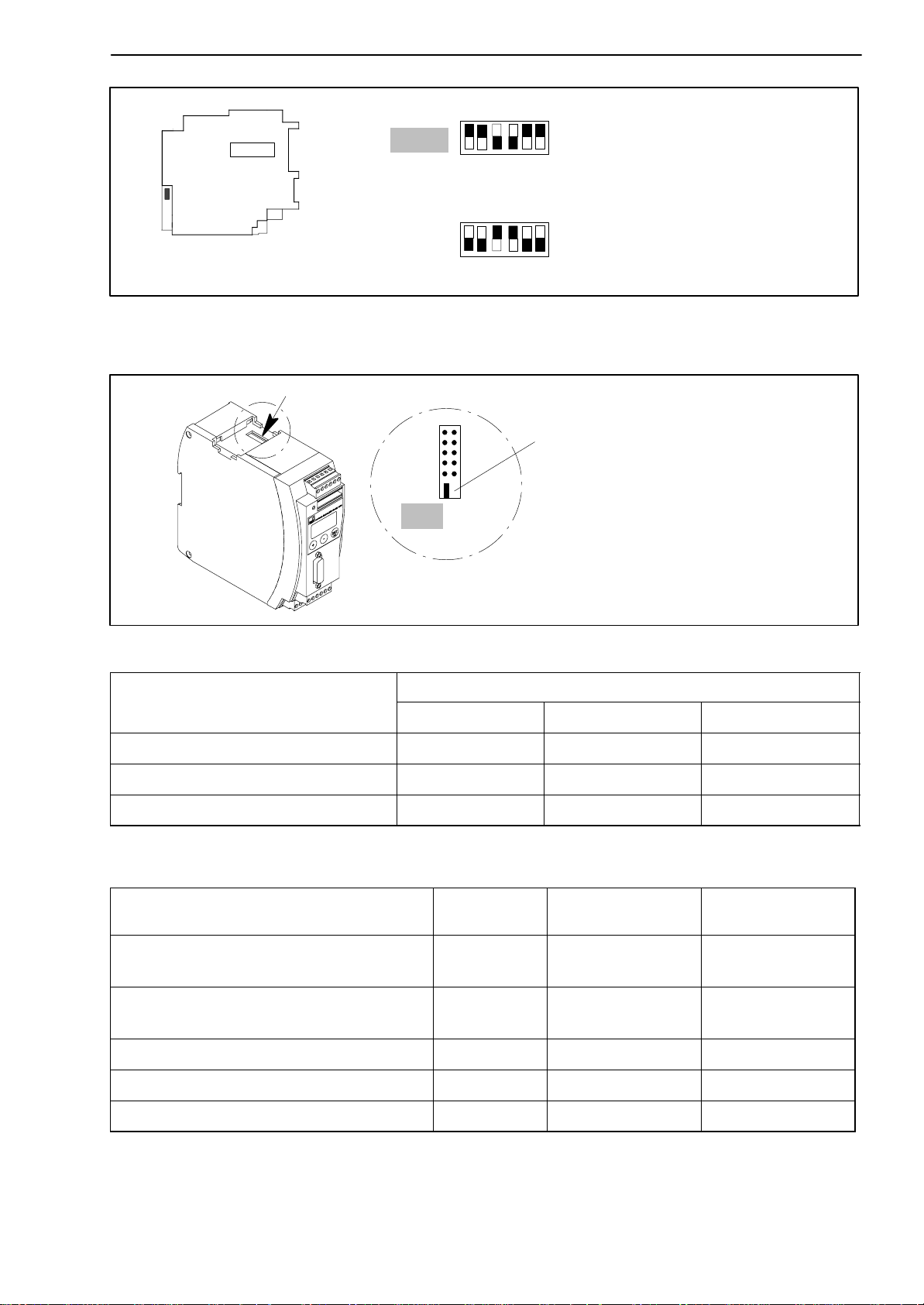

S10

Master

11

ON

Master/Slave

S10

123456

ON

Slave

S10

123456

Fig. 2.3: Setting up an amplifier (Continued)

Terminating bus resistor

S14

Toggle switch for termination resistor

(see page 19)

ON

Fig. 2.4: Toggle switch for termination resistor

Bridge excitation voltage [V] Input range [mV/V]

OFF

Switch position I Switch position II Switch position III

5 3 50 500

2.5 6 100 1000

1 15 250 2500

Tab. 1.1: Input ranges for different bridge excitation voltages

Transducer type and rated data Bridge type Bridge excitation

voltage

Strain gauge force transducer

Full bridge 5 V 3 mV/V

2 mV/V=20 kN

Inductive displacement transducer

Half bridge 2.5 V 100 mV/V

80 mV/V

Inductive displacem. trans. 10 mV/V Half bridge 1 V 15 mV/V

Piezoresistive transducer 400 mV/V Half bridge 1 V 250 mV/V

Potentiometric transducer 1000 mV/V Half bridge 2.5 V 1000 mV/V

Input range

Tab. 1.2: Useful options

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

HBMA0563-5.5 en

Page 13

12

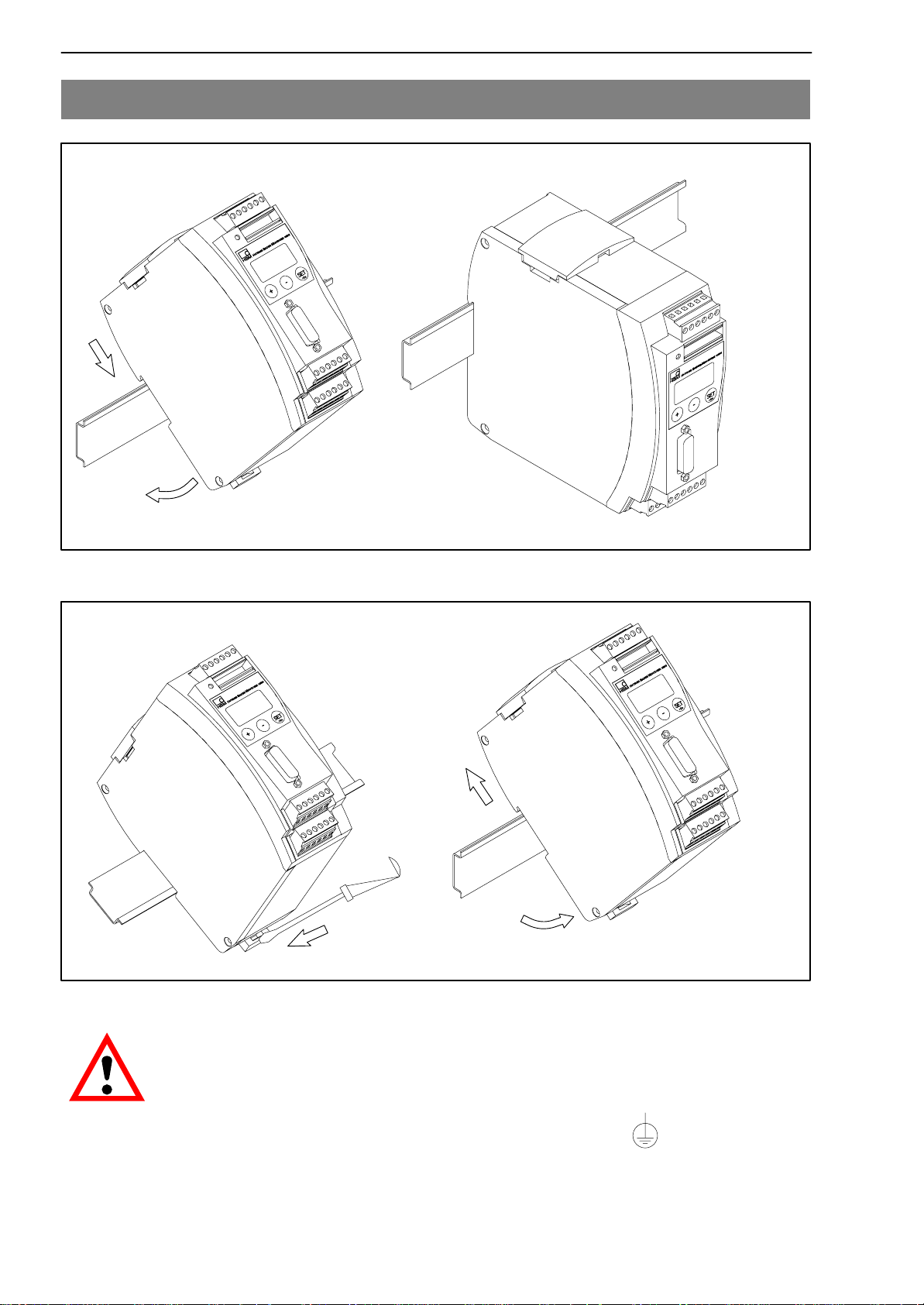

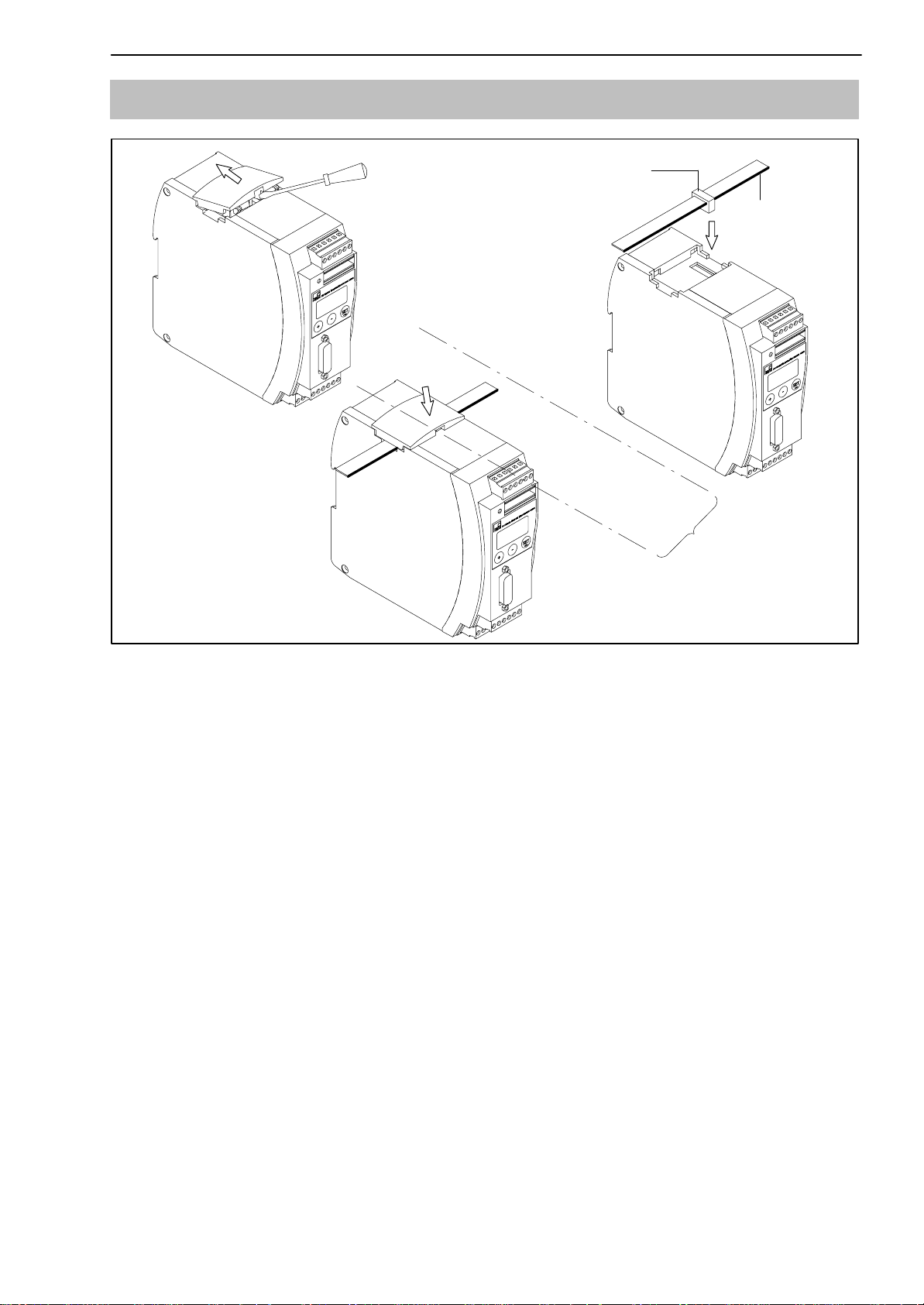

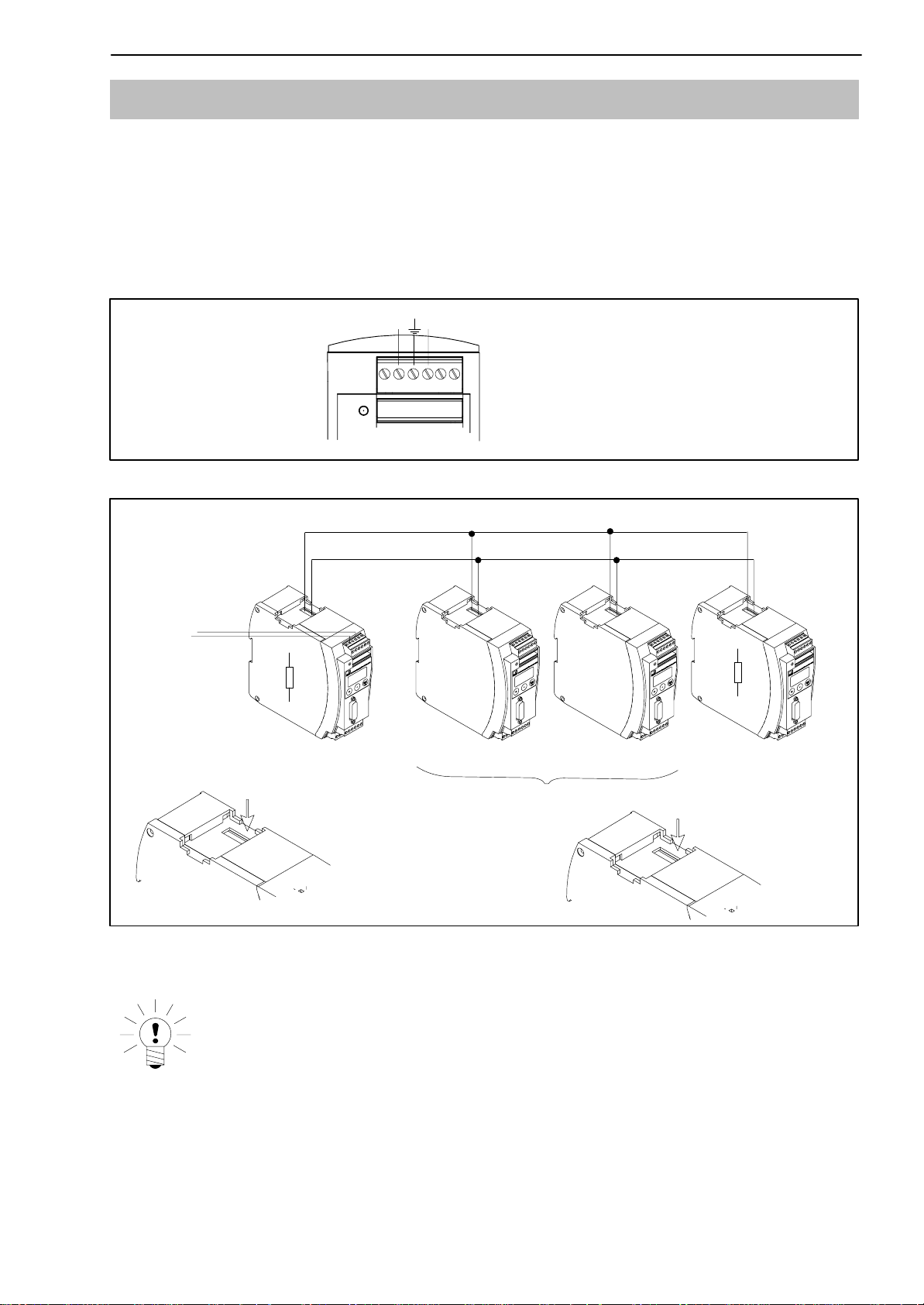

3 Fitting/removing the MP55

PME-MP55

Fig. 3.1: Fitting to a support rail

Fig. 3.2: Removal

CAUTION

The support rail must be on protection circuit potential .

HBM A0563-5.5 en

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 14

PME-MP55

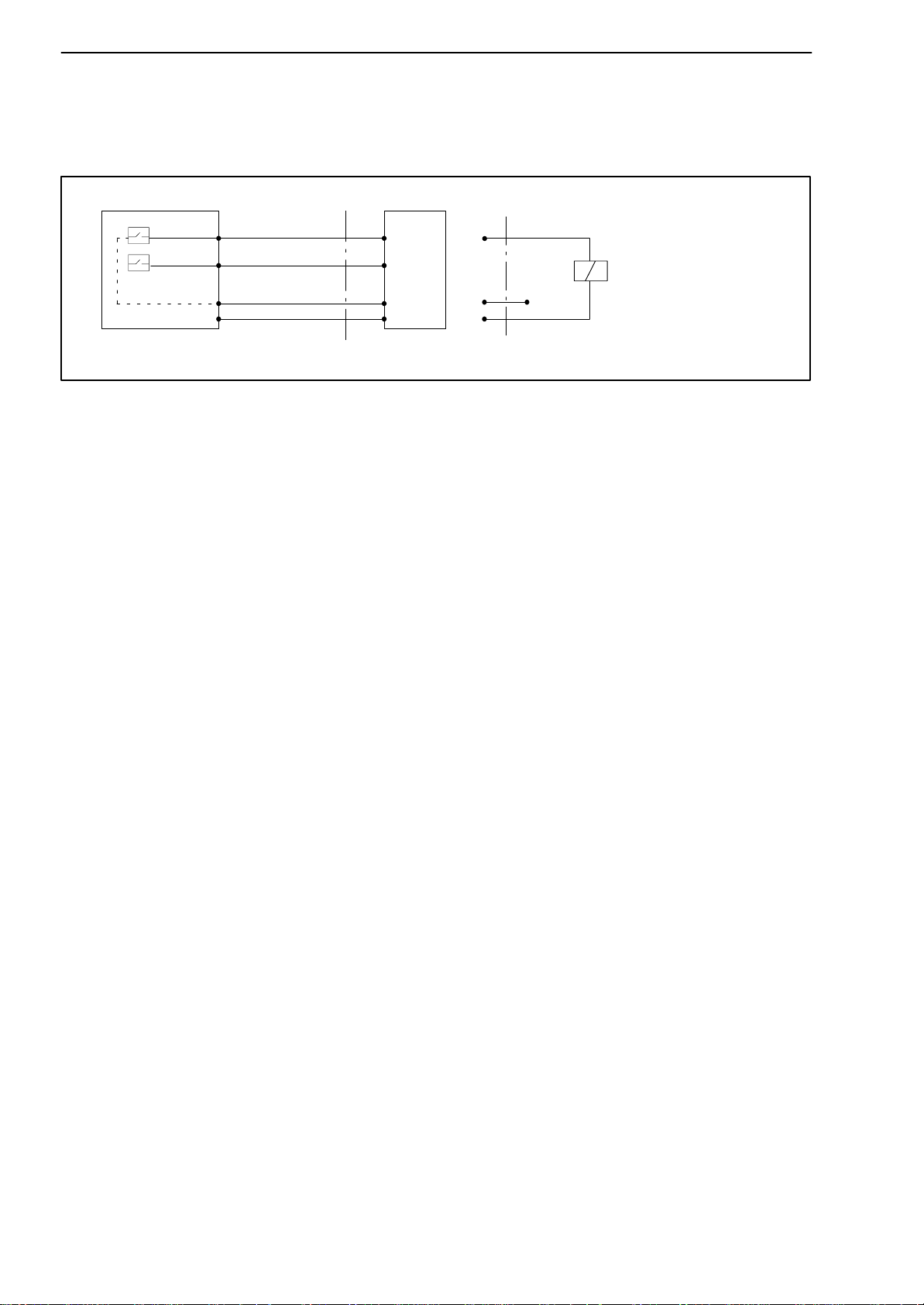

3.1 Linking several modules

Ribbon cable jack-connector

Further devices are interconnected

via this connector.

1st

3rd

13

Colour coding

on pin 1

2nd

58mm

Recommended distance from the ribbon cable jack-connector

Fig. 4.1: Connecting ribbon cable

Several MP55 modules can be connected via one ribbon cable. This cable

serves as the local link for supply voltage and synchronisation between modules. No more than eight modules should be interconnected over one ribbon

cable.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

HBMA0563-5.5 en

Page 15

14

PME-MP55

4 Connections

Warning

Comply with the safety instructions before putting the instrument into

service.

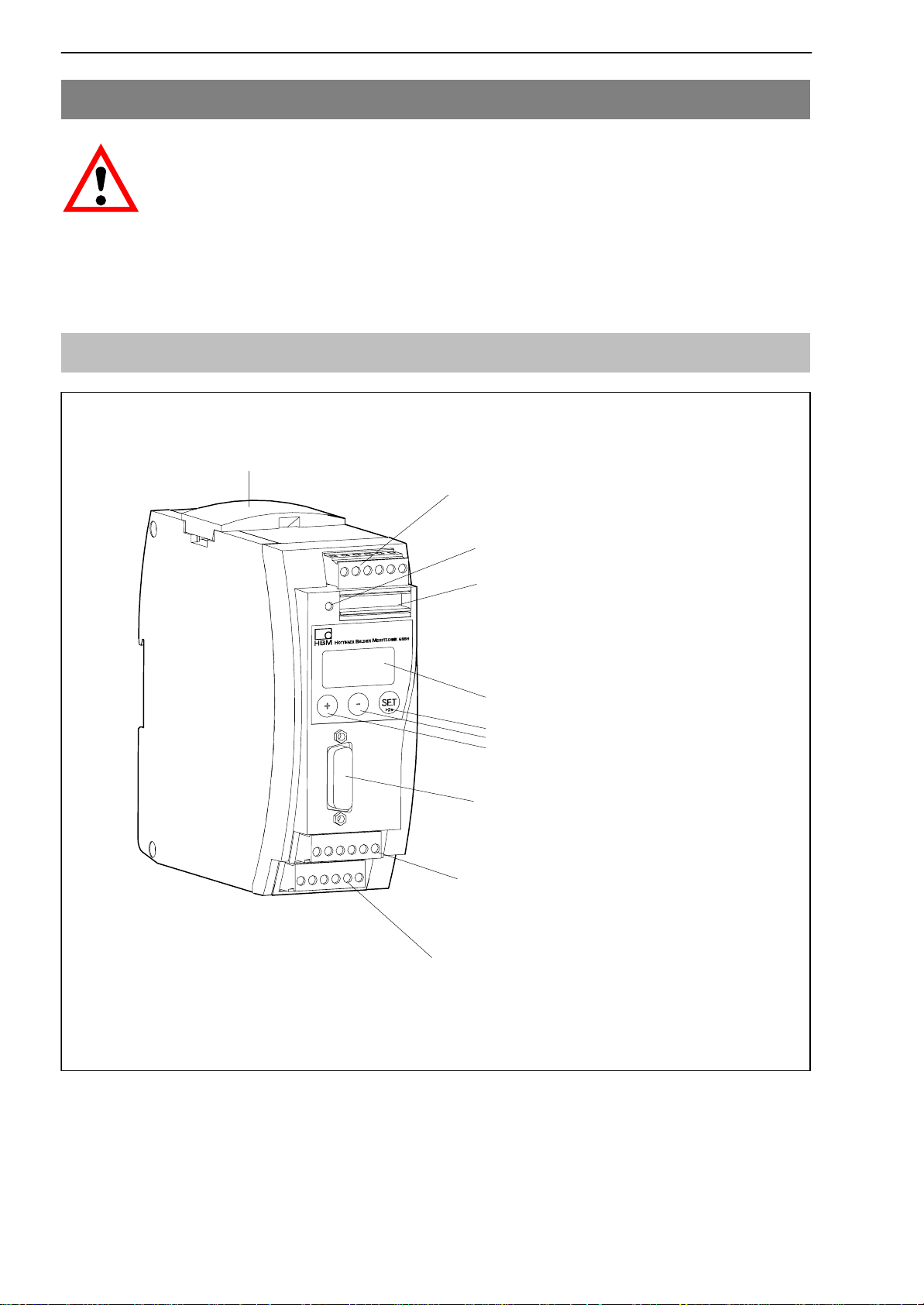

4.1 Functional overview of the MP55

Local link for CAN-bus, supply voltage and synchronisation between modules,

Terminating bus resistor

Terminal plug 1:

Power supply and CAN-bus,

synchronisation

LED

Terminal plug 2: (same pin

assignment as terminal plug 1)

CAN adapter for PC/laptop

connection, assigning parameters

via CAN-bus

2-line LCD display

Touch-sensitive

control keys

Transducer connection (15-pin sub-D

connector) including transducer

excitation

Terminal plug 3:

Potential-separated control inputs

(24 V-level), analogue output

Terminal plug 4:

Potential-separated control outputs

(24 V-level), external power supply for

control inputs

HBM A0563-5.5 en

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 16

PME-MP55

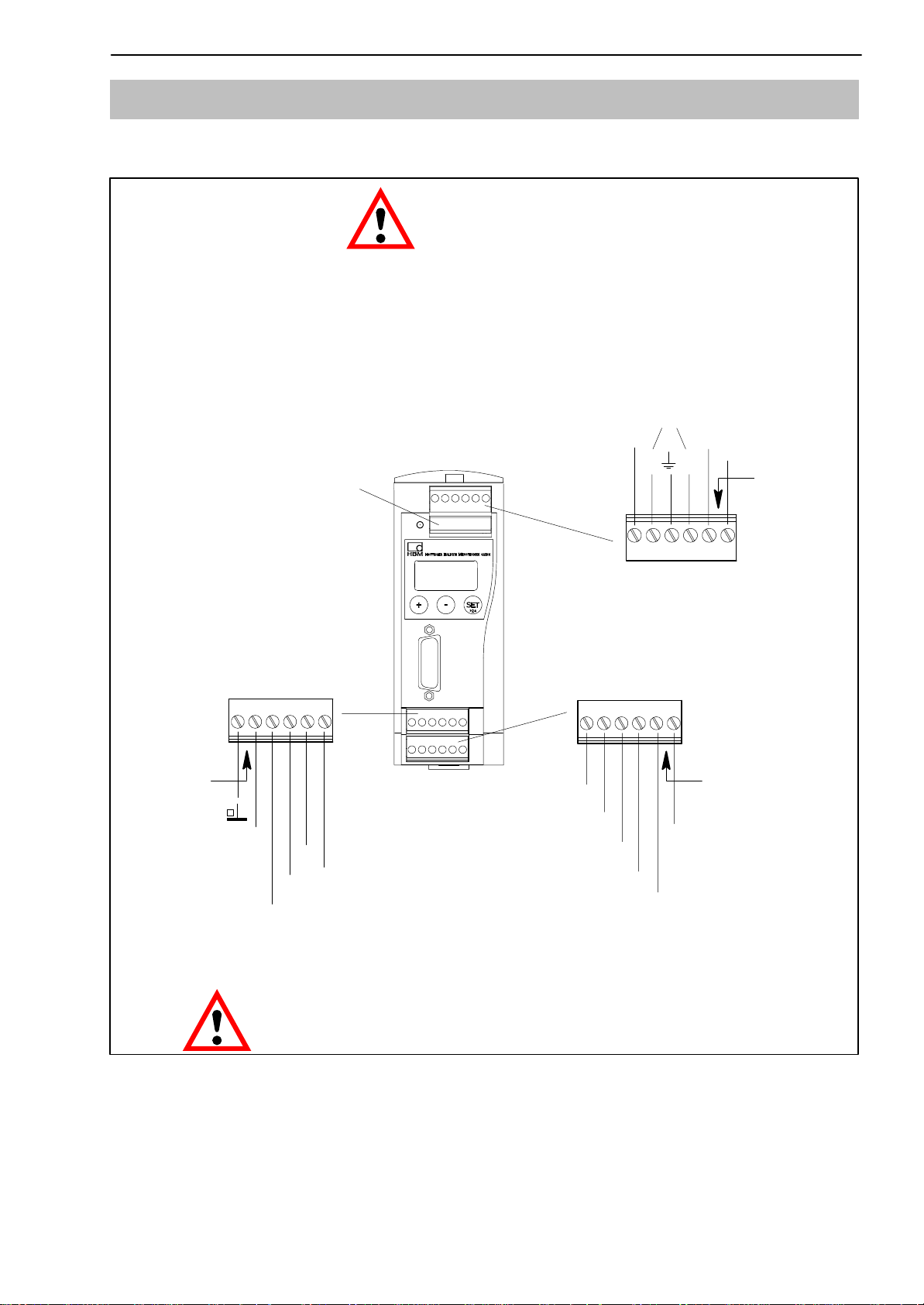

4.2 Supply voltage and remote contact I/Os

Four removable terminal plugs are available for connections.

Connecting the power

supply:

Terminal plug 2

The MP55 module must be connected to an external

18-30 V supply voltage (24 V

D Twist the power supply conductors and fit them with

sleeves.

D Screw the conductors to terminal plug 1.

D

Insert the terminal plug into the uppermost jack.

D Switch on power supply.

Warning

nominal

0 V

).

CAN

LH

15

24 V

SYN

Labeling

Labeling

Terminal plug 1

Terminal plug 3

0 V

24 V

Analogue-

IN2

IN1

IN3

IN4

OUT

"10 V

"20 mA

4...20 mA

IN = digital input OUT = digital output

More information on I/Os can be found in chapter 6, page 35.

CAUTION

In the event of a power failure to the MP55 module, all control

outputs are set to 0 V.

OUT1

OUT2

OUT3

Terminal plug 4

Labeling

OUT4

Fig. 4.2: Pin assignment for terminal plugs

The 4 terminal plugs are coded so that they can be inserted in the 4 jacks

without any confusion. Jacks are fitted with coded lateral guides and terminal

plugs are fitted with coded pins.

HBMA0563-5.5 en

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 17

16

4.2.1 External supply voltage for the control I/Os

Example: PLC connection

PME-MP55

MP55 module

OUT3

OUT1

24 V*

0 V*

Terminal plug 4

max. 0.5 A

PLC

Relay

max. 0.5 A

24 V

0 V*

Fig. 4.3: Connection to a PLC

The controlinputs are available on terminal plug 3, the controloutputs are

available on terminal plug 4, and they are all galvanically isolated from the internal supply voltage (see also chapter 6, ”Declaring the significant parameters” page 30).

)

The control-outputs must be supplied with an external voltage (ground

*

and 24 V).

HBM A0563-5.5 en

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 18

PME-MP55

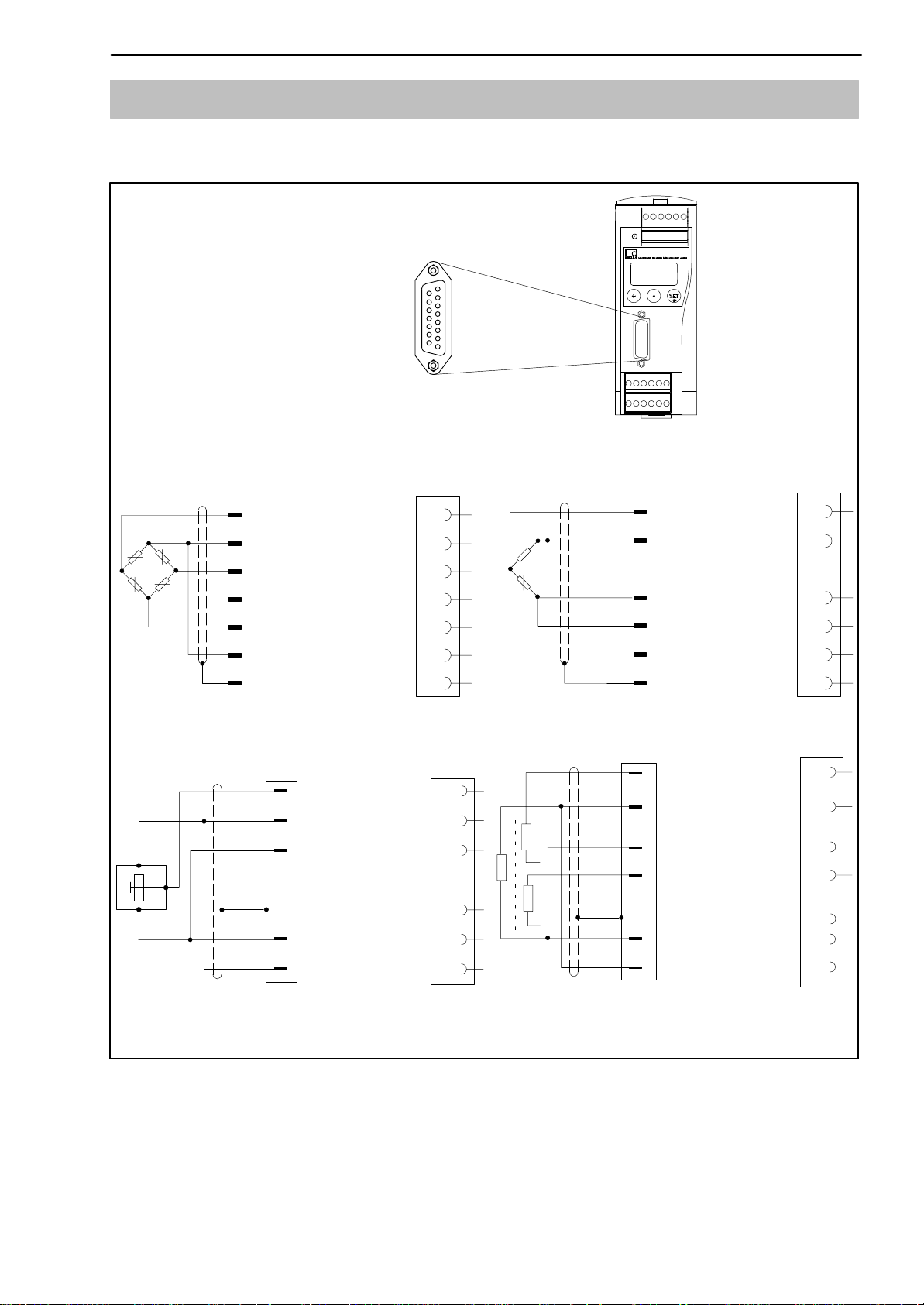

4.3 Transducers

The following transducer types can be connected to the MP55 module:

17

Transducer

15

connection jack

9

Strain gauge and inductive full

bridges, piezoresistive transducers

wh

Measuring signal (+)

bk

Bridge excitation

voltage (-)

re

Measuring signal (-)

bu

Bridge excitation

voltage (+)

gn

Sensor circuit (+)

gy

Sensor circuit (-)

ye

Cable shielding

8

5

15

6

13

12

Hsg.

8

1

Strain gauge and inductive half

bridges

wh

Measuring signal (+)

bk

Bridge excitation

voltage (-)

bu

Bridge excitation

voltage (+)

gn

Sensor circuit (+)

gy

Sensor circuit (-)

ye

Cable shielding

8

5

6

13

12

Hsg.

Potentiometric transducers

LVDT transducers

Measuring signal

Measuring

signal (+)

Bridge excitation

voltage (-)

2

Bridge excitation

8

5

6

voltage (+)

1

Cable shielding

Hsg.

3

Sensor circuit (+)

Sensor circuit (-)

13

12

(+)

Bridge excitation

voltage (-)

Bridge excitation

voltage (+)

Measuring signal

(-)

Cable shielding

Sensor circuit (+)

Sensor circuit (-)

Wiring colours: wh= white; bk= black; bu= blue; re= red; ye= yellow; gn= green;

gy= grey

Fig. 4.4: Connecting various transducers

8

5

6

15

Hsg.

13

12

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

HBMA0563-5.5 en

Page 19

18

PME-MP55

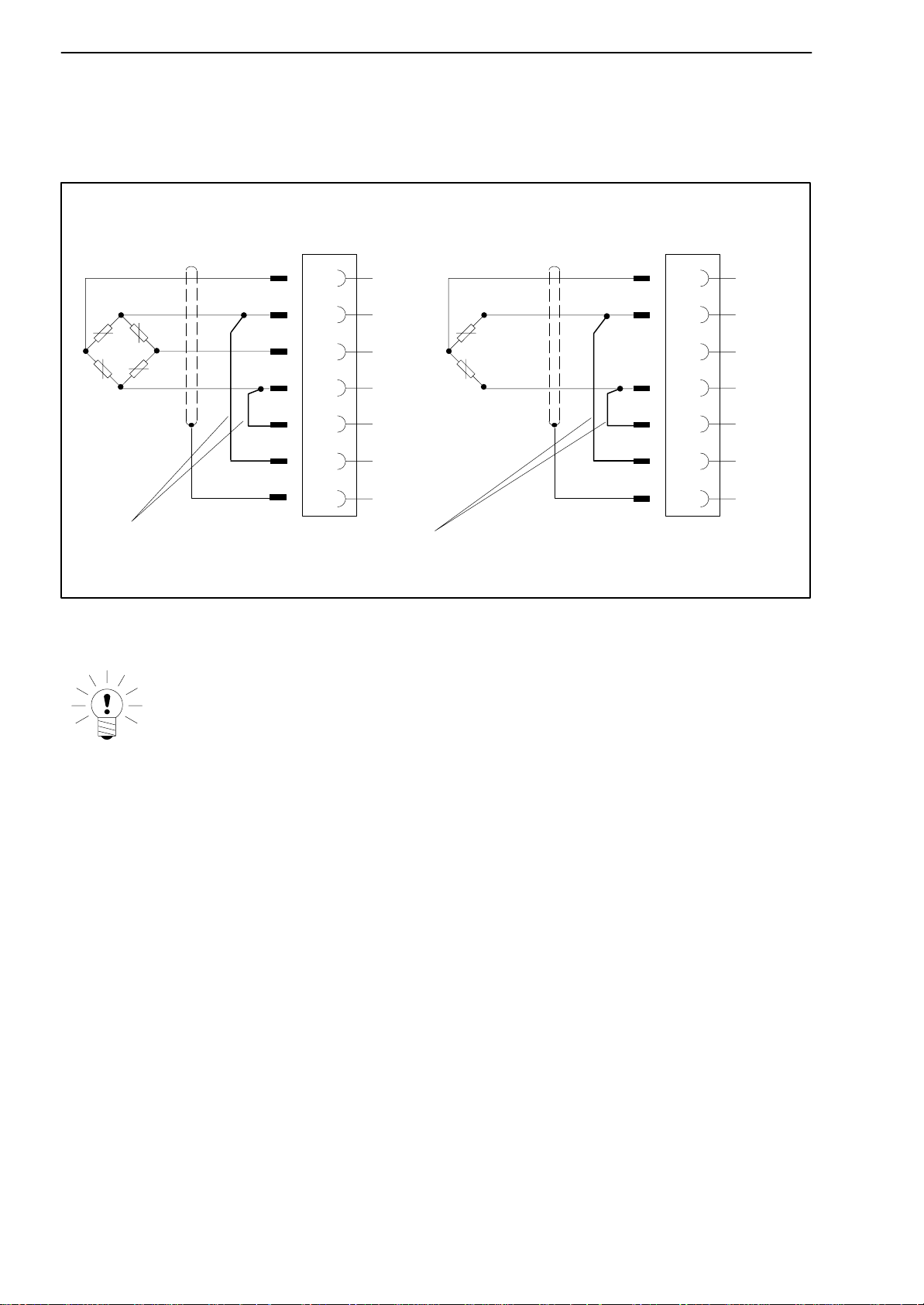

When installing a transducer with a four-wire connection, you must connect

the sensor lines with the corresponding bridge excitation line (Pin 5 with Pin

1)

12, Pin 6 with Pin 13)

.

Four-wire connection:

Full bridge

wh

bk

re

bu

ye

8

5

15

6

13

12

Hsg

.

Four-wire connection:

Half bridge

wh

bk

bu

gn

gy

ye

Hsg

8

5

15

6

13

12

.

Feedback bridges for four-wire connection

Wiring colours: wh= white; bk= black; bu= blue; re= red; ye= yellow; gn= green; gy= grey

Fig. 4.5: Four-wire transducer connection

NOTE

Use standard HBM cable for the transducer connection. When using

other shielded, low-capacitance measuring cable, connect the transducer cable shielding to the connector housing in accordance with the

HBM Greenline concept (publication S1578). This ensures EMC protection.

1)

For cable lengths in excess of 50 m, one resistor with half the value of the bridge resistance (RB/2) must

be switched on at the transducer in place of each of the feedback bridges. If the transducers are calibrated in six-core circuit, the resistors must be switched on directly in the sensor circuit.

HBM A0563-5.5 en

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 20

PME-MP55

19

4.4 CAN-interface

The CAN-bus is connected via terminal plug 1. A maximum of 32 CAN users

can be connected to a bus segment (in accordance with the CANopen specification). The CAN-bus needs a terminating impedance of 120 Ω in the first and

last bus users. The bus line can have a maximum of two terminating resistors.

The MP55 module has a built-in terminating resistor which is enabled by

toggle switch S14 (see page 11).

Low High

1st device

Fig. 4.6: Connecting the CAN interface

CAN-High

CAN-Low

CAN connection

in accordance

with Fig. 4.6

First device in

the bus line

connect the terminating

resistor here (toggle

switch)

Do not connect the termina-

ting resistor

Last device in

the bus line

connect the terminating

resistor here (toggle

switch)

Fig. 4.7: CAN-bus operation with several modules (maximum 32 in accordance

with standard)

NOTE

If the first or last device in the bus line is not a PME module, one 120 W

resistor must be connected for each of these outside devices.

HBMA0563-5.5 en

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 21

20

PME-MP55

4.5 Synchronisation

Synchronisation is advisable when

D the transducer cables are connected in parallel to several devices

D unshielded channels lie close together

Synchronisation prevents carrier-frequency differences giving rise to beat interference.

S10

ON

123456

S10

Master

S10

ON

Slave

123456

Fig. 4.8: Setting up master/slave

To synchronise several instruments, set up one of them as Master. Set up all

the other instruments as Slaves.

Synchronisation between modules should always be carried out via the ribbon

cable- even when you are not working with CAN-bus.

HBM A0563-5.5 en

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 22

PME-MP55

5 Setting up and operation (MP55)

5.1 Operating principles

Display in measuring mode:

21

-18.0024

Status field

↑

↓

The status field flashes if the parameter value can be edited

-

The keys are pressure-sensitive:

+

kg

Value

unit

Hold key down - the values scroll (the harder you press, the faster they scroll)

Press key briefly - go to next value

Function of the

buttons:

SET

+

-

1. Switch from measuring mode to

input mode

2. Choose the first parameter within

the group.

3. Confirm input

4. Return to measurement range

(press for 2 sec)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Select

parameter/group

+

-

HBMA0563-5.5 en

Page 23

22

PME-MP55

Measuring mode

Set-up mode

Change

settings:

Password status

inactive (factory setting):

SET

2 sec

DIALOGUE

+

Select

-

group

Password status

enabled

SET

2 sec

PASSWORD

Input password:

SET

Password

SET

Input mode

+

Input required password

(factory setting 0)

-

SET

Confirm

↑

↓

Example:

Input numerical

value

TRANSDUCER

Select table

value

CONDITIONING

Back to

measuring

mode:

2x

saves

directly

SET

-

SET

-

SET

Select first

parameter

+

Select required parameters

Go to input mode

+

Input numerical value or

Choose table value

Confirm

SET

SET

YES NO

↑

↓

PME asks: Save ?

2 sec

SET

Nom. mV/V

+/-

Save ?

No

unit

0.000

2.000

SET

>0< kN

Filter

_ _ Hz

0.5 Hz

HBM A0563-5.5 en

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 24

PME-MP55

-

During measurement you can press

+

play:

1. Display mode

2. The status of input and output

3. Error types (ERROR)

The status field also displays the symbols

23

- to look at the following in the dis-

!

, and .

Status field

+

-

-18.0024

kg

Symbol in status field Display mode

No character Gross signal

>T< Net signal

mV/V Input signal

V or mA Analogue output signal

Outp

Inpt

Value

unit

Maximum peak value signal

Minimum peak value signal

Peak/peak signal

set, not set

Status of input and output

e.g. StoreMax

Status field

)

*

see chapter 8 ”Error messages”, page 57

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

! Error occurred

Error messages

During measurement the character ! warns of an error

in the module.

Current errors are automatically displayed one after

another in display mode ”ERROR” (accessible

through ).

*)

+

Standstill status occurred

Shunt resistor on

HBMA0563-5.5 en

Page 25

24

PME-MP55

5.2 Commissioning

D Set up the DIP switches in accordance with chapter 2 (pages 10 and 11).

Example:

Transducer type and rated data Bridge type Bridge excitation

voltage

Strain gauge force transducer

2 mV/V=20 kN

Inductive displacement transducer 80 mV/V Half bridge 2.5 V 100 mV/V

Inductive displacement transducer 10 mV/V Half bridge 1 V 15 mV/V

Piezoresistive transducer 400 mV/V Half bridge 1 V 250 mV/V

Potentiometric transducer 1000 mV/V Half bridge 2.5 V 1000 mV/V

Full bridge 5 V 3 mV/V

Input range

D Connect the power supply cable and the transducer to the module, as

described in chapters 4.2 and 4.3.

CAUTION

Be sure to follow the safety instructions!

D Switch on the power supply.

The instrument carries out a function test (approx. 15 sec) and if

functioning correctly, switches to measuring mode. During the function

test, the remote contacts stay at 0 V.

NOTE

If the error message HardwOvf is displayed at this point, please refer to

chapter 8 ”Error messages” for more details.

A green LED also tells you whether the MP55 is ready to begin measuring.

If the LED shows yellow or red, please refer to chapter 8 ”Error messages” for

more details.

NOTE

When connecting transducers in parallel, please take into account the

resulting total resistance. If required, reduce the excitation voltage.

HBM A0563-5.5 en

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 26

5.3 Overview of all groups and parameters

1)

25

SET

+

Up

-

Down

SET

DIALOG DATA SET DISPLAY

Password Recall ? DecPoint Unit P1Meas.? >0< kN

PassStat Save ? Step Transd.Type P1 mV/V >0<set ? Mode UA Source InputMin ModeOut1 Address PrgVers

Language

I.DataS

I.Displ.

I.Transd Zero kN

I.Calibr Nom.mV/V

I.Condit NVal kN

I.Analog Zero.Adj

I.LimVal NomV.Adj Tare

I.PStore Shunt PkMomMax

I.I/O ShuntPol PkHldMax

I.CAN

I.AddFnc

MAINGR

MAINGR

TRANS-

DUCER

Excitatn P1 kN

InputRng

ZeromV/V P2 mV/V >T<set? EndV kN

MAINGR

TRANSD.-

CALIBRAT

P2Meas.? >T< kN

1)

P2 kN

MAINGR

1)

MAINGR

+

CONDITIONING

1)

-

1)

>0<save Zero kN

1)

>T<save EndV V On Del ms

filtre

FiltChar

Groups

ANALOG-

OUTPUT

SourceUa Operatn. Operatn. Output1 Baudrate AmplType

1)

Zero V Value kN

1)

MAINGR

LIMIT VAL.

1...4

SwtchDir InputMax Output2 Profil >0<Rf kN

Hyst kN

Off Del ms Output4

MAINGR

MAINGR

PEAK STORE IN/OUT CAN-BUS

1)

ClearPkV ModeOut2 Output MotionDsp

1)

1)

kN/s

MAINGR

Output3 OutR. ms MTime ms

ModeOut3 PDO-Frmt MAmp kN

MAINGR

ModeOut4 Keyboard

Zeroing SNo prior version

PkMomMin

PkHldMin

ParaCo1

ADDITION FUNC-

TION

HW Synchr

HW-Vers.

MAINGR

1)

1)

ParaCo2

Overview of parameters

InpFunc

MAINGR

Preset with DIP switches , MAINGRP with

1

) Depending on the unit chosen A0563-5.6 en HBM

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

SET

back to group

Page 27

Meas. value

2sec

SET

PassStat

active

5.3.1 Set up all parameters

A0563-5.6 en HBM

PASSWORD

SET

Password

Continue

with DIALOG

SET

+

_ _ _ _

↑

↓

Input

password

+/-

+

NoYes

DIALOG

SET

Password

PassStat

Language

I.DataS

I.Displ.

I.Transd

-

I.Calibr

I.Condit

I.Analog

I.LimVal

I.PStore

I.I/O

I.CAN

SET

SET

SET

+

_ _ _ _

↑

↓

Define

password

active

↑

↓

inactiv

Deutsch

↑

↓

English

Francais

SET

-

↑

↓

+/-

+/-

+/-

free

locked

SET

+/-

Groups

DATA SET

Recall ?

+

-

Save ?

back

MAINGRP

SET

SET

+

-

DataS1

↑

↓

DataS2

DataS3

+/-

DataS4

FactSet

No

DataS1

↑

↓

DataS2

DataS3

+/-

DataS4

No

SET

Parameter values

+

Select parameter

-

Flashes if the parameter

↑

↓

value can be edited

Confirm input:

+/-

=

+ -

or

Back to measuring mode:

Display

SETSET

DecPoint

+

-

Step

back

MAINGRP

SET

press

SET

2sec

SET

SET

+

Transducer

-

.00000

.0000

↑

↓

.000

.00

+/-

.0

.

0001

↑

↓

0002

0005

0010

0020

0050

0100

0200

0500

+/-

1000

SET

I.AddFnc

Note:

back

MAINGRP

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

If a group cannot be selected, check under DIALOG to see

whether the group is enabled.

26

Page 28

Display

-

+

TRANSDUCER

SET

Unit

Preset with DIP switches

S1 and S12

BrdgeTyp

FullBrdg

Preset with DIP switches

S2 and S11

Excitatn

5.0V

Preset with DIP switches

S1 and S11

InputRng

3mV/V

ZeromV/V

Zero kN

Nom.mV/V

NVal kN

1)

1)

SET

SET

SET

SET

SET

SET

SET

SET

fixed

w.switches

fixed

w.switches

fixed

w.switches

↑

0.0000

↓

↑

0.00

↓

↑

2.0000

↓

↑

10.00

↓

27

Groups

+

+/-

TRANSD.-CALIBRAT

-

SET

↑

kg

↓

T

P1Meas.?

kT

TON

lb

SET

SET

nein

no

↑

↑

↓

↓

ja

yes

+/-

+/-

CONDITIONING

SET

>0<set ?

>0< kN

1)

oz

N

kN

Bar

mBar

P1 mV/V

SET

↑

0.0000

↓

+/-

>0<save

Pa

+/-

Pas

hPas

kPas

psi

µm

mm

cm

m

inch

Nm

kNm

FTLB

P1 kN

P2Meas.?

1)

SET

SET

SET

↑

0.0000

↓

↑

↑

↓

↓

+/-

nein

no

ja

yes

+/-

+/-

-

+

>T<set?

>T< kN

>T<save

1)

INLB

+/-

+/-

+/-

µm/m

M/S

M/SS

p/0

p/00

ppm

S

MP

MN

g

P2 mV/V

P2 kN

SET

↑

0.0000

↓

+/-

1)

SETSET

↑

0.0000

↓

+/-

filtre

FiltChar

SET

SET

SET

SET

SET

SET

SETSET

SET

+

ANALOG OUTPUT

-

no

↑

↓

↑

↓

↑

↓

yes

0.00

save

volatil

+/-

+/-

+/-

SET

SourceUa

+

-

SET

+/-

Preset with DIP switches

S11 and S5

no

↑

↓

↑

↓

↑

↓

↑

↓

yes

0.00

save

volatil

+/-

Bessel

Butterw

+/-

+/-

+/-

-

+

Mode Ua

10V

Zero kN

Zero V

EndV kN

EndV V

SET

1)

SET

SET

1)

SET

SET

LimVal.1

GrosValu

↑

↓

NetValue

StoreMax

StoreMin

Store PP

CAN

fixed

w.switches

0.00

↑

↓

0.00

↑

↓

10.00

↑

↓

10.00

↑

↓

+/-

+/-

+/-

+/-

SET

Shunt

ShuntPol

back

MAINGRP

SET

SET

Off

↑

↓

On

+Unbala

↑

↓

-Unbala

+/-

+/-

1)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

-

+

SET

back

MAINGRP

Depending on the unit chosen

SET

back

MAINGRP

+/-

↑

↓

0.05 Hz

0.1 Hz

0.2 Hz

0.5 Hz

1 Hz

2 Hz

5 Hz

10 Hz

20 Hz

50 Hz

100 Hz

200 Hz

500 Hz

SET

back

MAINGRP

A0563-5.6 en HBM

Page 29

Groups

A0563-5.6 en HBM

Analogue output

LIMIT VAL.1

SET

Operatn.

Value kN

+

Hyst kN

-

On Del ms

Source

SwtchDir

LimVal1

LimVal2

LimVal3

LimVal4

Motion

Error

inactiv

Act. On

Act.Off

CAN-Bus

+/-

+/-

SET

SET

+

LIMIT VAL.2...4

-

On

↑

↓

Off

+/-

+

-

PEAK STORE

SET

Operatn.

SET

+

-

On

↑

↓

Off

+/-

As

IN/OUT

SET

Output1

+

SET

-

↑

↓

appropriate

for 1...4

GrosValu

↑

↓

NetValue

StoreMax

+/-

InputMin

SET

GrosValu

↑

↓

NetValue

+/-

ModeOut1

SET

↑

↓

StoreMin

SET

Store PP

Higher

↑

↓

Lower

+/-

+

InputMax

SET

GrosValu

↑

↓

NetValue

Zeroing

+/-

SET

Tare

1)

1)

SET

SET

SET

↑

↓

↑

↓

↑

↓

0.00

0.00

0000.0

+/-

+/-

+/-

-

ClearPkV

kN/s

SET

SET

↑

↓

↑

↓

No

Yes

0.00000

+/-

+/-

+

PkMomMax

-

PkHldMax

Input 1

↑

↓

Input 2

Input 3

Input 4

NoInput

+/-

PkMomMin

SET

Off Delms

SET

↑

↓

0000.0

back

MAINGRP

The same applies to limit values 2 to 4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

+/-

SET

1)

Depending on the unit chosen

back

MAINGRP

SET

PkHldMin

ParaCo1

ParaCo2

InpFunc

back

MAINGRP

SET

↑

↓

free

locked

+/-

28

Page 30

Groups

29

In/Out

+

SET

Baudrate

Address

Profil

-

Output

OutpR ms

PDO-Frmt

CAN-Bus

SET

SET

SET

SET

SET

SET

10 kB

↑

↓

20 kB

50 kB

125 kB

250 kB

500 kB

800 kB

1000 kB

↑

↓

↑

no Prof

↓

GrosValu

↑

↓

NetValue

StoreMax

StoreMin

Store PP

GrosDsp

NetDsp

↑

↓

float

↑

↓

integer

000

000

+

-

+/-

ADDITIONFUNCTION

SET

AmplType

+

-

MEAS MODE

SET

Save ?

SET

Yes

↑

↓

No

+/-

PrgVers

+/-

+/-

+/-

+/-

>0< Rf kN

MotionDsp

+

-

MAmp kN

HW Synchr

Slave

1)

MTime ms

1)

Keyboard

SET

SET

SET

SET

SET

SET

0.00000

↑

↓

Off

↑

↓

On

↑

0000.0

↓

↑

0000.0

↓

fixed

w.switches

slow

↑

↓

fast

+/-

+/-

+/-

+/-

Preset with

DIP switch S10

+/-

Meas. value

medium

+/-

SNo

SET

back

MAINGRP

1)

Depending on the unit chosen

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

SET

HW-Vers.

back

MAINGRP

A0563-5.6 en HBM

Page 31

30

6 Declaring the significant parameters

Group Parameter Meaning

DIALOG Password Define password (modify), 0000...9999

(Factory preset password: 0000)

PassStat Define password status:

active=password must be input;

inactive=PME can be operated without entering a password

PME-MP55

DATA SET

TRANS-

DUCER

I.DataS to

Access to group via keyboard enabled or disabled.

I.AddFnc

Recall ? You can load either the factory settings or one of the four

parameter sets that have been stored.

Save ? To protect all the instrument set-ups from power failure, they

can be stored in four parameter sets. Whenever you change

from set-up mode to measuring mode you are asked whether

you want the changes to be stored or not. The data will be

permanently saved if you confirm the security prompt with

”Yes” when you exit from set-up mode.

ZeromV/V

Zero kN

Nom.mV/V

NVal kN

Setting up in accordance with transducer characteristics

1)

1)

Physic. unit

Zero

kN

0

Transducer characteristics: Nominal value 10 kN;

Nom.kN

( 10 kN for 2 mV/V)

Zero mV/V

mV/V

Rated sensitivity 2 mV/V

1

) Depending on the unit chosen

Nom.mV/V ( 2 mV/V)

HBM A0563-5.6 en

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 32

PME-MP55

Group Parameter Meaning

31

TRANS-

DUCER

TRANSD.-

CALIBRAT

Shunt

ShuntPol

P1Meas.?

P1 mV/V

P1 kN

1)

Information on scaling

Input characteristics:

The range of values for scale factors is limited. Scaling is

dependent on the chosen resolution. In the case of set-ups

that lead to overshooting the respective limits, ”Scaling error”

is reported (see page 58).

Maximum display resolution: 999 999 digits at 6.67 % of the input range

Minimum display resolution: 10 Digits at 100 % of the

input range

Defines the polarity of the shunt resistor (positive or negative

effect). The mismatch amounts to approx. 1 mV/V at a

transducer sensitivity of 2 mV/V and a bridge resistance of

Ω. Accuracy approx. 4 %.

350

Assigning the signals issued by the transducer at a defined load

Example: A calibration weight of 10 kg is

Physic.

Unit

Note: If the zero point is modified, P1 and P2 will be discarded.

p2

p1

used to calibrate a 4 kg-load cell.

1. Relieve transducer

P1Meas.? Yes 0,0457 mV/V

P1 Enter 0 kg

(physic. Unit is assigned)

mV/V

2. Load transducer with 4kg

P2Meas.? Yes 7,873 mV/V

P2 Enter 4 kg

CONDI-

TIONING

1

) Depending on the unit chosen

Difference between taring and zeroing: zero balance

(>0 kN<) affects both gross and net values. Taring (>T<) affects only the net value.

Here is an example to illustrate the difference between zero

balancing and taring:

Platform

before 35 kg

after 0 kg

before 8 kg

after 0 kg

Steps in the

weighing procedure

Attach platform

(35 kg)

Attach container

(8 kg)

Container

Action

> 0<

Input 35 kg

> T<

Input 8 kg

Display

Gross Net

before 35 kg

after 0 kg

before 8 kg

after 8 kg

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

HBMA0563-5.6 en

Page 33

32

Group Parameter Meaning

CONDI-

TIONING

>0<kN

>0< set ? Trigger zero balance; set current measured value (physical

>0< save Each time there is a zeroing procedure the zero value is

>T< kN

>T< set ? Trigger taring; net value becomes 0

>T<save Save tare value immediately after taring

1)

Enter zero value. Zeroing effects both, the gross value and

the net value.

unit) to zero

adopted into the EEPROM (service life 100.000 cycles)

1)

Input tare value. Taring affects the net value.

Filter 0.05 Hz 1 Hz 20 Hz 500 Hz

0.1 Hz 2 Hz 50 Hz

0.2 Hz 5 Hz 100 Hz

0.5 Hz 10 Hz 200 Hz

PME-MP55

FiltChar

1

) Depending on the unit chosen

Step response

The diagram shows a linear amplitude response which falls away steeply above the

cut-off frequency. There is an overshoot of

approx. 10 %.

Time

Best frequency response

(Butterworth)

Step response

The diagram shows a step response with very

little (<1 %) or no overshoot. The amplitude

response falls away less steeply.

Time

Best course over time

(Bessel)

HBM A0563-5.6 en

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 34

PME-MP55

Group Parameter Meaning

33

ANALOG-

OUTPUT

SourceUa The gross or net value and the peak value can be chosen as

the source for the analogue signal.

Mode Ua Use DIP switches S11 and S5 to define the analogue output

signal mode. The following options are possible:

"10 V, "20 mA, 4...20 mA

V

Zero V

Zero kN

Zero V

EndV kN

1)

EndV V

1)

EndV V

0

Zero

kN

EndV

kN

Physical unit

Information on scaling

Output characteristics:

The scale factor for the analogue output is derived from the

input and output characteristics. If the span that has been set

up corresponds to the measurement range in mV/V, the

minimum output voltage that can be set up is 0.17 V. If the

settings cause the respective limits to be exceeded,

”Analogue scaling error” is reported (see page 58).

1

) Depending on the unit chosen

Scale range min. for analogue output: 0.17 V at 100 % of amplifier input

range

Scale range max. for analogue output: 10 V at 3.67 % of amplifier input

range

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

HBMA0563-5.6 en

Page 35

34

Group Parameter Meaning

PME-MP55

LIMIT VAL.

1...4

Source You can choose from the following as the source for the limit

value signal: Gross, Net, Peak value Max/Min / Peak-to-peak

SwtchDir

Value

Hyst

Over limit

Below limit

Functions and parameters of limit values

Limit1, ON

OFF

OFF

Limit2, ON

24 V

0 V

Limit1 ON

24 V

0 V

Limit2 ON

Value

Value

Hyst

Hyst

On Del ms Starting delay; in the event of exceeding a limit value level,

the change only takes effect after the delay time (On Del) at

the output.

Off Del

Cut-off delay, as for On Del

ms

PEAK

STORE

InputMin/Max The following can be chosen as the source for the peak

*)

value: Gross, Net,

ClearPkV The peak value can be cleared.

kG/s

Discharge rate of envelope function (in physical units/sec)

for both peak value stores.

Peak value stores can also be used to display the

envelope function. The envelope function is suitable for

measuring amplitude-modulated vibration. The discharge

rate of the envelope function (i.e. the decay time of the

discharge function) defines how quickly the current value is

discharged from the peak store.

, V

V

i

o

Discharge rate=0 V/s

Discharge rate=1 V/s

t

*) See also following page (Remotes)

HBM A0563-5.6 en

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 36

PME-MP55

35

Inputs/Outputs (I/Os)

Terminal plug 3: This is equipped with 4 inputs which you can use to control

the functions of the PME.

Terminal plug 4: This has 4 outputs available.

Group Parameter Meaning

IN/OUT Output1...4 Outputs1..4 can be assigned the following functions:

Limit switches 1 to 4, standstill, errors, inactive

Mode

Out1...4

Function

Taring Taring is started upon alternation from 0 V to 24 V

Zero

balance

PkMomMax Peak value operating mode

PkMomMin Peak value operating mode

PkHldMax Memory contents PkMax are

PkHldMin Memory contents PkMin

ParaCo1 Selecting parameter sets and binary coded inputs

ParaCo2

The output signal is inverted (pos.log) or not inverted

(neg.log).

Functions can be freely assigned to remotes (I/Os).

Input value 0 V Input value 24 V

Current measuring signal is set to zero upon alternation from

0 V to 24 V

Current value operating mode

for PkMax

Current value operating mode

for PkMin

Memory contents PkMax are

updated

Memory contents PkMin

updated

for PkMax

for PkMin

frozen

frozen

Parameter set ParaCo2 ParaCo1

1 0 0

2 0 1

3 1 0

4 1 1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

HBMA0563-5.6 en

Page 37

36

Group Parameter Meaning

PME-MP55

IN/OUT PkMom

Max

PkMomMin

PkHldMax

PkHldMax

PkHldMin

Peak value operating mode

Amplitude

Function

Operating

mode

Current value operating mode

Amplitude

Peak value (Store1)

Measuring signal

HoldRun Run

Measuring signal

Trend of stored

value

t

Current value

t

Hold

t

Function

Operating

mode

Run Run

Current value

Hold

Run

CAN-Bus Baudrate 10 kB, 20 kB, 50 kB, 125 kB, 250 kB, 500 kB, 800 kB, 1000 kB

Address From 0 to 127 (8-bit)

Profile DS401 (Device Profile for I/O-Modules)

or DS404 (Device Profile for Measuring Devices and Closed

Loop Controller)

Output You may choose which signal is output over the CAN bus:

Gross, Net or Peak value Max/Min.

OutR. ms Output rate. Specifies the interval (in ms) at which a value is

sent over the CAN-interface.

HBM A0563-5.6 en

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 38

PME-MP55

Group Parameter Meaning

37

Additional

function

>0< Rf

Example:

A displacement transducer 〈"20 mm nominal displacement) is fastened

at a height of 1m measured from the engine seating. When setting zero,

the analogue output is balanced to 0V. The display value is adjusted to

>0<Ref (+1000 mm).The display is to show a movement in absolute

terms, i.e. a display range of 980 mm to 1020 mm is available.

"20 mm

Engine seating

Zero reference

Displacement

transducers

Relative zero point of

transducer

Zero offset= -1000 mm

Absolute zero point

MotionDsp Motion count indication. If standstill occurs with ON selected,

the character is displayed

MTime ms

MAmp kg

Standstill time;

Standstill is reported if Amplitude MAmp is not exceeded in

standstill time ”t”.

Warning

Signal

24 V

0 V

MTi

me

MAmp

Time

(Standstill time)

Standstill

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

HBMA0563-5.6 en

Page 39

38

PME-MP55

7 CAN interface description

7.1 Introduction

The MP55 module has a built-in CAN-interface which may be used not only

for data transmission but also for assigning parameters to the module. The

baud rate is selectable; the maximum possible is 1 MBaud. The interface protocol is based on the CANopen standard.

7.2 Cyclical data transmission

Cyclical data is transmitted in the form of “Process Data Objects” (PDOs, as

defined in CANopen). The measurement module sends the measured values

concerned cyclically without additional flags, under a previously defined CAN

identifier. No prompt message is needed. A parameter defines how often the

PDOs are sent (see object directory). Data formats with a length of more than

one byte are always sent in the sequence LSB-MSB.

Send PDO:

CAN identifier 384 (180 Hex) + module address

1st-4th data byte Value (LSB-MSB), integer 32

5th data bytes Status (object 2010)

Receive PDO:

CAN identifier 512 (200 Hex) + module address

1st data byte Control word (object 2630)

In addition to these predefined PDOs, it is possible to set up more PDOs as

defined in CANopen (CiA-DS 301) using a technique known as mapping. Appropriate tools for this purpose are commercially available.

The exchange of cyclical PDOs only starts after the module has been placed

in ”Operational” status. This happens when the message ”Start_Remote_Node” is sent

CAN identifier 0

1st data byte 1

2nd data byte Module address (0 = all)

HBM A0563-5.6 en

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 40

PME-MP55

39

To exit from ”Operational” status use the message ”Enter_Pre_Operational_State”:

CAN identifier 0

1st data byte 128

2nd data byte Module address (0 = all)

7.3 Parameter assignment

Parameter assignment messages affecting the module are transmitted in the

form of “Service Data Objects” (SDOs, as defined in CANopen). These address the various parameters by an index and subindex number. For information on these index numbers please refer to the object directory. Data formats

with a length of more than one byte are always sent in the sequence LSBMSB.

Reading a parameter:

Request (PC or PLC to MP55)

CAN identifier 1536 (600 Hex) + module address

1st data byte 64 (40 Hex)

2nd + 3rd data byte Index (LSB_MSB)

4th data byte Subindex

5th-8th data byte 0

Response (MP55 to PC or PLC)

CAN identifier 1408 (580 Hex) + module address

1st data byte 66 (42Hex)

2nd + 3rd data byte Index (LSB-MSB)

4th data byte Subindex

5th-8th data byte Value (LSB-MSB)

Reading a parameter:

Send value (PC or PLC to MP55)

CAN identifier 1536 (600 Hex) + module address

1st data byte 47 (2FHex) = write 1 byte

43 (2BHex) = write 2 bytes

35 (23Hex) = write 4 bytes)

2nd + 3rd data byte Index (LSB-MSB)

4th data byte Subindex

5th-8th data byte Value (LSB-MSB)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

HBMA0563-5.6 en

Page 41

40

PME-MP55

Acknowledge (MP55 to PC or PLC)

CAN identifier 1408 (580 Hex) + module address

1st data byte 96 (60Hex)

2nd + 3rd data byte Index (LSB_MSB)

4th data byte Subindex

5th-8th data byte 0

Response in the event of an error when reading or writing parameters:

Error acknowledge (MP55 to PC or PLC)

CAN identifier 1408 (580 Hex) + module address

1st data byte 128 (80Hex)

2nd + 3rd data byte Index (LSB_MSB) or 0

4th data byte Subindex or 0

5th-6th data byte Additional error code:

10H: Parameter value invalid

11H: Subindex does not exist

12H: Too long

13H: Too short

20H: Service not available at present

21H: - due to local control

22H: - due to device status

30H: Range of values of parameter exceeded

31H: Parameter value too high

32H: Parameter value too low

40H: Value incompatible with other settings

41H: Data cannot be mapped

42H: Exceeds PDO length

43H: General incompatibility

7th data byte Error code:

1: Object access not supported

2: Object does not exist

3: Parameter inconsistent

4: Prohibited parameter

6: Hardware error

7: Type conflict

9: Object attributes inconsistent (subindex does not exist)

8th data byte Error class:

5: Service defective

6: Access error

8: Other error

HBM A0563-5.6 en

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 42

PME-MP55

7.4 Object directory: communications profile section

as defined in CANopen (CiA-DS301)

41

Index

(hex)

1000 0 Device type Unsigned32 ro

1001 0 Error register Unsigned8 ro Bit 0: Fatal error

1003 0 Predefined error array Unsigned8 rw Number of errors

1003 1..7 Predefined error array Unsigned32 ro Bytes 1-2: error code

1005 0 Identifier SYNC message Unsigned32 rw

1008 0 Manufacturer’s device

1009 0 Manufacturer’s hardware

100A 0 Manufacturer’s software

Sub-

index

Name Data type Attr. Values

Bit 4:

Communications

error

Bit 7: Manufacturerspecific

Bytes 3-4: Additional

information

Vis-String ro

designation

Vis-String ro

version

Vis-String ro

version

100B 0 Device address Unsigned32 ro

100C 0 Guard time Unsigned16 rw

100D 0 Life time factor Unsigned8 rw

100E 0 Node guarding identifier Unsigned32 rw

100F 0 Number of supported SDOs Unsigned32 ro

1010 0..2 Save communications

parameters

1011 0..2 Load communications

parameters as per factory

setup

1012 0..2 Time stamp identifier Unsigned32 rw

1014 0 Identifier EMERGENCY

message

1200 0..2 Server SDO parameter SDOParame

1400 0..2 1st Receive PDO parameter PDOComm

1401 0..2 2nd Receive PDO parameter PDOComm

Unsigned32 rw 65766173Hex

Unsigned32 rw 64616F6CHex

Unsigned32 rw

ro

ter

rw

Par

rw

Par

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

HBMA0563-5.6 en

Page 43

42

PME-MP55

Index

(hex)

1600 0..2 1st Receive PDO mapping PDOMapping rw

1601 0..2 2nd Receive PDO mapping PDOMapping rw

1800 0..2 1st Send PDO parameter PDOCommPar rw

1801 0..2 2nd Send PDO parameter PDOCommPar rw

1A00 0..2 1st Send PDO mapping PDOMapping rw

1A01 0..2 2nd Send PDO mapping PDOMapping rw

Sub-

index

Name Data type Attr. Values

Data structures:

PDO CommPar:

Index Subindex Name Data type

0020 0 Number of entries unsigned 8

1 CAN identifier for PDO unsigned32

2 Transmission type unsigned8

3 Off-time unsigned16

4 Priority group unsigned8

CAN identifier for PDO (subindex 1):

Bits Value Meaning

31 (MSB) 0

1

30 0

1

29 0

1

28..0 X CAN-ID

PDO valid

PDO invalid

RTR allowed

RTR not allowed

11 bit ID

29 bit ID

PDO mapping:

Index Subindex Name Data type

0021 0 Number of mapped objects unsigned8

1 1st mapped object unsigned32

2 2nd mapped object unsigned32

... ... unsigned32

Structure of a PDO mapping entry:

Index (16 bits) Subindex (8 bits) Object length in bits (8bit)

HBM A0563-5.6 en

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 44

PME-MP55

SDO parameter:

Index Subindex Name Data type

0022 0 Number of entries unsigned8

1 COB-ID client->server unsigned32

2 COB-ID server->client unsigned32

3 Node ID (optional) unsigned8

Error code (object 1003HEx):

Value Meaning

0 No error

1000 Fatal error

8100 Communication

FF00 Device-specific

Error code - additional information (object 1003Hex):

43

Value Meaning

0 No error

1 Transmission error

2 System error

3 Unknown command

4 Wrong number of parameters

5 Wrong parameter value

6 Filter frequency error

7 Amplifier overflow

8 Command cannot be executed

10 Wrong channel selection

11 Measuring error

12 Triggering error

13 Range error

14 Taring error

21 Filter frequency warning

22 Tare status warning

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

HBMA0563-5.6 en

Page 45

44

PME-MP55

7.5 Object directory: manufacturer-specific objects

Parameters that refer to measured values are scaled as long-coded (32-bit integer) with figures in the appropriate range. The position of the decimal point

is defined in object 2120Hex. Alternatively these quantities are also available

as floating values (IEEE754-1985 32-bit format) (see page 53).

Index

(hex)

2000 1 Gross measured value integer32 ro

2001 1 Net measured value integer32 ro

2002 1 maximum integer32 ro

2003 1 minimum integer32 ro

2004 1 Peak-to-peak integer32 ro

2005 1 Measured value in

2006 1 Analogue output value

2010 1 Measured value status unsigned8 ro Bit 0: Meas.val. overflow

2011 1 Measured value

Sub-

index

Name Format Attr. Values

Measured values:

mV/V

V

status_2

integer32 ro 5 Decimal places

integer32 ro 3 Decimal places

Bit 1: Analogue out. overfl.

Bit 2: Scaling defective

Bit 3: EEPROM error

Bit 4..7: Limit switch 1...4

unsigned32 ro Bit 0: Overfl. hardware

Bit 1: Overfl. ADC

Bit 2: Overfl. gross

Bit 3: Overfl. net

Bit 4: Overfl. anal. outp.

Bit 5: Overfl. maximum

Bit 6: Overfl. minimum

Bit 7: Negative overfl.

Bit 8: Limit value 1

Bit 9: Limit value 2

Bit 10: Limit value 3

Bit 11: Limit value 4

Bit 12: Input scaling

Bit 13: Output scaling

Bit 14: Span exceeded

Bit 15: Urcal.Error

Bit 16: Transducer error

2020* 1 I/O status unsigned8 ro Bits 0..3: Inputs 1...4

Bits 4...7:Outputs 1...4

HBM A0563-5.6 en

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 46

PME-MP55

45

Index

(hex)

Sub-

index

Name Format Attr. Values

2080 0 Edit mode unsigned8 ro 1: Edit mode on

0: Edit mode off

2081 0 Restart executed unsigned8 rw 1: Restart executed

0: Write = Delete

2082 0 Serial number vis.string ro 12 char.

2083 0 Exit from edit mode unsigned8 wo Value display after writing

with alloc. value

Dialog:

2101 0 Dialog language unsigned16 rw 1500 German

1501 English

2103 0 Password integer16 rw

2104 1 Enable keyboard and

menu

unsigned16 rw 0: Input enabled

1: Input disabled

Bit 0: Password input

Bit 1: Dialog

Bit 2: Parameter set

Bit 3: Display

Bit 4: Transducer

Bit 5: Conditioning

Bit 6: Analogue output

Bit 7: Limit values

Bit 8: Peak values

Bit 9: I/Os

Bit 10: CAN

Bit 11: Additional functions

Bit 15: Keyboard lock

Parameter sets

2110 1 Activate parameter set unsigned16 rw 6600: Factory set-up

6601: Parameter set 1

6602: Parameter set 2

6603: Parameter set 3

6604: Parameter set 4

2111 1 Save parameter set unsigned16 rw See above

2112 1 Number of the active

unsigned16 ro See above

parameter set

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

HBMA0563-5.6 en

Page 47

46

PME-MP55

Index

(hex)

Sub-

index

Name Format Attr. Values

Display adaptation

2120 1 Decimal point position unsigned16 rw 0..5

2121 1 Step unsigned16 rw 110: 1

111: 2

112: 5

113: 10

114: 20

115: 50

116: 100

117: 200

118: 500

119: 1000

Transducers

2122 1 Physical unit unsigned16 rw 1603: g

1604: kg

1605: T

1606: kT

1607: TON

1608: lb

1609: oz

1610: N

1611: kN

1612: bar

1613: mbar

1614: Pa

1615: Pas

1616: hPas

1617: kPas

1618: psi

1619: µm

1620: mm

1621: cm

1622: m

1623: inch

1624: Nm

1625: kNm

1626: FTLB

1627: INLB

1628: µm/m

1629: m/s

1630: m/s

1631: percent

1632: perthou

1633: ppm

1634: S

1635: MPas

1636: MN

1637: Blank

2

HBM A0563-5.6 en

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 48

PME-MP55

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

47

Index

(hex)

Sub-

index

Name Format Attr. Values

2130 1 Transducer type unsigned16 ro 350: Full bridge

351: Half bridge

380: LVDT

2131 1 Excitation unsigned16 ro 11: 1 V

13: 2.5 V

14: 5 V

2132

ÁÁ

ÁÁ

ÁÁ

ÁÁ

ÁÁ

ÁÁ

ÁÁ

ÁÁ

ÁÁ

1

Á

Á

Á

Á

Á

Á

Á

Á

Á

Range

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

unsigned16

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

Á

Á

Á

Á

Á

Á

Á

Á

Á

ro

ББББББББББ

ББББББББББ

ББББББББББ

ББББББББББ

ББББББББББ

ББББББББББ

ББББББББББ

ББББББББББ

ББББББББББ

for UB = 5 V

700: 3 mV/V

773: 50 mV/V

703: 500 mV/V

for U

= 2,5 V

B

771: 6 mV/V

774: 100 mV/V

776: 1000 mV/V

for U

= 1 V

B

772: 15 mV/V

775: 250 mV/V

777: 2500 mV/V

2133 1 Shunt unsigned16 rw 1: On

0: Off

2134 1 Shunt mismatch

direction

unsigned16 rw 44: positive

45: negative

2140 1 Transducer null mV/V integer32 rw Value in mV/V

2141 1 Transducer null phys.

integer32 rw Value e.g. in kN

unit

2142 1 Transducer sensitivity

integer32 rw Value in mV/V

mV/V

2143 1 Transducer nominal

integer32 rw Value e.g. in kN

value phys. unit

2150 1 Input characteristics at

integer32 rw Value in mV/V

1st point mVV

2151 1 Input characteristics at

integer32 rw Value in mV/V

2nd point mVV

2160 1 Input characteristics at

integer32 rw Value e.g. in kN

1st point in phys. unit

2161 1 Input characteristics at

integer32 rw Value e.g. in kN

2nd point in phys. unit

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

HBMA0563-5.6 en

Page 49

48

PME-MP55

Index

(hex)

Sub-

index

Name Format Attr. Values

Conditioning

2180 1 Tare value integer32 rw

2181 1 Zero balance value integer32 rw

2182 1 Memory mode for taring unsigned16 rw 6611: volatile

6610: permanent

2183 1 Memory mode for zeroing unsigned16 rw 6611: volatile

6610: permanent

2185 1 Zero reference integer32 rw

2190 1 Filter frequency unsigned16 rw 908: 0.05 Hz

914: 0.1 Hz

917: 0.2 Hz

921: 0.5 Hz

927: 1 Hz

931: 2 Hz

935: 5 Hz

941: 10 Hz

945: 20 Hz

949: 50 Hz

955: 100 Hz

958: 200 Hz

962: 500 Hz

2191 1 Filter characteristics unsigned16 rw 141: Butterworth

142: Bessel

21A0 1 Standstill monitoring by

unsigned32 rw ms

time window

21A1 1 Standstill monitoring by

integer32 rw

amplitude

21A2 1 Activate motion count

indication

unsigned16 rw 1: on

0: off

Analogue output

21C0 1 Mode of analogue output

(voltage/current)

unsigned16 ro 290: "10 V

291: "20 mA

292: 4..20 mA

21C1 1 Signal at analogue output unsigned16 rw 214: Gross

215: Net

204: Max

205: Min

218: Peak-to-peak

21D0 1 Zero point of analogue

integer32 rw Value e.g. in kN

output phys. unit

21D1 1 Final value of analogue

integer32 rw Value e.g. in kN

output phys. unit

21D2 1 Zero point of analogue

integer32 rw Value in V

output V

21D3 1 Final value of analogue

integer32 rw Value in V

output V

HBM A0563-5.6 en

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 50

PME-MP55

49

Index

(hex)

Sub-

index

Name Format Attr. Values

Limit switches

2210 1 Enable limit value 1 unsigned16 rw 1: yes

0: no

2211 1 Input signal for limit value 1 unsigned16 rw 214: Gross

215: Net

204: Min

205: Max

218: Peak-to-peak

2212 1 Direction of limit value 1 unsigned16 rw 130: Above limit

131: Below limit

2214 1 Starting delay LV 1 integer32 rw ms

2215 1 Cut-off delay LV 1 integer32 rw ms

2216 1 Switching level for limit

integer32 rw

value 1

2217 1 Hysteresis for limit value 1 integer32 rw

2218 1 Status of limit value 1 unsigned8 ro

2220 1 Enable limit value 2 unsigned16 rw 1: yes

0: no

2221 1 Input signal for limit value 2 unsigned16 rw 214: Gross

215: Net

204: Min

205: Max

218: Peak-to-peak

2222 1 Direction of limit value 2 unsigned16 rw 130: Above limit

131: Below limit

2224 1 Starting delay LV 2 integer32 rw ms

2225 1 Cut-off delay LV 2 integer32 rw ms

2226 1 Switching level for limit

integer32 rw

value 2

2227 1 Hysteresis for limit value 2 integer32 rw

2228 1 Status of limit value 2 unsigned8 ro

2230 1 Enable limit value 3 unsigned16 rw 1: yes

0: no

2231 1 Input signal for limit value 3 unsigned16 rw 214: Gross

215: Net

204: Min

205: Max

218: Peak-to-peak

2232 1 Direction of limit value 3 unsigned16 rw 130: Above limit

131: Below limit

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

HBMA0563-5.6 en

Page 51

50

PME-MP55

Index

(hex)

Sub-

index

Name Format Attr

.

Values

2234 1 Starting delay LV 3 integer32 rw ms

2235 1 Cut-off delay LV 3 integer32 rw ms

2236 1 Switching level for limit value

integer32 rw

3

2237 1 Hysteresis for limit value 3 integer32 rw

2238 1 Status of limit value 3 unsigned8 ro

2240 1 Enable limit value 4 unsigned16 rw 1: yes

0: no

2241 1 Input signal for limit value 4 unsigned16 rw 214: Gross

215: Net

204: Min

205: Max

218: Peak-to-peak

2242 1 Direction of limit value 4 unsigned16 rw 130: Above limit

131: Below limit

2244 1 Starting delay LV 4 integer32 rw ms

2245 1 Cut-off delay LV 4 integer32 rw ms

2246 1 Switching level for limit value

integer32 rw

4

2247 1 Hysteresis for limit value 4 integer32 rw

2248 1 Status of limit value 4 unsigned8 ro

Peak values

2260 1 Input signal Min store unsigned16 rw 214: Gross

215: Net

2261 1 Input signal Max store unsigned16 rw 214: Gross

215: Net

2262 1 Envelope curve function

integer32 rw Display / s

discharge

2263 1 Enable peak-value store unsigned16 rw 1: enabled

2: disabled

Additional functions

2271 0 Hardware synchronisation unsigned16 ro 6700: Master

6701: Slave

2272 0 Sensitivity of keyboard unsigned16 rw 7601: low

7602: medium

7603: high

HBM A0563-5.6 en

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 52

PME-MP55

51

Index

(hex)

Sub-

index

Name Format Attr. Values

Digital I/Os

2310 1 Function of output 1 unsigned16 rw 200: No function

221: Limit value 1

222: Limit value 2

223: Limit value 3

224: Limit value 4

230: Error / Warning

231: Standstill

2311 1 Mode Outp. 1 unsigned16 rw 135: normal

136: inverse

2312 1 Function of output 2 unsigned16 rw See above

2313 1 Mode Outp. 2 unsigned16 rw See above

2314 1 Function of output 3 unsigned16 rw See above

2315 1 Mode Outp. 3 unsigned16 rw See above

2316 1 Function of output 4 unsigned16 rw See above

2317 1 Mode Outp. 4 unsigned16 rw See above

2320 1 Remote function Taring unsigned16 rw 100: no input

101: Input 1

102: Input 2

103: Input 3

104: Input 4