Page 1

Operating Manual

English

MGCplus

Page 2

Hottinger Baldwin Messtechnik GmbH

Im Tiefen See 45

D-64239 Darmstadt

Tel. +49 6151 803-0

Fax +49 6151 803-9100

info@hbm.com

www.hbm.com

Mat.: 7-2002.0612

DVS:

A0534-30.0 HBM: public

03.2018

E Hottinger Baldwin Messtechnik GmbH.

Subject to modifications.

All product descriptions are for general information only.

They are not to be understood as a guarantee of quality or

durability.

Page 3

Table of contents

Table of contents

1 Safety instructions 11.......................................................................

1.1 Electromagnetic compatibility 14........................................................

2 Markings used 15...........................................................................

2.1 Markings on the device 15.............................................................

2.2 The markings used in this document 15..................................................

3 Introduction 17.............................................................................

3.1 Degree of protection 17................................................................

3.2 Notes on documentation 18............................................................

3.3 System description 19.................................................................

3.4 Layout of the MGCplus device 21.......................................................

3.5 MGCplus housing designs 22...........................................................

3.6 Possible amplifier/connection board combination 23.......................................

3.7 Installation of the CP52 communication processor 26......................................

3.8 Conditions at the place of installation 29.................................................

3.9 Maintenance and cleaning 30...........................................................

4 Connection 31.............................................................................

4.1 Connecting the MGCplus in a tabletop housing/rack frame 31...............................

4.1.1 Mains connection 31..........................................................

4.1.2 Synchronization of multiple CP52 devices 32.....................................

4.1.2.1 Synchronization of multiple CP52 devices via a synchronization jack 32.....

4.1.3 Synchronization of CP52 with CP22/CP42 34.....................................

4.2 Shielding design 36...................................................................

4.3 Connecting the transducer 39..........................................................

4.3.1 Connecting separate TEDS modules 39..........................................

4.3.2 SG full bridges, inductive full bridges 42..........................................

4.3.3 Full bridge circuits on AP810i/AP815i 43.........................................

MGCplus A0534-30.0 HBM: public 3

Page 4

Table of contents

4.3.4 Strain gage half bridges, inductive half bridge circuits 44...........................

4.3.5 LVDT transducers 45..........................................................

4.3.6 Strain gage half bridges on AP810i 46...........................................

4.3.7 Strain gage half bridges on AP815i 47...........................................

4.3.8 Single strain gage 48..........................................................

4.3.9 SG chains and strain gage rosettes on AP815i 51.................................

4.3.10 Torque flange T10 series, T40 series) 53.........................................

4.3.11 Torque shaft (T4A, T5, TB1A) 59................................................

4.3.12 Thermocouples 62............................................................

4.3.13 DC voltage sources 63.........................................................

4.3.14 DC power sources 70..........................................................

4.3.15 Resistors, Pt100 72...........................................................

4.3.16 Frequency measurement without directional signal 73..............................

4.3.17 Frequency measurement with directional signal 74................................

4.3.18 Pulse counting, single-pole 75..................................................

4.3.19 Pulse counting, differential 76...................................................

4.3.20 Active piezoelectric transducers 77..............................................

4.3.21 Piezoresistive transducers 78...................................................

4.3.22 Potentiometric transducers 79..................................................

4.3.23 Connection via the distributor board VT810/815i 80................................

4.3.8.1 Single strain gage on AP14 48.........................................

4.3.8.2 Single strain gage on AP814Bi 49......................................

4.3.8.3 Single strain gage on AP815i 50.......................................

4.3.10.1 Torque measurement 53..............................................

4.3.10.2 Rotational speed measurement (symmetrical signals) 55..................

4.3.10.3 Rotational speed measurement (symmetrical signals) with reference pulse 57

4.3.11.1 Torque measurement (slip rings or direct cable connection) 59.............

4.3.11.2 Rotational speed measurement with inductive transducers 61..............

4 A0534-30.0 HBM: public MGCplus

Page 5

Table of contents

4.4 Connecting CANHEAD modules 82.....................................................

4.4.1 Communication card ML74B 83.................................................

4.4.2 AP74 connection board 84.....................................................

4.5 Inputs and outputs, remote controls 85...................................................

4.5.1 Inputs/outputs of the CP52 85..................................................

4.5.2 Analog output on the front panel 87..............................................

4.5.3 Connection boards AP01i/AP03i/AP14/AP17 87...................................

4.5.3.1 Socket assignment AP01i/AP03i/AP14/AP17 88..........................

4.5.3.2 AP460i connector pin assignment 92...................................

4.5.3.3 AP77 93............................................................

4.5.4 Inputs and outputs of AP75 94..................................................

4.5.5 Analog outputs on the AP78 97.................................................

5 Starting up 99..............................................................................

5.1 Devices in the desktop housing and rack frame 99........................................

6 Functions and symbols of the AB22A 103.....................................................

6.1 Control elements of the AB22A 103......................................................

6.2 Display 104...........................................................................

6.2.1 The first display 104............................................................

6.2.2 Display in measuring mode 105..................................................

6.2.3 Messages of AB22A/AB32 109..................................................

6.3 AB22A in Setup mode 110..............................................................

6.3.1 Call menus 112................................................................

6.3.2 Exit menus 113................................................................

6.3.3 Channel selection in measuring mode 114.........................................

6.3.4 Channel selection in Setup mode 115.............................................

6.3.5 Saving settings 115............................................................

6.3.6 Drop-down menus 116..........................................................

6.3.7 Setting elements in the setup windows 116........................................

MGCplus A0534-30.0 HBM: public 5

Page 6

Table of contents

7 Measuring 121...............................................................................

7.1 General information 121................................................................

7.2 General principles for adjusting a measurement channel 122.................................

7.2.1 Adapting to the transducer 124...................................................

7.2.1.1 Extended functions of the ML38B 125....................................

7.2.2 TEDS transducers 126..........................................................

7.2.3 Signal conditioning 128.........................................................

7.2.4 Display 131...................................................................

7.2.5 Analog outputs (single-channel modules only) 132..................................

7.3 Adapting to the transducer 135..........................................................

7.3.1 SG transducers 135............................................................

7.3.1.1 Direct entry of transducer characteristics 136.............................

7.3.1.2 Calibrating the characteristic curve of the transducer 139...................

7.3.2 Strain gages 140...............................................................

7.3.2.1 Direct entry of transducer characteristics 143.............................

7.3.3 Inductive transducers 145.......................................................

7.3.3.1 Direct entry of transducer characteristics 146.............................

7.3.3.2 Calibrating the characteristic curve of the transducer 148...................

7.3.4 Torque transducer 151..........................................................

7.3.4.1 Direct entry of torque characteristics 153.................................

7.3.4.2 Calibration with shunt installed 155......................................

7.3.5 Adjusting the rotational speed channel, frequency measurement 159..................

7.3.6 Adjusting the rotational speed channel, power measurement 162.....................

7.3.7 Thermocouples 164............................................................

7.3.7.1 Direct entry of transducer characteristics 165.............................

7.3.8 Current and voltage measurement 166............................................

7.3.8.1 Direct entry of transducer characteristics 167.............................

7.3.9 Resistance temperature sensors 169.............................................

7.3.9.1 Direct entry of transducer characteristics 170.............................

6 A0534-30.0 HBM: public MGCplus

Page 7

Table of contents

7.3.10 Resistors 172..................................................................

7.3.10.1 Direct entry of transducer characteristics 172.............................

7.3.11 Pulse counting 174.............................................................

7.3.11.1 Direct entry of transducer characteristics 175.............................

7.4 Current-fed piezoelectric transducer 179..................................................

7.4.1 Direct entry of transducer characteristics 180......................................

7.5 Piezoresistive transducers 182...........................................................

7.5.1 Direct entry of transducer characteristics 182......................................

7.5.1.1 Calibrating the characteristic curve of the transducer 184...................

7.6 Potentiometric transducers 186..........................................................

7.6.1 Direct entry of transducer characteristics 187......................................

7.6.1.1 Calibrating the characteristic curve of the transducer 189...................

8 Additional functions 191.....................................................................

8.1 Remote control (single-channel modules only) 191.........................................

8.1.1 Turning on remote control 191...................................................

8.1.2 Assigning remote control contacts 192............................................

8.2 Limit values (single-channel modules only) 194............................................

8.2.1 Turning on limit switches 195....................................................

8.2.2 Adjusting limit values 196.......................................................

8.2.3 Selection keys in the Limit switches menu 198.....................................

8.3 Limit value combination (single-channel modules only) 199..................................

8.4 Set peak values 202....................................................................

8.4.1 Peak-value memory 202........................................................

8.4.2 Combining peak-value memories 203.............................................

8.4.3 Control of peak-value memory 205...............................................

8.4.4 "Peak value" operating mode 205................................................

8.4.5 "Instantaneous value" operating mode 206........................................

8.4.6 Envelope curve operating mode 207..............................................

8.4.7 Clear peak-value memory 208...................................................

MGCplus A0534-30.0 HBM: public 7

Page 8

Table of contents

8.5 Version 209...........................................................................

8.6 Switching 210.........................................................................

9 Display 213.................................................................................

9.1 Display format 213.....................................................................

9.1.1 Select setup window 214........................................................

9.1.2 Setup window Display format 215................................................

9.1.3 Setup window components 216..................................................

9.1.3.1 Numeric value display 217.............................................

9.1.3.2 Graphic display 227...................................................

9.1.4 Limit value status 230..........................................................

9.1.5 Recording status 231...........................................................

9.2 F keys 232............................................................................

9.2.1 F keys in measuring mode 232...................................................

9.2.2 F keys in Setup mode 234.......................................................

9.3 Channel names 235....................................................................

10 System 237.................................................................................

10.1 Password 237.........................................................................

10.1.1 Define new user 238............................................................

10.1.2 Password protection activation 239...............................................

10.1.3 Set access for operator 240.....................................................

10.1.4 Delete user 241................................................................

10.1.5 Change password 242..........................................................

10.2 Save/load 243.........................................................................

10.3 Recording series of tests 248............................................................

10.3.1 Setting parameters of test series 249.............................................

10.3.2 Format of the MGCplus measurement files 267....................................

10.3.2.1 Measured values 267..................................................

10.3.2.2 Time channels 269....................................................

10.3.3 MEA format in detail (MGC binary format 2) 270...................................

8 A0534-30.0 HBM: public MGCplus

Page 9

Table of contents

10.4 Interface 275..........................................................................

10.4.1 Port usage 279................................................................

10.4.2 Communication processor and multi-client mode 279...............................

10.5 Language 281.........................................................................

10.6 Time 282.............................................................................

11 Menu structure 283..........................................................................

MGCplus A0534-30.0 HBM: public 9

Page 10

Table of contents

10 A0534-30.0 HBM: public MGCplus

Page 11

1 Safety instructions

Safety instructions

Intended use

The amplifier system is to be used exclusively for measurement tasks and

directly related control tasks. Use for any purpose other than the above is

deemed to be non-designated use.

In the interests of safety, the device should only be operated as described in

the operating manuals. It is also essential to comply with the legal and

safety requirements for the relevant application during use. The same ap

plies to the use of accessories.

Each time, before starting up the equipment, you must first run a project

planning and risk analysis that takes into account all the safety aspects of

automation technology. This particularly concerns personal and machine

protection.

Additional safety precautions must be taken in plants where malfunctions

could cause major damage, loss of data or even personal injury. In the

event of a fault, these precautions establish safe operating conditions.

This can be done, for example, by mechanical interlocking, error signaling,

limit switches, etc.

General dangers of failing to follow the safety instructions

The amplifier system is a state of the art unit and as such is reliable. The

device may give rise to residual dangers if it is inappropriately installed and

operated by untrained personnel.

Any person instructed to carry out installation, commissioning, maintenance

or repair of the device must have read and understood the operating

manuals and in particular the technical safety instructions.

Residual dangers

The scope of supply and performance of the amplifier system covers only a

small area of measurement technology. In addition, equipment planners,

installers and operators should plan, implement and respond to the safety

engineering considerations of measurement technology in such a way as to

minimize residual dangers. On-site regulations must be complied with at all

times. There must be reference to the residual dangers connected with

measurement technology.

MGCplus A0534-30.0 HBM: public 11

Page 12

Safety instructions

After making settings and carrying out activities that are passwordprotected, you must make sure that any controls that may be connected re

main in a safe condition until the switching performance of the amplifier

system has been tested.

Working safely

The supply voltage connection, as well as the signal and sense leads, must

be installed in such a way that electromagnetic interference does not ad

versely affect device functionality (HBM recommendation: "Greenline

shielding design", can be downloaded from http://www.hbm.com/Greenline).

Automation equipment and devices must be designed in such a way that

adequate protection or locking against unintentional actuation is provided

(access checks, password protection, etc.).

When devices are working in a network, these networks must be designed

in such a way that malfunctions in individual nodes can be detected and

shut down.

Safety precautions must be taken both in terms of hardware and software,

so that a line break or other interruptions to signal transmission, such as via

the bus interfaces, do not cause undefined states or loss of data in the auto

mation device.

Error messages should only be acknowledged once the cause of the error is

removed and there is no further danger.

Conversions and modifications

The amplifier system must not be modified from the design or safety engi

neering point of view except with our express agreement. Any modification

shall exclude all liability on our part for any resultant damage.

In particular, any repair or soldering work on motherboards (replacement of

components, apart from EPROMs) is prohibited. When exchanging com

plete modules, use only original parts from HBM.

The amplifier system and/or individual components are delivered from the

factory with a fixed hardware and software configuration. Changes can only

be made within the possibilities documented in the operating manuals.

Qualified personnel

are persons entrusted with siting, mounting, starting up and operating the

product and who possess the appropriate qualifications for their function.

12 A0534-30.0 HBM: public MGCplus

Page 13

Safety instructions

This device is only to be installed and used by qualified personnel strictly in

accordance with the specifications and with the safety rules and regulations

which follow. It is also essential to comply with the legal and safety require

ments for the relevant application during use. The same applies to the use

of accessories.

Qualified personnel includes people who meet at least one of the following

requirements:

- Knowledge of the safety concepts of automation technology is a re

quirement and as project personnel, you must be familiar with these

concepts.

- As automation plant operating personnel, you have been instructed

how to handle the machinery and are familiar with the operation of the

systems, components and technologies described in this documenta

tion.

- As commissioning engineers or service engineers, you have success

fully completed the training to qualify you to repair the automation sys

tems. You are also authorized to activate, ground and label circuits

and equipment in accordance with safety engineering standards.

Safety rules

Before starting up, make sure that the mains voltage and type of current

stated on the type plate match the mains voltage and type of current at the

place of operation and that the circuit used is sufficiently protected.

The mains plug must only be inserted into a grounded socket with a protec

tion switch (protection class I).

Use only the mains cable included with delivery, which is fitted with a ferrite

core.

The device must be switched off and the mains plug disconnected from the

socket before opening the device.

Never pull the mains plug out of its socket by the supply lead.

Do not operate the device if the mains lead is damaged.

If an amplifier channel is removed, the module must be sealed with a blind

panel.

Only operate built-in devices once they are installed in the housing pro

vided.

MGCplus A0534-30.0 HBM: public 13

Page 14

Electromagnetic compatibility

The device complies with the safety requirements of DIN EN 61010 Part 1

(VDE 0411 Part 1); protection class I.

The insulation resistance of the connecting cables (v50V) must be at least

350V(AC).

1.1 Electromagnetic compatibility

The MGCplus device has been tested based on EMC product standard

EN 61326-1:2013. This standard includes definitions of limit values and test

levels for various electromagnetic environments.

Regarding emission (EME), requirements are included for class A (industrial

environments) and class B (residential, business and commercial environ

ments as well as small businesses). Laboratory applications also usually

require class B.

The product standard here references to EN 55011:2009+A1:2010.

Regarding immunity to interference, the product standard includes require

ments for controlled electro-magnetic environments (lowest requirements),

general environments and industrial environments (highest requirement).

MGCplus meet the following requirements:

-

Emission (EME): Class B

- Immunity to interference: Industrial environment

The MGCplus series and the individual modules thus essentially meet the

highest requirements and are therefore suitable for use in all environments

described in the product standard.

14 A0534-30.0 HBM: public MGCplus

Page 15

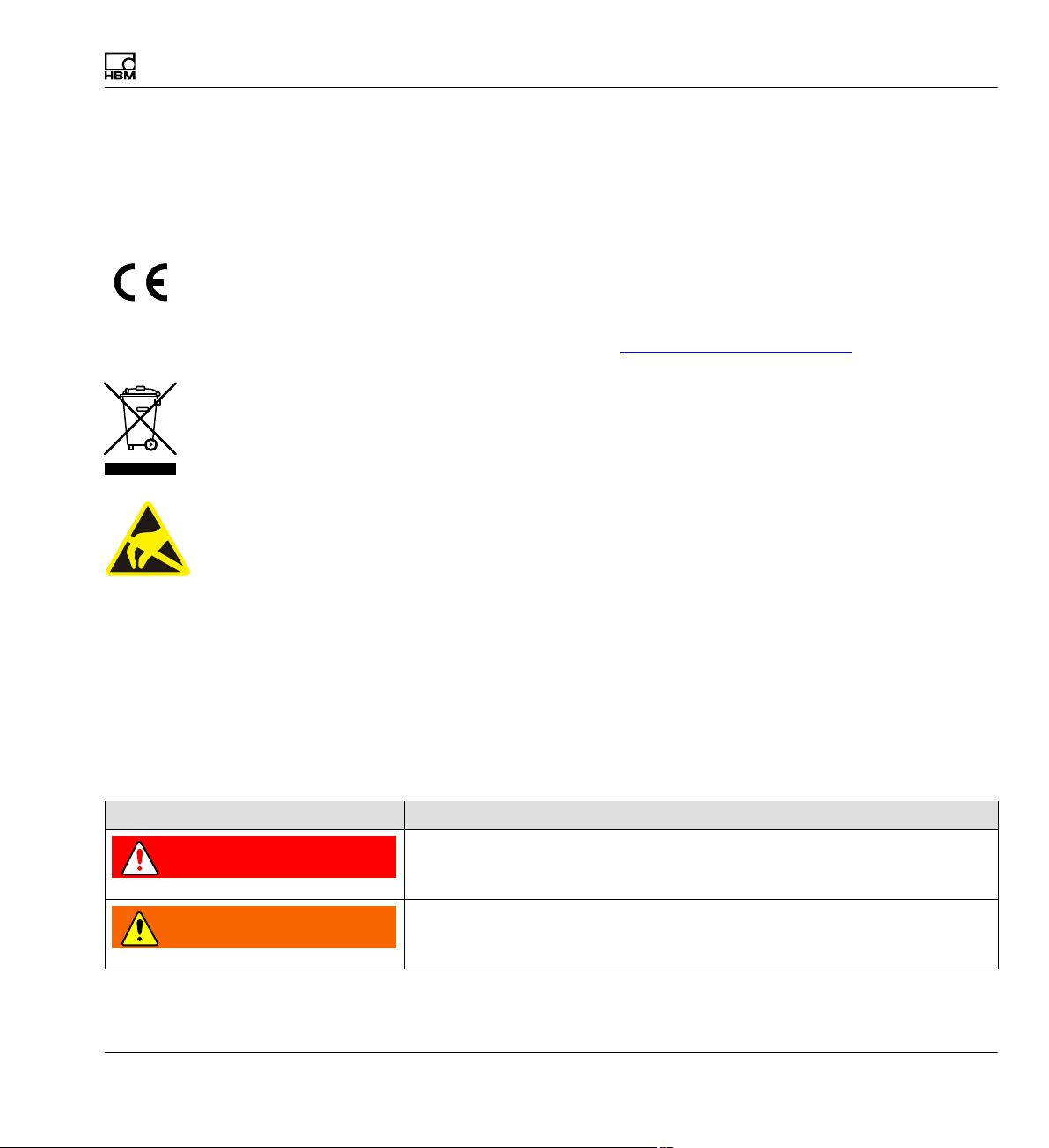

2 Markings used

Markings used

Markings on the device

2.1 Markings on the device

CE mark

By way of the CE mark the manufacturer guarantees that the product com

plies with the requirements of the relevant EC directives (the Declaration of

Conformity can be found at http://www.hbm.com/HBMdoc

Statutory waste disposal mark

In accordance with national and local environmental protection and material

recovery and recycling regulations, old devices that can no longer be used

must be disposed of separately and not with normal household garbage.

Electrostatic sensitive devices

Components marked with this symbol can be damaged beyond repair by

electrostatic discharge. Please observe the handling instructions for electro

static sensitive devices.

).

Any risk of residual dangers when working with the amplifier system are

pointed out in these instructions by means of the following symbols:

2.2 The markings used in this document

Symbol Meaning

DANGER

WARNING

MGCplus A0534-30.0 HBM: public 15

This marking warns of an imminently threatening dangerous situation in

which failure to comply with safety requirements will result in death or

extremely serious physical injury.

This marking warns of a potentially dangerous situation in which failure to

comply with safety requirements could result in death or serious physical

injury.

Page 16

Markings used

The markings used in this document

MeaningSymbol

CAUTION

Notice

Important

Tip

Information

Emphasis

See …

Device -> New Bold text indicates menu items, as well as dialog and window headings in

Sampling rate Bold text in italics indicates inputs and input fields in the user interfaces.

This marking warns of a potentially dangerous situation in which failure to

comply with safety requirements could result in slight or moderate physi

cal injury.

This marking draws your attention to a situation in which failure to comply

with safety requirements could lead to property damage.

This marking draws your attention to important information about the

product or about handling the product.

This marking indicates tips for use or other information that is useful to

you.

This marking draws your attention to information about the product or

about handling the product.

Italics are used to emphasize and highlight text and identify references to

sections, diagrams, or external documents and files.

the program environment. Arrows between menu items indicate the se

quence in which the menus and sub-menus are called up

16 A0534-30.0 HBM: public MGCplus

Page 17

3 Introduction

Introduction

Degree of protection

3.1 Degree of protection

The degree of protection given in the technical data indicates the suitability

of the housings for various ambient conditions and also the protection of

persons against potential risks when used. The letters IP (International Pro

tection) which are always present in the designation, are followed by two

digits. These indicate which degree of protection a housing offers against

contact or foreign objects (first digit) and moisture (second digit).

MGCplus devices are available with degree of protection IP20.

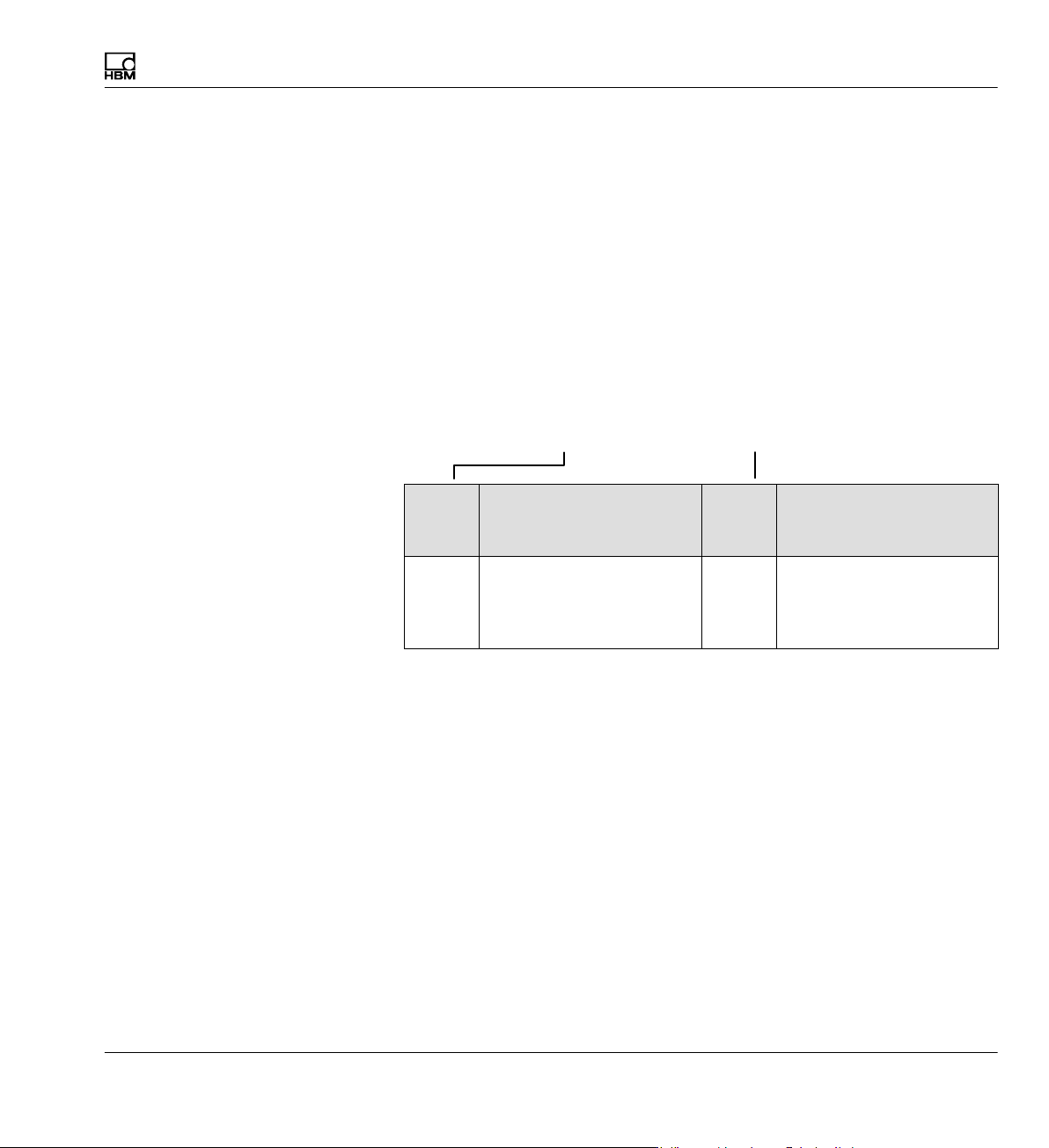

IP 2 0

Code

index

2 Protection against contact

Degree of protection

against contact and

foreign objects

with fingers, protection

against foreign objects

with > 12 mm

Code

index

0 No water protection

Degree of protection

against water

MGCplus A0534-30.0 HBM: public 17

Page 18

Introduction

Notes on documentation

3.2 Notes on documentation

The complete documentation for the MGCplus amplifier system includes the

following documents:

S The operating manual,

which explains manual operation of the device and how to perform mea

surements with it.

CD-ROMs containing the following documentation are included with every

system device:

S Operation with computer or terminal,

which contains commands for programming and measuring with com

puter or terminal.

S MGCplus Assistant,

Documentation of the program for parameterization and control of the

MGCplus measuring amplifier system.

This manual contains all the information required to operate the MGCplus.

Guides

Several guides are available to help you:

S The header shows you which section or sub-section you are currently

reading. For example:

Introduction

Notes on documentation

S See

è section 6 „Functions and symbols of the AB22A“ for explanations

of the AB22A display and control unit.

è Section 11 „Menu structure“ provides an overview of the drop-down

S

and setting menus of the display and control unit.

18 A0534-30.0 HBM: public MGCplus

Page 19

Introduction

System description

3.3 System description

The MGCplus system is structured modularly. Depending on the housing

variant, up to 16 slots are available for single and multi-channel amplifier

modules. Thus up to 128 measuring points can be measured in an

MGCplus.

Each amplifier module works independently through its own CPU. Data

preparation, for example taring, filtering and measuring range adjustment, is

carried out digitally. This eliminates the disadvantages of analog data prepa

ration, such as time and temperature-dependent drift, errors due to compo

nent tolerances, greatly limited flexibility and extensive circuitry. An essen

tial precondition for this is analog/digital conversion with no loss of

information. The digitally conditioned signal is directed to the internal bus.

For single-channel modules, two analog outputs (voltage) are available in

addition to the digital measured values.

An internal standard PC computer in credit-card format collects data with a

total sampling rate of up to 307,200 measured values per second (4-byte

integer format: 3-byte measured value + 1-byte status). All measurement

signals can be acquired in parallel, since each channel has its own ADU. No

Sample & Hold or Multiplexer is used in the MGCplus. This ensures continu

ous digital filtering and maximum signal stability.

Data is sent to an external computer or PLC via interfaces such as Ethernet.

A large part of the system functionality is implemented by device-internal

software (also called firmware). We therefore recommend you use our free

firmware updates and always keep your devices updated to the latest

firmware version. For further information go to www.hbm.com/downloads.

MGCplus A0534-30.0 HBM: public 19

Page 20

Introduction

System description

...

12 8

...

2400Hz

2400Hz

signal conditioning

Filtering, scaling,

zero balance, ...

2400Hz

Digital

CPU

8-channel

module

...

Digital signal

conditioning

Filtering

Scaling, zero

balance, ...

Single

channel

module

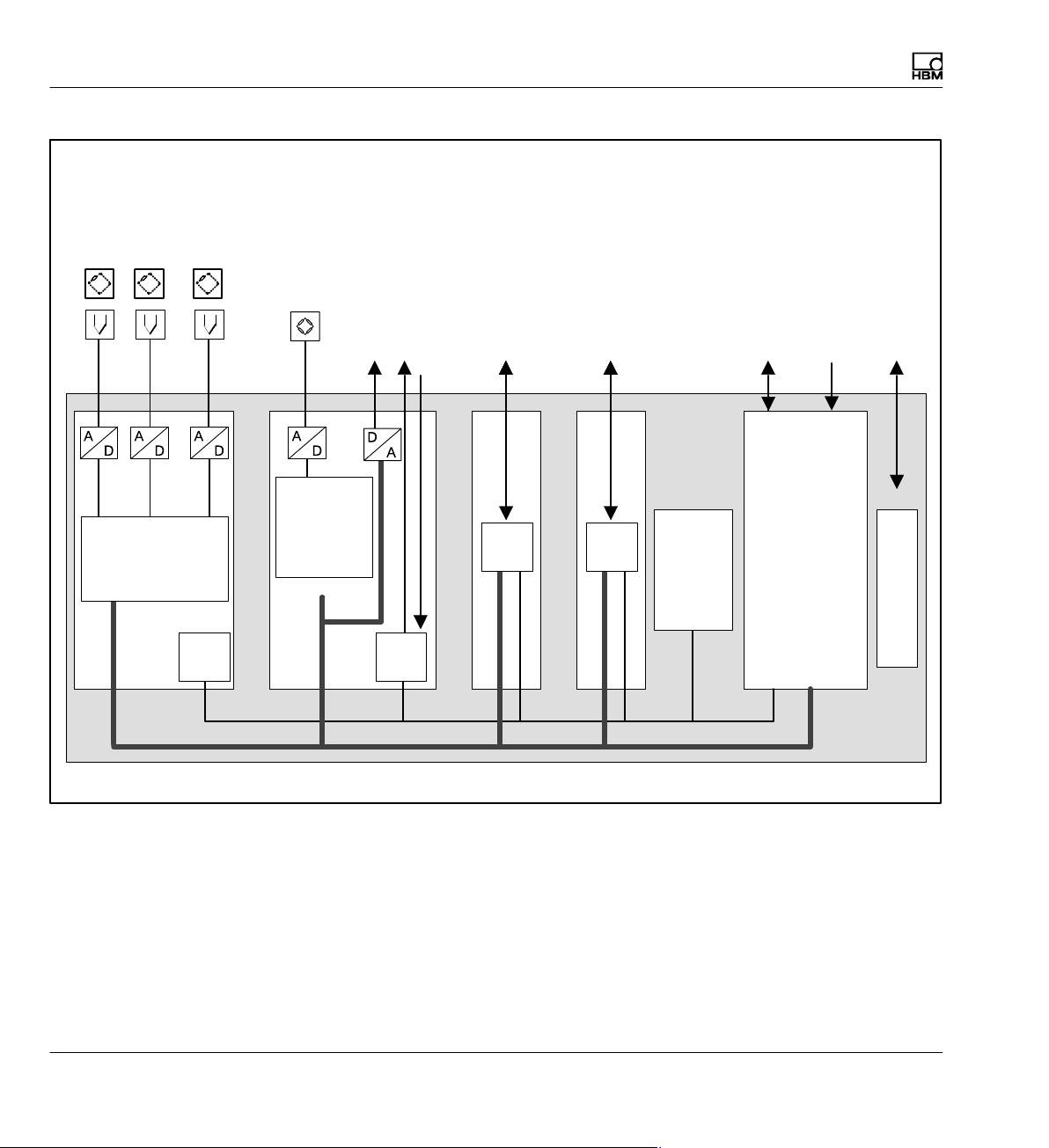

Fig. 3.1 Block diagram of MGCplus

"10V

Digital control inputs, limit

switches

...

CPU

CPU CPU

CPU

CAN

...

Profi-bus

CPU

Display

and

control

panel

Serial bus

Storage medium (optional)

Communication

processor CPxx

PC interface

Additional MGCplus

Synchronization

20 A0534-30.0 HBM: public MGCplus

Page 21

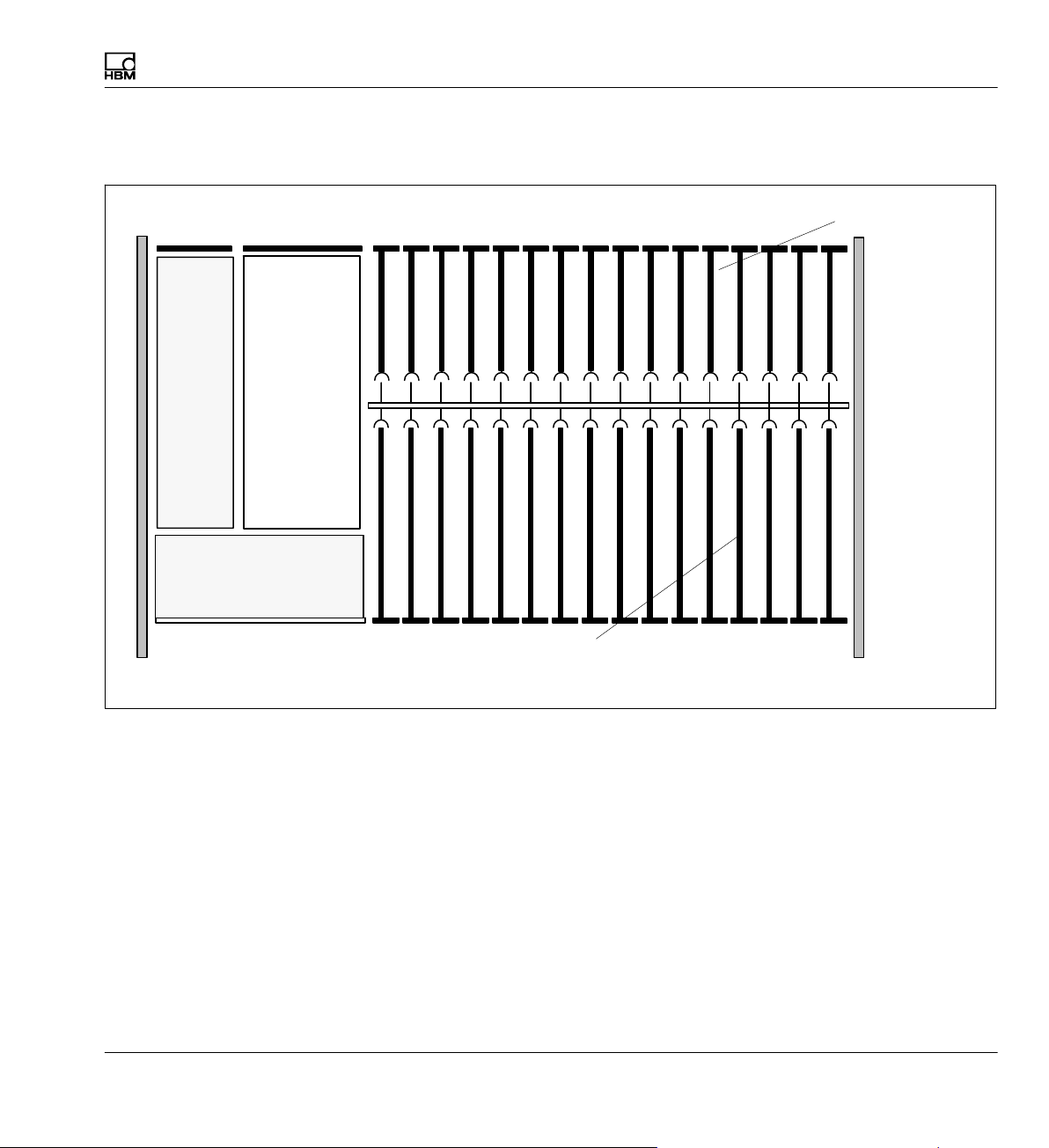

3.4 Layout of the MGCplus device

Introduction

Layout of the MGCplus device

Connection boards

(AP01i, AP815i, ...)

Power

supply

Communication

processor

AB22A

display and

control unit

CPxx

Amplifier

plug−in board

(ML30B, ML55B, ML801B...)

Fig. 3.2 Device layout with display and control unit AB22A

Double-width connection boards (AP03i, AP455i) must be plugged into the

odd-numbered slots. This also applies to the corresponding amplifiers, re

gardless of the width.

Double-width amplifiers (ML38B) must be plugged into the odd-numbered

slots. This also applies to the corresponding connection board, regardless of

the width.

When asynchronous modules are used (ML7XB with more than eight sub

channels), the sequence ‘asynchronous-synchronous-asynchronous’ is not

permissible.

MGCplus A0534-30.0 HBM: public 21

Page 22

Introduction

MGCplus housing designs

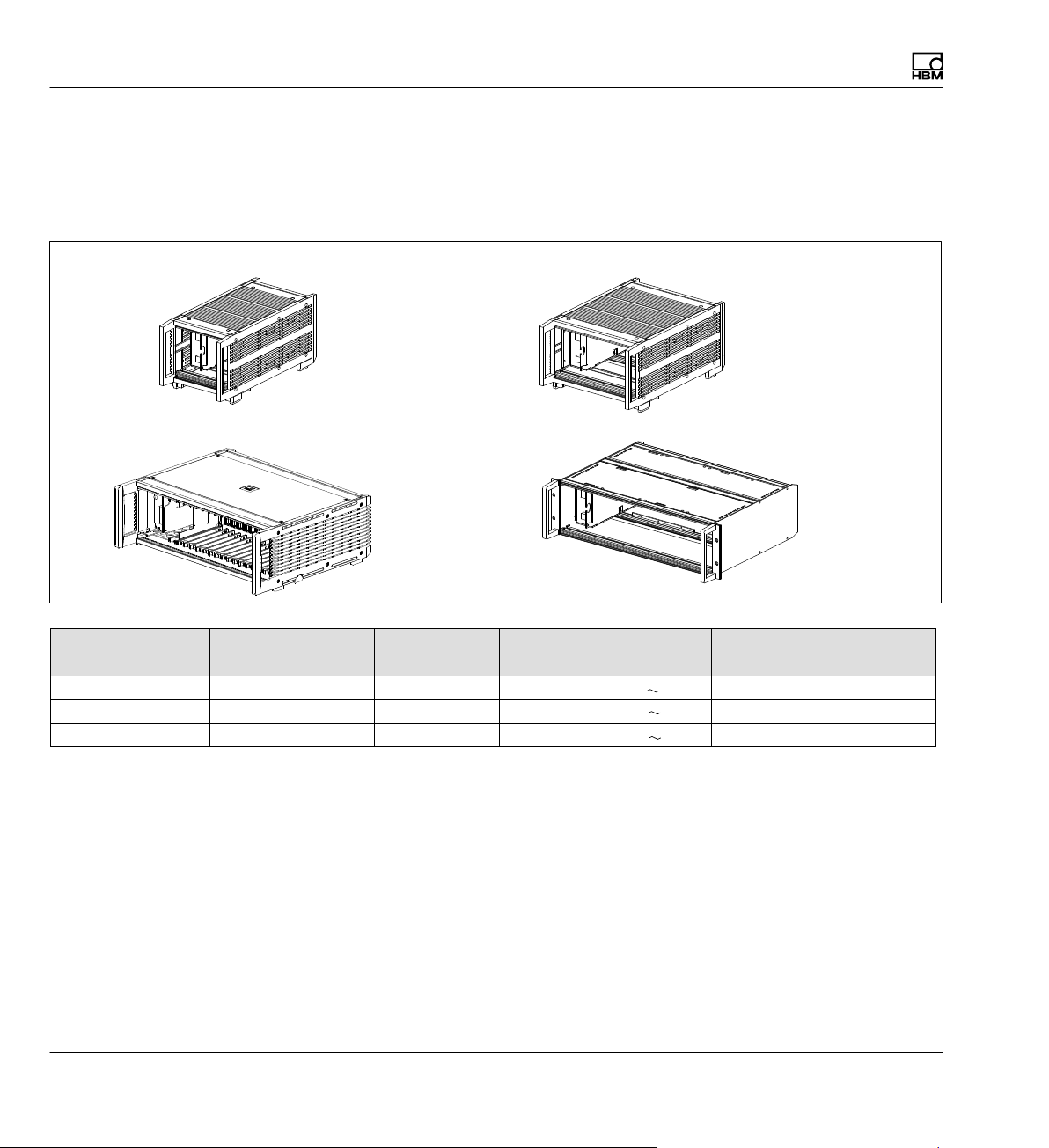

3.5 MGCplus housing designs

The MGCplus system is available with different housing versions

(dimensions in mm; 1 mm = 0.03937 inches):

Desktop housing TG009E (173x171x367) Desktop housing TG001E (255x171x367)

Desktop housing TG003E (458x171x367)

Desktop housing Rack frame Slots Supply voltage (V) Weight, approx. (kg)

TG001E − 6 230 (115) 5.9

TG003E ER003E 16 230 (115) 8.3 / 5.5

TG009E − 2 230 (115) 5.0

1)

With the NT030 power pack, the enclosures weigh about 150g less each

19” rack frame ER003E (482x133x375)

TG/ER

1)

1)

1)

All basic devices consist of the following components:

S AB22A display and control unit

S Amplifier modules (ML10B, ML30B, ML55B, ML801B ...)

S Housing

S Connection boards (AP01i, AP815i, ...)

S Power supply

Options:

S CP52 (Communication processor for communication with computer that

allows for data storage)

22 A0534-30.0 HBM: public MGCplus

Page 23

Introduction

MGCplus housing designs

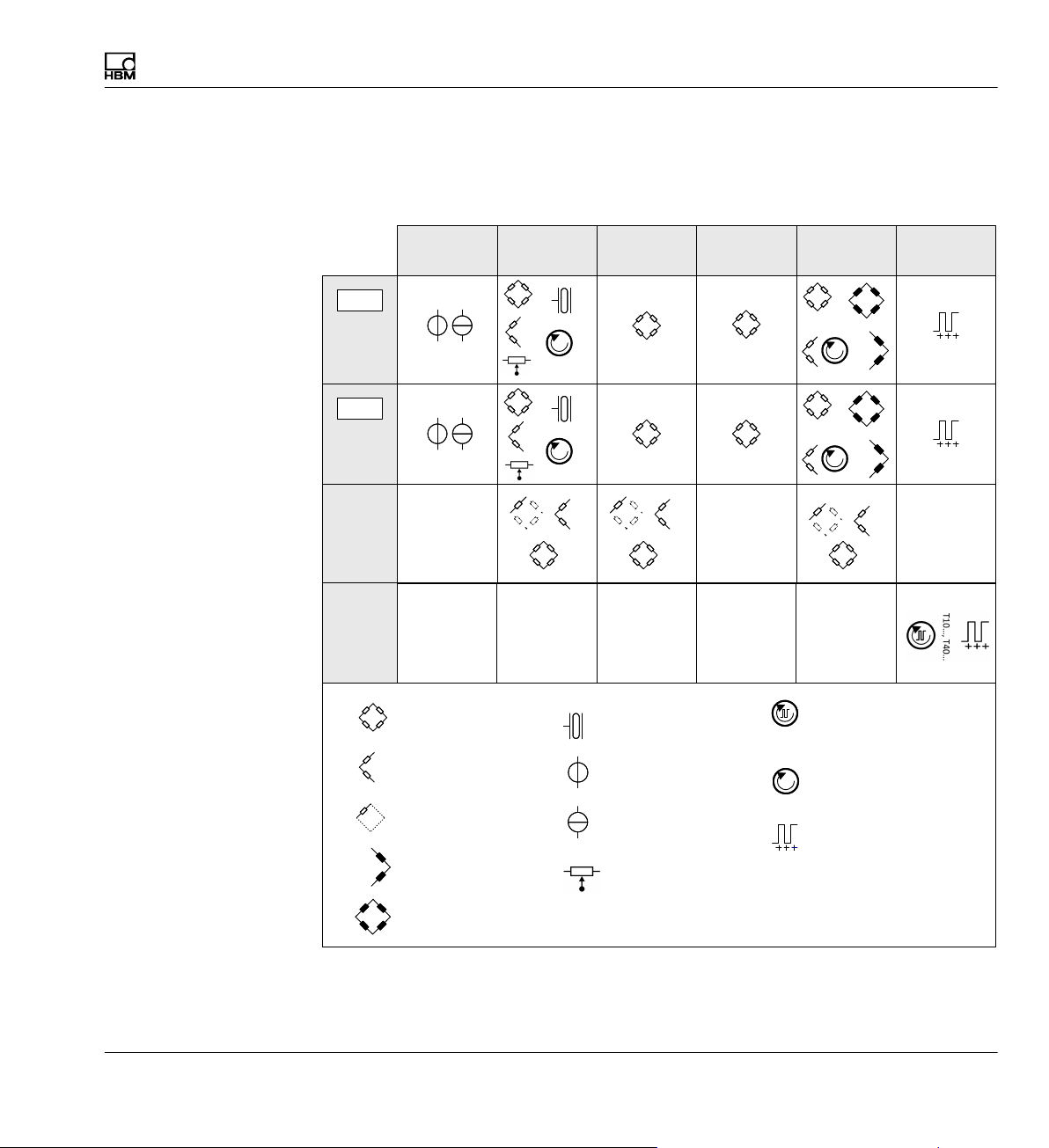

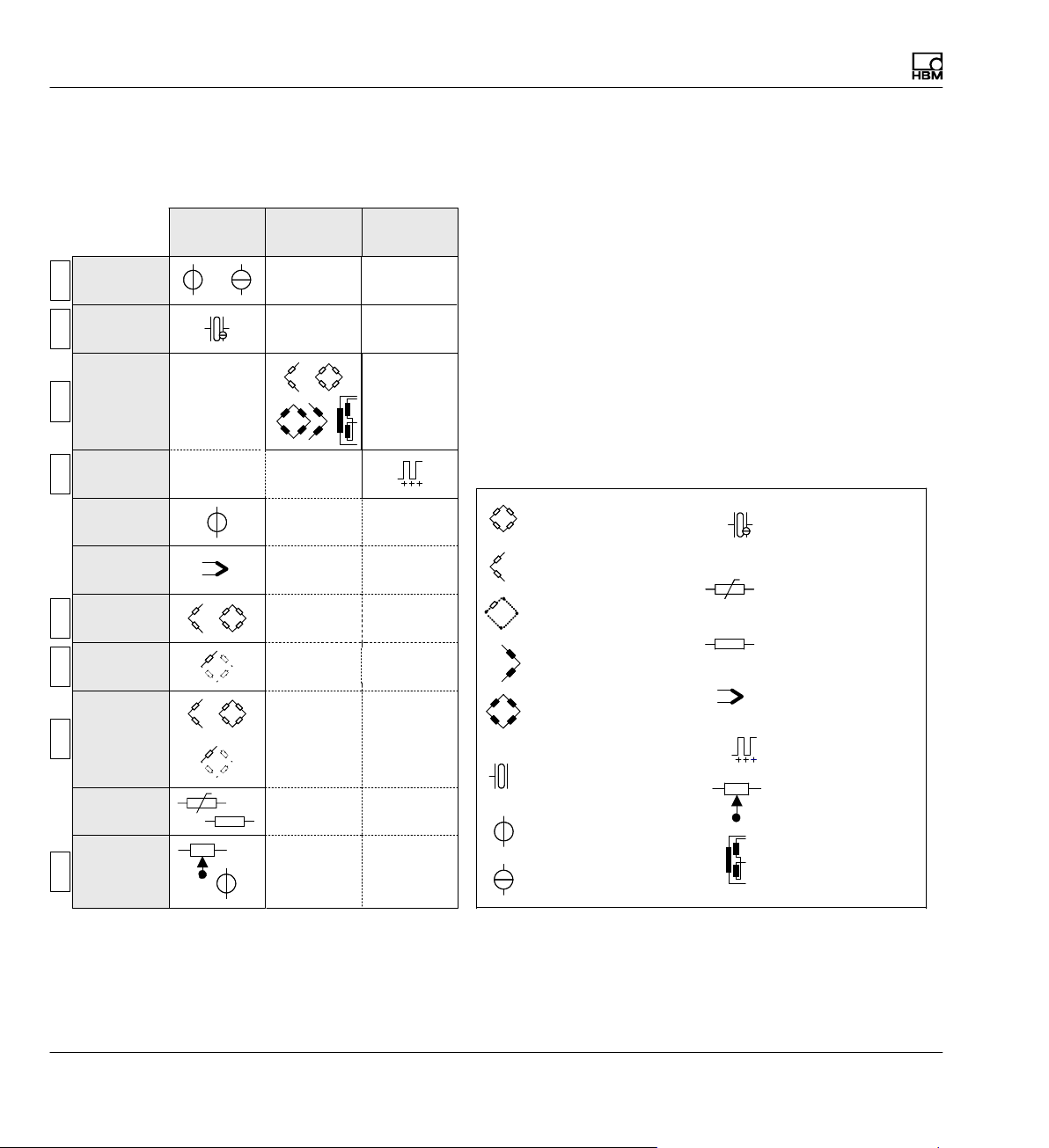

3.6 Possible amplifier/connection board combination

Single-channel amplifier

ML01B ML10B ML30B ML38B ML55B ML60B

TEDS

AP01i

TEDS

AP03i

AP14

AP17

SG full bridge circuit

SG half bridge circuit

R

1,4,5,B1

R

1,4,5,B1

R

Piezoresistive

transducer

Voltage

1,4,5,B1 1,4,5,B1

T3...T10

Torque / rotational speed

T3...T10

1,4,5,B1

Torque

T1, T4, T5, TB1

SG quarter bridge circuit

Inductive half bridge

Inductive full bridge

1)

For the combination of ML55B with AP14, a one-time zero calibration must always be

performed after setting up the measurement chain.

Current

Pulse counter, frequency

Potentiometric

transducers

MGCplus A0534-30.0 HBM: public 23

Page 24

Introduction

MGCplus housing designs

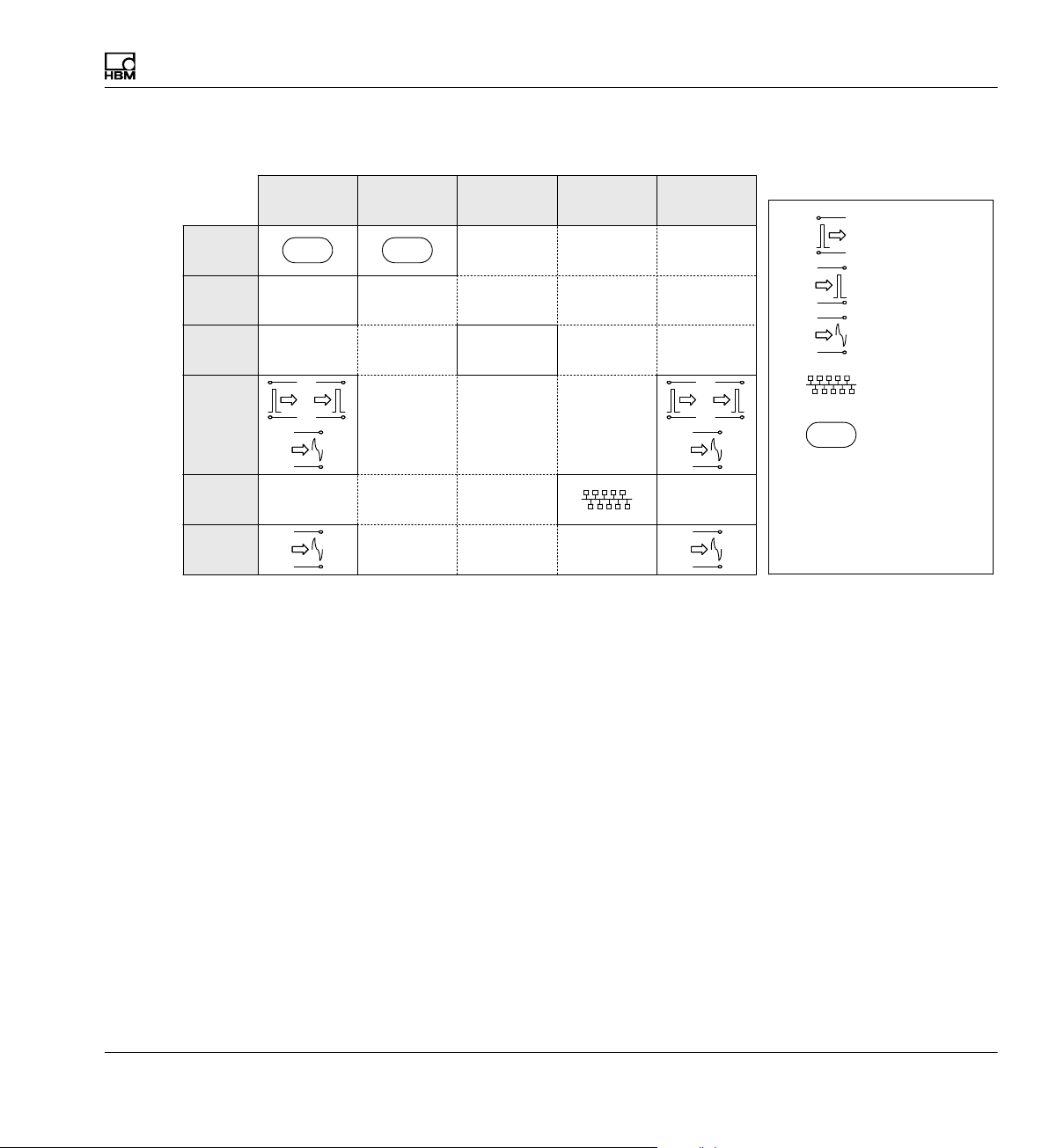

ML801B ML455 ML460

AP402i

TEDS

AP418i

TEDSTEDSTEDSTEDSTEDSTEDSTEDS

AP455i

AP455iS6

AP460i

Multi-channel amplifiers

AP801

AP801S6

AP809

AP810i

AP814Bi

AP815i

AP835

AP836i

SG full bridge circuit

SG half bridge circuit

SG quarter bridge circuit

Inductive half bridge

Inductive full bridge

R

Piezoresistive

transducer

Voltage

Current

Current−fed piezo−

electric transducer

Thermo−resistors

Thermo−resistors

PT100

PT

Ohmic resistor

Thermocouples

Pulse counter, frequency

Potentiometer

200 −5000

LVDT

24 A0534-30.0 HBM: public MGCplus

Page 25

Special function modules

Introduction

MGCplus housing designs

AP71

AP72

AP74

AP75

AP77

AP78

ML70B ML71B ML77B ML78B

CAN CAN

Serial I/O

ML74B

CANHEAD

Digital output

Digital input

Analog output

ProfiBus

CAN

CANBus

Serial I/O

CANHEAD HBM hardware

RS232, RS422,

RS485 I/O

MGCplus A0534-30.0 HBM: public 25

Page 26

Introduction

Installation of the CP52 communication processor

3.7 Installation of the CP52 communication processor

For type "D" housings (ER003D or TG001D, etc.) the existing communica

tion processor (CP22/CP42) can be replaced by the CP52 communication

processor.

► Loosen the screws on the old communication processor, the blind panel

(only with CP22) and the cover of the NT030 power supply unit.

► Remove the parts.

► Insert the new CP52 communication processor and screw it in place.

► Fit the power supply cover of the NT030 and screw the cover in place.

The process is similar when subsequently installing a CP52 communication

processor in an MGCplus housing (type "D" or type "E") that was initially

configured without a communication processor.

► Loosen the screws on the blind panels, if there are any, of the SY03 syn

chronization interface and the power supply cover.

► Remove the parts.

► Insert the new CP52 communication processor and screw it in place.

► Fit the power supply cover of the NT030 or NT040 and screw the cover

in place.

26 A0534-30.0 HBM: public MGCplus

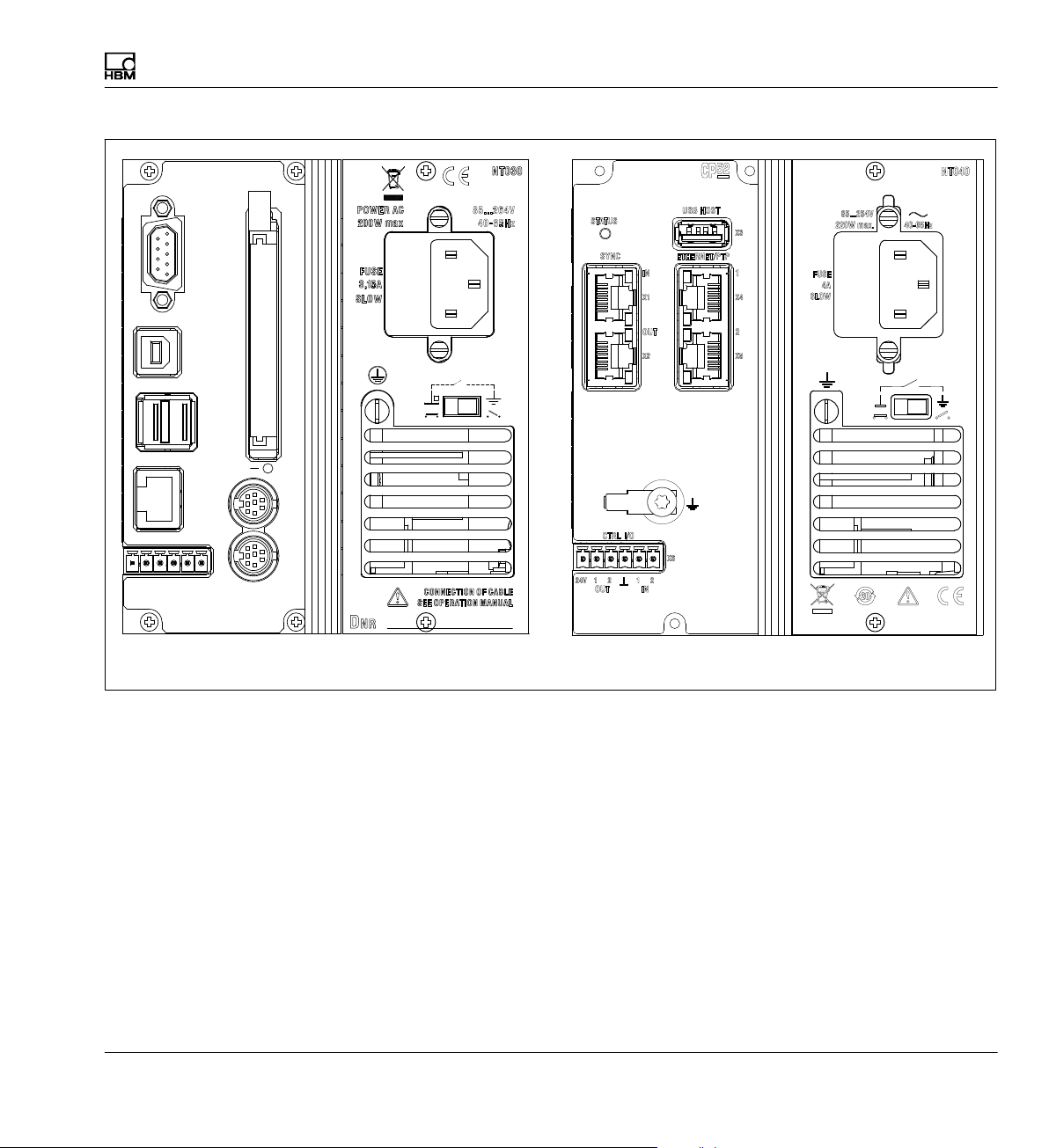

Page 27

Introduction

Installation of the CP52 communication processor

CARDBUS

YE SLAVE

RD ERROR

GN MASTER

12

IN

CP42

SYN

OU

IN

C

T

RS 232

USB DEVICE

USB HOST

ETHERNET

CTRL I/O

24V 21 GND

OUT

Communication processor CP42, power supply

unit NT030

Communication processor CP52, power supply

unit NT040

Fig. 3.3 Rear views

If the communication processor is installed subsequently in a system where

none was present before, the housing cover must also be removed to check

the setting of the CP switch (S3). It must be set to "yes" so the system can

be started with the communication processor. Then the housing cover can

be closed again.

MGCplus A0534-30.0 HBM: public 27

Page 28

Introduction

Installation of the CP52 communication processor

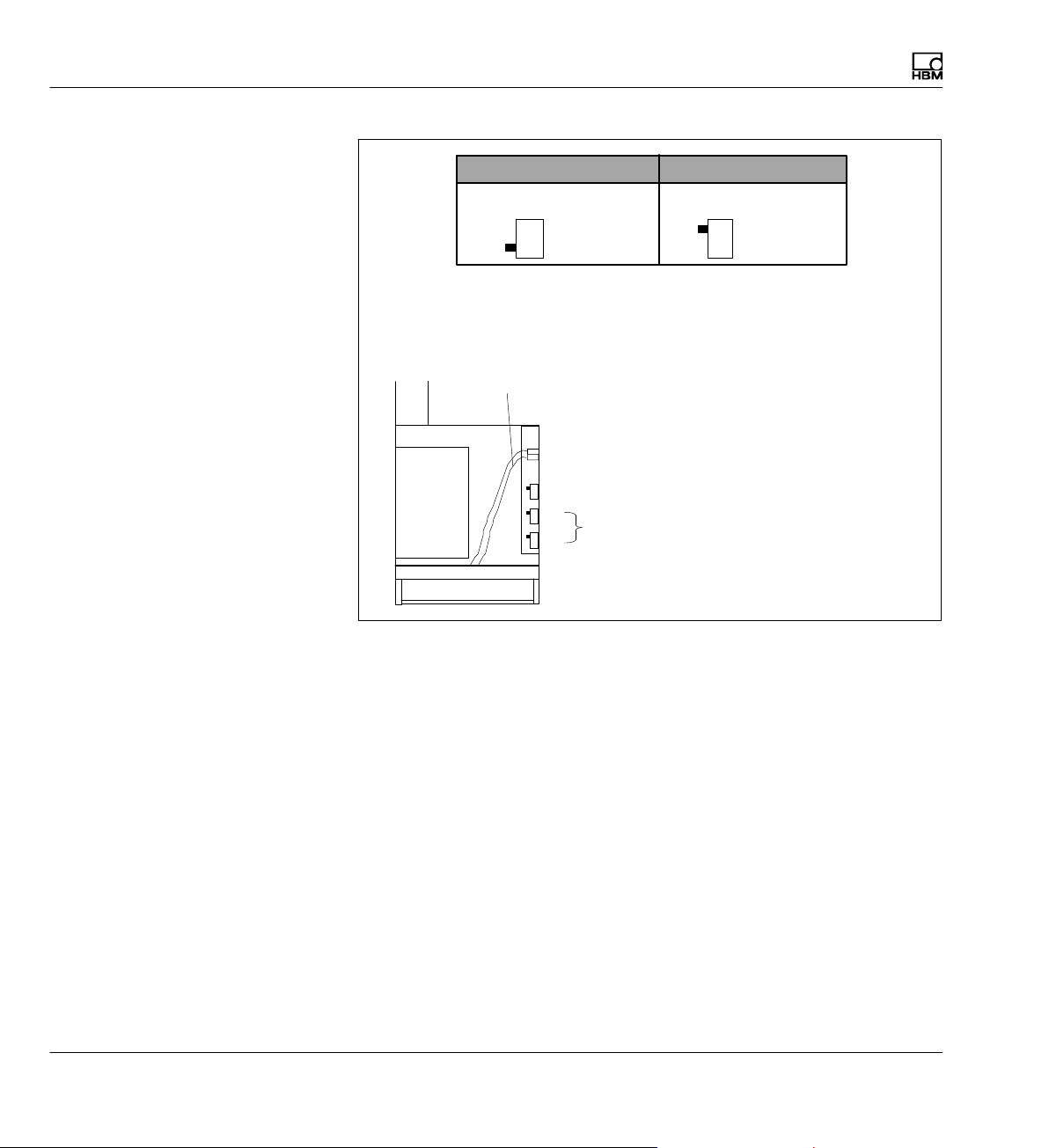

Without CP … View from above With CP … View from above

S3

CP

yes (1)

no (2)

S3

CP

yes (1)

no (2)

General plan of the interface switches(housing cover open, view from

above):

Housing

Flat ribbon

cable

S3

Power

supply

CP switch

p 2

Interface switch

S1

Fig. 3.4 General plan of the interface switches

Due to the new functions of the CP52 communication processor, a firmware

update of the AB22A display and control unit is necessary. The firmware

update program MGCpLoad and the latest firmware are available from

www.hbm.com/downloads.

28 A0534-30.0 HBM: public MGCplus

Page 29

Introduction

Conditions at the place of installation

3.8 Conditions at the place of installation

CAUTION

S Protect the devices in a desktop housing from moisture and dampness

or weather conditions such as rain, snow, etc.

S Make sure that you do not cover the ventilation openings at the side, the

openings for the power pack fan on the back side of the device and the

openings underneath the device.

S Do not expose the device to direct sunlight.

S Comply with the maximum permissible ambient temperatures for the sys

tem devices, as stated in the technical data sheet.

S For installation in 19" electrical enclosures, due to poorer heat dissipa

tion, measures must be taken to ensure that the maximum permitted am

bient temperature (refer to the technical data sheet) is not exceeded! We

recommend forced venting in any case and in especially critical cases

intermediate spaces between the upper and lower rack frames.

S The devices are classified in overvoltage category II, degree of pollution 2.

S Install the device so that it can be disconnected from the mains at any

time without difficulty.

S It is safe to operate the MGCplus up to an altitude of 2000 m.

MGCplus A0534-30.0 HBM: public 29

Page 30

Introduction

Maintenance and cleaning

3.9 Maintenance and cleaning

The MGCplus system devices are maintenance-free. Please note the follow

ing points when cleaning the housing:

CAUTION

Disconnect the mains plug from the socket before cleaning.

S Clean the housing with a soft, slightly damp (not wet!) cloth. You should

never use solvents, since this may damage the labeling on the front

panel and the display field.

S When cleaning, ensure that no liquid gets into the device or connections.

30 A0534-30.0 HBM: public MGCplus

Page 31

4 Connection

Mains

connection

Connection

Connecting the MGCplus in a tabletop housing/rack frame

4.1 Connecting the MGCplus in a tabletop housing/rack frame

4.1.1 Mains connection

The NT030 and NT040 power supply units are designed for a 115 - 230 V

connector and for a maximum configuration of 16 modules and connection

boards. Voltage adaptation to a 115V/230V network occurs automatically.

The power pack fan is temperature-controlled and is automatically switched

on only when necessary.

Housing ground

Grounding

switch

If the MGCplus is connected with the mains cable included with delivery, a

safe and reliable connection via the protective conductor is ensured.

The power pack is protected internally with a fine-wire fuse.

CAUTION

The power supply fuse may only be replaced by the manufacturer's service

personnel!

Grounding switch

In the factory setting (

zero with the protective conductor. If external devices (transducer, com

puter) have already set up this connection resulting in ground loops (hum-

pickups), the grounding switch must be opened (

), the grounding switch connects supply voltage

).

MGCplus A0534-30.0 HBM: public 31

Page 32

Connection

Connecting the MGCplus in a tabletop housing/rack frame

4.1.2 Synchronization of multiple CP52 devices

4.1.2.1 Synchronization of multiple CP52 devices via a synchronization jack

Connected devices are automatically detected and synchronized when syn

chronization jacks are occupied. Connect the master device with the first

slave device (Sync In, X1) via the output jack (Sync Out, X2). If there are

additional slave devices, connect the input jack (Sync In, X1) in turn with the

output jack (Sync Out, X2) of the previous slave device (Sync Out, X2).

LED Sync Out Status

Green Device is ready for operation and the time signal is

Yellow There is no valid time signal present on the Sync out

LED Sync In Status

Green The device is in slave mode, correctly synchronized

Yellow The device is in slave mode but is not synchronized.

present on the Sync output.

put.

and ready for operation.

Synchronization sockets

32 A0534-30.0 HBM: public MGCplus

Page 33

Connection

Connecting the MGCplus in a tabletop housing/rack frame

If several MGCplus systems are to be synchronized with each other, each

system must be equipped with a CP52 communications processor. To syn

chronize MGCplus systems with CP52, you need a synchronization cable

with the HBM part number 1-KAB2125-2 (2 m in length).

Fig. 4.1 Example of synchronizing two MGCplus systems equipped with CP52.

The overall length of the synchronization chain (total length of cable be

tween the sync master and the last sync slave) must be less than 150 m. A

termination resistor should be used if the line length is >15 m. We recom

mend that you attach a termination resistor connector to the Sync Out

socket (X2) of the last sync slave. This connector is available from HBM on

request. The maximum number of MGCplus units that can be synchronized

is 32.

MGCplus A0534-30.0 HBM: public 33

Page 34

Connection

Connecting the MGCplus in a tabletop housing/rack frame

Powering up the system

When connecting the system, the sync slaves must be connected first.

Connect the system that will work as the sync master last of all.

4.1.3 Synchronization of CP52 with CP22/CP42

The synchronization jack enables MGCplus systems with CP52 to be

synchronized with MGCplus systems with CP22/CP42.

To do this note the following points:

Both CP42 and CP52 can be the synchronization master. CP22 can only be

a synchronization slave.

Use the following cables for this:

1-KAB2126-2: CP52 (master) to CP22/CP42 (slave)

1-KAB2127-2: CP42 (master) to CP52 (slave)

The synchronization status for CP22/CP42 is indicated by a multicolor LED.

34 A0534-30.0 HBM: public MGCplus

Page 35

Connection

Connecting the MGCplus in a tabletop housing/rack frame

CP42

RS 232

CARDBUS

USB DEVICE

USB HOST

YE SLAVE

CTRL I/O

RD ERROR

GN MASTER

IN

SYNC

OUT

ETHERNET

24V 21GND12

OUT

IN

Fig. 4.2 Example of synchronizing two MGCplus systems equipped with CP52

and CP42.

MGCplus A0534-30.0 HBM: public 35

Page 36

Connection

Shielding design

4.2 Shielding design

Sources of interference can cause electromagnetic fields which can induce

interference voltages inductively or capacitively via the connection cable

and device housing in the measuring circuit and therefore interfere with the

device function. It must be ensured that the devices used in the system also

do not transmit any electromagnetic interference. Electromagnetic compati

bility (EMC), which encompasses both the required electromagnetic interfer

ence immunity (EMI) and the permissible electromagnetic interference emis

sions (EME), has become increasingly important over the years.

The HBM Greenline shielding design

The measurement chain is completely enclosed by a Faraday cage by

appropriate routing of the cable shield. The cable shield is extensively con

nected with the transducer housing and is routed via the conductive plug to

the amplifier housing. The influence of electromagnetic interference is signif

icantly reduced by these measures.

The conductive housing

ensures the connection

to the plug or device

housing

Signal-carrying

contacts

Fig. 4.3 Routing of the cable shield on the plug

The cable shield is connected with the

conductive housing via strain relief

36 A0534-30.0 HBM: public MGCplus

Page 37

Connection

Shielding design

Notice

All parts of the measurement chain (including all cable connection points

such as plugs and couplings) must be surrounded by a closed EMC-tested

shield. Shield junctions must represent a full contact, closed and low-imped

ance connection. This is the case for original HBM plug connections.

Ground connection and grounding

As the signal ground and shielding are separated in EMC-compliant cabling,

the shielding can be connected at more than one point to the ground, i.e. via

the transducer (metal housing) and the amplifier (housing is connected to

the ground conductor).

If there are differences in potential in the measuring system, a potential

compensating line must be laid (recommended value: highly flexible

stranded wire, wire cross section 10mm

set up so they are physically separated from current-carrying power lines.

Ideally, cable ducts made of sheet metal with an internal partition should be

used. Signal ground, ground and shielding must be laid out separated as

much possible.

2

). Signal and data leads must be

In order to minimize the effect of electromagnetic interference and differ

ences in potential, the signal ground and ground (or shielding) are designed

to be physically separate in the HBM devices. The ground connection or a

separate mains protective conductor should serve as the ground connec

tion, as is the case for potential compensation in buildings, for example. The

ground cable should not be connected to a radiator body, water pipe or simi

lar objects.

Connecting transducers with double shield technique

MGCplus A0534-30.0 HBM: public 37

Page 38

Connection

Shielding design

AP01i

AP14

AP03i

AP455i

1

9

A

B

G

C

15

8

Measurement signal (-)

Measurement signal (+)

2

1

4

3

Bridge excitation voltage (-)

Bridge excitation voltage (+)

Cable shield

Sense lead (+)

Sense lead (-)

15

Hsg.

13

12

A

8

5

6

B

C

D

Hsg.

F

G

4

RB / 2 (on the transducer)

Hsg. = Housing

HBM recommends this connection technique for measuring amplifiers

ML10B, ML30B, ML38B, ML55B and ML455 with connection boards

AP01i, AP03i, AP14 and AP455i with very small measuring ranges, in

environments especially subject to interference and when long cables

are used.

F

E

D

This applies to all bridge connections.

With cable lengths >50 m, a resistor with half the value of the bridge

resistance (R_B/2) must be connected in each sense lead of the trans

ducer.

38 A0534-30.0 HBM: public MGCplus

Page 39

Connection

Connecting the transducer

Measurement

signal (+)

Bridge excitation

2

1

4

3

Feedback

voltage (-)

Bridge excitation

voltage (+)

Measurement

signal (-)

Cable shield

Sense lead (+)

Sense lead (-)

bridges

4.3 Connecting the transducer

1)

Transducers with four-wire configuration

If you connect a transducer with a 4-wire cable, you must connect the sense

lead with the corresponding bridge excitation circuit in the transducer plug

(sense line (-) with bridge excitation voltage (-) and sense lead (+) with

bridge excitation voltage (+)

Important

1)

. A cable extension may only be implemented

with 6-wire configuration.

TEDS

TEDS data

AP01i

AP455i

1

8

4

9

4.3.1 Connecting separate TEDS modules

9

15

Single-channel amplifier MLxx (together with connection board AP01i) must

Important

have at least hardware revision 1.32 or higher.

1)

For cable lengths >50m, a resistor of half the value of the bridge resistance (RB/2) must be activated on the transducer instead of each

feedback bridge. If the transducers are calibrated in a 6-wire configuration, resistors must be activated directly into the sense lead.

MGCplus A0534-30.0 HBM: public 39

Page 40

Connection

Connecting separate TEDS modules

AP402i

4x

View of the mating connector

(solder side)

5

6

4

TEDS

TEDS data

Hsg.

1

3

2

1

4

3

5

40 A0534-30.0 HBM: public MGCplus

Page 41

TEDS

TEDS data

AP460i

10

1

2

4

Hsg.

9

8

Cable color code:

wh= white;

bk= black;

bu= blue;

rd= red;

ye= yellow;

gn= green;

gy= gray

8

1

67

910

3

2

Connection

Connecting separate TEDS modules

5

4

MGCplus A0534-30.0 HBM: public 41

Page 42

Connection

SG full bridges, inductive full bridges

4.3.2 SG full bridges, inductive full bridges

AP01i

AP03i

AP455iS6

AP14

AP455i

1

6

Hsg.

5

4

3

2

1

2

3

4

5

6

1

9

15

8

wh

Measurement signal (+)

bk

Bridge excitation

2

1

4

3

b

u

r

d

ye

gn

g

y

voltage (-)

Bridge excitation

voltage (+)

Measurement signal (-)

Cable shield

Sense lead (+)

Sense lead (-)

8

5

6

15

Hsg.

13

12

A

C

A

B

C

D

Hsg.

F

G

F

EB

G

D

Cable color code: wh= white; bk= black; bu= blue; rd= red; ye= yellow; gn= green; gy= gray

42 A0534-30.0 HBM: public MGCplus

Page 43

AP810i/AP815i

1

14

Subchannel 1...4

13

1

13

25

14

25

Subchannel 5...8

Full bridge circuits on AP810i/AP815i

4.3.3 Full bridge circuits on AP810i/AP815i

Subchannel

1/5

wh

Measurement signal (+)

bk

Bridge excitation

2

1

4

3

bu

rd

ye

gn

gy

voltage (-)

Bridge excitation

voltage (+)

Measurement signal (-)

Cable shield

Sense lead (+)

Sense lead (-)

)

2

1

3

15

Hsg.

16

14

Cable color code: wh= white; bk= black; bu= blue; rd= red; ye= yellow; gn= green; gy= gray

Subchannel

2/6

5

4

6

18

Hsg. Hsg.

19

17

Subchannel

3/7

8

7

9

21

22

20

Connection

Subchannel

4/8

11

10

12

24

Hsg.

25

23

MGCplus A0534-30.0 HBM: public 43

Page 44

Connection

Strain gage half bridges, inductive half bridge circuits

4.3.4 Strain gage half bridges, inductive half bridge circuits

AP01i

AP03i

AP455iS6

AP14

AP455i

1

Hsg.

5

6

4

3

2

1

2

3

5

6

A

1

9

15

8

wh

Measurement signal (+)

bk

Bridge excitation

2

1

3

b

u

ye

gn

g

y

voltage (-)

Bridge excitation

voltage (+)

Cable shield

Sense lead (+)

Sense lead (-)

8

5

6

Hsg. Hsg.

13

12

F

EB

G

D

C

A

B

C

F

G

Cable color code: wh= white; bk= black; bu= blue; rd= red; ye= yellow; gn= green; gy= gray

44 A0534-30.0 HBM: public MGCplus

Page 45

4.3.5 LVDT transducers

Connection

LVDT transducers

LVDT transducers

Measurement signal (+)

Bridge excitation voltage (-)

Bridge excitation voltage (+)

Measurement signal (-)

Cable shield

Sense lead (+)

Sense lead (-)

)

AP455i

8

5

6

15

Hsg.

13

12

AP455iS6

5

6

4

3

1

2

1

2

3

4

Hsg.

5

6

MGCplus A0534-30.0 HBM: public 45

Page 46

Connection

Strain gage half bridges on AP810i

AP810i

4.3.6 Strain gage half bridges on AP810i

1

14

1/5

Subchannel

Subchannel

2/6

Subchannel

3/7

Subchannel

4/8

Subchannel

1...4

13

1

25

14

2

1

rd

wh/rd

wh/gn

Sense lead (-)

Bridge excitation voltage (-)

Measurement signal (+)

Cable shield

Subchannel

5...8

13

25

3

wh/br

br

Bridge excitation voltage (+)

Sense lead (+)

16

14

1

2

Hsg.

3

17

20

4

5

Hsg. Hsg.

6

19

22

23

7

8

9

10

11

Hsg.

12

25

46 A0534-30.0 HBM: public MGCplus

Page 47

AP815i

Connection

Strain gage half bridges on AP815i

4.3.7 Strain gage half bridges on AP815i

1

14

1/5

Subchannel

Subchannel

2/6

Subchannel

3/7

Subchannel

4/8

Subchannel

1...4

13

1

25

14

Subchannel

2

1

4

5...8

13

25

3

rd

wh/rd

wh/gn

gn

wh/br

br

Sense lead (-)

Bridge excitation voltage (-)

Measurement signal (+)

Cable shield

Measurement signal (-)

Bridge excitation voltage (+)

Sense lead (+)

1)

1)

16

14

Hsg.

15

17

1

2

4

5

Hsg. Hsg.

18

3

6

19

20

21

22

23

7

8

10

11

Hsg.

24

9

12

25

AP815i can measure decentralized half bridge circuits for which the active

SGs are separated by a line.

1)

With decentralized half bridge circuits the measured value must be acquired at both ends of the connecting line between the active SGs.

With standard half bridge circuits a connector can also be bridged.

MGCplus A0534-30.0 HBM: public 47

Page 48

Connection

Single strain gage

4.3.8 Single strain gage

4.3.8.1 Single strain gage on AP14

AP14

1

9

15

8

SG

SG

Three-wire connection Four-wire connection

Sense lead (-)

Excitation voltage (-)

Excitation voltage (+)

Measurement signal (+),

sense lead (+)

12

5

Hsg.

15

8

48 A0534-30.0 HBM: public MGCplus

Page 49

AP814Bi

Connection

Single strain gage

4.3.8.2 Single strain gage on AP814Bi

1

14

1

1

2

3

Subchannels

4

65

7

8

Subchannel 1...8

13

25

Measurement signal (+),

excitation voltage (+)

5

2

5

5

8

SG

Cable shield

Excitation voltage (-)

Sense lead (-)

Hsg.

Hsg.

15

14

Hsg.15Hsg.

16

8

1

3

17

Hsg.5Hsg.

Hsg.

Hsg.18Hsg.

19

4

6

Hsg.

Hsg.

15

20

Hsg.21Hsg.

22

8

7

9

Hsg.11Hsg.

23

10

Hsg.24Hsg.Hsg.

25

12

Three-wire connection

Cable color code: wh= white; bk= black; bu= blue; rd= red; ye= yellow; gn= green; gy= gray

MGCplus A0534-30.0 HBM: public 49

Page 50

Connection

Single strain gage

AP815i

4.3.8.3 Single strain gage on AP815i

1

14

1/5

Subchannel

Subchannel

2/6

Subchannel

3/7

Subchannel

4/8

Subchannel

1...4

13

1

25

14

SG

2

2'

wh/rd

rd

Subchannel

5...8

13

25

1

4

wh/gn

gn

Excitation voltage (-)

Sense lead (-)

Cable shield

Measurement signal (+),

sense lead (+)

Excitation voltage (+)

15

14

Hsg.

1

4

17

Hsg. Hsg.

2

5

18

20

21

7

10

23

Hsg.

8

11

24

Cable color code: wh= white; bk= black; bu= blue; rd= red; ye= yellow; gn= green; gy= gray

50 A0534-30.0 HBM: public MGCplus

Page 51

1

13

13

1

AP815i

14

Subchannel

1...4

25

14

Subchannel

5...8

25

SG

Connection

SG chains and strain gage rosettes on AP815i

4.3.9 SG chains and strain gage rosettes on AP815i

Subchannel

1

2

2'

SG

SG

4/8

5

3/7

SG

2/6

SG

1

1

4

Excitation voltage (-)

Sense lead (-)

Cable shield

Measurement signal (+),

sense lead (+)

Excitation voltage (+)

1

14

Hsg.

2

15

Subchannel

2/6

Subchannel

5

18

3/7

Subchannel

4/8

Subchannel

5

8

21

11

24

2

15

You can operate a maximum of eight SGs at 120 ohms with a 5-V current

feed. Make certain that sensor point 2' of the SG chain is as close as possi

ble for the individual strain gages and the distances between the individual

strain gages are short.

MGCplus A0534-30.0 HBM: public 51

Page 52

Connection

SG chains and strain gage rosettes on AP815i

If the distances between the individual strain gages cannot be kept small

(for example two 90 strain gage rosettes in different places), they must be

connected as follows:

1

13

1

13

AP815i

14

Subchannel

25

14

Subchannel

25

1...4

5...8

SG2 SG1

SG4 SG3

Subchannel

1

2

2'

1

4

Excitation voltage (-)

Sense lead (-)

Cable shield

Measurement signal (+),

sense lead (+)

Excitation voltage (+)

1

14

Hsg.

2

15

Subchannel

2

5

18

Subchannel

5

2

2'

1

4

Excitation voltage (-)

Sense lead (-)

Cable shield

Measurement signal (+),

sense lead (+)

Excitation voltage (+)

1

14

Hsg.

2

15

Subchannel

6

5

18

52 A0534-30.0 HBM: public MGCplus

Page 53

Connection

Torque flange T10 series, T40 series

4.3.10 Torque flange T10 series, T40 series

4.3.10.1 Torque measurement

Plug 1

Md

23

7/5 6

4

1

bk

bu

r

d

w

h

ye

gn

g

y

Power supply (0V)

Supply voltage (18V ... 30 V)

Torque measurement signal, frequency output (+)

Torque measurement signal, frequency output (-)

Cable shield

Calibration signal trigger (approx. 5V)

Ground

1)

AP17

1

9

15

8

5

6

12

13

Hsg.

14

8

Cable color code: wh= white; bk= black; bu= blue; rd= red; ye= yellow; gn= green; gy= gray

1)

Does not apply to version KF1.

MGCplus A0534-30.0 HBM: public 53

Page 54

Connection

Torque flange T10 series, T40 series

AP460i

Plug 1

Md

7/5

r

4

1

d

w

h

ye

gn

g

y

Torque measurement signal, frequency output (+)

Torque measurement signal, frequency output (-)

Cable shield

Ground

1

2

Hsg.

10

Cable color code: wh= white; bk= black; bu= blue; rd= red; ye= yellow; gn= green; gy= gray

8

1

67

910

3

2

5

4

Information

The torque flanges must be powered externally.

54 A0534-30.0 HBM: public MGCplus

Page 55

Connection

Torque flange T10 series, T40 series

4.3.10.2 Rotational speed measurement (symmetrical signals)

AP17

1

8

9

15

Plug 2

81

6

7

3

n

bk

and

bu

rd

wh

gn

g

y

Ground

Rotational speed measurement signal, 0 (+)

Rotational speed measurement signal, 0 (-)

Rotational speed measurement signal, 90 (-)

Cable shield

Rotational speed measurement signal, 90 (+)

8

12

13

14

Hsg.

15

Cable color code: wh= white; bk= black; bu= blue; rd= red; ye= yellow; gn= green; gy= gray

MGCplus A0534-30.0 HBM: public 55

Page 56

Connection

Torque flange T10 series, T40 series

AP460i

Plug 2

n

81

3

6

7

ye

rd

wh

gn

g

y

Ground

Rotational speed measurement signal, 0 (+)

Rotational speed measurement signal, 0 (-)

Rotational speed measurement signal, 90 (-)

Cable shield

Rotational speed measurement signal, 90 (+)

10

1

2

4

Hsg.

3

Cable color code: wh= white; bk= black; bu= blue; rd= red; ye= yellow; gn= green; gy= gray

8

1

67

910

3

2

5

4

56 A0534-30.0 HBM: public MGCplus

Page 57

Connection

Torque flange T10 series, T40 series

4.3.10.3 Rotational speed measurement (symmetrical signals) with reference pulse

AP17

1

8

Plug 2

n

81

4

3

6

7

2

ye

rd

wh

gn

b

u

bk

g

y

Ground

Rotational speed measurement signal, 0 (+)

Rotational speed measurement signal, 0 (-)

Rotational speed measurement signal, 90 (-)

Cable shield

Reference signal (+)

Reference signal (-)

Rotational speed measurement signal, 90 (+)

5V (out)

8

12

13

14

Hsg.

2

3

15

11

9

15

Cable color code: wh= white; bk= black; bu= blue; rd= red; ye= yellow; gn= green; gy= gray

MGCplus A0534-30.0 HBM: public 57

Page 58

Connection

Torque flange T10 series, T40 series

AP460i

Plug 2

n

81

3

4

6

7

2

ye

rd

wh

gn

b

u

bk

g

y

Ground

Rotational speed measurement signal, 0 (+)

Rotational speed measurement signal, 0 (-)

Rotational speed measurement signal, 90 (-)

Cable shield

Reference signal (+)

Reference signal (-)

Rotational speed measurement signal, 90 (+)

10

1

2

4

Hsg.

5

6

3

Cable color code: wh= white; bk= black; bu= blue; rd= red; ye= yellow; gn= green; gy= gray

8

1

67

910

3

2

5

4

58 A0534-30.0 HBM: public MGCplus

Page 59

Connection

Torque shaft (T4A, T5, TB1A)

4.3.11 Torque shaft (T4A, T5, TB1A)

4.3.11.1 Torque measurement (slip rings or direct cable connection)

AP01i

AP14

2)

AP03i

AP455i

A

F

E

B

G

D

C

A

B

C

D

F

G

wh

bk

2

1

3

Feedback bridges for

transducer in a four wire

configuration *

2)

SG full bridge only

*)

Transducer in a 6-wire configuration: see connection diagram

page 42

b

u

r

d

4

ye

Measurement signal (+)

Bridge excitation

voltage (-)

Bridge excitation

voltage (+)

Measurement signal (-)

Cable shield

Sense lead (+)

Sense lead (-)

1

9

15

8

8

5

6

15

Hsg. Hsg.

13

12

Cable color code: wh= white; bk= black; bu= blue; rd= red; ye= yellow; gn= green; gy= gray

MGCplus A0534-30.0 HBM: public 59

Page 60

Connection

Torque shaft (T4A, T5, TB1A)

Jumper (factory settings 0V)

Supply voltage +16V

No function (for special versions only)

No function (for special versions only)

Supply voltage +8V

Supply voltage +5V

Connection board AP 460 (side view)

60 A0534-30.0 HBM: public MGCplus

Page 61

Connection

Torque shaft (T4A, T5, TB1A)

4.3.11.2 Rotational speed measurement with inductive transducers

AP460i

Rotational speed

Inductive

measurement signal

Rotational speed

measurement signal

(+)

U

= 30V

max

(-)

tachometer

(T-R coil)

Please note the setting information for T-R coils on page 152.

67

8

1

910

2

3

5

4

1

1 k 5 k

5 V

2

MGCplus A0534-30.0 HBM: public 61

Page 62

Connection

Thermocouples

4.3.12 Thermocouples

Thermocouple

Compensating

Compensating

line

(-)

(+)

line

Miniature thermo connector (see

table for matching type)

AP809

-

−

+

+

Miniature thermo connector, uncompensated

Type Thermal material 1 (+) Thermal material 2 (-)

J Iron Copper-nickel

K Nickel‐chrome (color code

green)

Nickel‐aluminum (color code

white)

T Copper Copper-nickel

62 A0534-30.0 HBM: public MGCplus

Page 63

4.3.13 DC voltage sources

Maximum input voltage against

ground = 12V

DC voltage sources

AP01i AP03i

1

9

15

8

A

B

C

F

E

G

D

Connection

U

(+)

Supply voltage zero

1)

(-)

Cable shield

1)

With a potential-free DC voltage source you must connect pin 15 with pin 6.

8

6

15

Hsg. Hsg.

A

C

D

MGCplus A0534-30.0 HBM: public 63

Page 64

Connection

DC voltage sources

AP402i

Maximum input voltage against

ground = " 100V

U

(+)

(-)

Cable shield

Hsg.

4x

1

4

5

6

1

4

3

2

64 A0534-30.0 HBM: public MGCplus

Page 65

Connection

DC voltage sources

Maximum input voltage against

ground = +50V

(+)

U

(-)

AP801

Hsg.

U

Supply voltage 8V/16V

Power supply 0V

*) For information on switching the supply voltage see next page

AP801S6

41

2

(+)

(-)

*)

Hsg.

3

1

2

3

4

MGCplus A0534-30.0 HBM: public 65

Page 66

Connection

DC voltage sources

Supply voltage +16V

No function (for special versions only)

Jumper

Connection board AP 801S6 (side view)

No function (for special versions only)

Supply voltage +8V

66 A0534-30.0 HBM: public MGCplus

Page 67

AP402i

4x

Connection

DC voltage sources

5

6

4

U

Supply voltage 5V/8V/16V

Power supply 0V

*)

For information on switching the supply voltage see next illustration

*)

Jumper

1

3

2

(+)

(−)

1

4

6

3

Hsg.

Supply voltage +5V

Supply voltage +8V

Supply voltage +16V

No function (factory setting)

Connection board AP402i (side view)

MGCplus A0534-30.0 HBM: public 67

Page 68

Connection

DC voltage sources

AP836i

1

13

AP836i

1

Subchannels

2/61/5 3/7 4/8

14

Subchannel 1...4

25

Subchannel 5...8

U

0 V

(+)

B

U

OUT

Bridge excitation voltage (+)

Sense lead (+)

Measurement signal (+)

Measurement signal (-)

Cable shield

Sense lead (-)

Bridge excitation voltage (-)

1)

16

15

14

3

2

Hsg.

1

19

18

17

Hsg.

6

9

22

5

8

21

Hsg.

20

4

7

12

25

24

23

10

Common signal and supply voltage zero, power line not corrected on one side.

Since the bridge excitation voltage used to supply the active transducer is symmetrical to GND/ground, the

design of the active transducer must without exception be potential-free!

Subchannels

2/61/5 3/7 4/8

14

11

Hsg.

Subchannel 1...4

13

25

Ub(-)

U

(+)

B

U_

OUT

0 V

Subchannel 5...8

Bridge excitation voltage (+)

Sense lead (+)

Measurement signal (+)

Measurement signal (-)

Cable shield

Sense lead (-)

Bridge excitation voltage (-)

1)

16

15

14

3

2

Hsg.

1

19

18

17

Hsg.

6

9

22

5

8

21

Hsg.

20

4

7

12

25

11

24

Hsg.

23

10

Separate signal and supply voltage zero, power lines not corrected

Since the bridge excitation voltage used to supply the active transducer is symmetrical to GND/ground, the

design of the active transducer must without exception be potential-free!

68 A0534-30.0 HBM: public MGCplus

Page 69

Connection

DC voltage sources

AP836i

1

13

AP836i

1

Subchannels

2/61/5 3/7 4/8

14

Subchannel 1...4

25

Subchannel 5...8

U

(+)

B

U_

OUT

0 V

Bridge excitation voltage (+)

Sense lead (+)

Measurement signal (+)

Measurement signal (-)

Cable shield

Sense lead (-)

Bridge excitation voltage (-)

1)

16

15

14

Hsg.

3

2

1

19

18

17

Hsg.

6

22

5

21

Hsg.

20

4

Common signal and supply voltage zero, power lines fully corrected.

Since the bridge excitation voltage used to supply the active transducer is symmetrical to GND/ground,

the design of the active transducer must without exception be potential-free!

Subchannels

2/61/5 3/7 4/8

14

12

9

25

8

11

24

Hsg.

23

10

7

Subchannel 1...4

13

25

U

(+)

B

U_

OUT

0 V

U

(-)

B

Subchannel 5...8

Bridge excitation voltage (+)

Sense lead (+)

Measurement signal (+)

Measurement signal (-)

Cable shield

Sense lead (-)

Bridge excitation voltage (-)

1)

16

15

14

Hsg.

3

2

1

19

18

17

Hsg.

6

22

5

21

Hsg.

20

4

12

9

25

8

11

24

Hsg.

23

10

7

Separate signal and supply voltage zero, power lines fully corrected.

Since the bridge excitation voltage used to supply the active transducer is symmetrical to GND/ground, the

design of the active transducer must without exception be potential-free!

MGCplus A0534-30.0 HBM: public 69

Page 70

Connection

DC power sources

4.3.14 DC power sources

Maximum input voltage against

ground = 12V

AP01i AP03i

1

9

15

8

A

B

C

F

E

G

D

Supply voltage zero

(-)

6

C

I

(+)

Cable shield

5

Hsg.

B

Hsg.

70 A0534-30.0 HBM: public MGCplus

Page 71

Maximum input voltage against

ground = ±100V

AP402i

4x

Connection

DC power sources

5

6

1

4

3

2

(-)

4

I

(+)

Cable shield

2

Hsg.

MGCplus A0534-30.0 HBM: public 71

Page 72

Connection

Resistors, Pt100

4.3.15 Resistors, Pt100

AP835

1

2

Excitation voltage (-)

Measurement signal (-)

R

Cable shield

Measurement signal (+)

Excitation voltage (+)

4

3

1

2

Hsg.

3

4

72 A0534-30.0 HBM: public MGCplus