Page 1

600 Hz Measuring Amplifier

for strain gauge transducers

measuring frequency 0...60 Hz

ME30

Operating manual

B 31.ME30.11 e

Page 2

Page 3

3

ME 30

Contents Page

Safety instructions 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Measuring Amplifiers on Eurocards ME30 8. . . . . . . . . . . . . . . . . . . . . . . .

2 Electrical Connection 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Transducer Connection 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Supply Voltage 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Output 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Supply Voltage for Additional Units 10. . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 Pin Assignment 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Putting into Operation 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Select Measuring Range 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Bridge Zero Balancing 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 MR Fine Adjustment 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Individual Settings 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Operational Setting 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Setting the Measuring Range 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 External Fine Balancing of the MR1 15. . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Bridge Fine Balancing 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Calibration signal 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 Measuring Frequency Range / Cut-off Frequency fco 17. . . . . . . . . . .

4.7 Synchronization 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Options 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Stabilized Power Supply 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 DC-DC Converter 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Current Output Module 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Safety Barriers for use in Hazardous Areas 19. . . . . . . . . . . . . . . . . . .

5.5 Additional Units 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 General Notes 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Disturbances 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Technical Data 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Component Layout 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Copy of Declaration of Conformity 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 4

4

ME 30

Safety instructions

In order to ensure sufficient immunity from disturbance only use Greenline

shielding (see HBM’s special publication ”Greenline” Screening Concept, electromagnetic compatibility of measuring cable, G36.35.0)

The connection lines’ ( ≤ 50V) minimum insulation strength must be

350V(AC).

Appropriate use

The ME30 with the connected transducers may be used for measurement and

directly related control and regulation tasks, only. Any other use is not appropriate.

To ensure safe operation, the ME30 may only be used according to the specifications given in this manual. When using the transducer, the legal and safety

regulations for the respective application must also be observed. The same

applies if accessories are used.

General dangers in the case of non-observance of the safety instructions

The ME30 complies with the state of the art and is operationally reliable. If the

device is used and operated inappropriately by untrained personnel, residual

dangers might develop.

Any person charged with device installation, operation, maintenance or repair

must in any case have read and understood the operating manual and the

safety instructions, in particular.

Conditions on site

Protect the device from moisture or atmospheric influences such as rain,

snow, etc.

Page 5

5

ME 30

Maintenance and cleaning

The Clip Electronic are maintenance-free. Please note the following points

when cleaning the front panel:

• Remove the mains plug from the socket before cleaning.

• Clean the front panel with a soft, slightly damp (not wet!) cloth. Never use

solvents, since they may damage the labelling on the front panel.

• When cleaning, please ensure that no liquid finds its way into the device or

onto the contacts.

Residual dangers

The ME30 scope of performance and supply covers part of the measuringtechnology, only. The plant designer/constructor/operator must in addition design, realise and take responsibility for the measuring-system’s safety such

that potential residual dangers are minimized. The respective regulations

must in any case be observed. Residual dangers regarding the measuring

system must be specified explicitly.

If there is any risk of remaining dangers when working with the, it is pointed

out in this introduction by means of the following symbols:

Symbol:

DANGER

Meaning:

Maximum danger level

Warns of a decidedly dangerous situation in which failure to comply with

safety requirements can lead to death or serious physical injury.

Symbol: WARNING

Meaning:

Possibly dangerous situation

Warns of a potentially dangerous situation in which failure to comply with

safety requirements can lead to death or serious physical injury.

Page 6

6

ME 30

Symbol:

CAUTION

Meaning:

Dangerous situation

Warns of a possibly dangerous situation in which failure to comply with safety

requirements can cause damage to property or lead to some form of physical

injury.

Symbol:

NOTE

Means that important information about the product or its handling is being

given.

Symbol

:

Meaning: CE mark

The CE mark is a guarantee by the manufacturer that his product meets the

requirements of the relevant EG Directives (see declaration of conformity at

the end of these operating instructions).

Page 7

7

ME 30

Safe operation

Do only quit error messages if the reason for the error has been eliminated

and there is no more danger.

Reconstruction and modifications

HBM’s express consent is required for modifications regarding the ME30

construction and safety. HBM does not take responsibility for damage resulting from unauthorized modifications.

In particular, repair and soldering works on the boards are prohibited. If complete componentry is replaced use original HBM components, only.

Qualified personnel

The device may be used by qualified personnel, only; the technical data and

the special safety regulations must in any case be observed. When using the

device, the legal and safety regulations for the respective application must

also be observed. The same applies if accessories are used.

Qualified personnel means: personnel familiar with the installation, mounting,

start-up and operation of the product, and trained according to their job.

Maintenance and repair work on an open device with the power on should

only be undertaken by trained personnel who are aware of the above-mentioned dangers.

Page 8

8

ME 30

1 Measuring Amplifiers on Eurocards ME30

The Eurocards ME30 is a 600 Hz carrier frequency amplifiers for strain gauge

transducers. An aluminium front panel (4 divs. wide) is delivered as standard.

Aplasticcs handle can be mounted instead of it if ordered separately.

All plug-in cards are delivered without housing without power supply unit so

that a 19” rack frame can be set up as required. Owing to the narrow width of

the plug-in cards (4 divs = 20.32mm) up to 21 cards can be inserted into a 19”

rack. The dimensions and connecting details correspond to the IEC standards

48D and 297.

All controls are accessible from the front.

Individual adjustments are described in chapter four; ex-works settings are

specified on the back of the Eurocard.

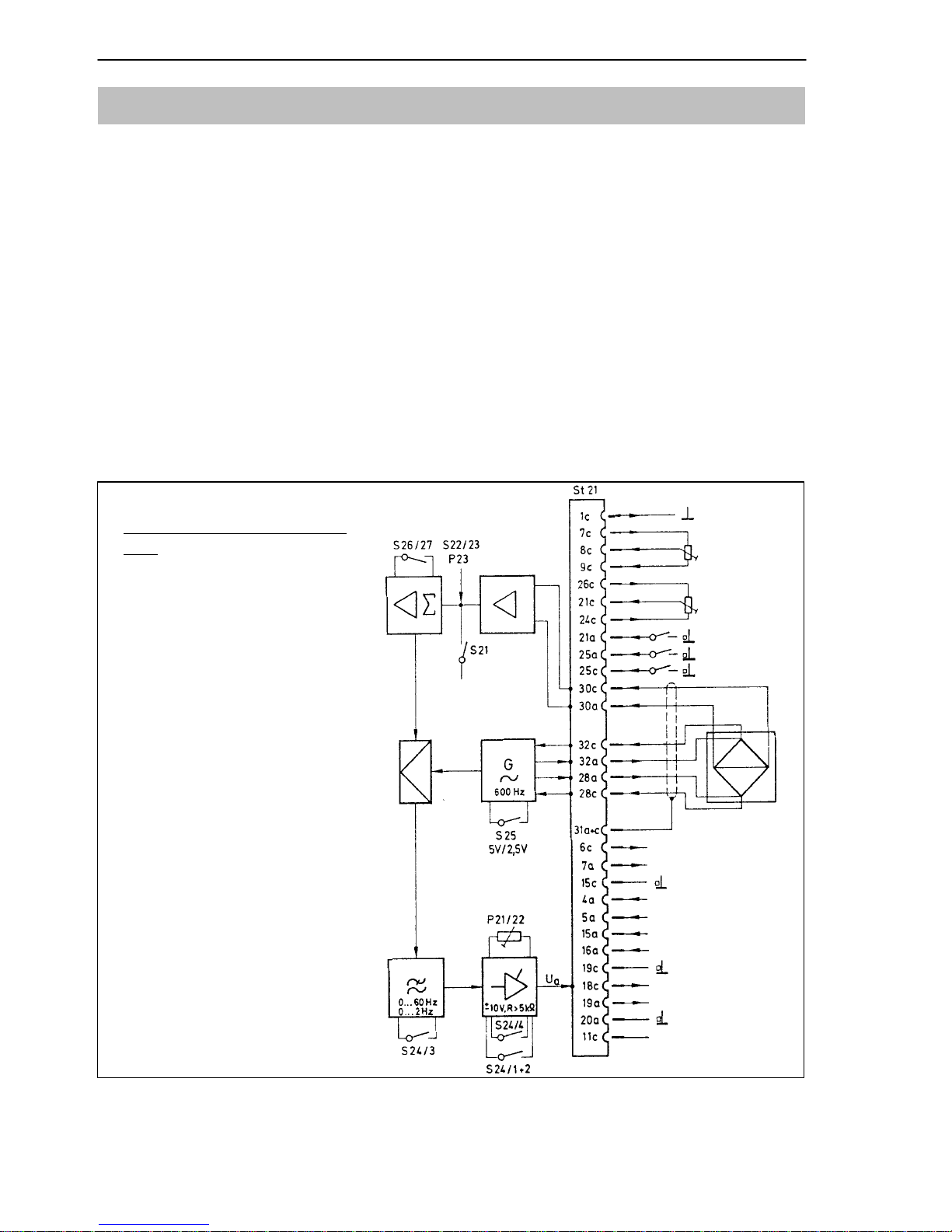

Notes for the diagram on the

right

S21:

calibration – measuring – zero

S22/23:

zero balancing (coarse)

S24/1+2:

MR1 fine balancing

internal/external

S24/3:

switch for measuring frequency

range 60Hz to 2Hz

S24/4:

MR changeover from MR1 to

MR2

S25:

switching the bridge excitation

voltage

S26/27:

setting of measuring range

(coarse)

P21/22:

fine balancing of MR

P23:

zero balancing (fine)

Cal. +1mV/V

zero

MR1

fine balancing

external

5kΩ

50kΩ

zero balancing

external

zero

calibr.

MR1–2

wh

gy

bk

bu

gn

14.5...15.5V <50mA

14.5...15.5V <50mA

–

+ 9V...+35V

(opt. DC/DC converter)

U

B

+14.5...+15.5V

UB –14.5...–15.5V

U

a

10V >5kOhm

option Ia 20mA

2.33V

ss

synchr.-voltage

or synchr. input

+

–

Fig. 1.1: Block diagram

Page 9

9

ME 30

2 Electrical Connection

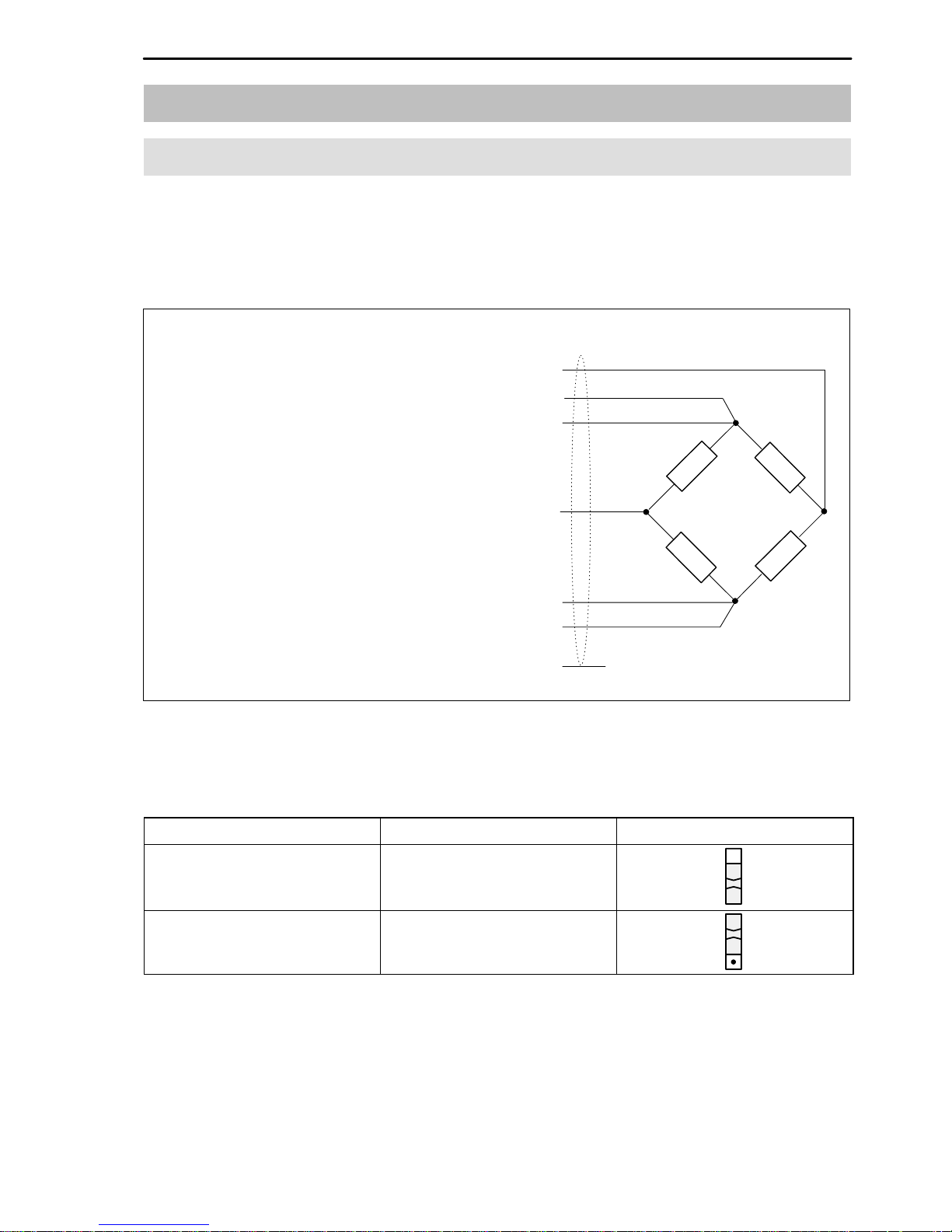

2.1 Transducer Connection

Strain gauge transducers are connected by means of 6-wire circuits.

With transducers in 4-wire technology the sensing leads are not needed. In

this case the contacts 32a+c and 28a+c on the connector must be linked.

screen pins 31a+c. . . . . . . . . . . . . . . . . .

rd

gy

bk

wh

bu

gn

ye

measuring signal (–) pin 30a. . . . . .

sensing line to 32a (–) pin 32c. . . . .

bridge supply voltage (–) pin 32a. .

measuring signal (+) pin 30c. . . . . .

bridge supply voltage (+) pin 28a. .

sensing line to 28c (+) pin 28c. . . . .

contact

(alternatively 29a+c)

Fig. 2.1: Bridge connection

The required bridge excitation voltage set by the factory is 5V(symmetrical

about ground). It can be switched to 2.5V by switch S25.

U

B

Bridge resistance Switch S25

2.5V R

B

≥60...4000Ω

5V

(ex-works settings)

R

B

≥110...4000Ω

The safety barriers SD01 must be wired into the connecting lines (see chapter 5.4) for transducers in EEx(i) design.

Page 10

10

ME 30

2.2 Supply Voltage

a) stabilized double-pole supply voltage

+14.5...+15.5V (max.70mA) . . . . . . . . . . .

–14.5...–15.5V (max.65mA) . . . . . . . . . . .

operating voltage zero . . . . . . . . . . . . . . .

The ripple on the supply voltage should not exceed 0.1V peak-to–peak. The

supply connections are internally protected against reverse polarity. Single

sided connection of the supply voltage should be avoided. The supply voltage

should be kept as low as possible within the permissible range of

±15.6...±25V in order to maintain the dissipation at a low value.

b) unstabilized double-pole supply voltage

If a stabilized voltage is not available, the amplifier can be operated by means

of a stabilizer(unstabilized supply) or a DC-DC converter (single-pole supply,

battery) (see chapter 5.1 and 5.2).

2.3 Output

output voltage: ±10V; RL ≥5 kΩ . . . . . . . .

operating voltage zero . . . . . . . . . . . . . . .

The output is provided for the connection of a display and/or recorders.

A current output is possible optionally (see chapter 5.3).

2.4 Supply Voltage for Additional Units

Stabilized voltages are available for current supply of additional function units.

+14.5V...+15.5V ; <50mA . . . . . . . . . . . . .

–14.5V...–15.5V ; <50mA . . . . . . . . . . . . .

operating voltage zero . . . . . . . . . . . . . . .

pin15a

pin16a

pin19c

+

pin18c

pin 20a

±

+

pin6c

pin 7a

pin15c

–

–

Page 11

11

ME 30

2.5 Pin Assignment

64-pin right angle plug

1c housing

2c not occupied

3c not occupied

4c not occupied

5c not occupied

6c output U

add.

=+14.5...+15.5V; <50mA

7c MR1 external fine balance (R=5kOhm)

8c MR1 external fine balance. tap

9c MR1 external fine balance (R=5kOhm)

10c not occupied

11c Synchronization

12c not occupied

13c not occupied

14c not occupied

15c operating voltage zero

16c not occupied

17c not occupied

18c output U

A

=±10V; R>5kOhm

19c operating voltage zero

20c not occupied

21c external zero balancing tap

22c not occupied

23c not occupied

24c external zero balancing

25c external switching from MR1 to MR2

26c external zero balancing

27c not occupied

28c sensing line (gn)

29c operating voltage zero

30c measuring signal (wh)

31c operating voltage zero (ye)

32c sensing line (gy)

St 21

1a not occupied

2a not occupied

3a not occupied

4a DC-DC converter positive pole

5a DC-DC converter negative pole

6a not occupied

7a output

U

add.

=–14.5...–15.5V; <50mA

8a not occupied

9a not occupied

10a not occupied

11a not occupied

12a not occupied

13a internally connected

14a internally connected

15a supply voltage

+14.5...+15.5V (standard)

16a supply voltage

–14.5...–15.5V (standard)

17a not occupied

18a not occupied

19a current output with EM002

20a operating voltage zero

21a zero function, external

22a not occupied

23a not occupied

24a not occupied

25a calibration function, external

26a not occupied

27a not occupied

28a bridge supply voltage (bu)

29a operating voltage zero

30a measuring signal (rd)

31a operating voltage zero (ye)

32a bridge supply voltage (bl)

Page 12

12

ME 30

3 Putting into Operation

If the factory settings, such as the measuring range or zero balance are retained, the operation is limited to setting the zero point and the measuring

ranges.

3.1 Select Measuring Range

With the factory setting

measuring range 1

(±2mV/V) is always switched on.

Measuring range 2 (calibration at ±0.2mV/V) can be selected either internally

via DIP switch 24/4 or externally by closing a single-pole change-over switch

to pin 25c against operating voltage zero (see chapter 4.2).

3.2 Bridge Zero Balancing

Carry out

bridge zero balancing

by means of the screwdriver potentiometers

P23 (fine) and switches S22 (coarse) and S23 (polarity). (See also chapter

4.4).

3.3 MR Fine Adjustment

The fine adjustment of the measuring range is made seperately for both

ranges by means of the screwdriver potentiometers P21 (measuring range 1)

and P22(measuring range 2). The potentiometers in the front panel permit

corrections of approx. 35% (related to the set measuring range). As far as

measuring range 1 is concerned, the fine adjustment is also possible via an

external potentiometer (for this see chapter 4.3).

Attention: P22 must not be altered in order not to detune the manufacturer’s

setting (MR2 ±0.2mV/V). (see chapter 4.5)

Page 13

13

ME 30

P21

P22

ME30

S21

P23

S22

S23

Fig. 3.1: Front view ME30

Page 14

14

ME 30

4 Individual Settings

Various ex-works settings on the measuring amplifier card can be altered.

Adaptations, which are of no problem, can be carried out by means of the DIP

switch on the board or also by externally wired switching elements. If requested with the order, they can be carried out by the manufacturer.

4.1 Operational Setting

Zero Measure Calibrate

S21

or connect pin 21a to pin 15c

or connect pin 25a to pin 15c

Switch

The transducer signal is switched off in the ”Zero” function, so that the ”Zero

Value” of the amplifier is applied to the output. This function enables amplifiers

to be replaced in measuring chain without the need for rebalancing the bridge

with the unloaded transducer. All that is required is that the amplifier balance

values are noted and then this value is set, if necessary, with P23, S22 and

S23.

4.2 Setting the Measuring Range

Measuring range 1 is get ex-works. Measuring range 2 can be activated by

switching DIP switch S24/4 or by external switching.

Measuring Range S 24/4 Externally

MR 1 = ±2mV/V

(ex-works setting)

–

MR 2 = ±0.2mV/V

from MR1 to MR2;

connect 25c and 15c

Any alteration to the measuring ranges between ±0.2mV/V and ±4mV/V with

U

B

= 5V (resp. ±0.4mV/V and ±8mV/V with UB = 2.5V) can be made by

means of the DIP switches S26 and S27. For fine balancing see 3.3.

Page 15

15

ME 30

UB = 5V MR1:S26 ; MR2:S27 ex-works sett.

Meas. range (mV/V) 1 2 3 4 5 6 7 8

0.17 0.24. . x o o o o o x o MR 2 ±0.2mV/V

0.22 0.32. . x o o o o o o x

0.30 0.42. . o x o o o o x o

0.39 0.55. . o x o o o o o x

0.52 0.73. . o o x o o o x o

0.68 0.97. . o o x o o o o x

0.90 1.28. . o o o x o o x o

1.18 1.69. . o o o x o o o x

1.56 2.23. . o o o o x o x o MR 1 ±2mV/V

2.07 2.94. . o o o o x o o x

2.73 3.88. . o o o o o x x o

3.61 5.13. . o o o o o x o x

o = open, x = closed

4.3 External Fine Balancing of the MR1

Connections:

potentiometer pin 9c. . . . . . . . . . . . .

wiper pin 8c. . . . . . . . . . . . . . . . . . . .

potentiometer finish pin 7c. . . . . . . .

An external 5kΩ potentiometer can be connected for fine adjustment of the

range. This will enable about 35% correction of the selected range.

R=5kΩ

Page 16

16

ME 30

4.4 Bridge Fine Balancing

a) Coarse Balancing

The 16-stage switch S22 is used for the coarse balancing carried out from the

front panel; the polarity of the balancing direction can be chosen via switch

S23. The overall balancing range is approximatly ±2mV/V.

b) Fine Balancing

The potentiometer P23 is used for the fine balancing (±0.08mV/V).

c) External Zero Balancing

A balance range of ±0.12mV/V set by the manufacturer can be passed with

an externally connected potentiometer of 50 kΩ

Pin assignment:

potentiometer pin 26c. . . . . . . . . . . . .

wiper pin 21c. . . . . . . . . . . . . . . . . . . .

potentiometer finish pin 24c. . . . . . . .

4.5 Calibration signal

Switching switch S21 to the right (calibration) detunes the amplifier by a defined amount (=+1mV/V). The measuring range can be adjusted without having to load the connected transducer respectively. The voltage at the amplifier

output which is equal to the calibration signal is added to an available voltage,

if any (additive calibration signal)

R=50kΩ

Page 17

17

ME 30

4.6 Measuring Frequency Range / Cut-off Frequency f

co

The Butterworth low pass of the amplifier has been set to 0...60Hz (–1dB) by

the manufacturer. It can be readjusted by switching the DIP switch S24/3 to

0...2Hz (–1dB).

Measuring frequency range S 24/3

0...60Hz (–1dB); (ex-works setting)

fco = 80Hz (–3dB)

0...2Hz (–1dB);

fco = 2.5Hz (–3dB)

4.7 Synchronization

When operating several ME30 amplifiers (in a common housing), one of them

has to be switched as the master the carrier frequency of which supplies the

clock pulses, the others are to be switched as slave. Pins 11c of all amplifiers

have to be joined for synchronization. The master amplifier is selected by

switch S28.

Synchronization Switch S28

Slave amplifier (ex-works setting)

Master amplifier

Page 18

18

ME 30

5 Options

5.1 Stabilized Power Supply

The module KM001 can be used if the amplifier is connected to a symmetrical unregulated supply voltage of ± 15.6...25.0V. The module supplies the two

stabilized supply voltages internally to the amplifier.When installing the module KM001, attention should be paid to the marking (bridge 3 and bridge 4 on

pin 1 and 2).

Pin assignment:

positive pole pin 15a. . . . . . . . . . . . . .

negative pole pin 16a. . . . . . . . . . . . .

supply zero pin 19c. . . . . . . . . . . . . . .

5.2 DC-DC Converter

The manufacturer can mount a DC-DC converter onto the board for the oper-

ation of a single-pole supply voltage (battery). The voltage converter is suitable for operation on +9...+35V (unstabilized).

Pin assignment:

positive pole pin 4a. . . . . . . . . . . . . .

negative pole pin 5a. . . . . . . . . . . . .

The DC-DC converter decouples the internal operating voltages from the supply voltage.

When using the modules KM001 resp. a DC-DC converter attention has to

be paid to the jumpers BR3 and BR4 which are re-configured.

ex-works setting:

1 2 3

BR3

BR4

I

I

With module KM001

resp. DC-DC converter

1 2 3

BR3

BR4

I

I

Page 19

19

ME 30

5.3 Current Output Module

The module EM002 can be installed to obtain a current output.

The pin assignment is as follows:

output current pin 19a. . . . . . . . . . . . .

supply zero pin 20a. . . . . . . . . . . . . . .

The power range is switched by the DIP switch 24/5.

Output current source S24/5

+4...+20 mA

+20 mA (ex-works setting)

When using an EM002, current and voltage outputs are not aligned to each

other. The required fine calibration can be carried out from the front panel (as

described in chapter 3)

5.4 Safety Barriers for use in Hazardous Areas

For transducer operation in potentially explosive atmospheres the safety barriers SD01 are used conforming to the protection classes (EEx ib IIC) according to VDE0171, EN 50 014 and EN 50 020 (see data sheet).

5.5 Additional Units

The following additional cards are available for the measuring amplifier ME30:

– automatic zeroing unit NE02

– peak / last value memory SE03

– limit switch GE04

Page 20

20

ME 30

6 General Notes

6.1 Disturbances

Certain regulations concerning electrical installation have to be observed in

plants with strongly disturbed supply mains systems. The most important

points are listed up in the HBM leaflet ”Hints for connection/disturbances”. An

extensive summary is given in the installation regulations VDI/VDE 3551. The

extent of certain measures to be taken depends on the specific applications.

Page 21

21

ME 30

7 Technical Data

Type ME30

Carrier frequency Hz 600±0.5%

Bridge excitation voltage V 2.5±2% 5±0.2%

Transducers which can be connected

strain gauge transducers (full bridge) W 60...4000 110...4000

maximum cable length m 500

Number of measuring ranges 2

measuring ranges, adjustable in 12 steps mV/V 0.4...8 0.2...4

continuous fine adjustment; % 35

ex-works setting: Measuring Range 1 mV/V ±2

Measuring Range 2 mV/V ±0.2

Calibration signal mV/V +1±0.1%

Bridge balance range

coarse balance, adjustable in 16 steps and

polarity

mV/V ±2

fine balance, with screwdriver potentiometer mV/V ±0.08

Measuring frequency (Butterworth low pass 3rd order;

switchable)

at –1dB Hz 0...2 0...60

at –3dB Hz 2.5 80

phase delay ms 135 4.8

rise time ms 170 7

surge voltage overshoot % <10 <10

residual carrier % <0.1 <0.2; typ. 0.1

Input (symmetrical)

input resistance MΩ

par.

pF

>10

470

perm. common-mode voltage V 12 (peak-to-peak) ; (±6V)

common-mode rejection (>50 dB) Hz 0...600

Output (asymetrical)

nominal voltage V ±10

permissible load resistance kΩ >5

internal resistance W <5

Page 22

22

ME 30

7 Technical Data (Continuation)

Noise, referred to input

µV/V <0.2 (peak-to-peak); typ.0.1

Linearity deviation

related to nominal voltage

% <0.02; typ. 0.01

Temperature influence

per 10K in nominal temperature range

on measuring sensitivity % <0.1; typ. 0.05

on zero point at amplifier output

in MR 2mV/V at UB=5V (4x350Ω) mV <4, resp.

in MR 0.2mV/V at UB=5V mV <13; additionally

<0.05% of the tare value

suppressed with the R compensation

Long term drift over 48h (after 1h warm-up) µV/V <0.05

Nominal temperature range °C –10...+60

Operating temperature range °C –20...+60

Storage temperature range °C –25...+70

Stabilized Voltage

for the operation of additional units V ±15

max. power consumption mA <50

Supply current standard;

stab.

KM001 DC-DC

converter

Supply voltage V 14.5... 15.5 15.6...

25

+9...+35

max. current consumption (without

additional units)

mA +70/–65 <+80/<–70 340...140

influence of supply voltage

for changes in the relevant range

the measuring sensitivity % <0.8 <0.02 <0.02

the zero point µV/V <0.1 <0.1 <0.1

Output current, with option EM002 mA 20 acc. +4...+20

permissible connection resistance W 0...500

internal resistance kΩ >100

current consumption

with standard and KM001 add. mA < + 30

with DC-DC converter mA 75...25

linearity deviation related to nominal current % <0.05

Page 23

23

ME 30

8 Component Layout

Page 24

24

ME 30

9 Copy of Declaration of Conformity

Page 25

25

ME 30

Page 26

26

ME 30

Page 27

27

ME 30

Page 28

HOTTINGER BALDWIN MESSTECHNIK

HBM Mess- und Systemtechnik GmbH

Postfach 10 01 51, D-64201 Darmstadt

Im Tiefen See 45, D-64293 Darmstadt

Tel.: +49/ 61 51/ 8 03-0; Fax: +49/ 61 51/ 89 48 96;

www.hbm.de

e–mail: TSC@hottinger–baldwin.com

Modifications reserved.

All details describe our products in

general form only.

They are not to be understood as express

warranty and do not constitute any liability

whatsoever.

IM–D 09.99–POD

Loading...

Loading...